Automatic centering type direct rock tensile test device

A tensile test, Chinese-style technology, used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of inflexible rotation of the ball head and spherical roller, can not avoid eccentric tensile stress, Inaccurate test results and other problems, to avoid the problem of eccentric tensile stress, shorten the loading and unloading time, and ensure the simplicity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

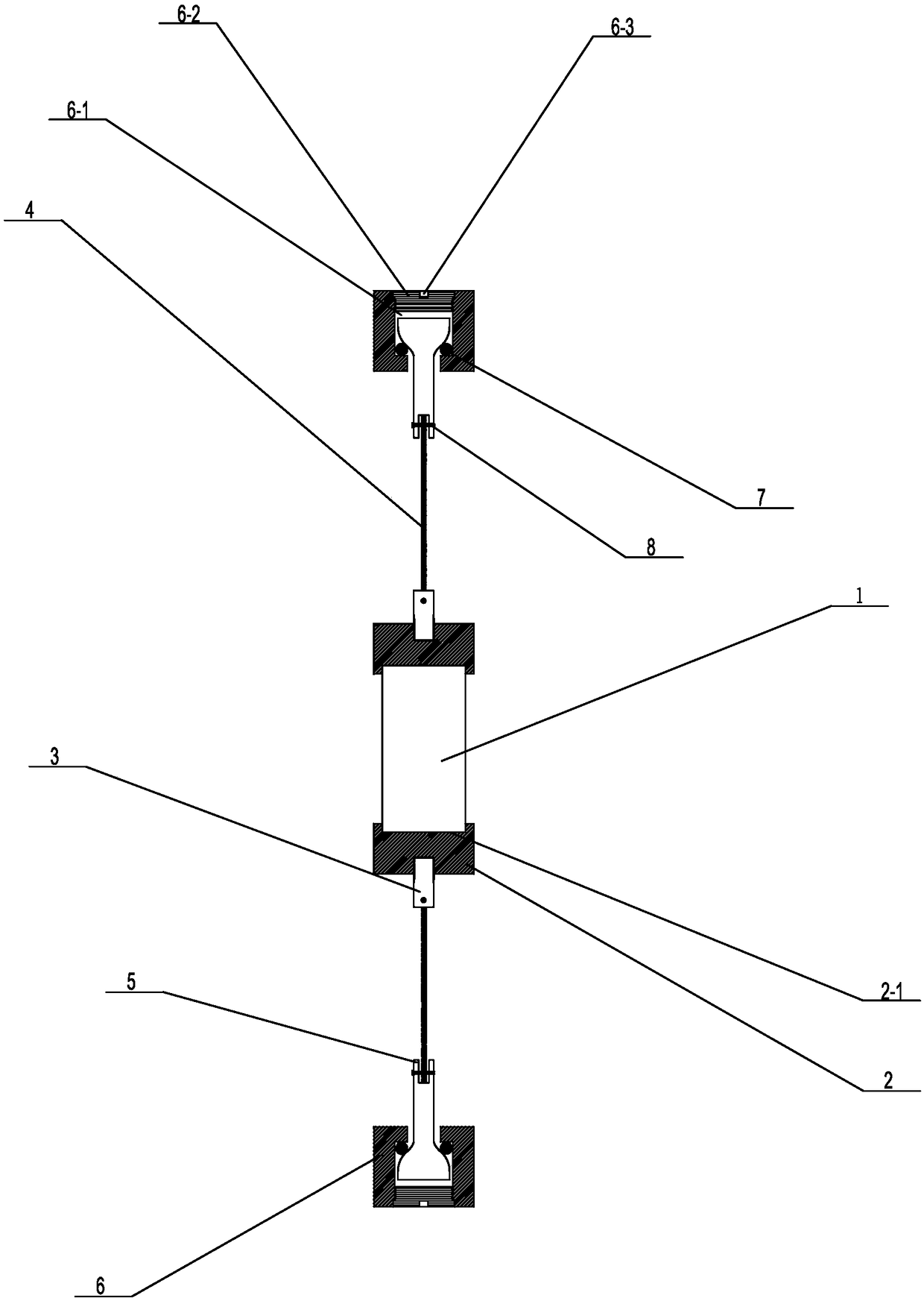

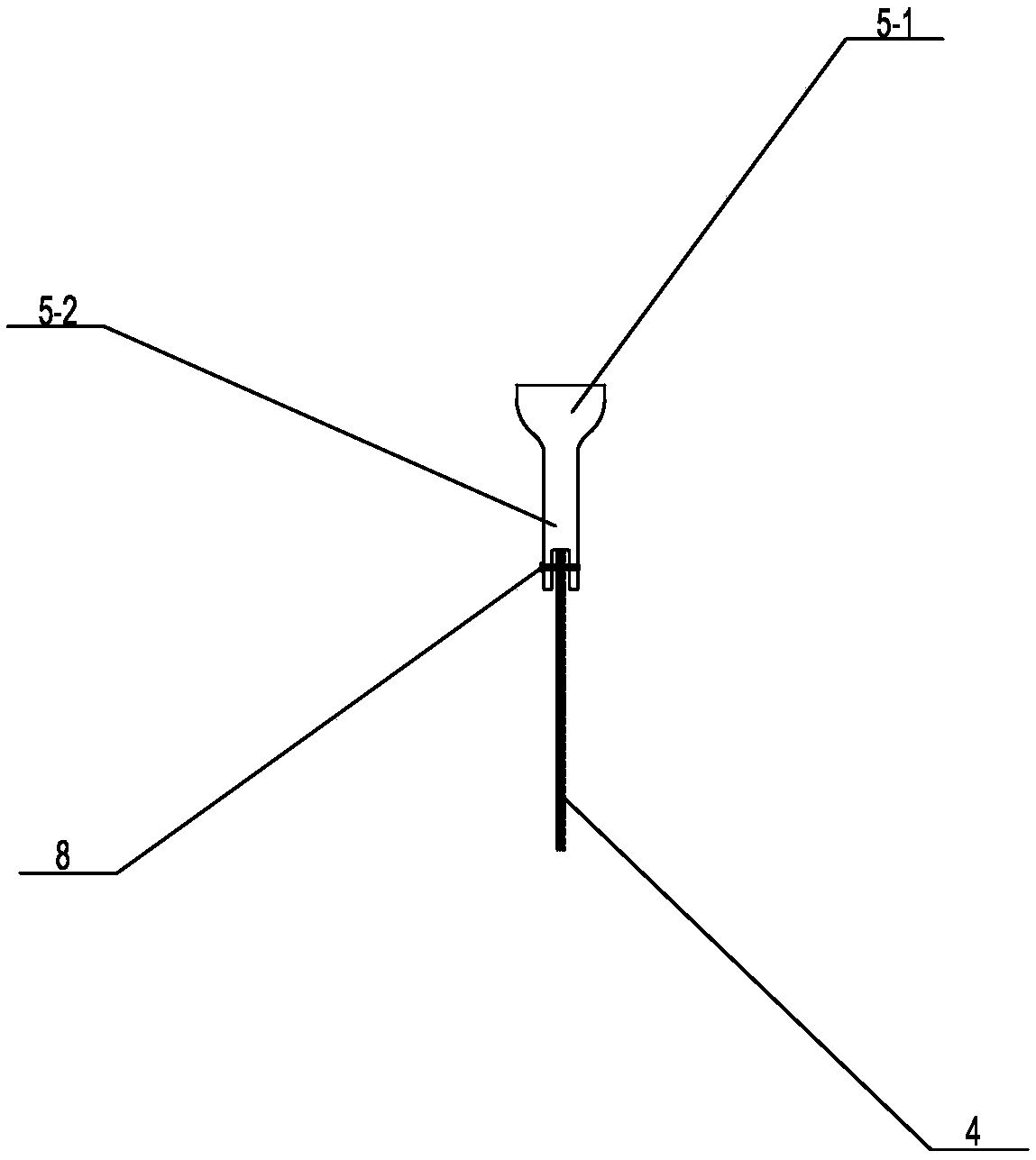

[0017] Such as figure 1 A specific embodiment of the present invention is shown, an automatic direct tensile test device for Chinese rocks, which is the same as the existing tensile test device: it includes a symmetrically arranged upper tensile test unit and a lower tensile test unit. The upper tensile test unit and the lower tensile test unit both include the sample cover cap 2, the ball end tie rod 5, the ball 7, and the sleeve 6. The sample cover cap is matched with the cylindrical rock sample 1 At the end, the ball head pull rod 5 includes a ball head rotating member 5-1 nested in the sleeve 6 and a connecting rod 5-2 arranged under the ball head rotating member 5-1; the difference is: A connecting piece 3 is connected to the sample cover cap 2. In this embodiment, the connecting piece 3 and the sample cover cap 2 are connected by a thread, that is, the end of the connecting piece 3 is provided with an external thread, and the sample cover cap 2 is provided with an external...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com