Patents

Literature

38results about How to "Avoid eccentric force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

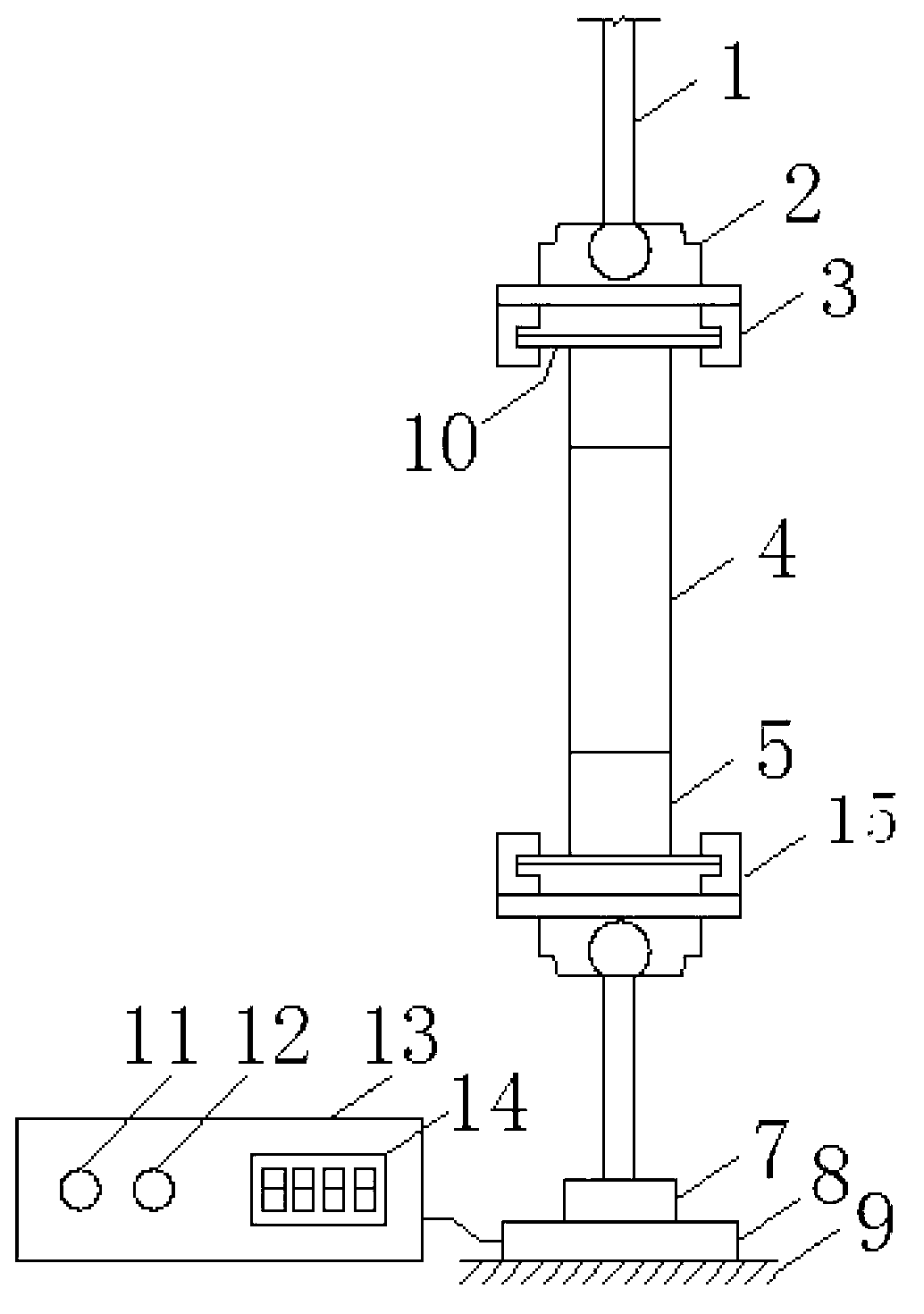

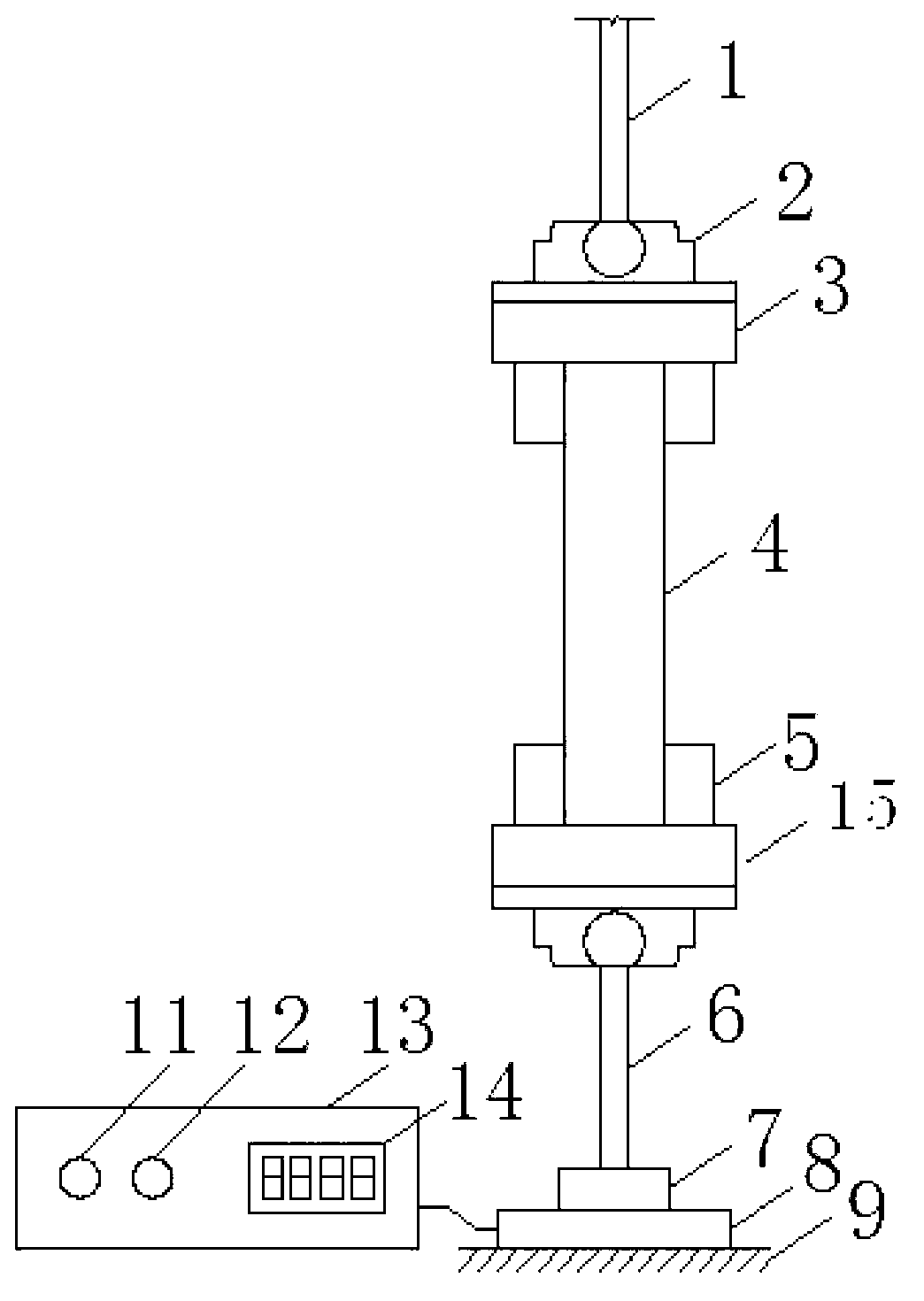

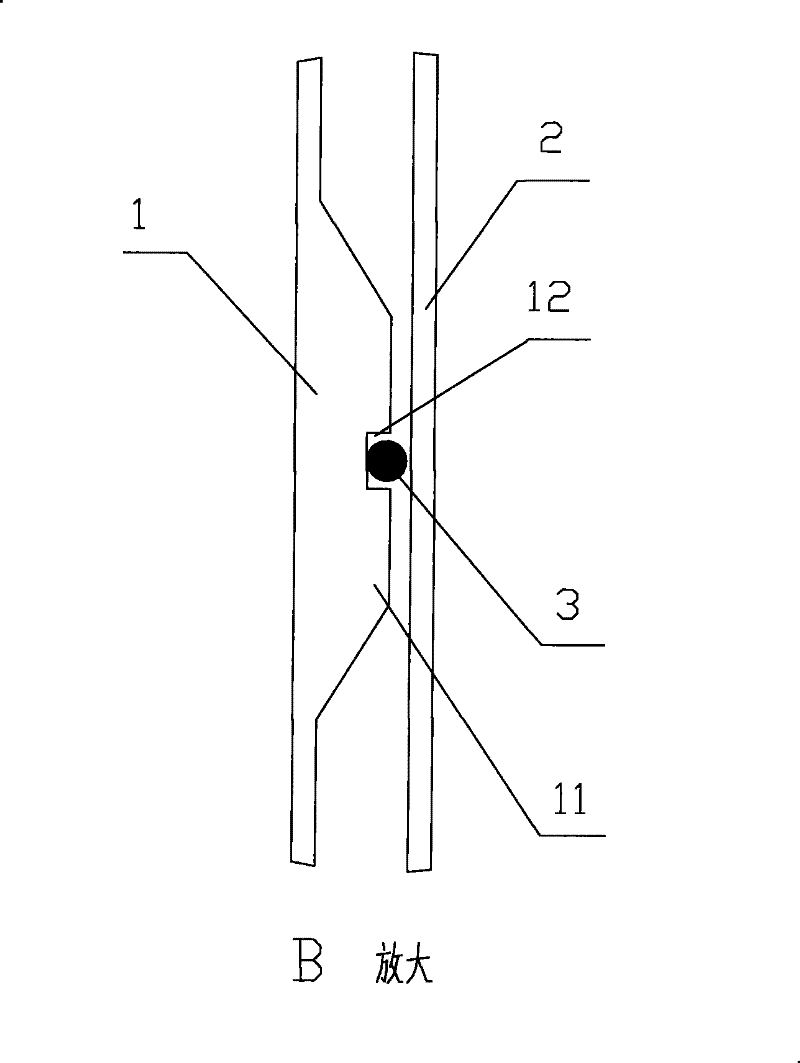

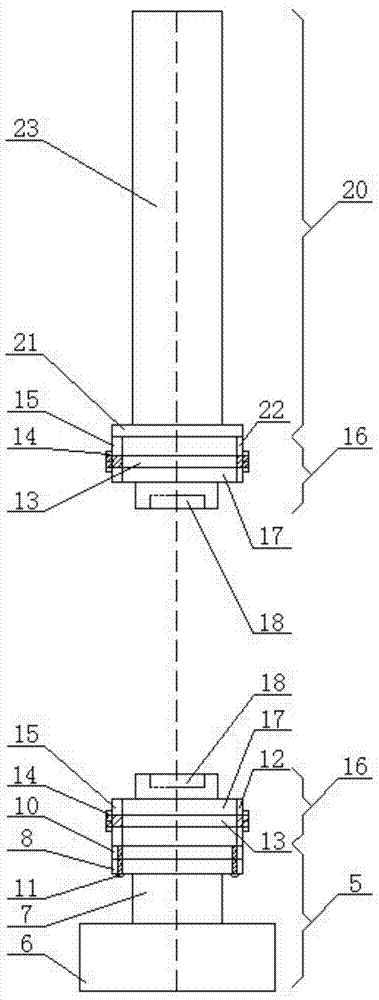

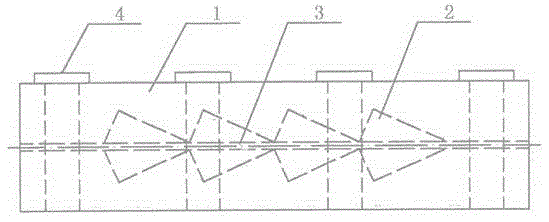

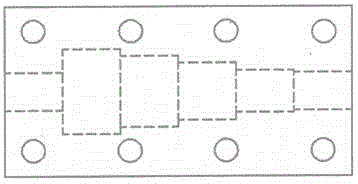

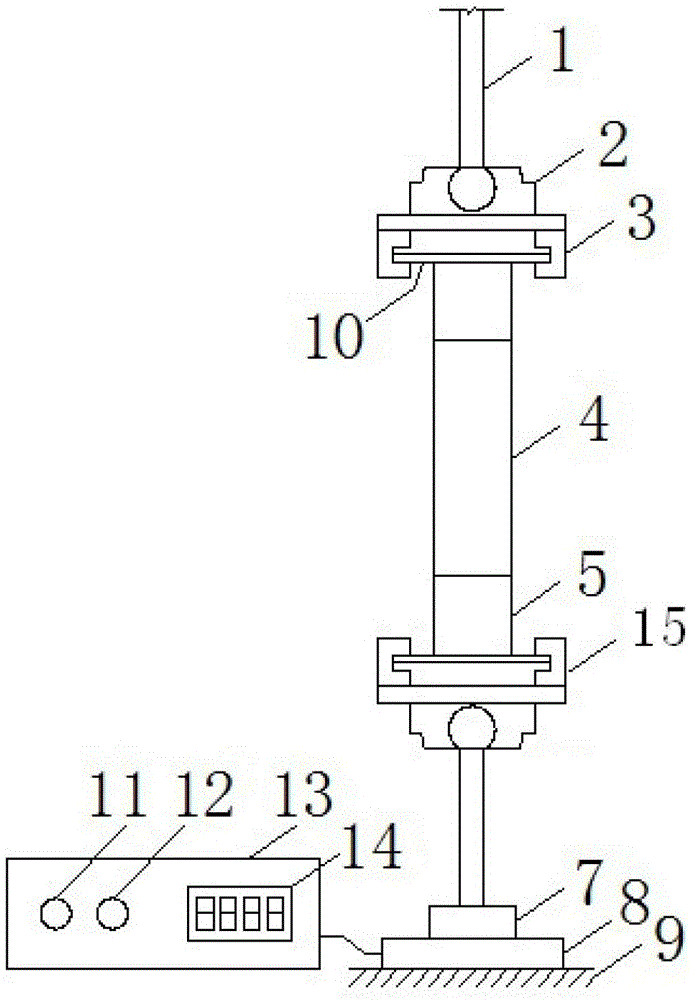

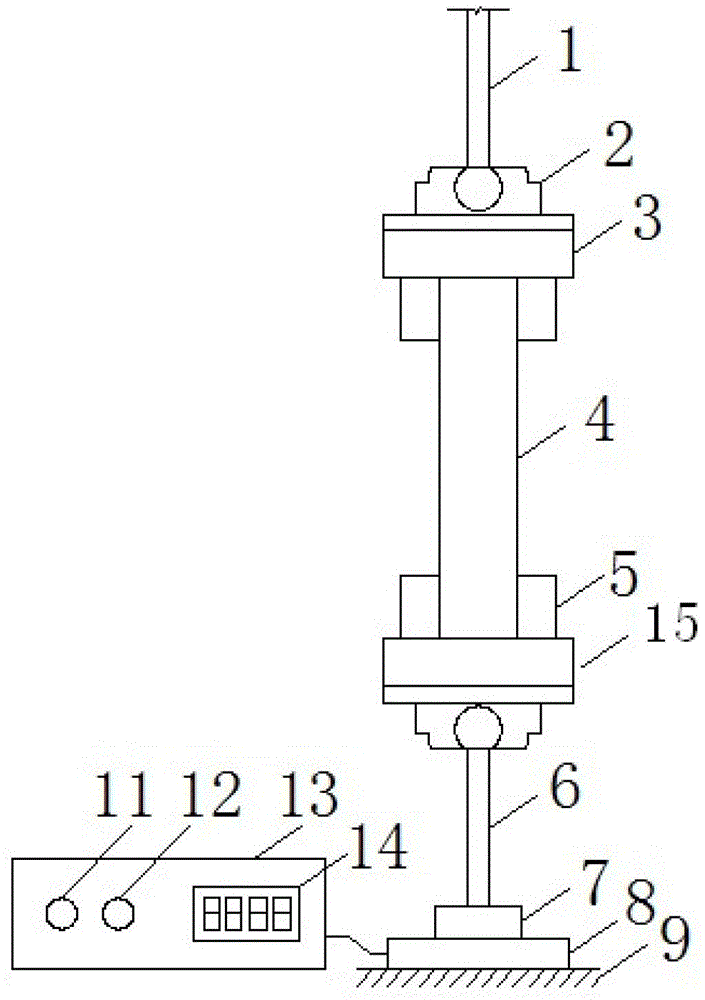

Pavement material direct tensile test apparatus with eccentric tension avoided and method thereof

InactiveCN103234825ASimple structureReduce mistakesMaterial strength using tensile/compressive forcesElectricityMagnetic tension force

The invention provides a pavement material direct tensile test apparatus with eccentric tension avoided and method thereof, and the apparatus comprises a test part, a detected part installed in the test part, and electromagnetic force control part, wherein, the test part comprises a hinged base on the spherical shape, and a spherical lower hinged base matched with the spherical upper hinged base, and the spherical upper hinged base is installed with a upper link which is connected to a mechanics test and simulation testing machine, and the spherical lower hinged base is connected with a cast iron block by the lower pull bar, and the test part is installed between the spherical upper hinged base and the spherical lower hinged base; the electromagnetic force control part is connected with the cast iron block. Because of the flexibly rotary spherical hinged base, in the test process, when the test part is tensioned, the test part can naturally drop depending on gravity, thereby the eccentric force being effected on the detected part during tensile test is avoided, and the test result is more accurate, in addition, the invention has the advantages of simple structure, convenient operation, economic utility, reliable test data provision and minimized test error.

