Patents

Literature

318results about How to "Reduce power supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

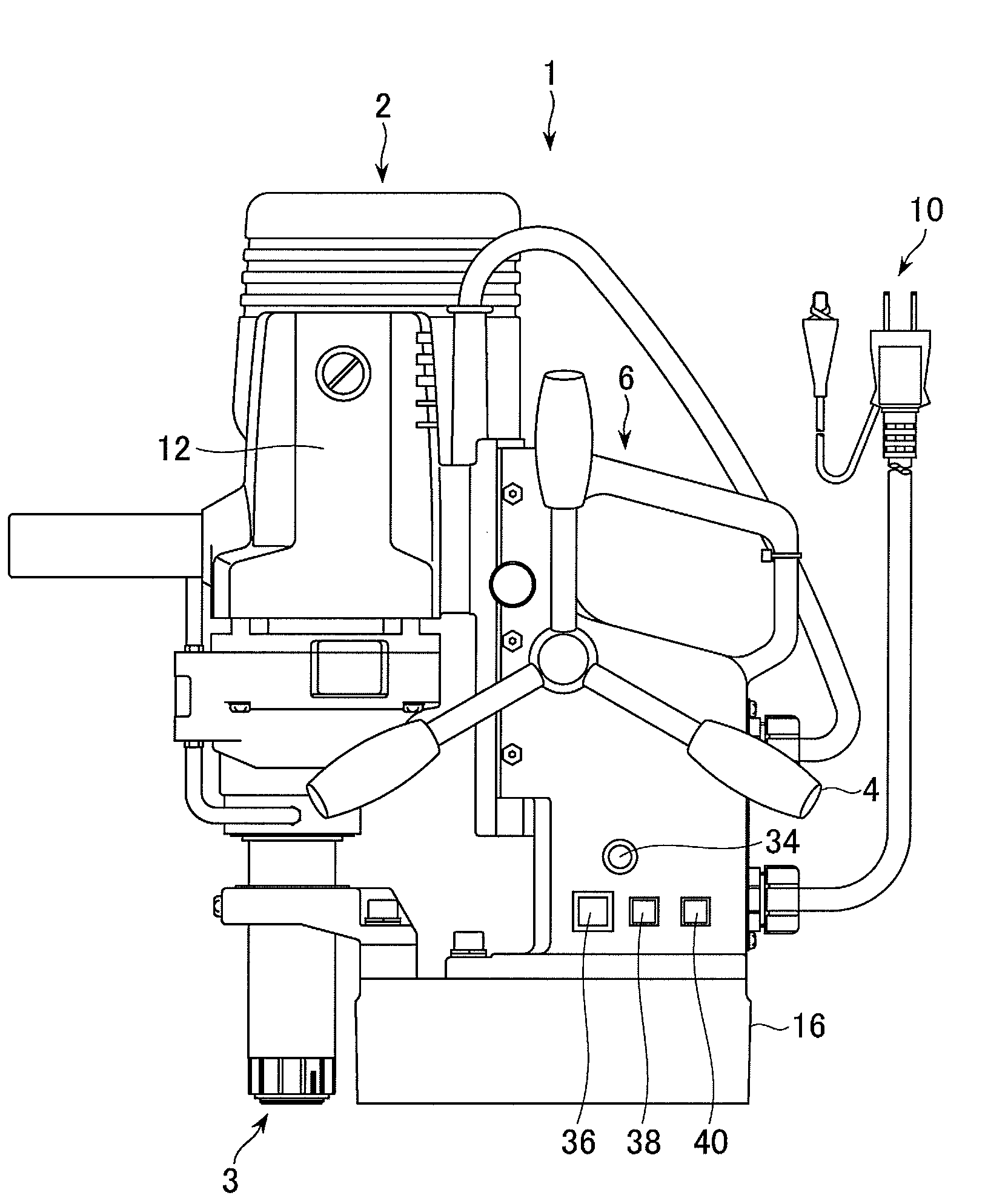

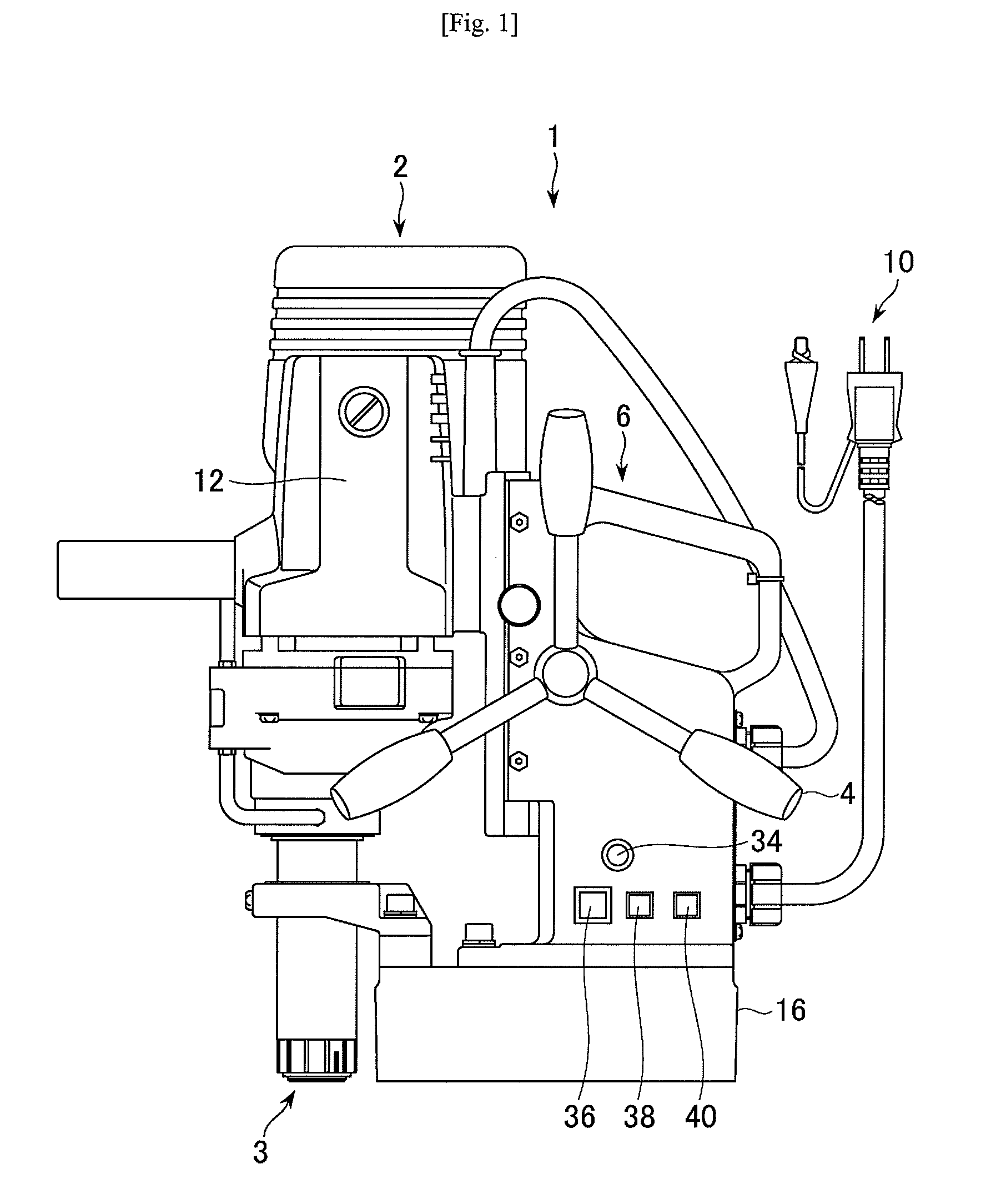

Portable drilling device

ActiveUS7936142B2Easy to operateImprove securityAC motor controlDC motor speed/torque controlFull waveEngineering

A drilling device prevents recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in the drilling device. A motor for rotating a drill is connected to an AC power source through a motor control unit, a current detector, and a power switch. A magnet is also connected to the AC power source through the power switch and a full-wave rectifier. The motor control unit rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch is on. The main control unit controls the motor control unit to gradually reduce a supply voltage to the motor when the motor becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

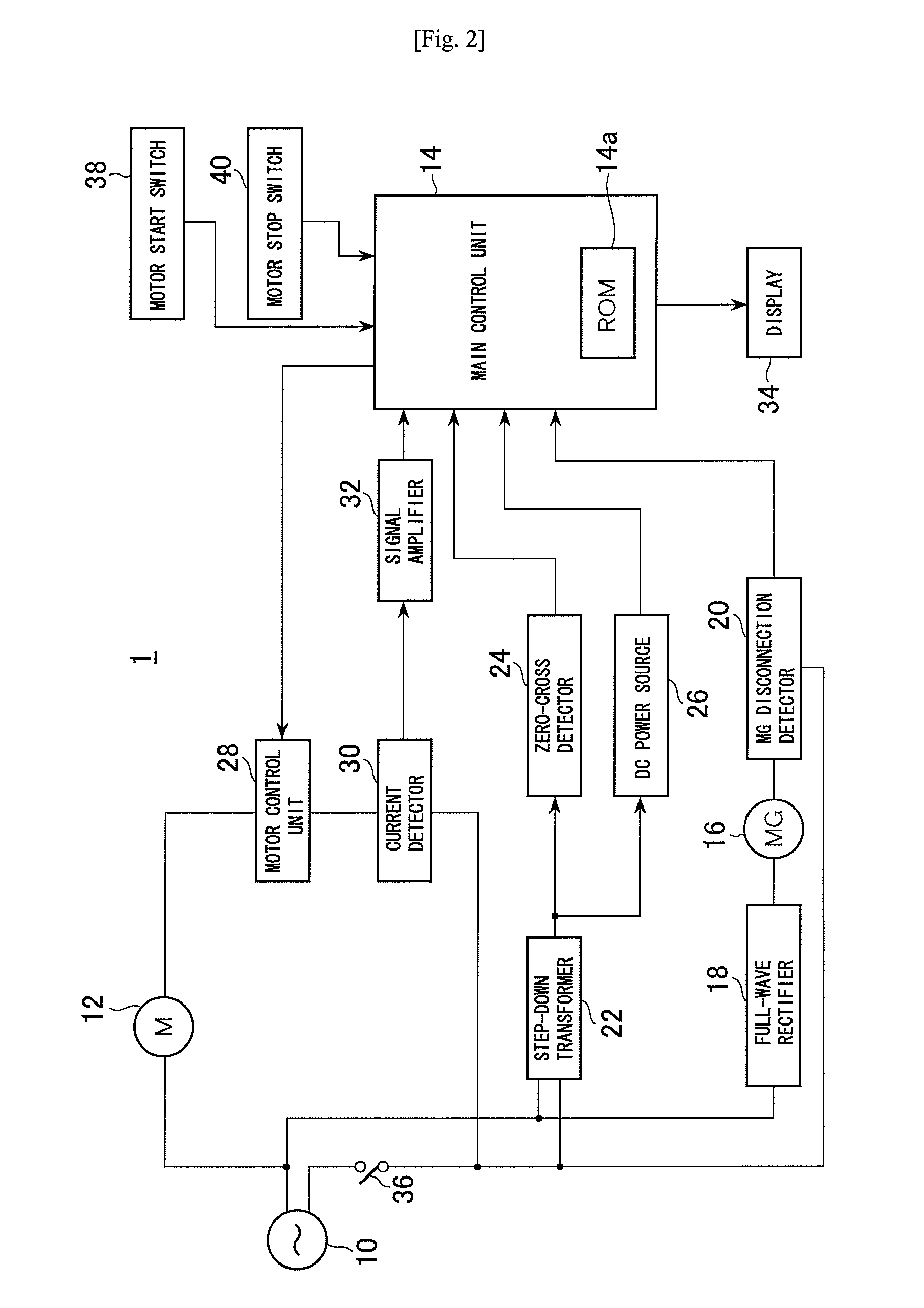

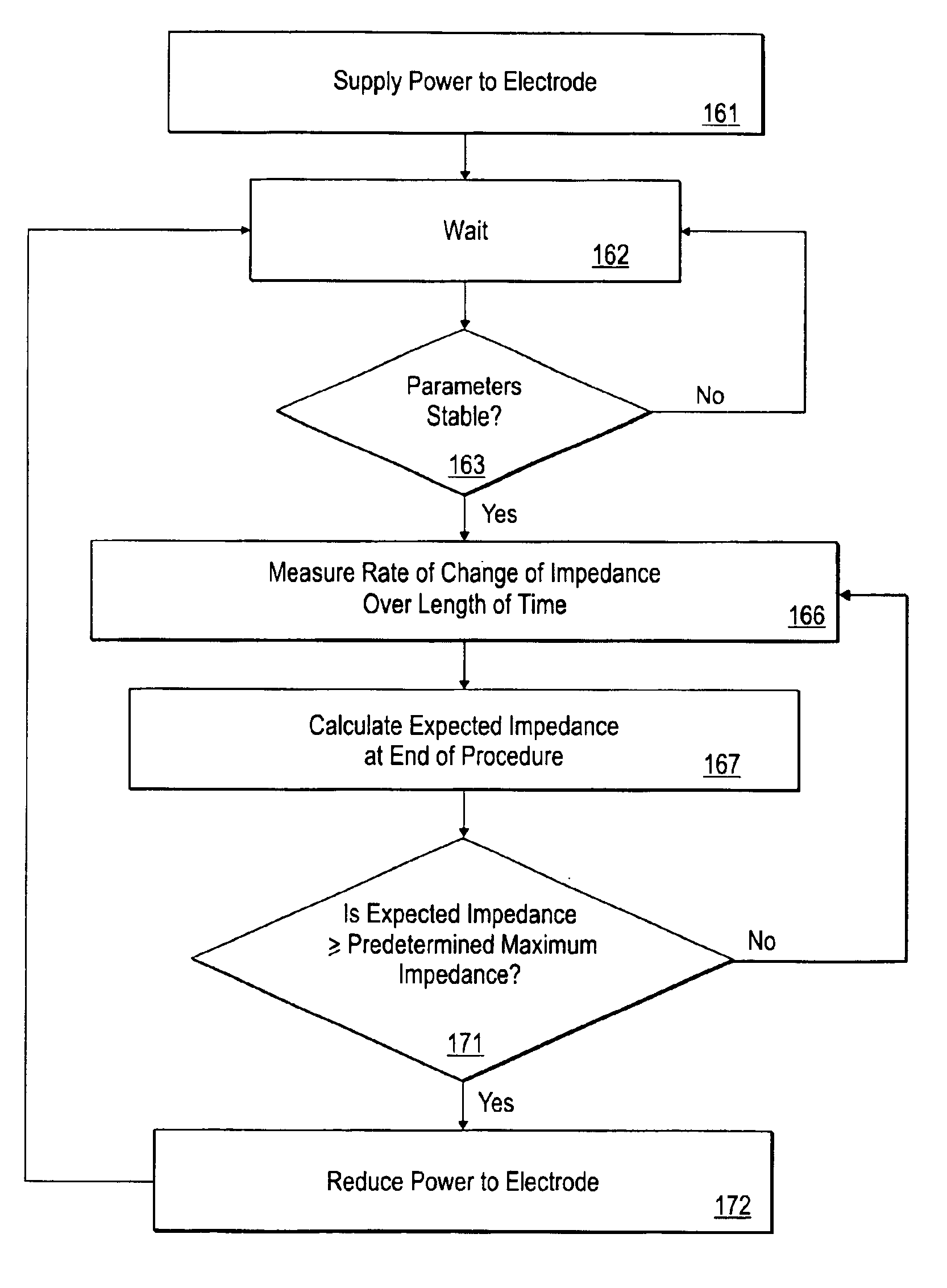

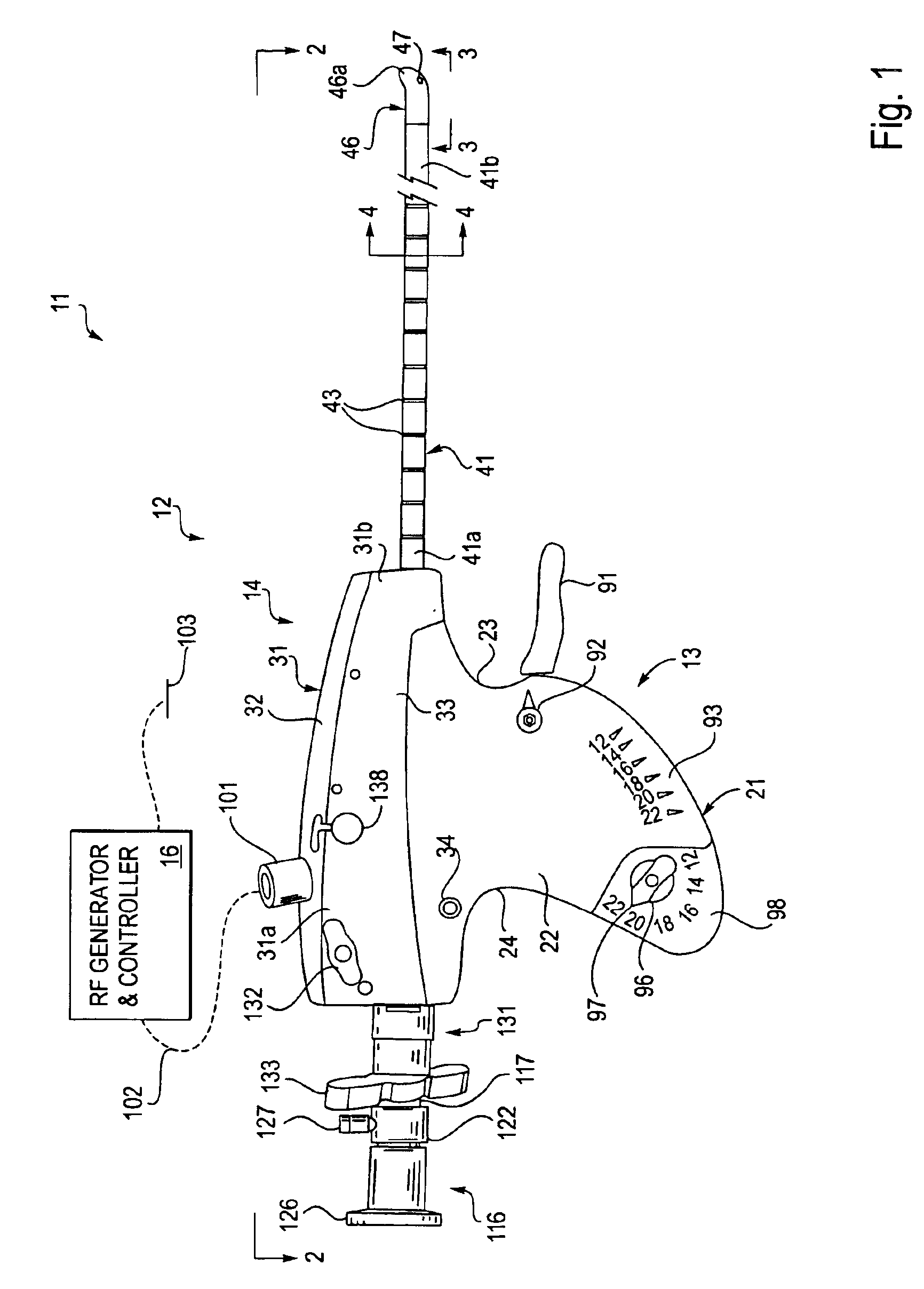

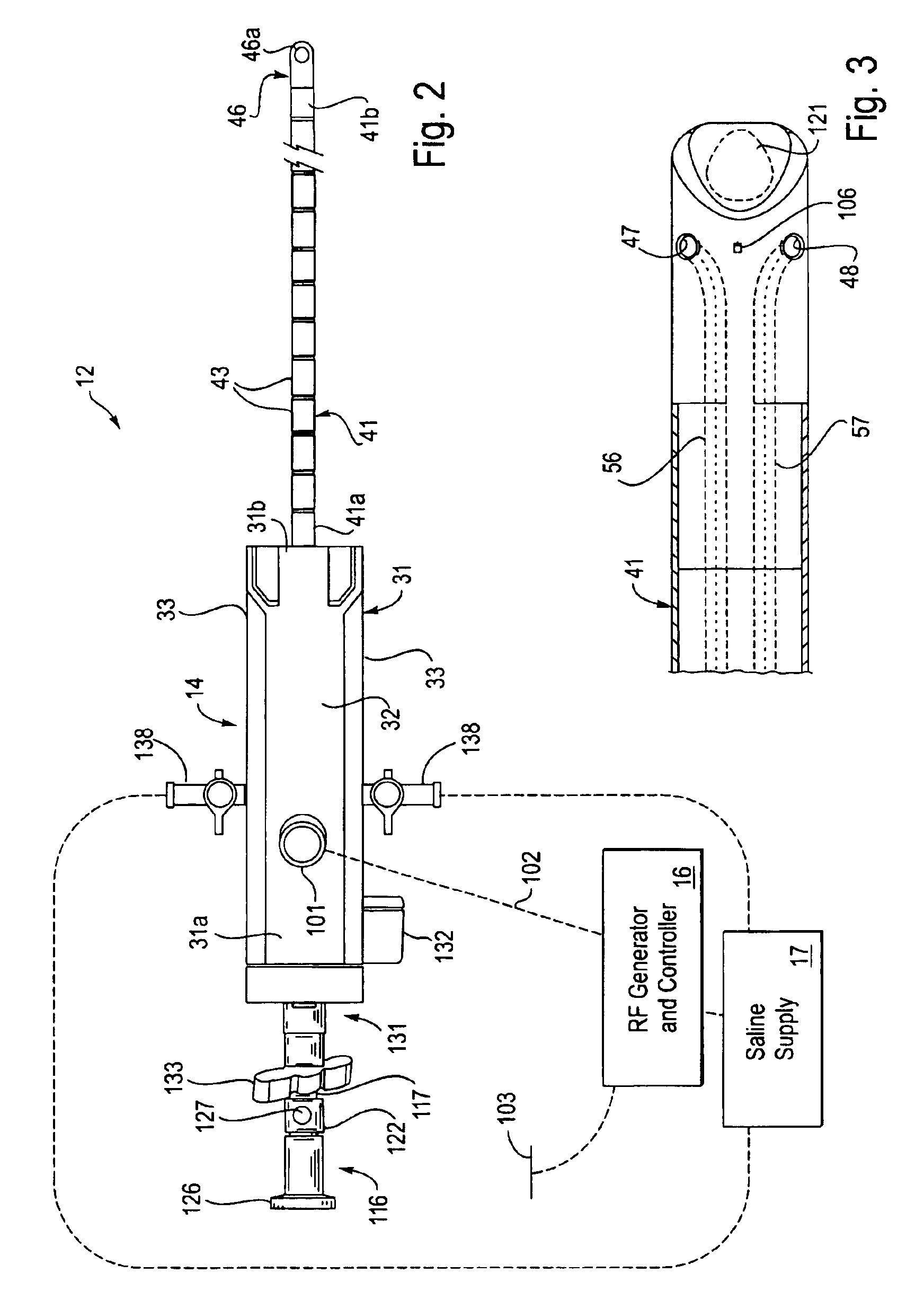

Method for monitoring impedance to control power and apparatus utilizing same

InactiveUS6855141B2Reduce power supplyReduce supplySurgical instruments for heatingRadio frequencyTreatment procedure

A method for monitoring the impedance in a circuit coupling a radio frequency electrode to a radio frequency generator to control the power supplied by the generator to the electrode during a treatment procedure. In the method, the impedance in the circuit is monitored over a length of time. An expected impedance at the end of the treatment procedure is calculated from the monitored impedance and compared to a predetermined maximum impedance. The power supplied to the circuit is reduced if the expected impedance is greater than the predetermined maximum impedance. A computer-readable memory and apparatus utilizing the method are provided.

Owner:PROJECT TROJAN INTPROP ACQUISITION LLC

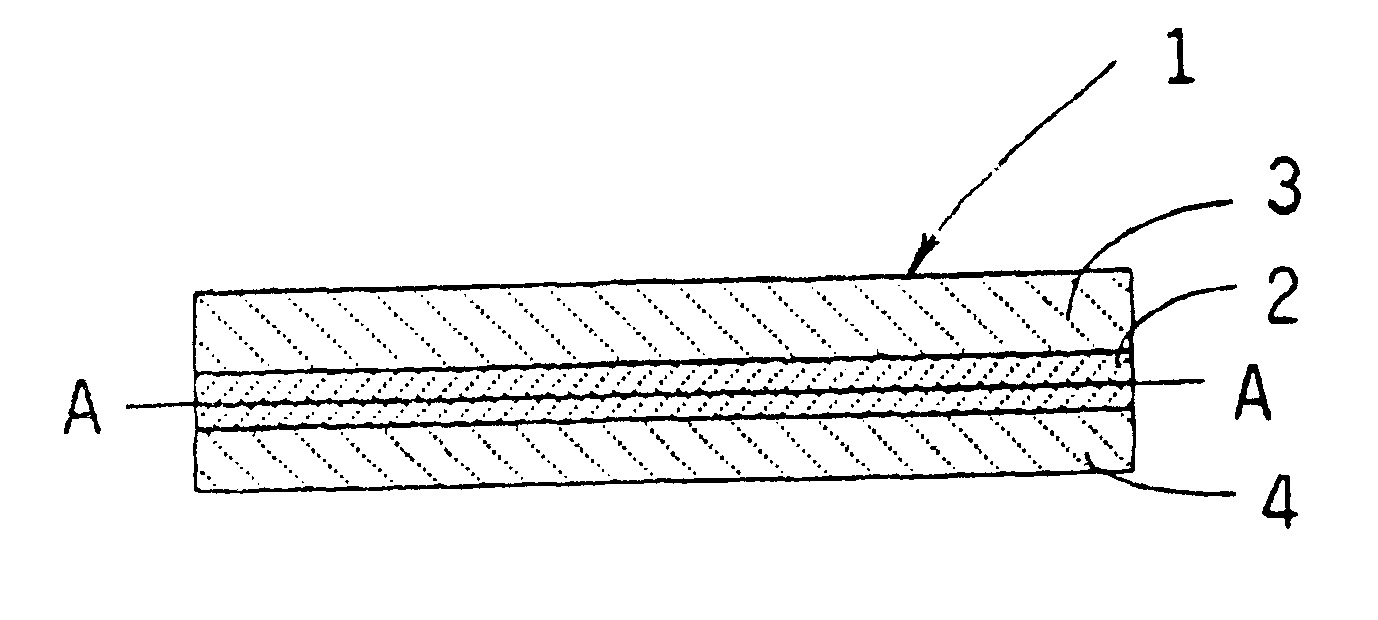

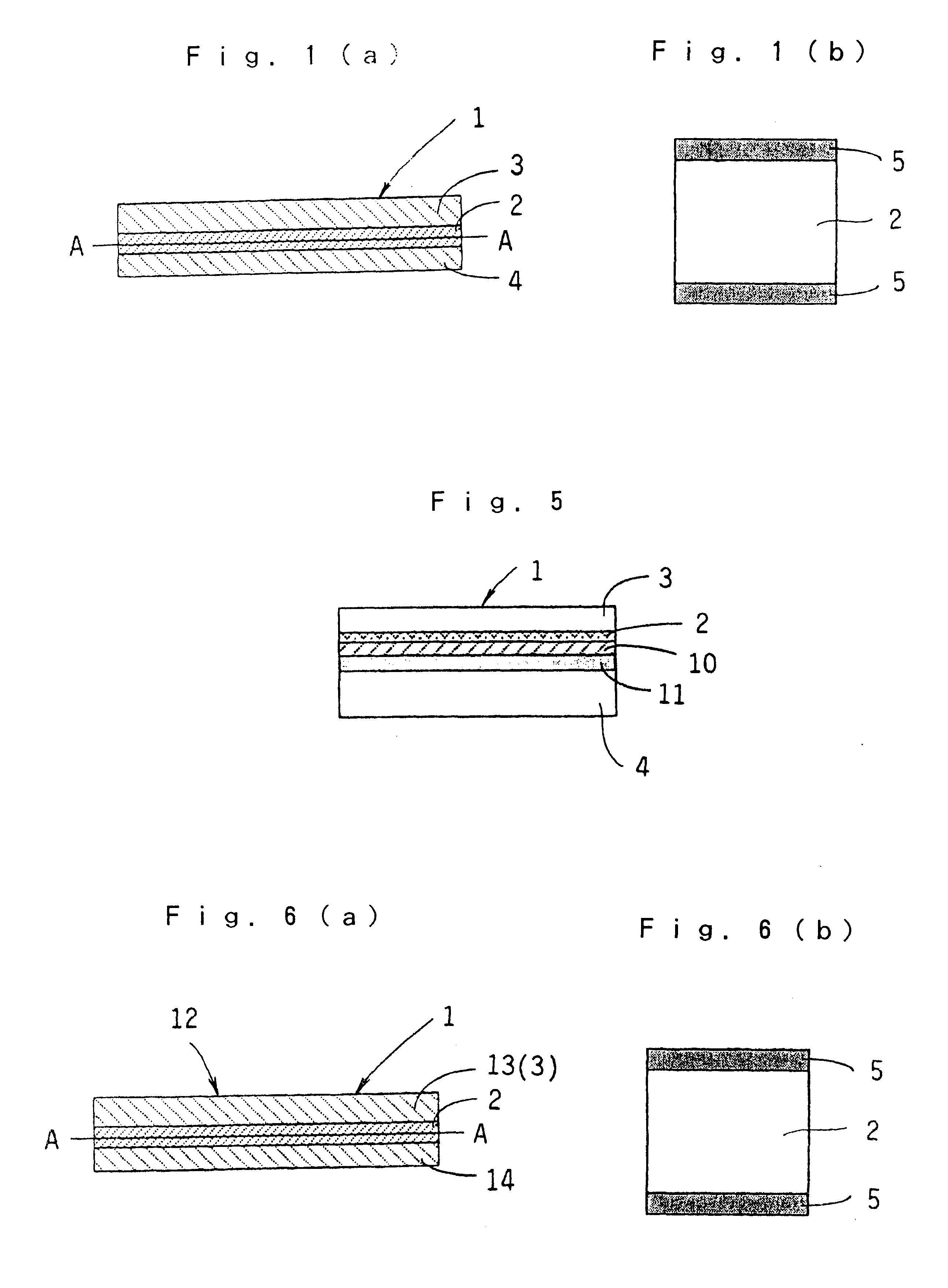

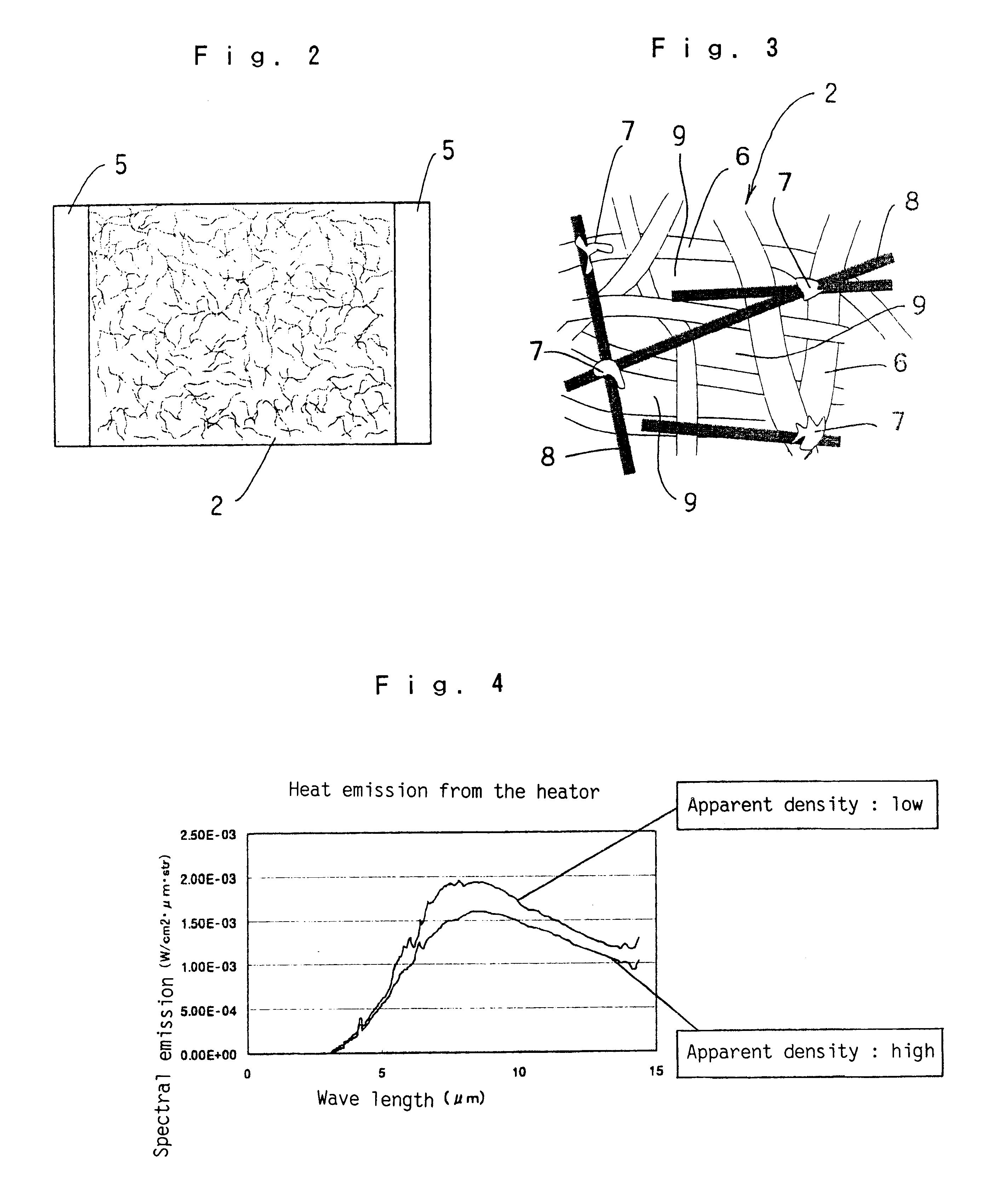

Heat radiator

InactiveUS6294758B1Excellent in quick heating capabilityReduce power supplyFluid heatersHeater elementsHuman bodyEngineering

A heat radiator for emitting infrared radiation to the human body has a heat source which is energized to emit infrared radiation, whose penetration depth into the human body is to near warmth sensing points of the human body, and an insulator for covering the surface of the heat source to be directed toward the human body. The free surface of the insulator forms a surface for contacting with the human body and the thickness of the insulator is less than the penetration depth of the infrared radiation into the insulator.

Owner:TOTO LTD

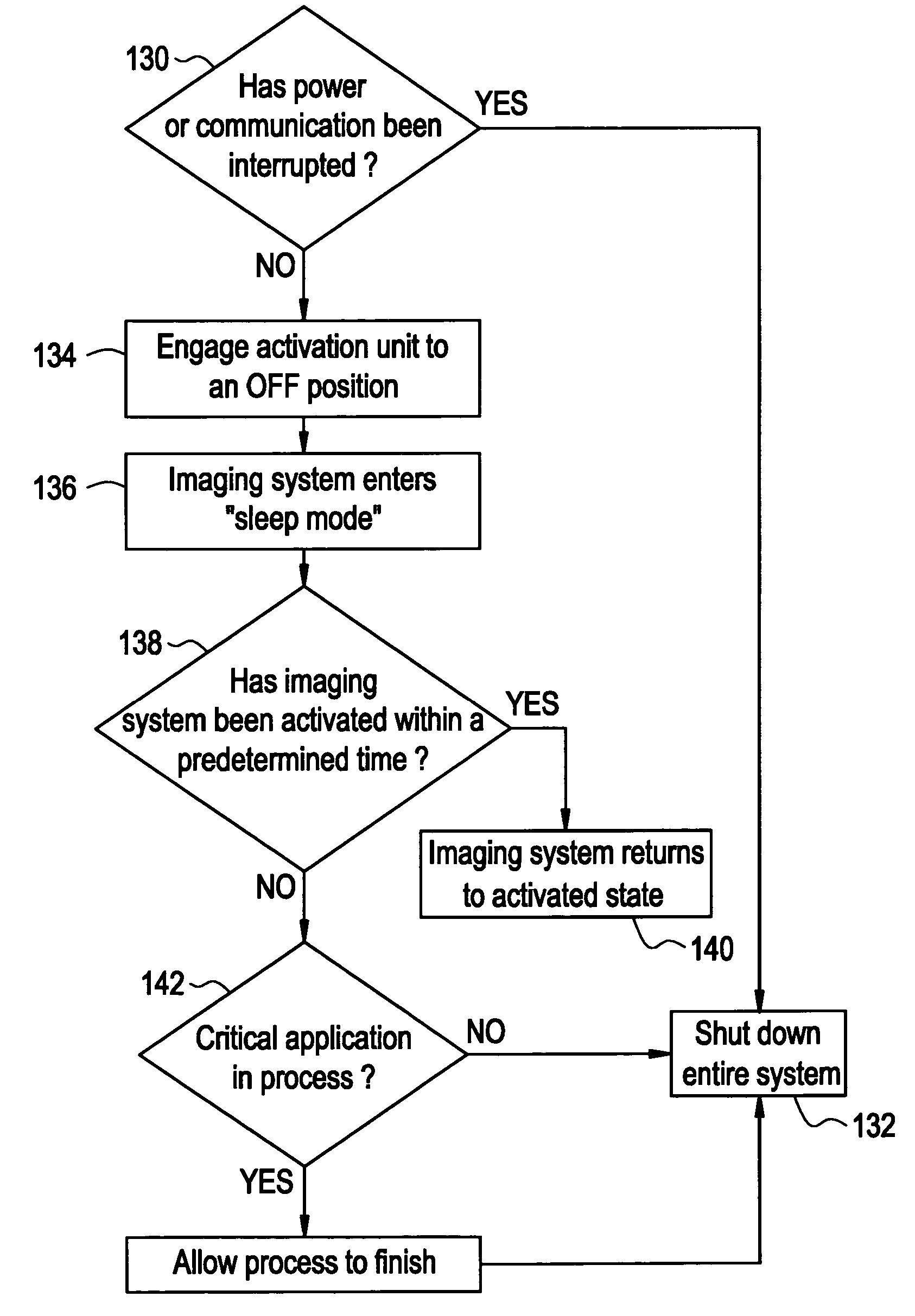

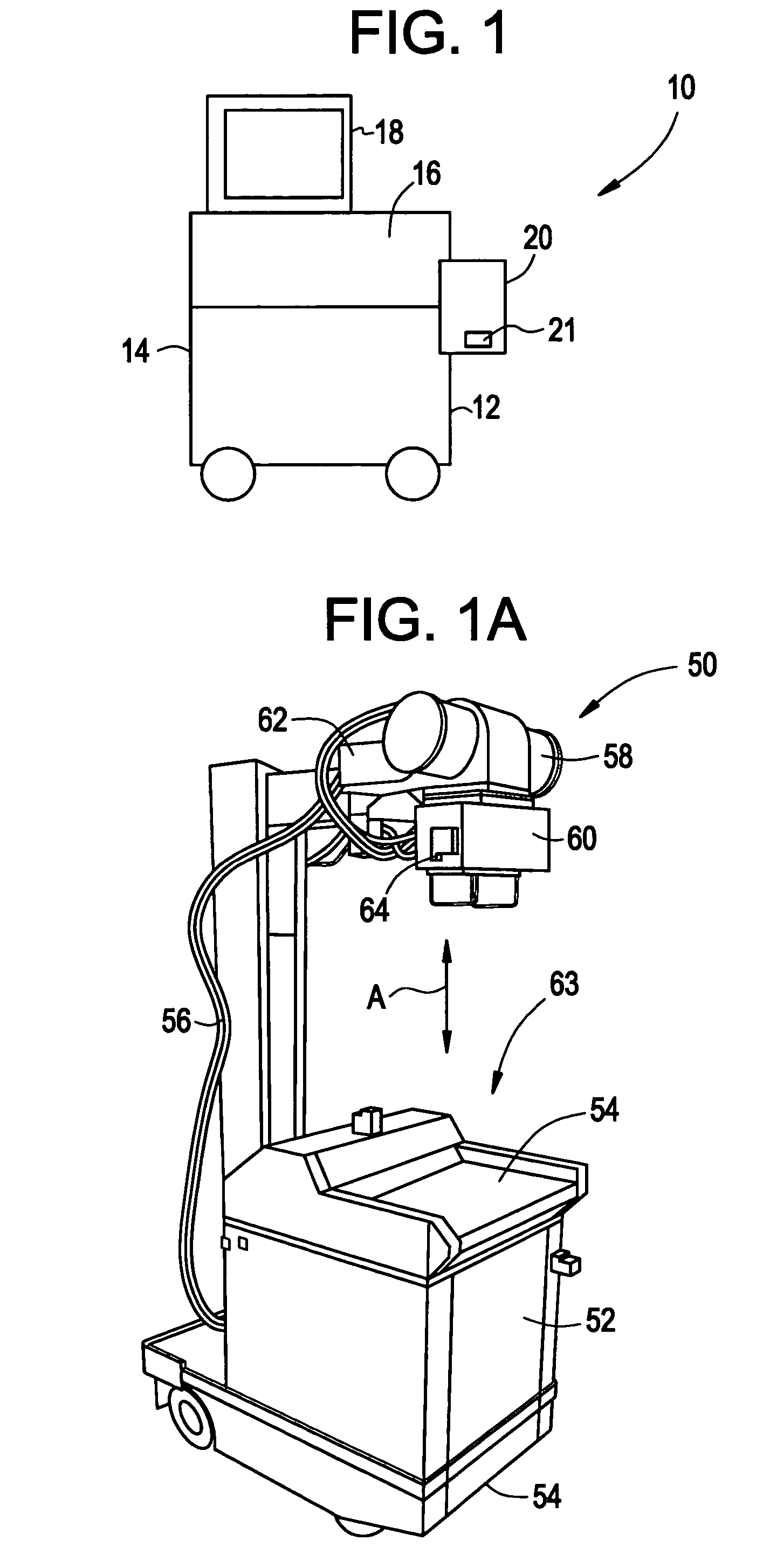

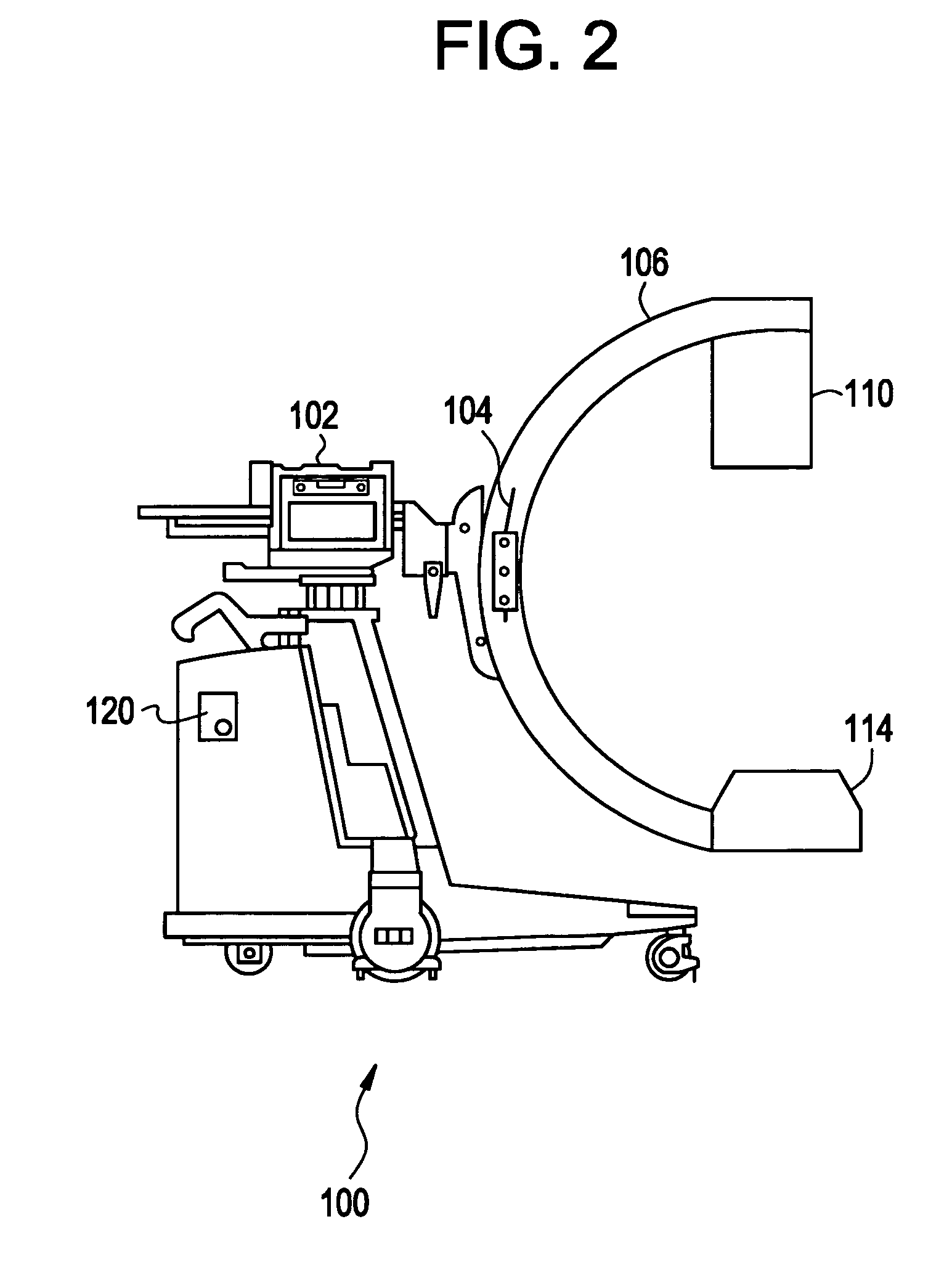

System and method for managing power deactivation within a medical imaging system

ActiveUS7720523B2Reduce power supplyUltrasonic/sonic/infrasonic diagnosticsRadiation diagnosis data transmissionMedical imagingNuclear medicine

A medical imaging system includes a medical imaging device, a medical imaging control subsystem, and an activation unit. The medical imaging control subsystem includes a processing unit and a monitor. The processing unit is in communication with the medical imaging device and the monitor. The activation unit is operatively connected to the medical imaging device and the medical imaging control subsystem, wherein the activation unit is operable to deactivate the medical imaging device and the medical imaging control subsystem.

