Patents

Literature

964results about "Steam traps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

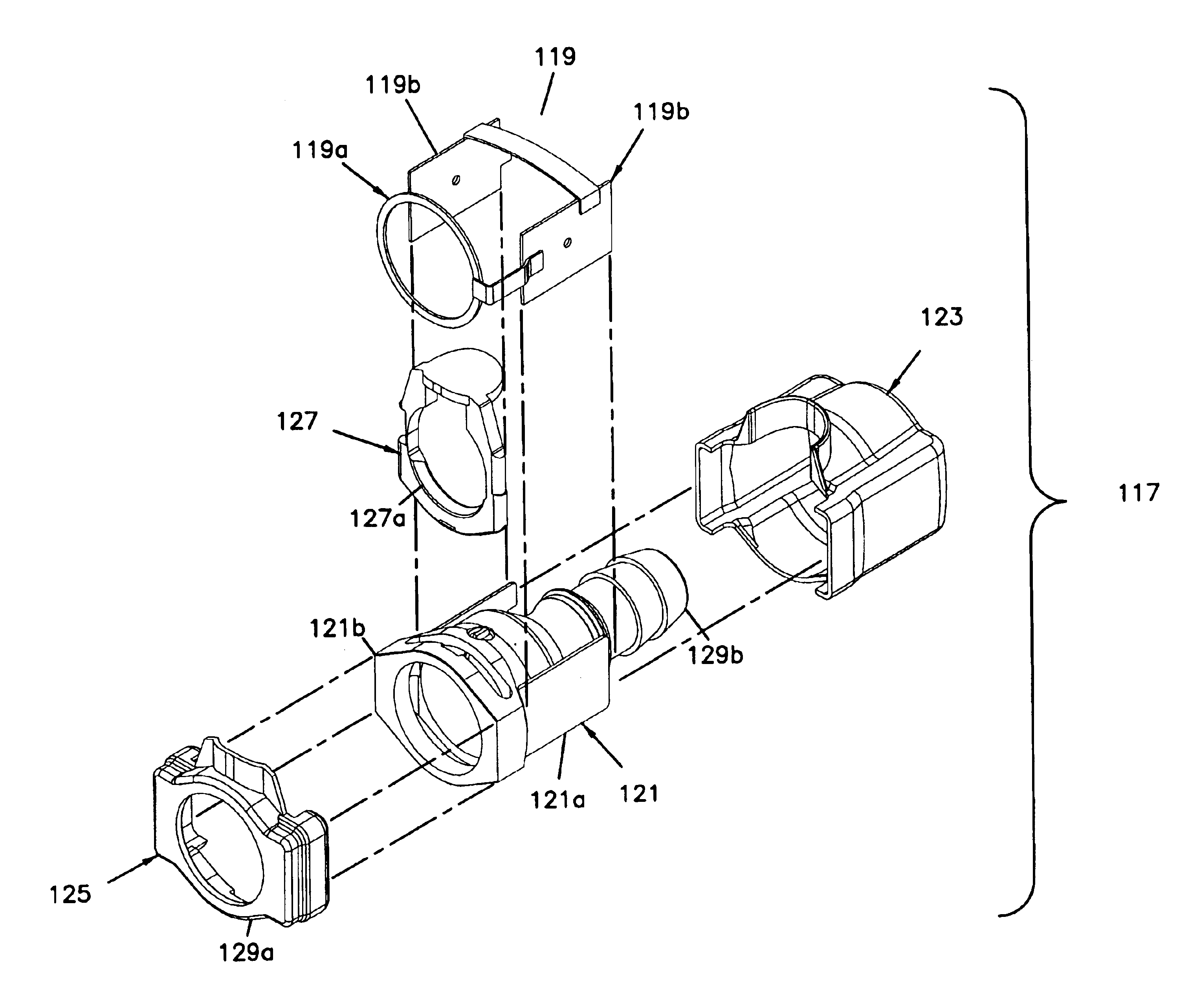

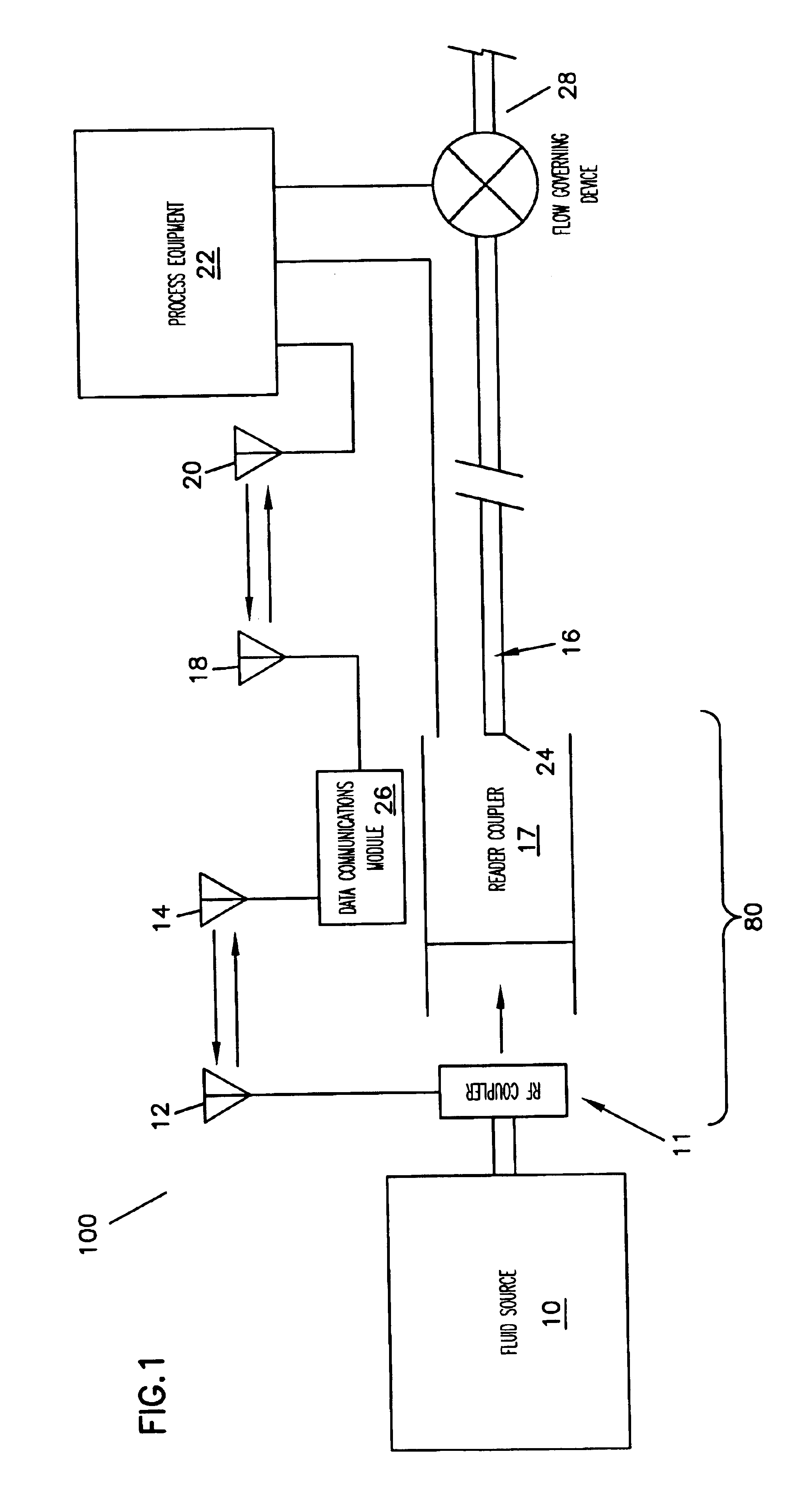

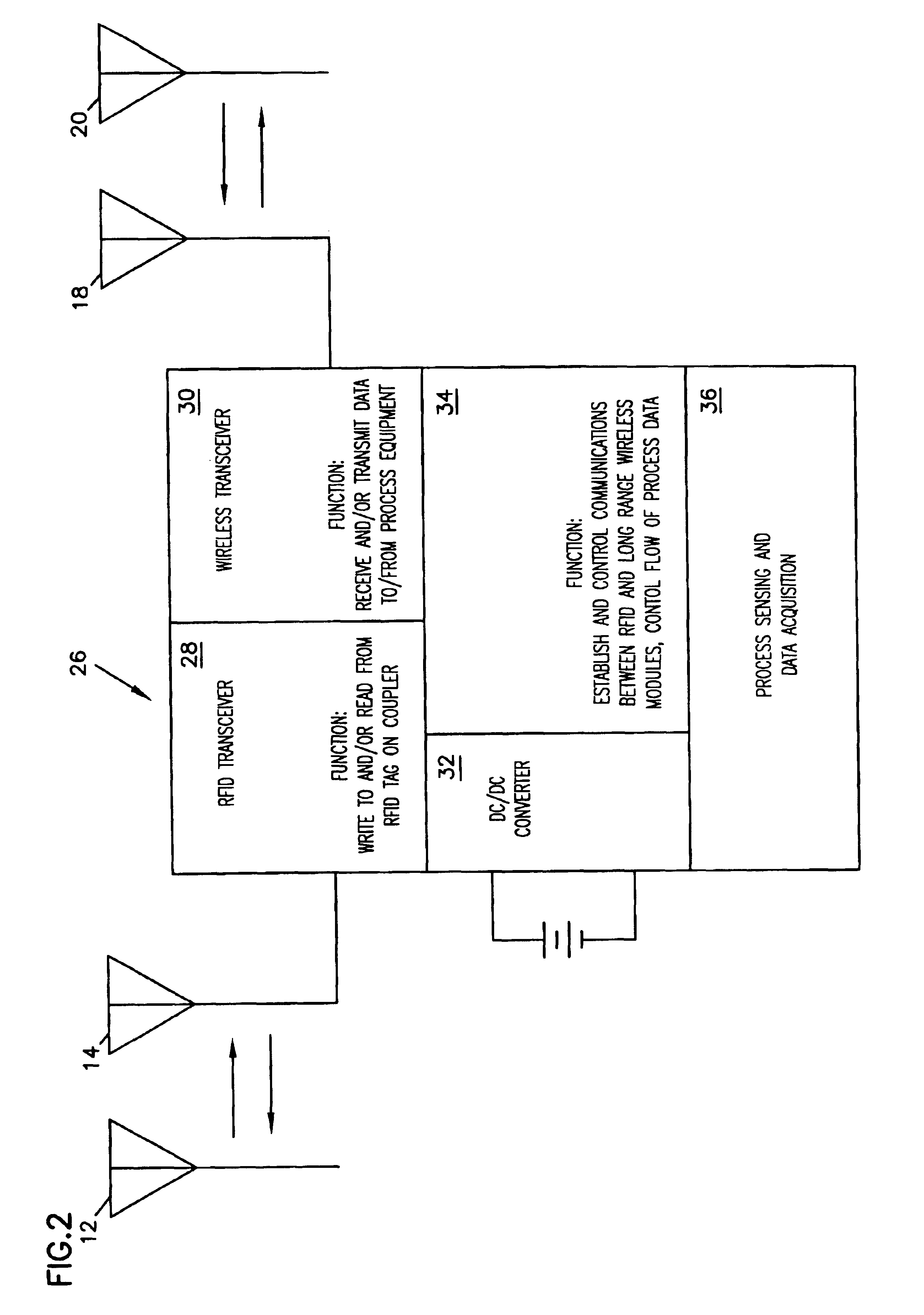

Connector apparatus and method for connecting the same

InactiveUS6897374B2Less powerAvoid misconnectionPipe couplingsInsulated cablesFluid controlEngineering

A connector apparatus for controlling fluid dispensing / transmission that includes a control component for communication between couplers thereof. A first coupler has a transmitter, and is releasably connected with a mating reader coupler that has a transmitter and fluid control device to exchange information with the transmitter of the first coupler. The transmitters communicate and are operated by wireless means such as by RF devices. Upon confirming that the first coupler is properly coupled to the mating coupler and that the first coupler has a proper identification, the fluid control device controls fluid flow, using the transmitters of the first coupler and the mating reader coupler, under predetermined parameters, e.g., pressure, temperature, duration, and flow rate, as indicated in the first coupler.

Owner:COLDER PRODS

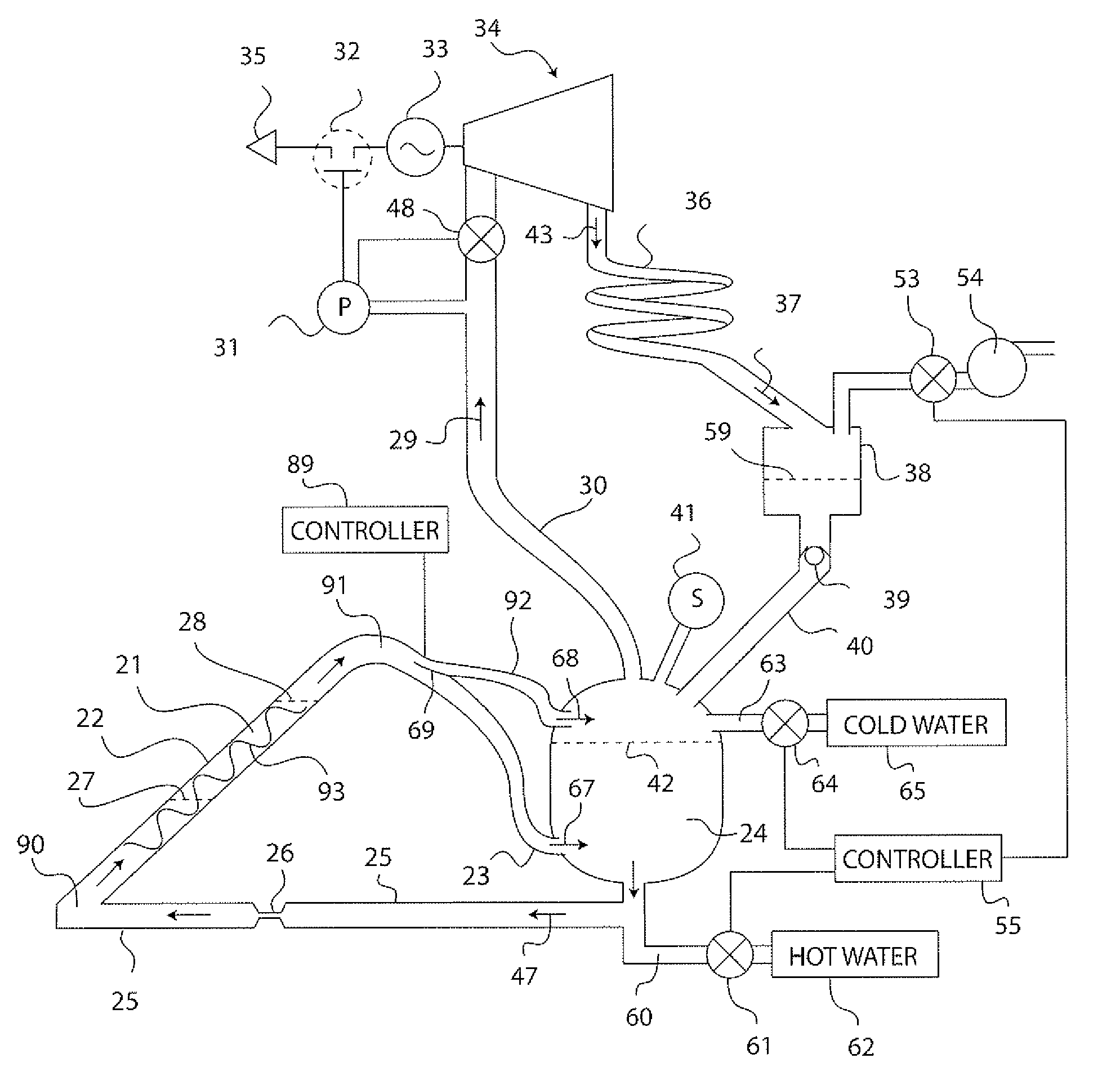

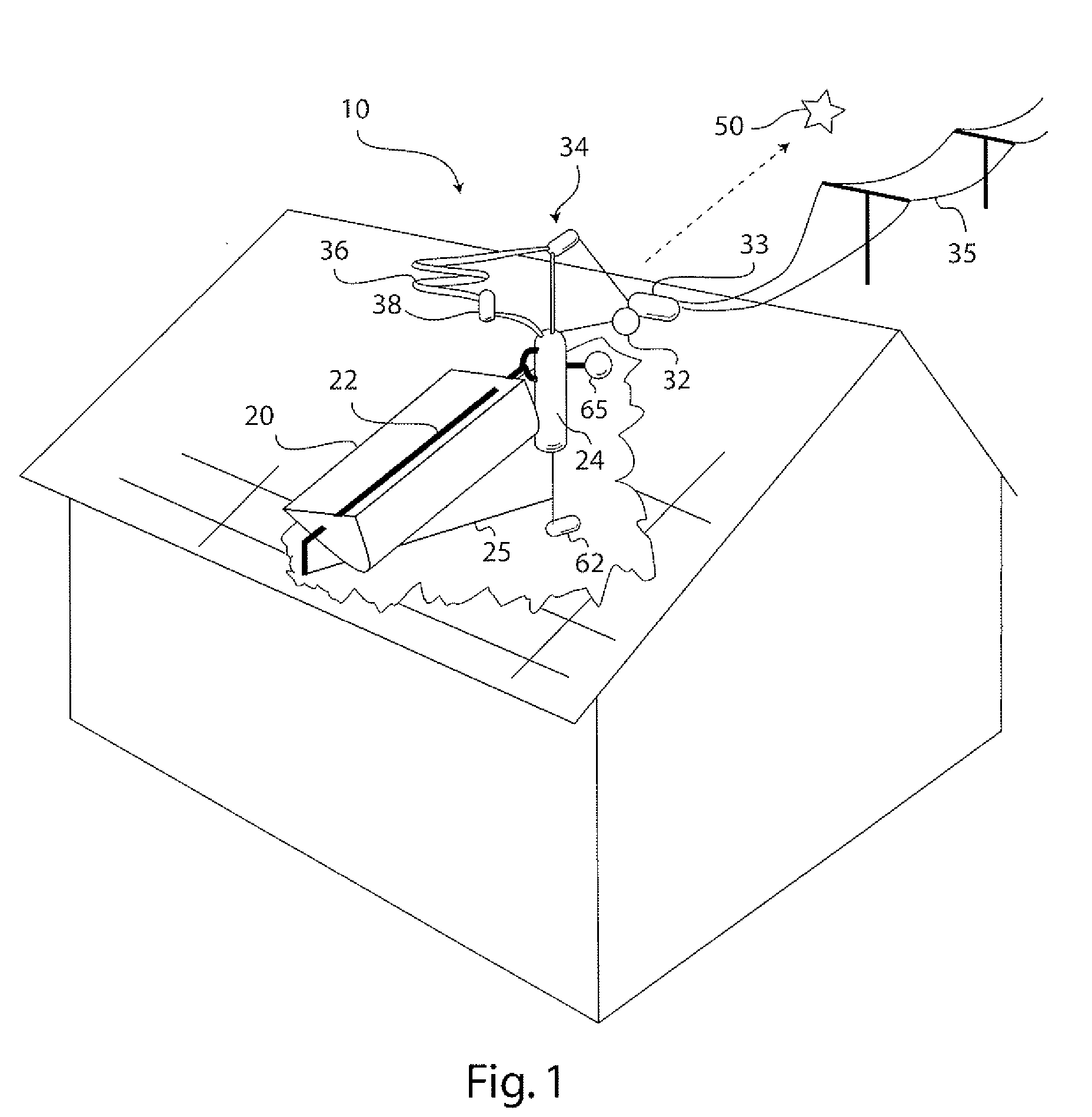

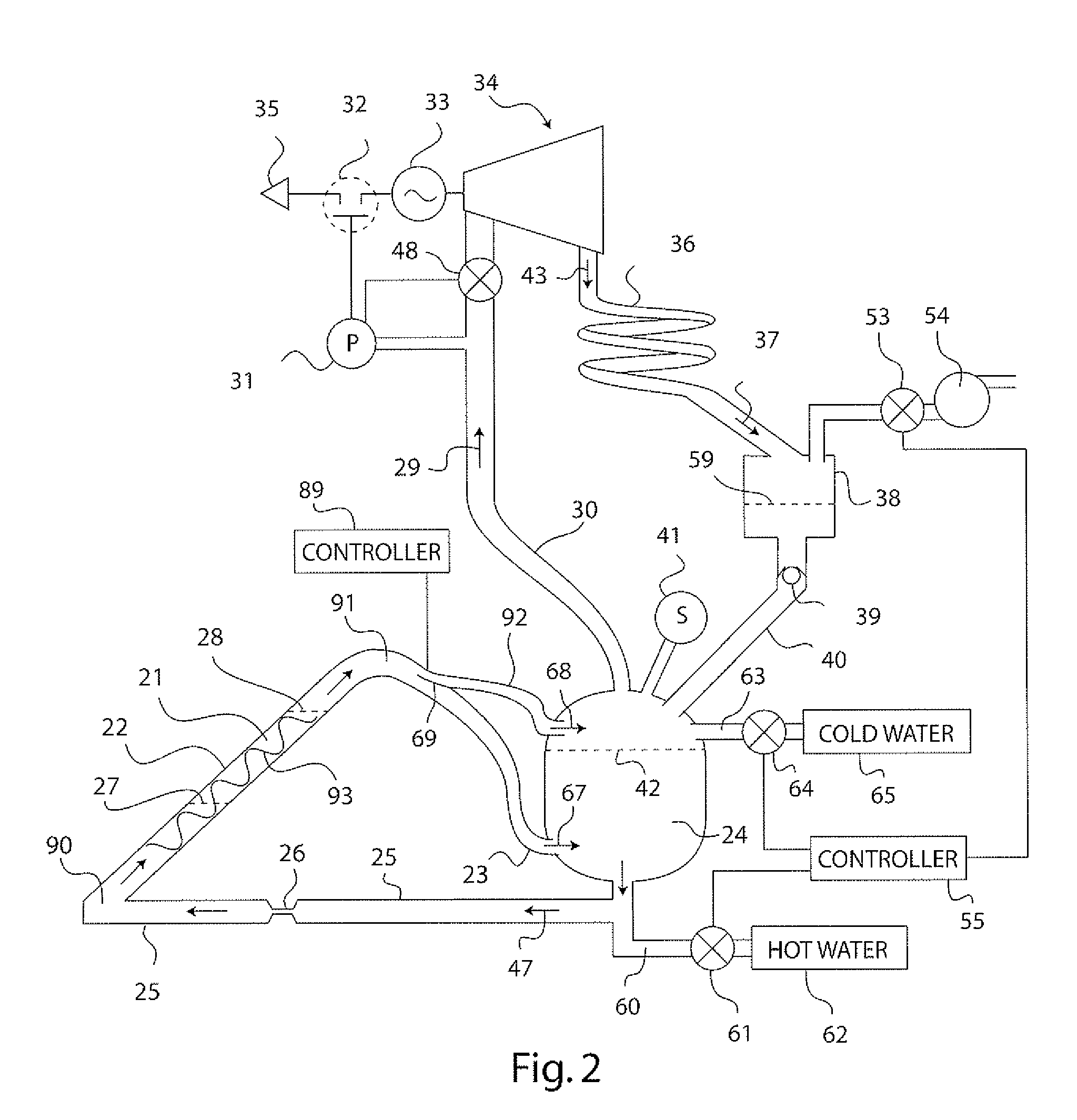

Solar Thermal Power System

InactiveUS20090199557A1Simple efficiencyTechnology being suitableAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

