Extensible dual-direction main shaft

A spindle and axial technology, which is applied in the field of lathes, can solve the problems of inability to extend the two-way spindle and the inability to collet, so as to improve the service life, reduce the cost of replacement and maintenance, and improve the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

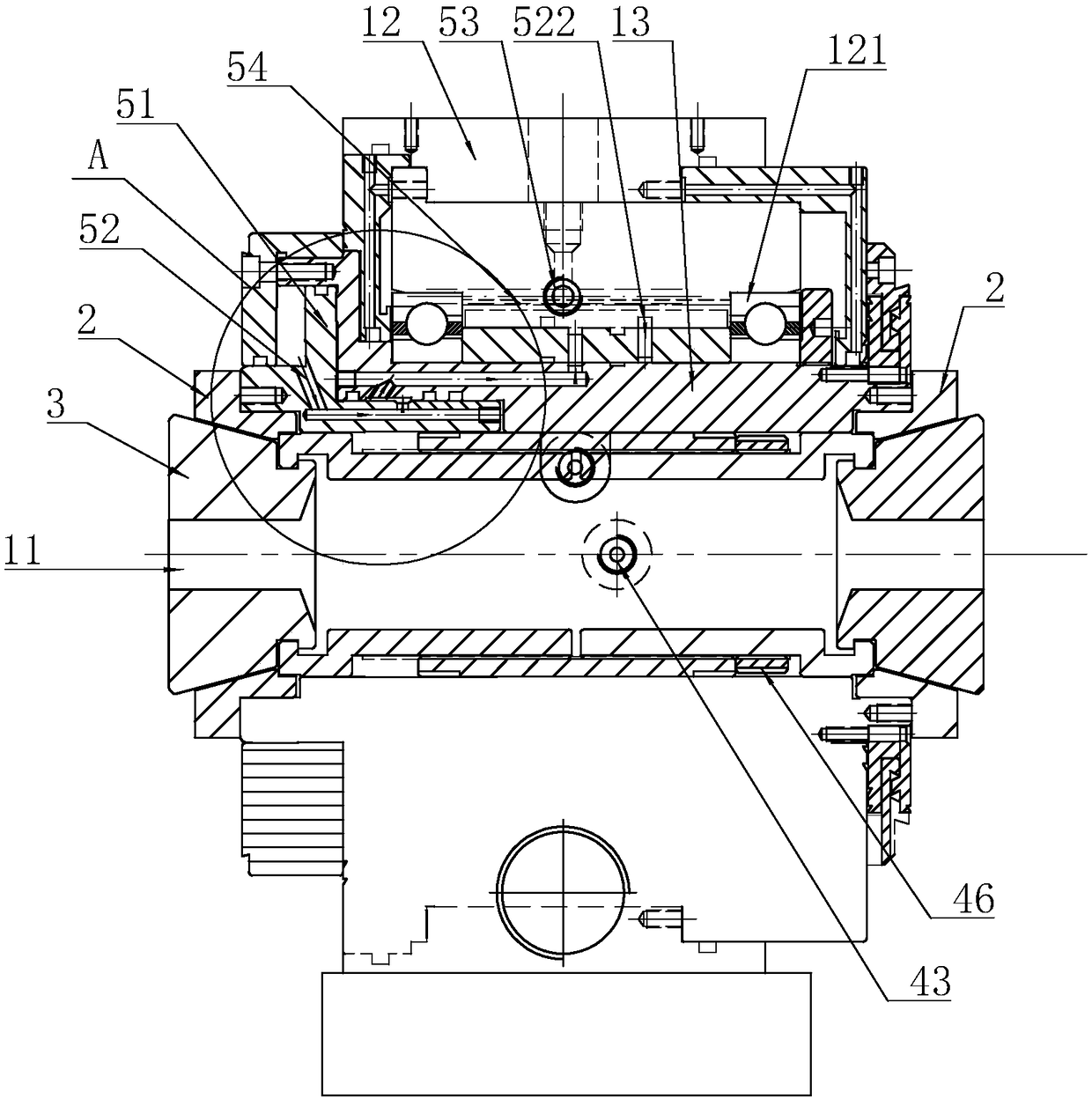

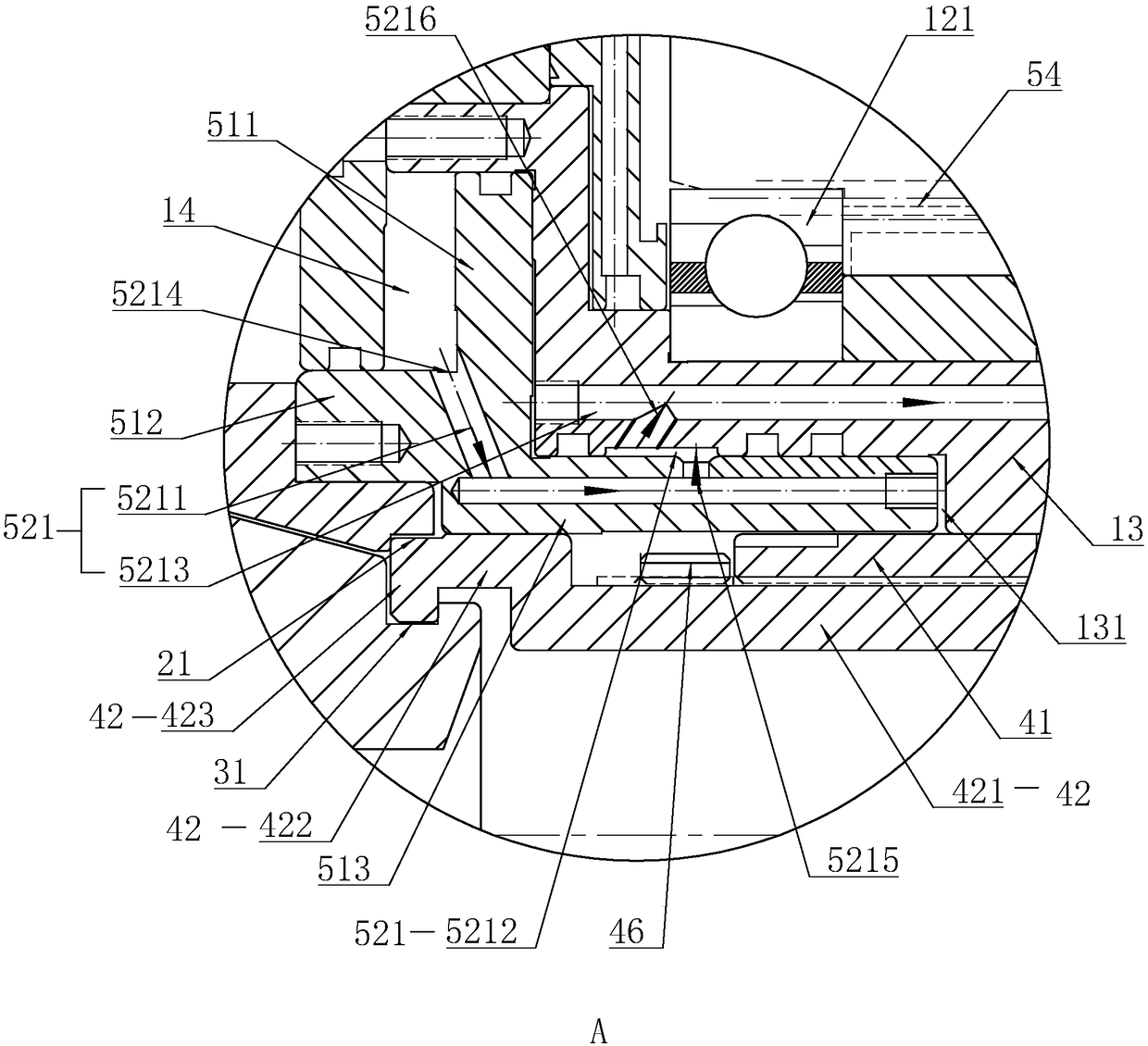

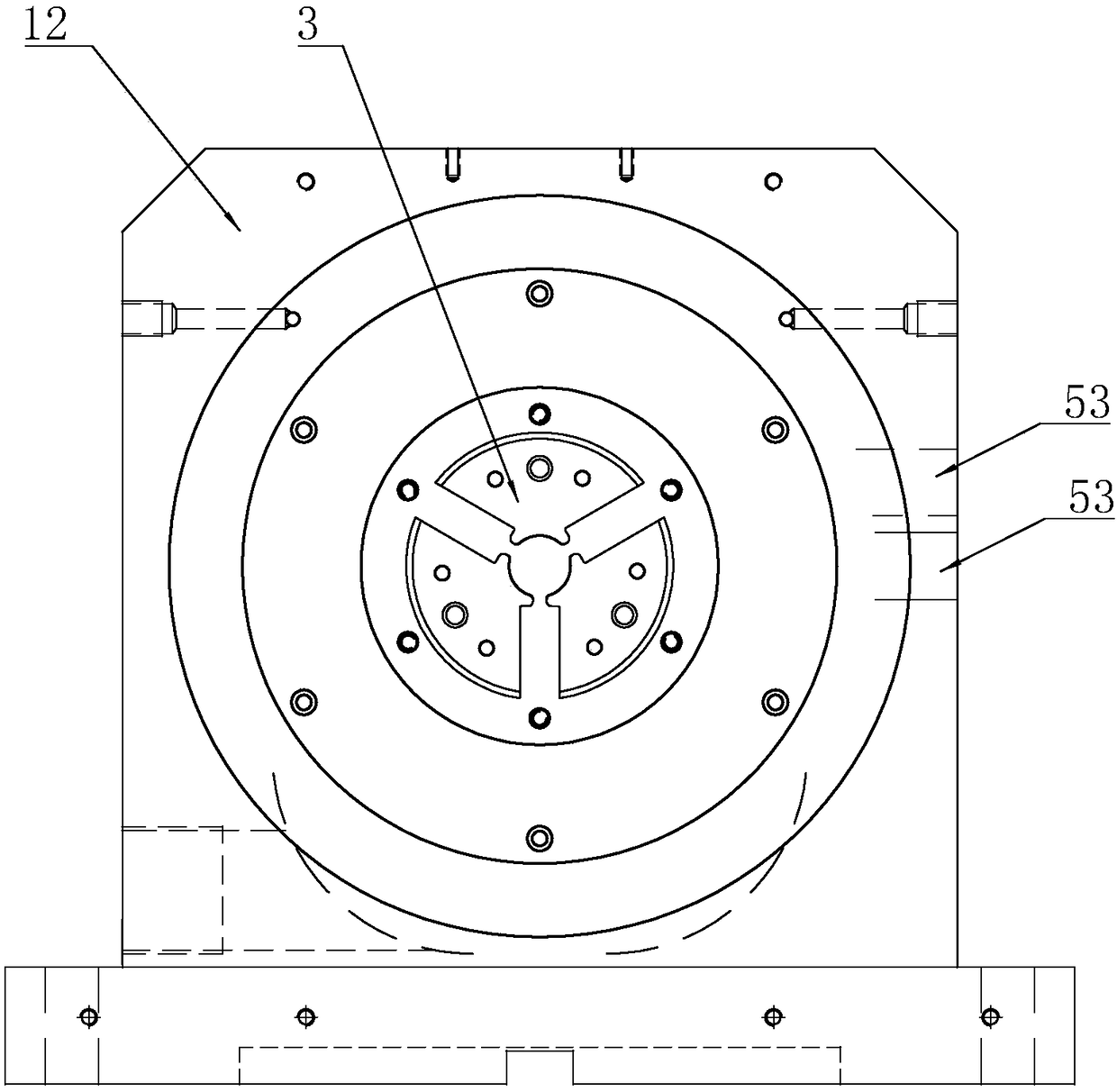

[0039] Example 1: An extendable bi-directional spindle such as figure 1 with image 3 As shown, it includes a shell assembly 1 with a through hole 11, two extension sleeves 2, two ferrules 3 embedded in the extension sleeves 2 for clamping workpieces, a pull sleeve 4 connecting two ferrules 3 and A control structure 5 that drives one of the extension sleeves 2 to move axially. When the extension sleeve 2 moves axially, the two ferrules 3 are forced to shrink.

