Patents

Literature

60 results about "Chemical breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

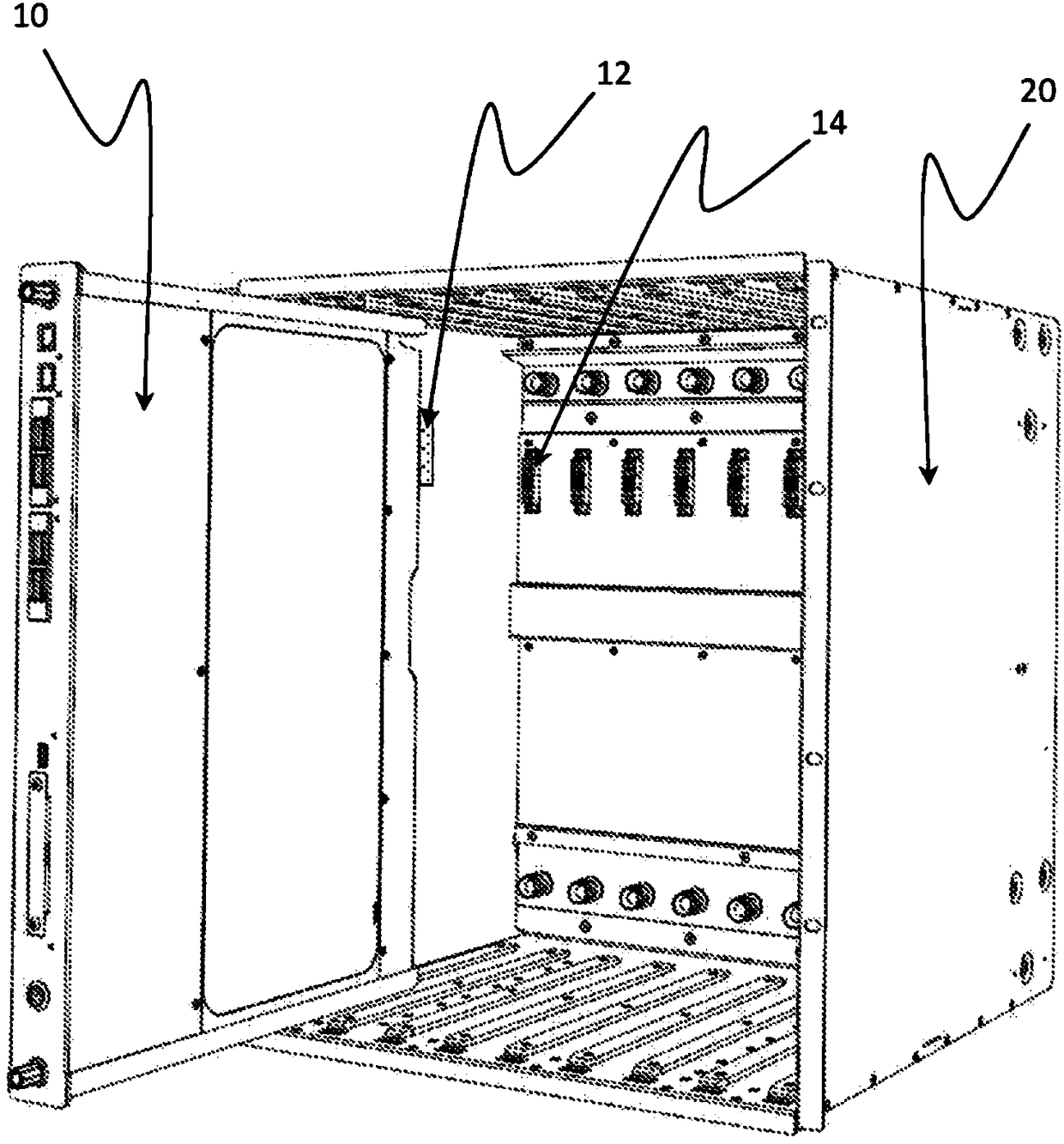

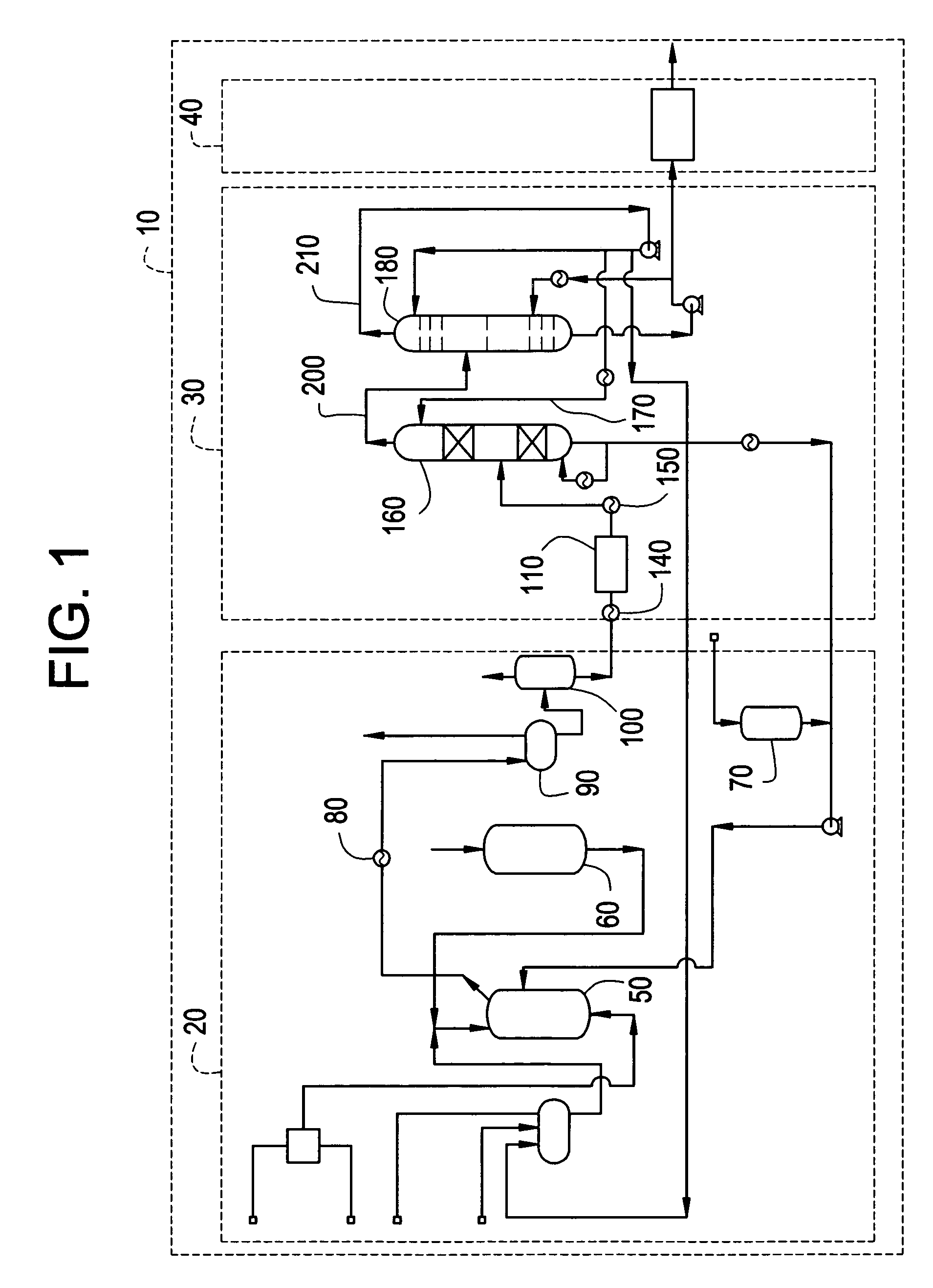

System and method employing direct gasification for power generation

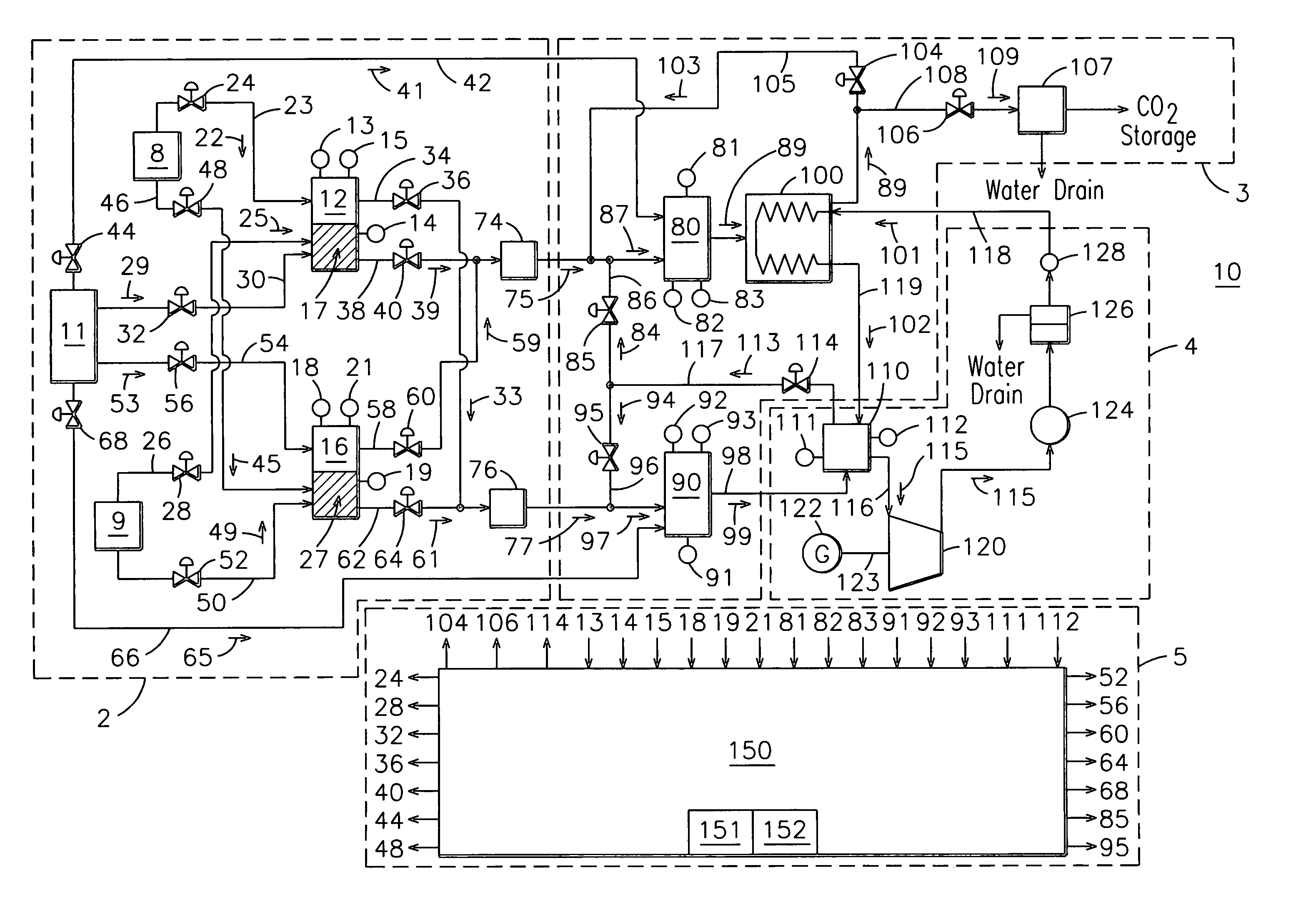

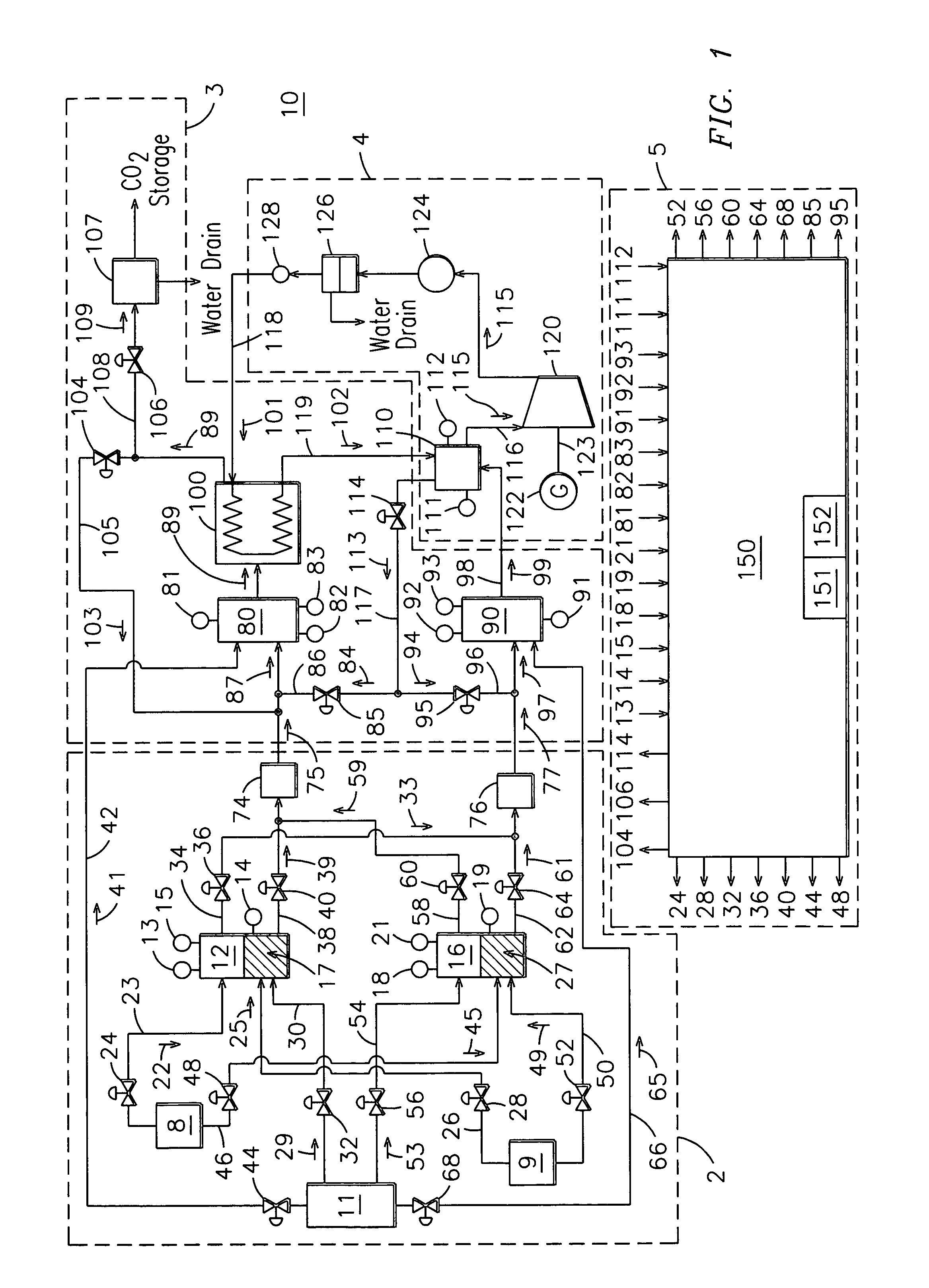

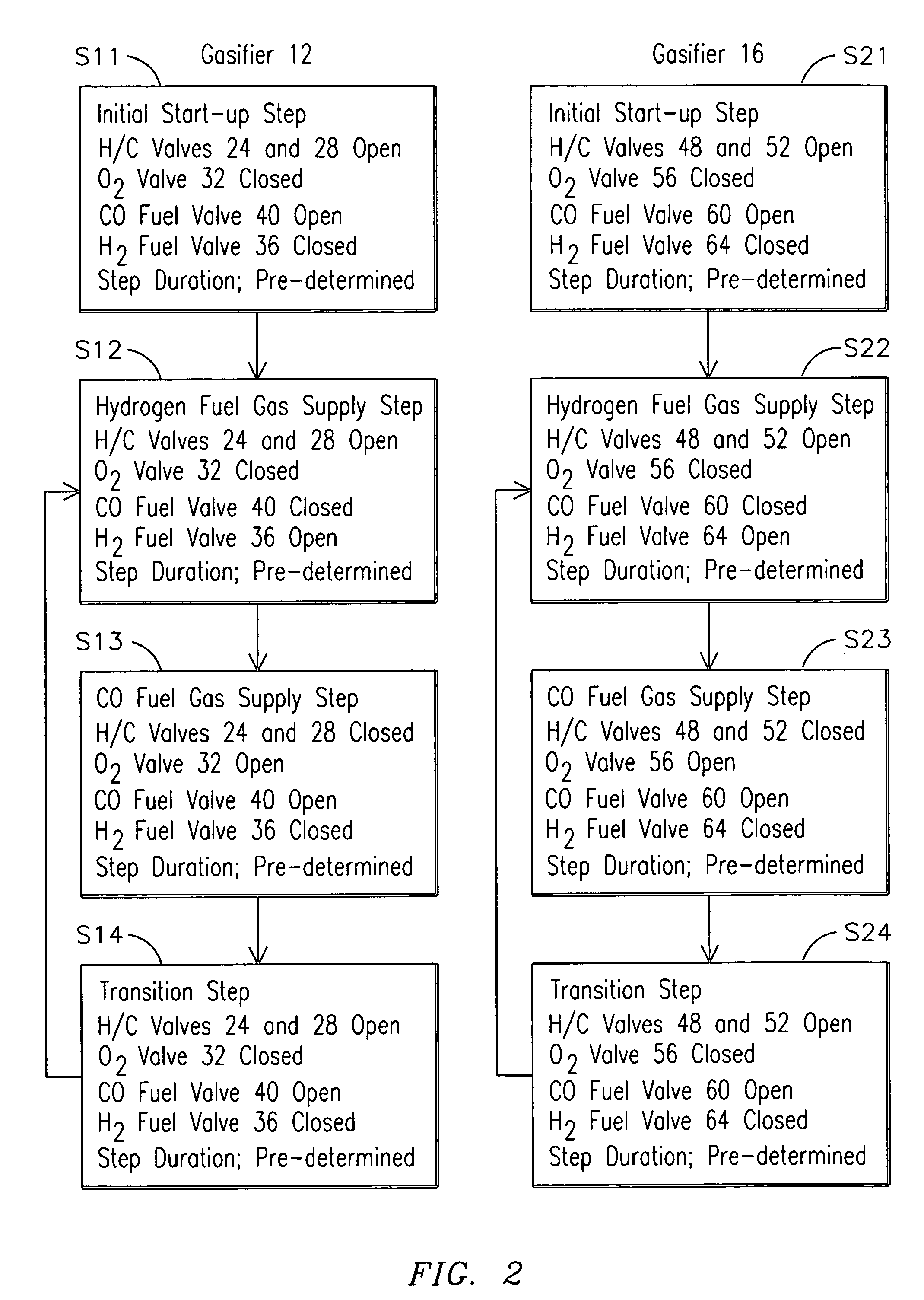

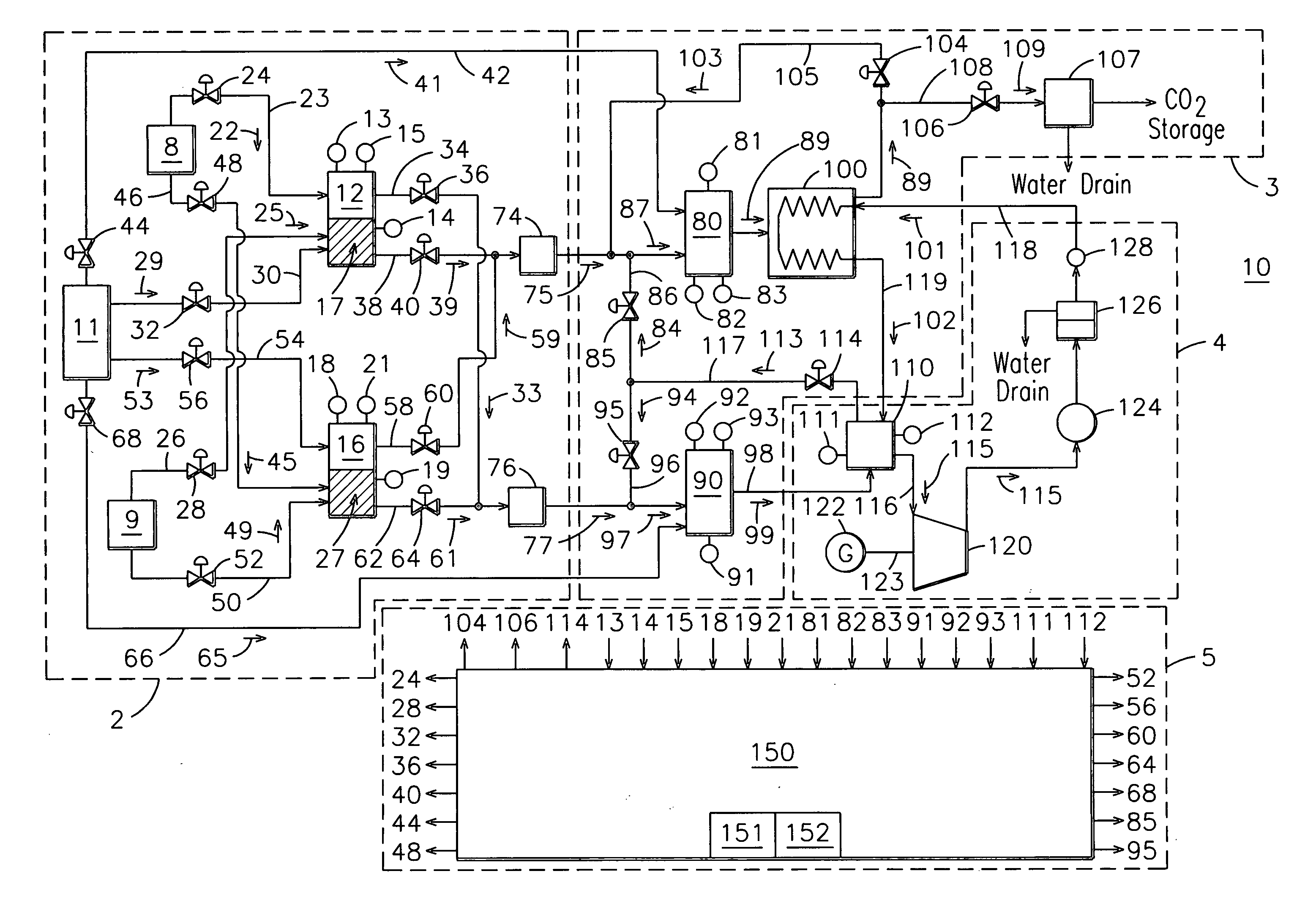

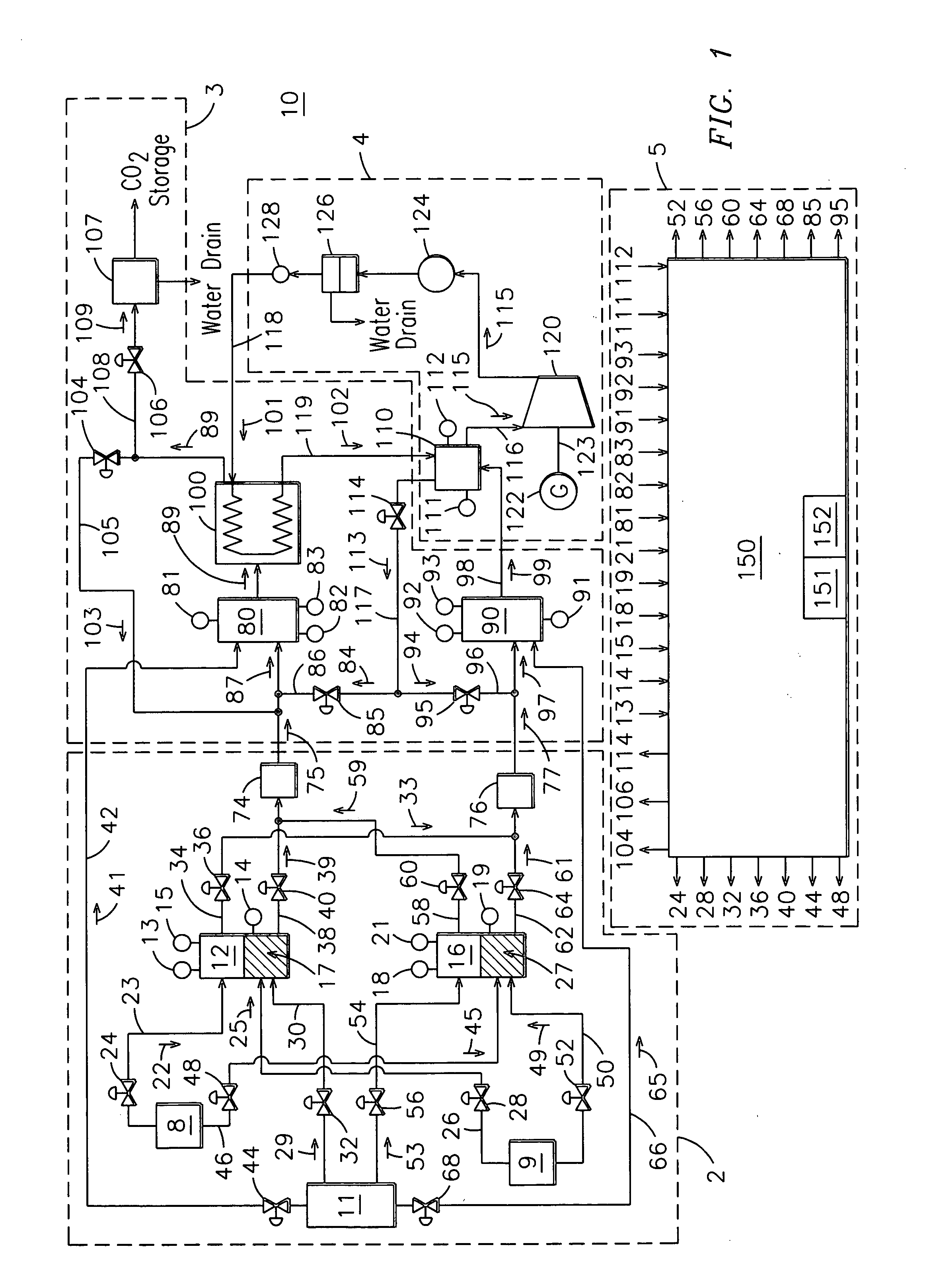

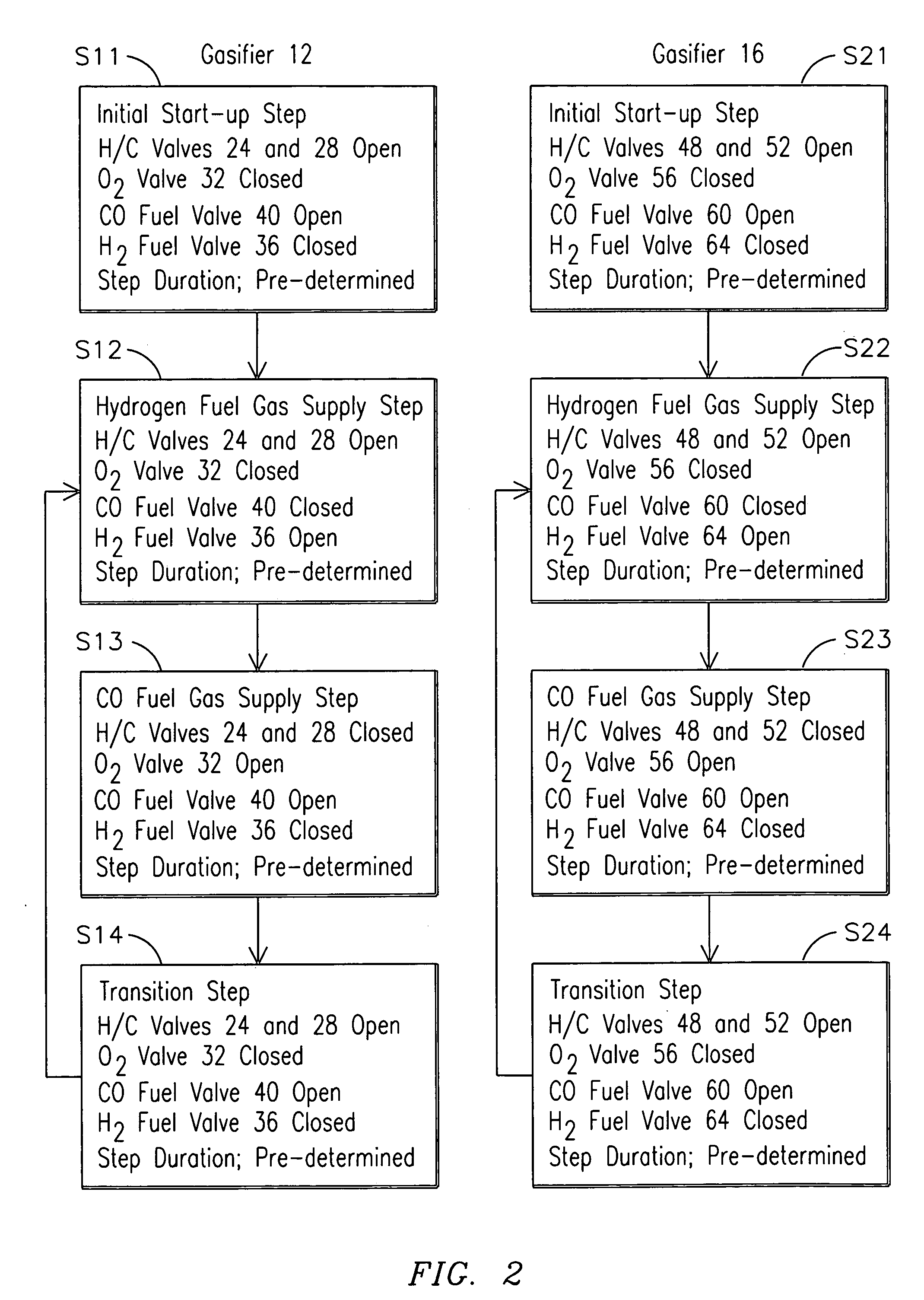

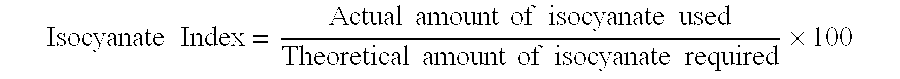

A power generation system (10) and method of operating a power generation system (10). An exemplary power generation system (10) shown in FIG. 1 includes a gasification system (2) for generating a supply (33) of a first gas comprising hydrogen and a supply (39) of a second gas comprising carbon monoxide based on a chemical breakdown of hydrocarbons in a melt (17). A component system (3) produces a supply of steam (99) by reacting one of the streams of gas and a steam turbine (120) generates mechanical power by expanding the steam (99). In an associated method, a melt (17) is created in a gasifier (12) which then receives a hydrocarbon source (22) to generate a continuous supply (33) of a first gas comprising hydrogen while increasing concentration of dissolved carbon in the melt (17). Hydrogen present in the first gas is supplied to a