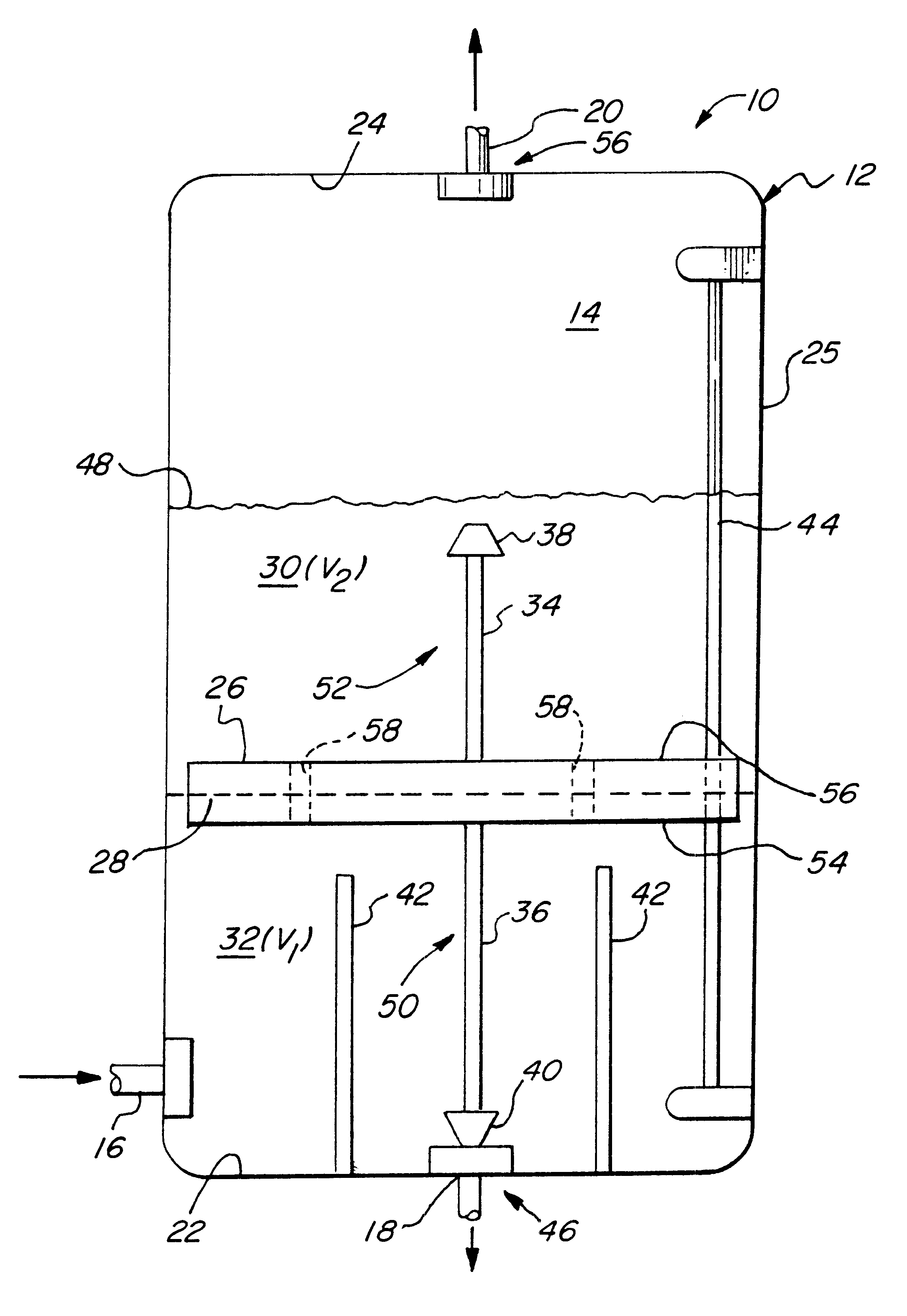

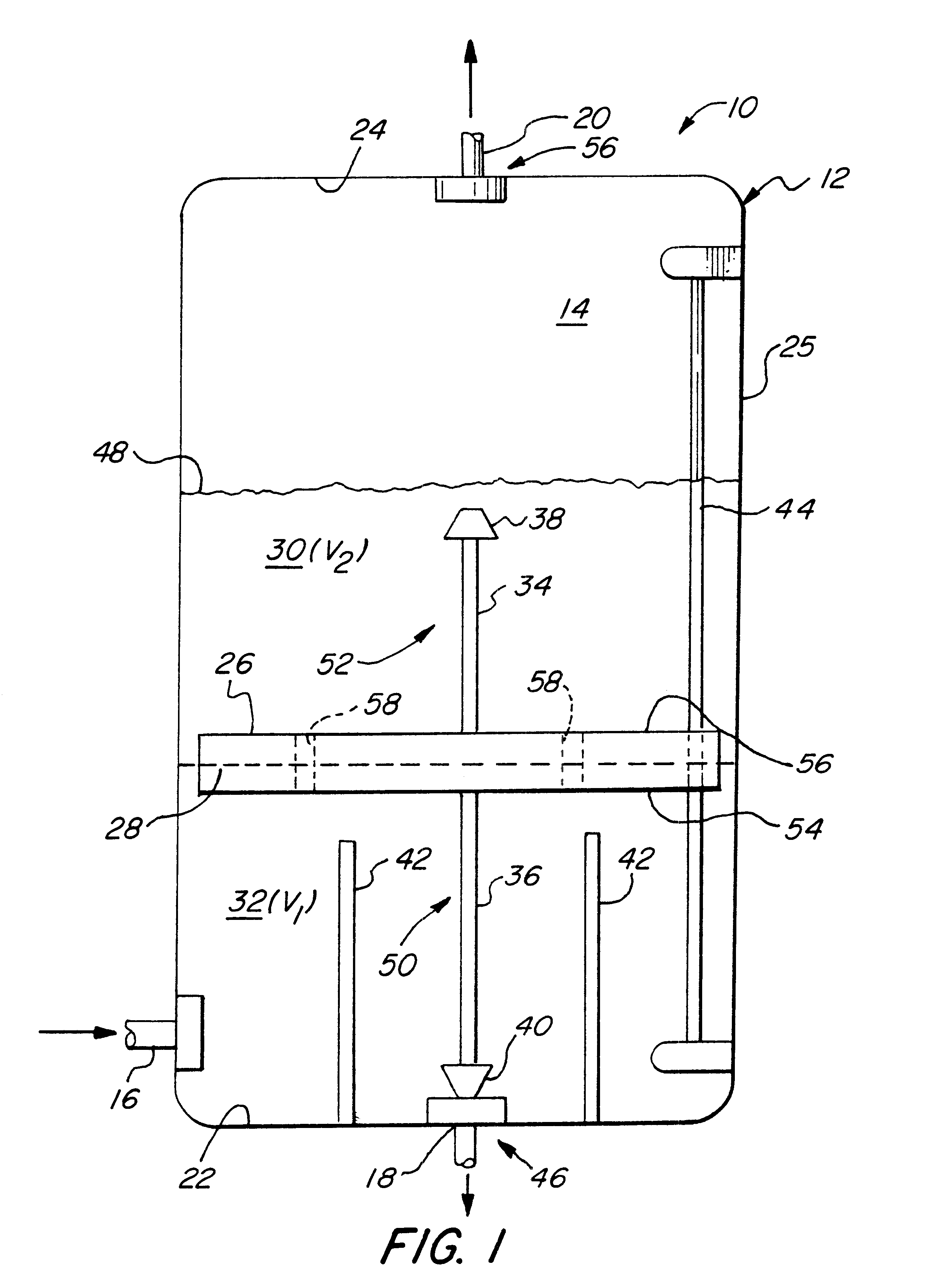

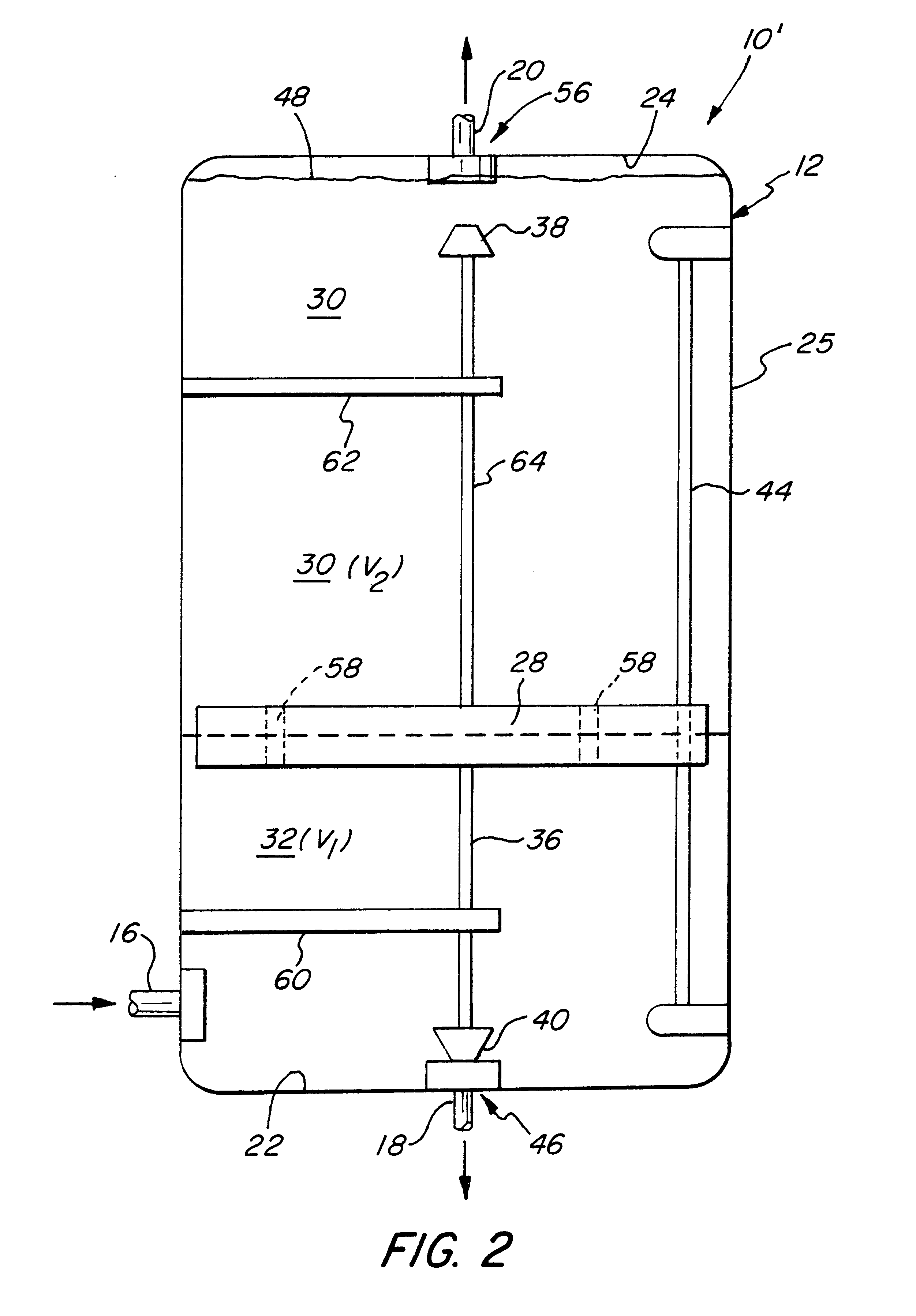

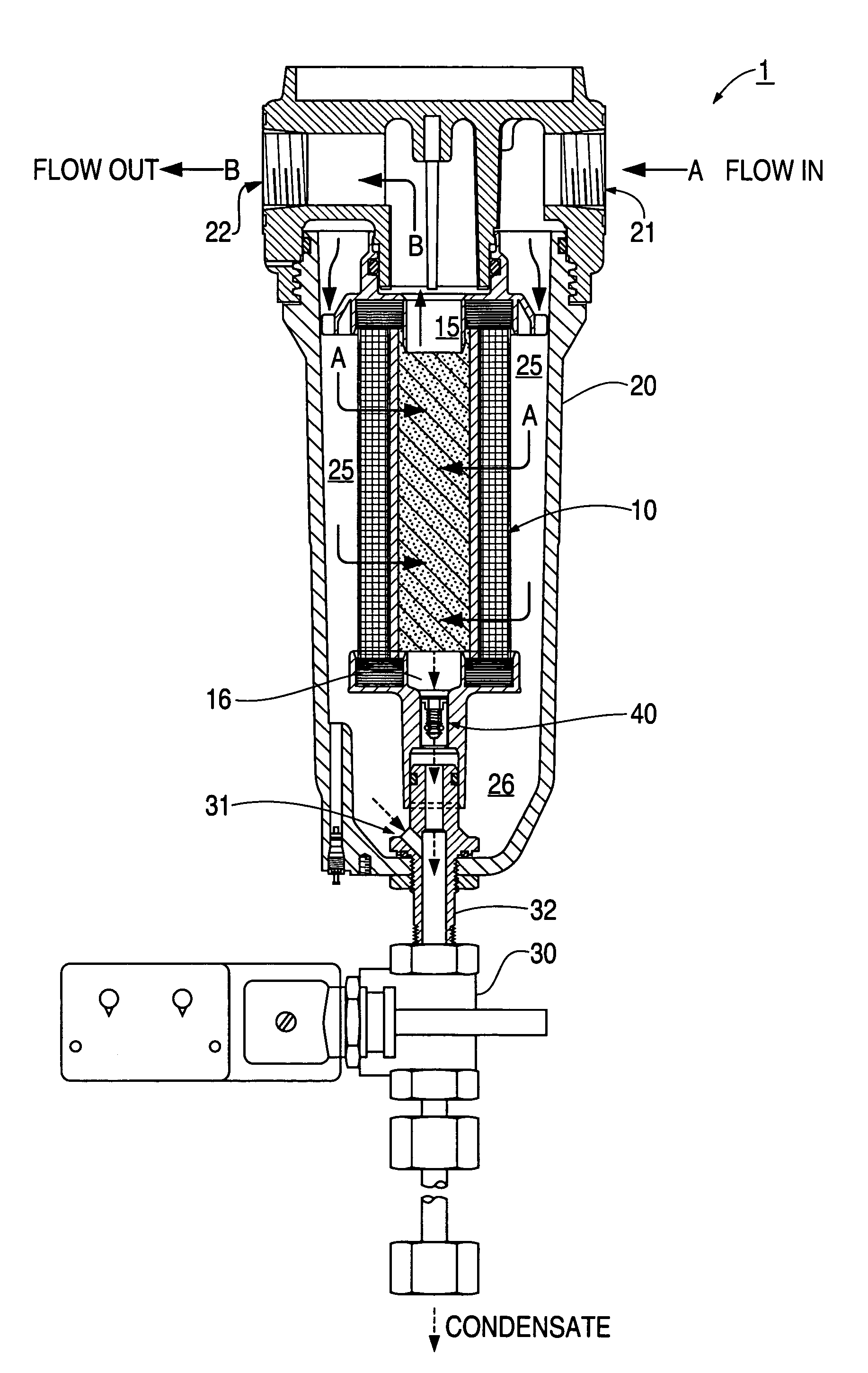

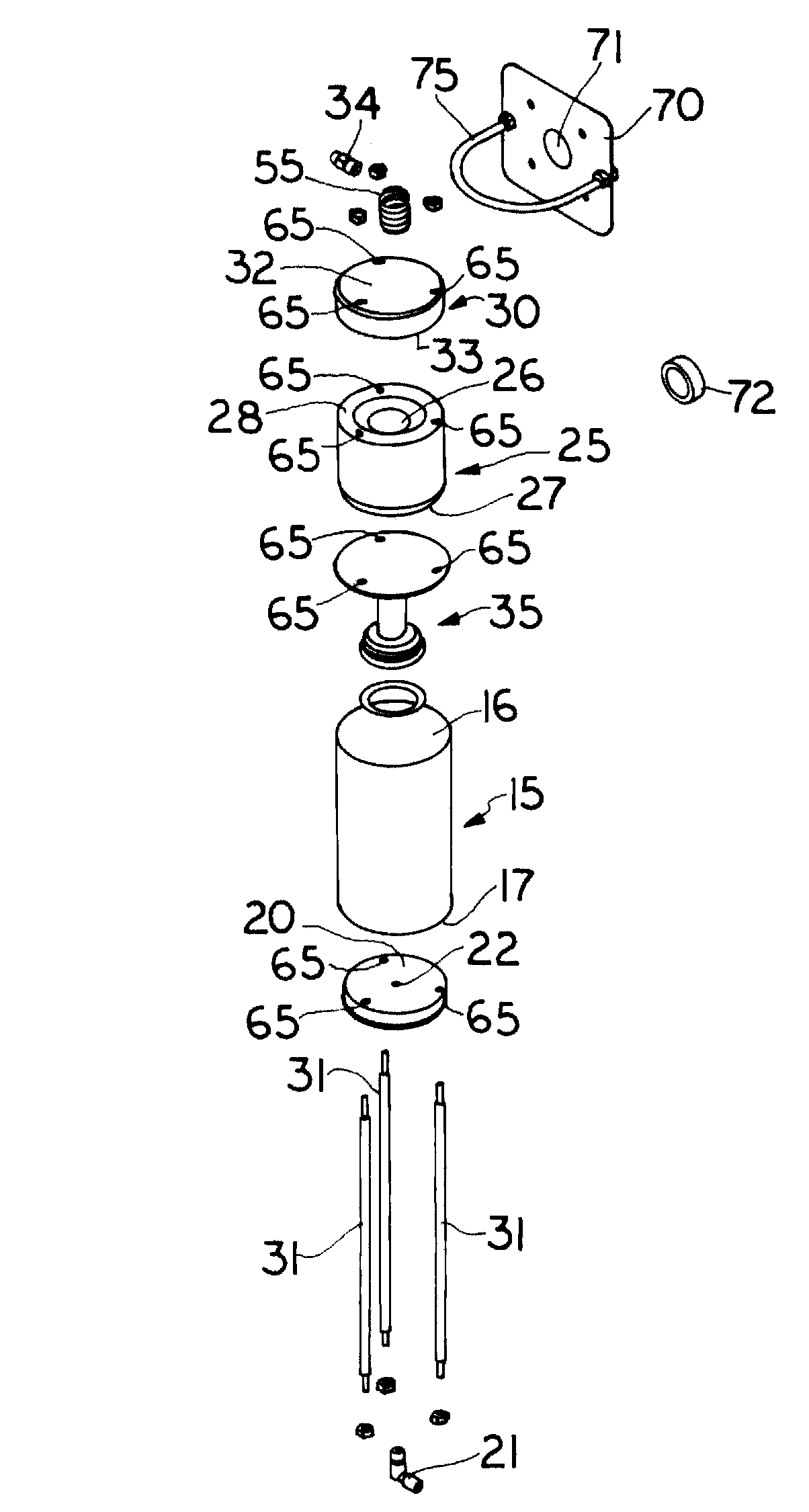

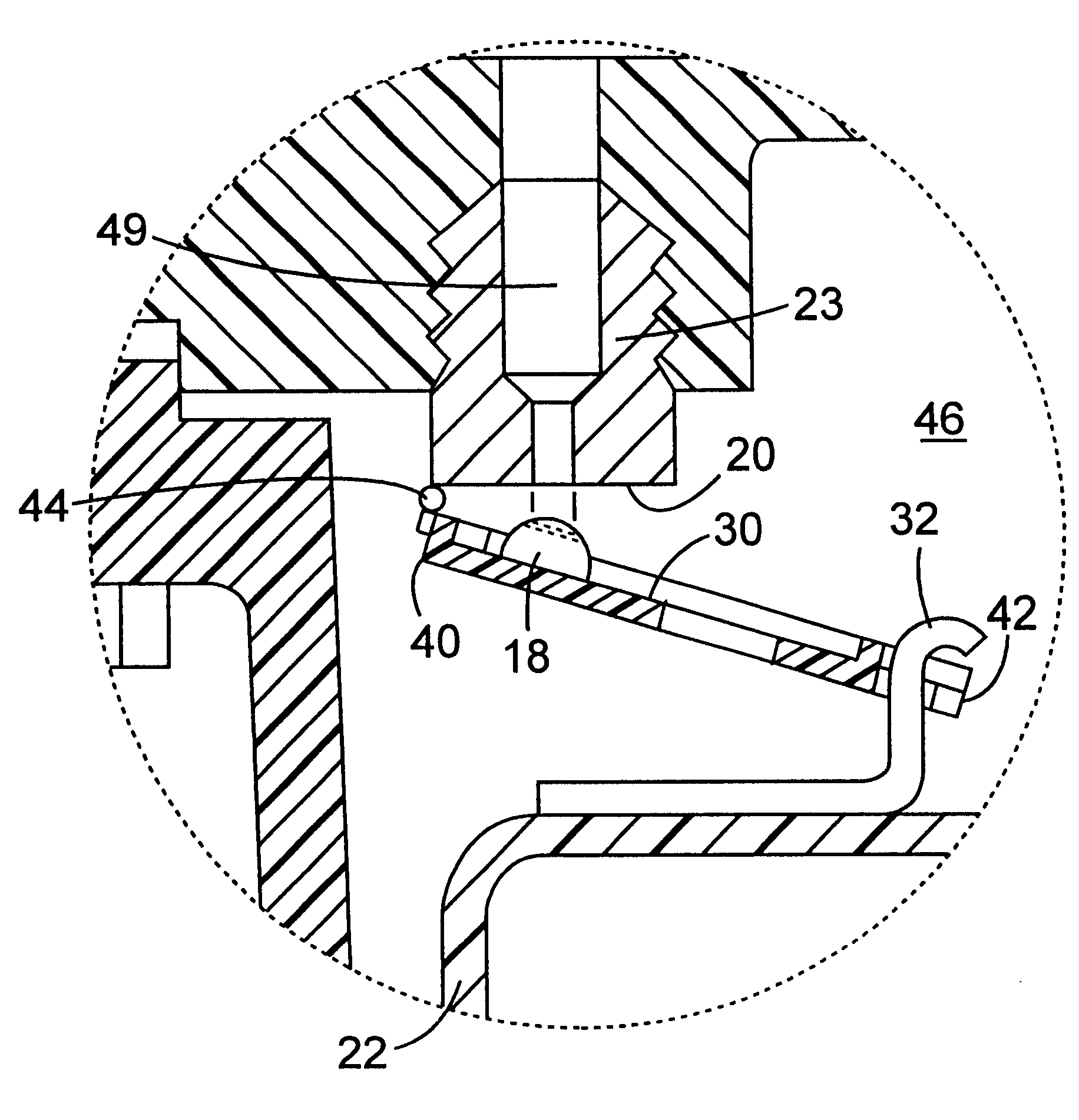

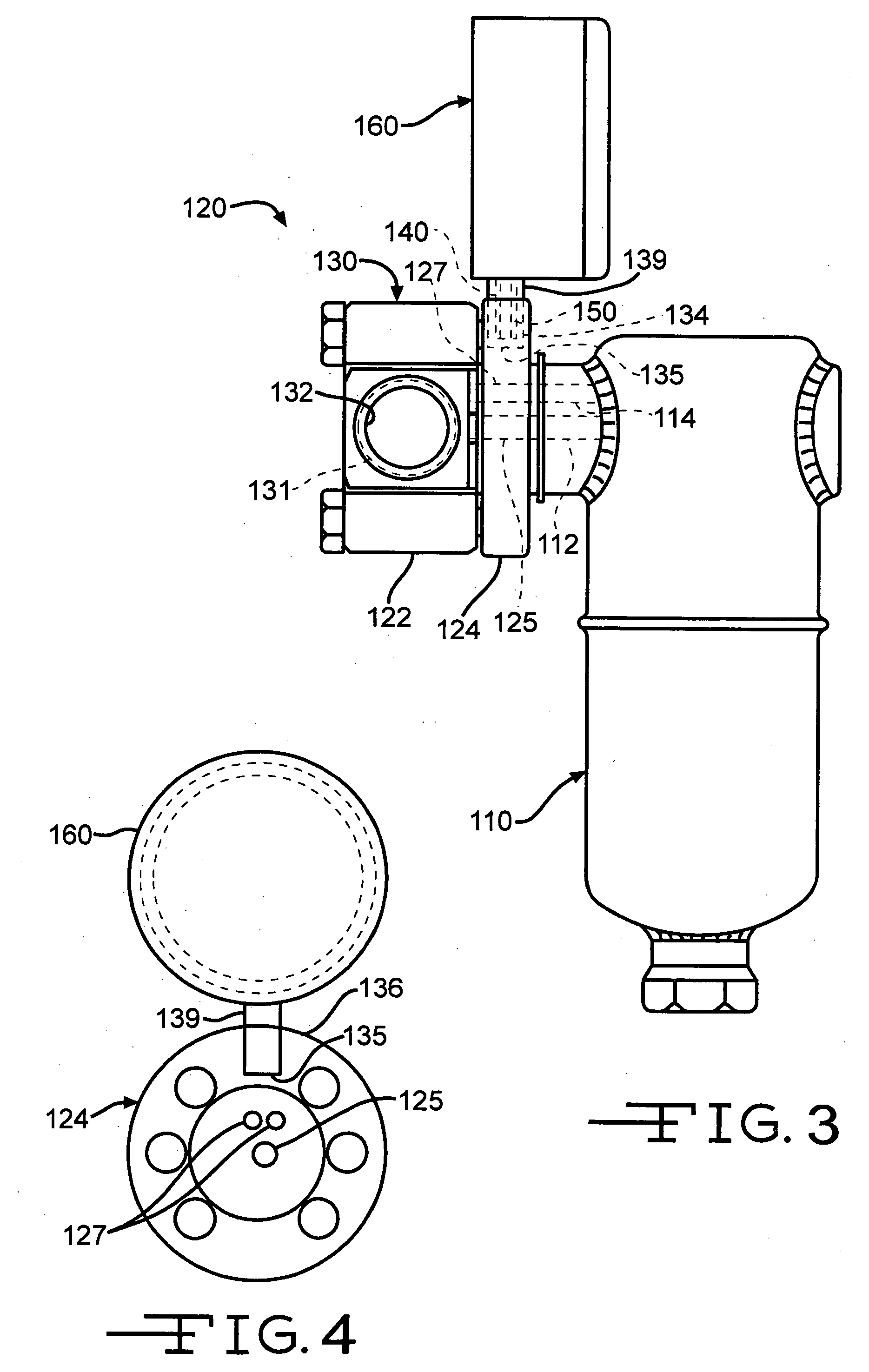

Liquid separator

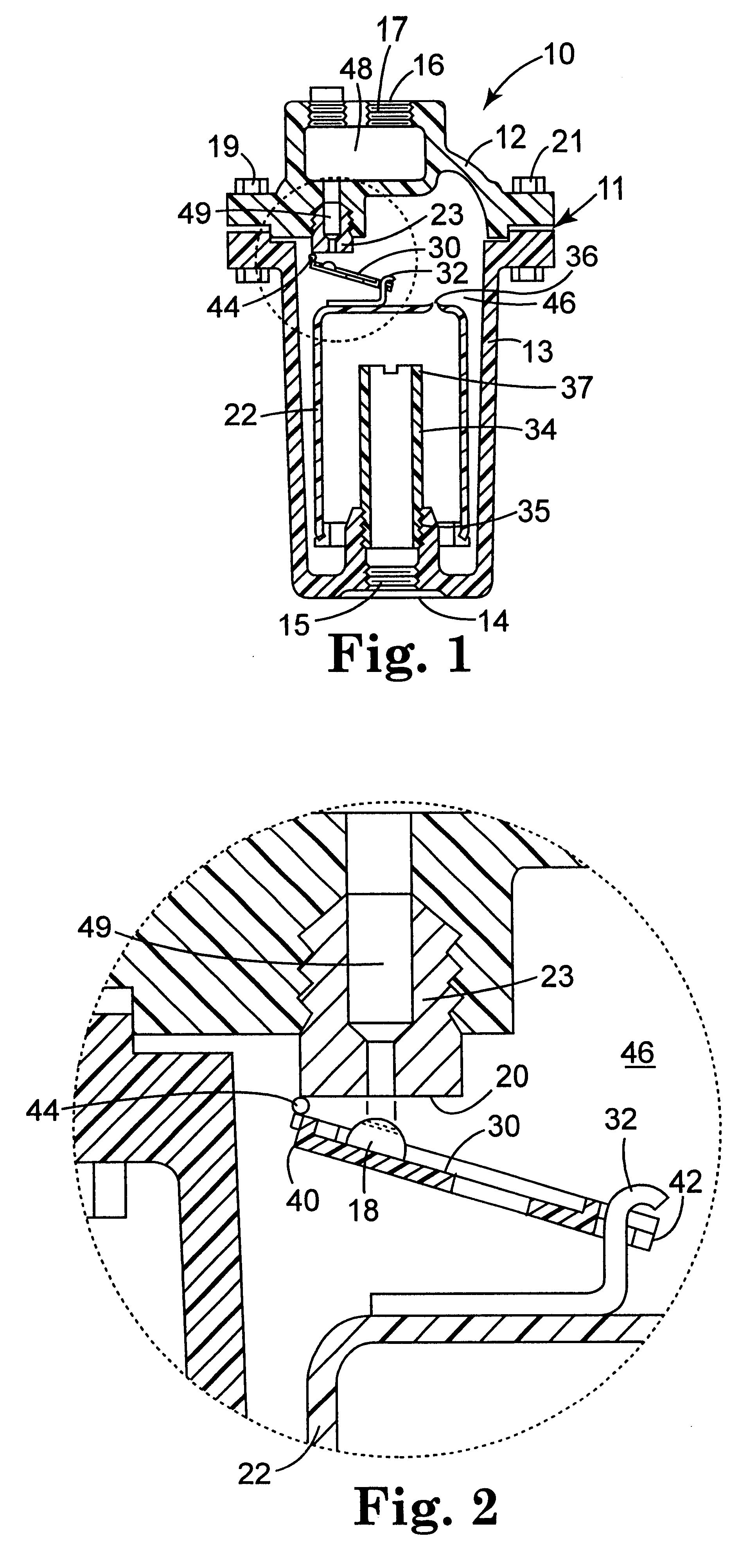

InactiveUS6368498B1Settling tanks feed/dischargeSolid sorbent liquid separationEngineeringValve seat

A liquid separator (10) for separating two immiscible liquids having different specific gravities, for example, a first liquid comprising water and a second liquid comprising oil. The liquid separator (10) has a housing (12) that defines a separation chamber (14) and liquid inlet (16), a first liquid outlet (18) and a second liquid outlet (20) mounted above the first liquid outlet (18). A float 26 is positioned within separation chamber 14 to translate in the vertical direction and has a specific gravity between that of the first and second liquids so that it floats at approximately the interface (28) between the two liquid phases (30 and 32). Valve closure devices (38 and 40) contact valve seats in the valves 46 and 56 of first and second liquid outlets (18 and 20) to control the flow of separated liquids from separation chamber 14 as determined by the level of the interface (28) and the length of the valve rods (34 and 36).

Owner:GUILMETTE PAUL

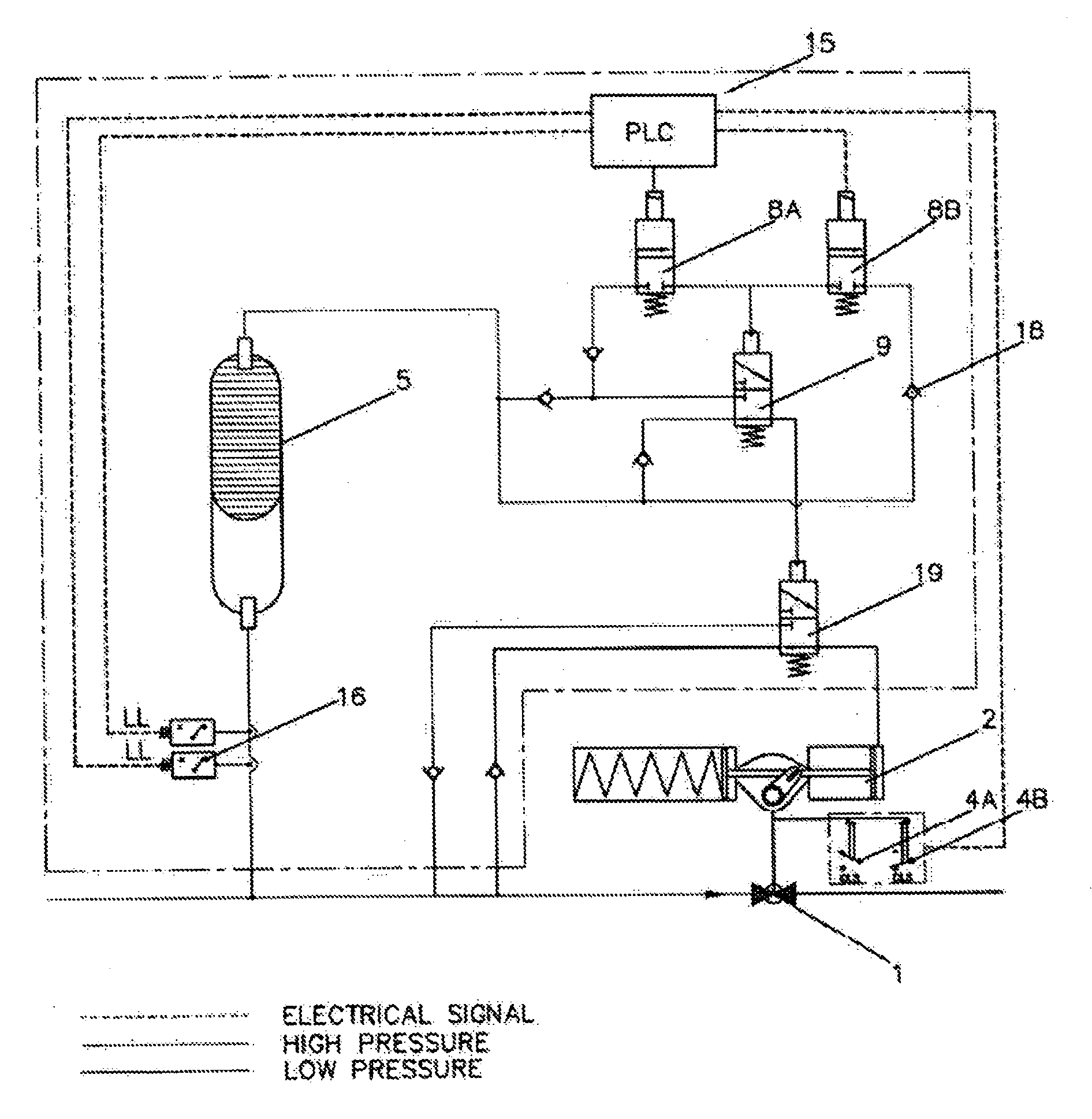

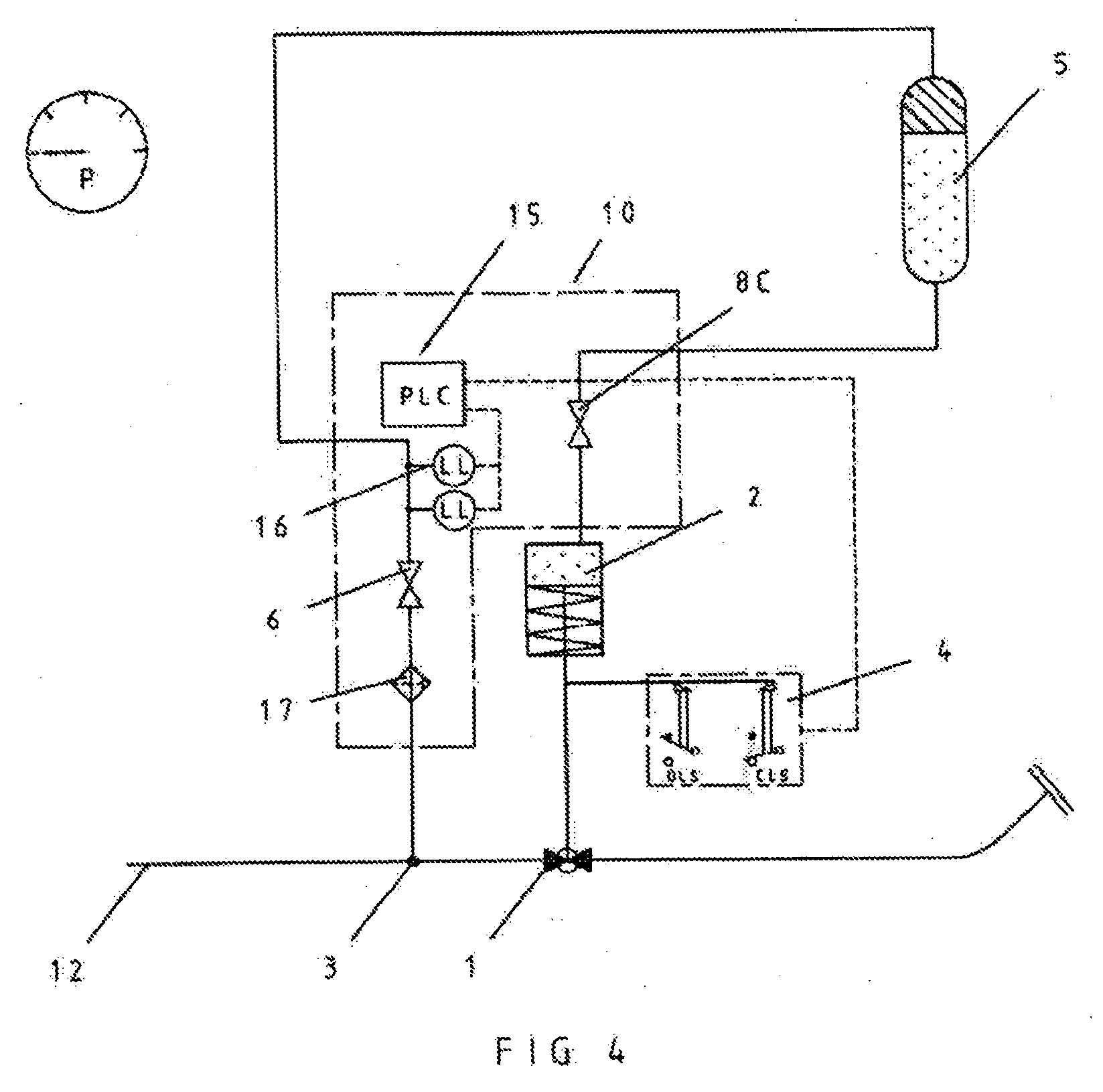

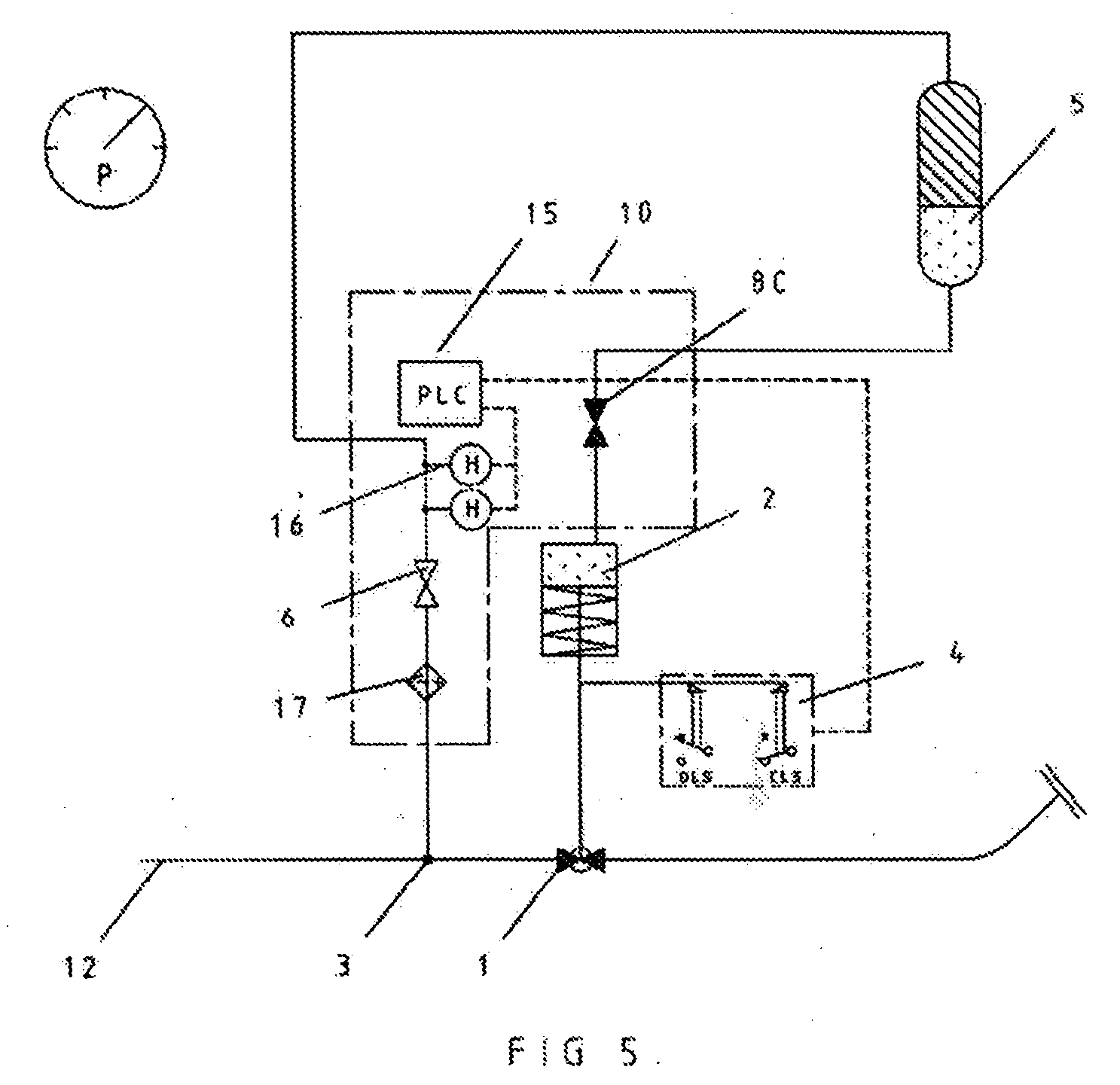

Autonomous Shut-Off Valve System

InactiveUS20090126798A1Little maintenanceLittle attendanceOperating means/releasing devices for valvesServomotor componentsValve actuatorEngineering

A pipeline (12) for the transportation of a process fluid comprises an autonomous shut-off valve system comprises a shut-off valve (1) including a fluid powered valve actuator (2) moveable between a closed and an open position by means of pressure generated by the process fluid, a pressure tapping (3) in the pipeline upstream of the shut-off valve, a fluid connection to the pressure tapping arranged to deliver process fluid to power opening of the said shut-off valve, at least one pressure sensor (16) arranged in a hydraulic line extending from the pressure tapping, at least one control valve (8A, 8B, 8C) operable to permit or prevent flow of pressurised fluid to the shut-off valve actuator; and a controller (15) arranged to open and close the control valve. The control valve is commanded to open and close when pressure thresholds are reached, the pressure thresholds being detected by the pressure sensor and the control valve being commanded to close by the controller.

Owner:MATHER SAM

Cooling control device for condenser

InactiveUS7174732B2Avoid yield lossInhibit productionCompression machines with non-reversible cycleEvaporators/condensersTemperature controlGas phase

Cooling control device for a condenser is provided which includes the condenser, a cooling device for cooling the condenser, and a control device for controlling the cooling device. The cooling device includes a first cooling fan for cooling a gaseous-phase portion of the condenser, and two second cooling fans for cooling a liquid-phase portion of the condenser independently of the first cooling fan. The control device also includes a pressure control section for optimally adjusting a pressure within the gaseous-phase portion, and a temperature control section for optimally adjusting a temperature within the liquid-phase portion. The pressure control section operates the first cooling fan, in accordance with a detected pressure within the gaseous-phase portion, to adjust the pressure within the gaseous-phase portion. The temperature control section operates the second cooling fans, in accordance with a detected temperature within the liquid-phase portion, to adjust the temperature within the liquid-phase portion.

Owner:HONDA MOTOR CO LTD

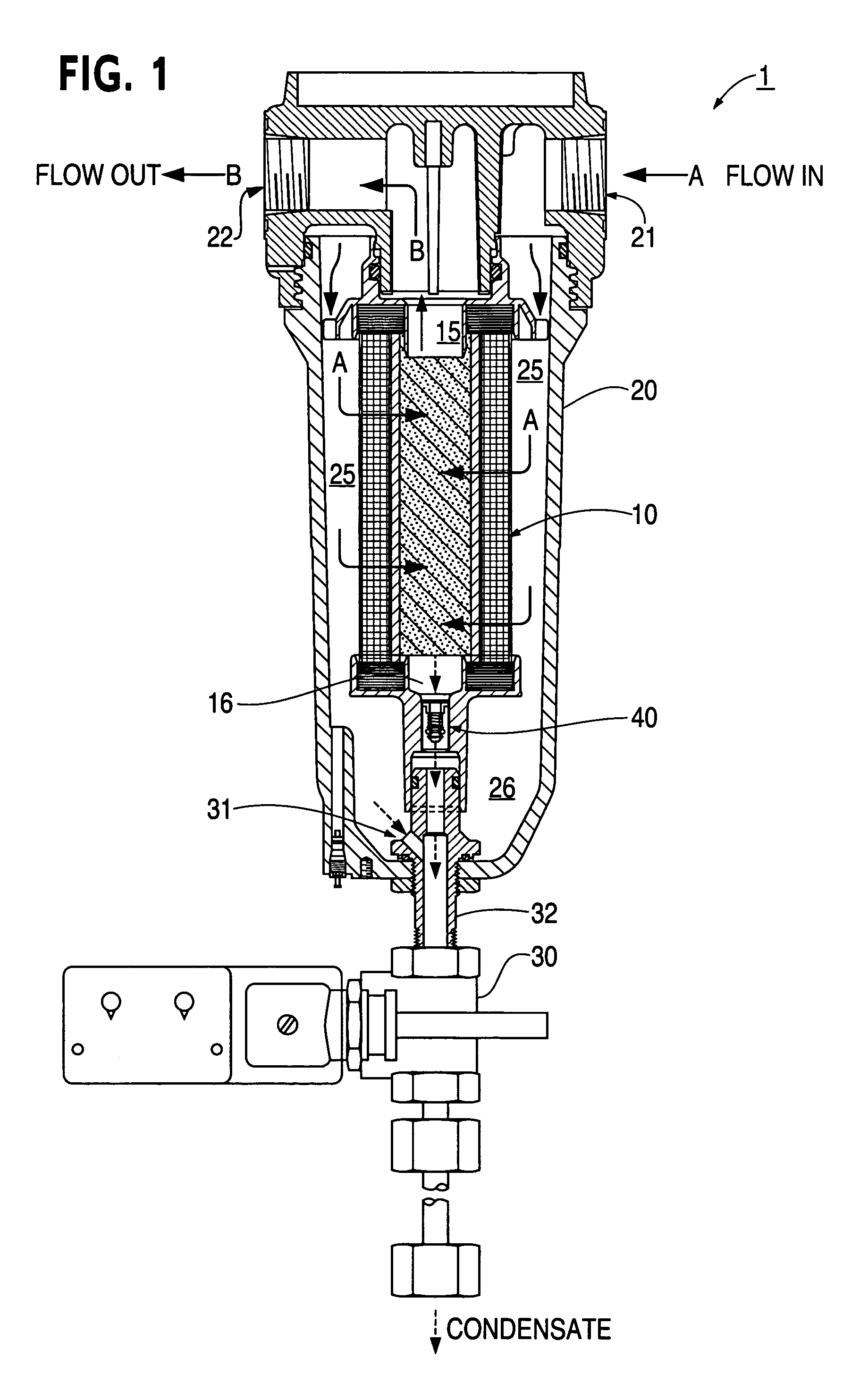

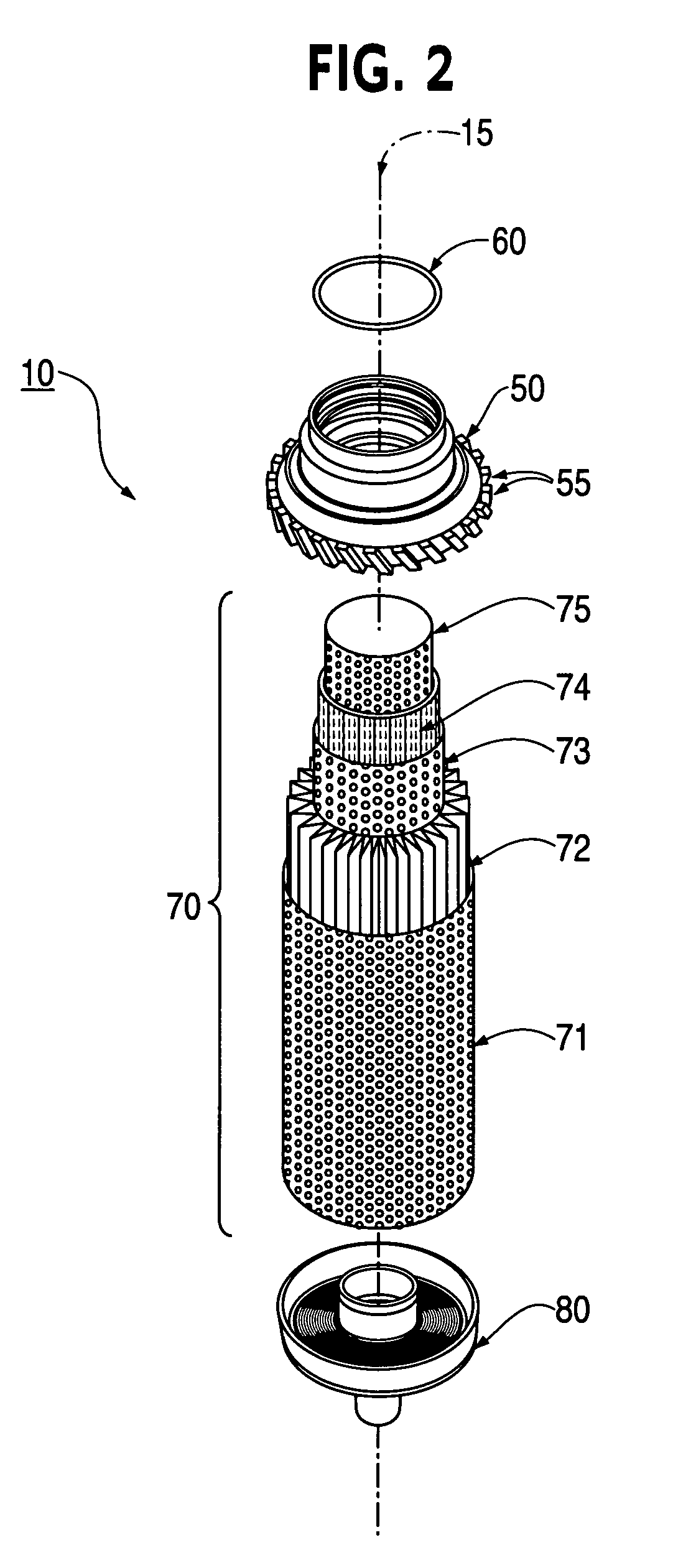

Coalescing type filter apparatus and method

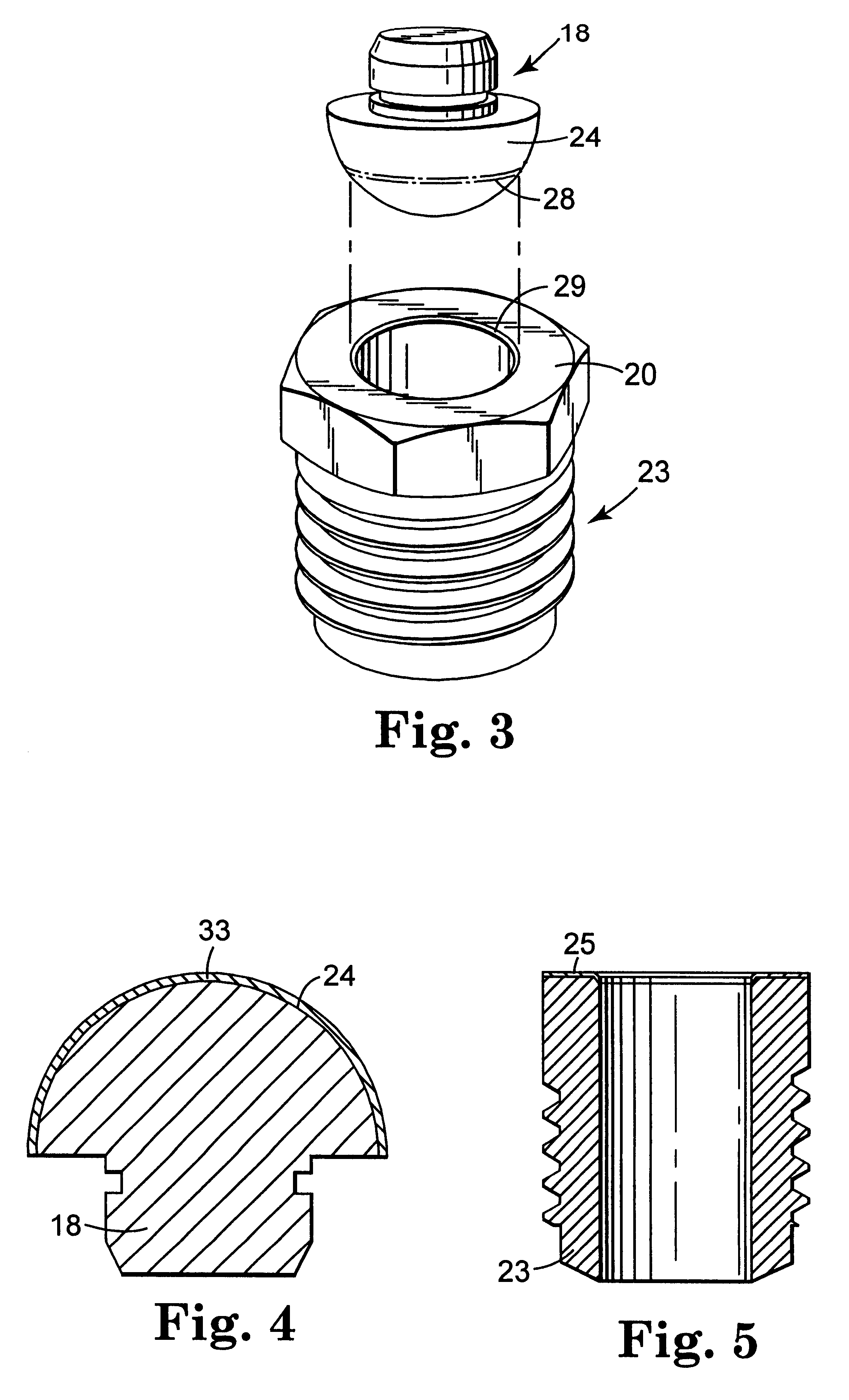

ActiveUS7326266B2Combination devicesOperating means/releasing devices for valvesEngineeringMechanical engineering

A coalescing type gas filter includes a filtering element enclosed in an inner chamber which is housed in an outer chamber and a drain device to simultaneously drain accumulated liquid in both the inner chamber and the outer chamber. The drain device contains a pressure sensitive valve that regulates opening of the drain in response to a drop in pressure.

