Utilization method for steel scoria

A steel slag and slag-making technology, applied in the field of steel slag utilization, can solve the problems of reducing the desulfurization rate, waste, and sulfur enrichment of refining furnaces, and achieve the effects of reducing electric furnace smelting costs, reducing pollution, and reducing power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

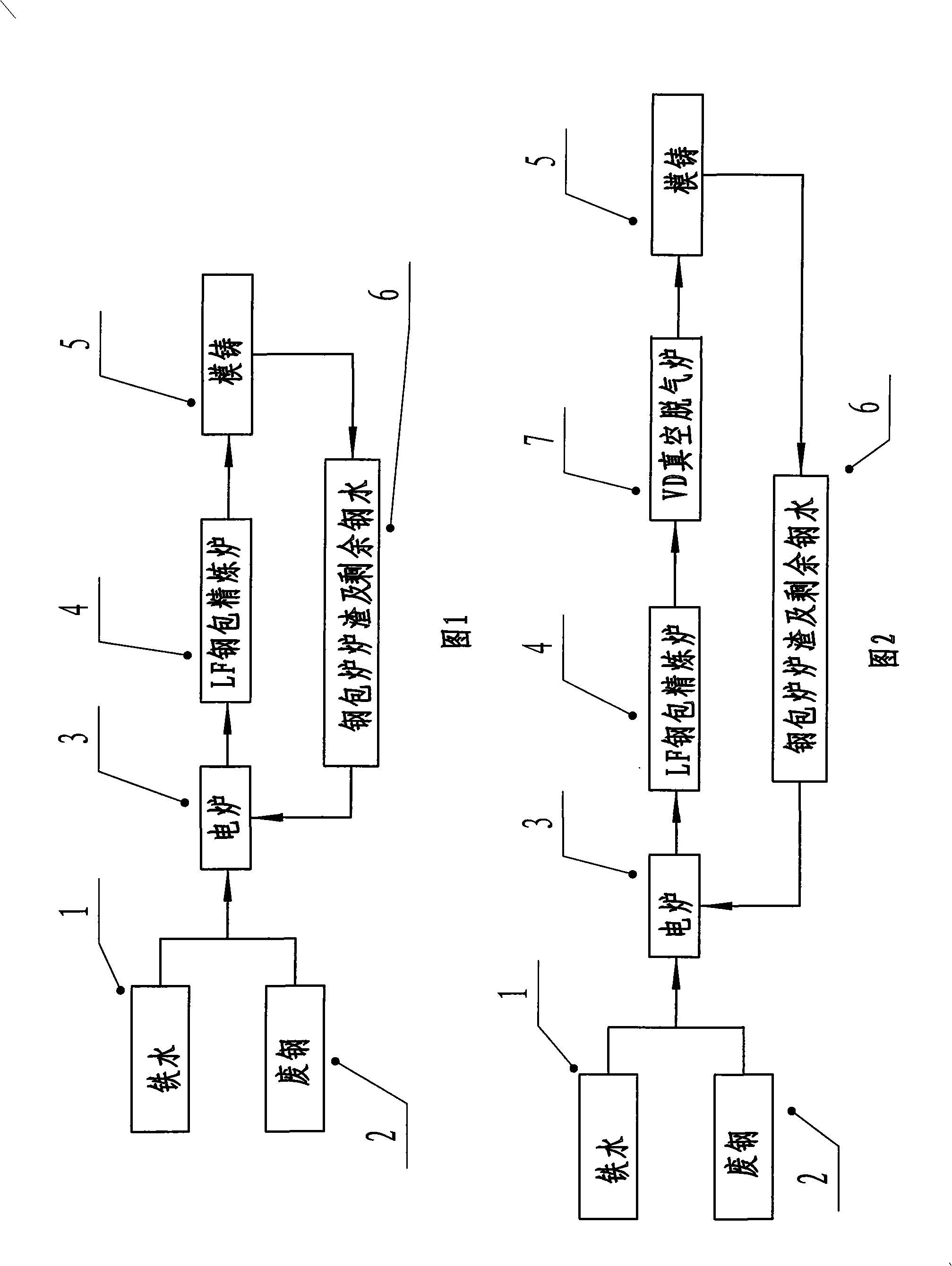

[0029] This embodiment is the recycling of steel slag in a 60-ton LF ladle refining furnace, and the smelted steel is ML20 steel. 60 tons of LF ladle refining furnace steel slag thermal circulation, its process is shown in Figure 1, according to the process, return to the electric furnace for use, the return amount of LF ladle refining furnace steel slag is 1000-2500kg, this embodiment is 2000kg, and the remaining molten steel is 500-1500kg, This embodiment is 1500kg. After blending into the electric furnace, the electric furnace can reduce the amount of slagging material lime added by 500-1200kg. , the present embodiment is 500 yuan. The basic method is as follows:

[0030] (1) Technological process: 50-ton high-power eccentric bottom electric furnace 3 adds molten steel to a 60-ton LF ladle refining furnace 4 and performs die-casting after refining 5 . Due to the use of an eccentric bottom electric furnace, the electric furnace 3 basically does not drop slag when tapping. ...

Embodiment 2

[0036] The present embodiment is a 60-ton LF ladle refining furnace steel slag recycling. The steel smelted is ML40 steel. 60 tons of LF ladle refining furnace steel slag thermal circulation, its process is shown in Figure 1, according to the process, return to the electric furnace for use, the return amount of LF ladle refining furnace steel slag is 1000-2500kg, this embodiment is 2000kg, and the remaining molten steel is 500-1500kg, This embodiment is 1500kg. After blending into the electric furnace, the electric furnace can reduce the amount of slagging material lime added by 500-1200kg. , the present embodiment is 500 yuan. The basic method is as follows:

[0037] (1) Technological process: 50-ton high-power eccentric bottom electric furnace 3 adds molten steel to a 60-ton LF ladle refining furnace 4 and performs die-casting after refining 5 . Due to the use of an eccentric bottom electric furnace, the electric furnace 3 basically does not drop slag during tapping. Duri...

Embodiment 3

[0043] In this embodiment, the steel slag of the applicant's 60-ton VD ladle furnace is circulated in a hot state and returned to the electric furnace for utilization. The smelted steel is LZ50 steel. The return amount of steel slag in VD ladle furnace is 1000-2500kg, which is 2000kg in this embodiment, and the remaining molten steel is 500-1500kg, which is 1000kg in this embodiment. For example, it is 1000kg. At the same time, due to the return of the hot state, the power supply of the electric furnace can be reduced. Using the hot steel slag to return to the electric furnace can reduce the smelting cost of the electric furnace by 300-700 yuan, which is 500 yuan in this embodiment. The basic process is as follows:

[0044] (1) Technological process: see Figure 2, the 50-ton high-power eccentric bottom electric furnace 3 adds molten steel to the 60-ton LF ladle refining furnace 4 for refining, and then adds it to the 60-ton VD vacuum degassing furnace 7 for vacuum degassing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com