Owner:GENERAL ELECTRIC CO

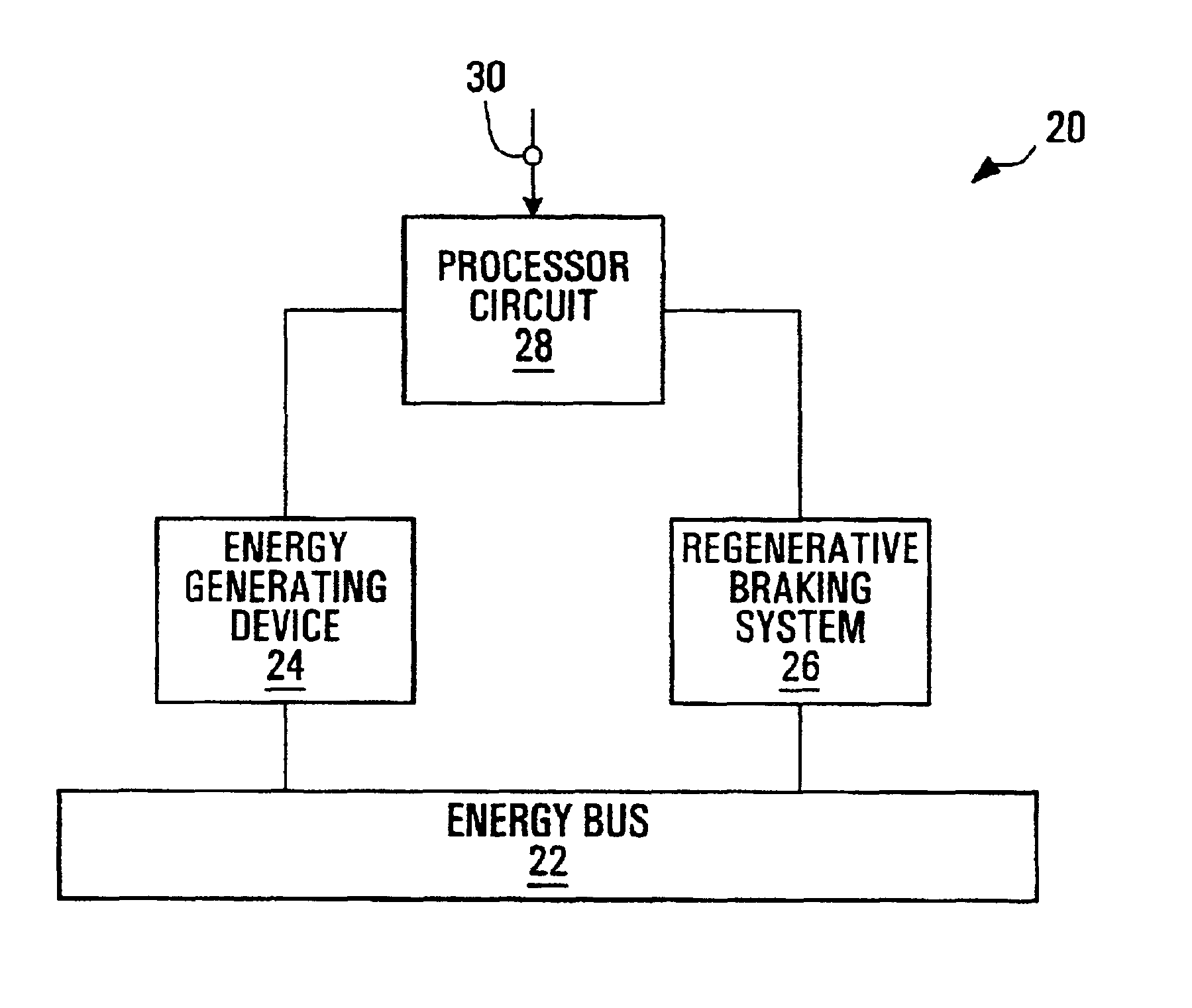

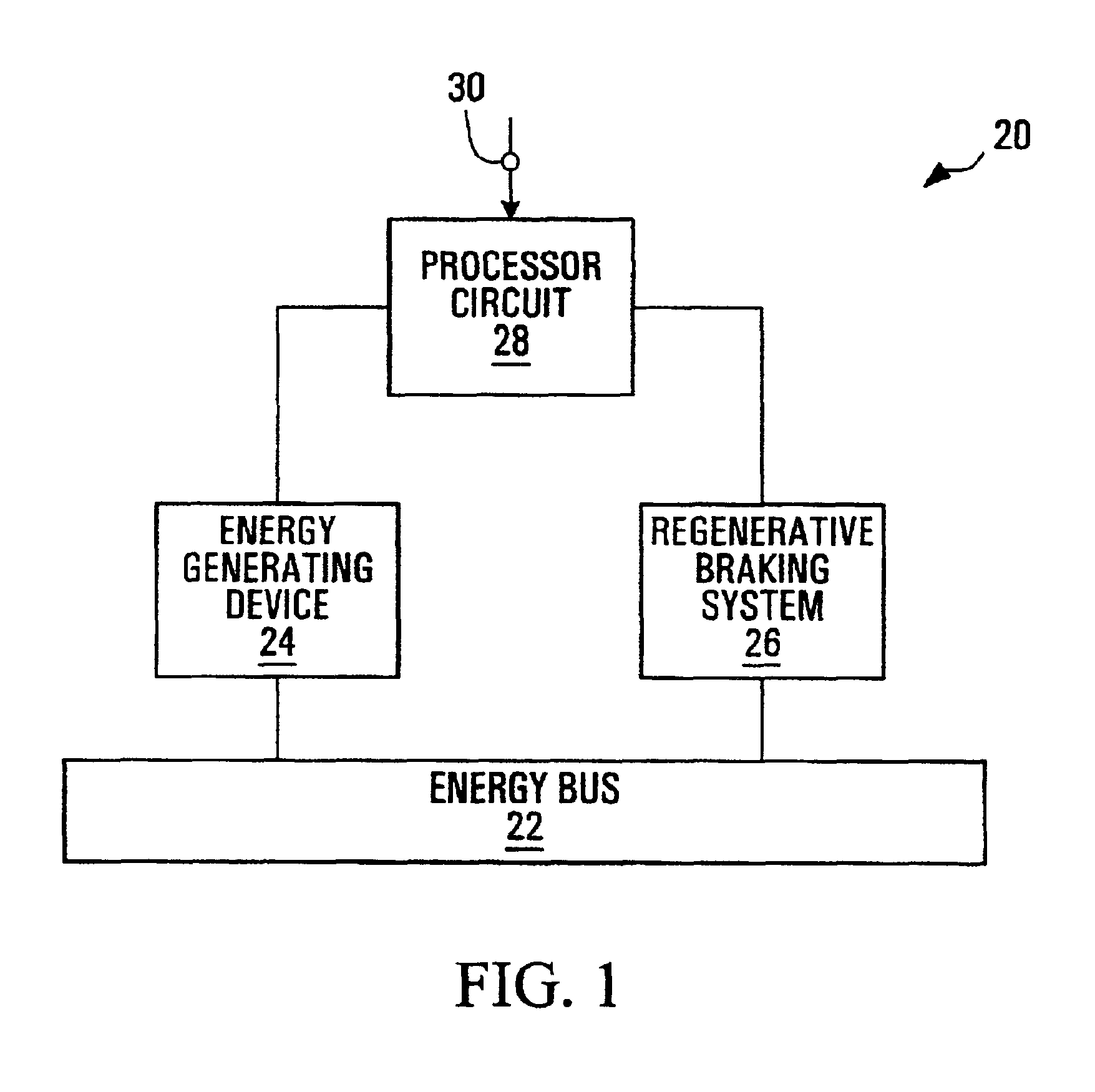

Methods of supplying energy to an energy bus in a hybrid electric vehicle, and apparatuses, media and signals for the same

InactiveUS6909200B2Reduce power supplyConvenient power supplyDigital data processing detailsPlural diverse prime-mover propulsion mountingEngineeringAuxiliary power unit

Methods, apparatuses, media and signals for supplying energy to an energy bus in communication with an energy generating device and with a regenerative braking system in a hybrid electric vehicle are disclosed. One such method includes controlling power supplied by the energy generating device to the energy bus, in response to a braking signal indicative of user brake actuation. Another such method involves controlling energy contributions onto the energy bus from the energy generating device and from the regenerative braking system respectively, to prevent the contributions from exceeding a desired total energy contribution. The energy generating device may include an auxiliary power unit, such as fuel cell, or a generator coupled to a prime mover such as an internal combustion engine, for example.

Owner:GE HYBRID TECH

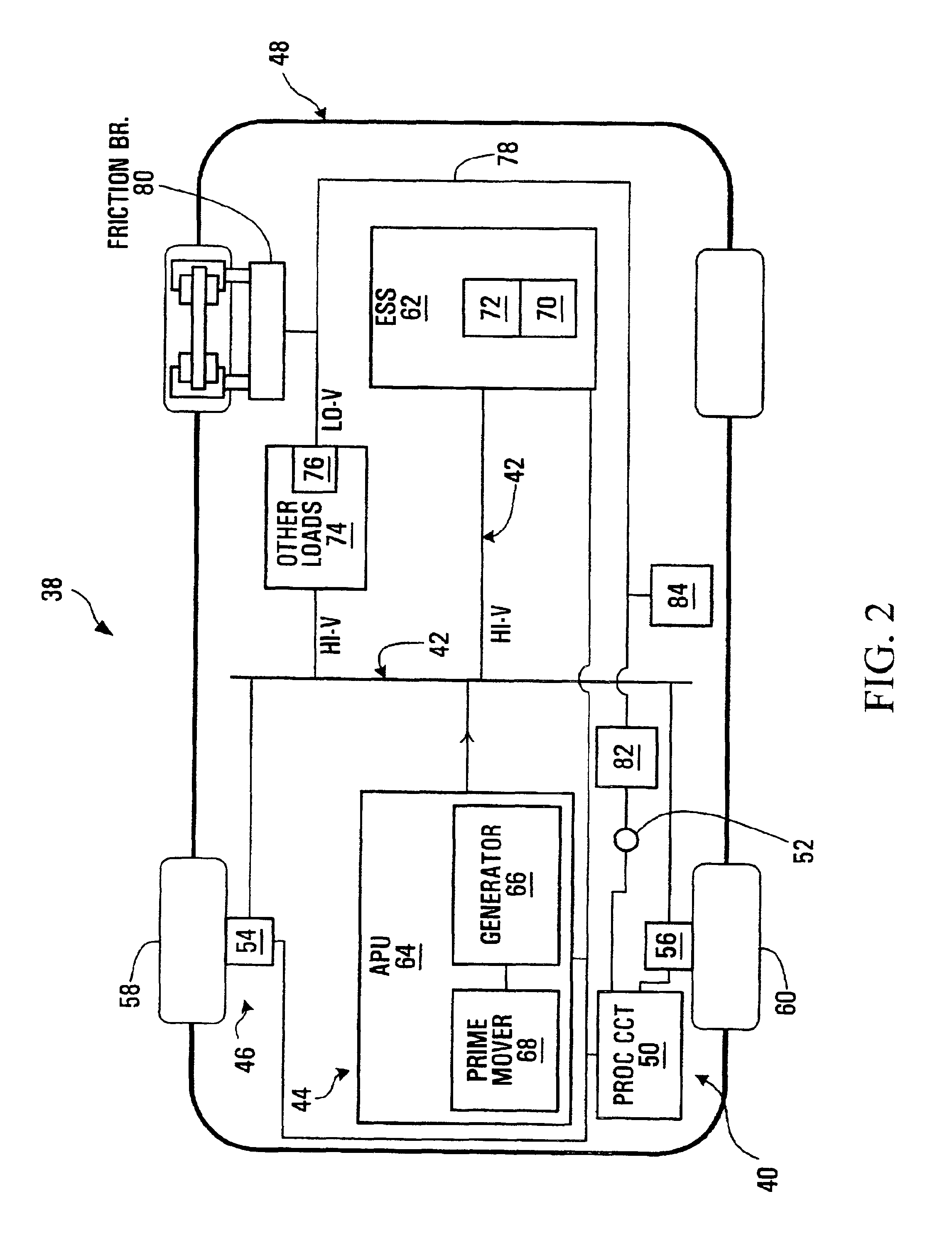

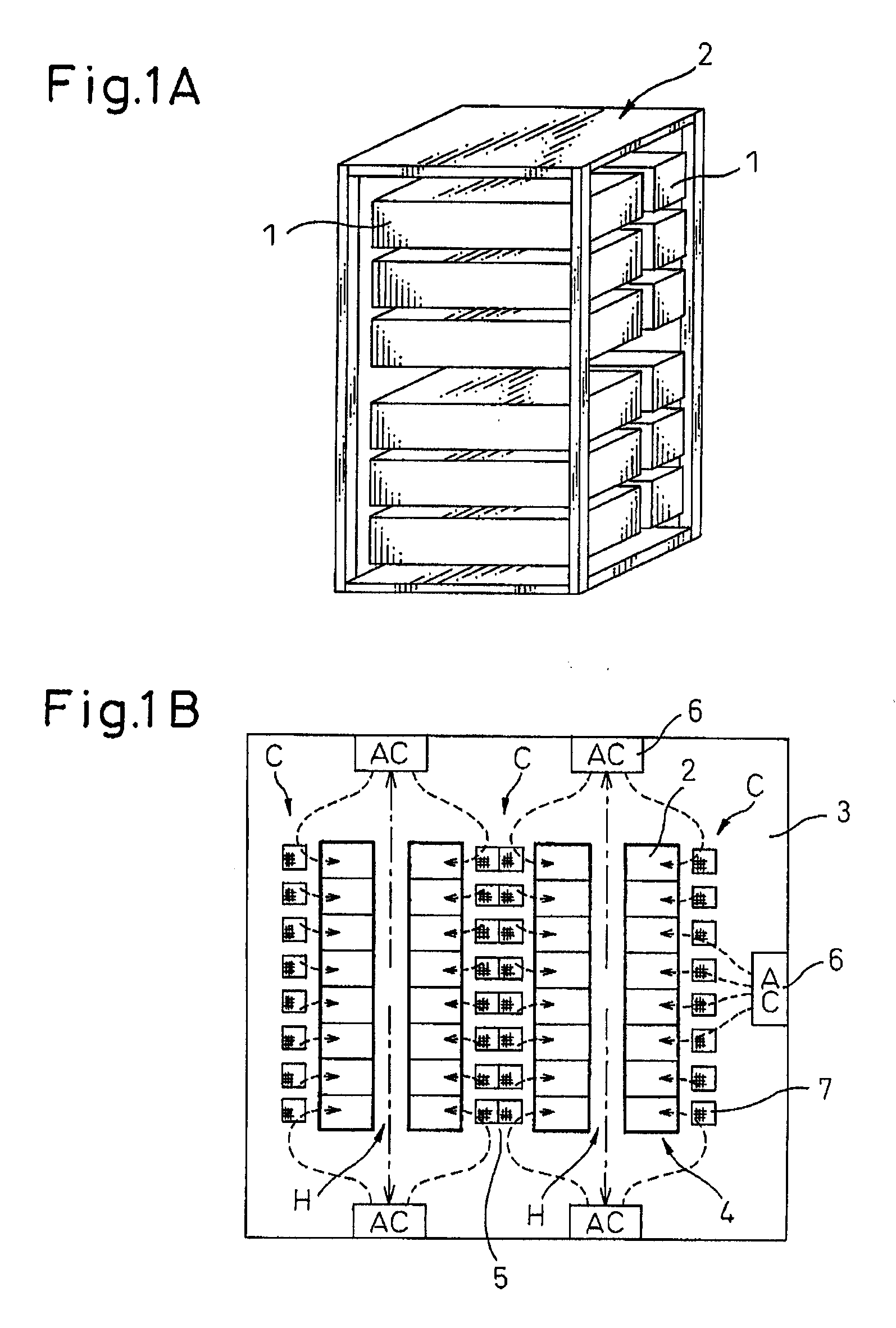

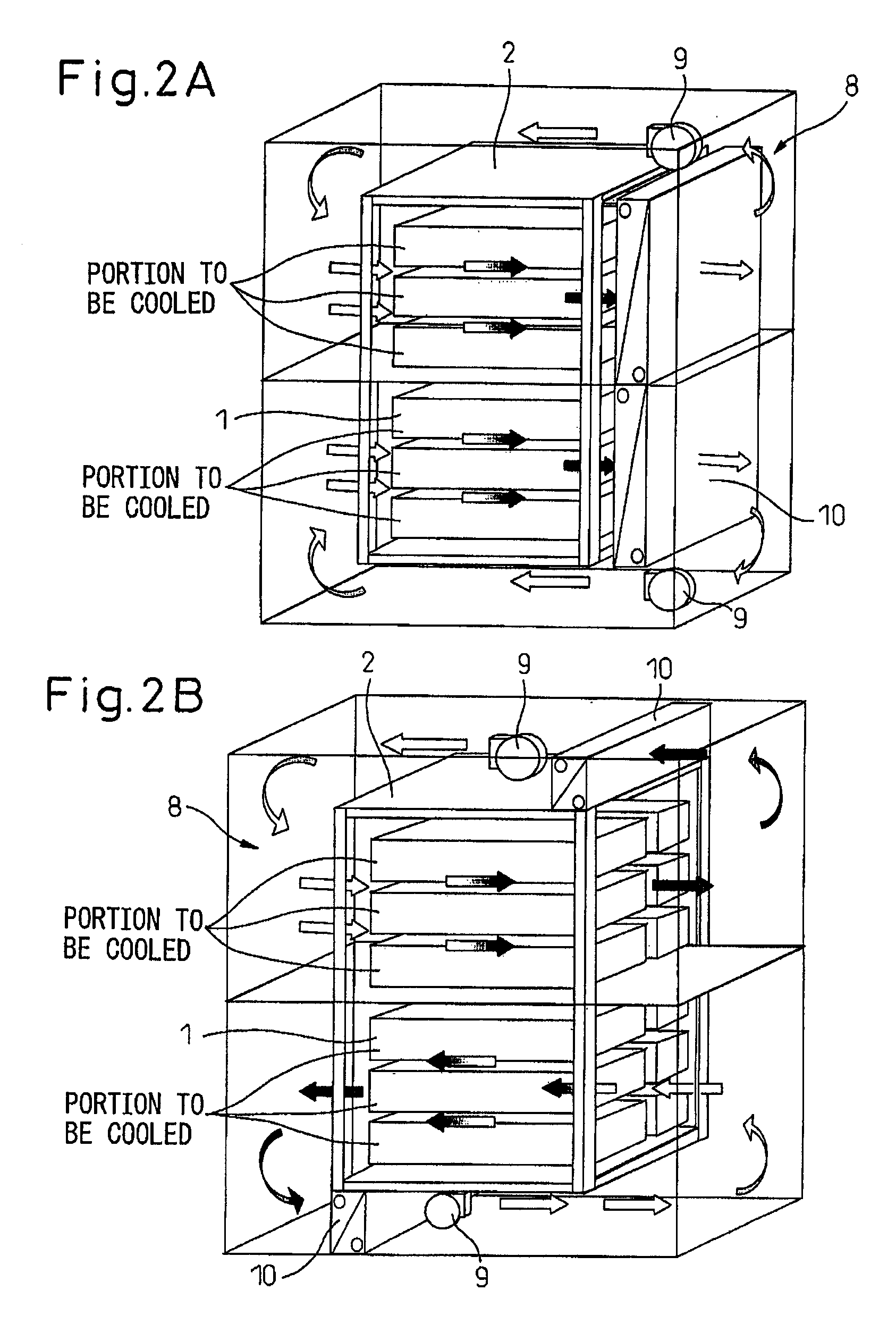

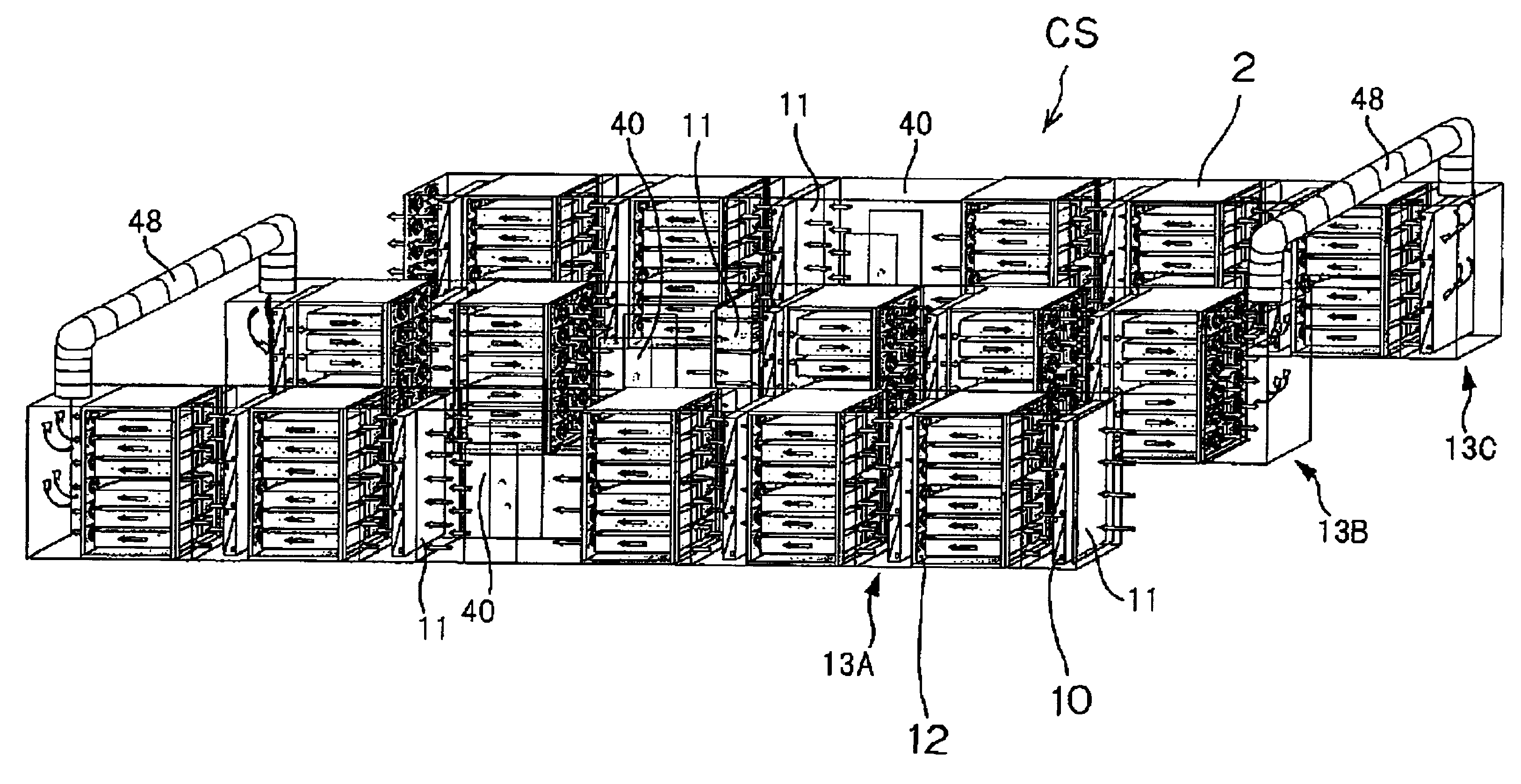

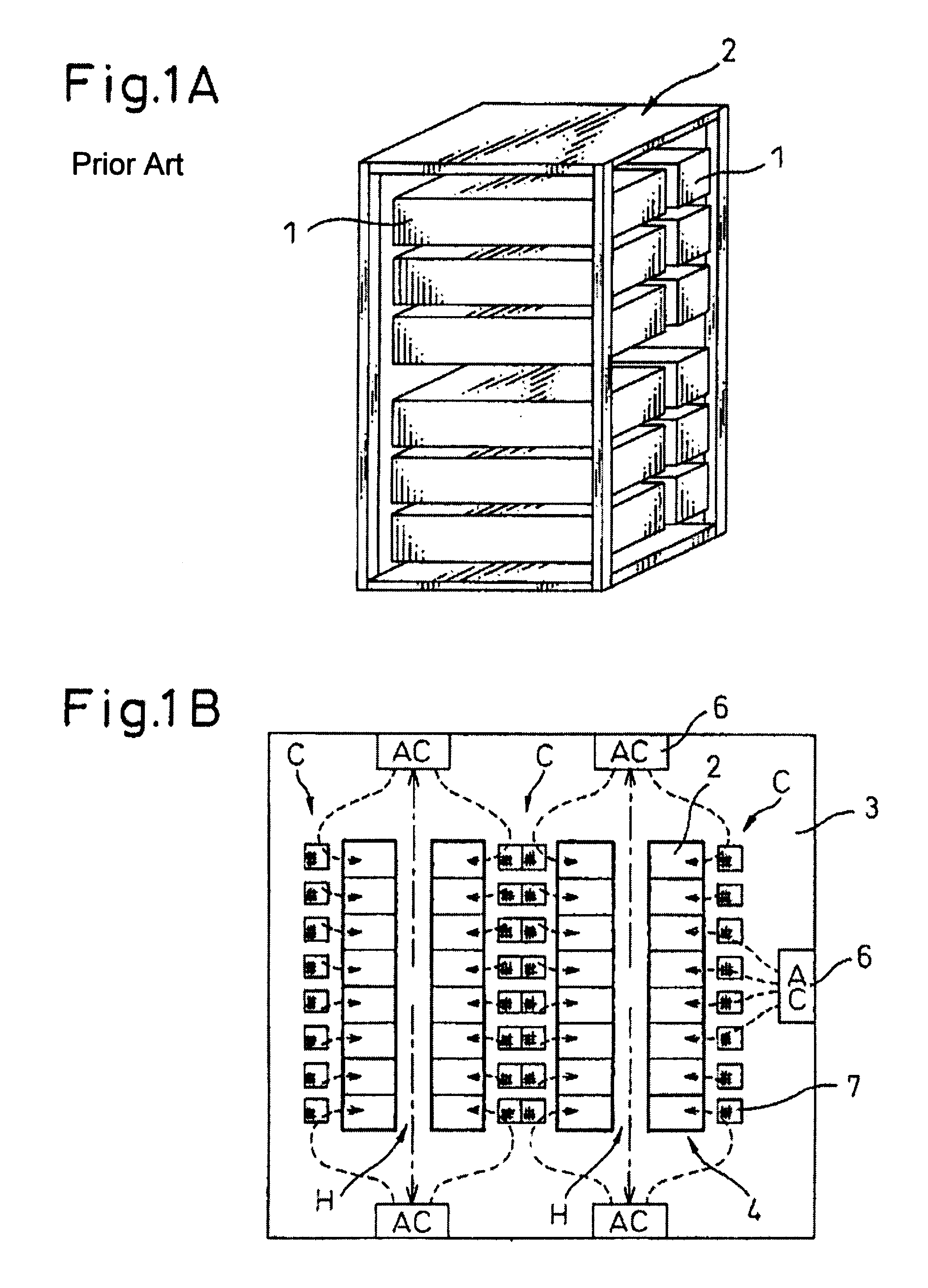

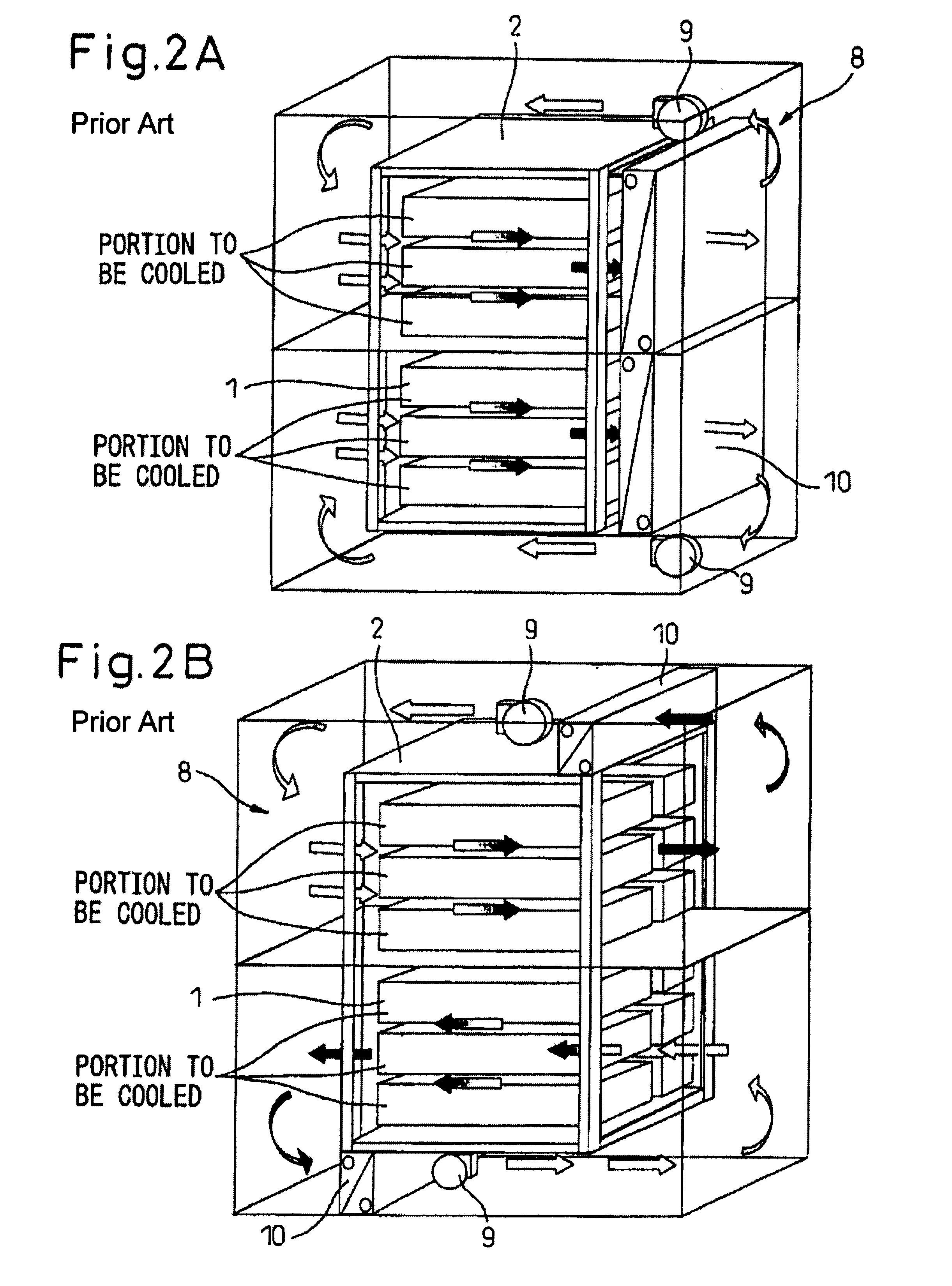

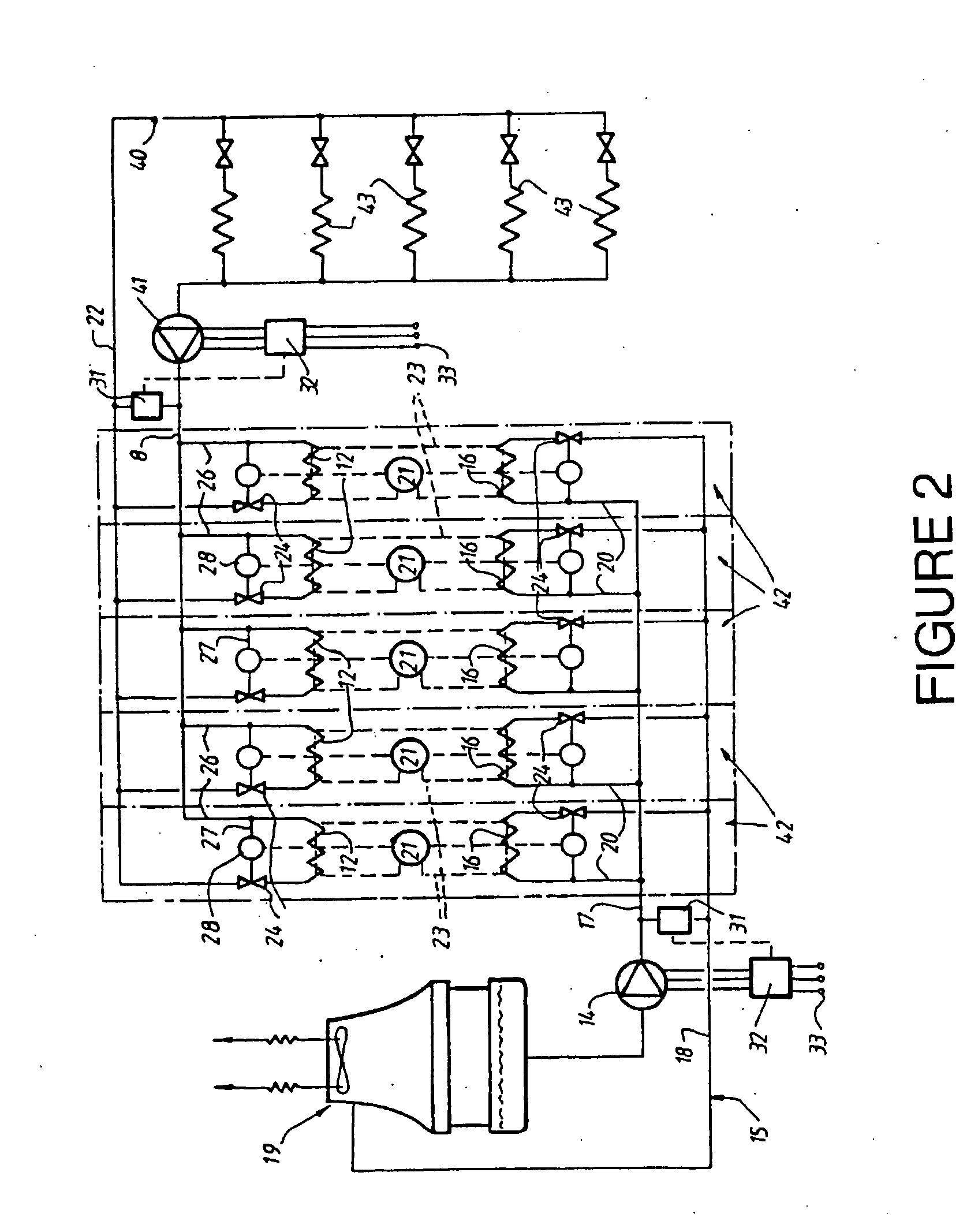

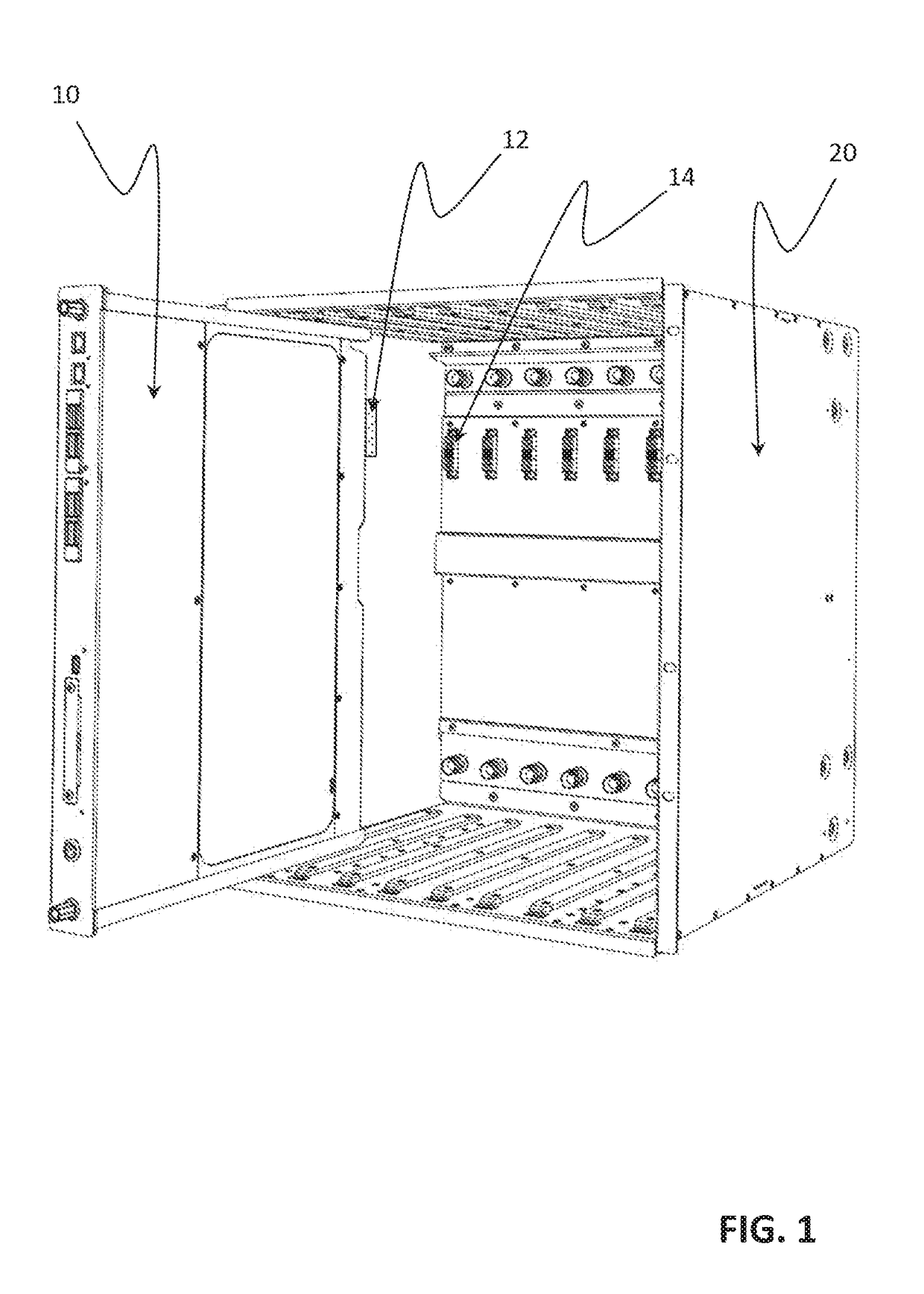

Cooling system for information device

ActiveUS20080232064A1Increase heatCool many racks efficientlyDigital data processing detailsSemiconductor/solid-state device detailsCooling coilInformation device

To cool a blade type server disposed in an air-conditioned room, the following arrangements are made. The first is at least one shell having a ventilation passage disposed in the air-conditioned room. The second is, the following are disposed in a ventilation passage: racks, in which blade type servers each composed of a case with slim boards housed therein are stacked; cooling coils each having a coolant passage and a cooling fin and cooling a passing air; and at least one fan unit having axial-flow fans placed therein and producing air currents in one direction. The third is the fan unit forces a cooling air to flow in one direction in the ventilation passage thereby to cool the servers in the racks. The cooling coils and racks are disposed alternately so that warmed cooling air after passing through the rack is cooled by the cooling coil and then cools the next rack.