first combustor (90). A continuous supply (39) of a second gas comprising carbon monoxide is generated with carbon present in the melt (17). Carbon monoxide present in the second gas is supplied to a second combustor (80).

Owner:SIEMENS ENERGY INC

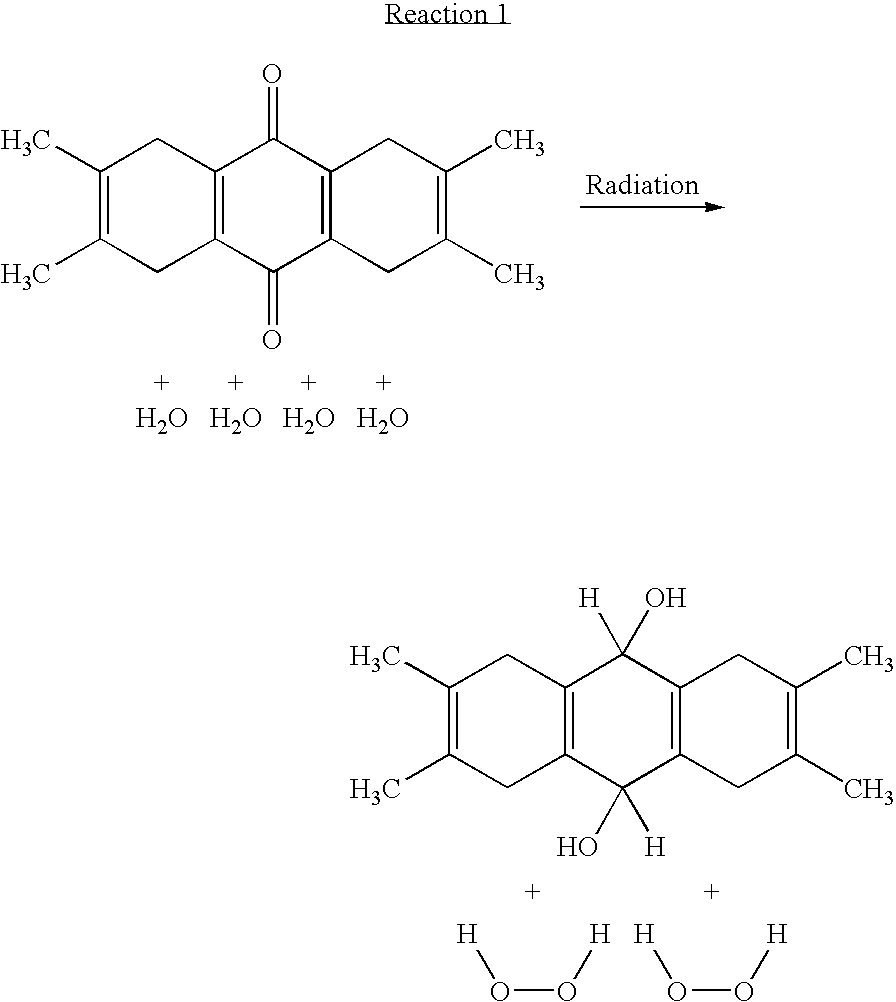

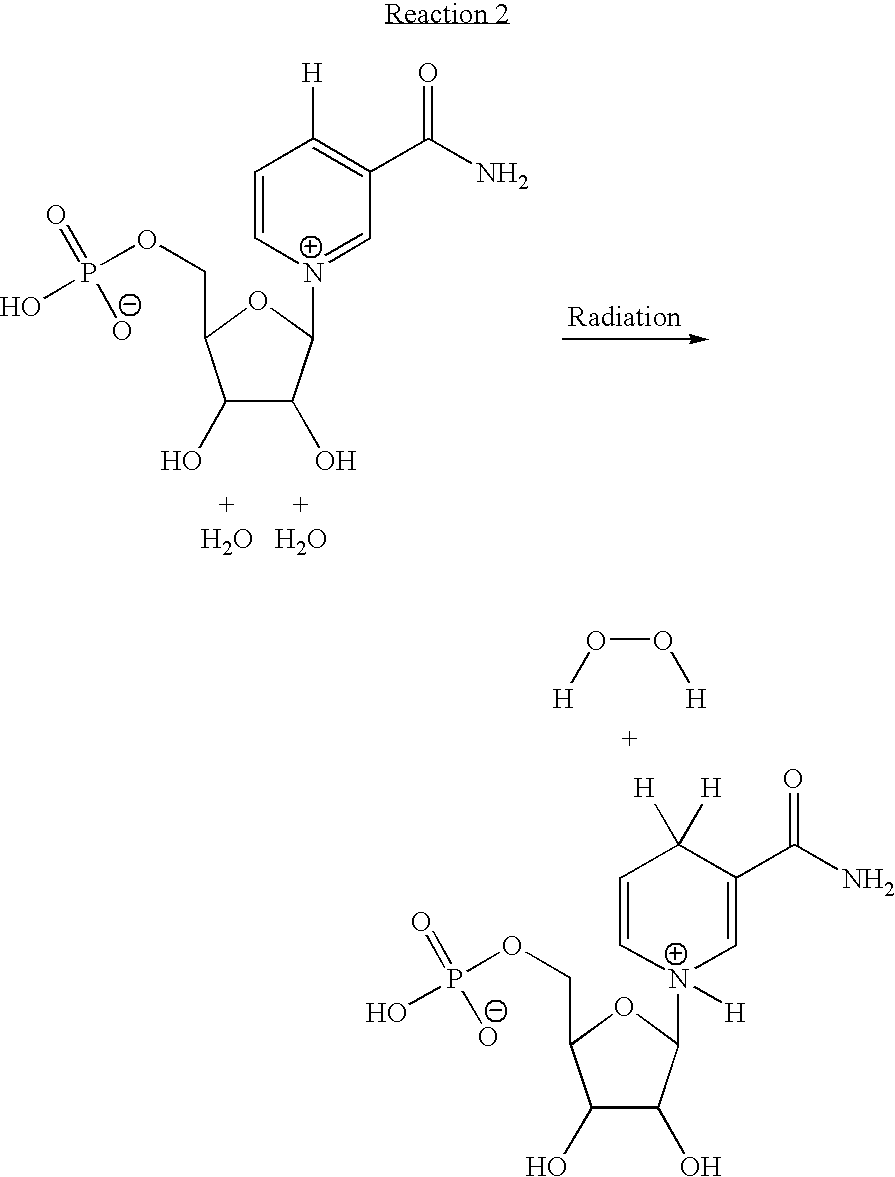

Utilizing electromagnetic radiation to activate filtercake breakers downhole

A downhole wellbore filtercake breaker is disclosed comprising one or more breaker chemicals (or activators thereof) capable of being activated with radiation to form one or more breaker reaction products which in turn are capable of reacting with the filtercake to chemically break down the filtercake. There is also disclosed a conventional reservoir drilling fluid modified to include an inactive, delayed, or sequestered breaker chemical or an activator thereof, wherein the breaker chemical (or activator) may be activated directly or indirectly by radiation, such as, microwave, visible, uV, soft x-ray, or other electromagnetic radiation. Also disclosed are methods for creating these filtercakes, and then breaking them via deploying a source of radiation that can be energized proximate to the filtercake. The breaker may be regenerated downhole by reaction with the filtercake breakdown products, and subjected again to a source of radiation to continue the breakdown of filtercake.

