Patents

Literature

62results about How to "Sustainability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

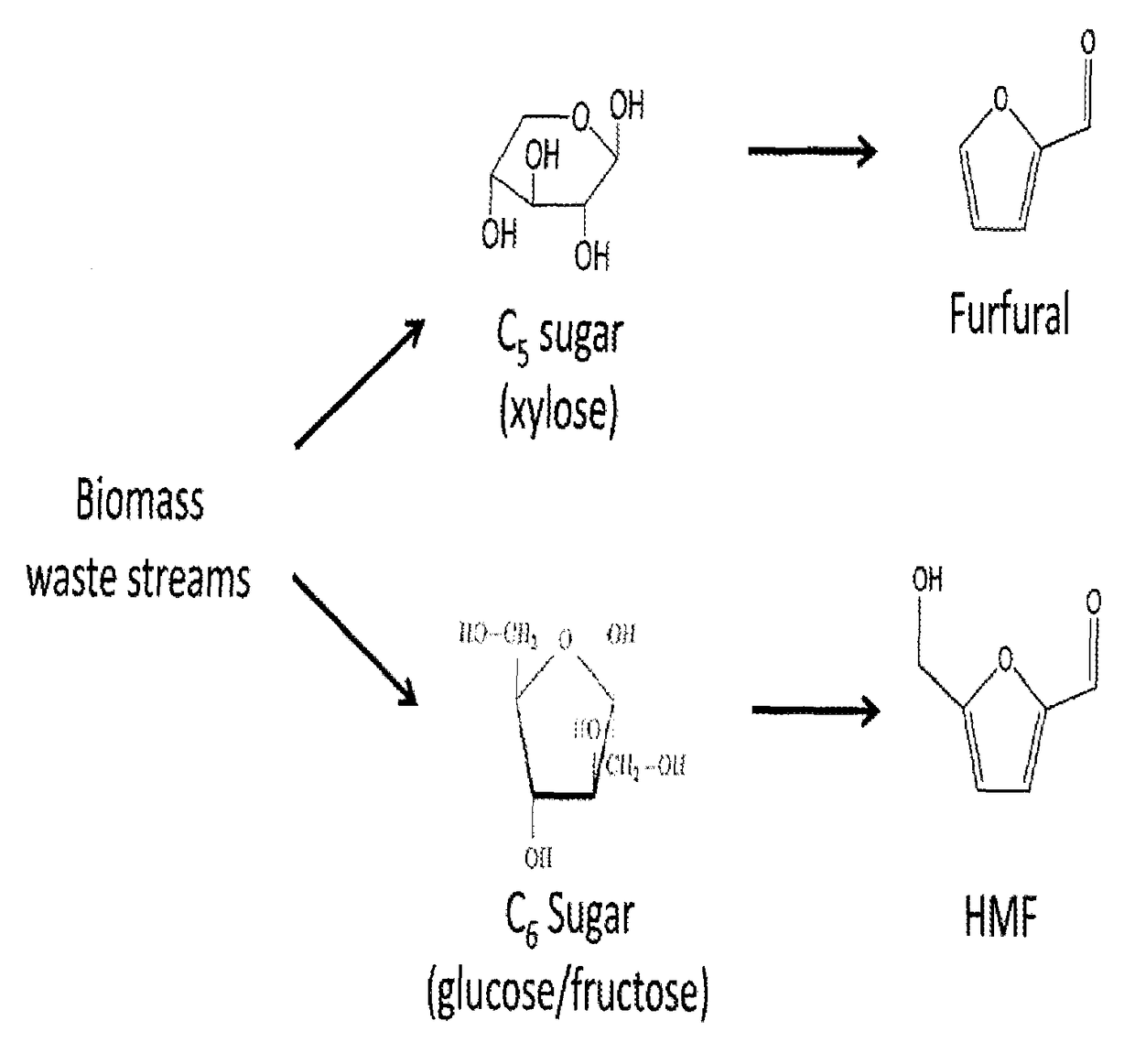

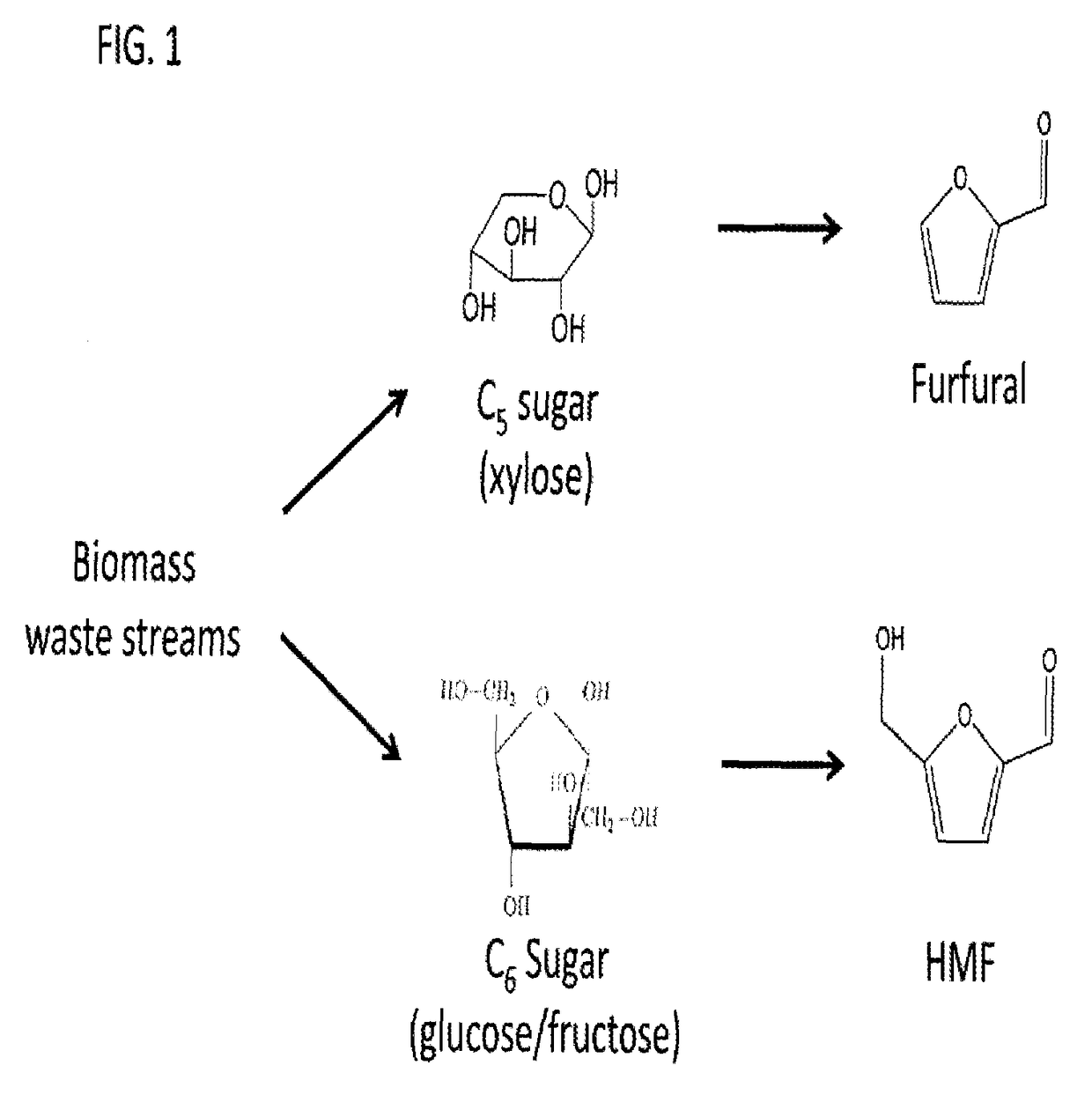

Method to convert monosaccharides to 5-(hydroxymethyl) furfural (HMF) using biomass-derived solvents

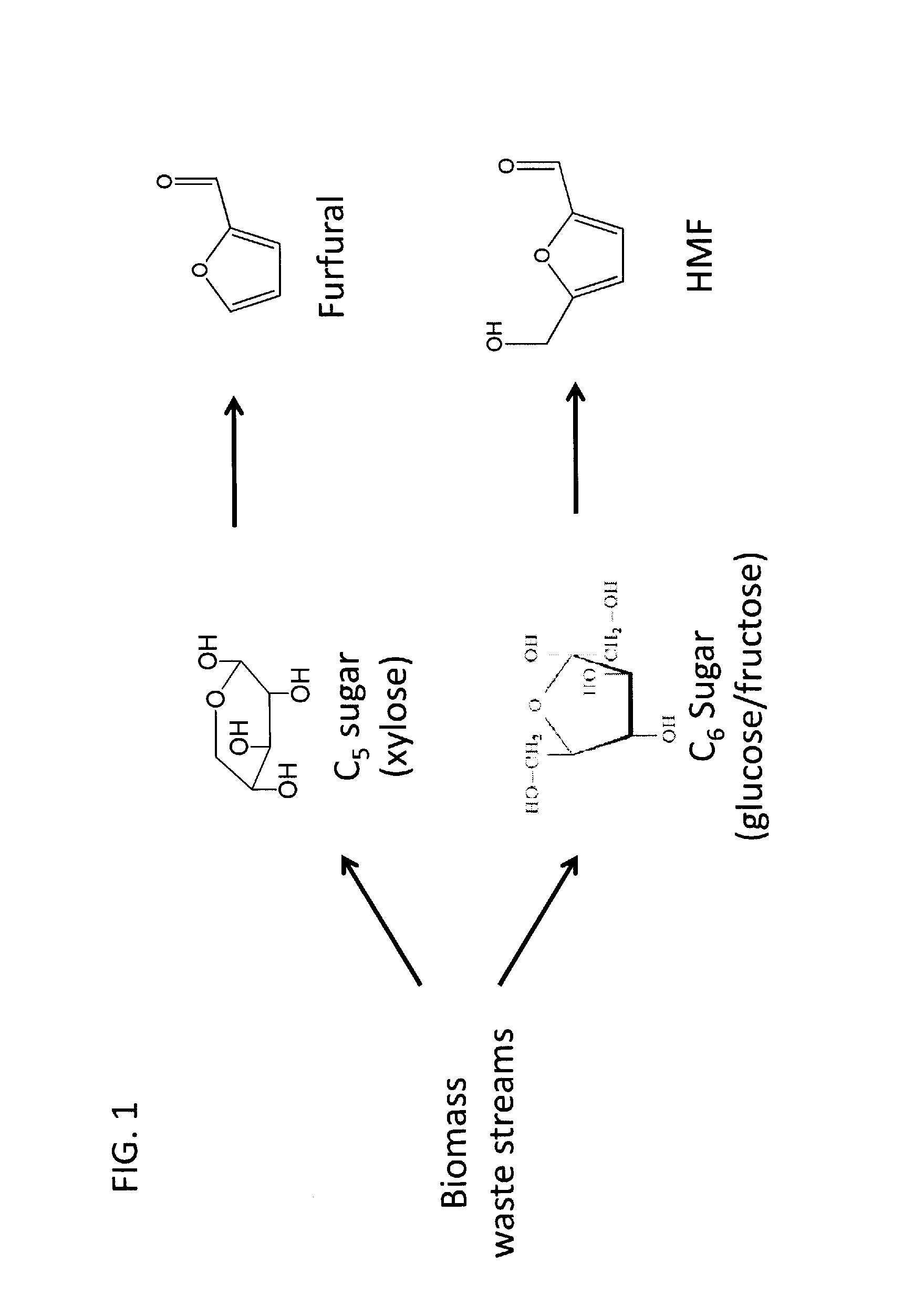

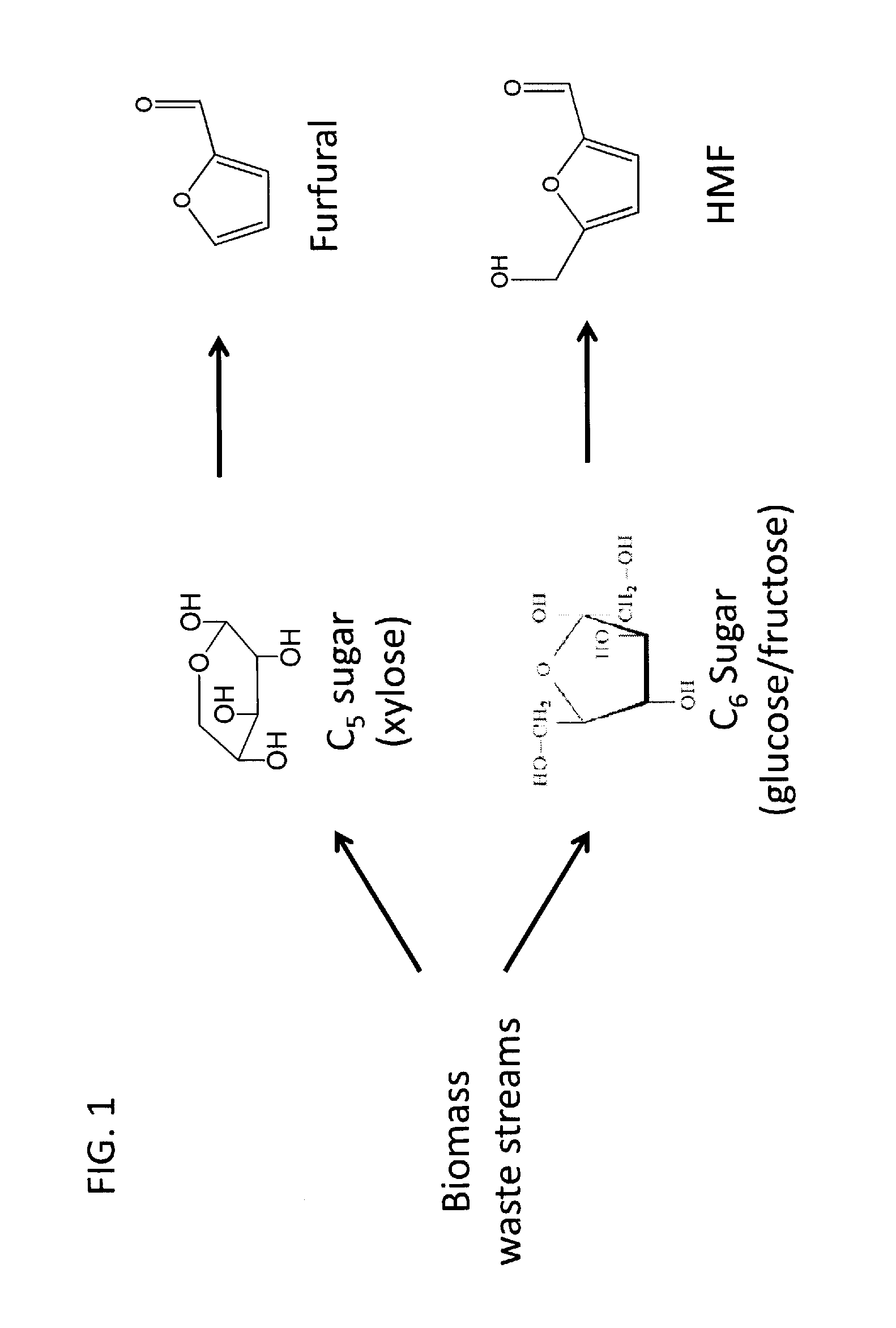

Described is a process to produce hydroxymethyl furfural (HMF) from biomass-derived sugars. The process includes the steps of reacting a C5 and / or C6 sugar-containing reactant derived from biomass in a monophasic or biphasic reaction solution comprising water and a co-solvent. The co-solvent can be beta-, gamma-, and / or delta-lactones derived from biomass, tetrahydrofuran (THF) derived from biomass, and / or methyltetrahydrofuran (MTHF) derived from biomass. The reaction takes place in the presence of an acid catalyst and a dehydration catalyst for a time and under conditions such that at least a portion of glucose or fructose present in the reactant is converted to HMF.

Owner:WISCONSIN ALUMNI RES FOUND

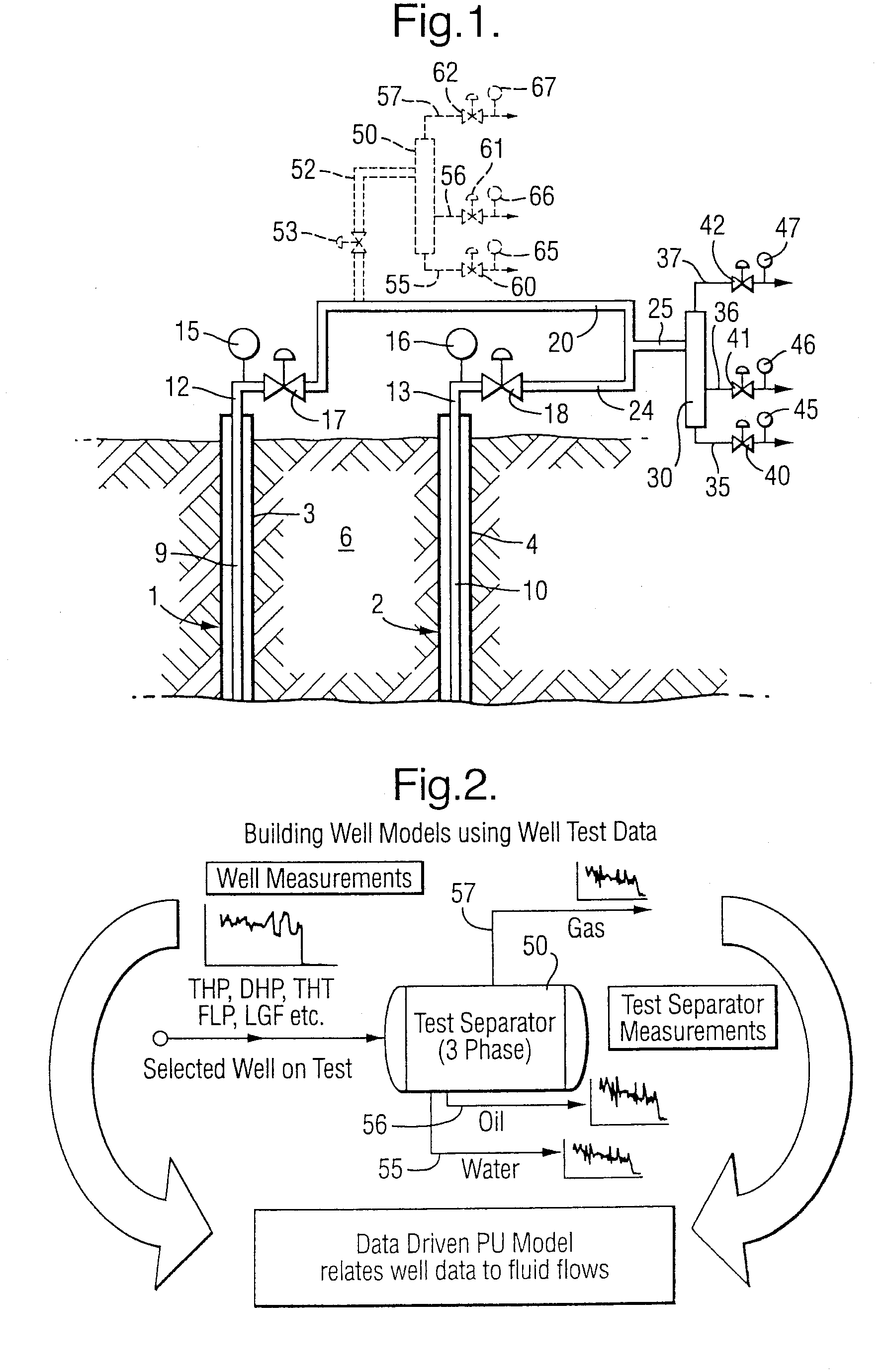

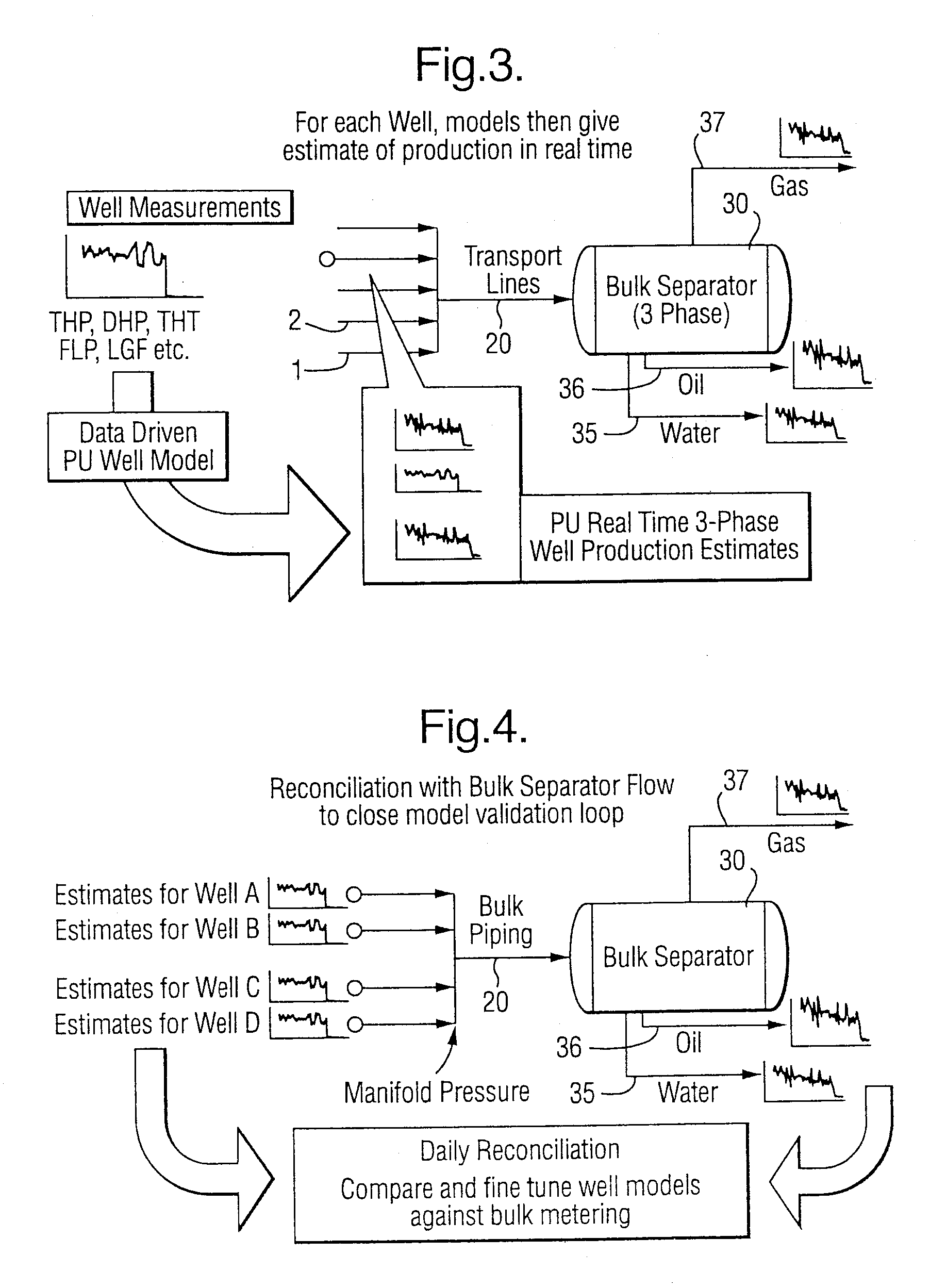

Method and System for Production Metering of Oil Wells

ActiveUS20070295501A1MaintainabilitySustainabilityElectric/magnetic detection for well-loggingSurveyStream flowOil well

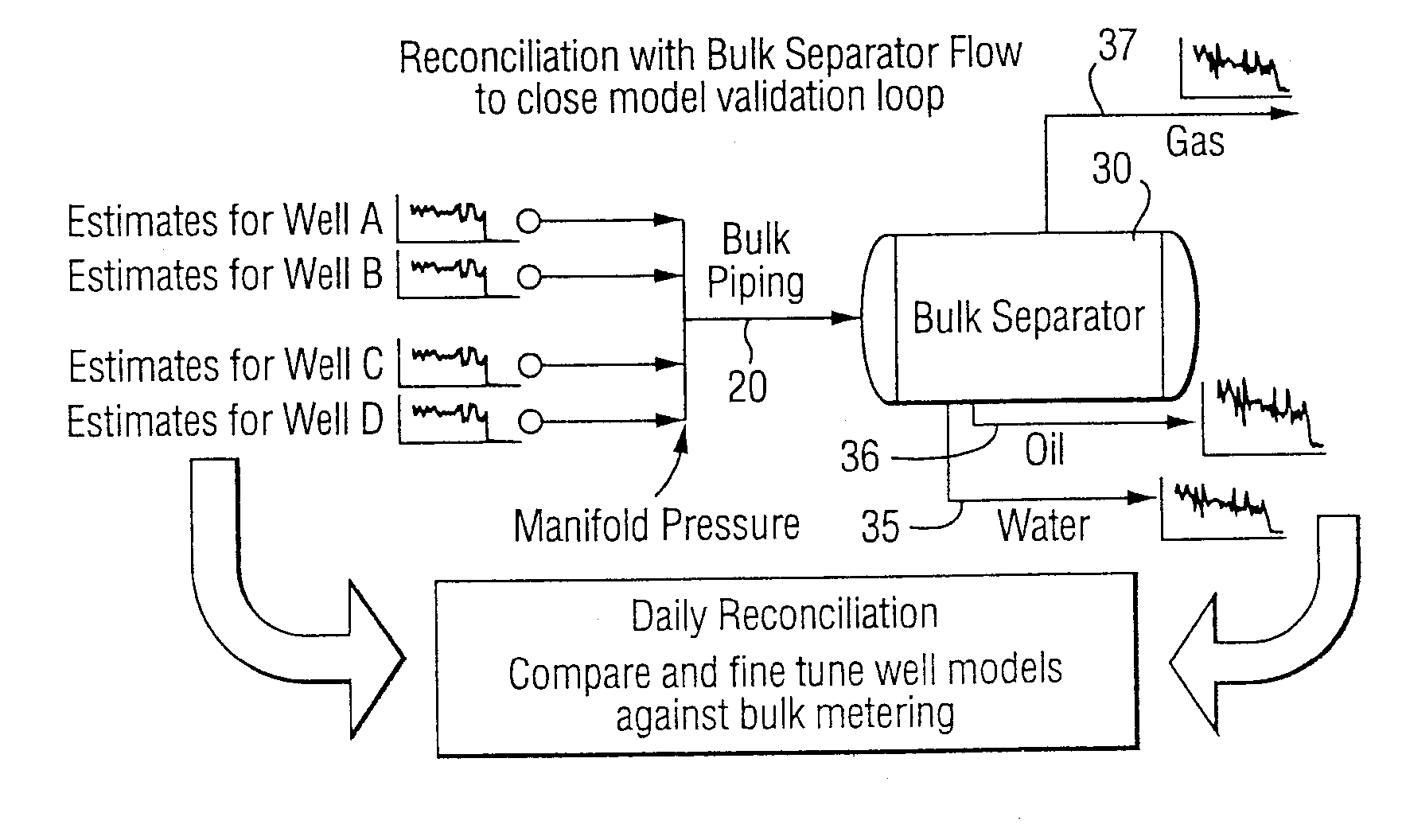

The present invention relates to a method and system for determining multiphase fluid streams flowing from individual wells of a cluster of crude oil, gas and / or other fluid production wells, wherein the fluid streams produced by the individual wells are commingled and routed via a fluid separation assembly into fluid outlet conduits for transportation of at least partly separated streams of crude oil, gas and / or other fluids.

