Patents

Literature

207 results about "Head turning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

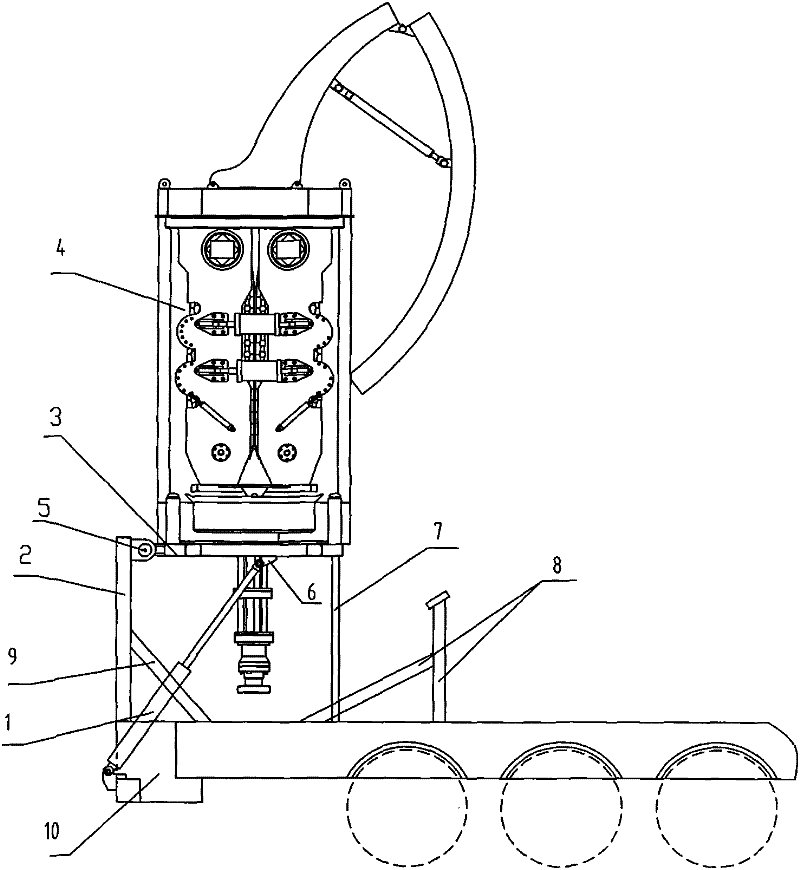

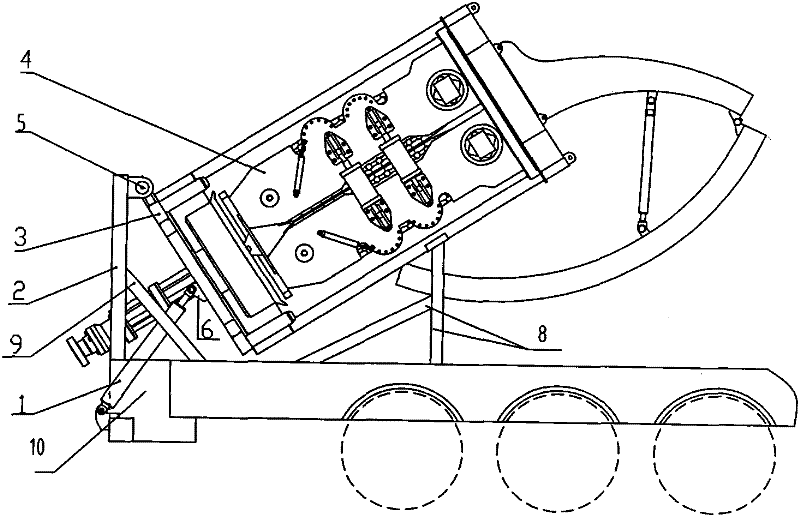

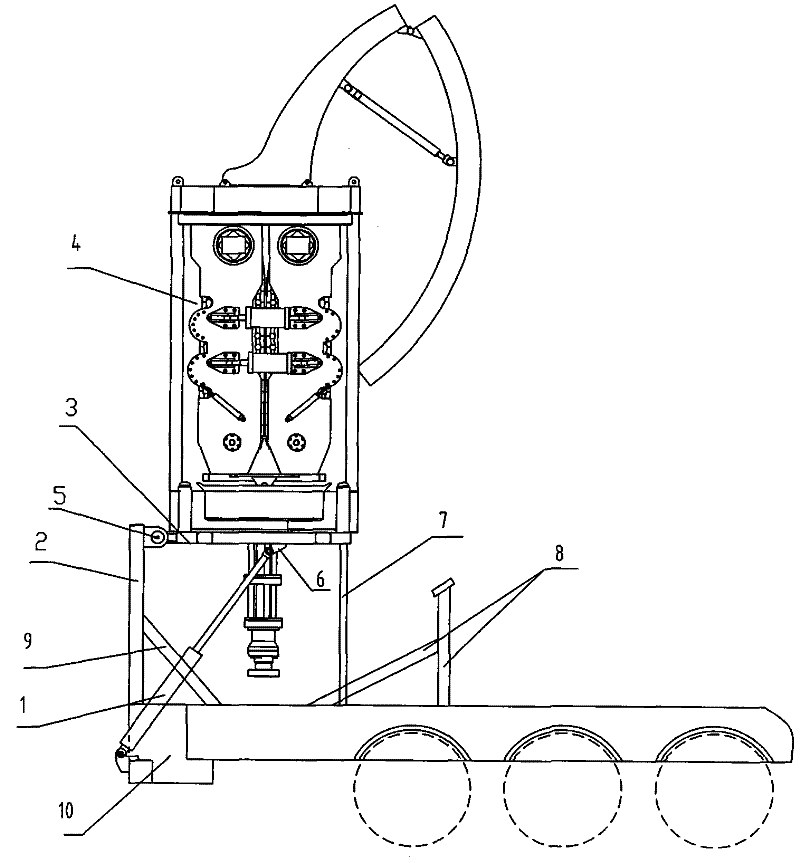

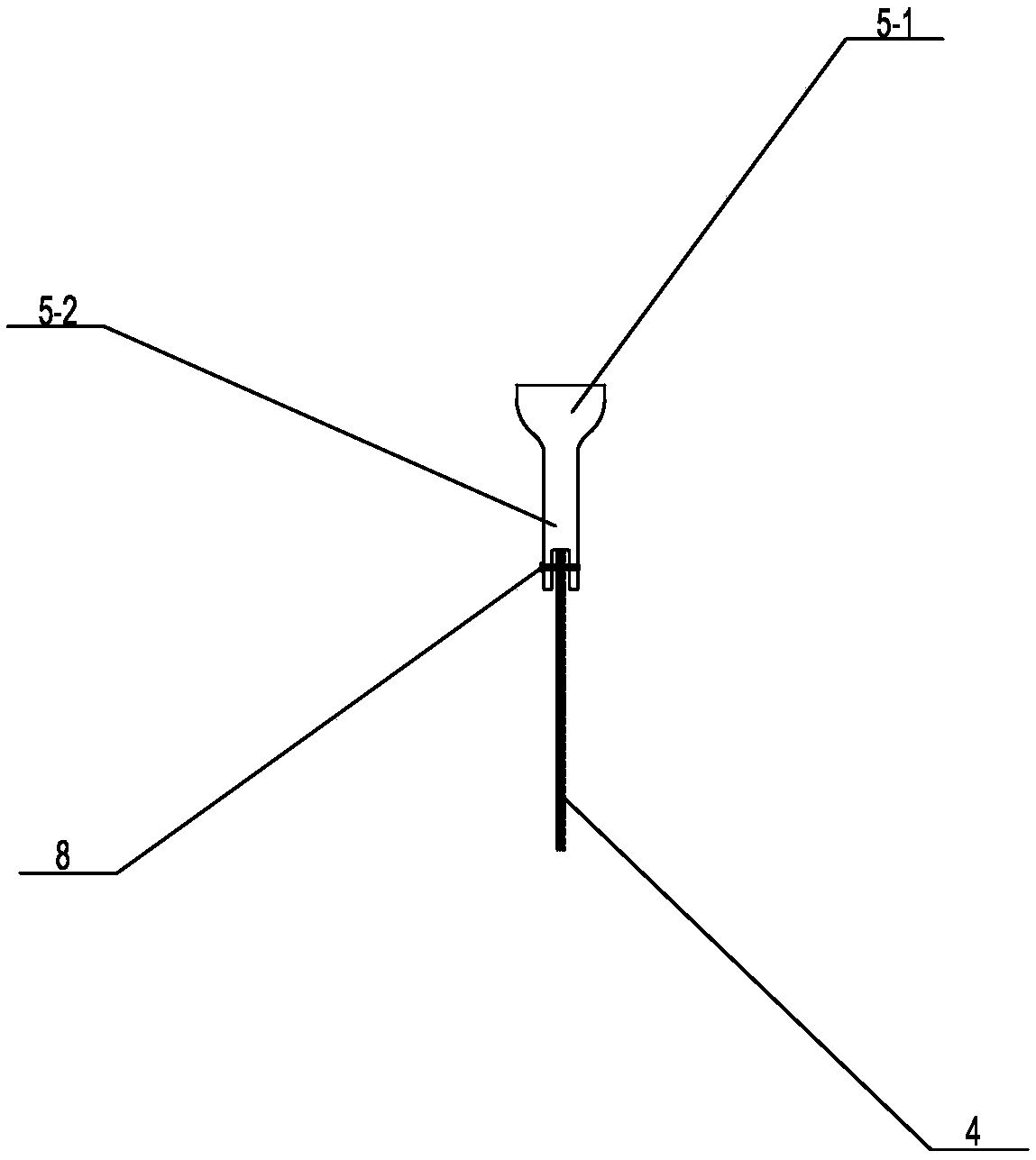

Novel injection head turning device

InactiveCN102383748AEasy to installEasy to disassembleDrilling rodsDrilling casingsPetroleum engineeringHead turning

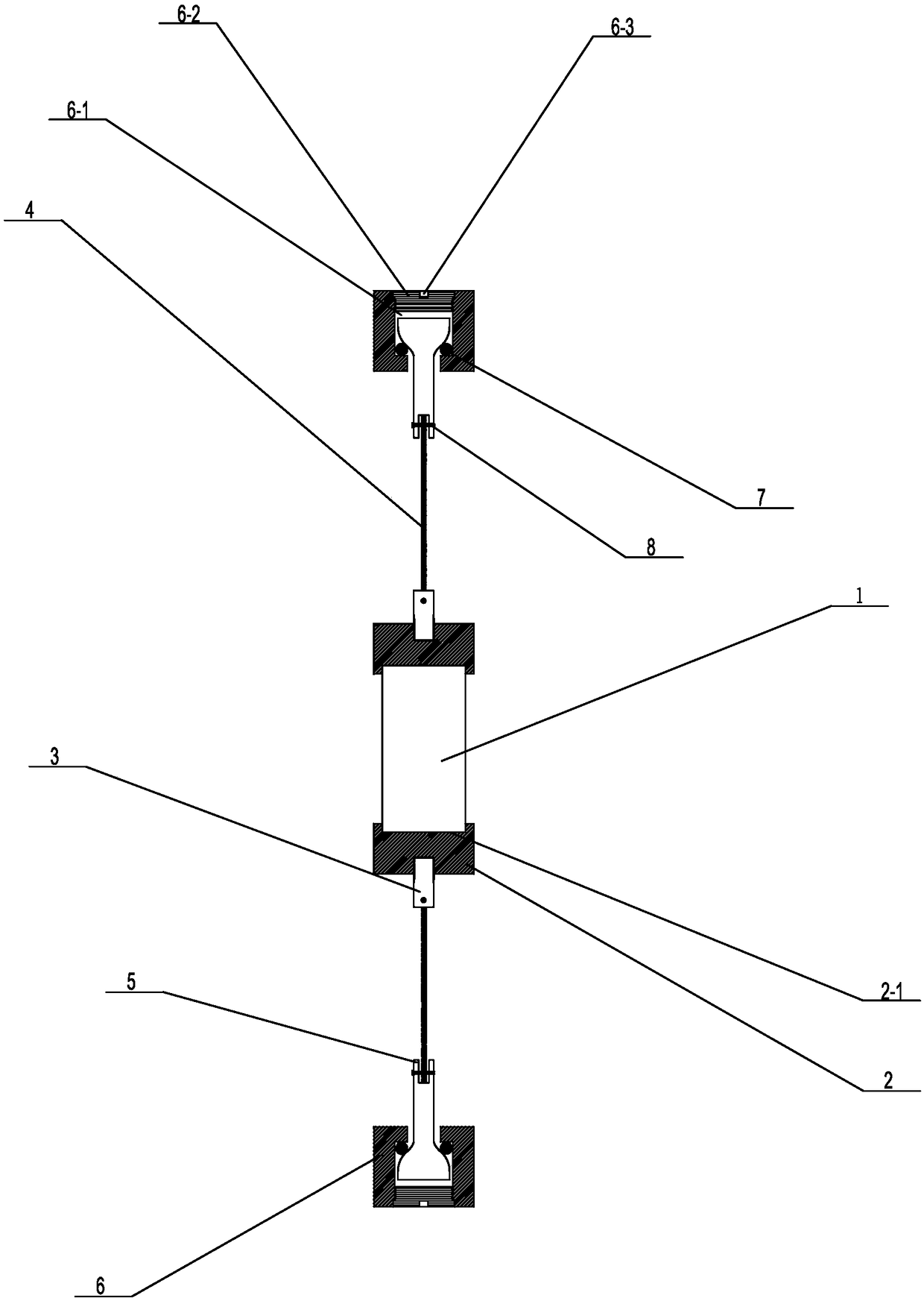

The invention relates to a continuous oil pipe injection head, in particular to a novel injection head turning device. The device comprises a trailer base, an injection head base, a hydraulic oil cylinder, a rotary bracket and a rotary shaft, and is characterized in that: a cylinder body of the hydraulic oil cylinder is articulated with the trailer base; a hydraulic rod of the hydraulic oil cylinder is articulated with the middle part of the injection head base through an oil cylinder ear plate; and one end of the rotary bracket is fixedly connected with the trailer base, and the other end is connected with the edge part of the injection head base through the rotary shaft. The device can conveniently turn the injection head from an oblique state to a vertical position before the injection head is hoisted, thereby avoiding damage to the oil pipe and injection head caused by a large-angle bending of the continuous oil pipe generated when the injection head in the oblique state is directly hoisted. The novel injection head turning device provided by the invention is simple to operate and is easy to maintain as the hydraulic oil cylinder is convenient to assemble and disassemble; and the device realizes stable turning process and is safe and reliable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

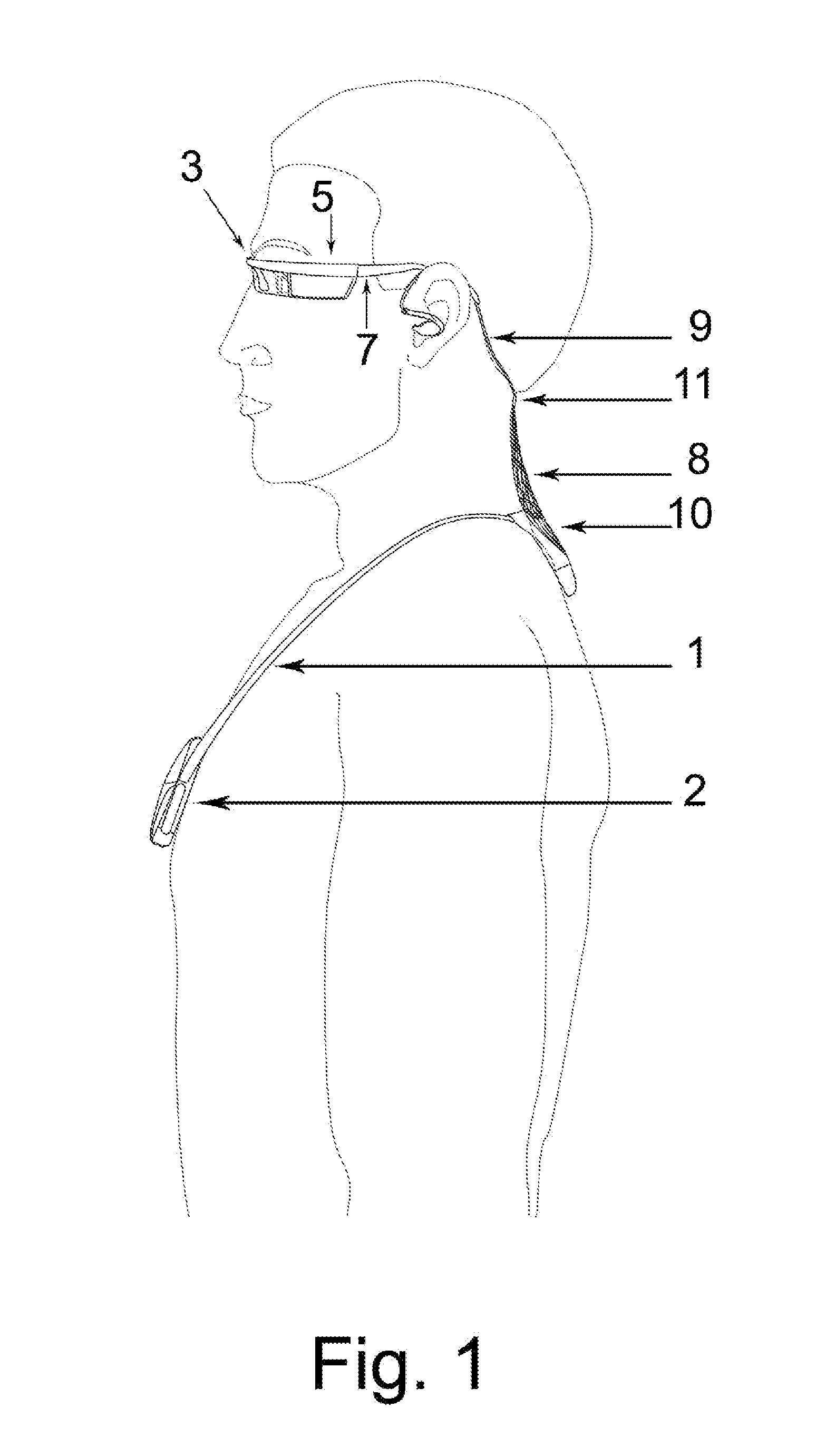

Immersion type virtual reality system and implementation method thereof

InactiveCN103197757AInput/output for user-computer interactionGraph readingMethods of virtual realityComputer graphics (images)

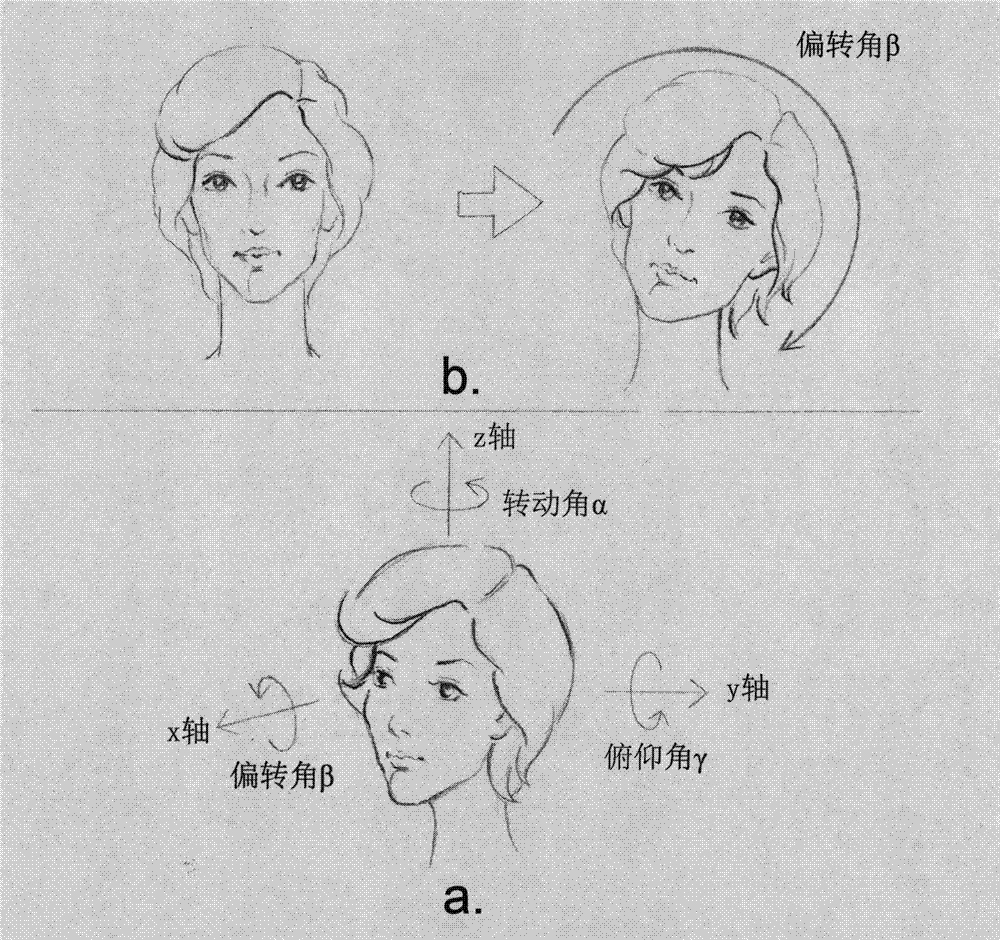

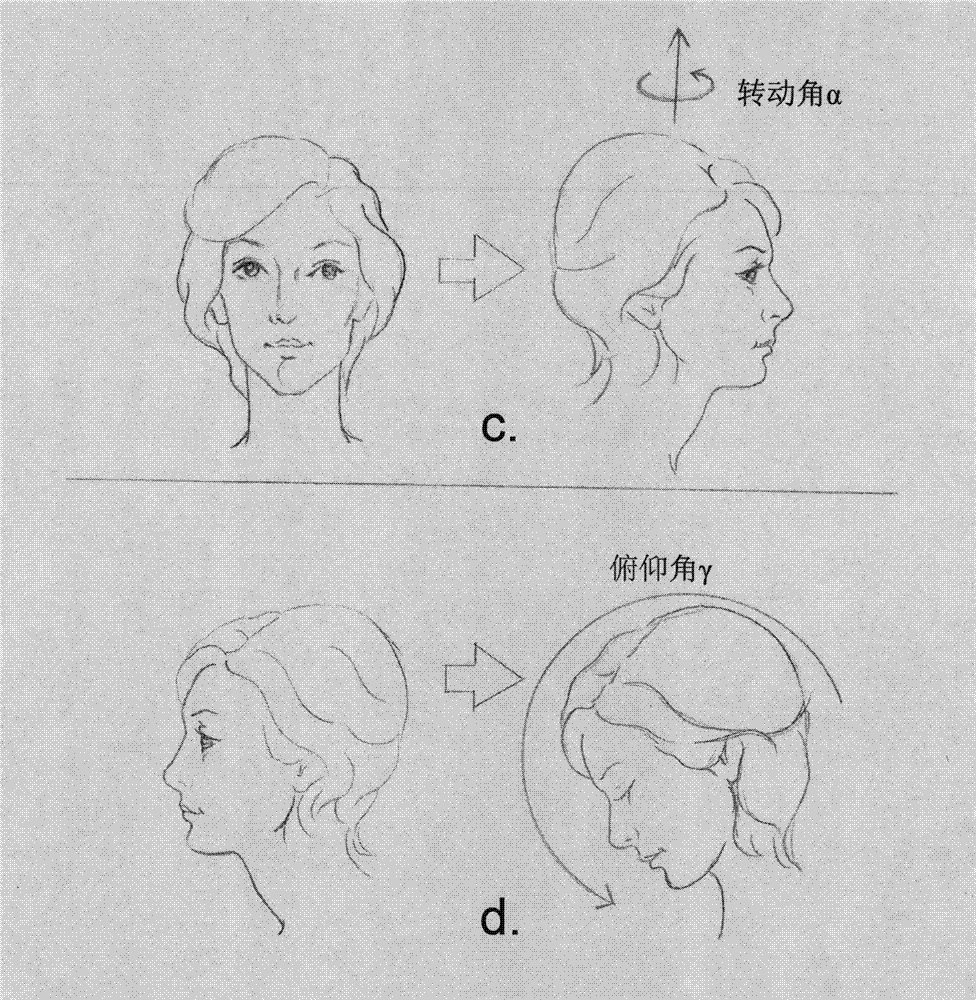

The invention provides an immersion type virtual reality system. The system comprises at least one display, at least one motion capture device and at least one data processing device, wherein the display can be worn on the body of a user, and is used for capturing the head turning motion of the user, sending the head turning motion data to the as least one data processing device, receiving data sent by at least one data processing device, and transmitting a video or audio of a virtual environment to the user; the motion capture device captures motion trails of main node parts of the user, and sends the motion trail data to the at least one data processing device; and the data processing device is used for processing data acquired from the at least one display and the at least one motion capture device and transmitted to the data processing device, and sending the processed result to the at least one display. The invention further provides an implementation method of the immersion type virtual reality system.