Owner:IND TECH & SERVICES AMERICAS INC

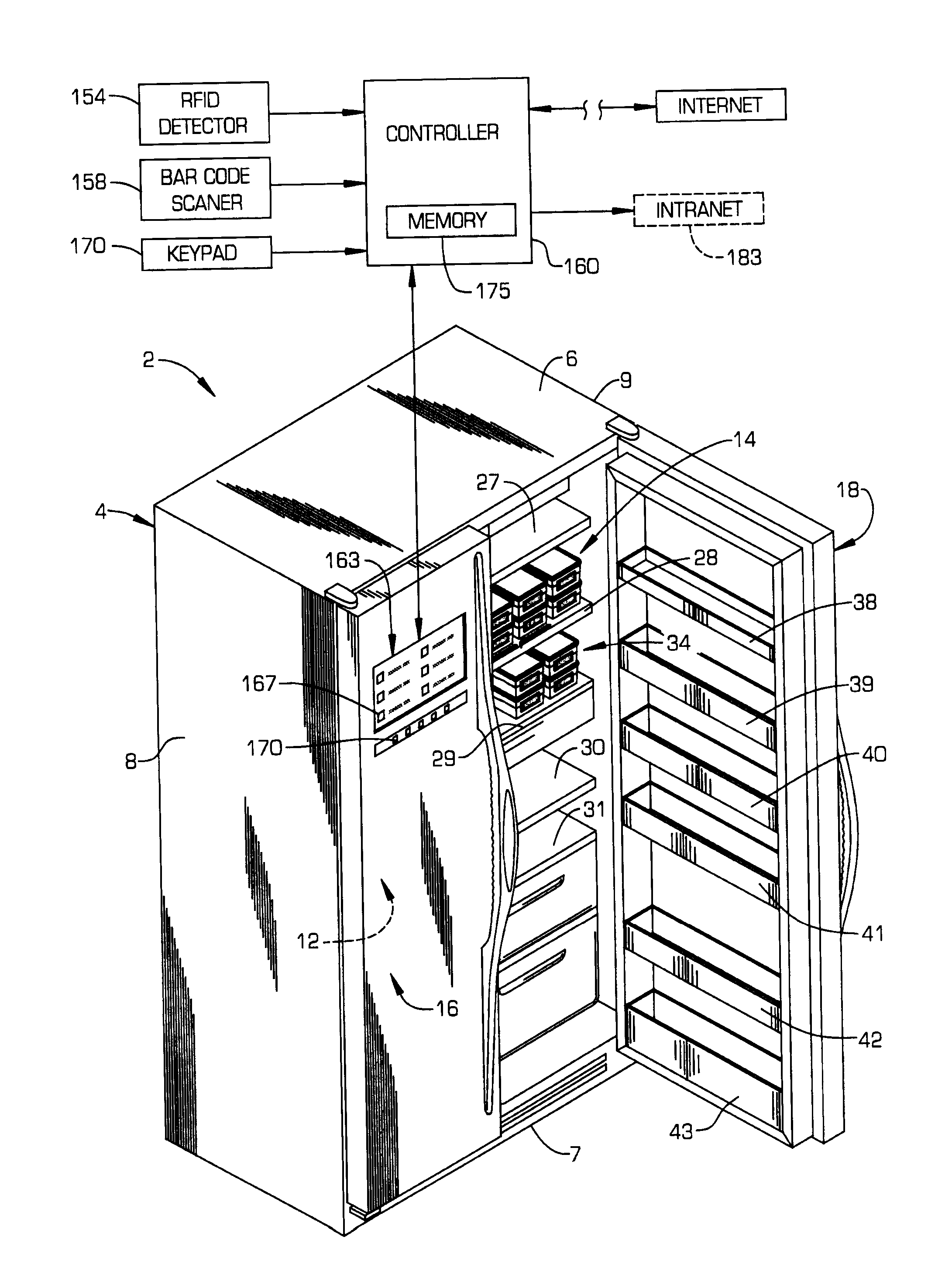

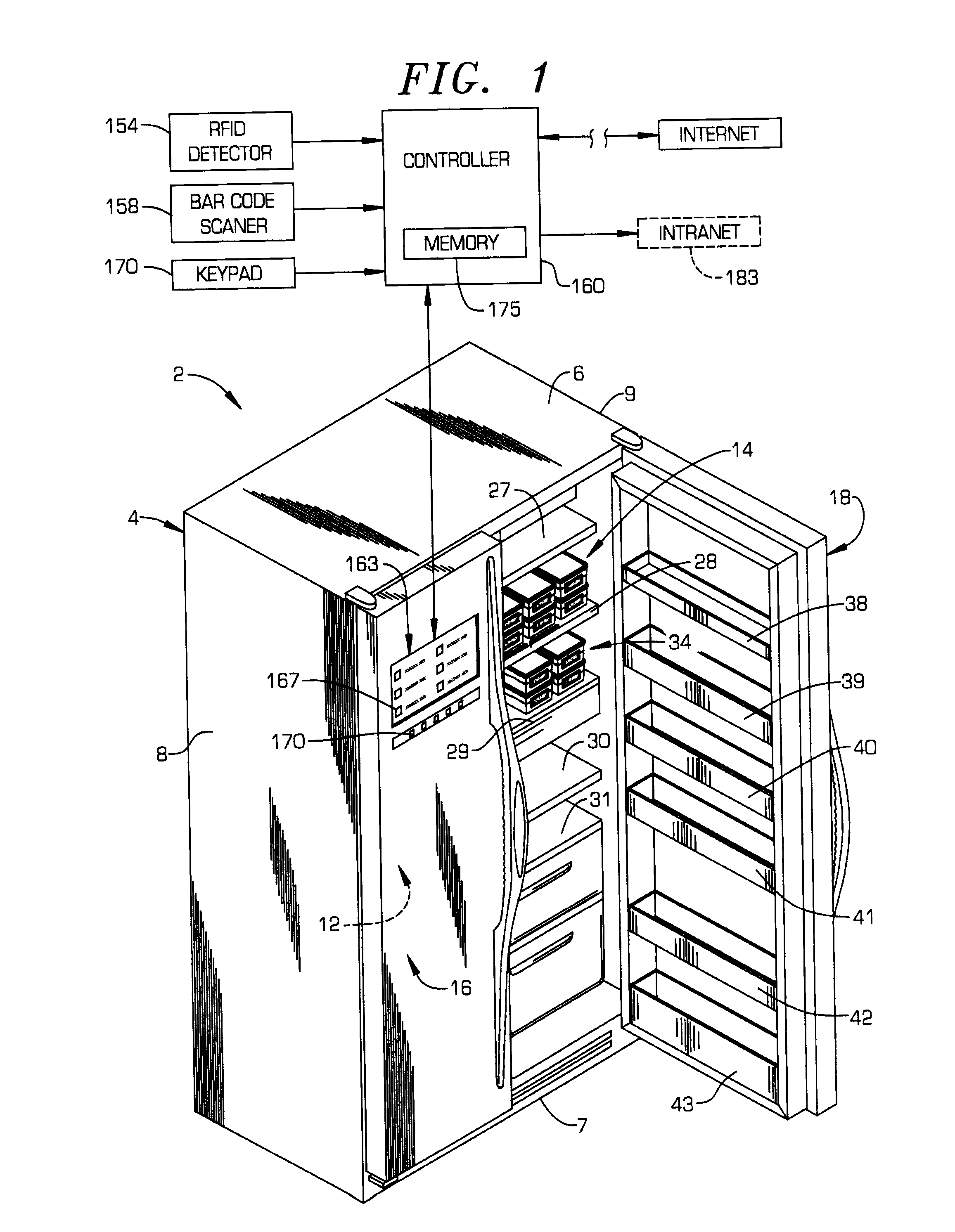

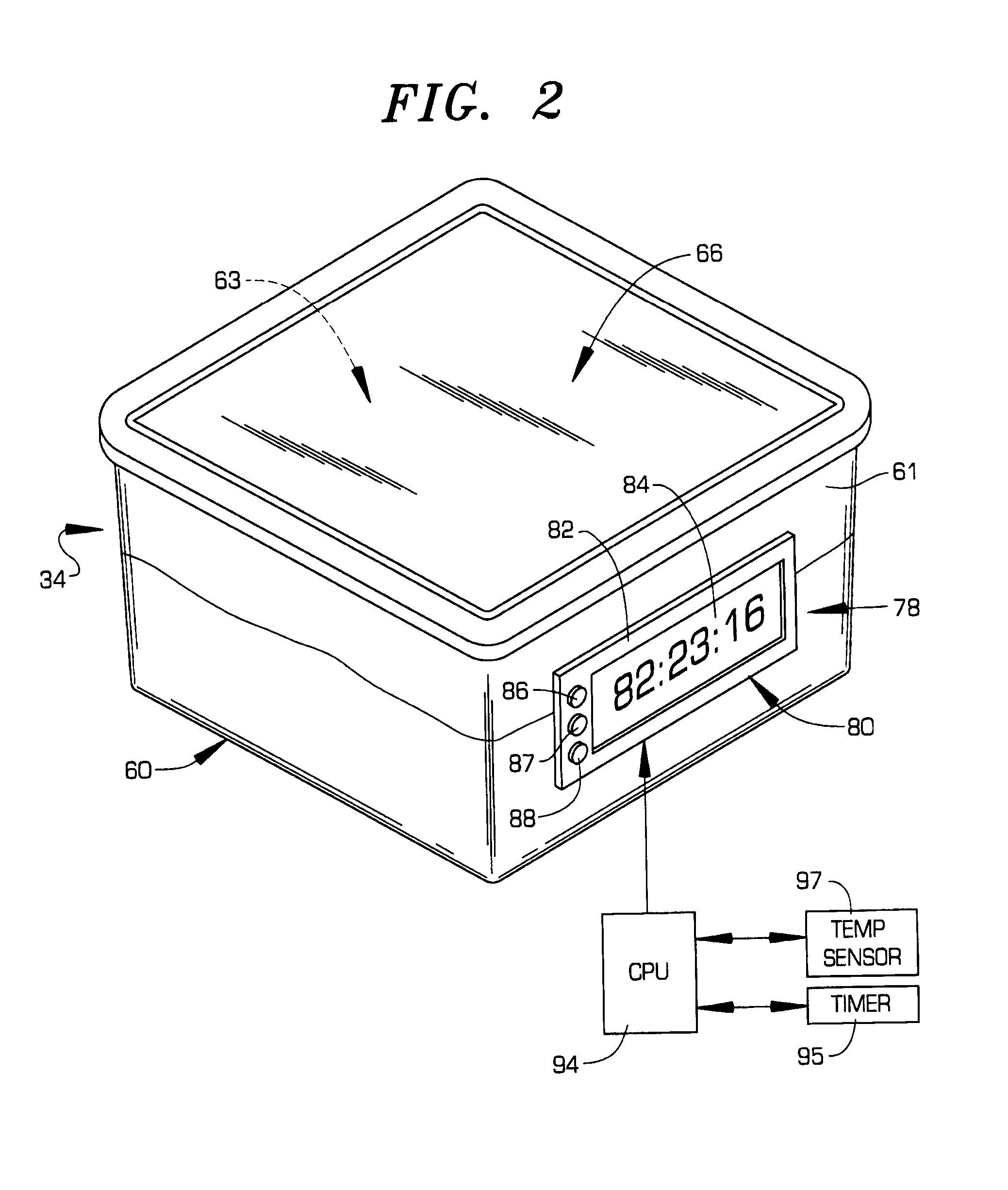

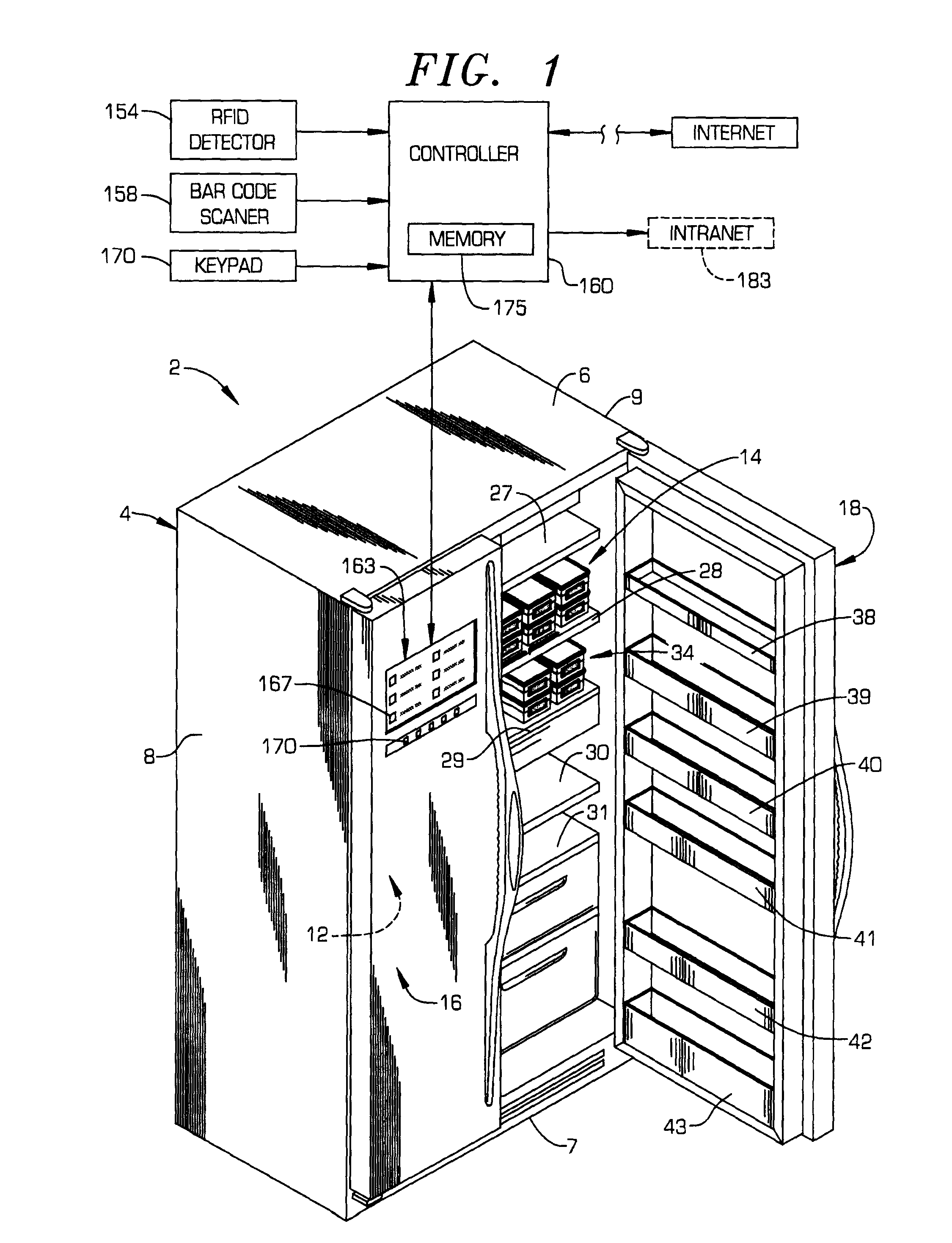

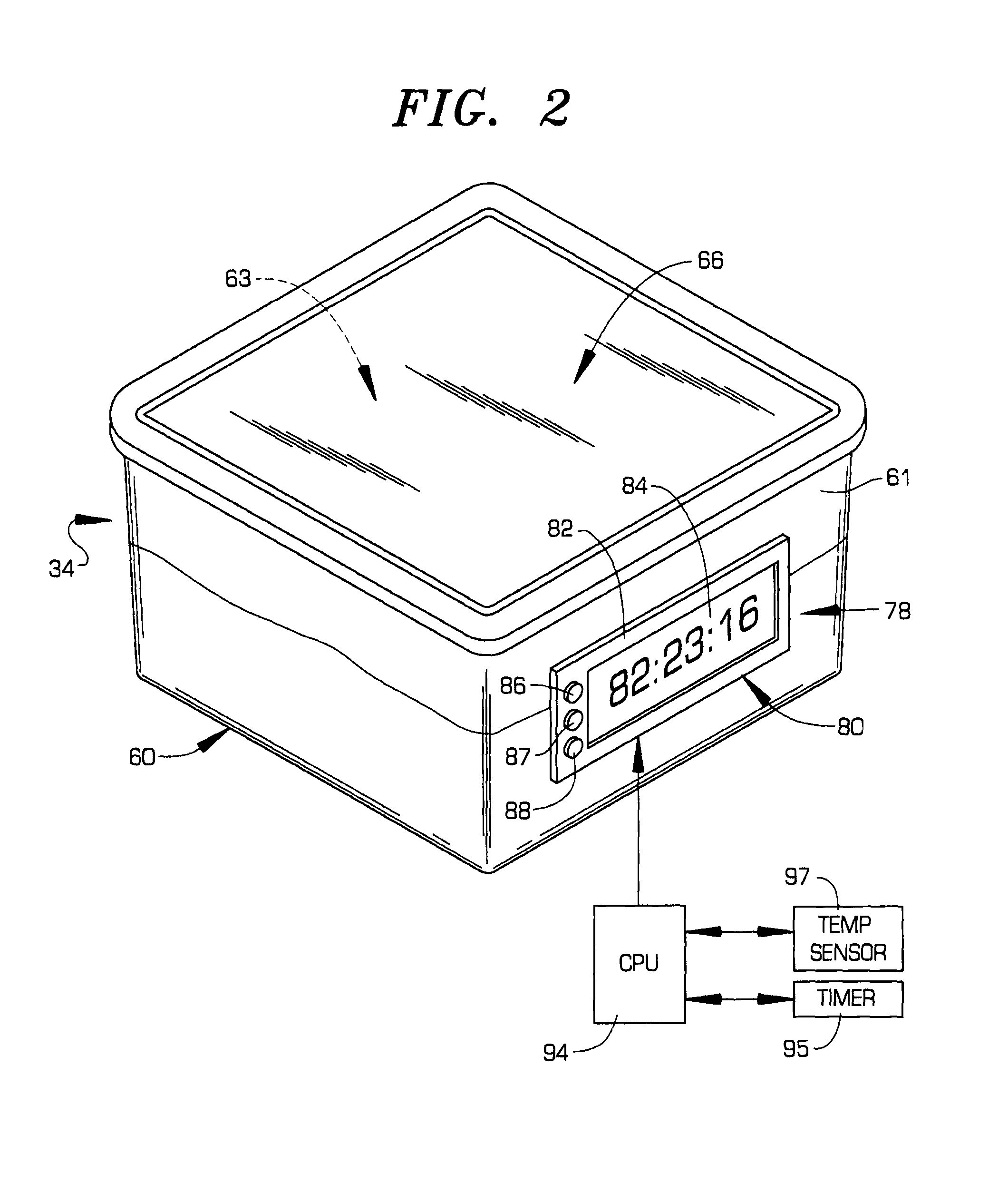

Refrigerator including food product management system

ActiveUS20080250797A1Time-programme switchesAuxillary controllers with auxillary heating devicesAdhesiveTime segment

A refrigerator includes at least one refrigerated compartment and a food product management system. The food product management system includes a container for storing foodstuffs in the at least one refrigerated compartment. The container includes a storage zone and a lid. A tag is arranged on the container to provide a consumer with an indication of whether a food item stored in the container is or is not spoiled. The tag can include a timer having a display, an indicator that changes state upon the passage of a predetermined time period and a computer that notifies a consumer, such as through an email, about a parameter associated with the food item in the container. The tag is affixed to the container with adhesive, snaps, clips, hooks and the like or, alternatively, simply integrally formed with the container.