Owner:CHANGAN UNIV

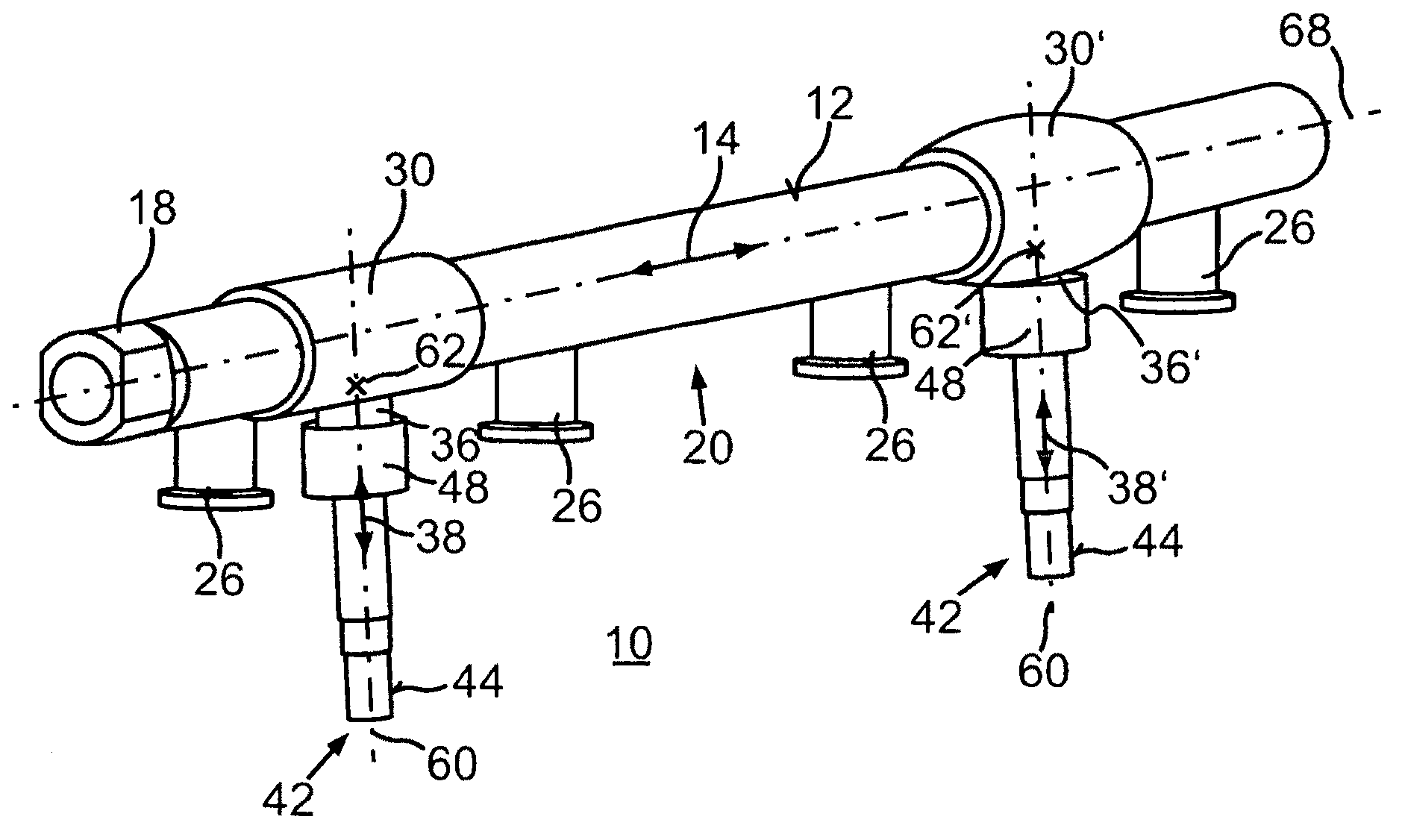

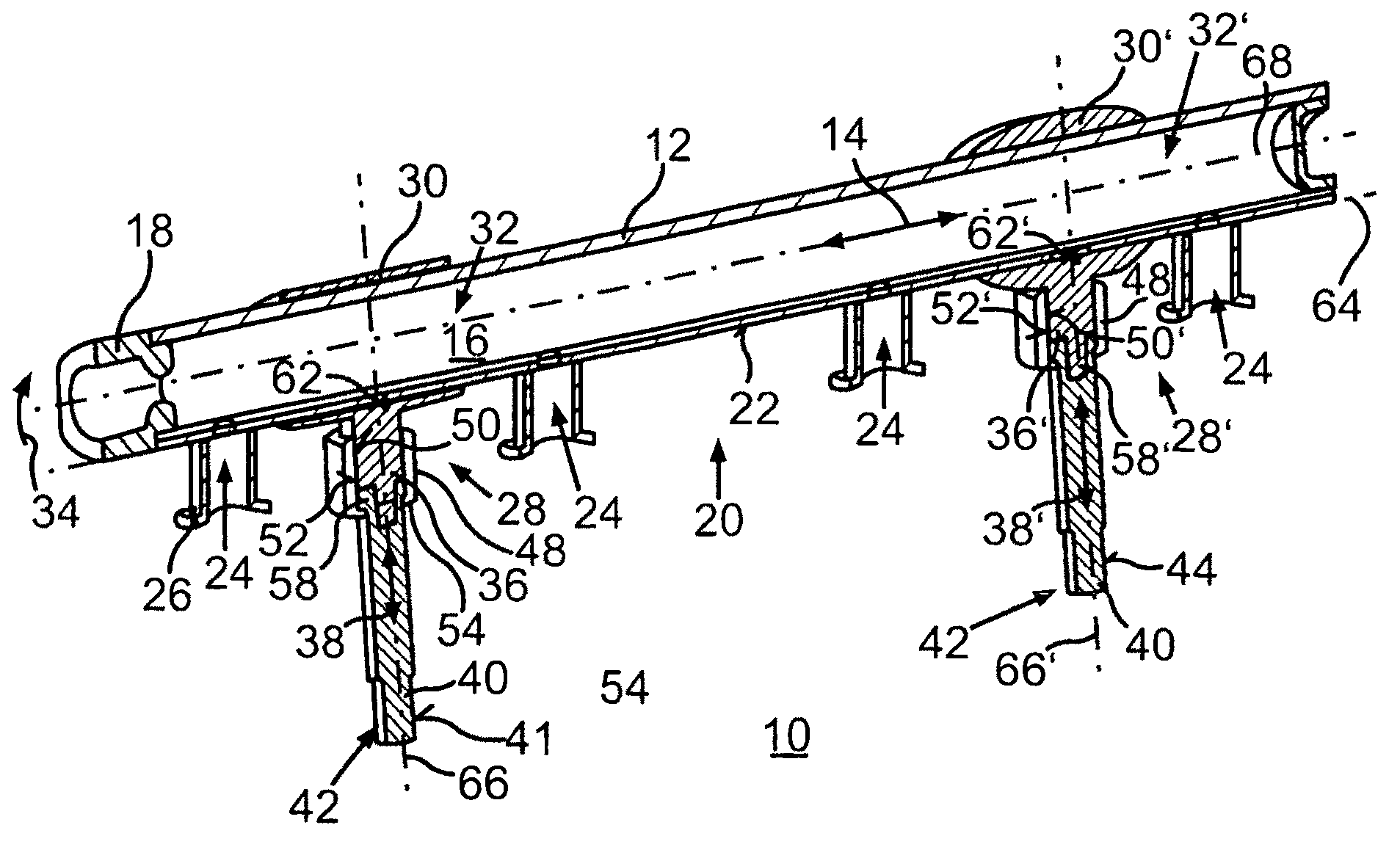

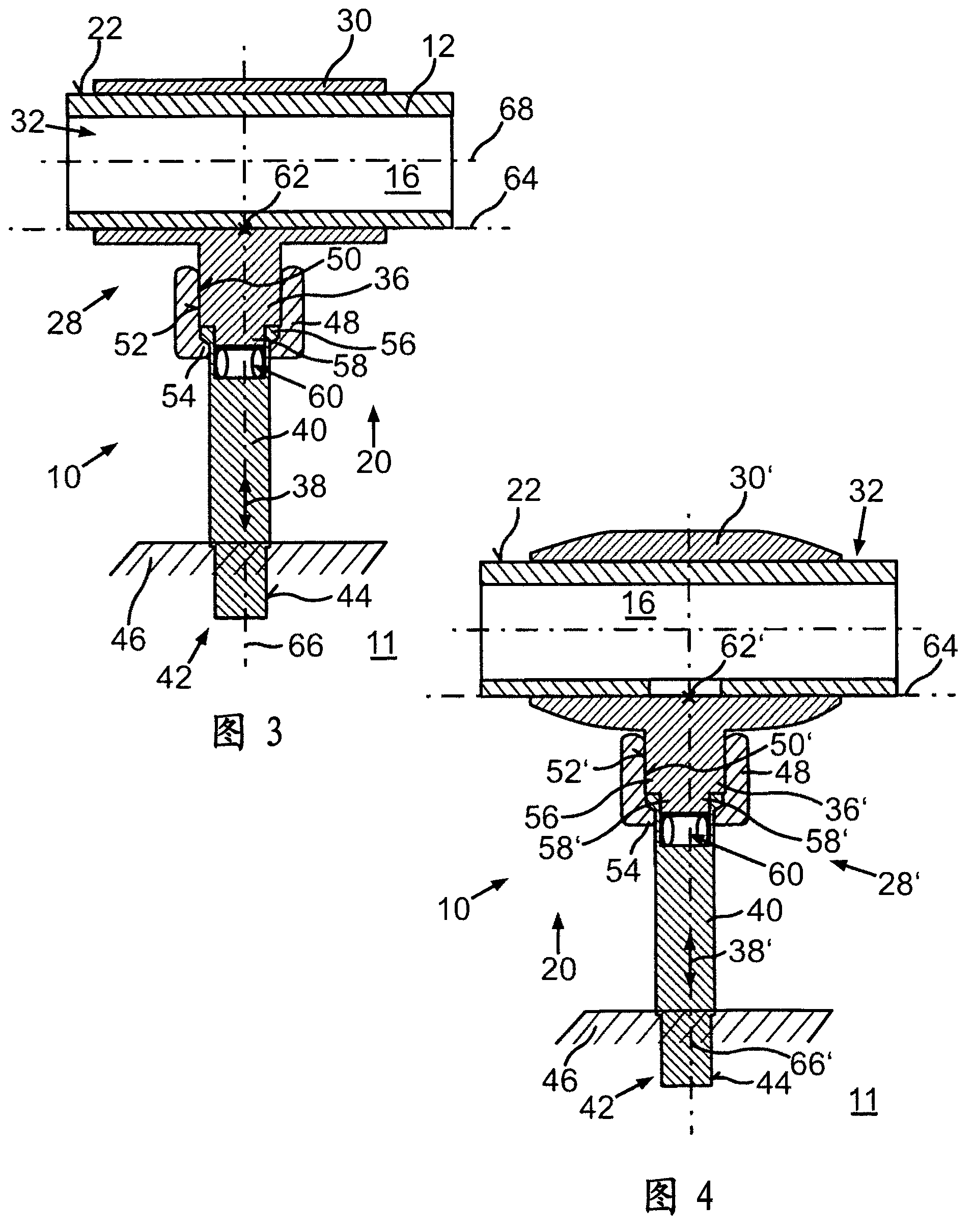

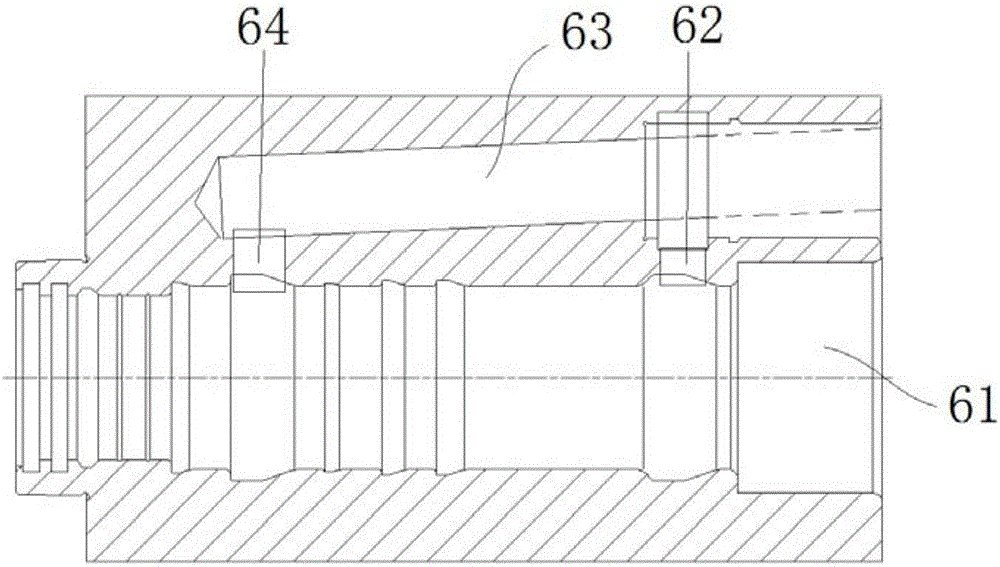

A fastening arrangement of a fuel supply device on an internal combustion engine, and a method for fastening a fuel supply device to the internal combustion engine

ActiveCN103210204AShorten the timeLow costLow-pressure fuel injectionMachines/enginesExternal combustion engineEngineering

The invention relates to a fastening arrangement (11) of a fuel supply device (10) on an internal combustion engine, and also relates to a method for fastening the fuel supply device (10) of said type to the internal combustion engine. In the fastening arrangement (11), at least one fuel distributing element (12) which runs along a longitudinal direction (14) and which has at least two connection openings (24) for connecting a respective fuel injection device is fastened to the internal combustion engine by means of at least one connecting part (36, 36'), wherein the connecting part (36, 36') is connected to the fuel distributing element (12) via a holding part (30, 30') which has a receptacle (32, 32') which completely surrounds at least one outer circumferential region of the fuel distributing element (12) and in which at least one portion of the fuel distributing element (12) is held, and wherein a point (62, 62'), which is situated in an elongation of the connecting element (36, 36') in a direction of extent (38, 38'), of the fuel distributing element (12) lies on a straight line (64) which connects the two connection openings (24).

Owner:AUDI AG

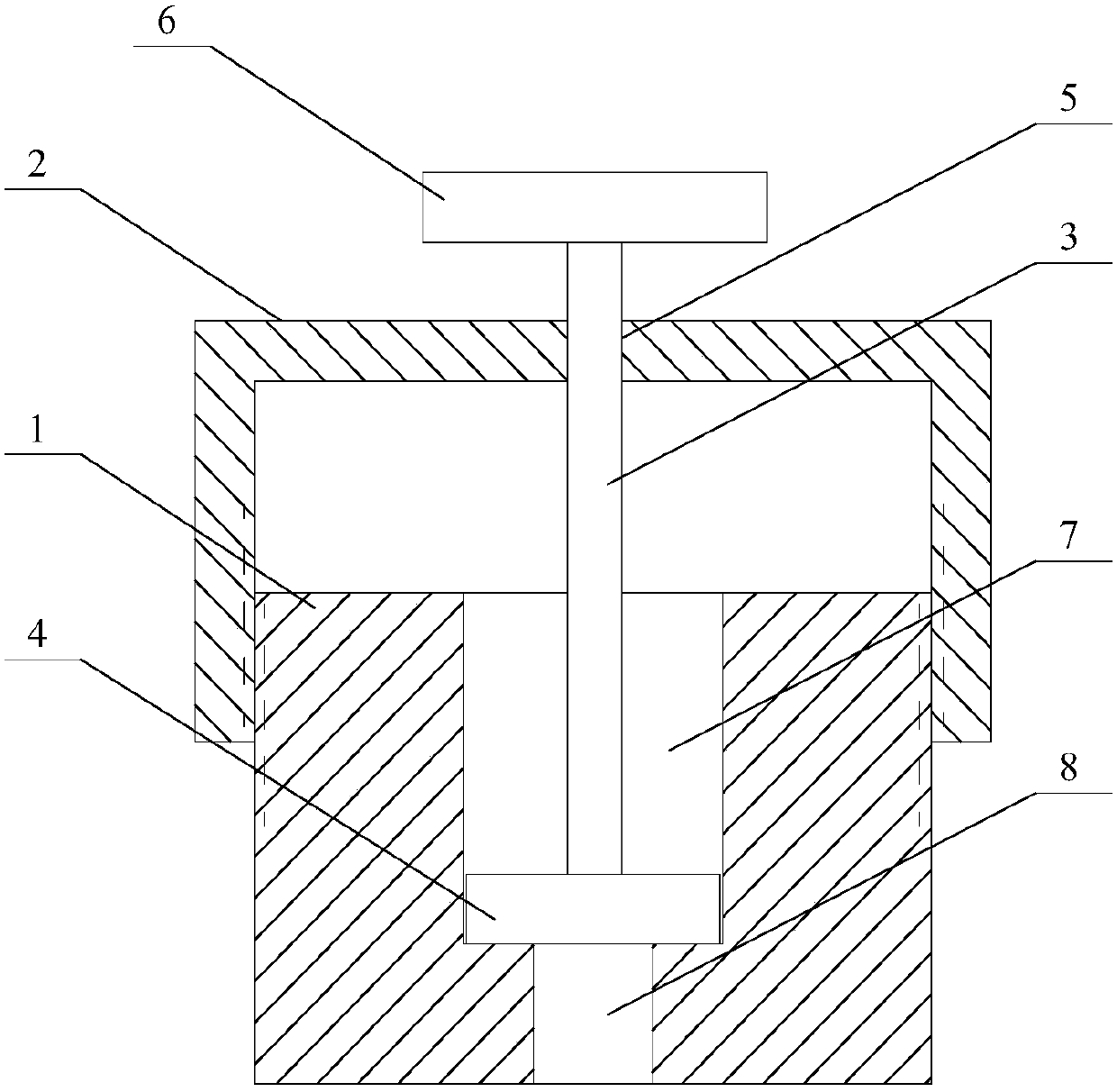

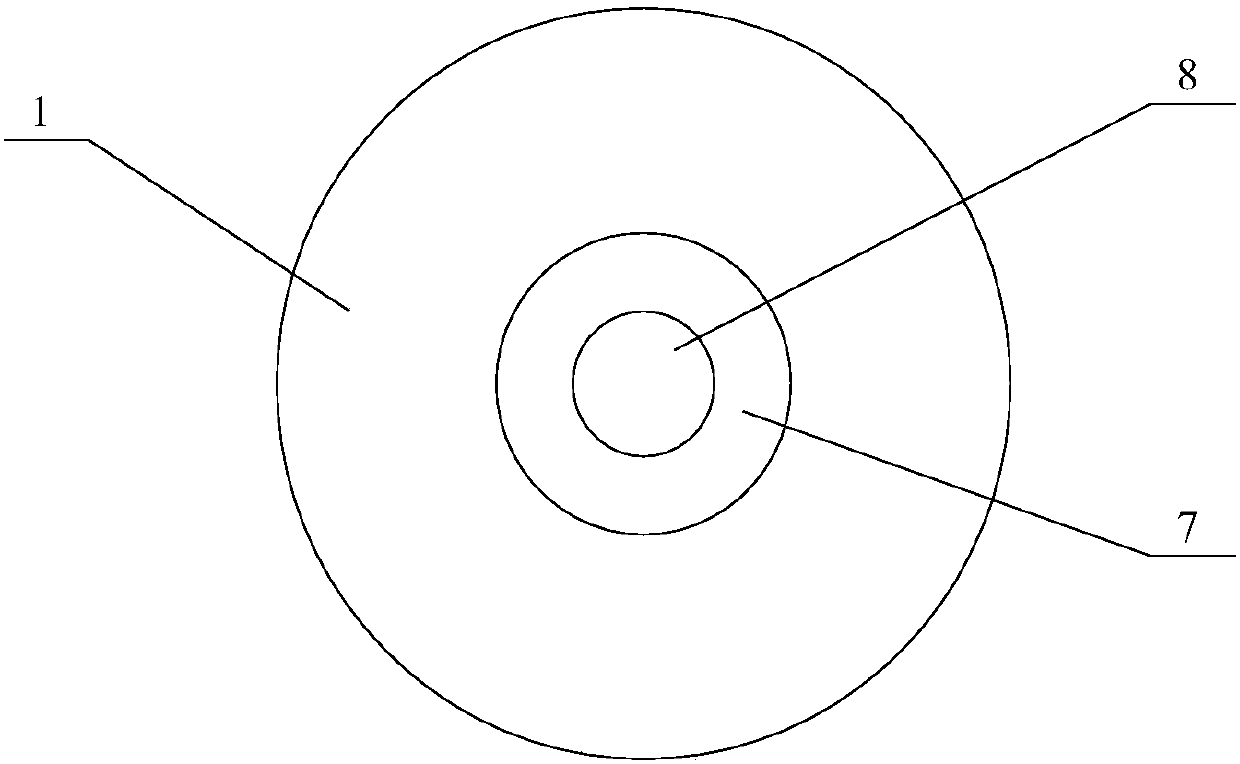

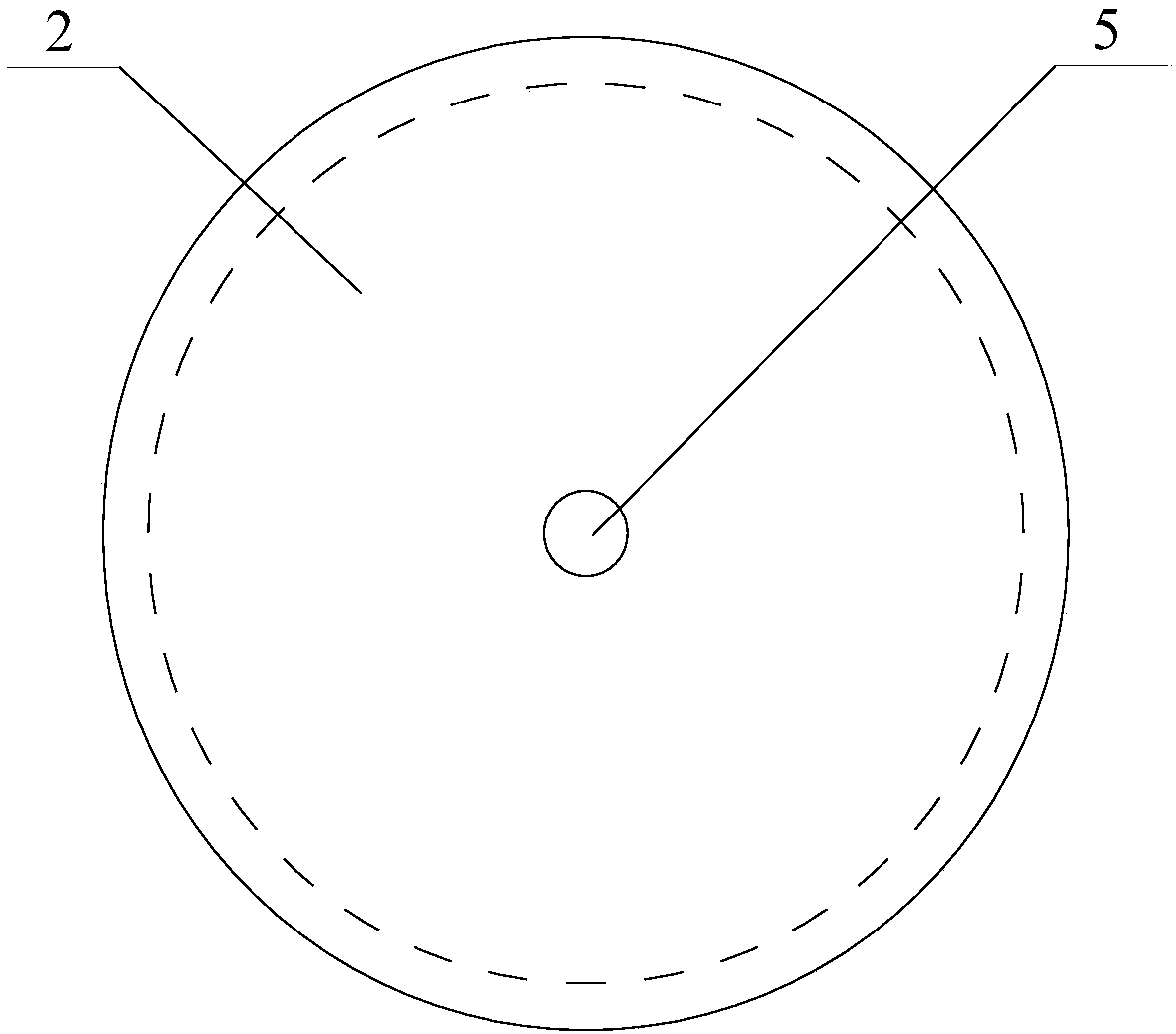

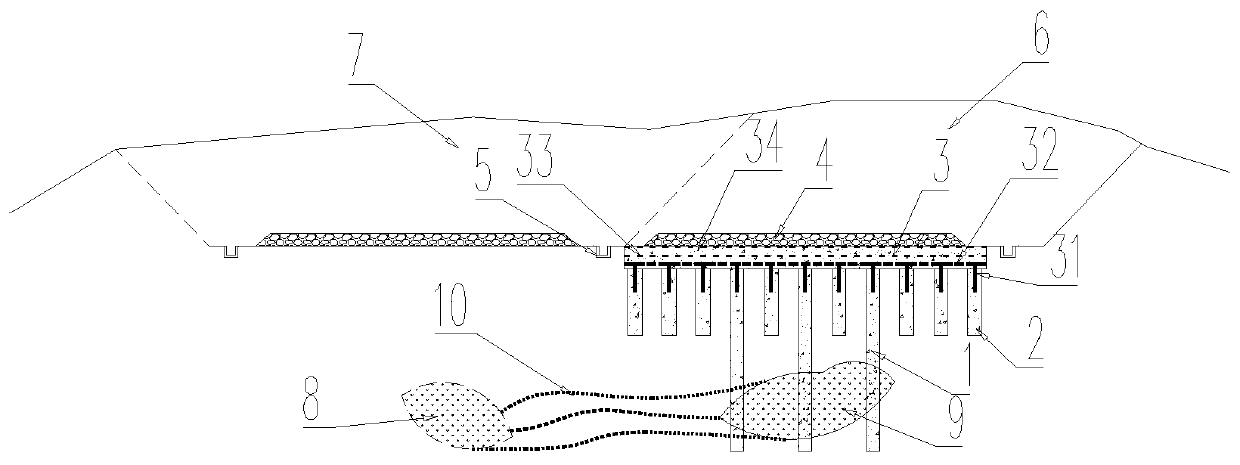

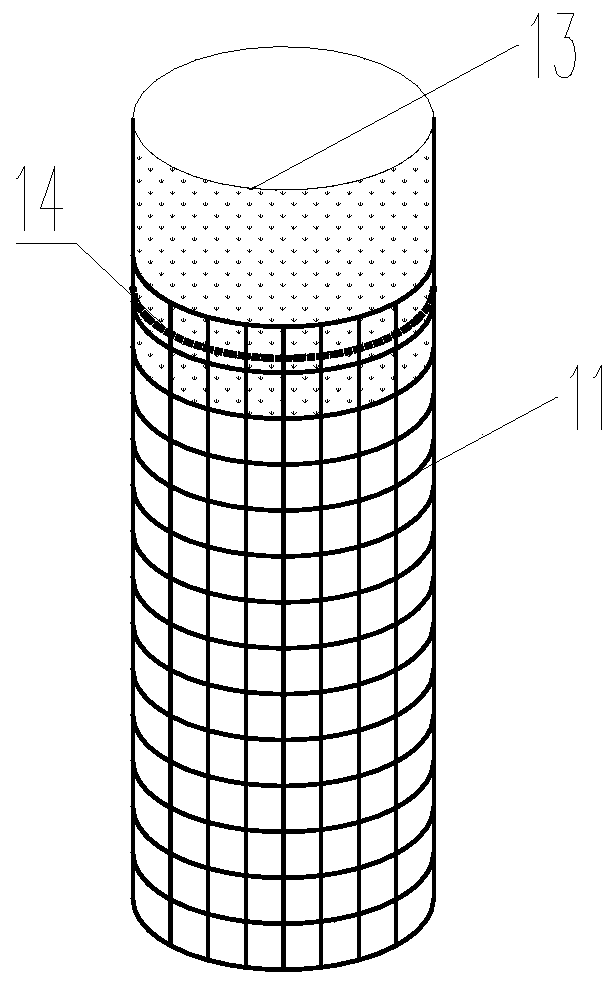

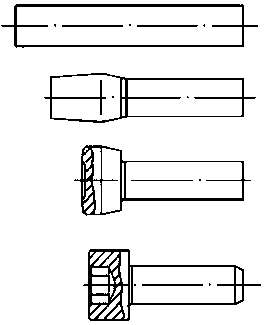

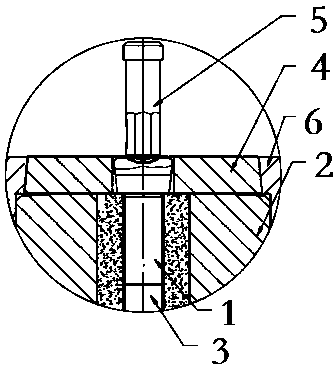

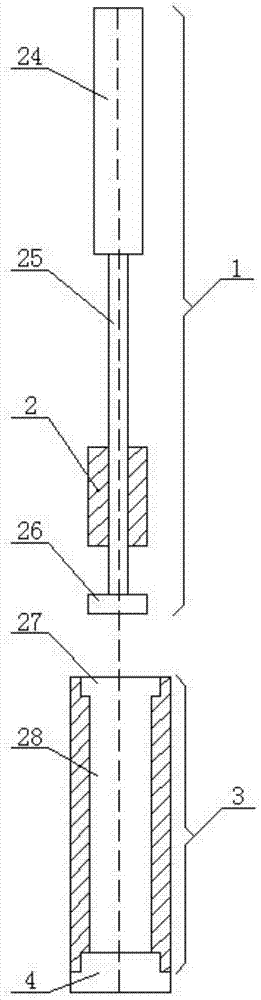

A device used for testing interlaminar interfacial shear strength of a fiber composite material bar

ActiveCN108037020AWide range of applicationsAvoid eccentric forceMaterial strength using steady shearing forcesFibrous compositesInterfacial shear

The invention provides a device used for testing interlaminar interfacial shear strength of a fiber composite material bar, and belongs to the technical field of devices used for testing interlaminarinterfacial shear strength of fiber composite material bars. The center of a bearing pedestal is provided with a cavity for a bar to be tested. The bearing pedestal below the cavity for the bar to betested is provided with a through hole. A fixing top cover is threaded to the bearing pedestal. The center of the fixing top cover is provided with a pressing bar hole. A force bearing pressing bar isconnected to the pressing bar hole in the fixing top cover in an up-down sliding manner. The top end of the force bearing pressing bar is fixed to a force bearing bar top disc. The inner hole diameter of the bearing pedestal and the height of the cavity can be designed according to different fiber bar diameters and testing heights, and shear strength of different cross sections can be obtained byadopting different pressing bar diameters, and therefore the application range of the device is wide. The fixing top cover firmly fixes the force bearing pressing bar to the bearing pedestal throughthreaded connection, thus ensuring vertical forcing applying on a fiber bar in a testing process of the device, and avoiding eccentric force applying.