Owner:癸水动力(北京)网络科技有限公司 +1

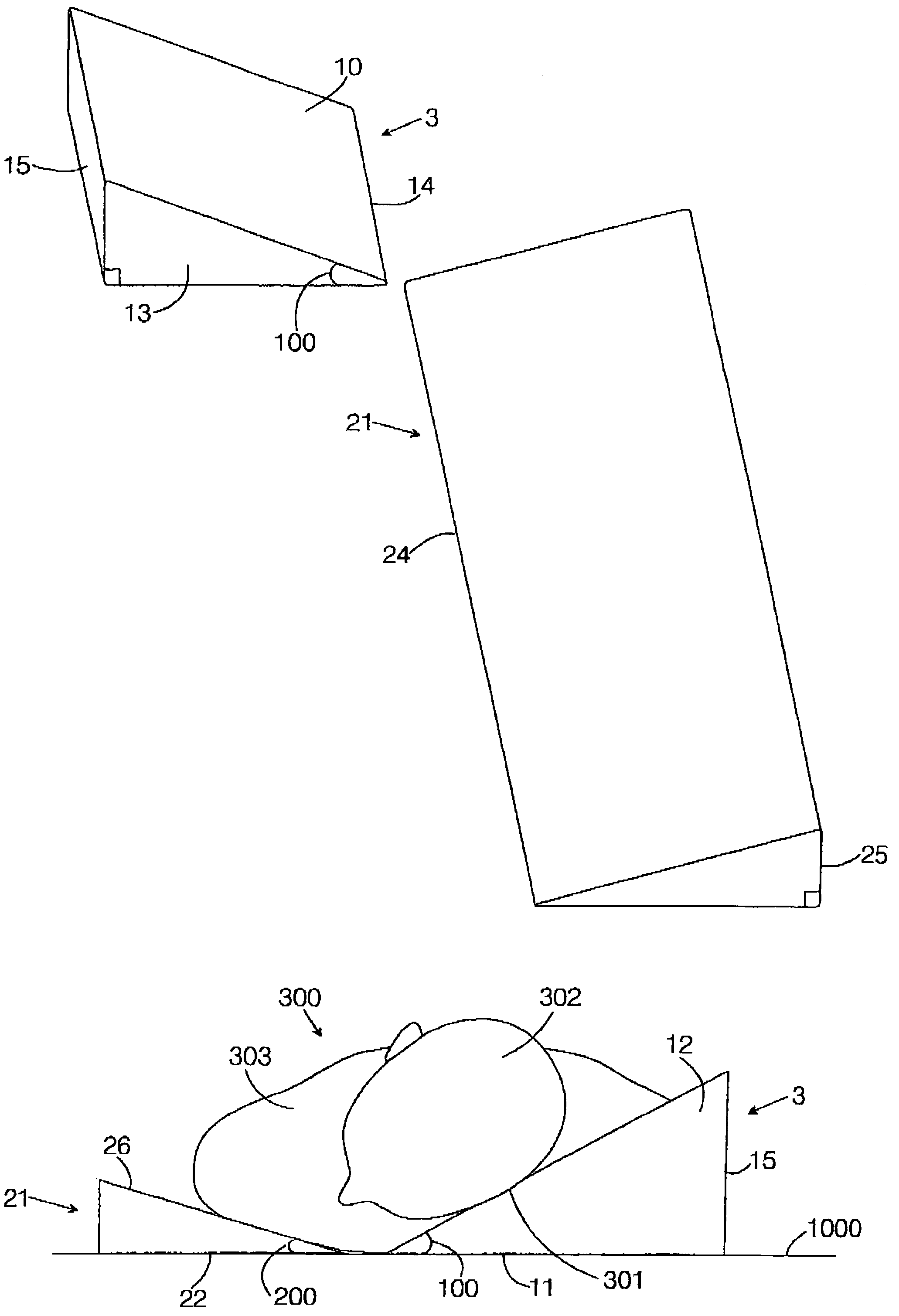

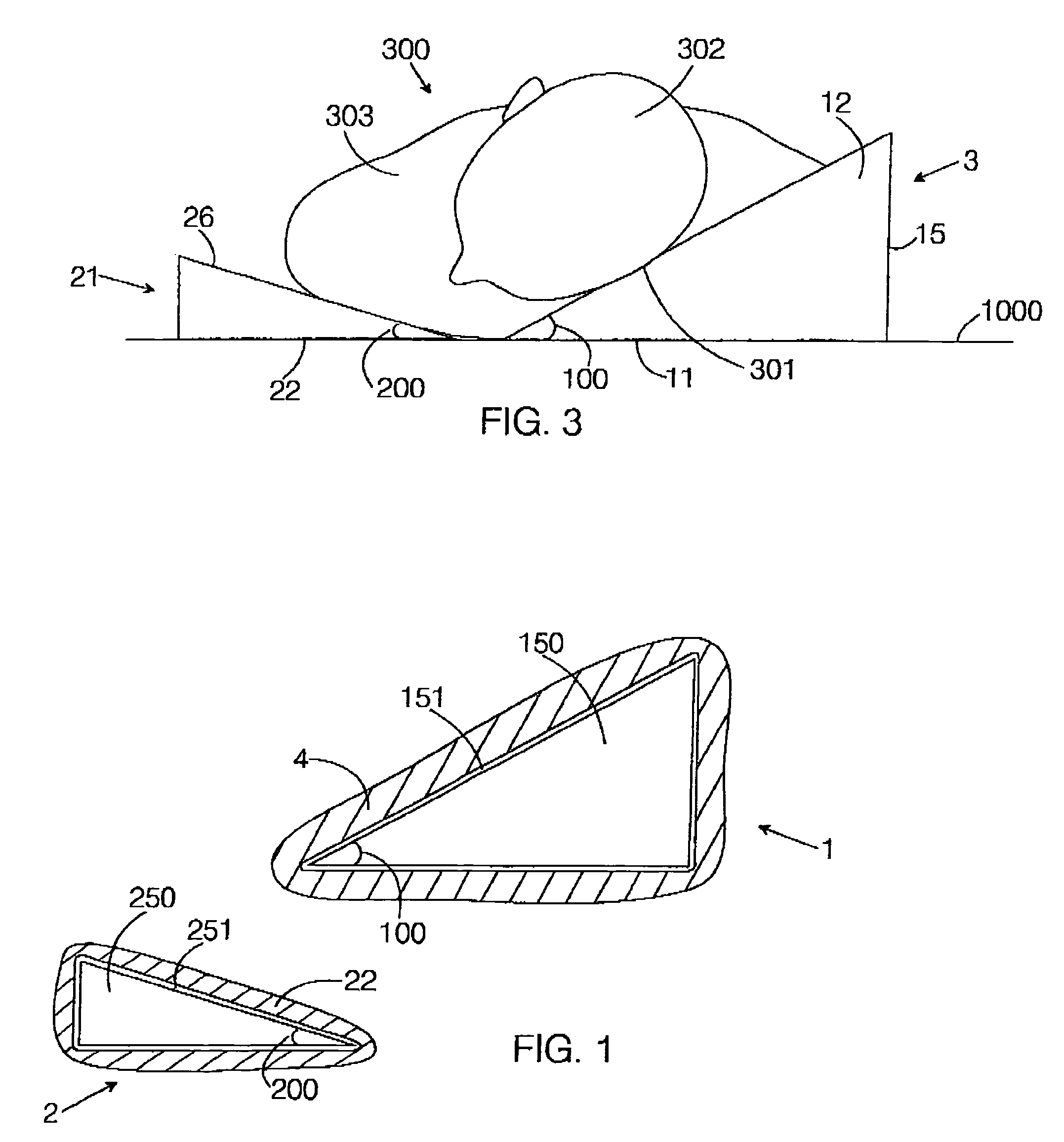

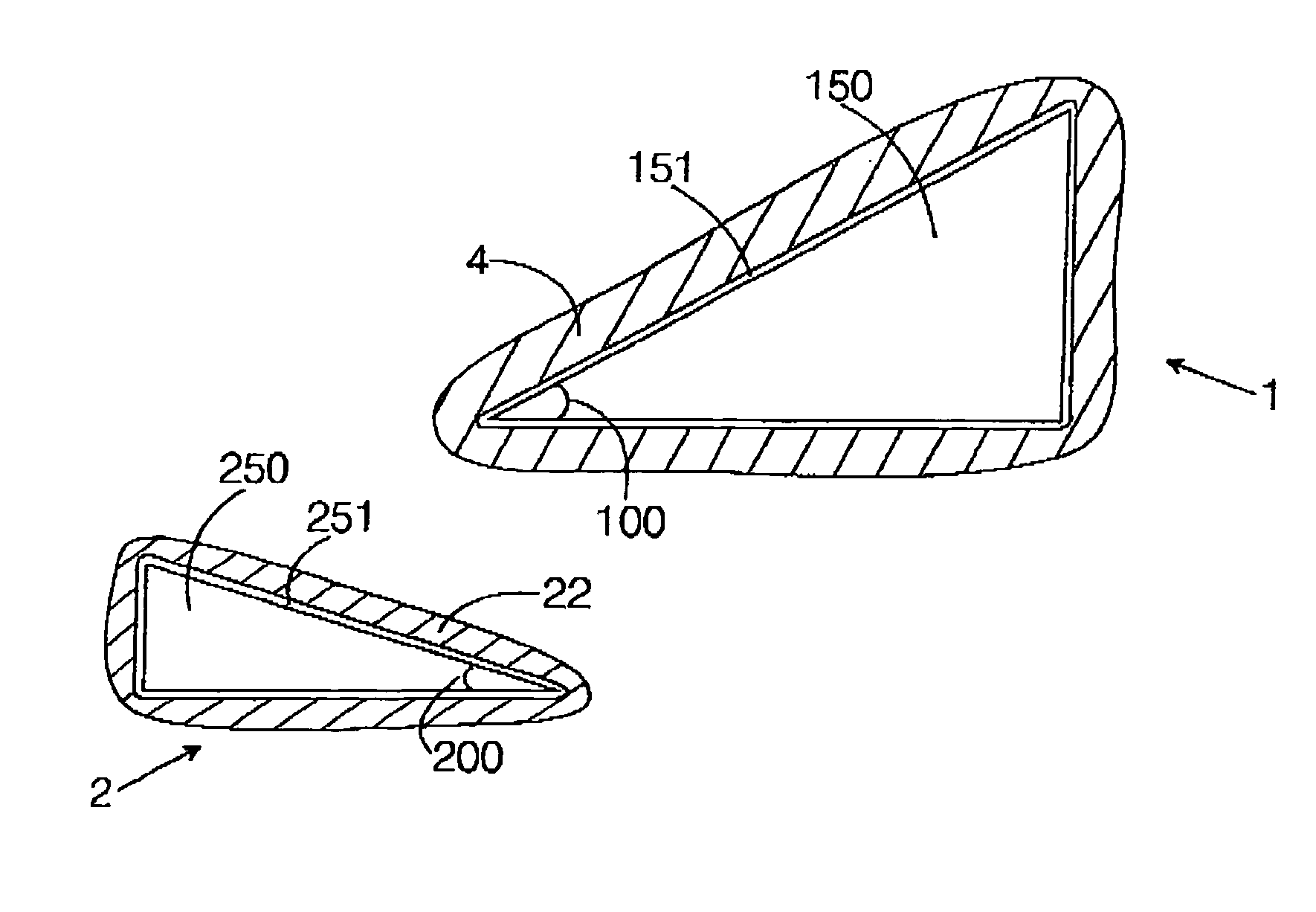

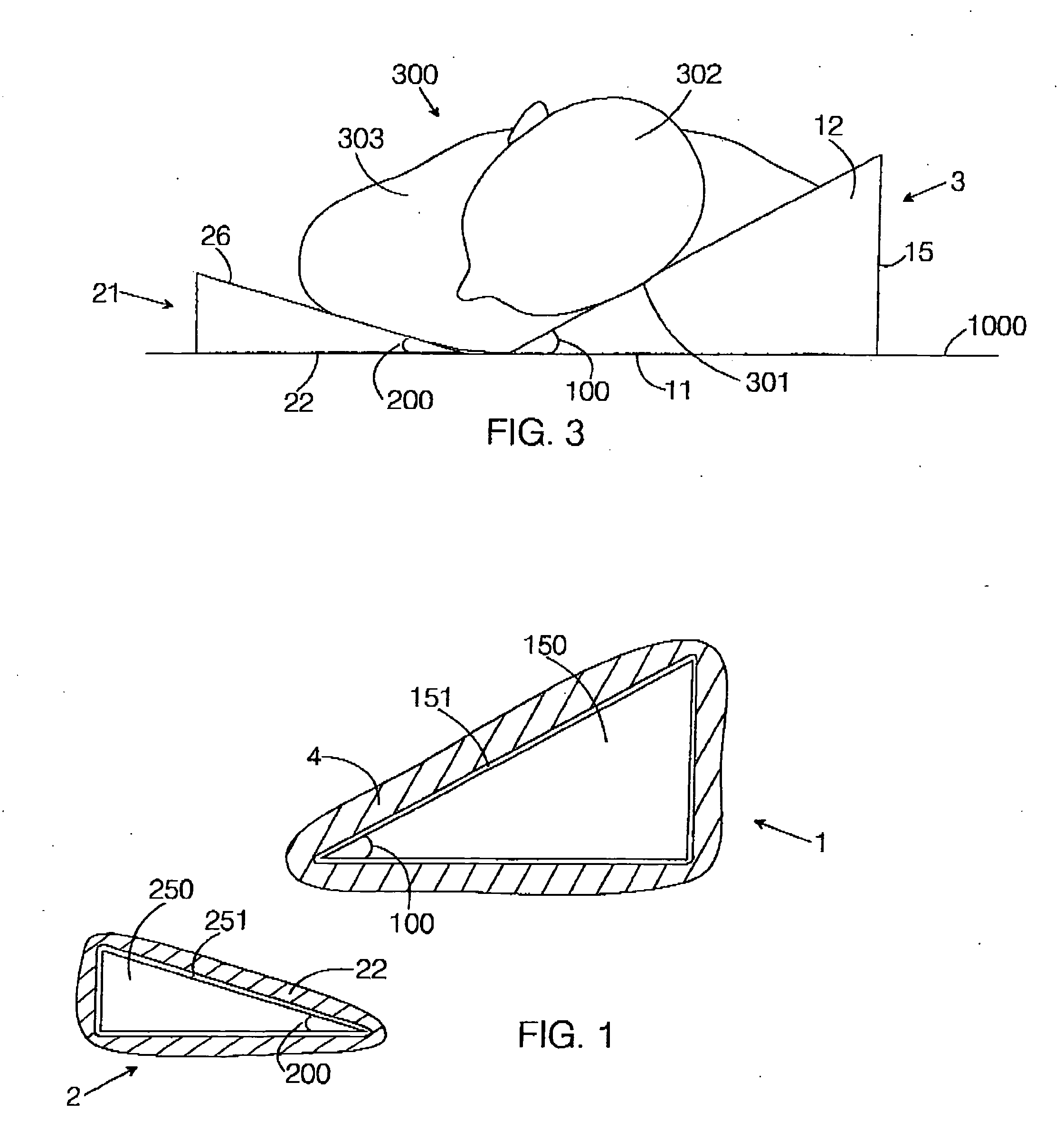

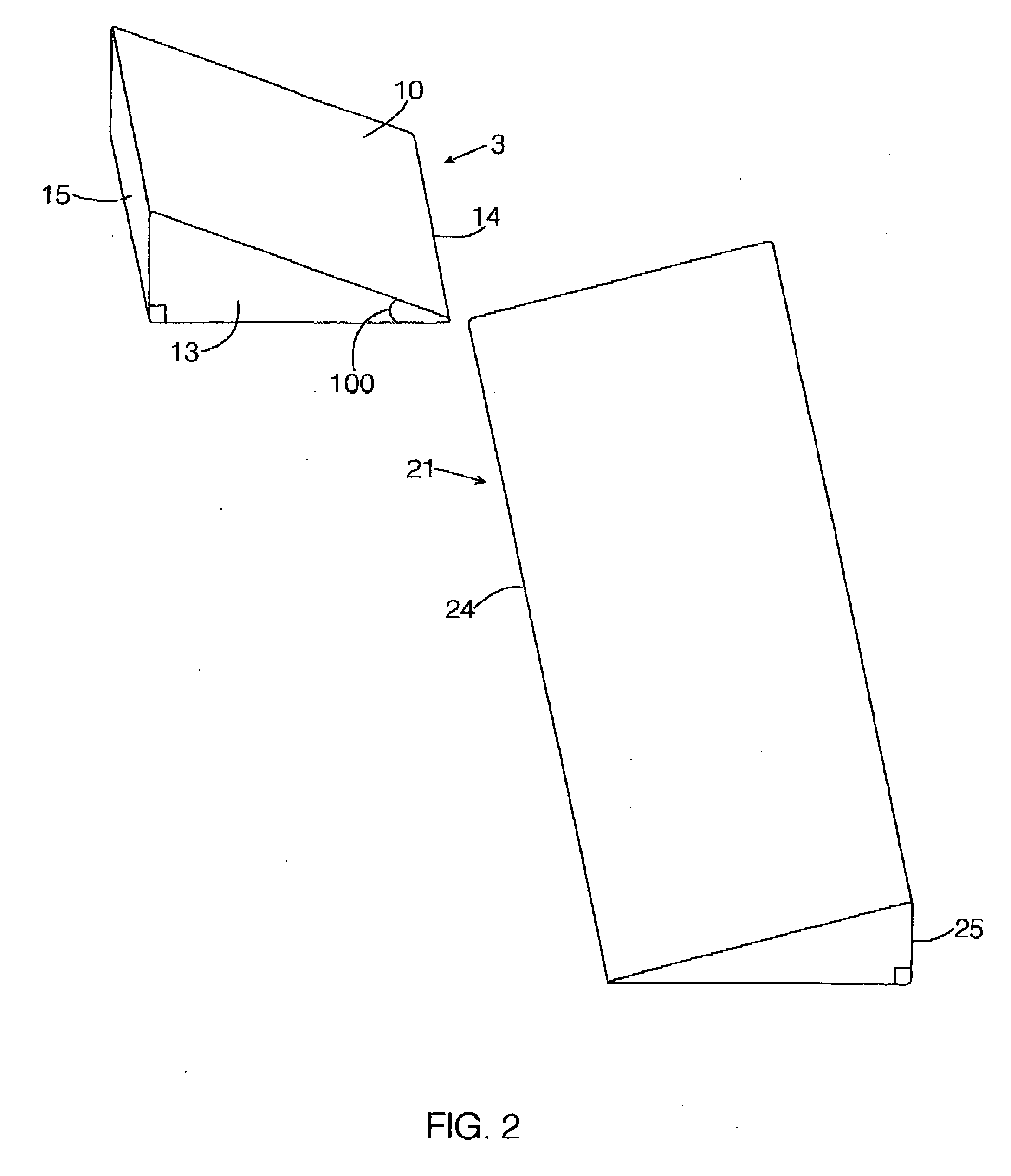

Stomach sleeper

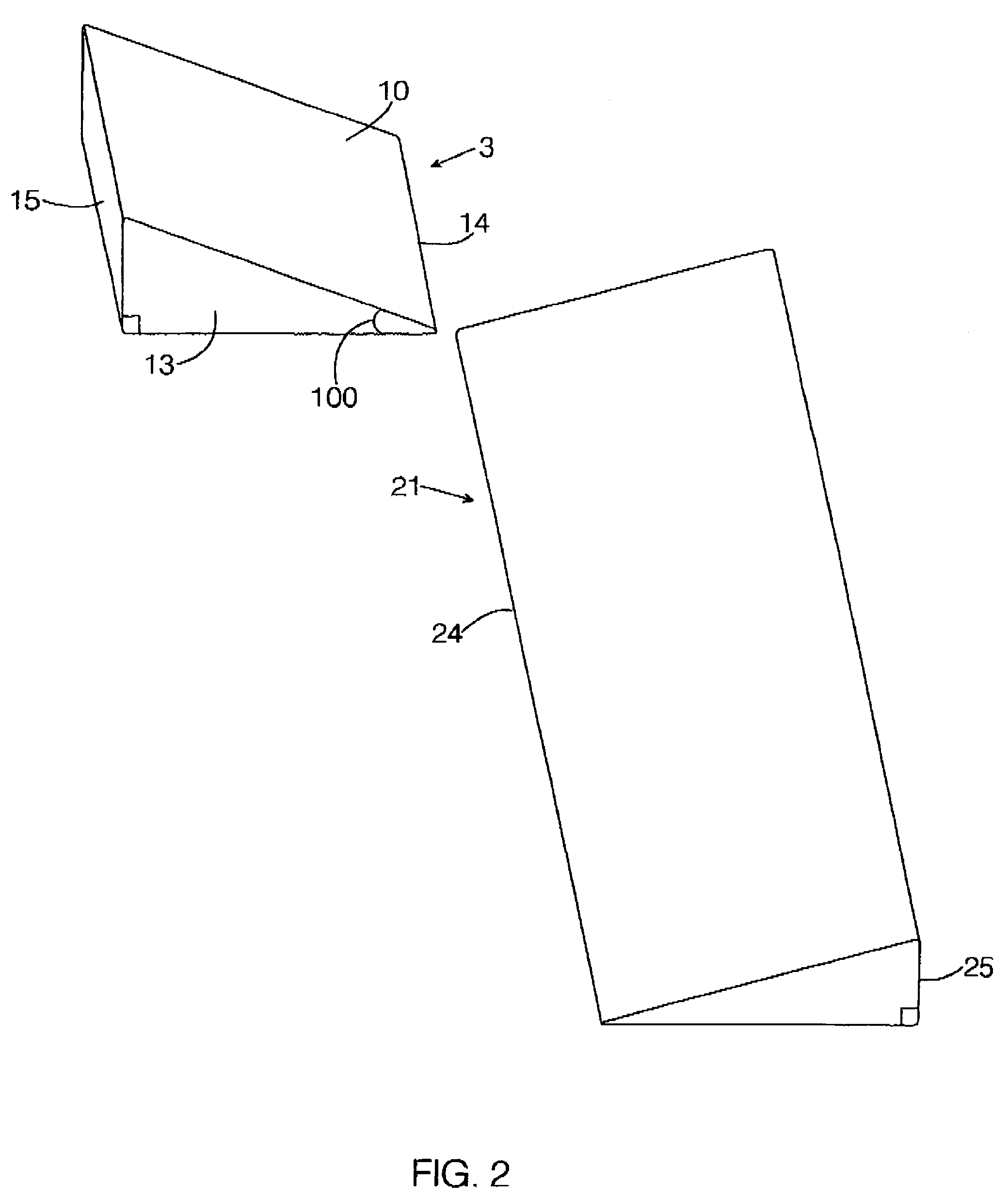

A sleeper-support device designed to minimize cervical rotation with respect to the torso for a person lying prone. The device includes a wedge-shaped head support that maintains the head in repose at an intermediate orientation between zero rotation and the traditional 90-degree rotation typical of the prone sleeper. The device also includes a wedge-shaped torso piece that constrains the torso from rotating in the direction that would increase the angle between the head and neck (the head-turn angle). The support this device provides prone sleepers allows them to sleep comfortably without incurring the back and cervical stress and strain commonly associated with sleeping in the prone position.

Owner:CHISARI JOSEPH

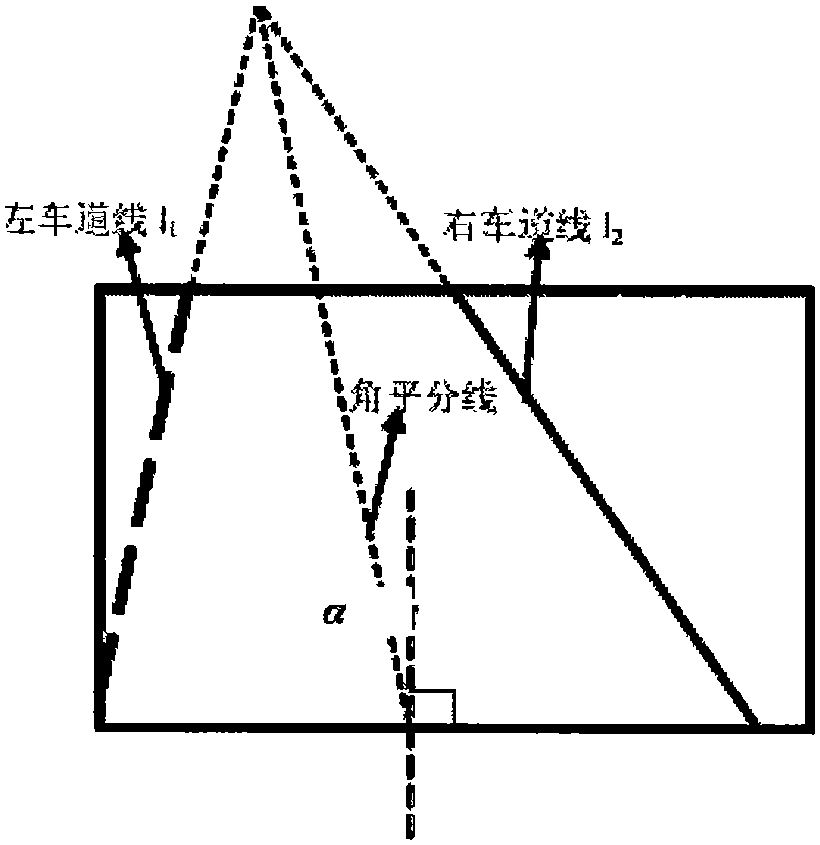

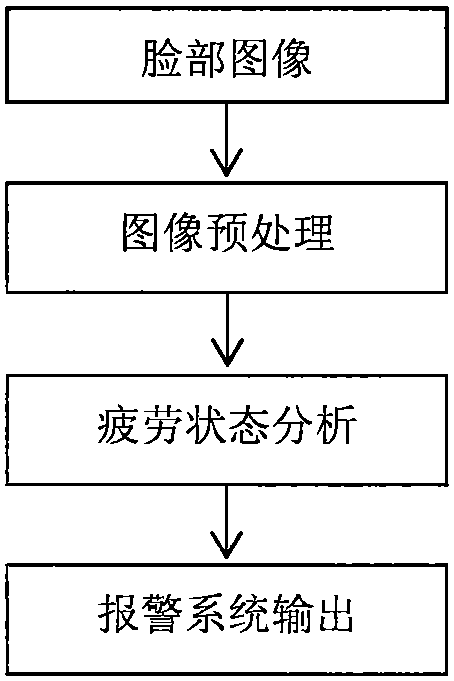

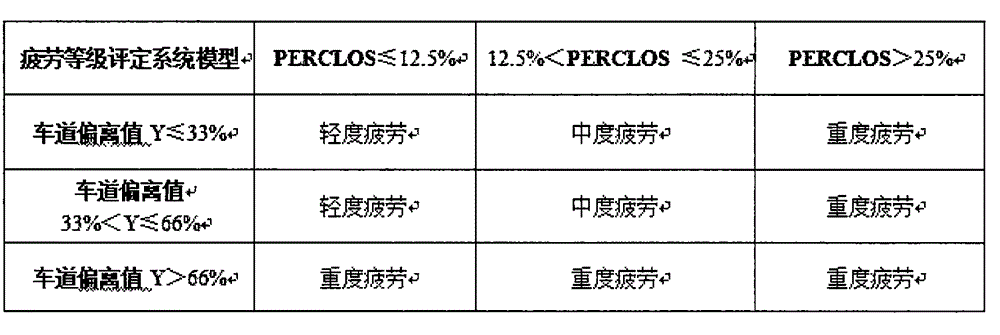

Early warning system based on driver face features and lane departure detection

InactiveCN105151049AAlarm in timeGood effectExternal condition input parametersDriver input parametersPattern recognitionEarly warning system

The invention discloses an early warning system based on driver face features and lane departure detection. The early warning system comprises a first camera, a second camera, an image storage module, an image analysis system and an alarm system. The first camera is used for collecting the open and closed states of the eyes of a driver and the head turning state of the driver. The second camera is used for collecting road images. The image storage module is used for storing information collected by the first camera and the second camera. The image analysis system is used for analyzing the information stored in the image storage module. The alarm system makes corresponding alarm prompt sounds according to the judgment result of the image analysis system. According to the early warning system, the fatigue state of the driver can be judged in good time through the face image of the driver and the road images, the corresponding alarm prompt sounds are produced according to the fatigue state, alarming is in time, and the effect is remarkable.

