Combined power and refrigeration cycle system of absorption steam turbine

A circulation system and steam turbine technology, applied in the direction of adsorption machines, steam engine devices, refrigerators, etc., can solve the problems of large amounts of electric energy and cooling capacity, unsatisfactory economy, environmental heat pollution, etc. in fertilizer plants, and achieve waste heat utilization process and The equipment is simple, conducive to popularization and implementation, and the effect of low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

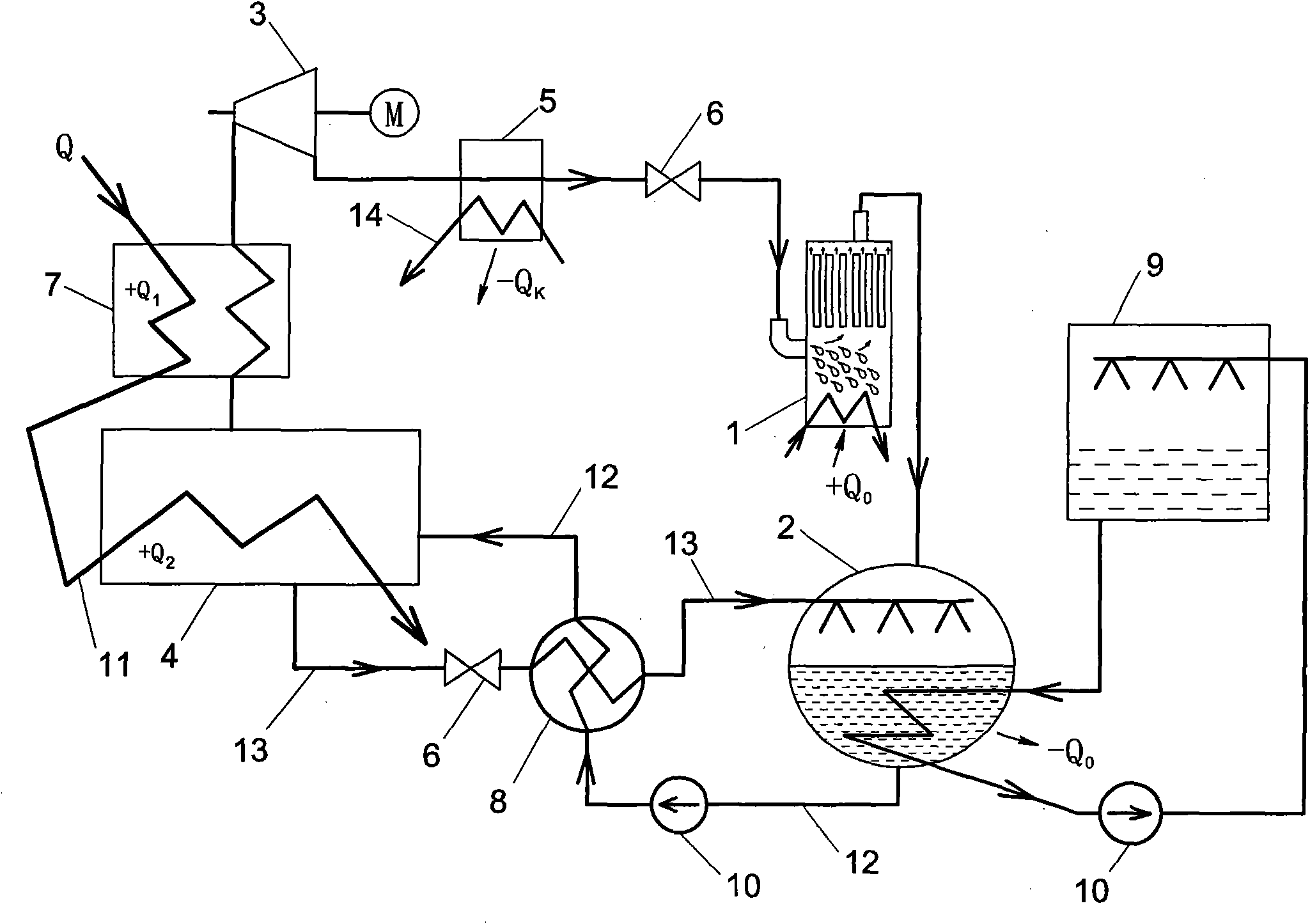

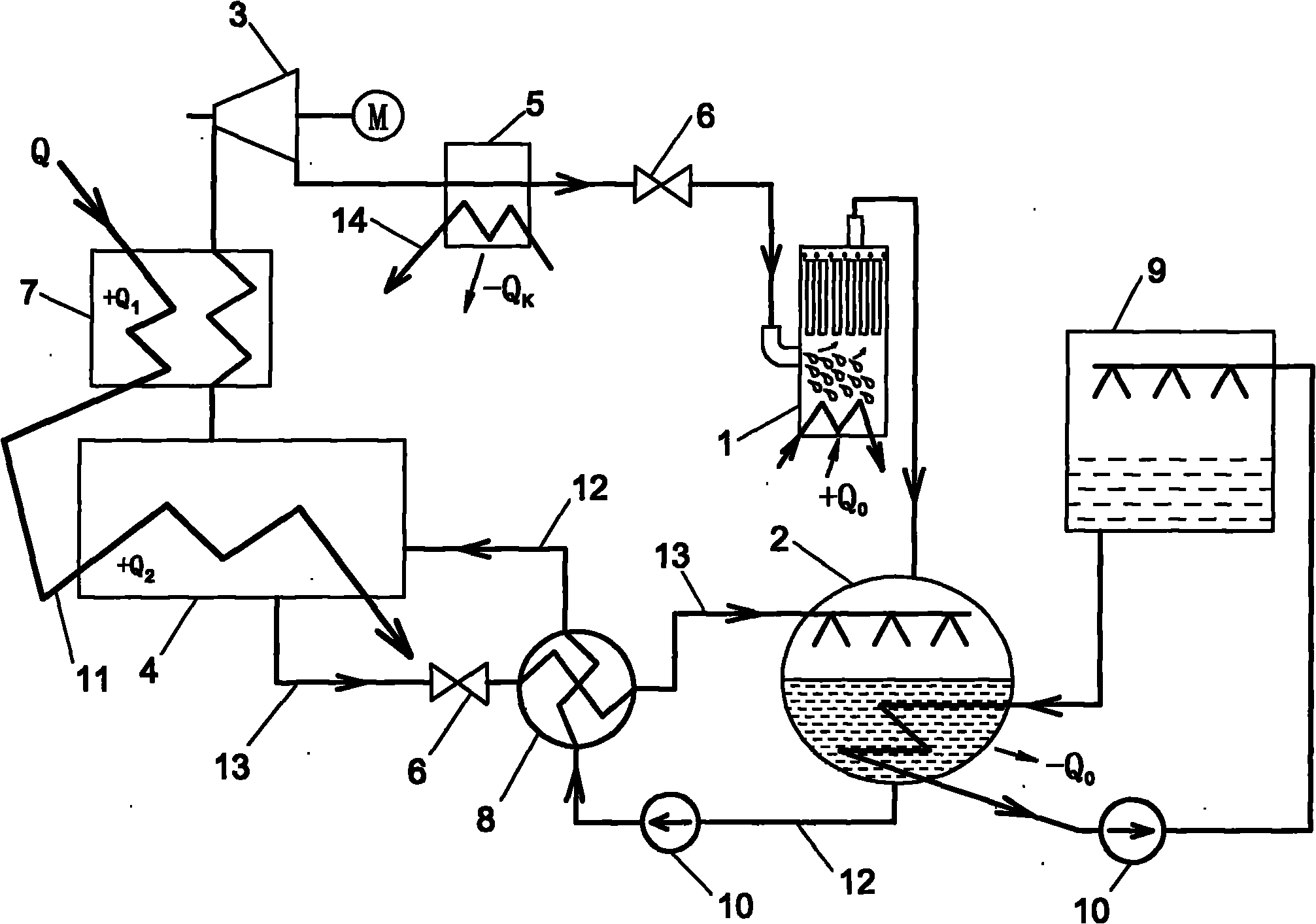

[0021] Example 1: see figure 1 , An absorption steam turbine power-cooling mixed cycle system, including an evaporator 1, an absorber 2, a steam turbine 3, a generator 4, a condenser 5 and a throttle valve 6, etc. In this embodiment, waste heat is used to heat the mixed working fluid, such as lithium bromide solution, and the steam generated after passing through the generator can drive the steam turbine to perform work. In the evaporator, the refrigerant absorbs heat and evaporates to produce cold energy.

[0022] The specific implementation is that the waste heat pipe 11 is in communication with the heat inlet of the heat exchanger of the generator 4, and the mixed working fluid is heated by the waste heat in the generator 4, the temperature rises, and the heat Q of the waste heat is absorbed. 2 (The + or-signs in the figure only indicate the absorption or release of heat), where the light floating working fluid is vaporized into hot steam, the steam outlet of the generator 4 pas...