Owner:SHELL USA INC

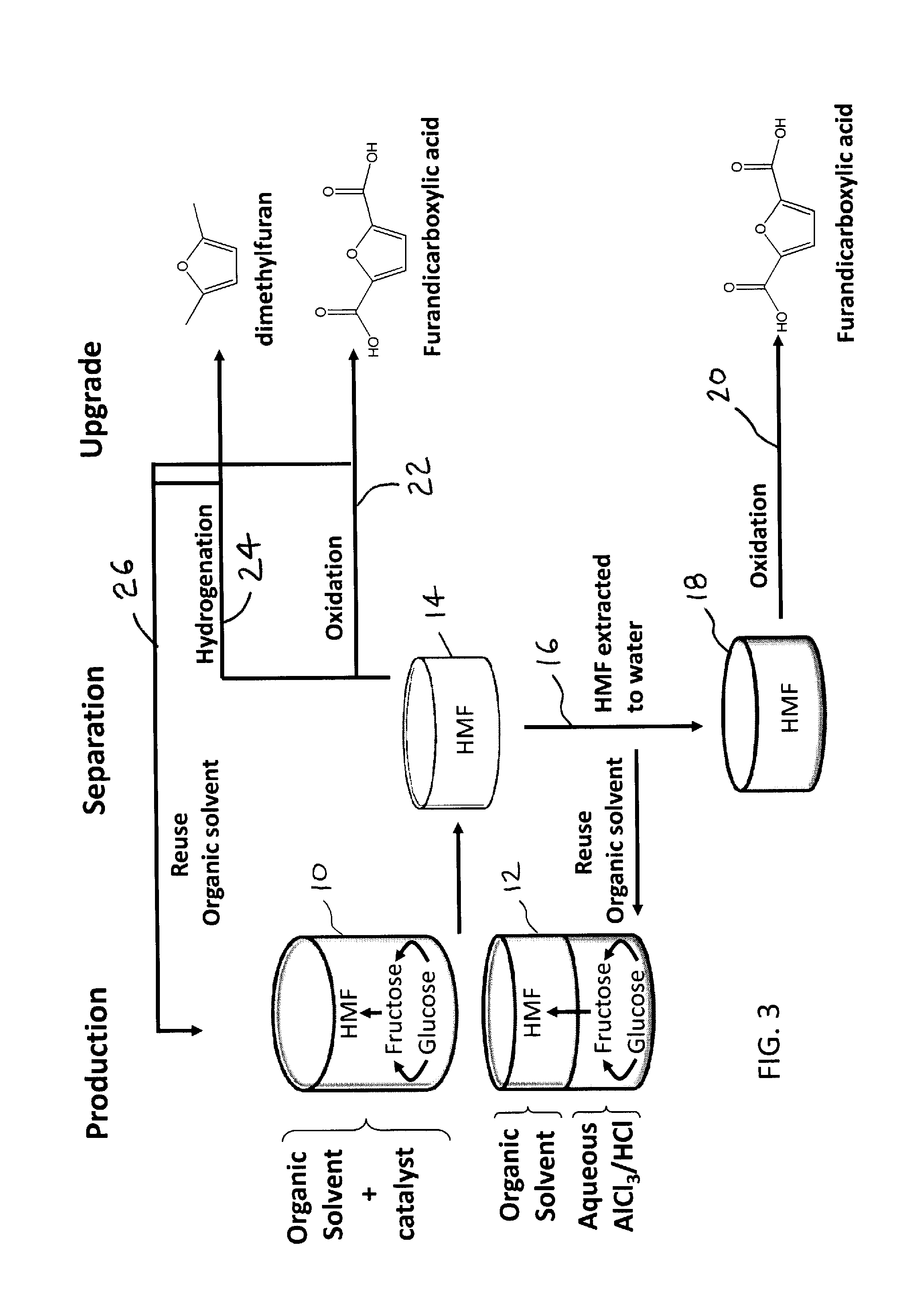

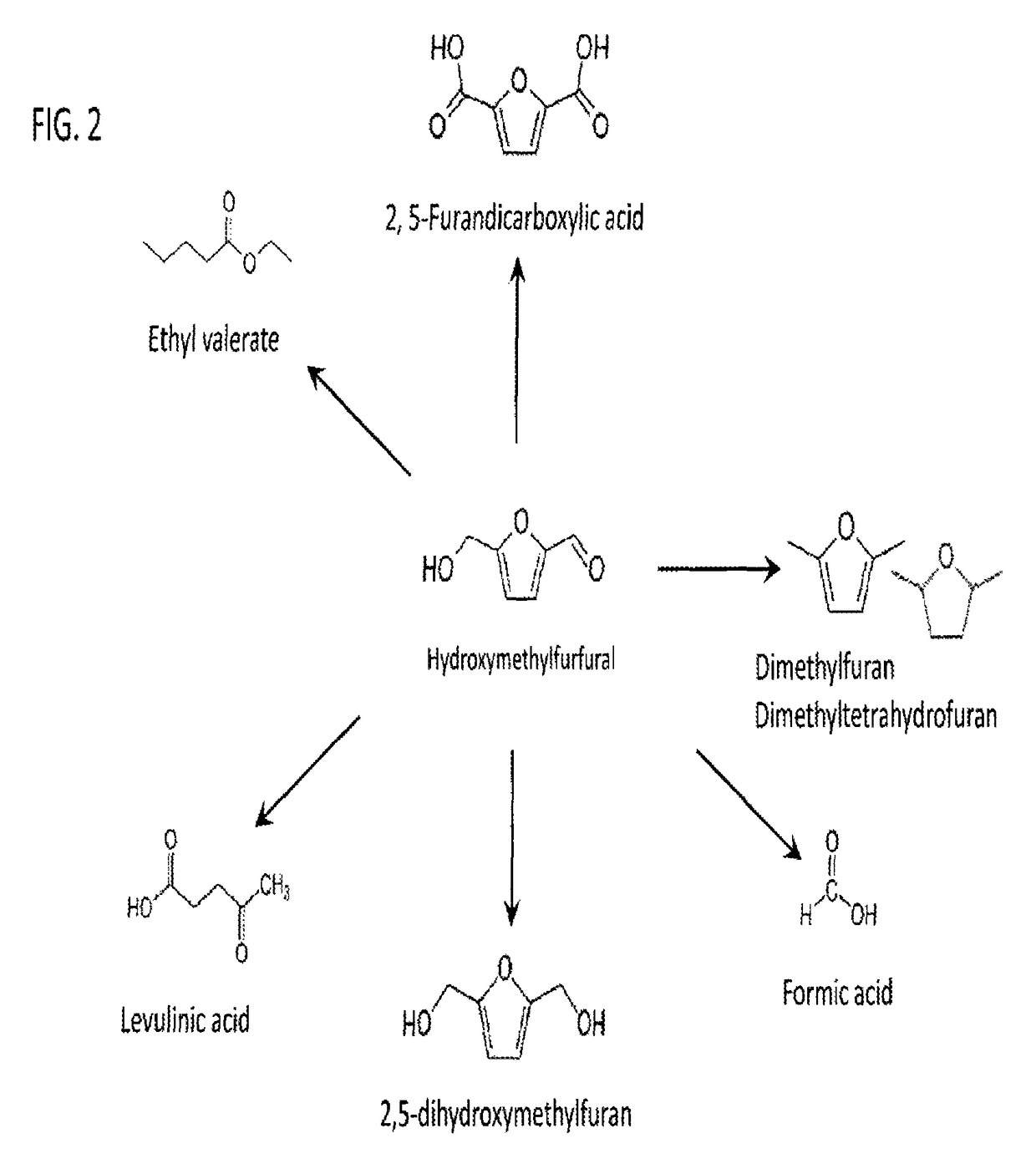

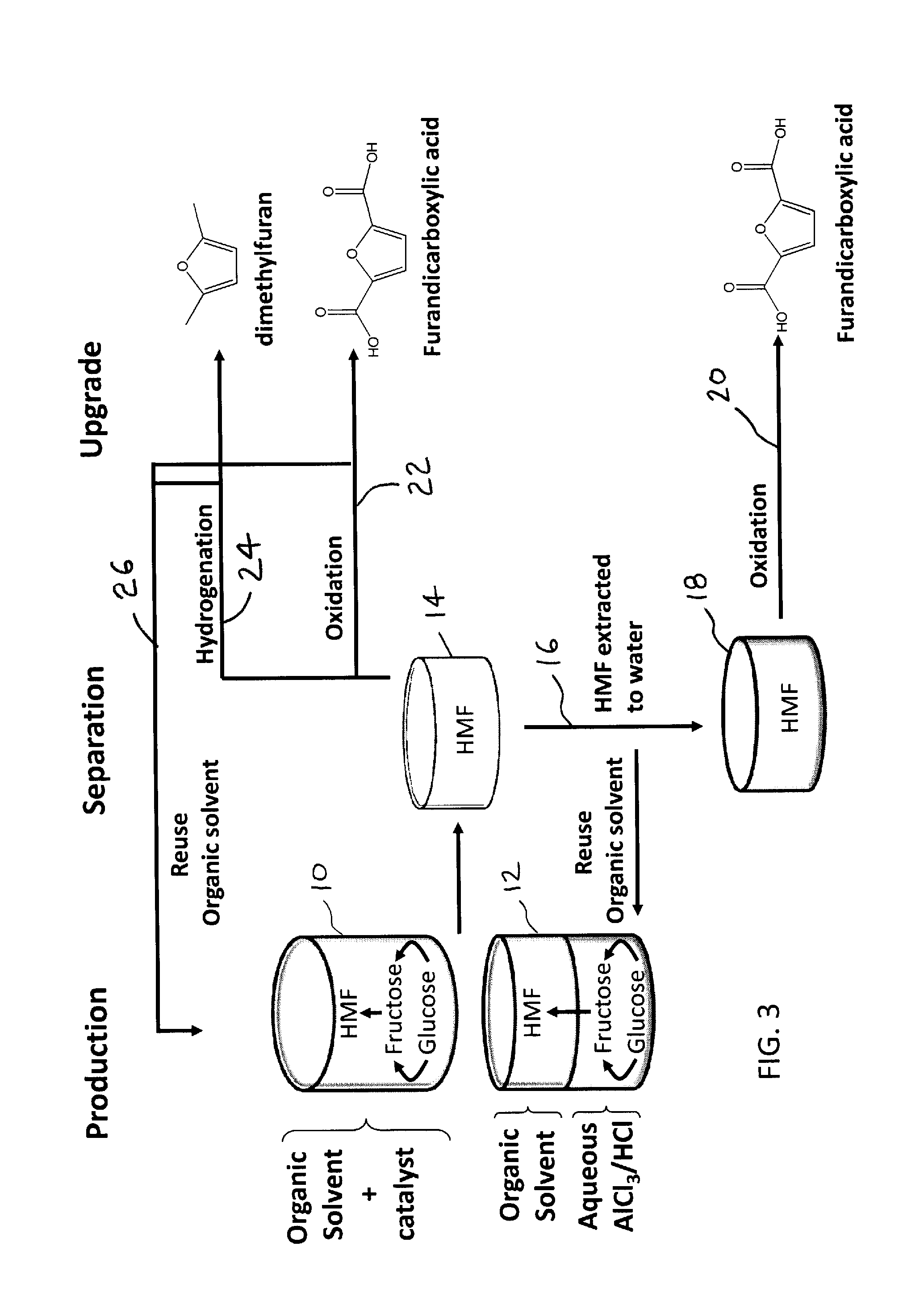

Method to produce furandicarboxylic acid (FDCA) from 5-hydroxymethylfurfural (HMF)

ActiveUS9617234B1Reduce economic potentialSeparation cost is highOrganic chemistryOrganic solventSugar

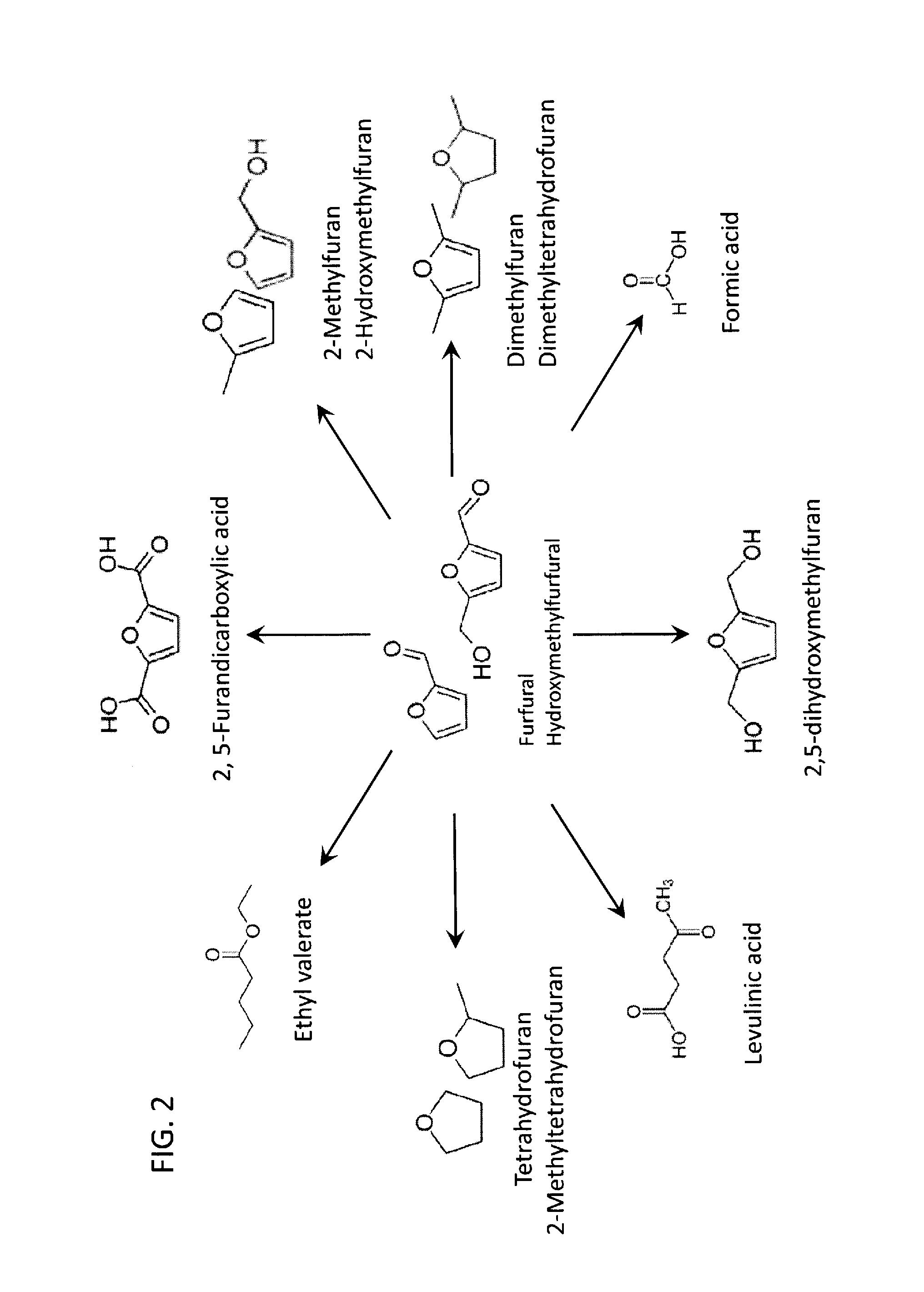

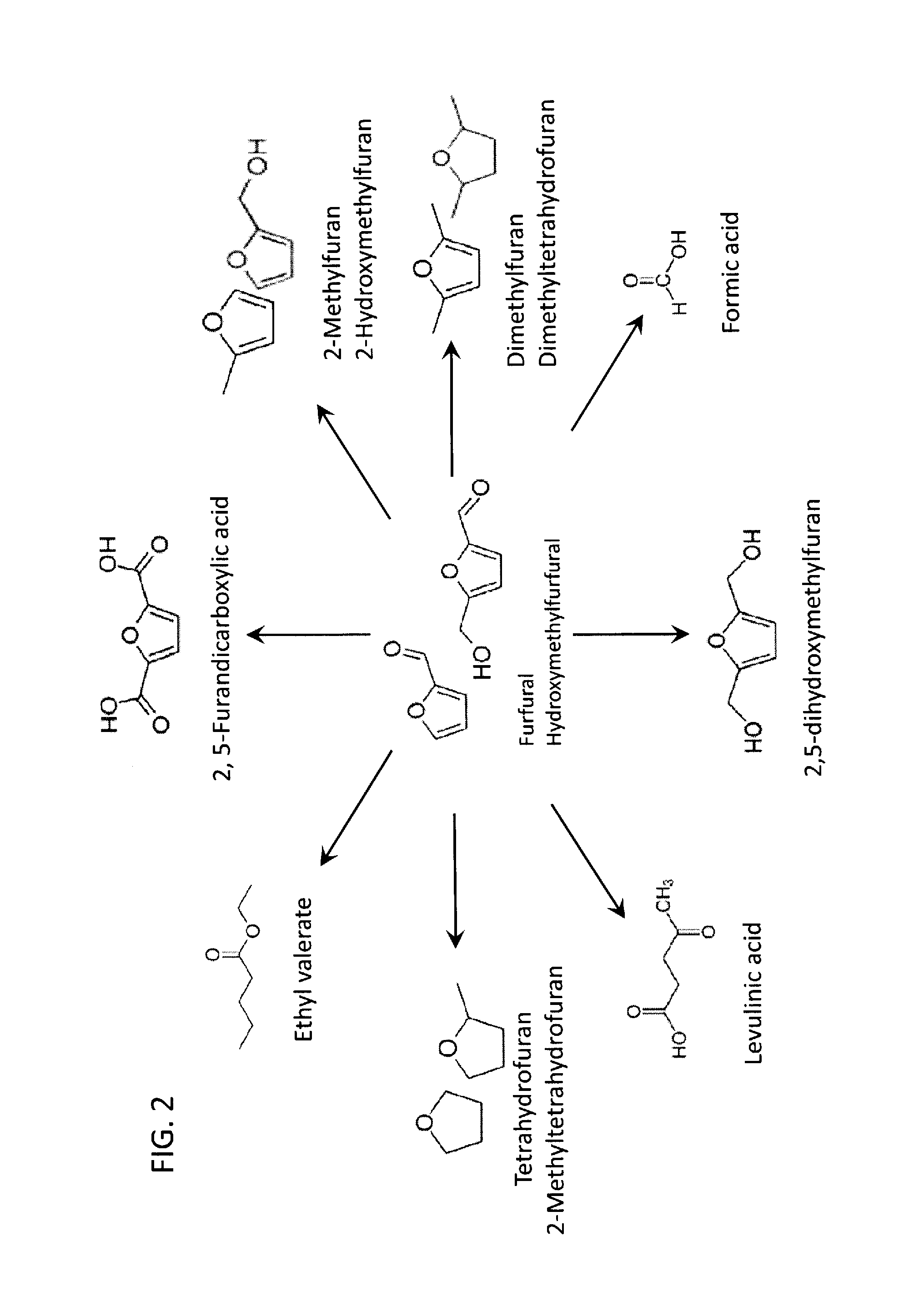

A process to produce furandicarboxylic acid (FDCA). The process includes the steps of reacting a C6 sugar-containing reactant in a reaction solution comprising a first organic solvent selected from the group consisting of beta-, gamma-, and delta-lactones, hydrofurans, hydropyrans, and combinations thereof, in the presence of an acid catalyst for a time and under conditions wherein at least a portion of the C6 sugar present in the reactant is converted to 5-(hydroxymethyl)furfural (HMF); oxidizing the HMF into FDCA with or without separating the HMF from the reaction solution; and extracting the FDCA by adding an aprotic organic solvent having a dipole moment of about 1.0 D or less to the reaction solution.

Owner:WISCONSIN ALUMNI RES FOUND

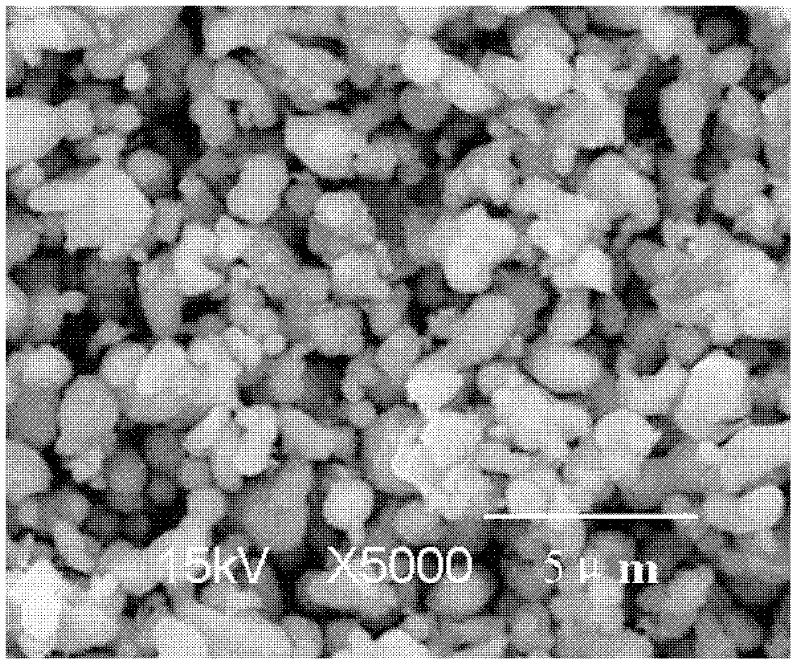

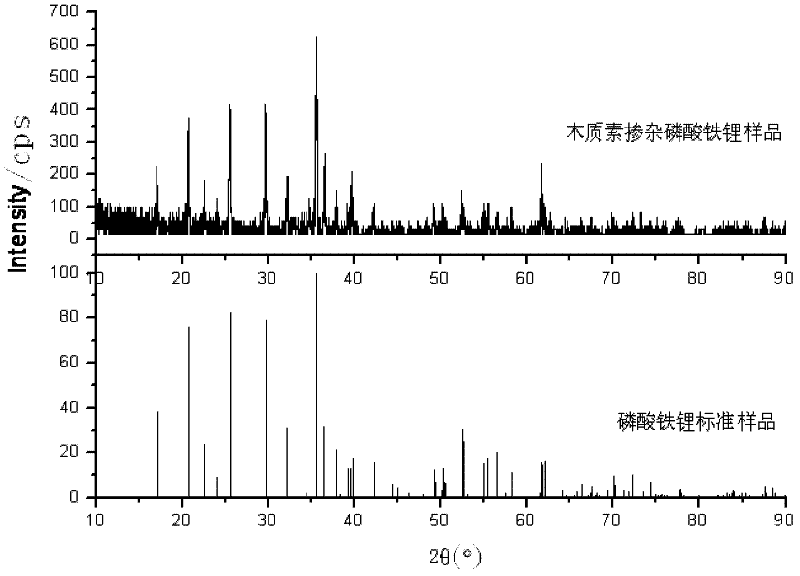

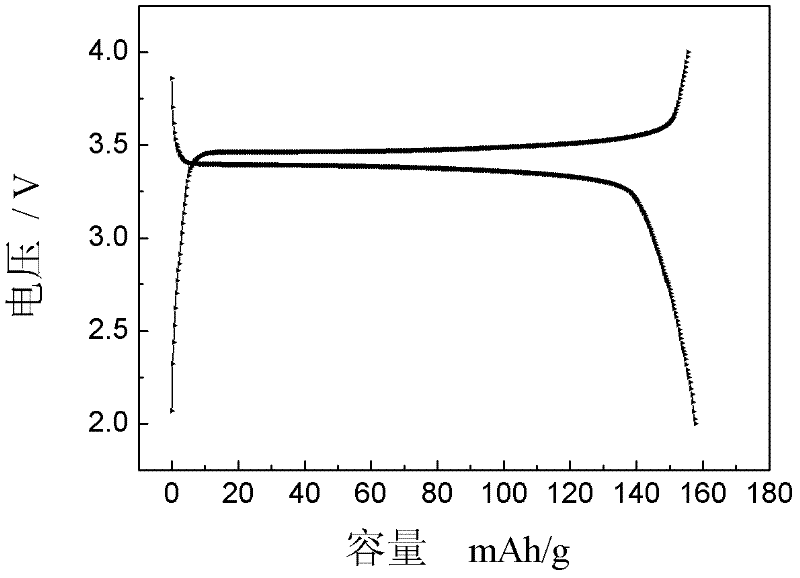

Preparation method for modified LiFePO4 lithium ion battery anode material

InactiveCN102361071ARich sourcesImprove electrochemical performanceCell electrodesCharge dischargeCellulose fiber

The invention relates to a preparation method for a modified LiFePO4 lithium ion battery anode material, which belongs to the field of lithium ion battery materials. In the process of preparing a LiFePO4 lithium ion battery cathode material, a modifier is added, and the modifier is cellulose fiber, a lignin salt or a mixture of the two. According to the invention, cheap lignin, a renewable natural high-molecular material, is used as a carbon source precursor for the LiFePO4 lithium ion battery anode material, and lignin is widely available and easy to well mix with lithium source compounds, iron source compounds and phosphor source compounds once and for all; the prepared LiFePO4 lithium ion battery anode material has high purity and good electrochemical performance; a process for the anode material is simple and is easy to control; low production cost is obtained; a lithium ion battery made of the cathode material has a stable quality and 0.2C charge-discharge reversible specific capacity higher than 157 mAh / g, and battery capacity of the prepared lithium ion battery does not attenuate after 50 times of cycle; the method is applicable to large scale industrial production.

Owner:HUNAN ZHONGTIAN NEW ENERGY

Method to convert biomass to 5-(hydroxymethyl)-furfural (HMF) and furfural using lactones, furans, and pyrans as solvents

Described is a process to produce hydroxymethyl furfural (HMF) from biomass-derived sugars. The process includes the steps of reacting a C5 and / or C6 sugar-containing reactant derived from biomass in a monophasic or biphasic reaction solution comprising water and a co-solvent. The co-solvent can be beta-, gamma-, and / or delta-lactones derived from biomass, tetrahydrofuran (THF) derived from biomass, and / or methyltetrahydrofuran (MTHF) derived from biomass. The reaction takes place in the presence of an acid catalyst and a dehydration catalyst for a time and under conditions such that at least a portion of glucose or fructose present in the reactant is converted to HMF.

Owner:WISCONSIN ALUMNI RES FOUND

Organic fertilizer prepared from sludge

InactiveCN103467148ASimple structureRipe fastBio-organic fraction processingOrganic fertiliser preparationFiberWaste rubber

The invention relates to an organic fertilizer prepared from sludge, which comprises the following components in percentage by weight: 60-70% of sludge, 27-35% of organic waste and 3-5% of biomass fermenting enzyme. The sludge is pure sludge in which heavy metals and substances that are harmful to plant growth are removed. The organic waste comprises 5% of plastic waste, 8% of waste rubber, 5% of fiber fabric, 12% of waste paper, 15% of rice bran, 14% of coconut shell, 6% of leaf, 10% of bark, 3% of flower and grass, 7% of kitchen peel, 5% of cake pulp, 5% of vinasse and 5% of bagasse. The organic fertilizer can effectively improve the soil structure, has longer effective time, can lower the fertilizer use cost, and enhances the environmental contribution rate.