Owner:HORTON AMY C +1

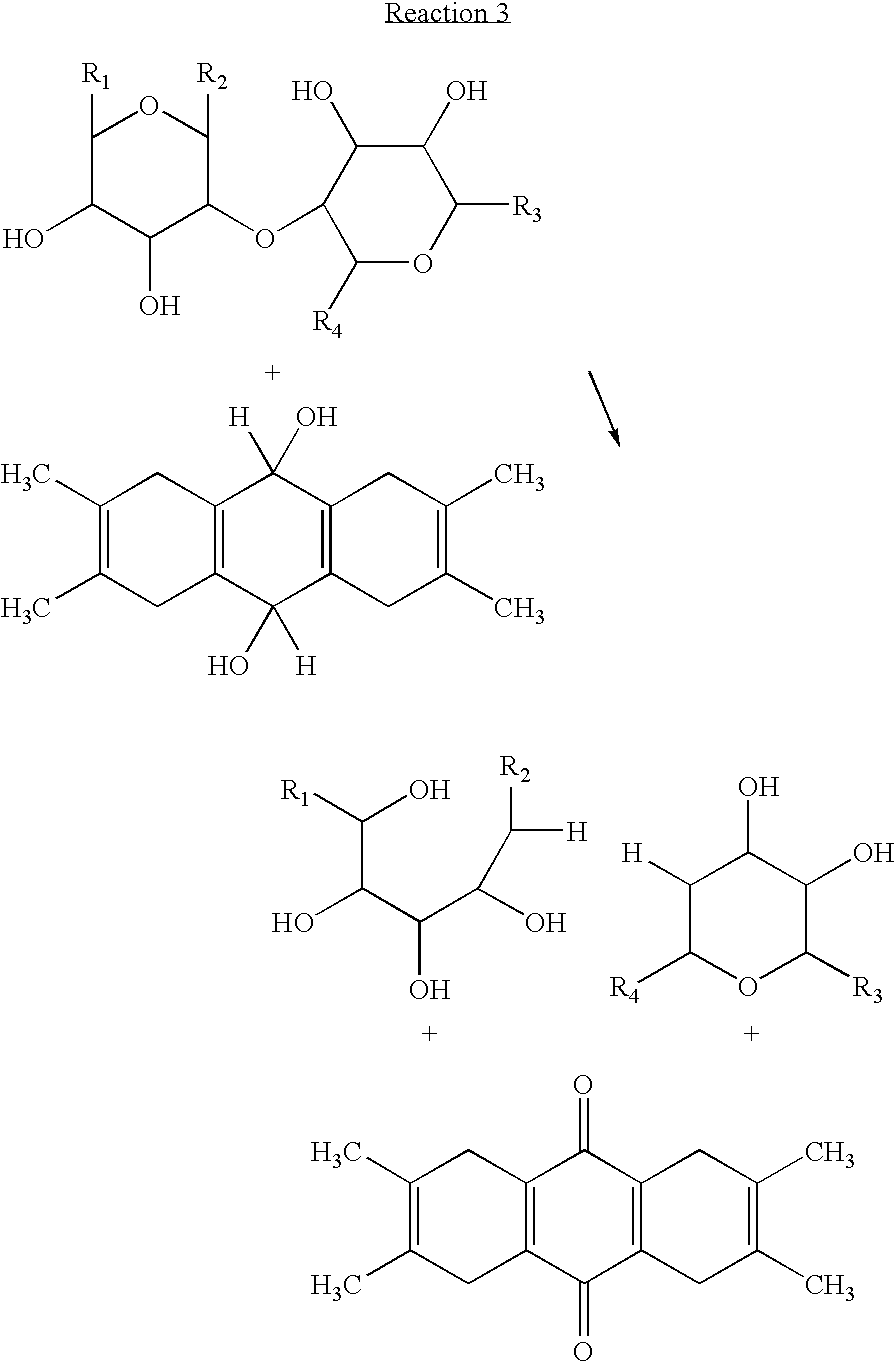

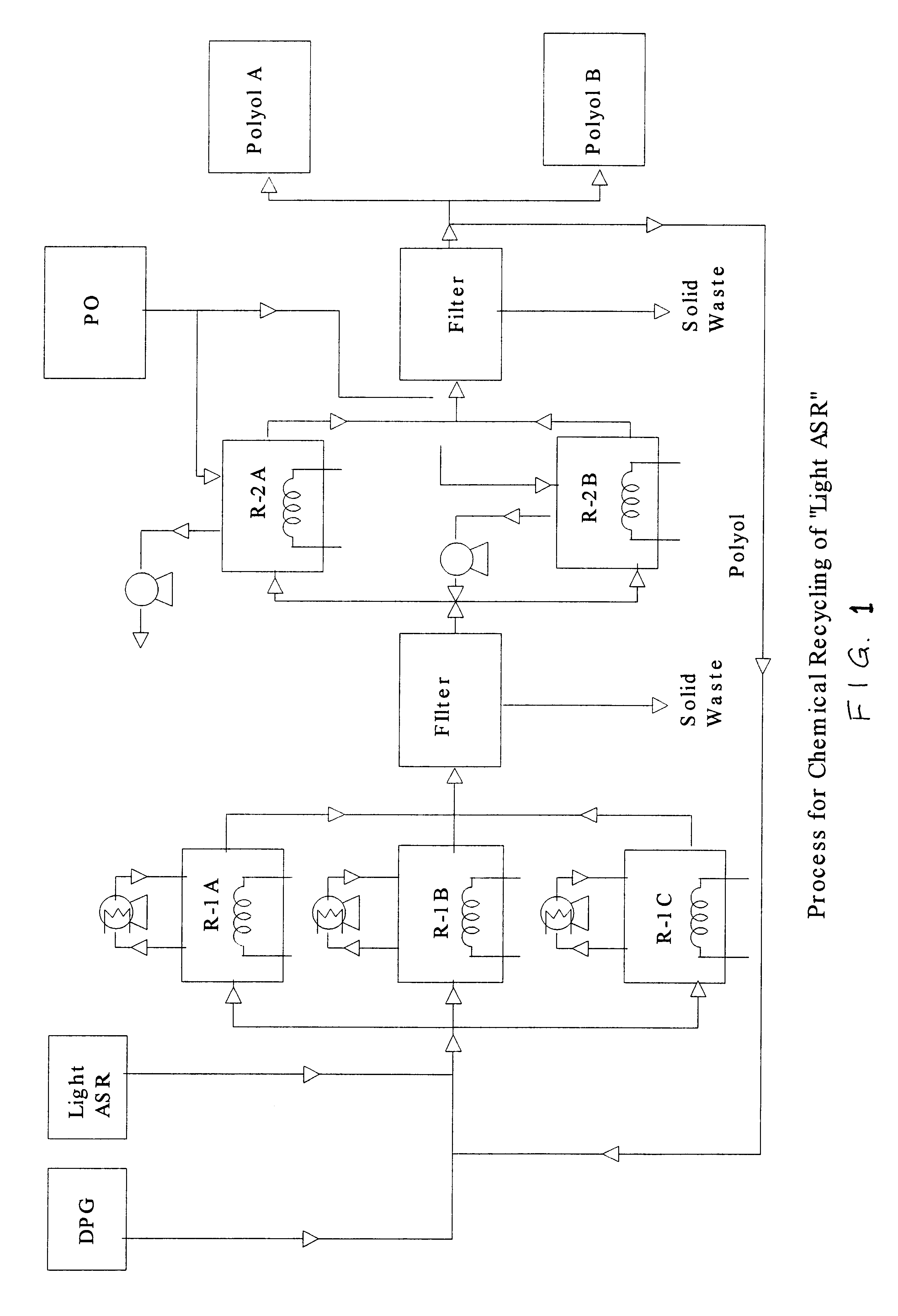

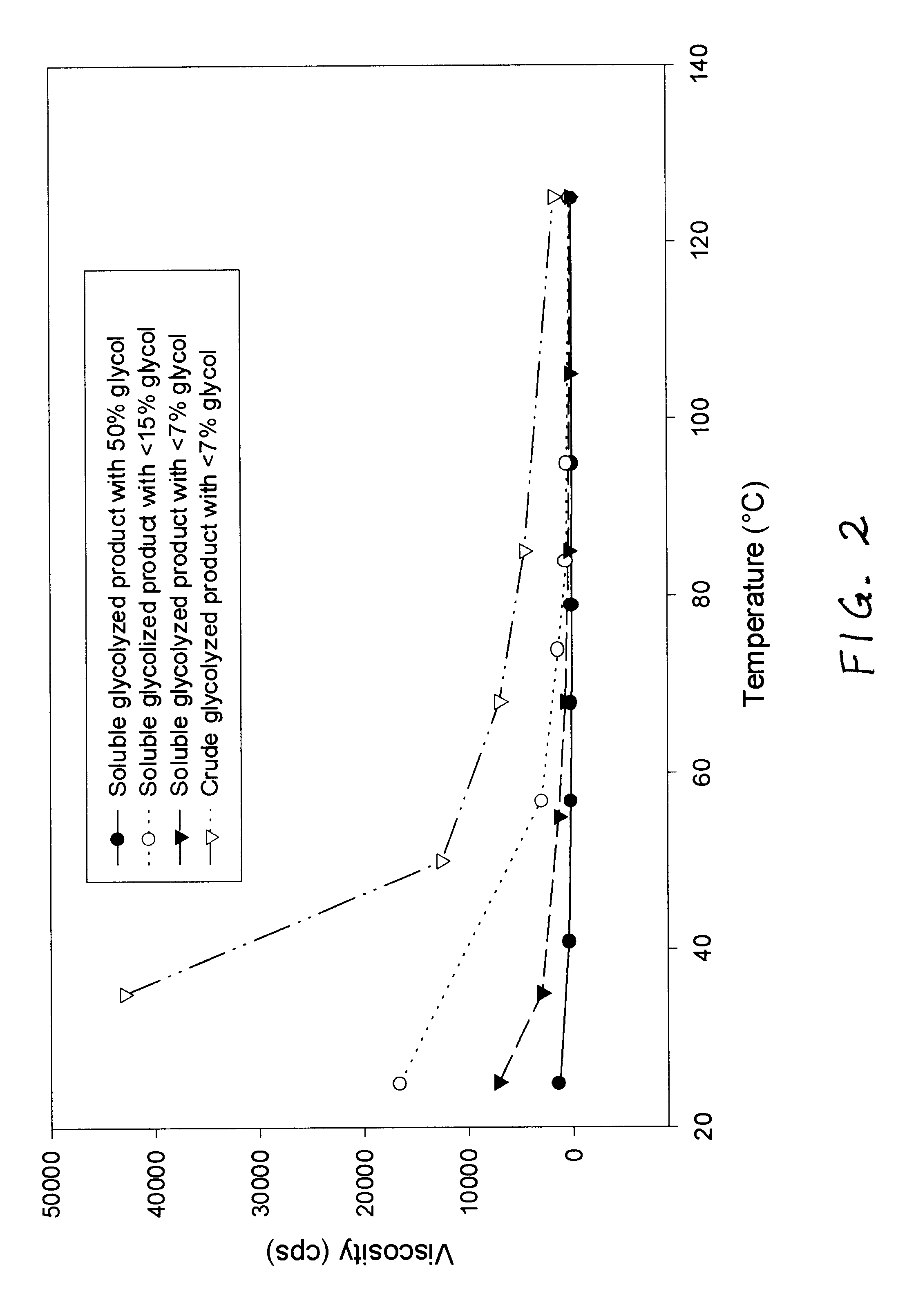

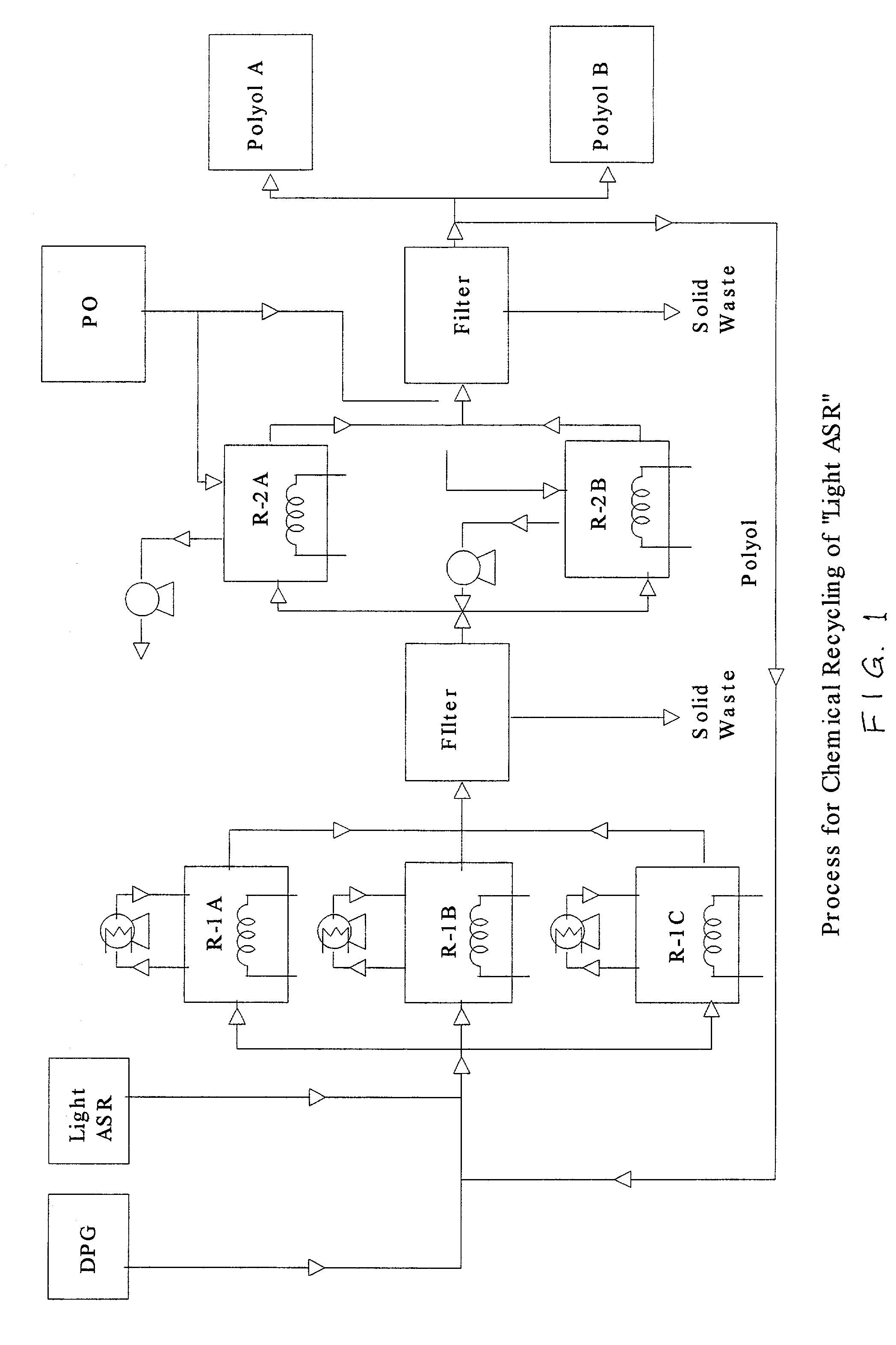

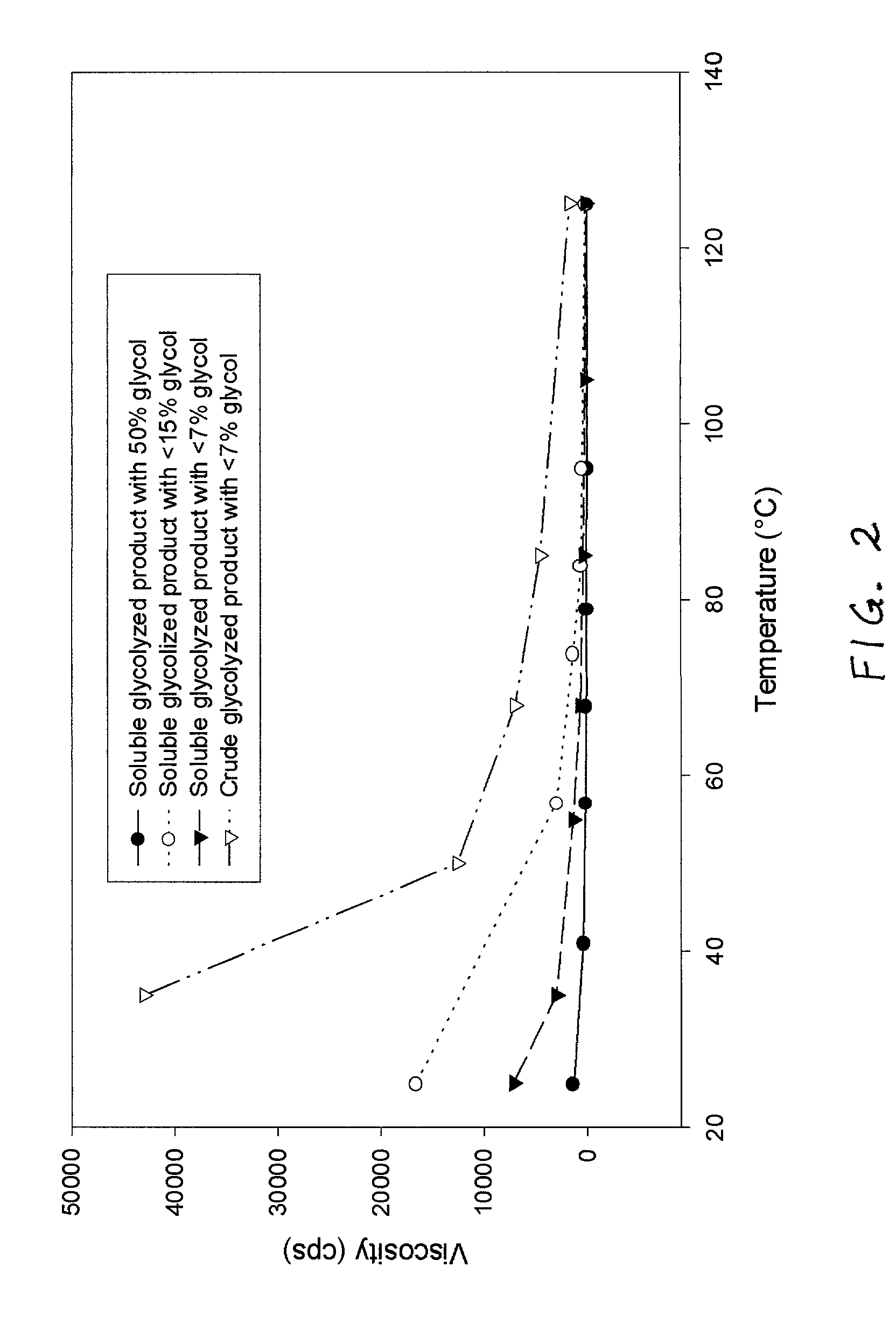

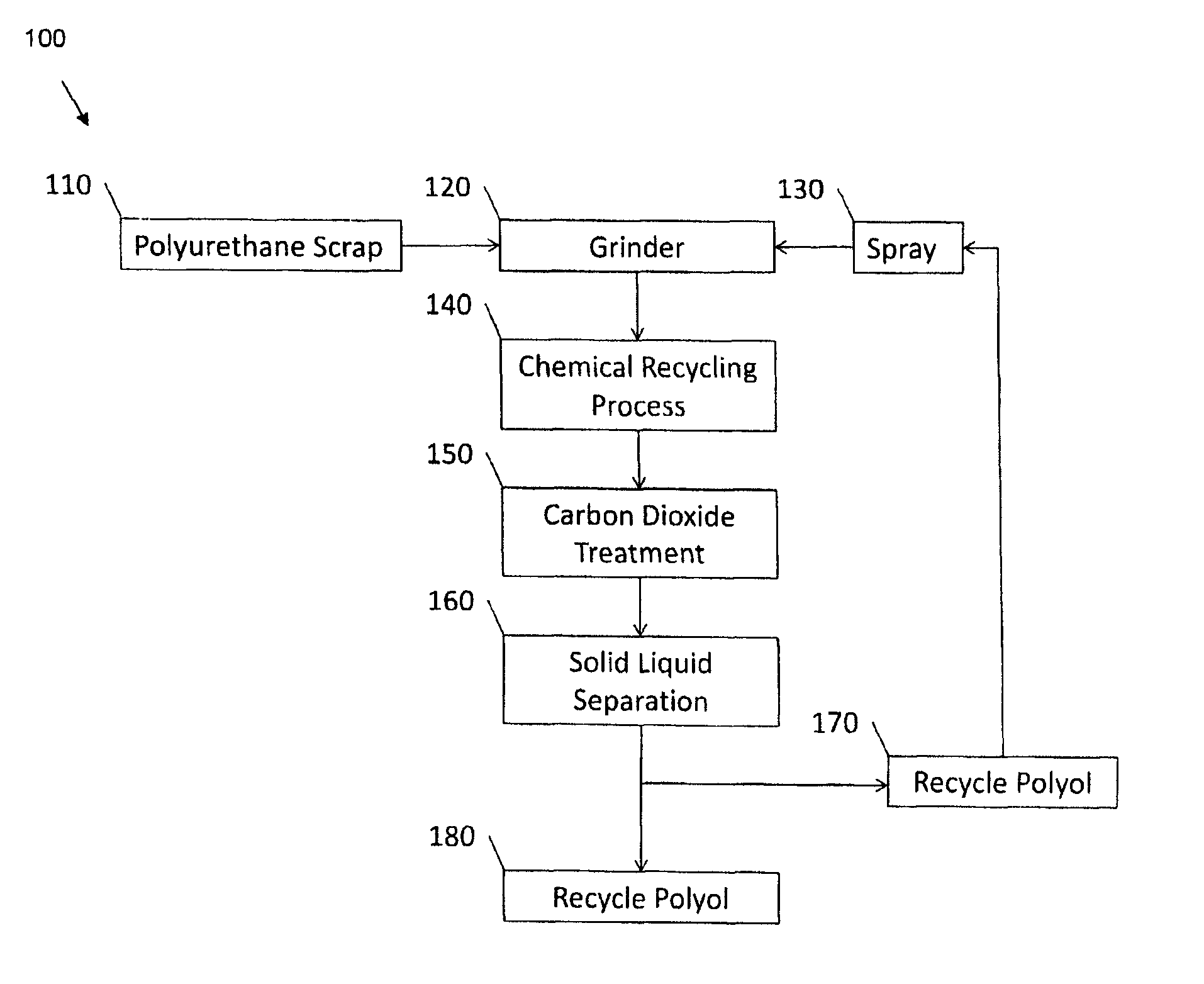

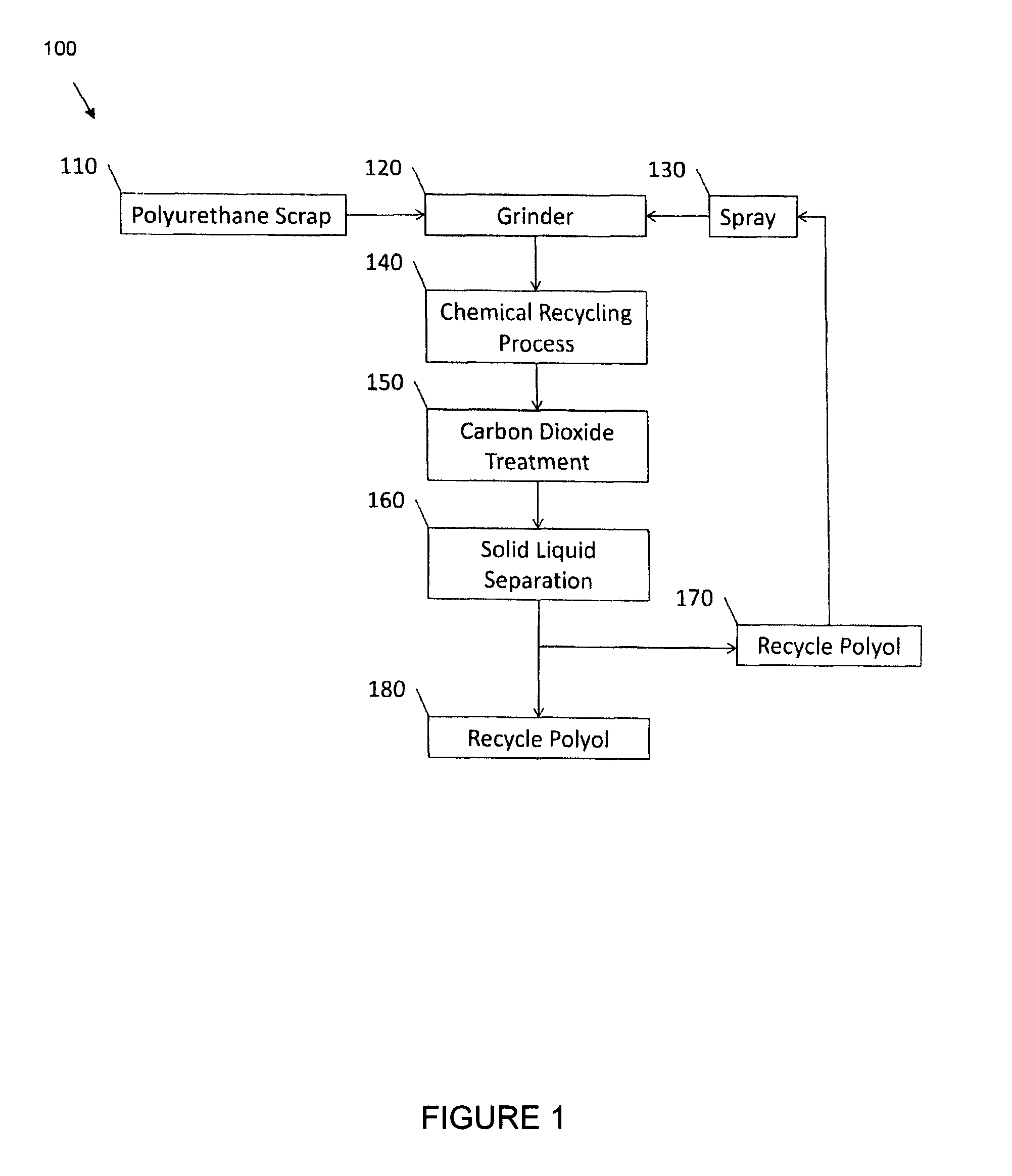

Process for chemical recycling of polyurethane-containing scrap

A process of chemically recycling polyurethane-containing scrap. Polyurethane-containing scrap is subjected to a chemolysis reaction to produce chemolysis polyol products. The chemolysis polyol products are used as initiators in a reaction with alkylene oxide to produce oxyalkylated polyols for preparing polyurethanes.

Owner:TROY POLYMERS

System and method employing direct gasification for power generation

A power generation system (10) and method of operating a power generation system (10). An exemplary power generation system (10) shown in FIG. 1 includes a gasification system (2) for generating a supply (33) of a first gas comprising hydrogen and a supply (39) of a second gas comprising carbon monoxide based on a chemical breakdown of hydrocarbons in a melt (17). A component system (3) produces a supply of steam (99) by reacting one of the streams of gas and a steam turbine (120) generates mechanical power by expanding the steam (99). In an associated method, a melt (17) is created in a gasifier (12) which then receives a hydrocarbon source (22) to generate a continuous supply (33) of a first gas comprising hydrogen while increasing concentration of dissolved carbon in the melt (17). Hydrogen present in the first gas is supplied to a first combustor (90). A continuous supply (39) of a second gas comprising carbon monoxide is generated with carbon present in the melt (17). Carbon monoxide present in the second gas is supplied to a second combustor (80).

Owner:SIEMENS ENERGY INC

Metallurgy method of metal sulfide M1S

InactiveCN101597776AEasy to produceIncrease added valueElectrolysis componentsMetallic materialsMetallic sulfide