Owner:WHIRLPOOL CORP

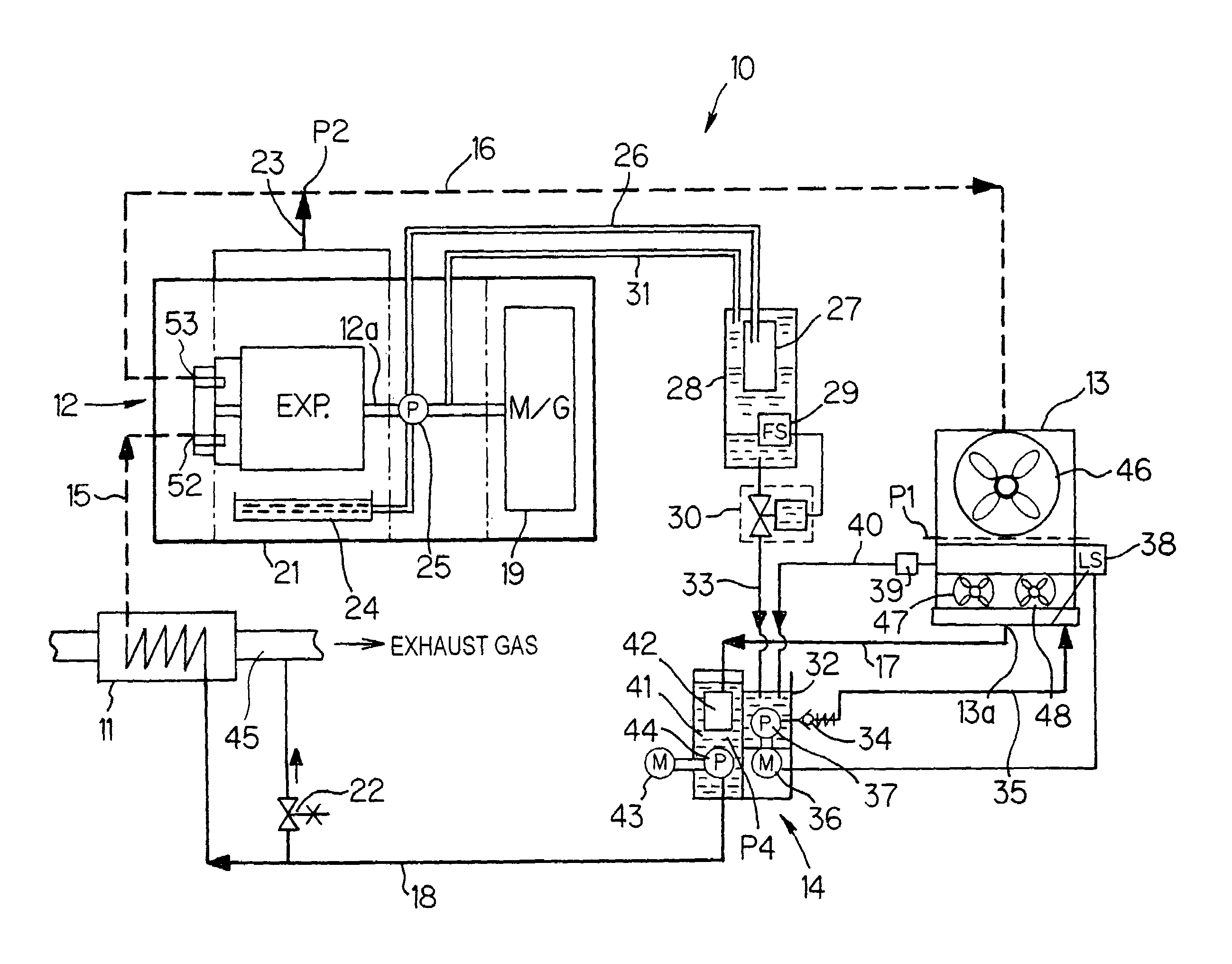

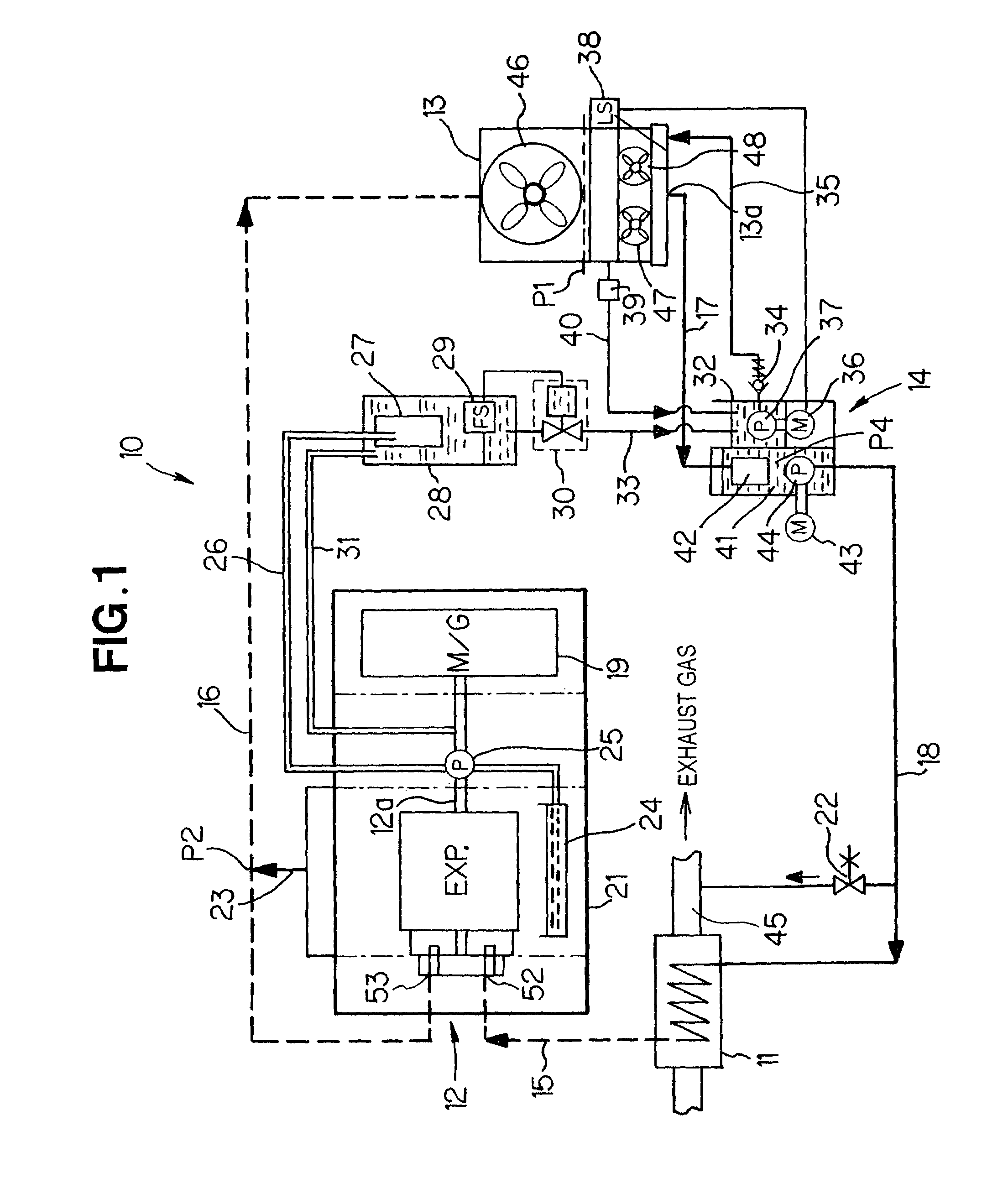

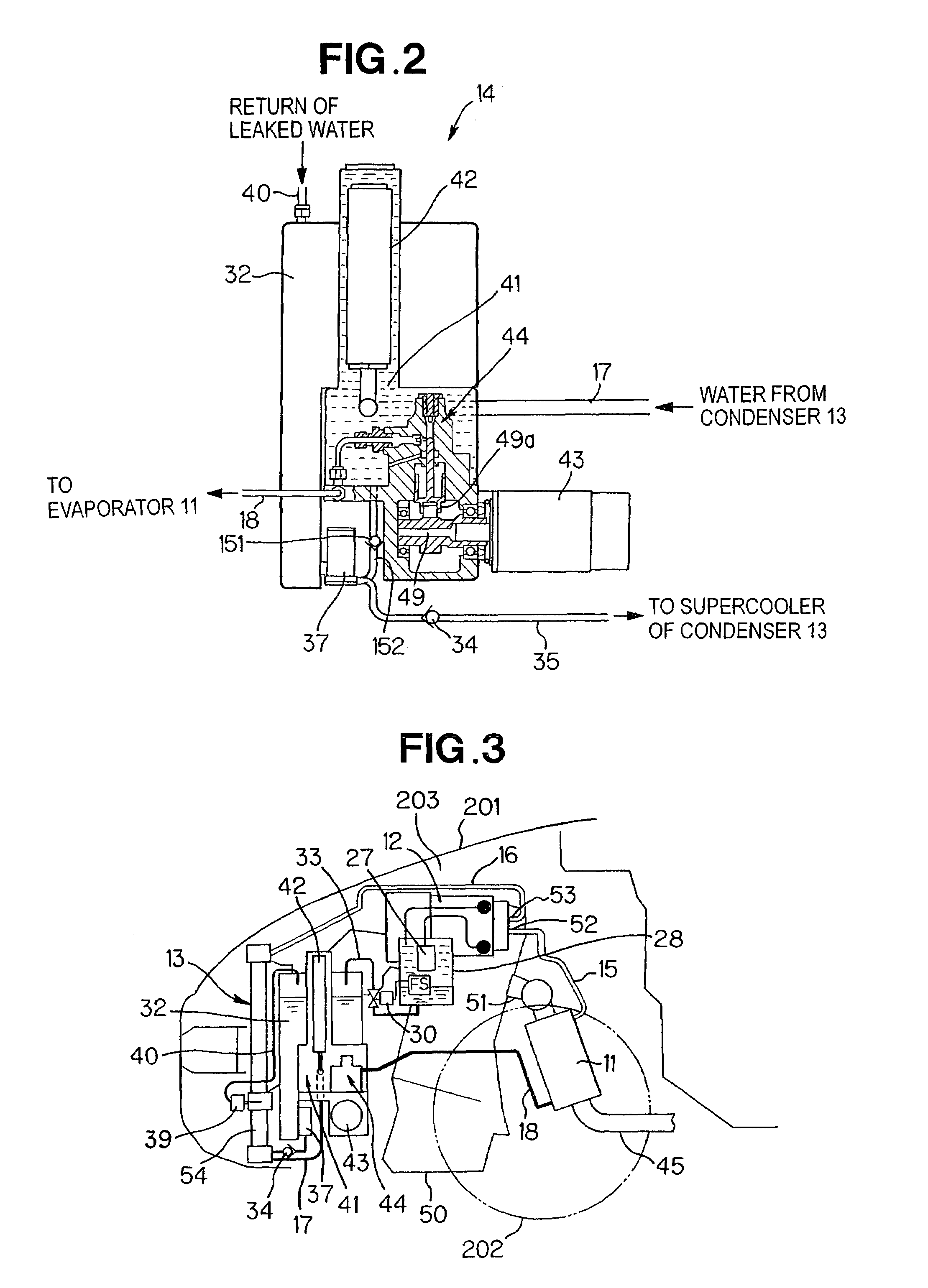

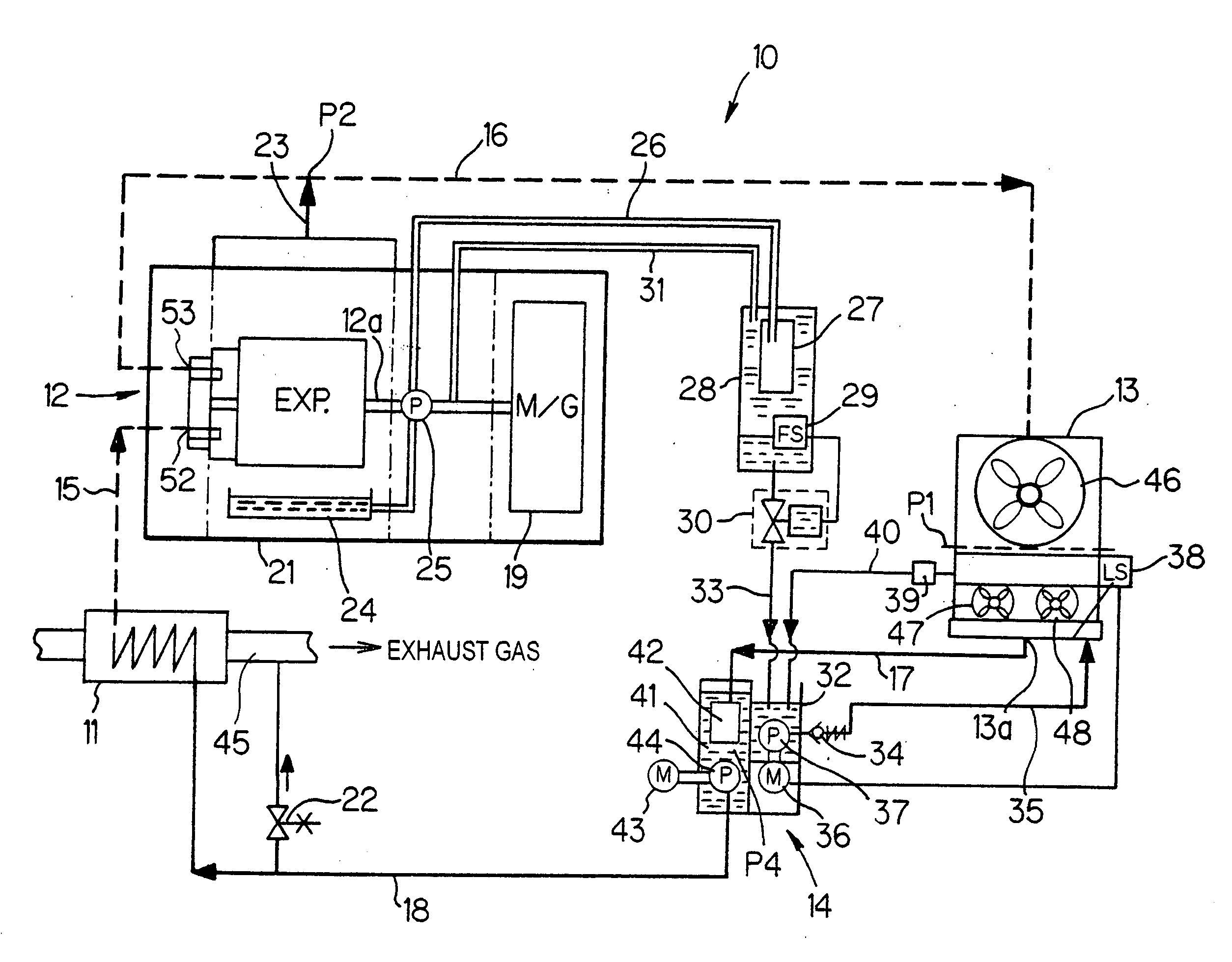

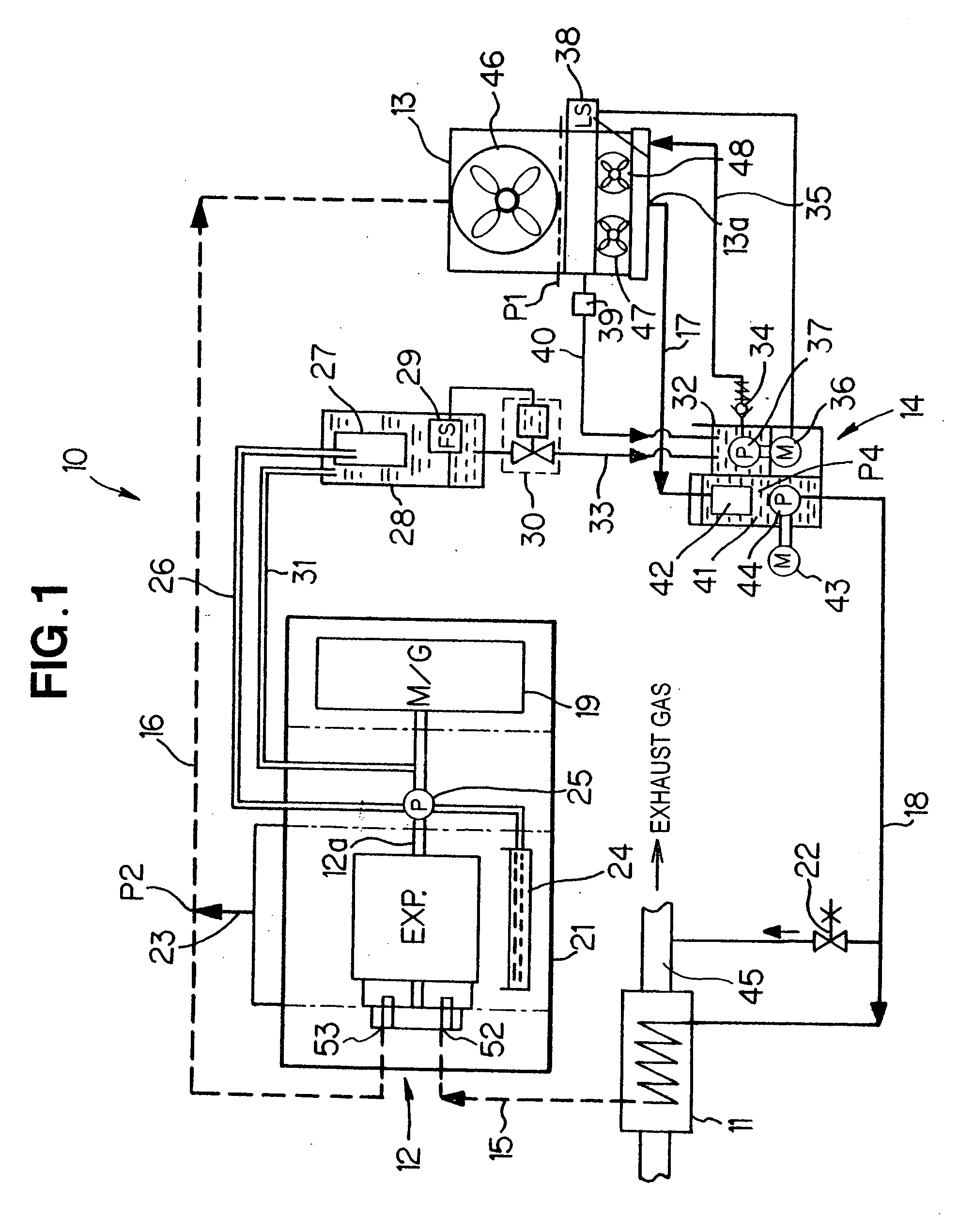

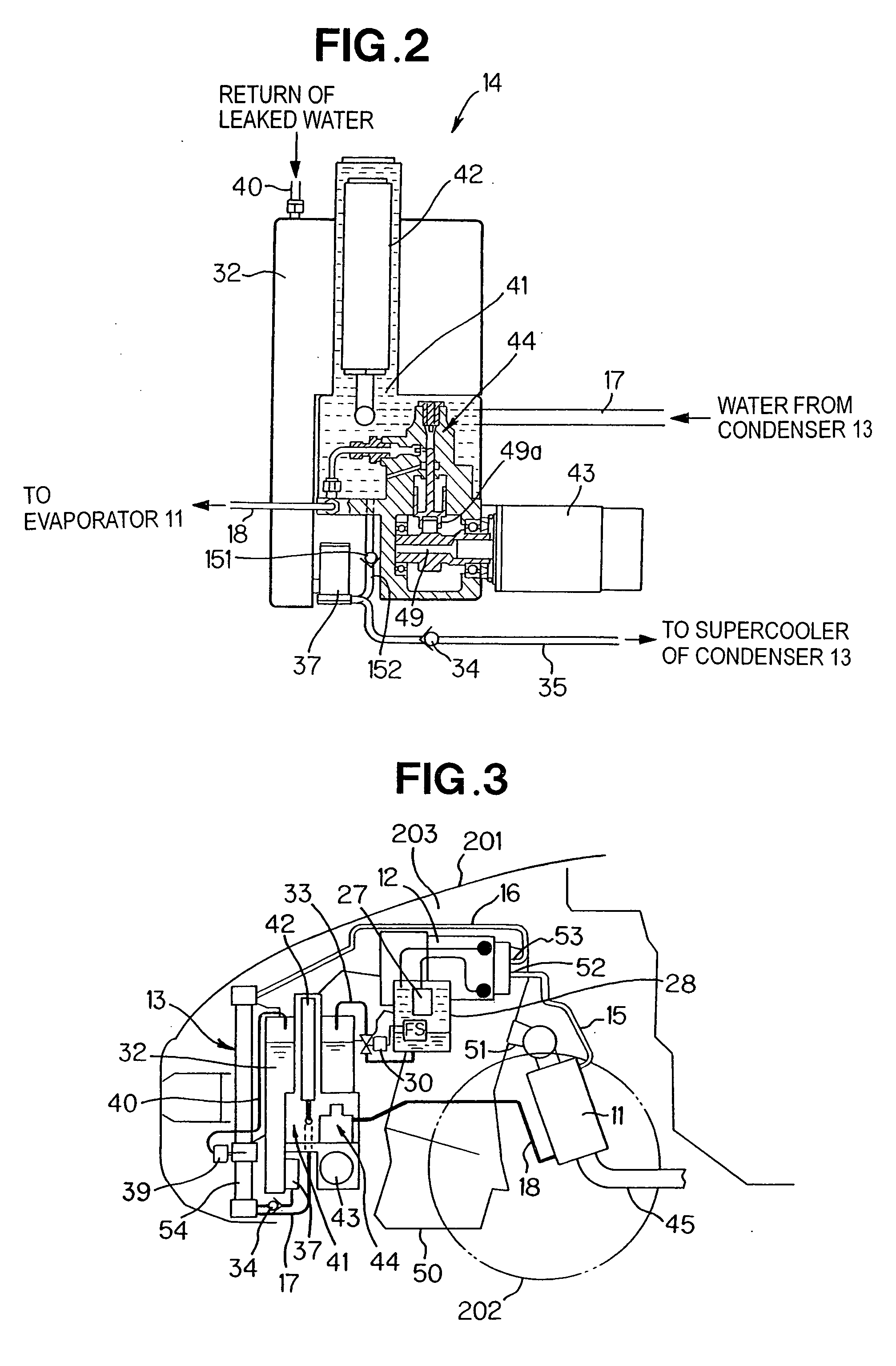

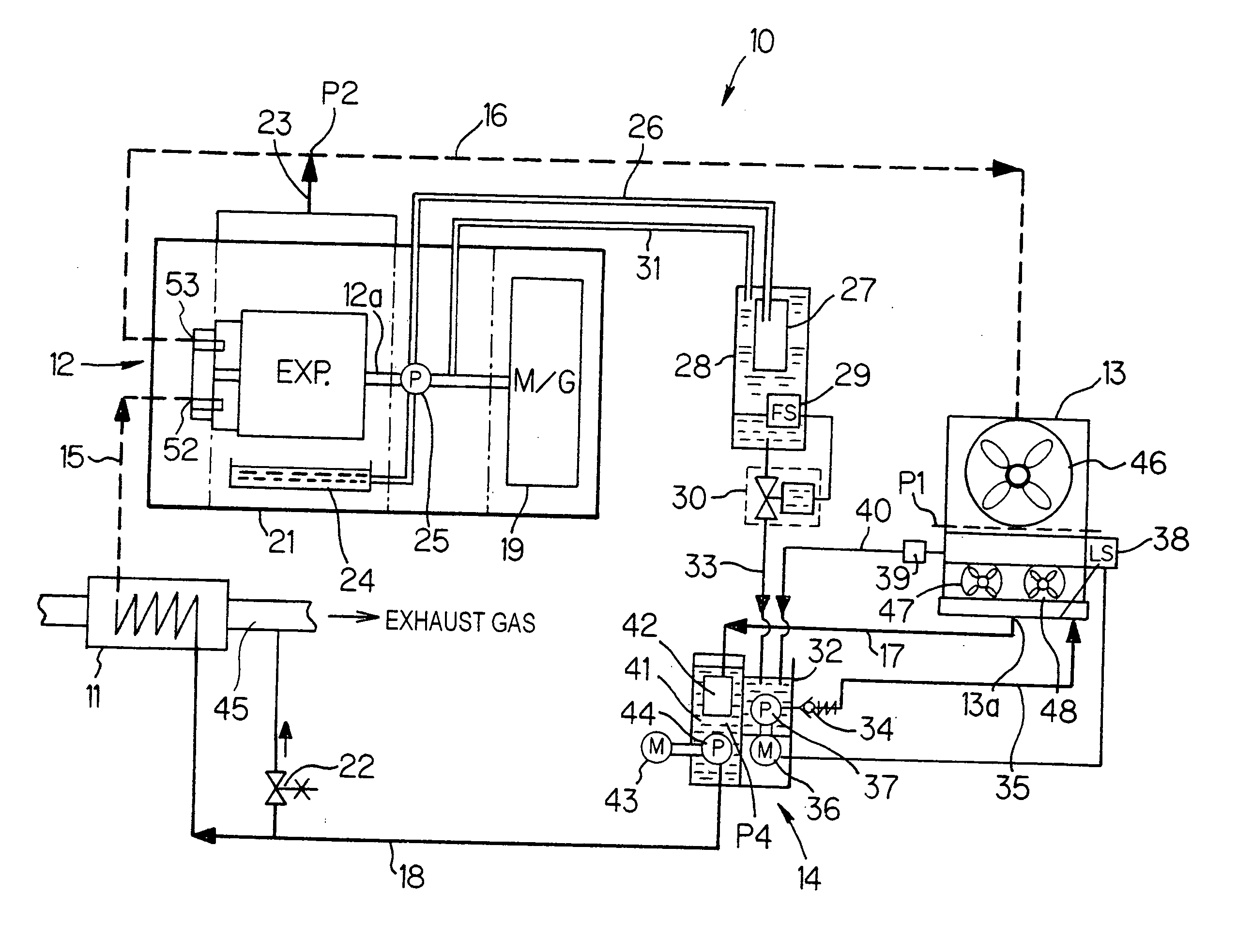

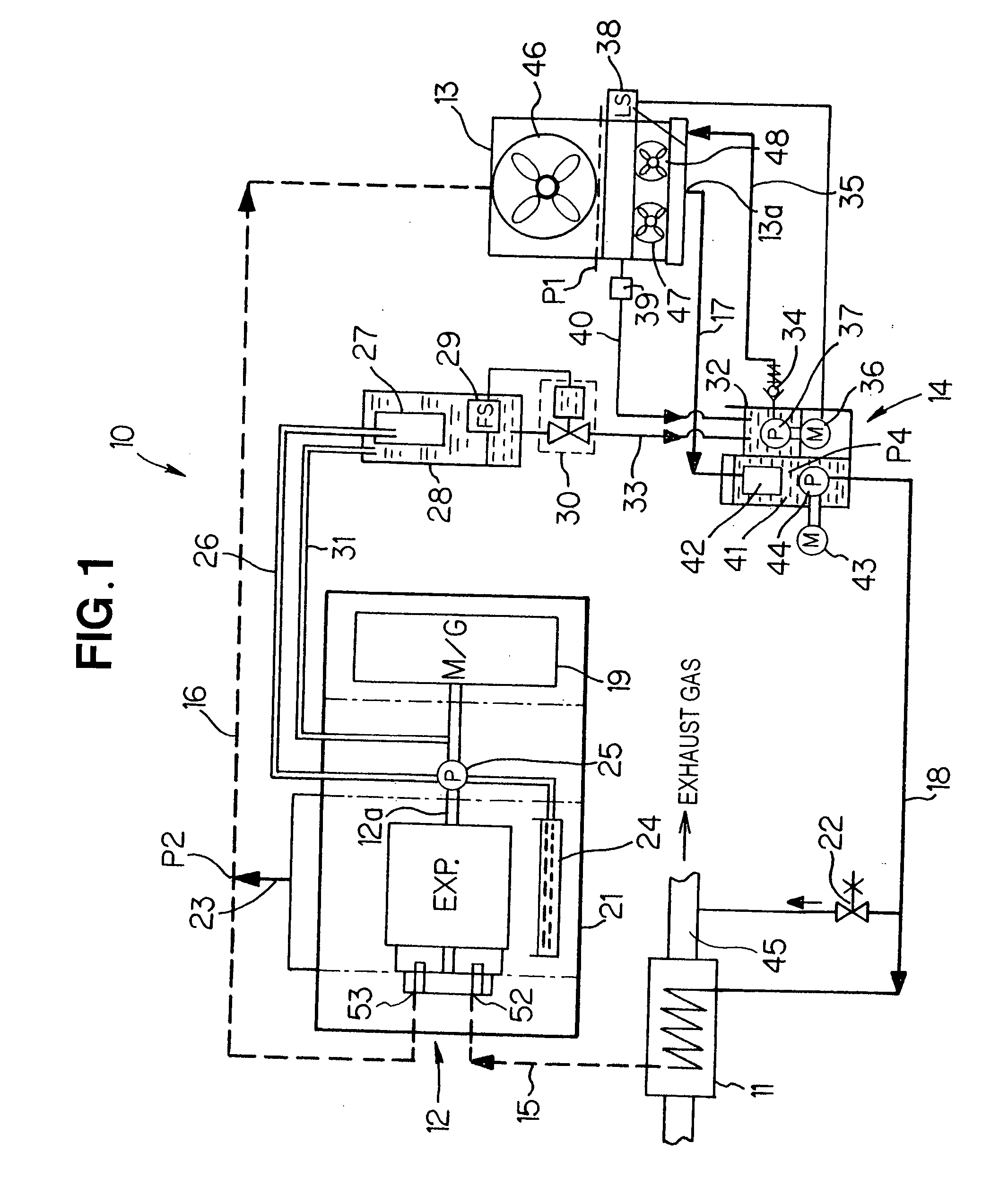

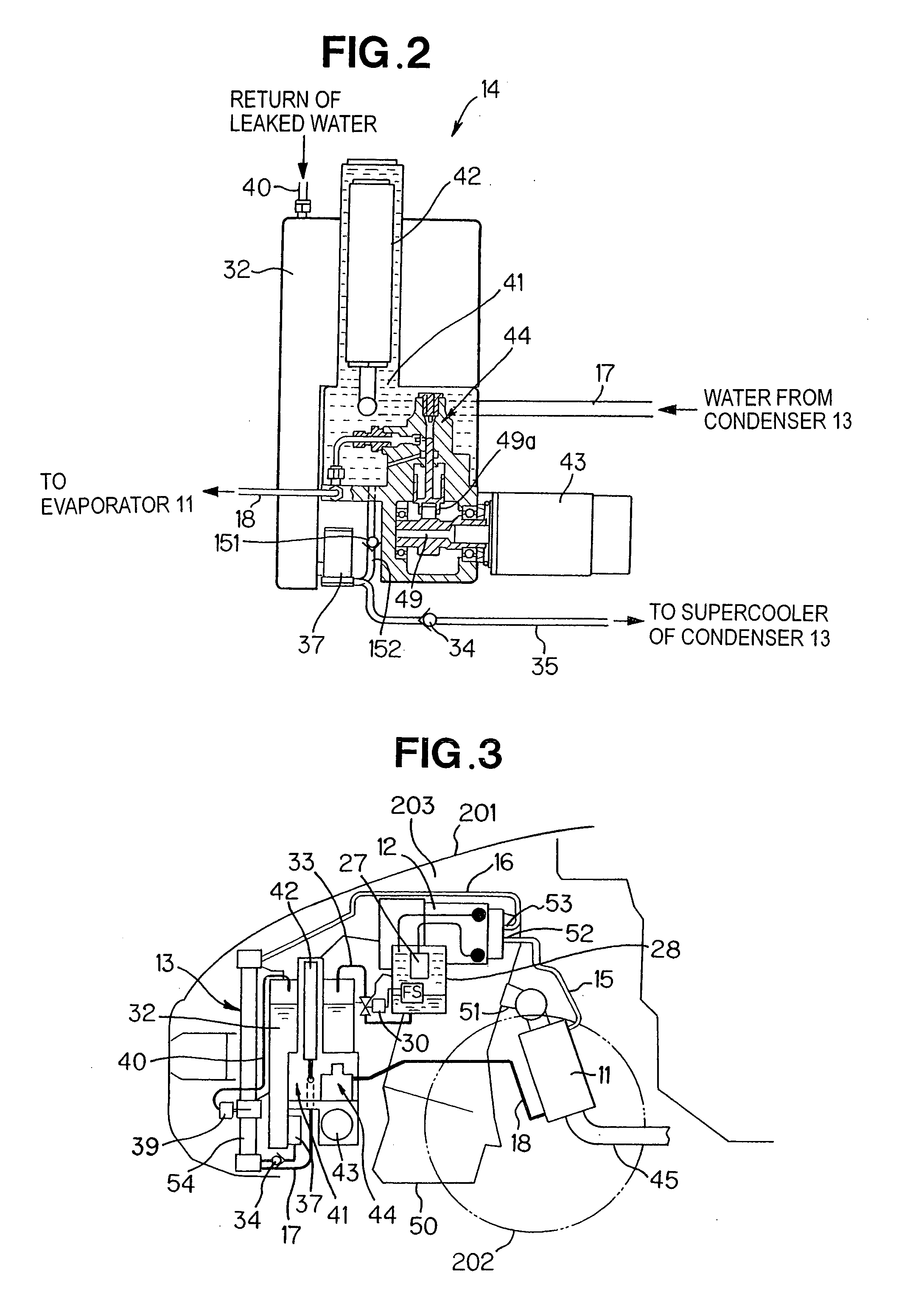

Device for controlling liquid level position within condenser in rankine cycle apparatus

InactiveUS20050072182A1Reduce variationMinimize changesCompression machines with non-reversible cycleEvaporators/condensersWater vaporFluid level

In a liquid-level-position control device for a condenser in a Rankine cycle apparatus, first and second reference liquid level positions are set. When a position of the fluid level is lower than the first reference liquid level position, water is replenished to a condenser by a liquid-phase working medium supply section. When the position of the fluid level is higher than the second reference liquid level position, the liquid-phase working medium is discharged from within the condenser by a liquid-phase working medium discharge section. In this way, the liquid level, which is a boundary surface between water vapor and condensed water within the condenser, can be constantly kept at an optimal position.

Owner:HONDA MOTOR CO LTD

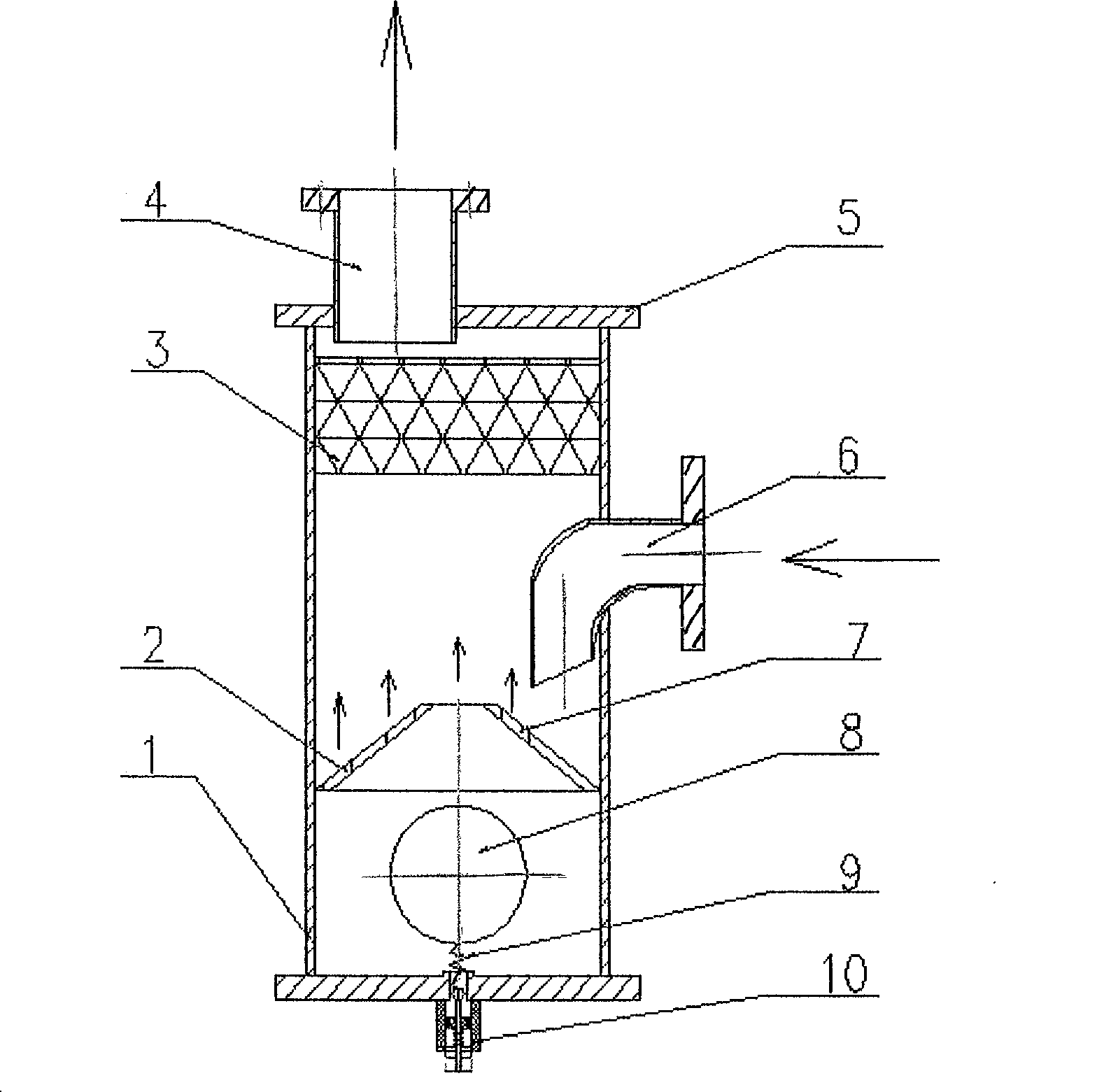

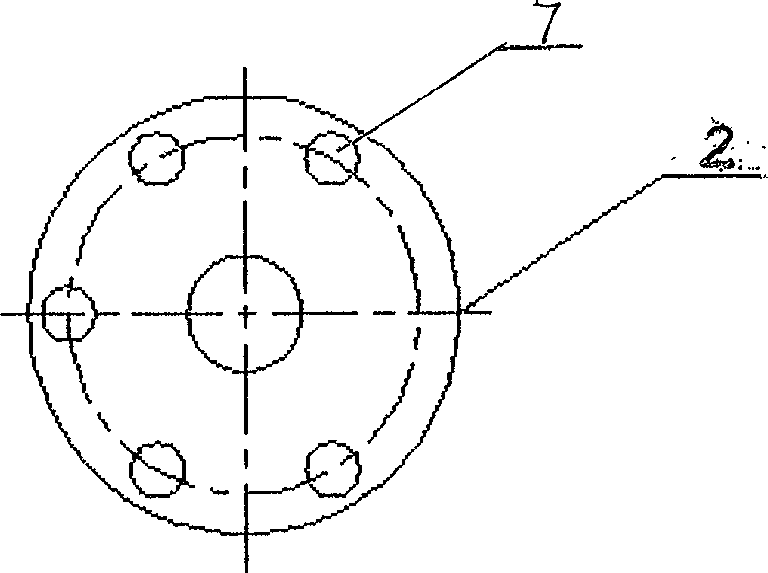

Gas and liquid separator

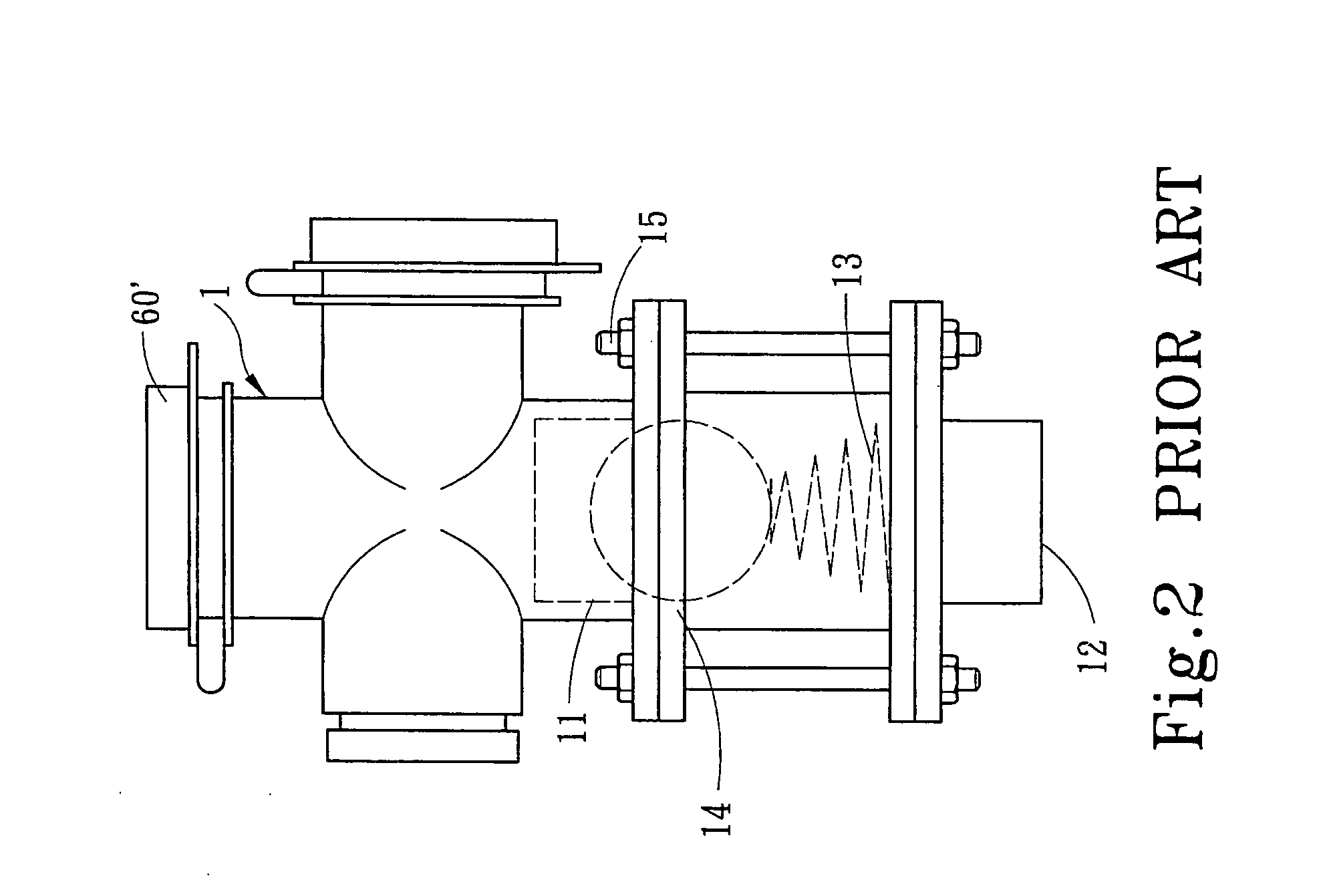

InactiveCN101371957AThe effect is obviousSimple structureLiquid degasificationDispersed particle separationChemical industryVapor–liquid separator

The present invention relates to a gas-liquid separator used as an oil-gas recycling system in oil and chemical industries. The separator comprises a cylinder body and a cylinder cover. The cylinder cover is provided with a gas outlet. A wire mesh demister is arranged in the cylinder body near the gas outlet at the top. A flow covering chute which has the same diameter as the inner diameter of the cylinder body, is fixed on the inner wall of the cylinder body and is provided with a gas-liquid through hole is arranged at the inner lower part of the cylinder body. The underside of the flow covering chute is provided with a ball float which is connected with a check valve core arranged at the bottom of the cylinder by a steel wire. A gas-liquid inlet is arranged on the lateral wall of the cylinder body between the wire mesh demister and the flow covering chute. The gas-liquid separator has the advantages of simple structure, small size and convenient operation. When the gas-liquid with pressure enters through the gas-liquid inlet, the flow covering chute at the inner lower part of the cylinder reduces the flow velocity of the gas-liquid, so as to ensure that liquid in the gas-liquid with the pressure is changed into the state of normal pressure and flows into the bottom of the cylinder body slowly to be discharged by a check valve, and gas is exhausted from the gas outlet.

Owner:江苏惠宇电仪设备有限公司

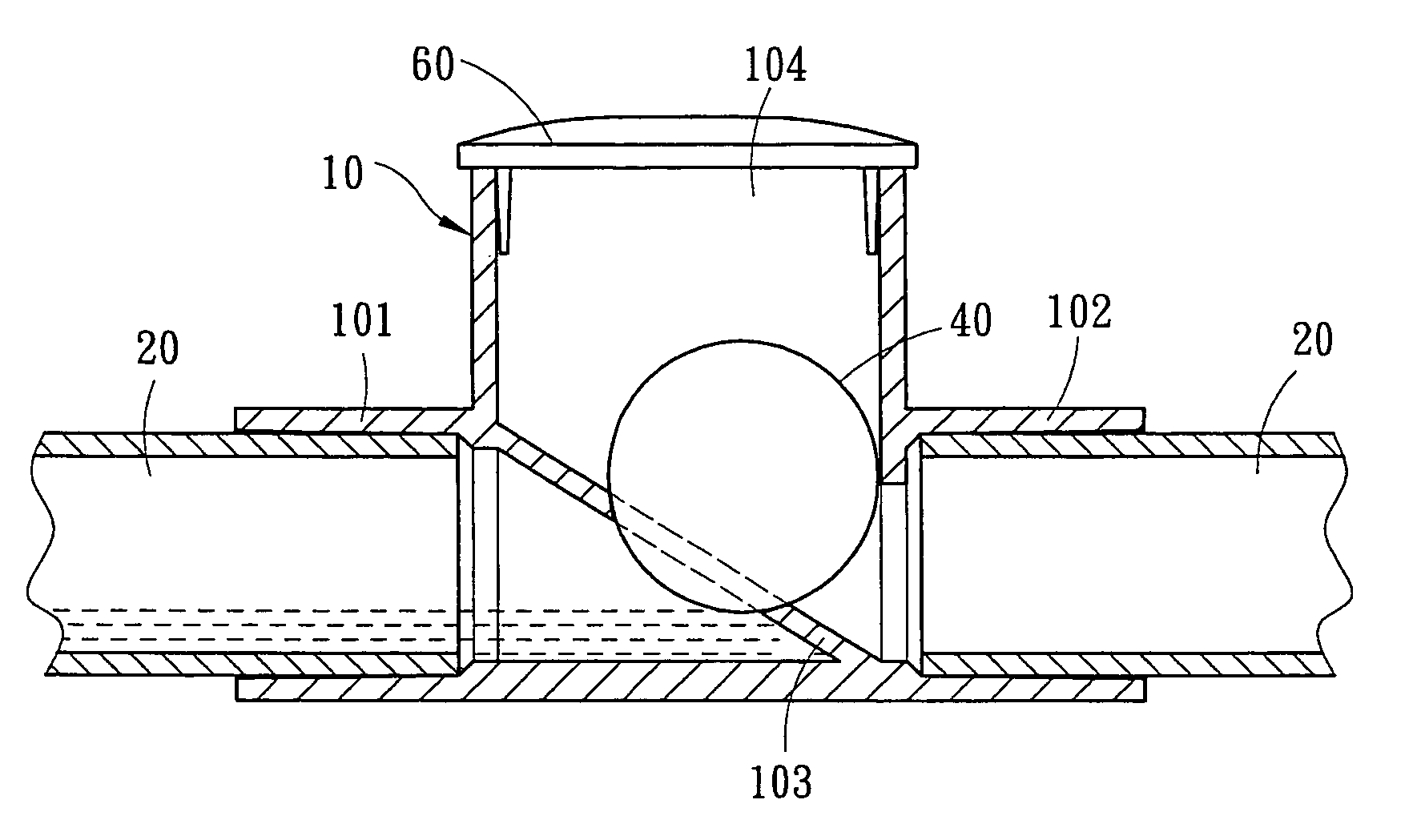

Dual function condensate drain trap for negative or positive pressure air handling unit

ActiveUS6931882B1Easy to installEasy to cleanCondensate preventionLighting and heating apparatusPositive pressureEngineering

A dual function condensate drain trap for positive or negative pressure air handling unit applicable in positive or negative pressure environments by switching connecting directions includes a drain trap which has a water inlet and a water outlet on two sides to connect to a drain pipe, and a valve seat and a retaining element located on the valve seat movable between a first position to be in contact with the valve seat and a second position to be away from the valve seat. When the pressure of water column in the water inlet is smaller than that of the water outlet, the retaining element is on the first position to form an air lock to prevent air from entering or escaping from air handling unit. By contrast, when the pressure of water column in the water inlet is greater than that of the water outlet, the retaining element is moved to the first position to drain water.

Owner:YANG SAM

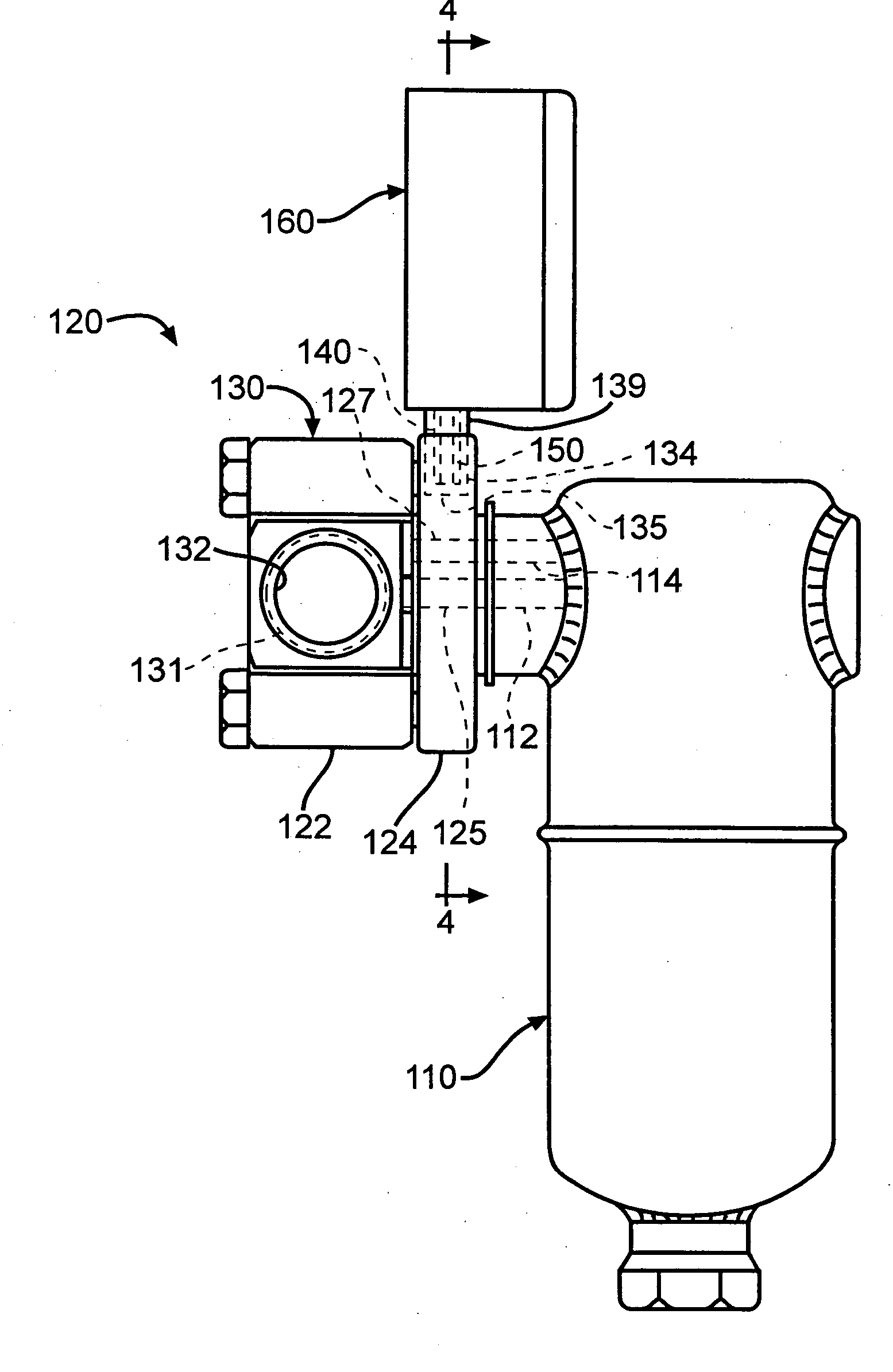

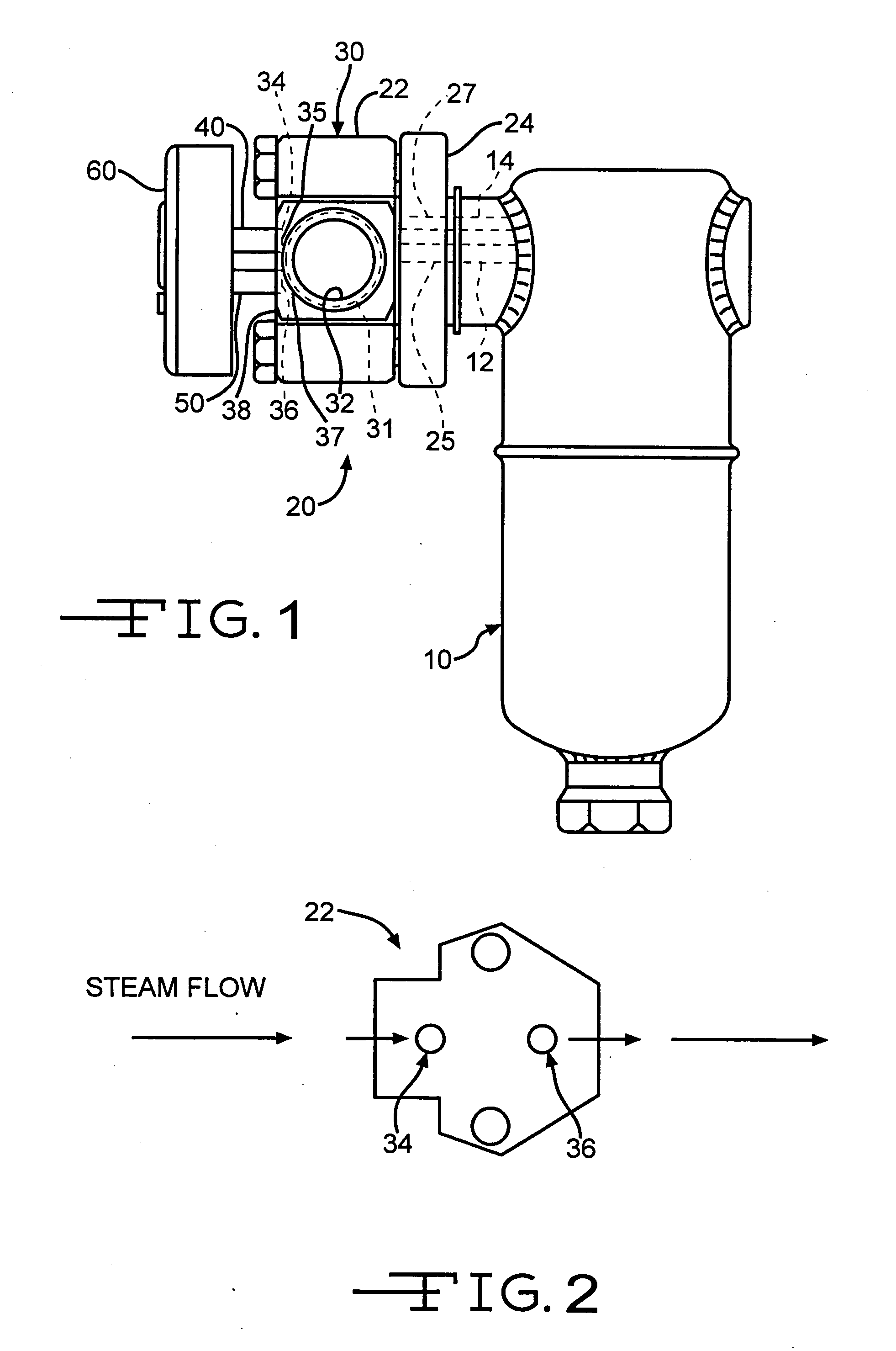

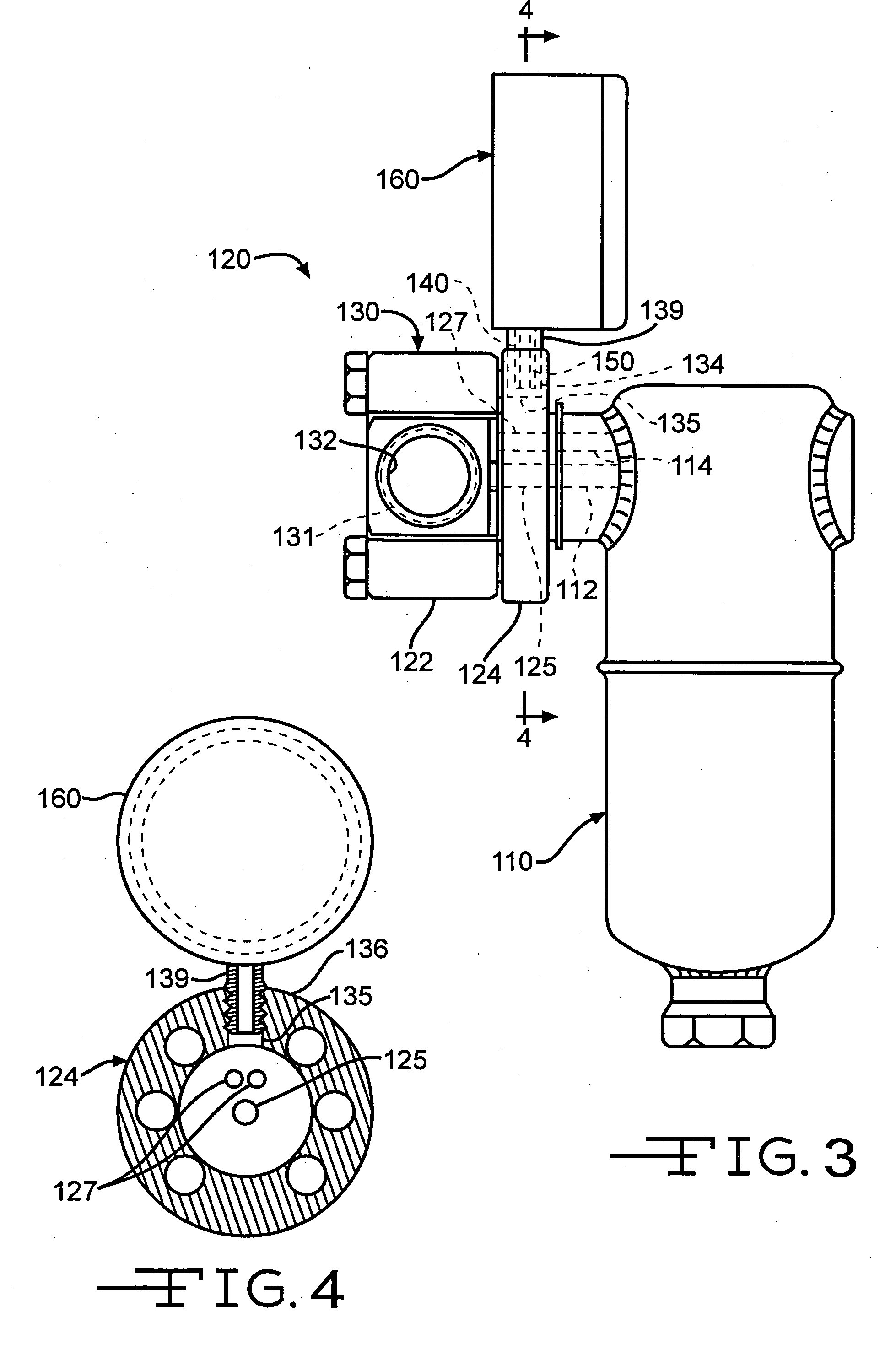

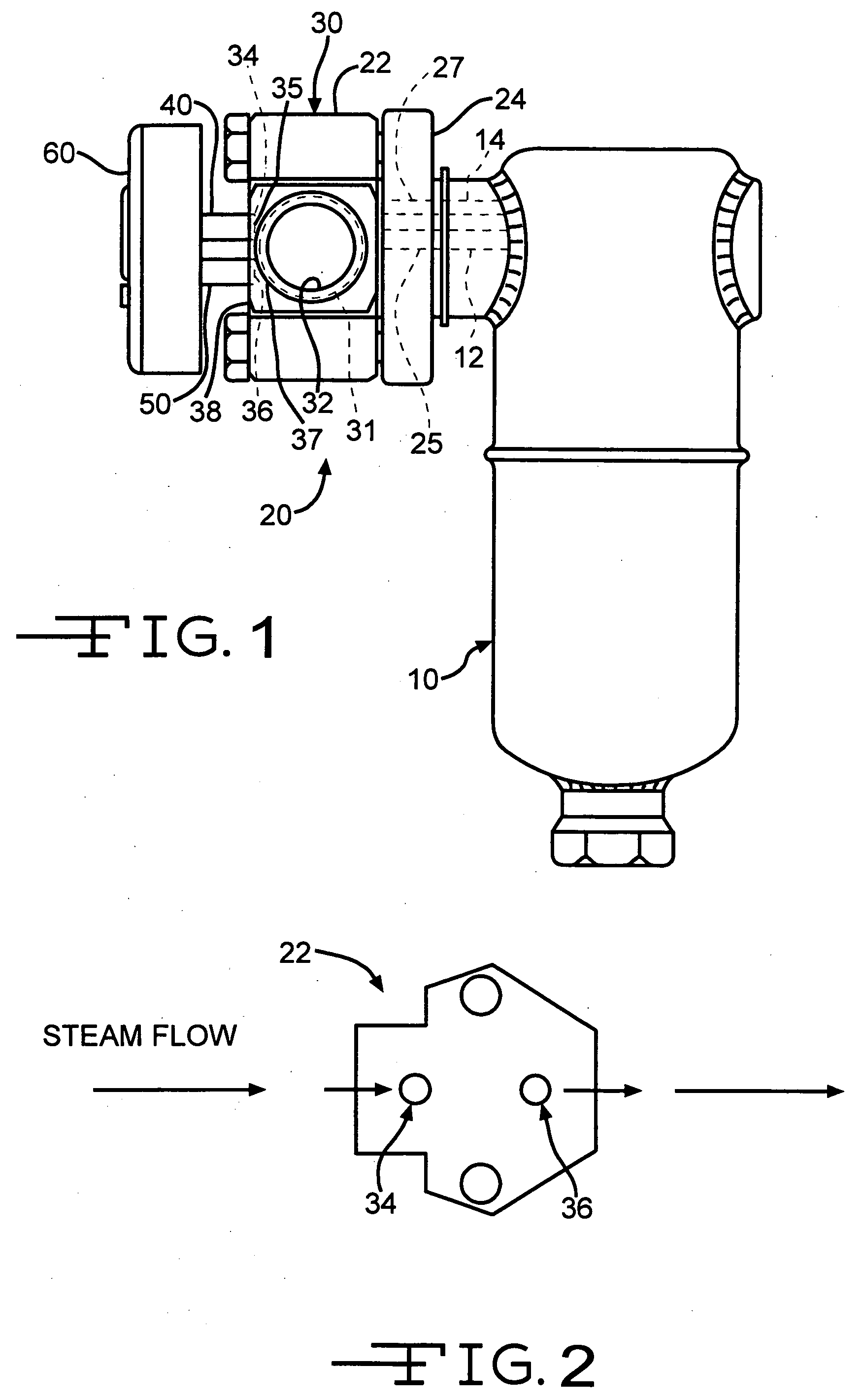

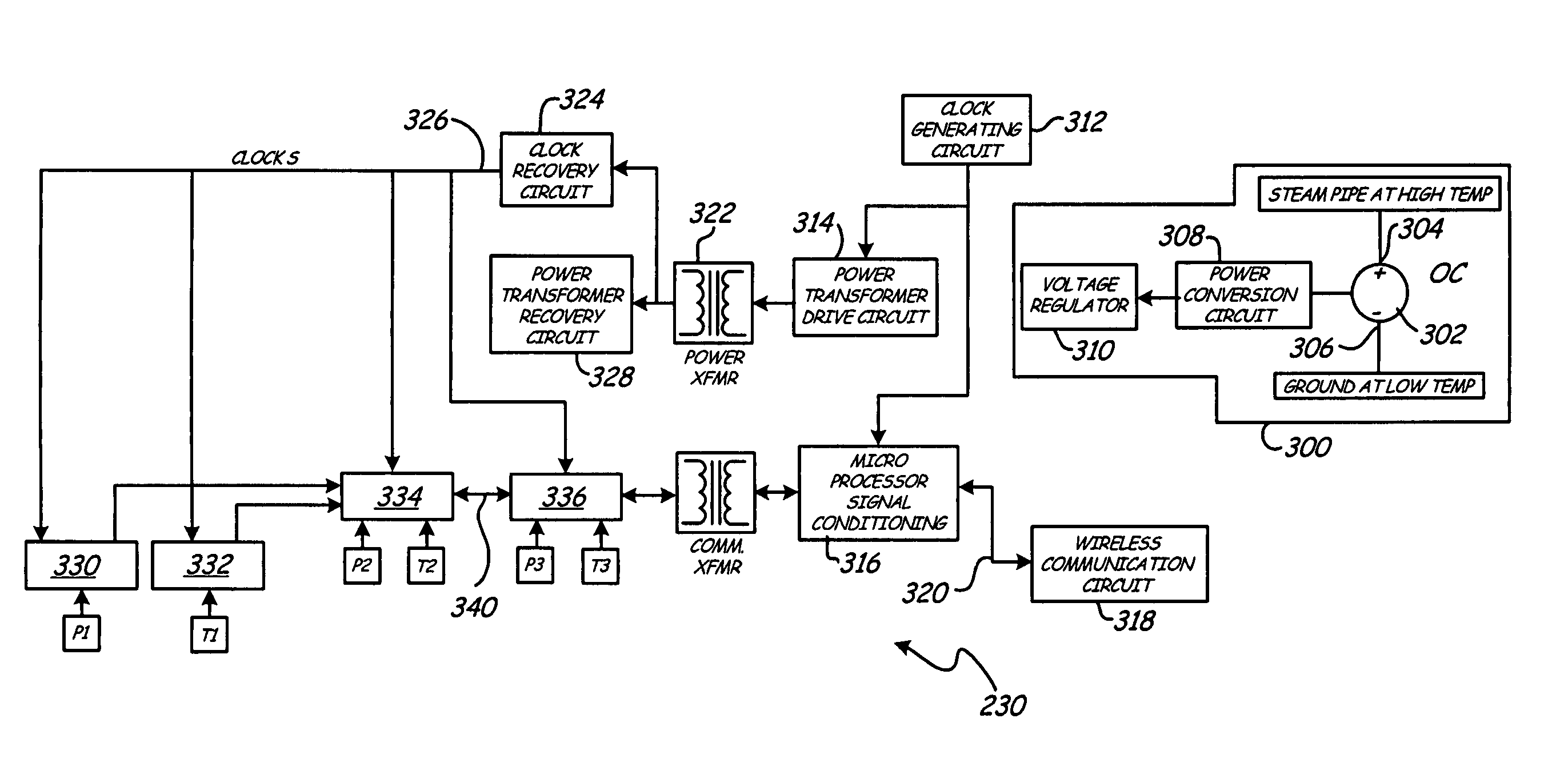

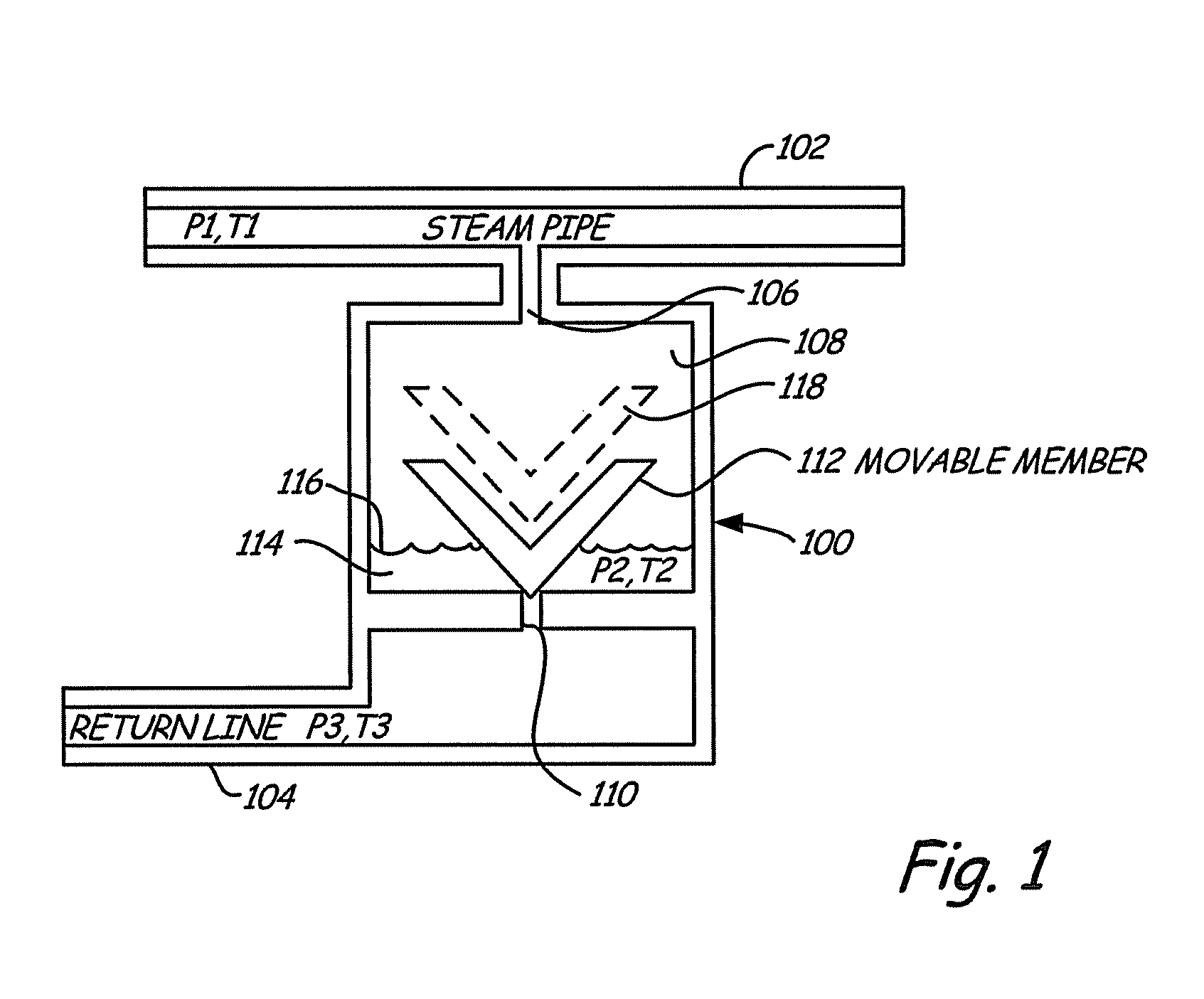

Steam trap monitoring

ActiveUS20060118648A1Temperature control without auxillary powerFlow propertiesEngineeringSteam trap

Owner:ARMSTRONG INT INC

Cooling control device for condenser

InactiveUS20050072170A1Avoid yield lossInhibit productionCompression machines with non-reversible cycleEvaporators/condensersTemperature controlGas phase

Cooling control device for a condenser is provided which includes the condenser, a cooling device for cooling the condenser, and a control device for controlling the cooling device. The cooling device includes a first cooling fan for cooling a gaseous-phase portion of the condenser, and two second cooling fans for cooling a liquid-phase portion of the condenser independently of the first cooling fan. The control device also includes a pressure control section for optimally adjusting a pressure within the gaseous-phase portion, and a temperature control section for optimally adjusting a temperature within the liquid-phase portion. The pressure control section operates the first cooling fan, in accordance with a detected pressure within the gaseous-phase portion, to adjust the pressure within the gaseous-phase portion. The temperature control section operates the second cooling fans, in accordance with a detected temperature within the liquid-phase portion, to adjust the temperature within the liquid-phase portion.