Owner:HARBIN INST OF TECH

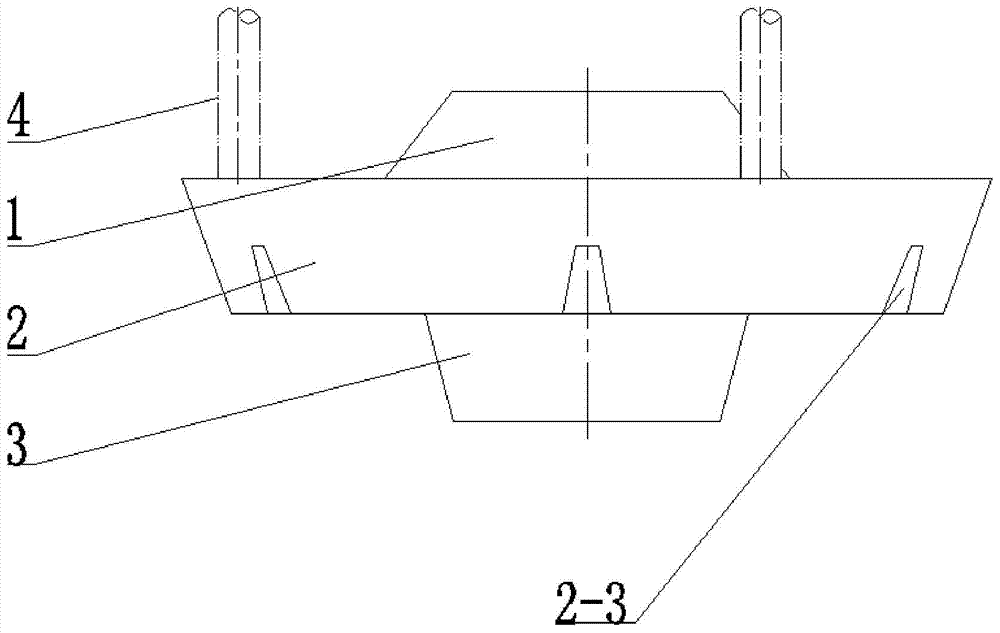

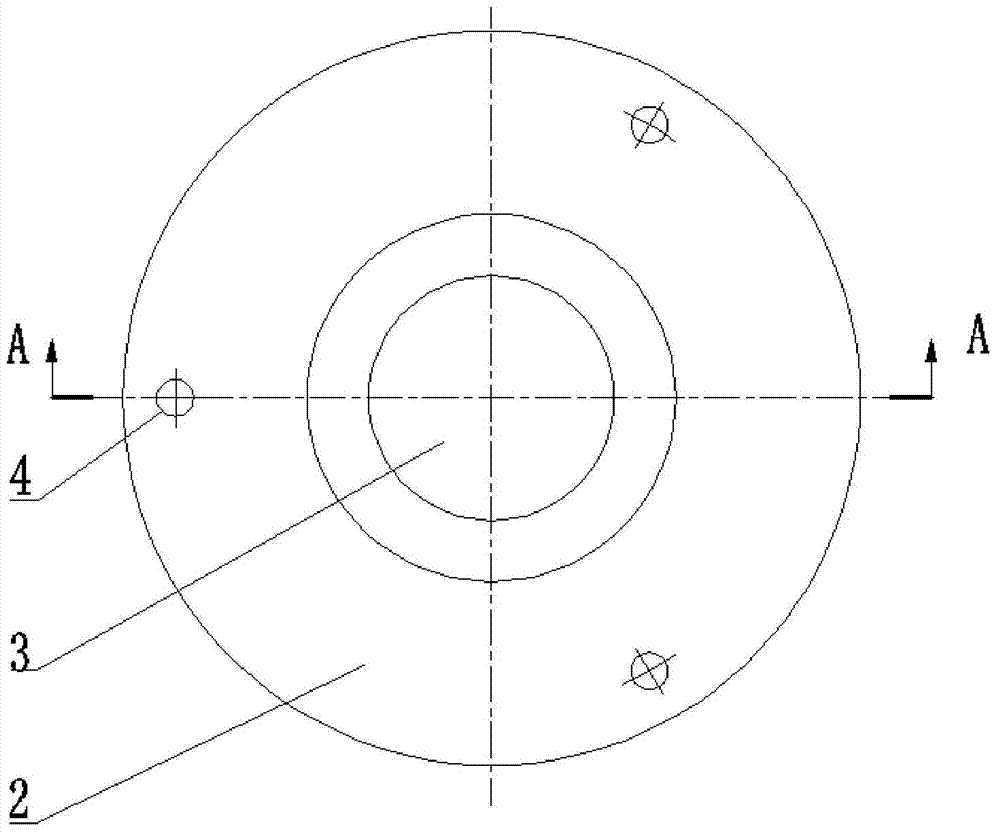

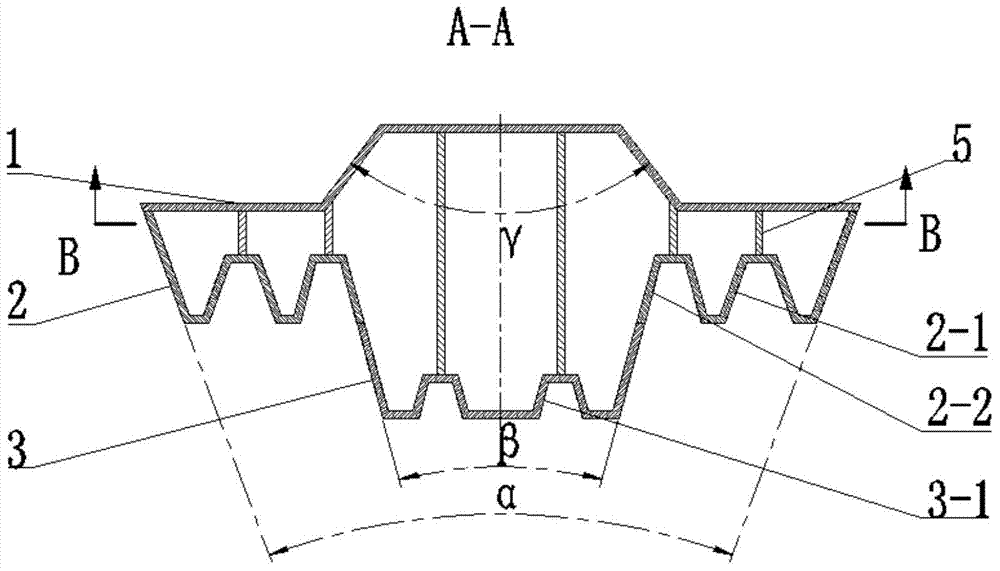

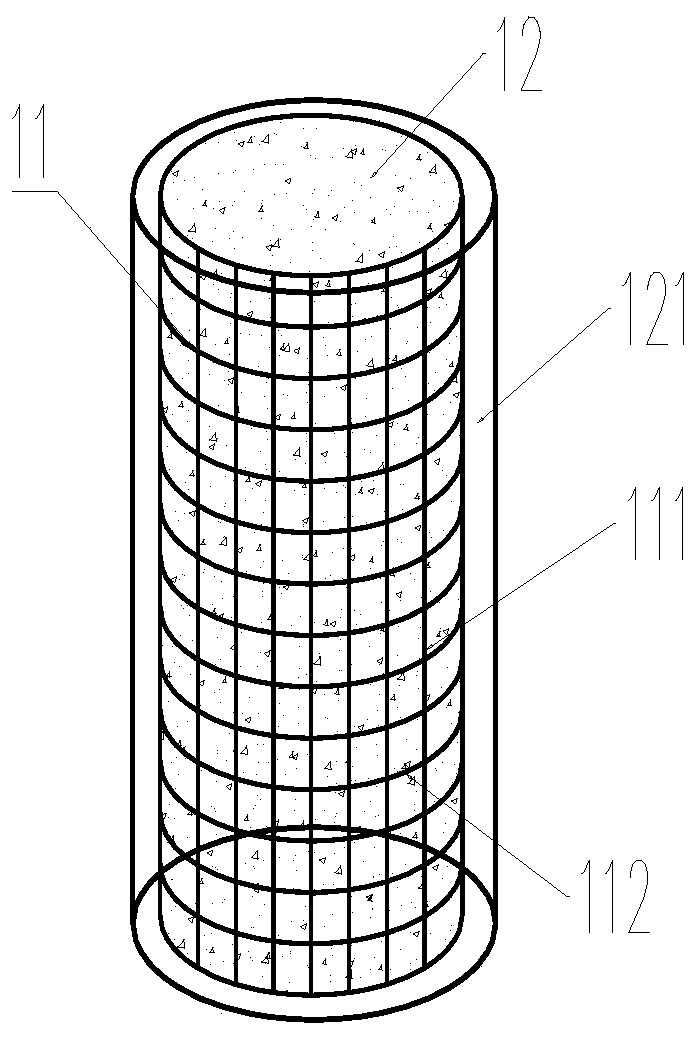

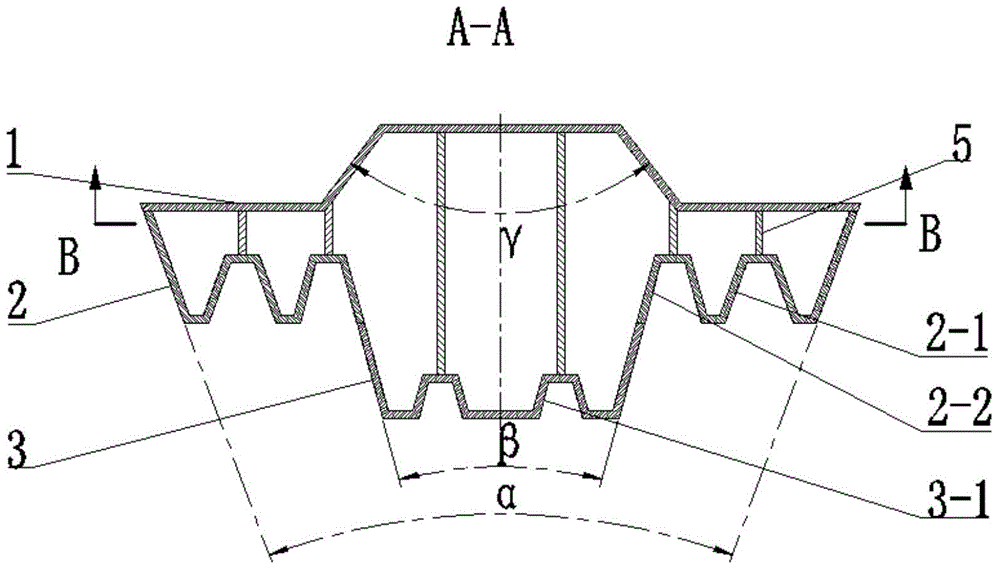

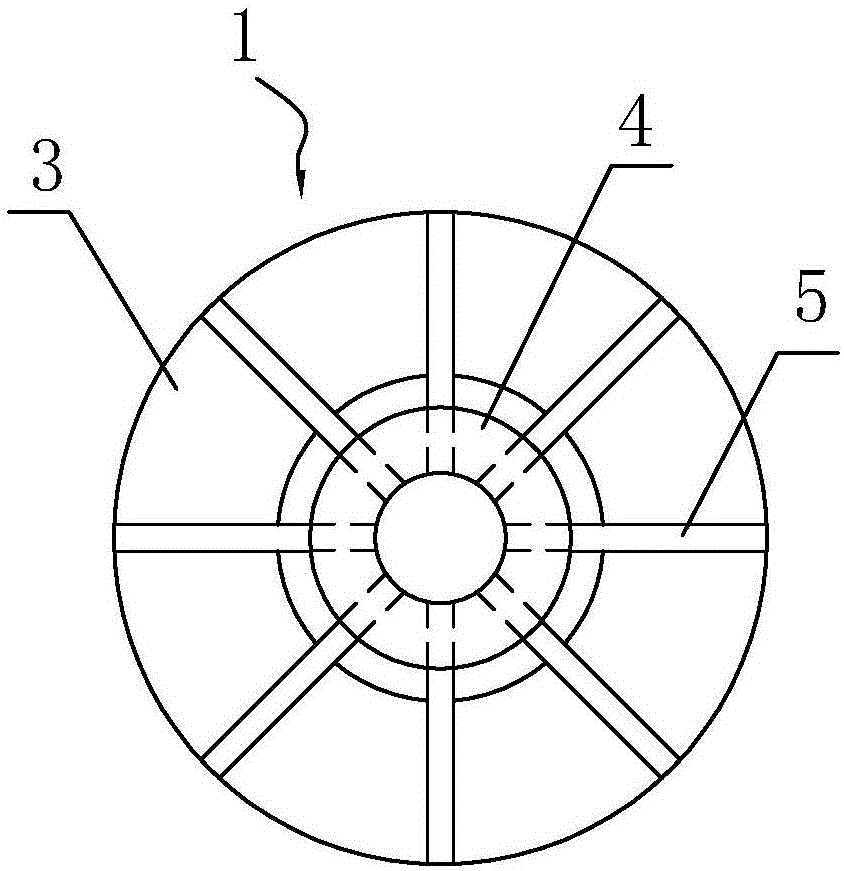

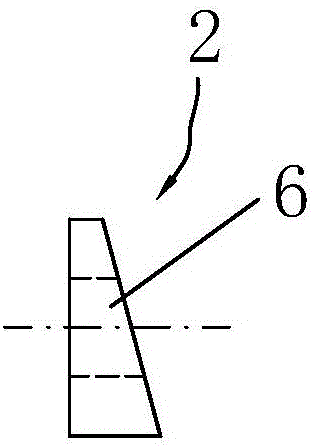

Double-truncated-cone type pile shoe

InactiveCN103485341AImprove crush resistanceImprove rigidityBulkheads/pilesStructural engineeringEngineering

The invention discloses a double-truncated-cone type pile shoe. The double-truncated-cone type pile shoe comprises a casing, reinforcing ribs arranged in the casing and a shoe cover connected with the upper end of the casing. The casing is composed of at least two inverted hollow truncated cones from top to bottom, wherein the upper truncated cone is provided with a coaxial central hole with the diameters tapering from top to bottom, and the lower truncated cone is in a bucket shape, the diameter of the mouth of the bucket is identical to the aperture of the small-diameter central hole of the upper truncated cone, and the mouth of the bucket is connected with the small-diameter central hole of the upper truncated cone; the end surface where the upper truncated cone and the lower truncated cone are connected is provided with a truncated cone shoulder which is provided with a plurality of ring grooves; a plurality of straight grooves are distributed on the circumferential surface along the radial direction from the center of the truncated cones; the bottom of the bucket of the lower truncated cone is provided with at least one ring groove; the circumferential surface of the upper end surface of the upper truncated cone, which is close to the edge of the upper truncated cone, is evenly provided with three holes for mounting chord members of a pile leg. The double-truncated-cone type pile shoe improves the compression-resisting capacity of the pile shoe and meanwhile has the advantages of lateral sliding resistance and ocean current scouring resistance.

Owner:JIANGSU UNIV OF SCI & TECH

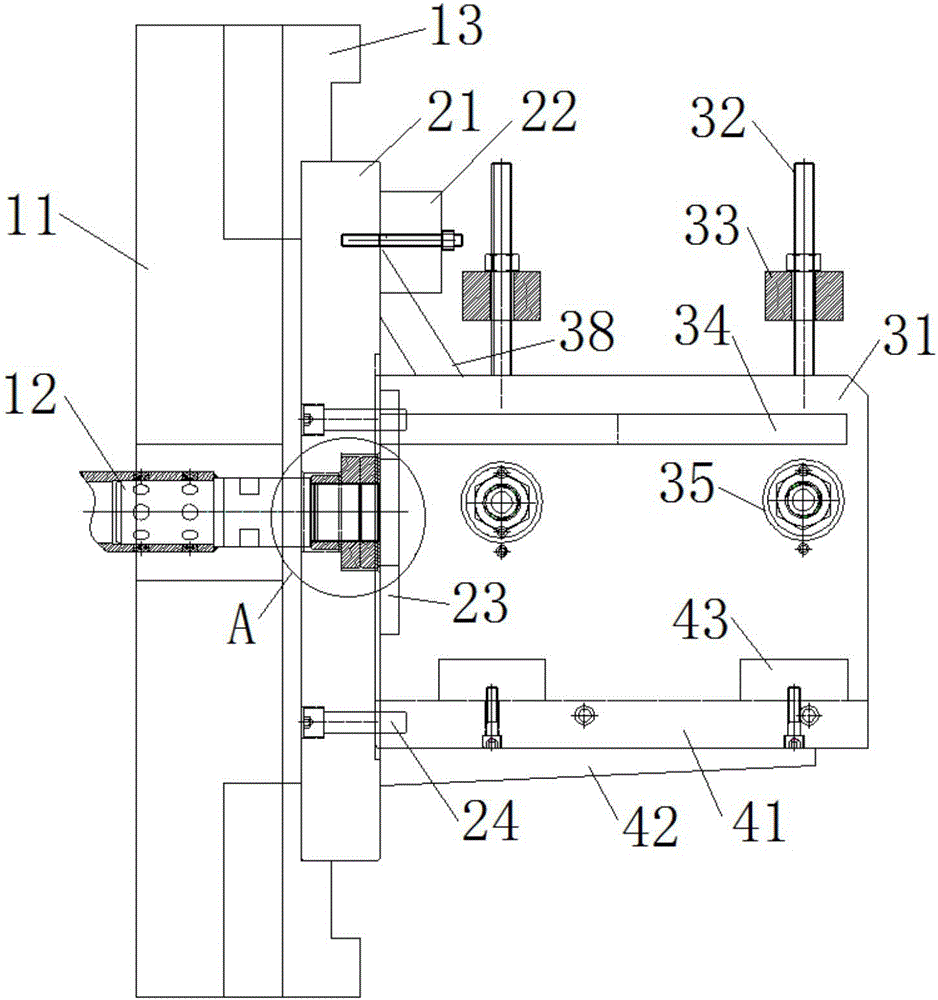

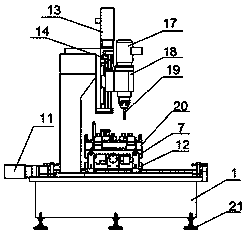

Method for processing piston inner cavity of middle cylinder

The invention discloses a method for processing a piston inner cavity of a middle cylinder and belongs to the field of quartering hammer processing. The method comprises the steps as follows: firstly, a piston hole and an oil inflow hole are drilled on a boring machine; then, a middle cylinder fixing mechanism is used for location and fixing to guarantee that the middle cylinder is attached to the datum plane; next, static balance debugging is performed for processing; the piston hole is processed firstly, a valve hole and a step surface hole are then processed, and the oil inflow hole and an oil outflow hole are processed with a special tool on a lathe tool shaft bar. The piston inner cavity of the middle cylinder is processed in cooperation with a high-strength cylinder fixing mechanism, the weight of the middle cylinder can be balanced, and the processing precision is high; by means of the processed oil holes, the performance of the middle cylinder can be further improve, and accordingly, the processing quality is greatly improved.

Owner:ANHUI ANTONG MACHINERY

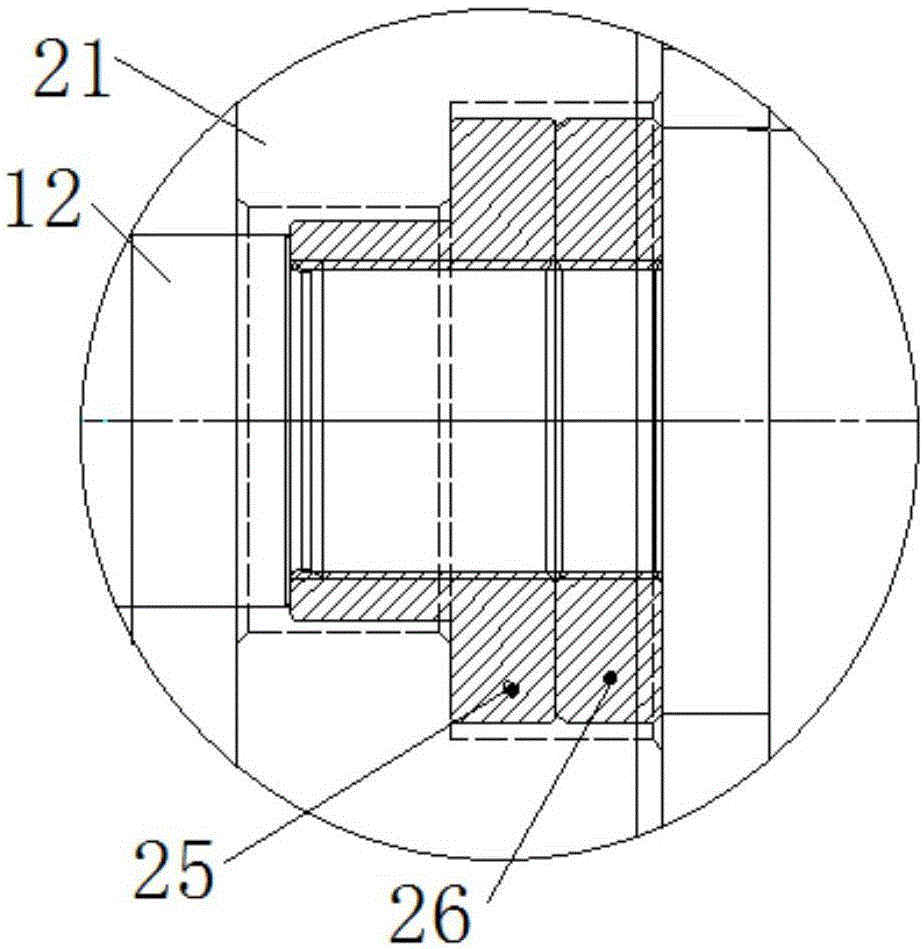

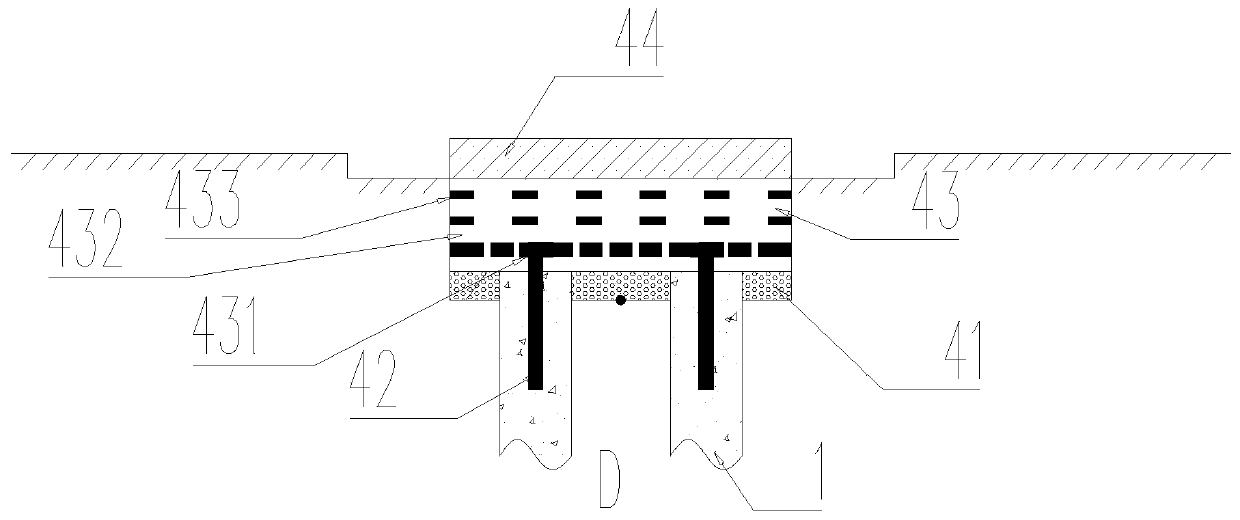

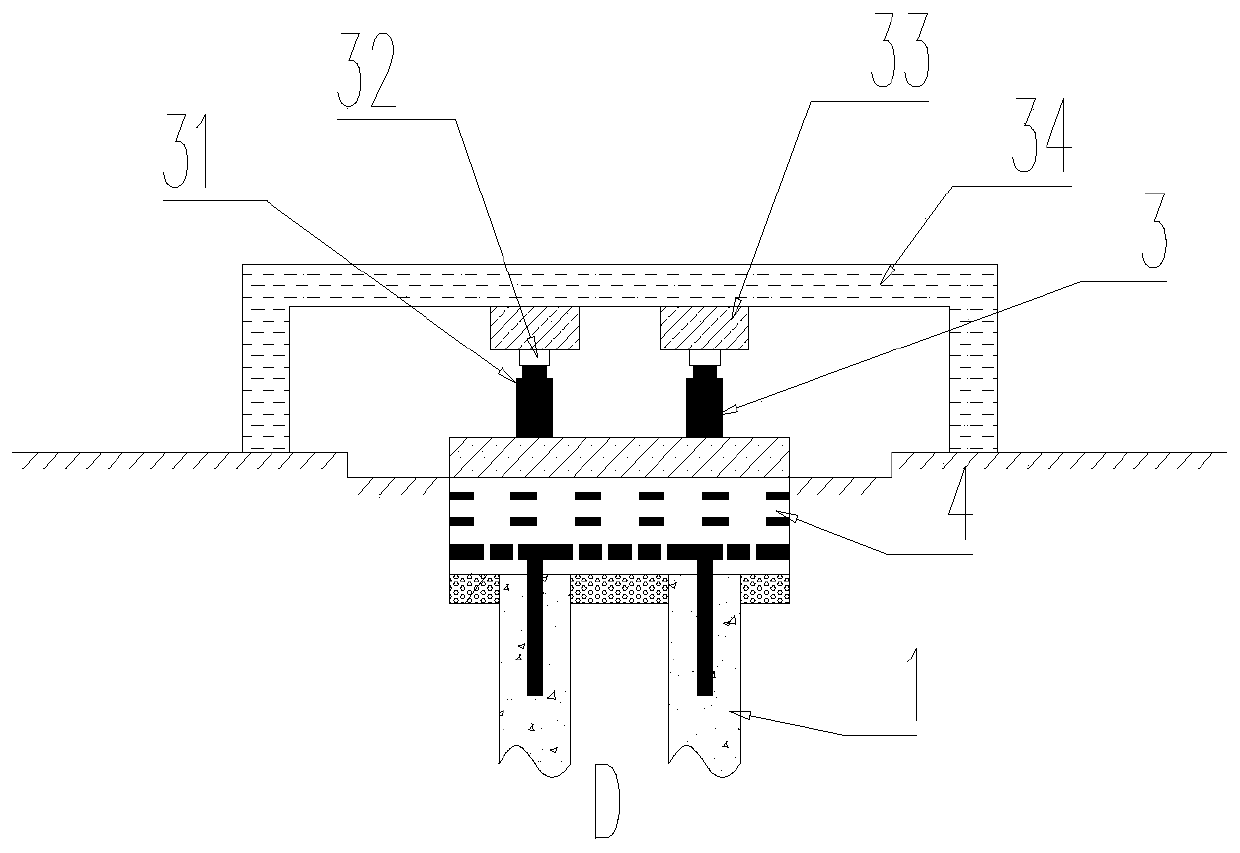

Existing cutting broadening roadbed structure in karst area and design and construction methods theref

The invention discloses an existing cutting broadening roadbed structure in a karst area. The structure comprises a basement karst cave area and a basement non-karst cave area. The basement karst cavearea is provided with long piles and short piles, the basement non-karst cave area is provided with short piles, the bottoms of the long piles are arranged in a stable stratum below the basement karst cave area, light replacement bodies are arranged on the tops of the long piles and the tops of the short piles and filled with soil fillers, and drainage ditches are formed in two sides of the lightreplacement bodies. The light soil material is low in density and high in pressure resistance, so that the additional stress for widening the roadbed is reduced; the light replacement body can improve the structural integrity, enables the load of an upper structure to be smoothly transmitted to the lower long pile and the lower short pile, so that the eccentric force is avoided; the load of an upper roadbed, a rail and a train is carried effectively, an equal-load replacement effect is realized, the additional stress acting on a karst cave top plate is reduced effectively, and deformation anddamage are avoided. On the basis of the structure, upward arching of an existing cutting caused by grouting can be avoided, and safe operation of a high-speed train is guaranteed; the structure is low in engineering cost, and engineering investment is effectively controlled.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

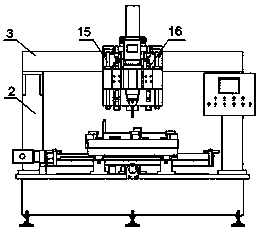

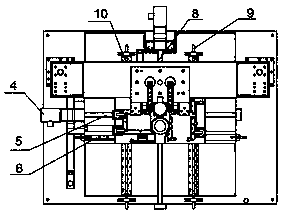

Gantry type three-shaft numerical control riveting machine

The invention discloses a gantry type three-shaft numerical control riveting machine. The machine comprises a machine base, the bottom of the machine base is supported by an adjusting cushion iron, astand column and a cross beam are fixedly arranged on the upper end face of the machine base, and the machine base, the stand column and the cross beam form a gantry type structure; a workbench is further installed on the machine base, the workbench is positioned on the lower side of the gantry type structure which is composed of the machine base, the stand column and the cross beam, an X-shaft servo motor is fixedly installed on the machine base, and a rotating shaft of the X-shaft servo motor is fixedly connected with a X-shaft screw rod; and the X-shaft screw rod is in transmission connection with an X-shaft sliding plate on a X-shaft linear line rail, a Y-shaft servo motor is fixedly installed on the X-shaft sliding plate, a Y-shaft screw rod is fixedly connected to an electric rotating shaft of the Y-shaft servo motor, and the Y-shaft screw rod is in transmission connection with a Y-shaft sliding plate located on the Y-shaft linear guide rail. According to the machine, the gantrytype three-shaft numerical control riveting machine has the advantages of being labor-saving, energy-saving, high in efficiency, high in stability and high in precision, and is worthy of popularization and application.