Owner:华益兰馨(北京)环境科技有限公司

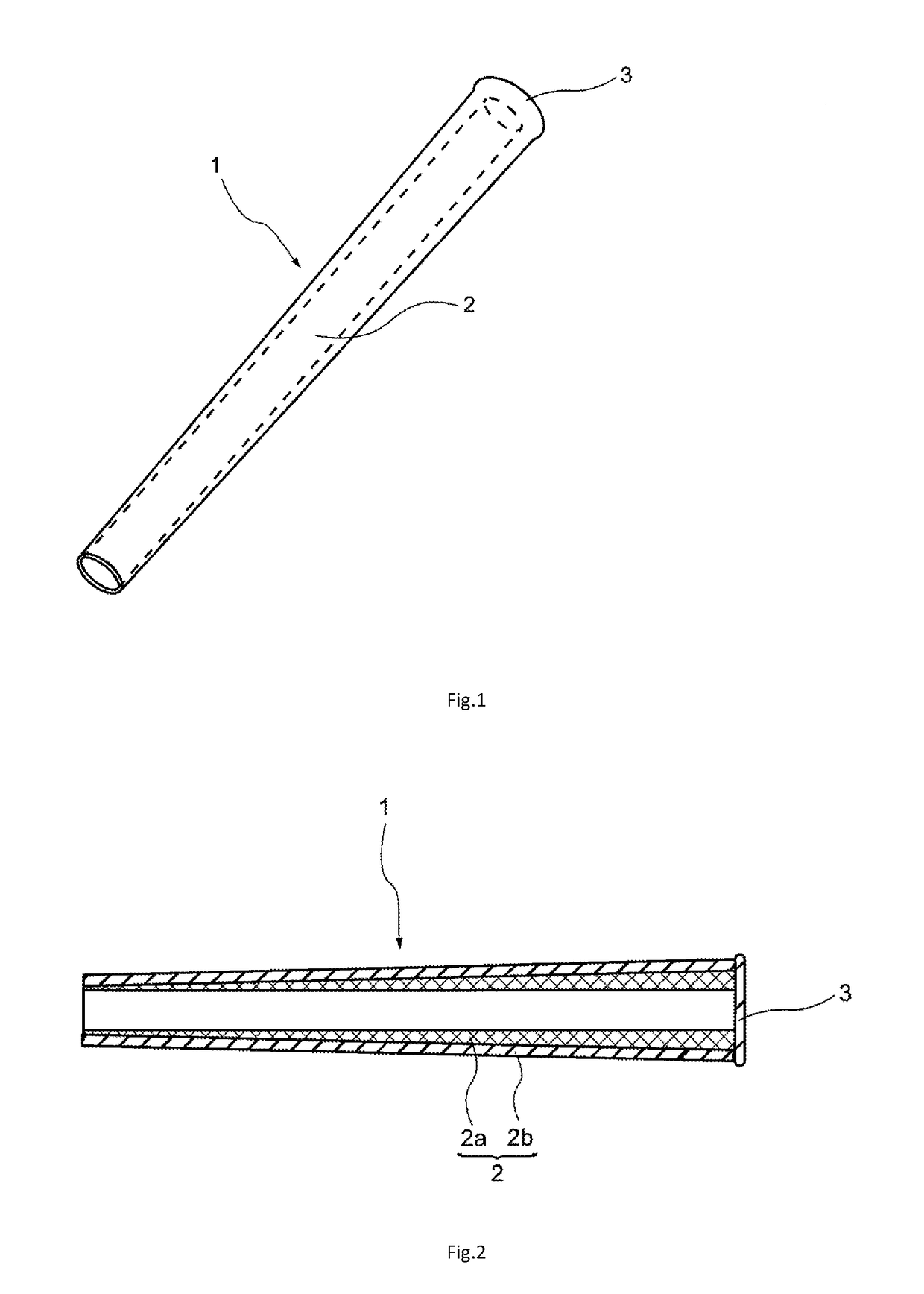

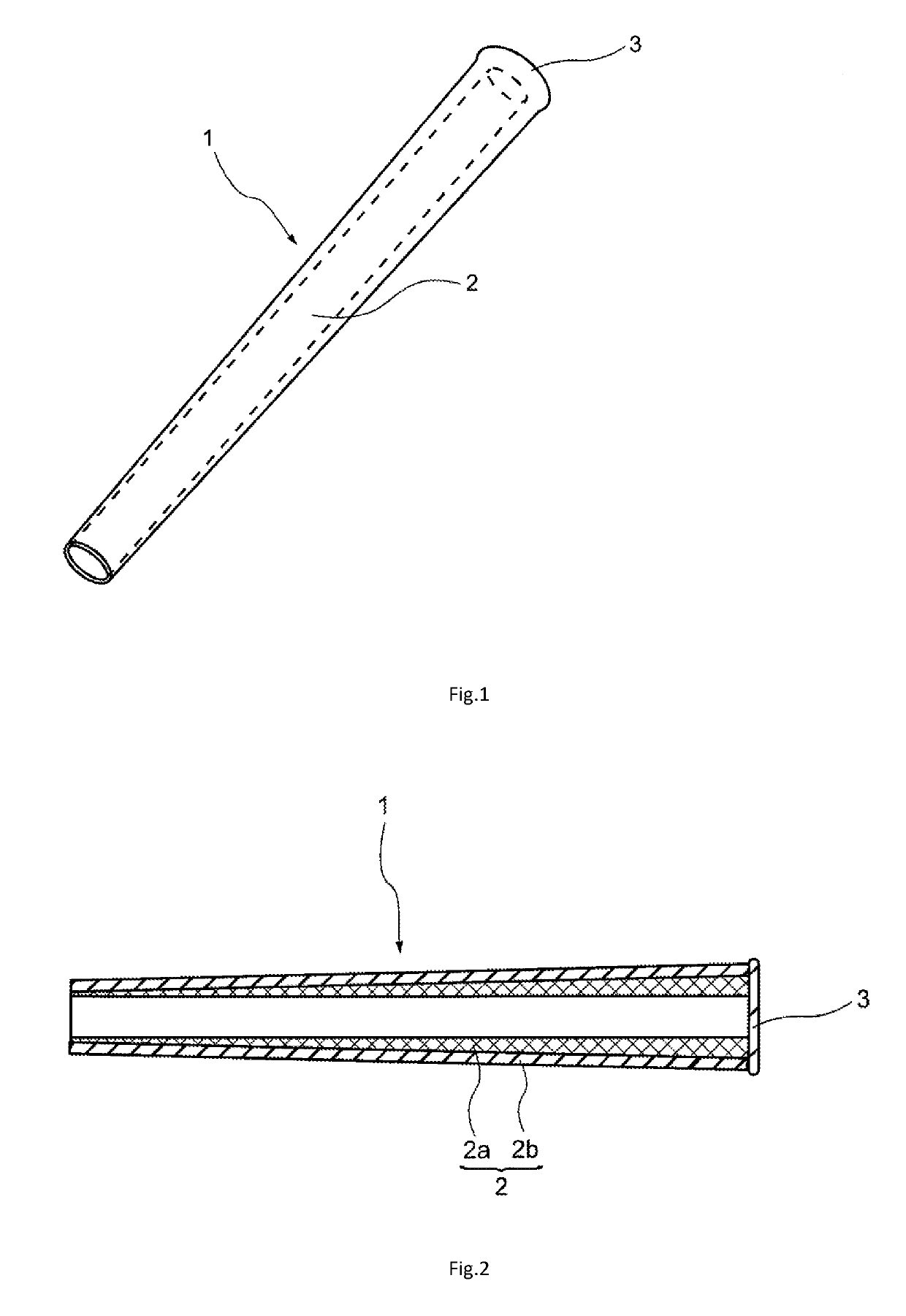

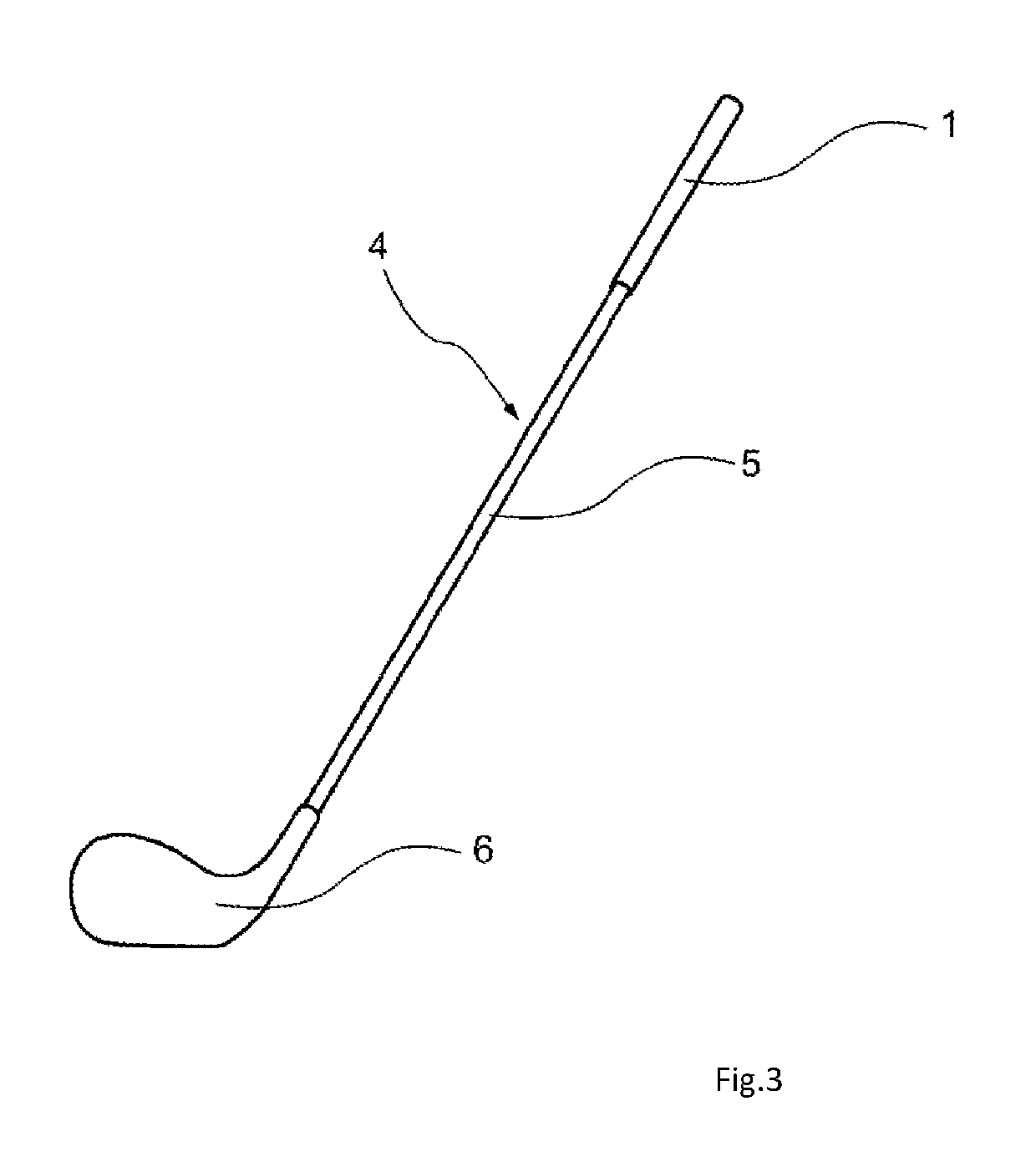

Grip for sporting goods and golf club

ActiveUS20170182386A1Improve grip performanceLower performance requirementsSnowboard bindingsSkisPolymer scienceSurface layer

An object of the present invention is to provide a grip for sporting goods containing an acrylonitrile-butadiene based rubber as a base rubber and having an excellent grip performance and sustainability of grip performance under a wet condition. The present invention provides a grip for sporting goods comprising an outermost surface layer formed from a surface layer rubber composition, wherein the surface layer rubber composition contains (A) a base rubber and (B) a resin having a softening point in a range from 5° C. to 120° C., (A) the base rubber contains an acrylonitrile-butadiene based rubber, and (B) the resin is at least one type selected from the group consisting of a hydrogenated rosin ester, a disproportionated rosin ester, an ethylene-vinyl acetate copolymer, a coumarone resin, a phenol resin, a xylene resin and a styrene resin.

Owner:SUMITOMO RUBBER IND LTD

Selenium-rich organic fertilizer and preparation method thereof

InactiveCN105777252AAvoid pollutionAvoid churnAnimal corpse fertilisersExcrement fertilisersFiberSludge

The invention discloses a selenium-rich organic fertilizer.The selenium-rich organic fertilizer is mainly prepared from, by weight, 70-90 parts of chicken manure, 30-42 parts of sheep manure, 20-28 parts of pond sludge, 5-8 parts of gecko manure, 4-7 parts of pangolin manure, 35-50 parts of fiber-containing biomass, 30-35 parts of bean pulp, 10-15 parts of fishbone, 3-6 parts of black peanut shells, 5-8 parts of a strain, 20-26 parts of potassium humate and 20-30 parts of activated selenium ore powder.A production method of the selenium-rich organic fertilizer includes the following steps that 1, fishbone powder, bean pulp, black peanut shells, fiber-containing biomass and the strain are subjected to primary fermentation; 2, a KOH solution is added to regulate the PH after primary fermentation, and then potassium humate, part of activated selenium ore powder, chicken manure, sheep manure, pond sludge, gecko manure and pangolin manure are added and subjected to secondary fermentation; 3, the rest of activated selenium ore powder is added after secondary fermentation.By applying the organic fertilizer, the selenium content in crops can be effectively increased.

Owner:李小婷

High-temperature-resistant composite antibacterial agent and preparation method thereof

ActiveCN104855416AGood resistance to high temperature discolorationImmediate effectBiocideFungicidesPhosphoric acidSilica gel

The invention discloses a high-temperature-resistant composite antibacterial agent and a preparation method thereof, and belongs to the technical field of bactericides. The composite antibacterial agent comprises a guanidine salt antibacterial agent and inorganic additives, wherein the inorganic additives are selected from one or more of boric acid, boric oxide, zinc oxide, titanium dioxide, phosphoric acid, zeolite powder, silica gel powder, glass powder, talcum powder and hydroxyapatite. The preparation method comprises the following steps: adding a small number of volatile solvents into the guanidine salt antibacterial agent and the inorganic additives, mixing to be pasty, and uniformly grinding to obtain the high-temperature-resistant composite antibacterial agent; or dissolving the guanidine salt antibacterial agent and the inorganic additives into the solvents, and steaming and removing the solvents to obtain the high-temperature-resistant composite antibacterial agent. The composite antibacterial agent can integrate the immediate action, the broad spectrum and the continuity of an organic system with the safety and the heat resistance of an inorganic system. Compared with an undoped antibacterial agent, the high-temperature-resistant composite antibacterial agent has the advantage that the heat stability is obviously improved. Other accessory components can be added into the antibacterial agent according to specific application.

Owner:WUHAN JASON BIOTECH CO LTD

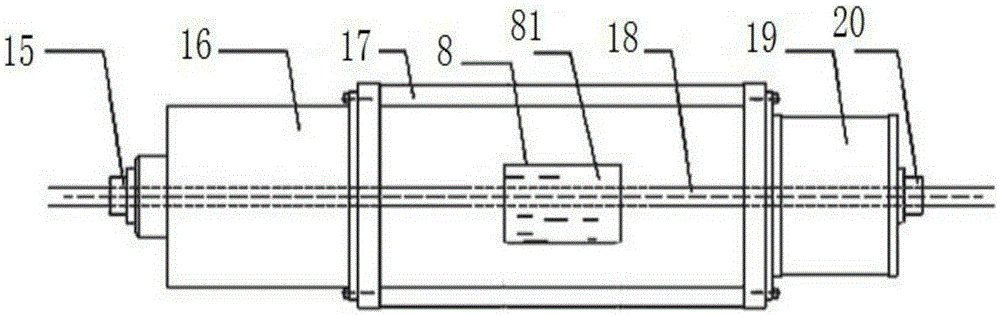

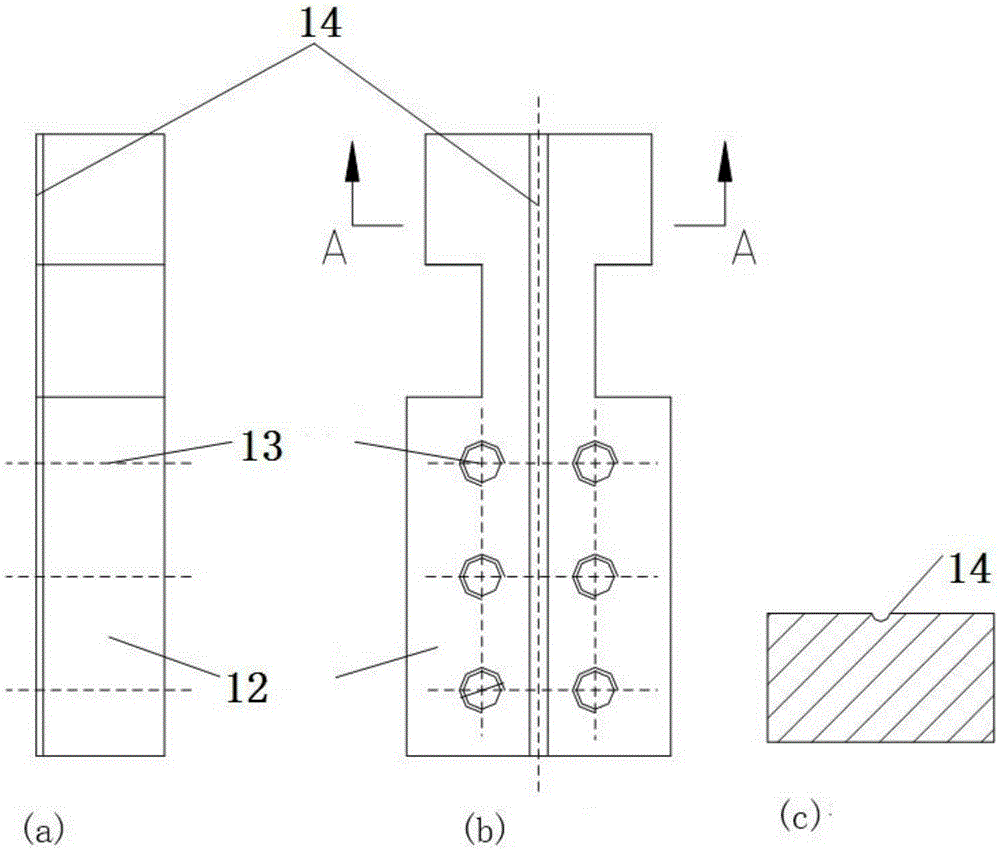

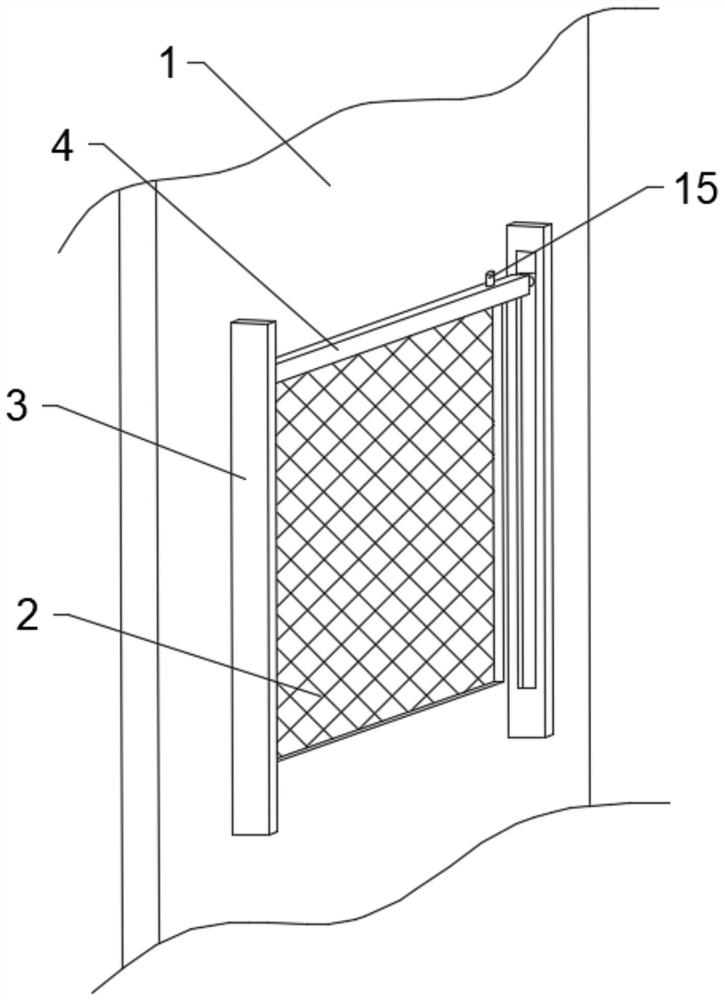

Tension force applying device for steel wire with small diameter

InactiveCN105352813AEasy force valueStaying power valueWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesEngineeringCorrosion

A tension force applying device for a steel wire with a small diameter is disclosed, is used for applying and maintaining tension force to a steel wire with a small diameter, and is particularly used for steel wire corrosion tests under tension states. The device is a balanced lever from the whole, and is free of an external fixing gear. Two ends of the steel wire are fixed to the device through specially prepared clamps, and then tension force is applied to the steel wire through a counterweight. The force with a specific value can be applied to the steel wire simply and conveniently and can be maintained permanently, and no energy is consumed in the maintaining period, thus achieving low carbon and environmental protection.