[0040] The shell assembly 1 includes a box body 12 and a seat cover 13 . The seat cover 13 is arranged in the box body 12 and an angular contact bearing 121 is connected between the box body 12 and the box body 12 .

[0041] refer to figure 1 with figure 2 , the control structure 5 includes a piston sliding sleeve 51 controlled by hydraulic pressure, a corresponding oil pressure channel 52 and an external oil pump. An outer oil passage 53 communicating with the oil pressure passage 52 is arranged inside the box b...

Embodiment 2

[0049] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that the structure of the pull sleeve 4 is different. The pull sleeve 4 includes a left sleeve 44 and a right sleeve 45 with hooks 423 on both ends facing away from each other. The hooks 423 are snapped into the limiting groove 31, and the outer wall of the left sleeve 44 is tightly embedded in the inner wall of the through hole 11. The inner wall of the left sleeve 44 is provided with an accommodating groove 441, and the right sleeve 45 also includes an extension part 421 threadedly connected with the accommodating groove 441 and an external connection part 422 tightly embedded in the inner wall of the through hole 11, and the hook part 423 is arranged on the external connection part 422 On the inner wall; between the outer connecting portion 422 and the left sleeve 44 is provided a locking piece 46 which is threadedly connected to the extension portion 421 and abuts against the left sleeve 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com