Owner:FUJI FURUKAWA ENG & CONSTR +1

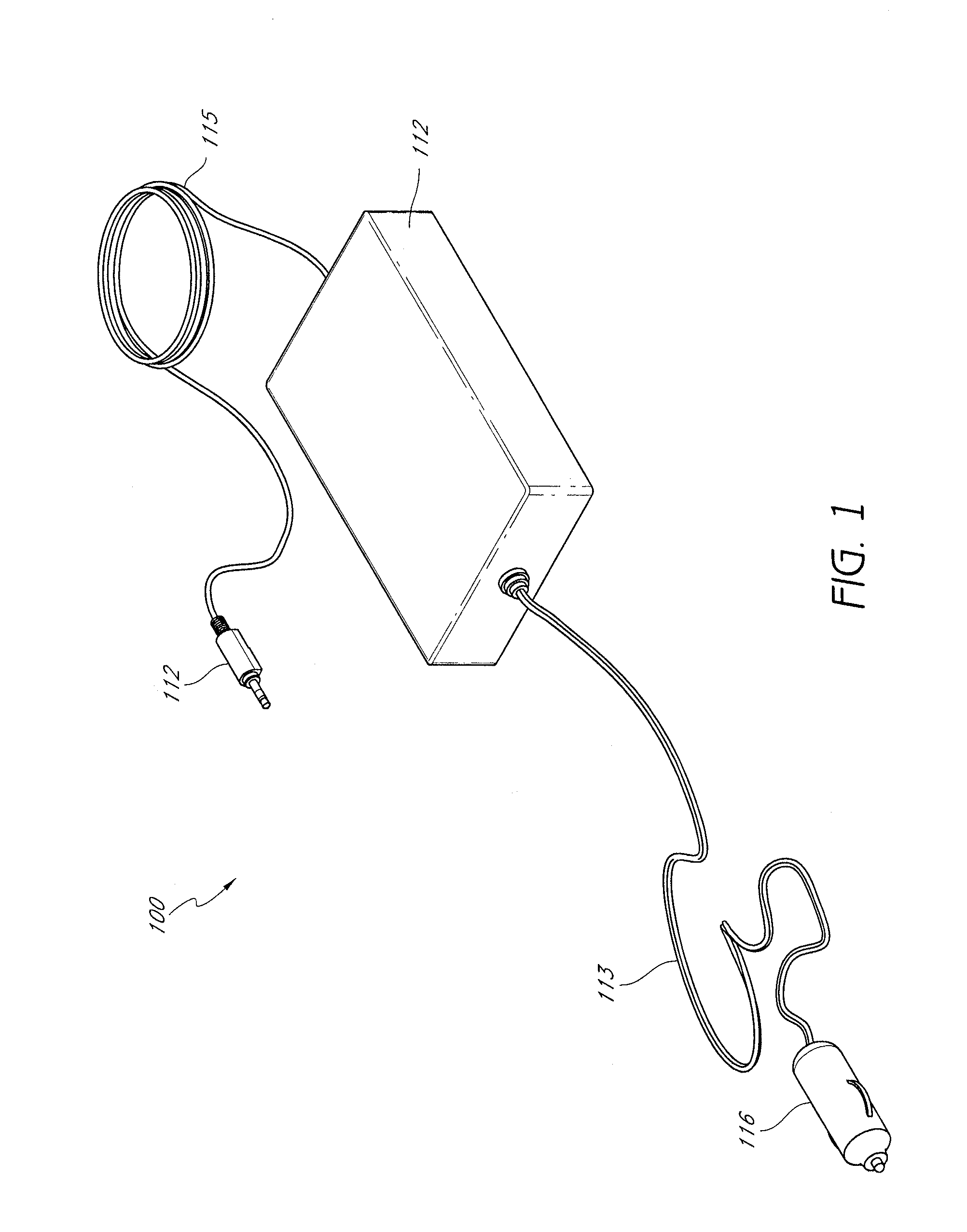

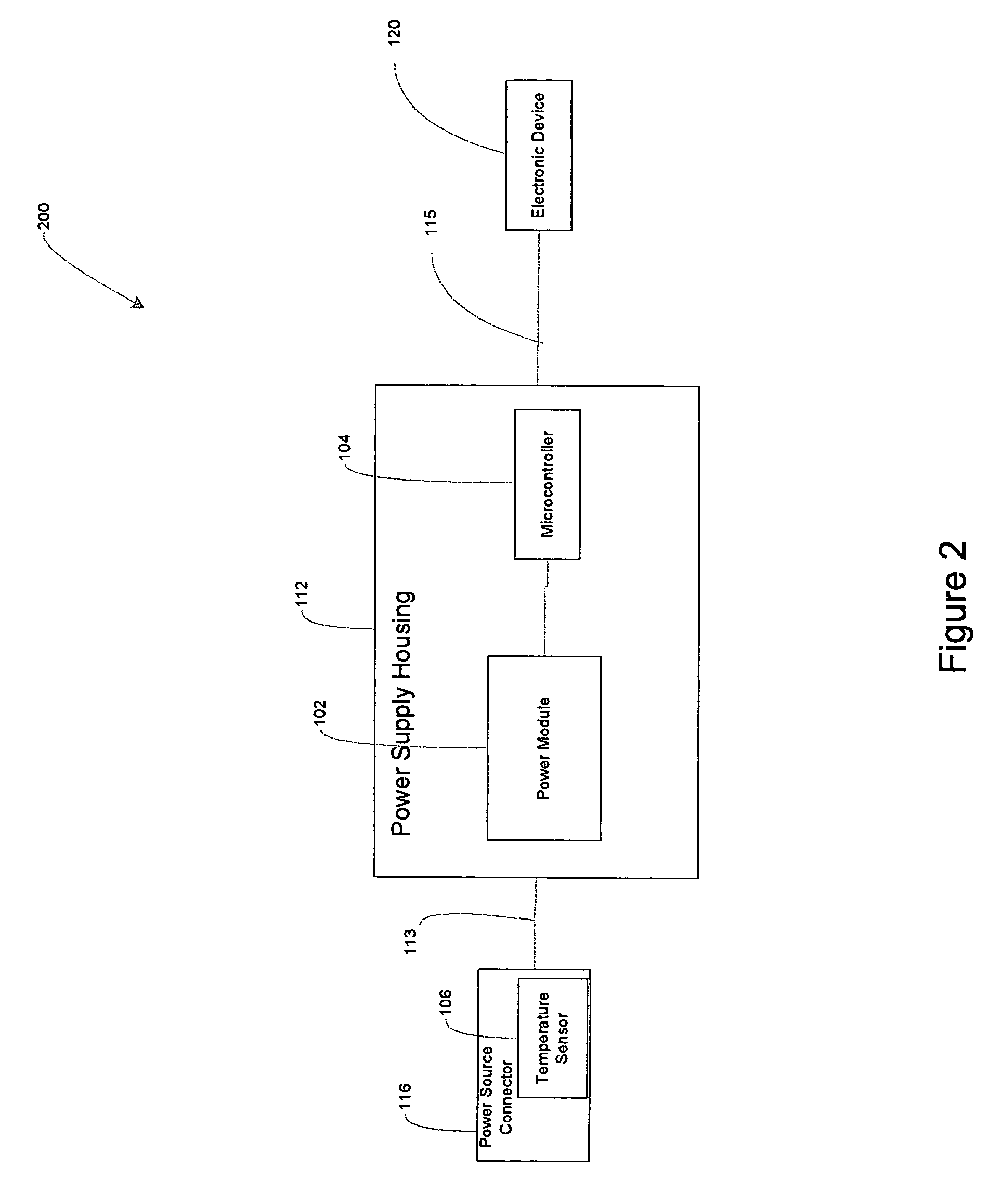

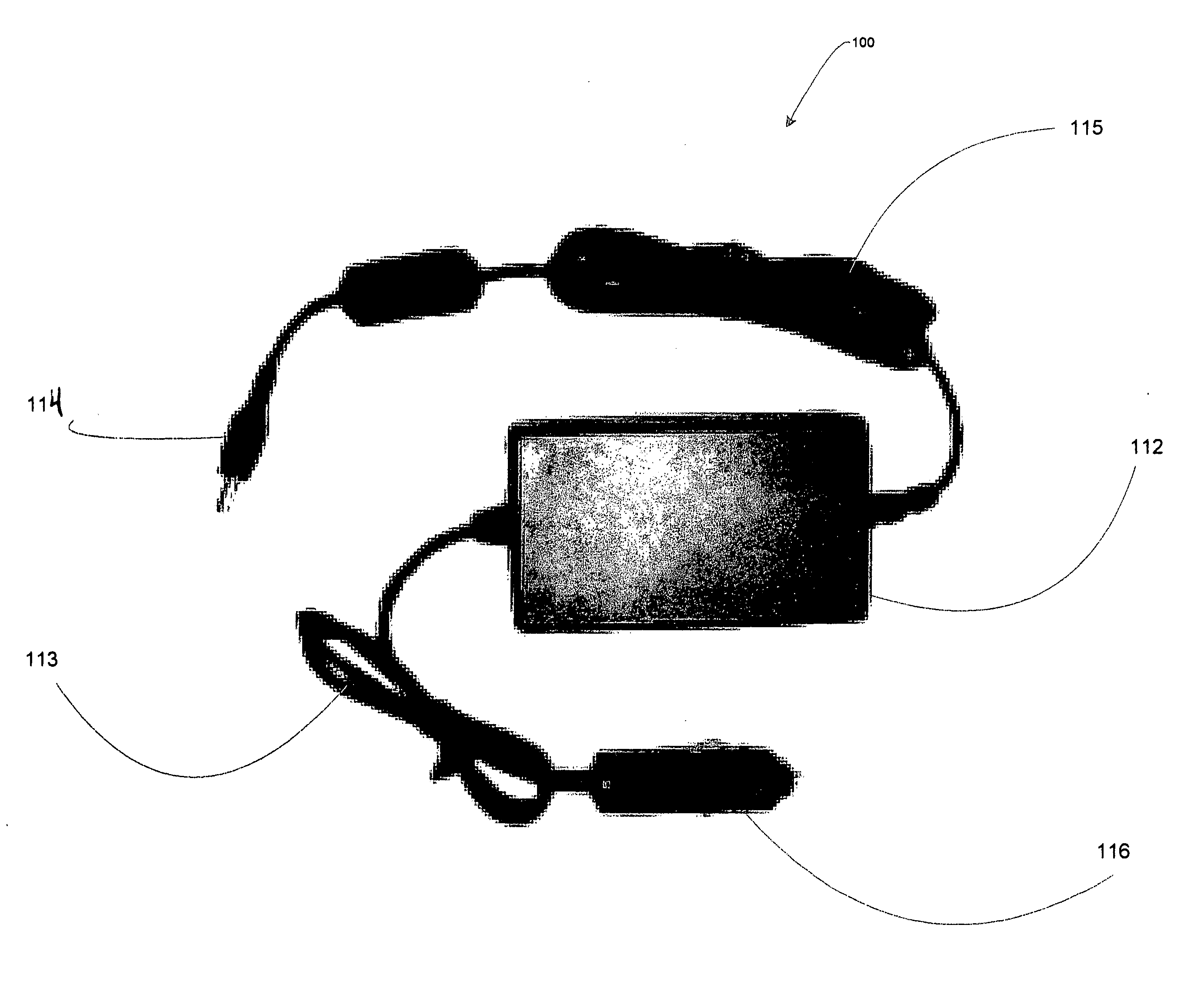

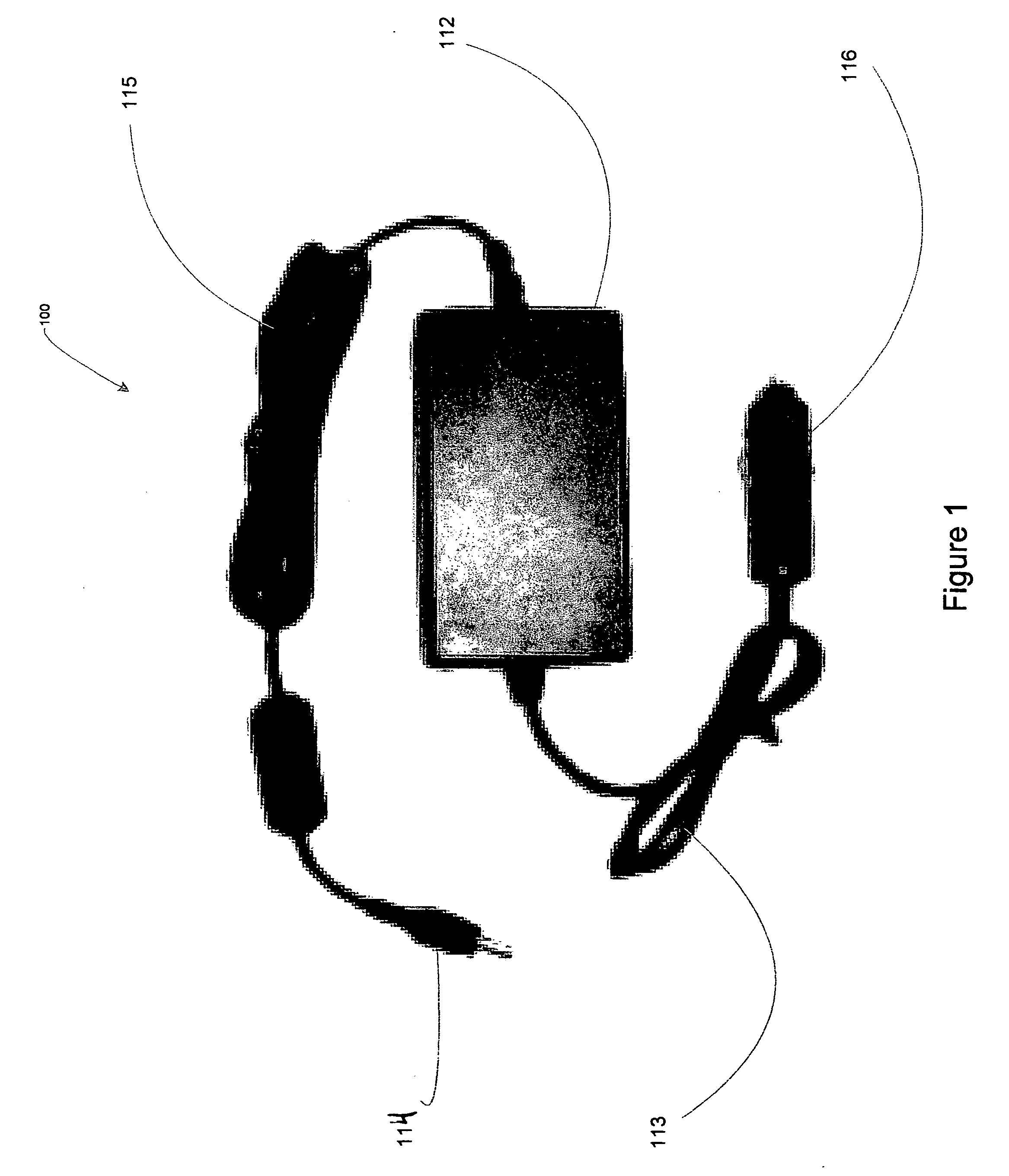

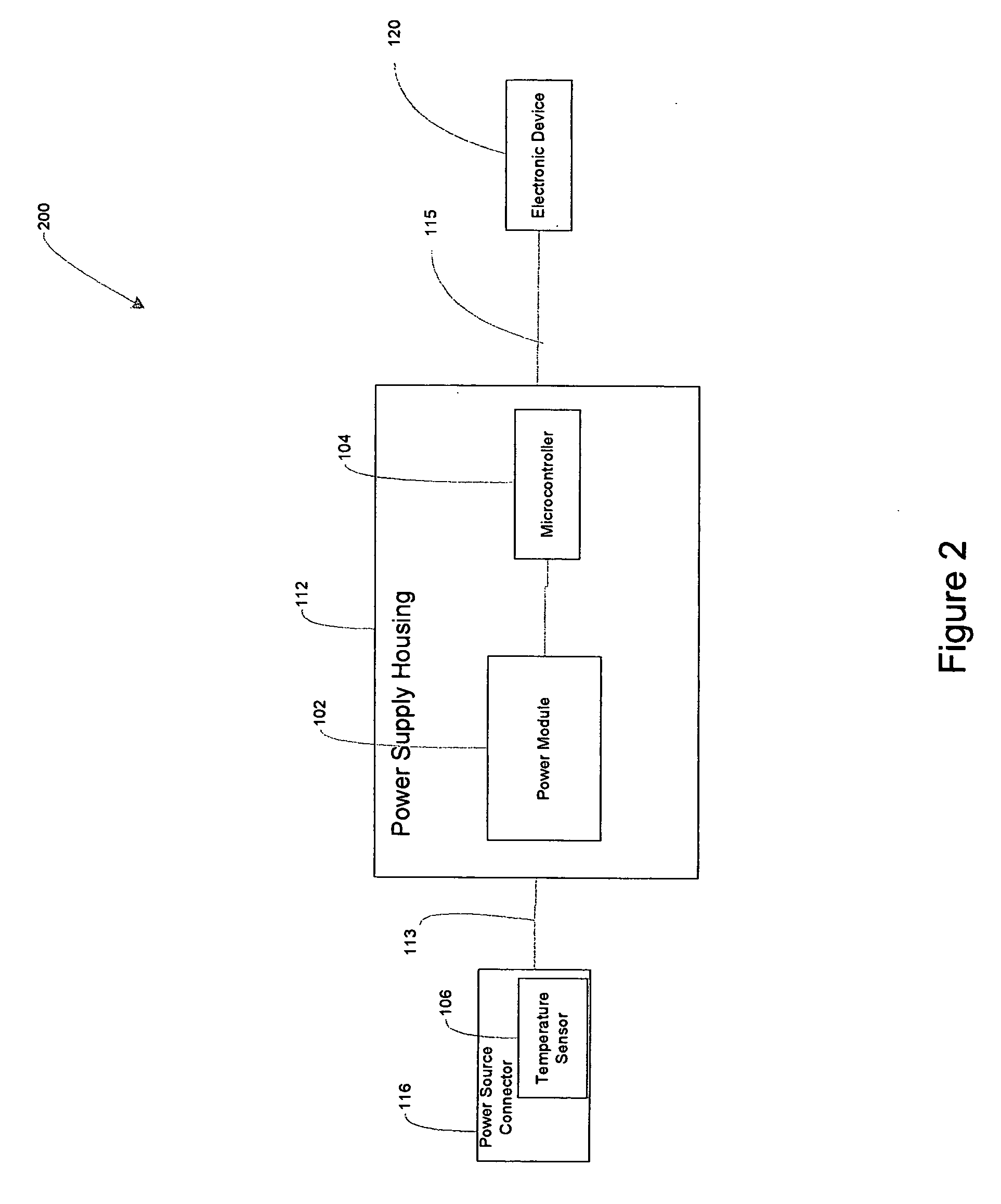

Temperature sensor for power supply

InactiveUS7408132B2Avoid lightAvoid damageElectric heatingEmergency protective arrangements for automatic disconnectionMicrocontrollerElectrical resistance and conductance

A temperature sensor, such as a thermistor, senses the temperature inside a power source connector, or other portion, of a power supply. This sensed temperature may then be used to determine if the output power should be reduced or switched off in order to avoid overheating of the connector, or other portion of the power supply. Overheating of the power supply may occur, for example, if contact between the connector and a cigarette lighter power receptacle is incomplete. A microcontroller may be used to monitor the temperature sensed by the temperature sensor and reduce or disable the power supply if the temperature is above a threshold temperate. Accordingly, heat damage to the plastic components of the power supply, the cigarette lighter receptacle, may be reduced.