Owner:ZHEJIANG JIAOKE TRAFFIC TECH CO LTD

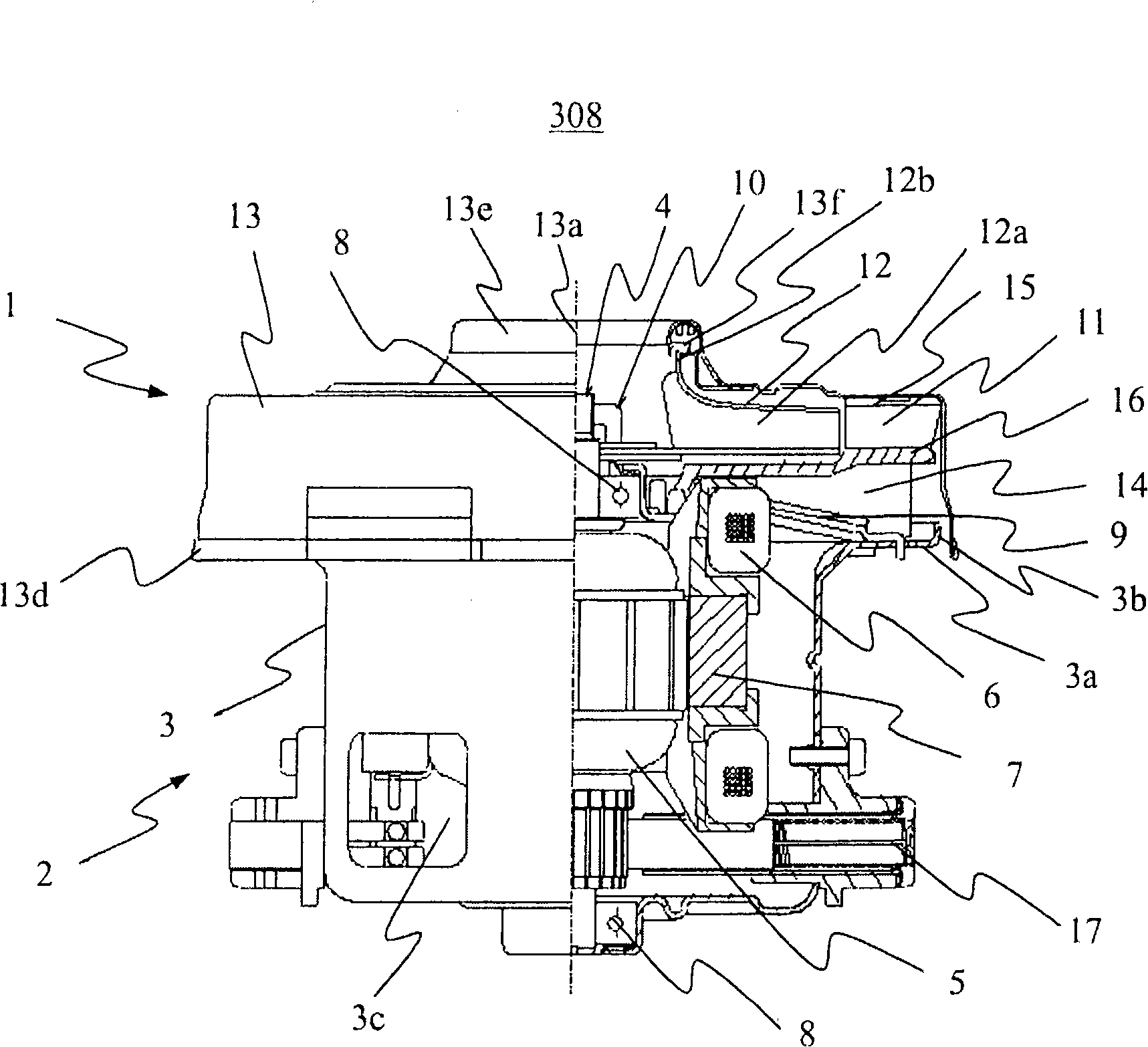

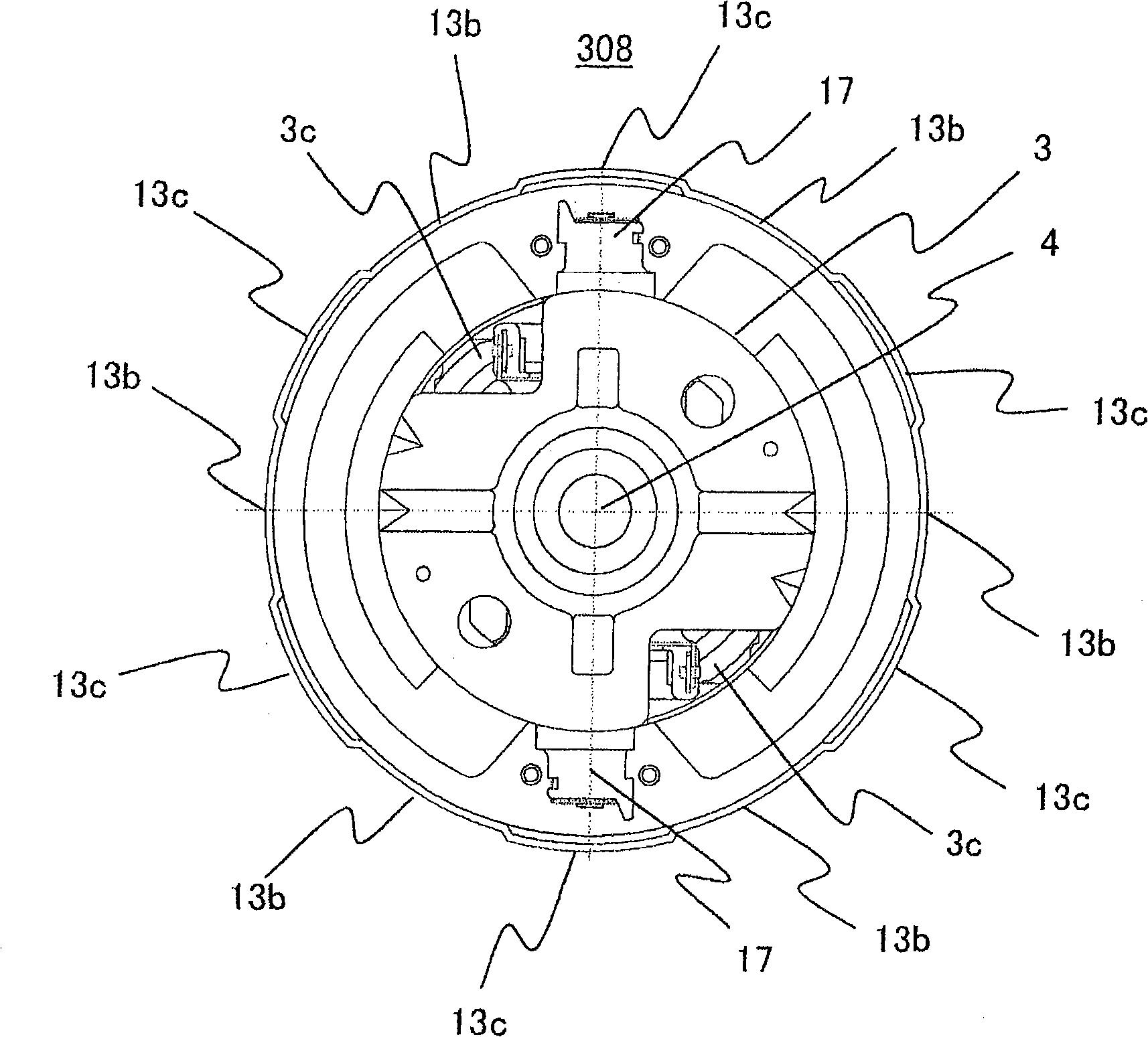

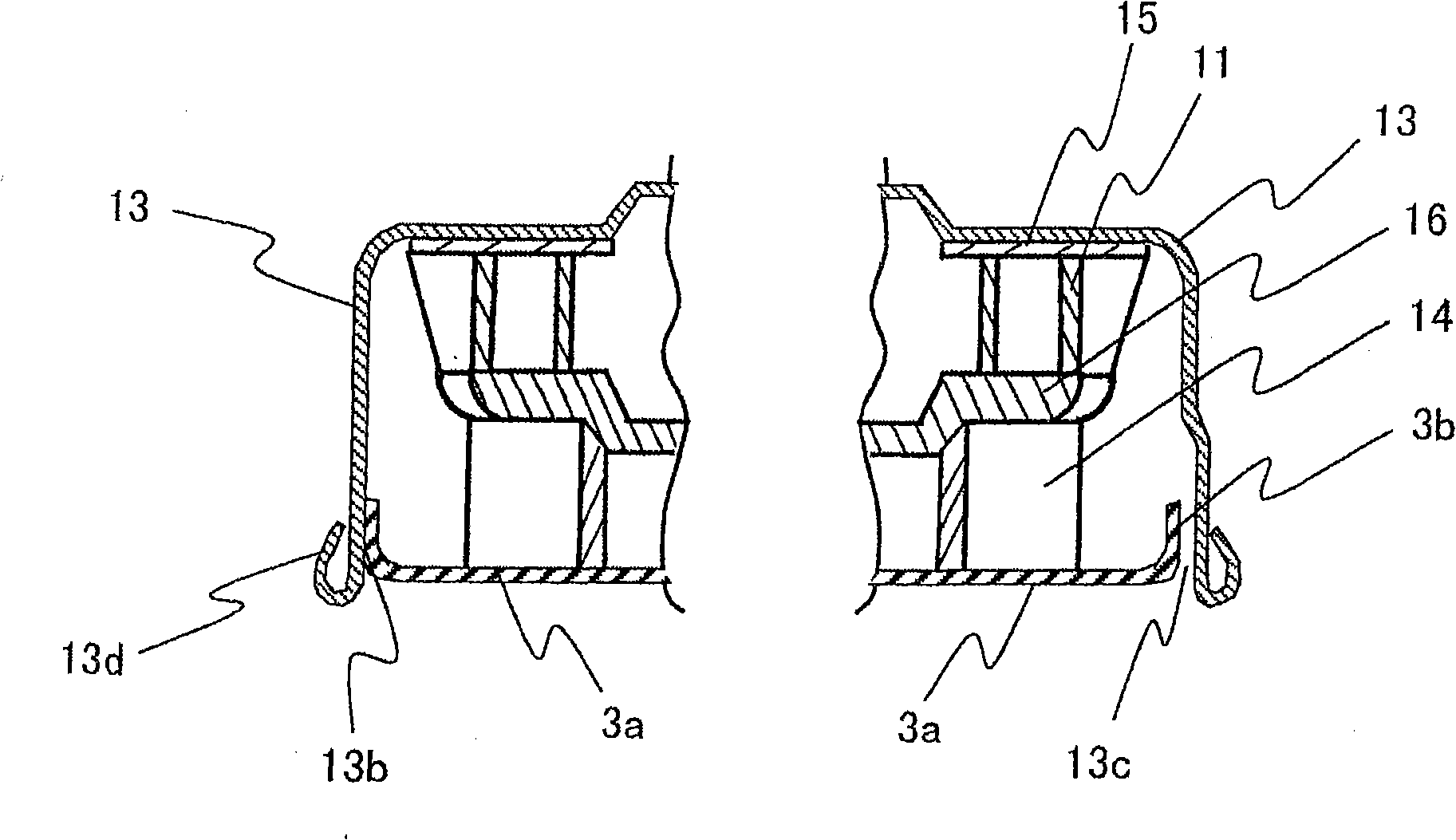

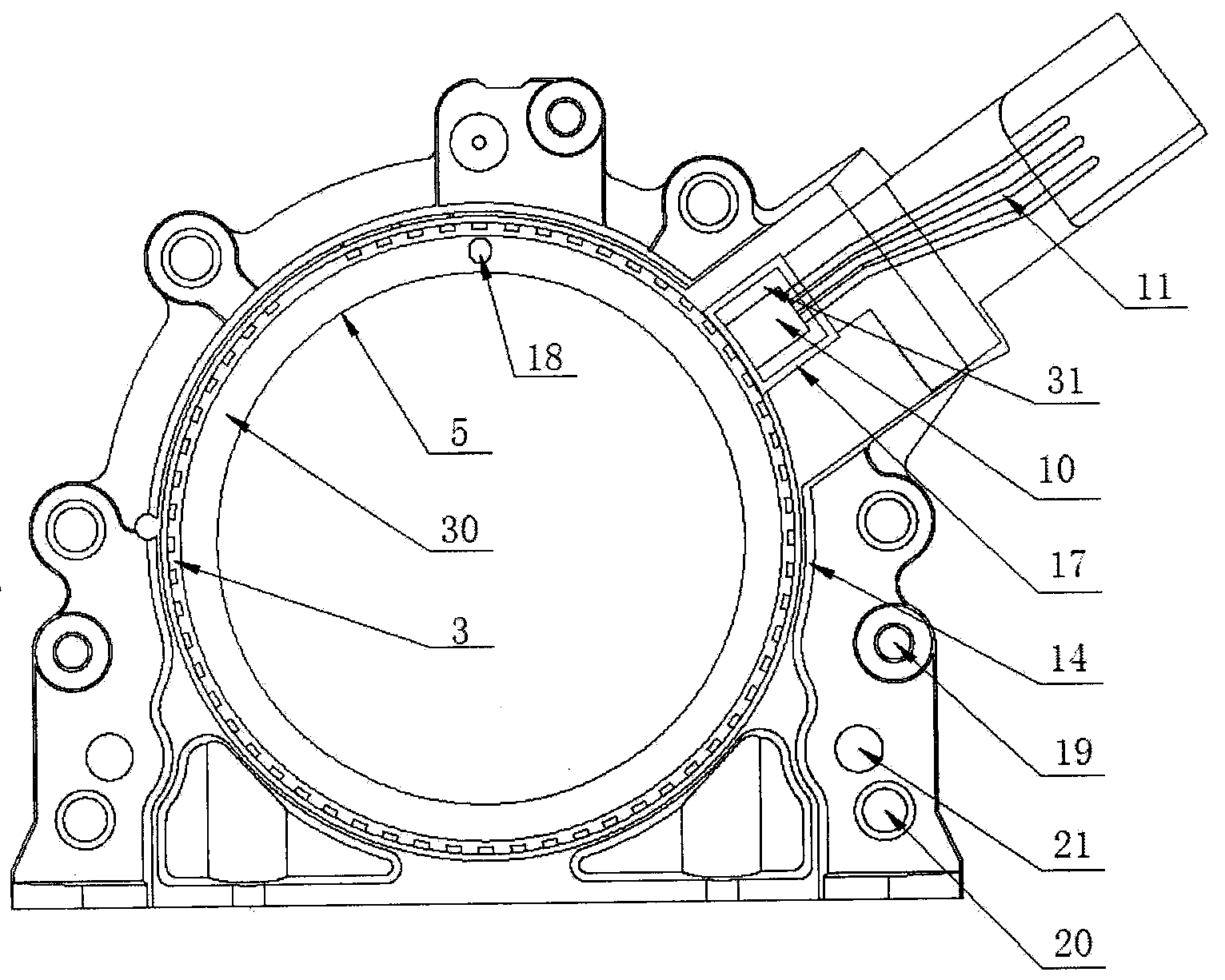

Electric blowing fan and electric vacuum cleaner equipped therewith

ActiveCN101349286APrecise positioningImprove reliabilityPump componentsSuction cleanersCentrifugal fanVacuum cleaner

The invention relates to an electrical blower and an electric dust collector equipped with it. The invention aims to solve the problem that: the shell is distorted while the fan casing is pressed into; and the fan casing can not be kept on the set position, and the eccentricity and inclined installation of the fan casing can reduce the efficiency of the electrical blower. The electrical blower in the invention comprises: a shell for containing the motor, a fan casing installed on the shell covering the centrifugal fan and the diffuser; an extruding part is formed on the opening edge of one end of the shell; a fan casing installing component disposed from the extruding part to the centrifugal fan side or its opposite side; and an installing part contacting with the installing component and a non-installing part not connecting with the installing component are disposed on the inner surface of the fan casing.

Owner:HITACHI APPLIANCES INC

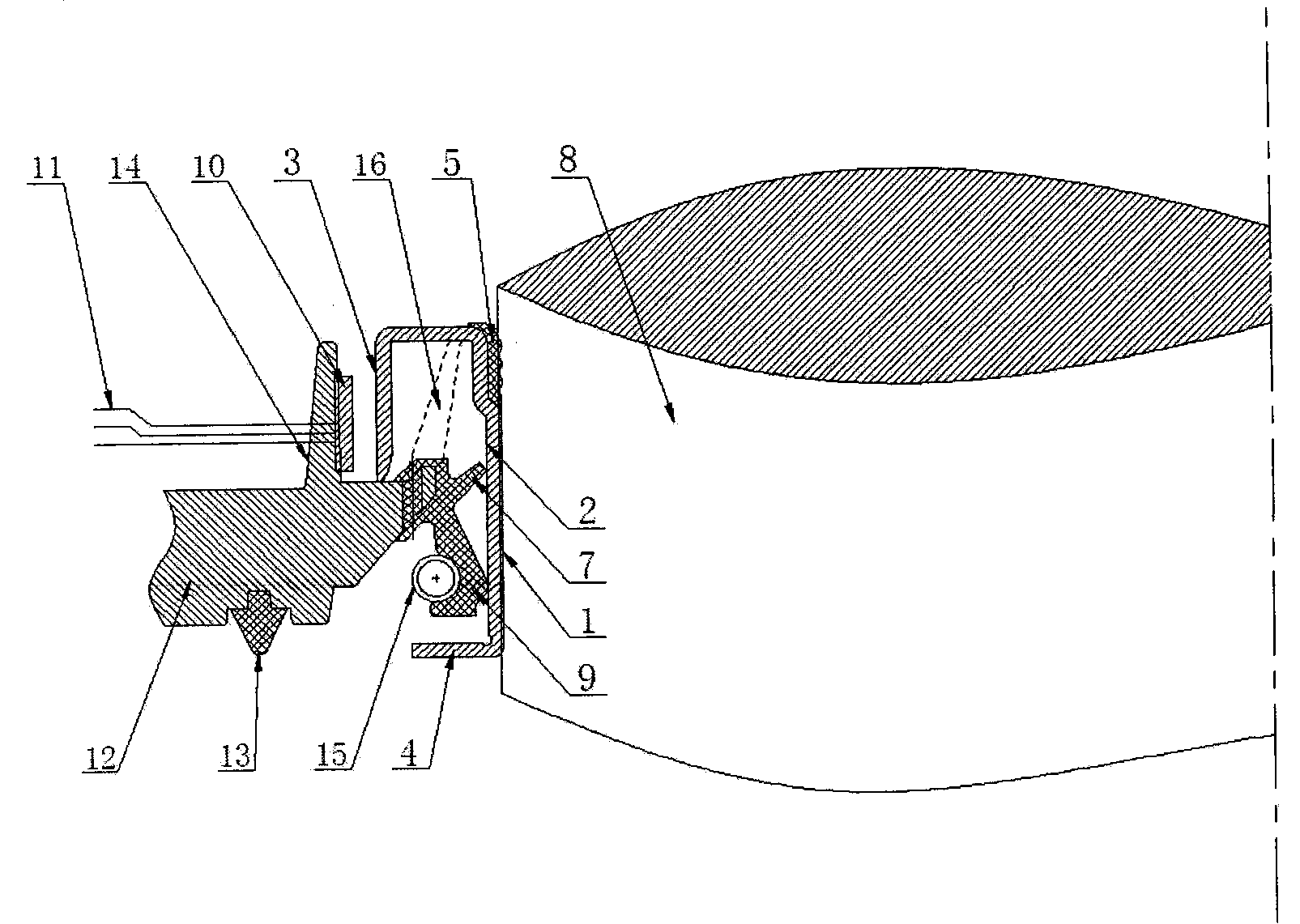

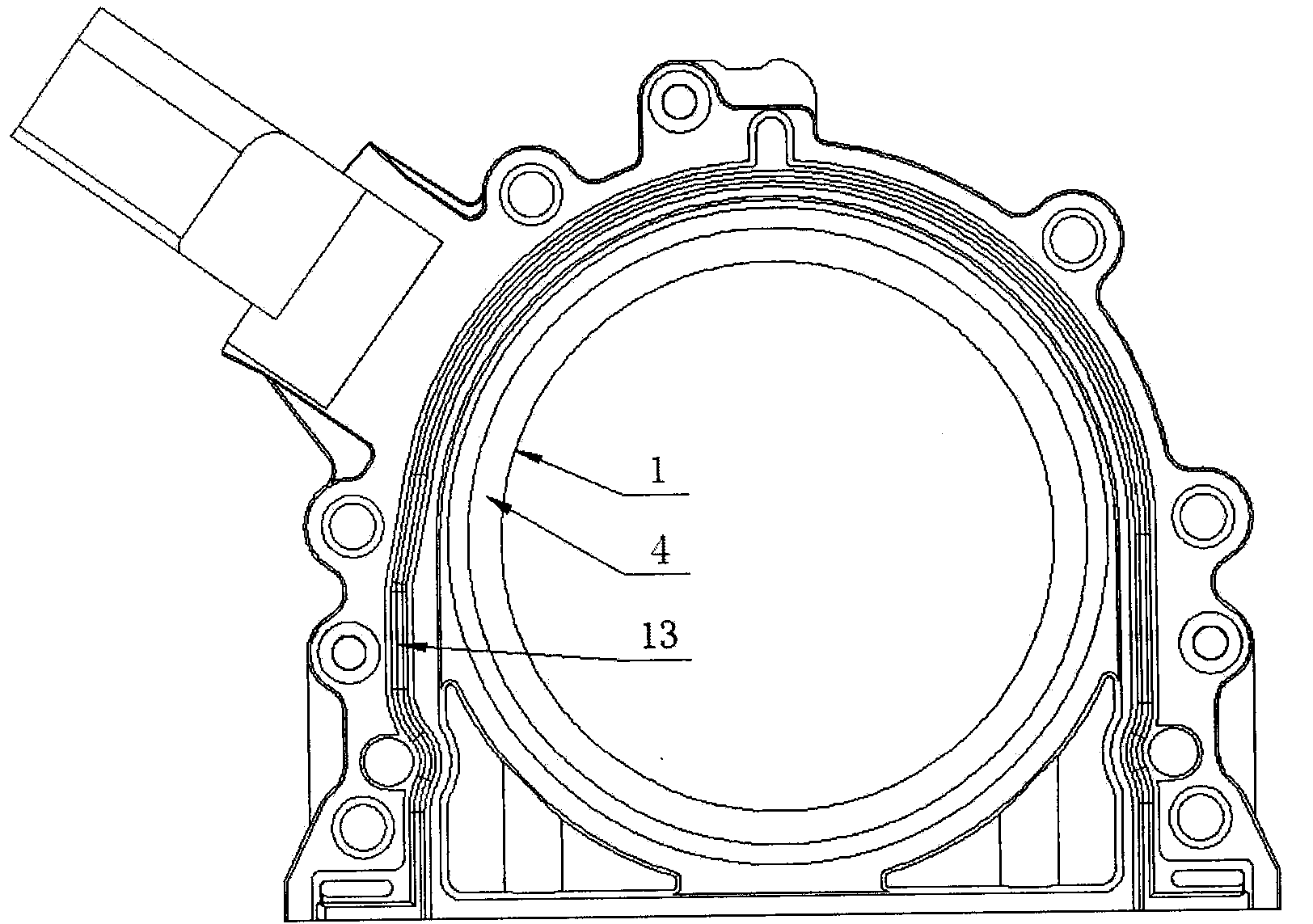

Assembly oil seal with sensing function

ActiveCN103821941AReduce mistakesReduce quality problemsEngine sealsDevices using optical meansCrankshaftInverted u

The invention provides an assembly oil seal with a sensing function. The assembly oil seal with the sensing function comprises a flange, an oil seal lip part matched with the inner ring of the flange, a coder and a sensor corresponding to the coder; the coder is an inverted U-shaped ring with one long end and one short end; the short end of the coder is a coder body arranged on the flange; the inner side of the long end of the coder is matched with the inner ring of the oil seal lip part. The assembly oil seal with the sensing function is durable, capable of accurately detecting the rotary speed of a crankshaft and integrated with the sensor.

Owner:董波 +1

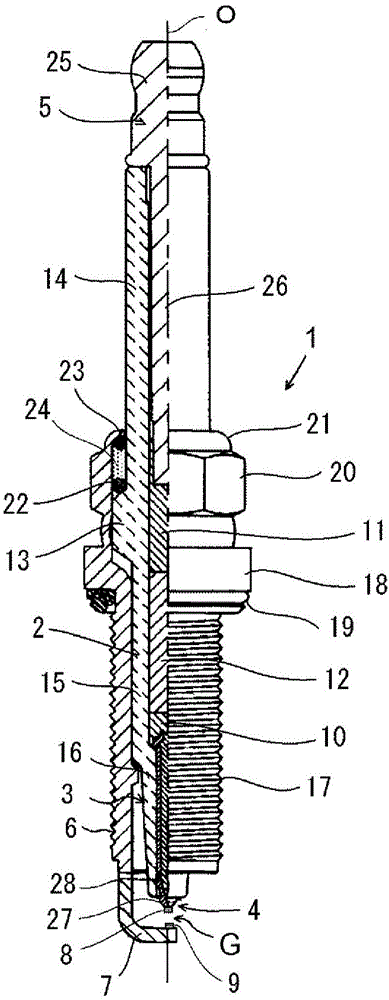

Spark plug

ActiveCN106030942AExcellent consumptionIncreased durabilitySparking plugs manufactureEngineeringPerovskite

The objective of the present invention is to provide a spark plug having excellent durability by providing a central electrode and / or a grounding electrode with a tip having excellent resistance to spark-wear under high-temperature environment. The spark plug is provided with a central electrode and a grounding electrode disposed with a gap from the central electrode, said spark plug being characterized in that: there is a tip forming the gap on the central electrode and / or the grounding electrode; the tip has a metal matrix, whereof the main constituent is Ir, and oxide particles containing at least one species of oxide having a perovskite structure represented by the general formula ABO3 (where A is at least one species selected from the group 2 elements of the periodic table, and B is at least one species selected from the metal elements); and the proportion of the surface area occupied by the oxide particles upon observation of the cross section of the tip is 1% to 13% inclusive.

Owner:NGK SPARK PLUG CO LTD

Vegetable seed coating agent and preparation method thereof

InactiveCN108558487AImprove survival rateWill not polluteBiocideAlkali orthophosphate fertiliserEnvironmental resistanceFilm-forming agent

The invention aims to provide a vegetable seed coating agent and a preparation method thereof, and discloses the vegetable seed coating agent. The vegetable seed coating agent is prepared from, by weight, 42-48 parts of slow release fertilizer, 2-4 parts of bactericide, 16-20 parts of traditional Chinese medicine extracts, 6-8 parts of curing agent, 4-6 parts of film-forming agent, 3-5 parts of humic acid and 2-6 parts of gibberellin, wherein the mass ratio of the slow release fertilizer to the bactericide to the traditional Chinese medicine extracts is (3-5):(1-3):1. The coating agent is goodin sterilization effect and environmentally friendly, and has high application values and good application prospects.

Owner:ANHUI HUAHE SEED CO LTD

Restoration amendment for heavy metal-contaminated soil of metal mine

InactiveCN106381149AImproved agglomeration structureImprove water and fertilizer retention performanceOrganic fertilisersSoil conditioning compositionsTreatment effectPotassium

The invention provides a soil amendment. The soil amendment comprises the following active components: elemental nitrogen, elemental potassium, elemental phosphorus, humic acid, organic matters and microbes. According to the invention, agricultural waste can be used as the restoration amendment for heavy metal contamination of a metal mine, so the soil amendment provided by the invention is convenient in preparation of raw materials, low in cost, simple to operate and good in applicability; the soil amendment has synergistic and complementary effect and exerts additive restoration and treatment effect; and the soil amendment realizes comprehensive utilization of the waste, is free of secondary pollution, accords with the concept of ecological environmental protection, achieves the purpose of recycling of resources and produces ecological, economical and social benefits.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