The invention relates to a metallurgy method of metal sulfide M1S; in the method, ionic liquid M2X is taken as electrolyte, metal sulfide is taken as a solid-state cathode, or the powder of metal sulfide added with electronic conduction matters or lumps and metal current collectors are compounded for being used as the solid-state cathode, graphite or inertia anode is taken as an anode, the electrolyte is carried out in inert atmosphere or air, the electrolyte temperature is controlled at 120-780 DEG C, the electrolyte time is controlled to lead the electrolysis electric quantity to reach theory needed theory electric quantity and above, the metal sulfide is decomposed into metal products and simple substance S by electrochemistry. The method has simple process, low energy consumption, high additional value of the product, wherein the prepared metal materials such as tantalum powder, tantalum, porous iron and other nanometer metal powder materials or superfine metal powder materials or porous metal materials can be directly used as hydrogen storage materials, battery materials, capacitor materials and the like or as the raw material for powder metallurgy and the like.

Owner:WUHAN UNIV

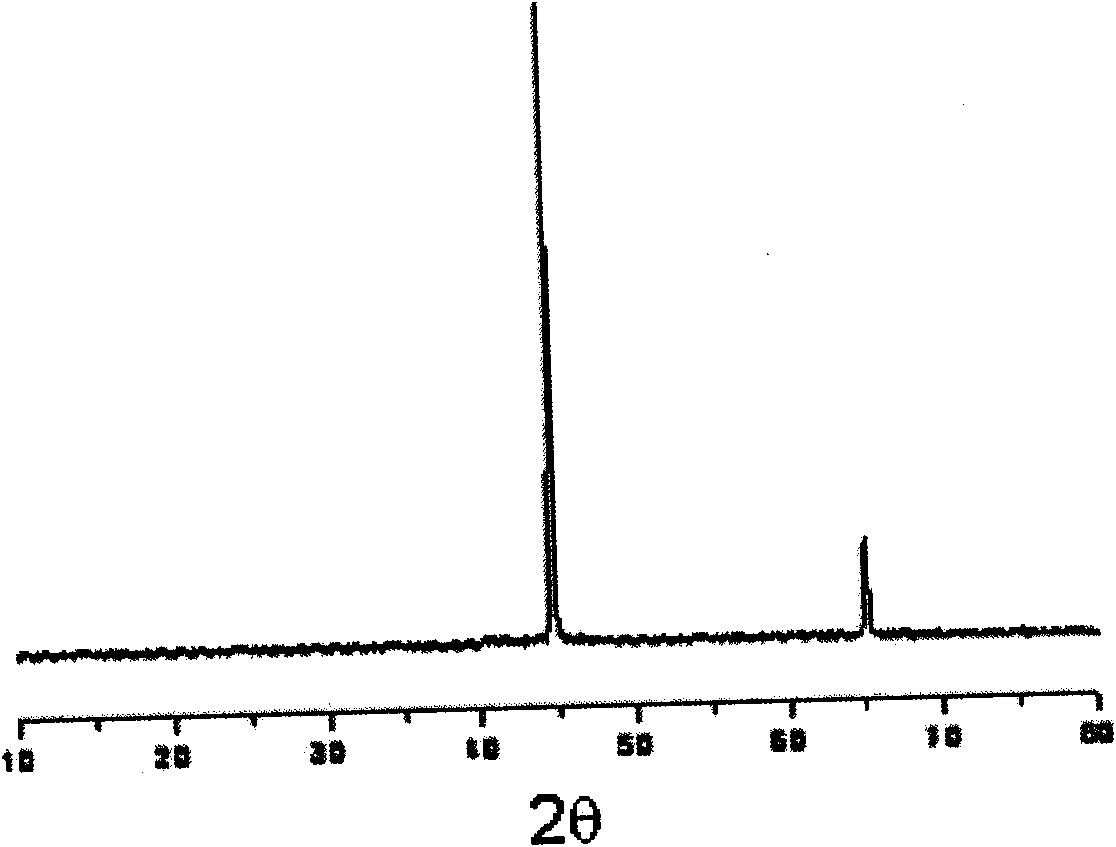

Production of transparent cationically-homogeneous nanostructured refractory oxides at reduced temperatures

InactiveUS6066305AHigh yieldEliminates and reduces disadvantageOxide/hydroxide preparationIron compoundsMolten stateLiquid water

This invention relates to a generic process for producing a refractory oxide which comprises reacting liquid water with: at least one metal fluoride reactant; or at least one metal fluoride reactant and at least one metal oxide reactant; or at least one metal oxide reactant and an aqueous hydrogen fluoride solution, to produce either a colloidal mixture or a solution; drying either the colloidal mixture or solution; heating the dried product to produce a solid state metal hydroxyfluoride; heating the hydroxyfluoride to a temperature at which it chemically decomposes into a cationically-homogeneous and nanostructured solid state metal oxyfluoride; and performing one of the following heating steps: (i) to a solid state decomposition-temperature where the oxyfluoride chemically decomposes into a refractory oxide; or, (ii) to a molten state decomposition-temperature where the oxyfluoride chemically decomposes into a refractory oxide; or, (iii) to a vapor state decomposition-temperature where the oxyfluoride chemically decomposes into a refractory oxide.

