Dedicated heat recovery chiller

a heat recovery chiller and dedicated technology, applied in the operation mode of machines, refrigeration components, light and heating apparatus, etc., can solve the problem of differential pressure change between supply and return manifolds, and achieve the effect of reducing system load, reducing power requirements for the pump, and reducing system load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

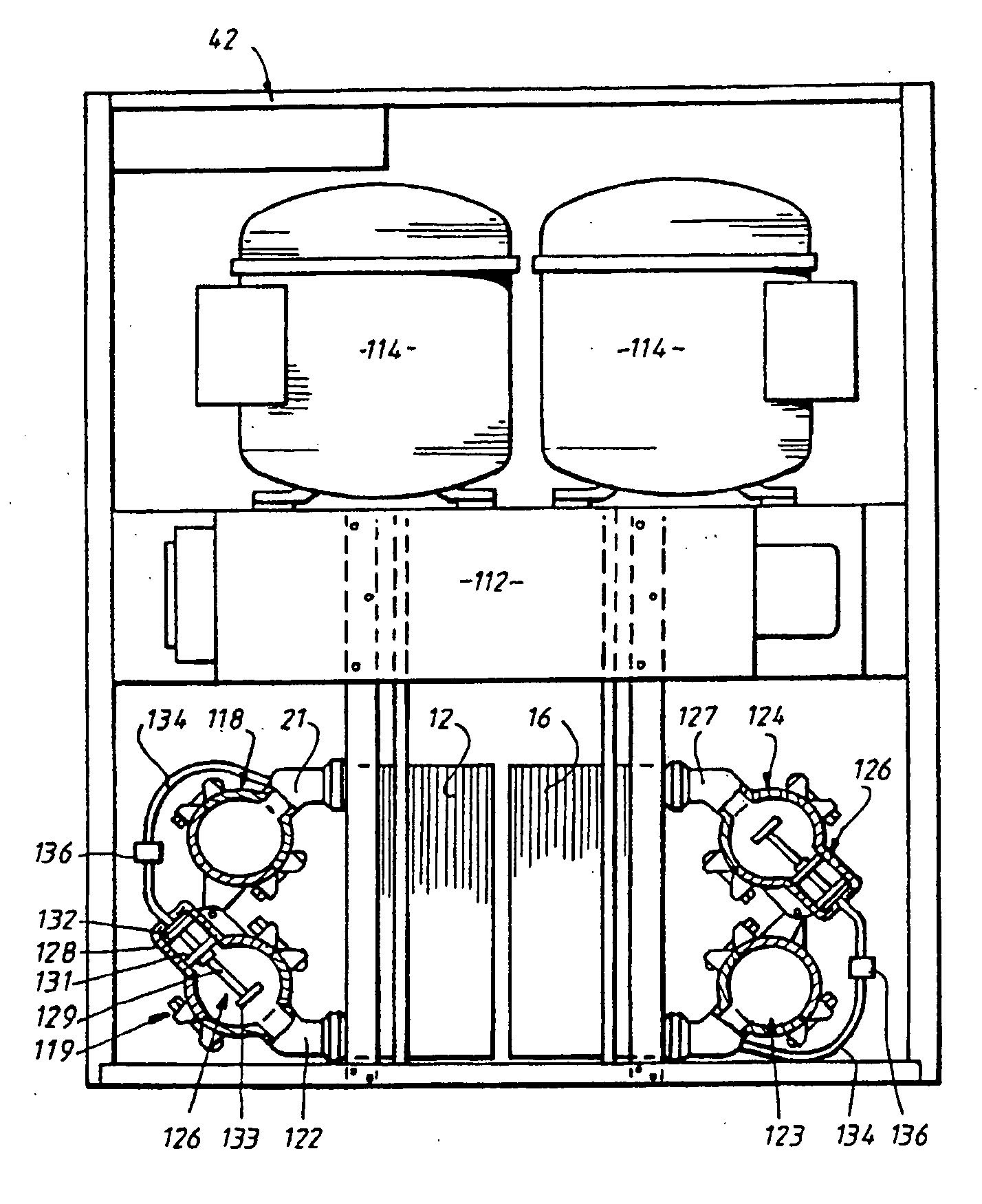

Image

Examples

example 1

Heating Mode

HUSP=125° F.

HLSP=115° F.