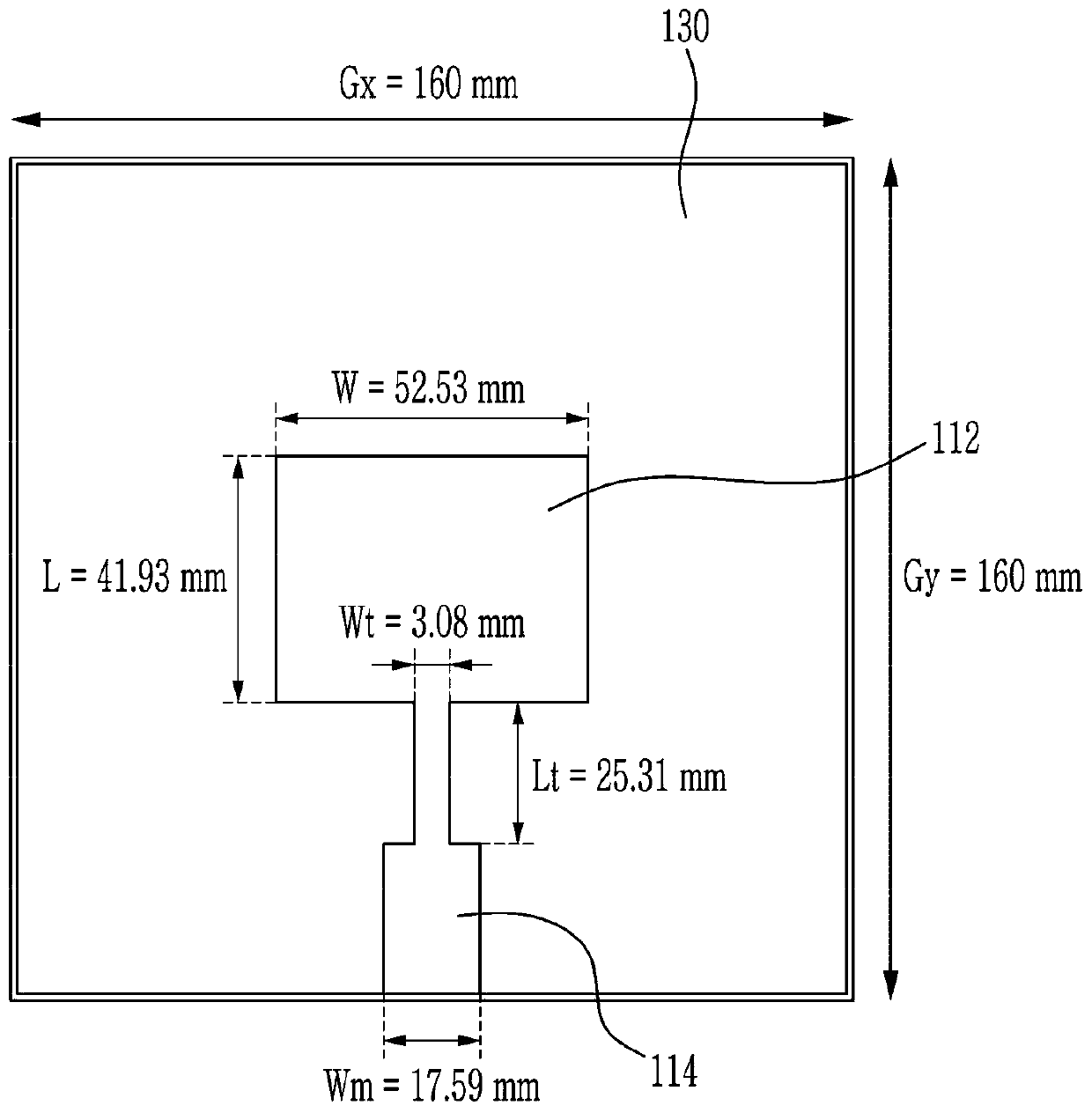

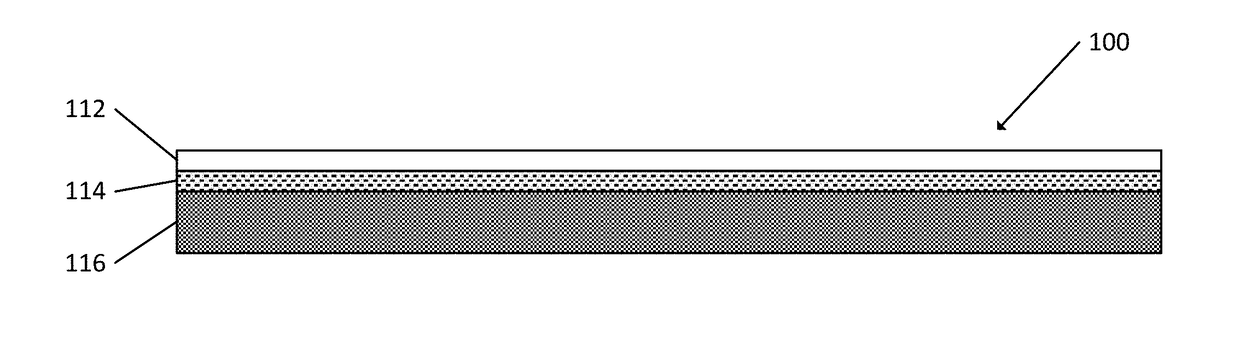

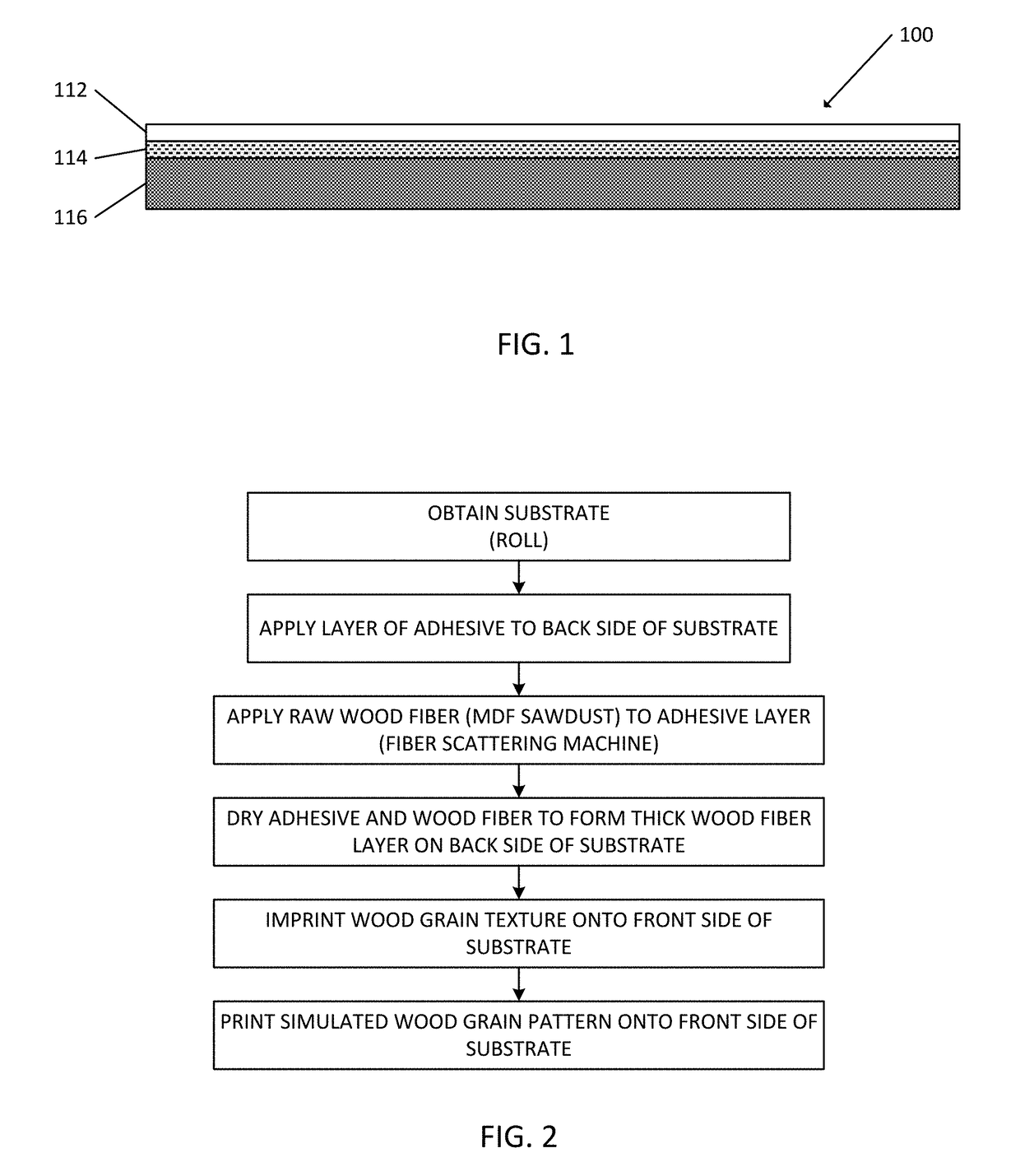

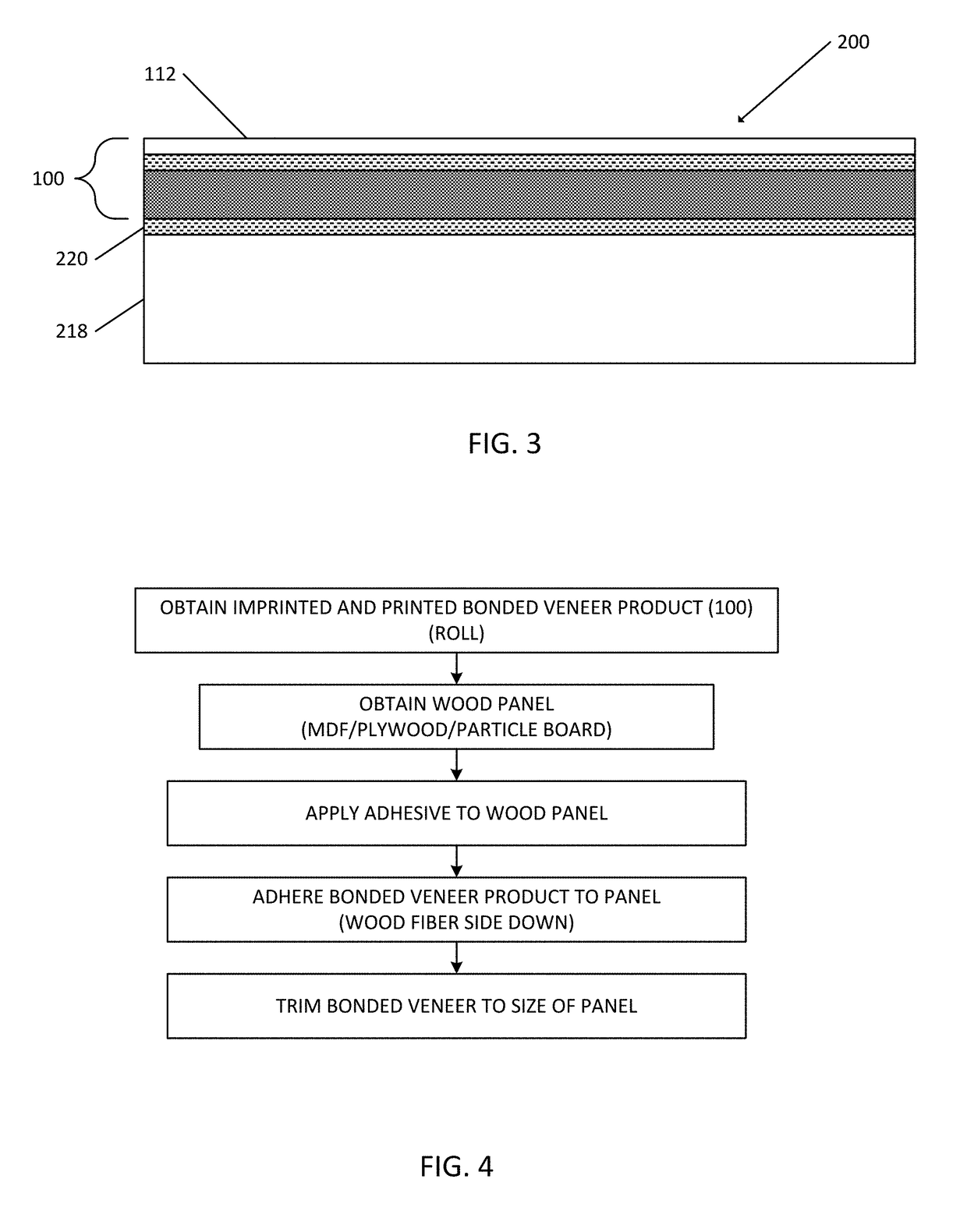

Bonded veneer with simulated wood grain and texture, bonded veneer panels and method of making the same

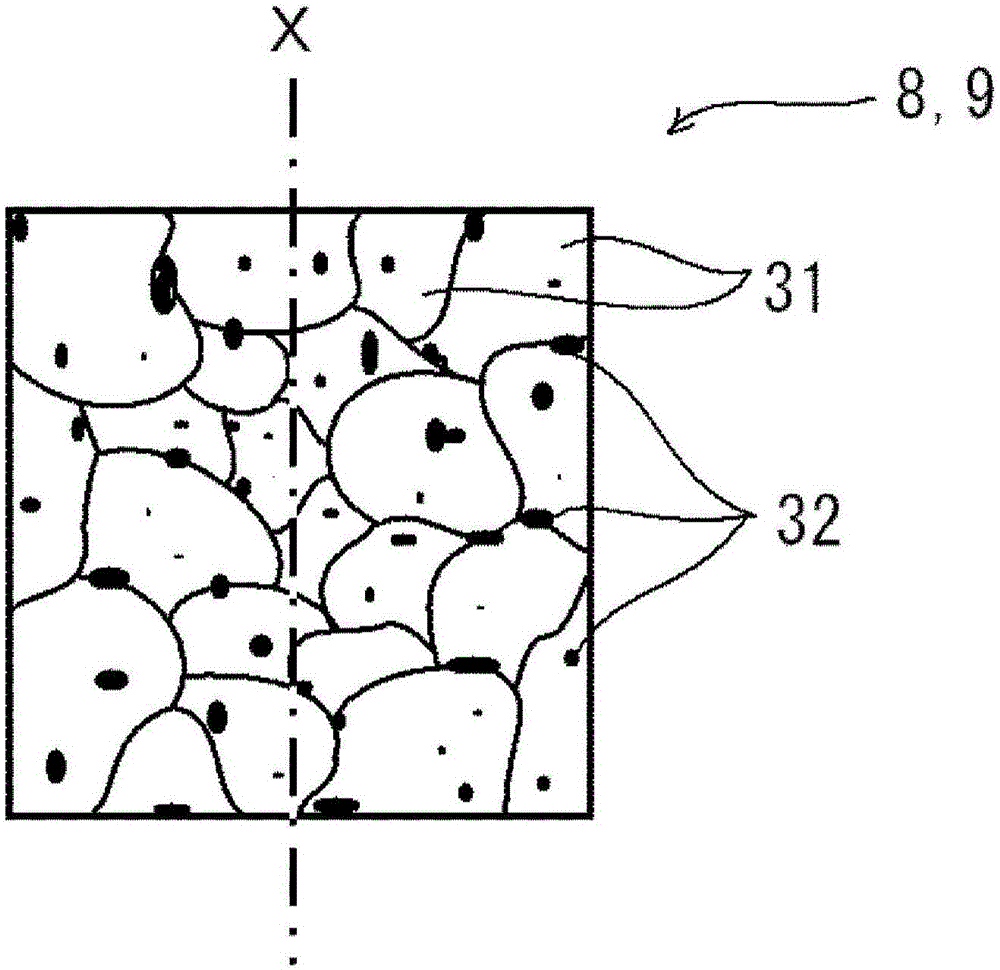

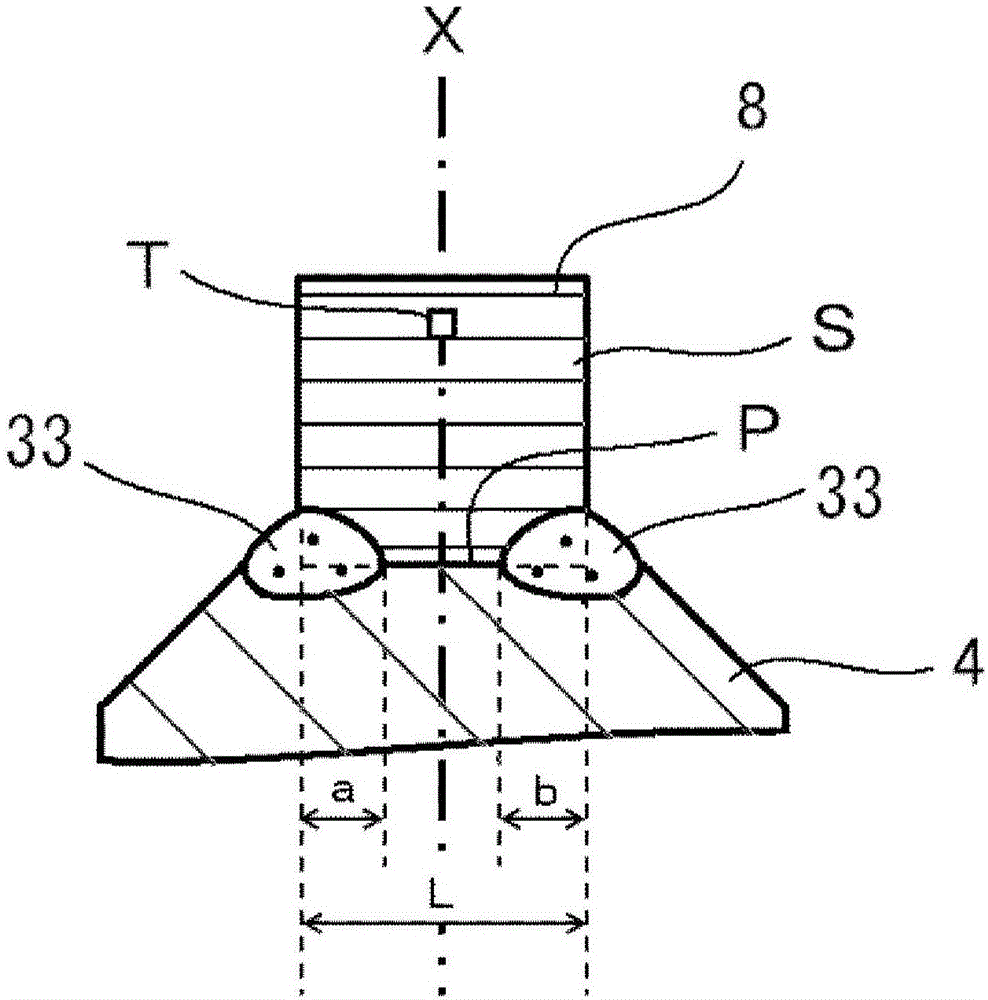

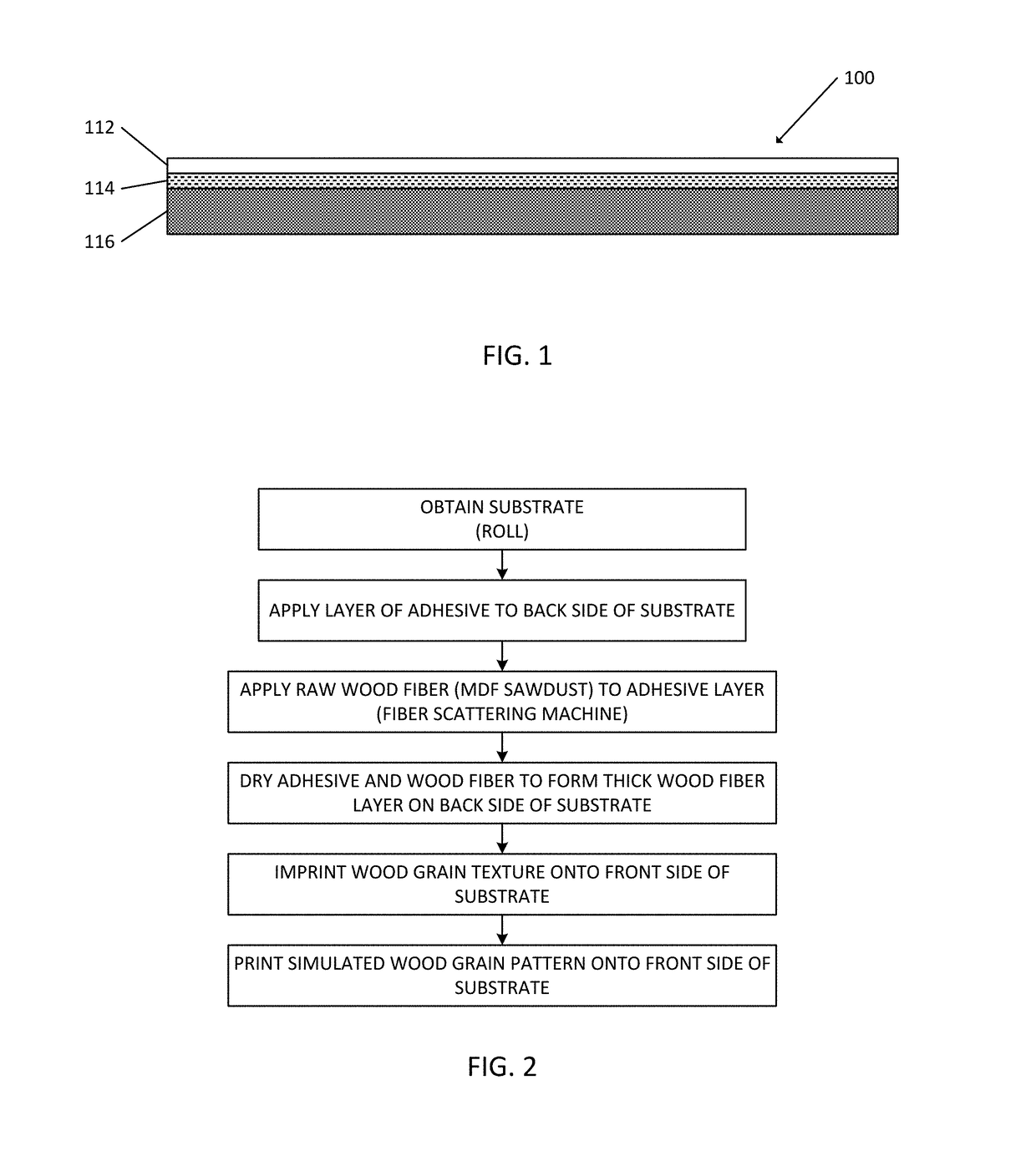

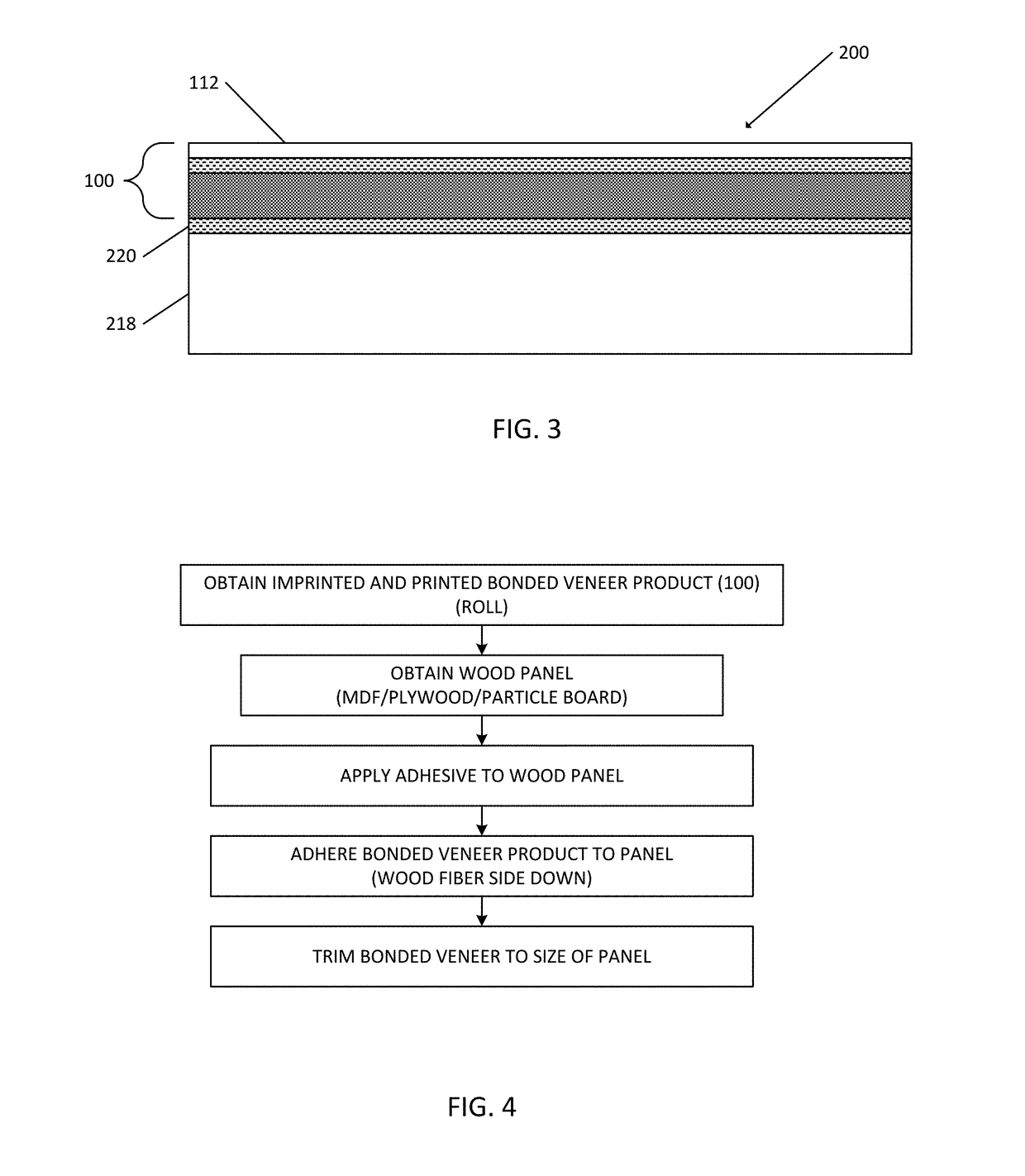

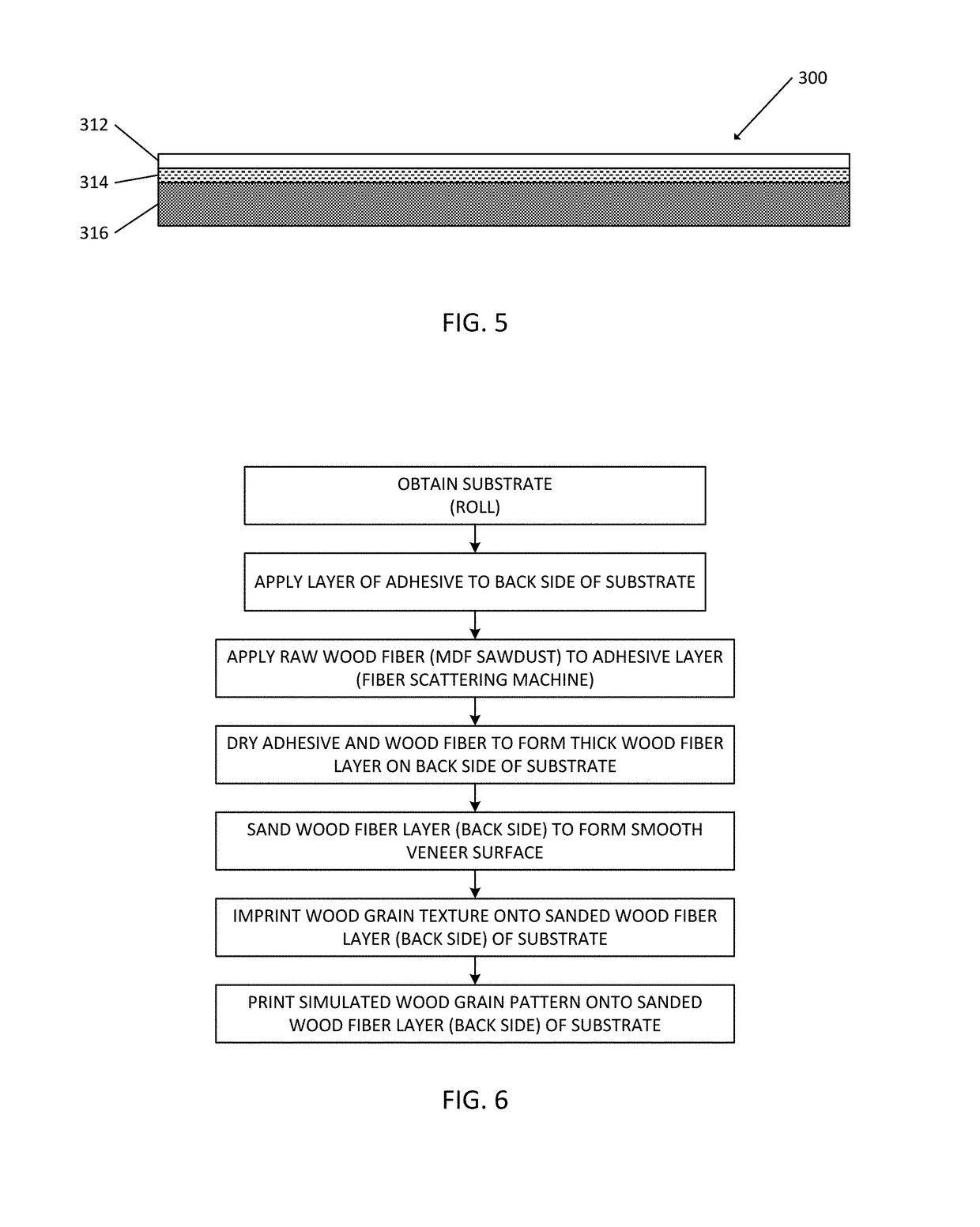

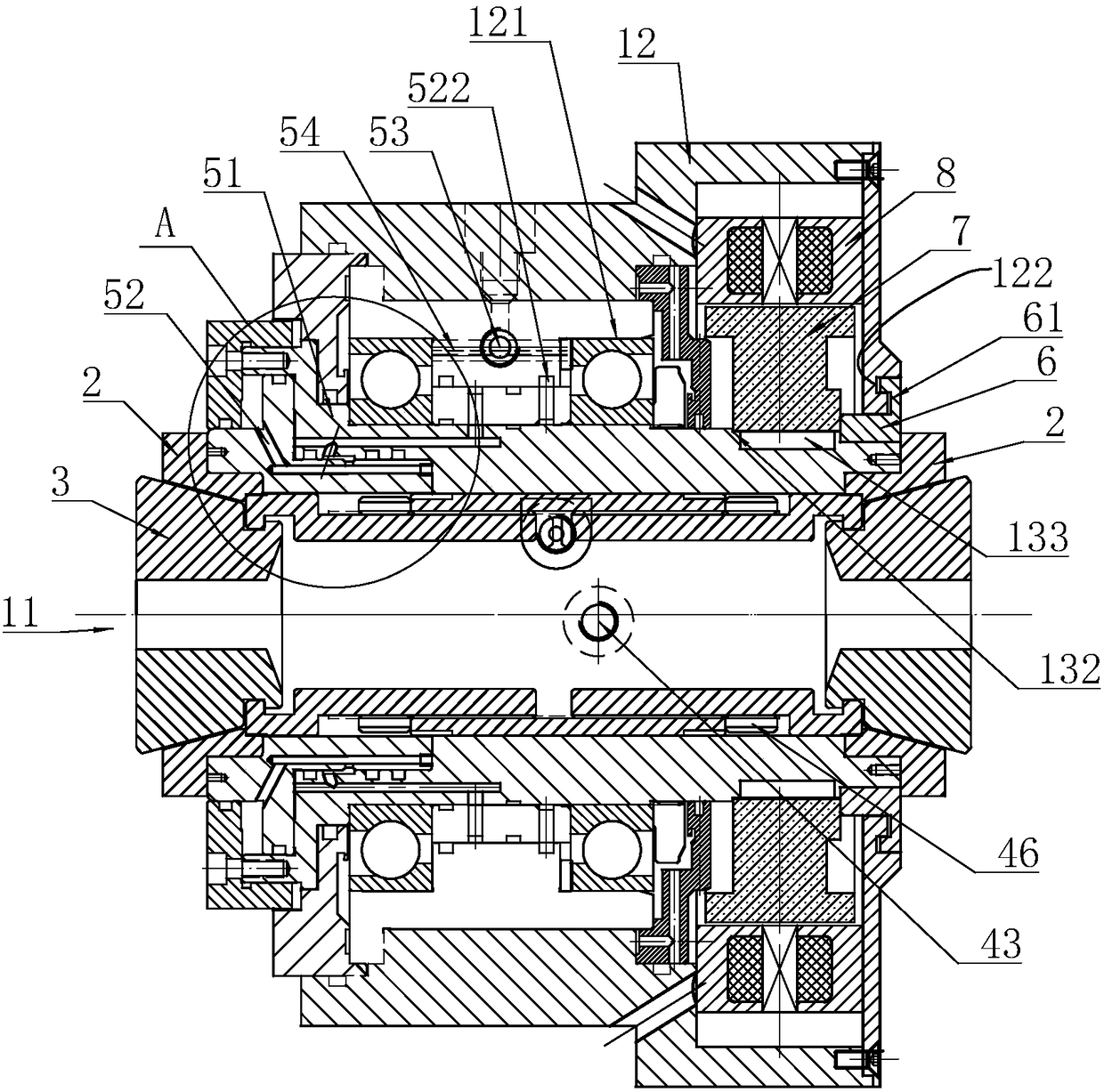

InactiveUS10220597B2Improves strength and stabilityLow costOther plywood/veneer working apparatusSpecial ornamental structuresWood veneerFiber

A simulated wood veneer product is disclosed. The simulated wood veneer product includes a paper substrate and an imprintable wood fiber material applied to one side of the paper substrate. The imprintable wood fiber material provides the paper substrate with depth and allows the paper to receive and retain an imprinted wood grain texture. Once imprinted, the veneer product is printed with a simulated wood grain pattern to create a realistic simulated veneer product which is referred to herein as a "bonded veneer". The bonded veneer product can then be adhered to a structural or composite wood panel, such as an MDF panel, to create a simulated wood veneer panel which can be used in the construction of furniture products.