Owner:吕向华

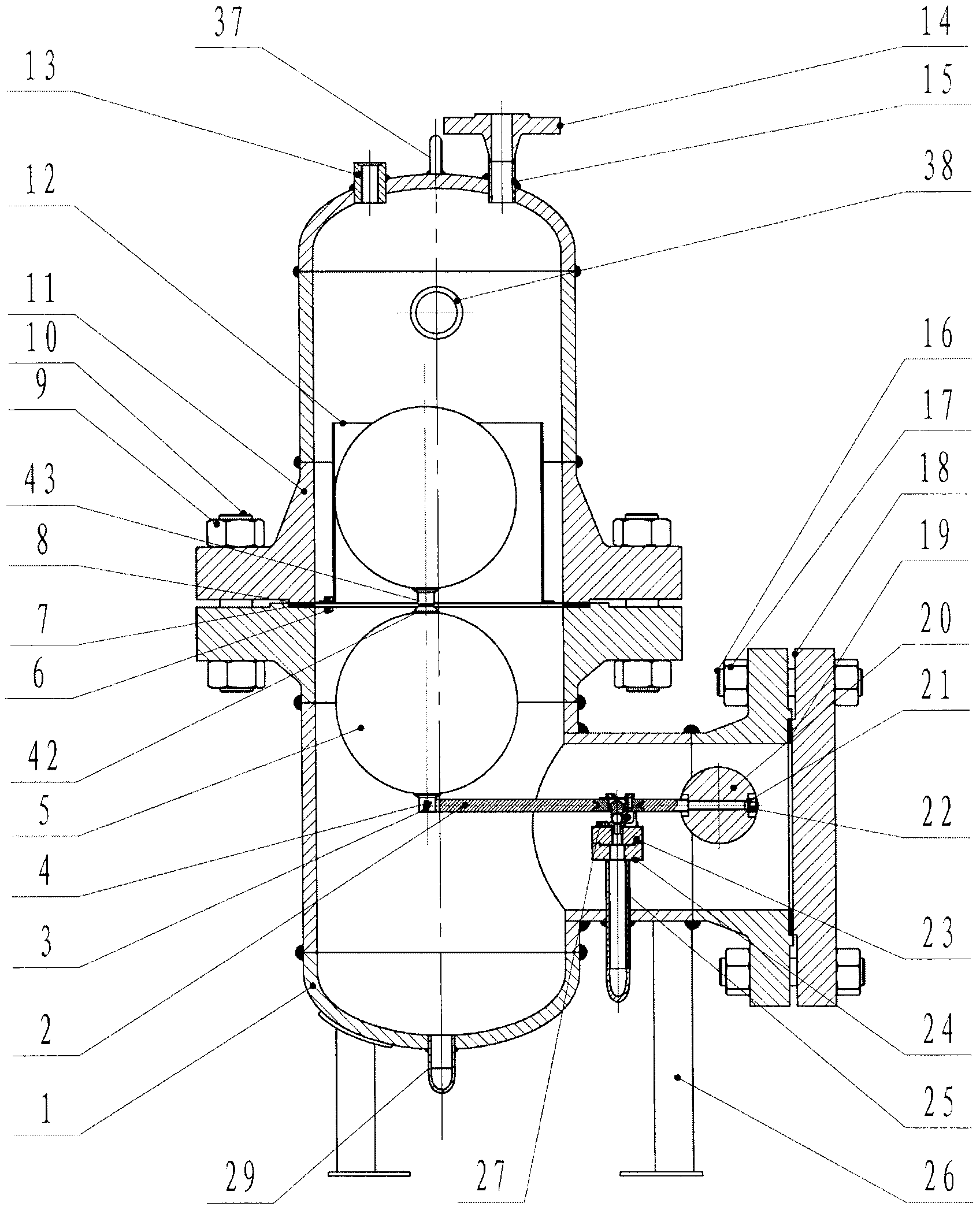

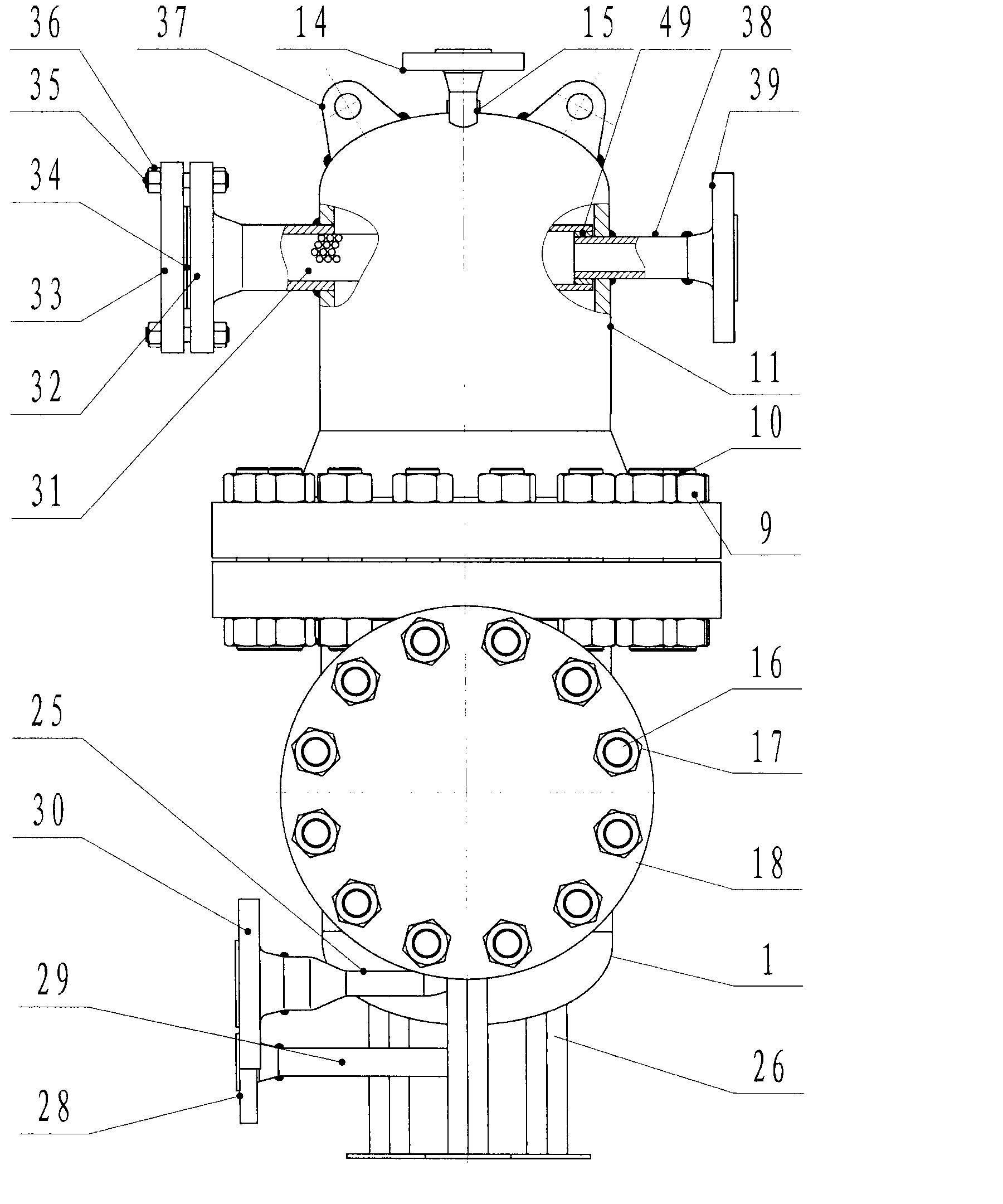

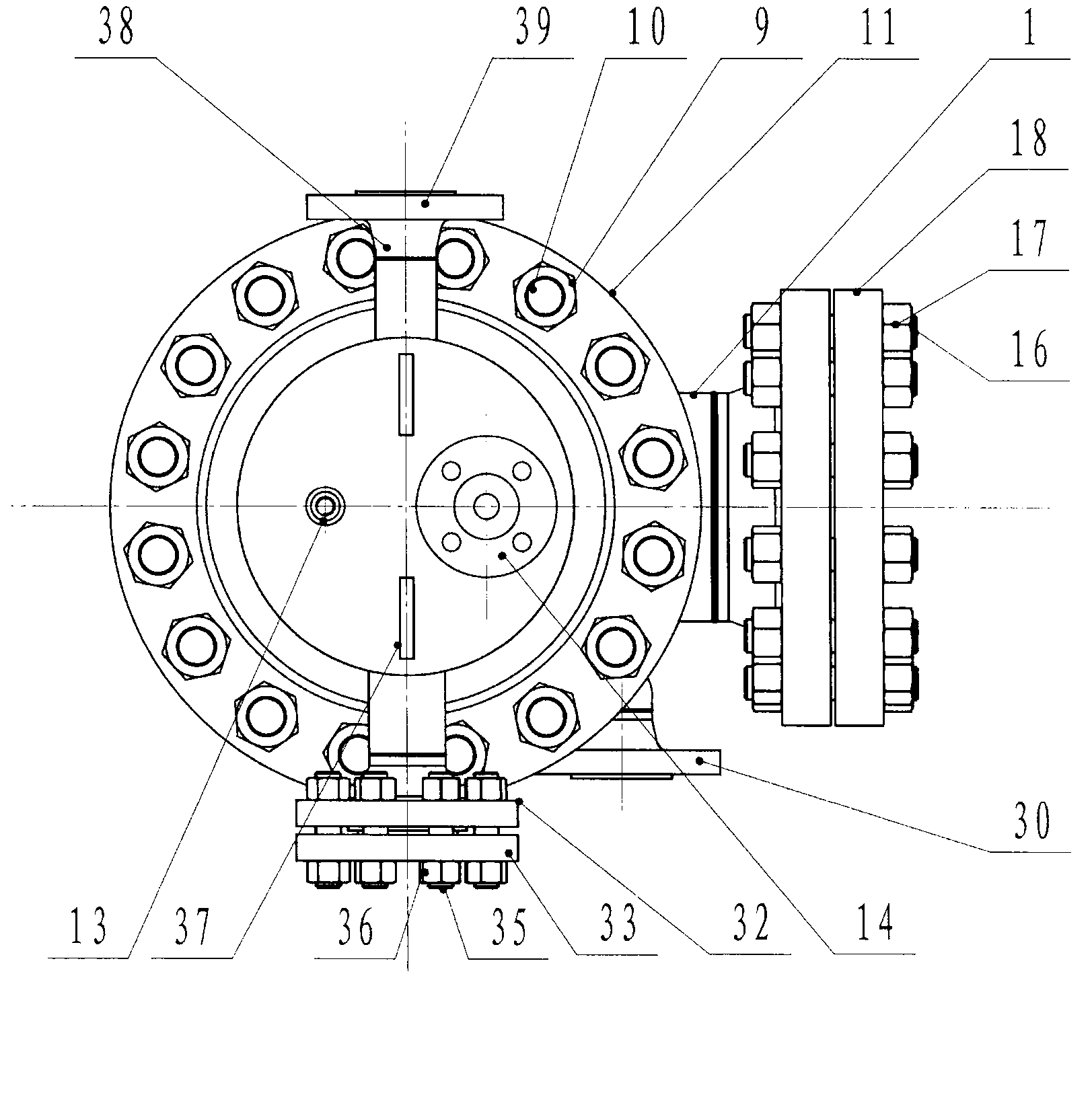

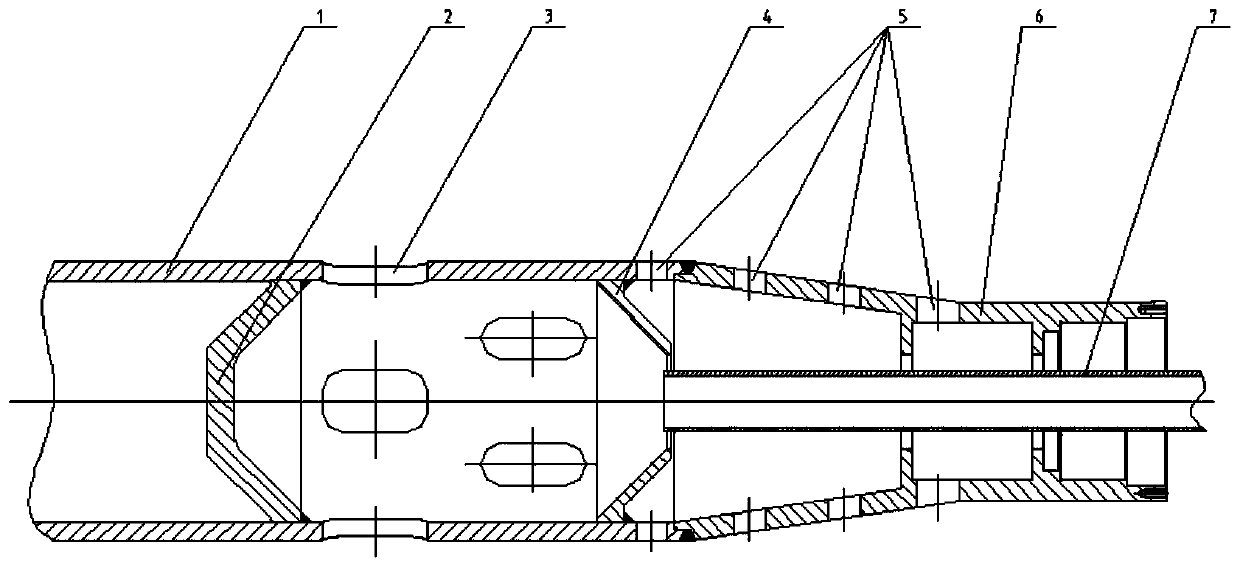

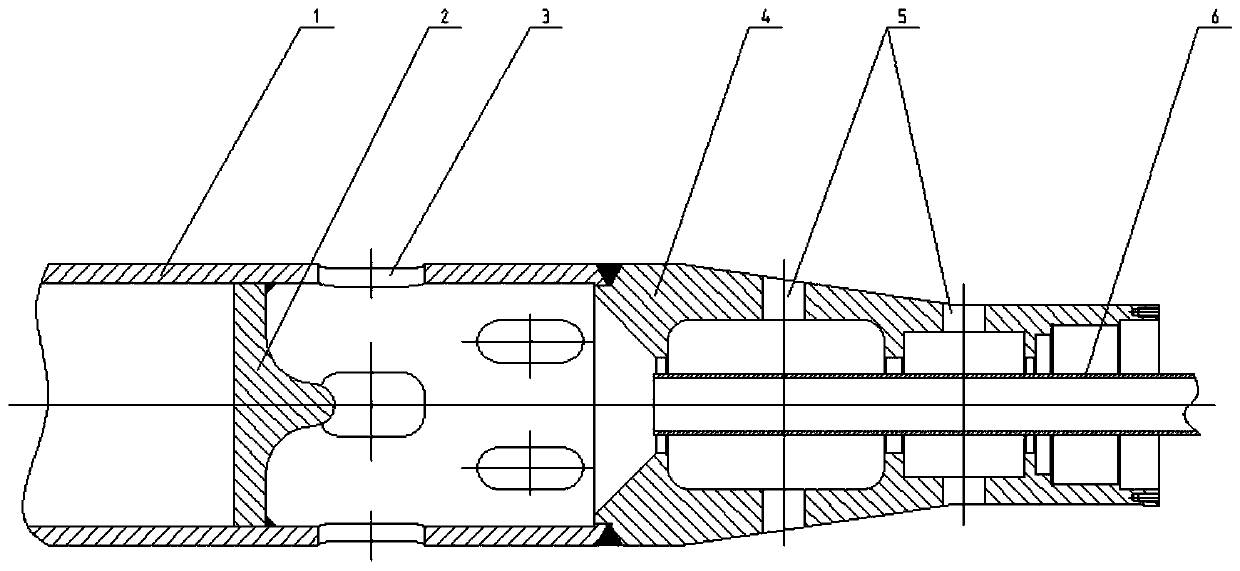

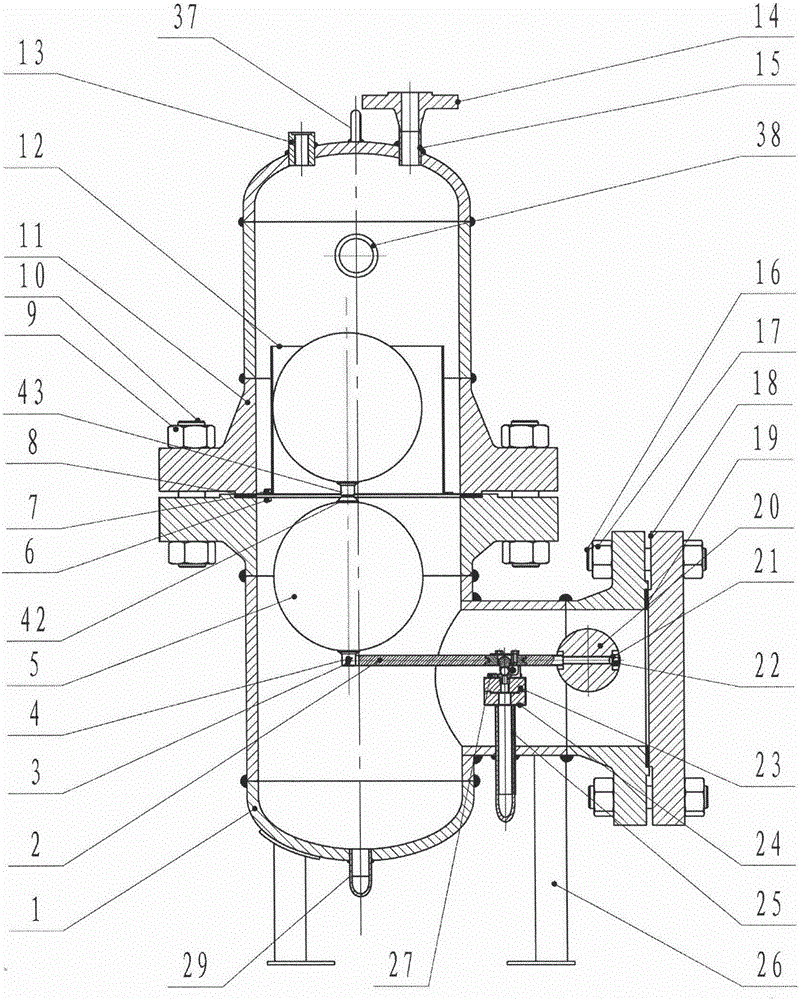

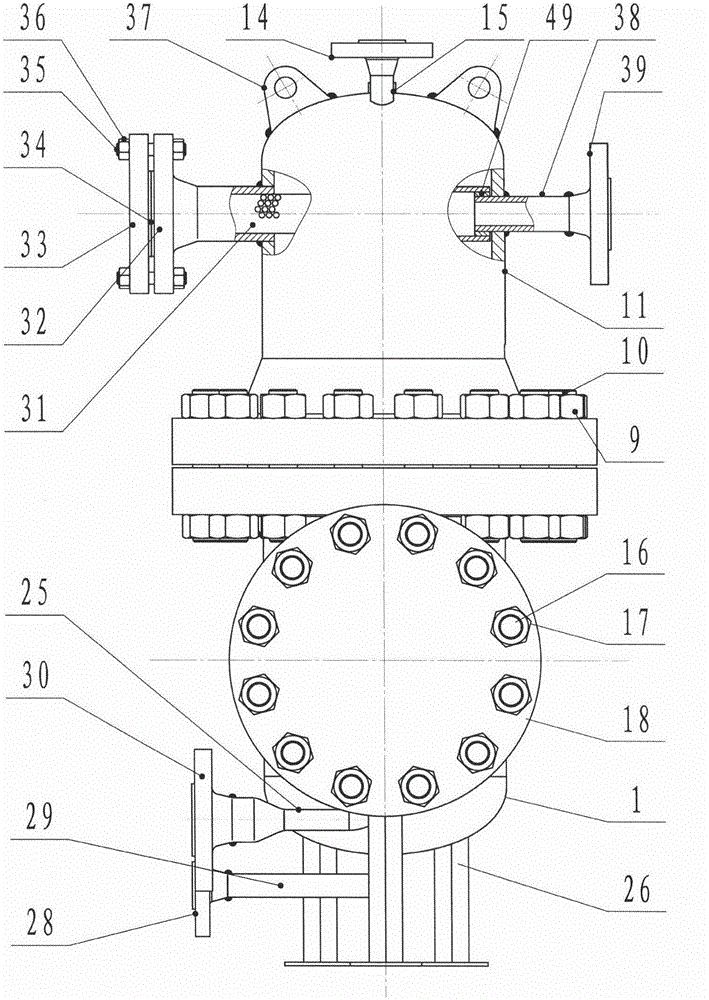

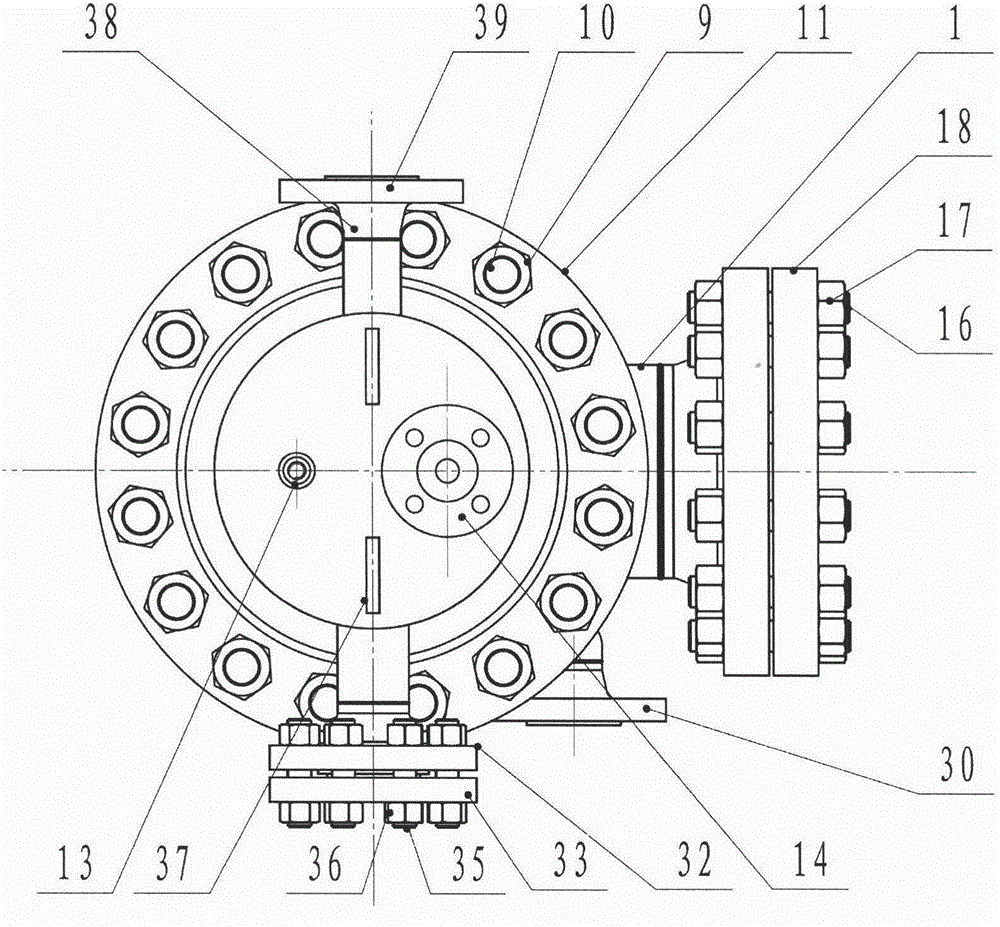

High-pressure single-guide natural gas trap

The invention relates to a high-pressure single-guide natural gas trap. The high-pressure single-guide natural gas trap is characterized in that an upper shell 11 is provided with a liquid diversion component 31 penetrating the upper middle of the upper shell, one end of the liquid diversion component 31 penetrates a flange fixing plate 32, a water inlet adapter tube 38 is welded at the other end of a welding connecting plate 33, a single-guide limit component 12 is connected to a fixable gasket 7, and a double-float link component 5 moves in a guide sleeve 46. One end of a long lever 50 is connected with a spool support 51, and the other end of the long lever 51 is connected with double floats 41. One end of a short lever 54 is connected with the spool support 51, and the other end of the short lever 54 is connected with a buoyancy increaser 20. A spool 55 is disposed in the spool support 51. A valve seat 58 is connected to a valve seat fixing plate 57 in a threaded manner. A connecting shaft 60 sequentially penetrates a fixing block I59-1, a connecting block I56-1, a connecting block II56-2 and a fixing block II59-2 to connect the spool support 51 and the valve seat fixing plate 57 together. A valve seat component connecting plate 24 is connected below the valve seat fixing plate 57. An outlet adapter tube 25 is welded at the lower end of a middle hole of the valve seat component connecting plate 24 and penetrates a split cavity wall. The high-pressure single-guide natural gas trap is small in size and low in cost and meets the technical requirement for no leakage.