Owner:DUGGER CORTLAND OTIS

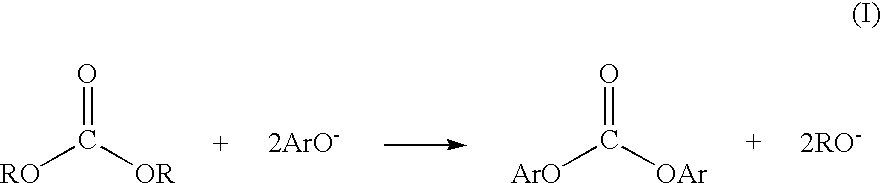

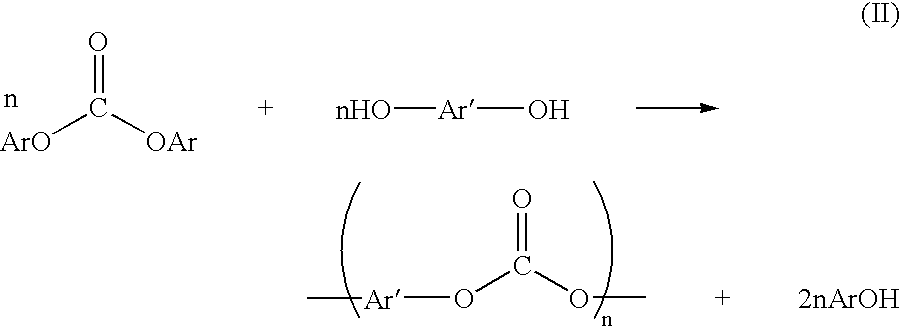

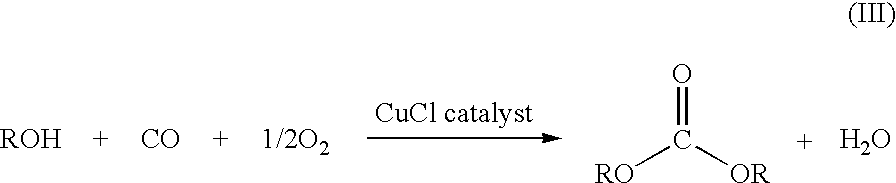

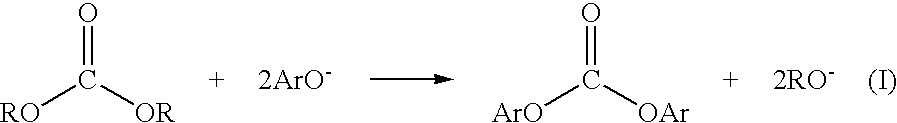

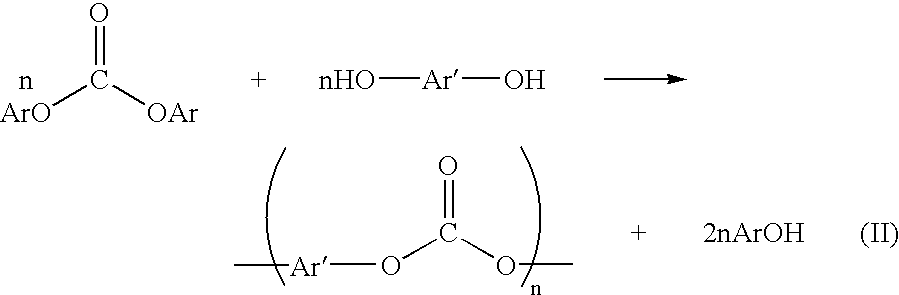

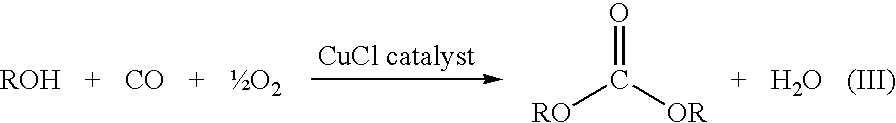

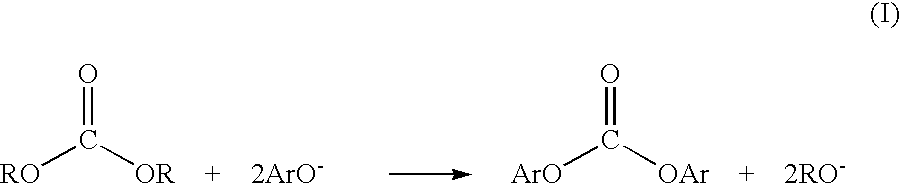

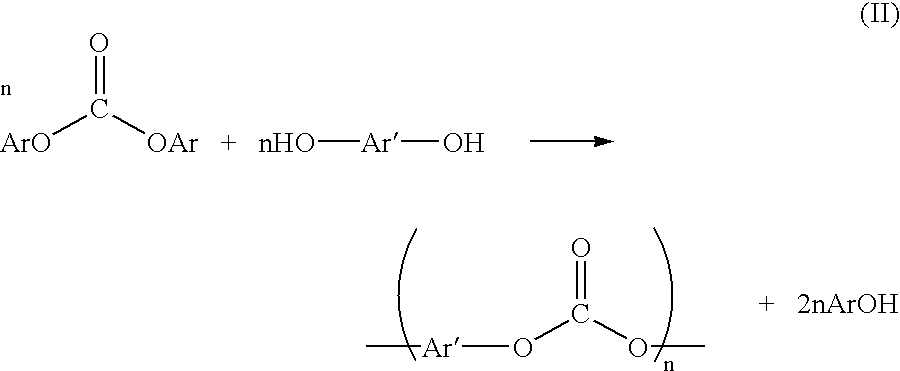

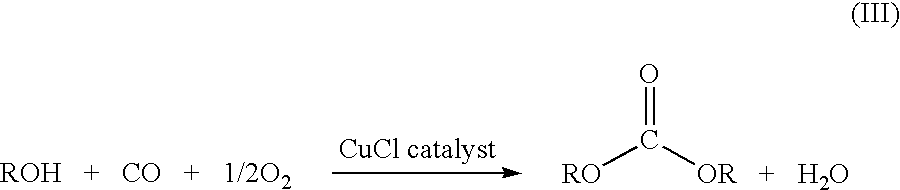

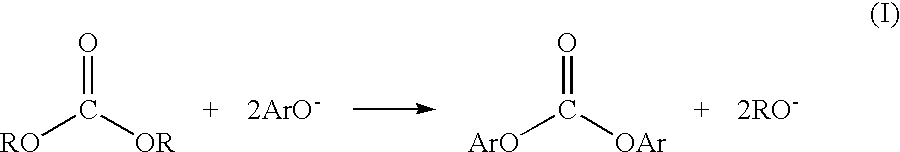

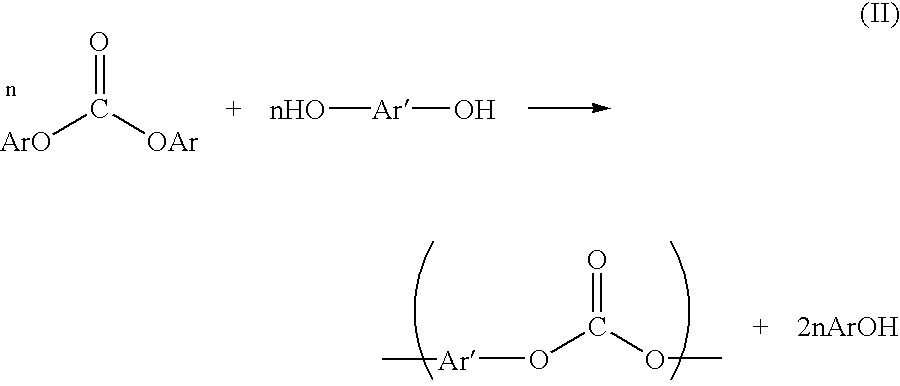

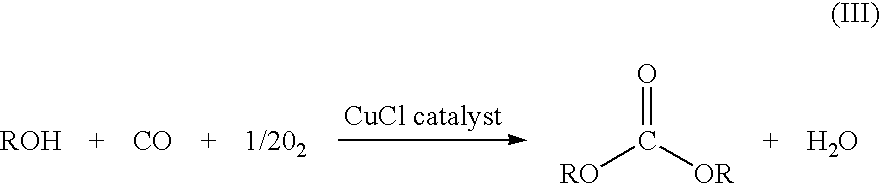

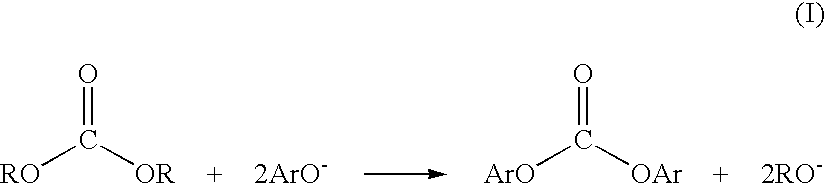

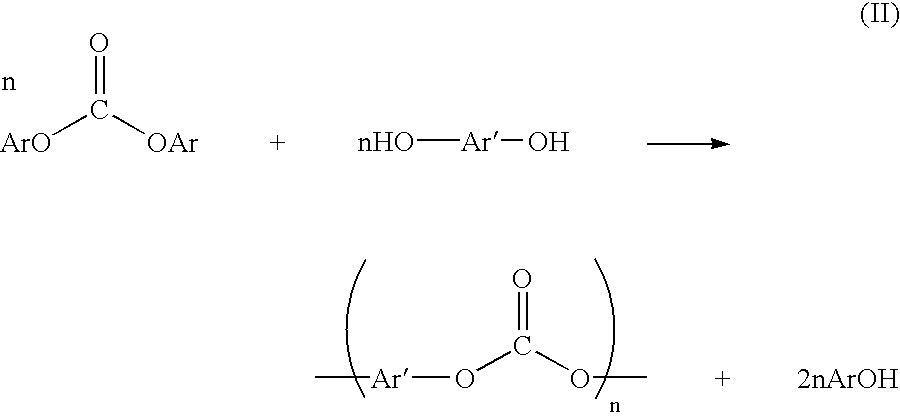

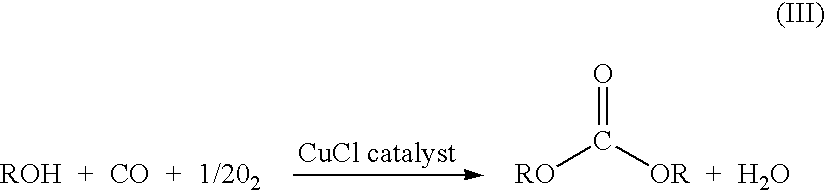

Method for preparing a dialkyl carbonate, and its use in the preparation of diaryl carbonates and polycarbonates

InactiveUS6784277B2Efficient use ofProcess control/regulationOrganic compound preparationPolycarbonateCarbonate

Owner:SABIC GLOBAL TECH BV

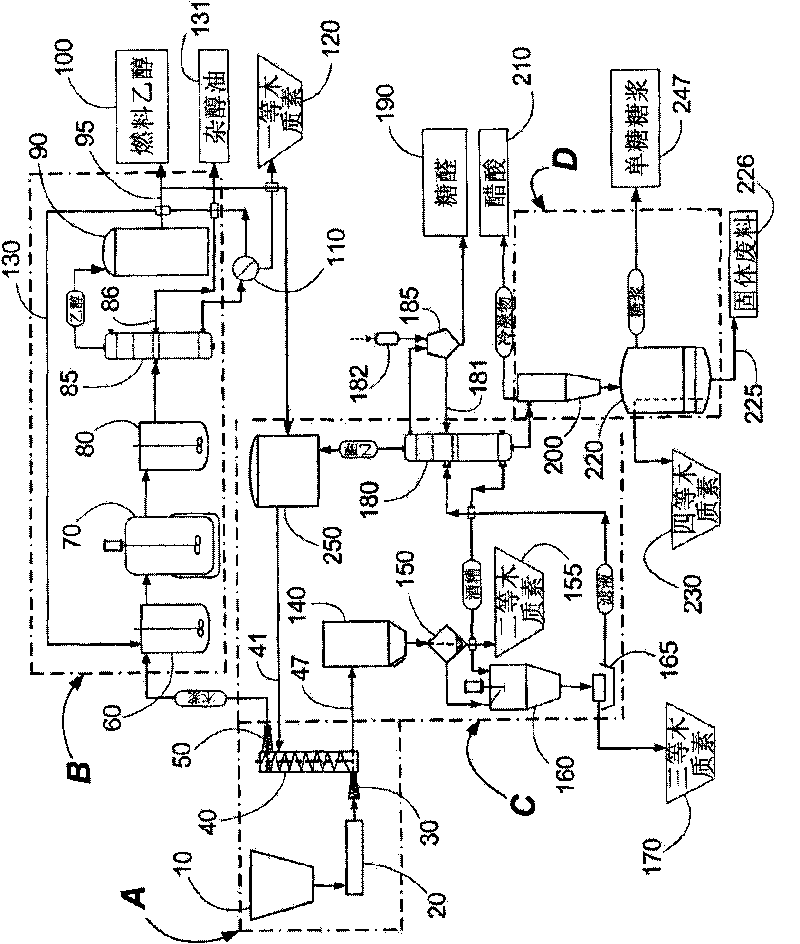

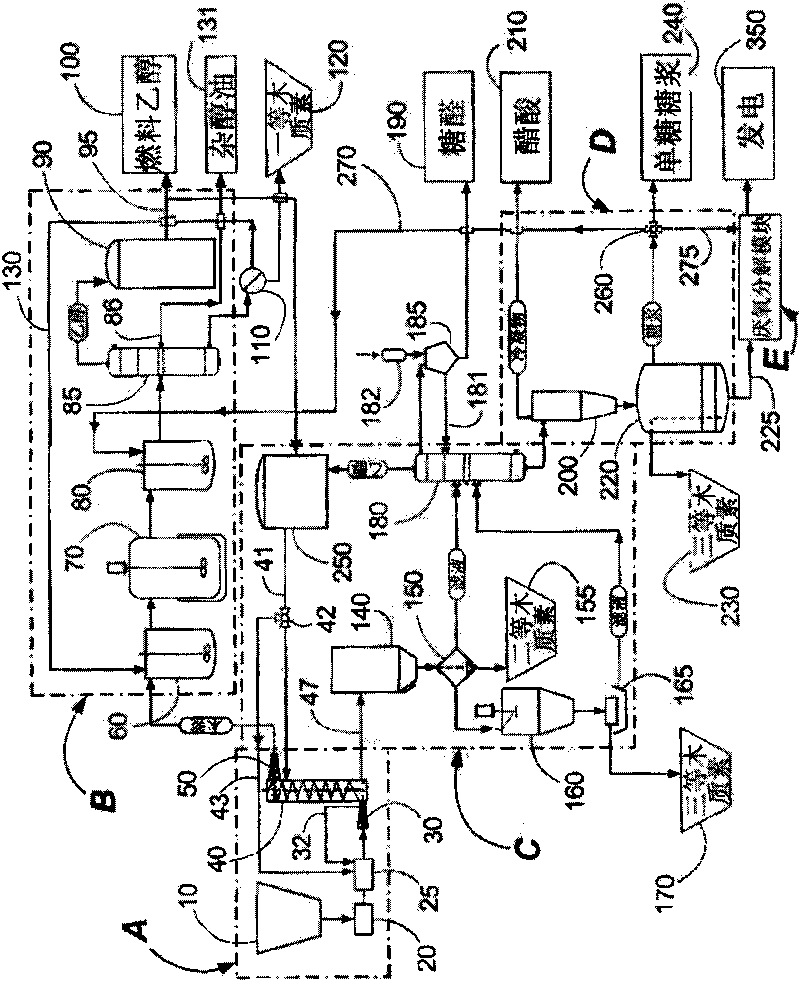

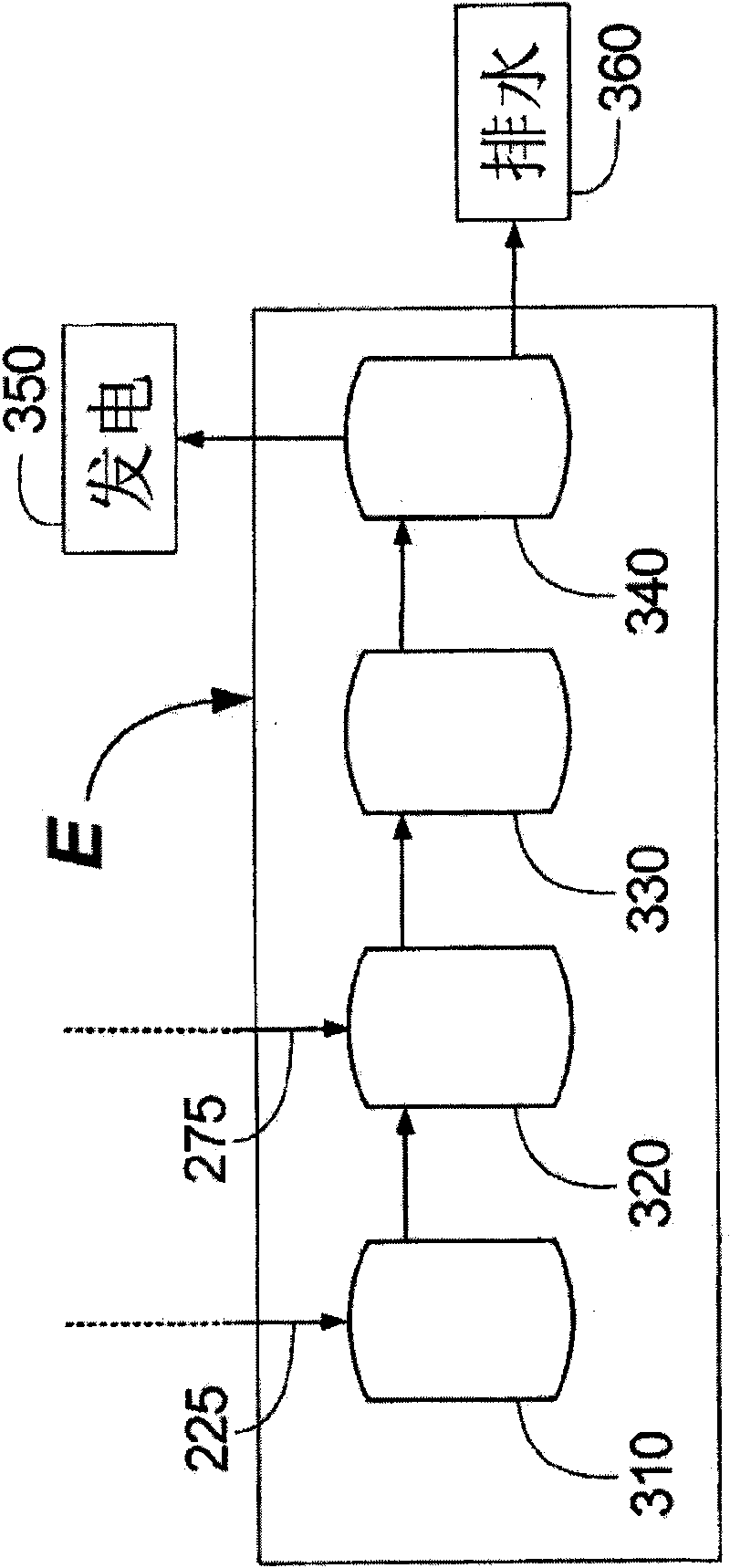

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveCN101711263APromote hydrolysisBioreactor/fermenter combinationsBiological substance pretreatmentsFiberFractionation

