Concrete axis tension self-balancing test device and test method thereof

A test device and a technology for concrete specimens, which are used in measuring devices, using stable tension/compression testing materials, instruments, etc. The stress distribution of the specimen is complex and other problems, so as to achieve the effect of small structural mass, easy transportation and installation, and avoidance of eccentric force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

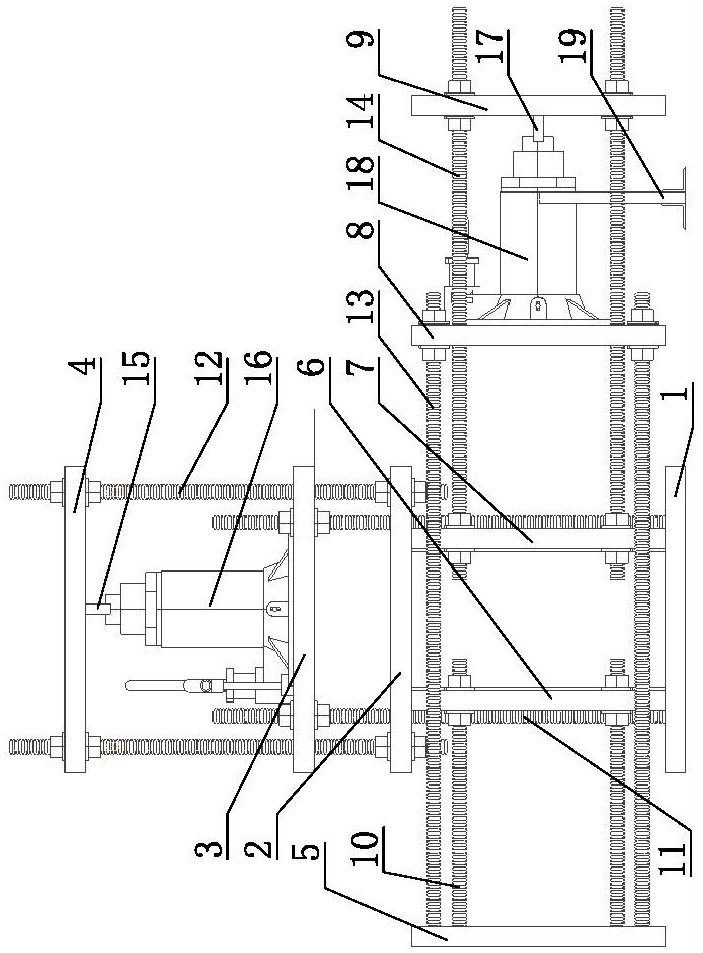

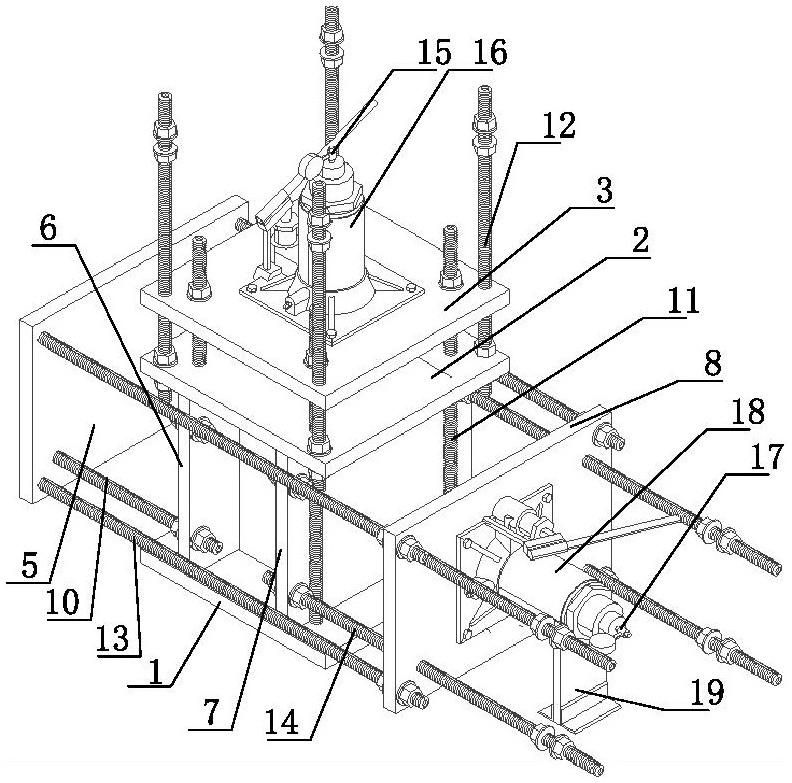

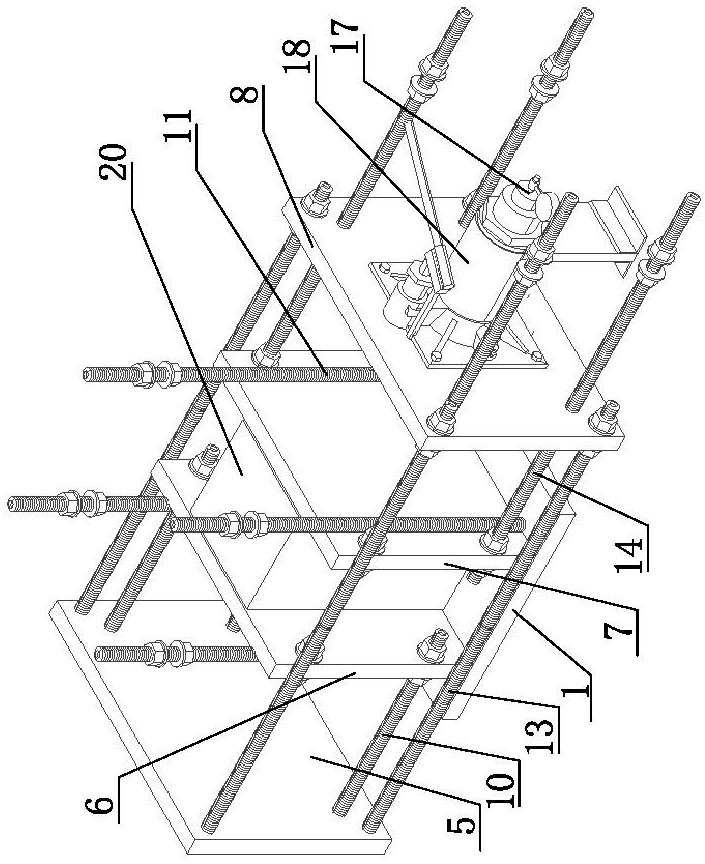

[0026] Such as Figure 1-3 As shown, it is a concrete axial tension self-balancing test device, which consists of a vertical tensile test mechanism and a horizontal tensile test mechanism.

[0027] Vertical tensile test mechanism: including reinforcement plate 1, reinforcement plate 2, reinforcement plate 3 and reinforcement plate 4, which are parallel to each other and centered on the same longitudinal axis, reinforcement plate 1, reinforcement plate 2, and reinforcement plate 3 3 and reinforcement plate four 4 are arranged sequentially from bottom to top; the four corners of reinforcement plate one 1 and reinforcement plate three 3 are respectively fixedly connected by four parallel first screw rods 11; the four corners of reinforcement plate two 2 and reinforcement plate four 4 Respectively fixedly connected through four second screw rods 12 arranged in parallel; the first screw rod 11 passes through the reinforcement plate two 2 with a gap, and the second screw rod 12 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com