Owner:HONDA MOTOR CO LTD

Dust clearing blow-back valve and reservoir

ActiveUS8070844B2Rapid opening of the valve stemCombination devicesAuxillary pretreatmentReflux valveFuel tank

An accumulator having an internal valve opened by applying air pressure to a diaphragm with a small solenoid to apply air to the diaphragm where the air is supplied from a pilot air supply. When the internal valve operated by the diaphragm opens, it snaps to a fully open position thereby opening the valve and uncovering a passageway leading to a filter for cleaning. The passageway is sufficiently wide that the resulting flow of air through the passageway is so explosive that air pressure on the filter is distributed over the surface area of the filter for a brief moment, blowing the dust on the filter free.

Owner:MAGUIRE STEPHEN B

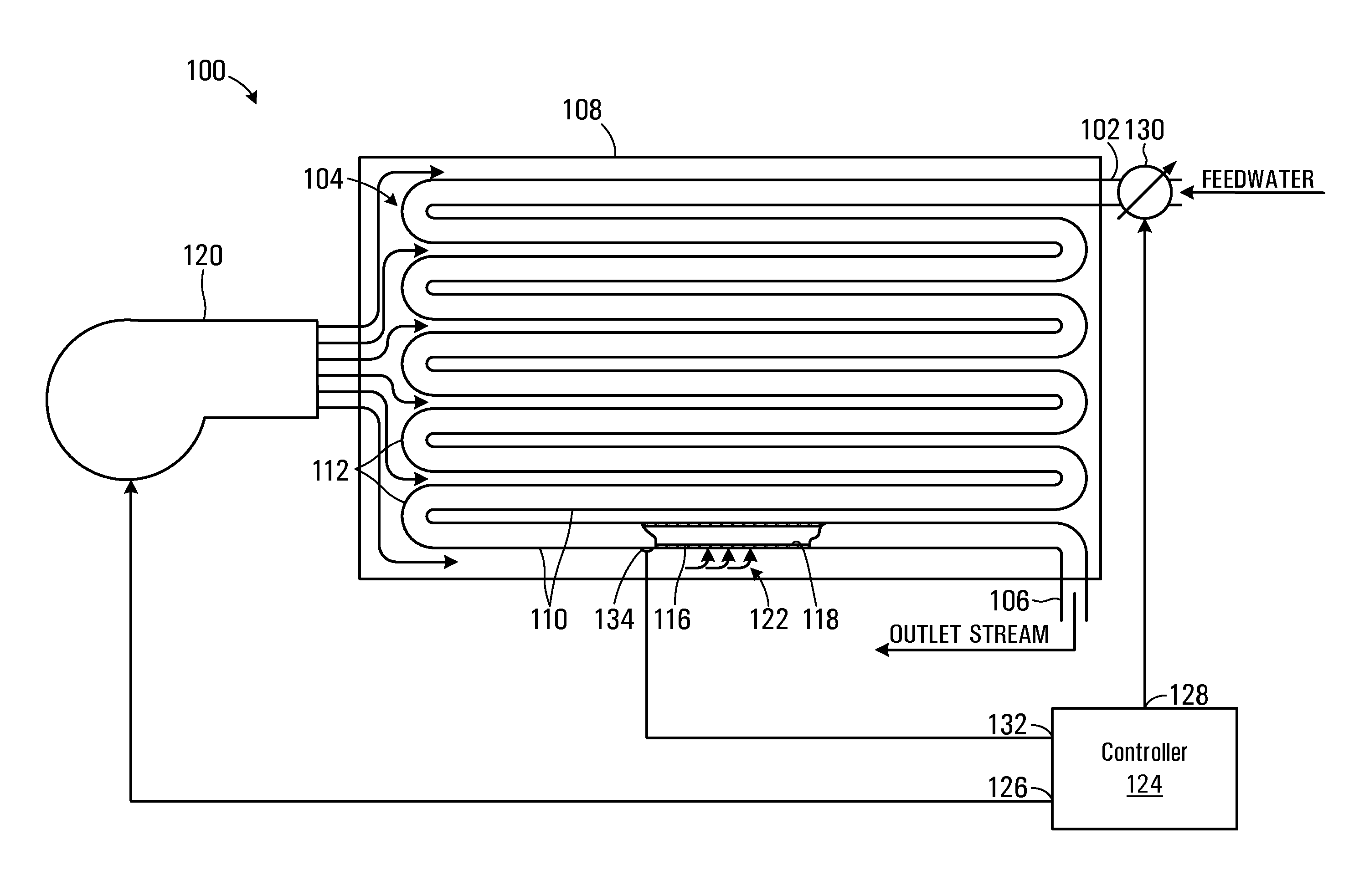

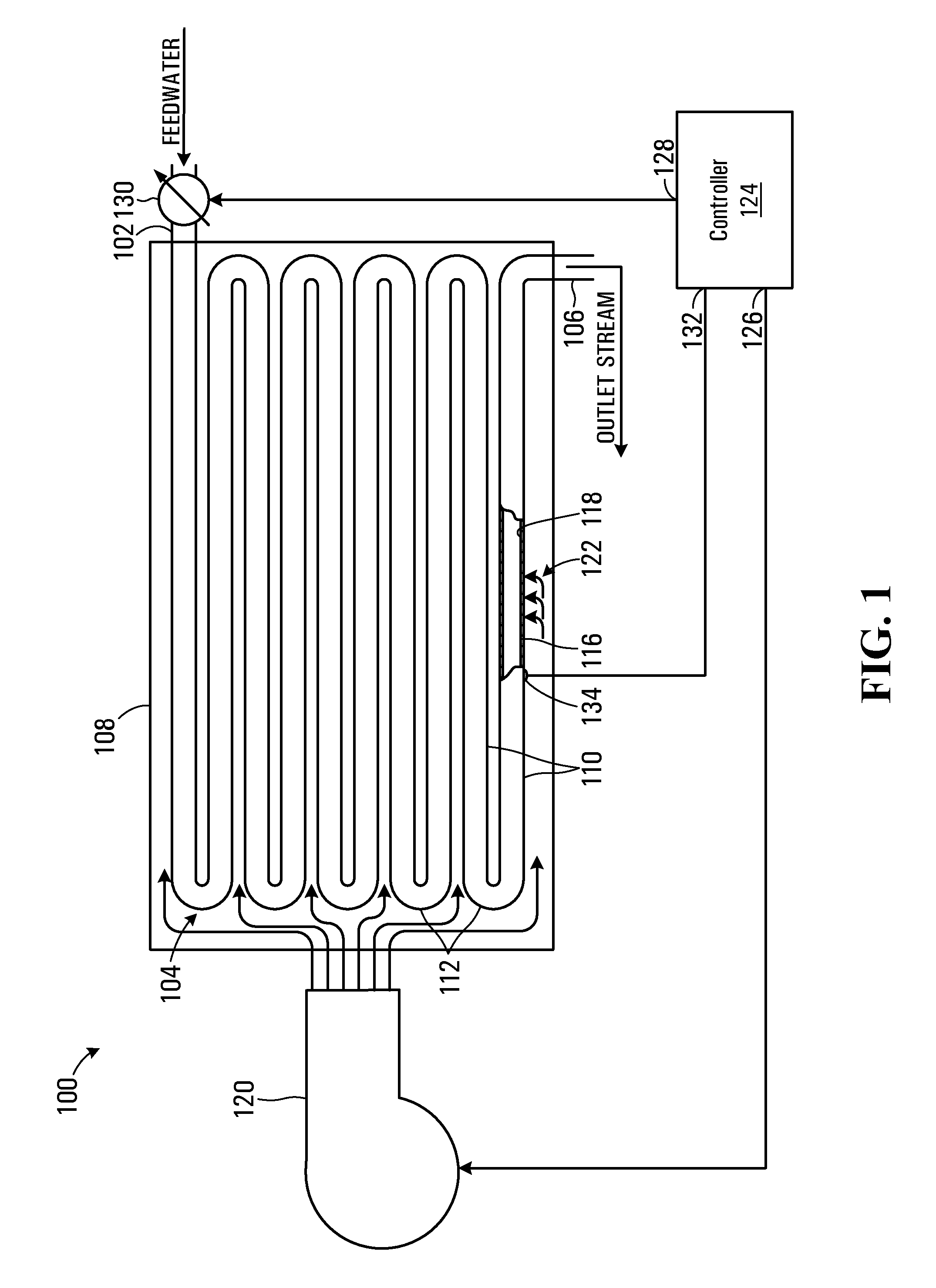

Steam generator and method for generating steam

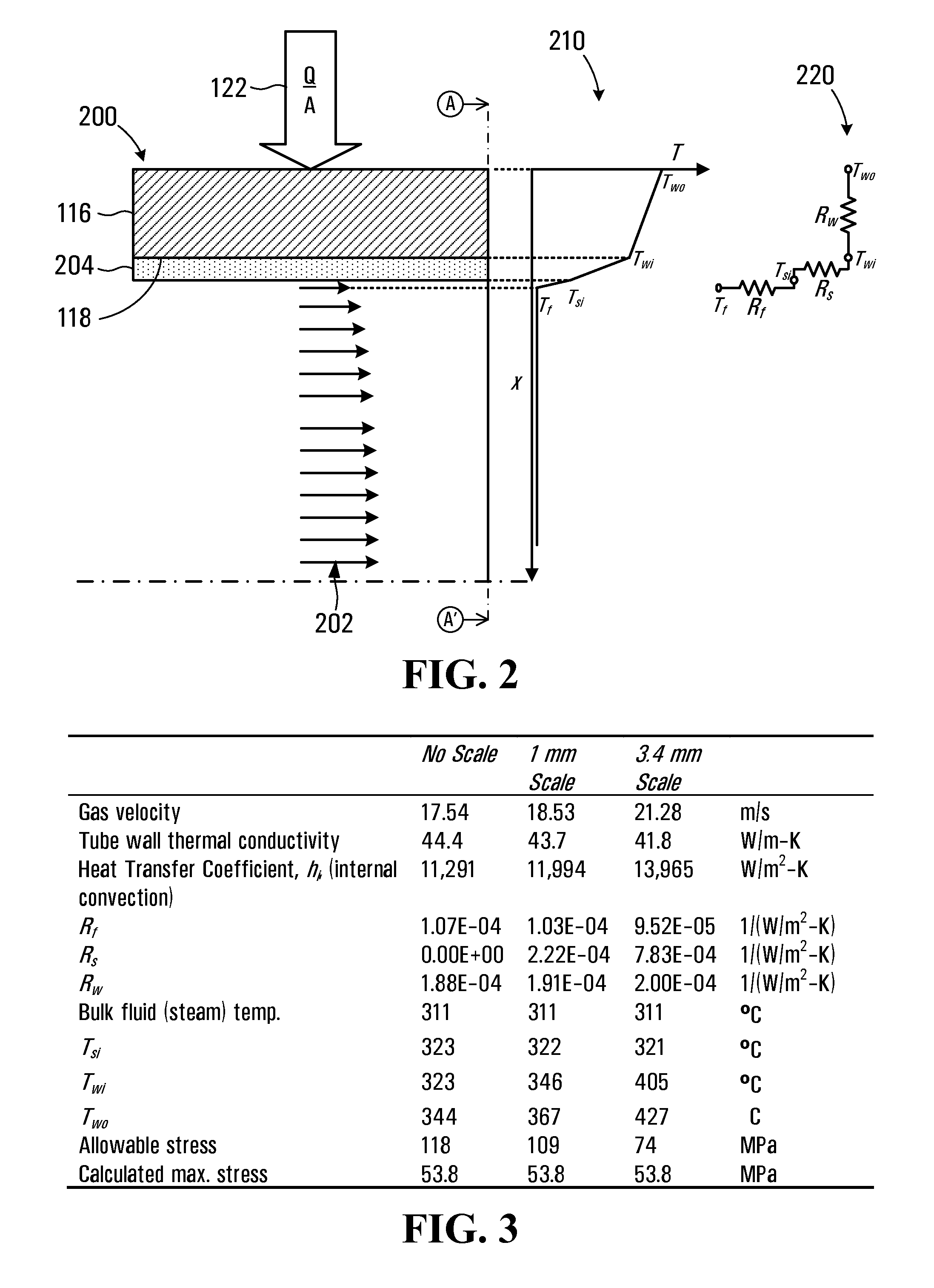

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

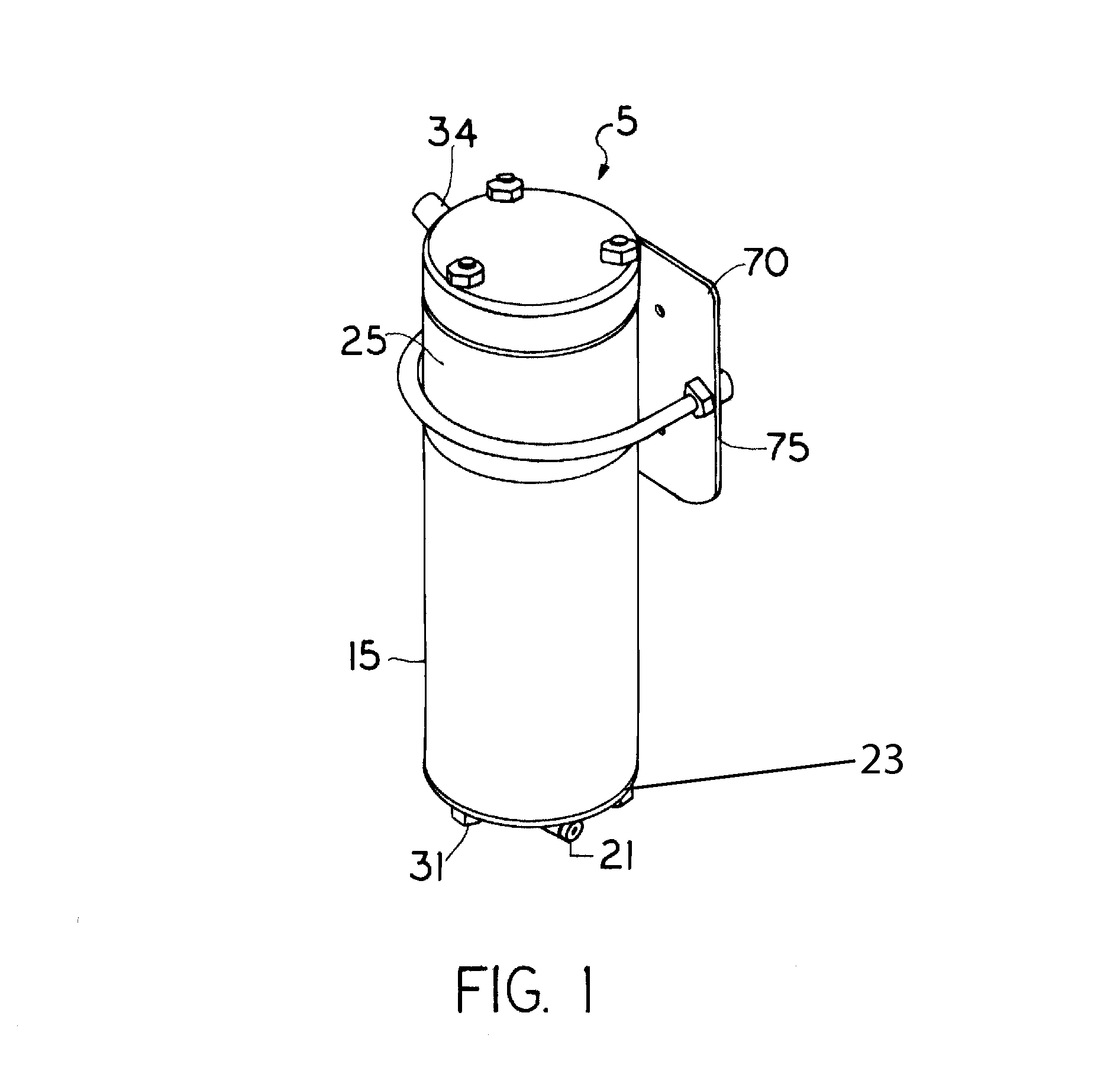

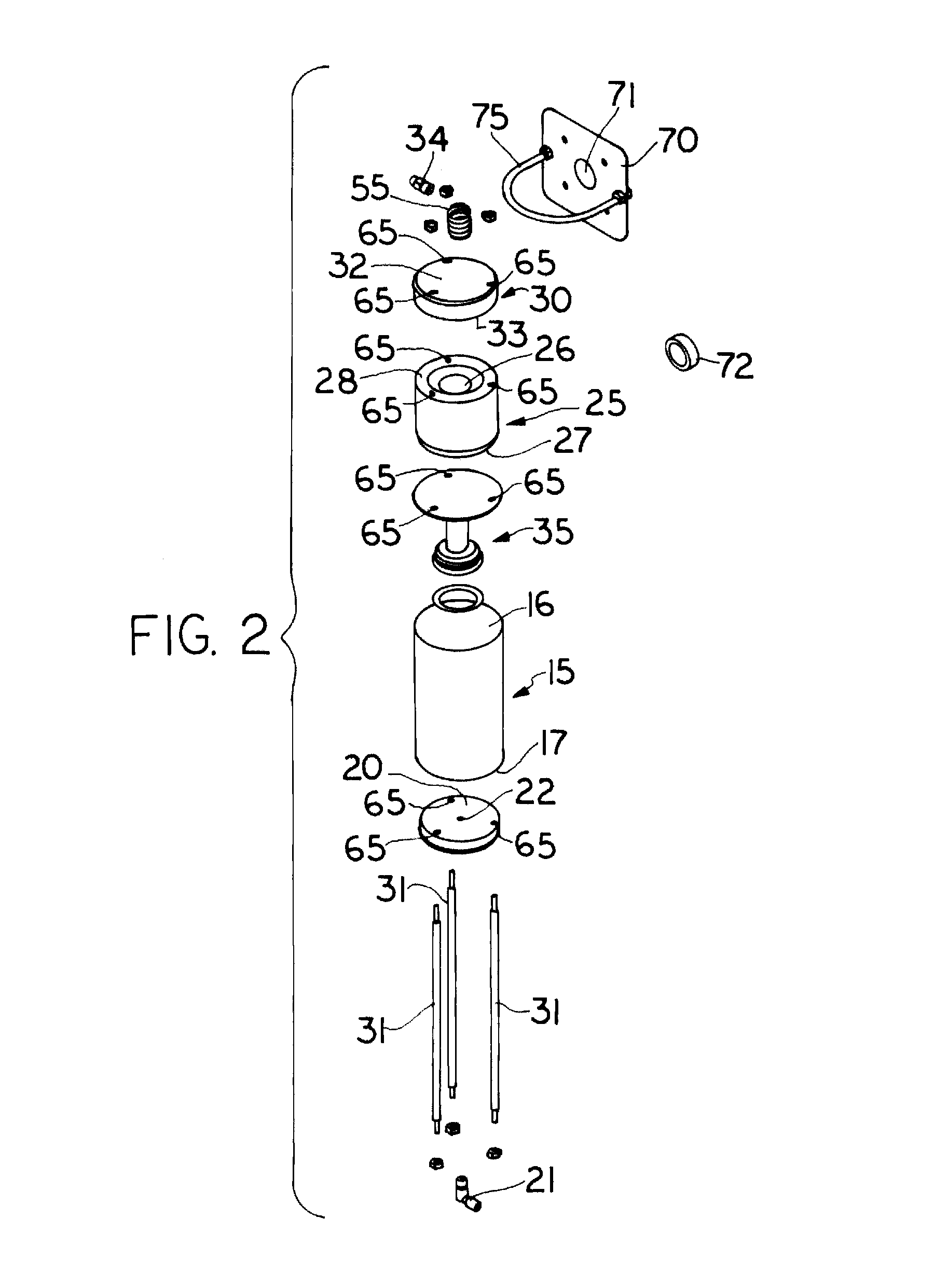

Self-contained steam trap monitor

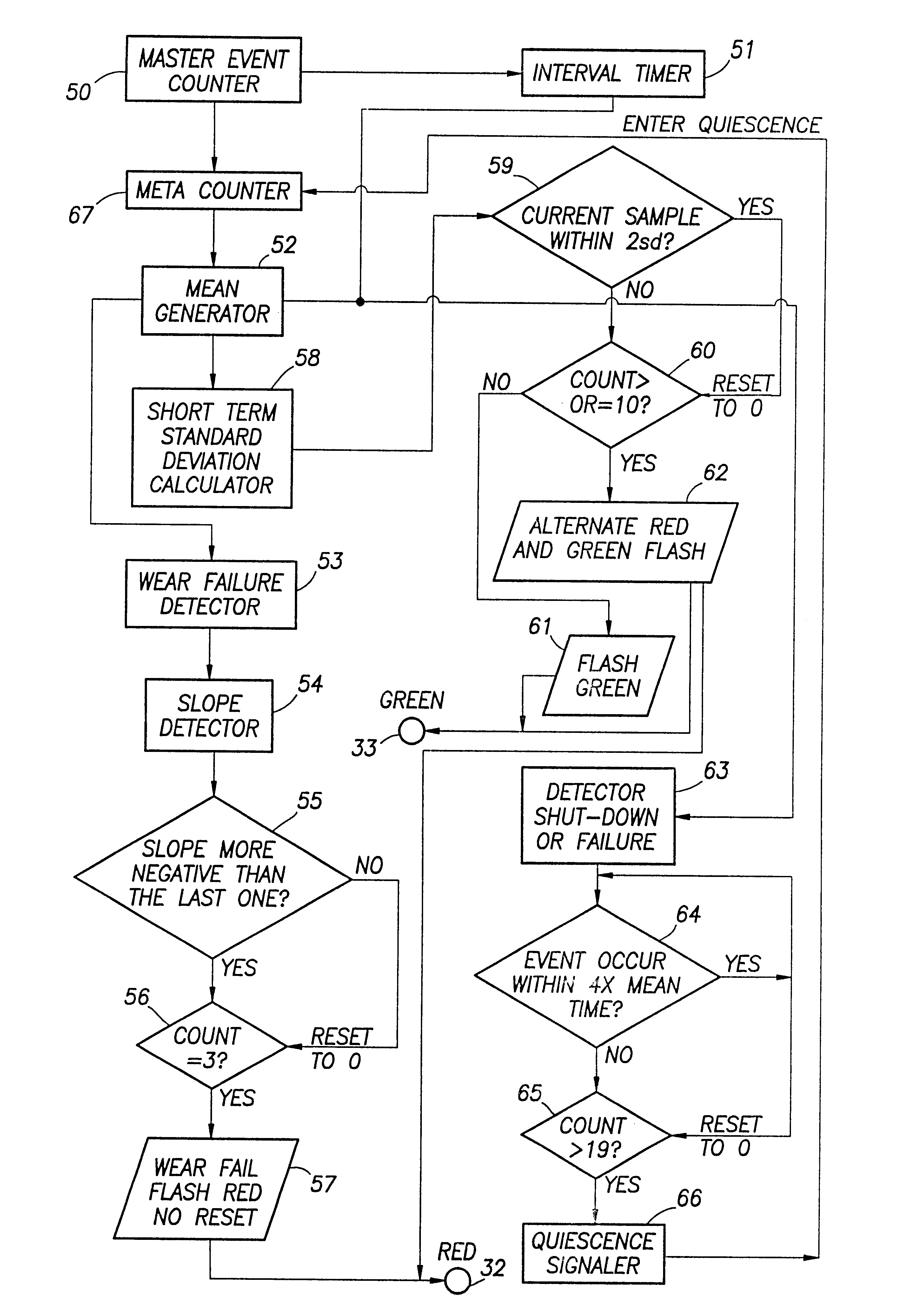

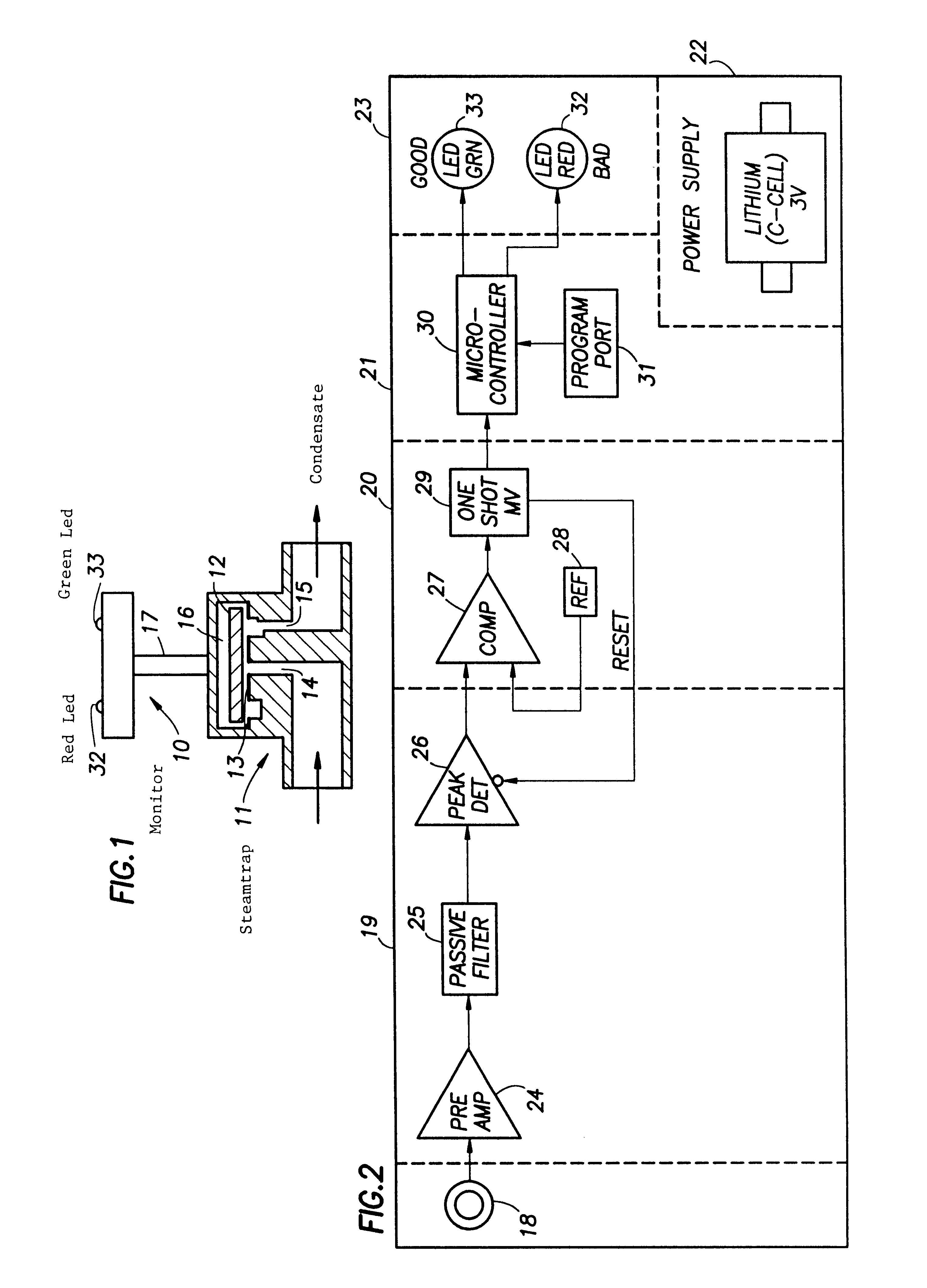

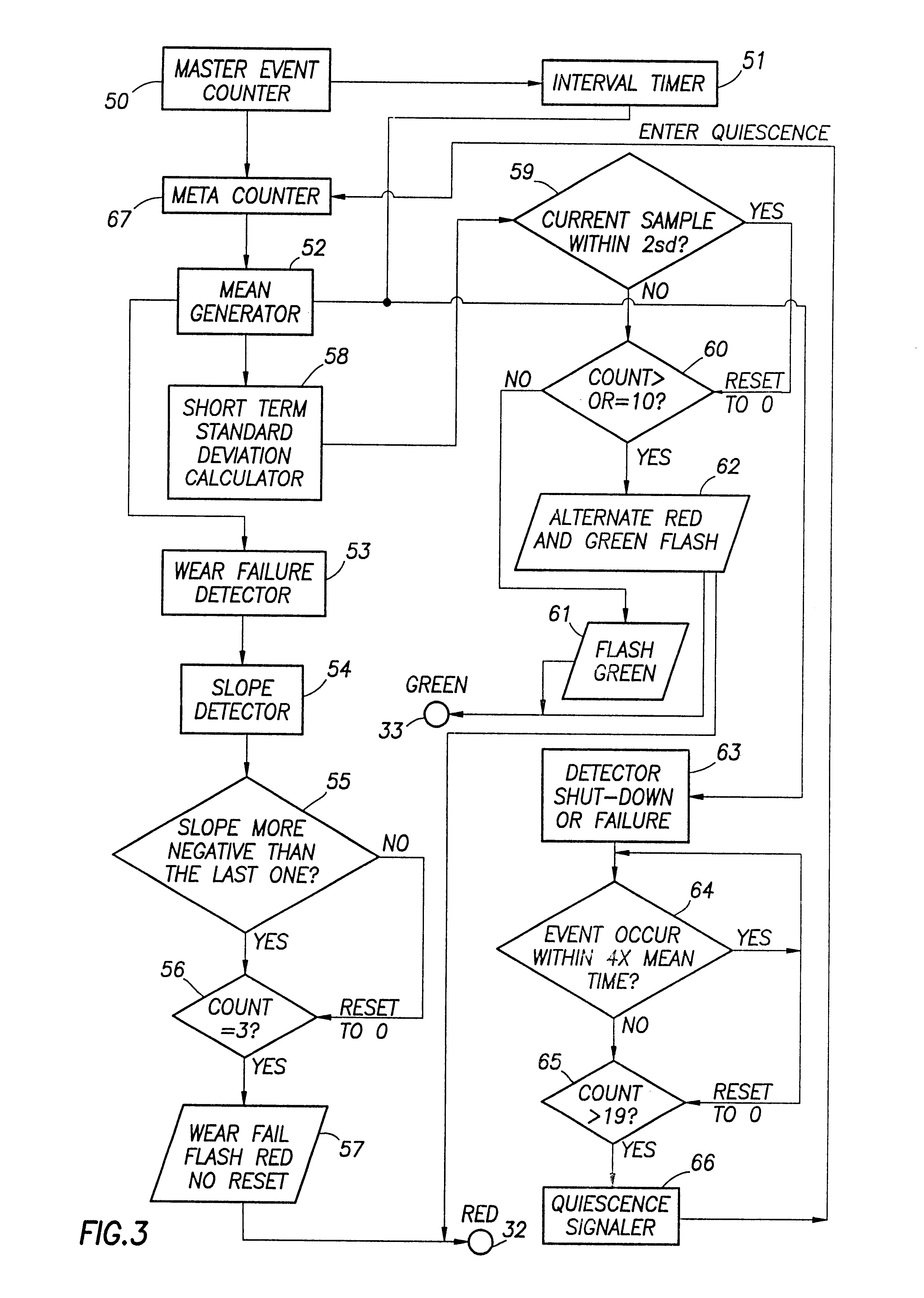

InactiveUS6571180B1Easy to moveProlong lifeDetection of fluid at leakage pointMachine part testingBaseline dataData set

A self-contained system to continuously monitor a mechanism used to process, control or regulate fluid flow or pressure and provide a continuing indication of the status or condition of the monitored mechanism. A specific form of the invention employs a low frequency sonic-to-electrical transducer that monitors opening and closing of a disk-type steam trap. The detected sonic signal is processed and sent to a microprocessor that is programmed to develop a time-based, baseline data set representative of normal operation of the steam trap in the environment in which it operates. The baseline data set is compared with the data from on-line operations of the steam trap. As the environment and the steam trap operation change during normal on-line operations, the baseline data set is updated to change with the changing environment and the changing steam trap operation.