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

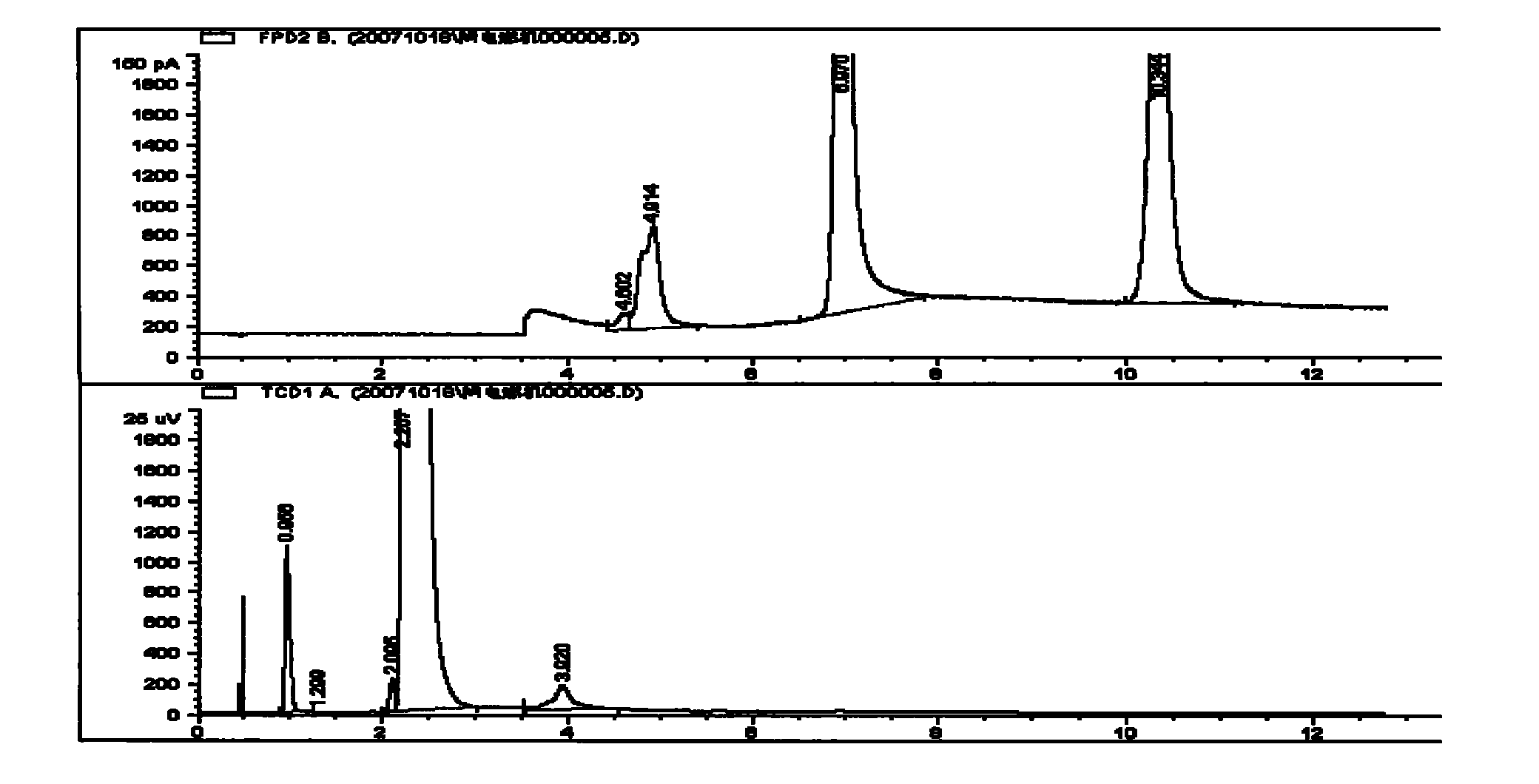

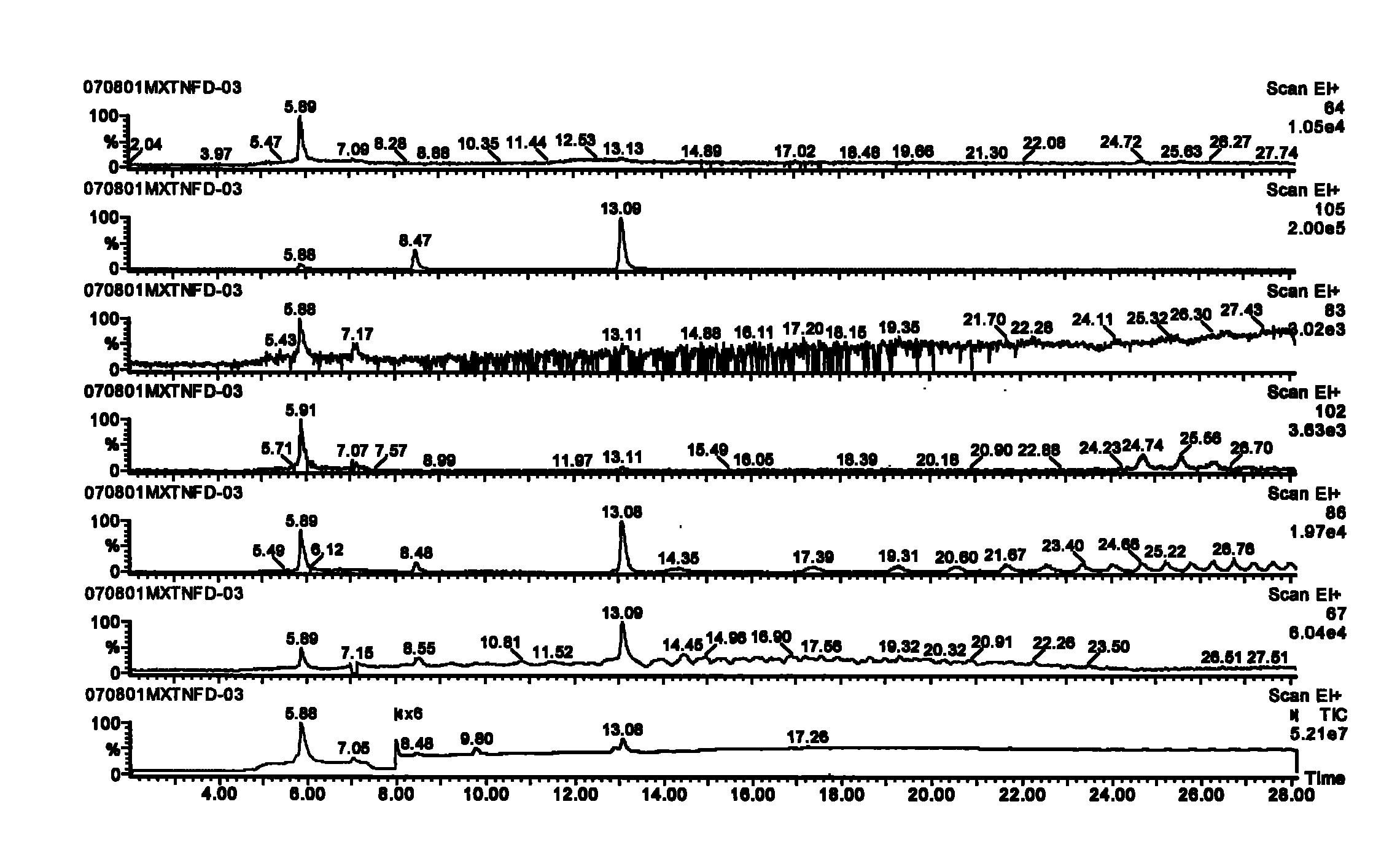

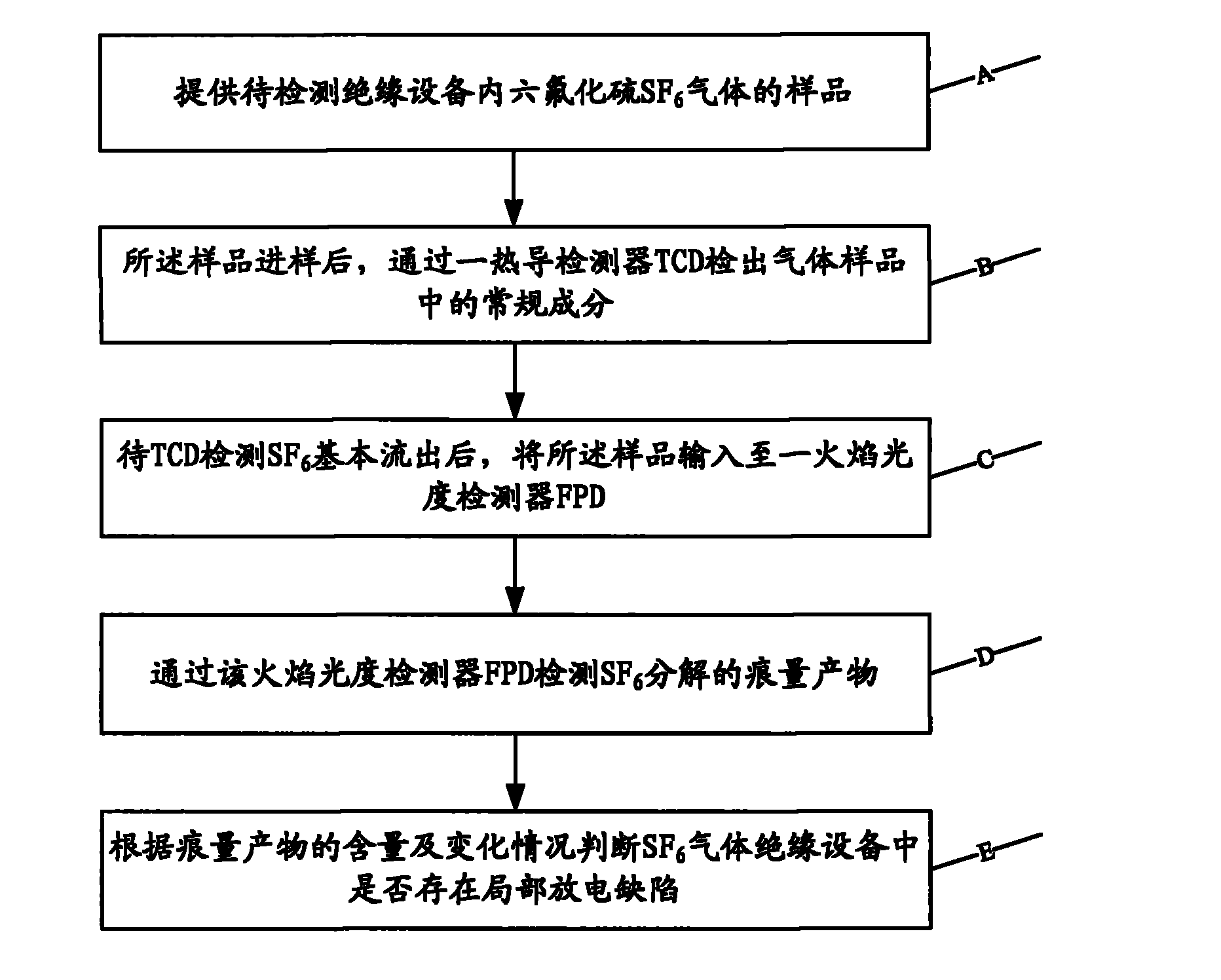

Internal discharge detection method of sulfur hexafluoride gas insulation equipment

InactiveCN101995532AEarly detection of discharge faultsPrecise positioningComponent separationElectrical testingAdditive ingredientSulfur hexafluoride

The invention discloses an internal discharge detection method of sulfur hexafluoride gas insulation equipment, comprising the following steps: A, providing a SF6 (sulfur hexafluoride) gas sample in the insulation equipment to be detected; B, after the sample is introduced in, detecting conventional ingredients in the gas sample by a TCD (thermal conductivity detector); C, After the TCD detects that SF6 almost flows out, inputting the sample into a FPD (flame photometry detector); D, detecting a trace product decomposed by SF6 via the FPD; and E, according to the content and the variation condition of the tract product, judging whether the SF6 gas insulation equipment has local discharge defects. In the invention, the internal insulation condition of electric equipment can be judged according to the chemical decomposer of SF6 gas. In the invention, a detection means for the internal insulation situation of GIS (Gas Insulated Switchgear) equipment is added, equipment station information is enriched, the internal discharge faults of GIS can be found as quickly as possible,equipment operation reliability is improved, a fault air chamber can be positioned quickly and accurately after discharge faults burst in GIS, and maintenance efficiency is improved.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST

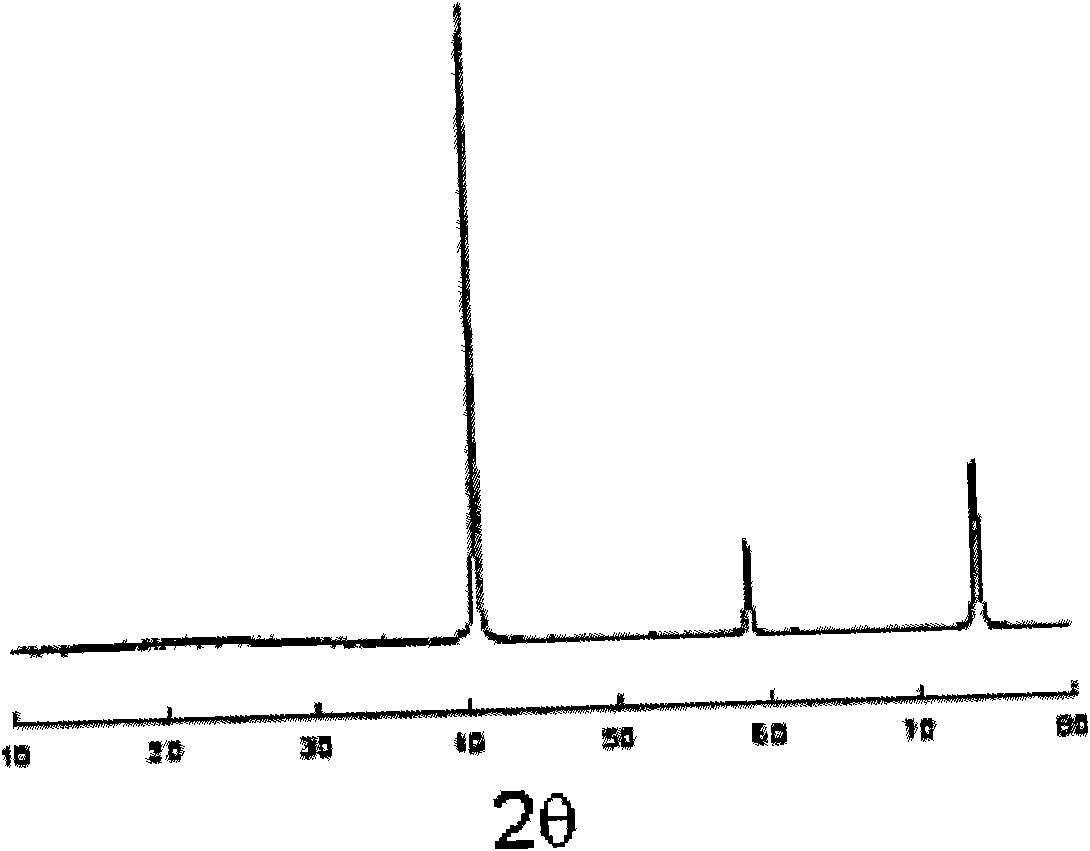

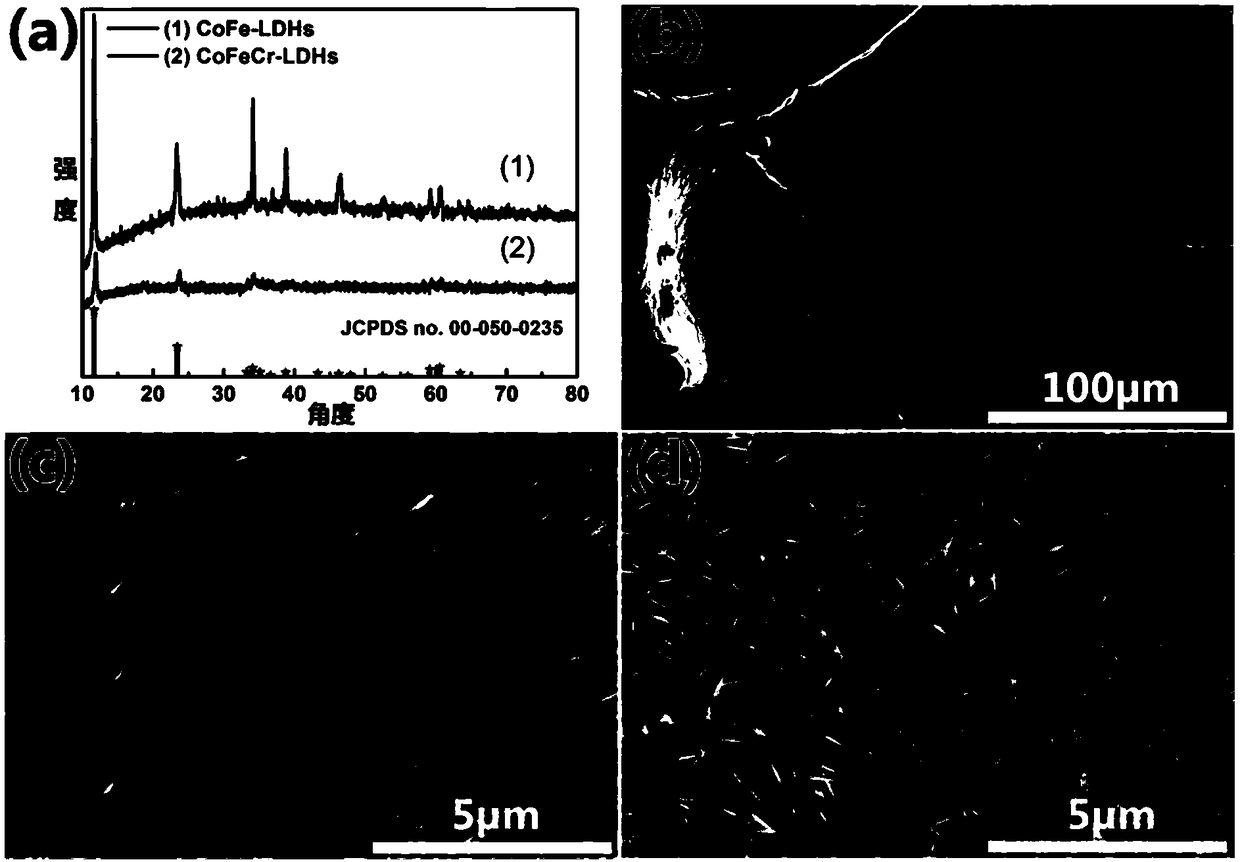

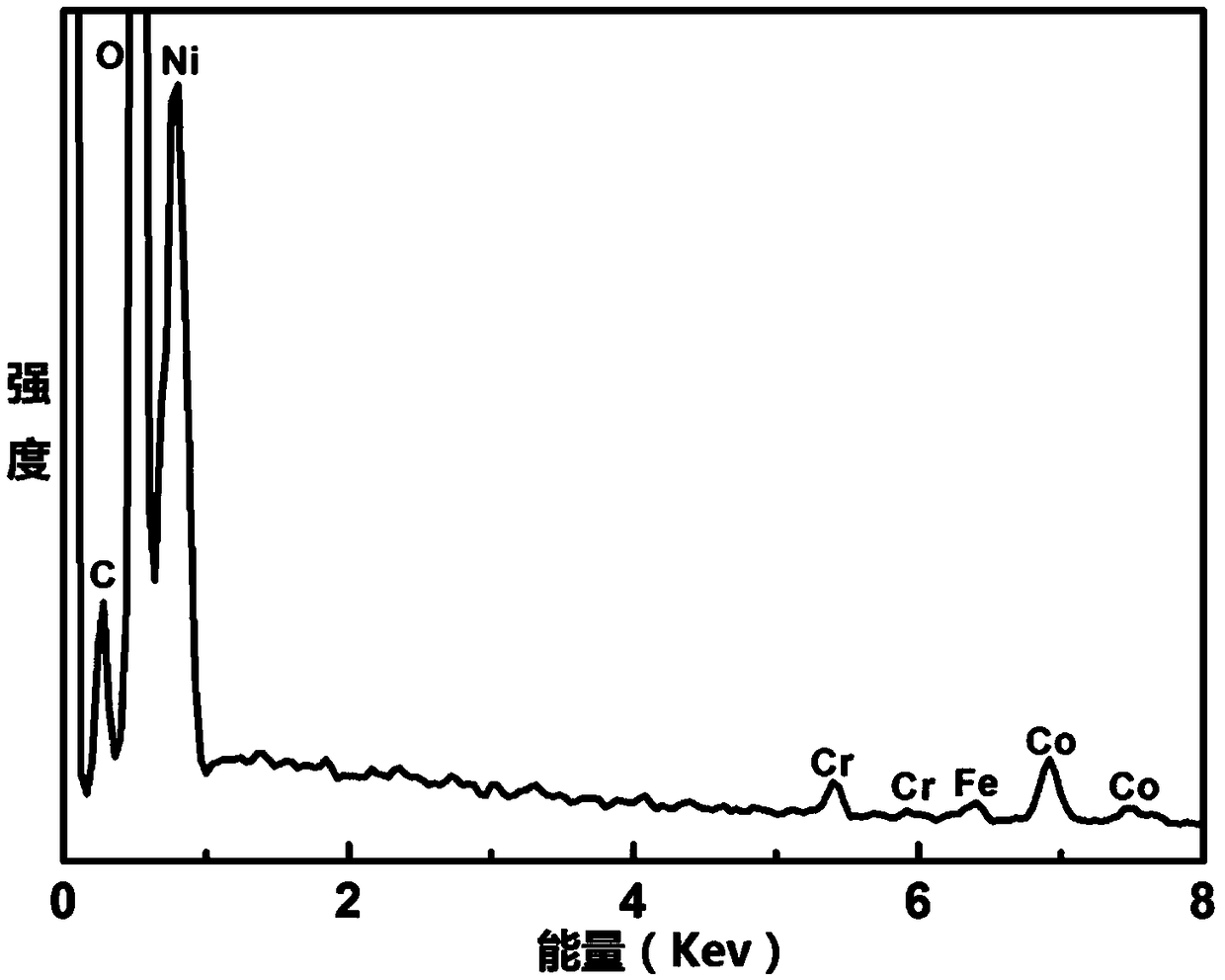

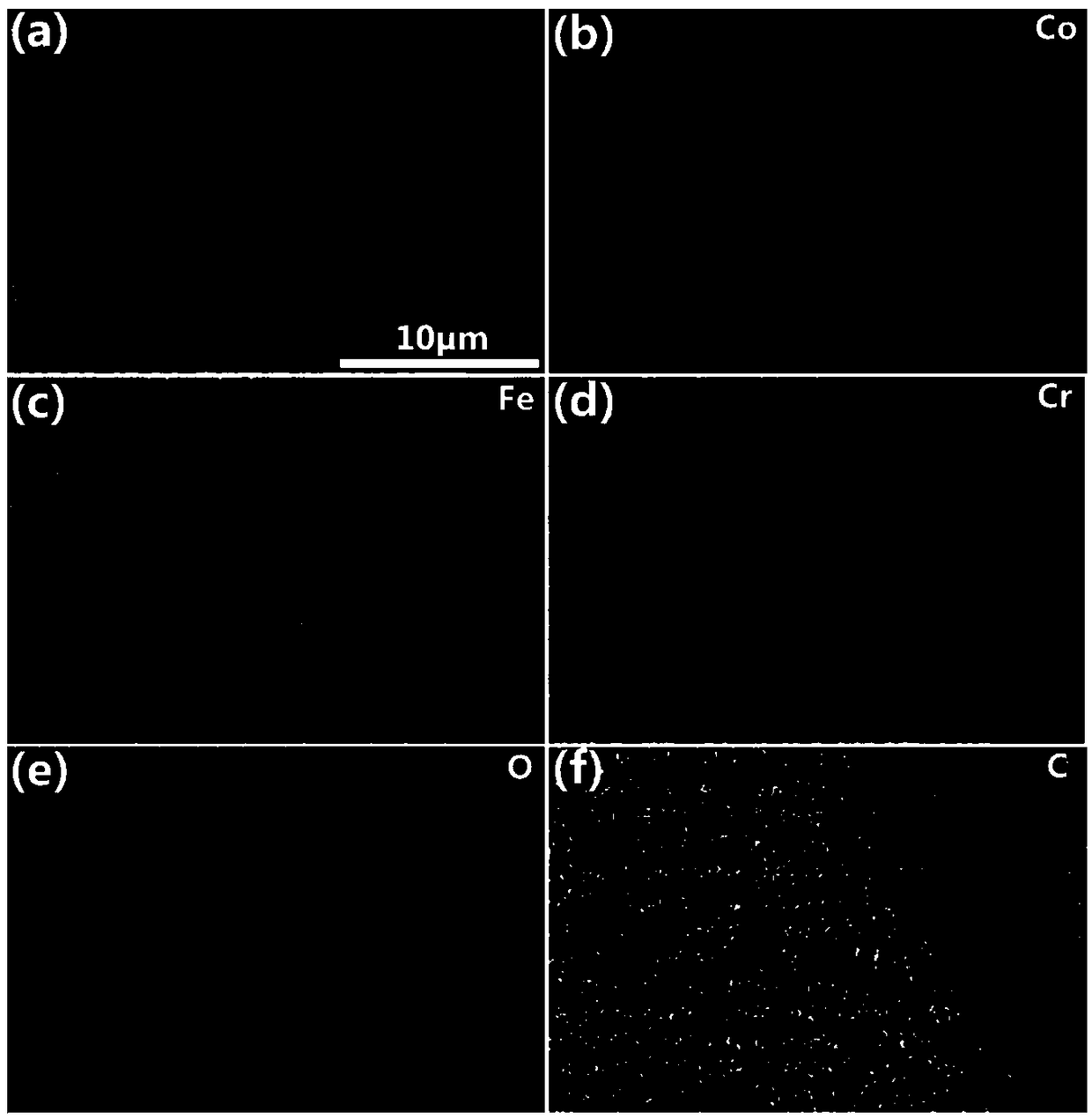

Ternary CoFeCr hydrotalcite nanorod and preparation method and application thereof

InactiveCN108910962ALower overpotentialLow costNanotechnologyCobalt compoundsElectrolysisElectrochemical decomposition

The invention discloses a ternary CoFeCr hydrotalcite nanorod and a preparation method and application thereof. The preparation method comprises the steps: mixing cobalt nitrate, iron nitrate, chromium nitrate, urea and ammonium fluoride in water so as to prepare a precursor mixed solution, placing a substrate in the precursor mixed solution, transferring the substrate together with the precursormixed solution to an autoclave, and then performing a reacting at 110-130 DEG C for 360-600 minutes so as to prepare the ternary CoFeCr hydrotalcite nanorod on the substrate. The ternary CoFeCr hydrotalcite nanorod together with the substrate is directly used as a working electrode for electrochemical decomposition of water. Not only the ternary CoFeCr hydrotalcite nanorod has better performance of water electrolysis and oxygen evolution than transition metal oxide in the prior art, but also the preparation process is simple, fast and efficient, has low production energy consumption, low production cost, environmental protection and no pollution, and is suitable for large-scale industrial production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for preparing a dialkyl carbonate, and its use in the preparation of diaryl carbonates and polycarbonates

InactiveUS20030055199A1Efficient use ofProcess control/regulationOrganic compound preparationPolycarbonateCarbonate

Unexpected corrosion of downstream sections of a dialkyl carbonate manufacturing apparatus has been traced to alkyl chloroformate impurities, which slowly decompose to yield hydrochloric acid. An improved process and apparatus for dialkyl carbonate synthesis reduce corrosion by physically removing or chemically decomposing the alkyl chloroformate impurities within the corrosion-resistant upstream sections of the apparatus.