Owner:LIVING STYLE B V I LTD

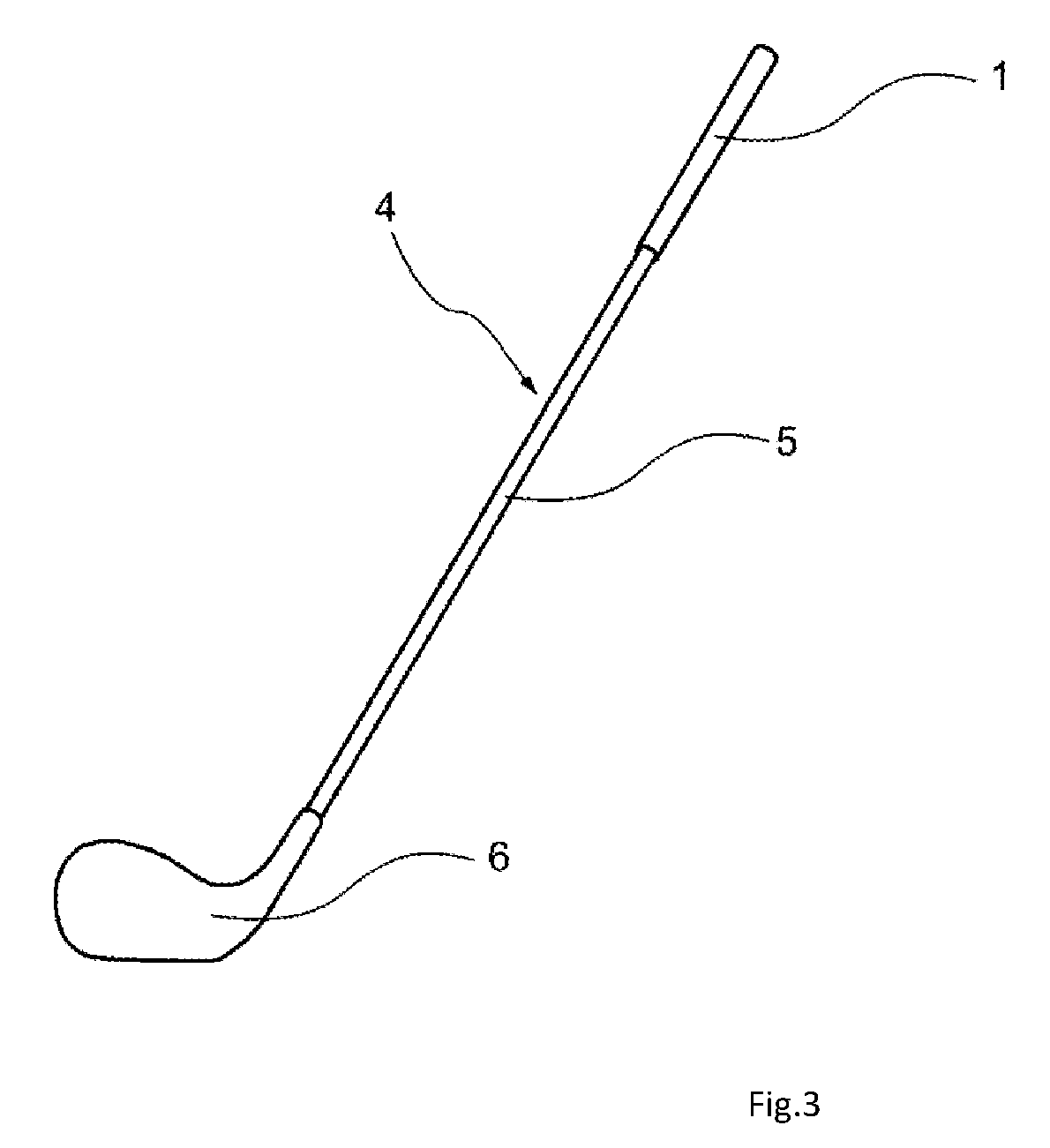

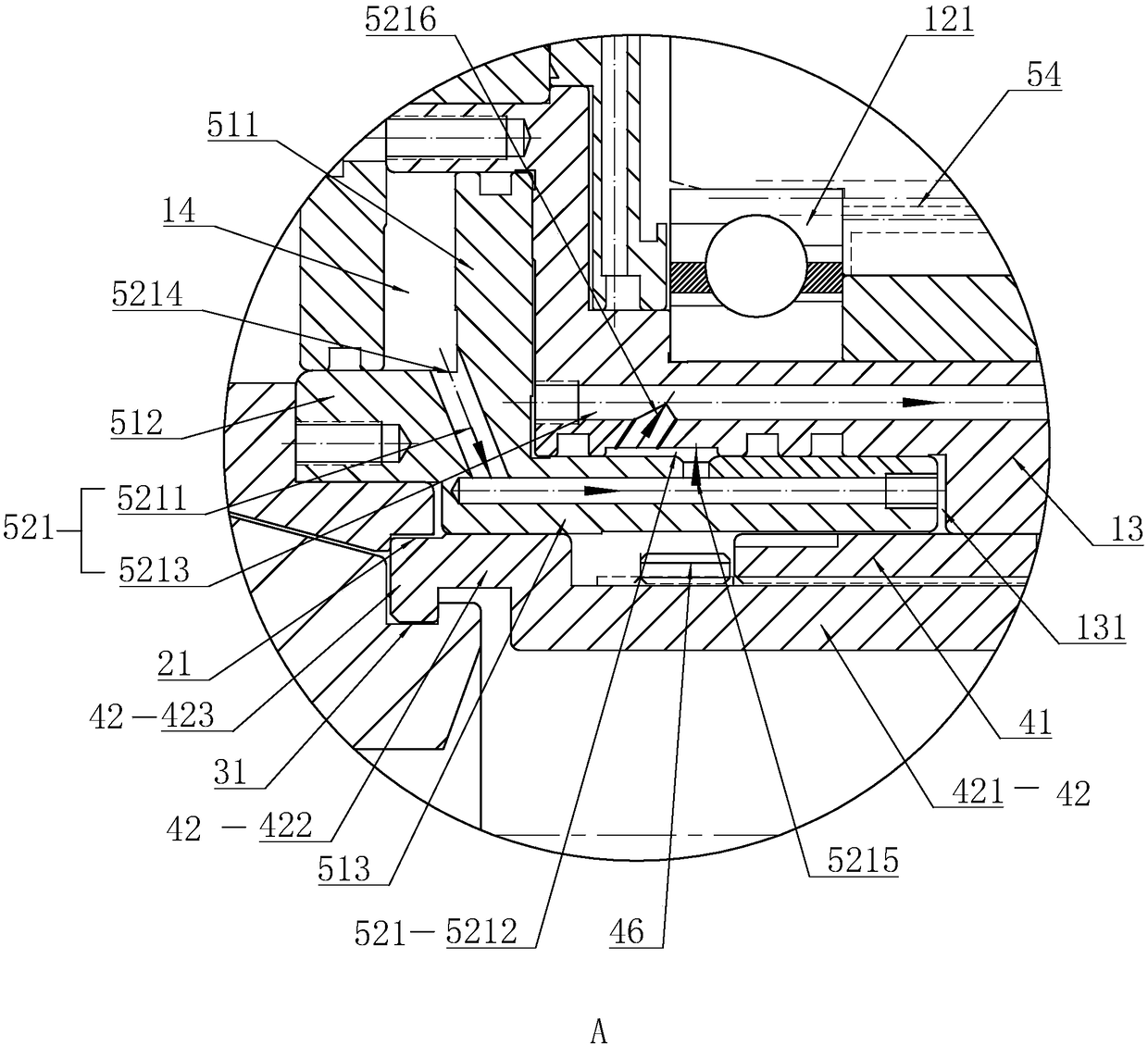

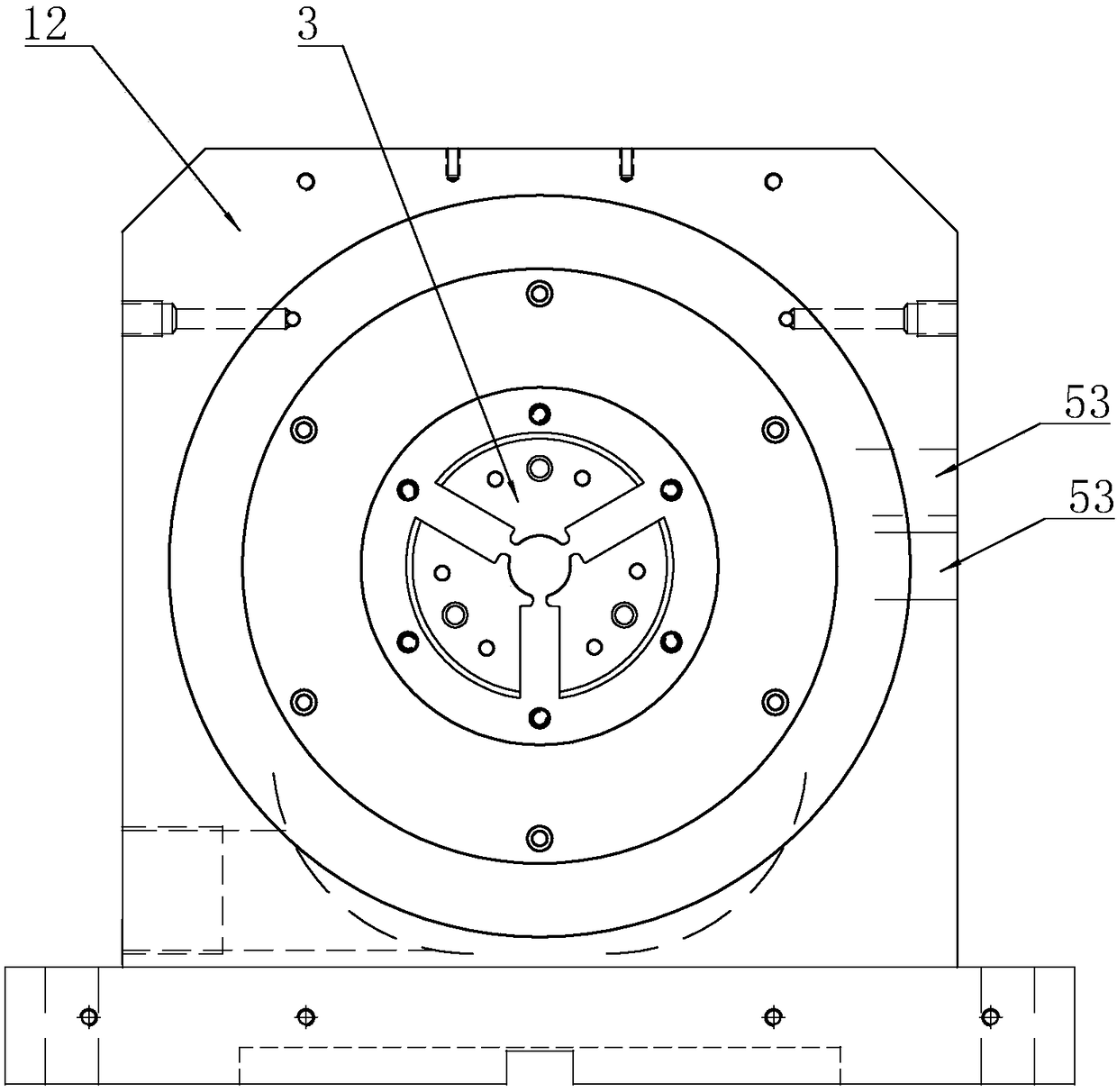

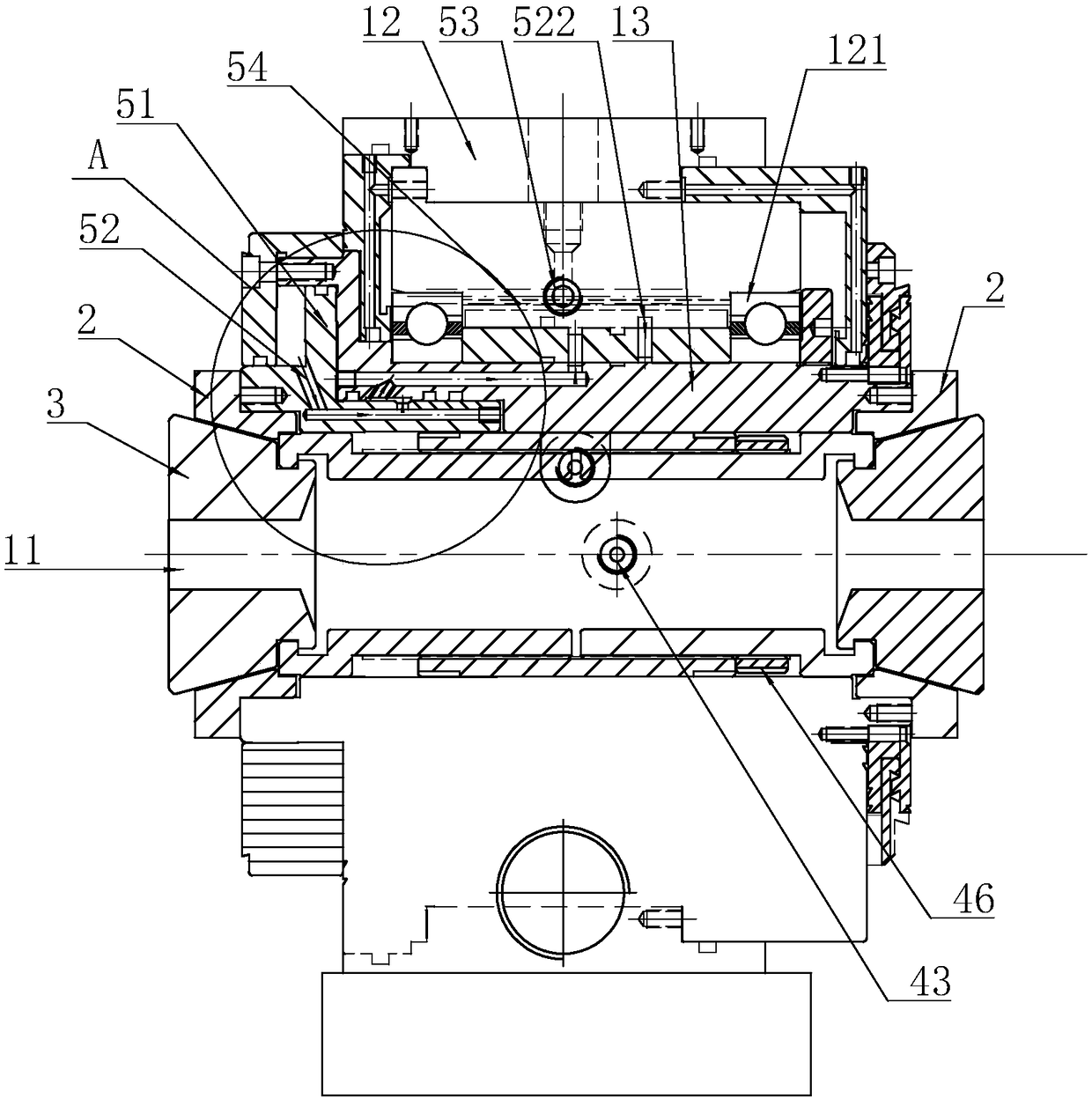

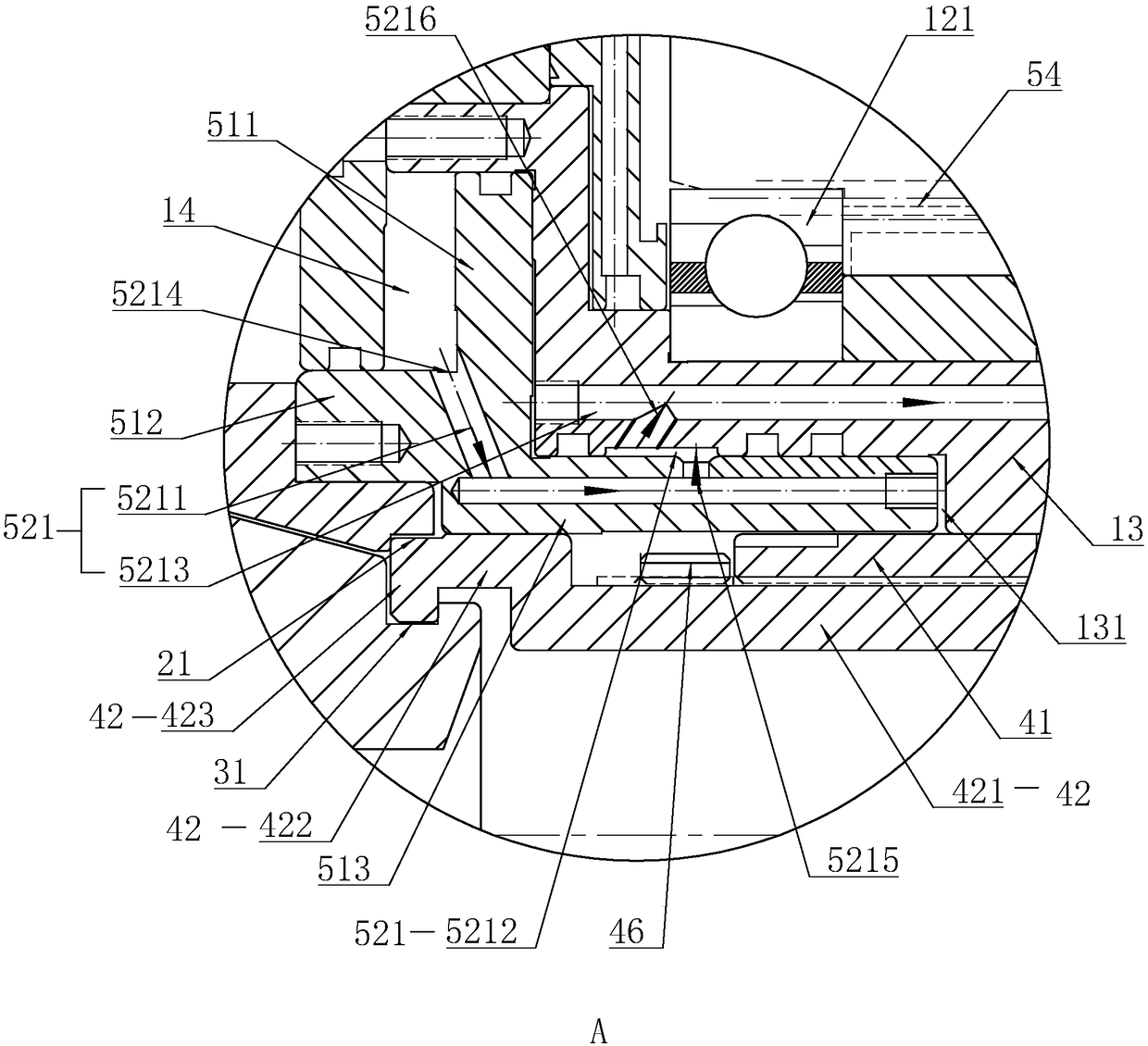

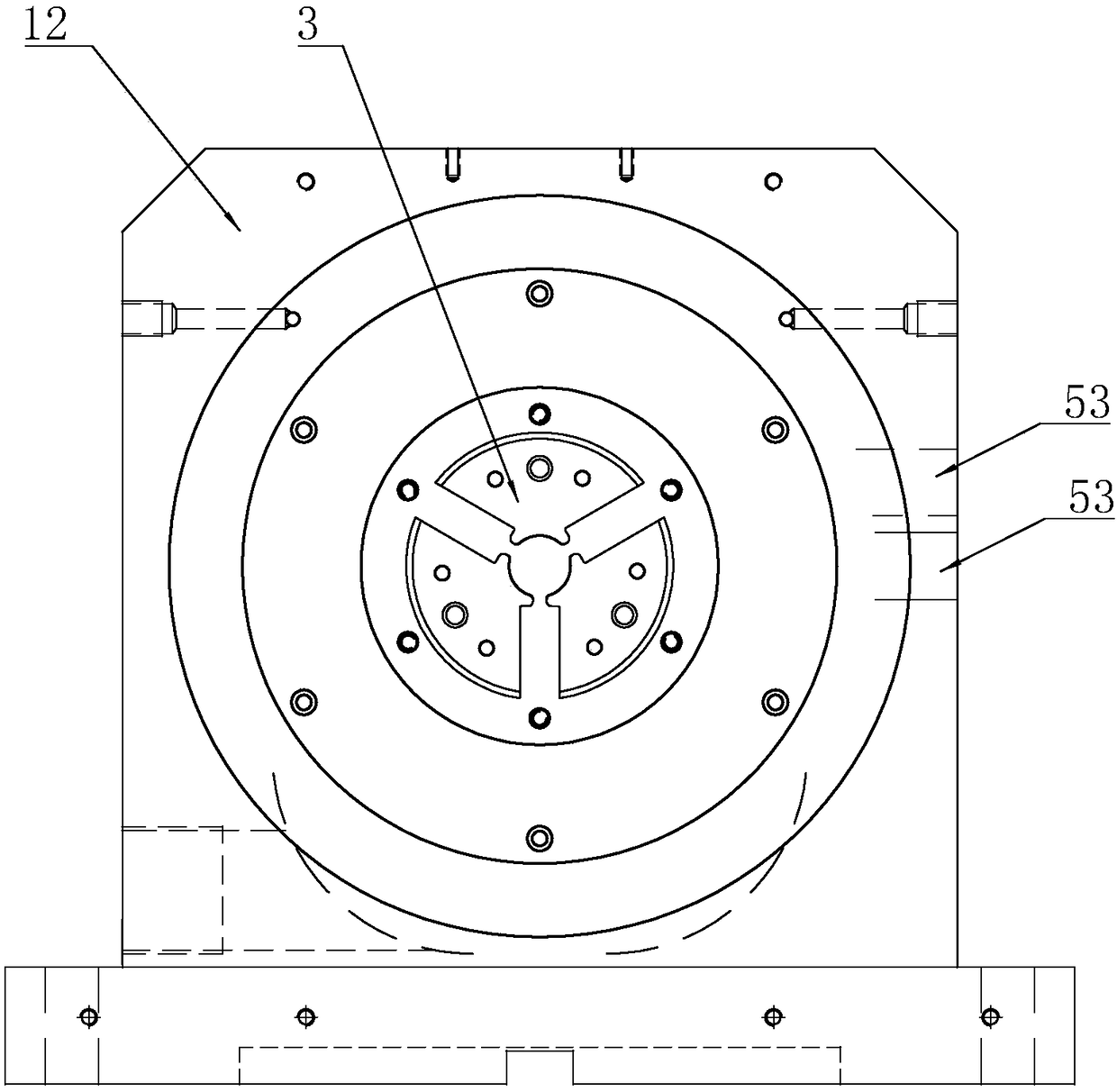

Middle driving electric spindle

The invention discloses a middle driving electric spindle. The middle driving electric spindle comprises a shell sleeve assembly, two extending sleeves and clamping sleeves, wherein the shell sleeve assembly is provided with through holes, the detachable extending sleeves are fixedly arranged at the two ends of the shell sleeve assembly, the clamping sleeves are embedded in the extending sleeves and used for clamping a work-piece, the surface of the circumference of each clamping sleeve is an oblique plane and abuts the inner wall of the corresponding extending sleeve, and a pull sleeve is connected between the two clamping sleeves; the shell sleeve assembly further comprises a box body and a seat sleeve rotationally connected to the inner portion of the box body, one end of one of the axial directions of the seat sleeve is provided with a control structure driving one of the extending sleeves to move along the axial direction; the outer wall of the other end of the seat sleeve is provided with an annular fixing connection groove, a rotor is sleeved with the fixing connection groove, and one end of the rotor abuts the side wall of the fixing connection groove; the other end of therotor abuts a water-proof ring in sleeved connection with the seat sleeve; a stator corresponding to the rotor is fixedly arranged in the box body; a driving structure is built-in, so that the structure is more compact, the transmission loss is reduced, the sealing effect of a spindle structure is effectively improved, and the service life of the spindle is greatly prolonged.