VSP=50%

[0091]The Heating No Load Point (HNLP) is then calculated as follows:

HNLP=HUSP−(VSP*(HUSP−HLSP)=125° F.−(50%*(125° F.−115° F.)=120° F.

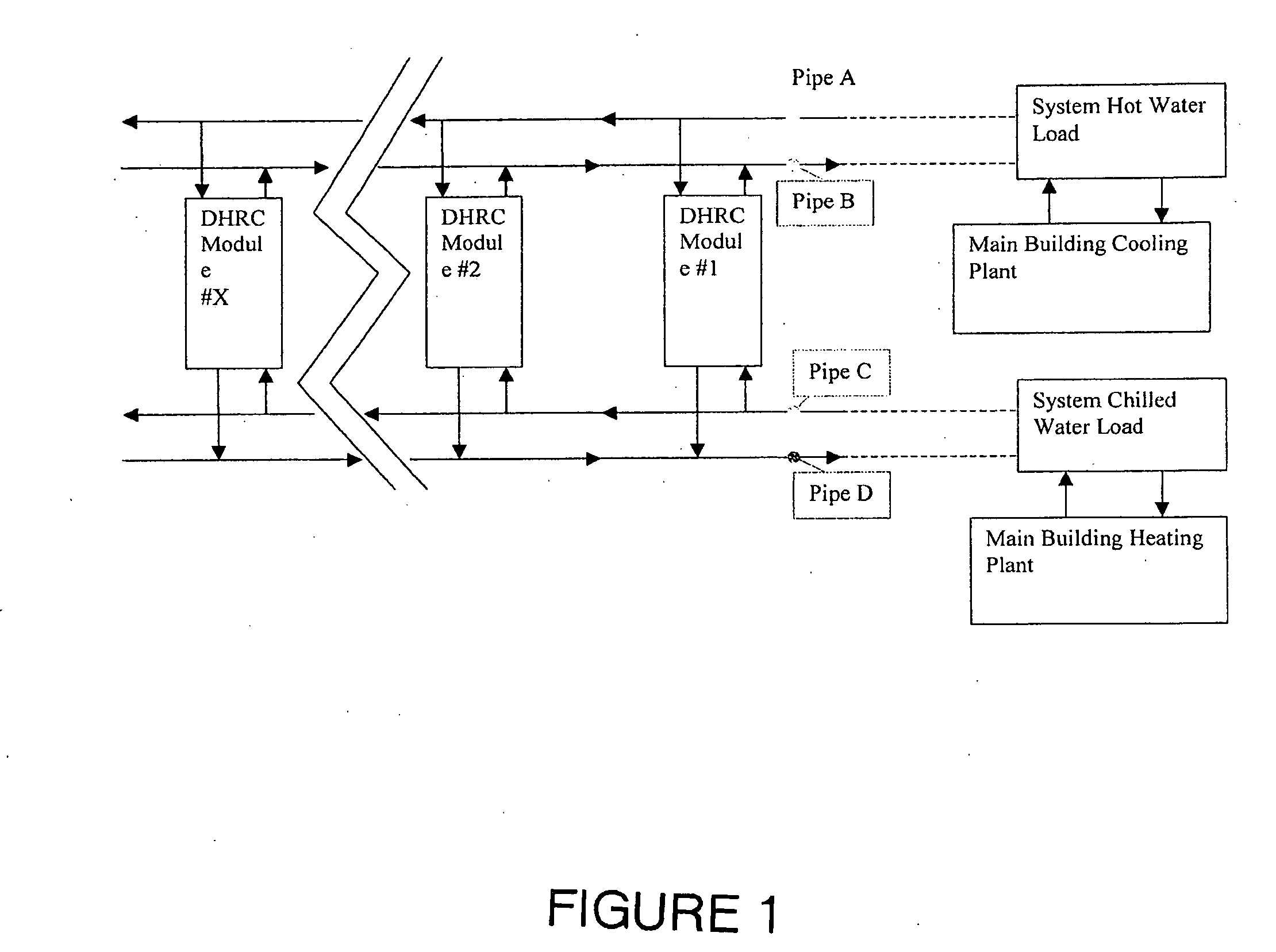

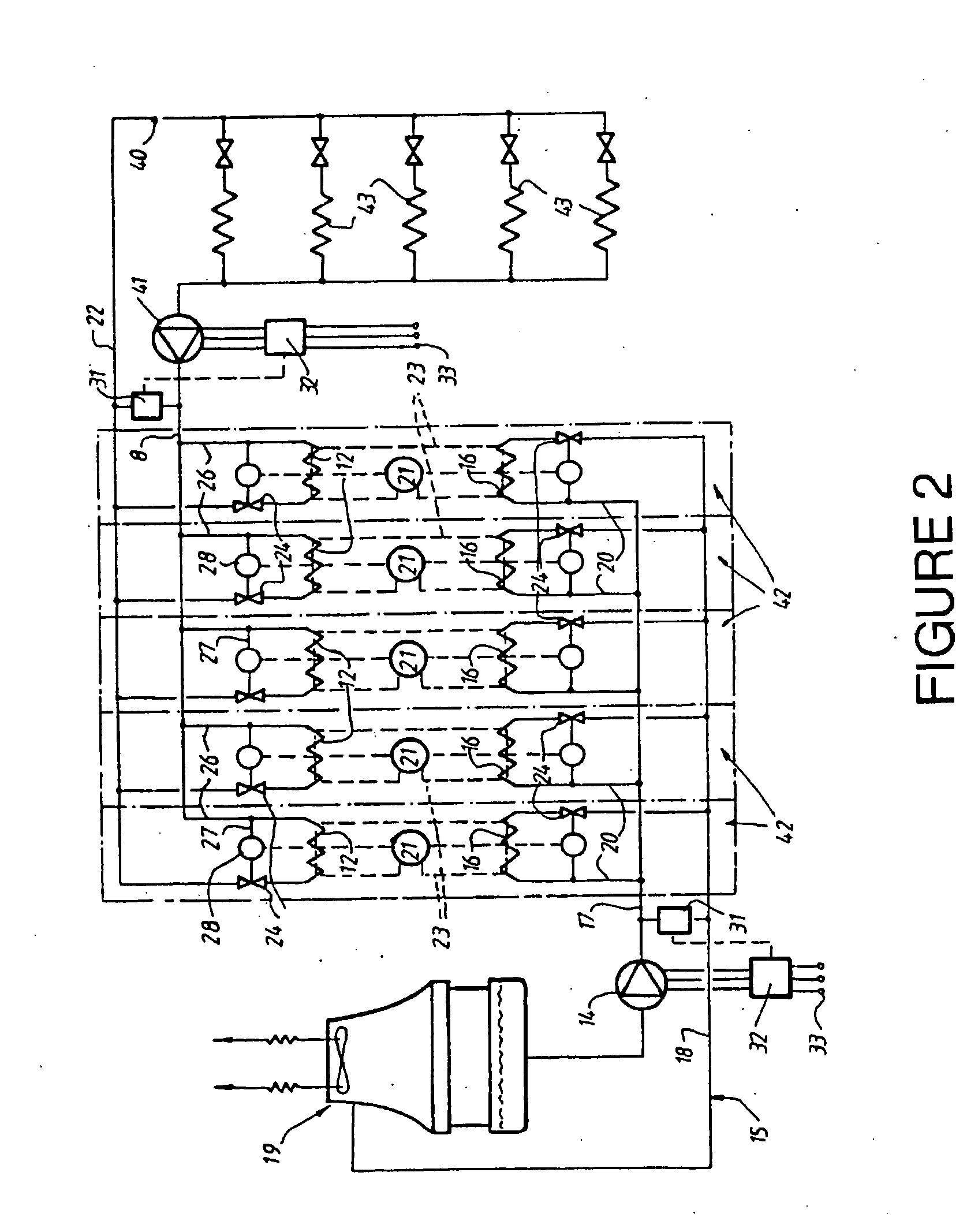

[0092]Therefore, in this case, the DHRC will operate its capacity controls based on temperature in Pipe A as it moves between the HLSP and the HNLP. That is, it will operate its capacity controls between measured temperatures of 115° F. and 120° F. in Pipe A. Any time the temperature in Pipe A is at or below the HLSP (115° F.), the DHRC will operate at 100% capacity. Any time the temperature in Pipe A at or above the HNLP (120° F. in this case), the DHRC will operate at 0% capacity. In between these two temperatures in Pipe A, there will be a linear relationship between capacity and temperature based on the DHRC's ability to step down. That is, if the DHRC has five-steps of capacity control (0%, 20%, 40%, 60%, 80%, and 100%). Then the following control logic will dictate DHRC loading:

Whenever the temperature ...

example 2

Cooling Mode

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com