Owner:RRC POWER SOLUTIONS

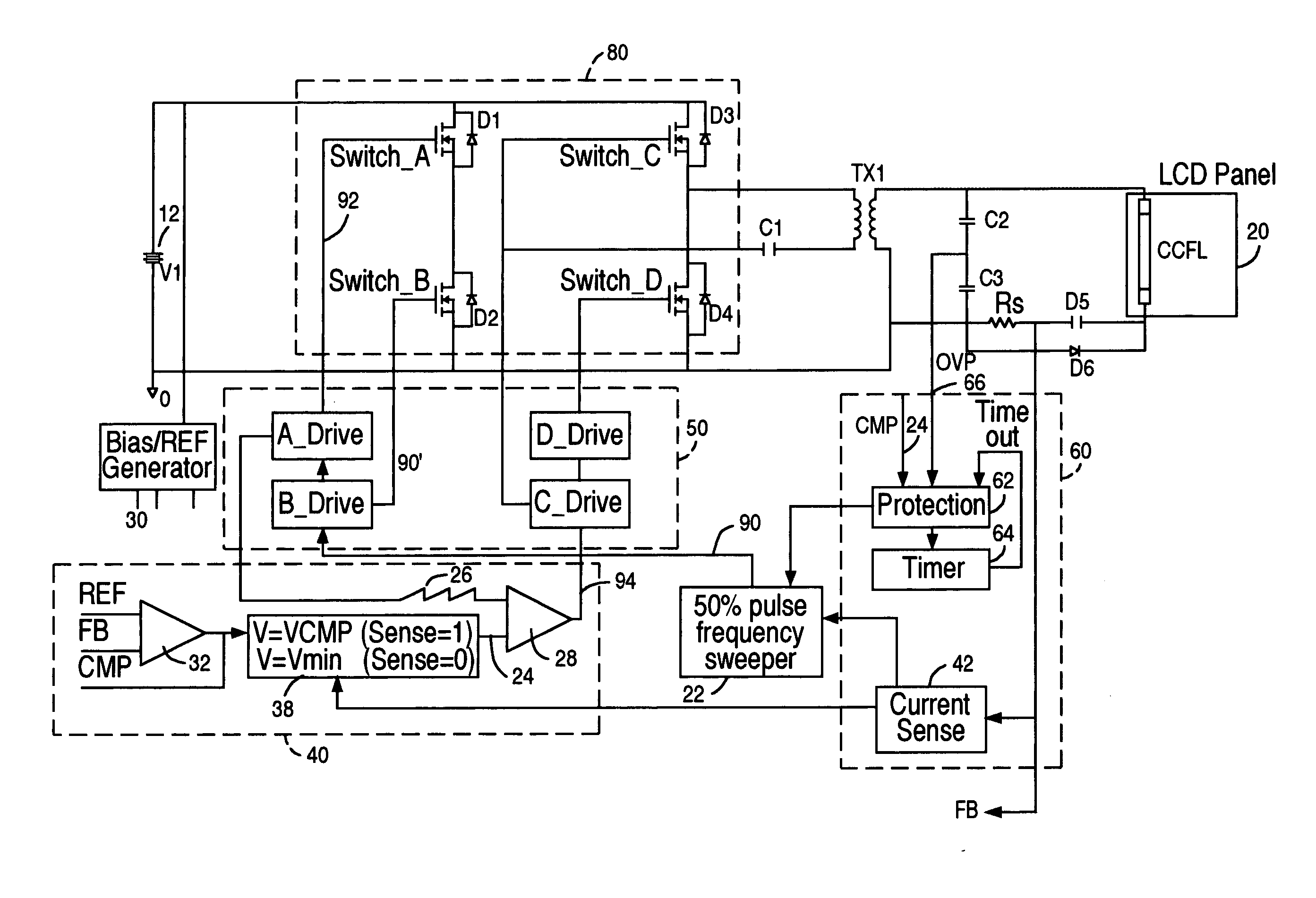

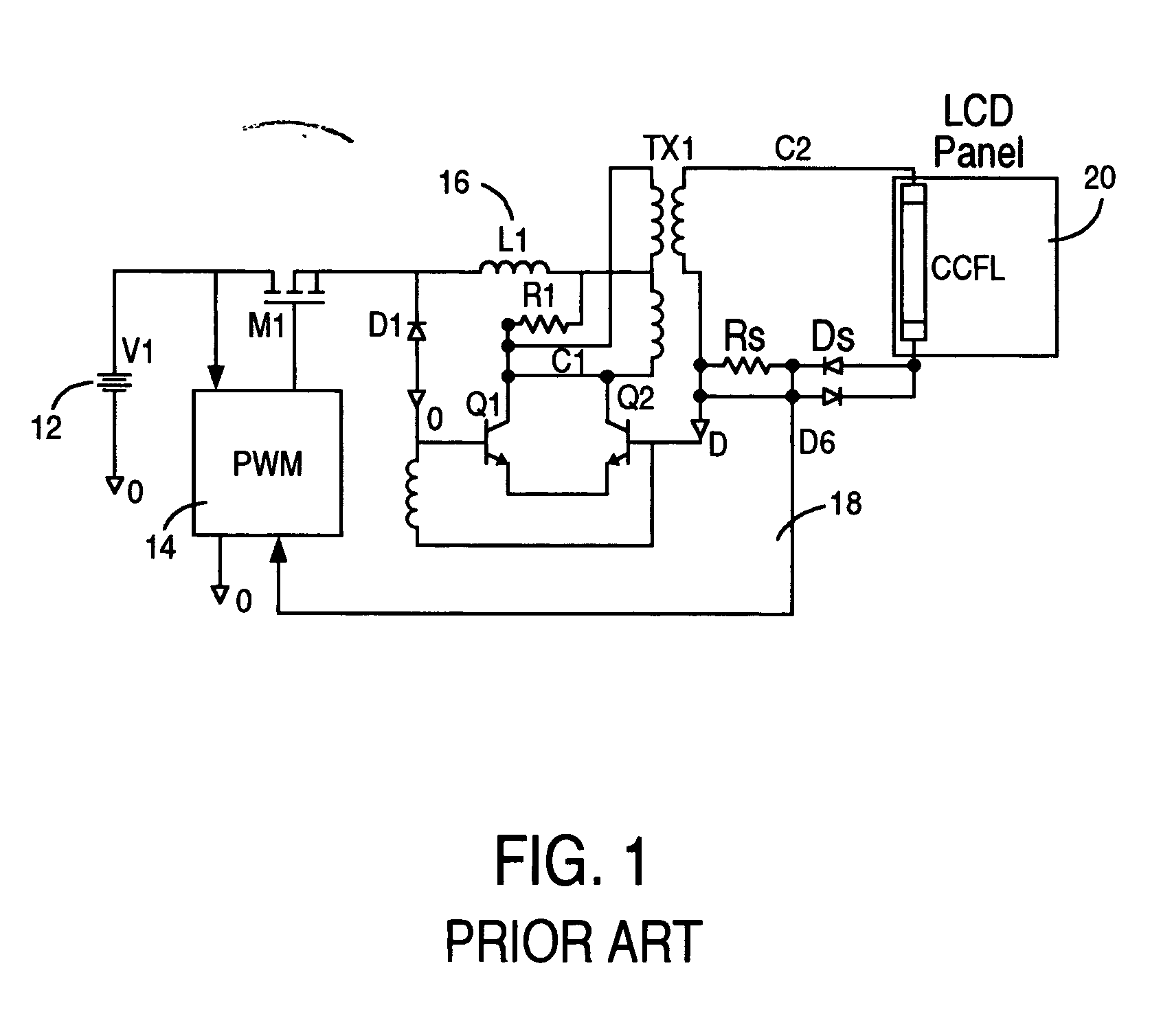

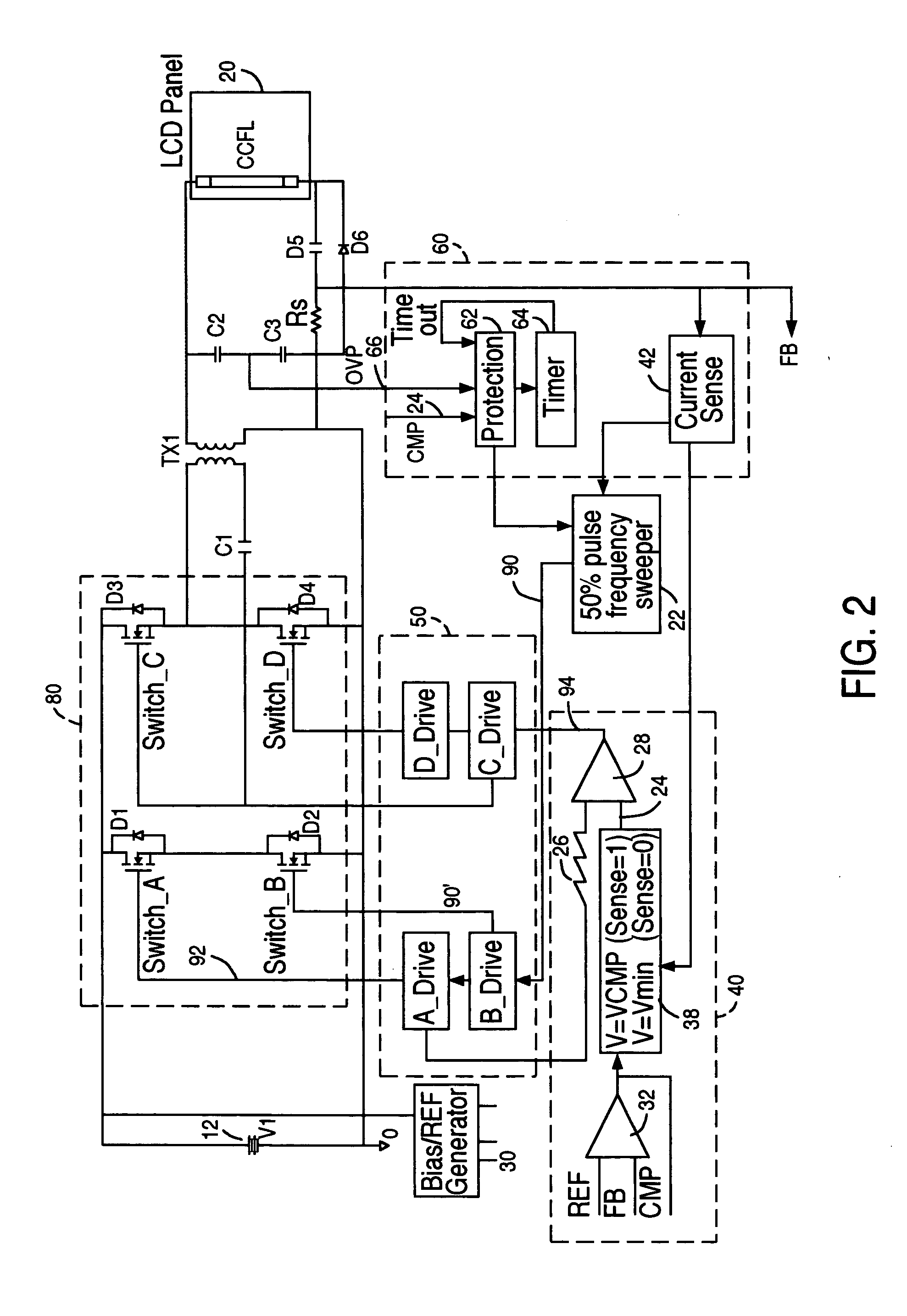

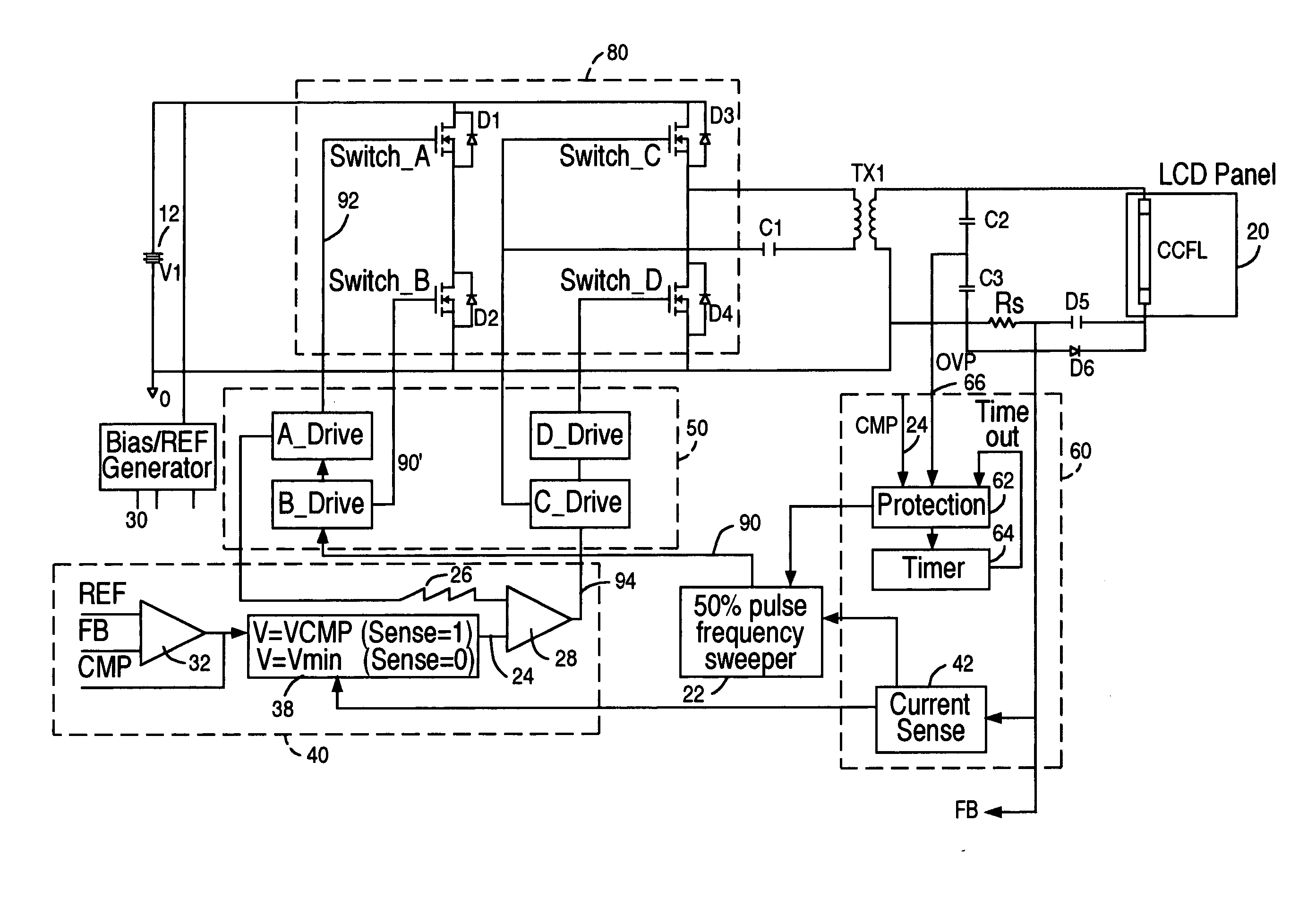

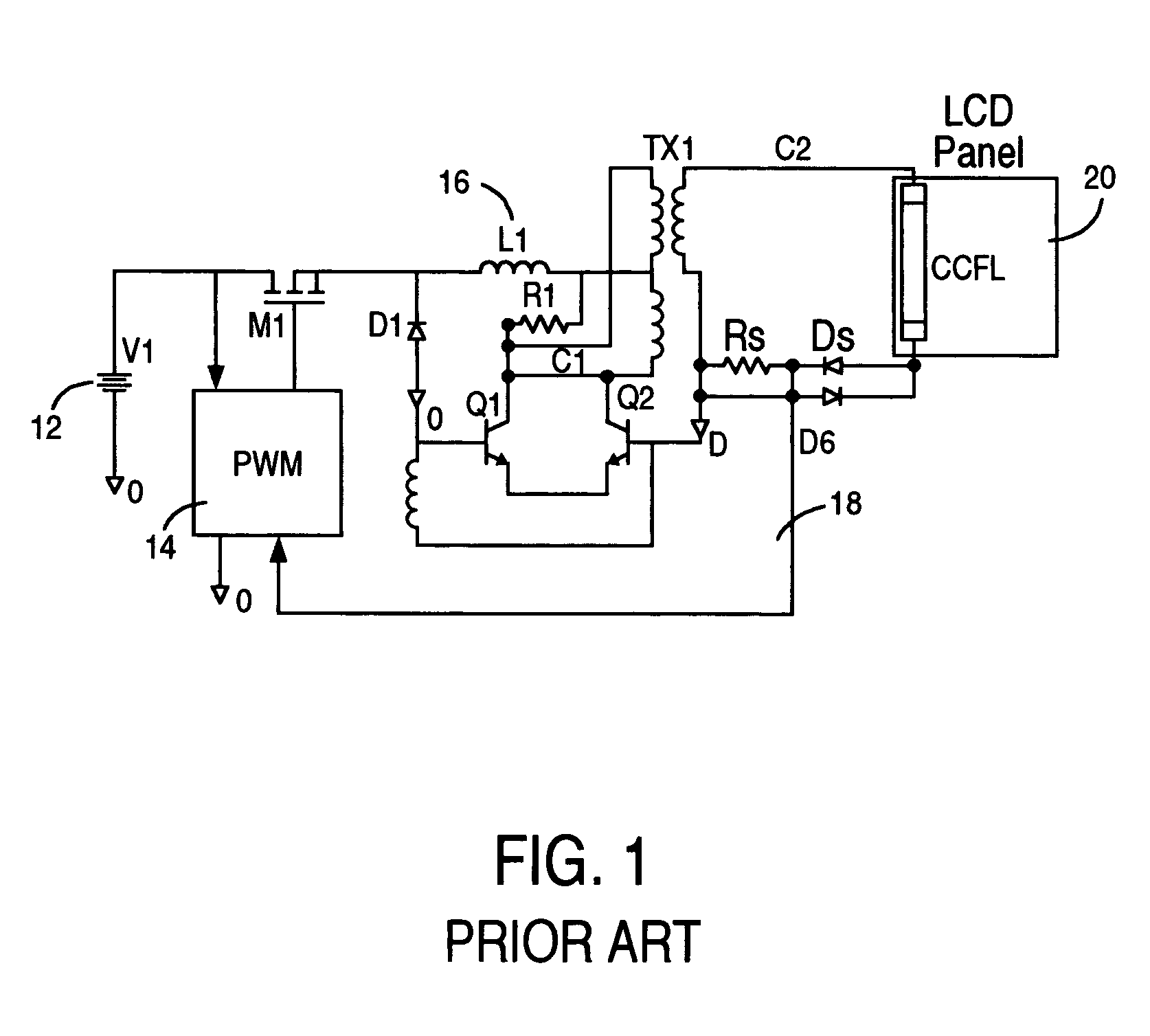

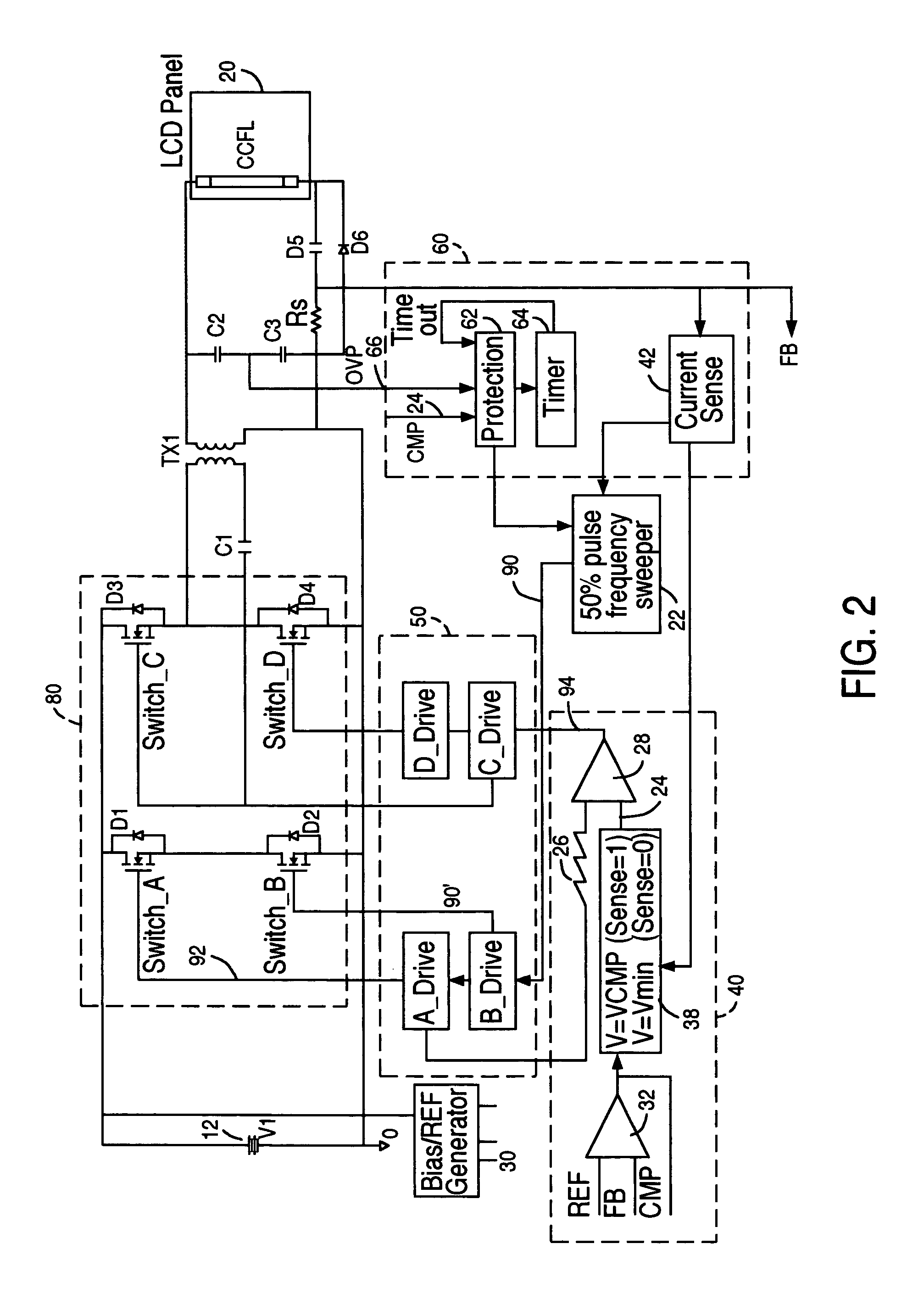

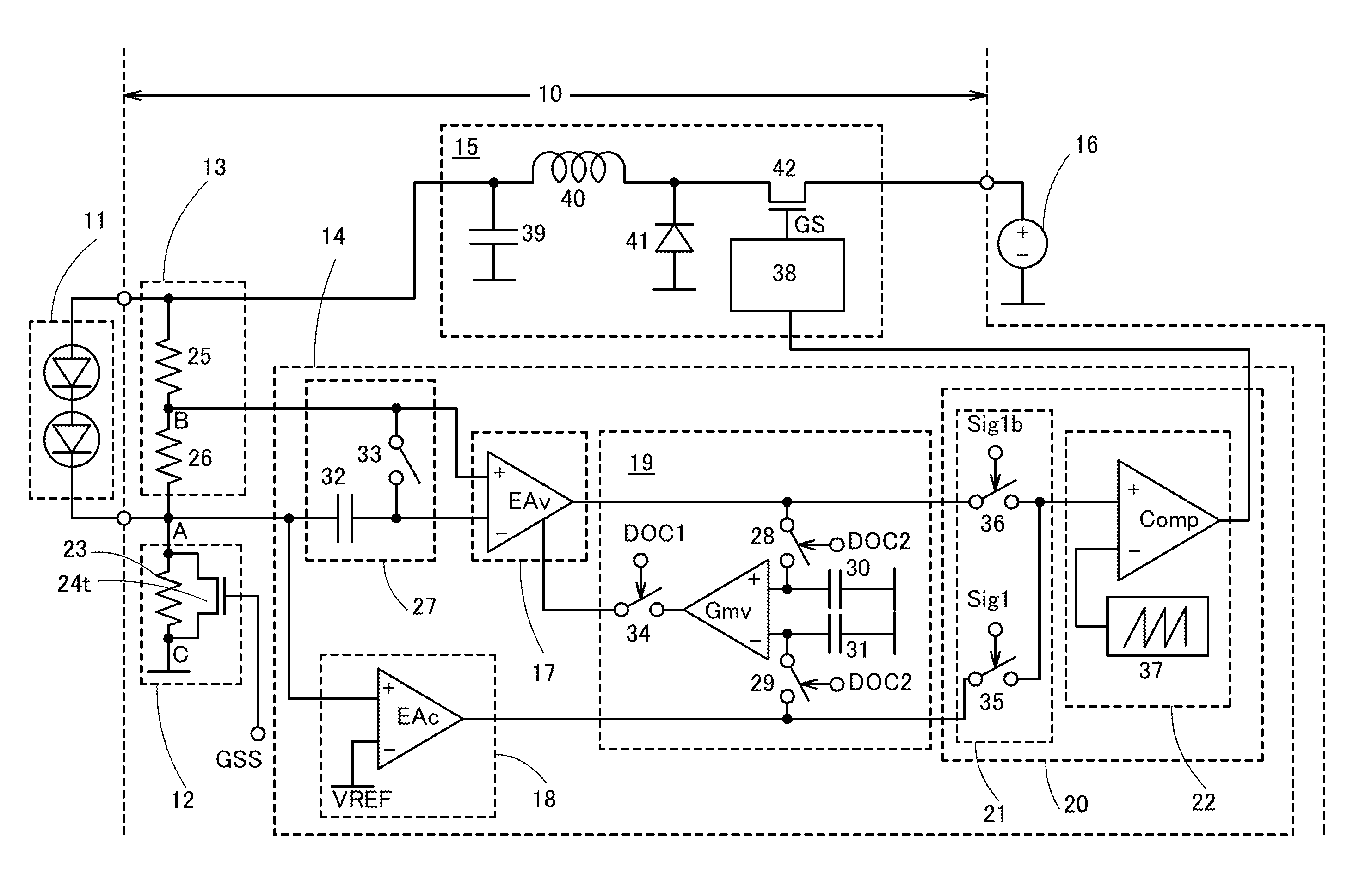

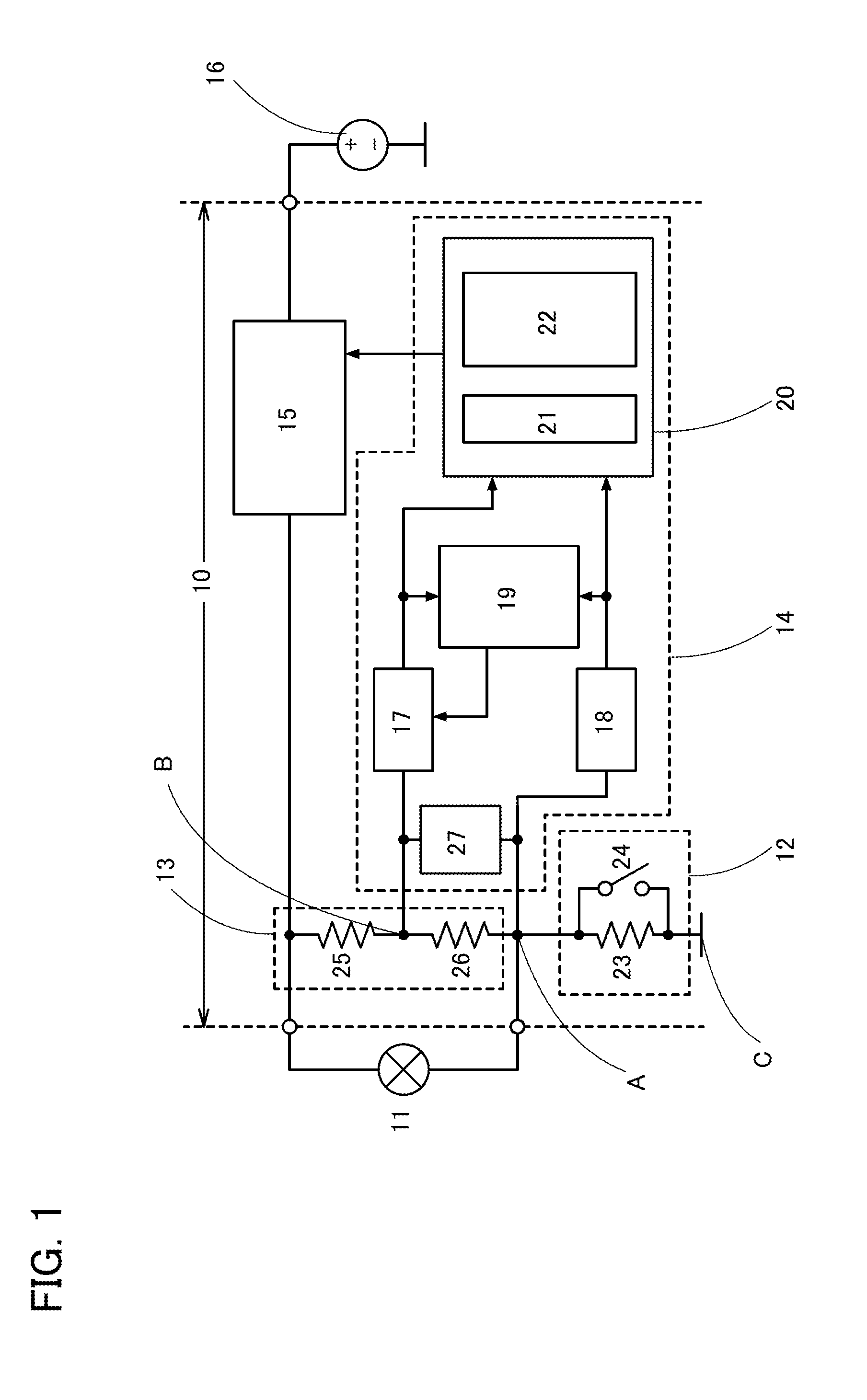

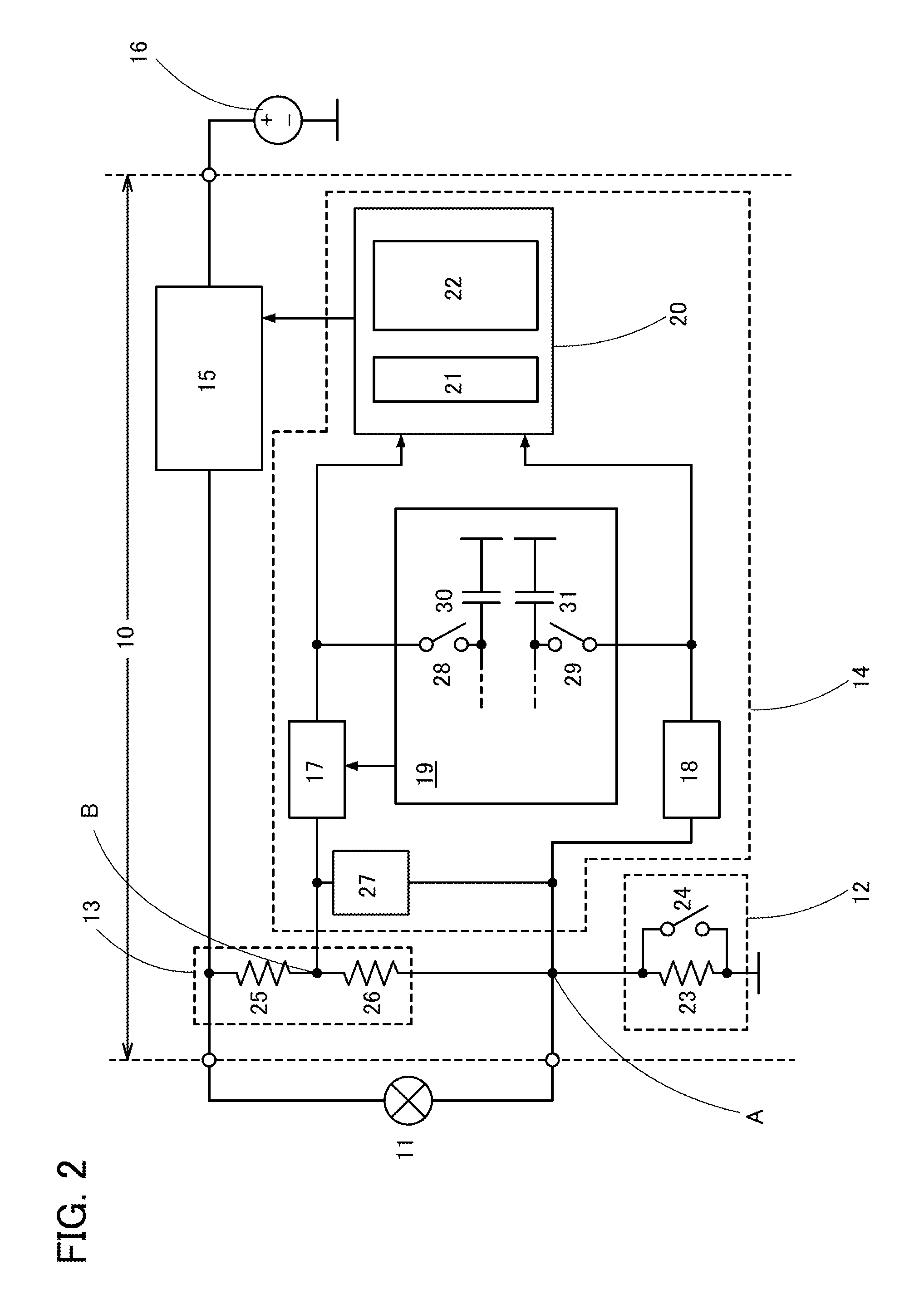

Liquid crystal display system with lamp feedback

InactiveUS20050174818A1Reduce power supplyEfficient power electronics conversionConversion with intermediate conversion to dcLiquid-crystal displayEngineering

A liquid crystal display system and CCFL power converter circuit is provided using a high-efficiency zero-voltage-switching technique that eliminates switching losses associated with the power MOSFETs. An optimal sweeping-frequency technique is used in the CCFL ignition by accounting for the parasitic capacitance in the resonant tank circuit. Additionally, the circuit is self-learning and is adapted to determine the optimum operating frequency for the circuit with a given load. An over-voltage protection circuit can also be provided to ensure that the circuit components are protected in the case of open-lamp condition.

Owner:O2 MICRO INT LTD

Cooling system for information device

ActiveUS8004839B2Increase heatCool many racks efficientlyDigital data processing detailsSemiconductor/solid-state device detailsCooling coilEngineering

To cool a blade type server disposed in an air-conditioned room, the following arrangements are made. The first is at least one shell having a ventilation passage disposed in the air-conditioned room. The second is, the following are disposed in a ventilation passage: racks, in which blade type servers each composed of a case with slim boards housed therein are stacked; cooling coils each having a coolant passage and a cooling fin and cooling a passing air; and at least one fan unit having axial-flow fans placed therein and producing air currents in one direction. The third is the fan unit forces a cooling air to flow in one direction in the ventilation passage thereby to cool the servers in the racks. The cooling coils and racks are disposed alternately so that warmed cooling air after passing through the rack is cooled by the cooling coil and then cools the next rack.

Owner:FUJI FURUKAWA ENG & CONSTR +1

Liquid crystal display system with lamp feedback

InactiveUS7394209B2Reduce power supplyEfficient power electronics conversionConversion with intermediate conversion to dcLiquid-crystal displayParasitic capacitance

Owner:O2 MICRO INT LTD

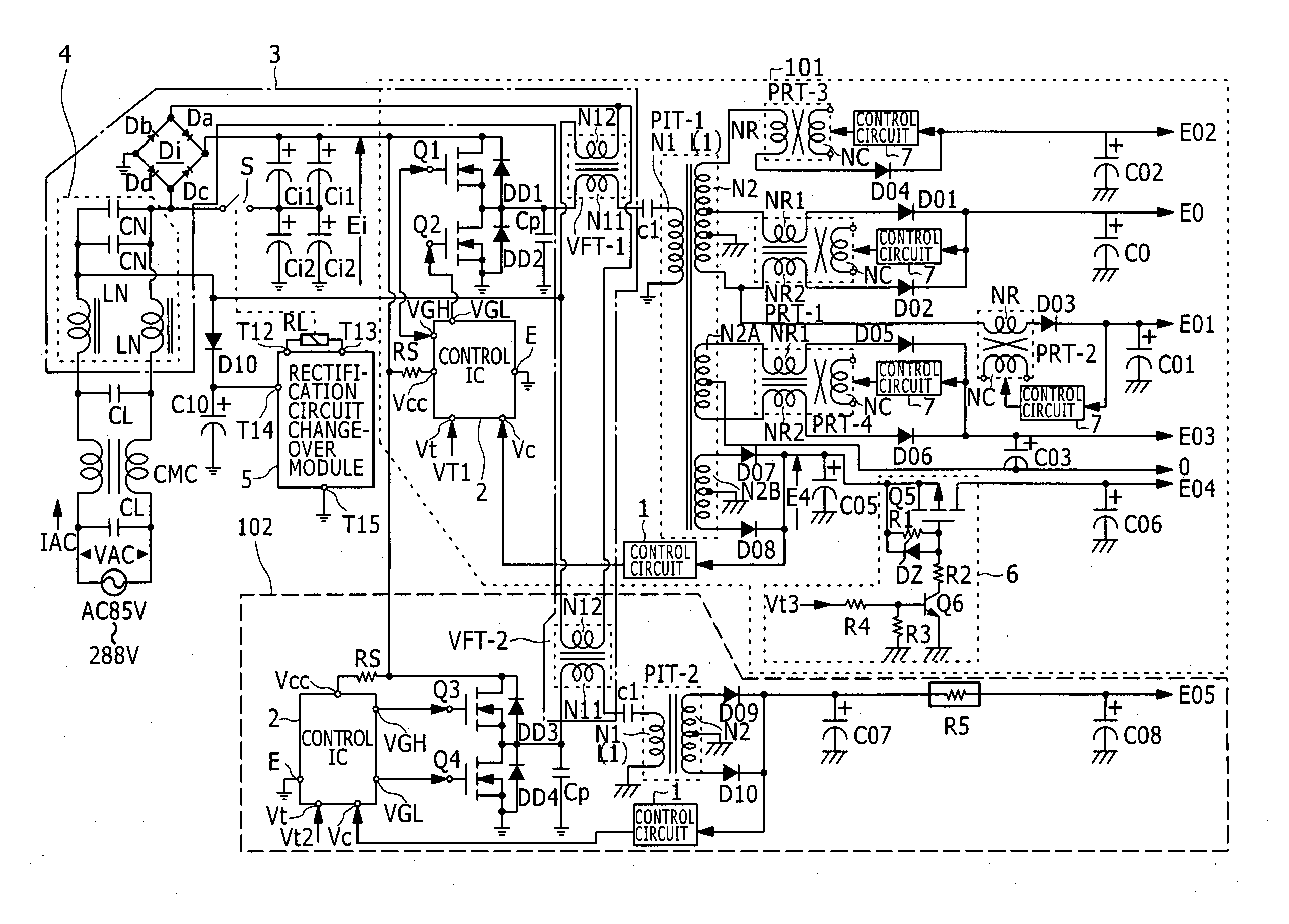

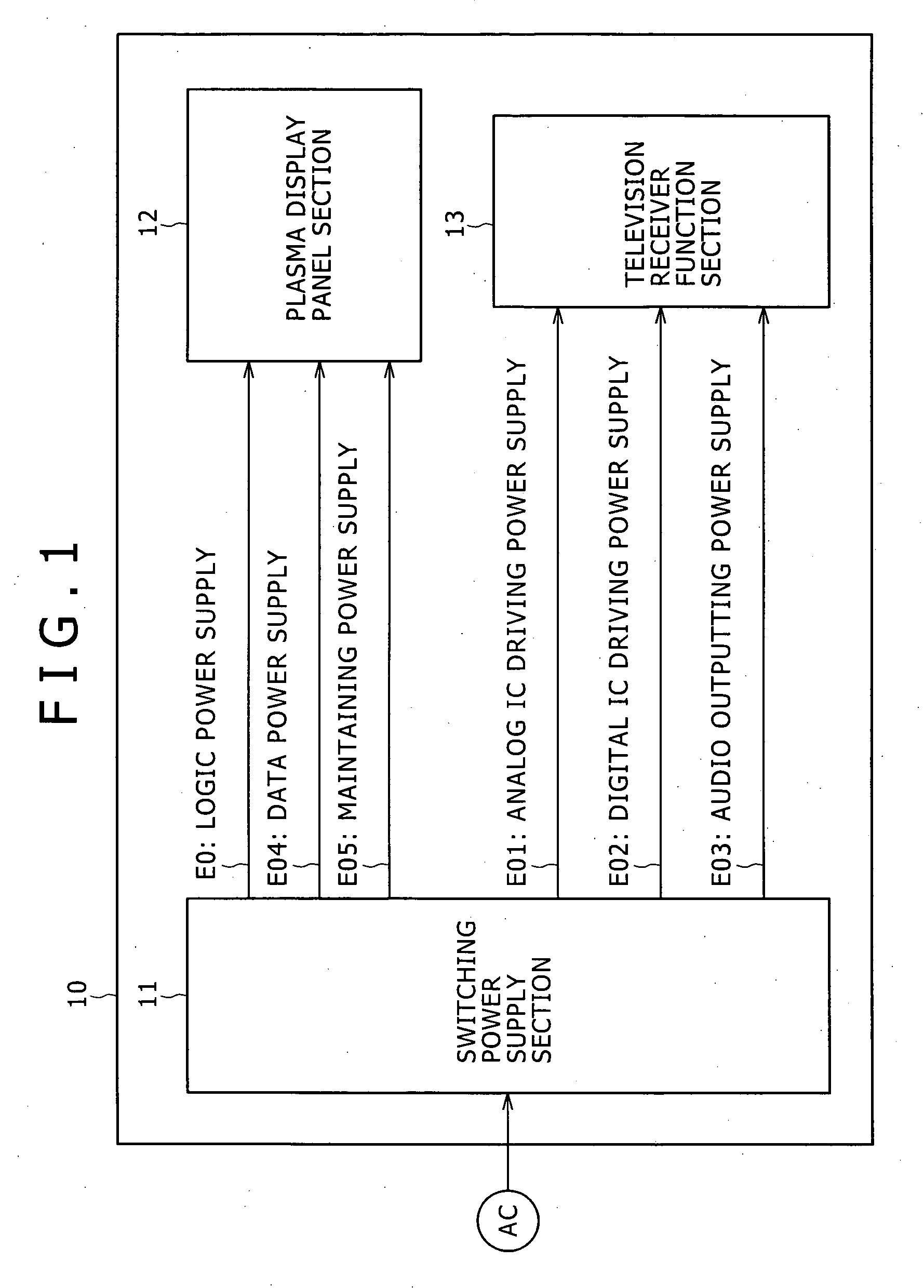

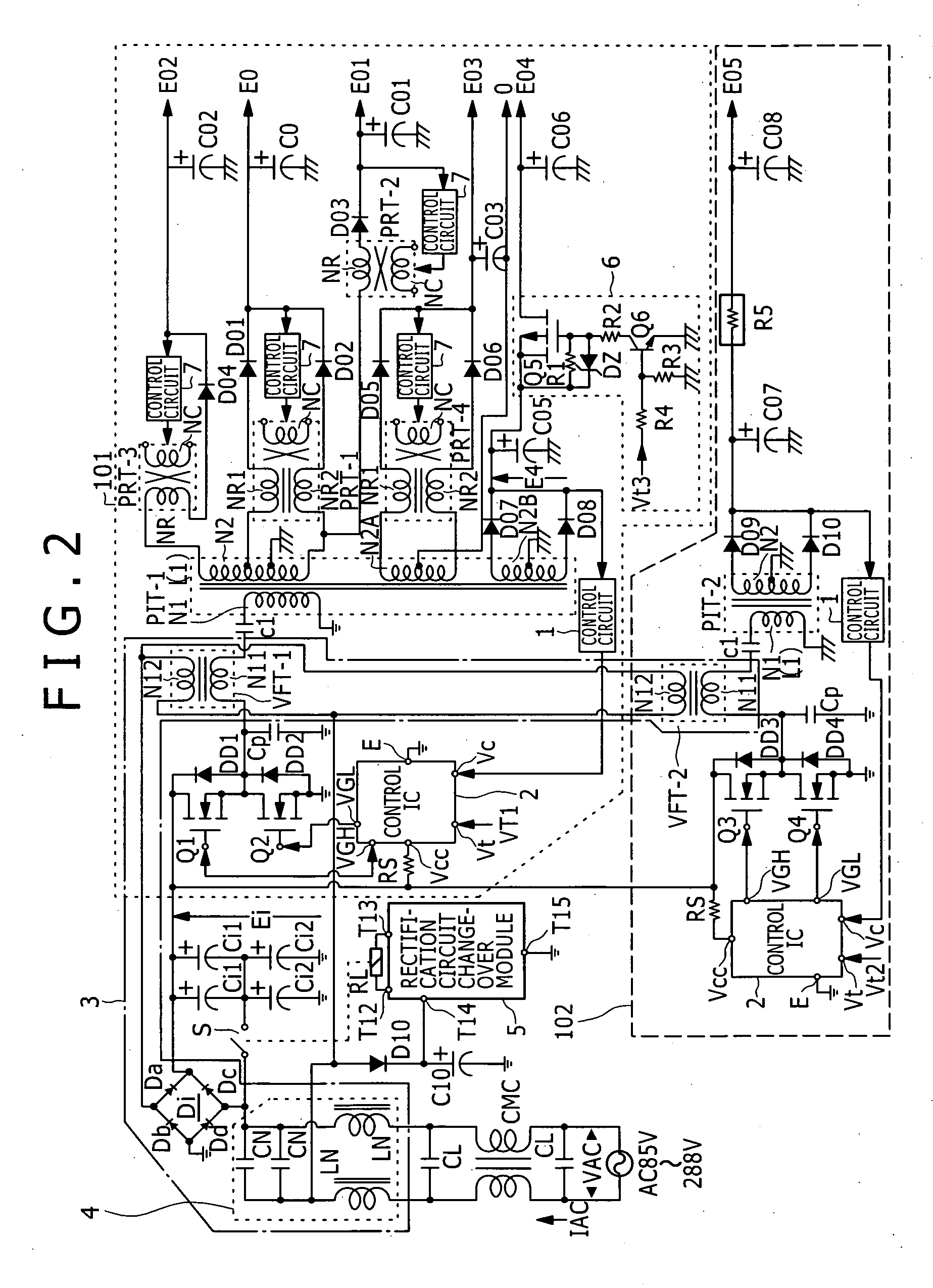

Switching power supply circuit

InactiveUS20060192774A1Improve conversion efficiencyImprove power factorAc-dc conversion without reversalEfficient power electronics conversionFull wavePower factor

A switching power supply circuit ready for a wide range and including a power factor improving function is disclosed which can achieve reduction in cost, reduction in size and weight of the circuit and reduction of the power loss by reducing the number of converter sections with respect to the number of stages in a starting order of secondary side DC output voltages. A plurality of switching converters (101), (102) are of the composite resonance type wherein a partial resonance voltage circuit is combined with a switching converter of the current resonance type according to a half-bridge connection system. Changeover control is performed such that a rectification circuit serves as a voltage doubler rectification circuit at an AC voltage equal to or lower than 150 V, but serves as a full-wave rectification circuit at another AC voltage equal to or higher than 150 V. Power factor improvement is implemented by feeding back the voltages of outputs of the converters to a rectification current path by a power factor improving transformer (VFT) and interrupting the rectification current by means of a rectification diode to expand the

Owner:SONY CORP

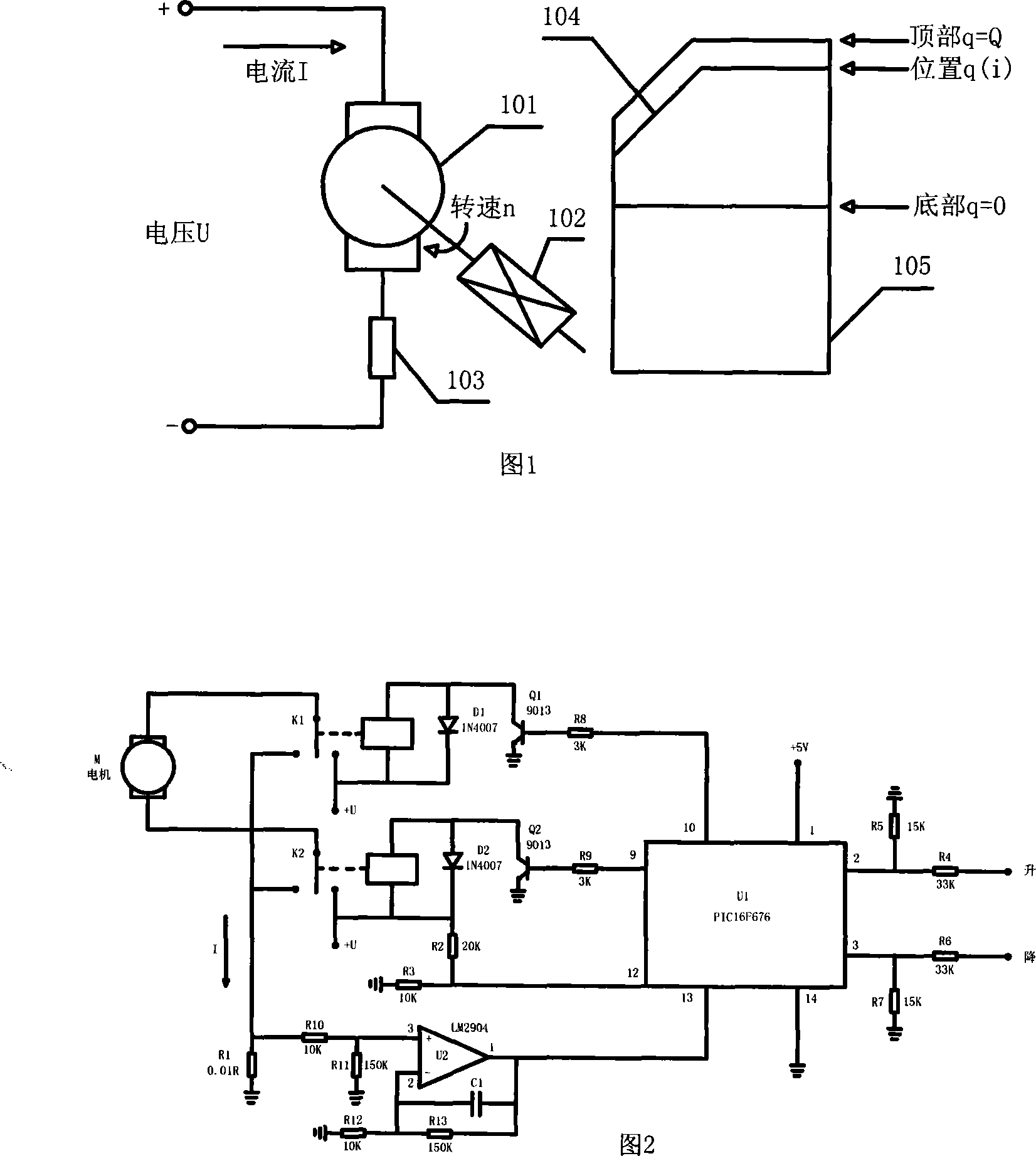

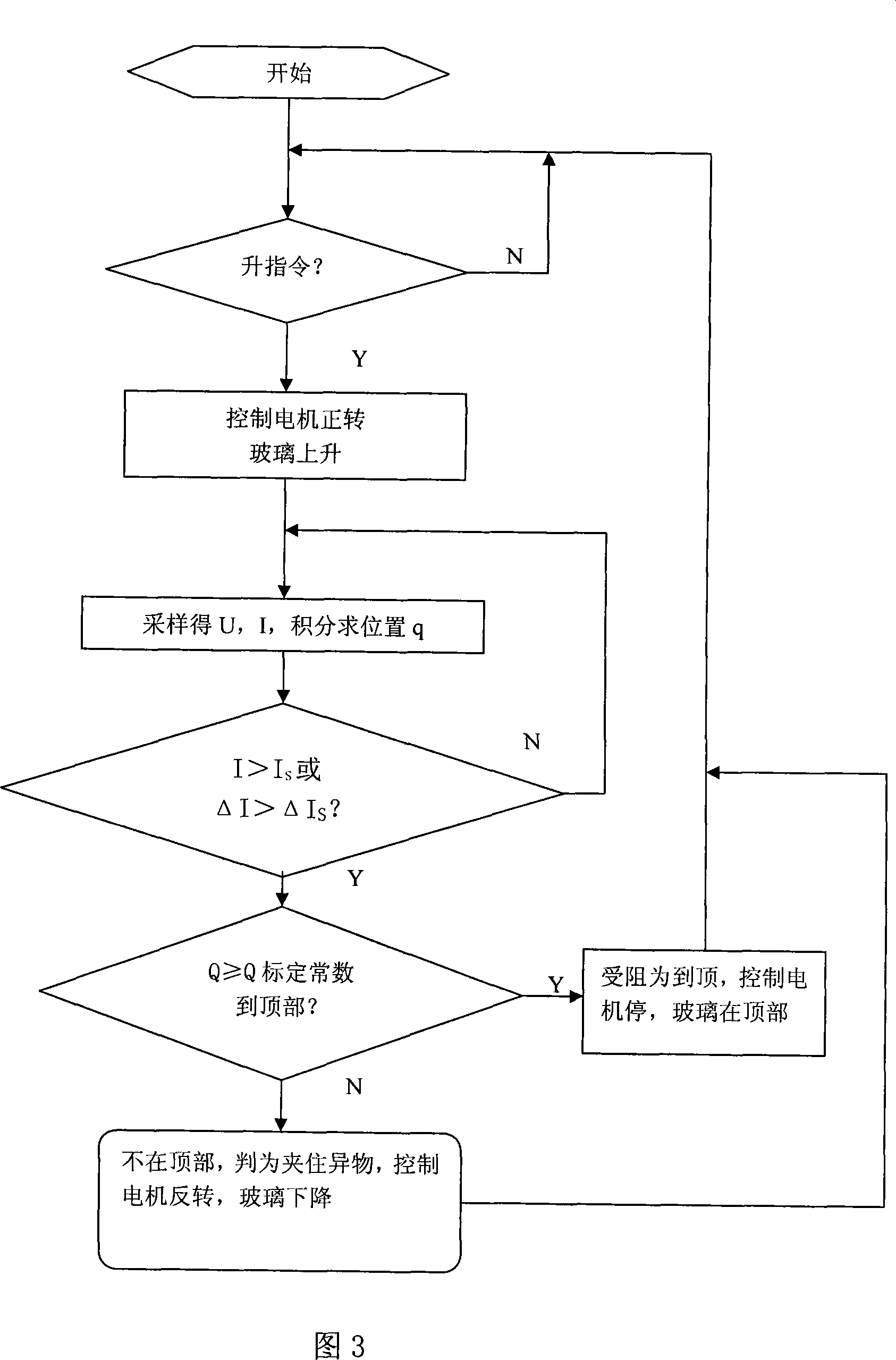

Anti-clip control method for electric window of vehicle

The invention relates to an ant-pinch controlling method for the electric window of the automobile, which is characterized in that a sampling resistance and a magnifying filter circuit are adopted to obtain the armature current signal of a motor, and a divider resistance or an amplifier is adopted to obtain the armature voltage signal of the motor; a singlechip utilizes A / D to sample and filter to obtain the digital value of the armature voltage U and the electric current I, then a rotation speed n can be obtained according to the functional relationship between the motor speed n and the armature voltage U and the electric current I; the rotor position can be obtained by calculating the integral of the rotation speed, and thereby the position q of the electric window glass can be obtained; on the other hand, the singlechip can judge if the motion of the electric window glass is obstructed according to the current I; Whether the electric window glass reaches the top or nips foreign matter can be distinguished according to the motion condition and the glass position q, then the electric window glass can be lifted, lowered or stopped by comprehensively analyzing the external instruction. The method provided by the invention has the advantages that the method is simple and practical; an anti-pinch device for the electric window can be designed and manufactured without a sensor.