Owner:JIAXING ITRUN INFORMATION TECH CO LTD

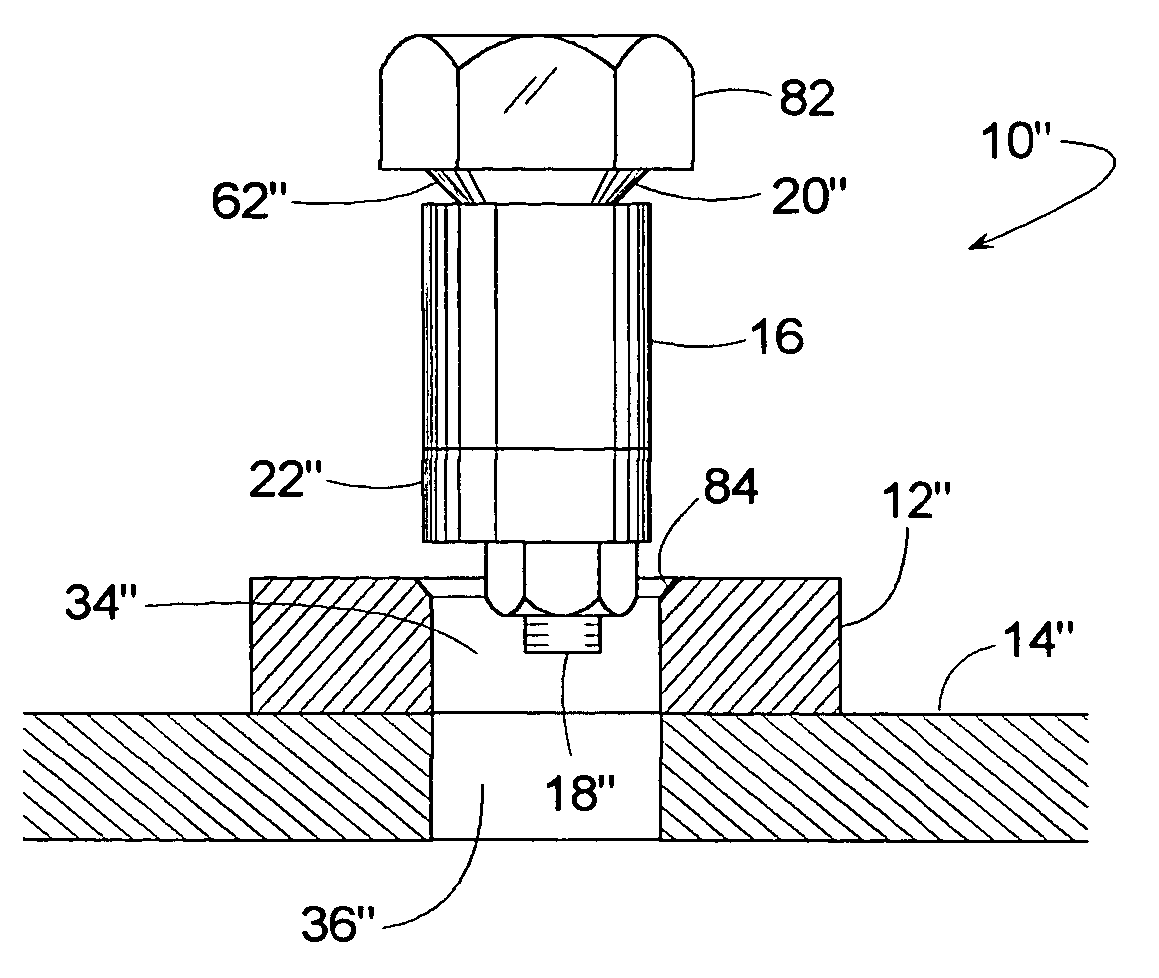

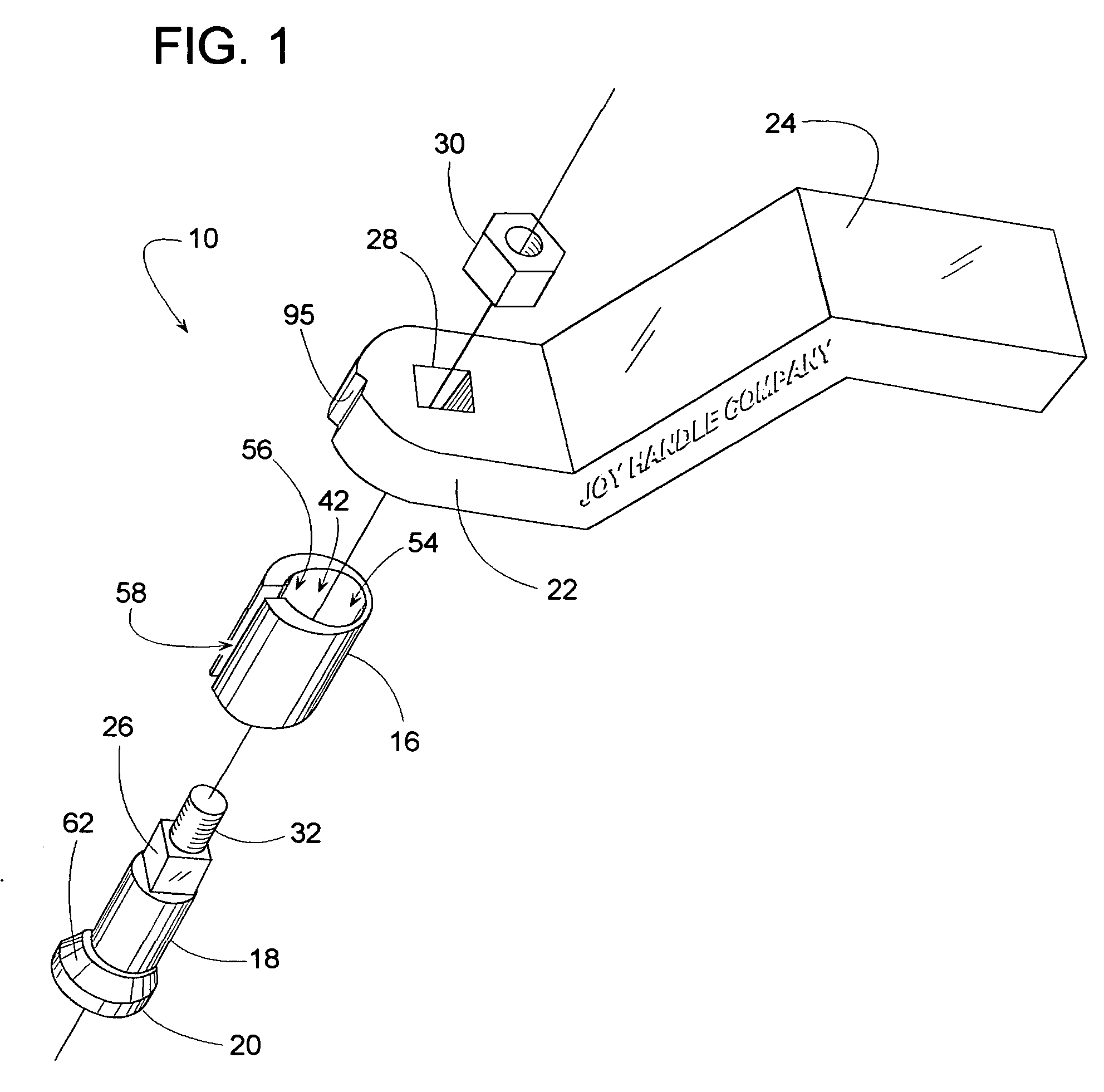

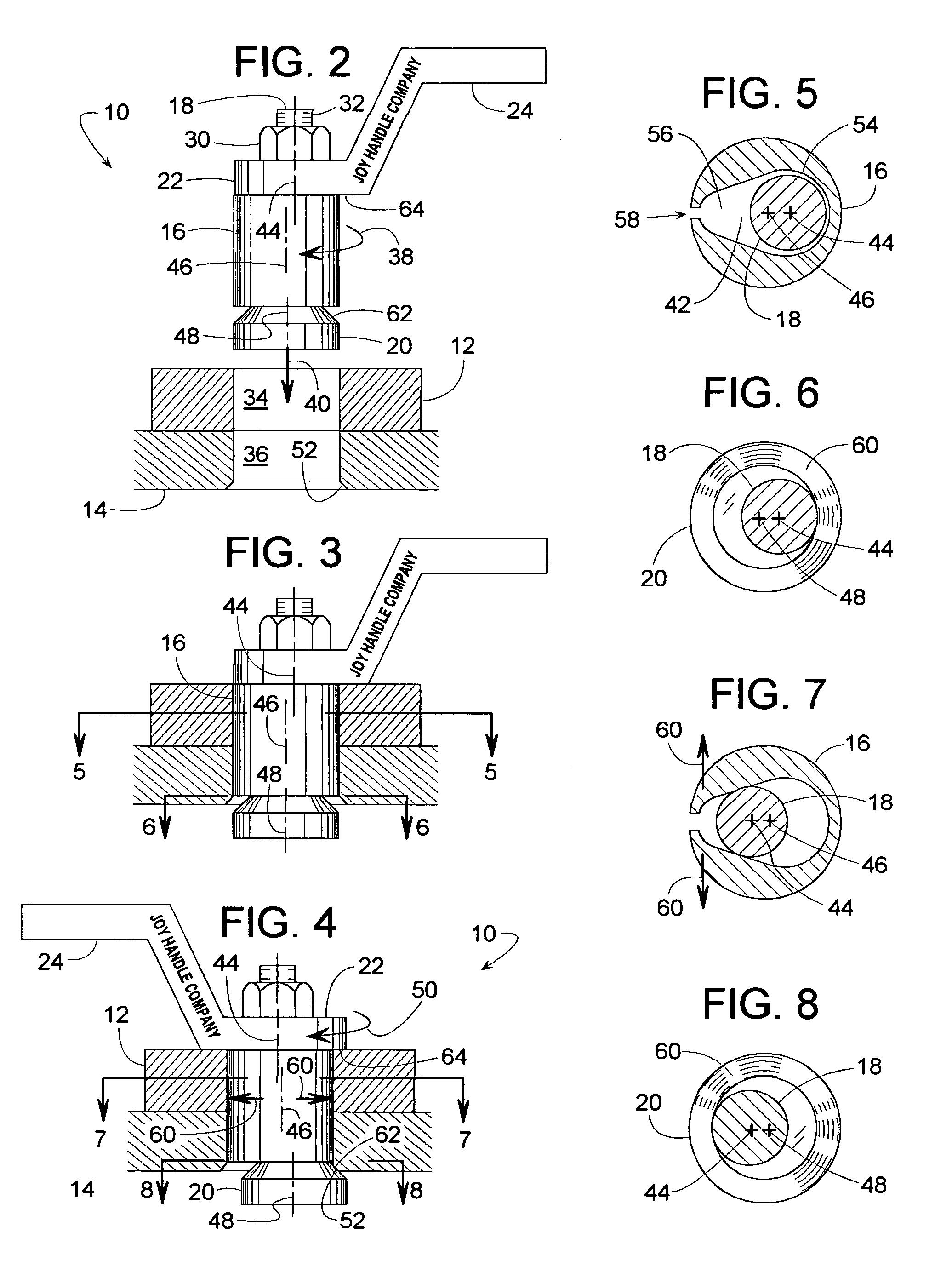

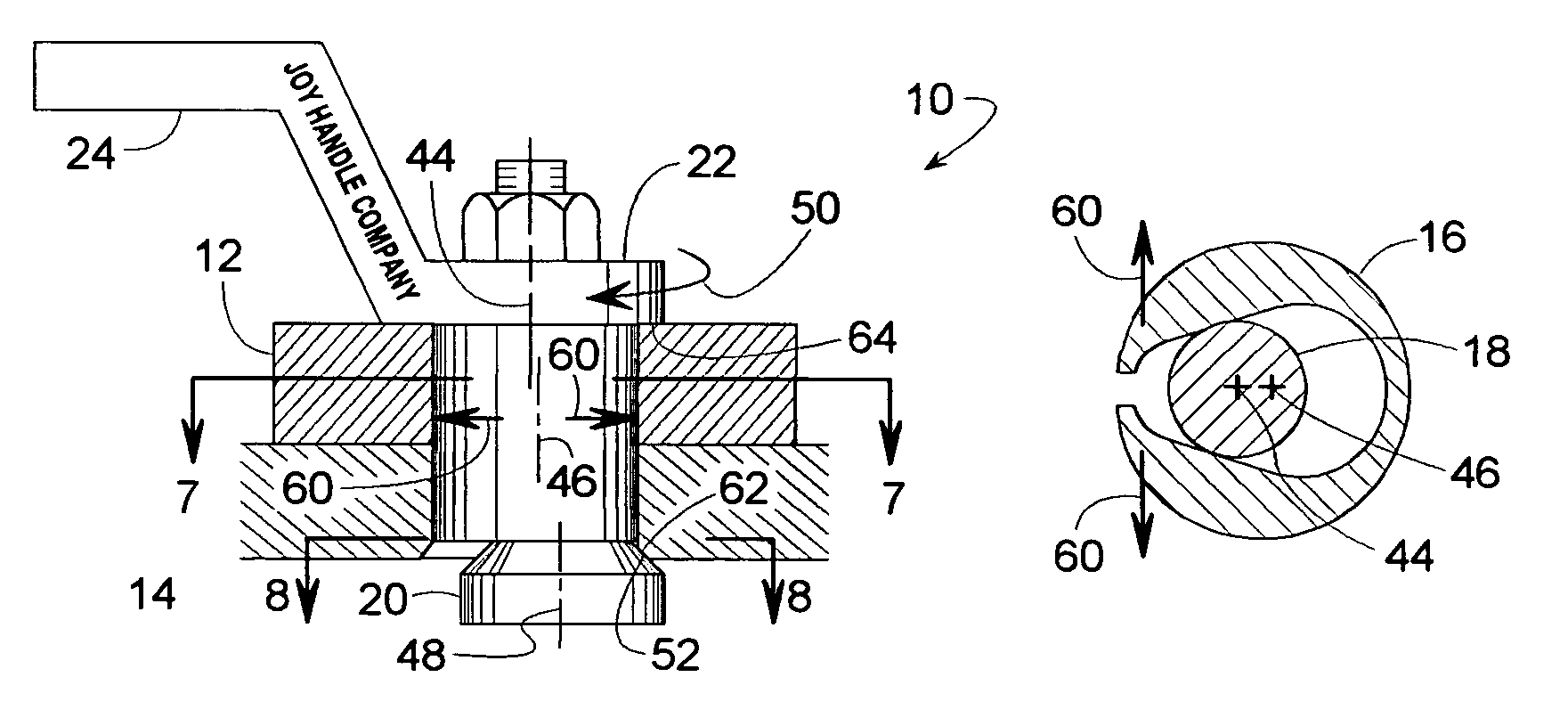

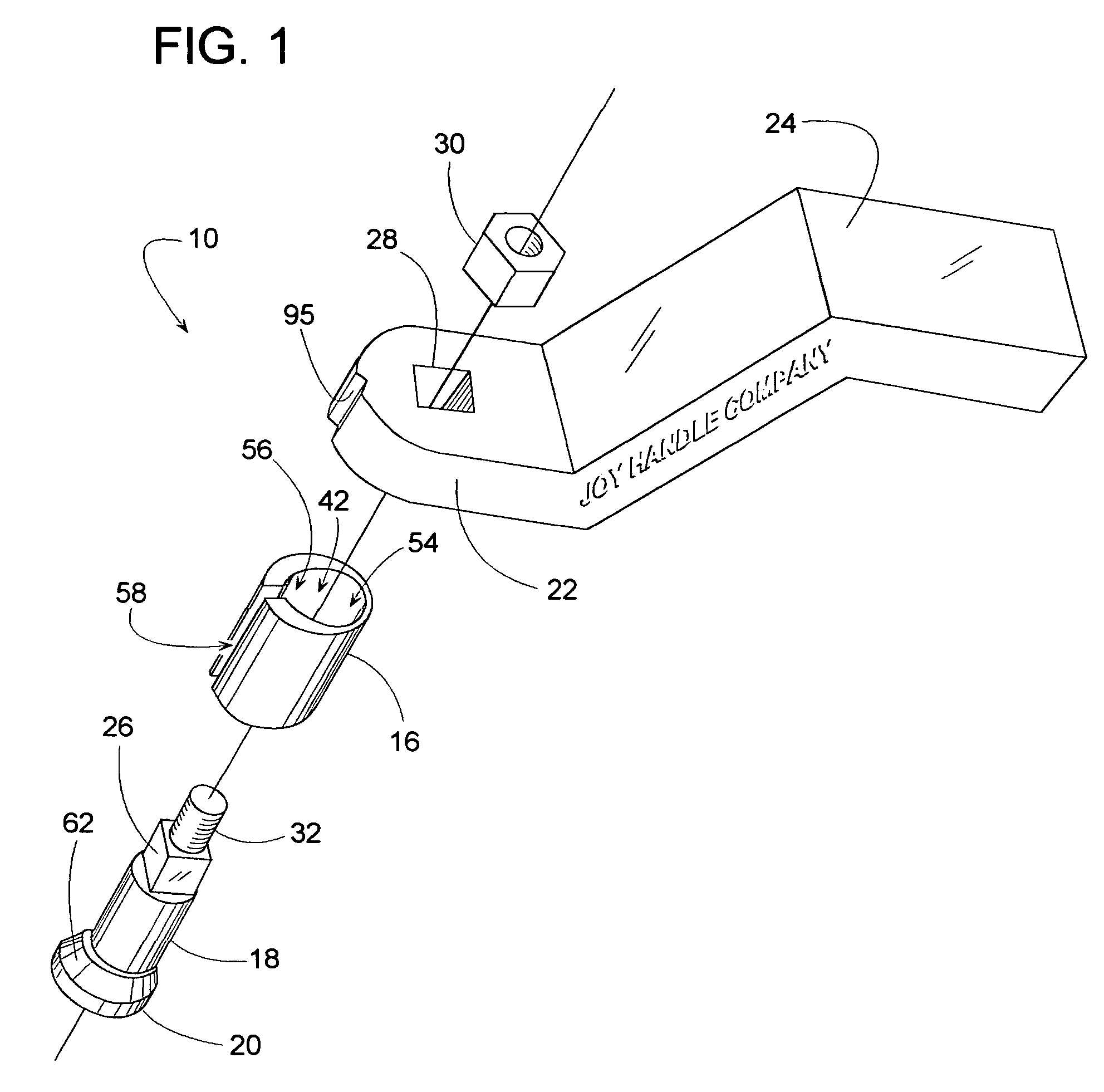

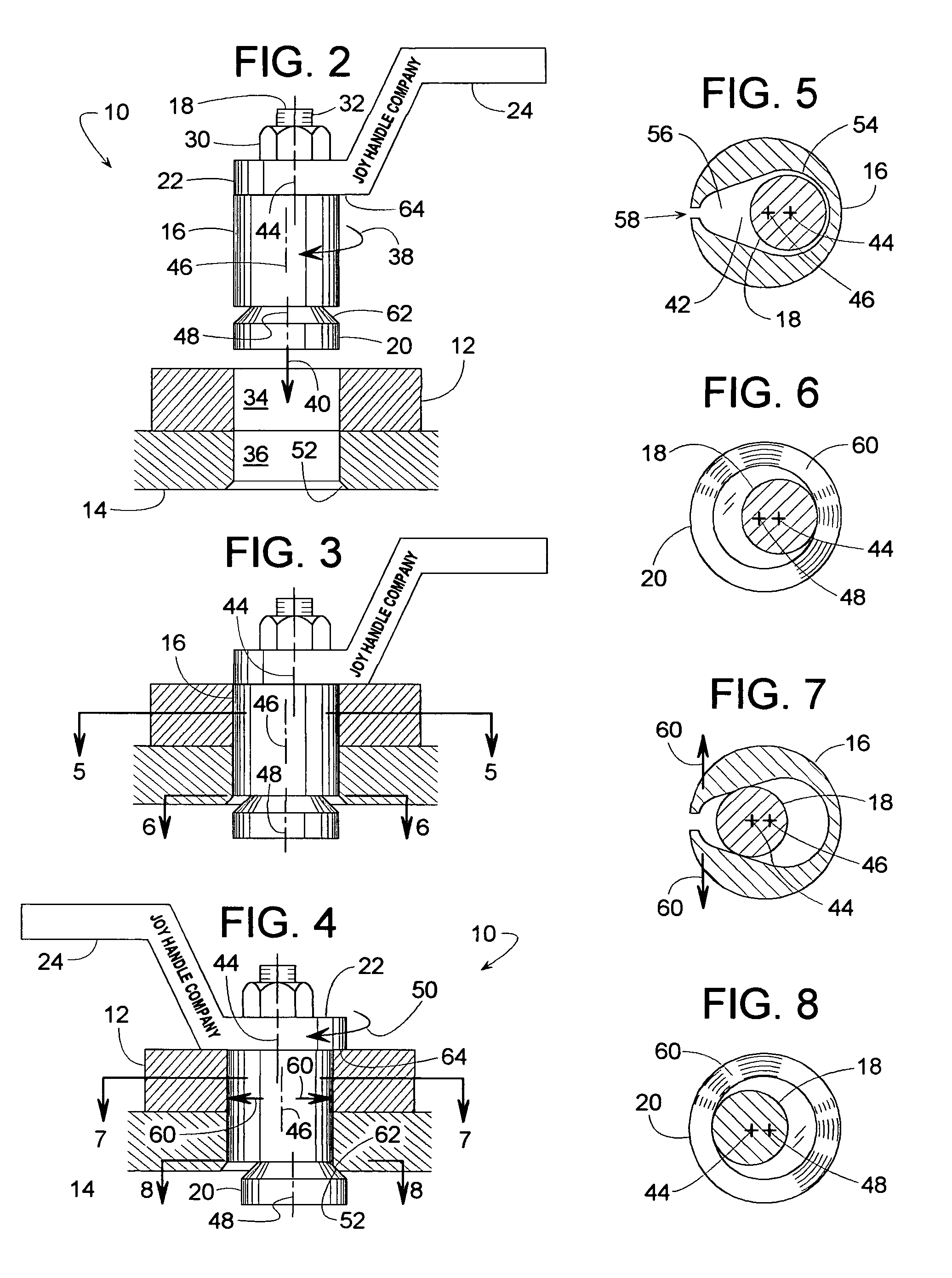

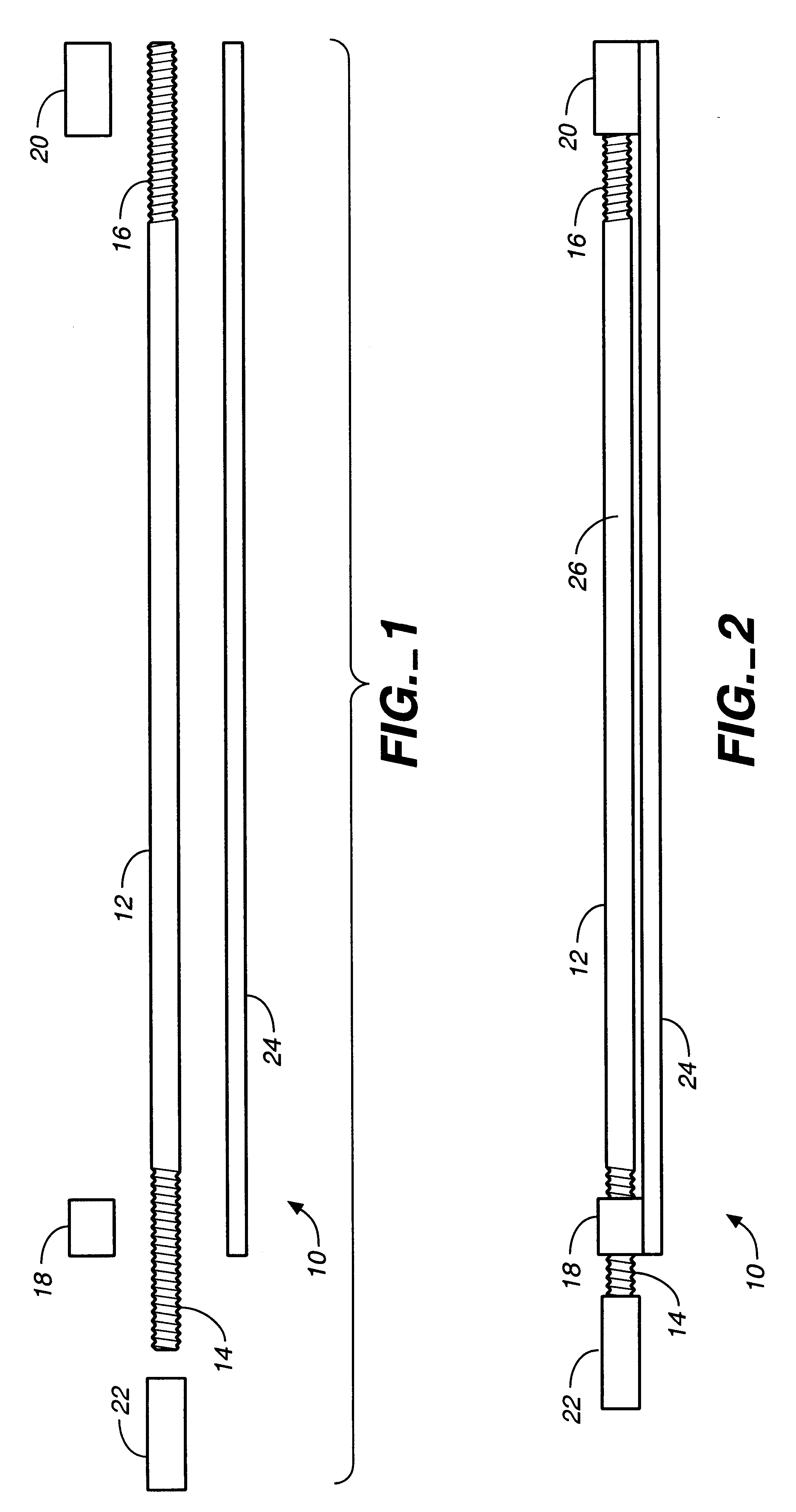

Alignment pin and fastener with bi-directional clamping

InactiveUS20050084361A1Snap fastenersLocking fastenersEngineeringElectrical and Electronics engineering

An alignment pin or fastener includes a radially eccentric part such that when the fastener is tightened, the eccentric part shifts radially to simultaneously align the holes of two plates in a radial direction and clamp the two plates together in an axial direction. The bi-directional fastener includes two heads at opposite ends of a shaft, wherein the two plates become sandwiched and clamped between the two heads. The shaft and the two heads remain fixed relative to each other, so turning one head turns the other. This allows the fastener to be tightened even when only one of the heads is accessible.

Owner:FLY DAVID E

Alignment pin and fastener with bi-directional clamping

An alignment pin or fastener includes a radially eccentric part such that when the fastener is tightened, the eccentric part shifts radially to simultaneously align the holes of two plates in a radial direction and clamp the two plates together in an axial direction. The bi-directional fastener includes two heads at opposite ends of a shaft, wherein the two plates become sandwiched and clamped between the two heads. The shaft and the two heads remain fixed relative to each other, so turning one head turns the other. This allows the fastener to be tightened even when only one of the heads is accessible.

Owner:FLY DAVID E

Stomach sleeper

A sleeper-support device designed to minimize cervical rotation with respect to the torso for a person lying prone. The device includes a wedge-shaped head support that maintains the head in repose at an intermediate orientation between zero rotation and the traditional 90-degree rotation typical of the prone sleeper. The device also includes a wedge-shaped torso piece that constrains the torso from rotating in the direction that would increase the angle between the head and neck (the head-turn angle). The support this device provides prone sleepers allows them to sleep comfortably without incurring the back and cervical stress and strain commonly associated with sleeping in the prone position.

Owner:CHISARI JOSEPH

Full automatic brazing machine for radiator

InactiveCN1701888AImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention discloses full automation soldering machine for heating radiator and belongs to welding machine field, which comprises frame, locating device of heating radiator, welding device, clamping device and its arm brace composed clamp head, turn power device to bring clamp head turn and lifting power device to drive the lift of drive clamp head, radiator and power device. First, weld the branch pipe and connected link box pipe; then, lifting device drives clamp head, radiator and turn device to lift and leave their locating devices; turn device drives radiator to turn for 180Deg; lifting device drives clamp head, radiator and turn device to drop and locate and clamp, welding device take similar operation to other link points; finally, it comes to the finish of the automatic welding, which increases greatly the work efficiency.

Owner:杜明干

Hydraulic wrench control valve systems

A wrench assembly including a drive head and an attached socket for engaging a bolt or nut. When the drive head turns, the socket and any engaged threaded member will also rotate. A hydraulic motor and cylinder are also included. The hydraulic motor and cylinder rotate the drive head and socket independently of each other. Typically, the hydraulic motor will rotate the drive head faster than the cylinder but at lower torques. Thus, the hydraulic motor will spin the threaded member down until it is snug, and then the hydraulic cylinder will tighten the threaded member to the desired torque. Alternatively, the hydraulic cylinder may break the threaded member out when it is tight. The hydraulic motor will then spin the loosened threaded member out. Finally, the wrench assembly includes a hydraulic fluid distribution system, including one or more valves that regulate hydraulic fluid flow through the wrench assembly.

Owner:POWER TORK HYDRAULICS

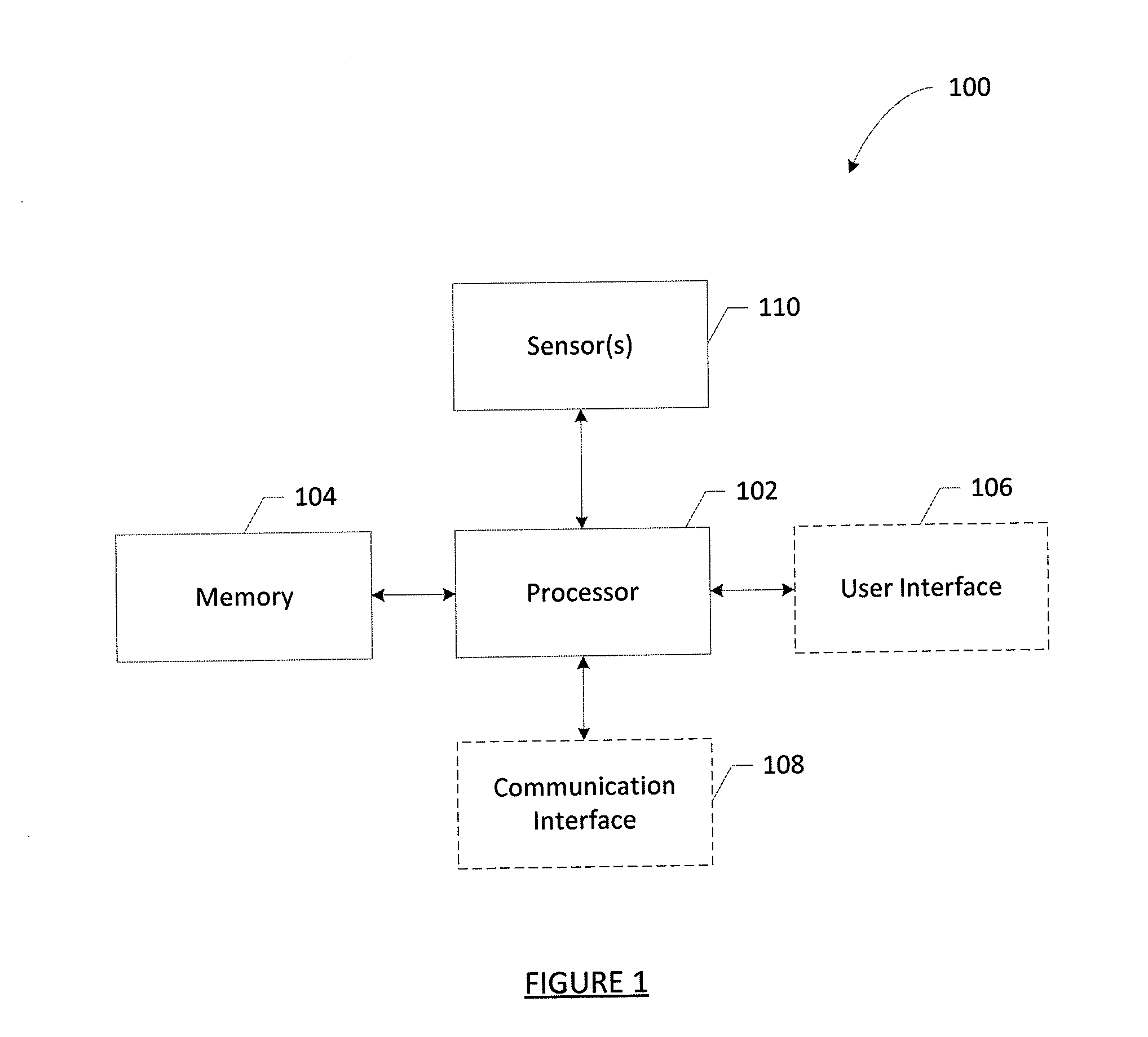

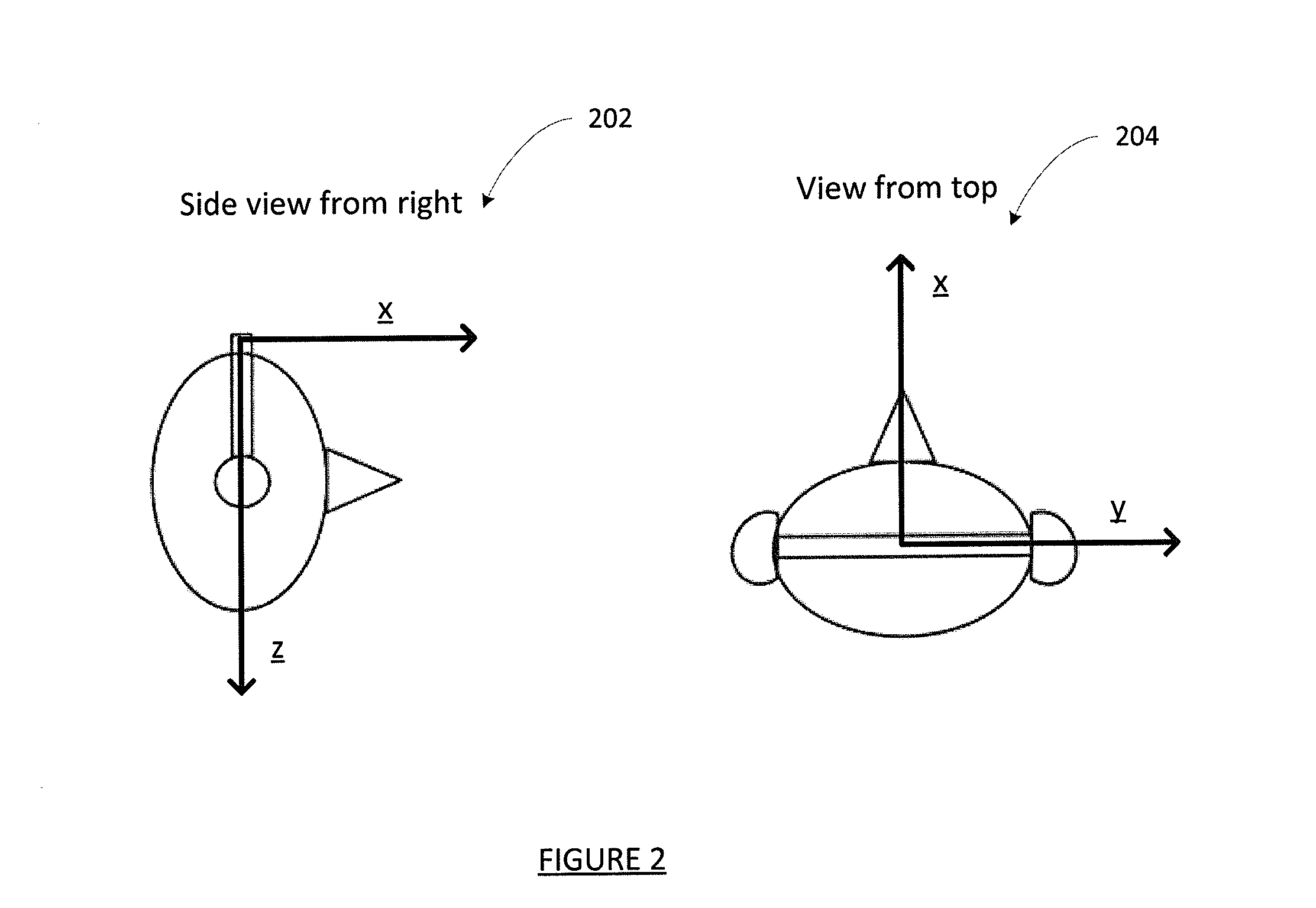

Orientation Free Handsfree Device

ActiveUS20140254817A1Headphones for stereophonic communicationEarpiece/earphone attachmentsComputer visionHeadphones

Methods, apparatuses, and computer program products are provided to indicate or automatically configure headphone channel orientation based on a physical orientation determination. An apparatus is provided that is configured to at least determine an orientation of the headphone device; analyze the determined orientation; and provide an indication of the determined orientation or adjust the output channel configuration of the apparatus for the headphone device. The apparatus may be further configured to determine the orientation of the headphone device based on at least one of: a head turn position; a direction of one or more audio signals; a direction of movement, wherein the movement is determined based on a determination of acceleration or trajectory of the headphone device; two or more compass data, wherein at least one compass is located in each of the apparatus and the headphone device; and a difference in characteristics of one or more audio signals.