Owner:TYCO VALVES & CONTROL INC

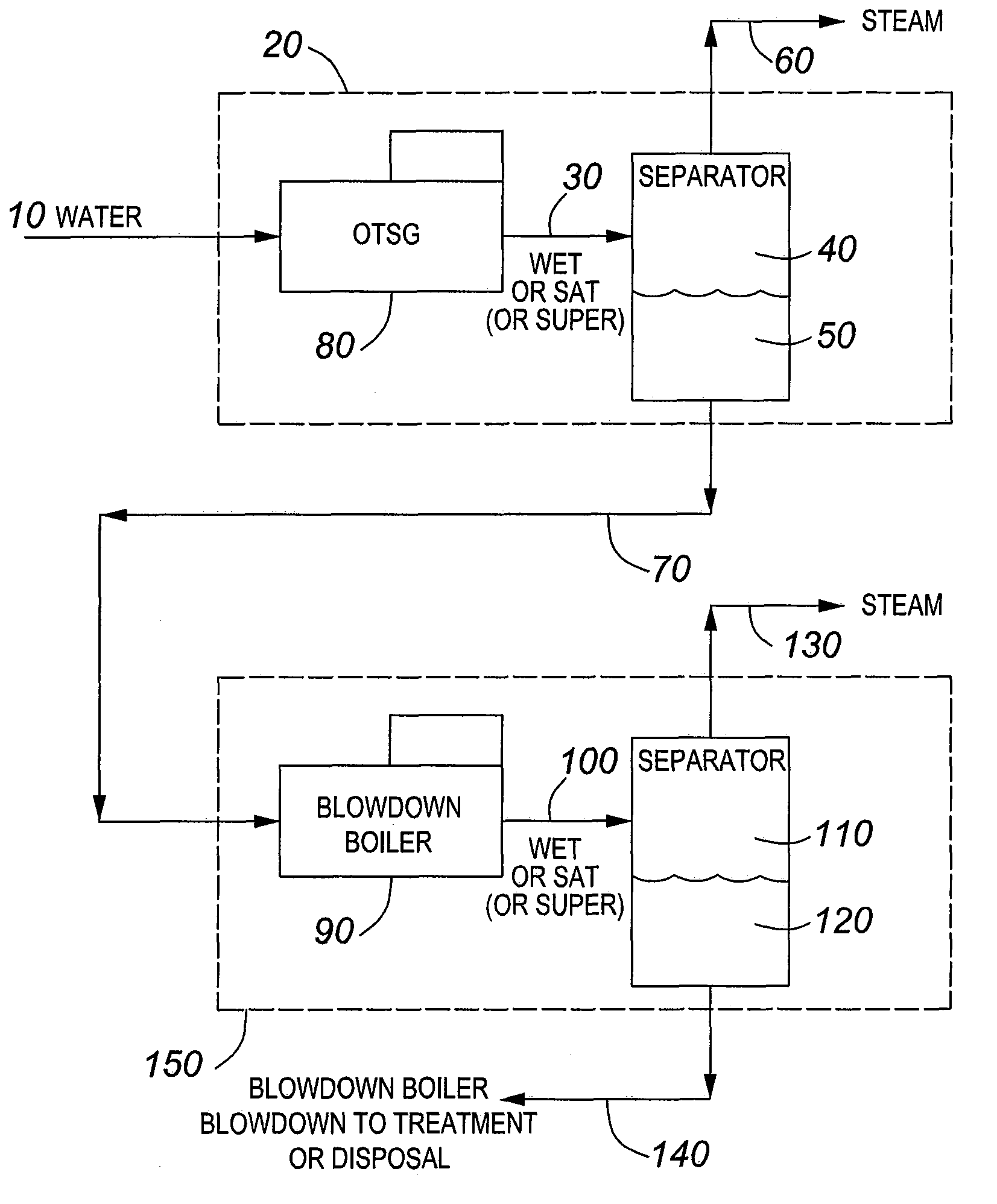

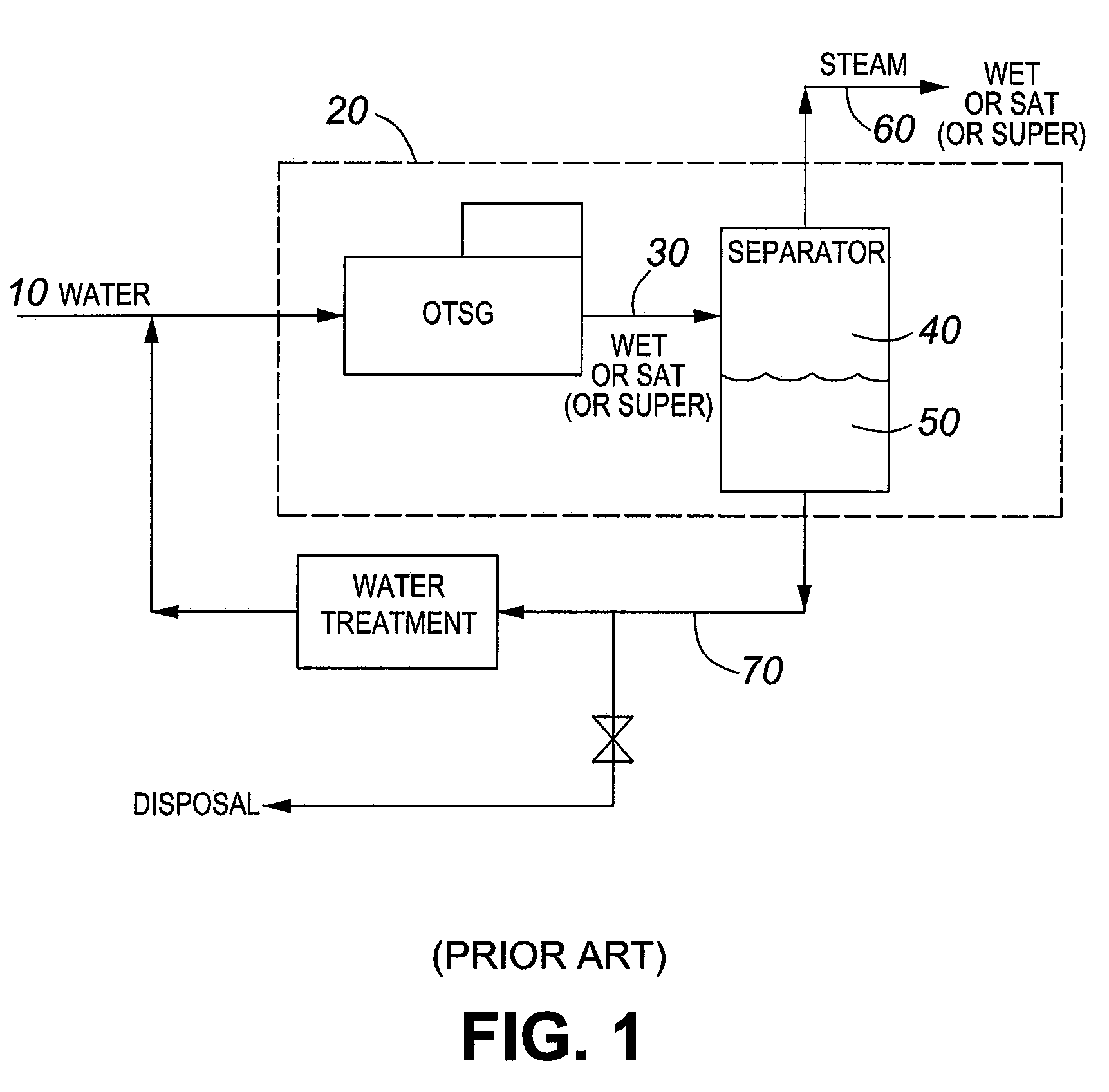

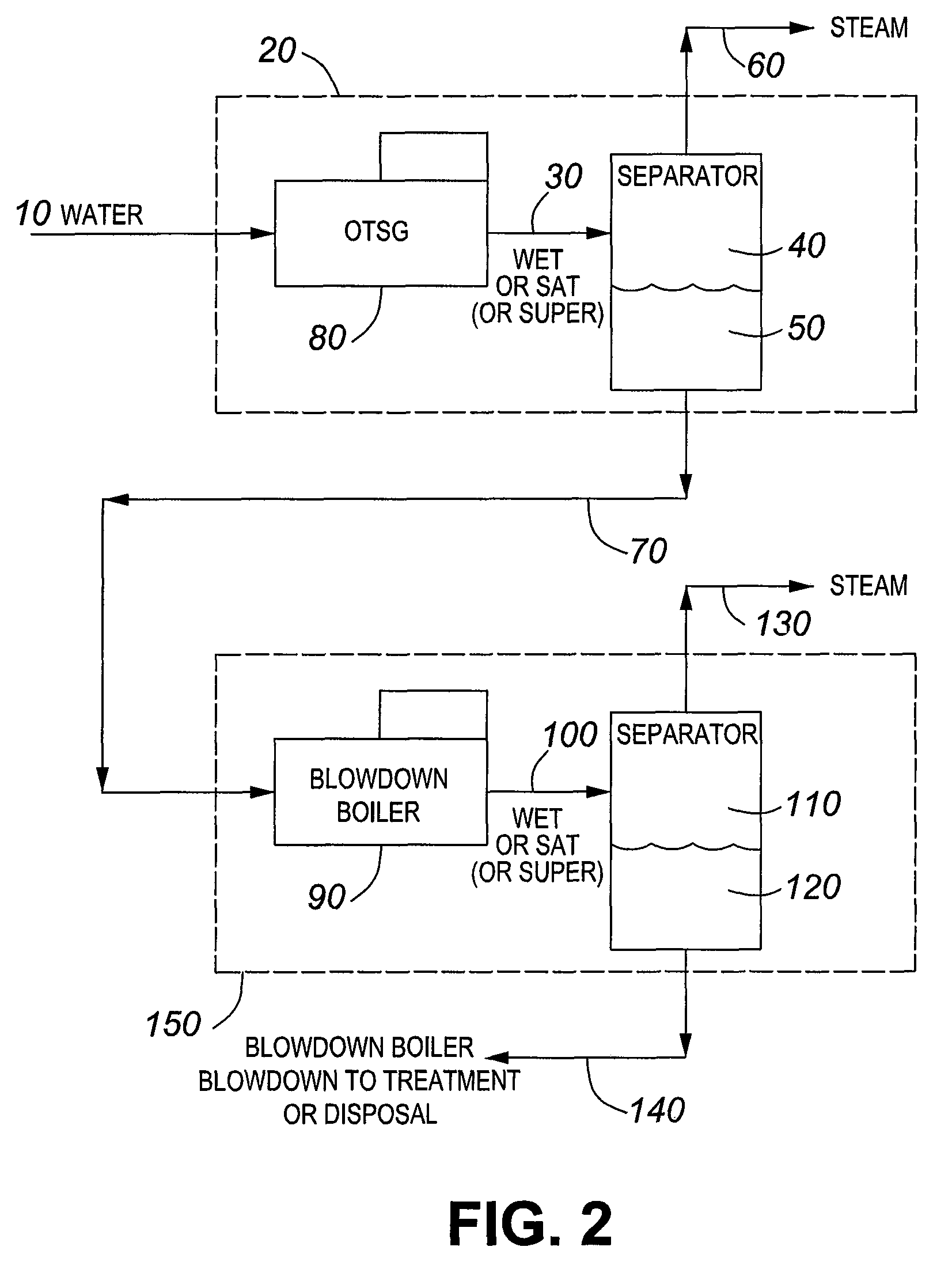

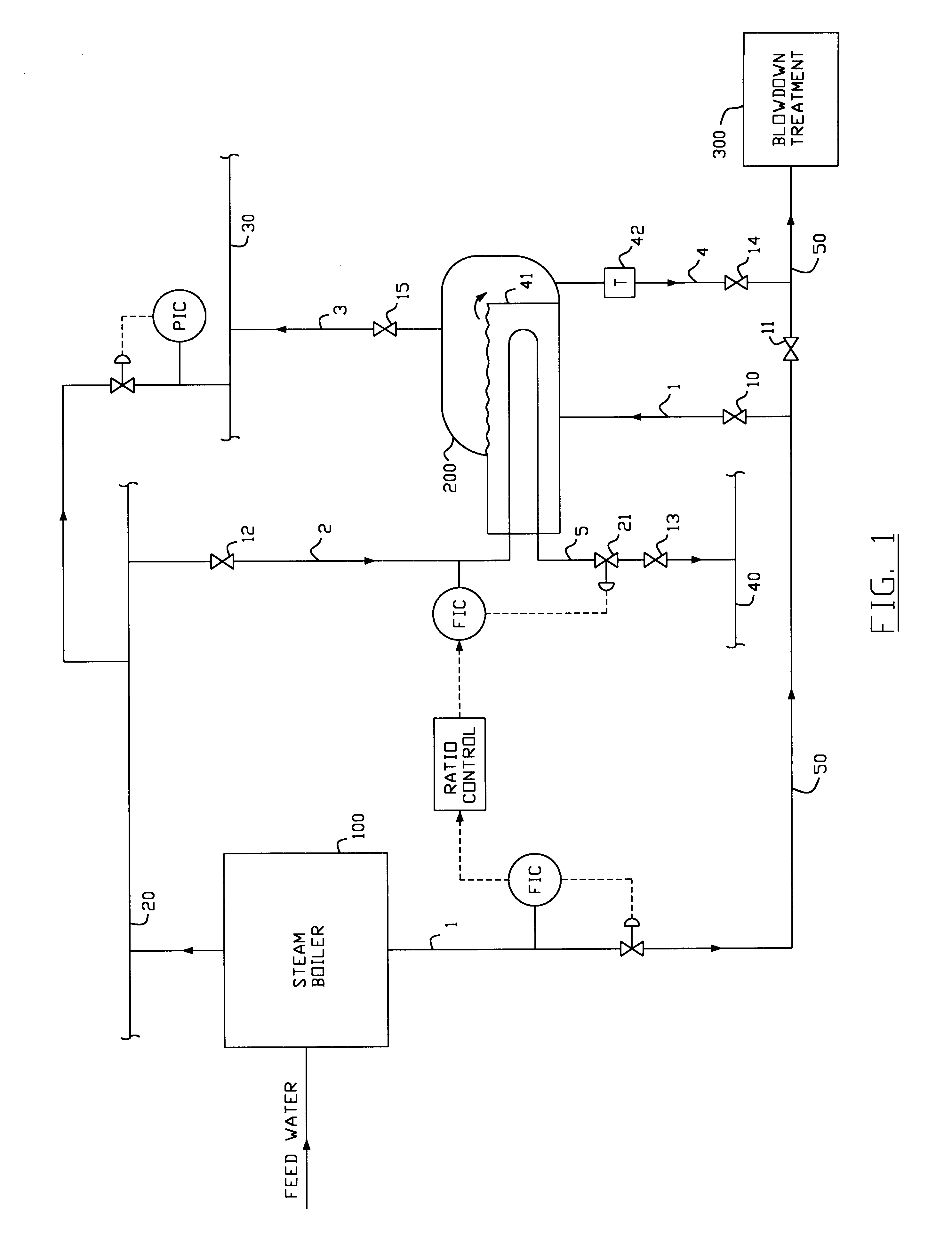

Method and apparatus for steam generation

ActiveUS8166925B2Reduce in quantityIncrease volumeWater circulationFuel injection apparatusBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

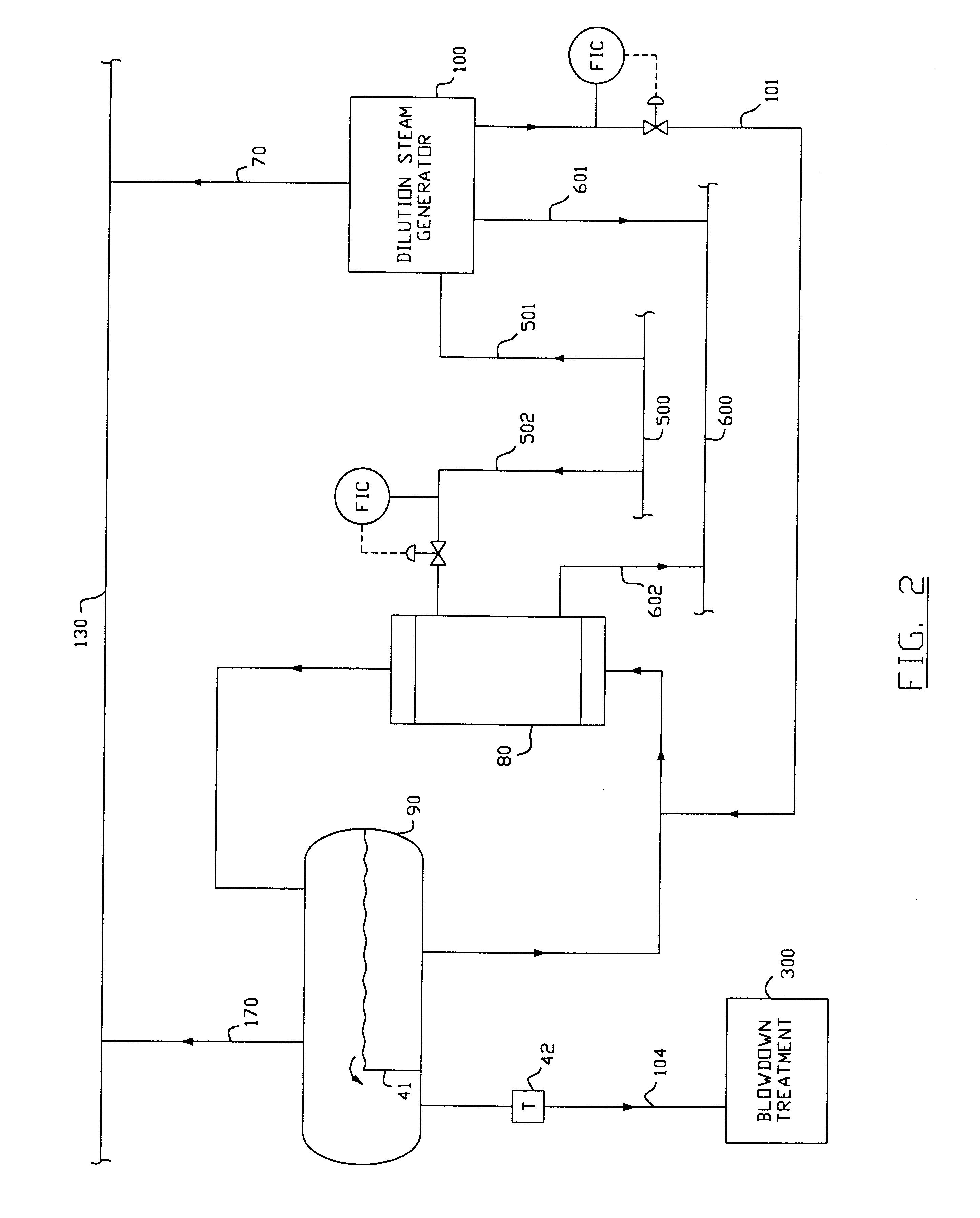

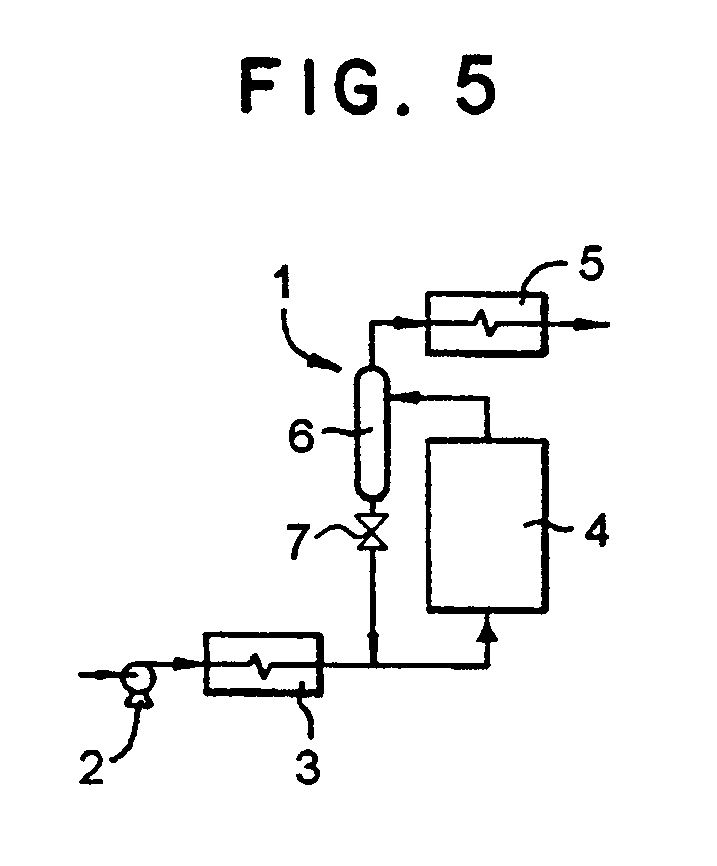

Methods for recycling process wastewater streams

InactiveUS6371058B1High mean blowdown rateChemical treatment costDrying using combination processesSteam separation arrangementsShell and tube heat exchangerWastewater

This invention provides cost-effective alternatives to reduce the cost associated with customary blowdown from steam generating equipment. By selectively recycling process blowdown streams using secondary vaporizers, the net result is a partial replacement of wastewater stream with almost an equivalent quantity of clean steam condensate. The heat transfer is carried out by indirect contact devices, such as shell and tube heat exchanger and the like, without mixing of the two process streams to allow condensate recovery while avoiding cross contamination. This invention carries economic as well as environmental credits. A condensate recovery apparatus can be designed to enable easy connection to existing equipment already in service, as well as easy removal, without causing process disruption.

Owner:TUNG PETER

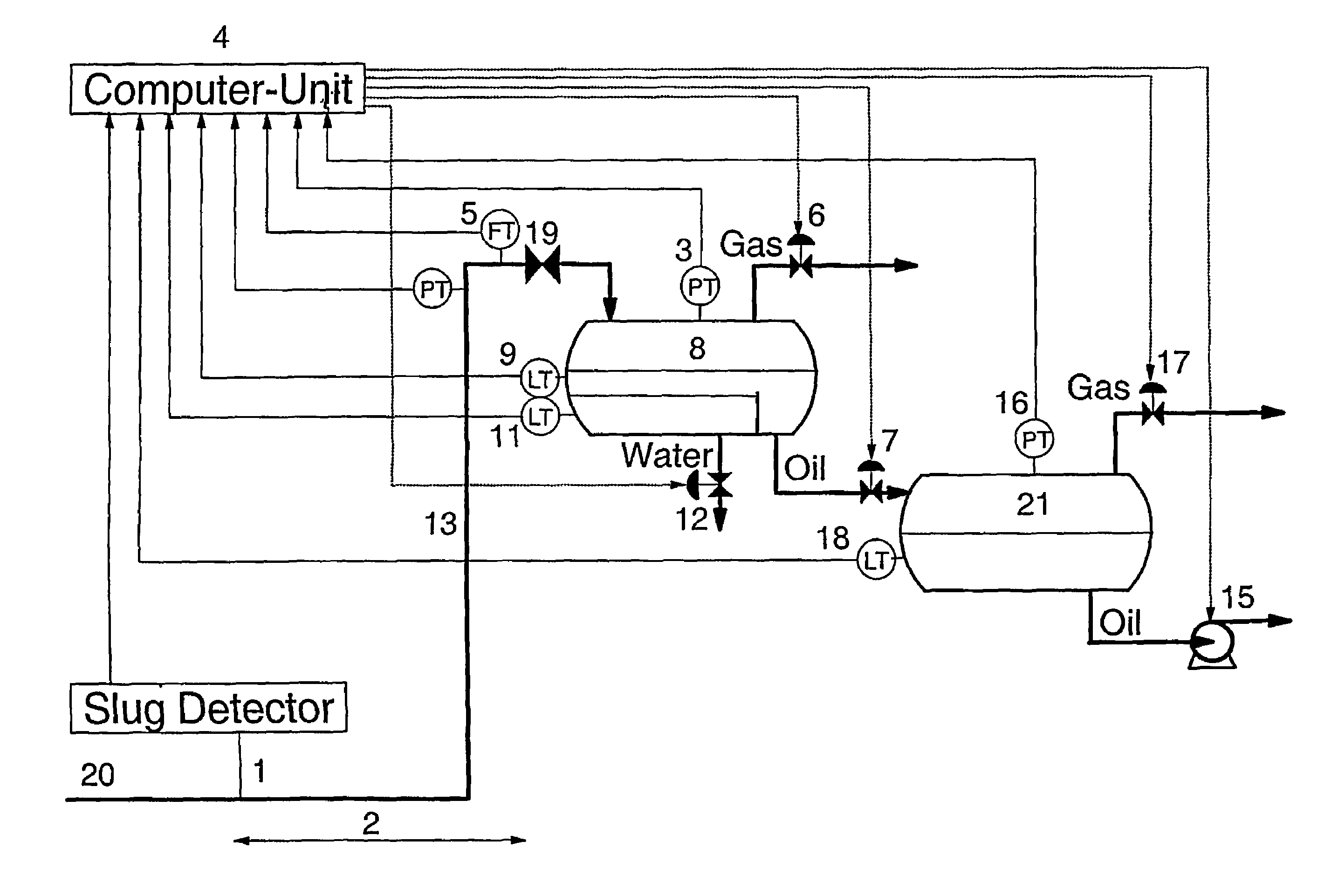

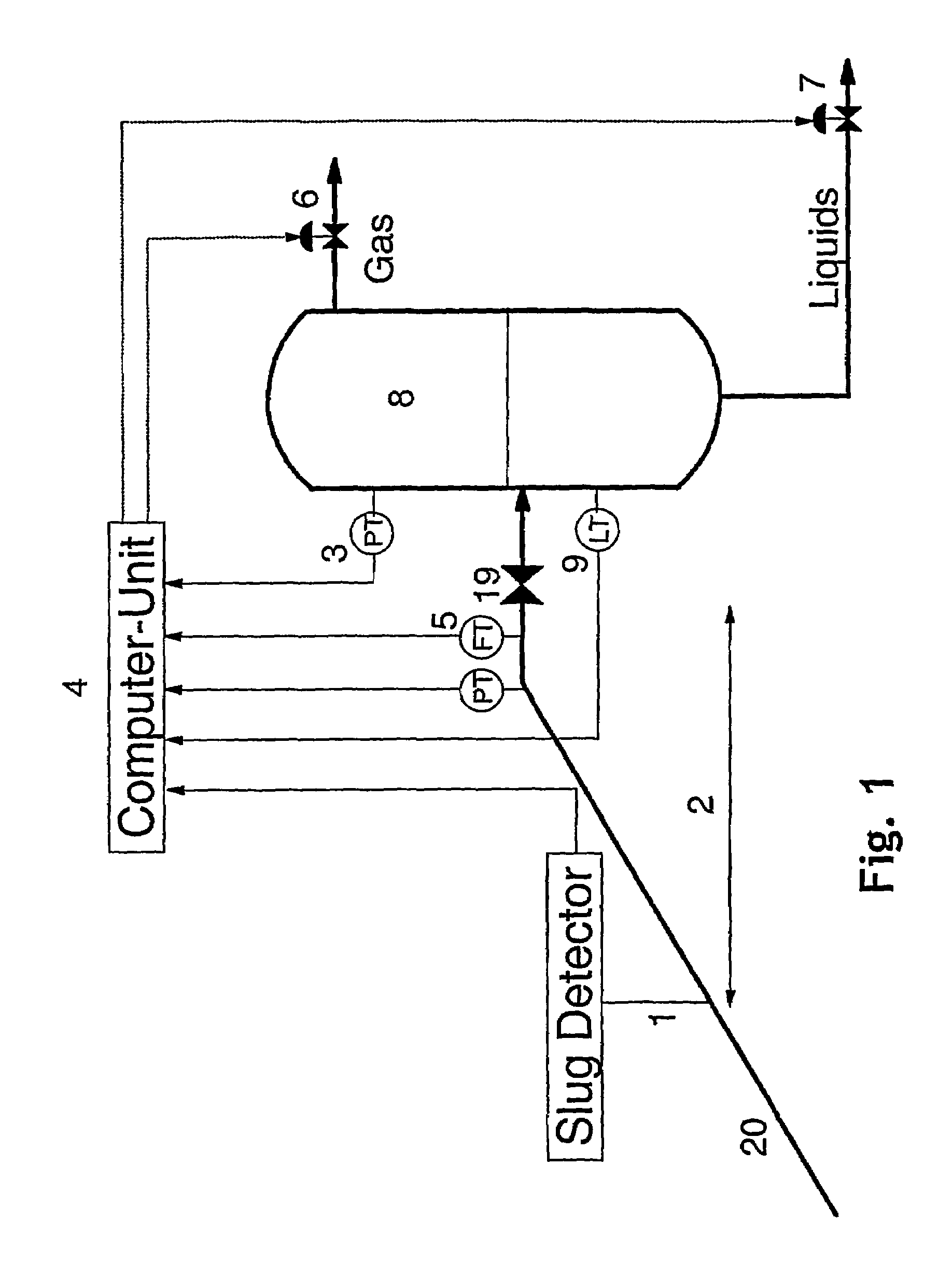

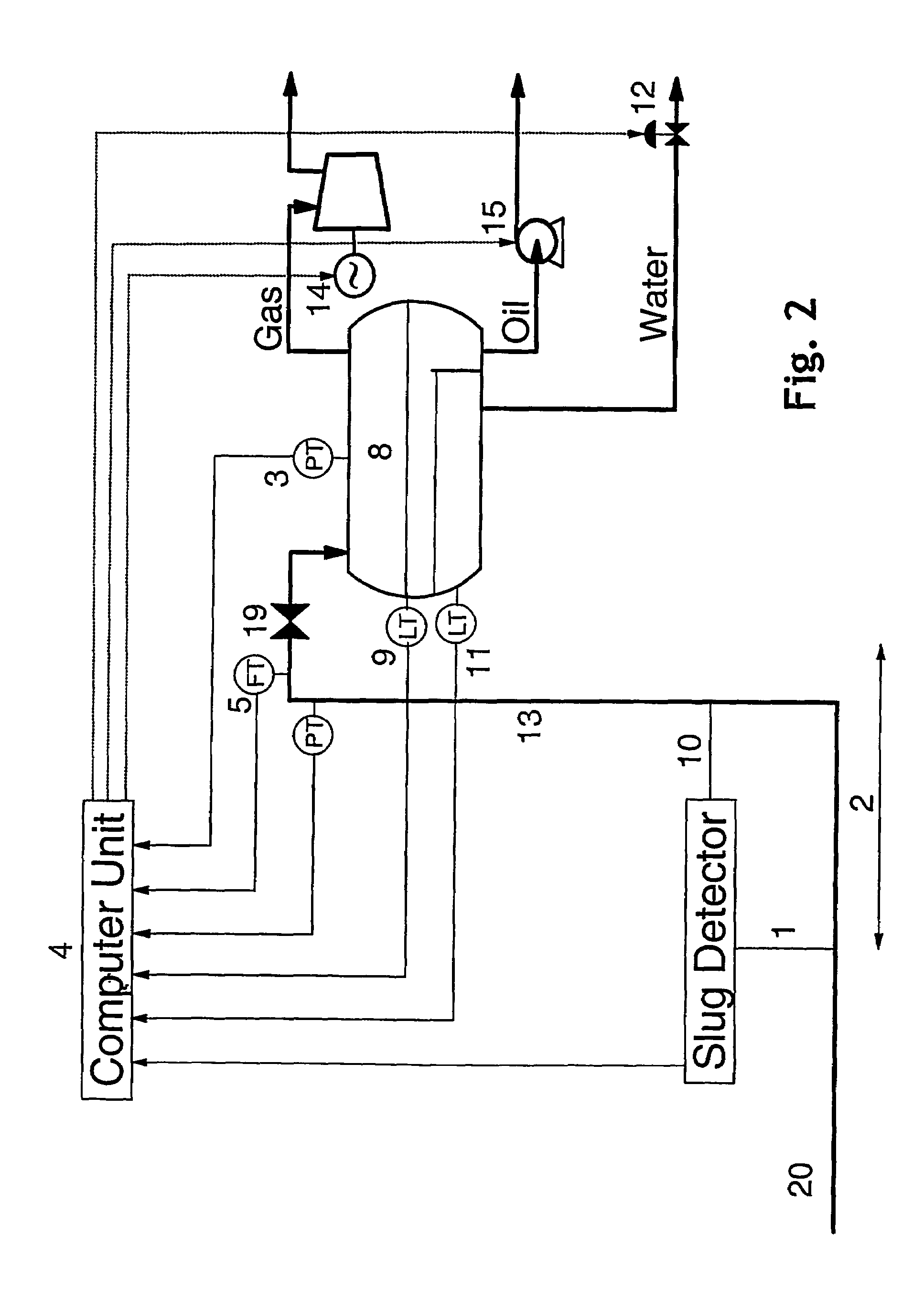

System and a method for prediction and treatment of slugs being formed in a flow line or wellbore tubing

ActiveUS7434621B2Eliminate disadvantagesFluid removalWater/sewage treatmentLine tubingProcess engineering

A system and a method for prediction and treatment of all kinds of slugs being formed in a flow line system or wellbore tubing transporting a multiphase fluid towards a downstream process including a separator or a slug catcher at the process inlet. The system includes a slug detector (1) located downstream of the point for slug initiation and upstream of the process and a computer unit (4) integrating the flow line system and the downstream process including software which determines the type of the slug, its volume and predicts its arrival time into the downstream process. The computer unit processes all its incoming data to obtain an optimum regulation of the process so that process perturbations due to incoming slugs are reduced to a minimum through the process.

Owner:DEN NORSKE STATS OLJESELSKAP AS

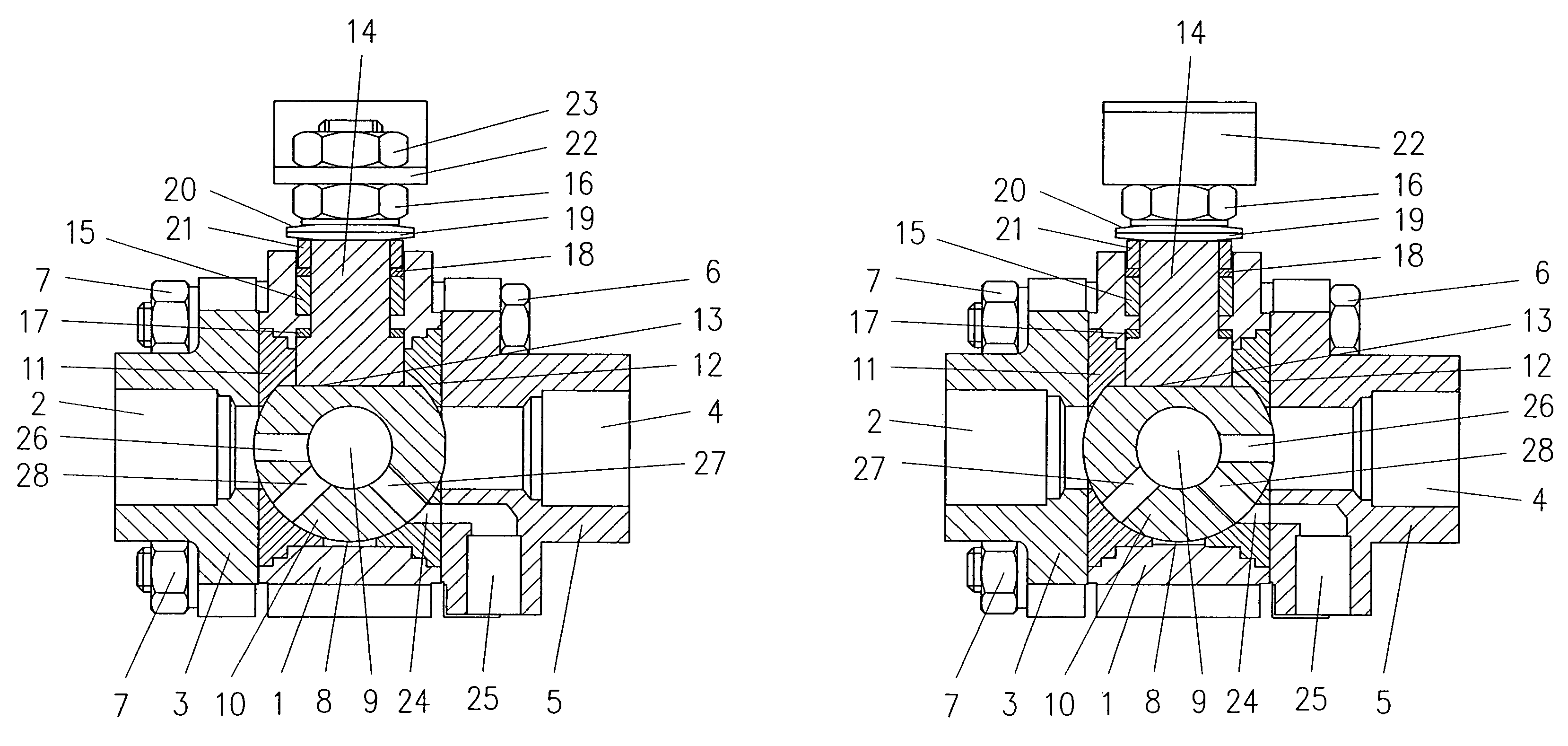

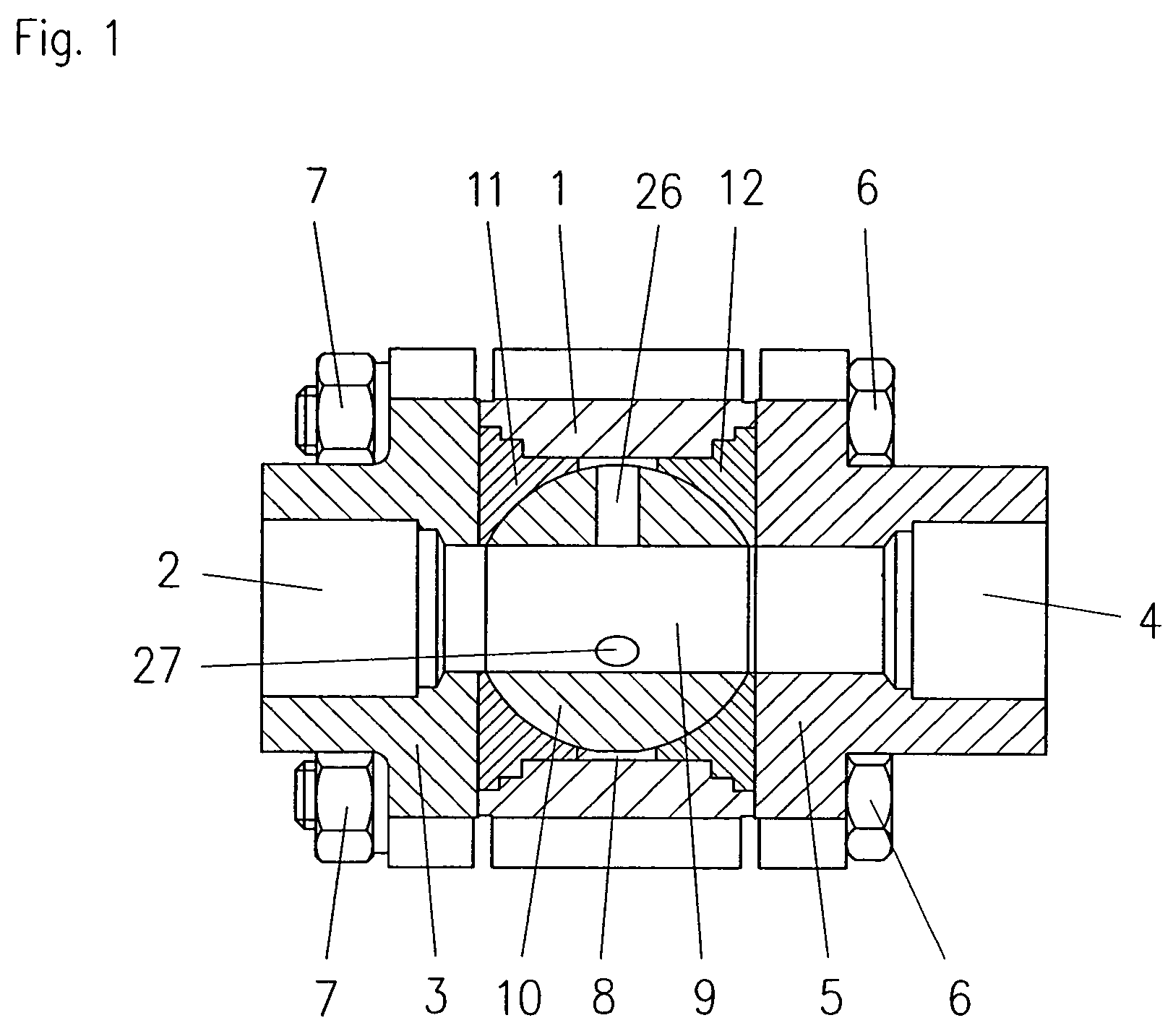

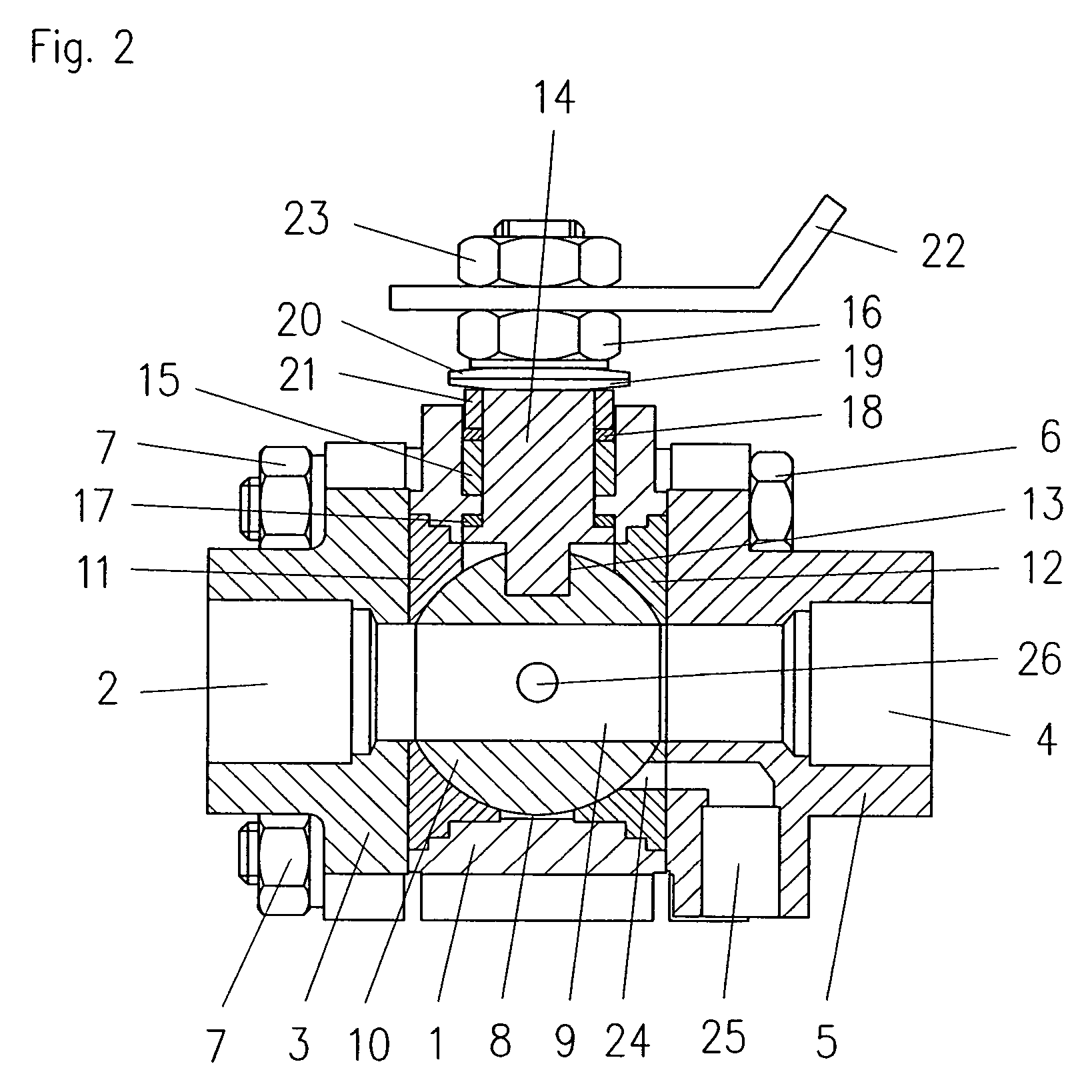

Ball valve

The present invention is a ball valve which may be attached to a fluid pipe for connection / disconnection between an entrance and an exit. More particularly, the present invention is a ball valve having a discharge orifice communicating with ambient air in addition to the entrance and the exit for connection / disconnection between the entrance and the discharge orifice and / or between the exit and the discharge orifice. The ball valve of the present invention may be attached to piping systems such as, for example, the secondary side of a steam trap, which blocks steam but automatically discharges condensed water, and is used for checking a discharging state of the primary side steam trap and / or releasing remaining pressure on the secondary side.