Owner:张建华

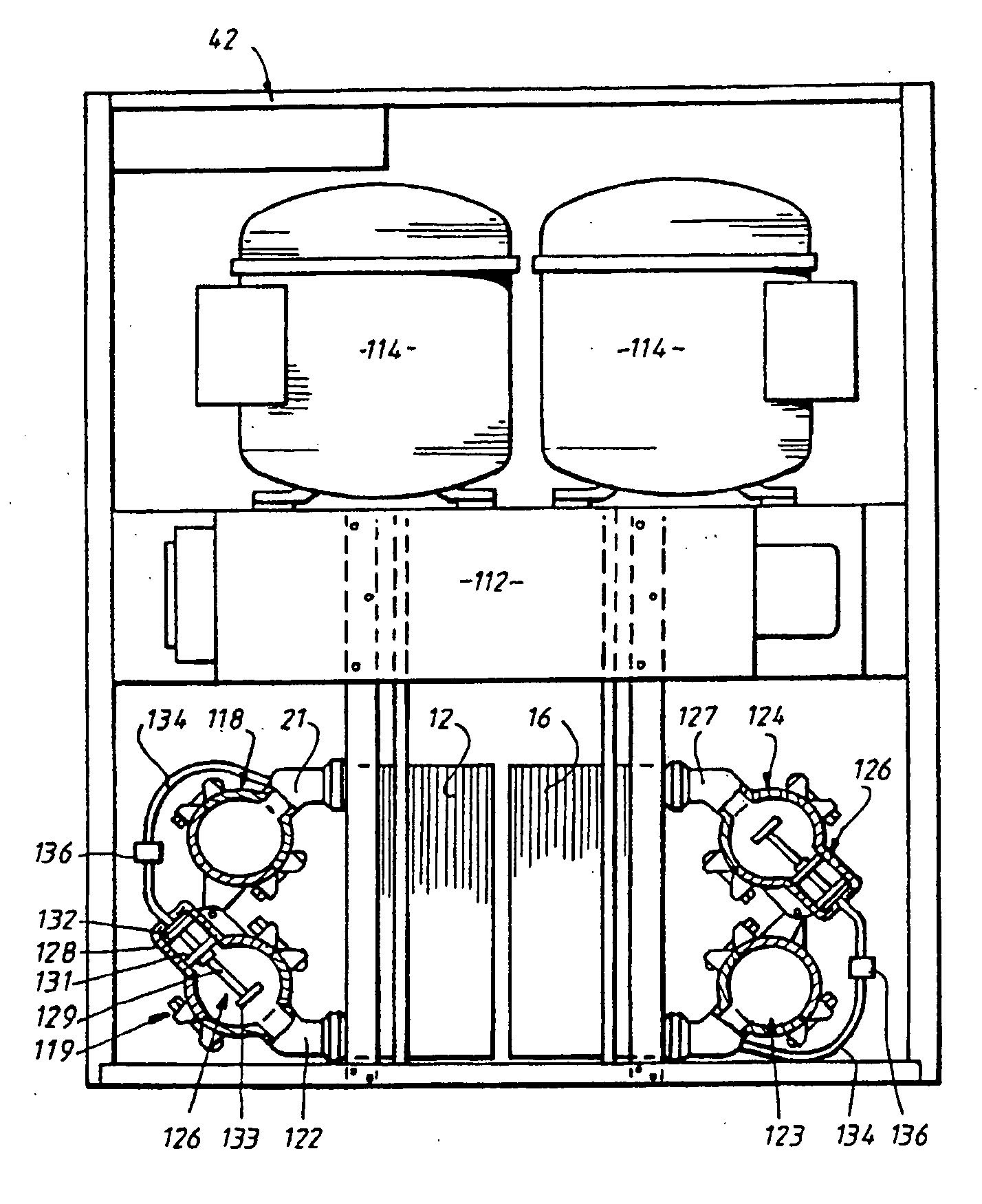

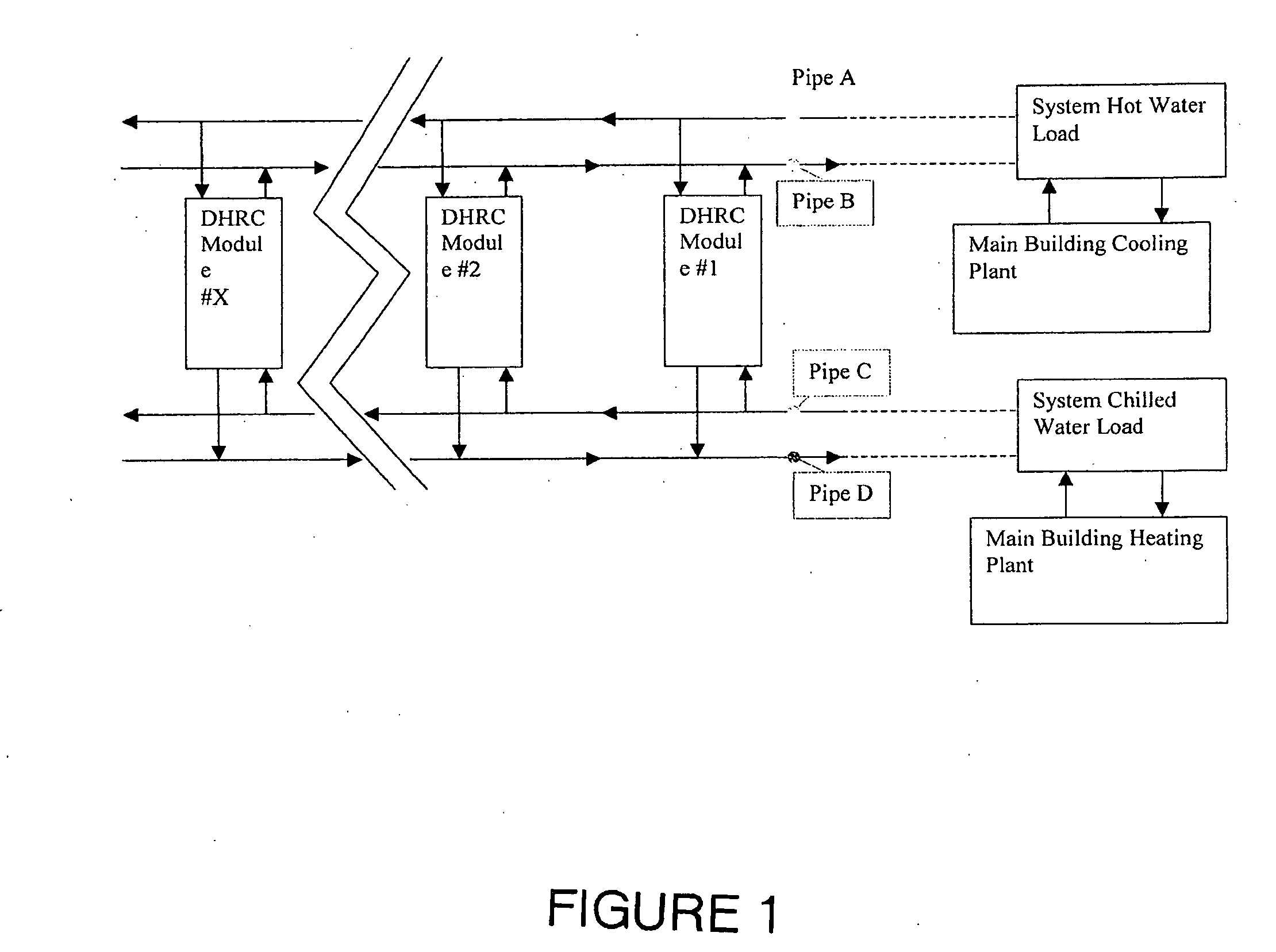

Dedicated heat recovery chiller

InactiveUS20090151388A1Reduced Power RequirementsReduce system loadCompression machines with non-reversible cycleEfficient regulation technologiesMotor speedWater cycling

A heating and / or cooling system which incorporates one or more modular dedicated heat recovery refrigeration units each of which includes at least one compressor, an evaporator and a condenser. The system captures and utilizes condenser circuit heat which would otherwise be wasted. A variable speed circulating water pump circulates water through each evaporator / condenser, which are connected in parallel across the respective supply line and return line. A master controller activates and deactivates individual compressors in accordance with load demand. Shut-off valves close off the water flow through the respective evaporator and / or condenser of any units deactivated and the resulting changes in the pressure differential in the supply and return lines is sensed by sensor which sends a signal to the pump motor speed controller which changes the output of the pump to restore a predetermined pressure differential.

Owner:MULTISTACK

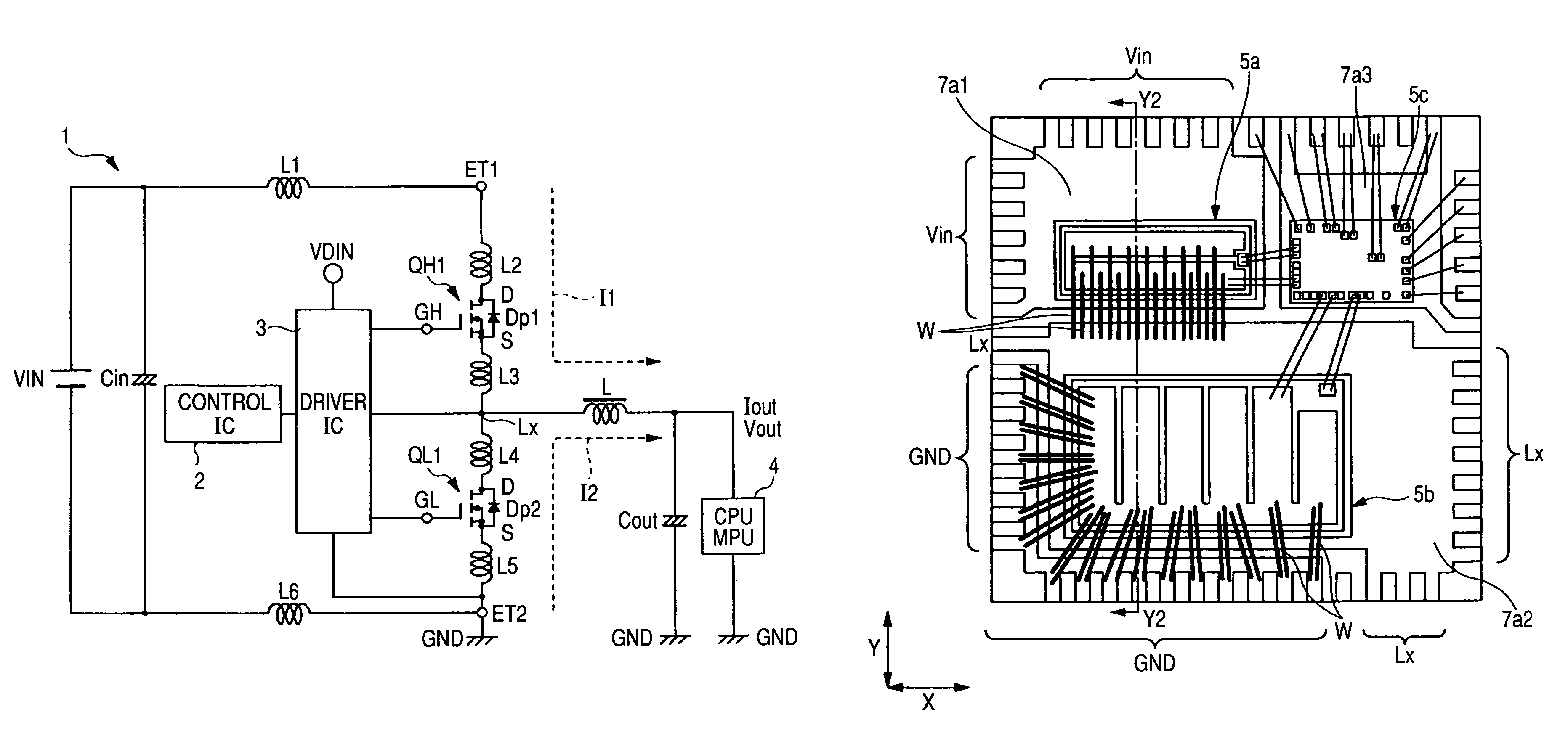

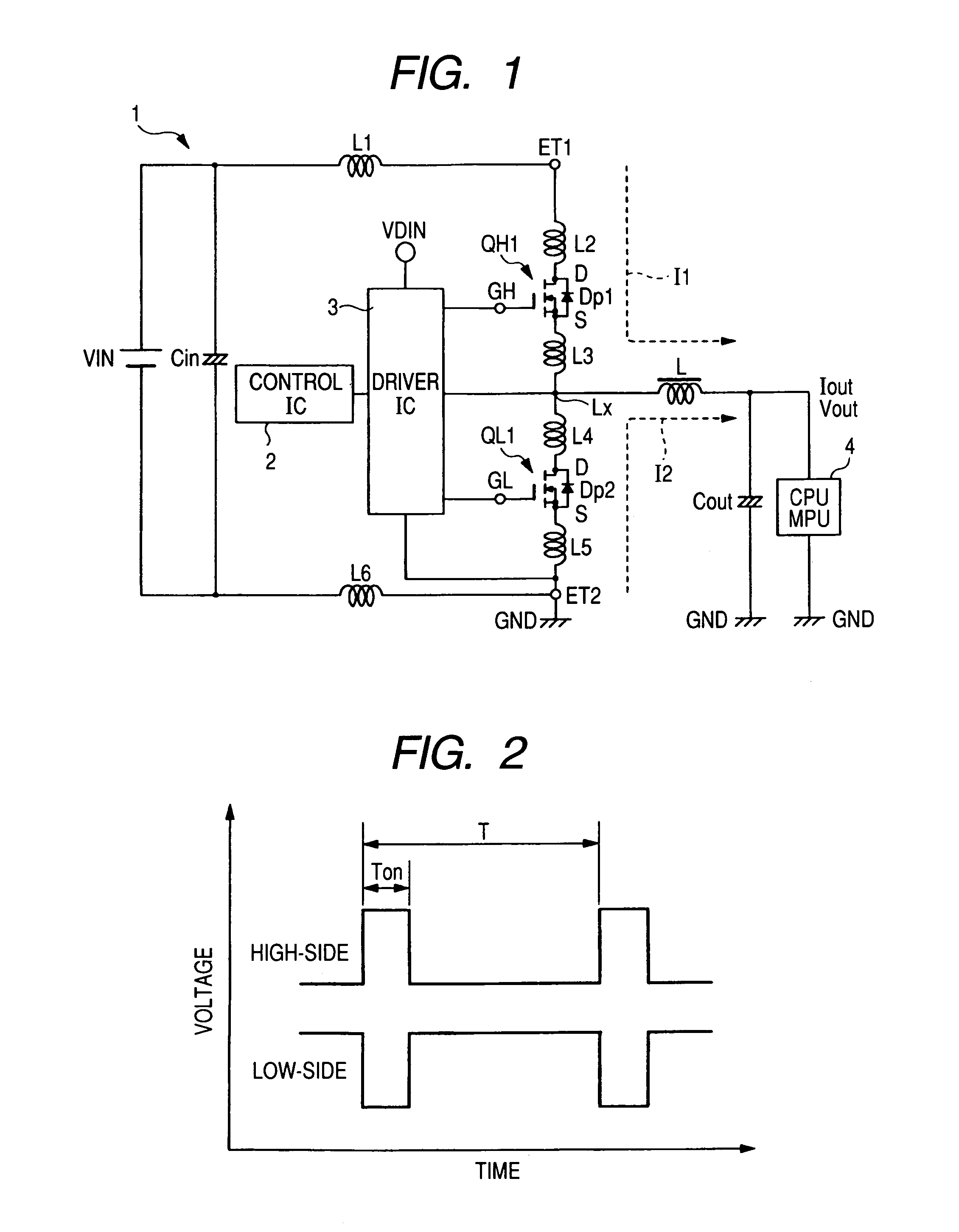

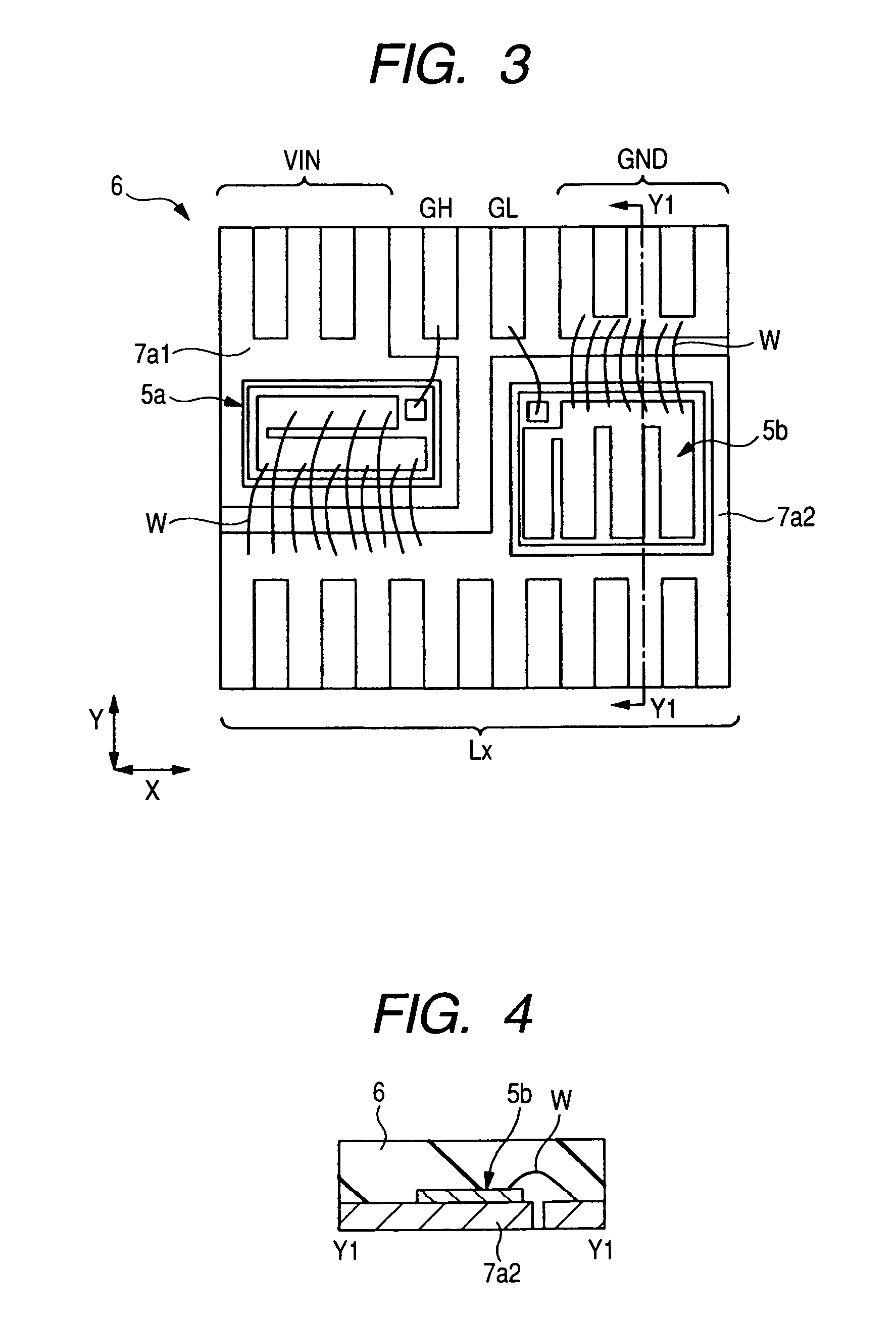

Semiconductor device

InactiveUS7295453B2Reduce power supplyImprove power efficiencySemiconductor/solid-state device detailsCircuit arrangements on support structuresPower semiconductor deviceDc dc converter

The object of the present invention is to reduce parasitic inductance of a main circuit in a power supply circuit. The present invention provides a non-insulated DC-DC converter having a circuit in which a power MOS• FET for a high-side switch and a power MOS•FET for a low-side switch are connected in series. In the non-insulated DC-DC converter, the power MOS•FET for the high-side switch is formed by a p channel vertical MOS•FET, and the power MOS•FET for the low-side switch is formed by an n channel vertical MOS•FET. Thus, a semiconductor chip formed with the power MOS•FET for the high-side switch and a semiconductor chip formed with the power MOS•FET for the low-side switch are mounted over the same die pad and electrically connected to each other through the die pad.

Owner:RENESAS ELECTRONICS CORP

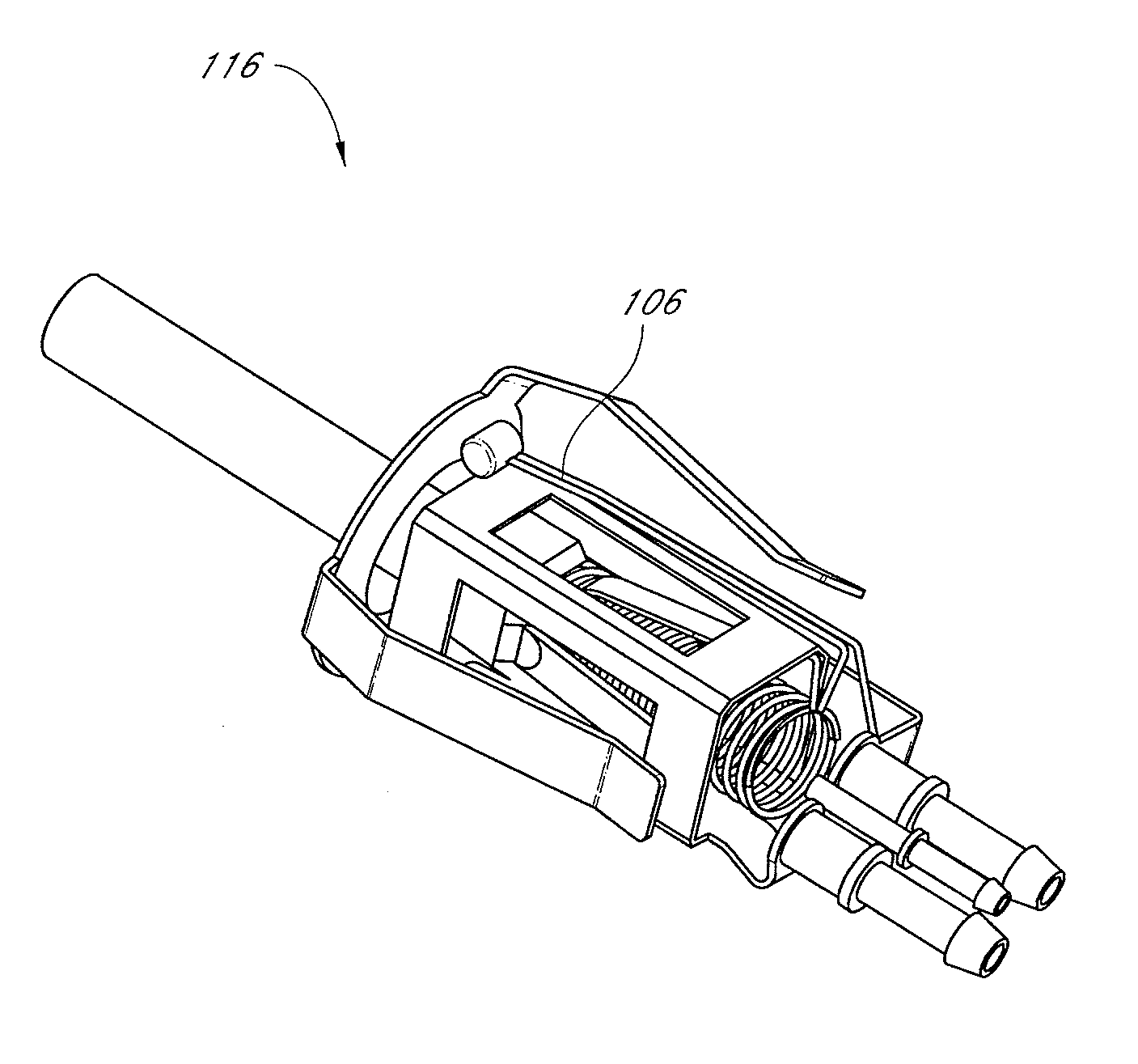

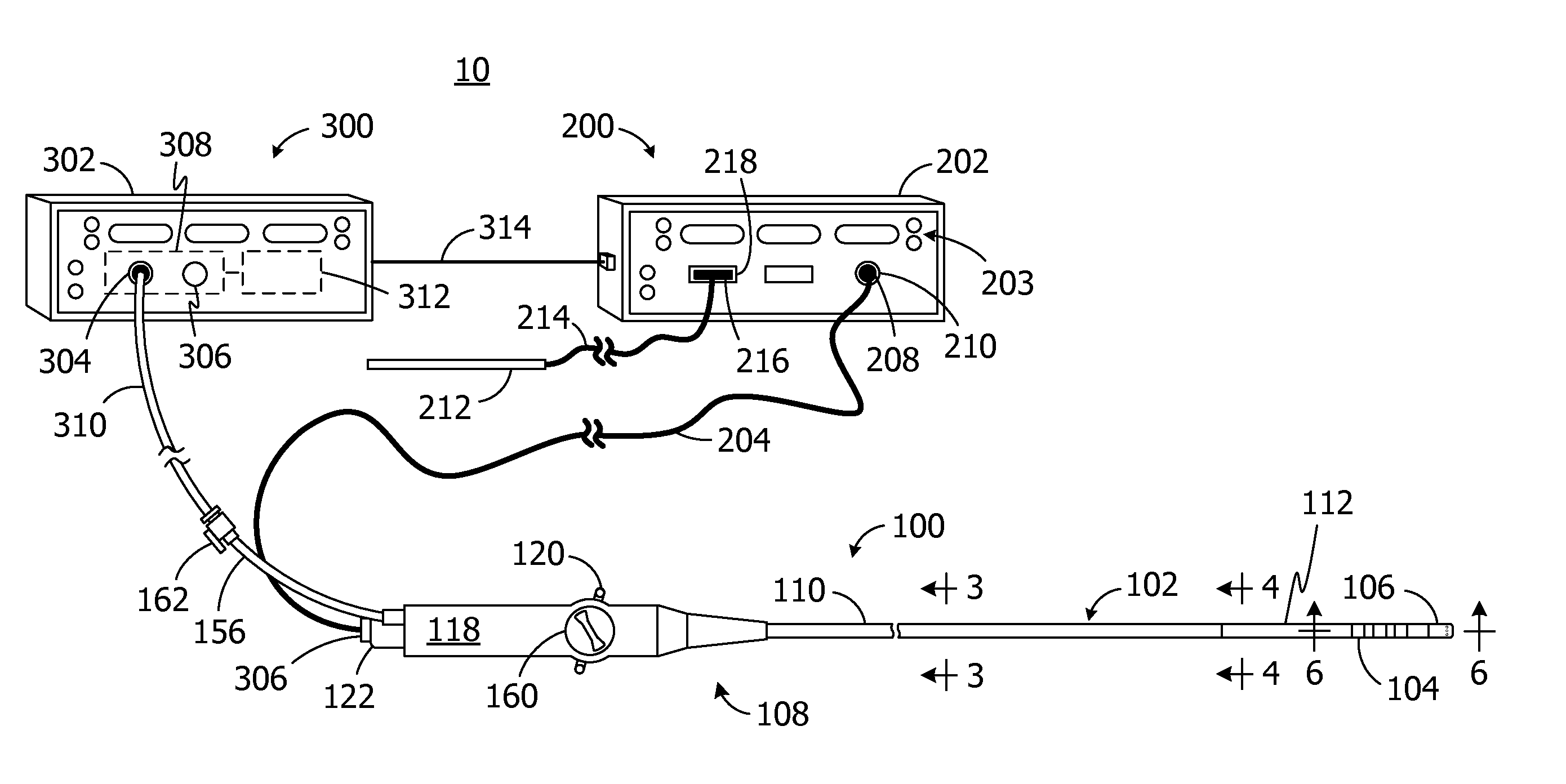

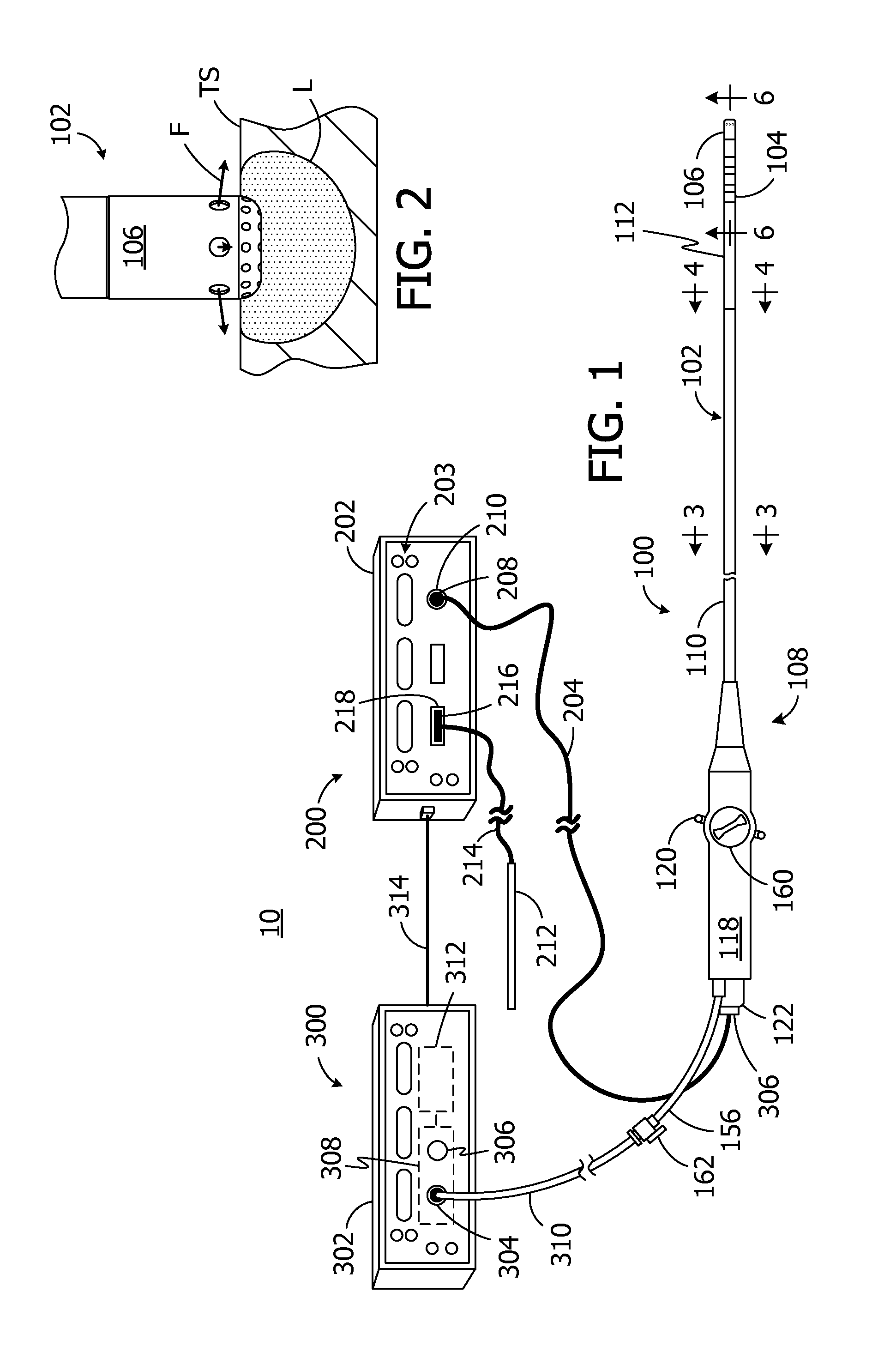

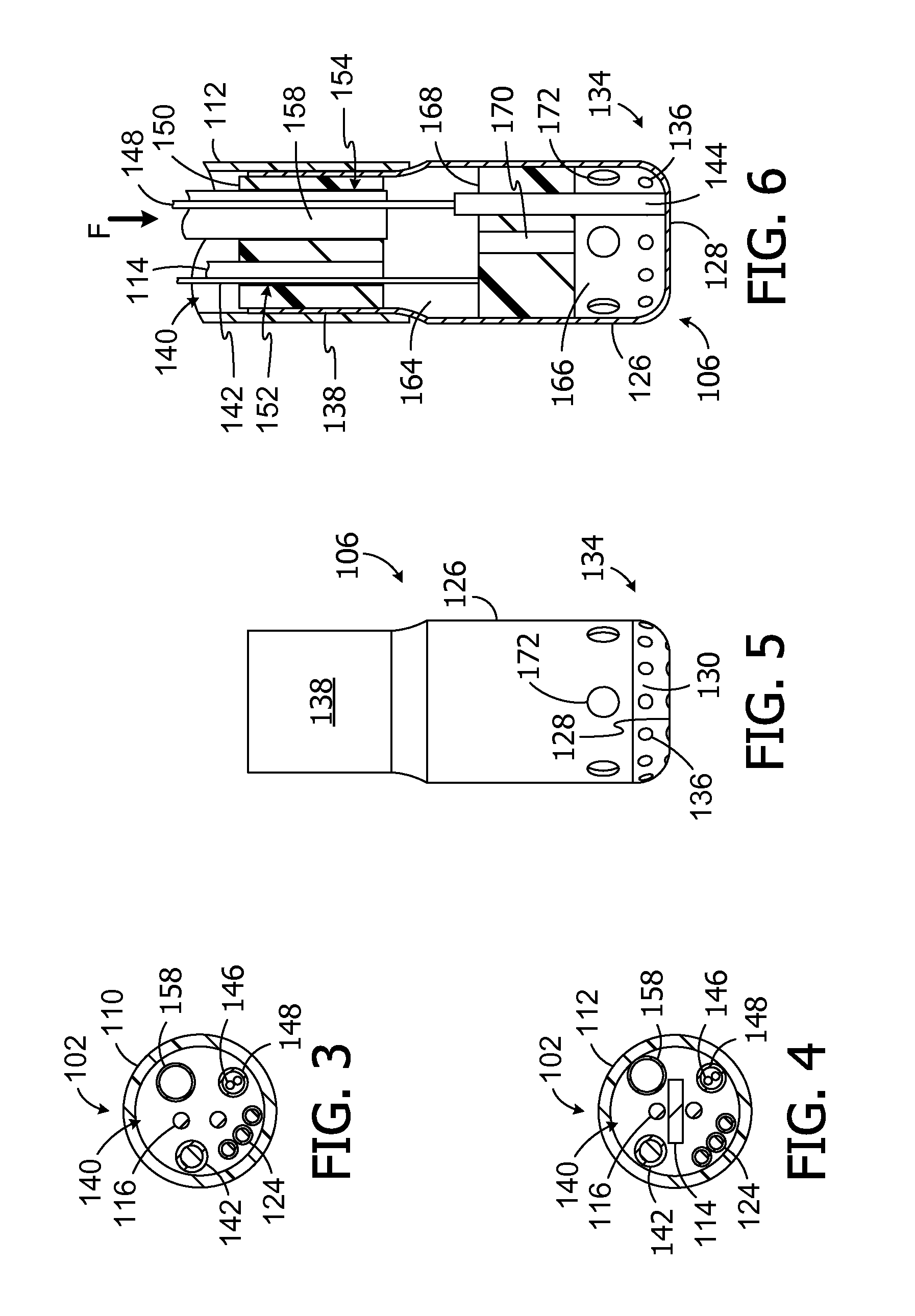

Apparatus and methods for supplying fluid to an electrophysiology apparatus

InactiveUS8702693B2Lower the volumeReduce power supplySurgical instruments for heatingSuction devicesElectrophysiologyBiomedical engineering

Owner:BOSTON SCI SCIMED INC

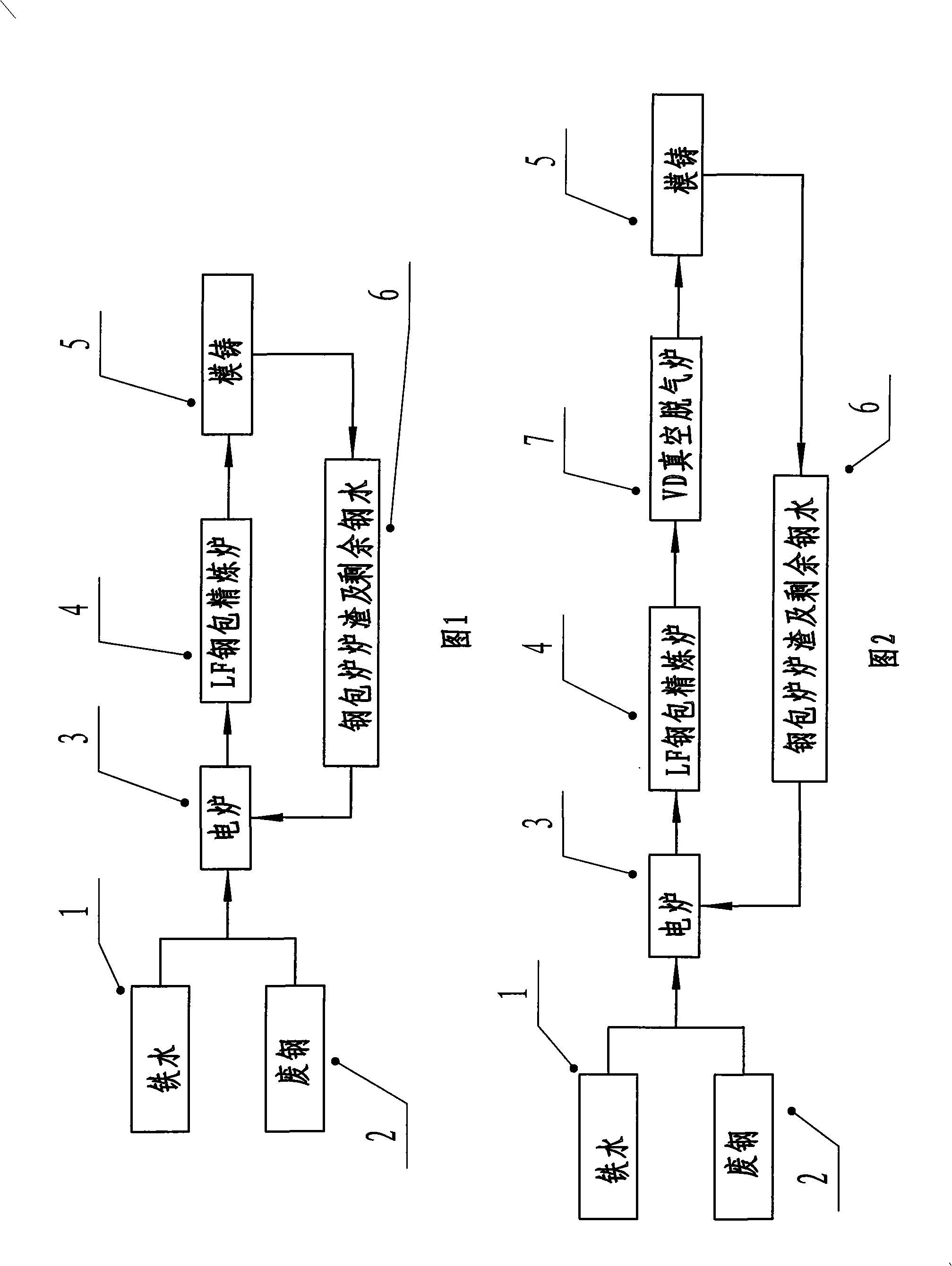

Utilization method for steel scoria

InactiveCN101403021ARealize hot recyclingReduce pollutionElectric furnaceElectric arc furnaceSmelting process

The invention relates to an utilization method of steel slag, which includes the following steps: slagging materials are added into an LF ladle refining furnace for slagging and refining and 20kg to 50kg / t of the slagging materials are added into each ton of molten steel; then in the moulding process, the slags of the ladle furnace and remanent molten steel after moulding are returned to an electric furnace for smelting; the slagging materials are added into the electric furnace and 50kg to 70kg / t of the slagging materials are added into one ton of the molten steel; in the smelting process of the electric furnace, the adding amount of the slagging material lime and the power supply volume of the electric furnace are decreased; as for steel grades which need to be deaerated, after the LF ladle refining furnace is refined and slags are made after the slagging materials are added, the molten steel is sent to a VD vacuum degassing furnace for deaeration; then moulding is carried out; and the slags of the ladle furnace and remanent molten steel after moulding are returned to the electric furnace for smelting. The utilization method of the steel slag is lower in cost and can avoid sulfur enrichment in the ladle refining process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