Owner:NOKIA TECHNOLOGLES OY

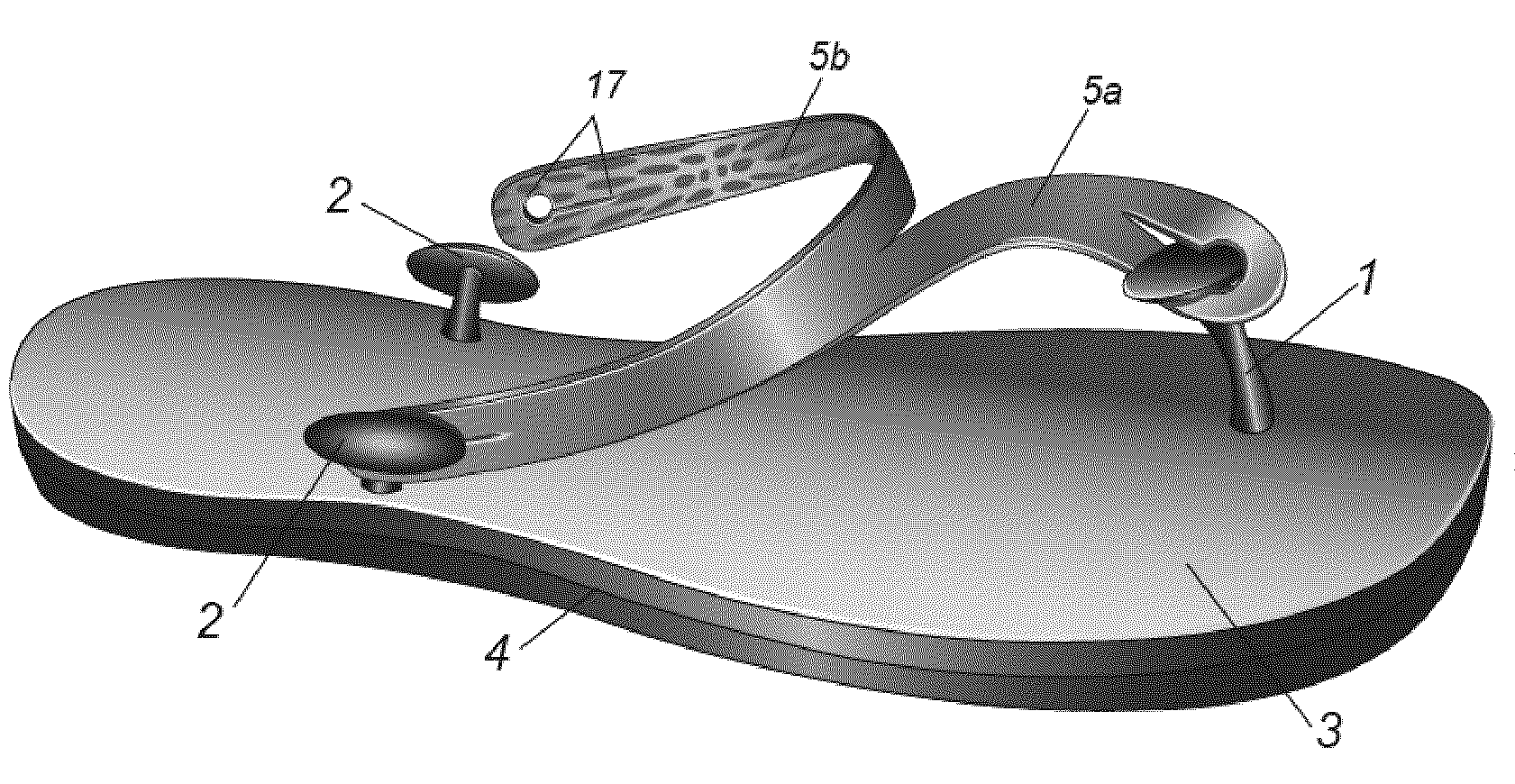

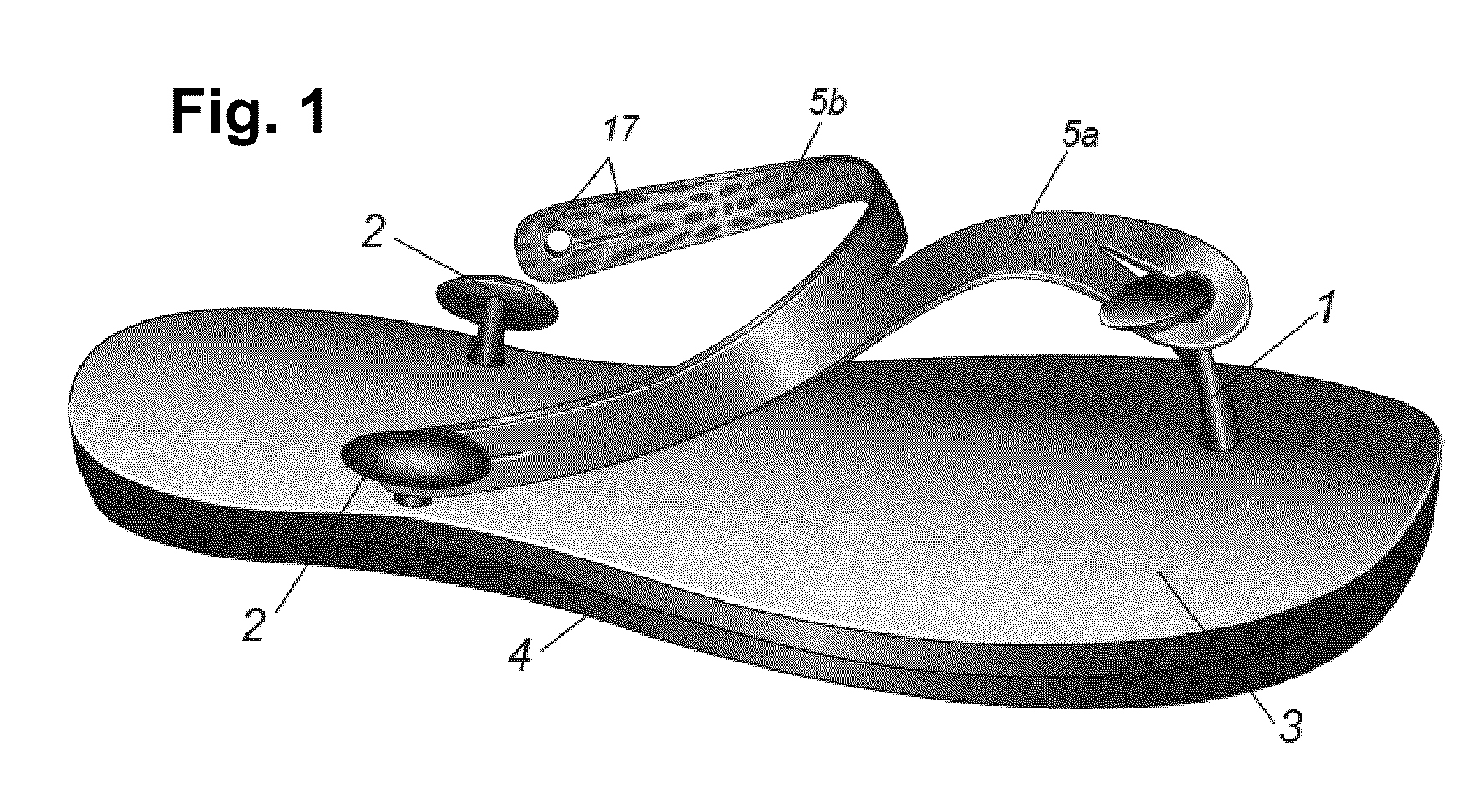

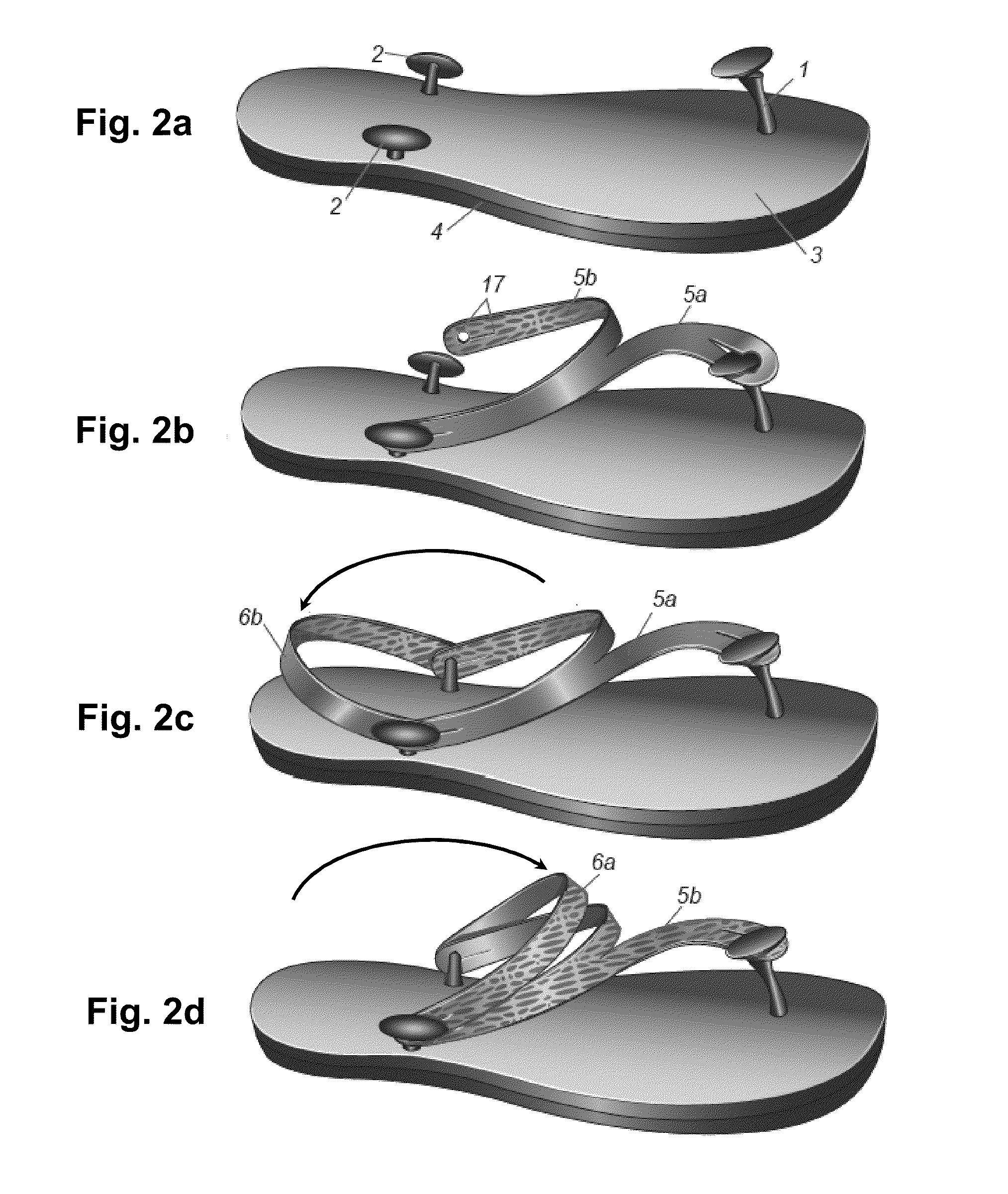

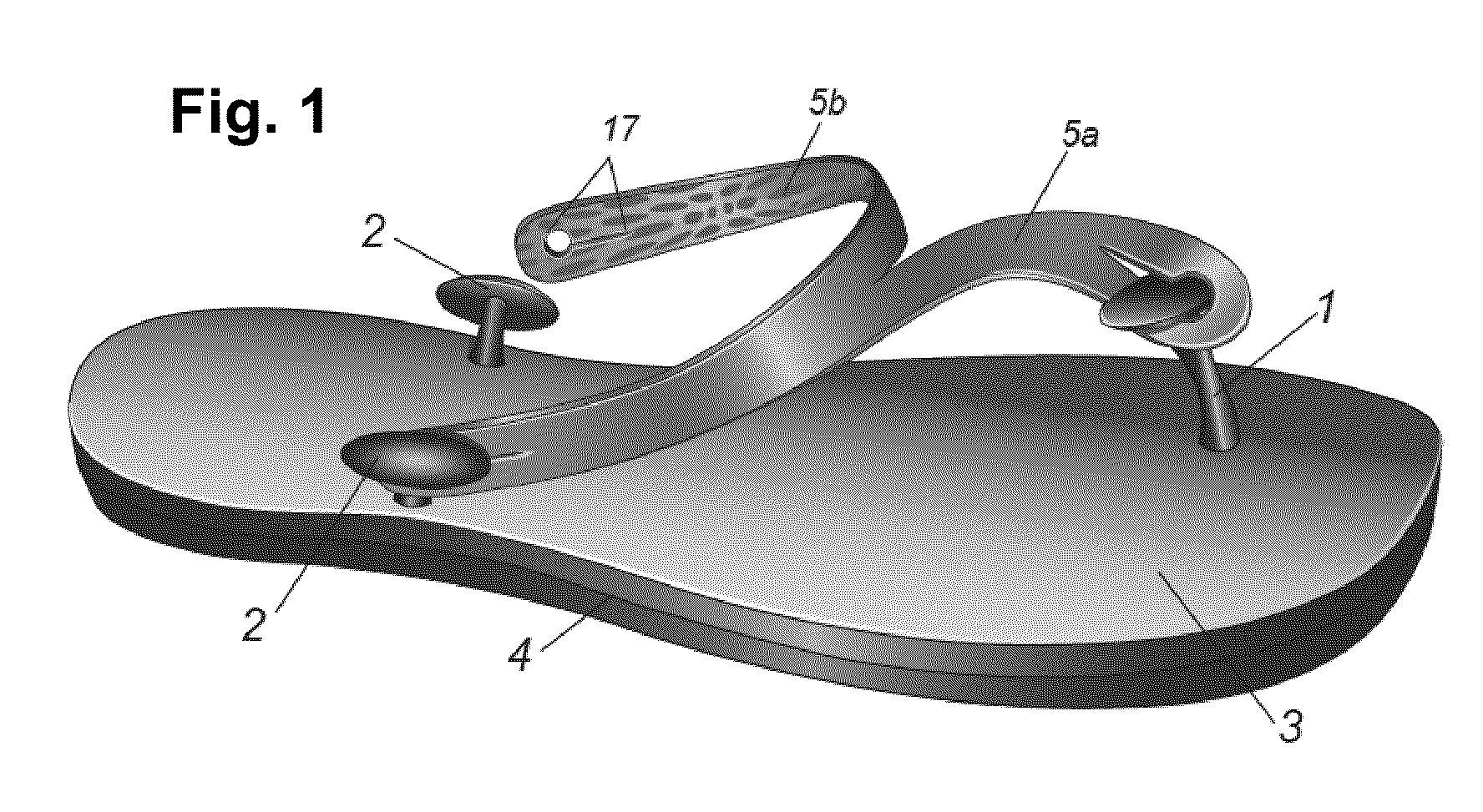

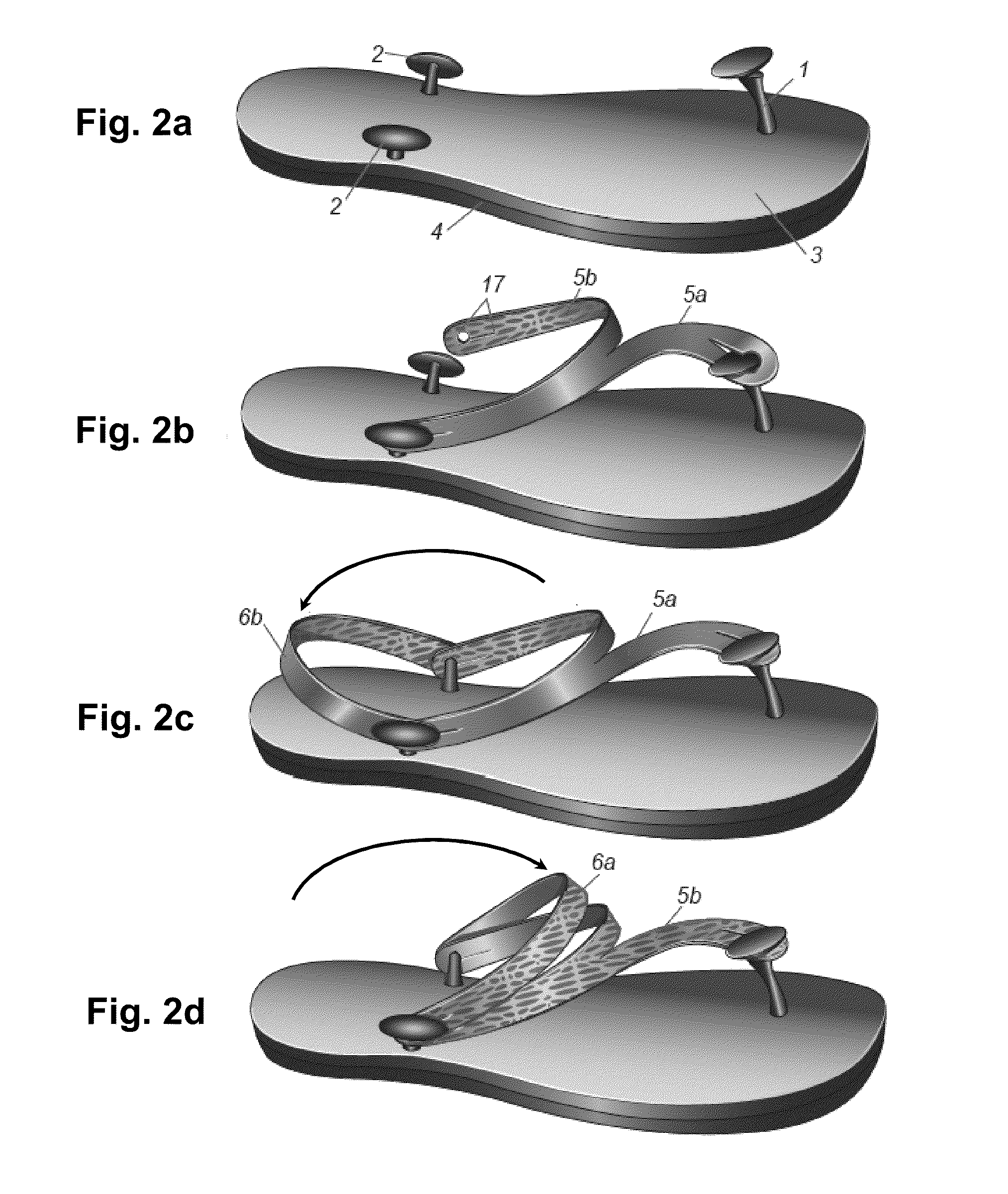

Shoe with removable and reconfigurable uppers

An shoe assembly includes a sole and one or more detachable upper pieces that can be made from materials such as fabric, PVC, leather, plastic, rubber, other similar materials and combinations. The upper, in one or more pieces, is removably attached at spaced points on the sole, where nail-shaped posts are permanently mounted. The heads of the posts function as buttons or cleats for buttonholes, keyholes, edge loops or the like on the uppers. Interchangeable uppers can have different materials, shapes and decorative aspects, for quickly and efficiently changing the appearance and style of the footwear. Three posts can be provided, with a front post being inclined rearward and having a slot under the head or cleat, where the upper is attached, and lateral posts with heads turned outwardly. A variety of alternative configurations are possible for the uppers.

Owner:STYLSH

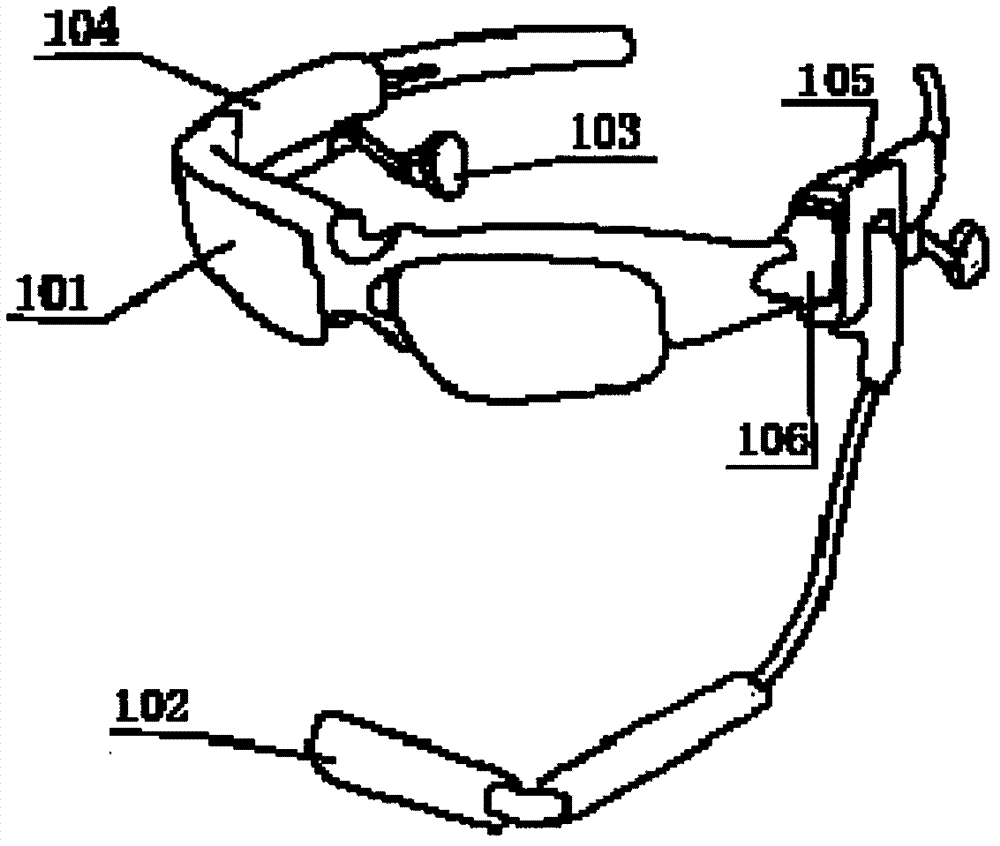

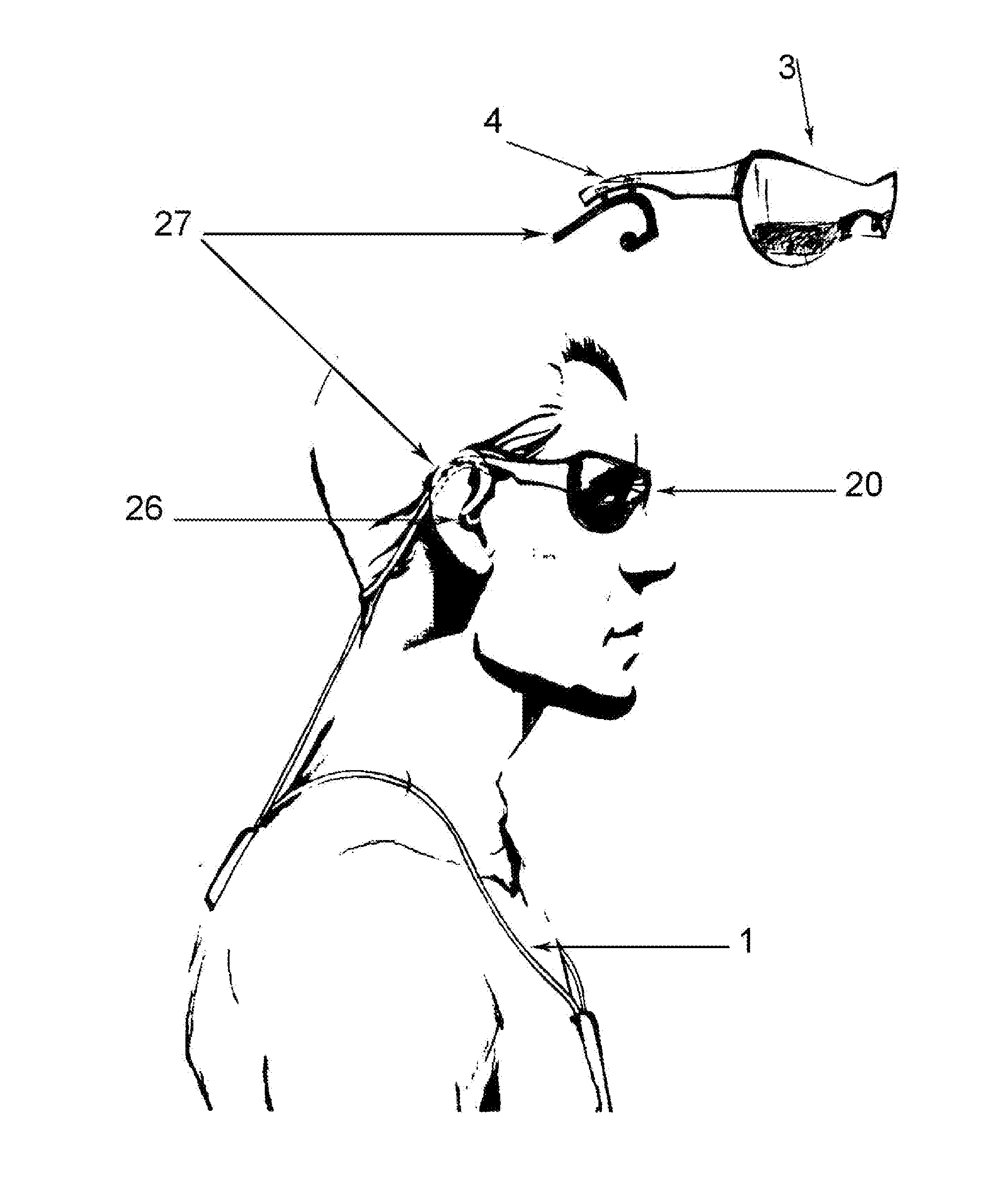

Composite wearable electronic communication device

InactiveUS20160070110A1Shorten the lengthAvoid breakingTelevision system detailsTransmission systemsElectricityDorsal parts

A composite wearable electronic communication device comprising a neck loop configured to bear electronic components and control means, a spectacle frame configured to bear display and videocamera, a flexible adapter comprising two wires, wherein at least one of the wires is electrically connected the neck loop and the spectacle frame, wherein the two wires of the flexible adapter are connected to the neck loop in close proximity to each other and form a dorsal wire joint disposed on the lower dorsal part of the user's neck while wearing the device, wherein in addition, the two wires are mechanically connected to each other in the wire portions between the spectacle frame and the dorsal joint, thus forming a suboccipital wire joint disposed below the user's occiput while wearing the device.Said composite method of coupling a wearable communication device allows to reduce the overall length of the connecting wires, organizing their mobility to compensate the user's head turns, and in some embodiments, when the device comprises winding mechanisms and storage pockets, extra batteries, microphone—array microphones, the method allows to use the wearable communication device for a long time and to wear it on the body under the clothing in operating and non-operating state.

Owner:USHAKOV ALEXEY LEONIDOVICH

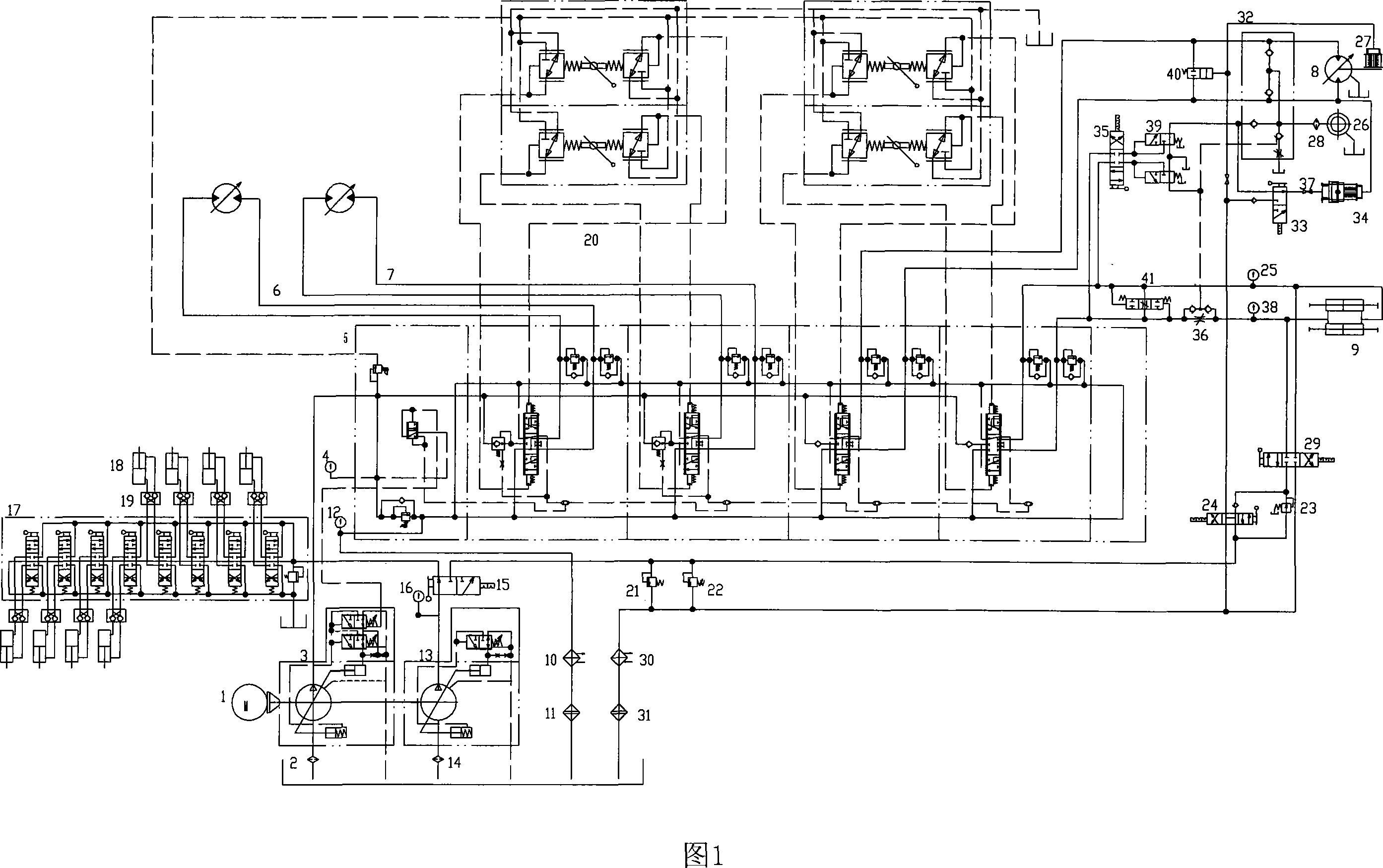

Caterpillar belt self-walking type tunnel drilling rig hydraulic system

InactiveCN101122233AEasy to operateEasy to controlPropulsionDrilling machines and methodsControl systemShortest distance

The invention is a hydraulic system of a pedrail self-walking tunnel driller. With the prior art, a fully-hydraulic tunnel driller is moved manually or by a walking mechanism for a short distance, and a rotation speed and a torque can only be controlled in the manner of drilling by power turning at a hole mouth and in the manner of manual variation. Thus, the prior tunnel driller is provided with the problem of the lagged control, the low control precision, the low efficiency of the hydraulic system, and so on. The hydraulic system of a pedrail self-walking tunnel driller of the invention comprises a pedrail walking loop, a power head turning loop, a feeding and pulling loop, a driller stabilizing loop, a brake loop of a principal axis of the power head, and so on, and can realize the straight walking and turning of the driller, the turning and feeding of the power bead, the interacting of a chuck and a clamping device with the feeding and pulling, the braking of a principal axis of a turning device, the floating of a feeding cylinder, and other functions. Moreover, as the hydraulic feedback control system and the interacting function are adopted, the driller moving is rapid and convenient, the labor intensity is low, the driller drilling techinics is widely applicable, the operation is simple and the system is energy-saving.

Owner:煤炭科学研究总院西安研究院

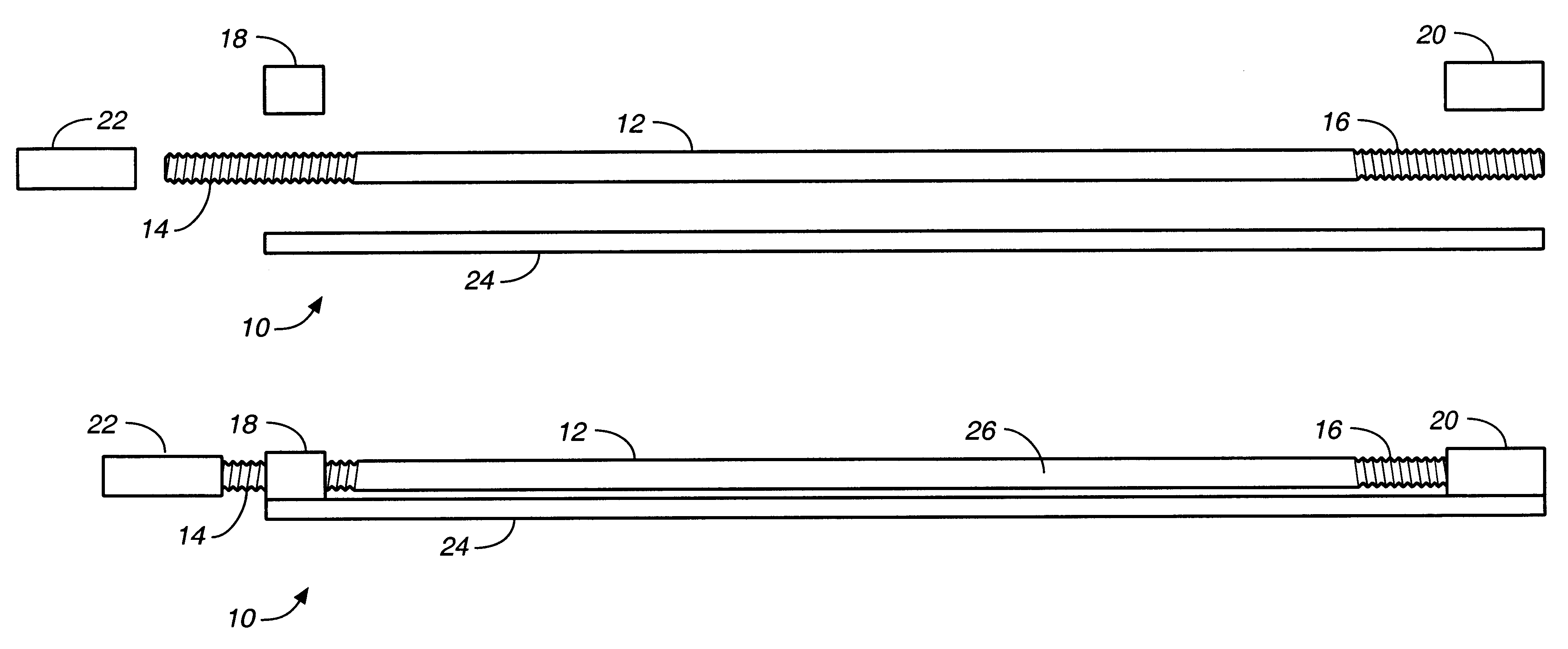

Double-action truss rod for stringed instruments

A truss rod for selectively bowing the neck of a stringed instrument includes a segment of round stock having a pair of threaded ends, one set of threads in a first thread direction, and the other set of threads in the reverse direction. Complementary threaded blocks are threaded onto these threaded ends, and the blocks are secured to a length of flat bar stock. A head bearing a socket is fixed to an end of the round stock, so that turning of the head turns the round stock. The reversed nature of the respective threaded ends causes the length of the portion of the round stock between the fixed blocks to either increase or decrease when the round stock is turned, which correspondingly causes the flat bar to bend either in or out.