Owner:GANSU HONGFENG MASCH CO LTD

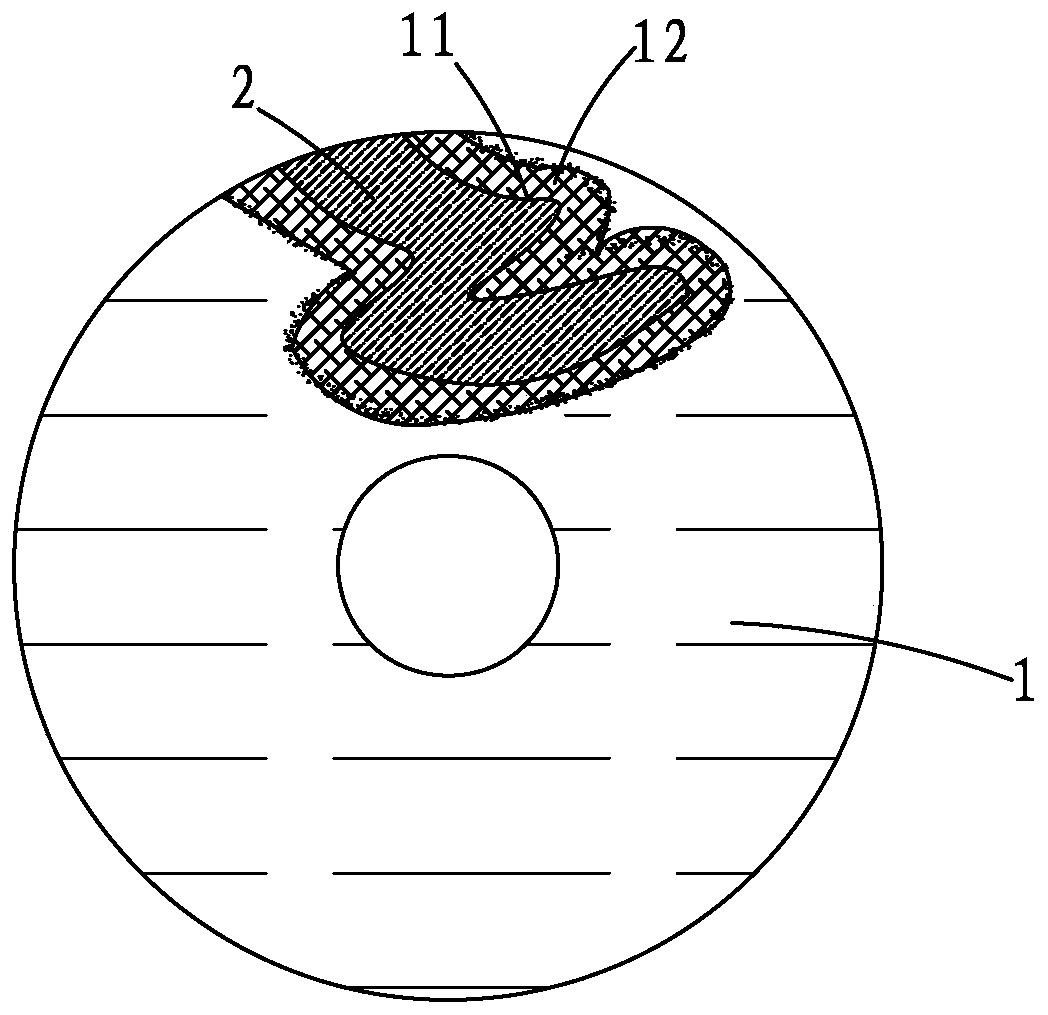

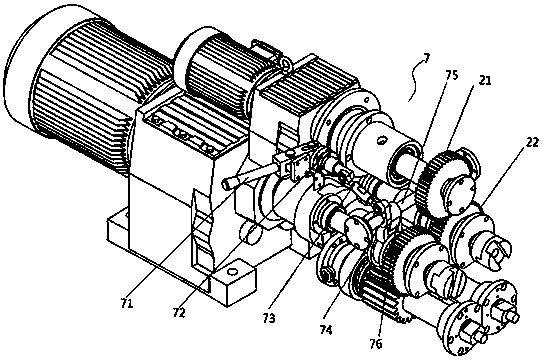

Mandrel structure of spiral pusher of horizontal decanter centrifuge

PendingCN111420811AReduce in quantityReduce reverse flowRotary centrifugesEngineeringMaterial distribution

The invention discloses a mandrel structure of a spiral pusher of a horizontal decanter centrifuge. The mandrel structure is composed of a cylindrical spiral body, a conical spiral body and a partition plate, the spiral pusher is divided into a large end and a small end according to the size of the outer diameter of the spiral pusher, a feeding pipe enters a material distribution bin from the small end of the spiral pusher, the material distribution bin is an inner cavity formed by the conical spiral body, the cylindrical spiral body and the partition plate of the spiral pusher, the conical spiral body, the cylindrical spiral body and the partition plate are sequentially connected in the feeding direction of materials, the partition plate is arranged in the circumferential direction of theinner wall of the cylindrical spiral body, the partition plate is provided with a protrusion capable of rebounding materials and preventing the materials from reversely flowing into the conical spiral body in direction facing the feeding pipe, a first outlet which communicates with the material distribution bin is formed in circumference of the cylindrical spiral body, and the large end of conical spiral body adopts a conical surface structure. According to the mandrel structure of the spiral pusher of the horizontal decanter centrifuge, the rigidity of a spiral mandrel is improved, the reverse flow of the materials is reduced, a small amount of the reverse flow materials can be discharged in time, the operation load and the vibration intensity of the centrifuge are reduced, and the service life of the centrifuge is prolonged.

Owner:CSSC NANJING LUZHOU MACHINE

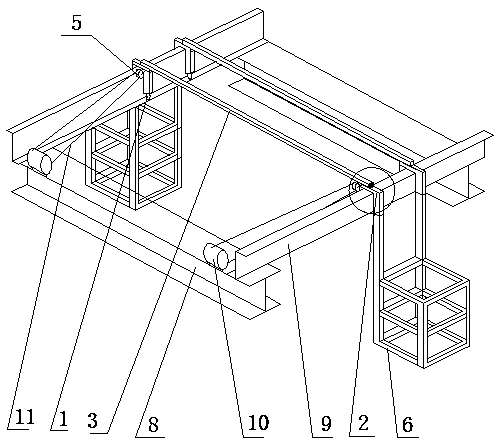

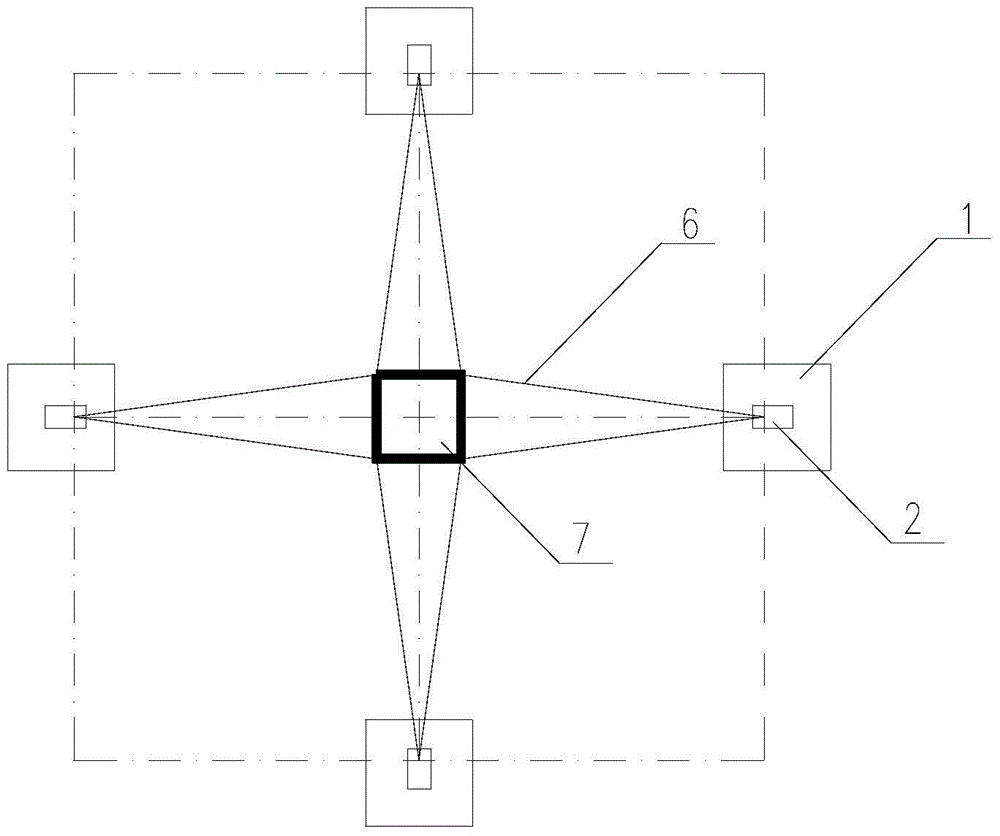

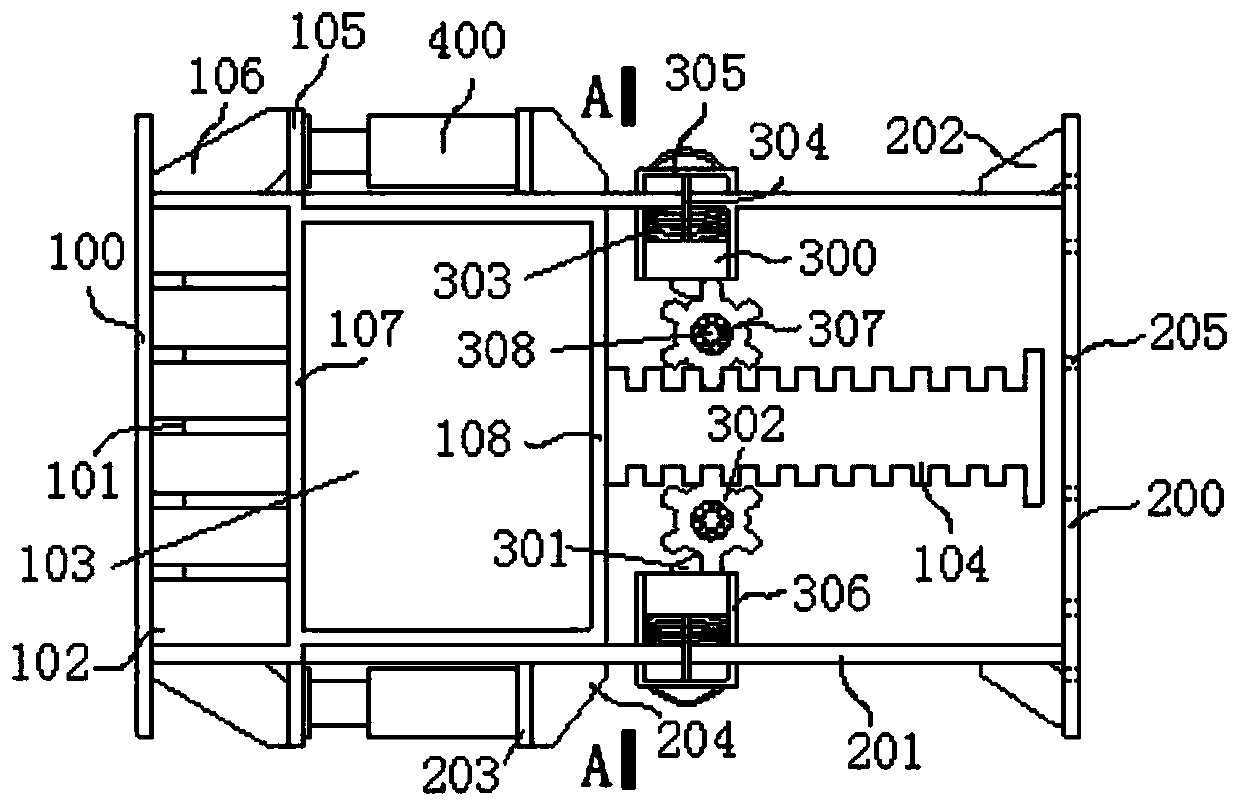

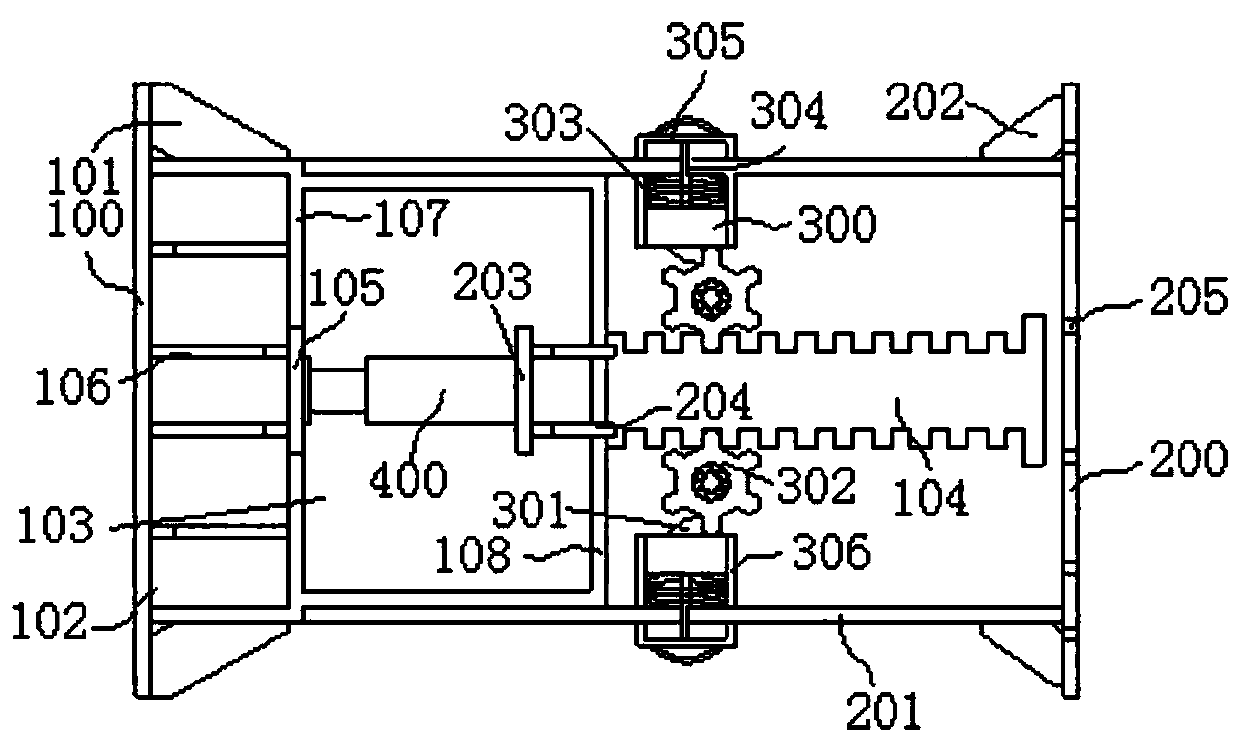

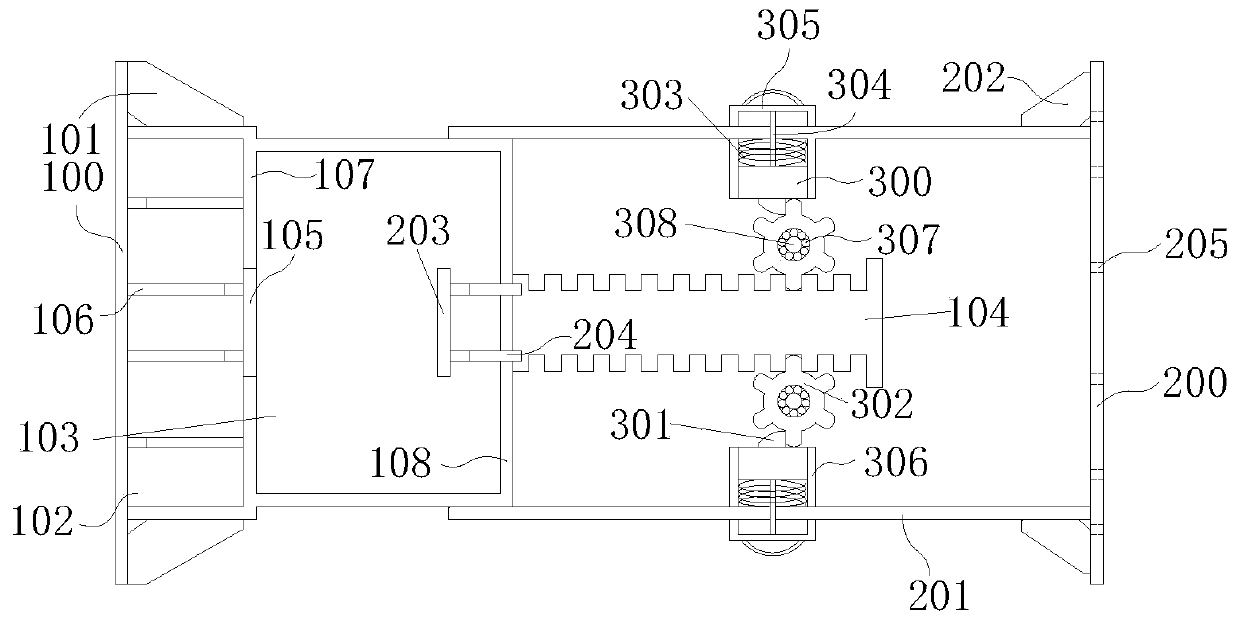

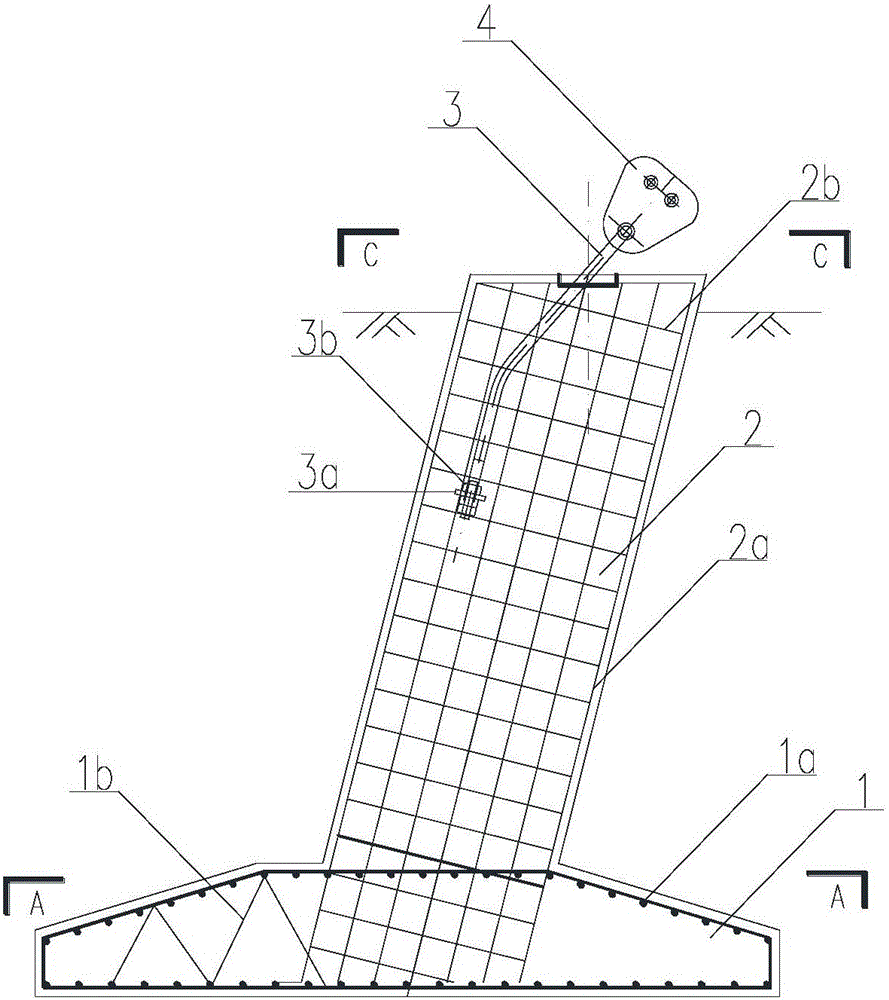

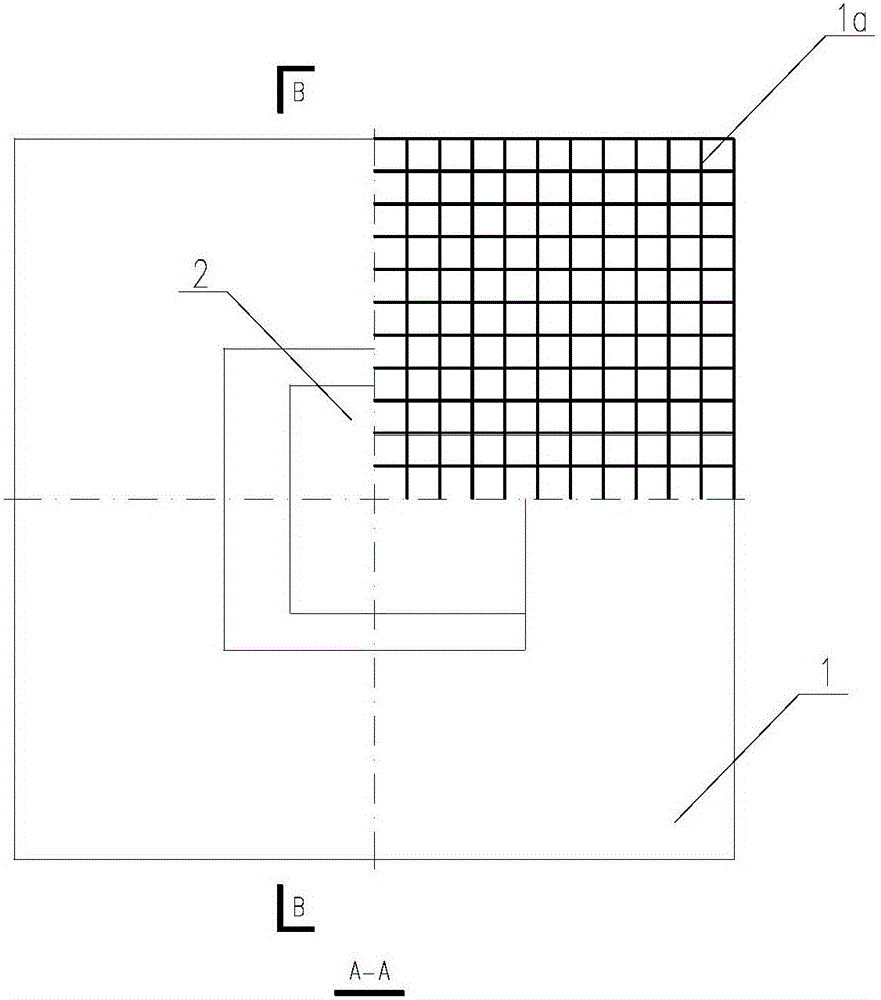

Color plate reverse ceiling upper-air sliding device and reverse ceiling construction method

PendingCN108190808ASave spaceOptimize the construction processLifting devicesBuilding material handlingEngineeringProtection KIT

The invention provides a color plate reverse ceiling upper-air sliding device and a reverse ceiling construction method. As for a traditional roof color plate inner plate, mounting work procedures arecomplex, needed environment factors are many, and consumption in the aspects of manpower, funds and machines is over large. The color plate reverse ceiling upper-air sliding device comprises two hanging baskets (6), the hanging baskets are connected with idler wheels (1) through U-shaped connecting devices (2), and the two hanging baskets are connected together through the U-shaped connecting devices, bolts (4) and connecting square steel (3). The outer ends of the U-shaped connecting devices are provided with protecting sleeves, the side edges of the U-shaped connecting devices are providedwith fixed pulley sets A (5), and the U-shaped connecting devices are placed on Z-shaped purlines (9). The two ends of the Z-shaped purlines are welded to I-shaped steel (8). The invention discloses the color plate reverse ceiling sliding device and a using method.