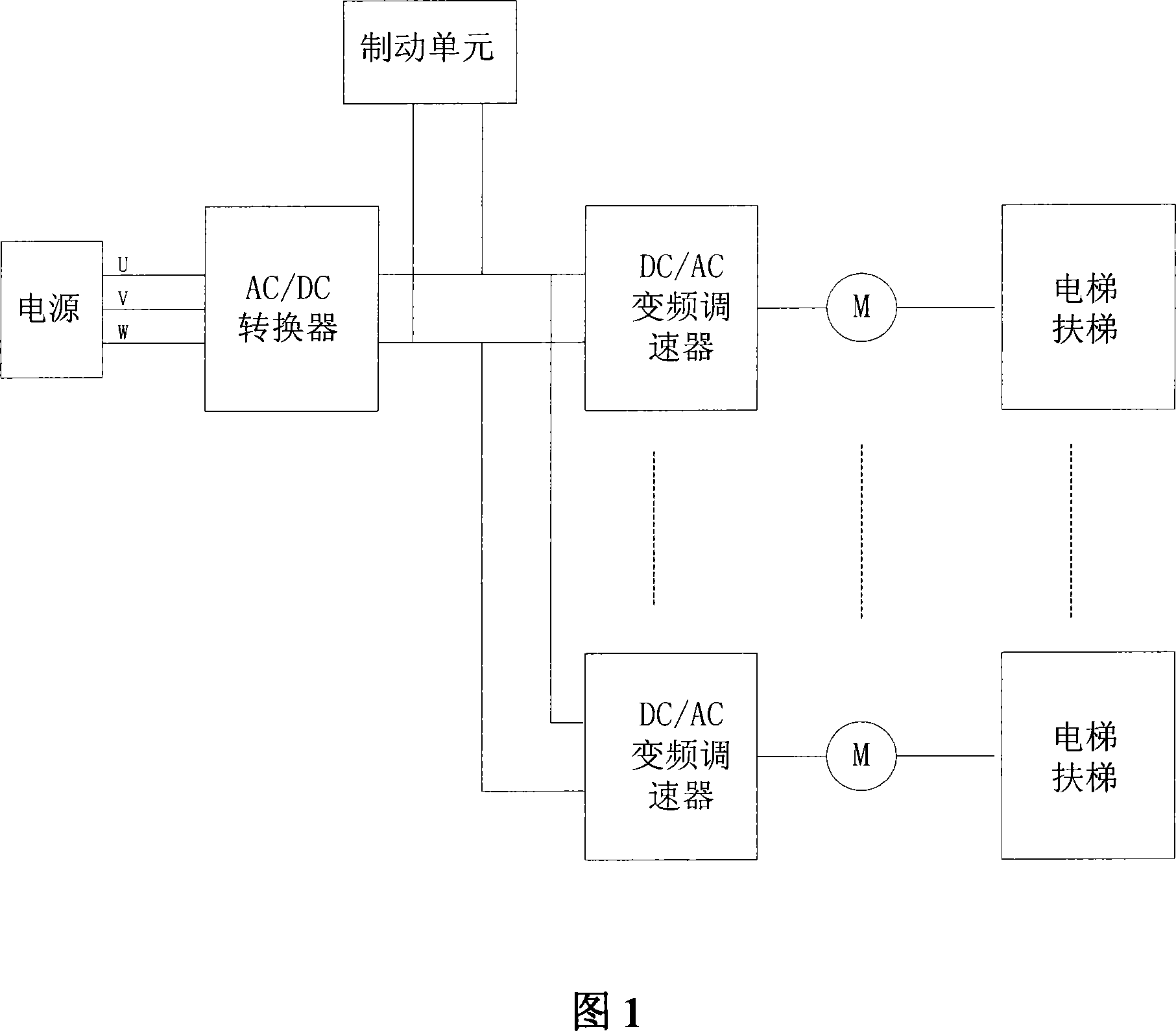

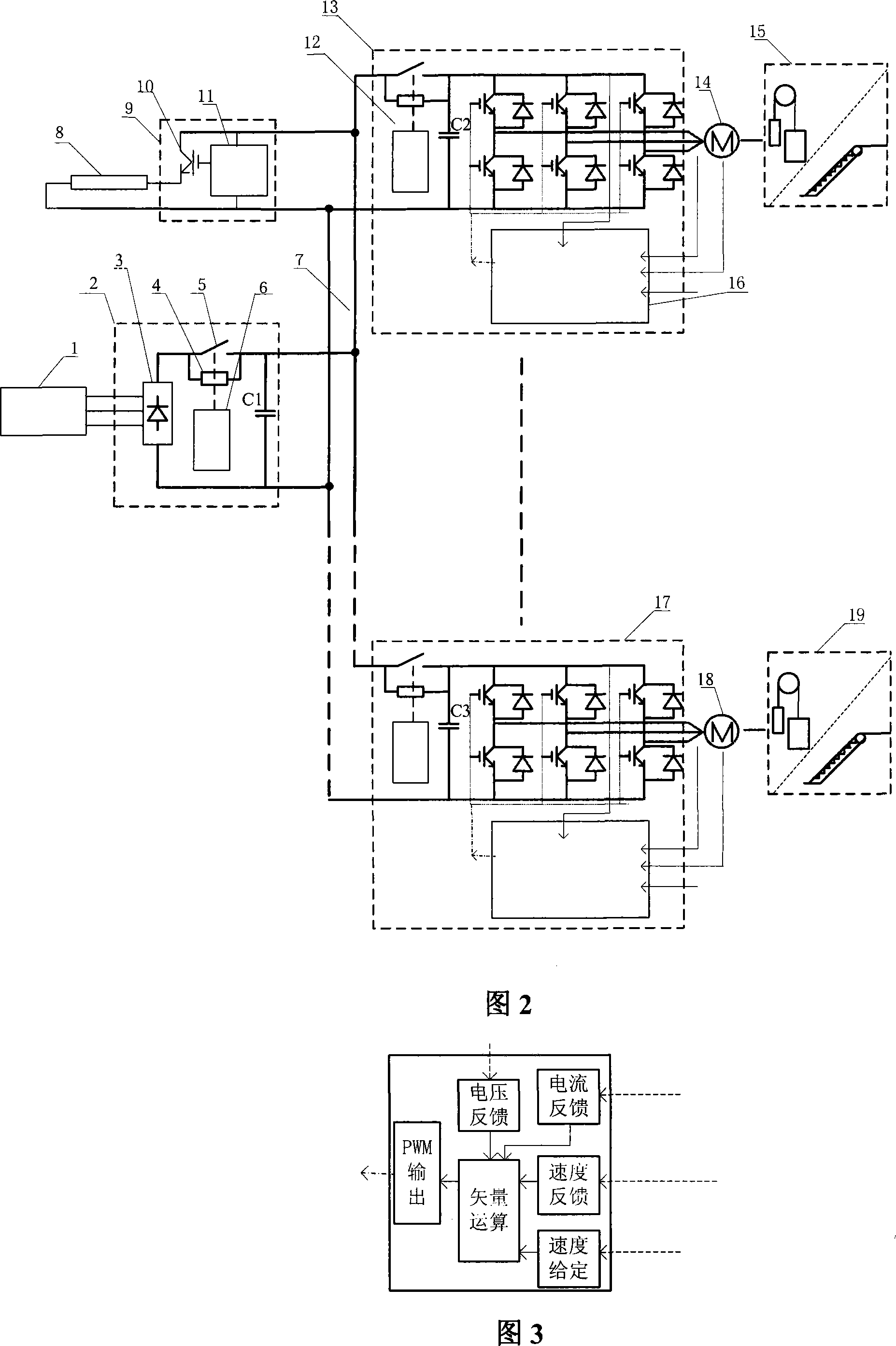

Elevator staircase group frequency conversion drive united power supply energy-saving operation method and apparatus

InactiveCN101159425AImprove energy savingMeet the requirementsAC motor controlConversion with intermediate conversion to dcFrequency conversionPower grid

A method and mechanism for unified power supply and energy-saving operation of variable-frequency drive for escalator group adopts one AC / DC transducer in parallel connection with a braking unit to provide DC power source to multiple DC / AC variable-frequency speed regulators and motors in the group that control all elevators and escalators; therefore forming a channel for energy exchange among various drive units in the group to provide electric energy in the drive units in power-generating operation in the group to other drive units that are in the state of electrically-driven operation. The invention effectively solves the problems in prior art such as energy waste and liability for power grid to contamination. The operating method has a reasonable design and simple structure with safe operation. Compared to operating methods and devices of its kind, the operating method enables the electric energy fed back by the downward escalators to be utilized by the upward escalators, thus reducing the power supply of the electric network, achieving evident energy saving effects, and meanwhile ensuring stable operation of the electric network and reducing the manufacture cost of the device.

Owner:王武 +2

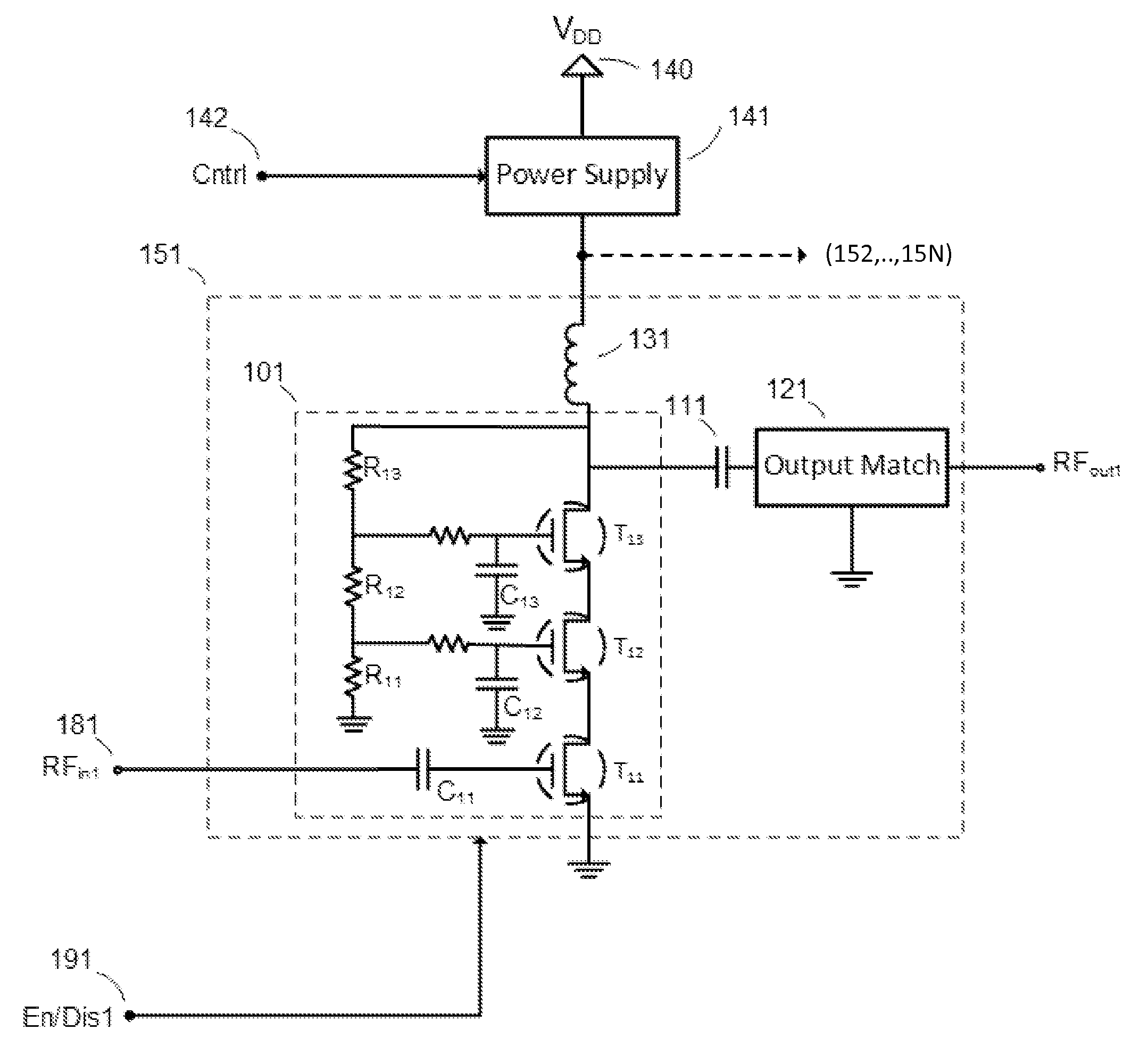

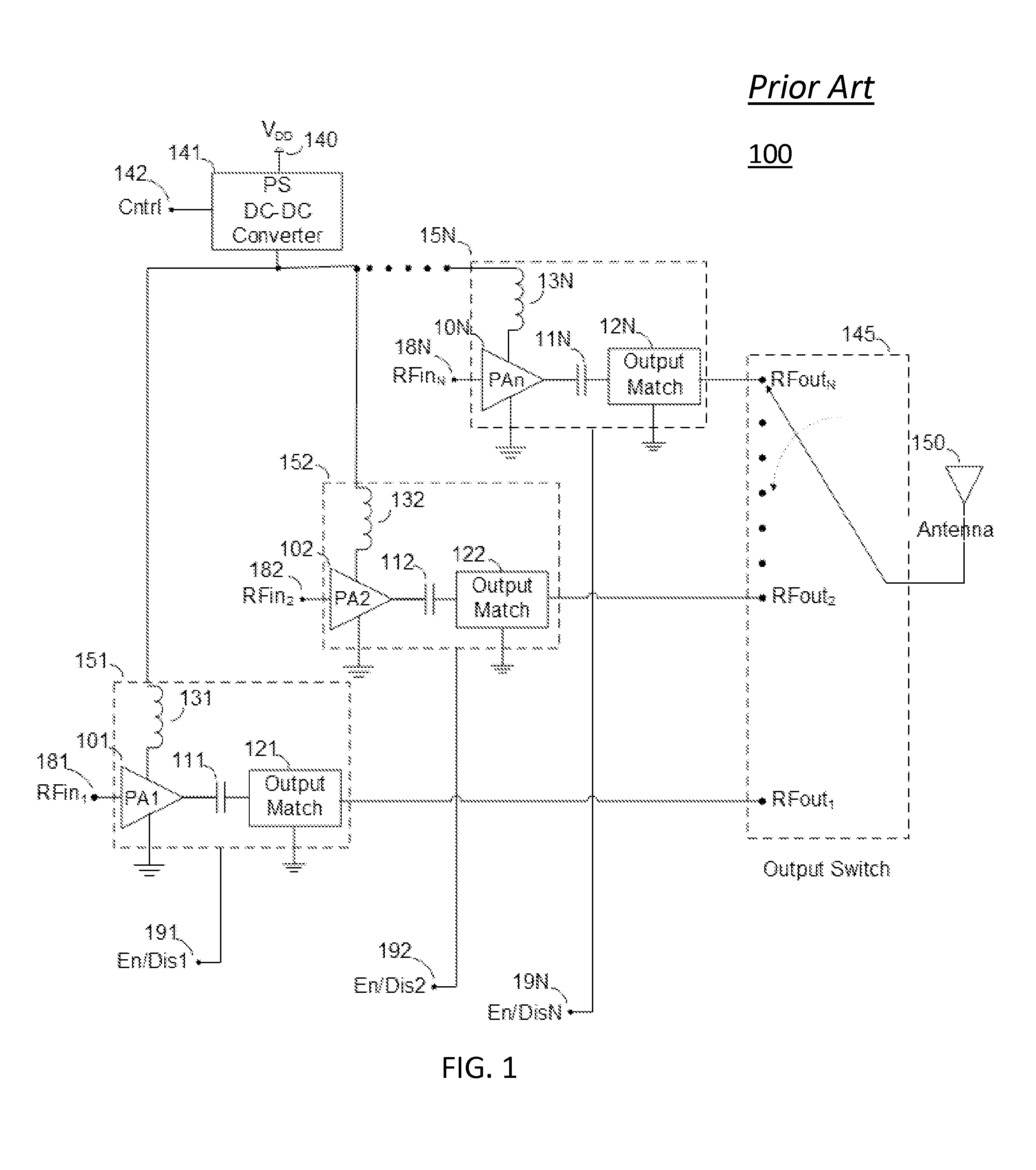

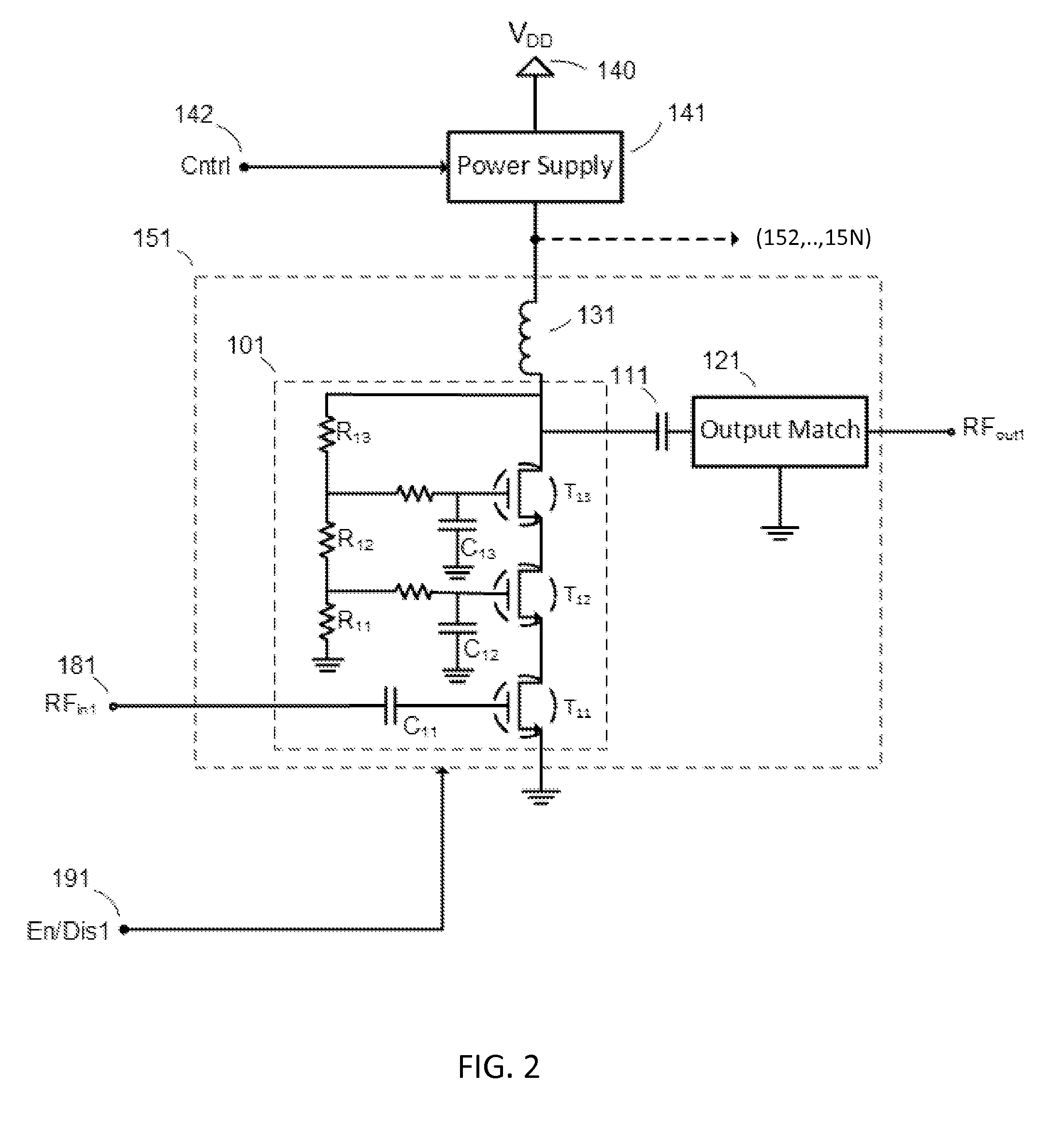

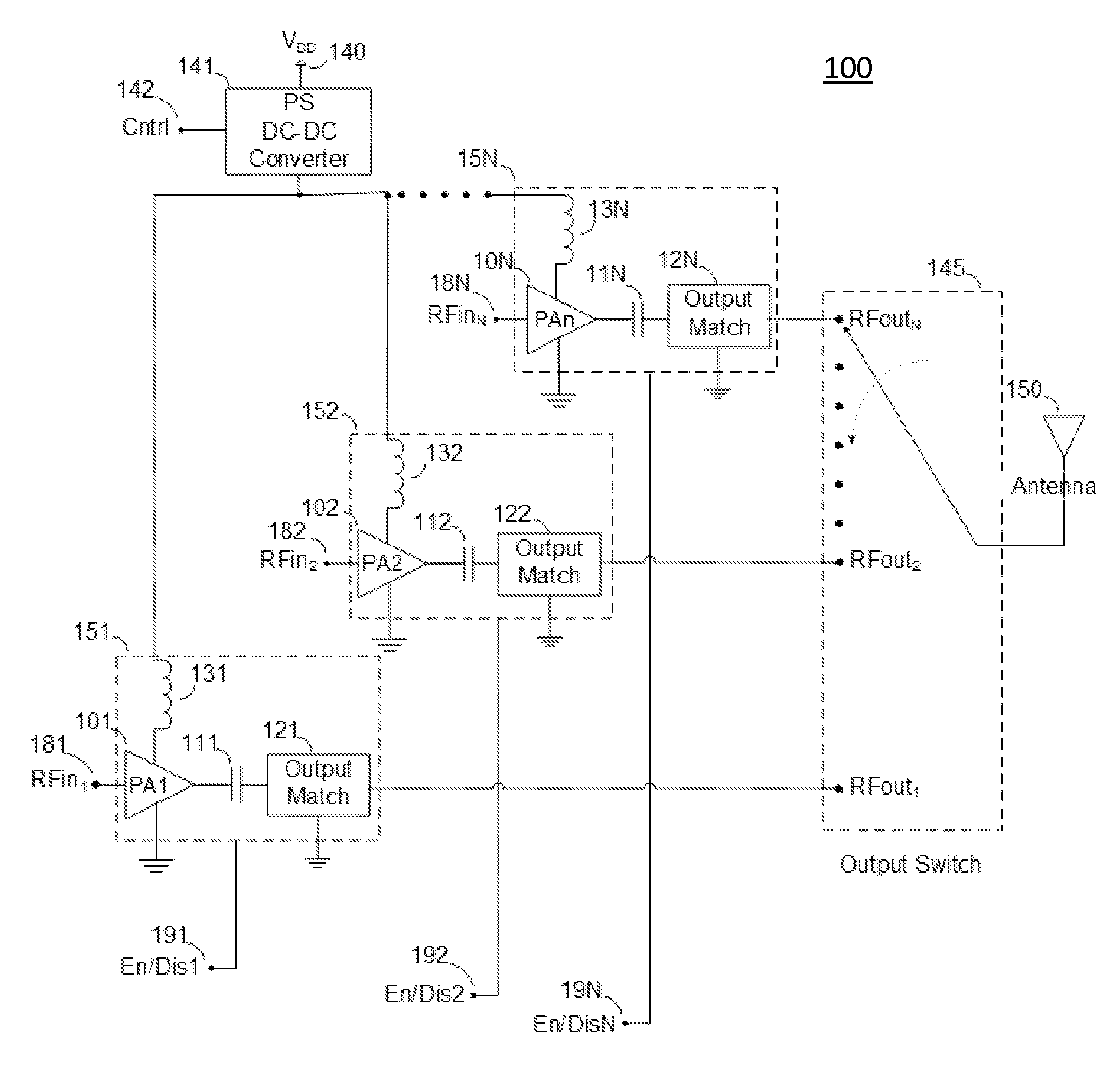

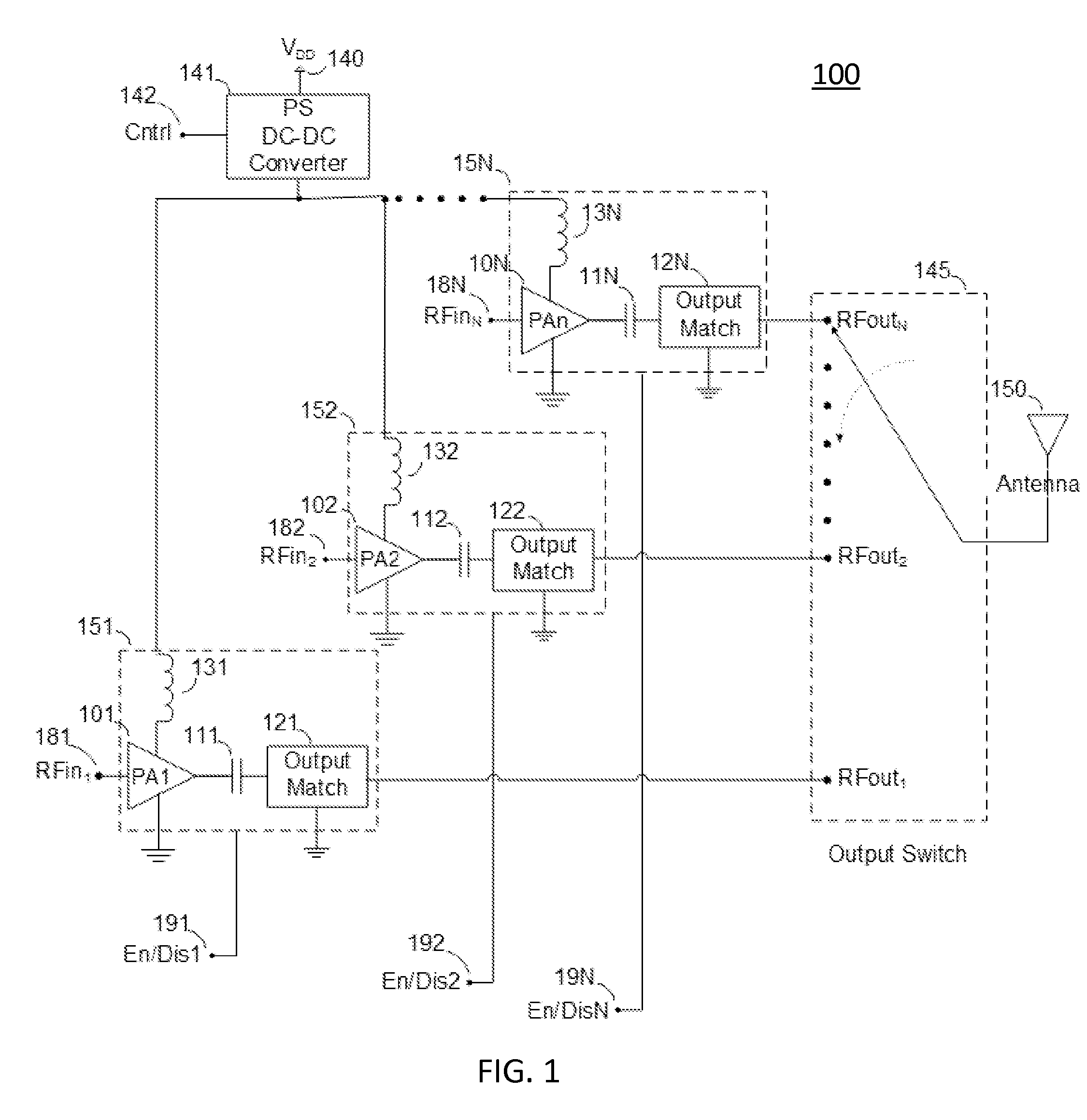

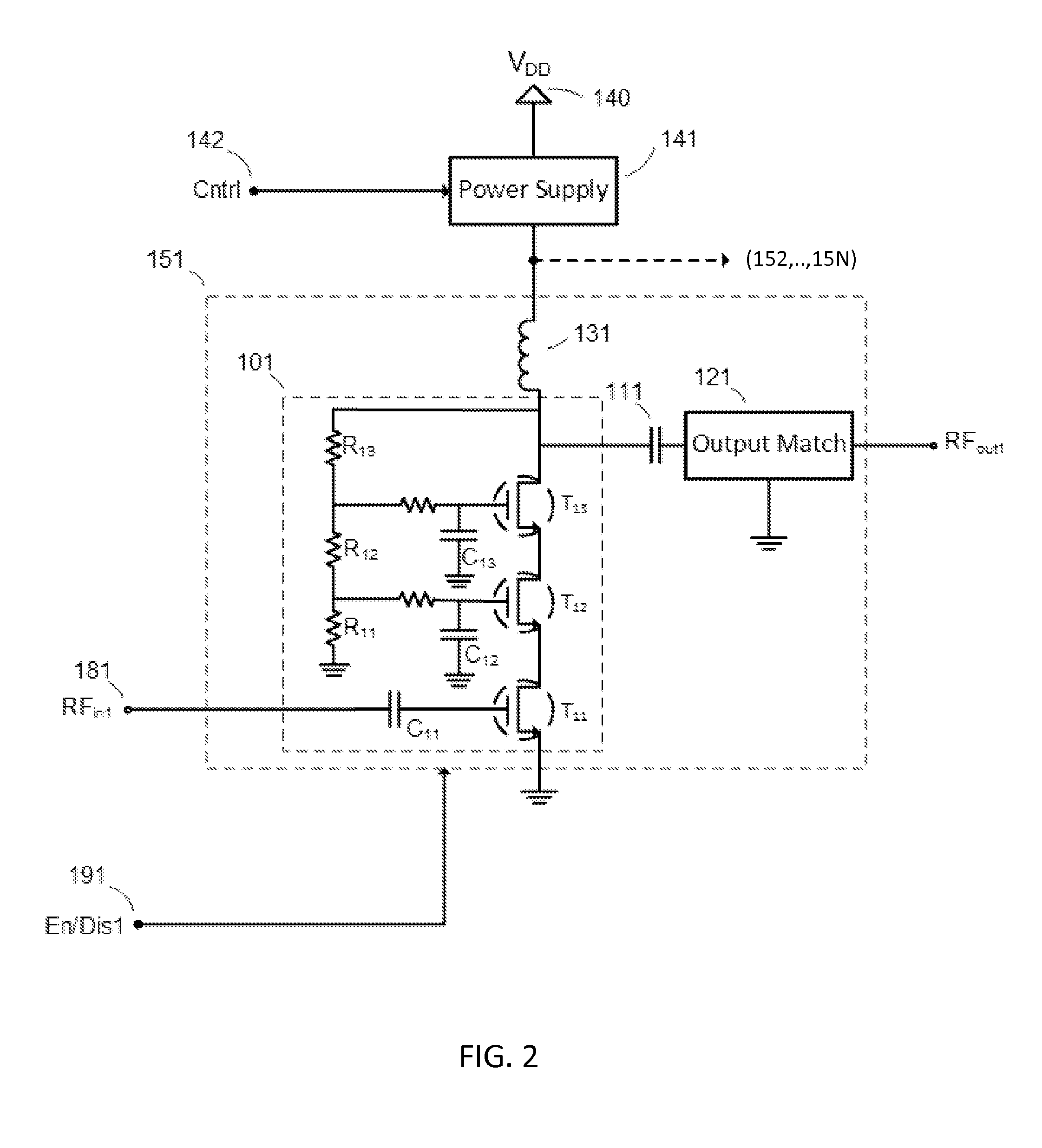

Load compensation in RF amplifiers

ActiveUS9160292B2Reduce power supplyReduce load effectHigh frequency amplifiersPower amplifiersRF power amplifierParasitic load

Methods and systems for reducing parasitic loading on a power supply output in RF amplifier arrangements used in multiband and / or multitude RF circuits are presented. Such RF circuits can comprise a plurality of RF amplifiers of which only one is activated for a given desired transmission mode and / or band.

Owner:PSEMI CORP

Load Compensation in RF Amplifiers

ActiveUS20150097624A1Reduce load effectReduce power supplyHigh frequency amplifiersPower amplifiersTransfer modeEngineering

Methods and systems for reducing parasitic loading on a power supply output in RF amplifier arrangements used in multiband and / or multitude RF circuits are presented. Such RF circuits can comprise a plurality of RF amplifiers of which only one is activated for a given desired transmission mode and / or band.

Owner:PSEMI CORP

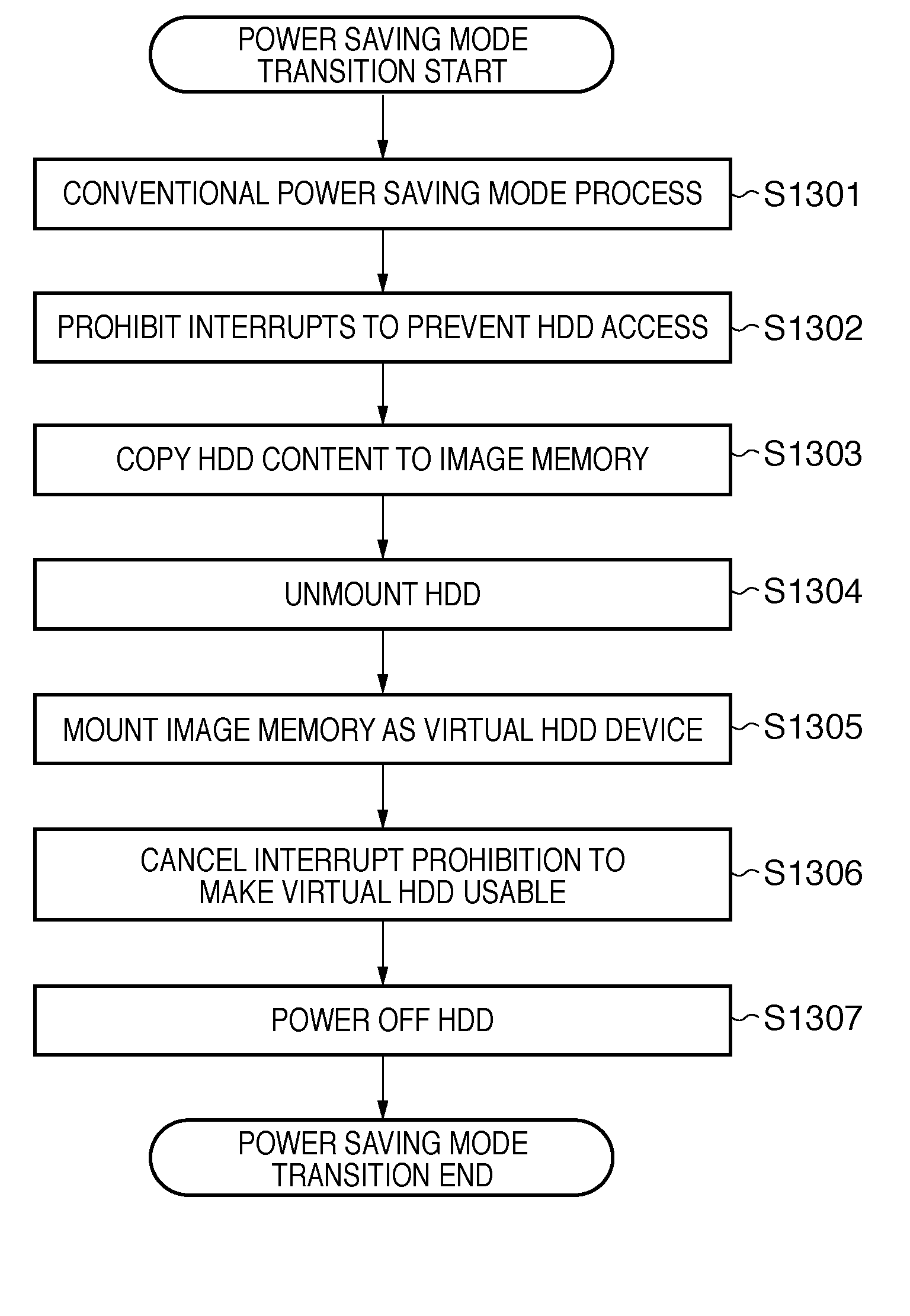

Information processing apparatus and control method thereof

InactiveUS20090235102A1Reduce power supplyEnergy efficient ICTVolume/mass flow measurementPower savingVolatile memory

An information processing apparatus used to reduce power supply to nonvolatile memory when in power saving mode. To accomplish this, the information processing apparatus stores data in the nonvolatile memory that can be used in power saving mode to a volatile memory to which power will still be supplied while in power saving mode. Further, the information processing apparatus enables the operating system to recognize the storage area in which the data is stored as a replacement for the nonvolatile memory.