Owner:SABIC GLOBAL TECH BV

Process for chemical recycling of polyurethane-containing scrap

A process of chemically recycling polyurethane-containing scrap. Polyurethane-containing scrap is subjected to a chemolysis reaction to produce chemolysis polyol products. The chemolysis polyol products are used as initiators in a reaction with alkylene oxide to produce oxyalkylated polyols for preparing polyurethanes.

Owner:TROY POLYMERS

Production of cationically-homogeneous nanostructured refractory oxides at reduced temperatures

InactiveUS20020025294A1High yieldEliminates and reduces disadvantageMaterial nanotechnologyOxide/hydroxide preparationMolten stateHydrogen fluoride

This invention relates to a generic process for producing a refractory oxide which comprises reacting an aqueous hydrogen fluoride solution or its derivatives with: at least one metal fluoride reactant; or at least one metal fluoride reactant and at least one metal oxide reactant; or at least one metal oxide reactant, to produce either a colloidal mixture or a solution; drying either the colloidal mixture or solution; heating the dried product to produce a solid state metal hydroxyfluoride; heating the hydroxyfluoride to a temperature at which it chemically decomposes into a cationically-homogeneous and nanostructured solid state metal oxyfluoride; and performing one of the following heating steps: (i) to a solid state decomposition-temperature where the oxyfluoride chemically decomposes into a refractory oxide; or, (ii) to a molten state decomposition-temperature where the oxyfluoride chemically decomposes into a refractory oxide; or, (iii) to a vapor state decomposition-temperature where the oxyfluoride chemically decomposes into a refractory oxide.

Owner:DUGGER CORTLAND OTIS

Process for recovery of ruthenium from a ruthenium-containing supported catalyst material

InactiveUS20080287282A1High purityHigh purity gradeCell electrodesFinal product manufactureHydrogen halideRuthenium Compounds

Process to recover ruthenium in the form of ruthenium halide, particularly ruthenium chloride, from a ruthenium-containing supported catalyst material comprising:a) chemically decomposing the ruthenium-containing supported catalyst material;b) producing a raw ruthenium salt solution;c) purifying the raw ruthenium salt solution and optionally stripping gaseous ruthenium tetroxide from the raw ruthenium salt solution; andd) treating the purified ruthenium compound obtained in c), particularly the ruthenium tetroxide, with hydrogen halide or hydrohalic acid to obtain ruthenium halide, particularly with hydrogen chloride or hydrochloric acid to obtain ruthenium chloride.

Owner:BAYER MATERIALSCIENCE AG

Negative ion putty

InactiveCN1624053AImprove immunityImprove water resistanceFilling pastesPolyvinyl alcoholSilicon dioxide

A negative-ion putty able to durably release hydroxy negative ions to eliminate the harmful gases and odor in indoor air, such as formaldehyde, benzene, ammonia, NOx, etc and emit infrared rays to improve human immunity is prepared from polyvinyl alcohol, colloidal powder surfactant, active SiO2, bihydrated gypsum, talc powder, hydroxymethyl cellulose, heavy calcium carbonate, calcium hydroxide and negative-ion ore powder.

Owner:马国栋

Method for preparing a dialkyl carbonate, and its use in the preparation of diaryl carbonates and polycarbonates

InactiveUS20030092872A1Efficient use ofProcess control/regulationOrganic compound preparationManufactured apparatusPolycarbonate

Unexpected corrosion of downstream sections of a dialkyl carbonate manufacturing apparatus has been traced to alkyl chloroformate impurities, which slowly decompose to yield hydrochloric acid. An improved process and apparatus for dialkyl carbonate synthesis reduce corrosion by physically removing or chemically decomposing the alkyl chloroformate impurities within the corrosion-resistant upstream sections of the apparatus.

Owner:SABIC GLOBAL TECH BV

Method and apparatus for preparing a dialkyl carbonate, and its use in the preparation of diaryl carbonates and polycarbonates

InactiveUS20030060650A1Efficient use ofProcess control/regulationOrganic compound preparationManufactured apparatusPolycarbonate

Unexpected corrosion of downstream sections of a dialkyl carbonate manufacturing apparatus has been traced to alkyl chloroformate impurities, which slowly decompose to yield hydrochloric acid. An improved process and apparatus for dialkyl carbonate synthesis reduce corrosion by physically removing or chemically decomposing the alkyl chloroformate impurities within the corrosion-resistant upstream sections of the apparatus.

Owner:SABIC GLOBAL TECH BV

Creosote and soot destroying fire log

InactiveUS20040168366A1Reduce corrosionImproved creosote and soot removing compositionBiofuelsSolid fuelsCreosoteSolid fuel

A processed solid fuel composition incorporating agents for destroying creosote and soot within flue ducts and chimneys of fireplaces, solid fuel stoves and other heating devices is disclosed, along with a method for its manufacture and a method for its use. The composition is made up of a combination of compressed cellulosic particulate material and a chemical and / or catalytic creosote and soot removing agent, and is molded in the form of a fire log in the preferred embodiment. The composition may be used alone, but is ideally applied to an active fire to treat a chimney flue by combined heating and chemical disaggregation of accumulated creosote and soot deposits.

Owner:SCHAEFER CLARK

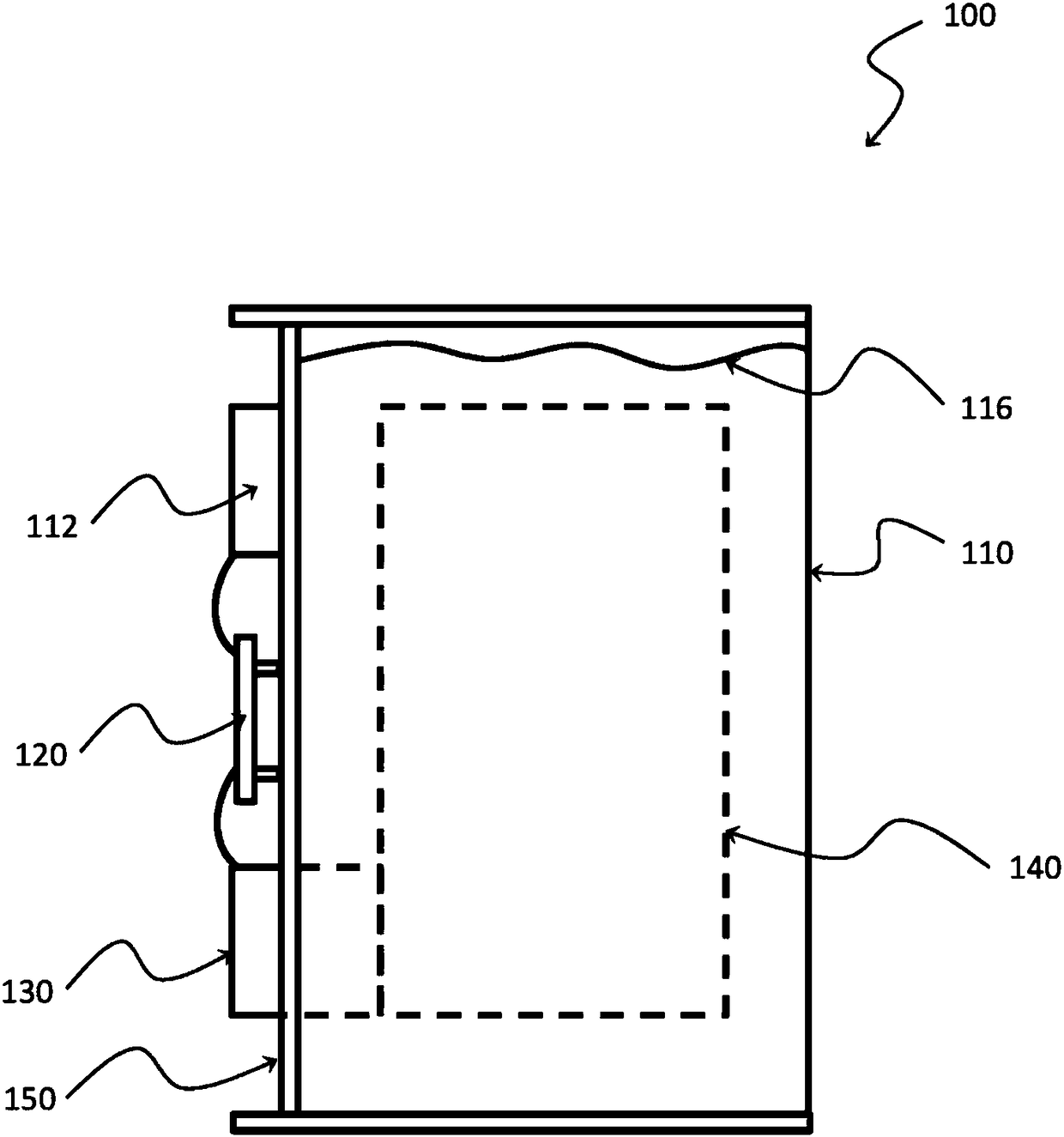

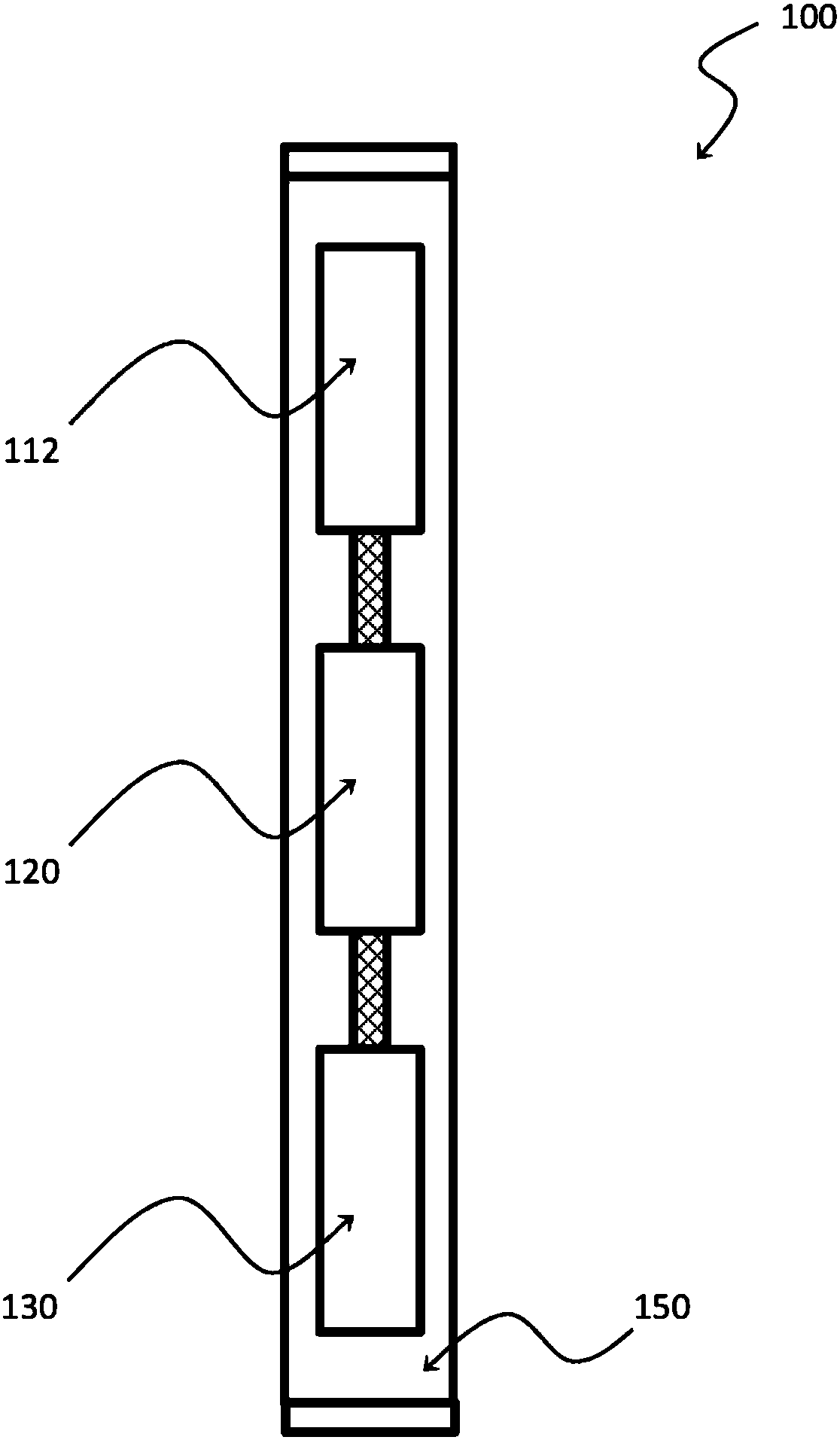

An immersion cooling system

A cooling system for cooling of a heat generating electrical component, in particular to reduce the likelihood of overheating of electrical components or chemical breakdown of coolant fluid. The cooling system has a coolant liquid to absorb excess energy from the heat generating electrical component, the coolant liquid having an energy input threshold above which chemical breakdown of the coolantliquid occurs. A cooling module defines a volume containing the coolant liquid, wherein the heat generating electrical component is mounted within the volume and immersed in the coolant liquid. A power input is arranged to supply power into the cooling module to the heat generating electrical component, and a power regulator is provided external to the volume of the cooling module and connected tothe power input so as to regulate the power supplied into the cooling module. Cooling systems are also described having coolant liquid comprising dissolved oxygen, having at least one element arranged within the volume comprising aluminium and / or aluminium oxide, and / or having a sealed volume with at least one seal which opens at a predetermined pressure or temperature corresponding to a temperature below the temperature at which the coolant liquid breaks down.