Embodiment 2

[0025] Embodiment 2: The drawings are not drawn, and the content is basically the same as that of Embodiment 1. The similarities are not repeated. The difference is that the outlet of the concentrated solution of the generator is connected to the inlet of the absorber through a throttling tube.

Embodiment 3

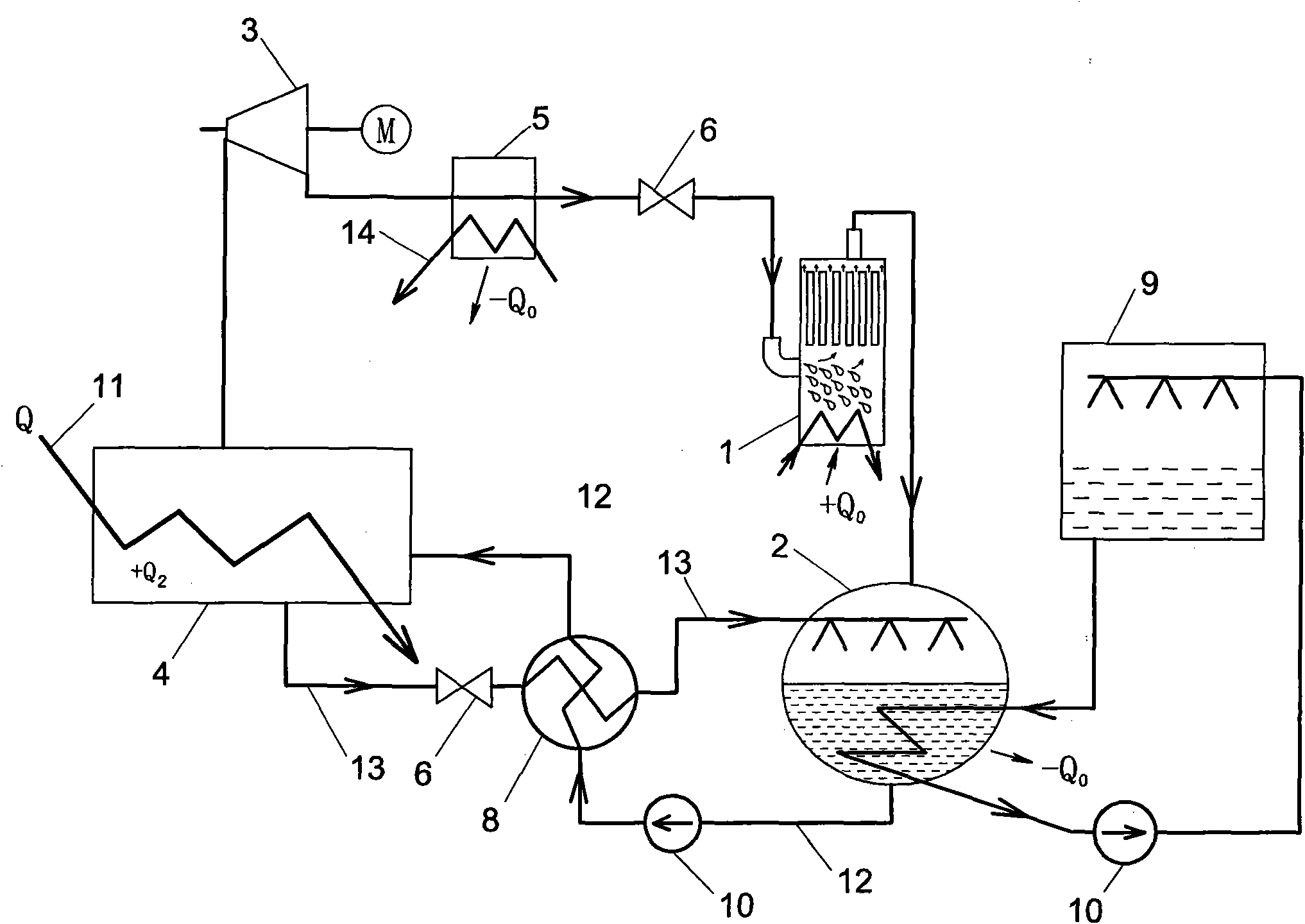

[0026] Example three: see figure 2 , The content is basically the same as the first embodiment, and the similarities are not repeated. The difference is: the steam in the generator directly drives the steam turbine to do work through the pipeline, and there is no superheater in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com