Owner:CANON KK

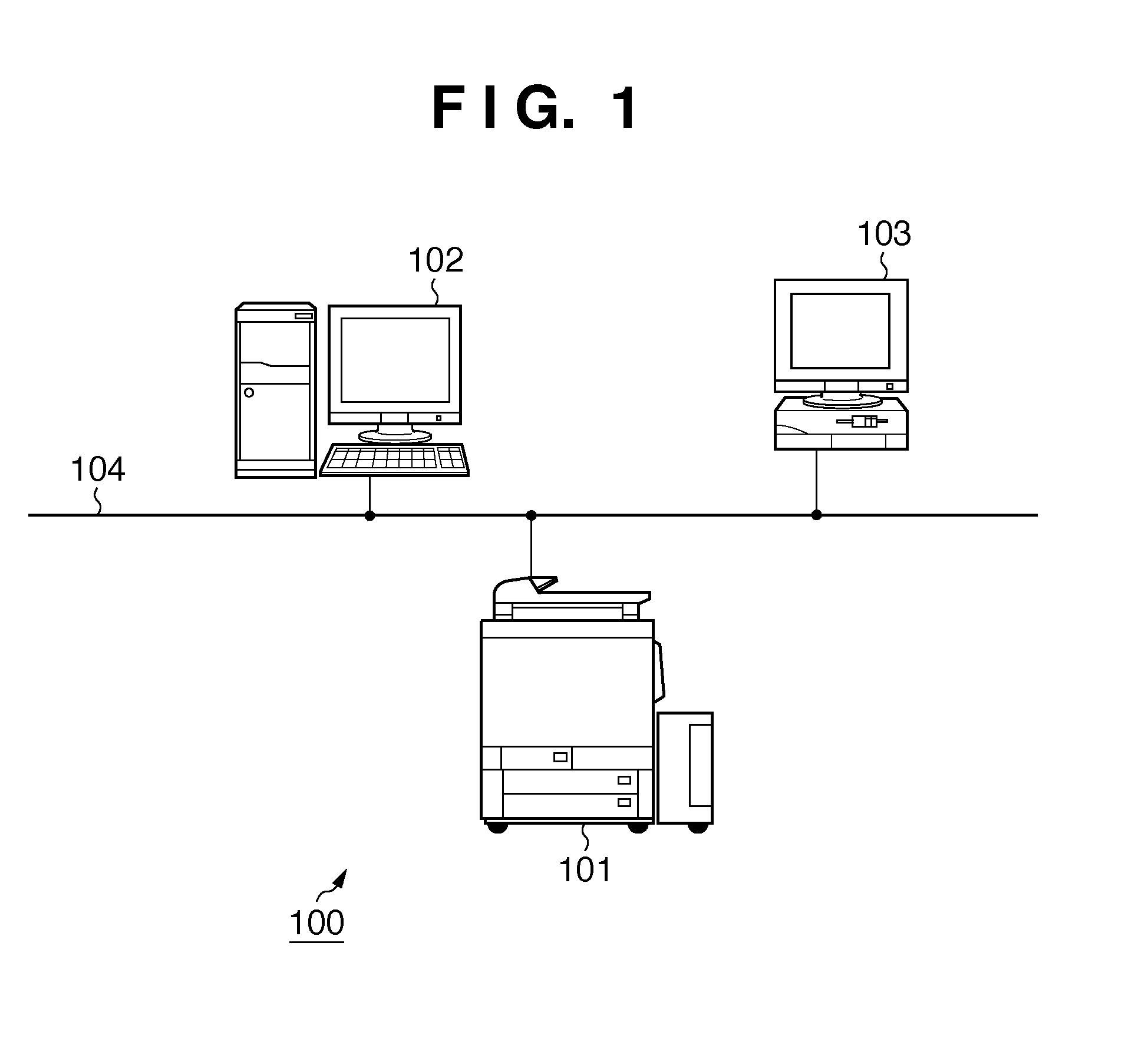

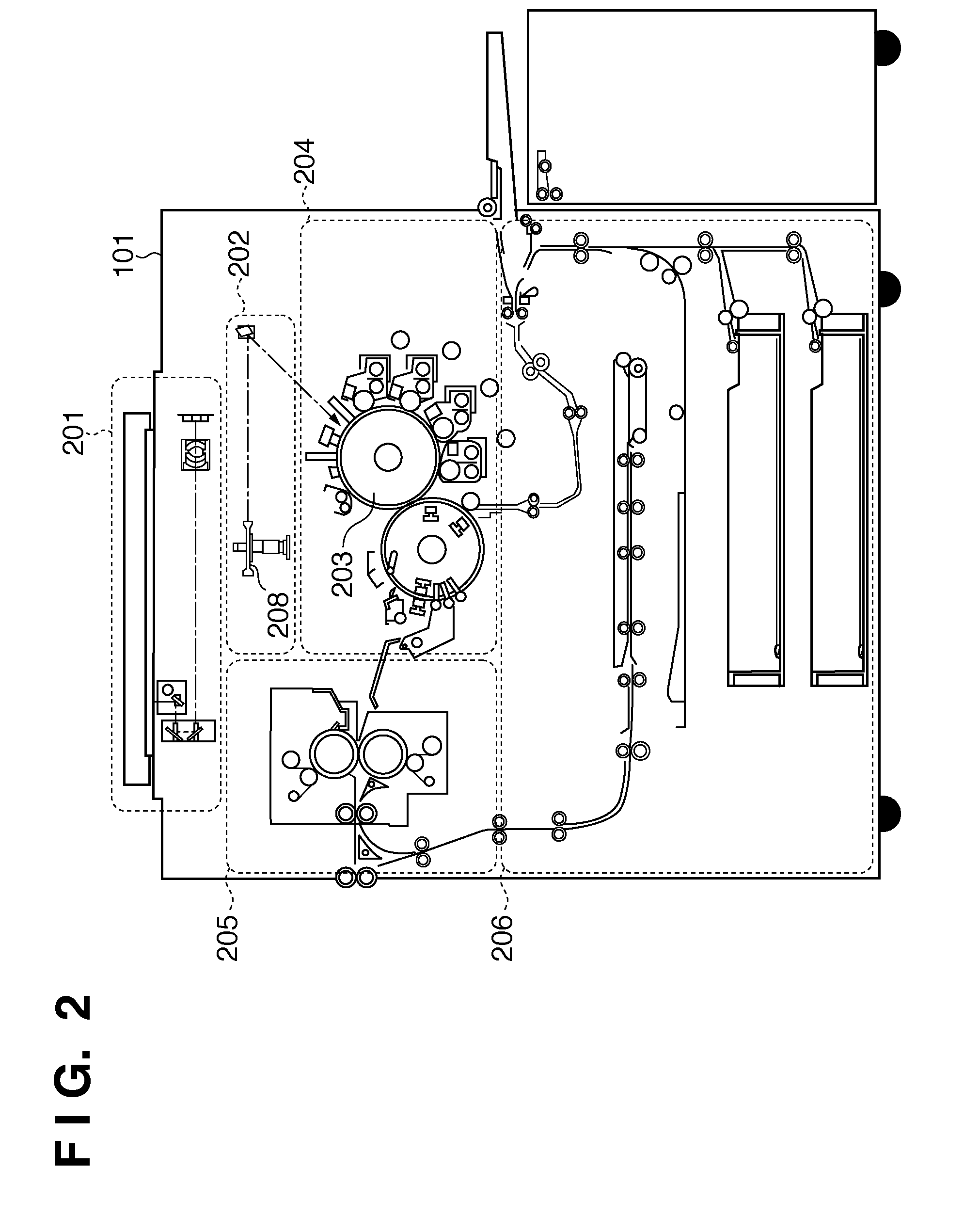

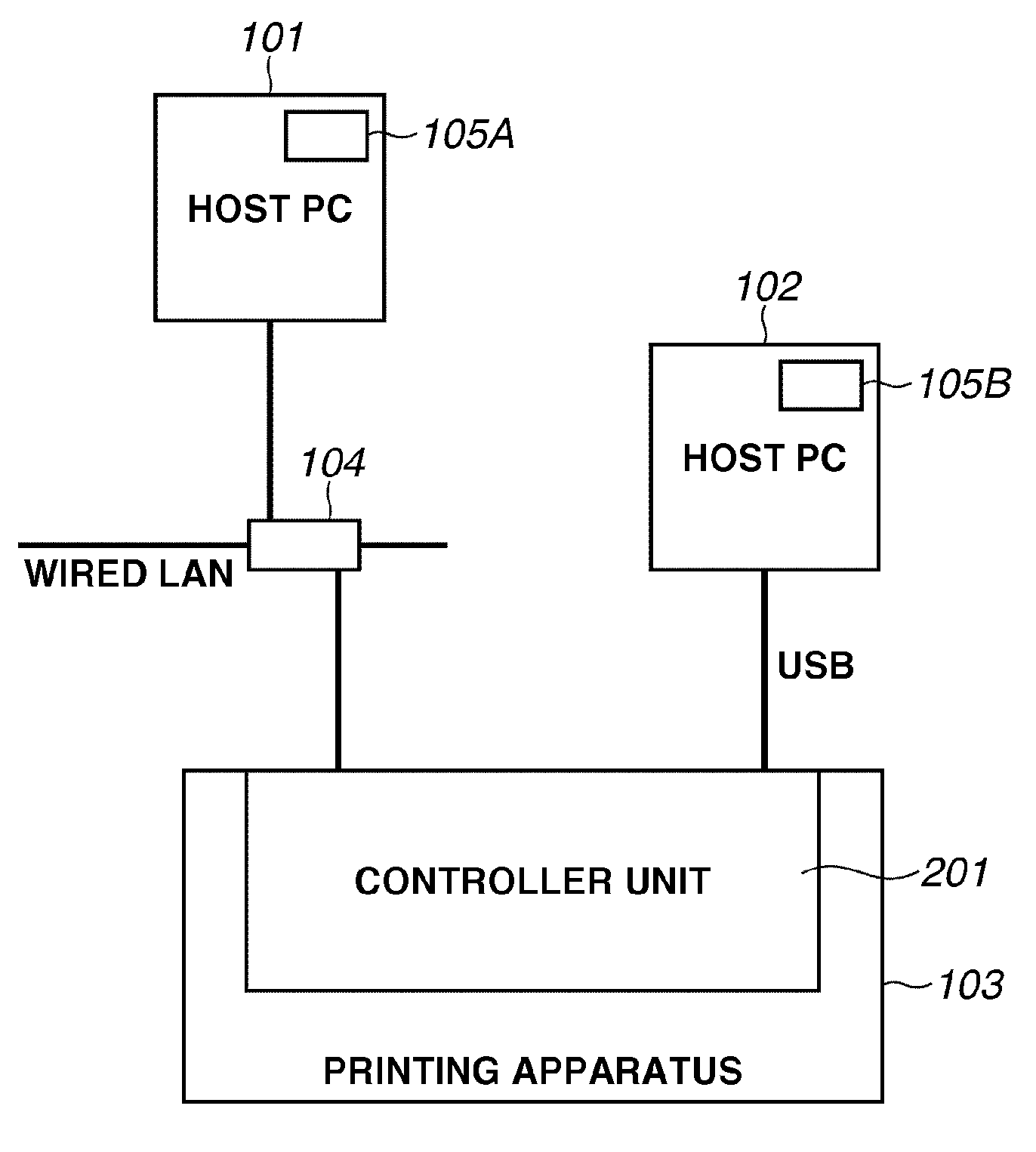

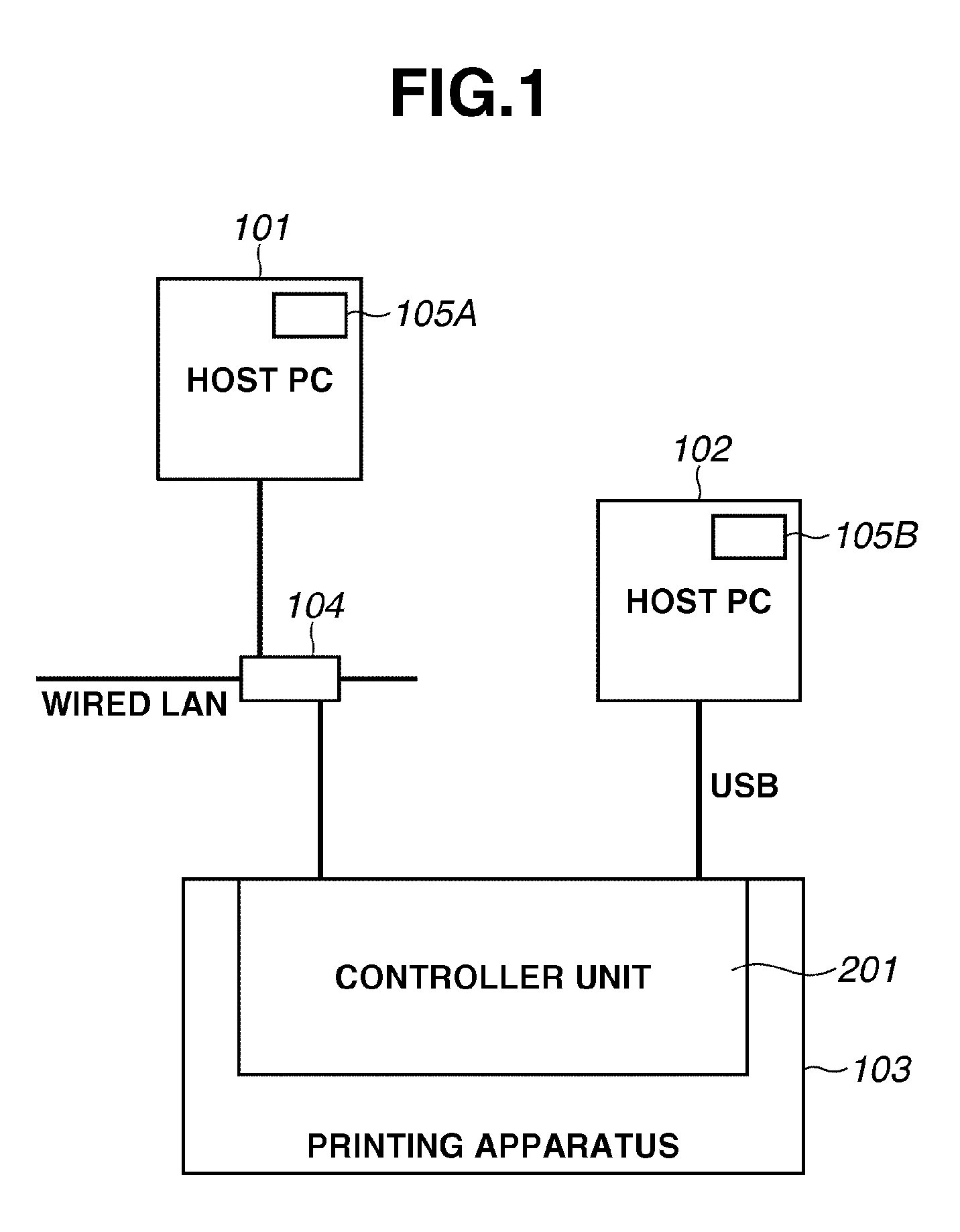

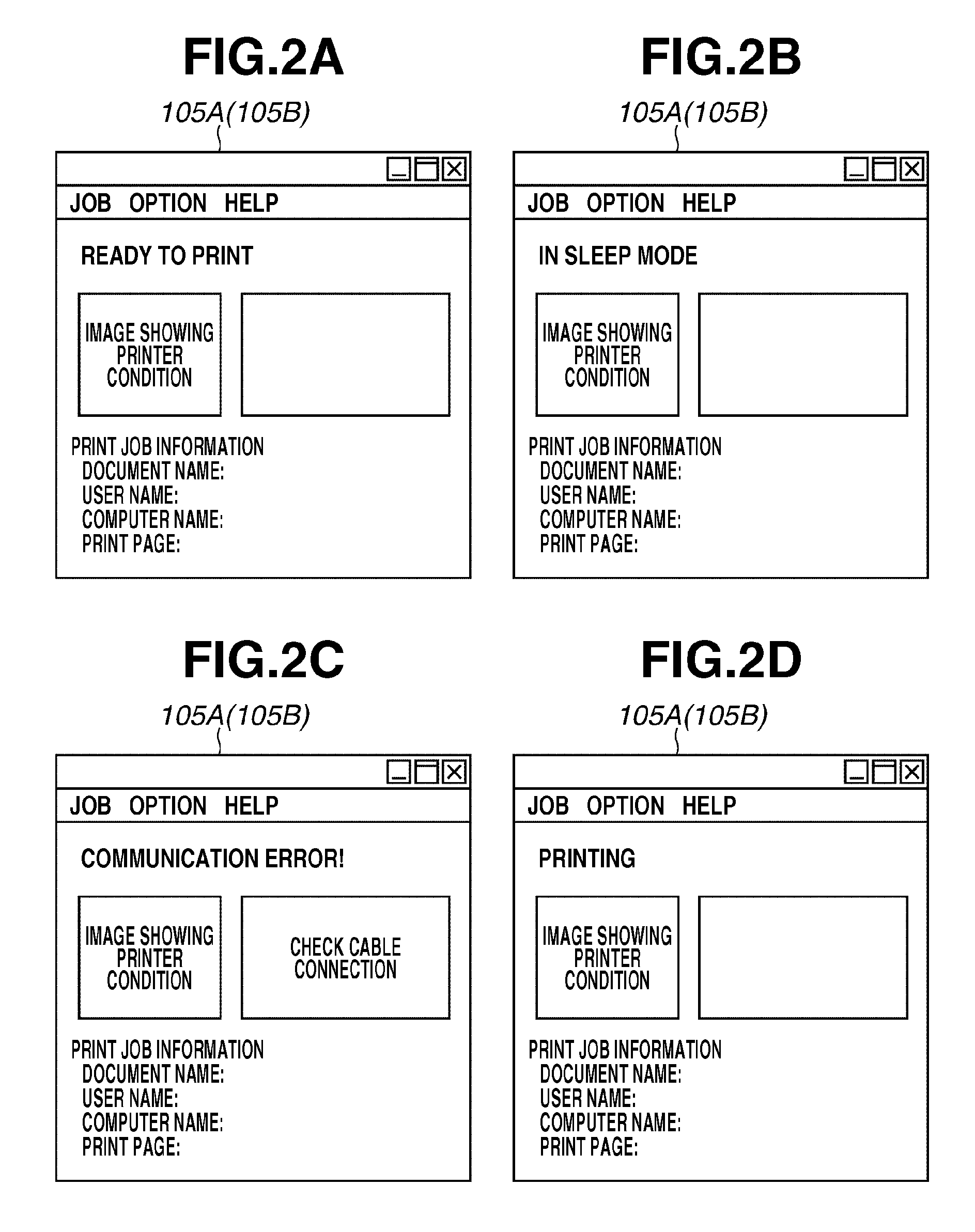

Image forming apparatus, information processing apparatus, control method for image forming apparatus, and storage medium

ActiveUS20120287467A1Reduce power supplyEnergy efficient ICTDigital data processing detailsInformation processingImage formation

An image forming apparatus communicates with a plurality of data processing apparatuses via a plurality of interfaces. The image forming apparatus includes a determination unit configured to determine a communication state with the plurality of interfaces, and a control unit configured to perform control to switch between a first sleep mode in which power supplied to any one of the plurality of interfaces is turned off and a second sleep mode in which power supplied to the plurality of interfaces is repeatedly turned on and off at predetermined time intervals according to the communication state determined by the determination unit.

Owner:CANON KK

Temperature sensor for power supply

InactiveUS20060098371A1Avoid lightAvoid damageElectric heatingEmergency protective arrangements for automatic disconnectionMicrocontrollerElectrical resistance and conductance

A temperature sensor, such as a thermistor, senses the temperature inside a power source connector, or other portion, of a power supply. This sensed temperature may then be used to determine if the output power should be reduced or switched off in order to avoid overheating of the connector, or other portion of the power supply. Overheating of the power supply may occur, for example, if contact between the connector and a cigarette lighter power receptacle is incomplete. A microcontroller may be used to monitor the temperature sensed by the temperature sensor and reduce or disable the power supply if the temperature is above a threshold temperate. Accordingly, heat damage to the plastic components of the power supply, the cigarette lighter receptacle, may be reduced.

Owner:RRC POWER SOLUTIONS

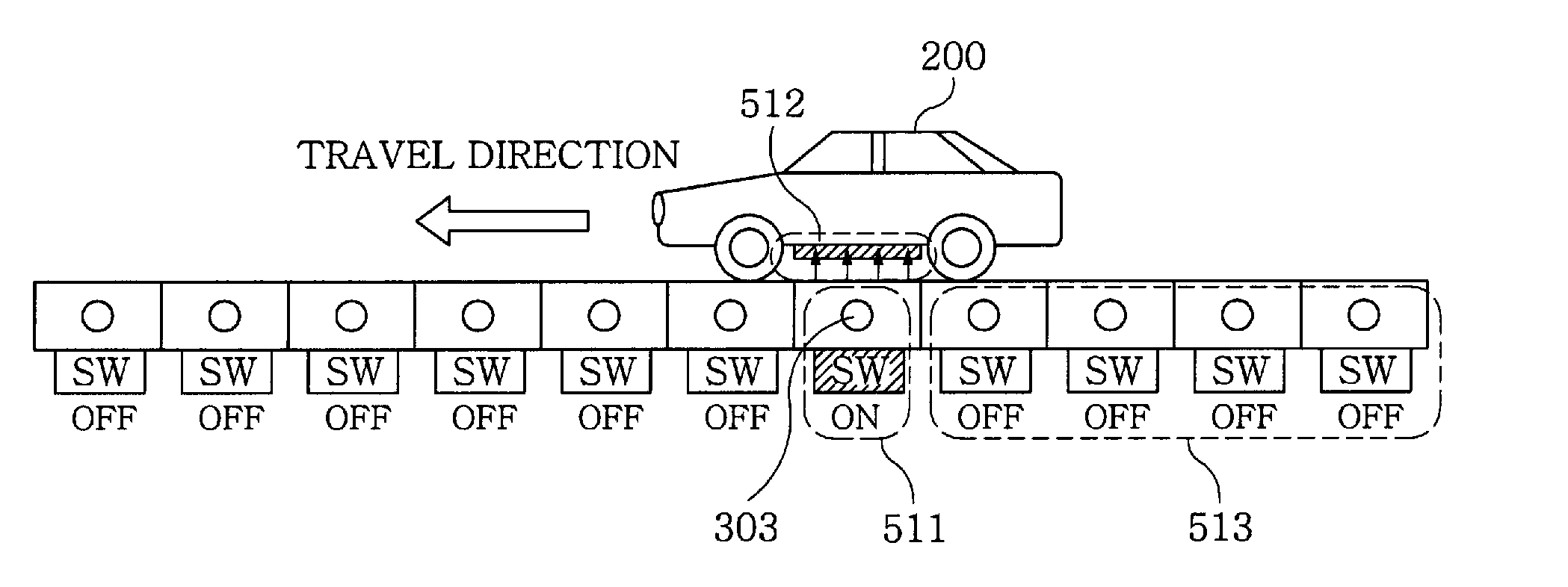

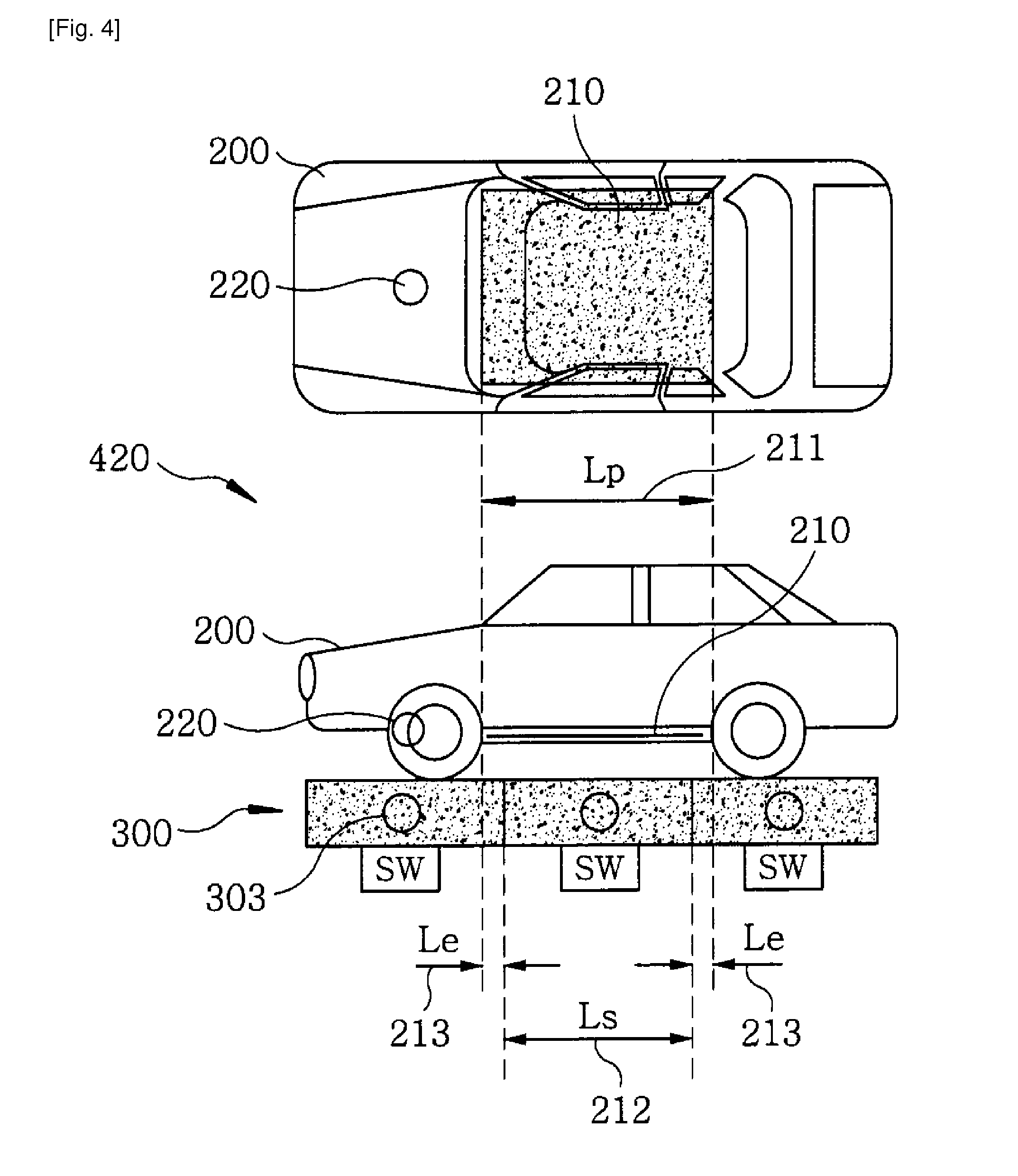

Method and apparatus for transporting power to electric vehicle with segments of power supply road

InactiveUS20130098723A1Reduce power supplyImprove transportation efficiencyPropulsion using dc motorsCharging stationsElectricity deliveryBattery electric vehicle

A power transport apparatus for transporting electric power to an electric vehicle on the road is provided. The apparatus includes a plurality of power supply units provided at a road in a longitudinal direction of the road, one or more of the power supply units simultaneously transporting the electric power to the electric vehicle; and a power line supplying the electric power to the respective power supply units.

Owner:KOREA ADVANCED INST OF SCI & TECH

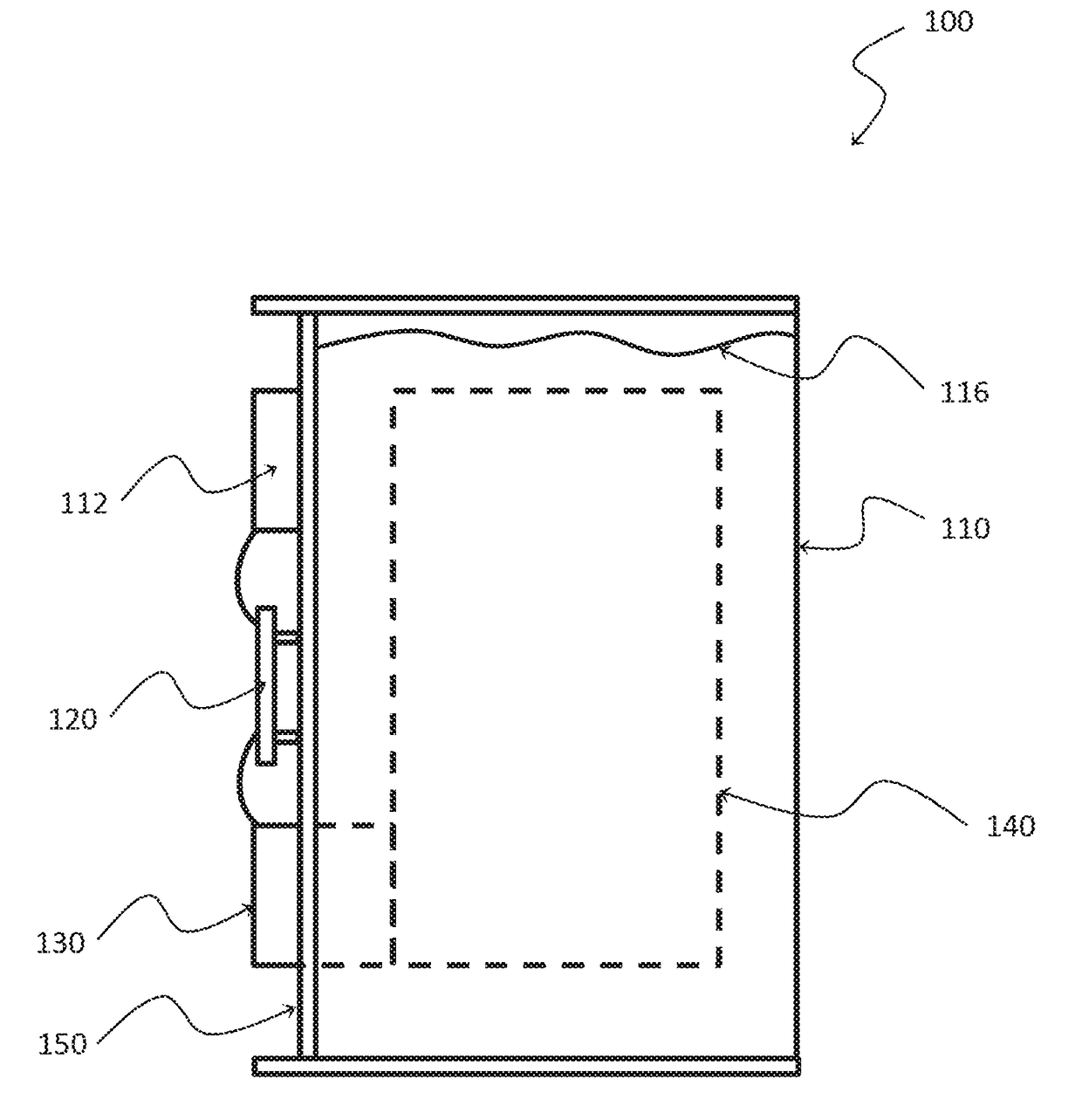

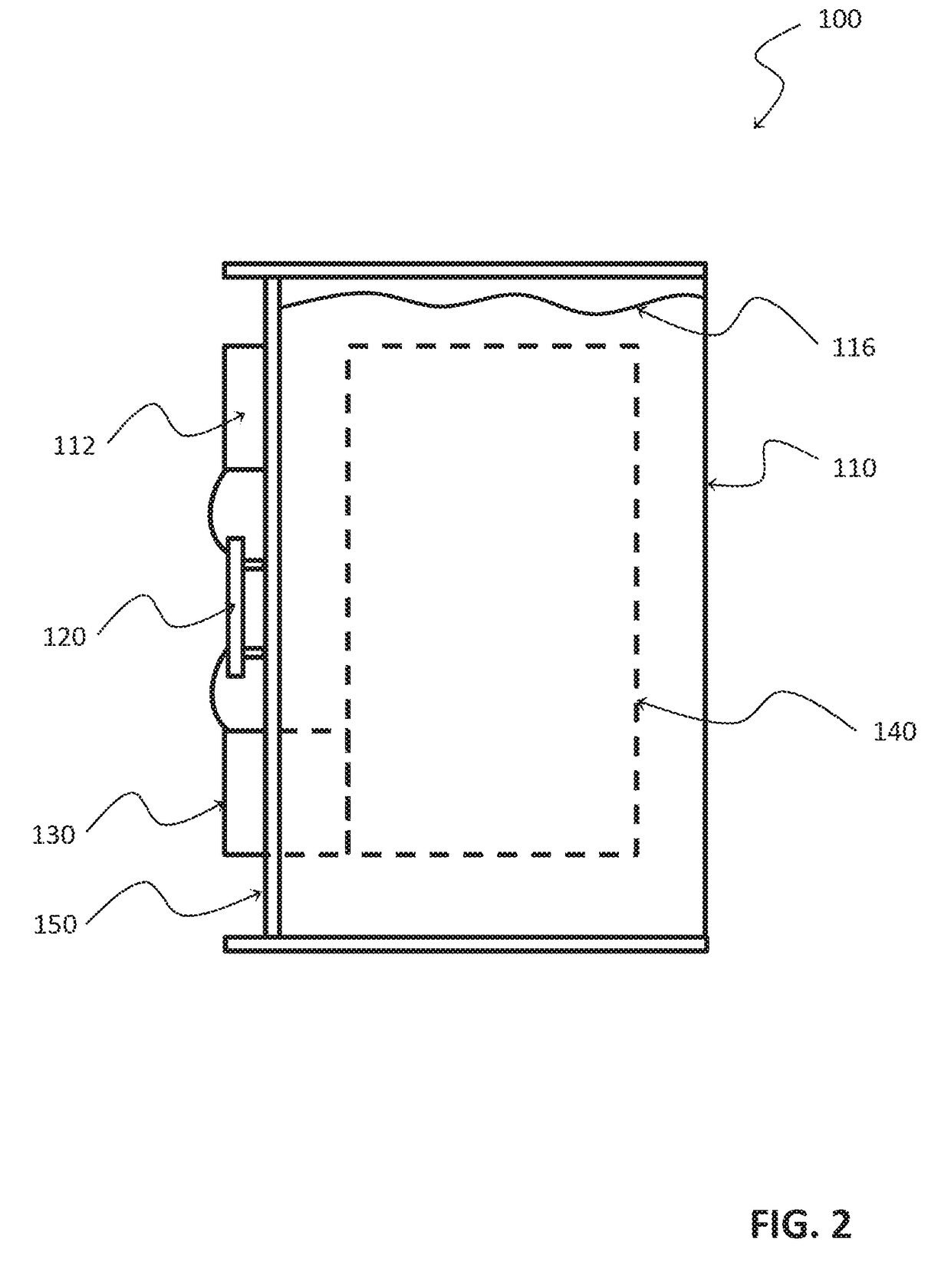

An immersion cooling system

InactiveUS20180288906A1Avoid excessive heatingReduce temperatureServersCooling/ventilation/heating modificationsNuclear engineeringAluminium

A cooling system for cooling of a heat generating electrical component, in particular to reduce the likelihood of overheating of electrical components or chemical breakdown of coolant fluid. The cooling system has a coolant liquid to absorb excess energy from the heat generating electrical component, the coolant liquid having an energy input threshold above which chemical breakdown of the coolant liquid occurs. A cooling module defines a volume containing the coolant liquid, wherein the heat generating electrical component is mounted within the volume and immersed in the coolant liquid. A power input is arranged to supply power into the cooling module to the heat generating electrical component, and a power regulator is provided external to the volume of the cooling module and connected to the power input so as to regulate the power supplied into the cooling module. Cooling systems are also described having coolant liquid comprising dissolved oxygen, having at least one element arranged within the volume comprising aluminium and / or aluminium oxide, and / or having a sealed volume with at least one seal which opens at a predetermined pressure or temperature corresponding to a temperature below the temperature at which the coolant liquid breaks down.

Owner:ICEOTOPE

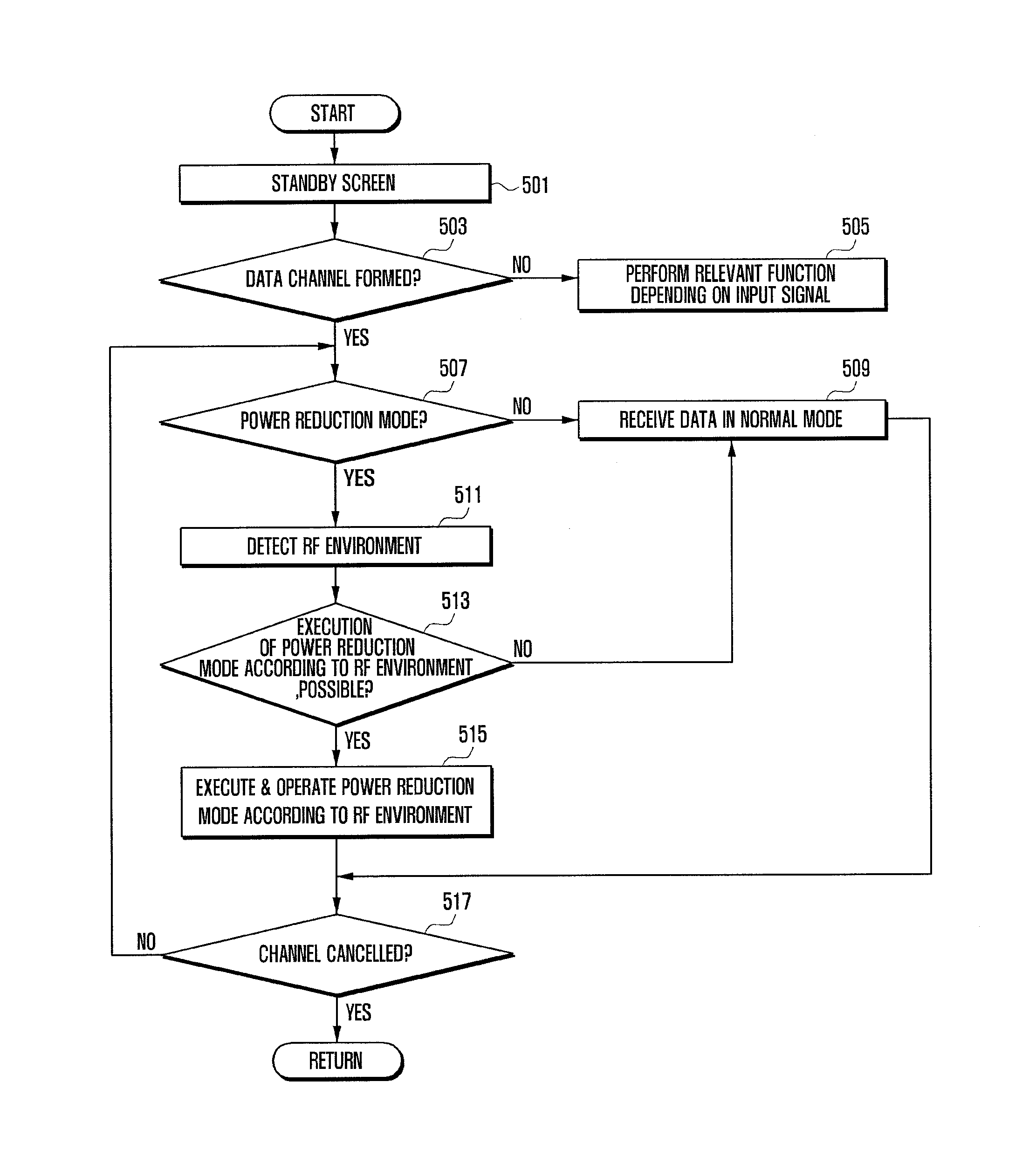

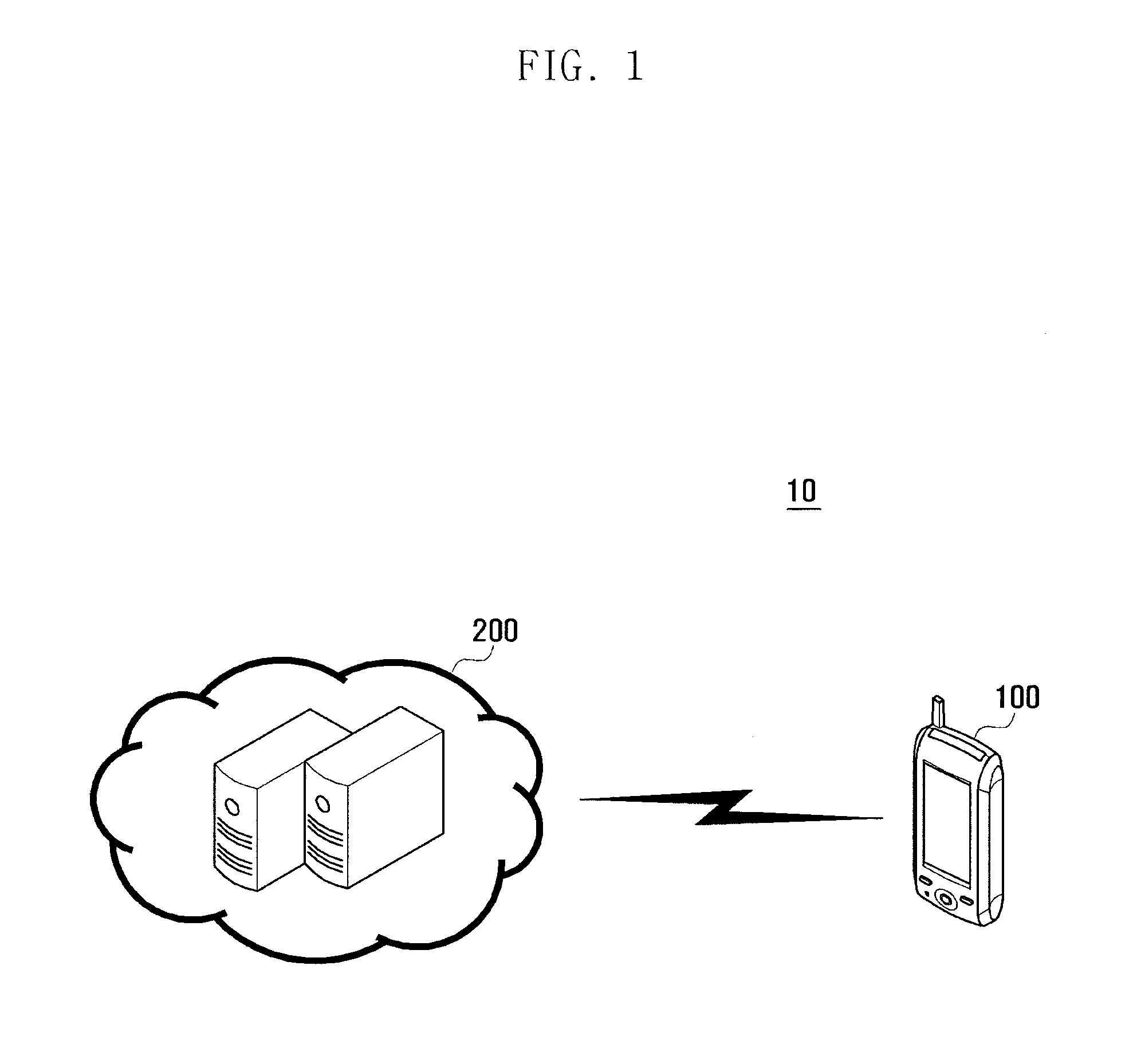

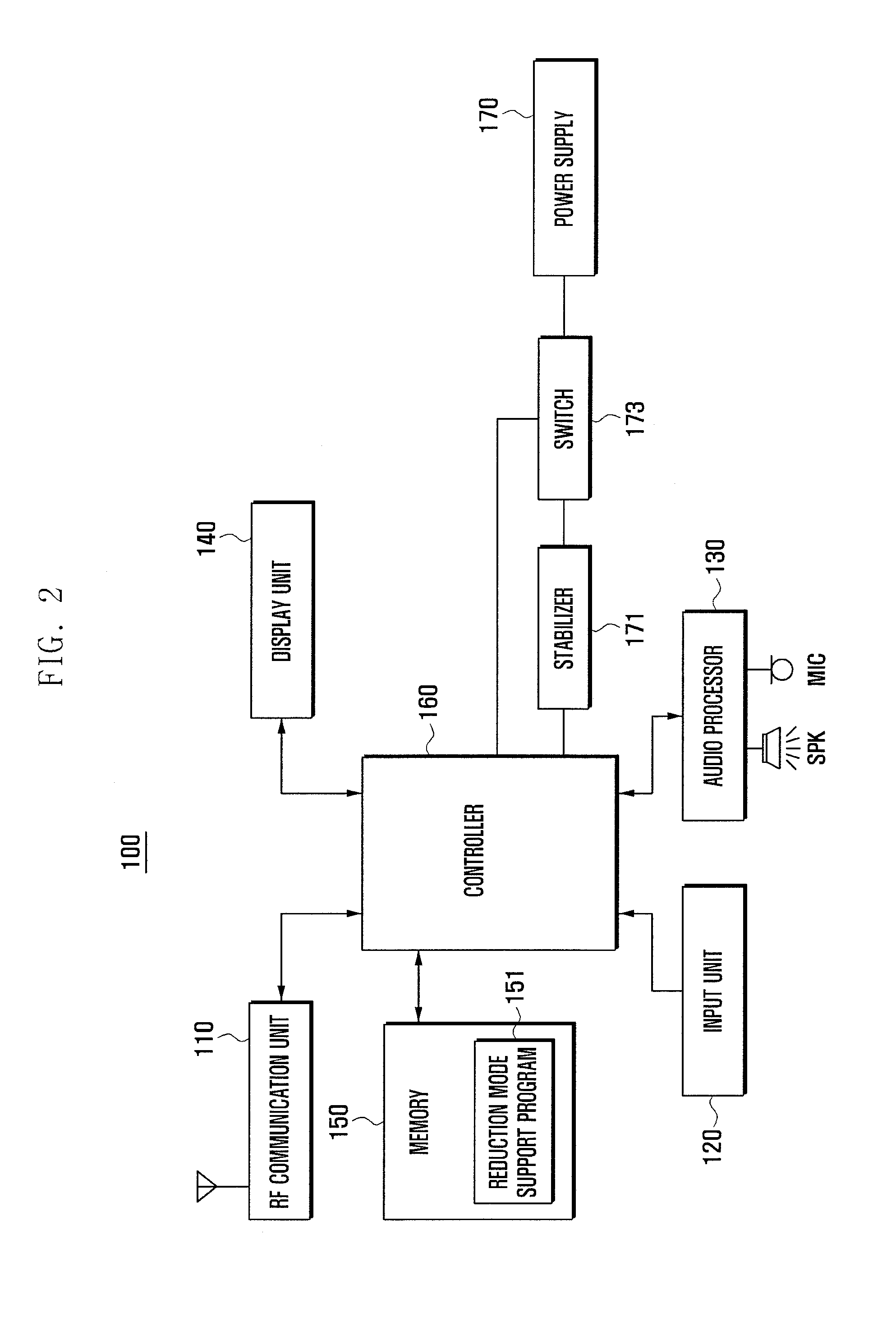

Method for operating portable terminal to reduce power during support of communication service and portable terminal supporting the same

ActiveUS20120258699A1Reduce the required powerReduce power consumptionPower managementEnergy efficient ICTCommunication unitIdle time

A method for operating a portable terminal so as to reduce power consumption during the support of a communication service and a portable terminal supporting the same is provided. The method includes activating a Radio Frequency (RF) communication unit, downloading a part of data of predetermined contents through the RF communication unit, buffering the downloaded part of the data in a buffer so as to output the buffered downloaded part of the data, and executing an idle time for terminating or reducing a power supply of the RF communication unit when the downloading of the part of the data of the predetermined contents is completed.