Owner:台州屹捷数控机床股份有限公司

Method for preventing leaf falling of zanthoxylum bungeanum maxim in autumn and winter and application thereof

ActiveCN114258817AImprove leaf area indexImprove the effect of ecological restorationFertilising methodsCultivating equipmentsZanthoxylum bungeanumEssential amino acid

The invention discloses a method for preventing leaf falling of zanthoxylum bungeanum maxim in autumn and winter and application of the method, and belongs to the technical field of crop planting. The method mainly comprises the following steps: (1) water and fertilizer management; (2) red rust prevention and control; (3) branch management. According to the method, the leaf falling condition of the zanthoxylum bungeanum maxim can be remarkably improved, meanwhile, the yield of the zanthoxylum bungeanum maxim is increased, and the content of essential amino acid, non-essential amino acid, umami amino acid, bitter amino acid, pharmacodynamic amino acid, carotene, vitamin E and the like in the peel of the zanthoxylum bungeanum maxim and the dry matter content of the zanthoxylum bungeanum According to the method for preventing leaf falling of the zanthoxylum bungeanum maxim in autumn and winter, the yield and quality of the zanthoxylum bungeanum maxim are improved, and a foundation is laid for stability and sustainability of the zanthoxylum bungeanum maxim ecological industry.

Owner:GUIZHOU NORMAL UNIVERSITY

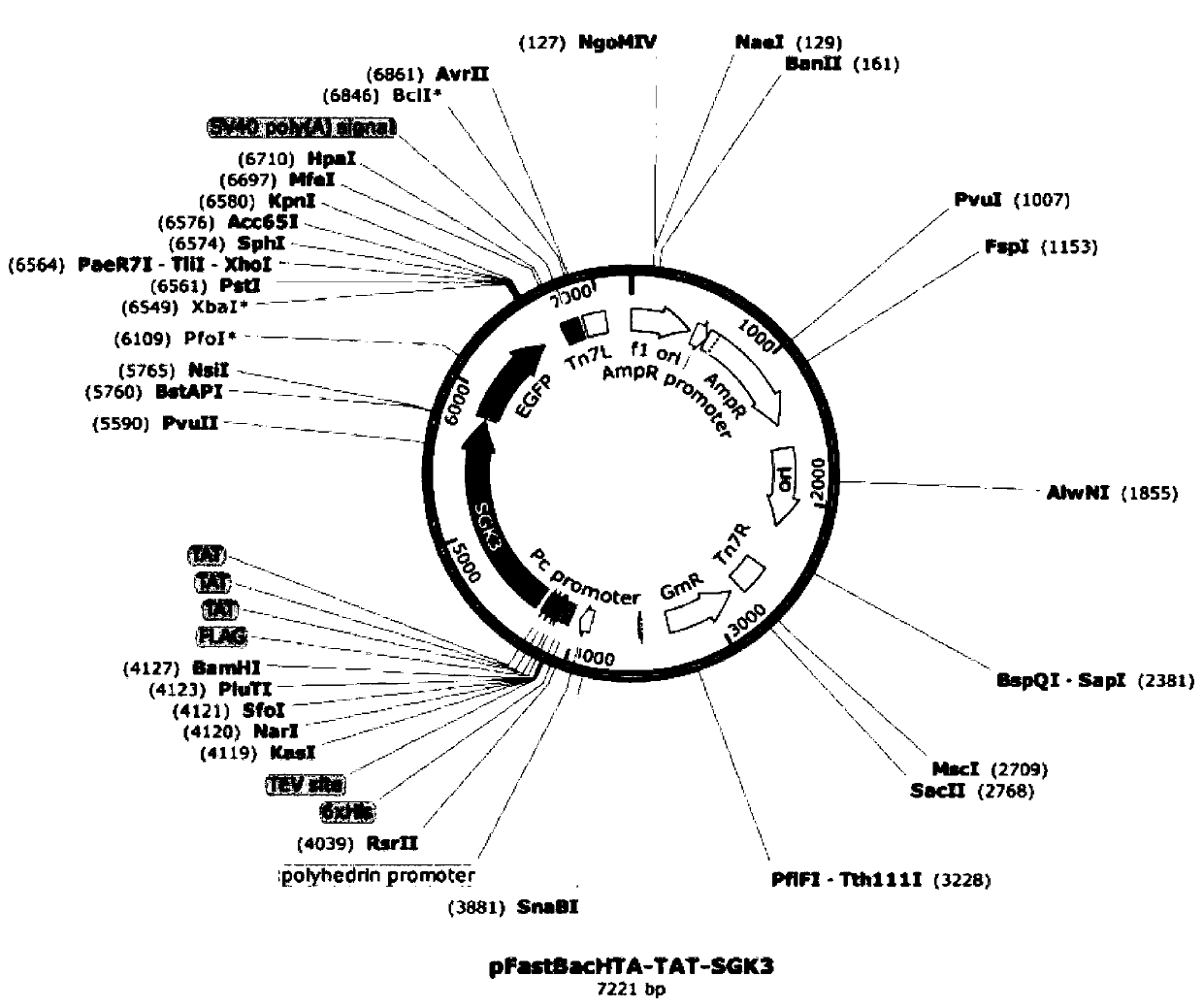

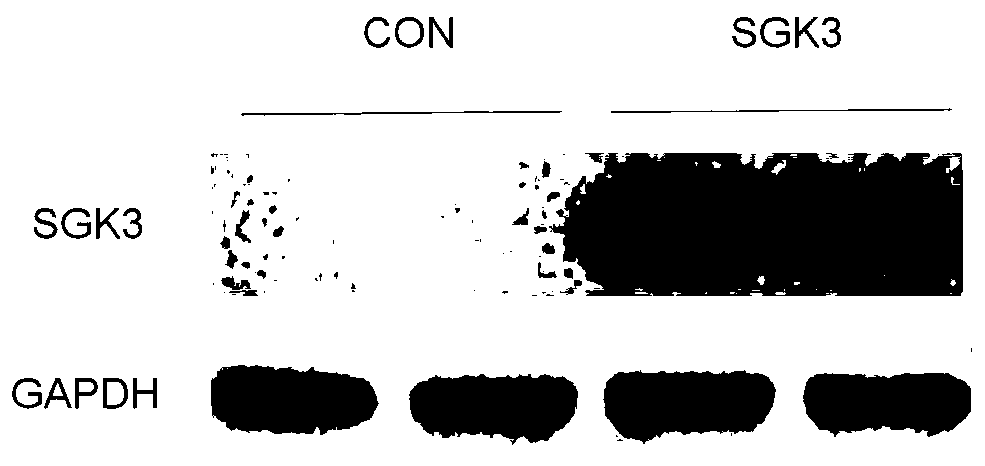

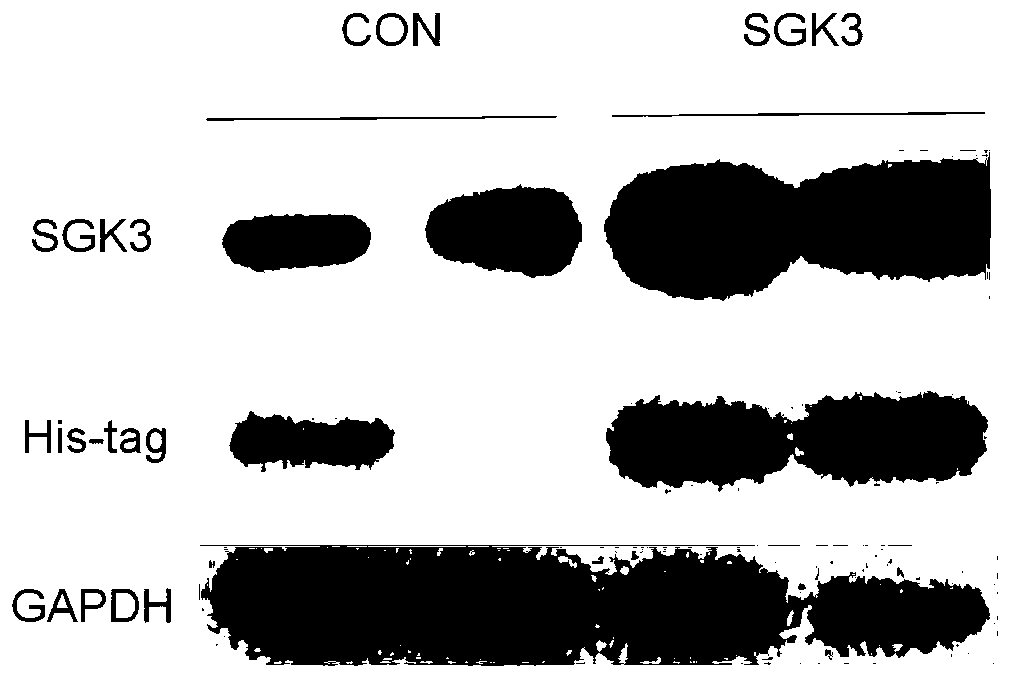

Recombinant human SGK3 protein kinase hydrogel as well as preparation method and application thereof in promoting myocardial regeneration

PendingCN110982802APromotes cardiomyocyte proliferationPromote myocardial regeneration and repairPolypeptide with localisation/targeting motifPeptide/protein ingredientsBiophysicsCell cycle

The invention provides recombinant human SGK3 protein kinase hydrogel as well as a preparation method and an application thereof in promoting myocardial regeneration, which relate to the technical field of biomedicine. The injectable hydrogel is prepared by mixing a gelling precursor molecule prepolymer solution and recombinant human SGK3 protein kinase according to a certain ratio. The recombinant human SGK3 protein kinase is formed by connecting an SGK3 protein kinase sequence and a cell-penetrating peptide sequence through a connecting peptide, and after local administration, the SGK3 protein kinase can regulate the cell cycle progress by activating a key pathway of cell proliferation, promote myocardial regeneration and repair after myocardial infarction, reduce the scar area and improve the cardiac function. Besides, after solid-phase conversion of the liquid-phase hydrogel at body temperature is generated, slow release of the recombinant human SGK3 protein kinase is facilitated to continuously play a role, and support is provided for regenerated myocardial cells.

Owner:王连生

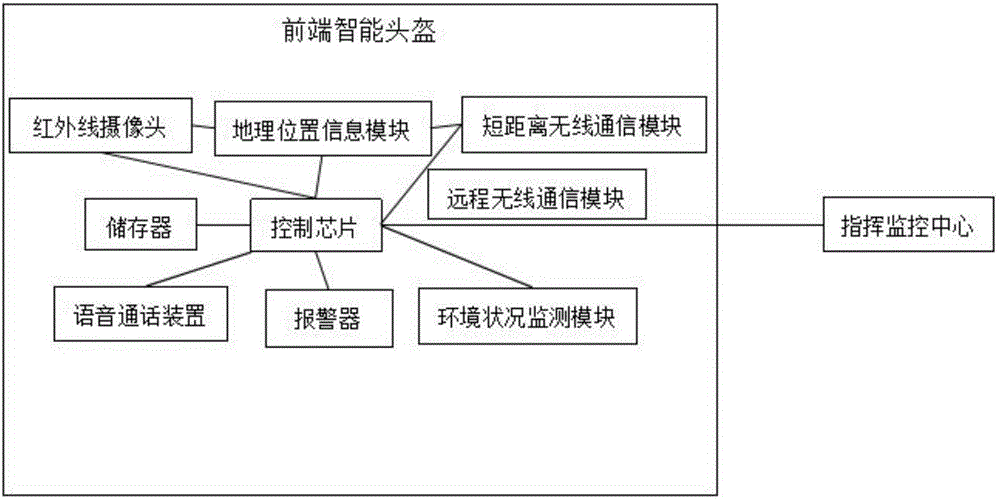

Front-end smart helmet control system

InactiveCN106773856AImprove securityImprove adaptabilityProgramme control in sequence/logic controllersInfraredVoice communication

The invention discloses a front-end smart helmet control system. The front-end smart helmet control system comprises a plurality of front-end wireless individual wearable devices and a command and monitor center; every front-end wireless individual wearable device is communicated with the command and monitor center and comprises a helmet body, the outer surface of the helmet body is provided with an infrared camera, a voice communication device, an alarming device and a display screen, the helmet body is provided with two layers of cavity structures front outside to inside, including an external-layer cavity structure and an internal-layer cavity structure, the external-layer cavity structure is filled with nano carbon fiber layers, and the inside of the internal-layer cavity structure is provided with a positioning module, a microprocessor, a memory, a short-distance wireless communication module and a remote wireless communication module. The front-end smart helmet control system is high in safety performance, strong in adaptability to emergencies and high in communication quality.

Owner:GUANGZHOU TUWEIHUI INFORMATION TECH CO LTD

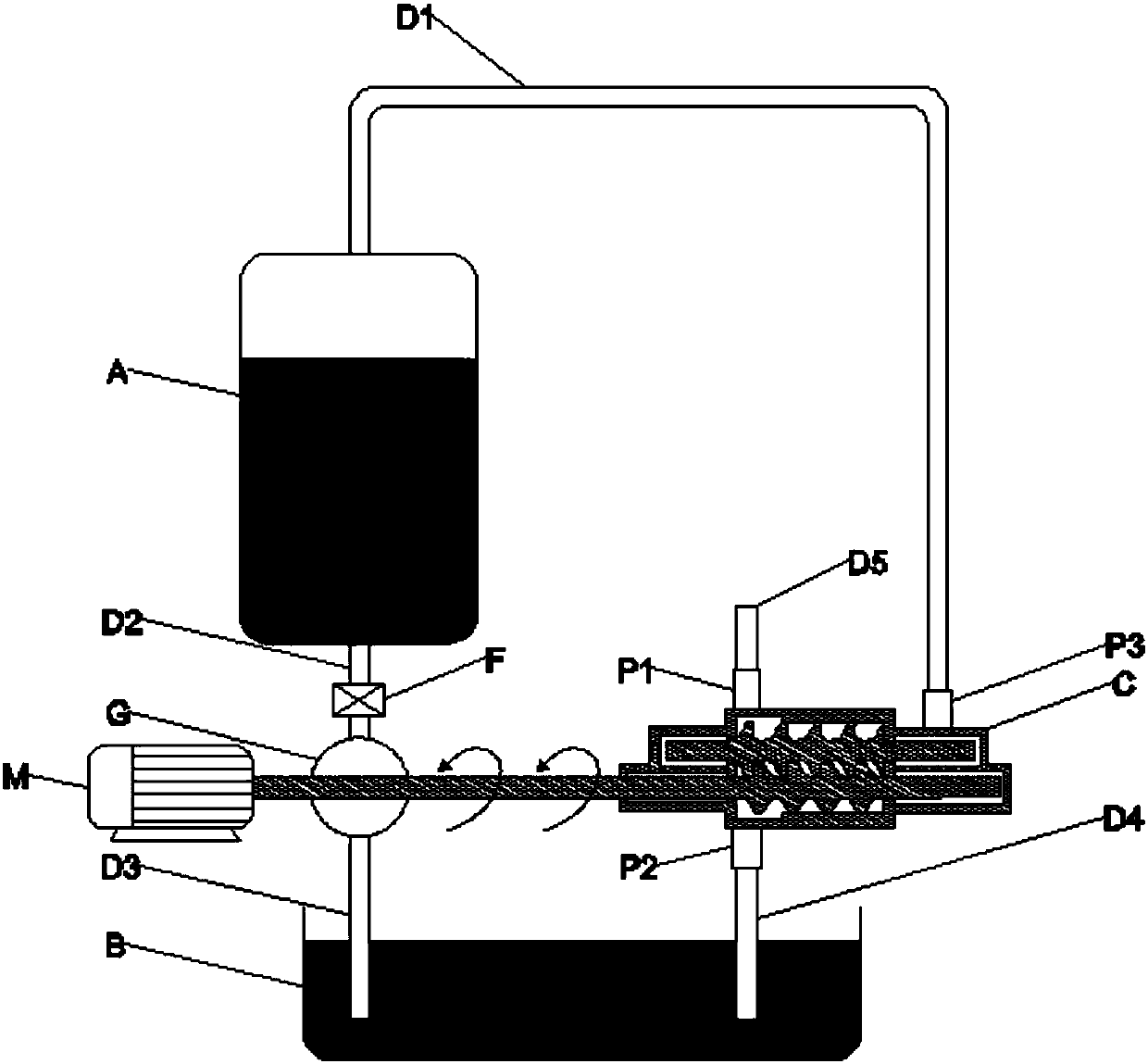

Special air compressor system for supplying air to constant-pressure air storage source

ActiveCN107917074AImprove compression efficiencyReduce complexityHydro energy generationRotary/oscillating piston combinationsPower storageAir compressor

The invention belongs to the technical field of power storage and particularly relates to a special air compressor system for supplying air to a constant-pressure air storage source. The system comprises a motor M, a water turbine G and a screw-type air compressor C which are connected sequentially and coaxially; one end of the water turbine G is connected with the bottom of a pressure vessel A bythe aid of a high-pressure liquid pipeline D2; a flow valve F is mounted on the high-pressure liquid pipeline D2; the top of the pressure vessel A is connected with an exhaust opening P3 of the screw-type air compressor C by the aid of a high-pressure air pipeline D1; the other end of the water turbine G and a water inlet P2 of the screw-type air compressor C are connected with a low-pressure reservoir B separately; and an air inlet P1 of the screw-type air compressor C is connected with the atmosphere. During operation, the screw-type air compressor C is driven by the motor M to rotate, outside air and low-pressure water flow into the air compressor to be mixed and compressed and then are sent to the pressure vessel A, meanwhile, the flow valve F is controlled to discharge high-pressurewater in the equal volume in the pressure vessel A to the water turbine G, and the water turbine G drives the screw-type air compressor C to run continuously by the aid of the high-pressure water.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

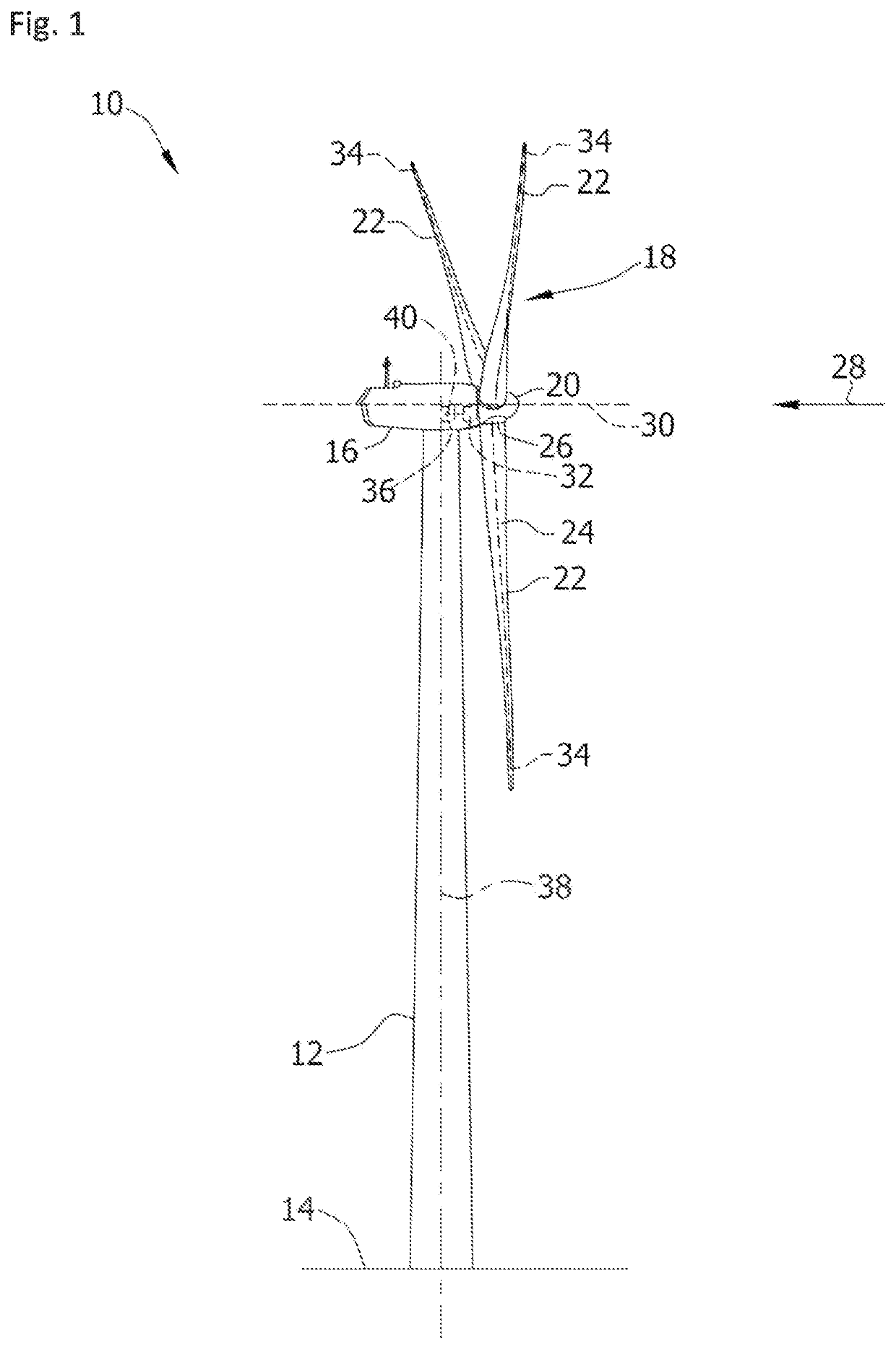

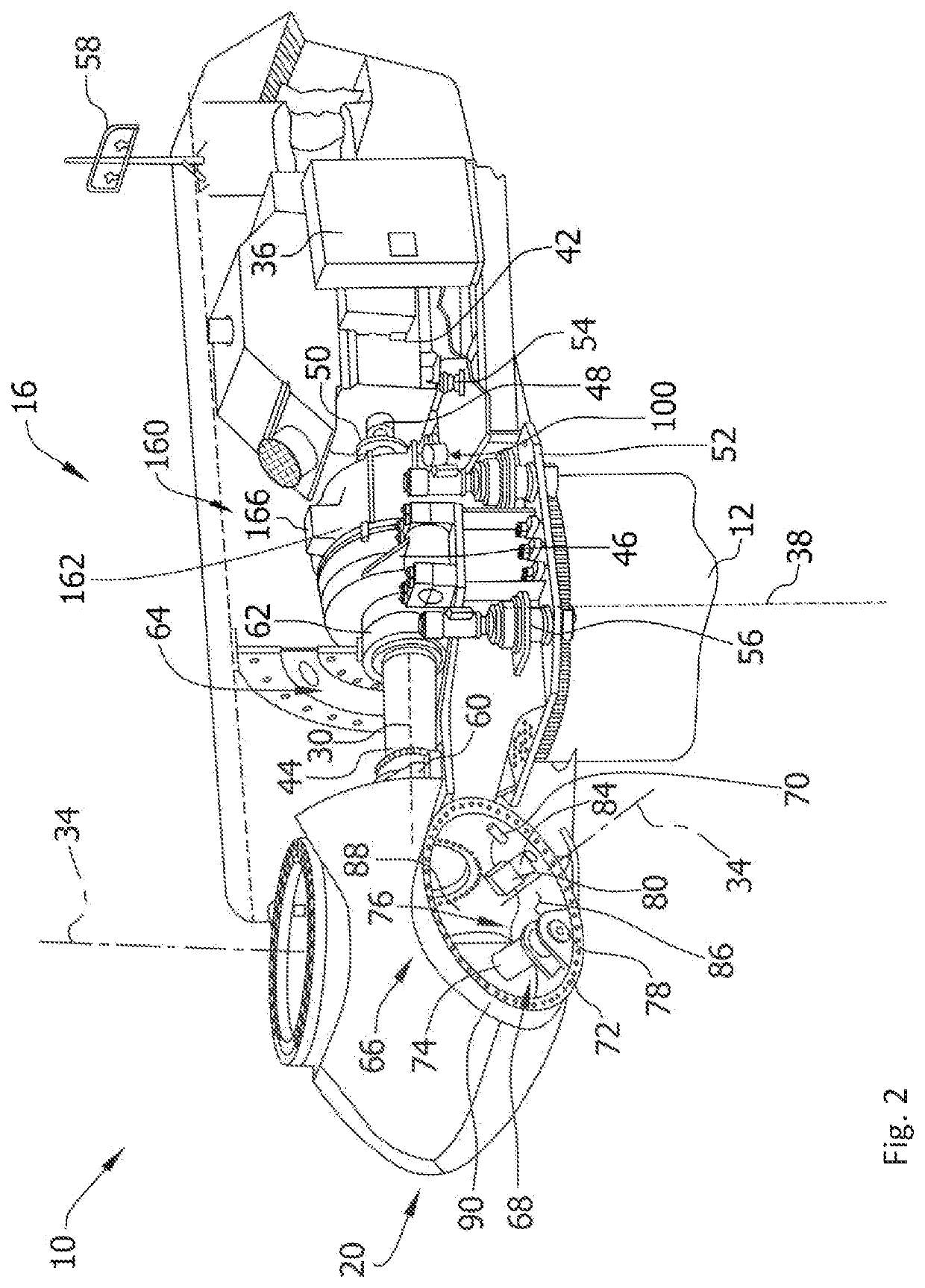

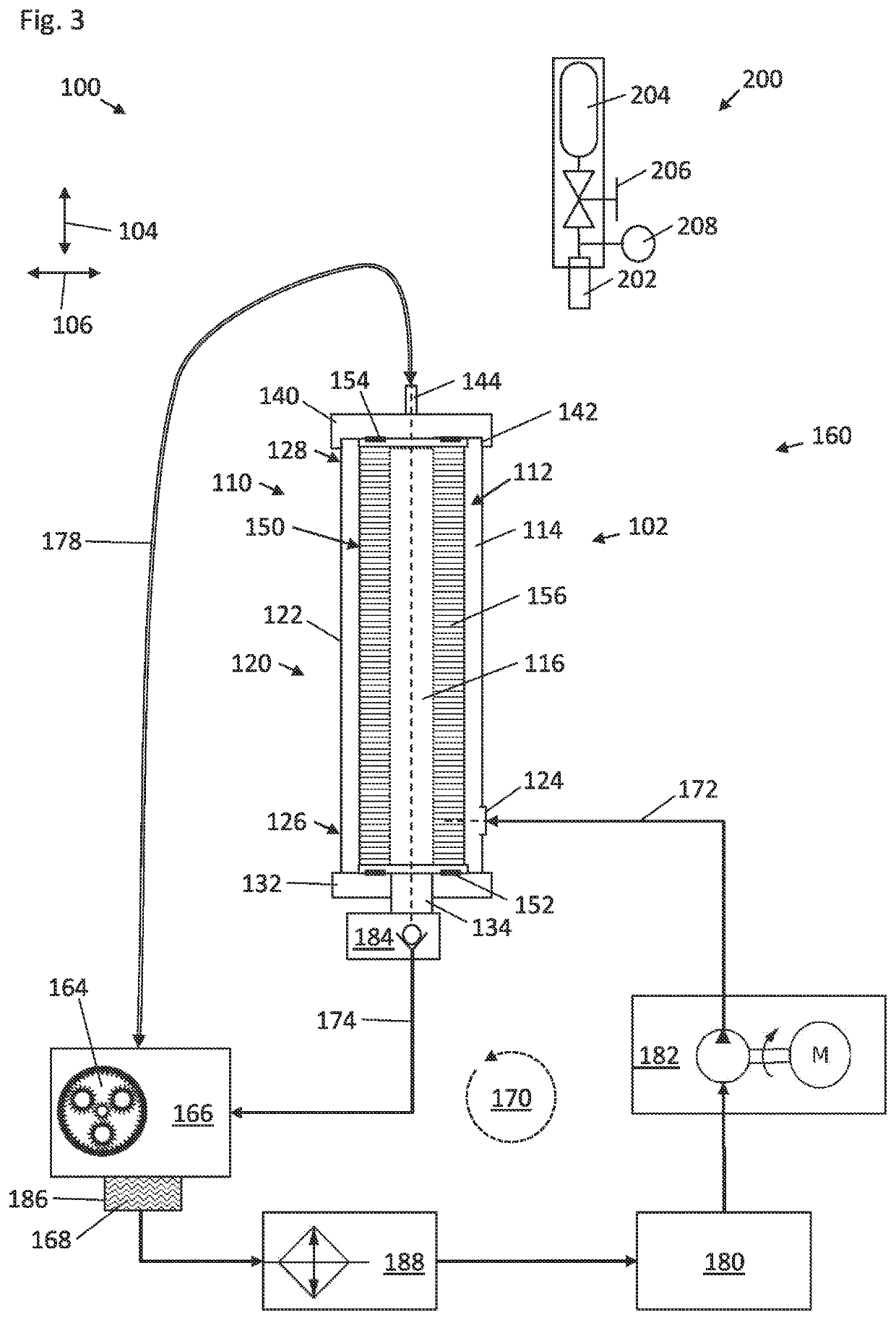

Filter system for a wind turbine, a wind turbine having a filter system and method for changing an oil filter of a filter system

ActiveUS20210332878A1Process stabilityMaintenanceGear lubrication/coolingMachines/enginesFilter systemTurbine

The present disclosure is directed to a filter system for a wind turbine, comprising at least a filter device having a filter housing with a volume portion and a cap portion, both defining a filter volume for receiving the oil filter. The filter housing is equipped with an inlet port, an outlet port and a pressure port. The filter system further comprises a pressurizing device having an interface port, and supply means for providing pressurized gas via the interface port, preferably into the filter housing of the filter device. The pressurizing device is configured for being connectable to the pressure port, preferably via a compensation duct. Furthermore, a method is disclosed, wherein the pressurizing device is connected to the filter housing, lubricant is discharged by applying pressurized gas into the filter volume, the cap portion is removed and an oil filter is subsequently replaced.