Owner:EDDINGER STEVEN W +1

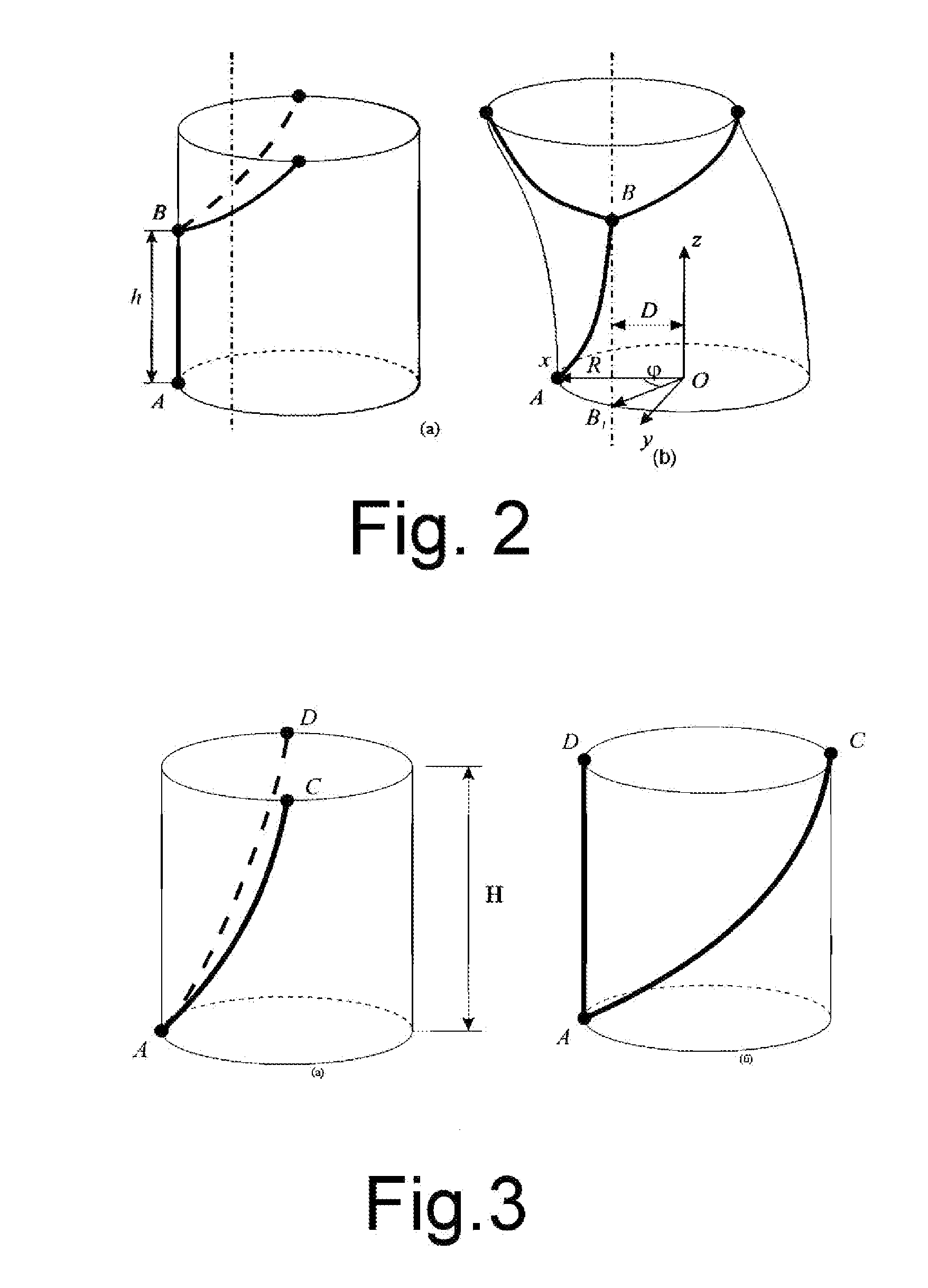

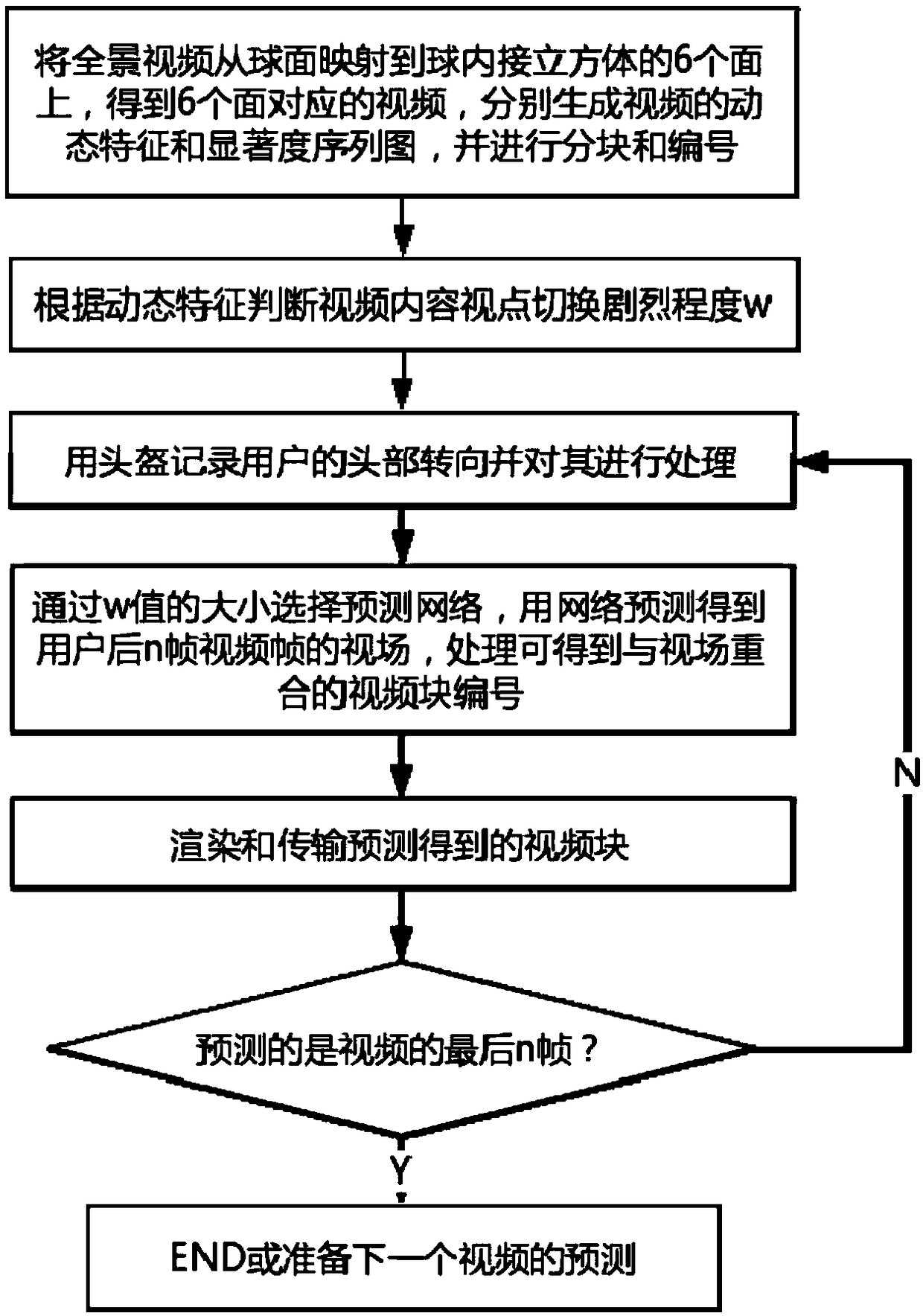

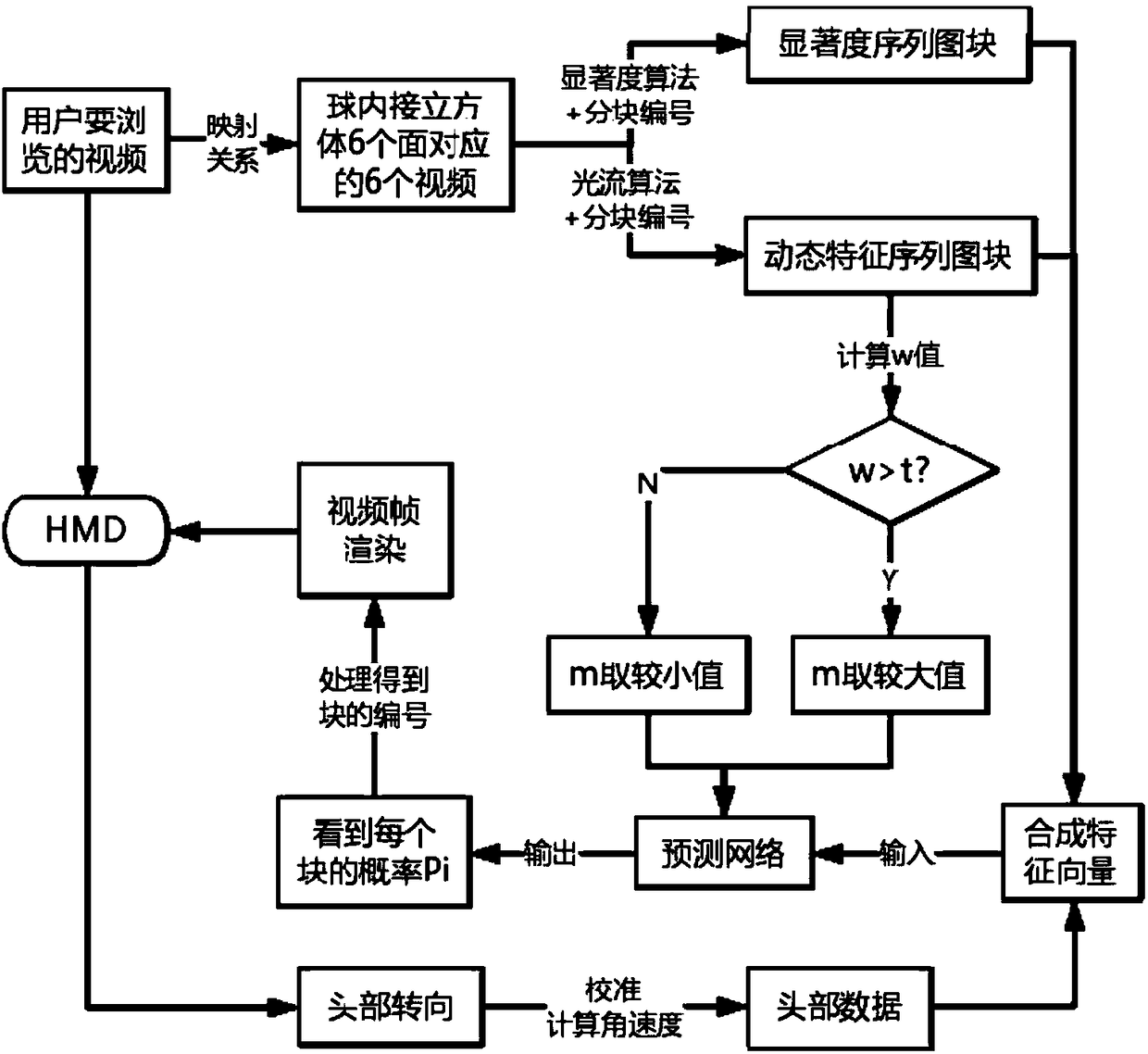

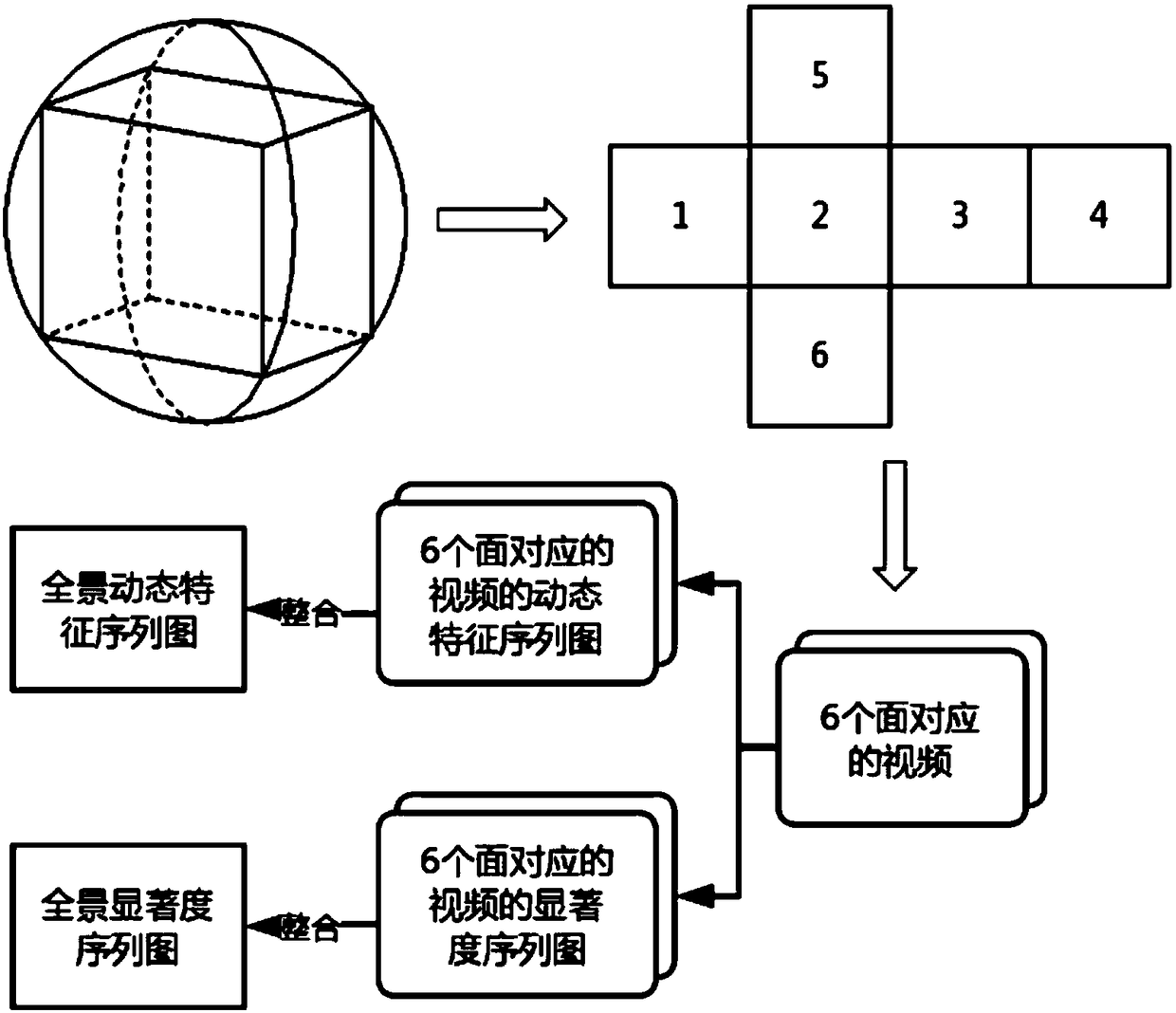

Method for predicting field of view of user based on deep learning

ActiveCN108492322AReduce the impactReduce transmission delayInput/output for user-computer interactionImage enhancementViewpointsSequence diagram

The invention discloses a method for predicting the field of view of a user based on deep learning, which comprises the steps of (1) mapping a panoramic video from a spherical surface to six surfacesof a sphere inscribed cube to obtain videos corresponding to the six surfaces, respectively generating a dynamic feature sequence diagram and a saliency sequence diagram of the videos, and performingblocking and numbering; (2) judging the video content viewpoint switching intensity w according to dynamic features; (3) recording the head turning of the user by a helmet, and processing the recordedhead turning; (4) selecting a prediction network according to the size of the w value, obtaining the field of view of the user in the last n video frames by network prediction, and processing to obtain the number of a video block overlapped with the field of view; and (5) rendering the transmitting the video block obtained by prediction, and repeating the steps until the final n frames are predicted. The method disclosed by the invention reduces influences imposed on input video features by the panorama distortion, and pre-judgment grading of the video information is added at the same time, so that the field of view of the user when watching video in a VR HMD (Head Mount Display) can be predicted with high accuracy.

Owner:NANJING UNIV

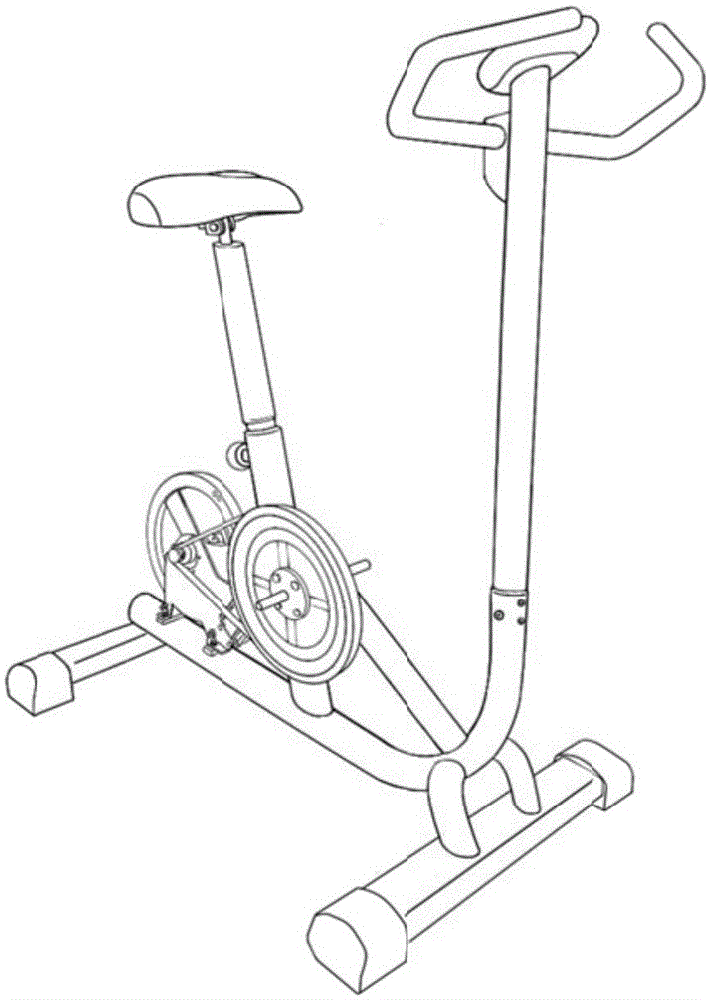

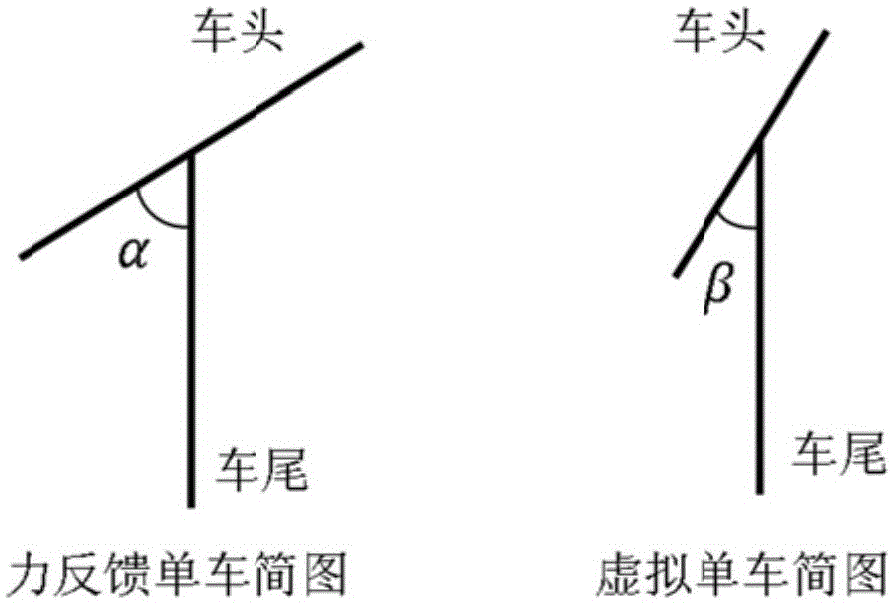

Riding data processing method for virtual riding exercise bicycles

InactiveCN105045379ARealize processingSolve the problem of insufficient immersion in virtual cycling fitnessInput/output for user-computer interactionGraph readingSimulationSingle vehicle

The present invention discloses a riding data processing method for virtual riding exercise bicycles. The method comprises steps of calculating and updating in real time the riding speed, direction and resistance while a riding exerciser rides on a force feedback bicycle and drives a virtual bicycle to move. The riding speed is calculated according to pedaling frequency and the location of the virtual bicycle is updated. Real-time riding direction information is calculated according to head turning direction information of the force feedback bicycle, and the riding direction is updated. A riding resistance value is calculated according to gradient information of the real-time location of the virtual bicycle in combination with wind resistance in a scenario and the riding resistance value is transmitted to the force feedback bicycle in real time, and the bicycle riding resistance is updated. The method realizes transmission and processing of speed information, direction information and resistance information between force feedback bicycles and virtual riding scenarios. The method can be used in different virtual riding scenarios and solves the problem of lacking of feedback and interaction due to independent work of exercise bicycles and virtual riding scenarios, thus bringing real riding exercise experience in any virtual riding scenario to riding exercisers.

Owner:杭州映墨科技有限公司

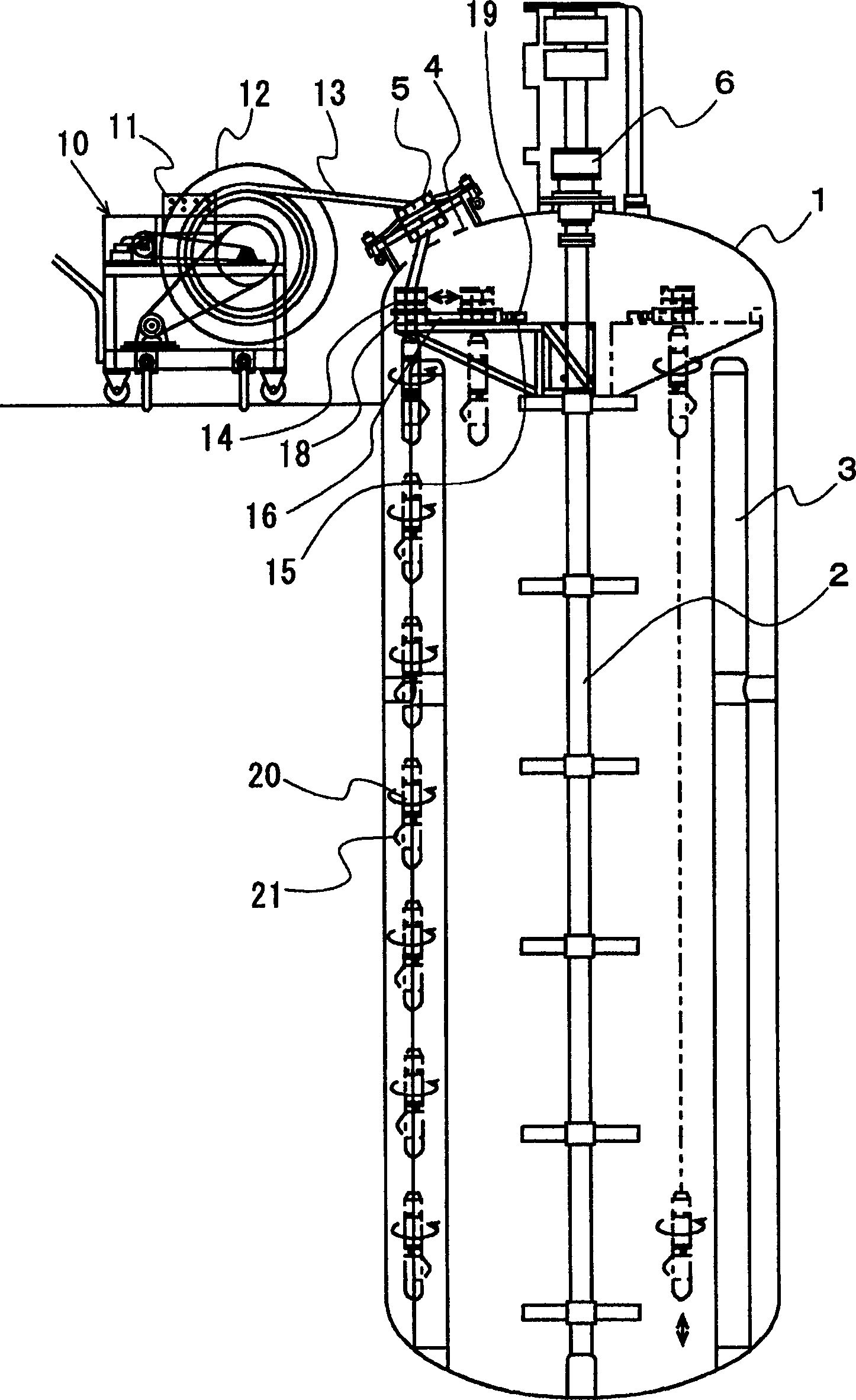

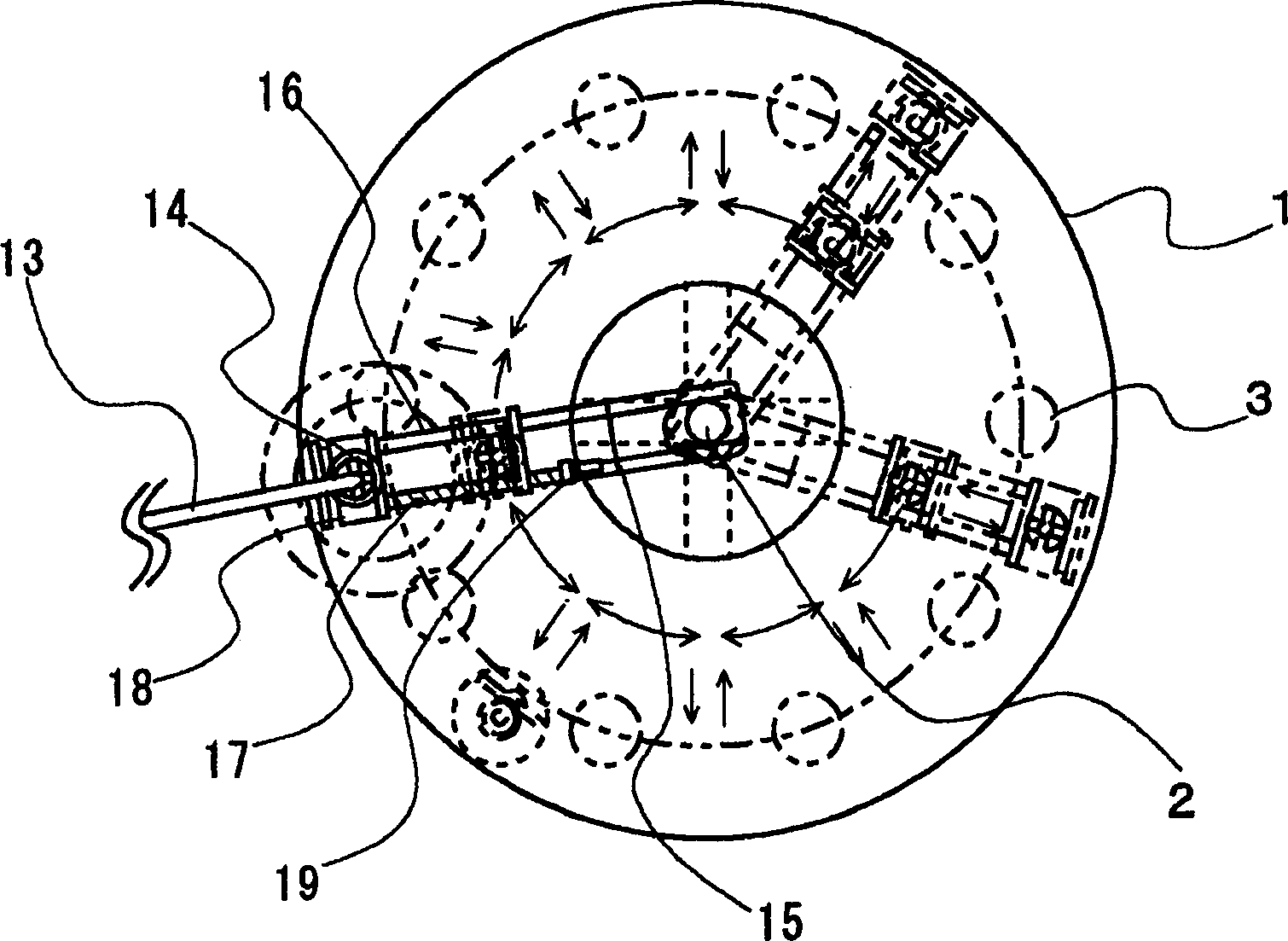

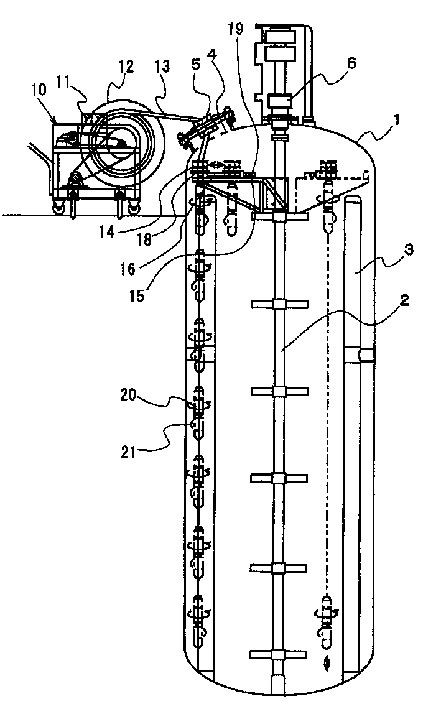

Device for automatically washing inner of pot

InactiveCN1389307AReduce dead angleImprove cleaning efficiencyLiquid surface applicatorsMovable spraying apparatusImpellerEngineering

An automatic washing apparatus for the interior of a tank capable of sufficiently washing all parts of the inner wall surface of the tank easily without restricting the movement of a nozzle head by the internal structure of the tank. The automatic washing apparatus for the interior of the tank is equipped with a high pressure water generation means, the hose having a rotary nozzle head turning on its axis while revolving around a main body to eject high pressure water to the leading end guided into the tank, the rotary arm attached to the upper part of the impeller shaft arranged on the center axis in the tank in a state rotatable around a shaft axis in a rotatable manner to extend in the radial direction of the tank, a hose guide for guiding the hose arranged along the radial direction of the tank of the arm so as to be movable to both ways into the tank, a reel means for feeding the hose into the tank and drawing out the same from the tank and a control means for controlling the rotary operation of the rotary arm, the going and returning moving operation of the hose guide and the feed-in and drawing-out operation of the hose by the reel means.

Owner:SUGINO MACHINE

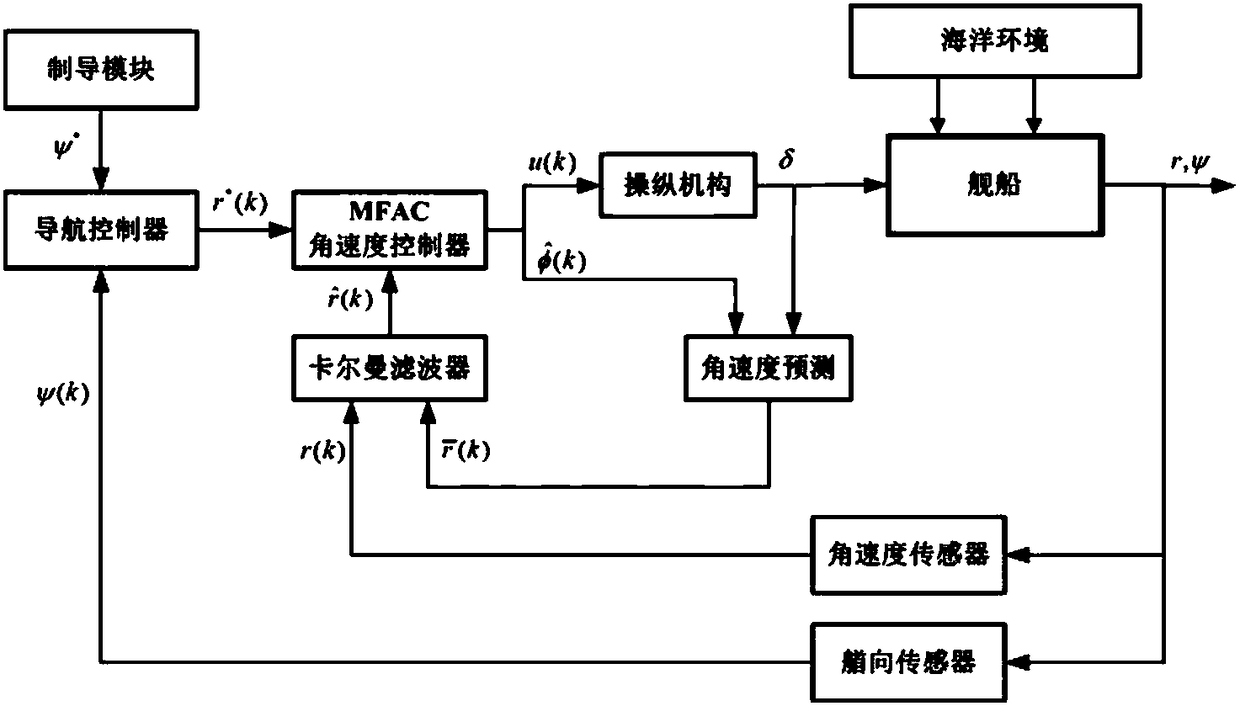

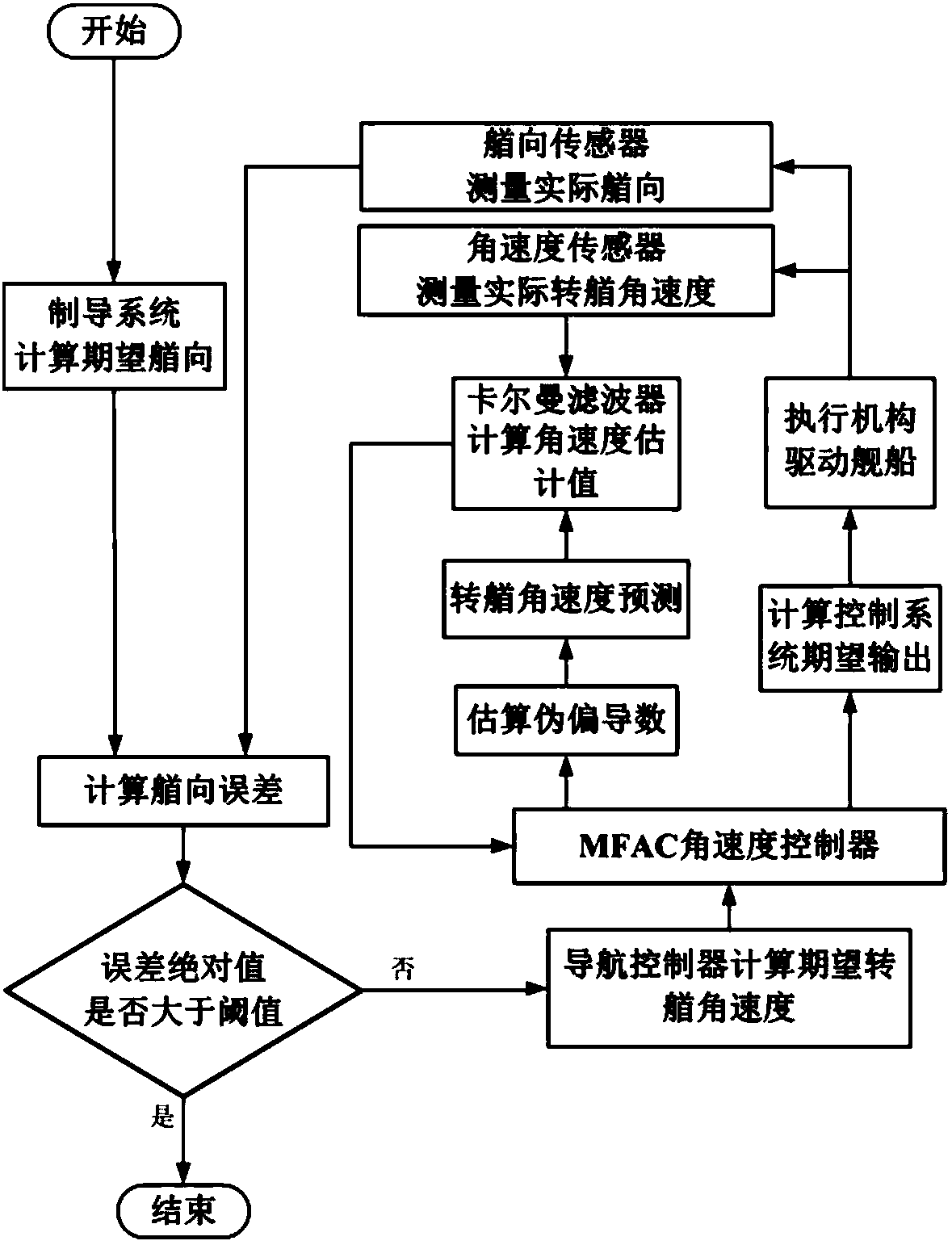

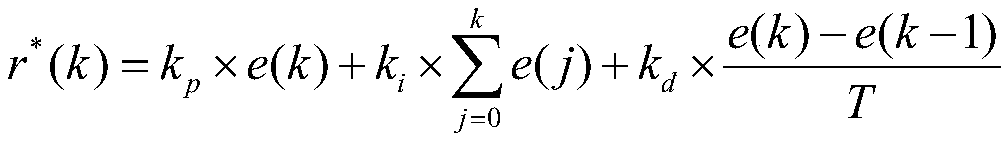

Multi-loop model-free self-adaptation heading control method for ship

The invention provides a multi-loop model-free self-adaptation heading control method for a ship. A control system adopts a combination mode of an outer ring navigation controller and an inner ring angular velocity controller, the outer ring navigation controller is used for calculating an expected heading turning angular velocity, the inner ring MFAC angular velocity controller finishes angular velocity control, and the purpose of yaw control is indirectly achieved. In practical application, an angular velocity sensor is loud in noise, and angular velocity prediction is carried out by utilizing historical input and output data of the control system; angular velocity data is filtered through a Kalman filter to serve as feedback input of the inner ring angular velocity controller, the noiseof the angular velocity sensor is inhibited, and a control effect in actual application is effectively improved. According to the method, an MFAC theory is introduced into the ship heading control field, the special advantages of self-adaptability and online data driving of the MFAC theory are used, and the multi-loop model-free self-adaptation heading control method for the ship has high self-adaptability.

