Gas and liquid separator

A gas-liquid separator and separator technology, applied in separation methods, dispersed particle separation, liquid degassing, etc., can solve the problems of large volume, complex structure, high price, etc., and achieve the effect of small volume, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

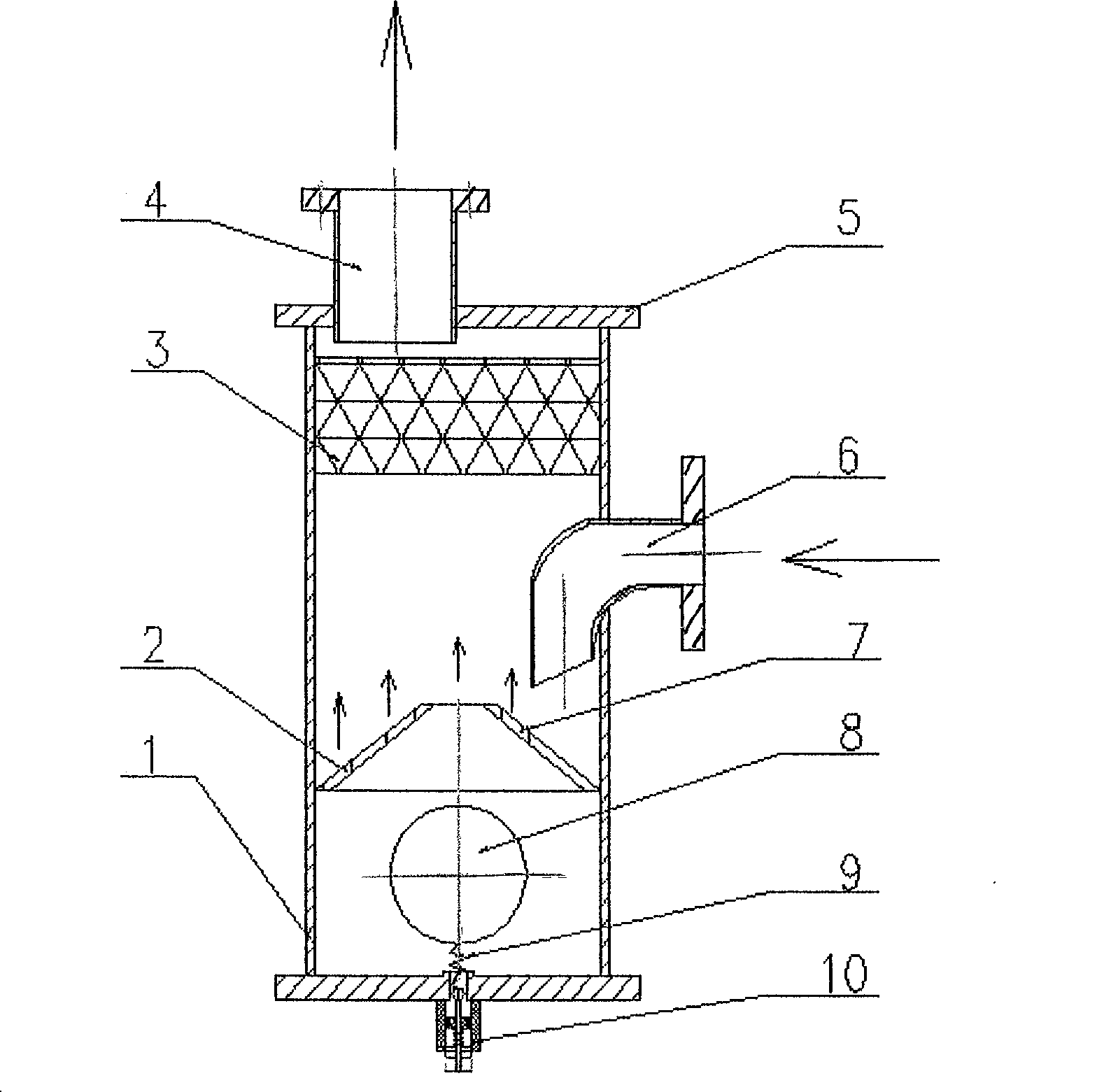

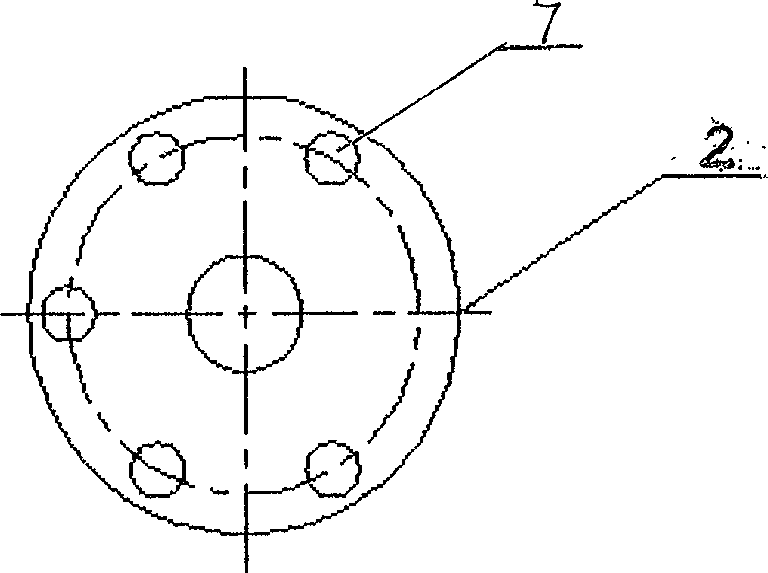

[0011] Such as figure 1 , the present invention comprises a cylinder body 1 and a cylinder cover 5, characterized in that: the cylinder cover is provided with an air outlet 4, a wire mesh demister 3 is provided near the top air outlet in the cylinder body, and the inner and lower part of the cylinder body is provided with a diameter corresponding to that of the cylinder The shielding umbrella 2 with the same internal diameter and fixed on the inner wall of the cylinder with a gas-liquid through hole is provided with a floating ball 8 under the shielding umbrella. Connected; on the side wall of the cylinder 1 between the wire mesh demister 3 and the cover umbrella 2, a gas-liquid inlet 6 is provided.

[0012] When the present invention is working, when the gas-liquid with pressure enters from the gas-liquid inlet 6 along the direction of the arrow in the figure, and passes through the shielding umbrella 2 at the bottom of the cylinder, the flow velocity of the gas-liquid is slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com