Color plate reverse ceiling upper-air sliding device and reverse ceiling construction method

A sliding device and anti-ceiling technology, which is applied in the direction of hoisting device, winch device, building structure, etc., can solve the problems that the stability of scaffolding cannot be guaranteed, and the safety of construction personnel cannot be guaranteed, and the cost of labor and machine tools can be reduced. Reduced, high practical value, increased protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

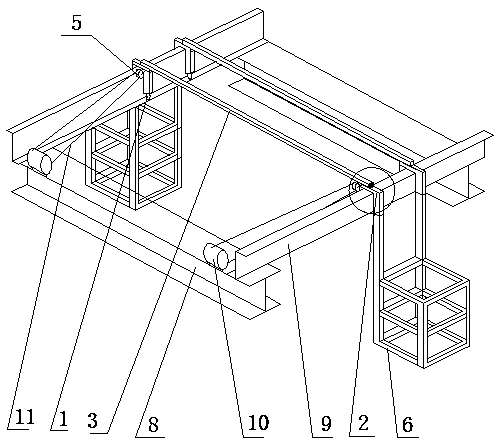

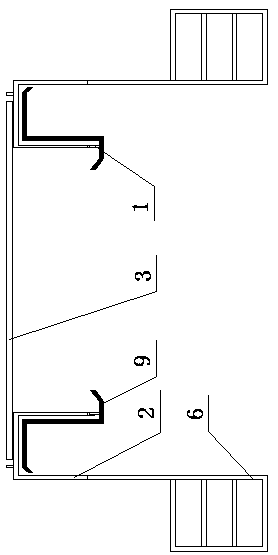

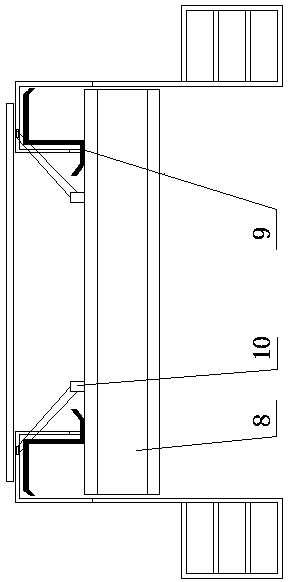

[0034] A color steel plate anti-ceiling high-altitude sliding device, which consists of: two hanging baskets 6, the hanging baskets are connected to the roller 1 through a U-shaped connecting device 2, and the two hanging baskets are connected by a U-shaped connecting device , the bolt 4 and the connecting square steel 3 are connected together, the outer end of the U-shaped connecting device has a protective sleeve, and the side of the U-shaped connecting device has a fixed pulley block A5, and the described U-shaped connecting device is placed on the Z-shaped On the purlin 9, the two ends of the Z-shaped purlin are welded on the I-beam 8.

Embodiment 2

[0036] In the high-altitude sliding device of the color steel plate anti-ceiling described in Example 1, a set of fixed sliding wheels B10 is welded on the side of the I-beam, and the fixed sliding wheels B and the fixed sliding wheels A pass through the traction rope 11 Connection, the U-shaped connection device and the connection square steel are connected by the bolts, and the surface of the hanging basket fixing device is fixedly installed with a rubber wear-resistant layer.

Embodiment 3

[0038] A construction method using the color steel plate anti-ceiling high-altitude sliding device described in Example 1-2. This method is to first use BIM to arrange the roof color plates, and then measure the setting out on site according to the construction drawings to obtain accurate values. The measured value is provided to the color plate manufacturer, and the processing plant reviews and processes the color plate according to the on-site measurement defense line. After the color plate is transported to the site, the supervisor will inspect and accept it on site, and provide the product qualification certificate, quality inspection report, etc. After the completion, use the truck crane to hoist the color plate to the Z-shaped purlin and fix it with a rope;

[0039] Then hang the hanging basket on the Z-shaped purlin and install the lifeline, install a temporary sliding device on the steel beam, and connect the hanging basket and the temporary sliding device with a wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com