Owner:HARBIN ENG UNIV

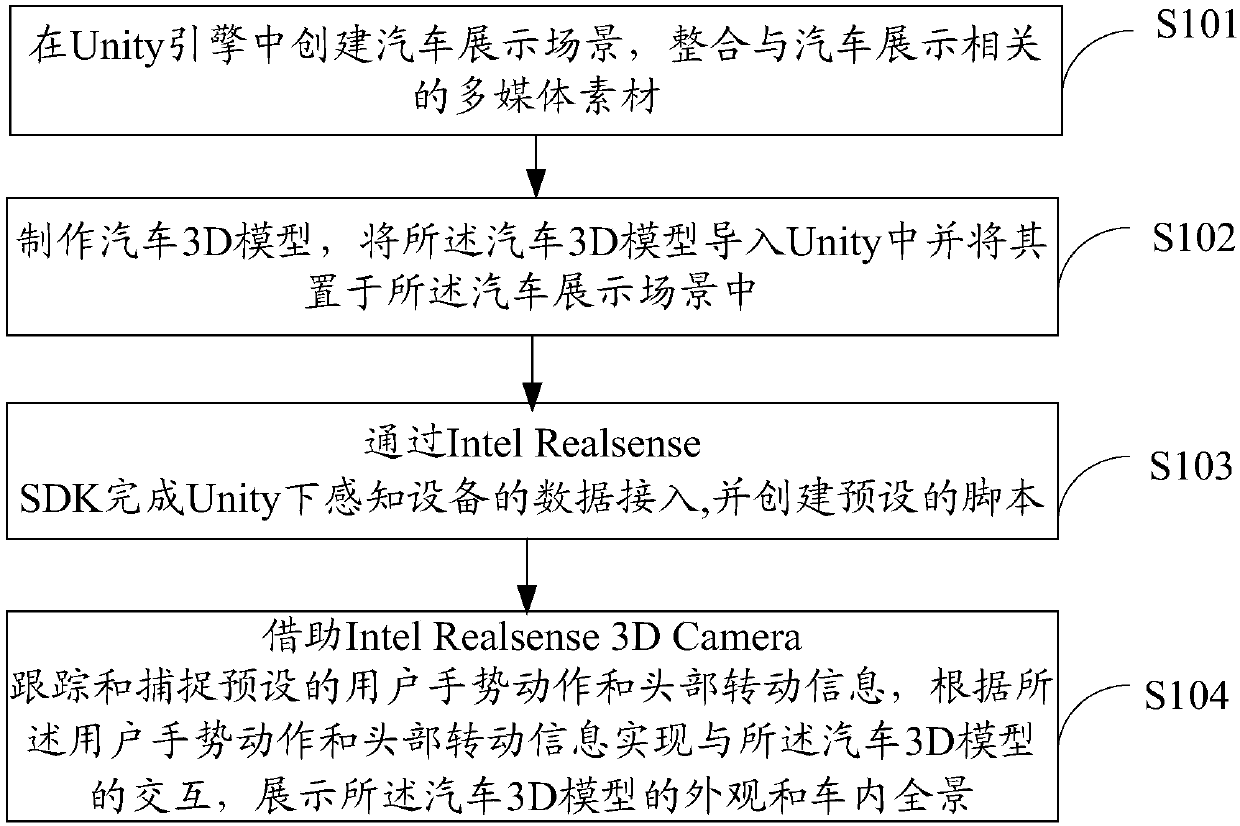

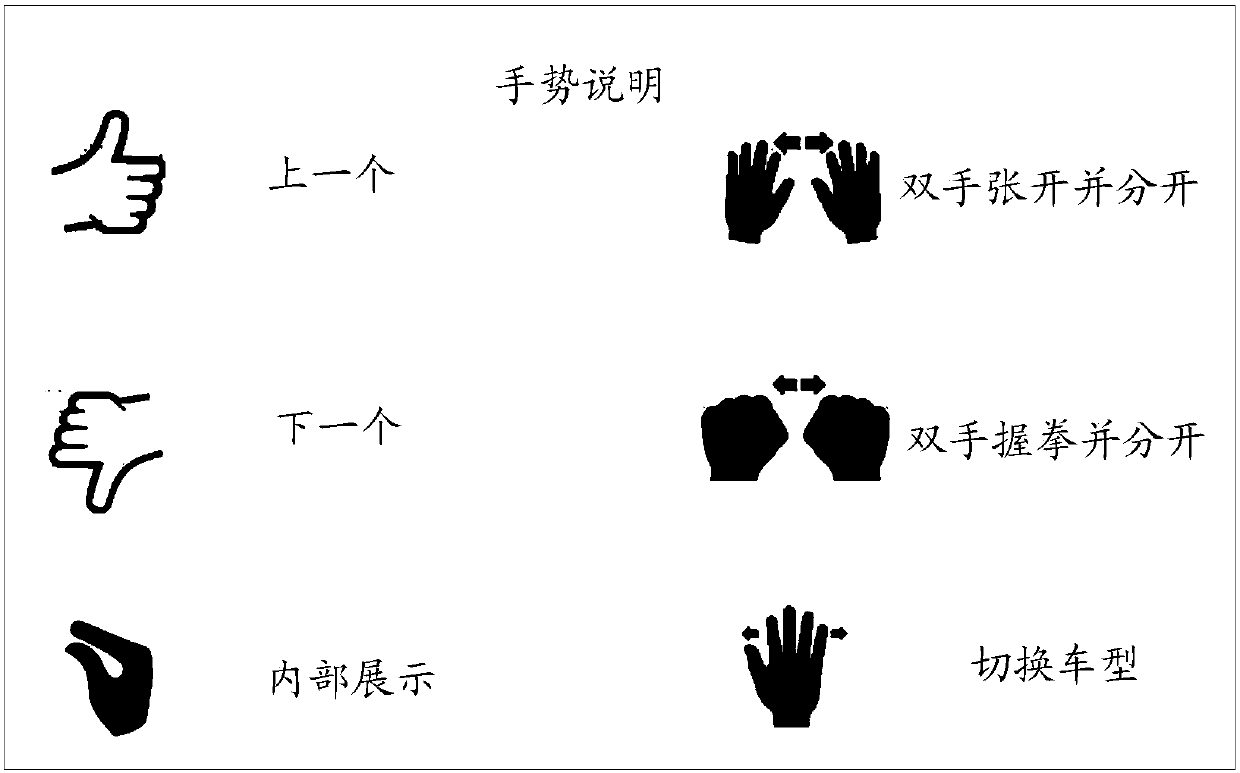

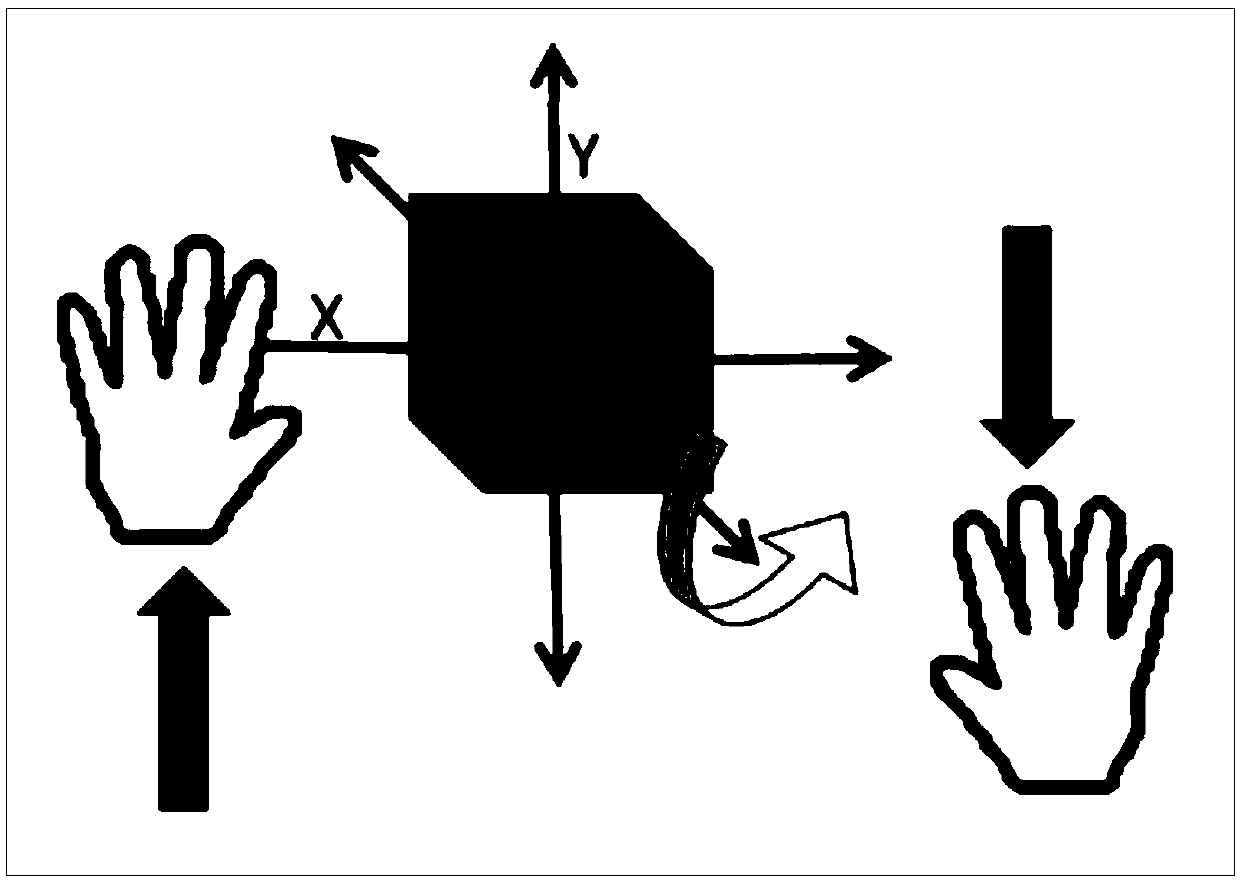

Intel Real Sense-based automobile display application development method and system

ActiveCN107861714ARealize remote controlAchieve interactionInput/output for user-computer interactionSoftware designComplete dataData access

The invention relates to an Intel Real Sense-based automobile display application development method and system. The method comprises the following steps of: creating an automobile display scene in aunity engine, making an automobile 3D model and guiding the automobile 3D model into the automobile display scene; completing data access through Intel Real Sense SDK and creating a preset script; andtracking and capturing a preset user gesture action and head turning information by means of an Intel Real Sense 3D Camera, so as to realize interaction between users and the automobile 3D model anddisplay appearances and inner panoramas of automobiles. According to the method and system, developers compile a few codes to realize interaction operation of automobile display through making the automobile 3D model and the scene and creating the preset script and by means of an Intel Real Sense technology, so that the workload of the developers is greatly decreased; and users do not need to wearany equipment, so that entertaining interaction experience is brought to the users and the interestingness is strengthened.

Owner:TIANJIN UNIV OF SCI & TECH

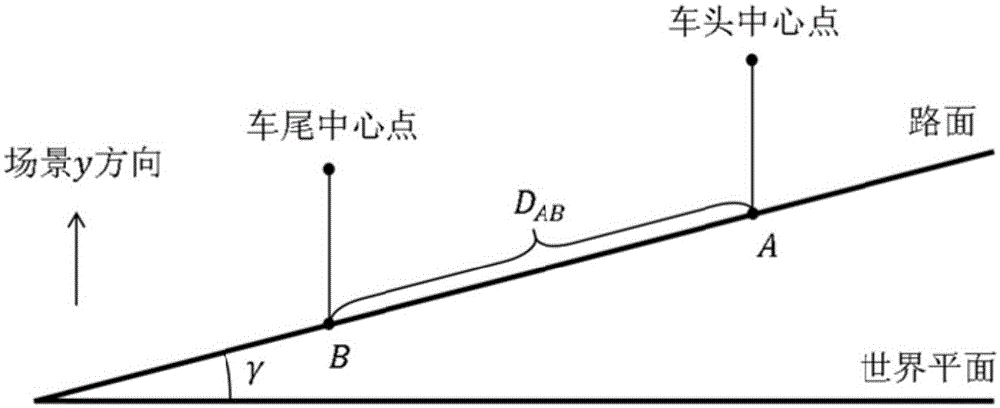

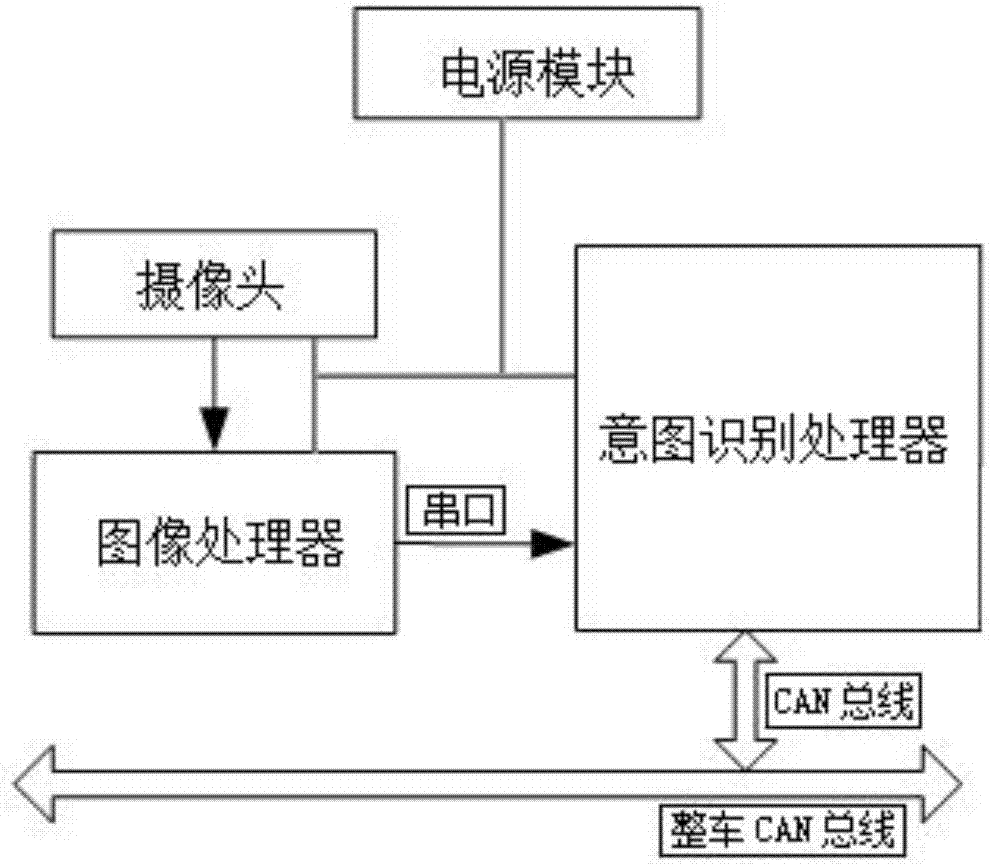

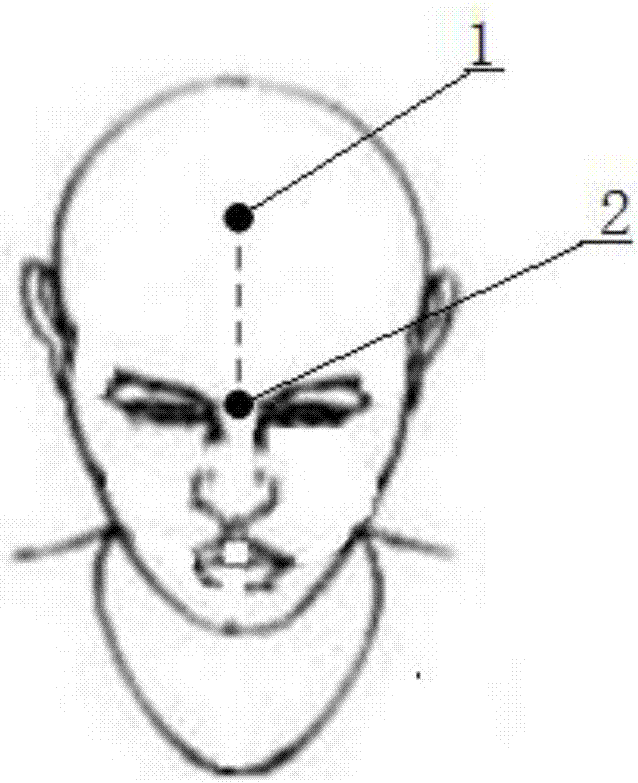

Sensing device for behavior recognition of driver and recognition method thereof

PendingCN107323459ATroubleshoot misidentification issuesImprove accuracyCharacter and pattern recognitionElectric/fluid circuitCamera lensTurn angle

The invention discloses a sensing device for behavior recognition of a driver and a recognition method thereof. The sensing device comprises a camera, an image processor, an intention recognition processor and a power supply module. The camera is connected with the image processor; the image processor is connected with the intention recognition processor; the intention recognition processor is connected with a vehicle CAN through a CAN bus; the camera is installed on the upper front portion of a driver seat; and the included angle between the primary optical axis of the camera and the horizontal plane is 30-60 degrees, and a camera lens faces downwards. According to the method, intentions of the driver are divided into decelerating, vehicle following, braking and steering. The steering intention is recognized based on the head turning angle and frequency, and the turning angles of a steering lamp and a steering wheel; the decelerating and vehicle following intentions are recognized based on the open degree and the starting speed of an accelerator and the gear; and the braking intention is recognized based on a braking switch, the releasing speed of an accelerator pedal and the gear. The misrecognition problem caused by an abnormal single signal can be effectively solved, and recognition accuracy is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

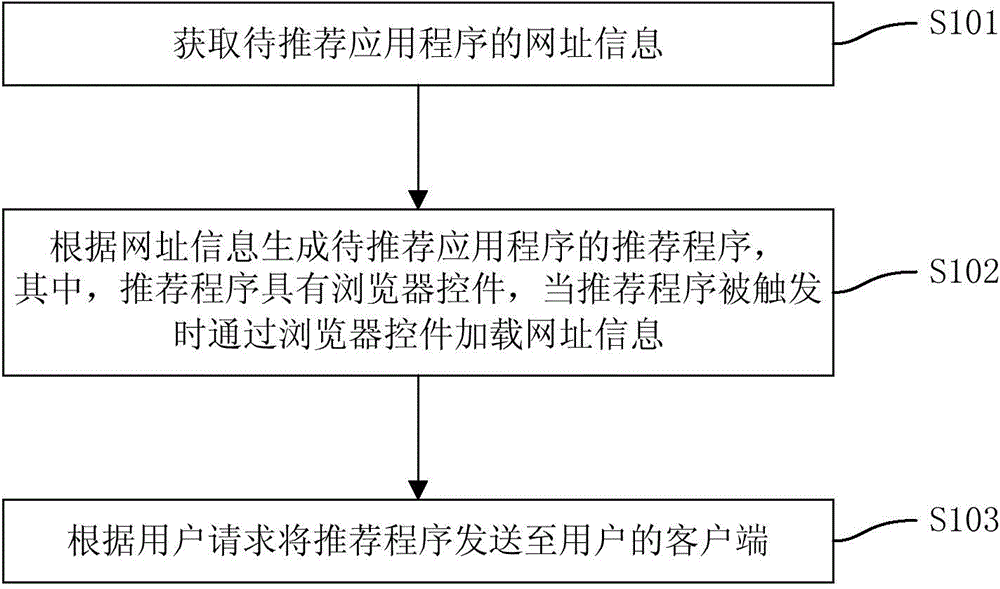

Application recommendation method and system as well as application store server

ActiveCN104158896AWeakening featureGood for distributing recommendationsTransmissionApplication serverApp store

The invention discloses an application recommendation method. The method comprises the following steps: acquiring website information of an application to be recommended; generating a recommendation program of the application to be recommended according to the website information, wherein the recommendation program has a browser control, and the website information is loaded through the browser control when the recommendation program is triggered; and transmitting the recommendation program to a client of a user according to a user request. By adopting the application recommendation method disclosed by the embodiment of the invention, the user operates in windows while enjoying a web game and the user feels like playing a client game, so that the characteristics of the web game are weakened; and meanwhile, through a micro-end form, the game downloading success rate is increased, and the head-turning rate of a game is increased. The invention further discloses an application recommendation system as well as an application store server.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Shoe with removable and reconfigurable uppers

An shoe assembly includes a sole and one or more detachable upper pieces that can be made from materials such as fabric, PVC, leather, plastic, rubber, other similar materials and combinations. The upper, in one or more pieces, is removably attached at spaced points on the sole, where nail-shaped posts are permanently mounted. The heads of the posts function as buttons or cleats for buttonholes, keyholes, edge loops or the like on the uppers. Interchangeable uppers can have different materials, shapes and decorative aspects, for quickly and efficiently changing the appearance and style of the footwear. Three posts can be provided, with a front post being inclined rearward and having a slot under the head or cleat, where the upper is attached, and lateral posts with heads turned outwardly. A variety of alternative configurations are possible for the uppers.

Owner:STYLSH

Piezoresistive integrated three-dimensional turning force sensor

ActiveCN103551921AHigh measurement accuracyHigh measurement sensitivityMeasurement/indication equipmentsForce measurement using piezo-resistive materialsEngineeringForce sensor

The invention relates to a piezoresistive integrated three-dimensional turning force sensor. A turning tool is installed in a head turning tool slot of a sensor main structure, a first vertical octagonal semi-ring and a second vertical octagonal semi-ring are arranged on an upper surface and a lower surface of a middle portion of the sensor main structure respectively, a front side and a rear side of the middle portion of the sensor major structure are connected with a first horizontal octagonal semi-ring and a second horizontal octagonal semi-ring respectively, a tail portion of the sensor major structure is provided with a sensor handle, and a micro-electromechanical system (MEMS) silicon micro force sensor chip is packaged on an outer surface of the octagonal semi-ring. According to the piezoresistive integrated three-dimensional turning force sensor, two octagonal ring structures which are perpendicular to each other are used so that independent measurement of three-dimensional turning forces is achieved, and interaction influence and coupling among effective lateral forces are reduced; the MEMS silicon micro force sensor chip is used, so that measurement accuracy and sensitivity of the chip are greatly improved, and measurement of stress and stain can be achieved by only packaging the MEMS silicon micro force sensor chip in one place; accurate measurement of three-dimensional turning forces is achieved, and both dynamic forces and static forces can be measured.

Owner:XIAN WINWAY TOOLS

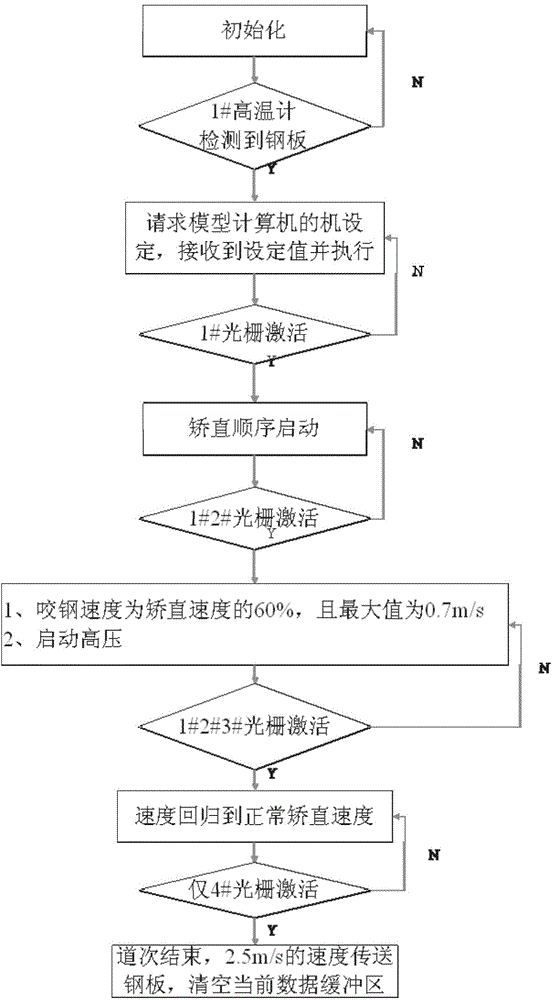

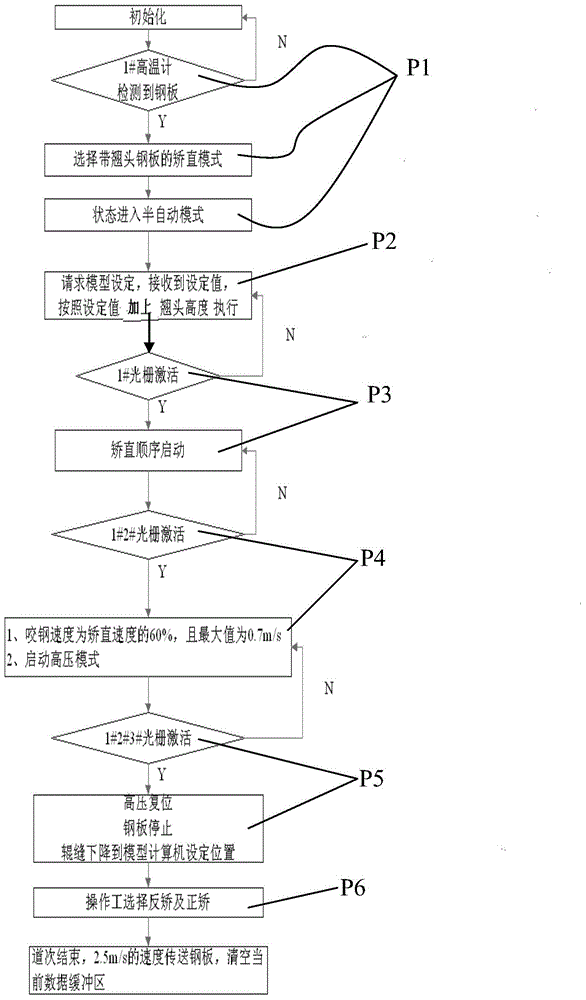

Straightening method of head turning steel plate

ActiveCN104438458AProtection subjectHigh degree of automationMetal working apparatusGratingSheet steel

The invention discloses a straightening method of a head turning steel plate. The method comprises the following steps: when a high temperature meter detects that the steel plate is discharged from a finish mill, a turning head steel plate straightening mode is selected, the reverse correction is synchronously selected, and the state enters a semi-automatic mode; a set value of a model computer is requested, and the operation is performed by adding a head turning height according to the set value after receiving the set value; when a first grating is activated, the straightening sequence is started; when first and second gratings are activated, a position tracking and high pressure mode is started, and the steel is bitten with a speed of not higher than 0.7 m / s; when first, second and third gratings are activated, the steel plate enters a straightening machine, a steel plate stop button is pressed down to stop the steel plate, the high-pressure return is performed, and a roller gap is descended to the set position of the model computer; and when the position of the roller gap arrives at the set value of the model computer, the reverse correction is selected, and the forward straightening is performed to finish the straightening sequence. The method can set the roller gap according to the height of the steel plate turning head to guarantee normal steel biting and straightening effects.

Owner:BAOSHAN IRON & STEEL CO LTD

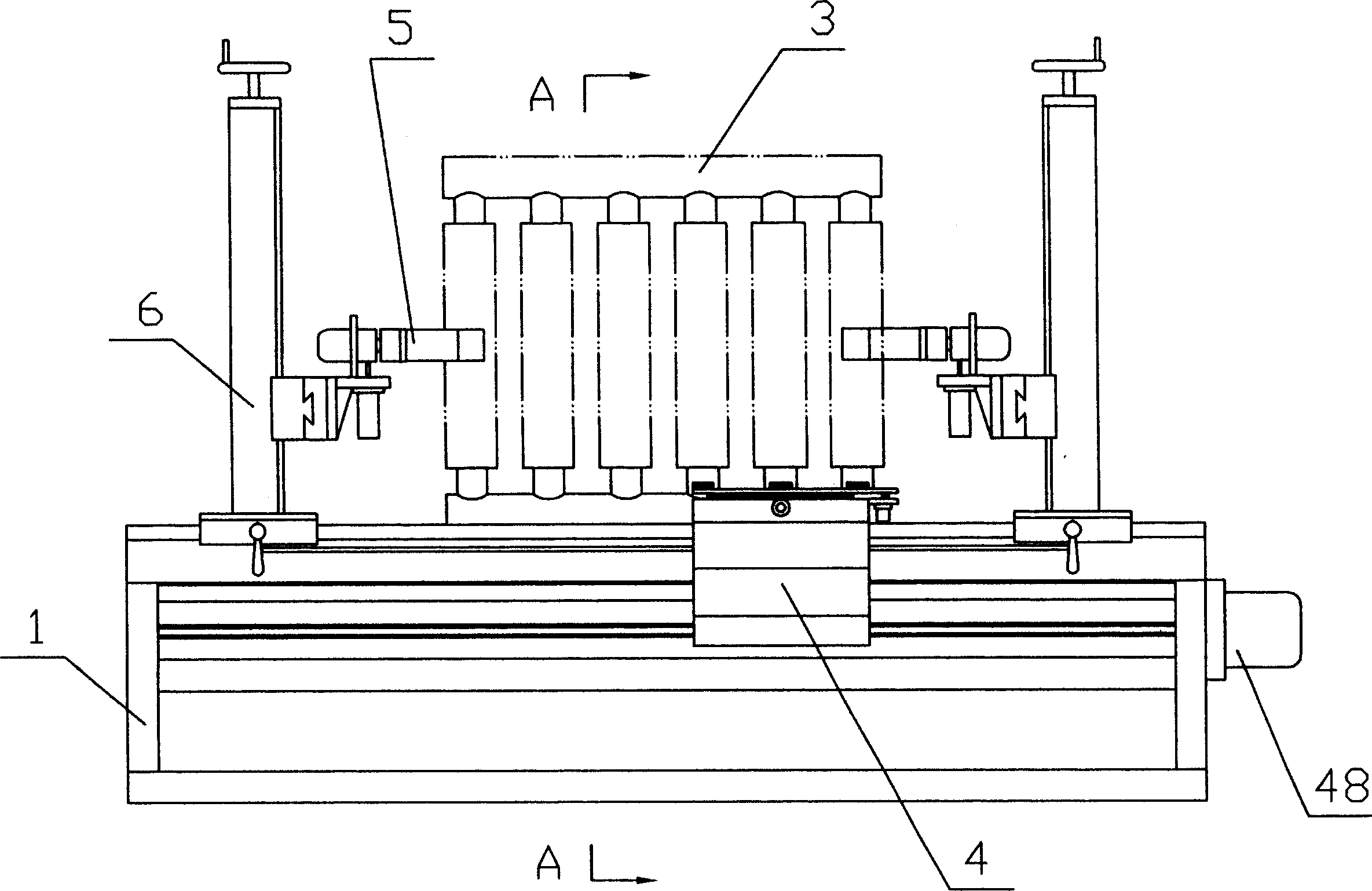

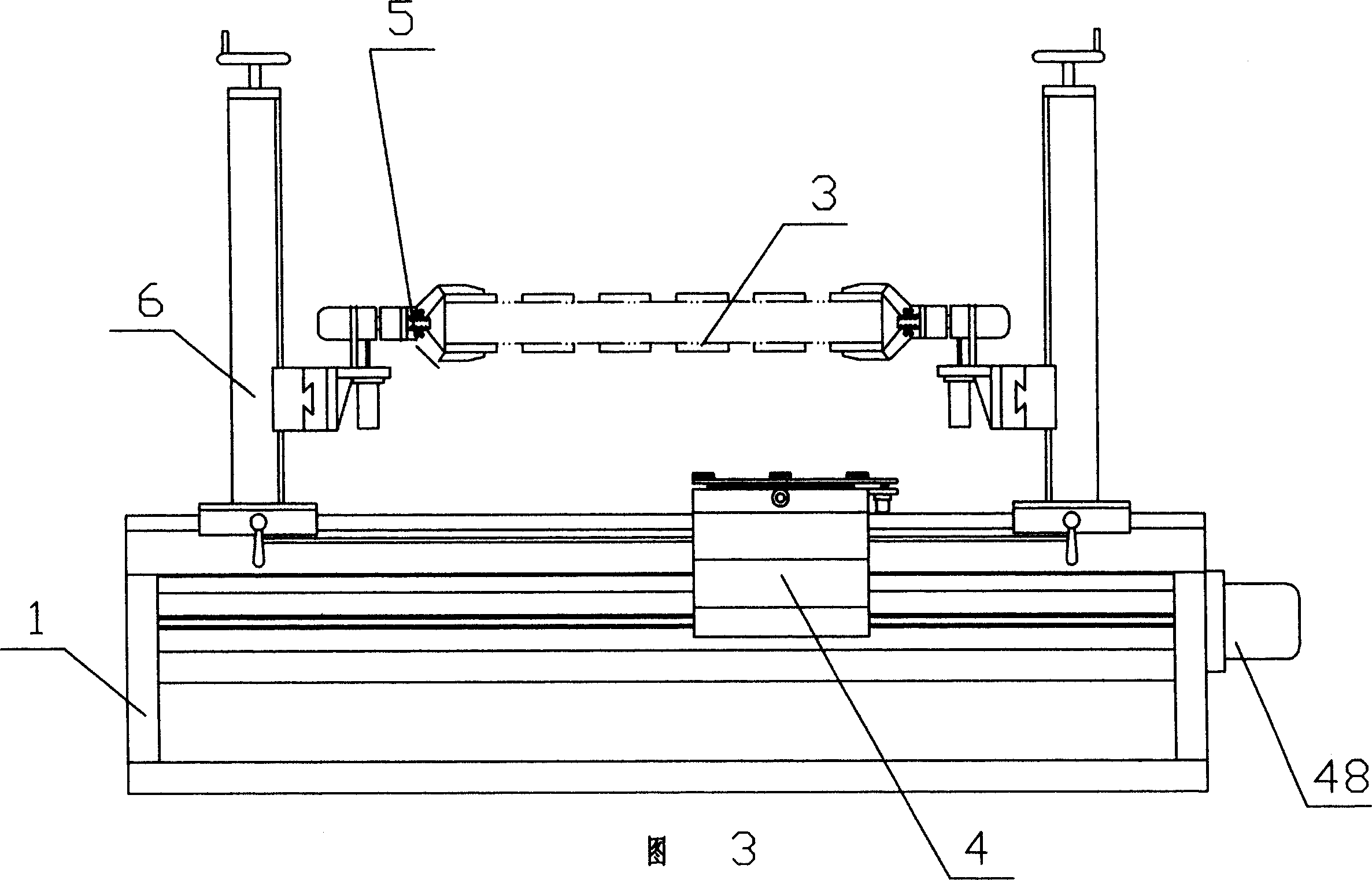

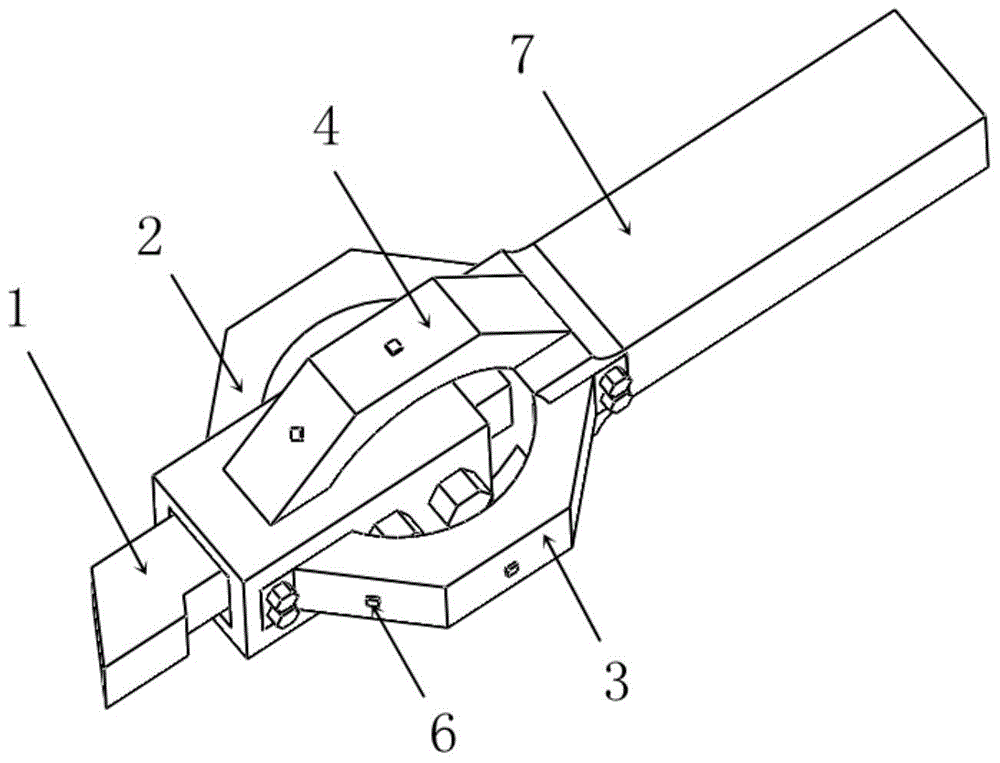

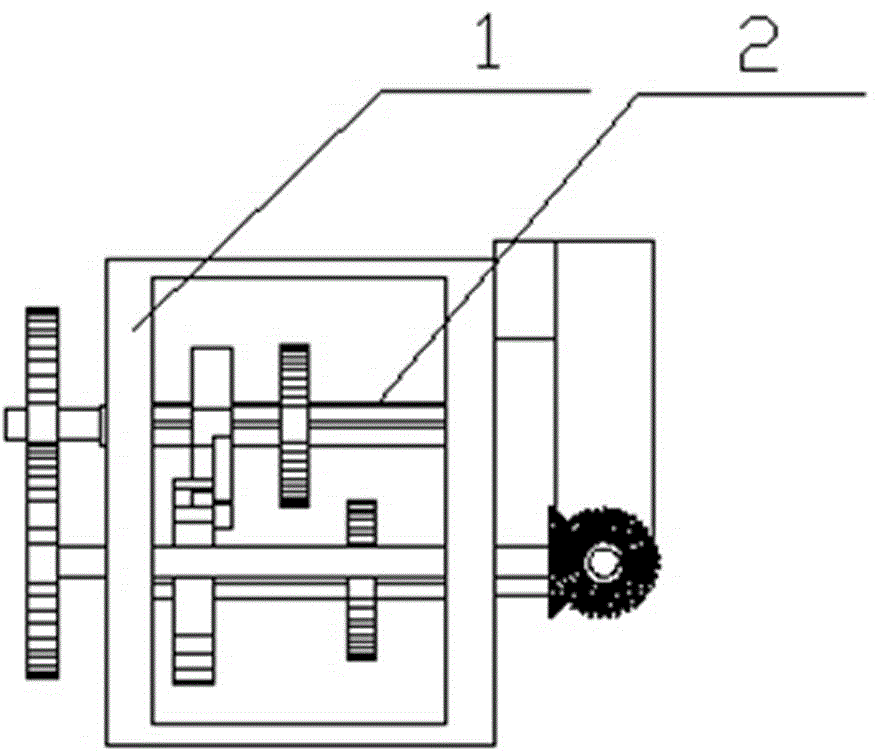

Screwdriver head turning-milling combined machine

ActiveCN103934686ATo achieve different rotation requirementsSave space costOther manufacturing equipments/toolsLarge fixed membersTool bitMilling cutter

The invention discloses a screwdriver head turning-milling combined machine. A driving shaft, a driven shaft and a turning-milling main shaft are positioned in parallel in a main shaft box in a rotating mode, the driving shaft is driven by a power output device, a first driving meshing gear at one end of the driving shaft and a first driven meshing gear at one end of the driven shaft are meshed for transmission, a second driving meshing gear and a third driving meshing gear can be synchronously and axially positioned on the driving shaft in a sliding mode and can be meshed with a second driven meshing gear and a third driven meshing gear which are fixed to the two ends of the turning-milling main shaft respectively to form a first transmission pair and a second transmission pair, and the first transmission pair and the second transmission pair can be alternatively meshed for transmission; the other end of the driven shaft and a second bevel gear on a tool rest are meshed for transmission through a first bevel gear, the second bevel gear is coaxially and fixedly connected with an installation shaft for installing a turning tool and a milling tool, and the other end of the turning-milling main shaft is provided with a screwdriver head clamping device corresponding to the turning tool and the milling tool. A screwdriver head can be turned and milled through one-off clamping, machining accuracy and machining speed are high, and space occupied by machining equipment and machining cost are saved.