Owner:SAMSUNG ELECTRONICS CO LTD

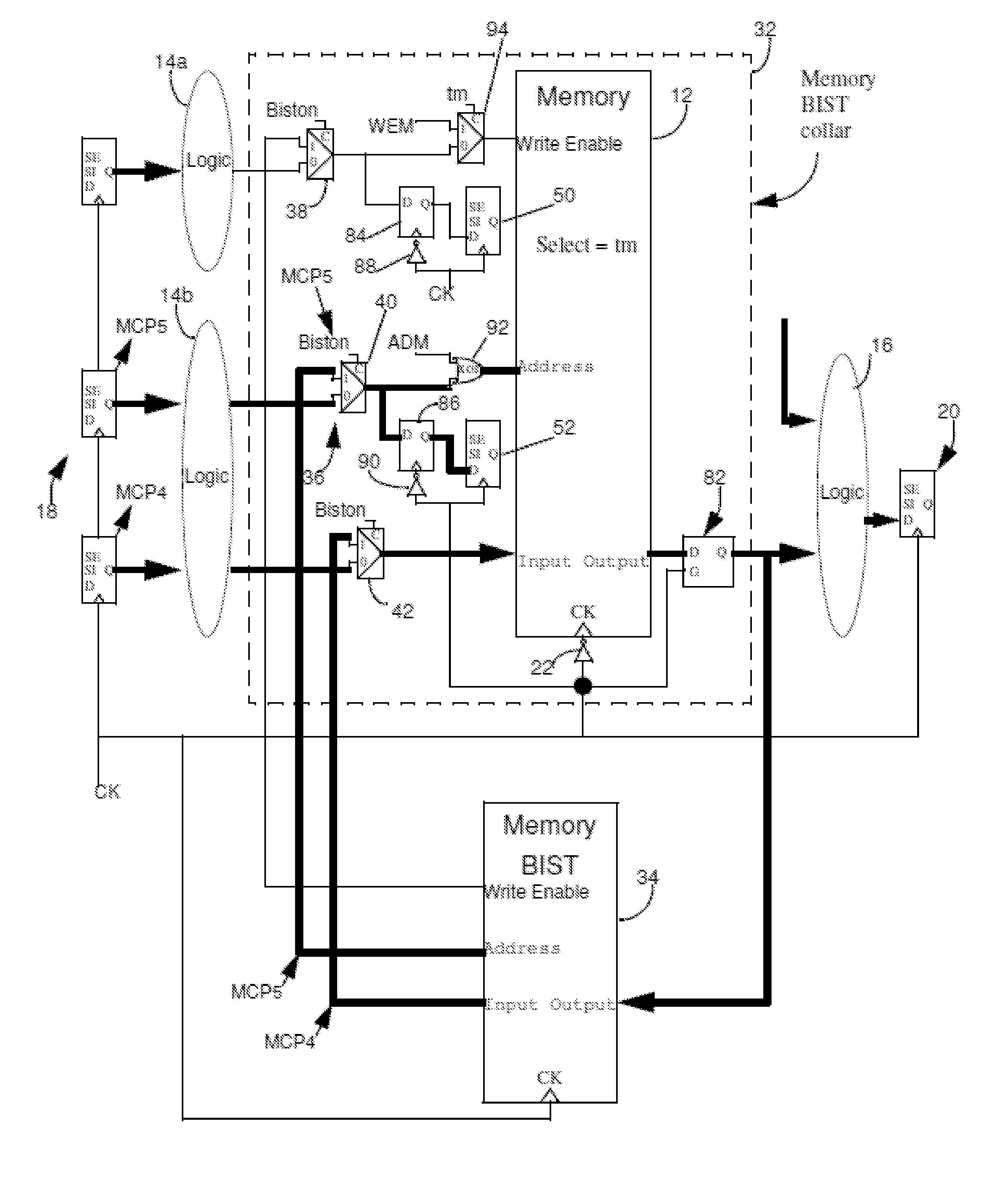

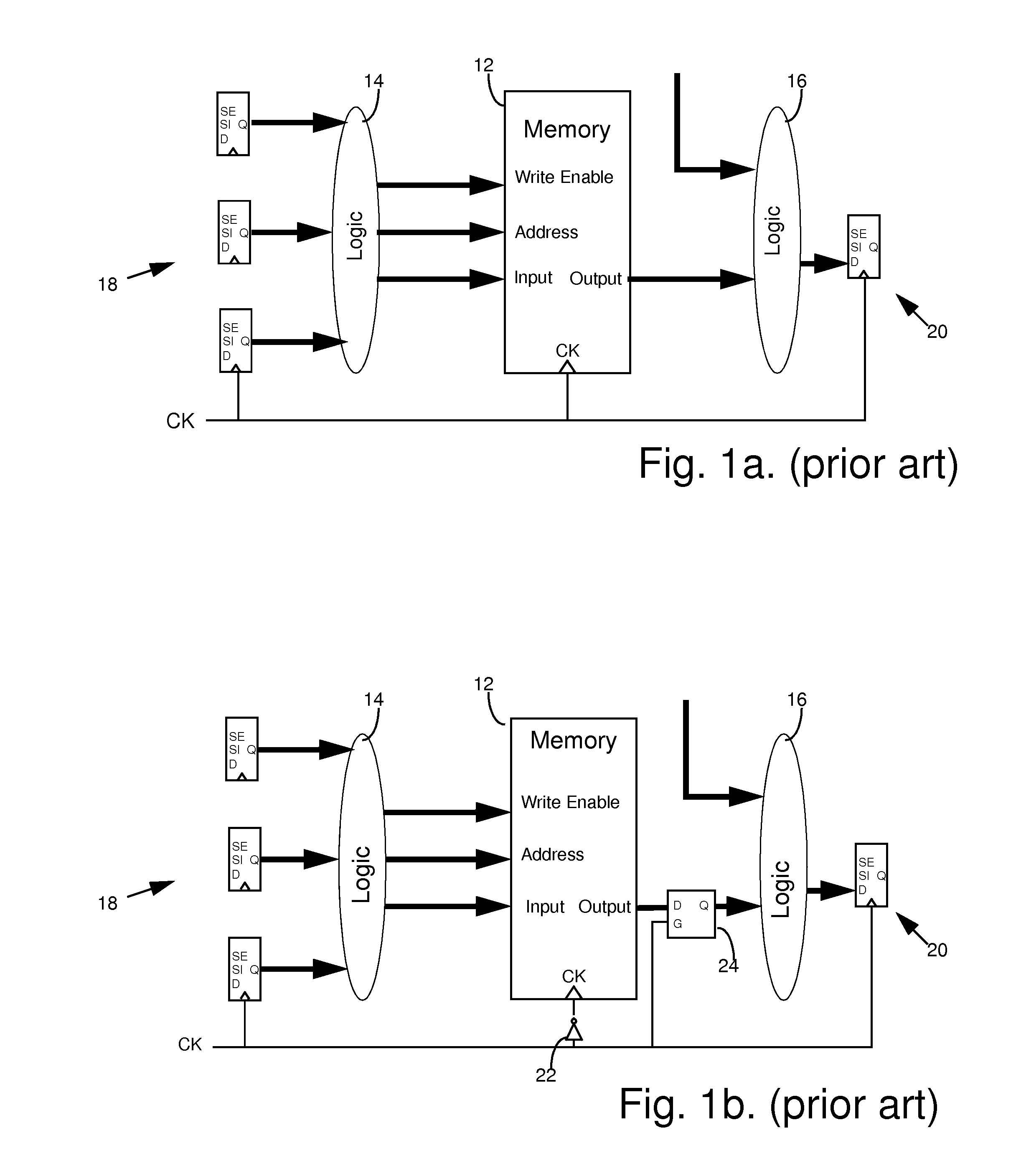

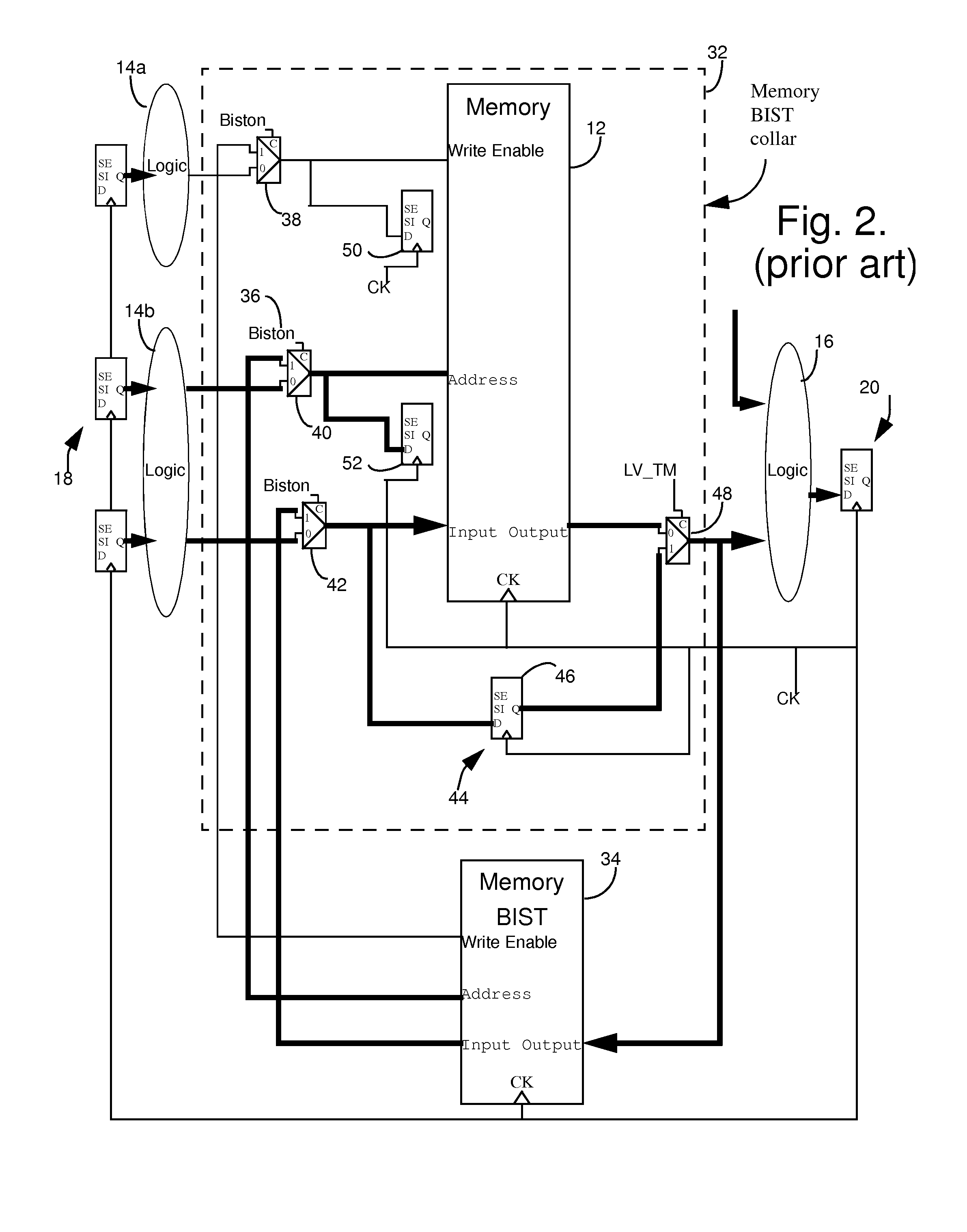

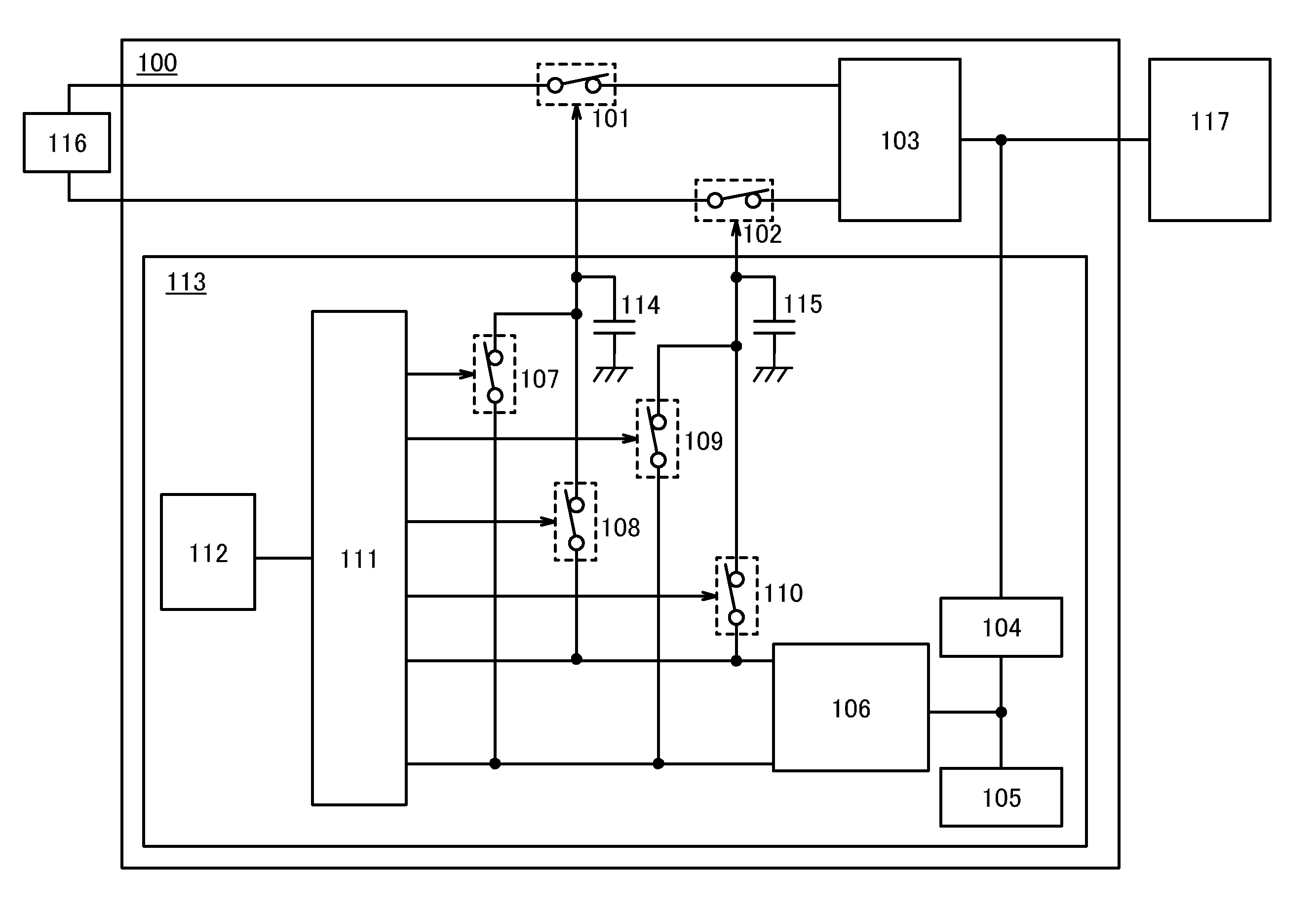

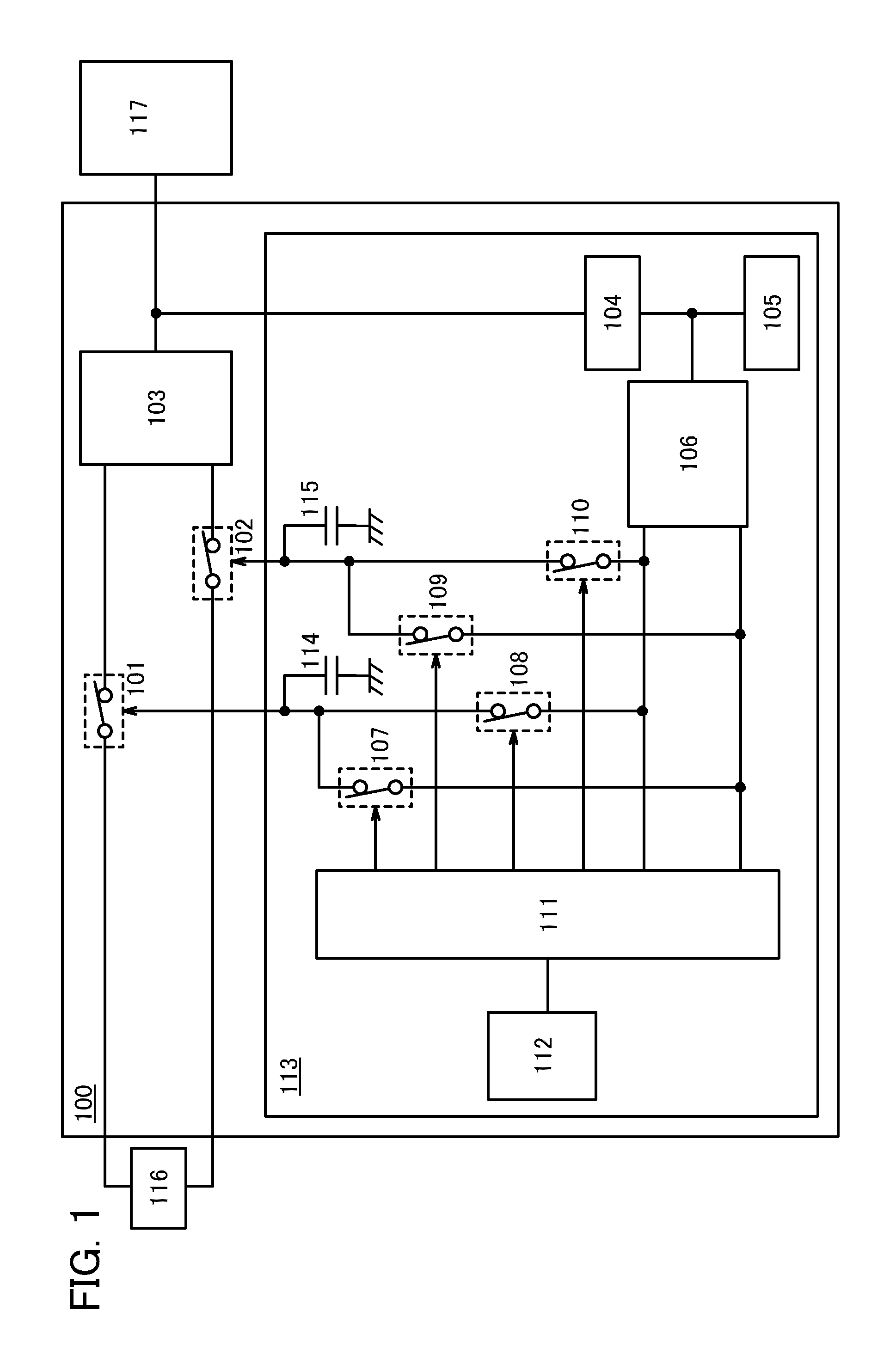

Methods For At-Speed Testing Of Memory Interface

ActiveUS20120198294A1Reduce power supplyTest-dedicated circuitry may be reduced or eliminatedElectronic circuit testingError detection/correctionMemory interfaceEmbedded memory

Methods for at-speed testing of a memory interface associated with an embedded memory involves in general two write operations in succession, two read operations in succession, and a capture operation using scan cells. The write and read operations may be performed during a single clock burst, two separate clock bursts in a clock signal, or two separate clock bursts in separate clock signals.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Power supply circuit and semiconductor device including the same

ActiveUS20130285470A1Reduce power consumptionLow power consumptionPower reduction in field effect transistorsTransistorVoltage regulationVoltage regulator

A power supply circuit includes a first switch, a voltage regulator circuit connected to the first switch, and a control circuit for controlling the first switch. The control circuit includes a second switch, a third switch, and a voltage generation circuit. For controlling the first switch, first voltage output from the voltage generation circuit is applied to the first switch through the second switch, and second voltage output from the voltage generation circuit is applied to the first switch through the third switch. Power consumption of the power supply circuit can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

Dc-dc converter, semiconductor device, and electronic device

ActiveUS20150249385A1Improve power conversion efficiencyReduce power consumptionDc-dc conversionElectric light circuit arrangementElectricityDc dc converter

A DC-DC converter with improved voltage conversion efficiency is provided. The DC-DC converter includes a first circuit configured to generate a first signal containing data on current flowing through a load, a second circuit configured to amplify the first signal, a third circuit configured to generate a second signal containing data on voltage applied to the load, a fourth circuit configured to hold the second signal, a fifth circuit configured to amplify the second signal held by the fourth circuit, a sixth circuit configured to correct a difference in electrical characteristics between the second circuit and the fifth circuit, a seventh circuit configured to convert a first voltage to a second voltage supplied to the load, and an eighth circuit configured to control a level of the second voltage generated by the seventh circuit in accordance with either the amplified first signal or the amplified second signal.

Owner:SEMICON ENERGY LAB CO LTD

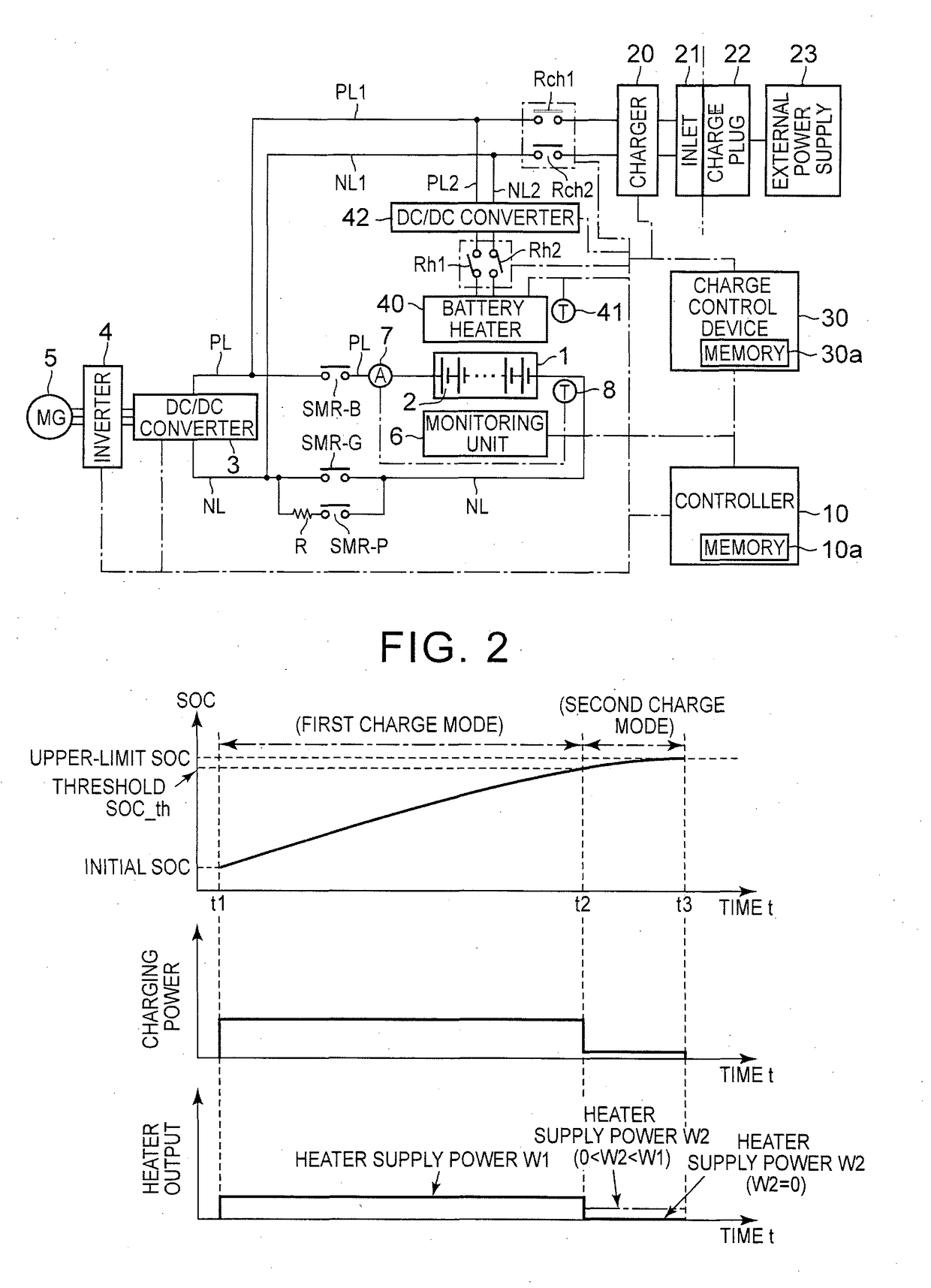

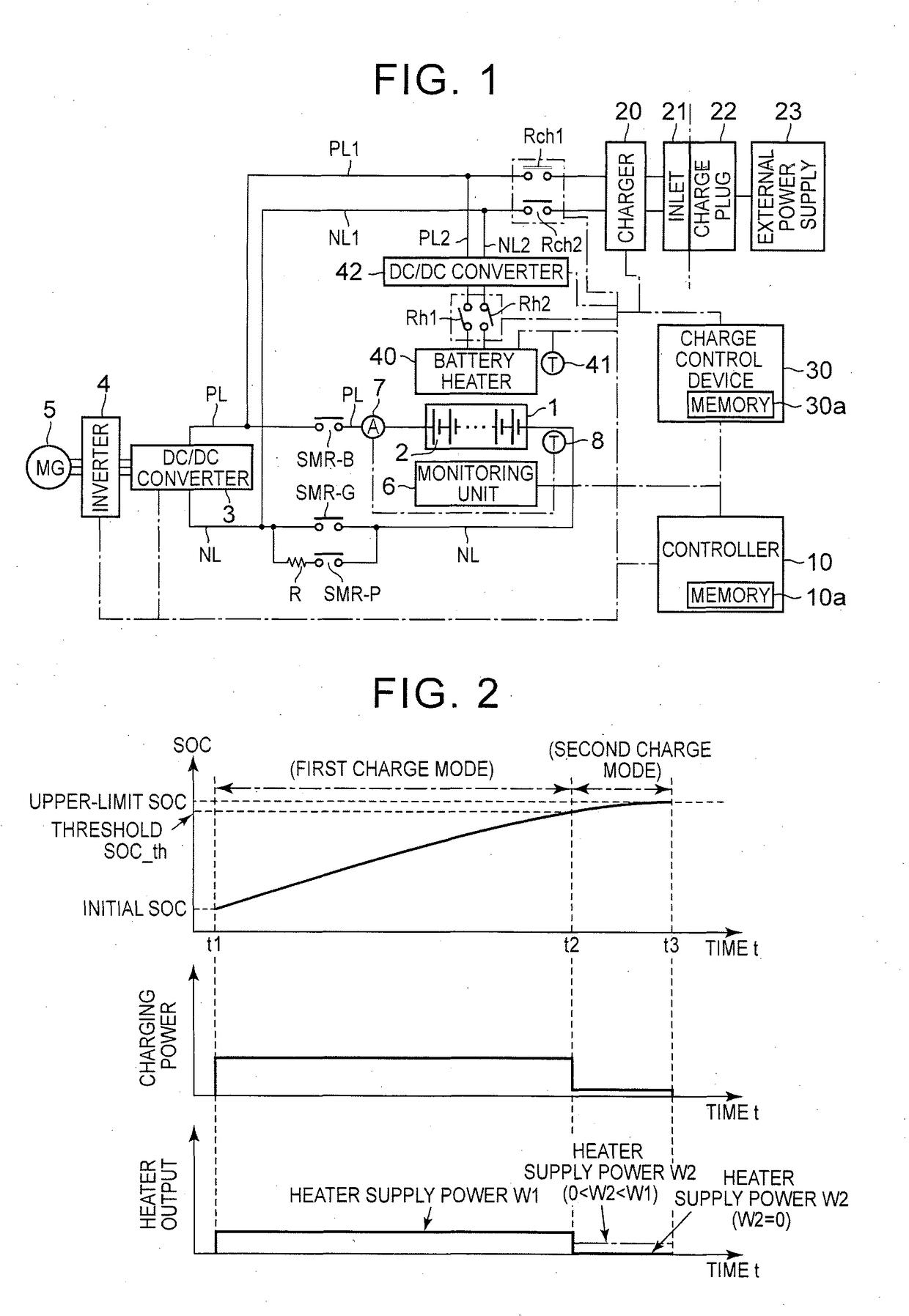

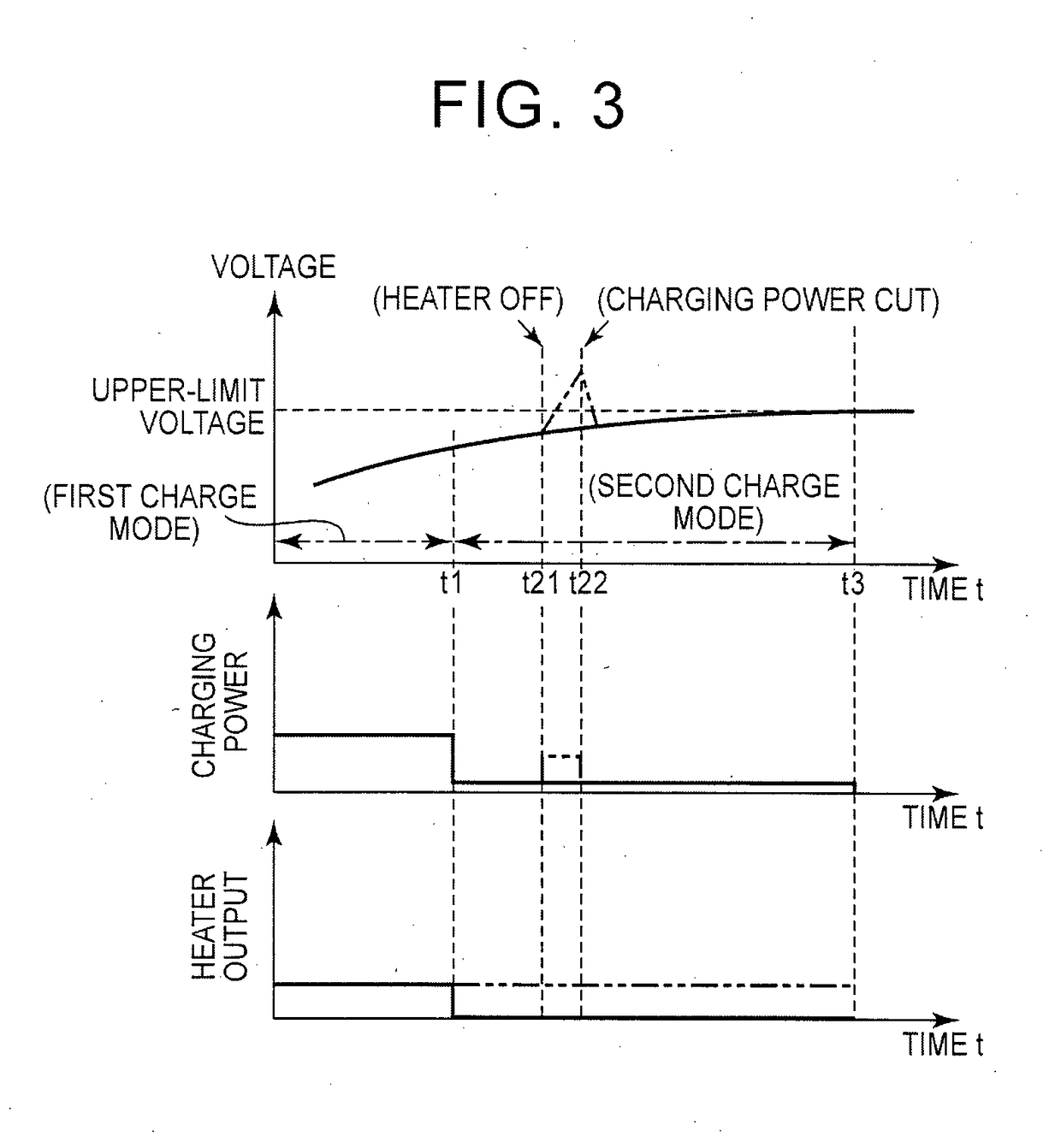

Electric power storage system

ActiveUS20170120775A1Increase temperatureReduce charging powerBatteries circuit arrangementsCharging stationsElectrical batteryState of charge

An electric power storage system for a vehicle includes a temperature sensor configured to detect a temperature of a battery, a battery heater, a charger connectable with an external power supply and configured to deliver external power to the battery and the battery heater, and a controller. In the system, a first electric power is supplied to the battery heater when the state of charge of the battery is larger than a predetermined value and the temperature of the battery is equal to or lower than the predetermined temperature, and a second electric power is supplied to the battery heater when the state of charge of the battery is equal to or smaller than the predetermined value and the temperature of the battery is equal to or lower than the predetermined temperature. The first electric power is smaller than the second electric power.

Owner:TOYOTA JIDOSHA KK

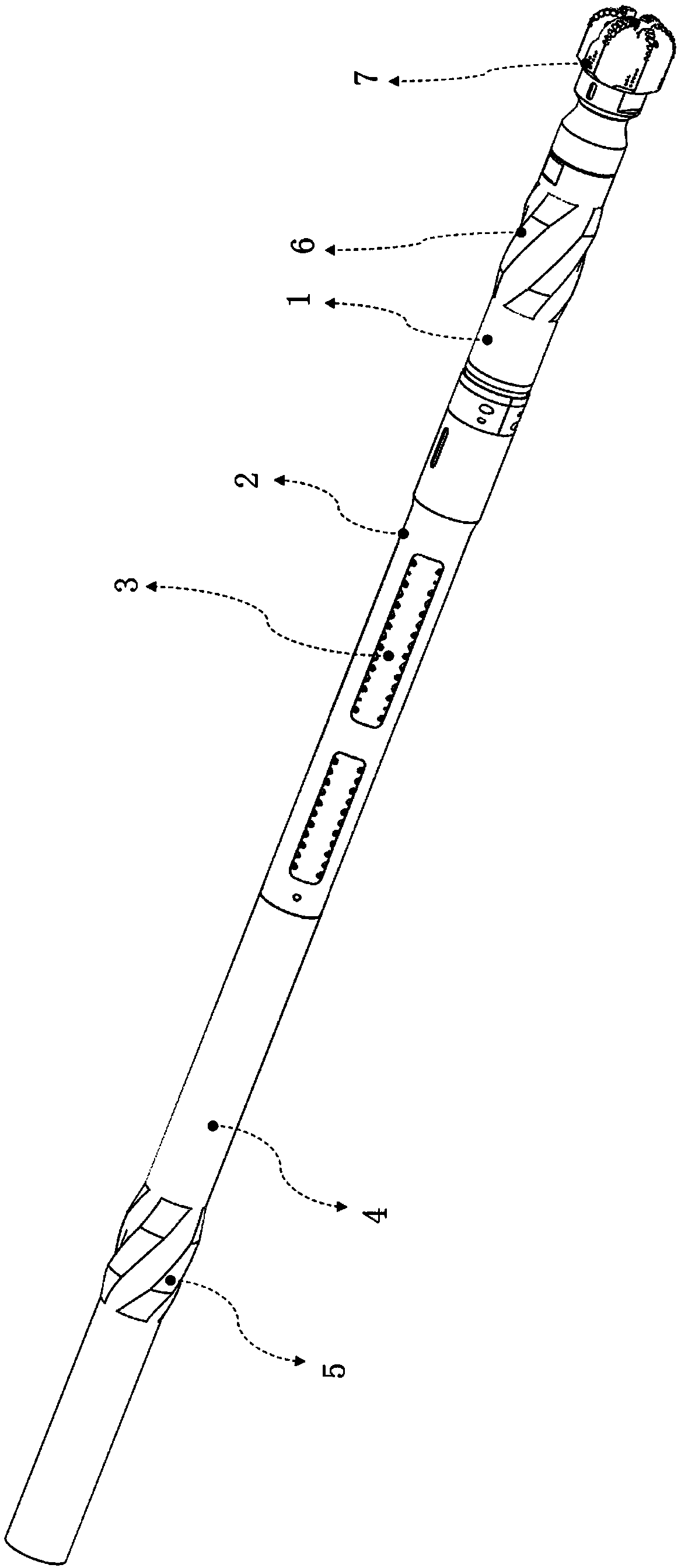

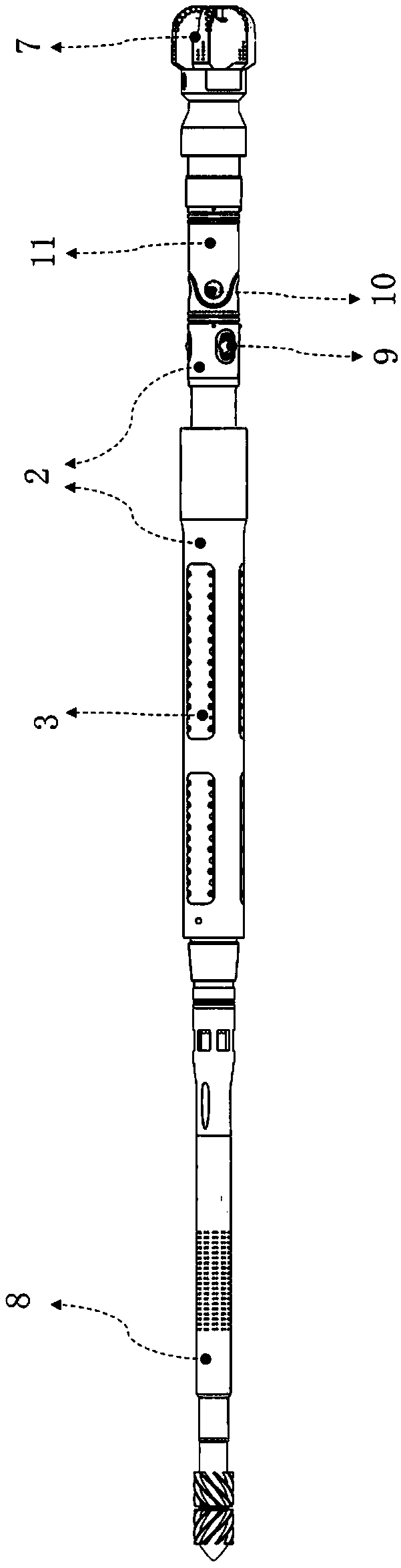

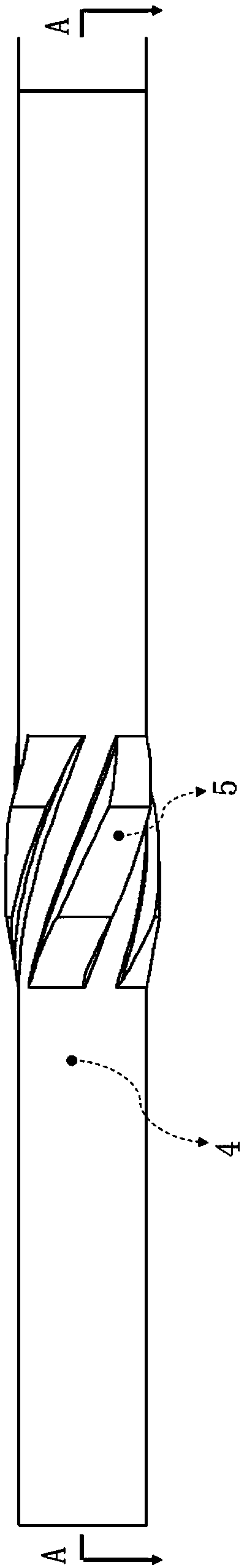

Full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool

ActiveCN109025820AReduce in quantityReduce power supplyDirectional drillingMachines/enginesPush outPiston

The invention mainly belongs to the technical field of rotary guide systems, and particularly relates to a full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool. The full-rotation hydraulic inward-pushing-type high-build-up-rate rotation guide tool adopts a hydraulic system driven by a turbine and a generator set to convert the energy of the pressure mud into the hydraulic energy. By adopting the hydraulic system driven by the turbine and the generator set, the power is provided for a piston through the hydraulic mode, so that the lateral force obtained by a drillbit is larger. Meanwhile, the hinged mode is adopted, so that the optimal steering capability is achieved. As a result, the high build-up rate is easier to achieve. The hydraulic piston pushes againstthe inner wall of a lower rotating sleeve instead of the wall of a well, so that the abrasion can be reduced. At the same time, only one set of pushing piston assemblies is pushed out at the same moment, so that the unnecessary work is reduced. The service life of the piston is prolonged.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com