Owner:GENERAL ELECTRIC RENOVABLES ESPANA SL

Celery culture liquid capable of promoting rooting and water culture application thereof

InactiveCN108046930AGuaranteed supplyHigh rooting rateSuperphosphatesMagnesium fertilisersDiseaseCulture fluid

The invention provides a celery culture liquid capable of promoting rooting and water culture application thereof. The celery culture liquid comprises culture liquid and medicament granules, wherein the medicament granules comprise a coating layer, a carrier and a composite filling agent which are arranged sequentially from outside to inside; the coating layer is a composition of beta-cyclodextrinand chitosan; the carrier is a composition of zeolite and expanded vermiculite; and the composite filling agent comprises a rooting agent, a plant extract, calcium citrate and chitosan. Through reasonably prepared culture liquid and the medicament granules in the culture liquid, the supply of nutritional components is effectively guaranteed, a good slow release effect is achieved, the sustainingforce is strong, certain antibacterial and anti-disease efficacy is achieved, the nutritional components are sufficient, and the rooting rate and the growth velocity of the celery are effectively increased.

Owner:HEXIAN LVYUAN VEGETABLE PLANTATION CO LTD

Extensible dual-direction main shaft

ActiveCN108500301AReduce replacement costsReduce maintenance costsMetal-working apparatusEngineering

The invention discloses an extensible dual-direction main shaft which comprises a shell sleeve assembly with a through hole, two extension sleeves detachably fixed to the two ends of the shell sleeveassembly and clamping sleeves embedded in the extension sleeves for clamping workpieces. The circumferential surfaces of the clamping sleeves are inclined faces and abut against the inner walls of theextension sleeves, the circumferential end faces of the sides, in the through hole, of the clamping sleeves are provided with limiting grooves in a concaved mode, a pull sleeve with the two ends clamped into the limiting grooves and capable of being spirally stretched or locked is embedded in the through hole, and the shell sleeve assembly is provided with control structure which drives one extensions sleeve to move in the axial direction. The main shaft has the advantages that the clamping specifications of the dual-direction main shaft are changed on the condition of only changing some parts, the replacing cost and maintenance cost of the main shaft are greatly reduced, and the application range of the main shaft is effectively enlarged.

Owner:台州屹捷数控机床股份有限公司

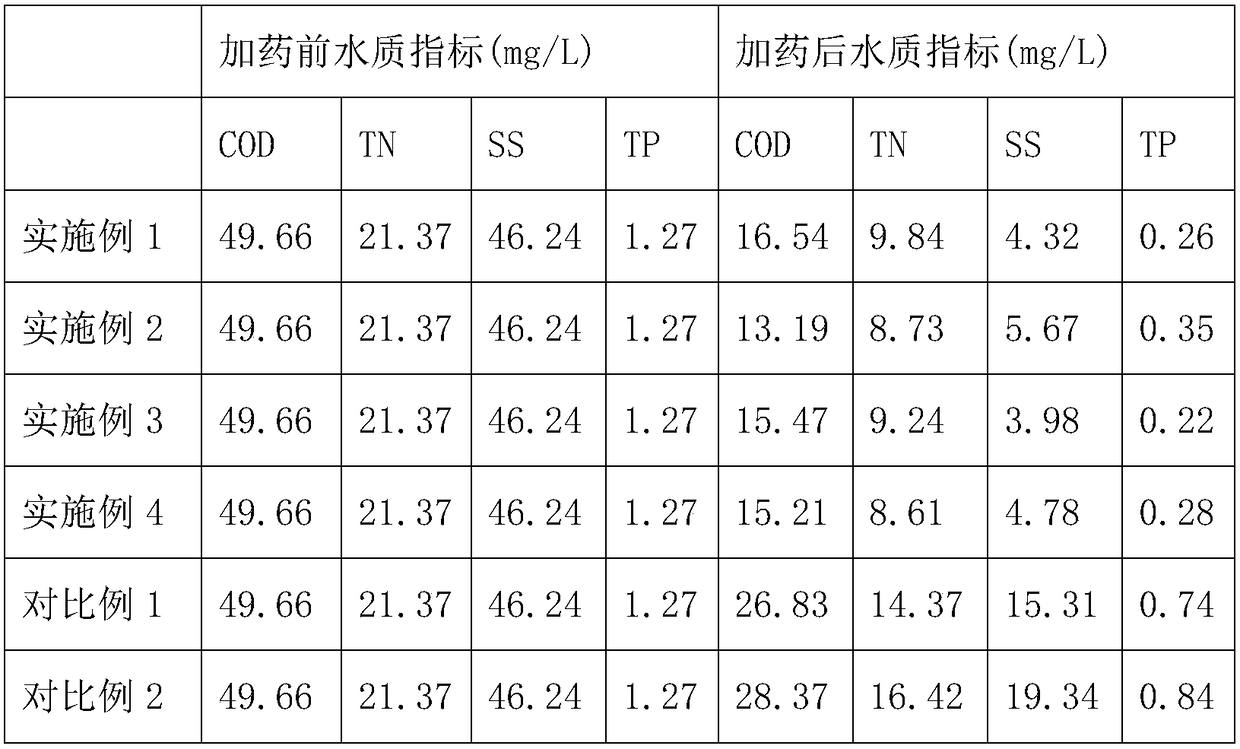

Treatment chemical for treating domestic sewage and preparation method of treatment chemical

InactiveCN108862500AWide variety of sourcesGood processing effectWater/sewage treatment by flocculation/precipitationGlycerolTherapeutic effect

The invention discloses a treatment chemical for treating domestic sewage and a preparation method of the treatment chemical. The treatment chemical for treating the domestic sewage is prepared from the following raw materials in parts by weight: 14 to 19.5 parts of maleic acid-acrylic acid copolymer, 5.6 to 7.5 parts of steel residues, 6 to 9.6 parts of beewax, 8 to 12 parts of acrylic emulsion,4 to 7.2 parts of plant starch, 6 to 8.8 parts of chitosan, 3.4 to 5.2 parts of hydroxymethyl cellulose, 3.8 to 4.6 parts of dodecyl dimethyl tertiary amine, 1.5 to 2.4 parts of chloramphenicol, 5 to6.6 parts of cactus, and 14 to 18.5 parts of glycerol. Different raw materials are prepared into different products by adopting different preparation processes, then the different products are mixed,various products are in synergistic effect, and a prepared finished product has good treatment effect for domestic sewage; and by adopting the steel residues, chitosan and the like, no aluminum salt water purifier is adopted, and the loss of the aluminum ore can be reduced.

Owner:王玲

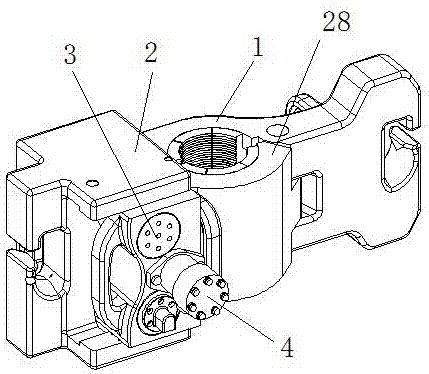

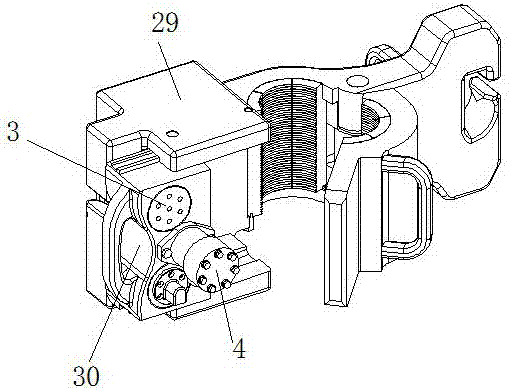

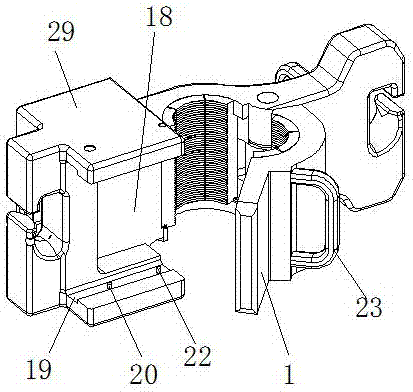

Drill-rod fixed clamp and control method thereof

The invention relates to a drill-rod fixed clamp device for preventing blowout of oil and gas field well drilling, in particular to a drill-rod fixed clamp and a control method thereof. The drill-rod fixed clamp comprises a first fixed clamp assembly and a second fixed clamp assembly, and the first fixed clamp assembly is hinged to one end of the second fixed clamp assembly; one end of the first fixed clamp assembly is fixedly connected with a locking device, and the other end of the first fixed clamp assembly is hinged to the second fixed clamp assembly; one end of the second fixed clamp assembly is hinged to the first fixed clamp assembly, and the other end of the second fixed clamp assembly is a free end; and the locking device comprises a locking device body and a sliding part capable of sliding along the locking device body, and a groove used for placing the free end of the second fixed clamp assembly is formed between the sliding part and the locking device body. According to the drill-rod fixed clamp and the control method thereof, the first fixed clamp assembly and the locking device are fixedly connected, the locking device is arranged to be of a push-pull structure, and locking and unlocking of the second fixed clamp assembly are completed by pushing and pulling the sliding part, so that the fixed clamp assemblies and the locking device are integrated; and one-time hoisting is only needed to complete installation and removal, and installation and removal are both very convenient.

Owner:CHENGDU ZHUOXIN IND

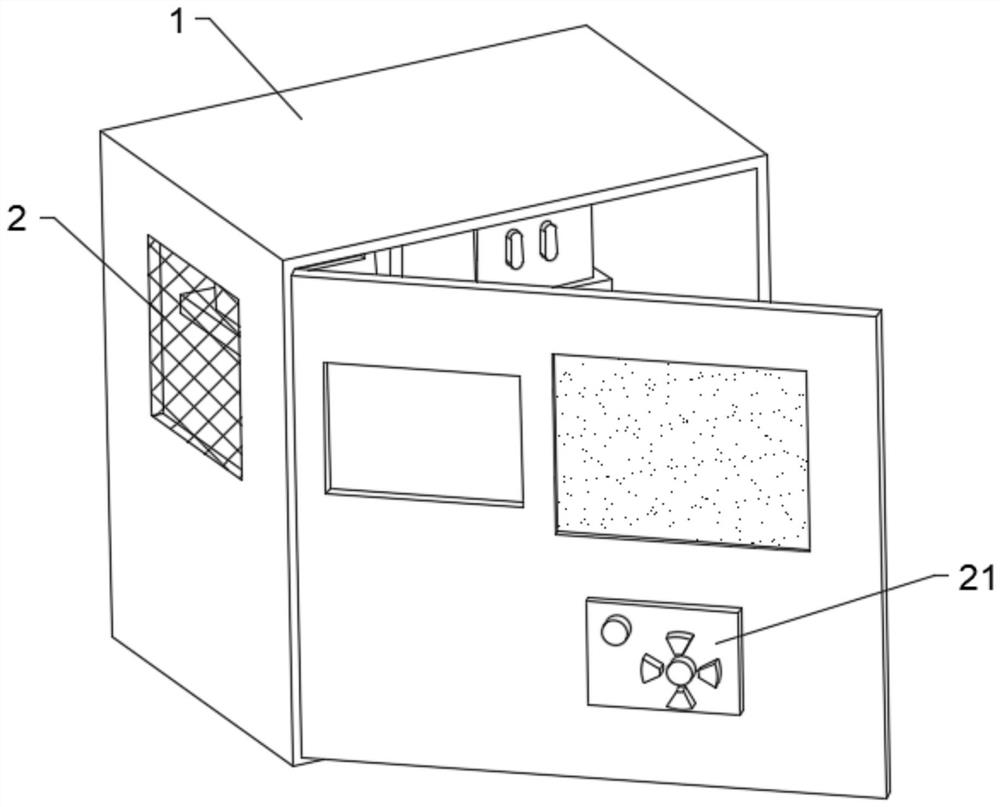

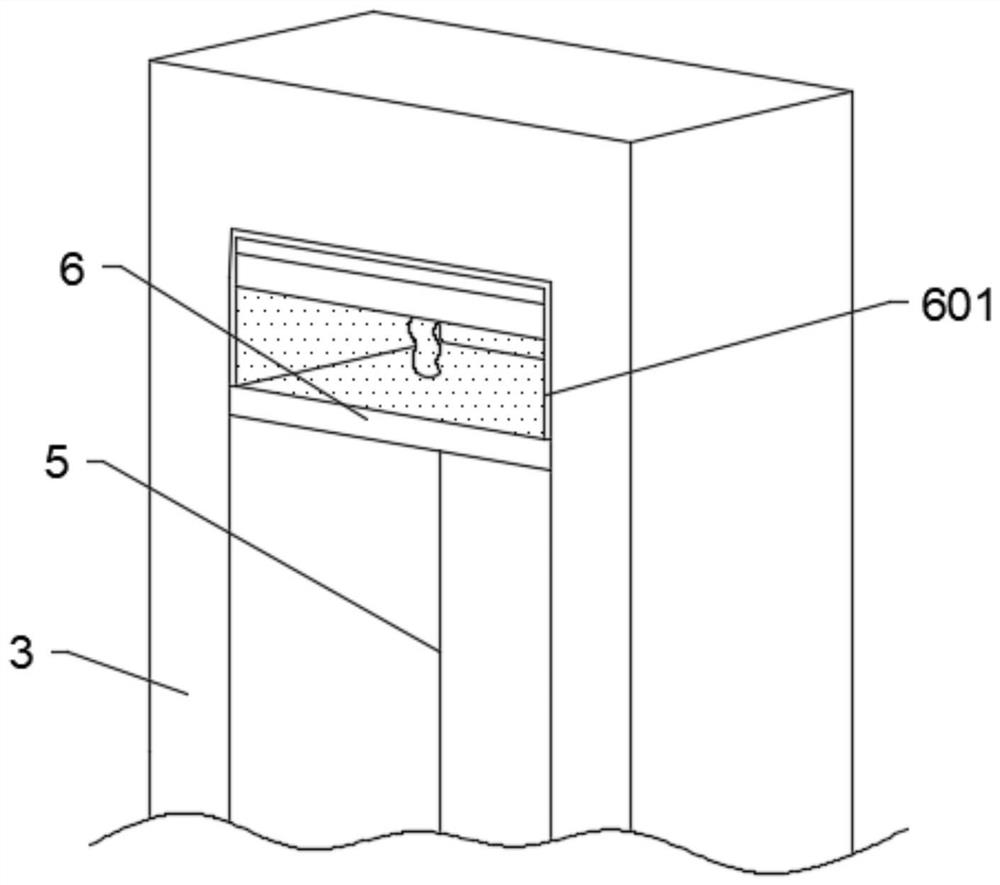

Electric energy measuring instrument cabinet

ActiveCN114247225AGuaranteed temperature balanceHigh degree of automationDispersed particle filtrationTransportation and packagingMeasuring instrumentDust control

The invention, which belongs to the electric energy metering field, discloses an electric energy metering instrument cabinet comprising a metering instrument cabinet, the left end of the metering instrument cabinet is fixedly provided with a ventilation dustproof net, the left inner wall of the metering instrument cabinet is symmetrically and fixedly provided with guiding slide rails, and the sides, close to each other, of the two guiding slide rails are provided with guiding slide grooves. A self-cleaning wind power box and a power production assembly are additionally arranged in the measuring instrument cabinet to be used in cooperation, so that dust accumulated on the surface of a ventilation dustproof net can be cleaned in time, smooth ventilation in the measuring instrument cabinet is effectively kept, temperature balance in the measuring instrument cabinet is further kept, and the measuring instrument cabinet is convenient to use. And continuous and normal use of equipment in the measuring instrument cabinet is facilitated, the cleaning area of the self-cleaning wind power box is enlarged through use of the heating driving assembly, and the dust removal effect is further improved.

Owner:江苏百维能源科技有限公司

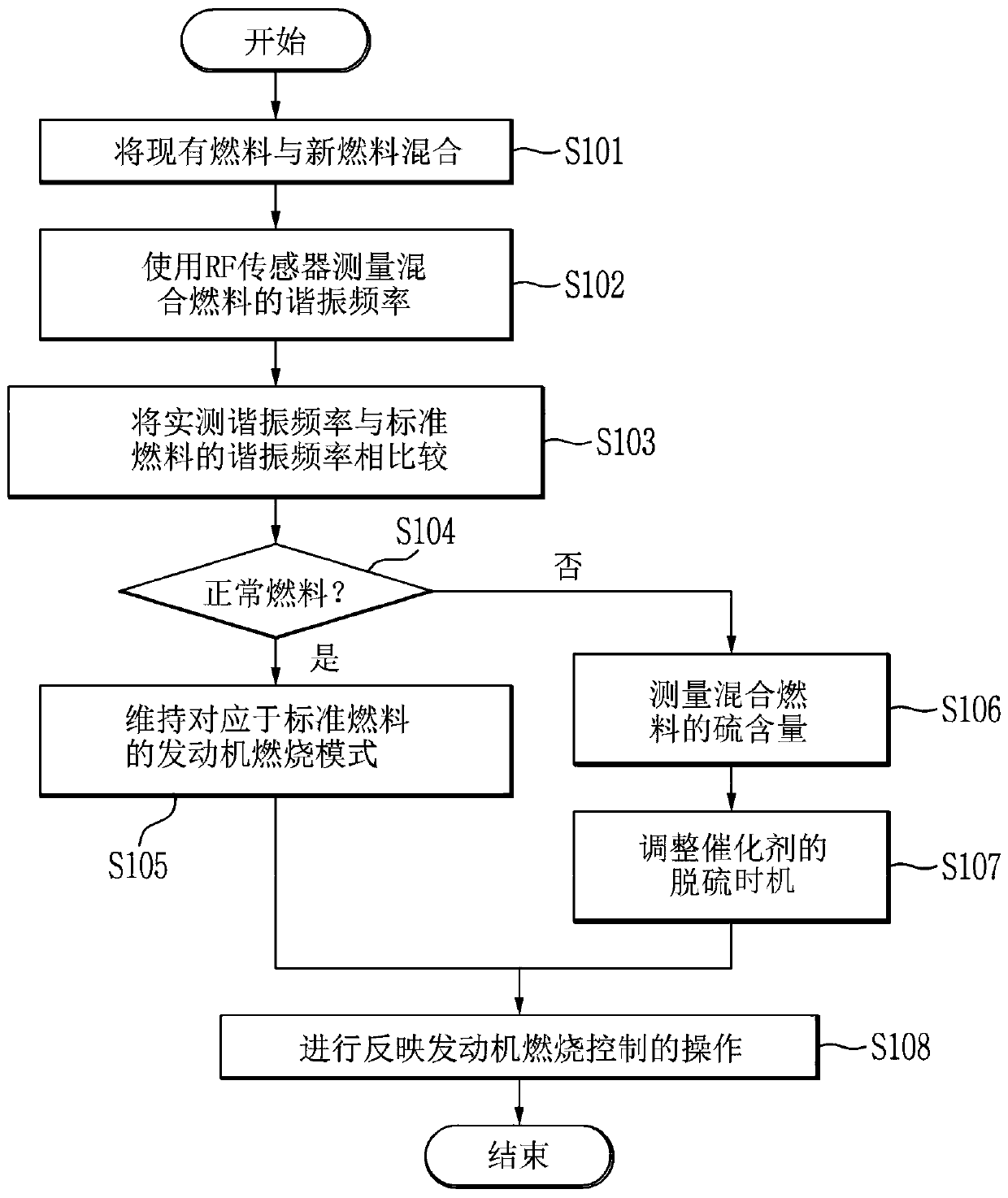

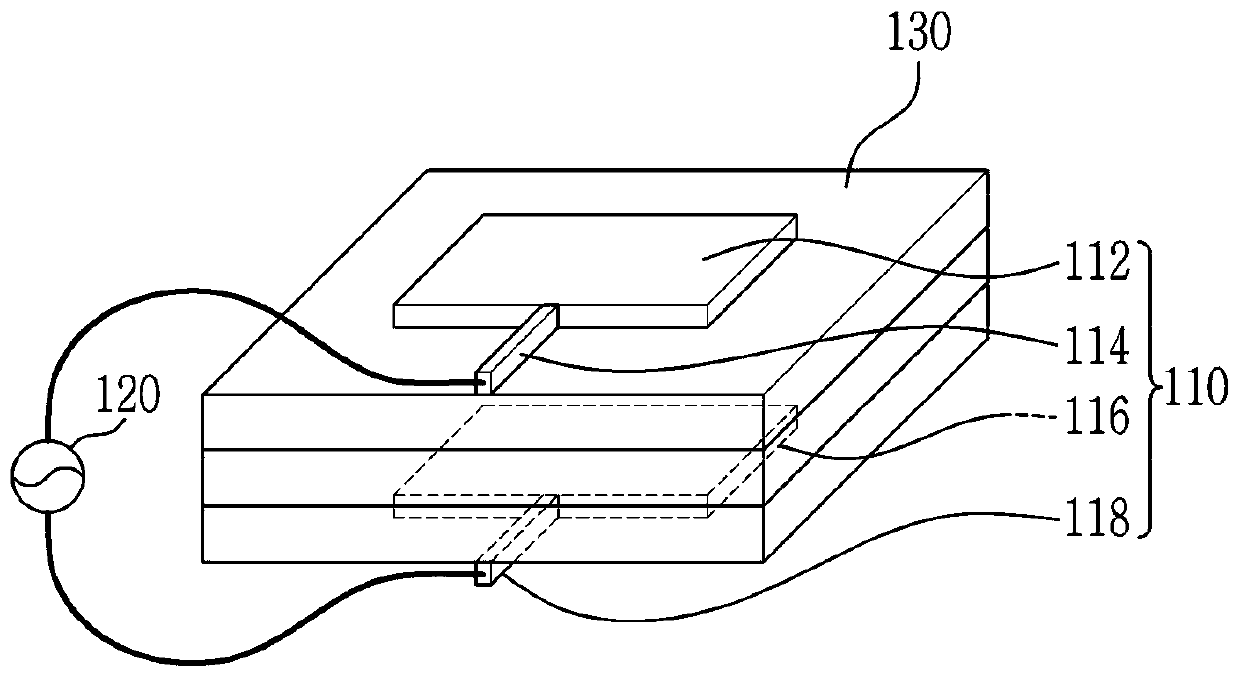

Method of analyzing fuel component using an RF sensor for a vehicle

ActiveCN110863918AAccurate identification of sulfur contentAccurate decision cycleMaterial analysis using sonic/ultrasonic/infrasonic wavesElectrical controlMixed fuelRadio frequency

A method of analyzing fuel component using an RF (Radio Frequency) sensor for a vehicle includes: receiving a new fuel into a fuel tank so as to mix existing fuel in the fuel tank with the new fuel, measuring a resonance frequency of the mixed fuel using an RF sensor, comparing the measured resonance frequency of the mixed fuel with a resonance frequency of a standard fuel, determining whether themixed fuel is a normal fuel through the comparison, maintaining an engine combustion pattern corresponding to the standard fuel when the mixed fuel is a normal fuel, and operating reflecting an engine combustion control.

Owner:HYUNDAI MOTOR CO LTD +2

Bonded veneer with simulated wood grain and texture, bonded veneer panels and method of making the same

InactiveUS20170246843A1Improve stabilityHigh strengthOther plywood/veneer working apparatusSpecial ornamental structuresWood veneerWood fibre

A simulated wood veneer product is disclosed. The simulated wood veneer product includes a paper substrate and an imprintable wood fiber material applied to one side of the paper substrate. The imprintable wood fiber material provides the paper substrate with depth and allows the paper to receive and retain an imprinted wood grain texture. Once imprinted, the veneer product is printed with a simulated wood grain pattern to create a realistic simulated veneer product which is referred to herein as a “bonded veneer”. The bonded veneer product can then be adhered to a structural or composite wood panel, such as an MDF panel, to create a simulated wood veneer panel which can be used in the construction of furniture products.

Owner:LIVING STYLE B V I LTD

Grip for sporting goods and golf club

ActiveUS10286269B2Improve grip performanceLower performance requirementsSnowboard bindingsSkisPolymer scienceSurface layer

An object of the present invention is to provide a grip for sporting goods containing an acrylonitrile-butadiene based rubber as a base rubber and having an excellent grip performance and sustainability of grip performance under a wet condition. The present invention provides a grip for sporting goods comprising an outermost surface layer formed from a surface layer rubber composition, wherein the surface layer rubber composition contains (A) a base rubber and (B) a resin having a softening point in a range from 5° C. to 120° C., (A) the base rubber contains an acrylonitrile-butadiene based rubber, and (B) the resin is at least one type selected from the group consisting of a hydrogenated rosin ester, a disproportionated rosin ester, an ethylene-vinyl acetate copolymer, a coumarone resin, a phenol resin, a xylene resin and a styrene resin.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com