Owner:美事满工具(海安)有限公司

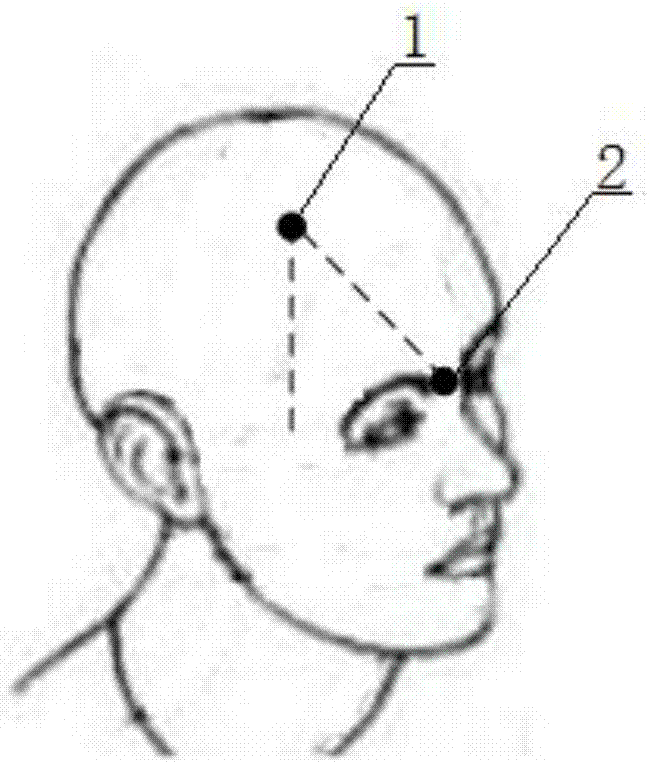

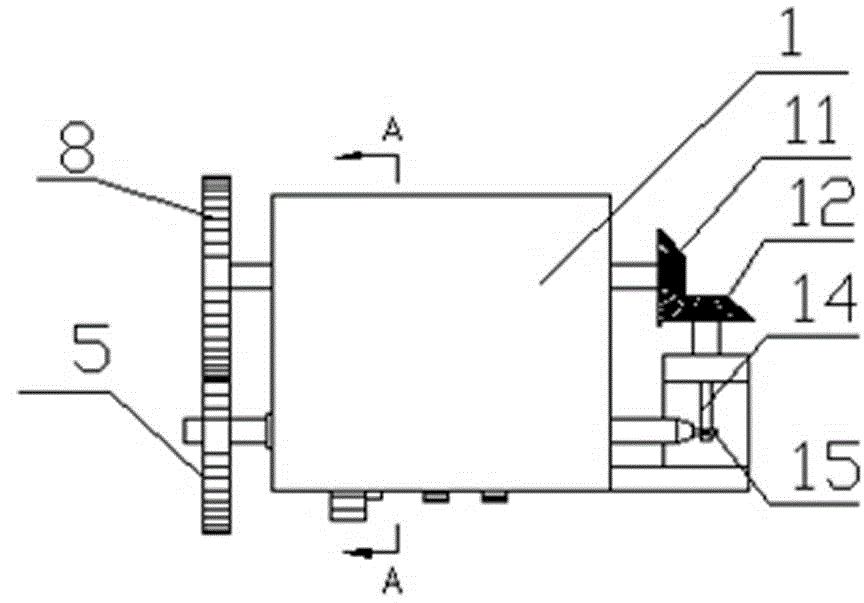

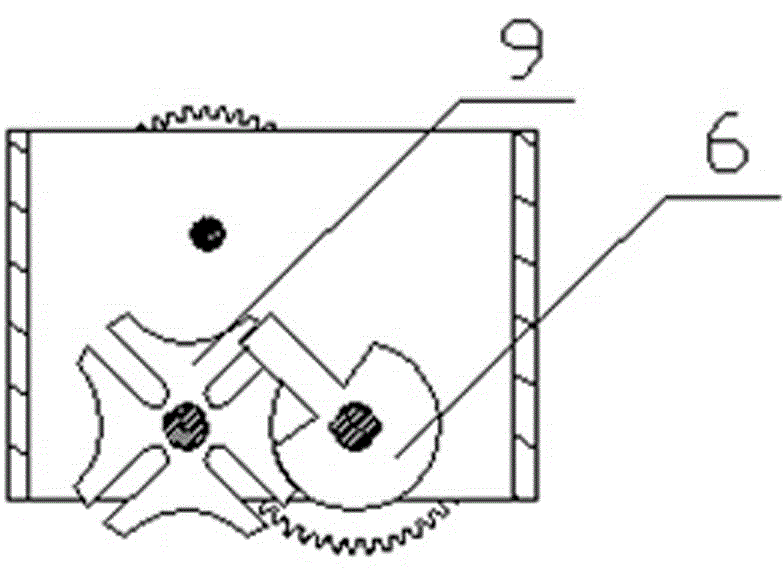

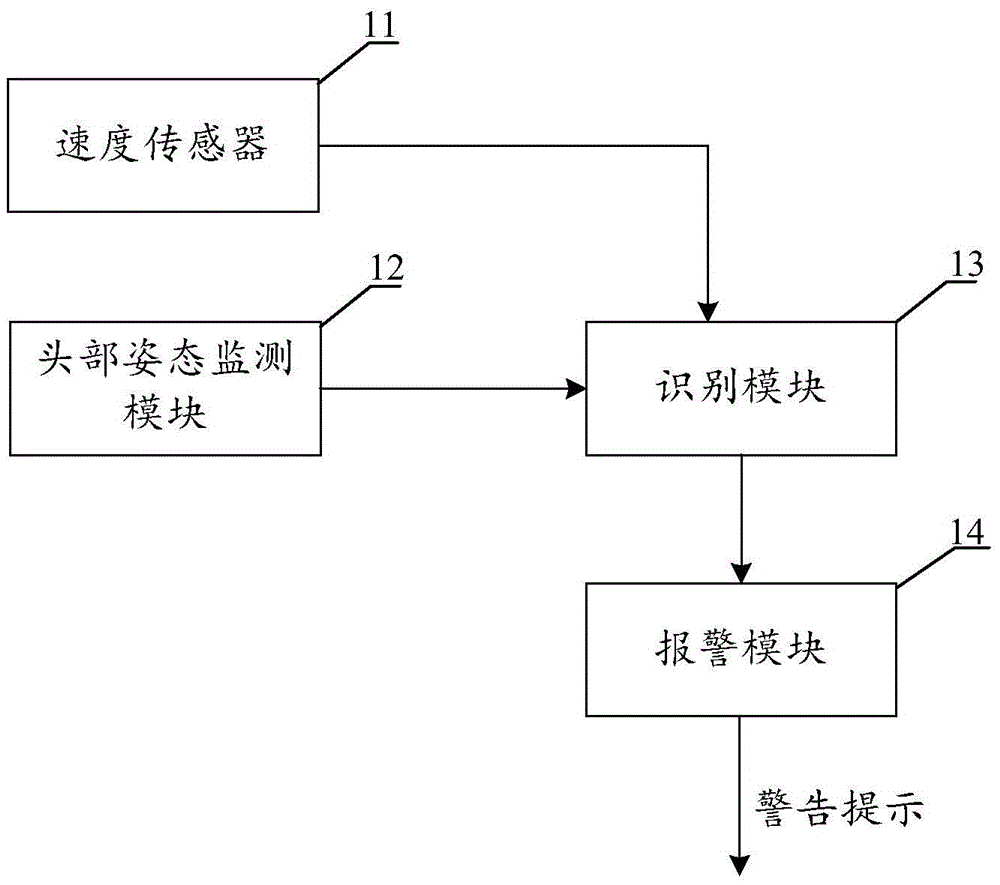

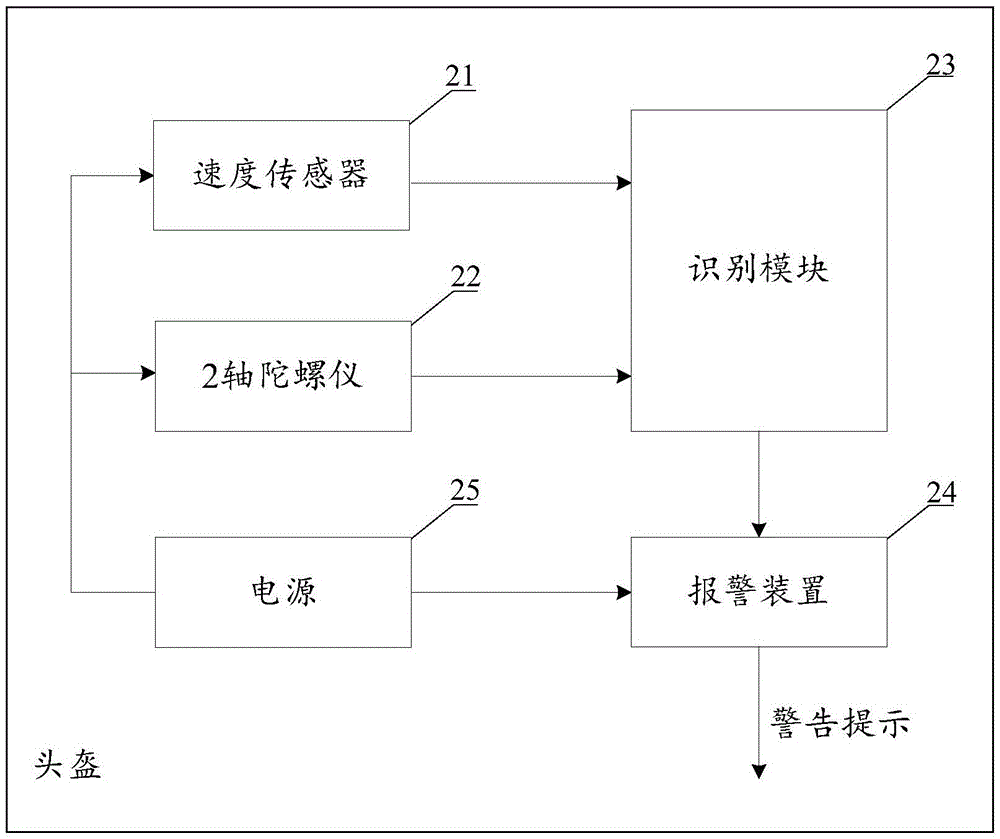

Head lowering and head turning reminding device, control method thereof and helmet

ActiveCN105575048AAvoid traffic accidentsRoad vehicles traffic controlDiagnostic recording/measuringComputer moduleTraffic accident

The invention discloses a head lowering and head turning reminding device, a control method thereof and a helmet, which relate to the field of safety protection. Two direction actions for head lowering and head turning can be monitored, an alarm is given for the action for a long time, and happening of a traffic accident can be avoided. The head lowering and head turning reminding device is arranged on a traffic tool or worn on a traffic tool user, and comprises a speed sensor, a head posture monitoring module, a recognition module, and an alarming module, wherein the speed sensor is used for detecting the speed over the ground of the traffic tool; the head posture monitoring module is used for monitoring the head posture of the user; the recognition module is used for receiving a signal of the head posture monitoring module to recognize head lowering and head turning actions and the action keeping time; and the alarming module is used for giving a warning prompt for reminding the user when the speed over the ground of the traffic tool is larger than a speed threshold and the head lowering or head turning keeping time of the user exceeds a preset time.

Owner:BOE TECH GRP CO LTD

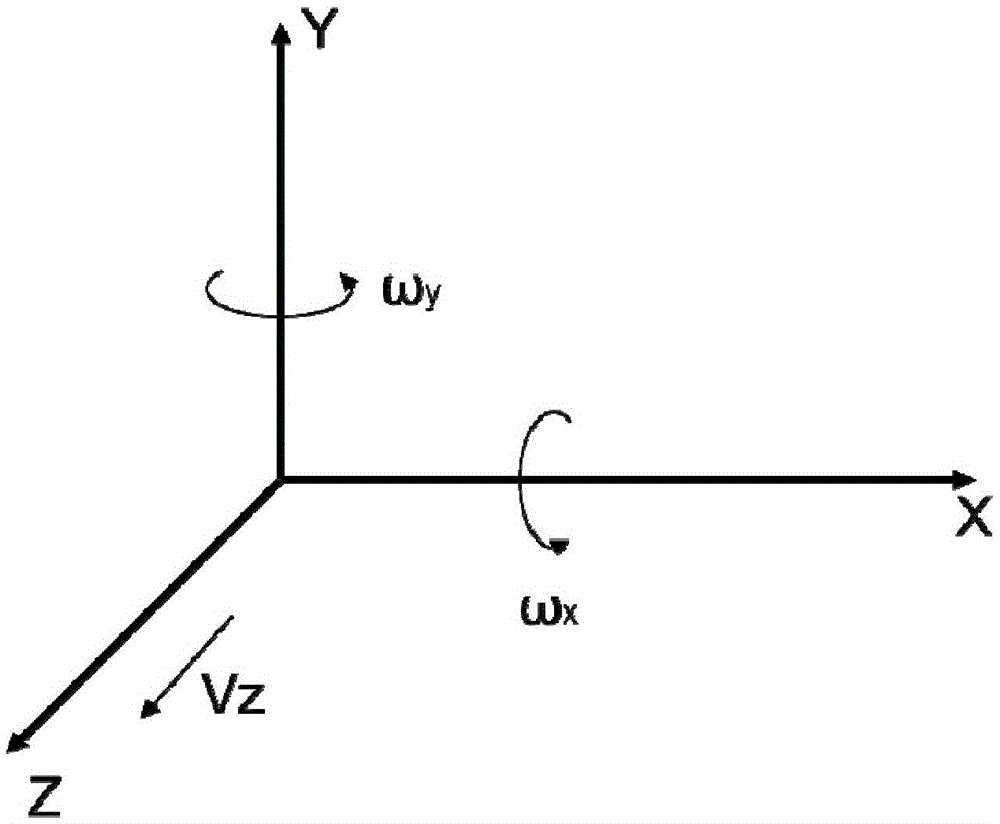

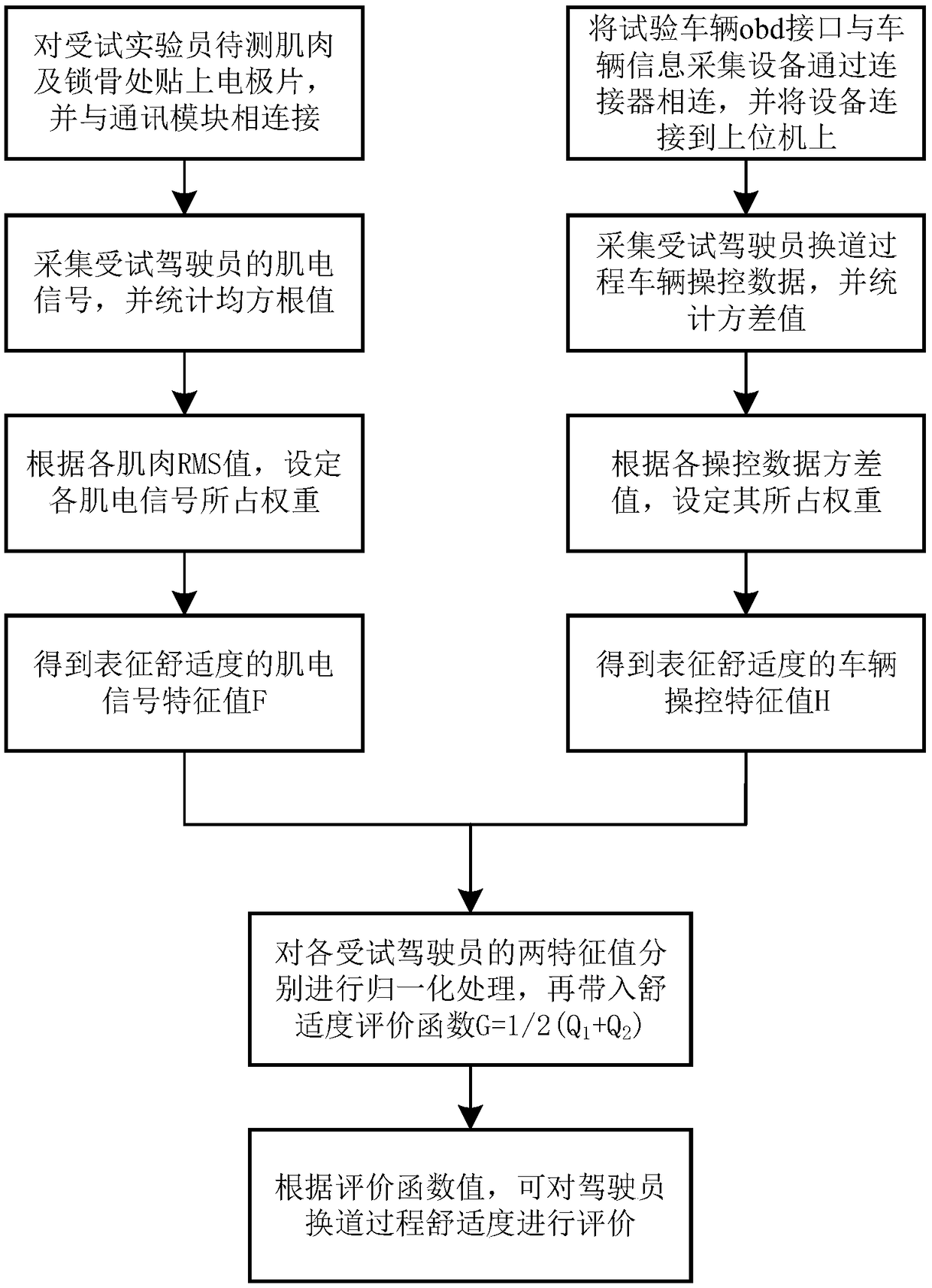

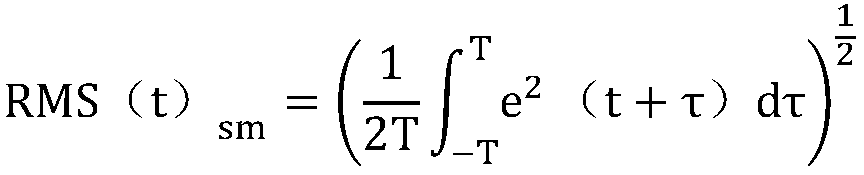

Method for evaluating driver lane change comfort based on myoelectricity and control information

The invention discloses a method for evaluating the driver lane change comfort based on myoelectricity and control information. The method comprises the steps that main force exerting muscles on the neck and the back of each tested driver during head turning are selected as muscles to be tested; a multi-channel electromyographic signal testing recorder is adopted as a signal collecting facility for measuring electromyographic information of each muscle of each testee when a lane change action is carried out; then car information collecting equipment is used for reading control data generated under the work condition that the tested drivers complete lane change from a car CAN network; then collected electromyographic signals are subjected to root-mean-square processing, the collected control data is subjected to square deviation processing, and weights are set; finally, the comfort of the drivers in the lane change process is comprehensively determined according to the weights.

Owner:JILIN UNIV

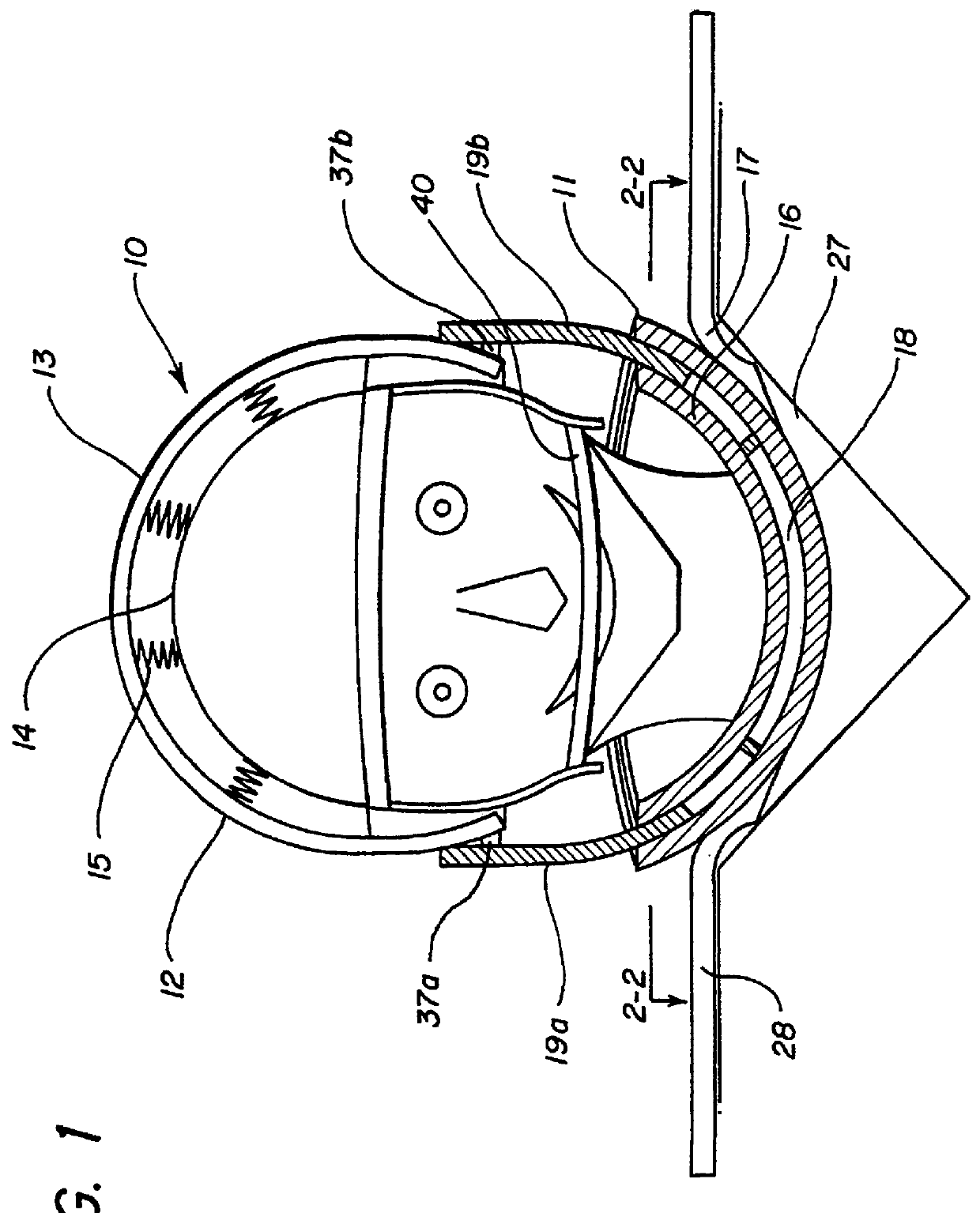

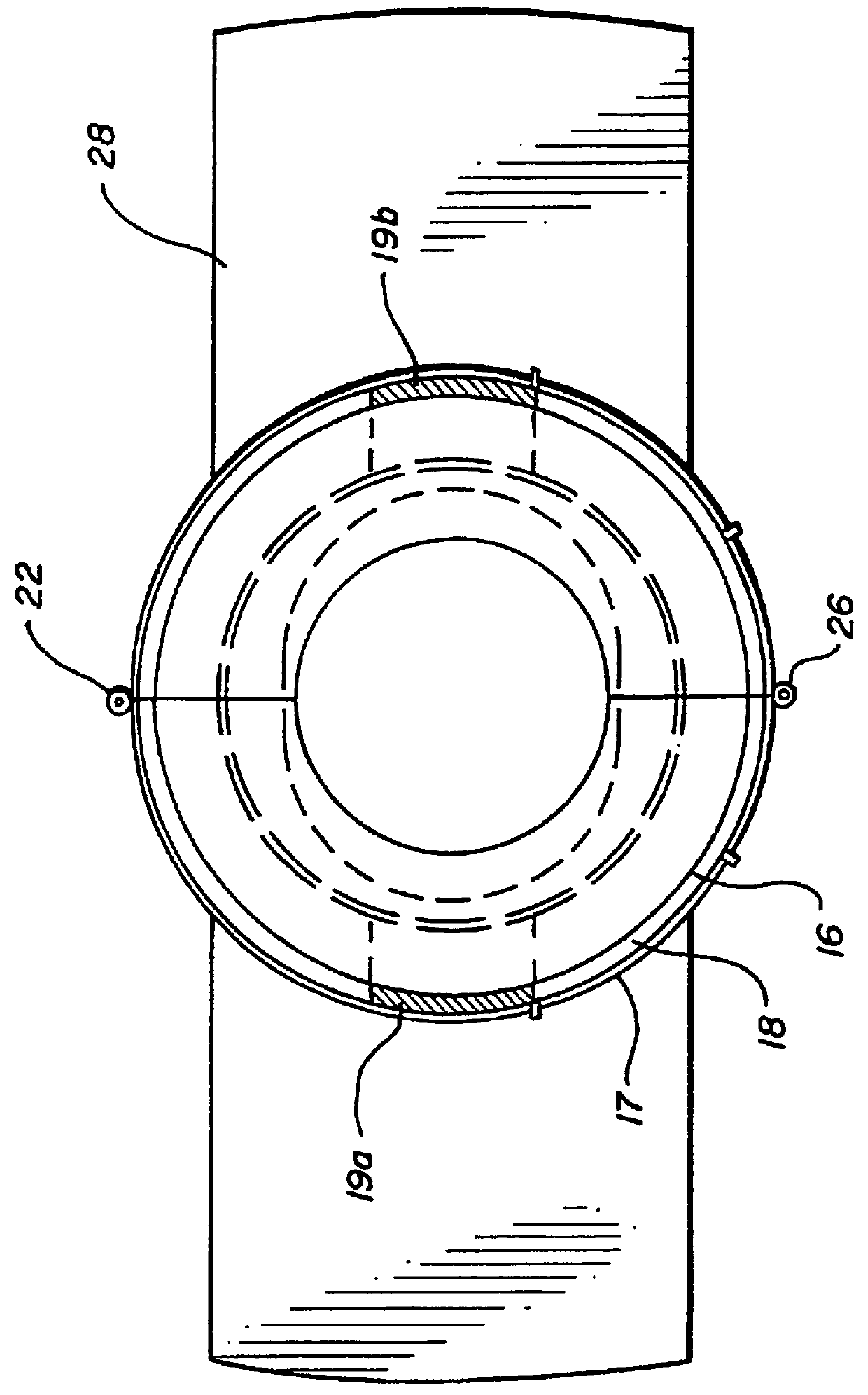

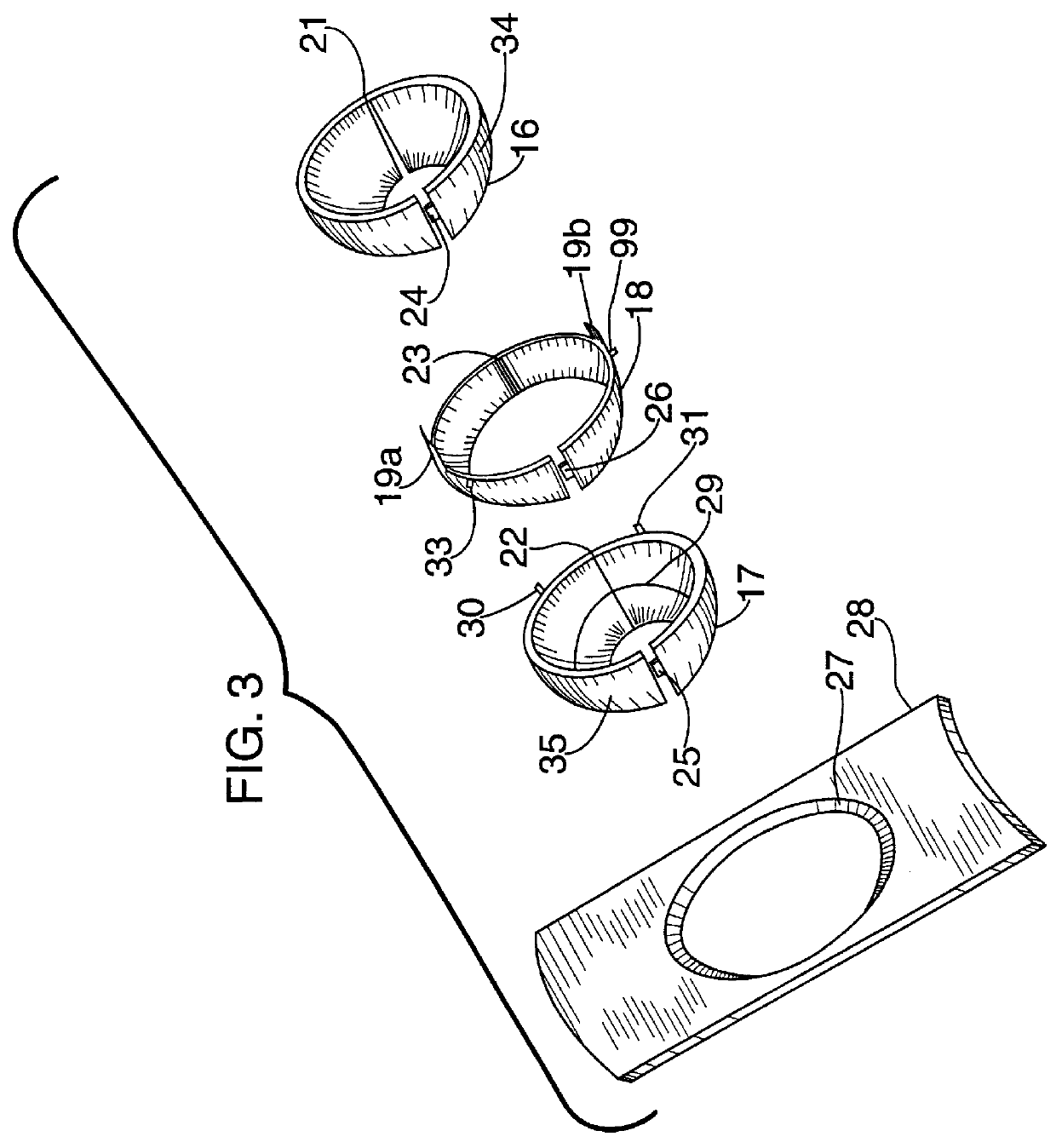

Football helmet and shoulder pad combination

A football helmet and shoulder pad combination are designed to prevent head and neck injuries. An outer helmet is connected to a neck assembly which permits but limits head turning mobility as well as up-down and left and right head tilt. The neck mechanism which is mounted about the neck comprises substantially circular inner and -outer spherical guides and a concentric movable inner element therebetween with an upwardly extending member on each side of the neck. The guides contain stops to limit the motion permitted by the helmet and the lower portion of the mechanism is mounted on the shoulder pads to distribute the load during impact. The helmet portion with a resilient coupling joining the portions. The upwardly extending members on the inner element are mounted to respective sides of the outer helmet. The helmet may also be retrofitted to existing equipment.

