High-pressure single-guide natural gas trap

A technology of natural gas and steam traps, applied in steam traps, mechanical equipment, etc., to reduce the volume of the shell, improve the sealing performance, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

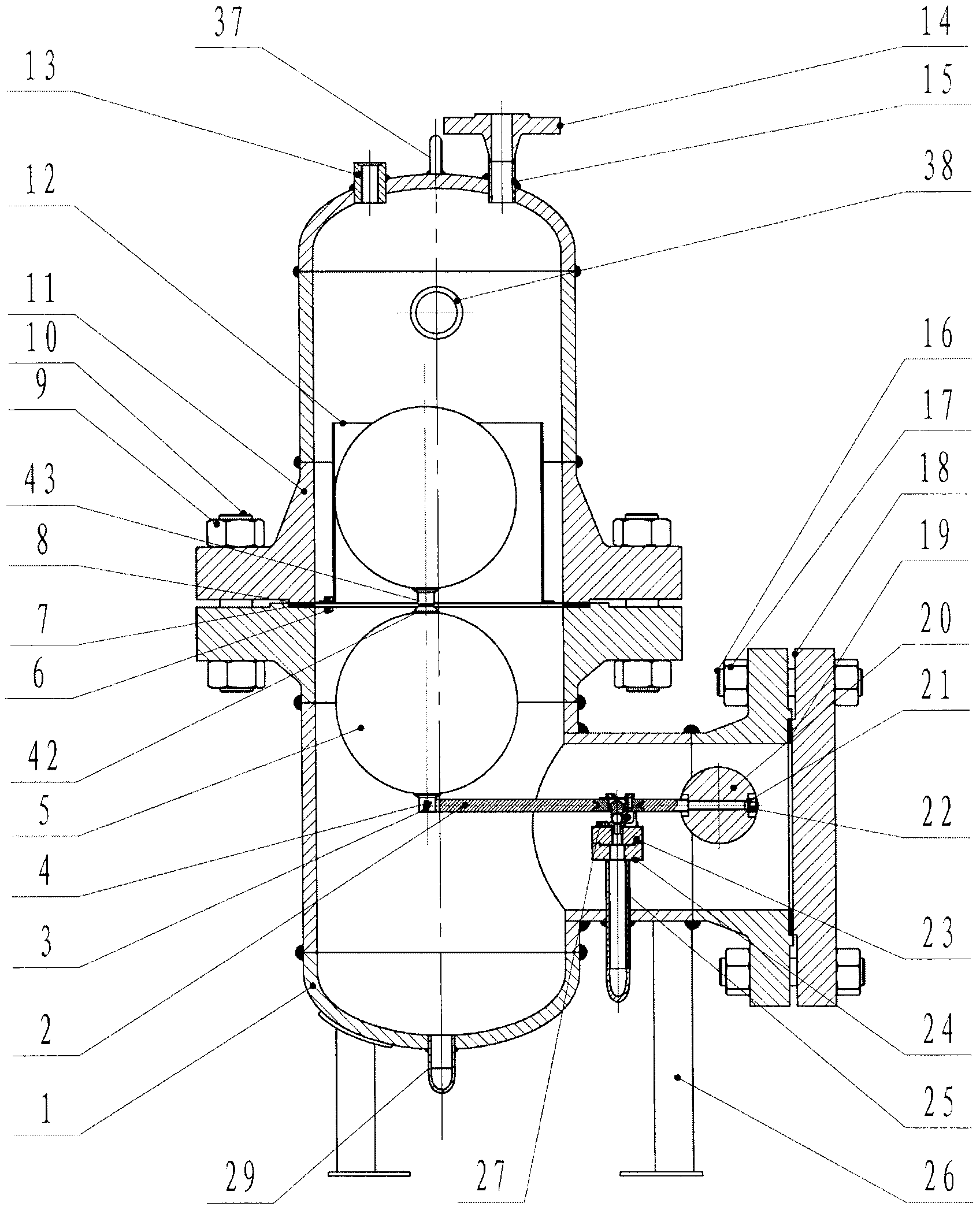

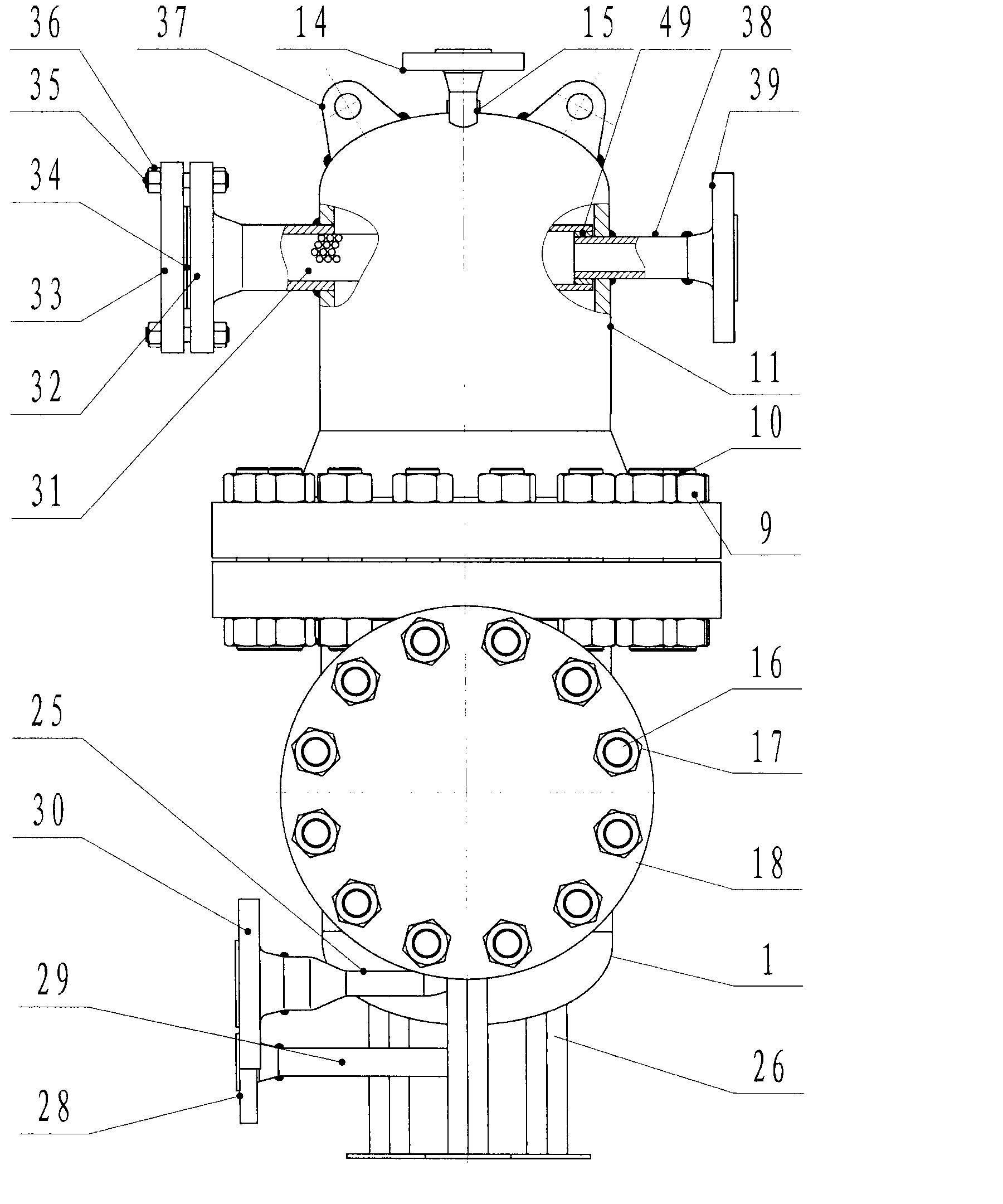

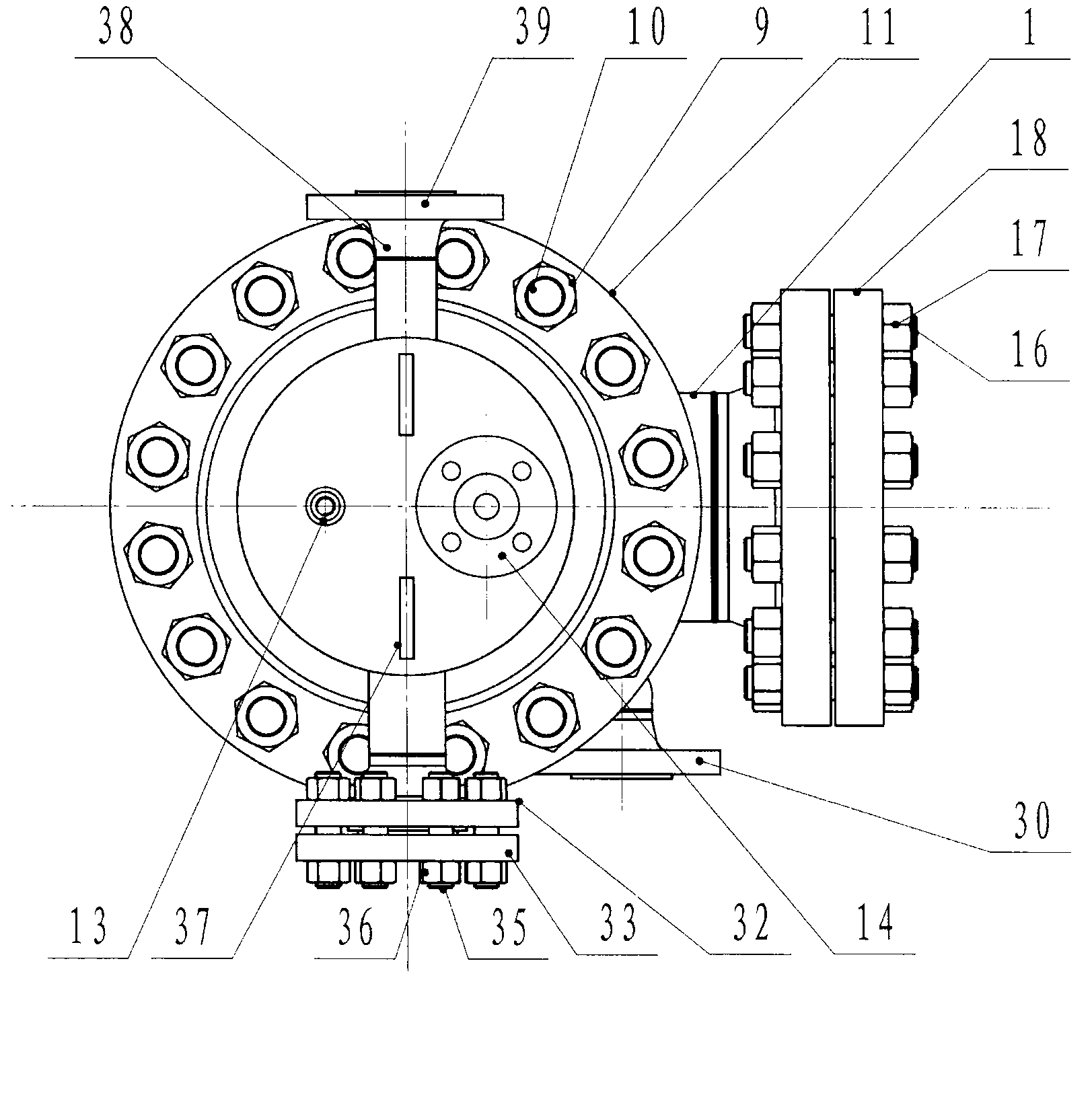

[0034] exist figure 1 , 2 , 3, 4, 6, 7, 8: a fixed gasket 7 is installed between the one-way split lower shell 1 and the upper shell 11, all of which are connected by special double-ended studs I10 and thickened hex nuts 9 fixed. The upper shell 11 and the one-way split lower shell 1 are designed according to PN150, all forged steel parts, and the shell material and strength design conform to "GB150-2011 Pressure Vessel". The right side of the one-way split type lower housing 1 is provided with a split cavity of one-way small cavity, and its function is to reduce volume and cost. A gasket I19 is installed between the split cavity and the blind plate 18, connected by a special double-ended stud II16, and fixed by a hex nut I17. Connect the single guide limit assembly 12 to the fixed sealing gasket 7, respectively connect the three connecting holes I63 with the hexagon head bolt I8, and fix it with the hexagon nut II6. The single guide limit assembly 12 is welded by the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com