Owner:TLV CO LTD

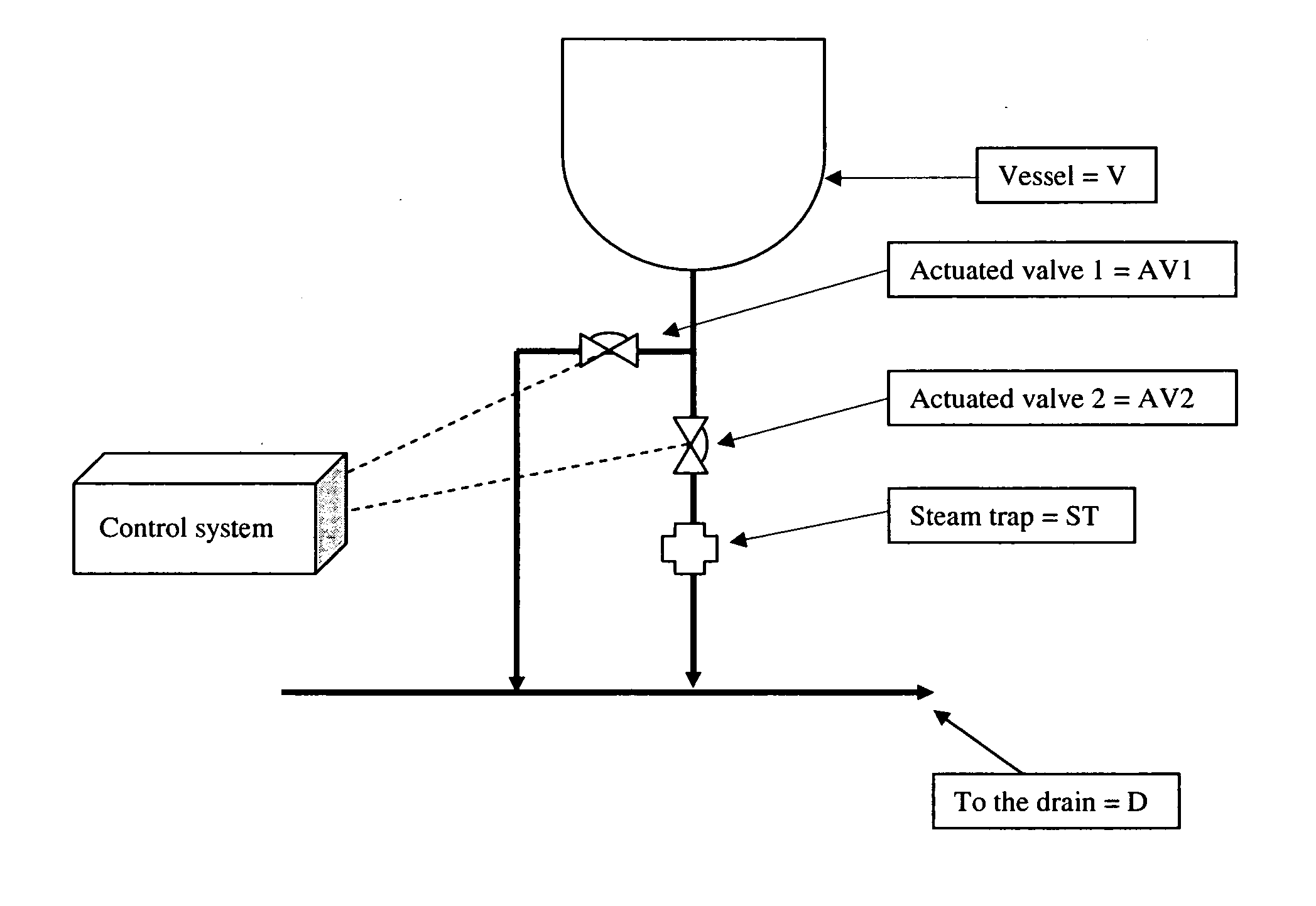

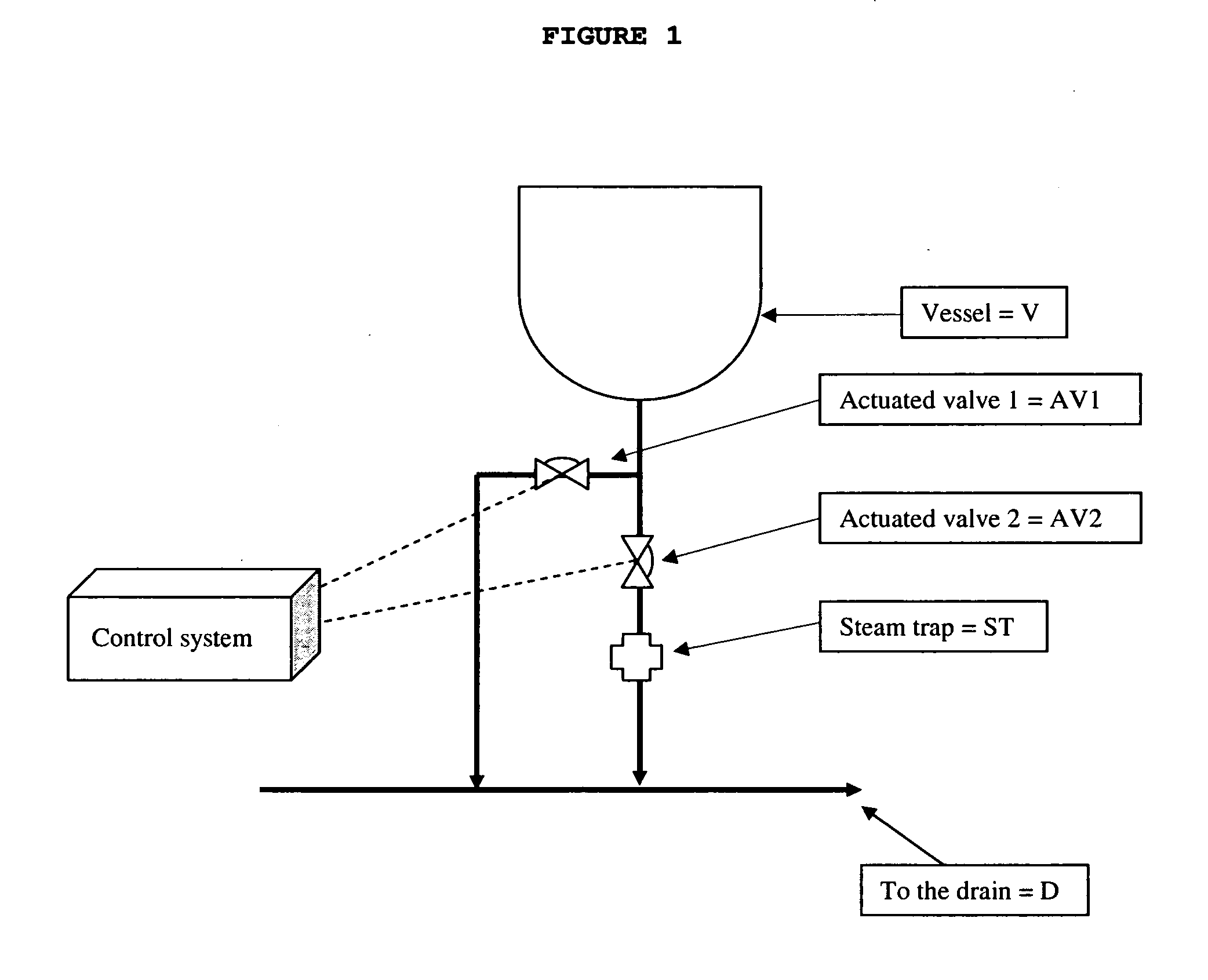

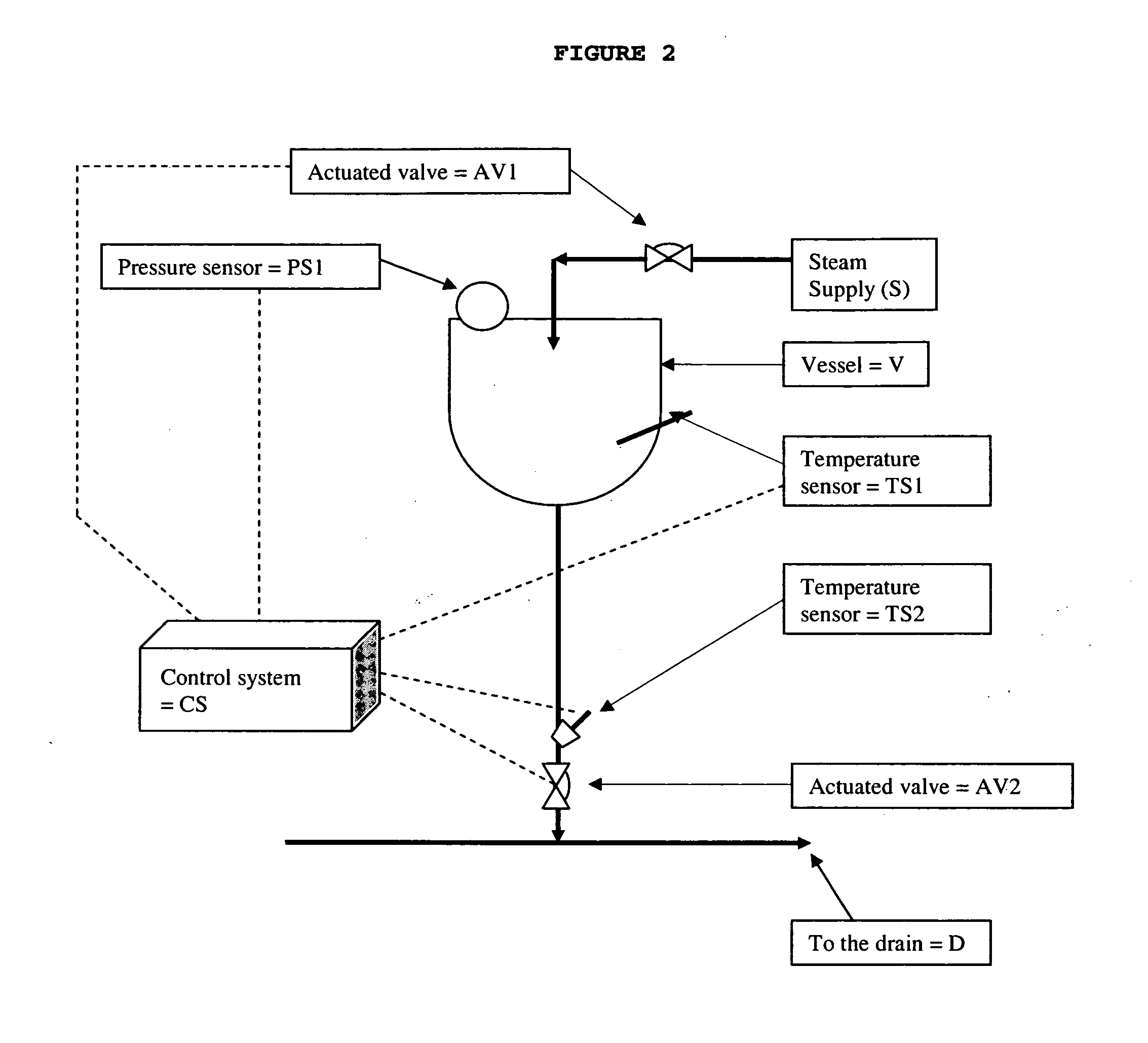

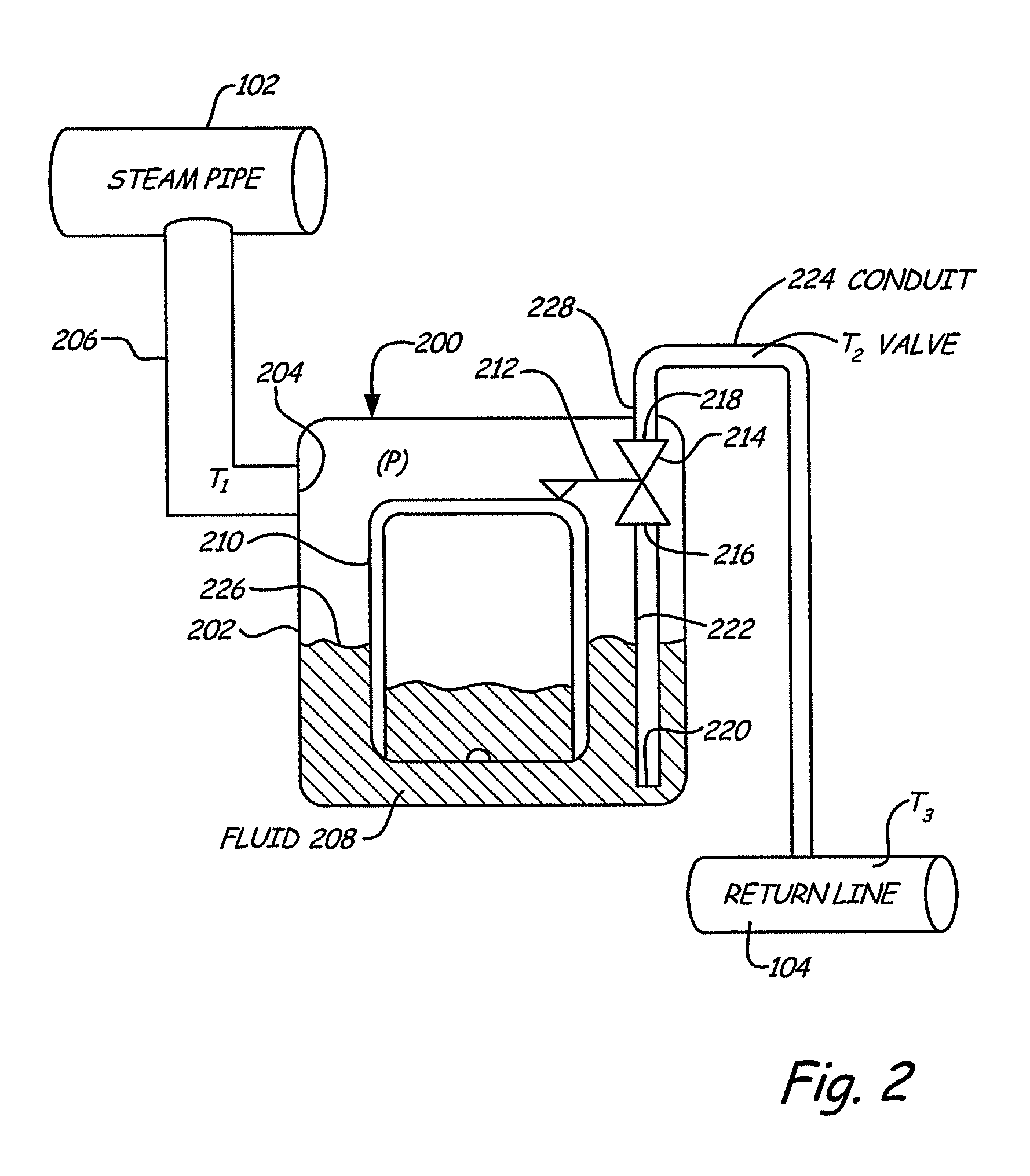

Programmable steam trap apparatus

An apparatus and a method for removing condensate and unwanted gas from vapor / liquid systems while preventing steam loss are provided. The steam trap apparatus replaces the automatic valve type steam trap with an efficient, controllable, and programmable steam trap. In addition, the improved steam trap apparatus allows for real-time data collection during sterilization and other operations.

Owner:TEVA PHARMA IND LTD

Steam valve

InactiveUS6302136B1Easy to useExtended service lifeOperating means/releasing devices for valvesSteam trapsCarbide coatingNitride

Owner:3M INNOVATIVE PROPERTIES CO

Remote monitor for steam traps

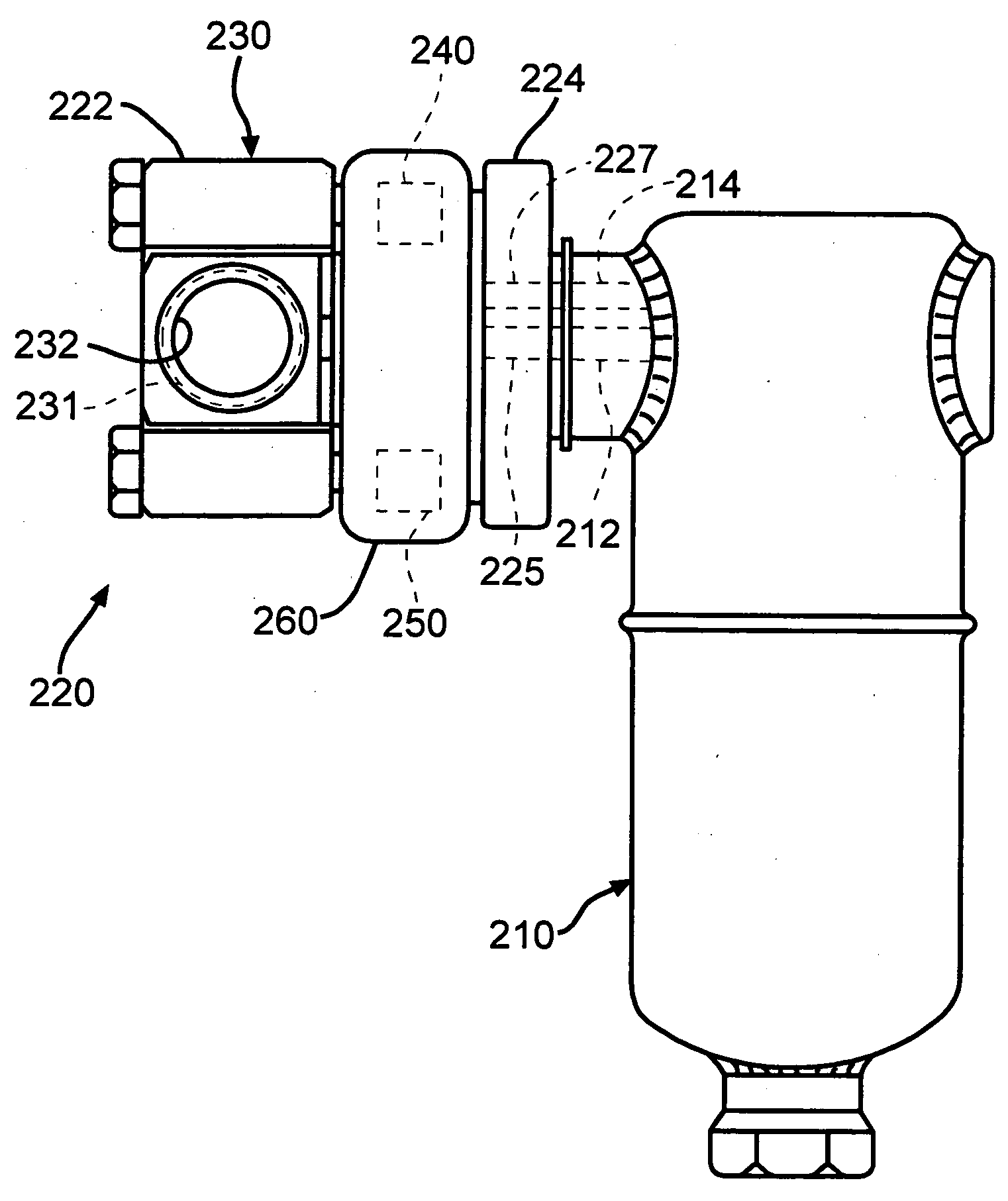

ActiveUS20060118647A1Temperature control without auxillary powerFlow propertiesEngineeringSteam trap

An apparatus and method for monitoring the status of at least one steam trap includes at least one monitor including at least one sensor for sensing at least one process condition of the steam trap; at least one means for calculating an average of the at least one monitored process condition; and, at least one transmitter for transmitting at least one signal responsive to the averaged monitored process condition.

Owner:ARMSTRONG INT INC

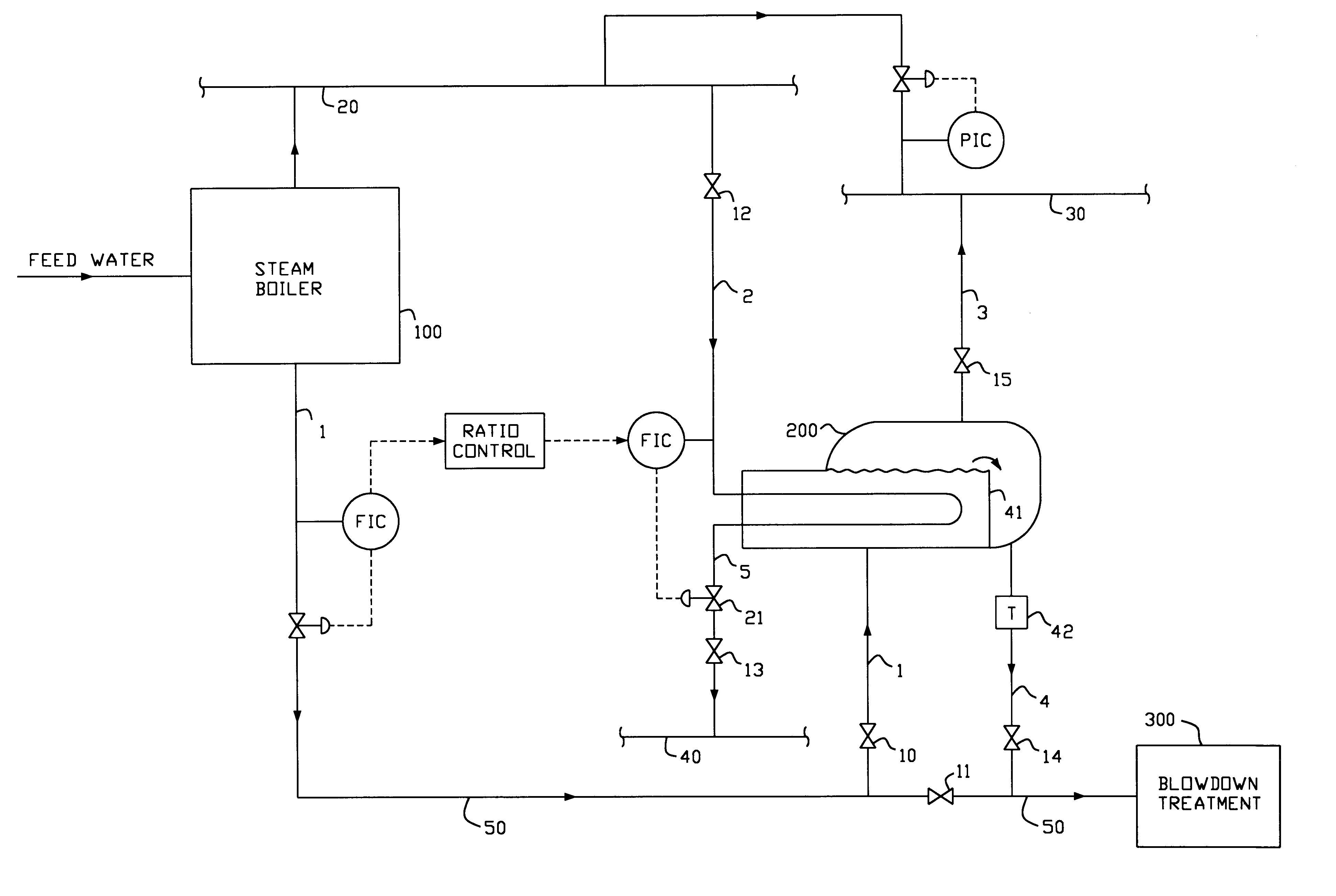

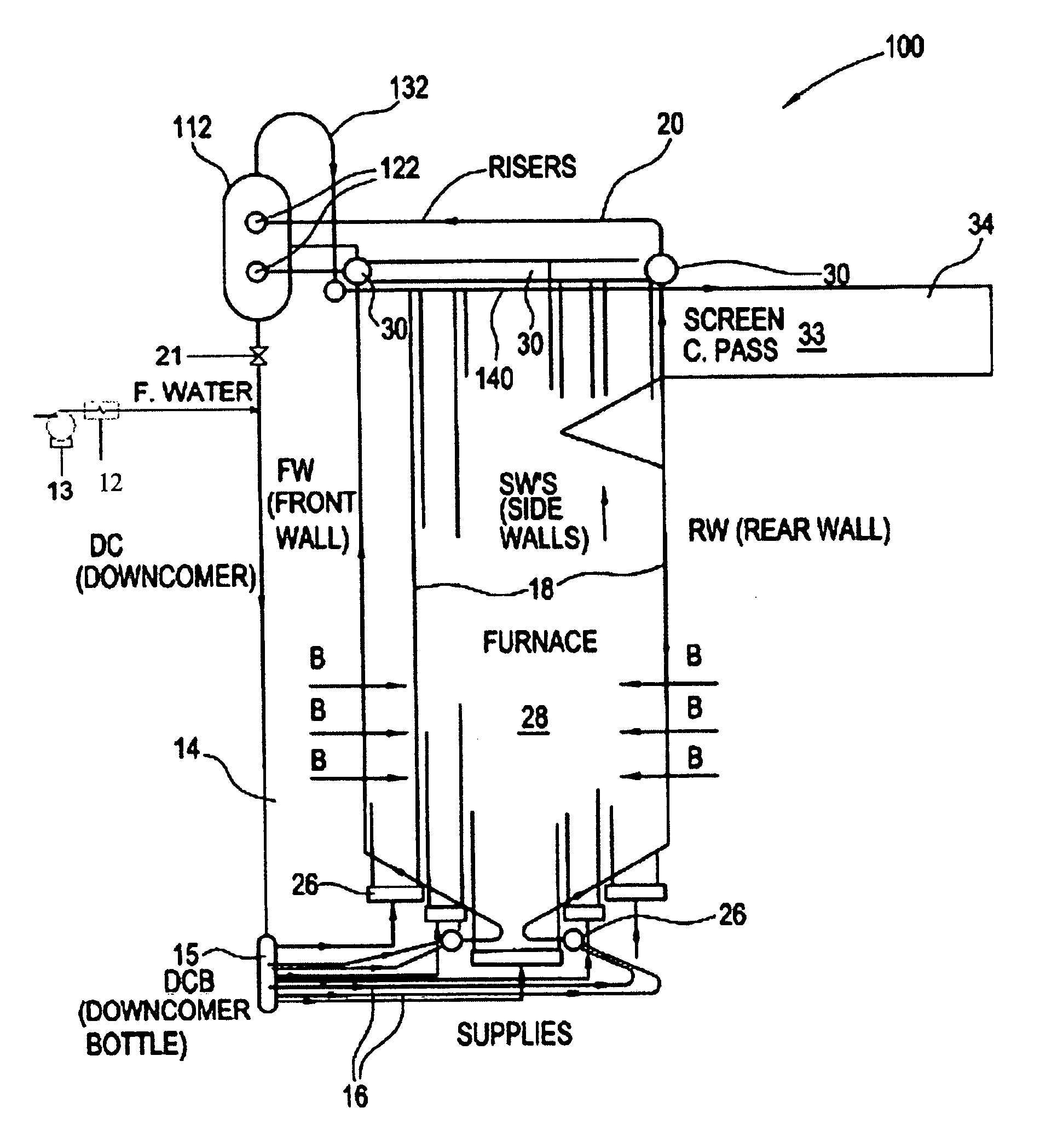

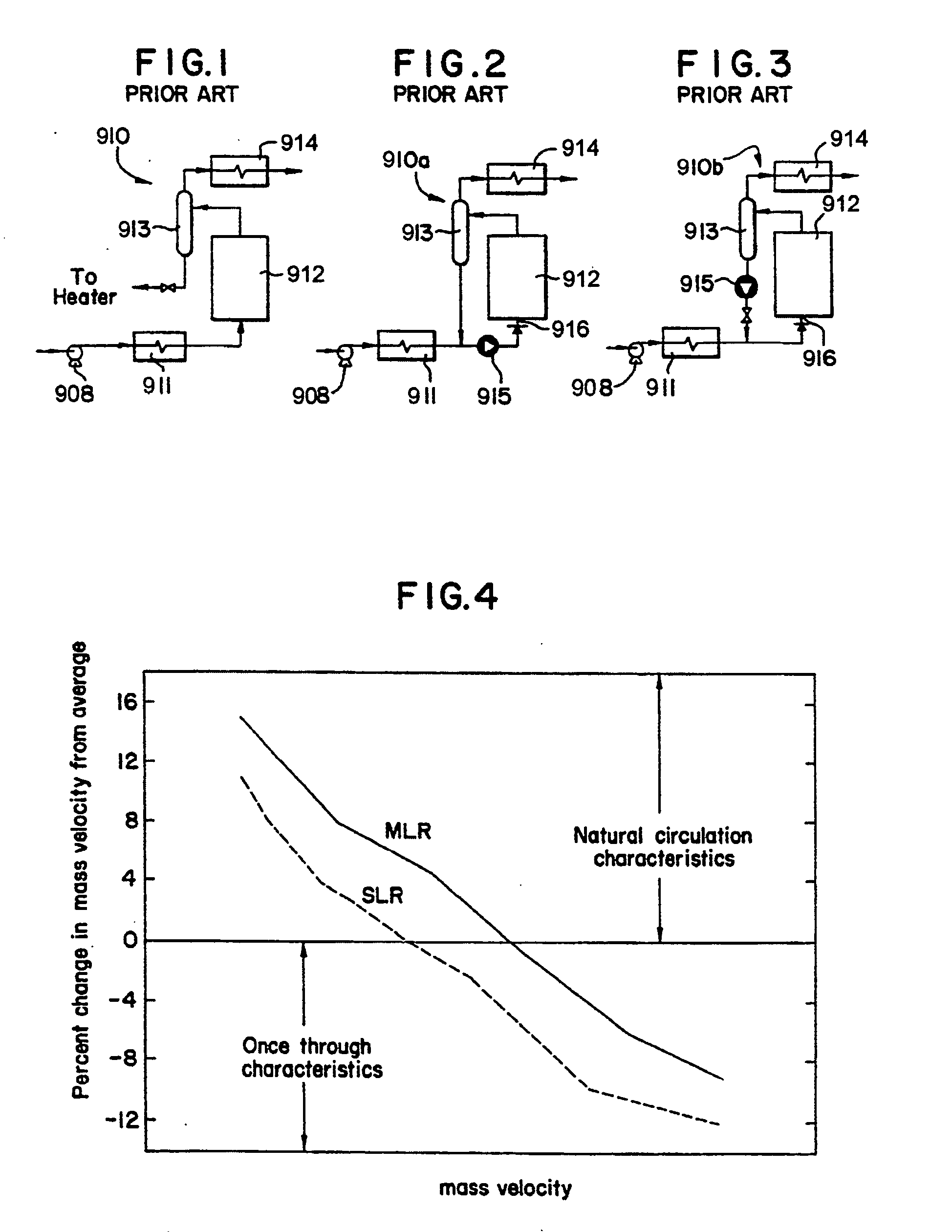

Circulation system for sliding pressure steam generator

InactiveUS20070283906A1High densityImprove abilitiesWater circulationFuel injection apparatusBoiler feedwater pumpEngineering

A steam generator circulation system is provided and includes a boiler feed pump for forcing water through an economizer, and through the waterwall tubes of an evaporator. A separator receives a mixture of steam and water and sends the steam to a steam utilization unit such as a superheater. A valve is provided below the separator. If the valve is open, the saturated water from the separator is mixed with feedwater and recirculated through the tubes of the evaporator. If the valve is closed, recirculation is terminated. At loads below the critical point, the valve below the separator system would be open and the boiler would operate like a natural circulation drum boiler. At loads above the critical point, the valve below the separator system would be closed resulting in a boiler that operates like a once-through boiler.

Owner:THE BABCOCK & WILCOX CO

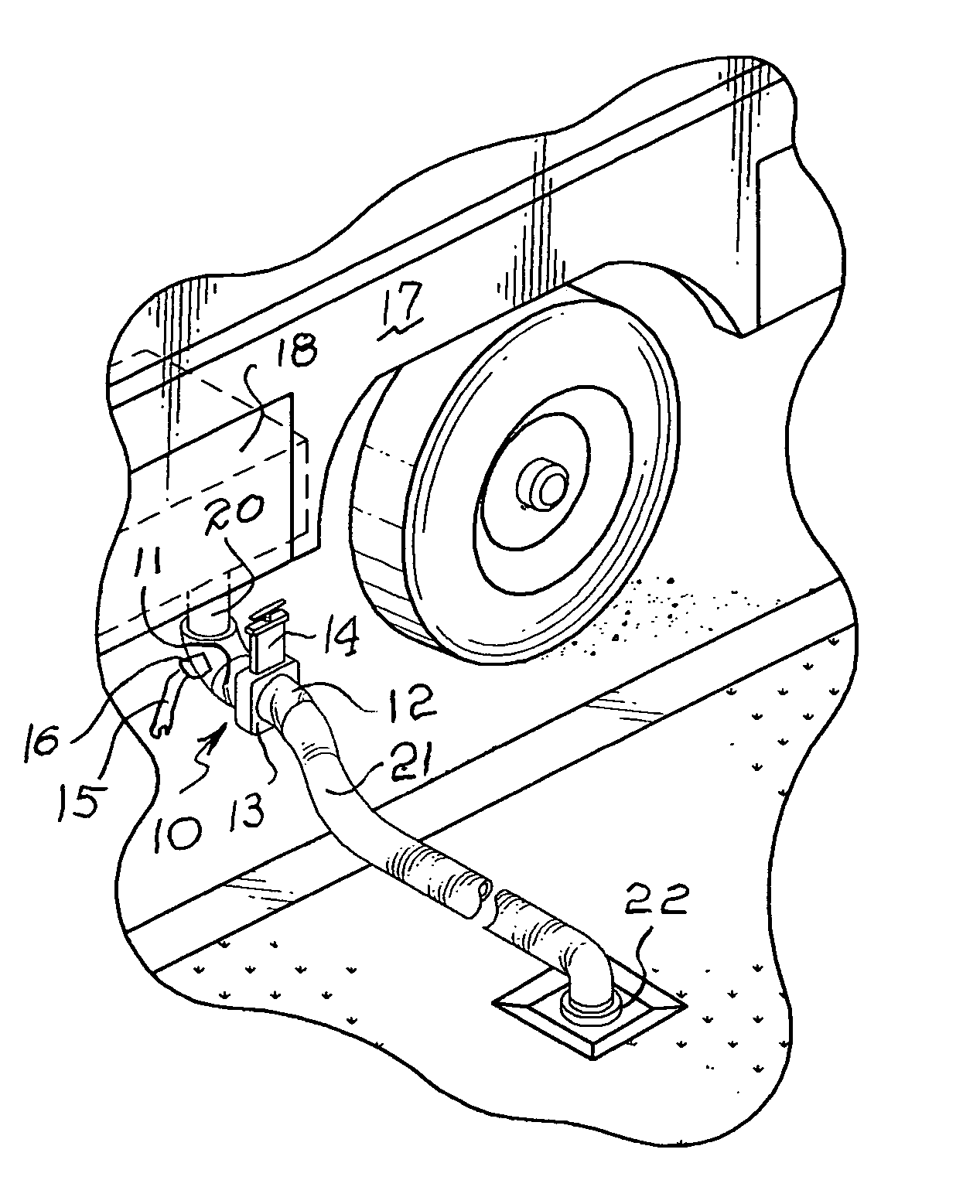

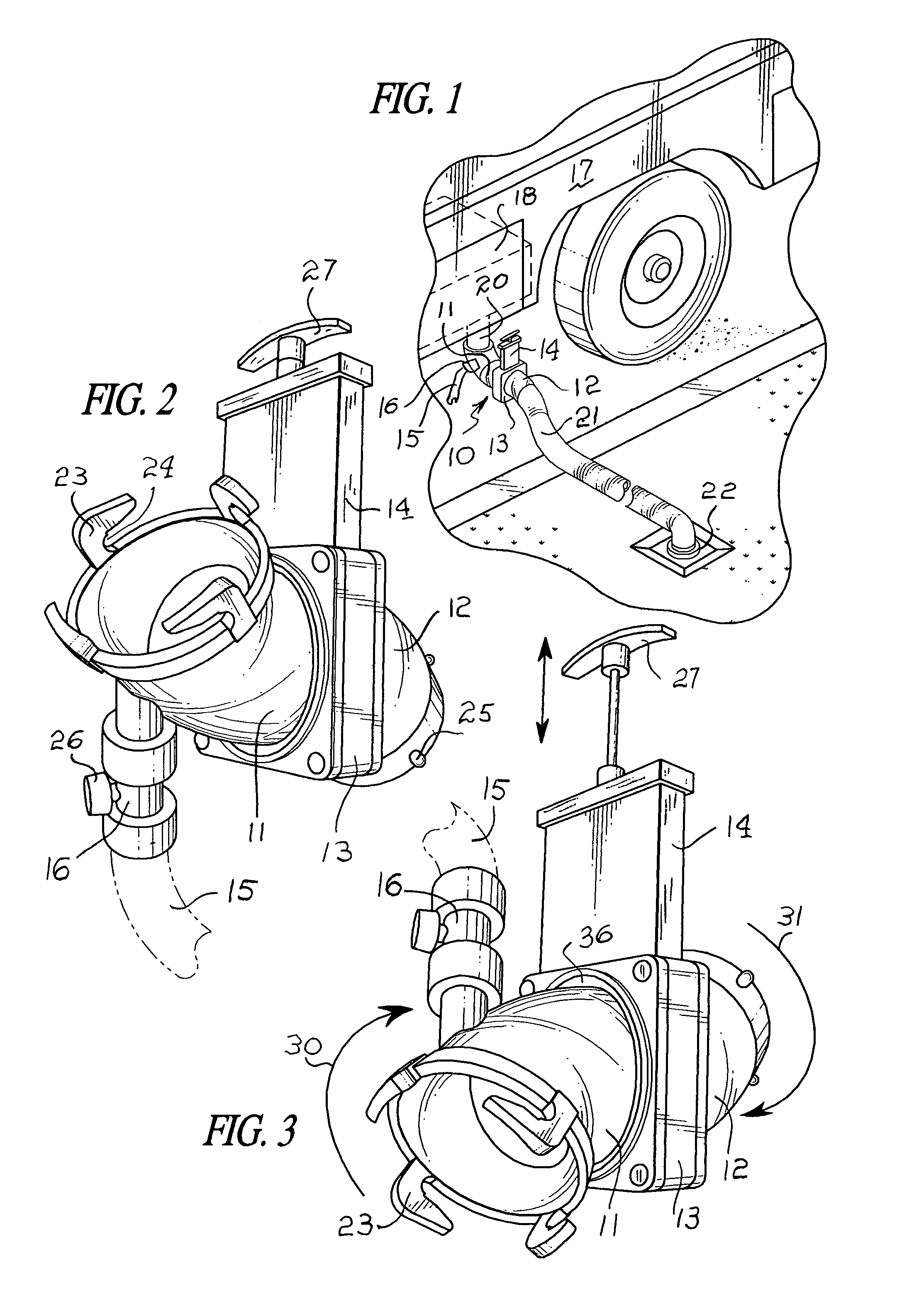

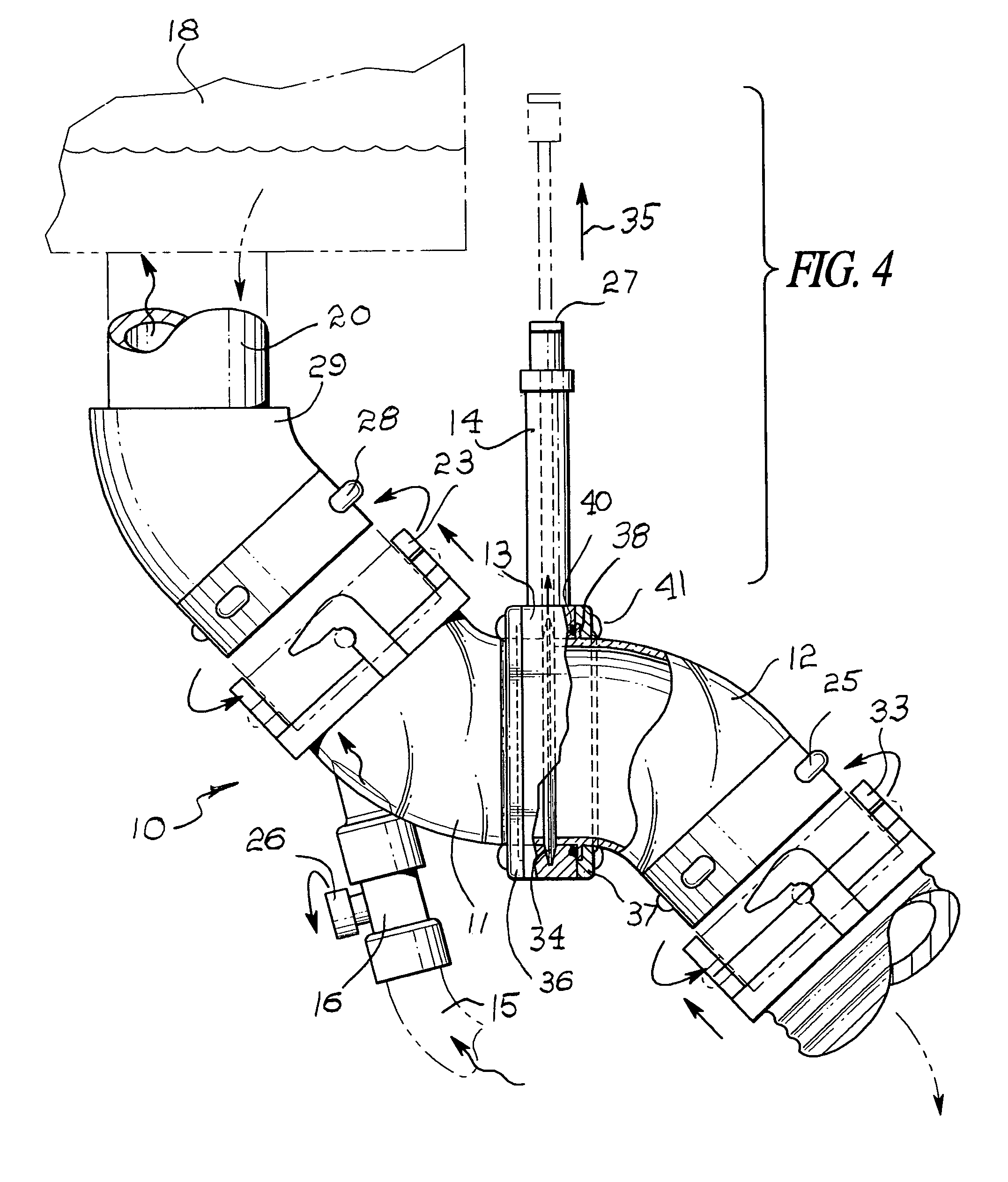

Flush valve and drain system for recreational vehicles

ActiveUS7156574B1Readily detachably connectedFirmly connectedFlushing devicesAdjustable jointsWater sourceSewage

A transparent drain and flush valve component combination detachably connected between a vehicle drain outlet and a disposal conduit which leads to a sewage receptacle. The apparatus includes a main body having a pair of end plates which are joined to the body by fasteners. The end plates and the body are separated by mated flanges adapted to rotate with respect to each other. An elastomeric O-ring between the flanges not only seals but accommodates rotation of transparent attachment pipes for both the vehicle and the disposal conduit. Also, a shut-off valve is included in the body which is manually operated and takes the form of a slide or gate valve which can partially or fully open or close fluid communication between the pair of attachment pipes. A pressurized water supply is selectively attached to an attachment pipe for introducing pressurized water to the vehicle plumbing system, including the holding tank for flushing and rinsing purposes.