Owner:PINSEN DAVID

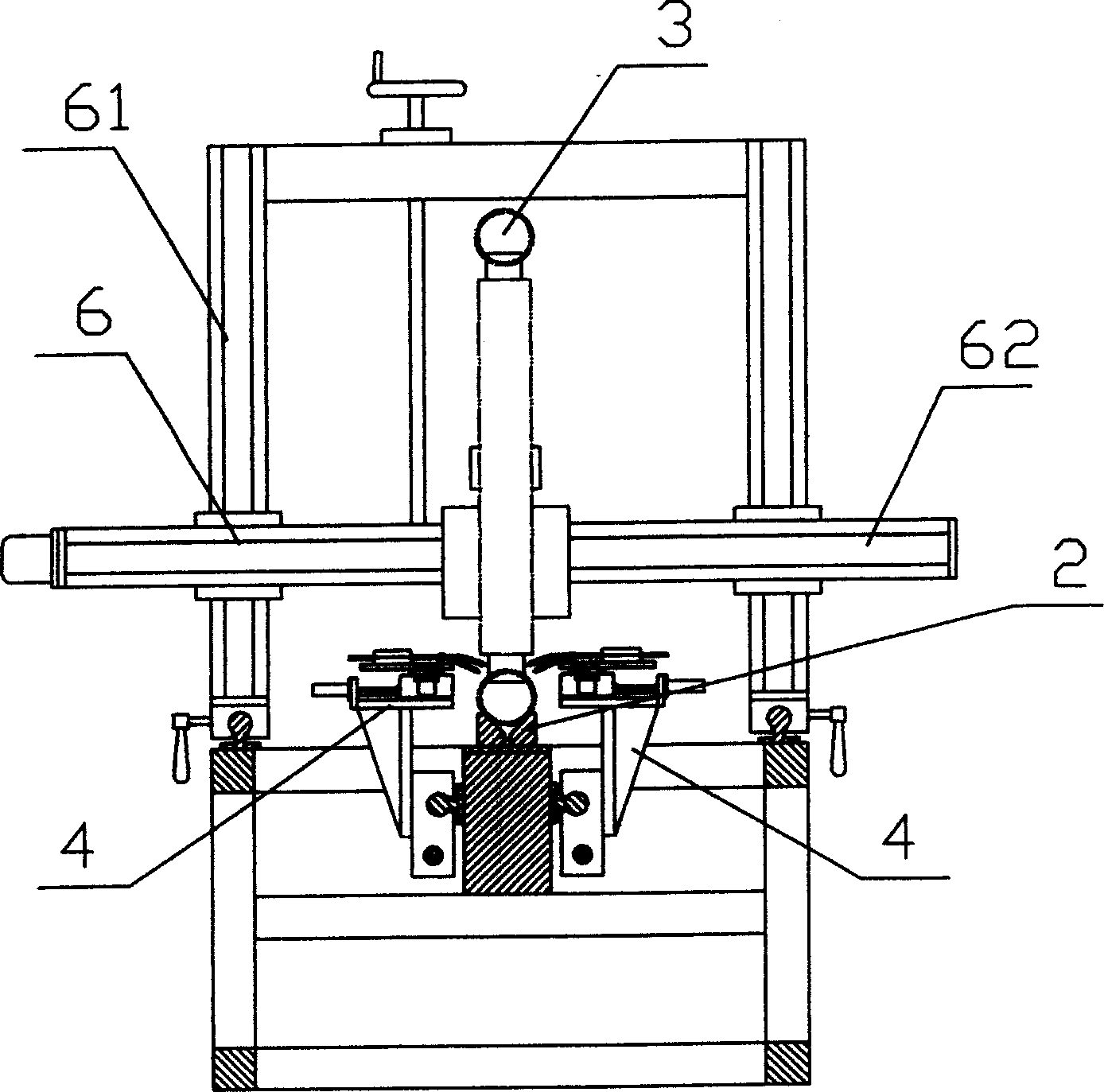

Automatic centering type direct rock tensile test device

PendingCN108562491AAccurately Test Tensile StrengthFlexible rotationMaterial strength using tensile/compressive forcesEngineeringRock sample

The invention discloses an automatic centering type direct rock tensile test device. The device comprises sample sleeve caps, ball-head tension rods, roll balls and sleeves; the sample sleeve caps areconnected with connecting members; ends of the connecting members are hinged with flexible anti-tensile ropes; the ends of the flexible anti-tensile ropes are hinged to the ends of tension rods of the ball-head tension rods; a plurality of the roll balls are disposed in embedding grooves along the end surfaces of the ball-head tension rods; and embedded groove covers are detachably disposed on the sleeves and located above the embedding grooves. According to the tensile test device, flexible anti-tensile ropes are adopted to connect ball-head turning members and the sample sleeve caps, and the roll balls and the sleeves as well as the roll balls and the ball-head turning members are in point contact, so that angles of the test device can be adjusted in all directions with flexible rotation and automatic deviation adjustment; after a rock sample is stressed, the tensile stress of the rock sample is always ensured along the axis, so that the problem of eccentric tensile stress is avoided; and the device is simple in structure, easy to operate, and easy to load and unload, and can accurately test the anti-tensile strength of the rock sample.

Owner:QINZHOU UNIV

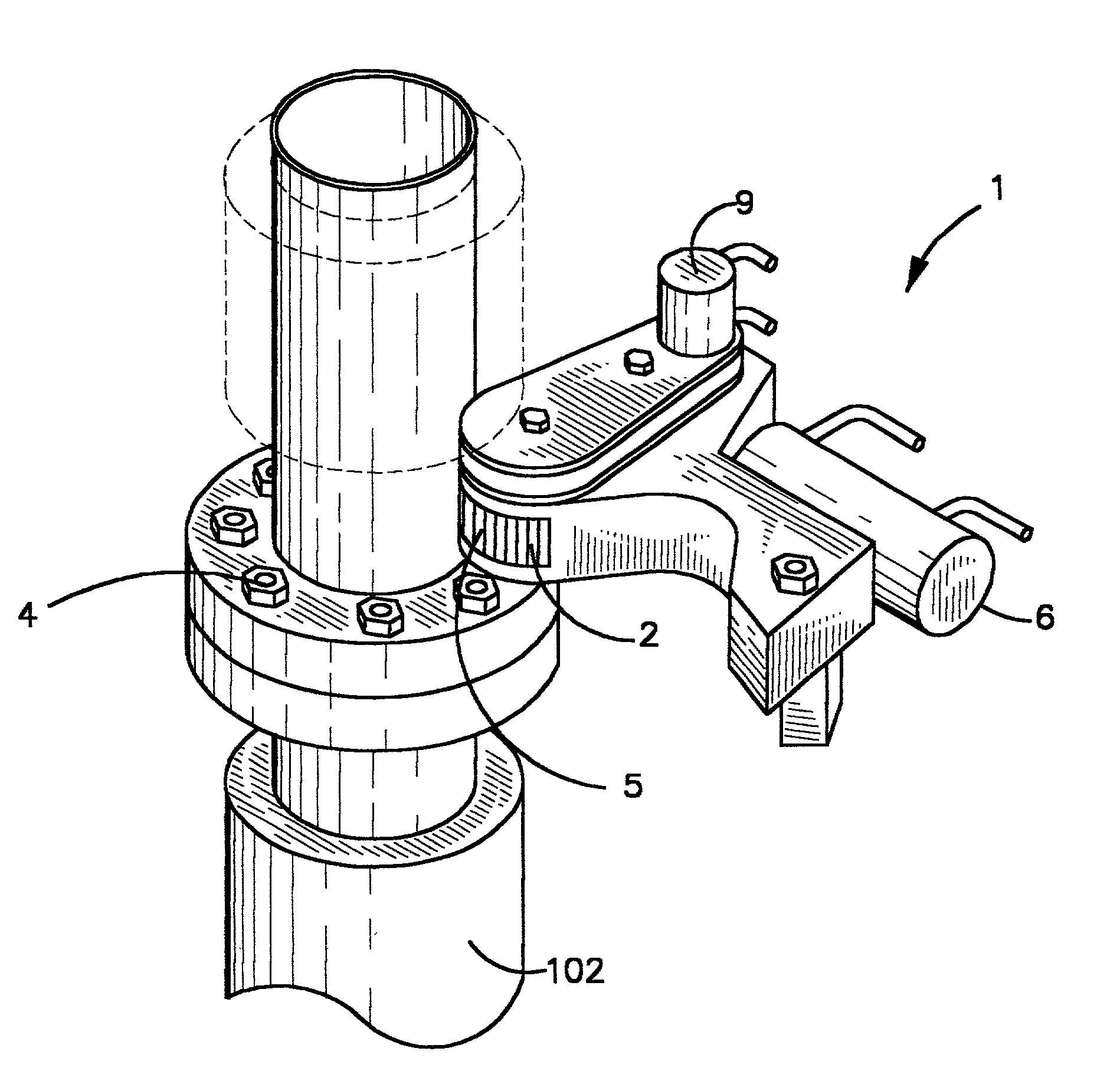

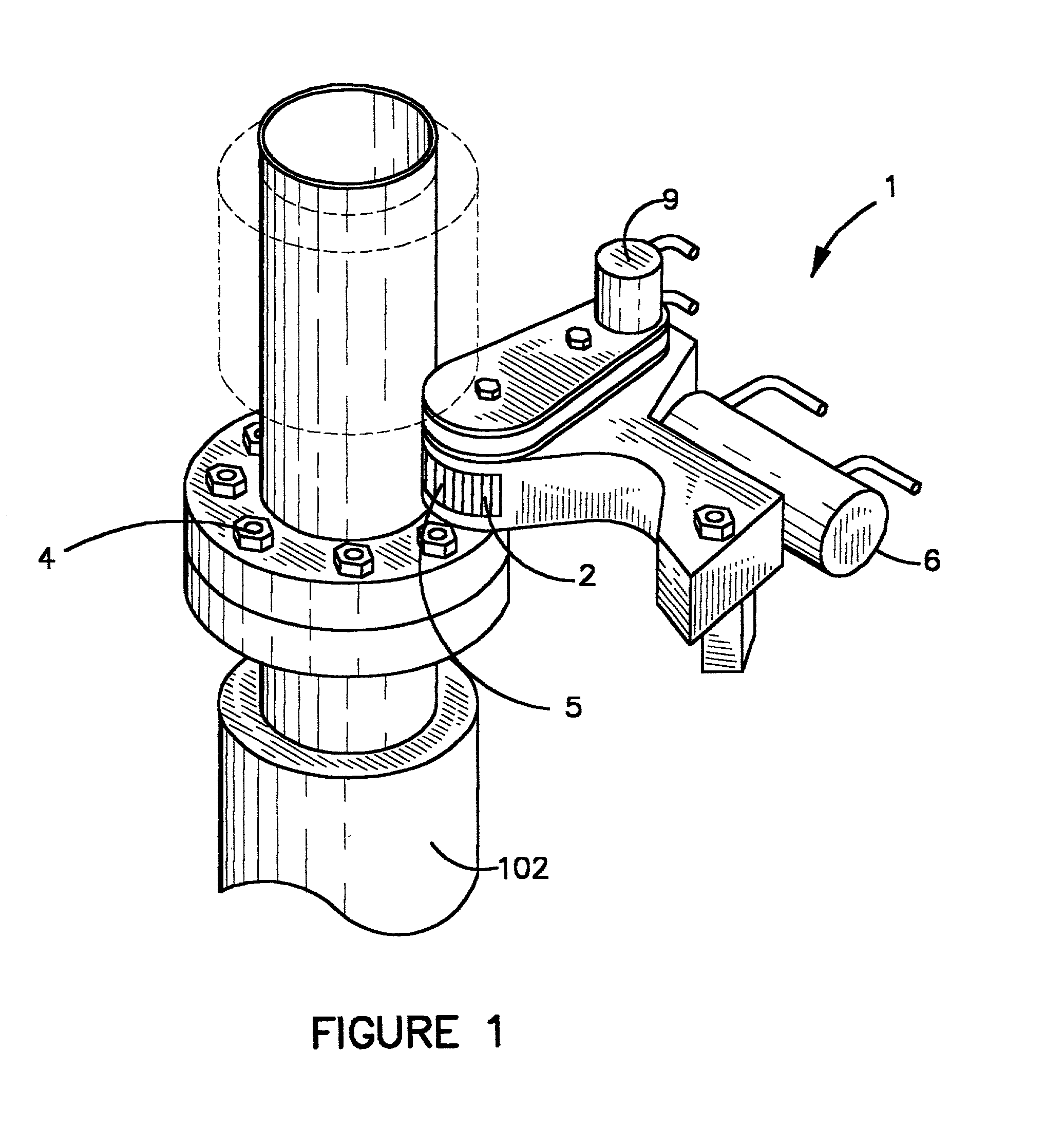

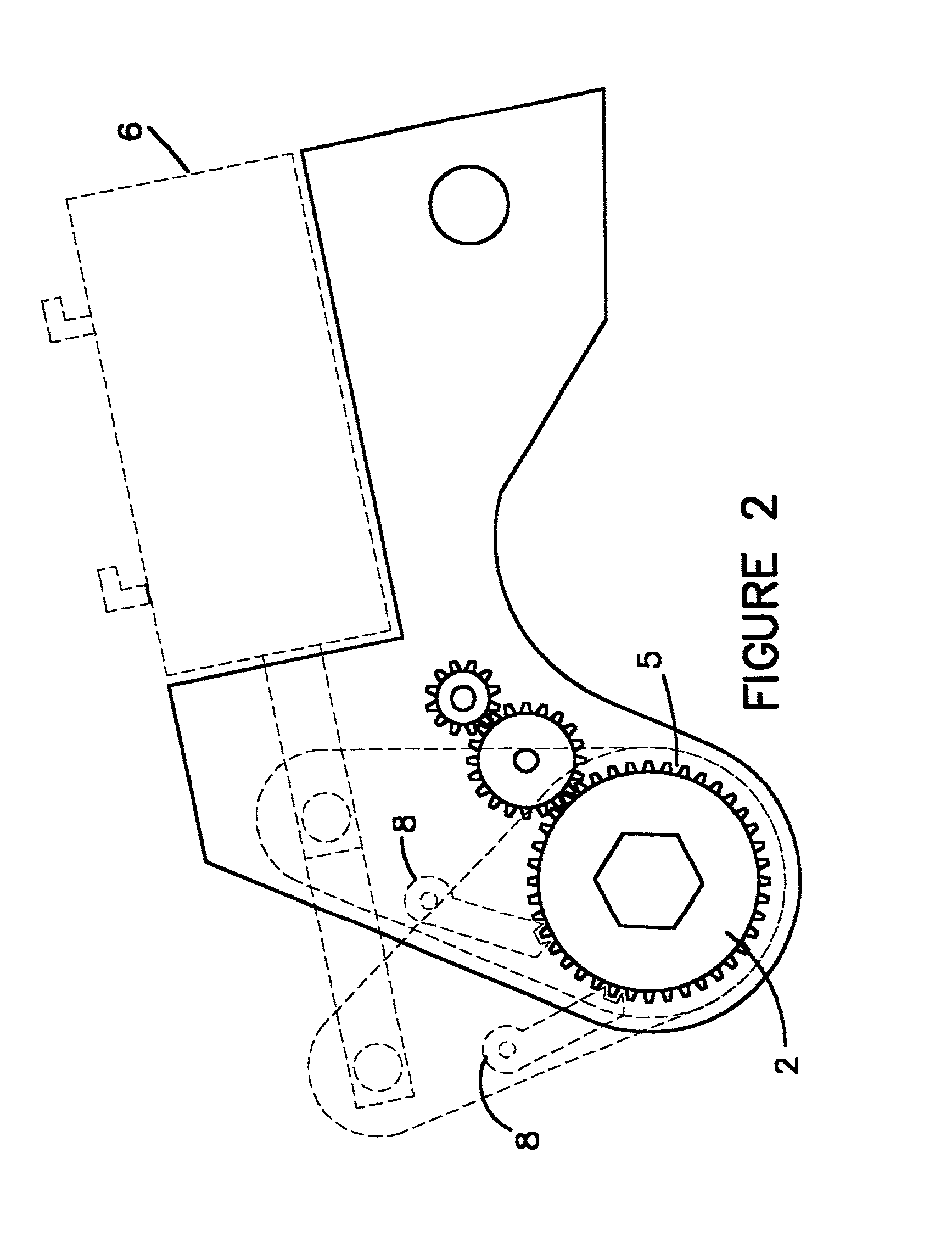

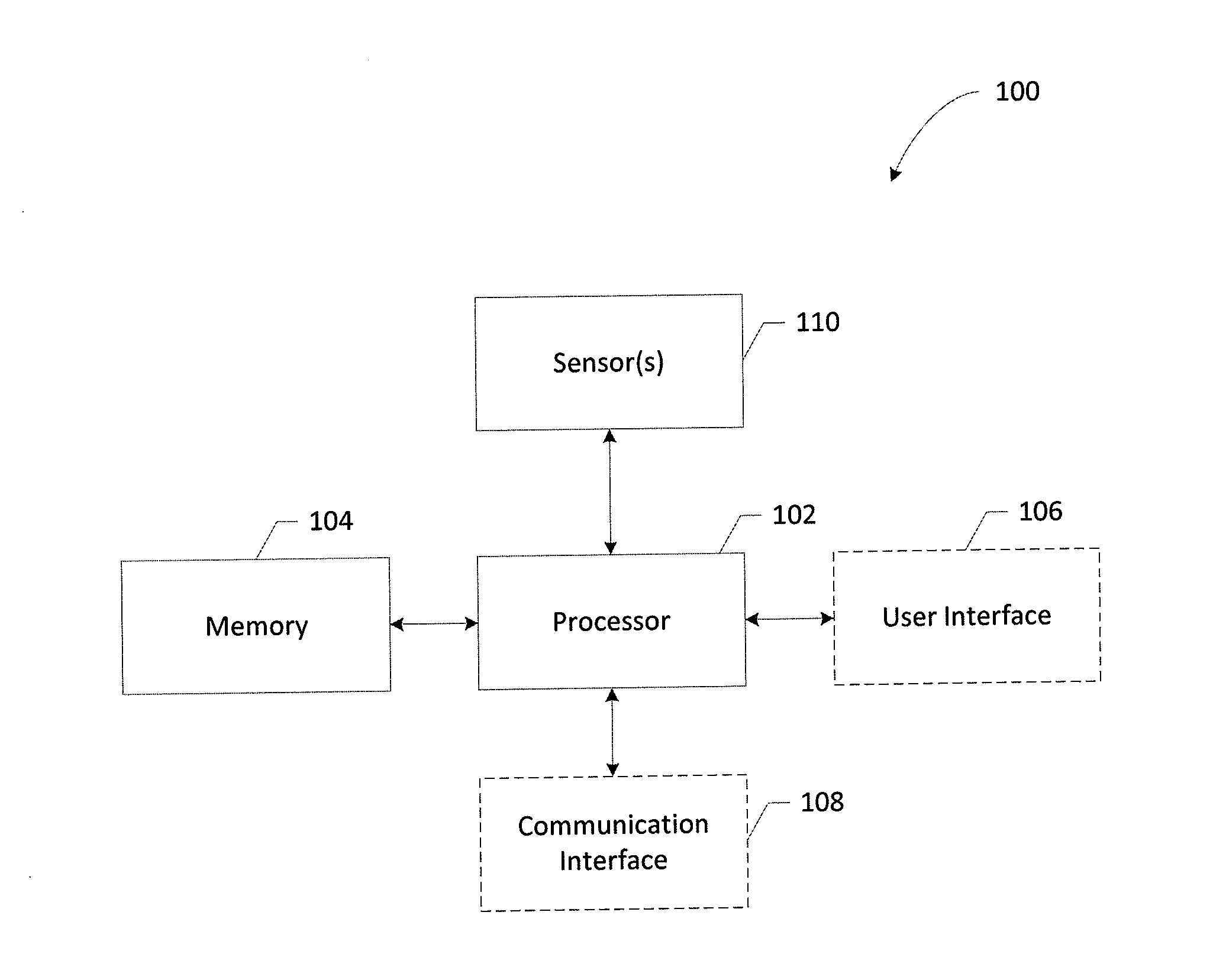

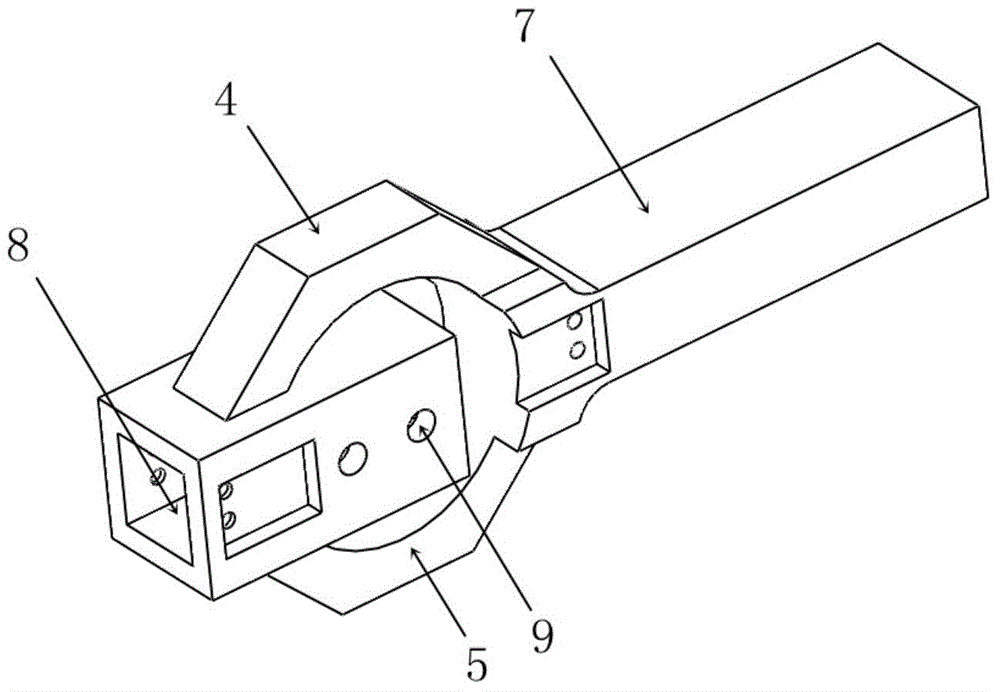

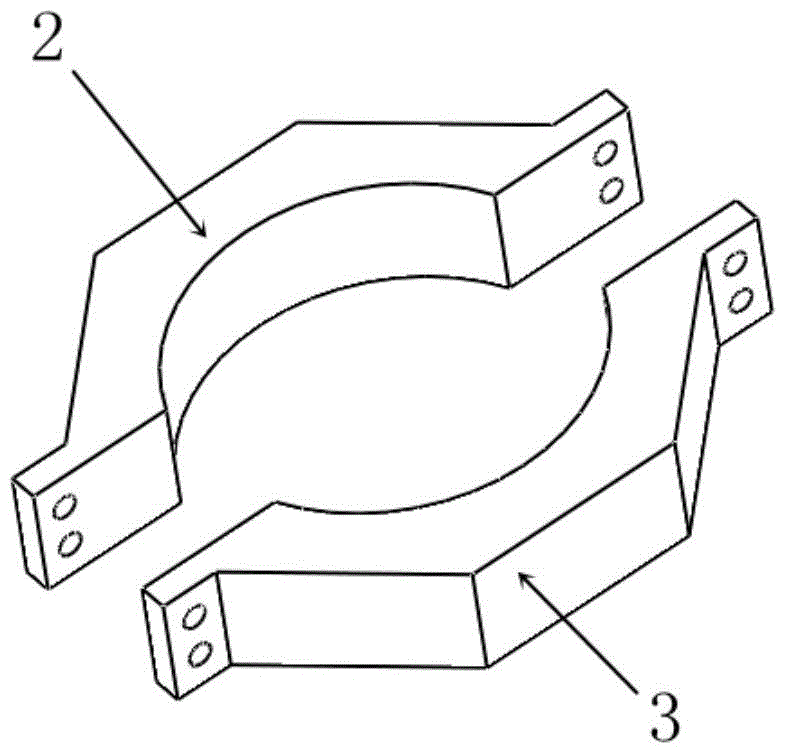

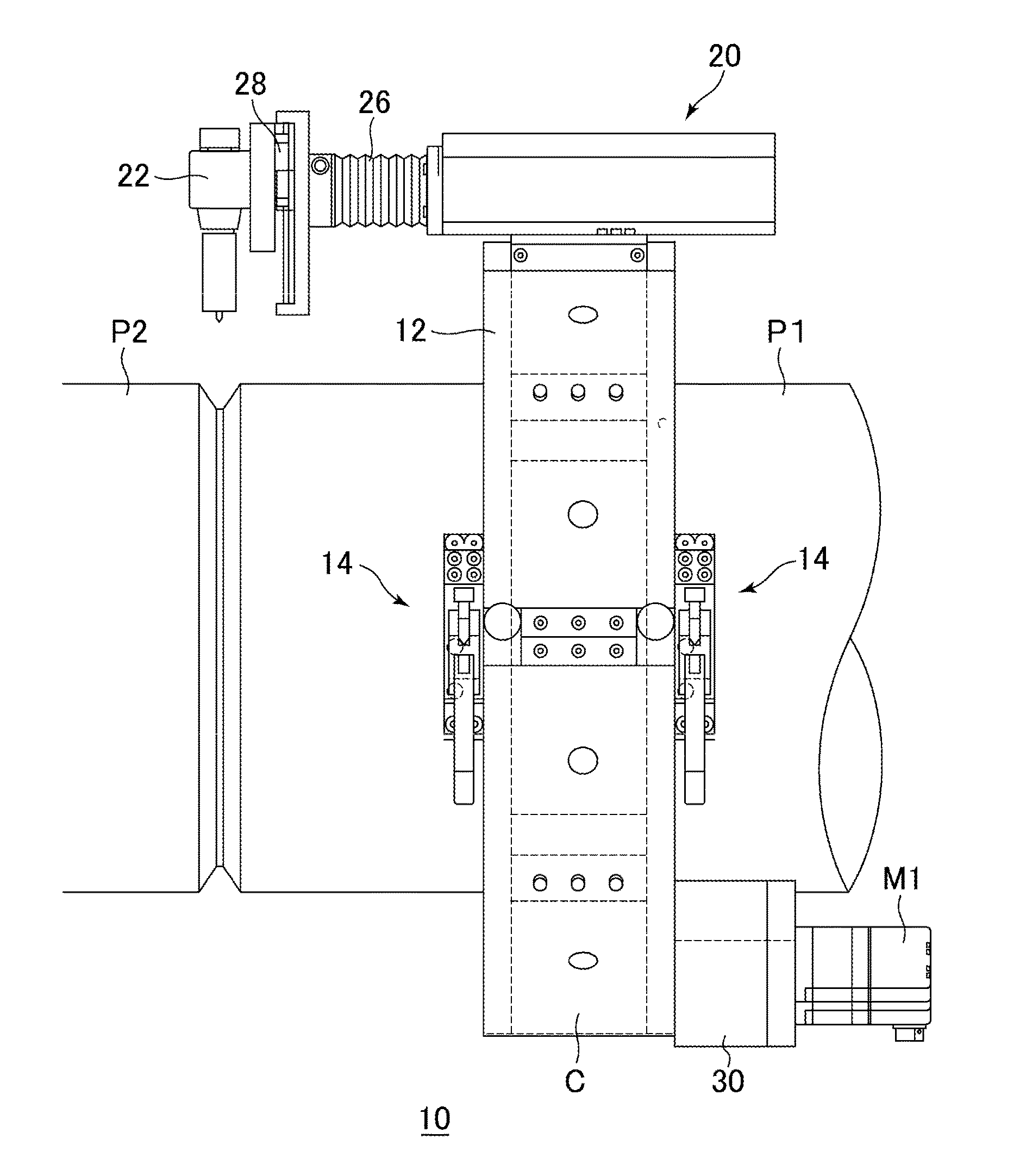

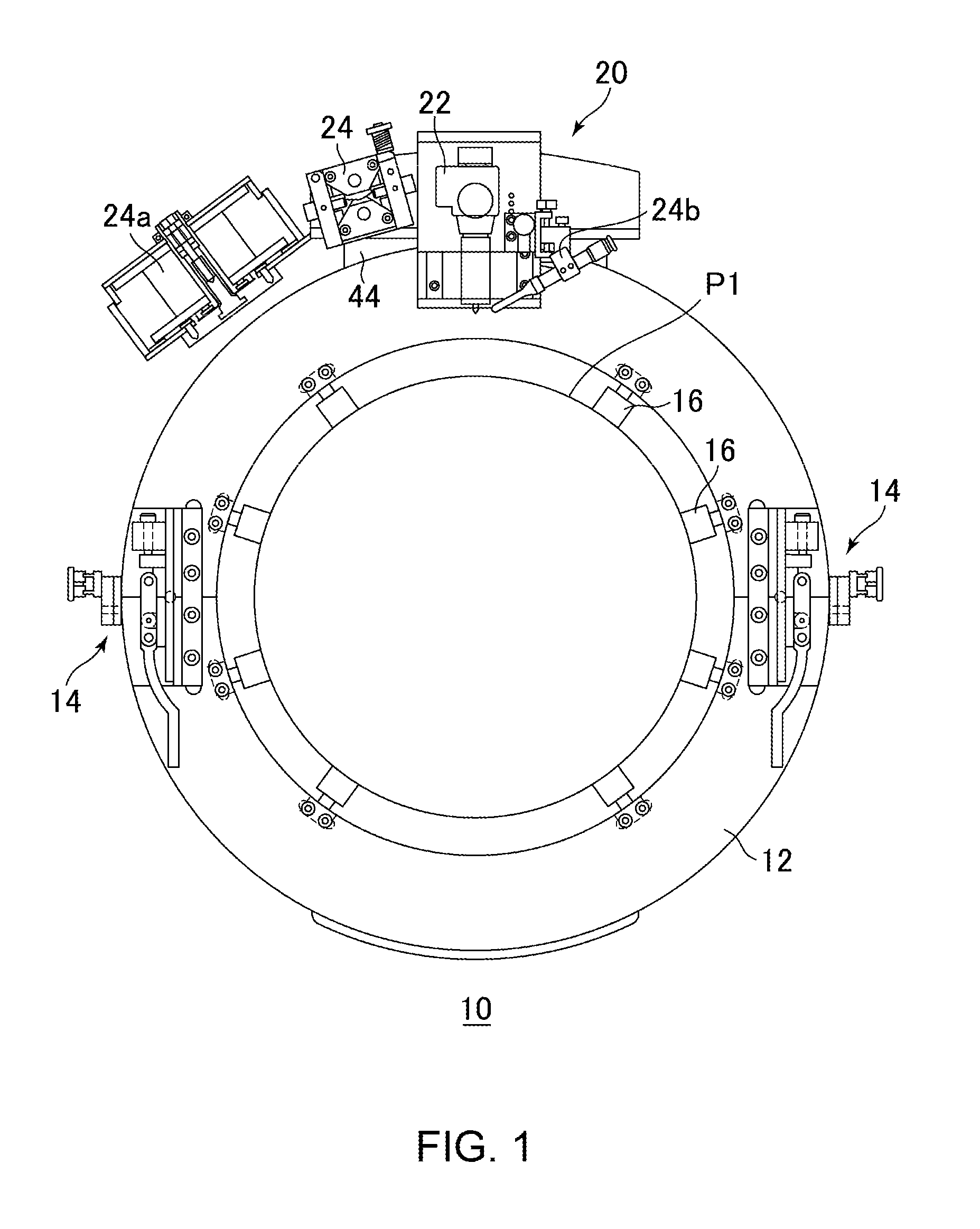

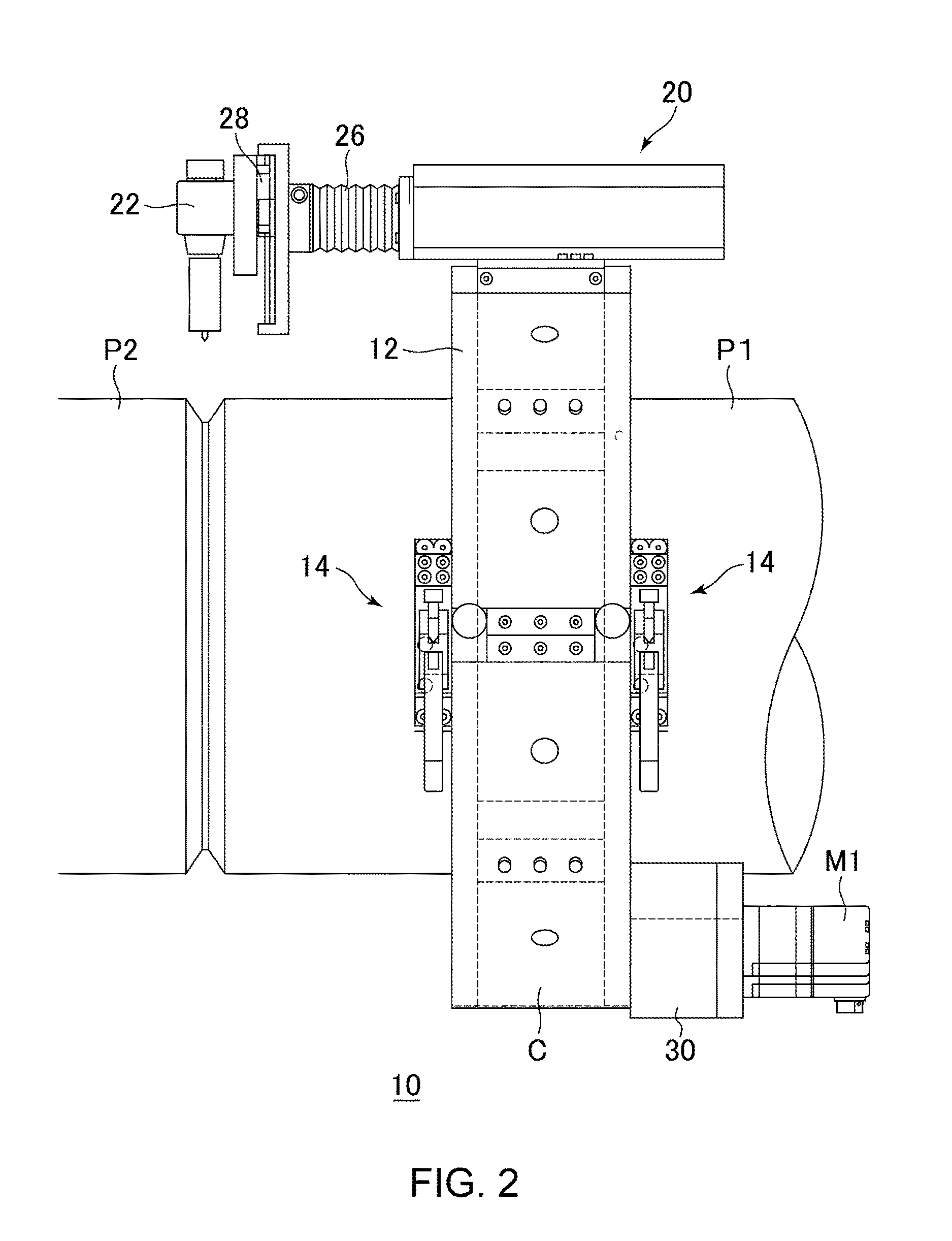

Welding apparatus

ActiveUS20170056998A1Light weightReduce radial sizeWelding/cutting auxillary devicesArc welding apparatusGear wheelEngineering

A welding apparatus includes a housing having facing surfaces in the axial direction, and a welding head turning gear and first to third ring gears inside of the housing. A guide surface is formed on the facing surfaces. The welding head turning gear is coupled to a guide member, and the first to third ring gears are supported by the welding head turning gear and the guide member. Since a roller provided to the guide member rolls on the guide surface to rotatably support the first to third ring gears with respect to the housing, the welding apparatus can be lighter in weight and more compact compared to a conventional welding apparatus.

Owner:CUTLAND JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com