Owner:黑龙江省建筑安装集团有限公司

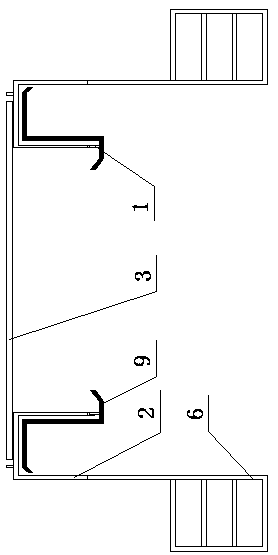

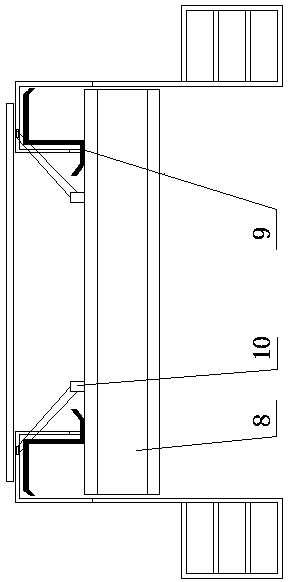

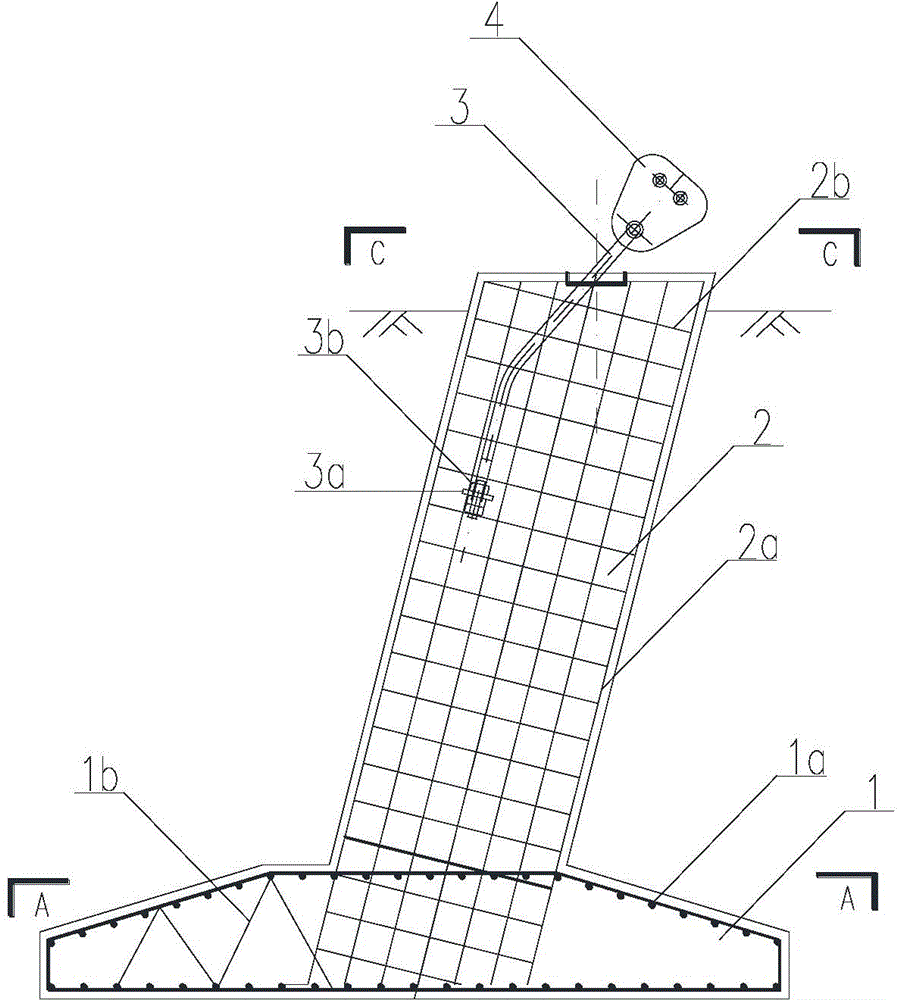

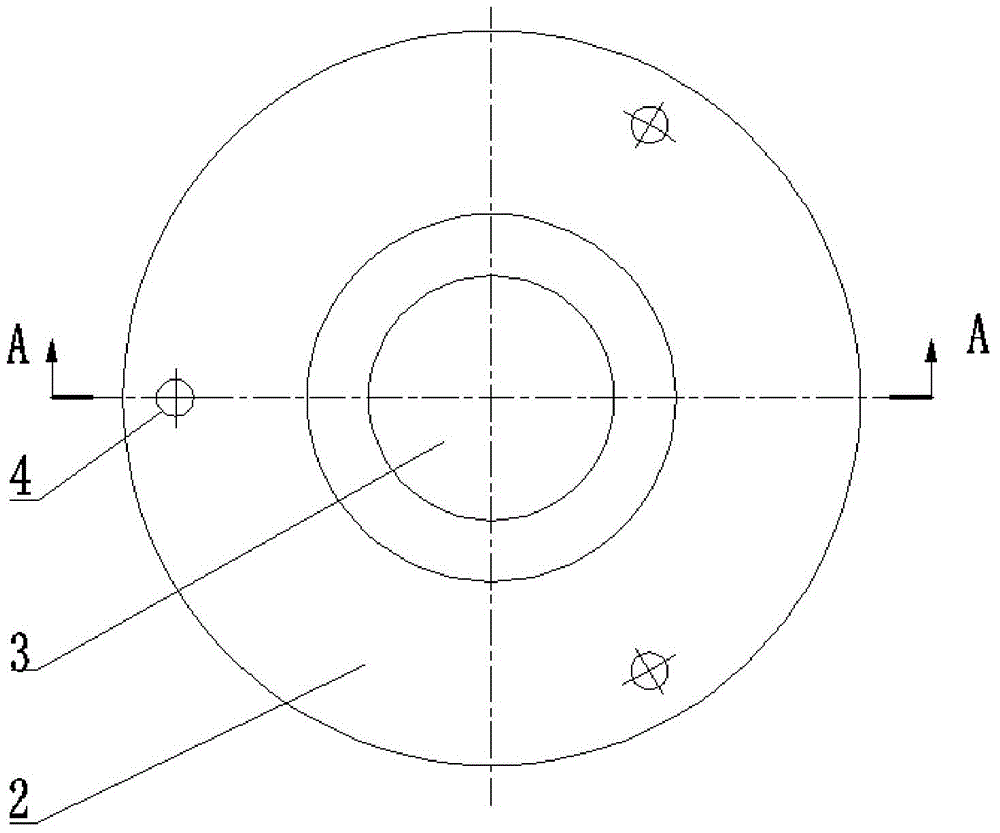

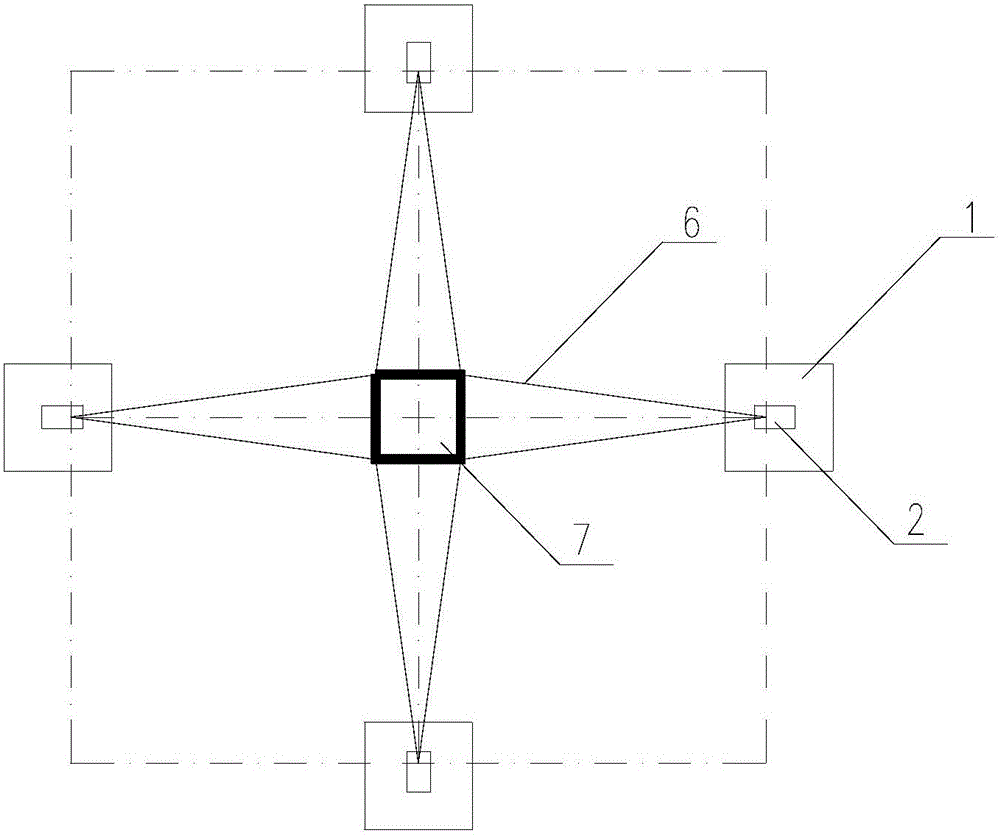

Basic structure for extra-high-voltage single-column guyed tower V-shaped stayguys

ActiveCN104358272AEasy downward force transferAvoid eccentric forceFoundation engineeringPolygonal lineEngineering

The invention discloses a basic structure for extra-high-voltage single-column guyed tower V-shaped stayguys. The basic structure comprises stayguys, a tower column connected by the stayguys, and a plurality of basic structure main bodies, wherein each basic structure main body comprises a base plate, an inclined main column fixed on the top surface of the base plate, a U-shaped stayguy rod of which one end is embedded into the inclined main column and the other end is exposed out of the top surface of the inclined main column, and a triangular connecting plate fixed on the exposed end of the U-shaped stayguy rod, the stayguys are fixed on the triangular connecting plate, two stayguys are arranged between each basic structure main body and the tower column in a V shape, the U-shaped stayguy rod is bent in the inclined main column, a bending line of the lower section is parallel to a geometric center line of the inclined main column, and a bending line of the upper section is parallel to a plane on which the two stayguys on the basic structure main body are positioned. The basic structure can be preferably matched with a V-shaped stayguy arrangement structure, the bearing requirement of an extra-high-voltage guyed tower can be satisfied, the quantity of foundations is reduced, the form is simple, and the basic structure is easy to realize.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

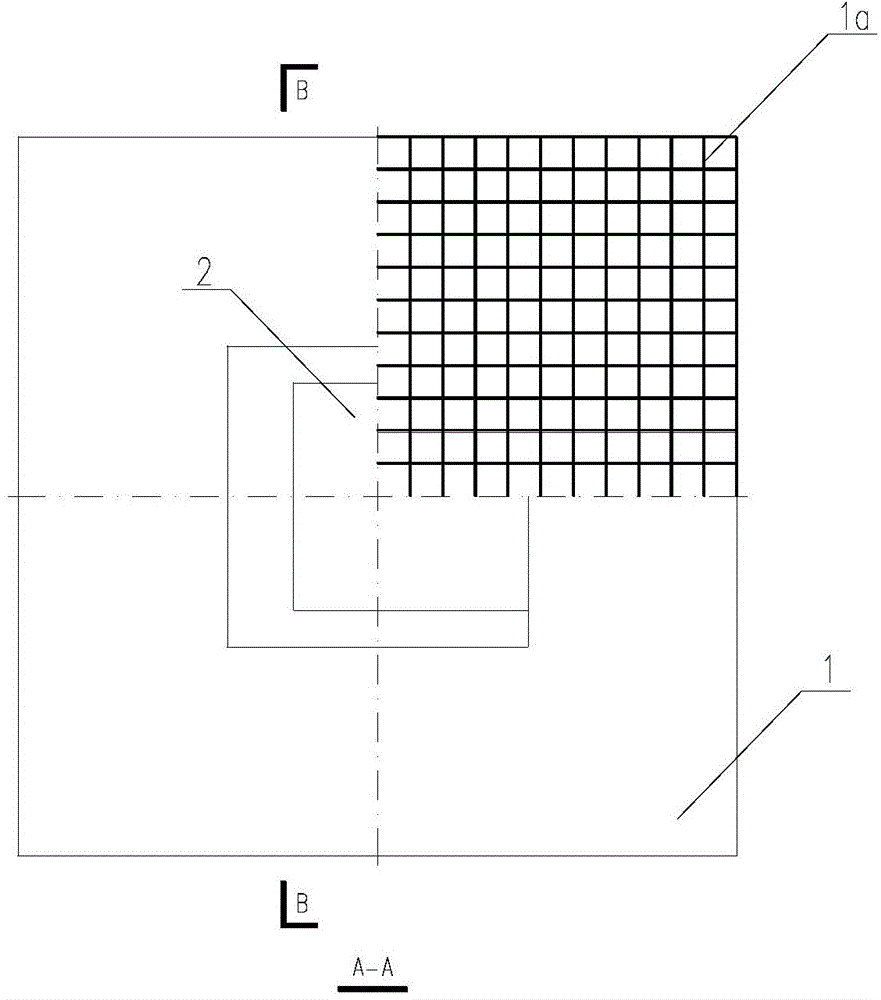

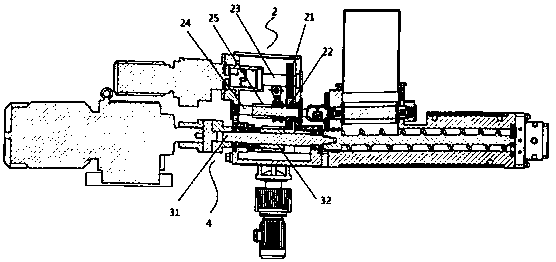

Punching bar and die for secondary preformation of inner hexagonal cylinder head and forming method

InactiveCN108480543AAvoid eccentric forceExtended service lifeBoltsForging/hammering/pressing machinesEngineeringCylinder head

The invention discloses a punching bar for secondary preformation of an inner hexagonal cylinder head. A circular truncated cone-shaped protrusion part is arranged in the middle of the head of the punching bar, and an inverted circular truncated cone is arranged at the top of the protrusion part. The invention further discloses a die for secondary preformation of the inner hexagonal cylinder headand a forming method of the inner hexagonal cylinder head. The punching bar for secondary preformation is structurally modified, so that when the inner hexagonal punching bar makes contact with a workpiece, positioning is accurate, center deviation is avoided, the situation that the inner hexagonal punching bar is broken due to eccentric force generated by the punching bar is avoided, and thus, the service life of the inner hexagonal punching bar is prolonged; and the die cost is reduced, the operation and replacement time is shortened, and the production efficiency is improved.

Owner:LENGSHUIJIANG TIANBAO IND

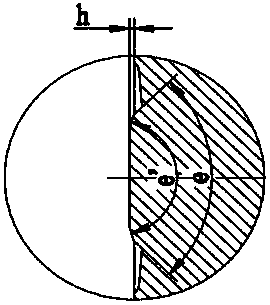

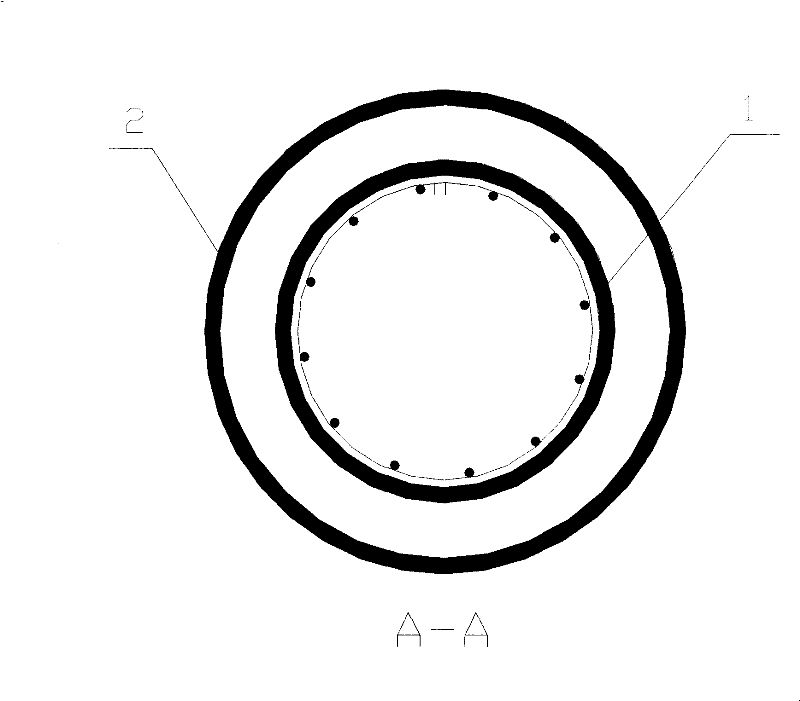

Double sleeve for pile foundation test and construction technique thereof

The invention discloses a double sleeve for a pile foundation test. The double sleeve comprises an inner sleeve and an outer sleeve, wherein the inner sleeve is concentrically sleeved in a pipe cavity of the outer sleeve; the inner sleeve and the outer sleeve are made of glassfiber reinforced plastic mortar pipes; a plurality of sealing limit grooves are arranged on the surface of the outer wall of the inner sleeve along the axial direction; an O-shaped rubber ring is embedded in the sealing limit grooves; a clearance between the periphery of the O-shaped rubber ring and the inner wall of theouter sleeve is between 2 and 4 mm. The invention also discloses a method for constructing the double sleeve for the pile foundation test, which applies carbon fiber restoration reinforcing technology to carrying out multi-connector integral butting joint adhesion on a pipe section of a glassfiber reinforced plastic mortar double pipe on the ground. The double sleeve has the advantages of light weight, high strength, smooth surface, small frictional resistance between the pipe wall and a soil body, simple construction, safe operation, short construction period and the like, can significantly improve the reliability and accuracy of a result of the pile foundation test, and is applicable to pile foundation bearing tests of various foundation ditches.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Asphalt mortar forming, measuring device and test method for dynamic shear parameters of asphalt mortar

ActiveCN105300758BWon't hurtEnsure accuracy andPreparing sample for investigationMaterial strength using steady shearing forcesMeasurement deviceMaterials science

The invention relates to an asphalt mortar forming and measuring device and a test method for the dynamic shear parameter of the asphalt mortar, belonging to the field of testing the dynamic shear parameter of the asphalt mortar. Asphalt mortar specimens produced by existing molding methods are easily damaged, and the existing measuring devices and methods for asphalt mortar specimens cannot meet the requirements of high temperature performance testing. Asphalt mortar forming device, one end of the test mold (3) is oppositely provided with a guide rod (1), and the other end is matched with the base (4) for insertion. Asphalt mortar dynamic shear parameter testing device, a detachable fixture (9) and a fixture loading body (20) arranged opposite to each other are respectively installed in cooperation with a connection base (16). Asphalt mortar dynamic shear parameter testing method, preparing asphalt mortar specimen (19), performing inertia moment correction, zeroing, and geometric correction operations on the uninstalled specimen connection base (16), starting the DHR-II rheometer environment box for testing. The invention has the advantages of simple operation and accurate test results.

Owner:HARBIN INST OF TECH

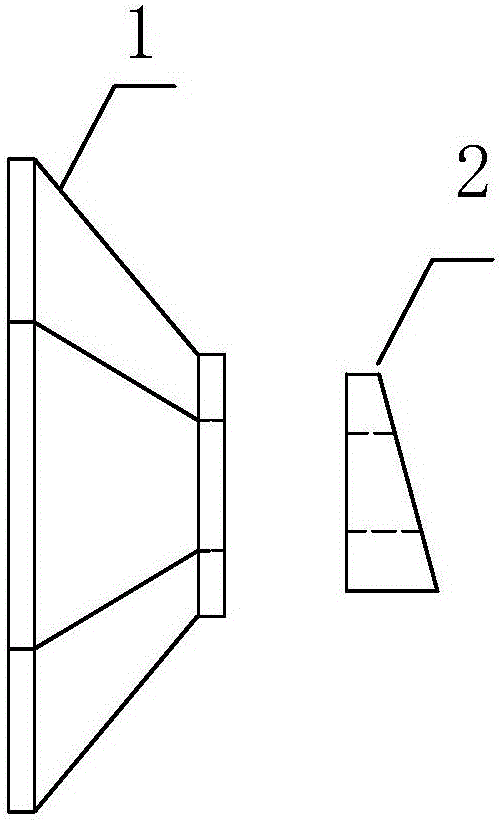

Prestressed carbon fiber-reinforced plastic plate anchorage device and manufacturing method thereof

The invention discloses a prestressed carbon fiber-reinforced plastic plate anchorage device and a manufacturing method thereof. The device comprises an upper steel plate and a lower steel plate and the upper and lower steel plates are used for clamping a plate. The manufacturing method comprises that multiple wedge-shaped grooves are arranged between the upper and lower steel plates, the surfaces of the wedge-shaped grooves are uniformly coated with a release agent, the grooves are filled with epoxy resin, the upper and lower steel plates are fastened through anchor bolts, the plate is slowly inserted into one end of the two steel plates from the other end along the surface groove, and after the epoxy resin is completely cured, the plate is anchored to a concrete member to be reinforced through anchor bolts. The prestressed carbon fiber-reinforced plastic plate anchorage device is prepared through the above method. The anchorage device has a simple design, reasonable force transmission, good reliability and good stability. The anchorage device has high efficiency anchoring performances. The plate does not slide or the anchorage device inner plate is not damaged even if the carbon fiber plate can be stretched until cracking.