Owner:GARST ROGER

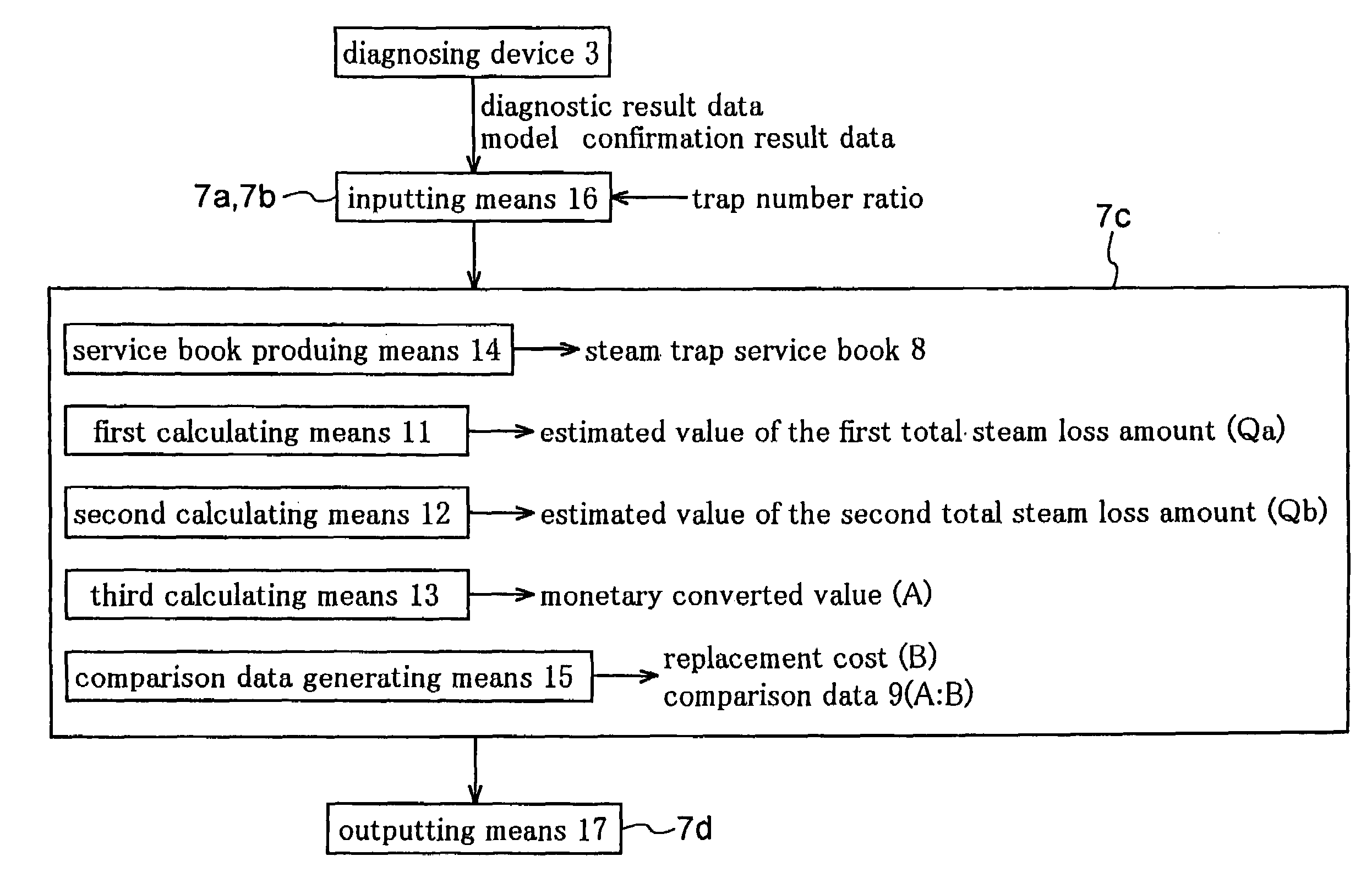

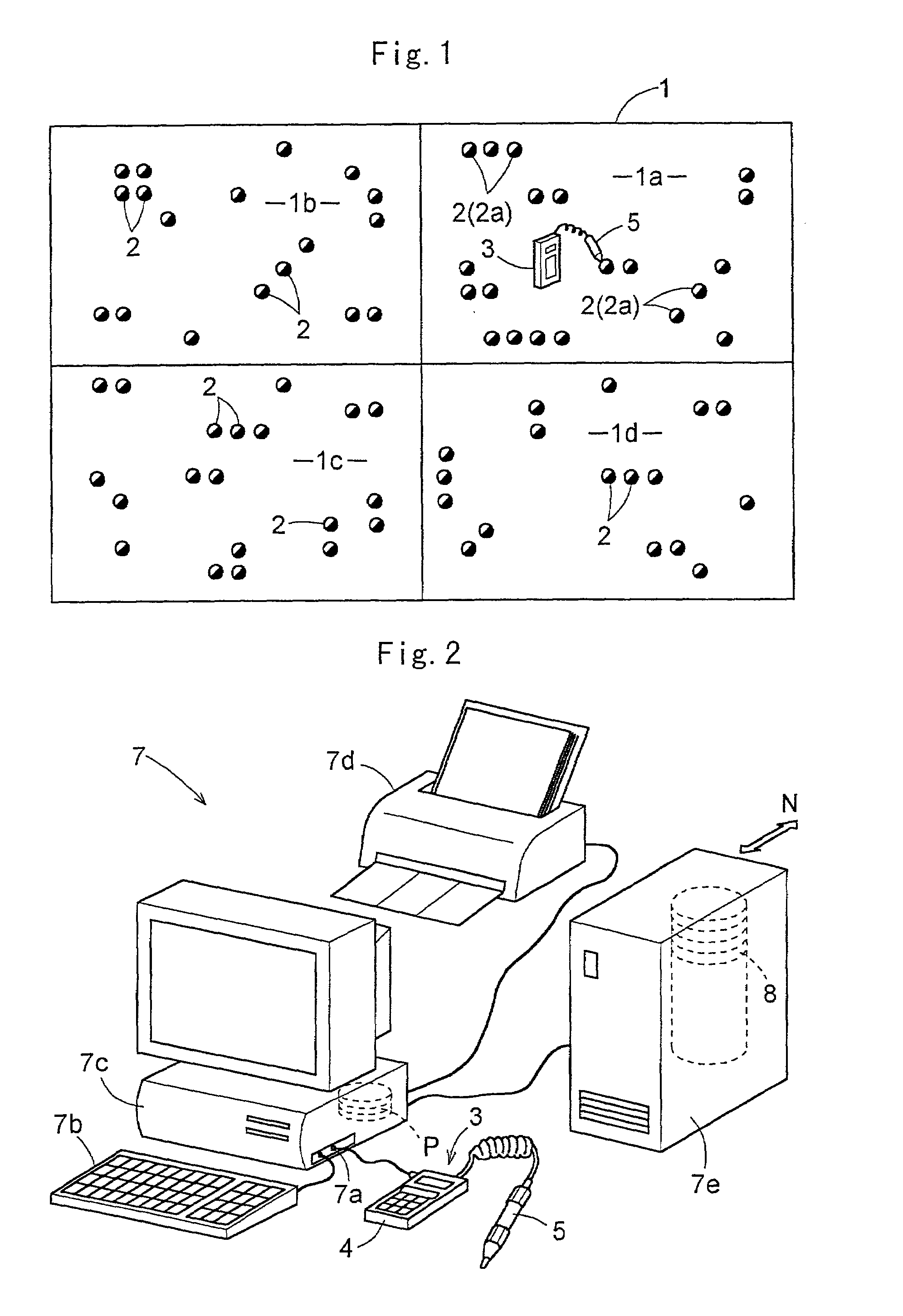

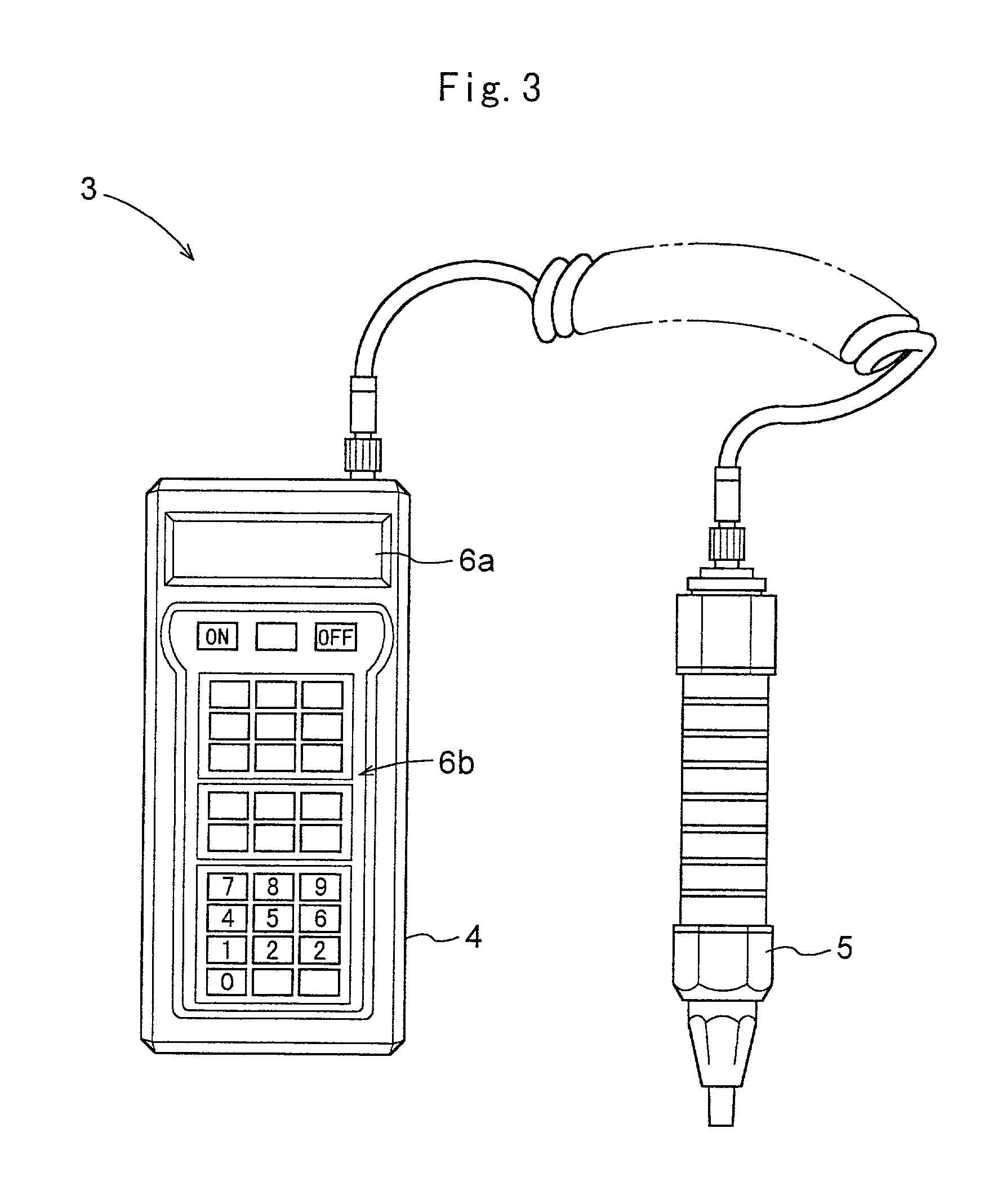

Method of supporting sales and maintenance of steam traps and aggregating system for use in the method

ActiveUS7130804B2Easy to implementEasy to operateRegistering/indicating machine productionNuclear monitoringSteam trapEngineering

Disclosed is a system for supporting sales and maintenance activities of steam traps by a seller of the traps to a customer. The system utilizes an aggregating system which effects a step of inputting stored diagnostic result data and model confirmation result data from a diagnostic device which has diagnosed a working condition of each of a plurality of existing steam traps installed in a customer's plant. Based on the diagnostic result data, a first total steam loss amount due to malfunction of steam traps is calculated, the first total steam loss amount comprising aggregation of steam leak amounts of all the existing steam traps. Based on the model confirmation result data, a second total steam loss amount is calculated, which comprises aggregation of differences between inherent steam leak amounts of the existing steam traps under their normal working conditions and inherent steam leak amounts of recommended steam traps under their normal working conditions. A monetary conversion value of an integrated value of a sum of the first total steam loss amount and the second total steam loss amount integrated for a predetermined period is calculated. Comparison data is generated allowing comparison between the monetary converted value and a replacement cost required for lump-sum replacement of all the existing steam traps by the recommended steam traps. The comparison data is outputted for presentation to the customer in sales and / or maintenance activities of the recommended steam traps.

Owner:TLV CO LTD

Steam trap monitoring

Owner:ROSEMOUNT INC

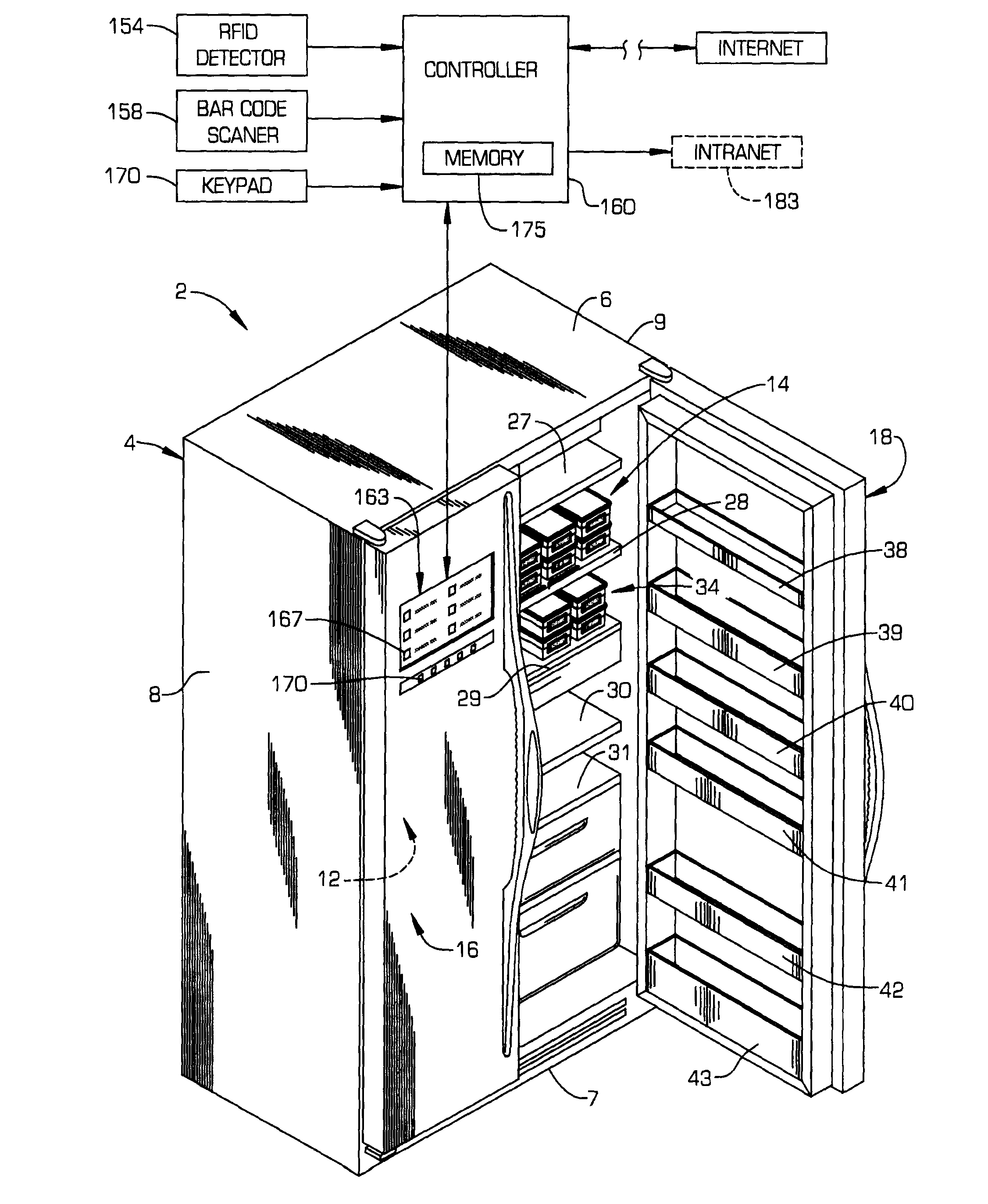

Refrigerator including food product management system

ActiveUS7861542B2Time-programme switchesAuxillary controllers with auxillary heating devicesAdhesiveTime segment

A refrigerator includes at least one refrigerated compartment and a food product management system. The food product management system includes a container for storing foodstuffs in the at least one refrigerated compartment. The container includes a storage zone and a lid. A tag is arranged on the container to provide a consumer with an indication of whether a food item stored in the container is or is not spoiled. The tag can include a timer having a display, an indicator that changes state upon the passage of a predetermined time period and a computer that notifies a consumer, such as through an email, about a parameter associated with the food item in the container. The tag is affixed to the container with adhesive, snaps, clips, hooks and the like or, alternatively, simply integrally formed with the container.

Owner:WHIRLPOOL CORP

Online leak detection device for steam trap of steaming-water pipeline of thermal power plant

InactiveCN103016948AAccurate judgmentEasy to install and maintainSteam trapsPower stationEngineering

The invention relates to an online leak detection device for a steam trap of a steaming-water pipeline of a thermal power plant. The online leak detection device is composed of digital temperature sensors, a digital temperature signal collector, a 485 communication cable, an optical modem, an optical cable and a data processing computer, wherein the digital temperature sensors adopt DS18B20, and a plurality of digital temperature sensors arranged in the circumferential direction of the outer side of the downstream drain water pipeline of the same steam trap share one digital temperature signal collector; the digital temperature signal collector adopts a microprocessor ARM7, and collected signals are transmitted to the data processing computer through a data communication line to be processed; and according to the data of the downstream wall surface temperature of the steam trap and the rate of change of the data, a principle of fuzzy pattern recognition is adopted to carry out fuzzy recognition on the leakage level of the steam trap. The online leak detection device has the advantages of simple system and convenience for installation and maintenance, can monitor on line in real time, and accurately judges the leakage of the steam trap in time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

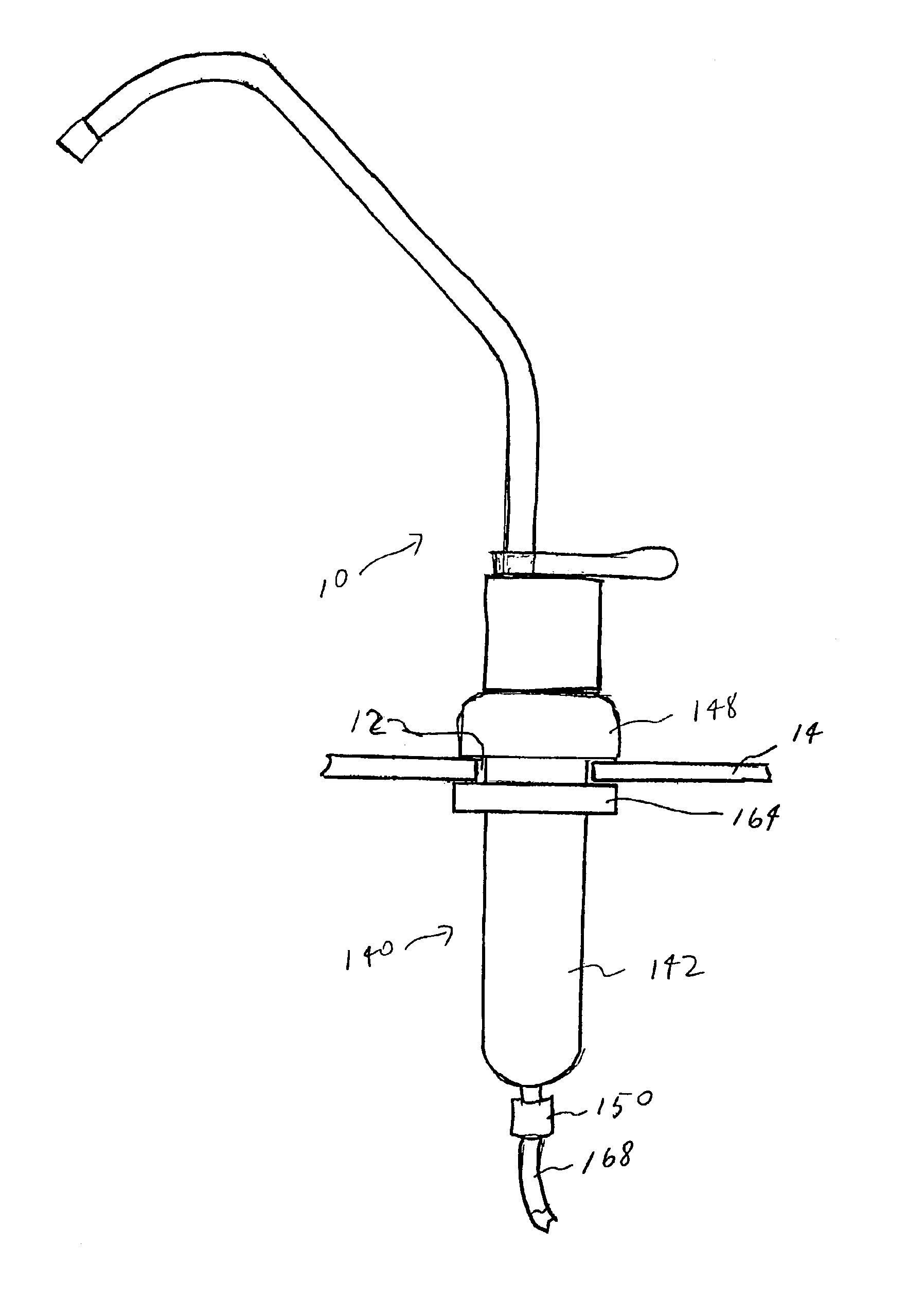

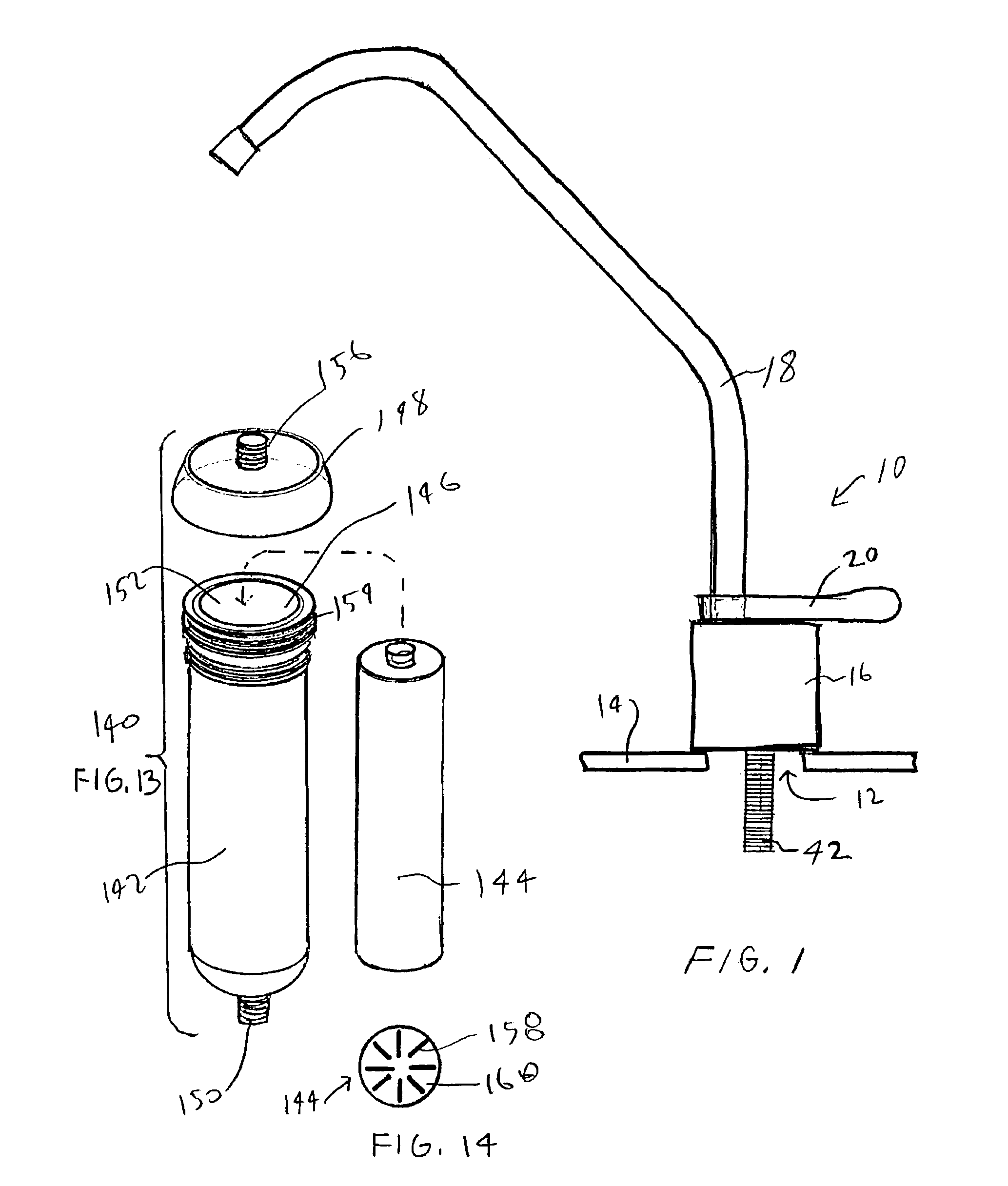

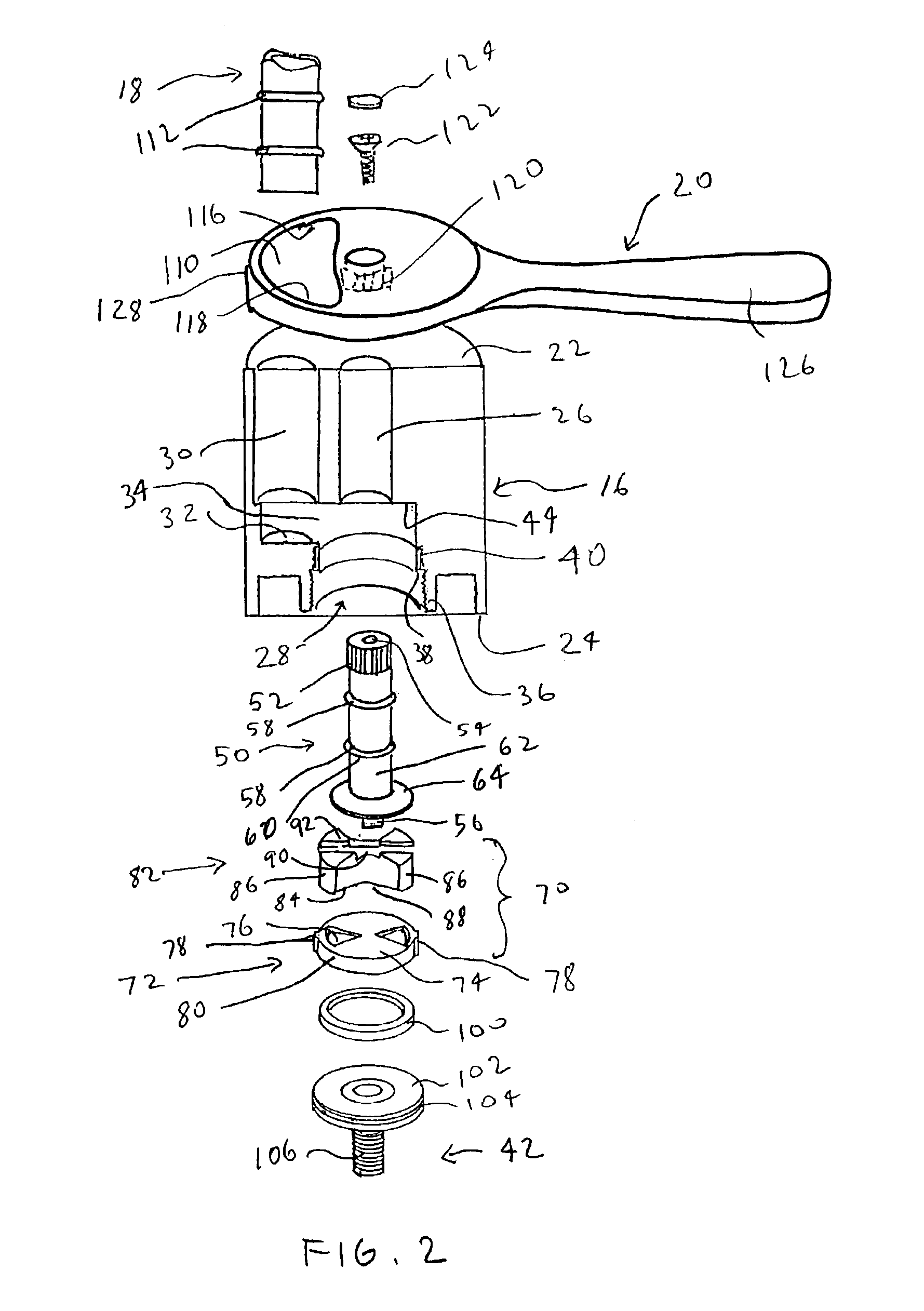

Fluid spigot and filter unit

A fluid spigot with a spigot body, a spigot tube, a rotary disc valve located in a valve cavity in the spigot body, the rotary disc valve having an opened and closed positions, a valve stem for turning the rotary disc valve, and a handle for turning the valve stem. The invention further provides a filter unit for attachment to a water spigot or faucet. The filter unit has a filter cannister with a hollow body with a fluid inlet and an open mouth portion, a filter sized to fit within the filter cannister, and an adapter that fits over the open mouth portion of the filter canister, wherein the filter cannister is sized to fit through a hole in a sink rim, the filter being replaceable from above the sink by removing the adapter to access the filter.

Owner:QMP

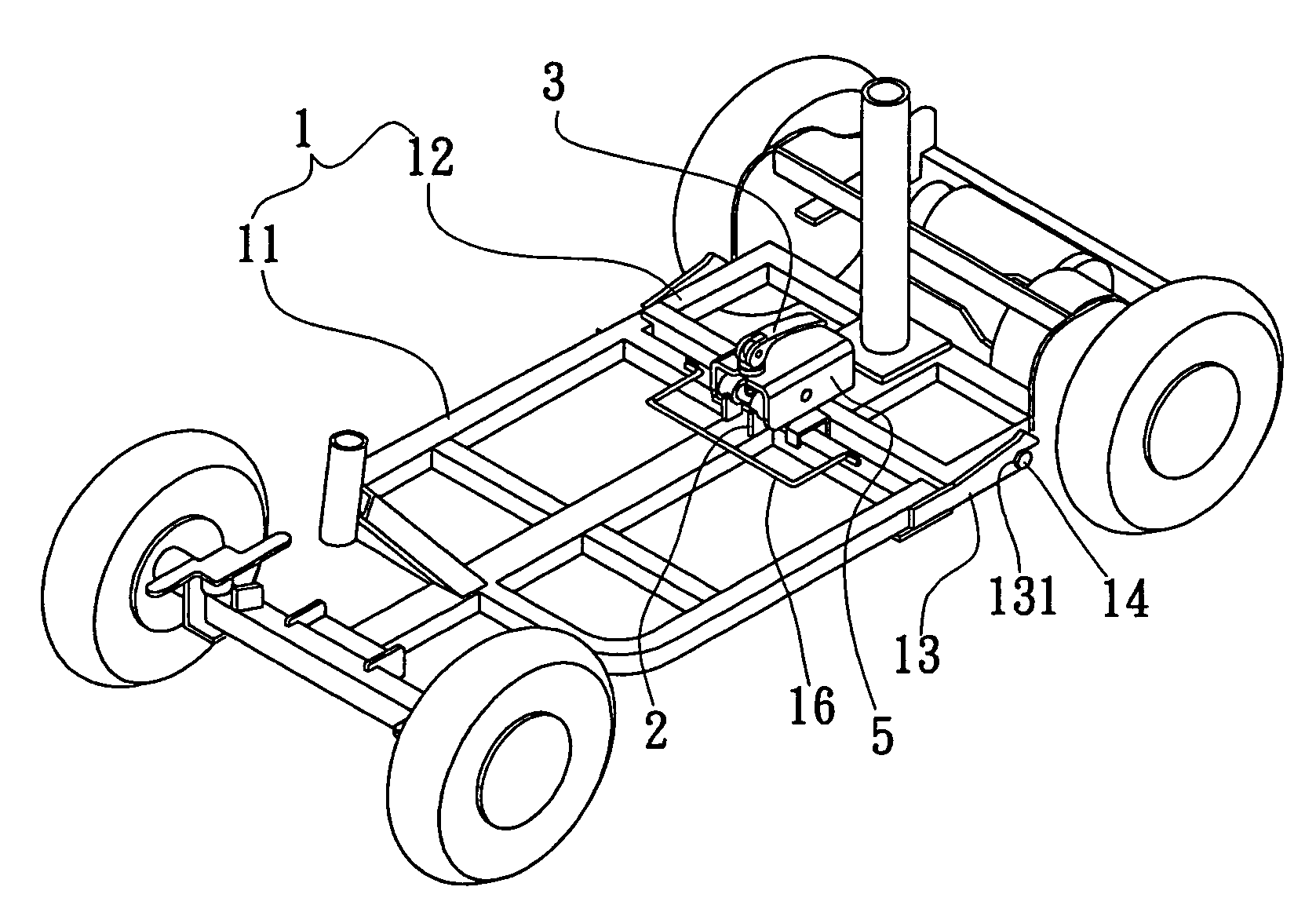

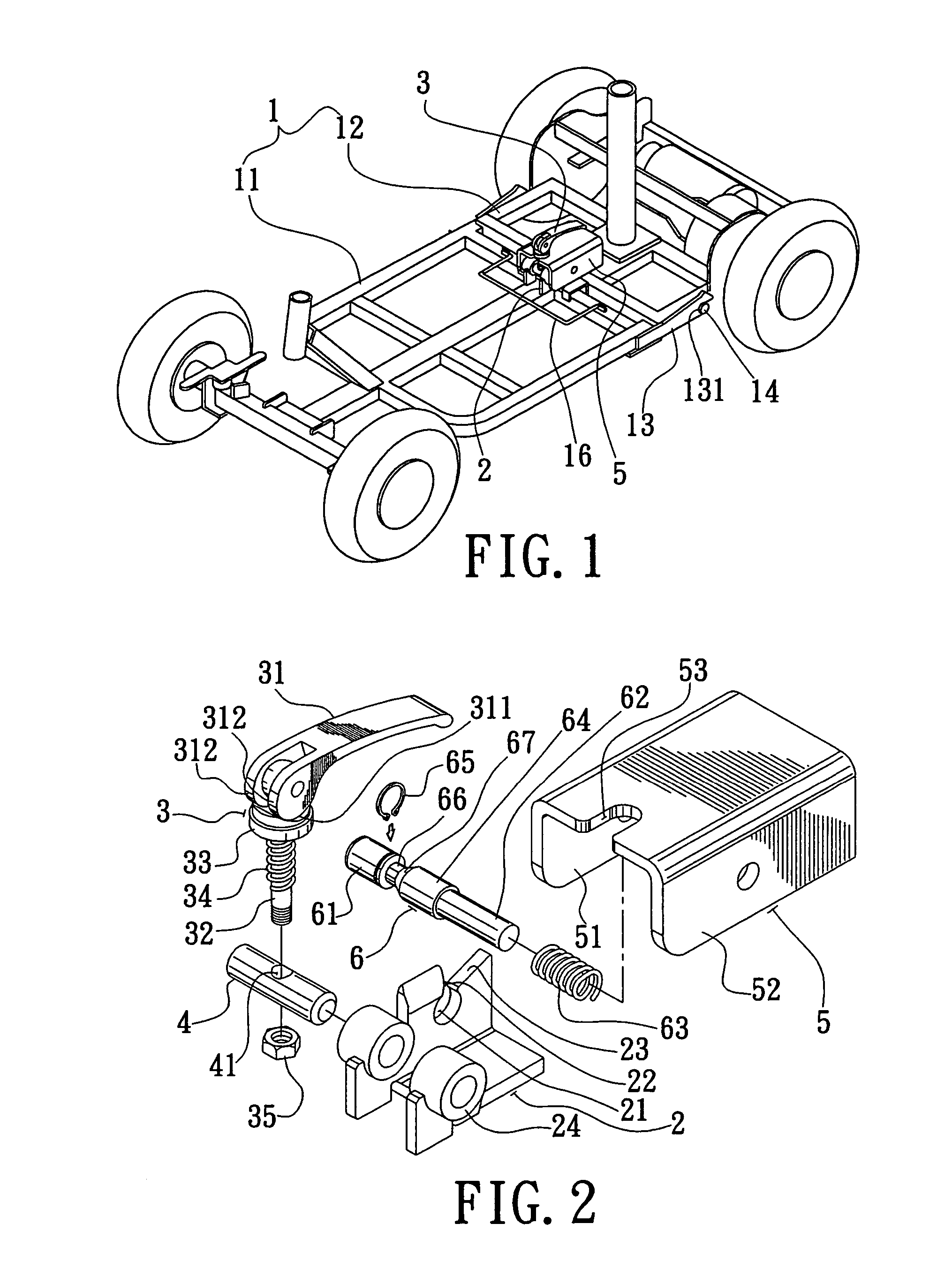

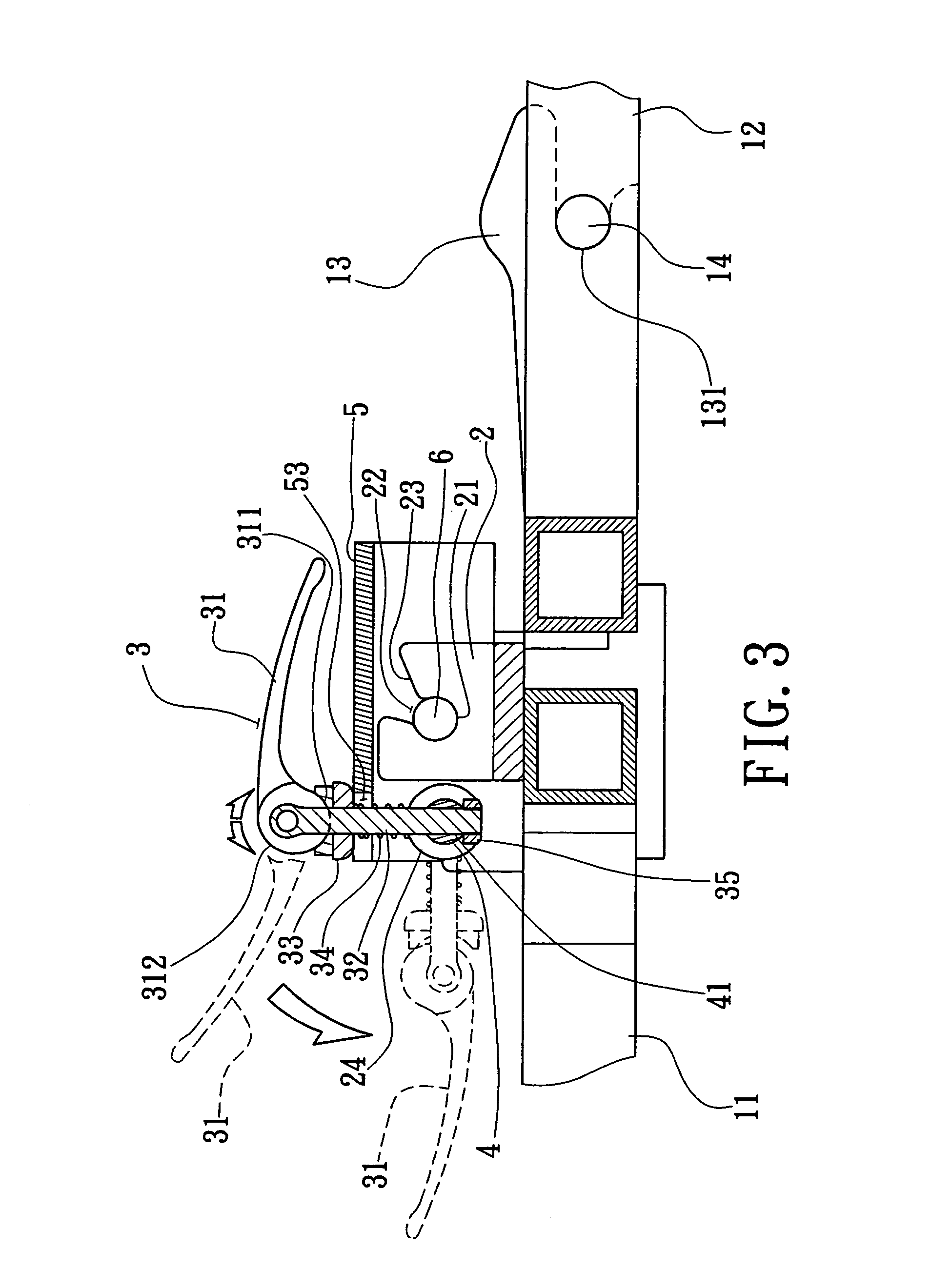

Structure of a frame of an electric cart for a person to ride on

A frame of an electric cart includes a front part, and a rear part separable from the front part; the front part has a locating member secured on a rear end thereof; the rear part has a connecting member secured on a front end thereof for engaging the locating member, which connecting member has a spring-loaded engaging pin passed through it; the pin is made such as to be capable of engaging the locating member automatically while the rear part is being moved so as to fit the connecting member onto the locating member, thus securely joining the rear part to the front part; the engaging pin will be disengaged from the fitting portion when it is pressed at a first end, thus allowing the rear part to be separated from the front part.

Owner:SUNPEX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com