Owner:HARBIN INST OF TECH

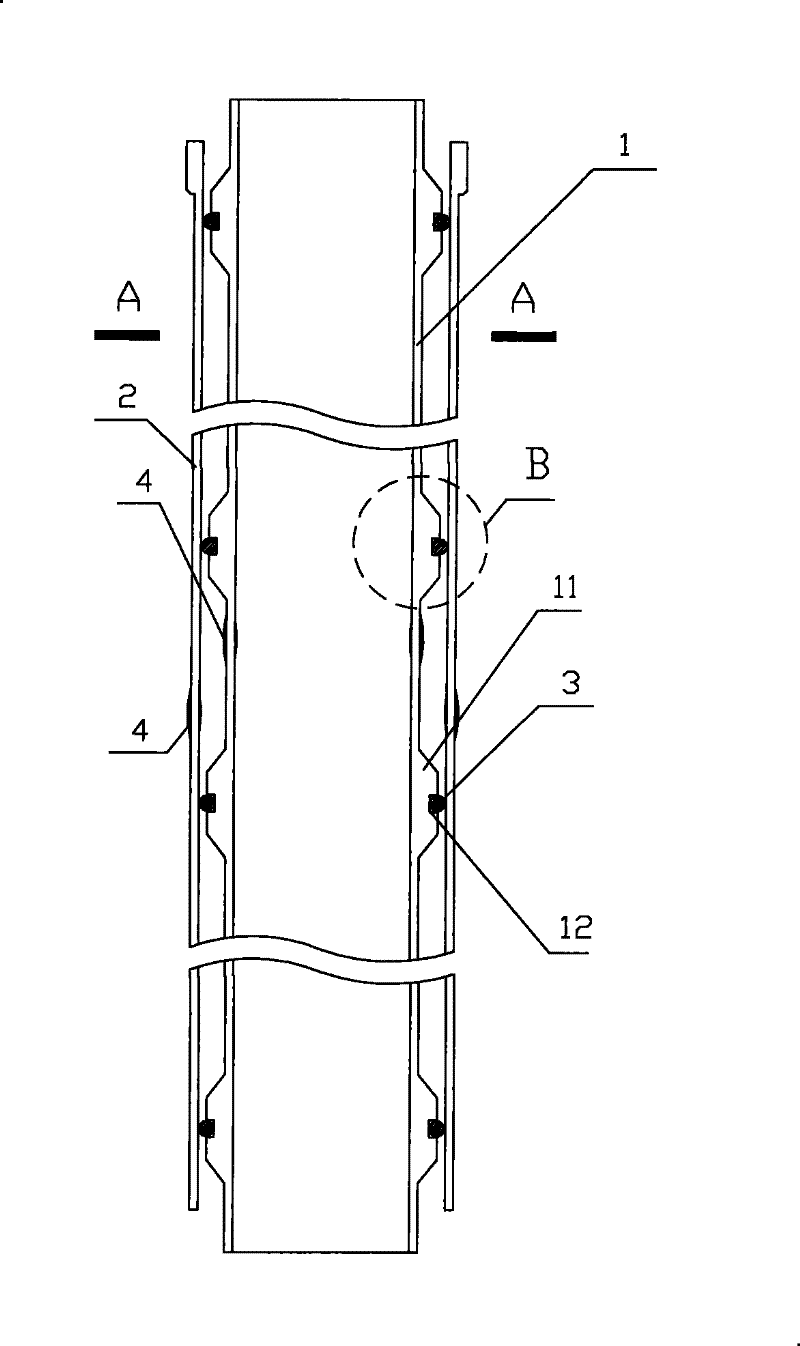

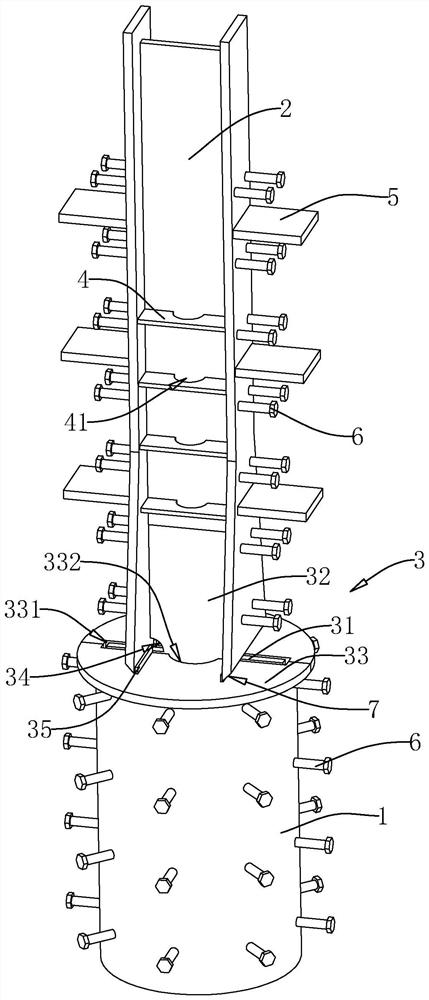

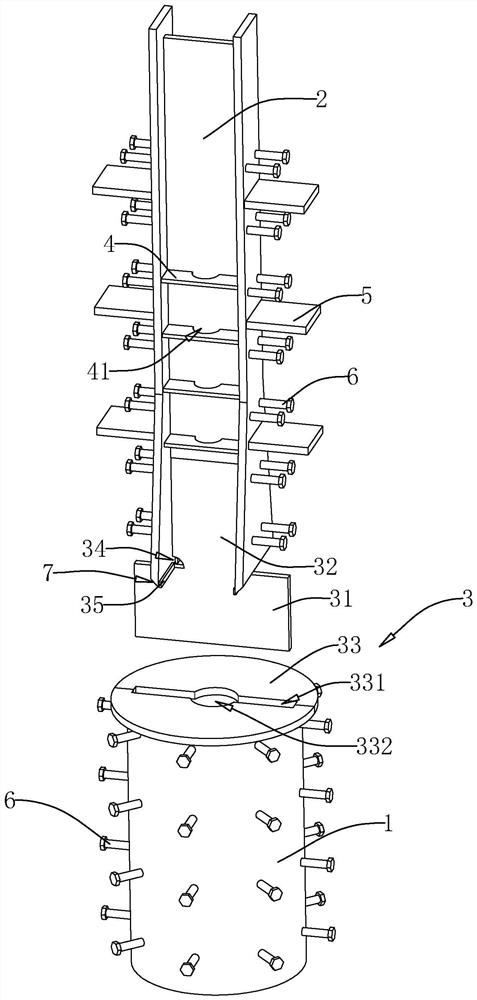

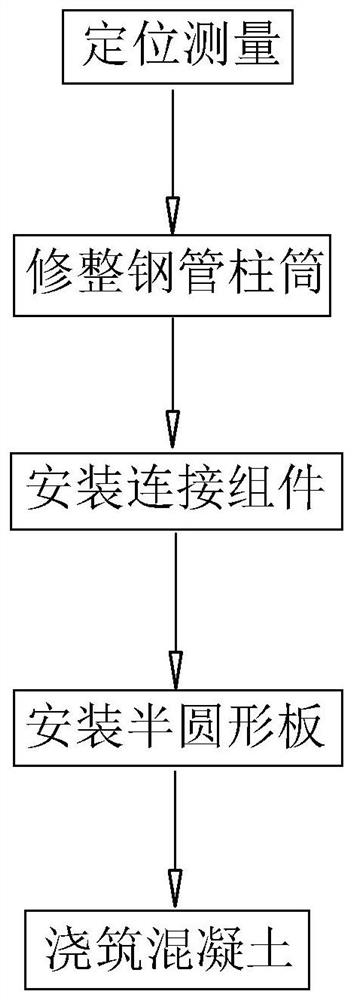

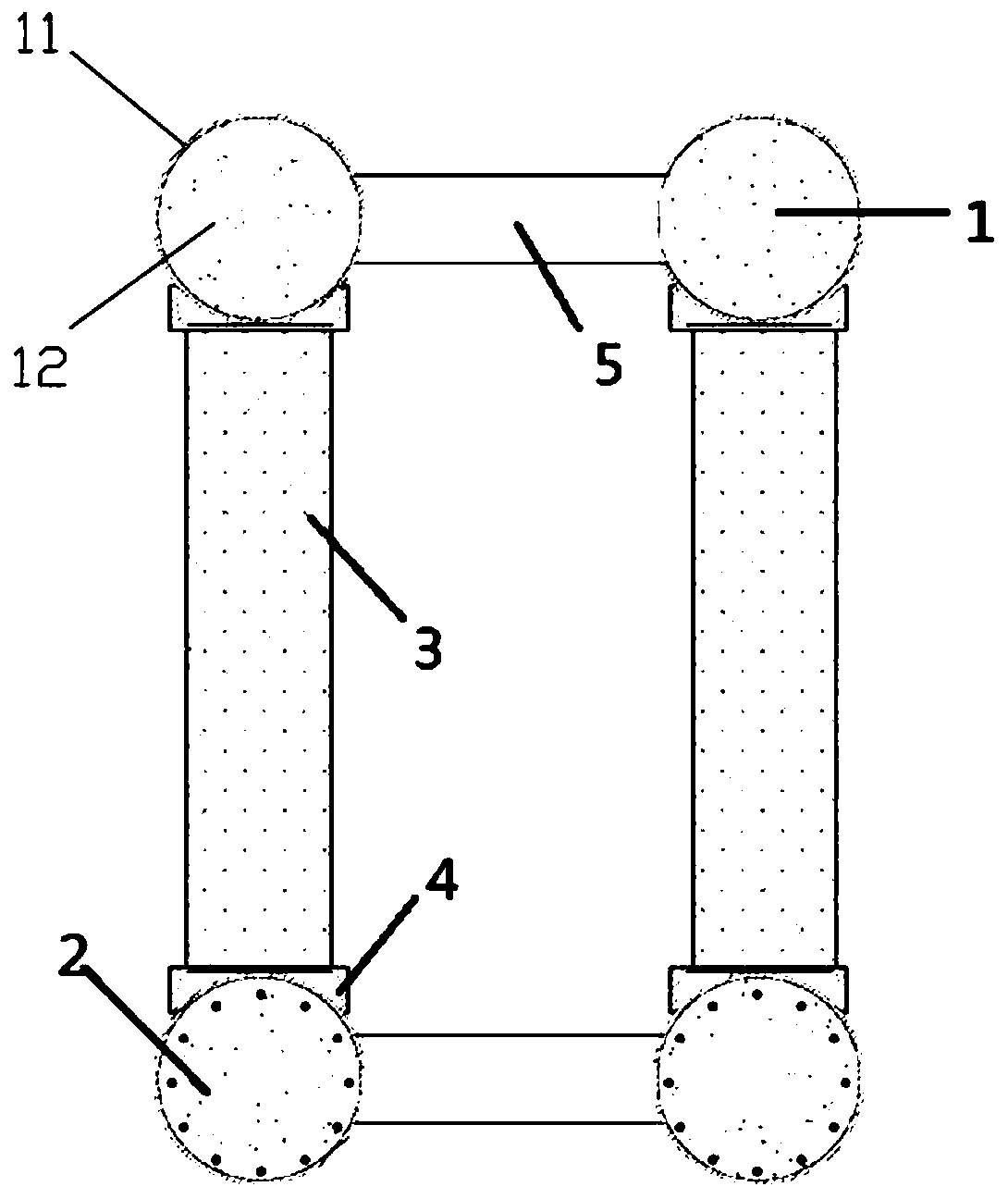

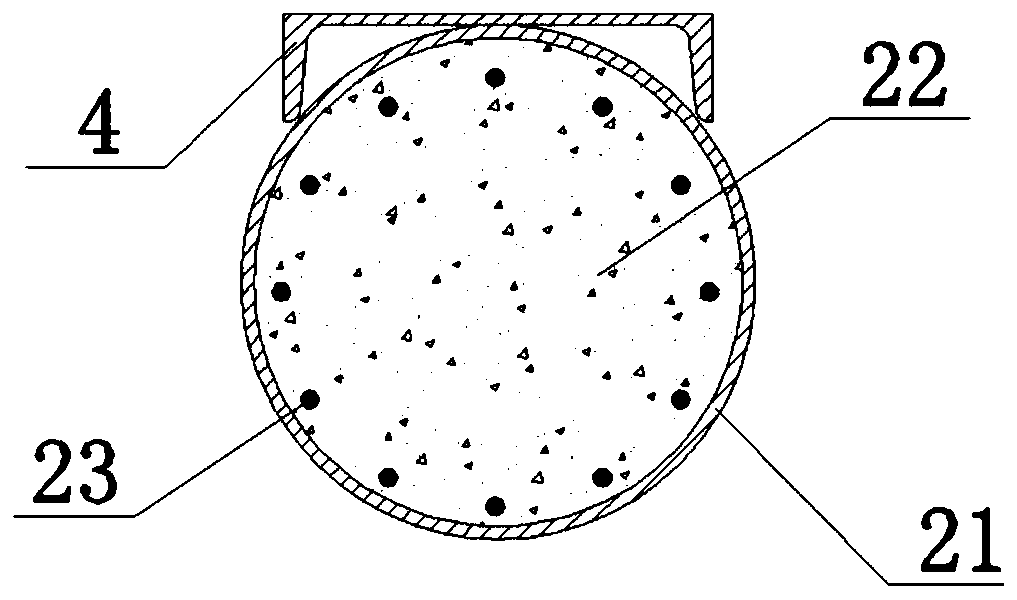

One-pile-one-column connecting structure adopting reverse building method and construction method of one-pile-one-column connecting structure

ActiveCN114134898AAvoid eccentric forceIncrease the welding areaStrutsExcavationsPipeUltimate tensile strength

The invention relates to the field of building construction, in particular to a reverse construction method one-pile one-column connecting structure which comprises a steel pipe column casing and a steel rib column arranged at the upper end of the steel pipe column casing, a connecting assembly is arranged between the steel pipe column casing and the steel rib column, and the connecting assembly comprises a first connecting plate fixed in the steel pipe column casing and a second connecting plate fixed on the steel rib column. The invention discloses a construction method for one-pile-one-column connection through a reverse building method. The construction method comprises the steps that S1, coordinates of a constructed steel pipe column casing are measured; s2, a post-cast strip space of at least 300 centimeters is reserved in the steel pipe column casing; s3, the steel reinforced column is hoisted, the first connecting plate is inserted into the steel pipe column cylinder, then the position of the steel pipe column is rechecked on site and is checked with the position of the drawing, and the position of the steel reinforced column is properly adjusted according to the deviation condition; s4, the two semicircular plates are installed at a cylinder opening of the steel pipe column cylinder; and S5, concrete is poured into the post-cast strip space reserved in the steel pipe column casing. The connecting structure has the effect of improving the structural strength of the one-pile-one-column connecting joint.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

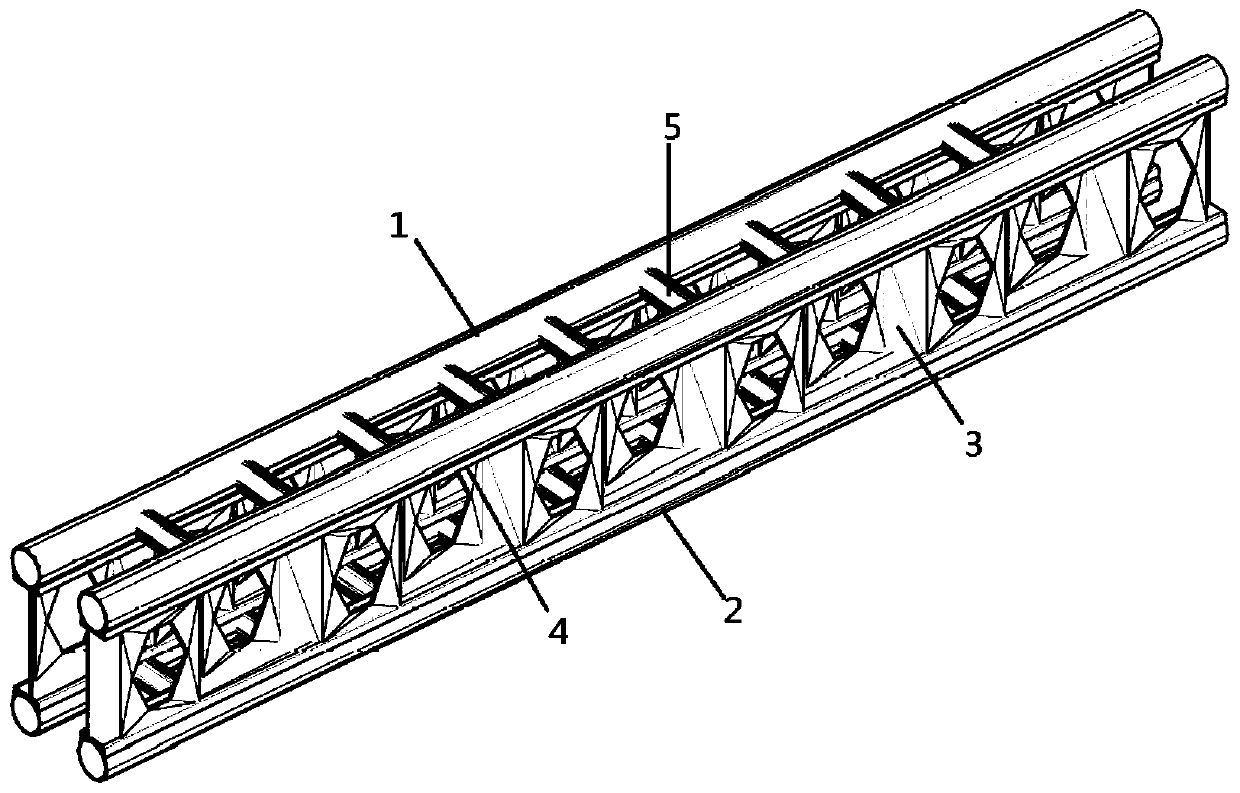

Girdle truss, manufacturing method of girdle truss and super high-rise building giant frame

PendingCN111188408AImprove bearing capacityIncrease stiffnessLoad-supporting elementsPre stressArchitectural engineering

The invention relates a girdle truss, a manufacturing method of the girdle truss and a super high-rise building giant frame. The girdle truss comprises an upper chord, a lower chord and a corrugated steel web, wherein the upper chord adopts a steel tube concrete-filled upper chord, the lower chord adopts a prestressed steel tube concrete-filled core rod, and the upper end and the lower end of thecorrugated steel web are in rigid connection with the upper chord and the lower chord respectively to form the girdle truss; and a plurality of honeycomb through holes are formed in the corrugated steel web at equal intervals. According to the girdle truss, the manufacturing method of the girdle truss and the super high-rise building giant frame, the steel tube concrete-filled upper chord is usedas an upper chord member of the girdle truss, so that the compression bearing capacity and rigidity of the upper chord of the girdle truss are enhanced; the prestressed steel tube concrete-filled corerod is used as a lower chord member of the girdle truss, so that the tensile bearing capacity and rigidity of the lower chord of the girdle truss are improved; the corrugated steel web with the honeycomb through holes are adopted to replace a girdle truss diagonal web member, so that the shear bearing capacity is improved, daylighting performance and permeability of the girdle truss are improved,and girdle truss construction is simplified. The girdle truss is excellent in stress performance and has a good application prospect.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

Direction-adjustable ratchet wheel type self-locking movable joint

The invention discloses a direction-adjustable ratchet wheel type self-locking movable joint which comprises a movable end, a fixed end and a direction-adjustable ratchet wheel mechanism. The movableend mainly comprises a movable end flange, a movable end rib plate, a movable end steel pipe, a movable end embedded steel pipe, movable end wing plates and a rack. The movable end rib plate is arranged between the movable end flange and the movable end steel pipe, and the movable end wing plates are symmetrically arranged on the two sides of the movable end steel pipe. One side of the fixed end steel pipe is provided with an opening, the movable end embedded steel pipe is embedded in the side, and the other side is coaxially connected with the fixed end flange. Fixed end wing plates are symmetrically arranged on the two sides of the opening end of the fixed end steel pipe and correspond to the movable end wing plates. The ratchet wheel is engaged with the rack, and movement of the rack can drive the ratchet wheel to rotate. A direction-adjusting handle is arranged outside the fixed end steel pipe, and a connecting rod penetrates through the fixed end steel pipe and a spring in the fixed end steel pipe to connect the ratchet and the direction-adjusting handle. The movable joint is simple and convenient in structure, free of redundant accessories, capable of being self-locked, convenient to erect and disassemble and capable of bearing pressure and tension at the same time.

Owner:BEIJING UNIV OF TECH

Tubular pile joint slurry leakage repairing method

The invention provides a tubular pile joint slurry leakage repairing method. Resin and an initiator are adopted to prepare a repairing agent; the slurry leakage joint of the tubular pile is filled with the repairing agent, a slurry leakage gap is repaired, the advantages of the resin that is in liquid state, is good in permeability, has no granular impurities and the like are utilized, the repairing agent can quickly permeate into the slurry leakage gap of the tubular pile, and meanwhile, the initiator in the repairing agent plays a role in accelerating resin solidification, so that the repairing agent can be quickly solidified, pile sinking can be performed after 24 hours after repairing, the slurry leakage gap is effectively filled, and eccentric stress and pile explosion during pile sinking are avoided.

Owner:FUJIAN JIANHUA CONSTR MATERIALS CO LTD

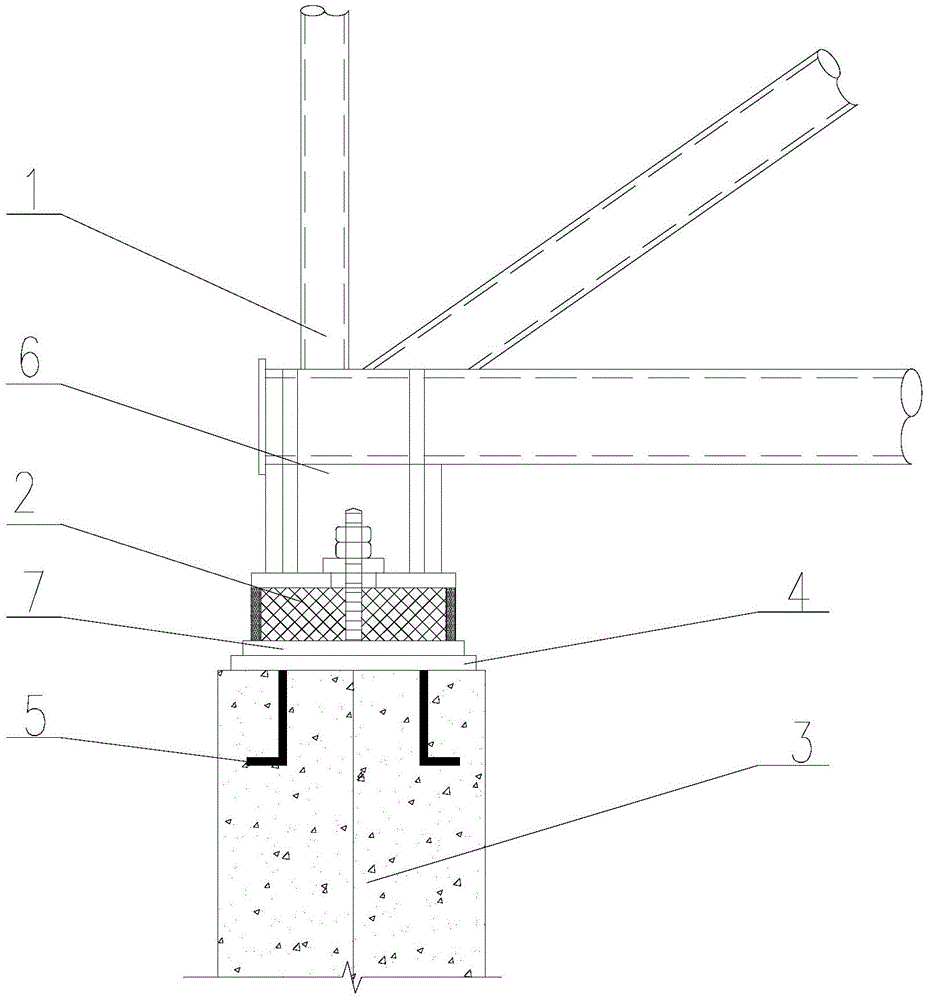

Steel pipe truss hinged joint device

ActiveCN103774752BSatisfy the requirements for hinged jointsImprove bearing capacityBuilding constructionsSteel barFriction force

The invention discloses a steel pipe truss hinging node device, which is mainly formed by a steep pipe truss, a rubber heel block, an embedded part and a concrete fixing device; the embedded part comprises a horizontal steel plate and steel bars vertically fixedly welded with the horizontal steel plate; the steel bars are arranged in the concrete fixing device; a support and a support transition plate which are integrally molded with the steel pipe truss are arranged at the lower end of the steel pipe truss; the rubber heel block is arranged between the support and the support transition plate by an anchor bolt; the support transition plate is fixed at the upper end of the horizontal steel plate in a welding mode. The steel truss hinging node device has the advantages that right angle hooks are arranged at the lower ends of the steel bars, thus greatly enhancing the friction between the embedded part and the concrete fixing device; the support arranged at the lower end of the steep pipe truss is welded with the steel pipe truss, so stressed centers of all steep pipes of the truss cannot be converged at one point, the existence of eccentric force at a node is avoided, the bearing force and rigidity of the hinging node are effectively improved, and the demands of the building field on the steel pipe truss hinging node are met.

Owner:SHANDONG HANGXIAO STEEL STRUCTURE CO LTD

Double-truncated-cone type pile shoe

InactiveCN103485341BImprove crush resistanceImprove rigidityBulkheads/pilesStructural engineeringEngineering

The invention discloses a double-truncated-cone type pile shoe. The double-truncated-cone type pile shoe comprises a casing, reinforcing ribs arranged in the casing and a shoe cover connected with the upper end of the casing. The casing is composed of at least two inverted hollow truncated cones from top to bottom, wherein the upper truncated cone is provided with a coaxial central hole with the diameters tapering from top to bottom, and the lower truncated cone is in a bucket shape, the diameter of the mouth of the bucket is identical to the aperture of the small-diameter central hole of the upper truncated cone, and the mouth of the bucket is connected with the small-diameter central hole of the upper truncated cone; the end surface where the upper truncated cone and the lower truncated cone are connected is provided with a truncated cone shoulder which is provided with a plurality of ring grooves; a plurality of straight grooves are distributed on the circumferential surface along the radial direction from the center of the truncated cones; the bottom of the bucket of the lower truncated cone is provided with at least one ring groove; the circumferential surface of the upper end surface of the upper truncated cone, which is close to the edge of the upper truncated cone, is evenly provided with three holes for mounting chord members of a pile leg. The double-truncated-cone type pile shoe improves the compression-resisting capacity of the pile shoe and meanwhile has the advantages of lateral sliding resistance and ocean current scouring resistance.

Owner:JIANGSU UNIV OF SCI & TECH

A base structure for UHV single-column cable tower V-shaped cable

ActiveCN104358272BEasy downward force transferAvoid eccentric forceFoundation engineeringPolygonal lineTower

The invention discloses a basic structure for a V-shaped cable of an UHV single-column cable tower. column, one end of which is embedded in the inclined main column and the other end of which exposes the top surface of the inclined main column. Two stay wires arranged in a V shape are connected between the tower columns. The U-shaped stay wire rod is bent inside the inclined main column. The lower section of the folding line is parallel to the geometric center line of the inclined main column. The planes where the two stay wires are located are parallel. The invention can be used well with the V-shaped cable arrangement structure, not only meets the bearing requirements of UHV cable towers, reduces the number of foundations, but also has a simple type and is easy to implement.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

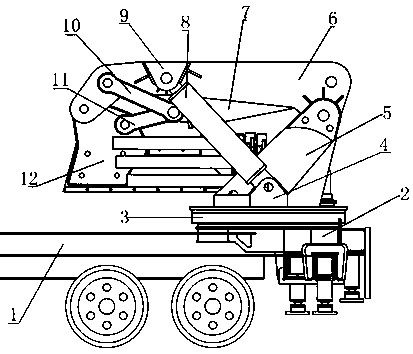

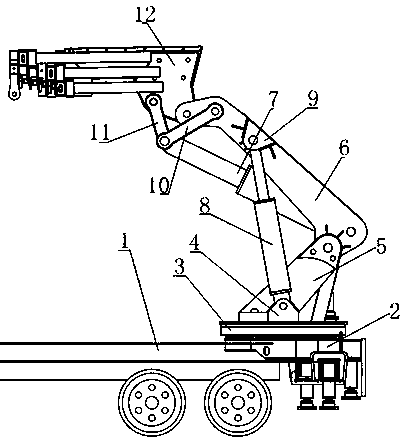

Middle folding type foldable suspension arm of automobile crane

InactiveCN111483930AMaximum lifting weightSafe and reliable hoisting forceCranesControl theoryMechanical engineering

Provided is a middle folding type foldable suspension arm of an automobile crane. A rotary seat is fixedly mounted on a base, two triangular middle columns are symmetrically and fixedly mounted on thefront side and the rear side of the rotary seat respectively, a cavity is formed between the two middle columns, the tops of the two middle columns are movably connected with the tail part of a second arm, a downward bending part is arranged at each of the head and the tail of the second arm, oil cylinder seats I are symmetrically and fixedly mounted on the outer sides of the two middle columns,front and rear sides of the middle front part of the second arm are symmetrically provided with oil cylinder seats II, a first variable-amplitude oil cylinder is connected between the oil cylinder seats I and the oil cylinder seat II, the head of the second arm is movably connected with a telescopic arm, first connecting rods are movably arranged on two sides of the tail of the telescopic arm, second connecting rods are movably arranged on two sides of a bending point of the head of the second arm, the section of the second arm is in an inverted U shape, the inner side of the bending point ofthe tail of the second arm is movably connected with a second variable-amplitude oil cylinders, and the other end of the second variable-amplitude oil cylinder is movably connected with the first connecting rods and the second connecting rods. According to the middle folding type foldable suspension arm of the automobile crane, the loading space is saved, goods are convenient to ship, and the transportation cost is saved.

Owner:湖北振华汽车科技有限公司

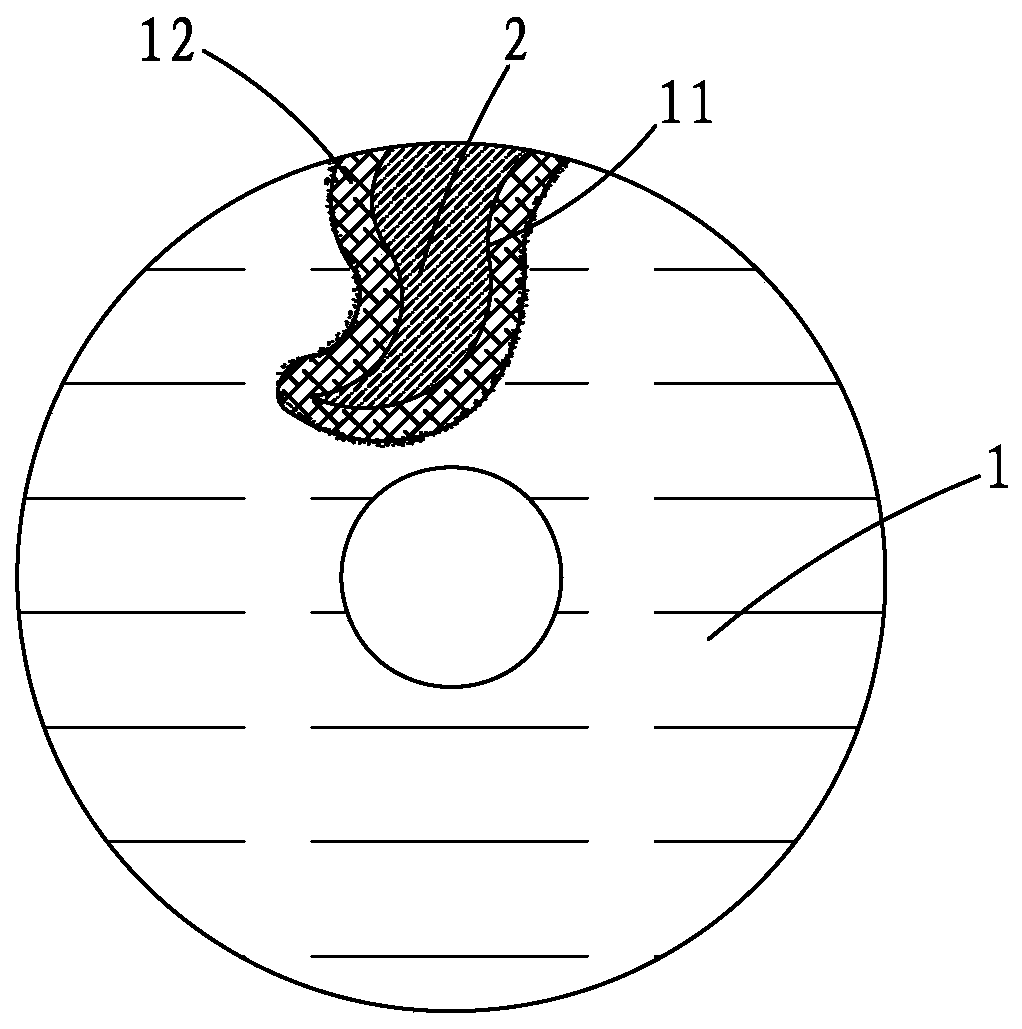

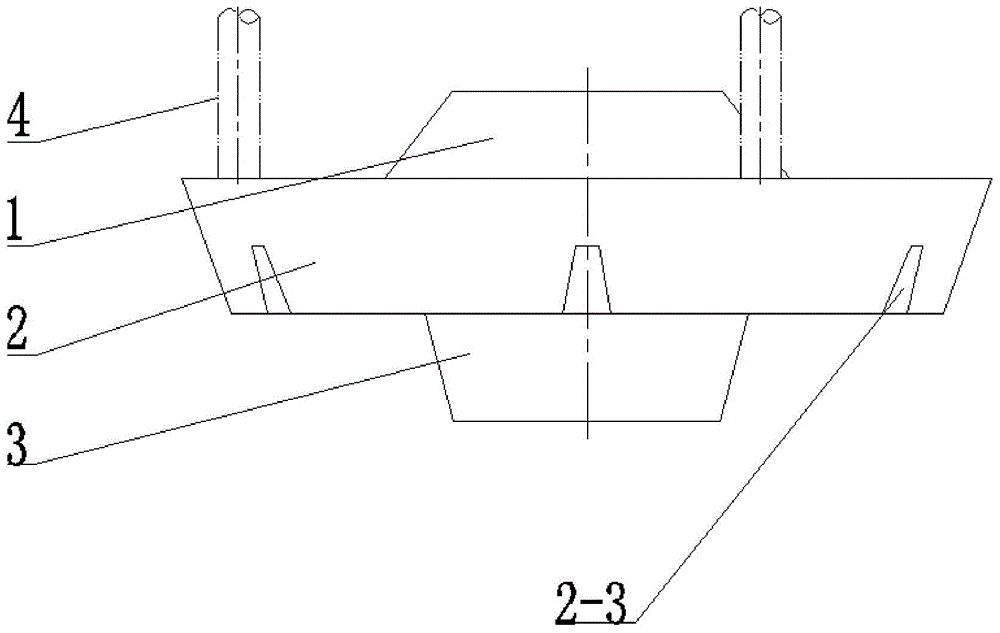

Circular pull-out test supporting device

The invention provides a circular pull-out test supporting device, and relates to an auxiliary device in a pull-out test.The circular pull-out test supporting device comprises a support ring and a wedge-shaped cushion block, the support ring comprises a bottom plate, a top plate and support ribs, the bottom plate and the top plate are each a circular steel plate, the bottom plate is larger than the top plate, the support ribs are connected between the bottom plate and the top plate in an inclined mode, the bottom end of each support rib is connected to the upper surface of the bottom plate, and the top end of each support rib is connected to the lower surface of the top plate; a penetrating through hole is formed in the middle of the wedge-shaped cushion block, the bottom face of the wedge-shaped cushion block is a plane perpendicular to the axis of the through hole, and the top face of the wedge-shaped cushion block is an inclined plane which is not perpendicular to the axis of the through hole.When the circular pull-out test supporting device is adopted for conducting an anchor bolt pull-out test, the circular pull-out test supporting device effectively supports a jack, destruction of a concrete wall surface is avoided, whether an anchor bolt is perpendicular to the concrete wall surface or not, it can be effectively guaranteed that the center line of an oil cylinder of the jack is basically overlapped with the axis of the anchor bolt, the jack is prevented from being subjected to eccentric force, and the detection precision is improved.

Owner:GUANGXI ZHONGCHENG PROJECT QUALITY TEST CO LTD

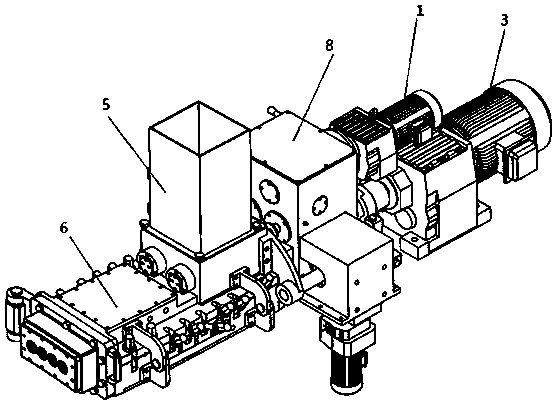

Extruding machine

The invention discloses an extruding machine. The extruding machine is characterized by comprising a feeding driving motor, a feeding transmission system, an extrusion screw driving motor, an extrusion transmission system, a feeding cabin and an extrusion cabin; the feeding driving motor is connected with the feeding transmission system through a speed reducer, and an output end of the feeding transmission system is connected to the feeding cabin; and the extrusion screw driving motor is connected with an extrusion transmission system through a reduction gearbox, and an output end of the extrusion transmission system is connected with the extrusion cabin. According to the extruding machine, an operating mechanism is arranged on driven gears, the driven gears are connected to transmission shafts through transmission gear sleeves, and the transmission gear sleeves are operated through the operating mechanism so that the time can be shortened and the efficiency can be improved when the gears are disassembled or replaced; and a universal rod structure is adopted in the operating mechanism so that the problem that the service life of a connecting rod is reduced because a large amount ofeccentric force is generated in the process of using a common connecting rod can be solved.

Owner:RUGAO PACKING FOOD MACHINERY

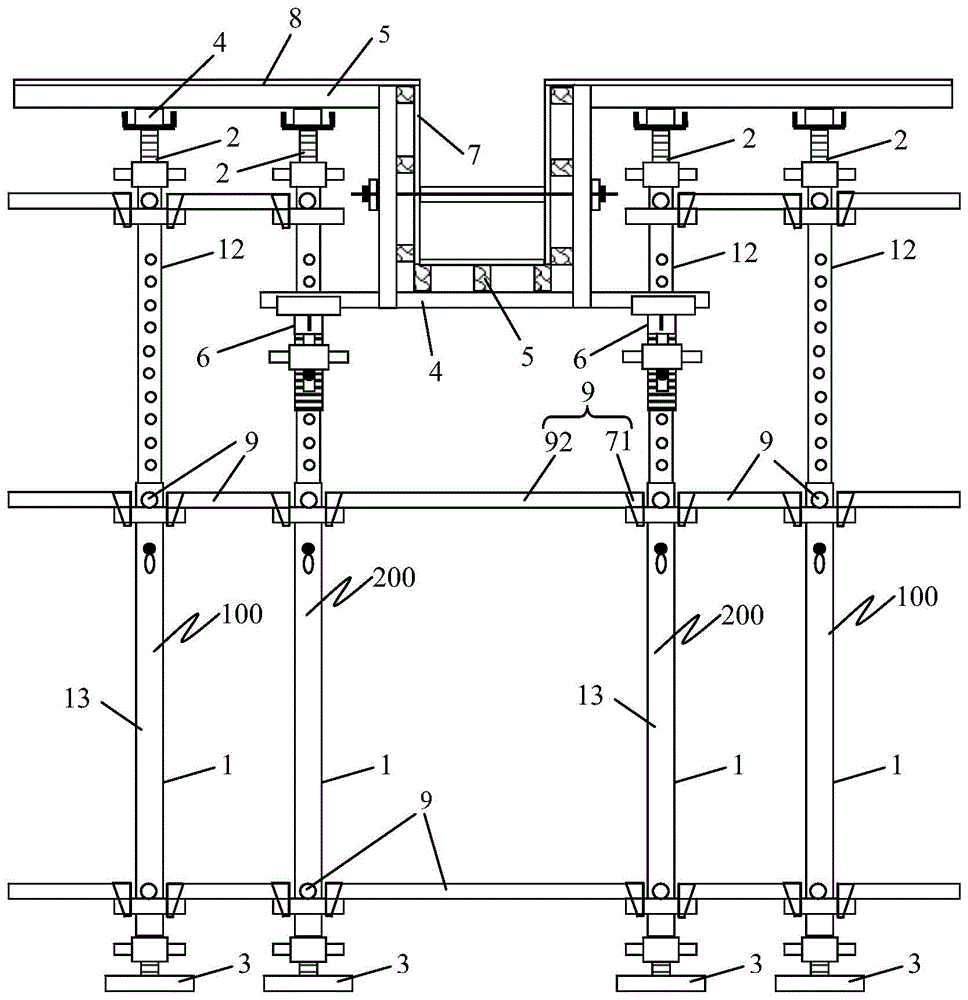

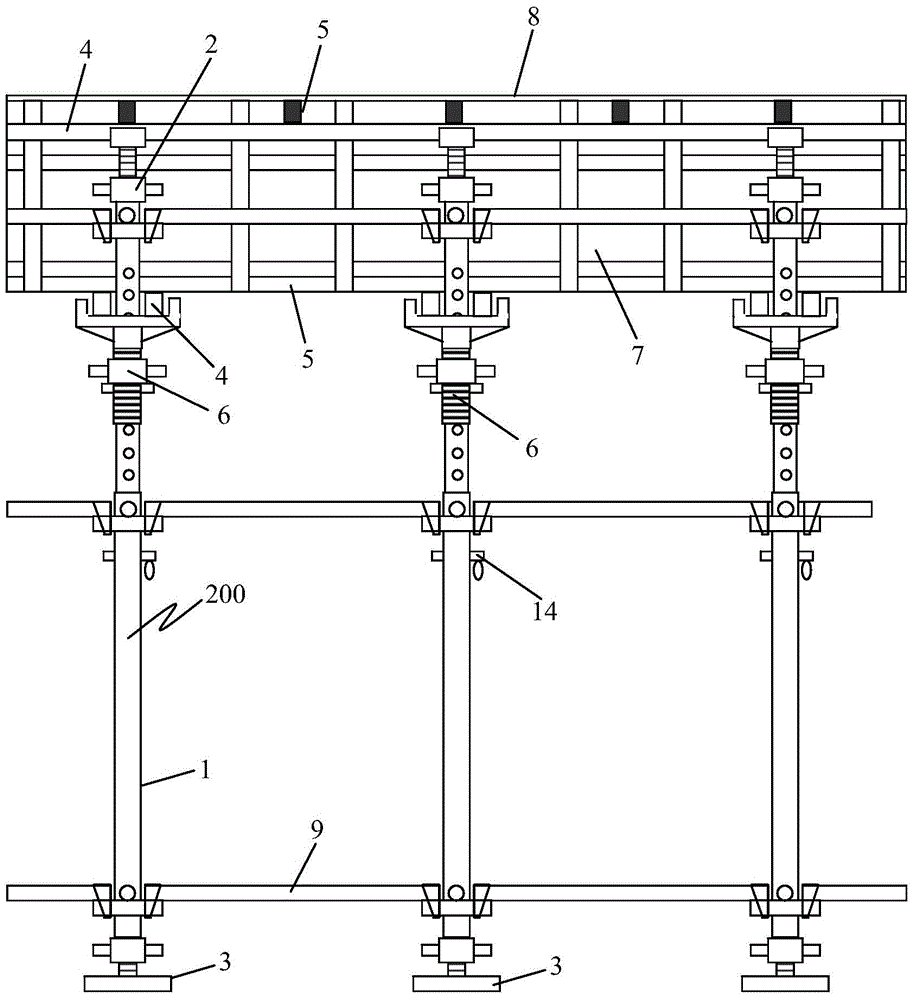

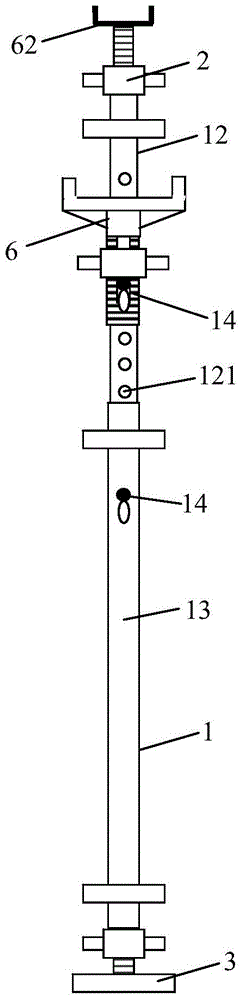

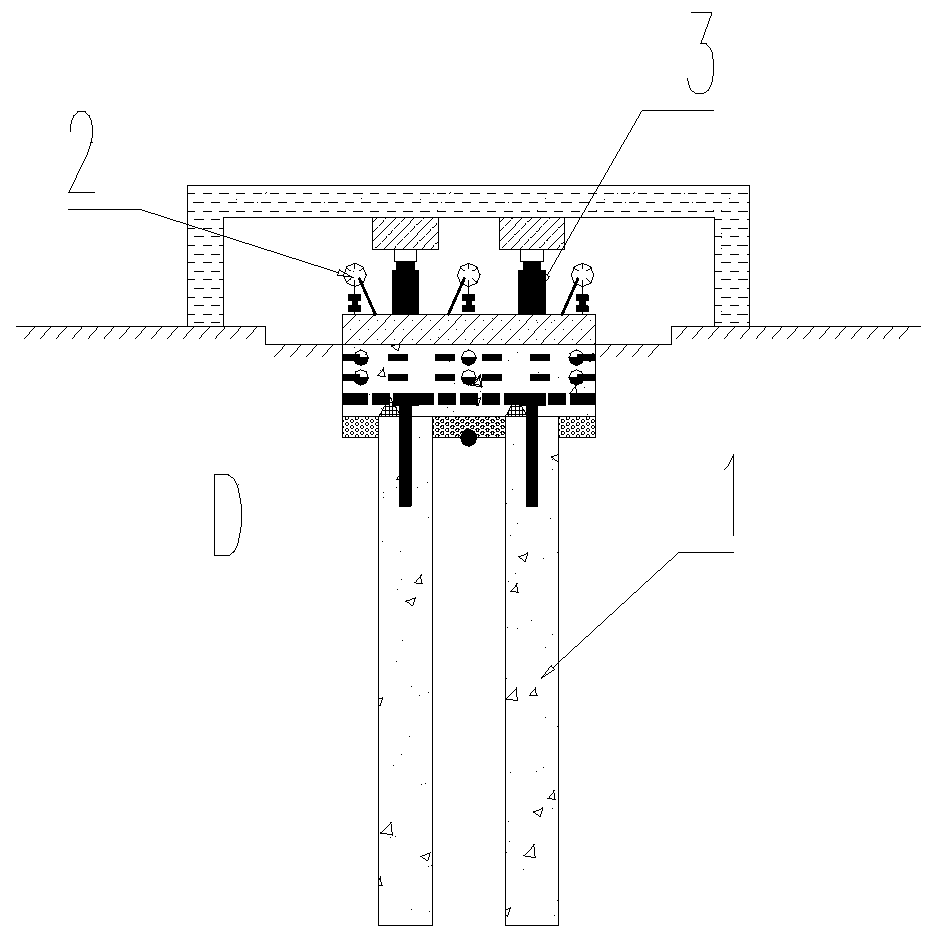

Formwork support system and construction method of cast-in-place concrete beam-slab structure

InactiveCN104594628BEasy to set upReduce dosageForms/shuttering/falseworksSupporting systemConcrete beams

The invention provides a structure template supporting system for a cast-in-place concrete beam plate. The supporting system comprises a plurality of groups of supporting rod components, wherein each group of supporting rod components comprises a first supporting rod component and a second supporting rod component; each first supporting rod component comprises a telescopic supporting vertical rod, an adjustable top support, an adjustable base, a supporting beam and a joist; a plurality of trays are arranged on the telescopic supporting vertical rods in a sleeving mode; the adjustable top supports are arranged on the tops of the telescopic supporting vertical rods, and each second supporting rod component is formed in a manner that the beam support is additionally arranged on the telescopic supporting vertical rod of the first supporting rod component; the beam supports are arranged on the beam supports or the adjustable top supports, and the joists are arranged on the supporting beams; a horizontal rod is arranged on trays of the two adjacent telescopic supporting vertical rods, and the trays of all telescopic supporting vertical rods are connected to form the supporting system. The invention further provides a construction method for the structure template supporting system. The structure template supporting system is simple in structure and convenient to operate, so that the construction quality is improved.

Owner:FUJIAN UNIV OF TECH +1

Composite light pile group pile bearing capacity detection device, system and method

ActiveCN111289351AImprove integrityMeet testing needsMaterial strength using tensile/compressive forcesGratingArchitectural engineering

The invention discloses a composite light pile group pile bearing capacity detection device, system and method. The detection device comprises a support subsystem, a loading subsystem and a test subsystem, wherein the detection device is used for detecting a composite light pile group; the support subsystem comprises connecting steel bars, a light subbase and a bearing platform; the loading subsystem comprises a loading device, a pressure sensor, a main beam and a counter-force device; and the testing subsystem comprises a dial indicator, a horizontal grating tension sensor, a load sensor, a soil pressure box and a composite reinforcement cage dynamometer. The connecting steel bars can improve the integrity of the composite light pile and the light subbase; the bearing platform can transmit the acting force of the loading device for simulating the real load of the roadbed to the light subbase; the detection system comprises the detection device and the composite light pile group, the detection requirement of the bearing capacity of the composite light pile group can be met, the detection system can also be used for researching the stress characteristic and the deformation control effect, the light subbase can well simulate the actual engineering situation, and the engineering detection requirement is met.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

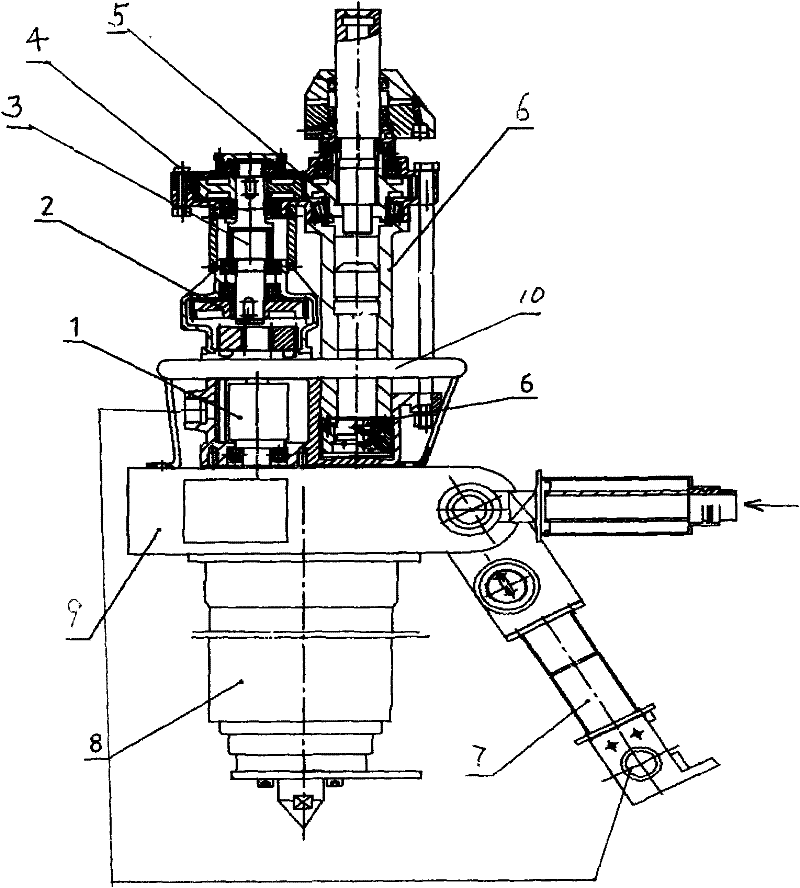

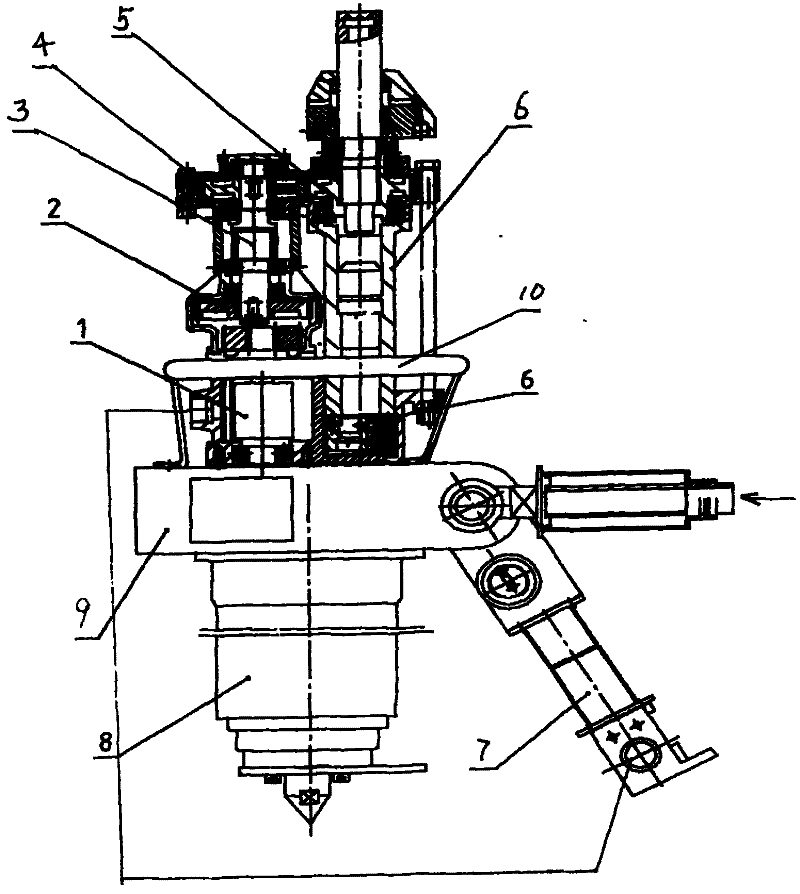

Pneumatic anchor rod hammer drill

ActiveCN101575942BEasy to controlEasy to operateDerricks/mastsDrilling drivesEngineeringGravity line

The invention discloses a pneumatic anchor rod hammer drill, which is mainly characterized in that a power output shaft of a speed change gear box of the prior rotary impact combination hammer drill is connected with a lengthened shaft on which a transmission gear is arranged, and the transmission gear is meshed with a fiber tail sleeve gear; a rotating part and a shell of the hammer drill are corporately fixed on a drill body seat to form a hammer drill whole; a support axis of an air leg is arranged on a gravity line of the weight of the hammer drill whole; and an air inlet pipe of an air motor is directly connected to a valve of an operating arm. The pneumatic anchor rod hammer drill realizes downward shift of the weight of the rotating part, avoids the top-heavy phenomenon, improves the integral stability, avoids direct impact, reduces strong shock during working, and is convenient for a worker to operate.

Owner:青岛达邦钻机有限责任公司

Device and method for direct tensile test of pavement materials avoiding eccentric tension

InactiveCN103234825BSimple structureReduce mistakesMaterial strength using tensile/compressive forcesElectricityEngineering

The invention provides a pavement material direct tensile test apparatus with eccentric tension avoided and method thereof, and the apparatus comprises a test part, a detected part installed in the test part, and electromagnetic force control part, wherein, the test part comprises a hinged base on the spherical shape, and a spherical lower hinged base matched with the spherical upper hinged base, and the spherical upper hinged base is installed with a upper link which is connected to a mechanics test and simulation testing machine, and the spherical lower hinged base is connected with a cast iron block by the lower pull bar, and the test part is installed between the spherical upper hinged base and the spherical lower hinged base; the electromagnetic force control part is connected with the cast iron block. Because of the flexibly rotary spherical hinged base, in the test process, when the test part is tensioned, the test part can naturally drop depending on gravity, thereby the eccentric force being effected on the detected part during tensile test is avoided, and the test result is more accurate, in addition, the invention has the advantages of simple structure, convenient operation, economic utility, reliable test data provision and minimized test error.

Owner:CHANGAN UNIV

A high-pressure single-guided natural gas trap

The invention relates to a high-pressure single-guide natural gas trap. The high-pressure single-guide natural gas trap is characterized in that an upper shell 11 is provided with a liquid diversion component 31 penetrating the upper middle of the upper shell, one end of the liquid diversion component 31 penetrates a flange fixing plate 32, a water inlet adapter tube 38 is welded at the other end of a welding connecting plate 33, a single-guide limit component 12 is connected to a fixable gasket 7, and a double-float link component 5 moves in a guide sleeve 46. One end of a long lever 50 is connected with a spool support 51, and the other end of the long lever 51 is connected with double floats 41. One end of a short lever 54 is connected with the spool support 51, and the other end of the short lever 54 is connected with a buoyancy increaser 20. A spool 55 is disposed in the spool support 51. A valve seat 58 is connected to a valve seat fixing plate 57 in a threaded manner. A connecting shaft 60 sequentially penetrates a fixing block I59-1, a connecting block I56-1, a connecting block II56-2 and a fixing block II59-2 to connect the spool support 51 and the valve seat fixing plate 57 together. A valve seat component connecting plate 24 is connected below the valve seat fixing plate 57. An outlet adapter tube 25 is welded at the lower end of a middle hole of the valve seat component connecting plate 24 and penetrates a split cavity wall. The high-pressure single-guide natural gas trap is small in size and low in cost and meets the technical requirement for no leakage.

Owner:GANSU HONGFENG MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com