Owner:爱思欧托普集团有限公司

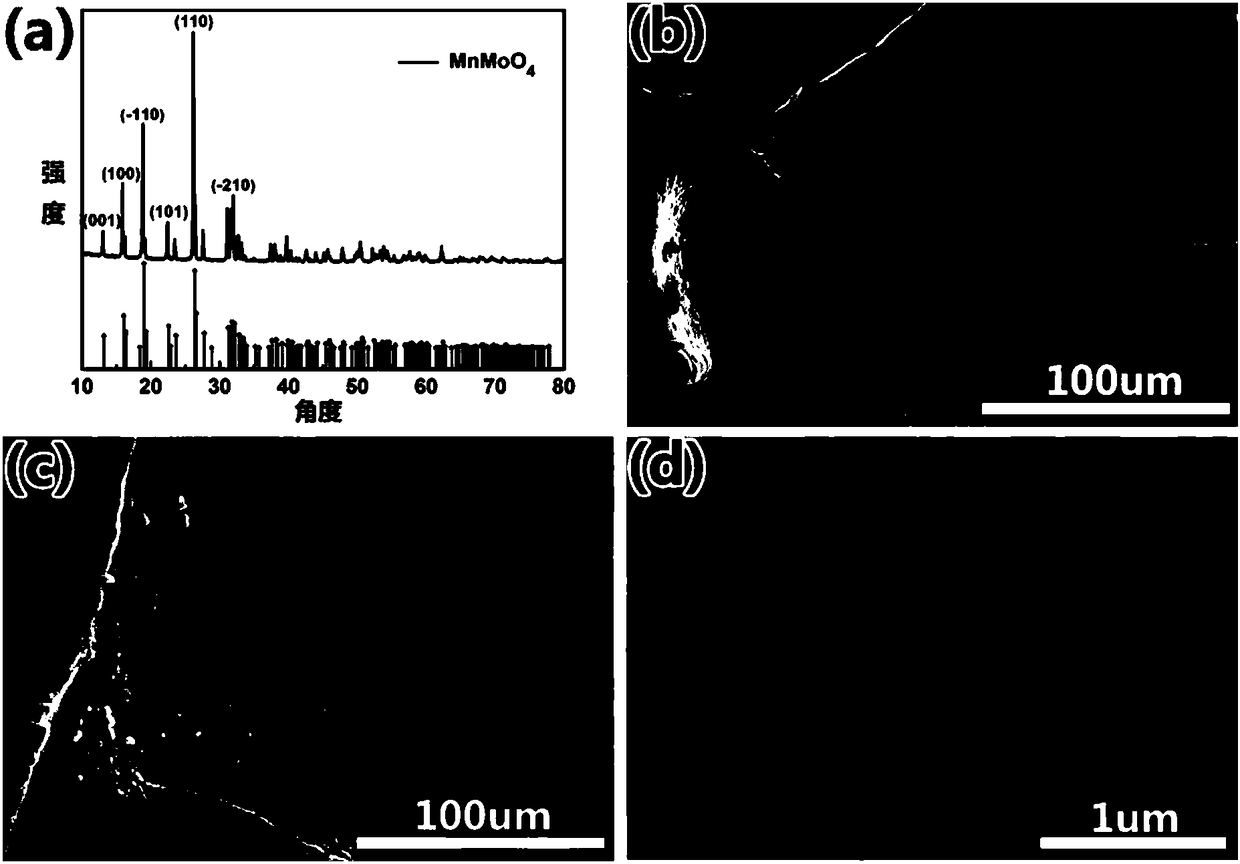

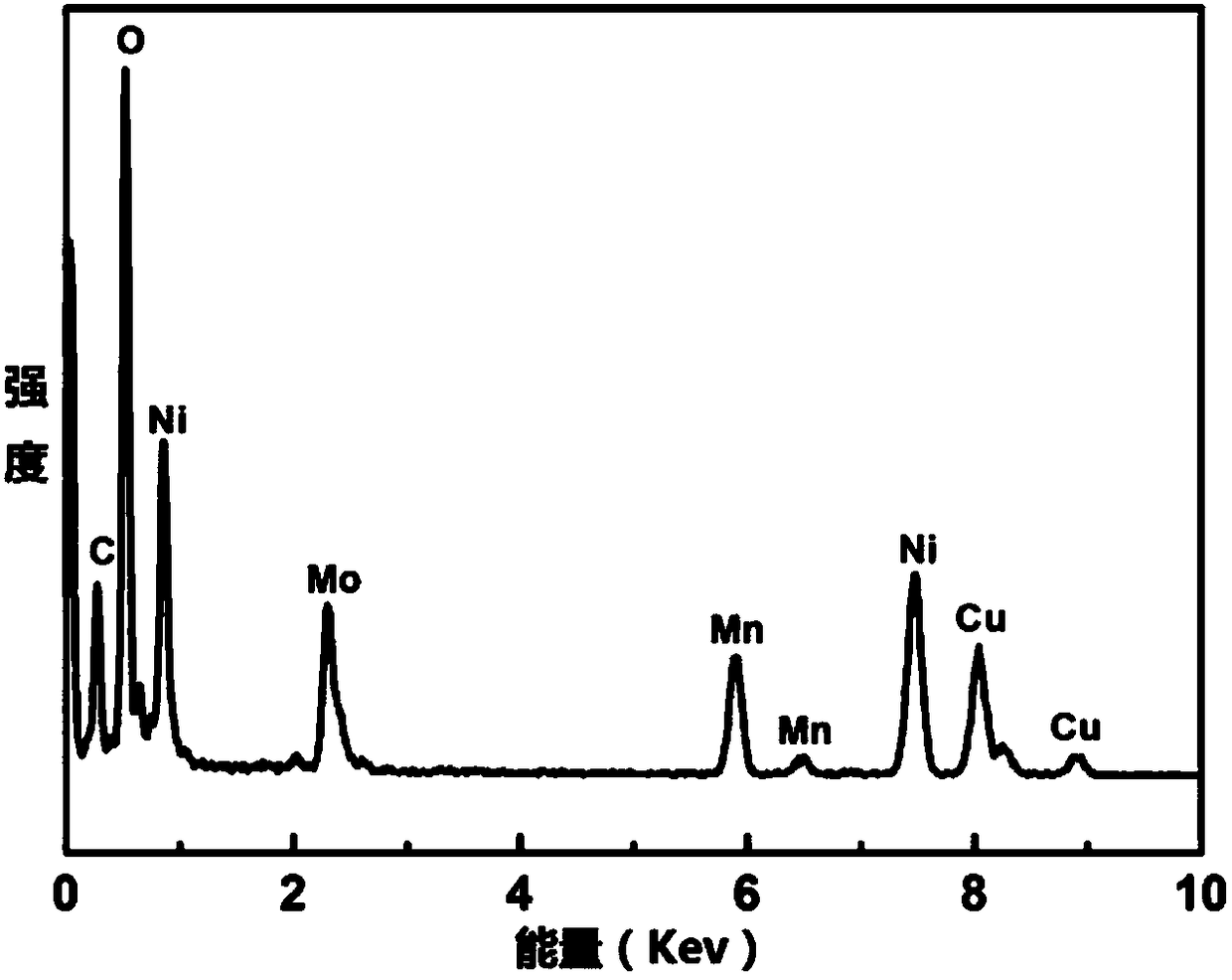

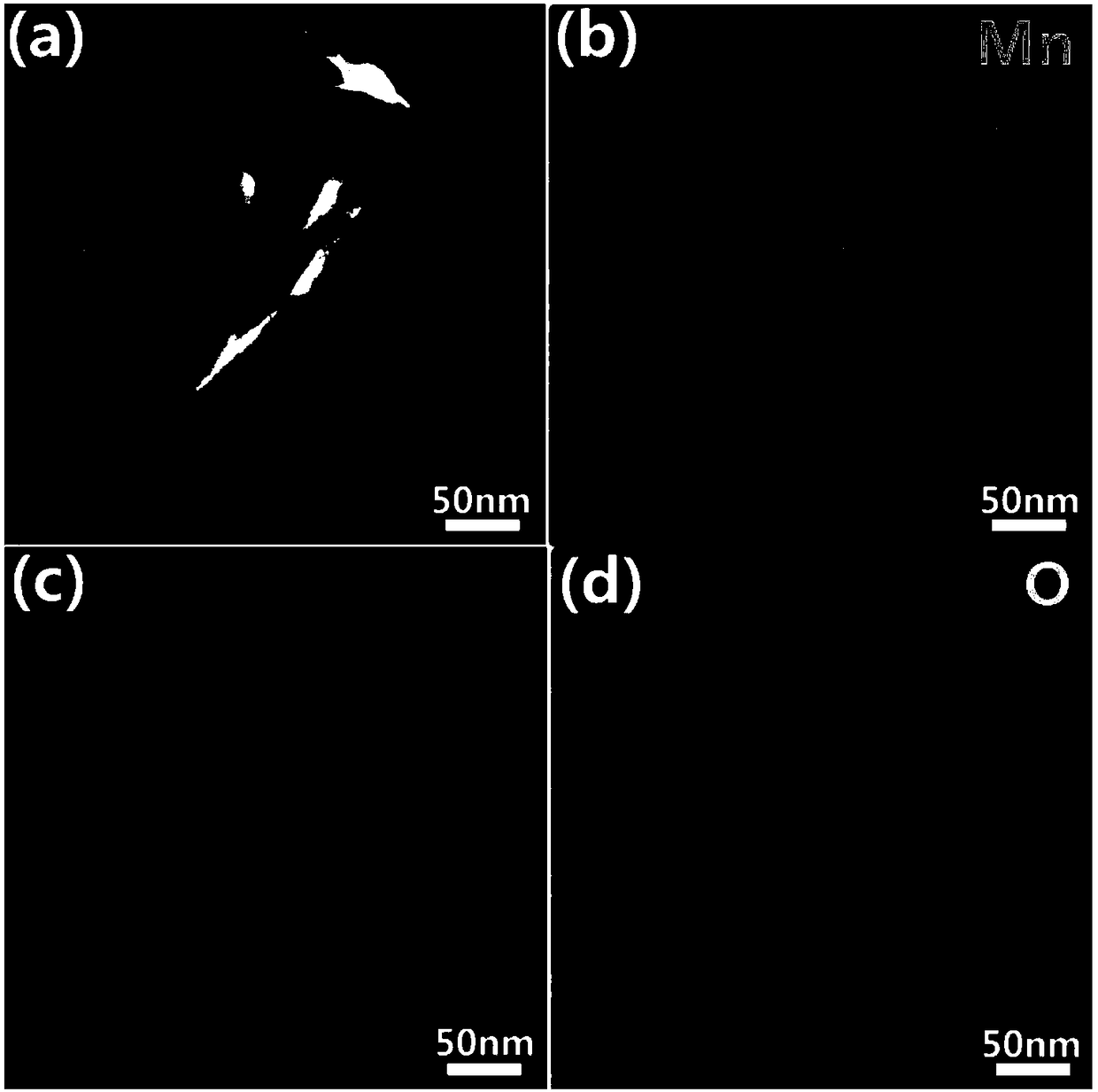

Manganese molybdate nanosheet material and preparation method and application thereof

InactiveCN108251862AFast preparationEfficient preparationMetallic material coating processesElectrodesSodium molybdateMolybdate

The invention discloses a manganese molybdate nanosheet material and a preparation method and application thereof. The preparation method comprises the steps of mixing sodium molybdate and manganese chloride in water regulating the concentration of sodium molybdate in the mixed solution to be 0.5-1.5mmol / l and regulating the concentration of manganese chloride to be 0.5-1.5mmol / l, thus obtaining aprecursor mixing solution; feeding a substrate into the precursor mixing solution; transferring the substrate and the precursor mixing solution into a high-pressure kettle; reacting for 360-480min under the temperature of 160-180 DEG C; and washing and drying, thus obtaining the MnMoO4 nanosheet on the substrate. The manganese molybdate nanosheet material is directly used as a working electrolytefor electrochemically decomposing water; the manganese molybdate nanosheet material is high in water electrolyzing catalyzing activity in electrolyte environments with different pH, and moreover, themanganese molybdate nanosheet material is quick to act, high in efficiency, low in cost, simple to prepare, environmentally friendly, and suitable for massive industrial production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

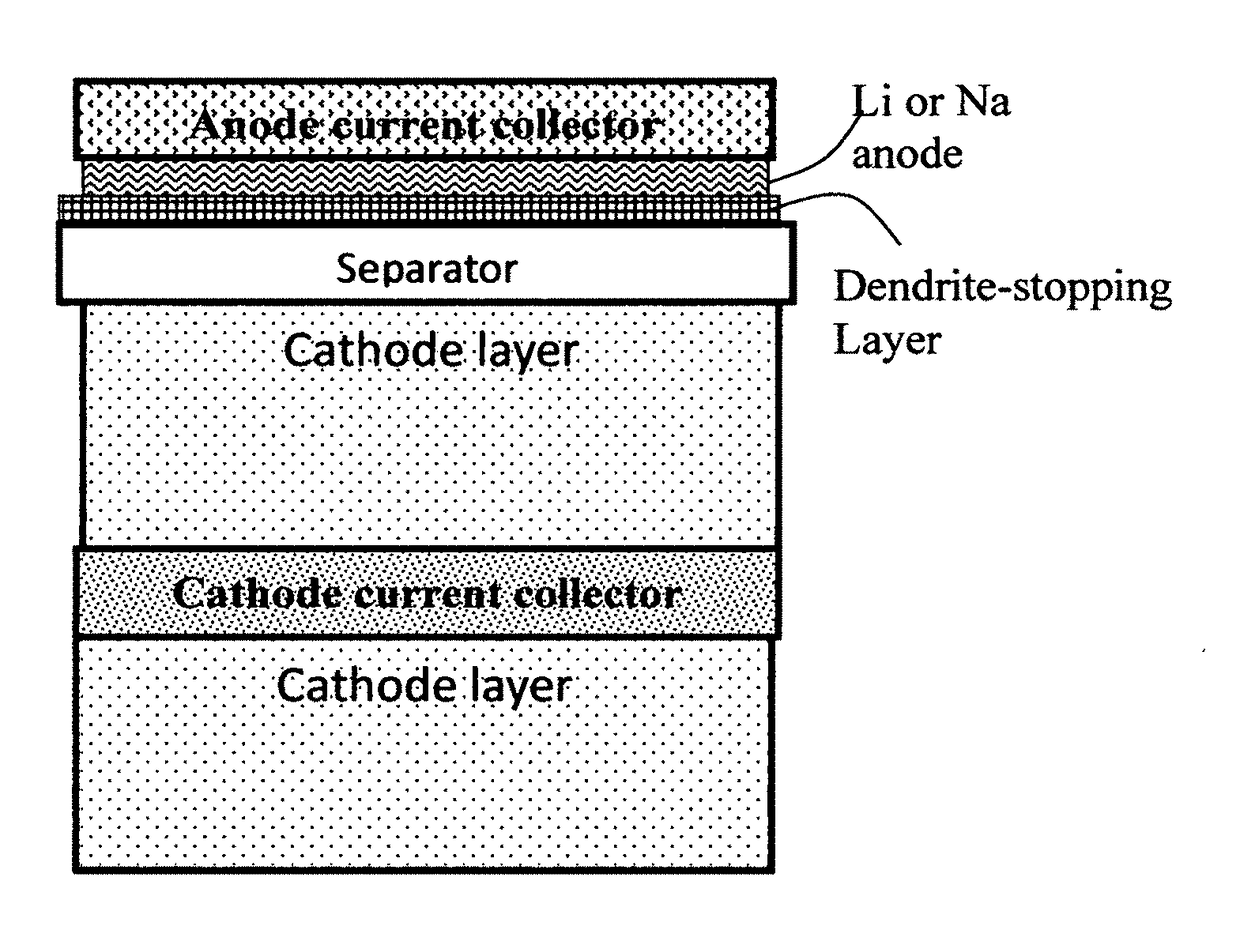

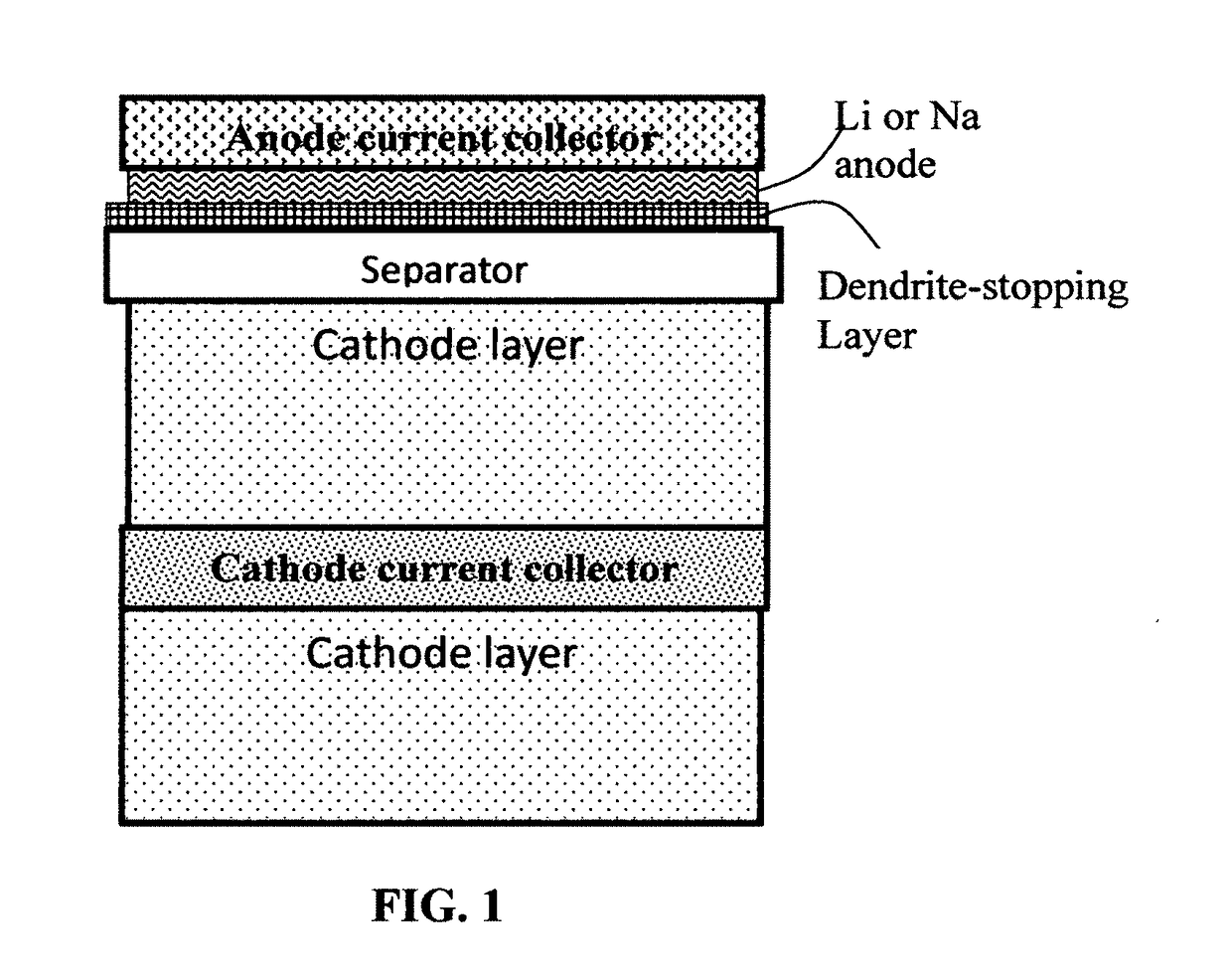

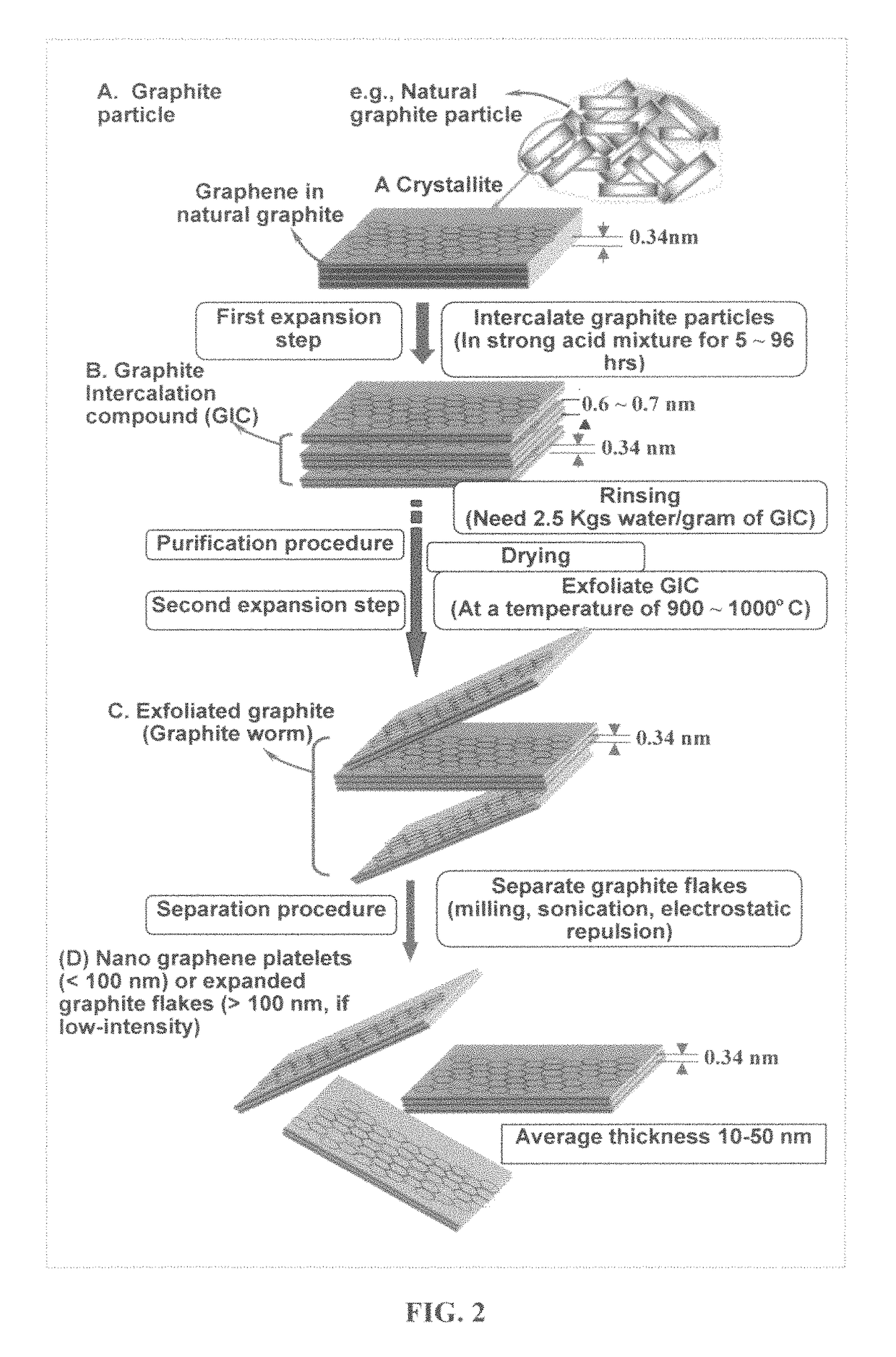

Carbon matrix- and carbon matrix composite-based dendrite-intercepting layer for alkali metal secondary battery

ActiveUS9780349B2Improve scalabilityEnough timeFuel and secondary cellsElectrolytic inorganic material coatingLithiumGraphite

A dendrite penetration-resistant layer for a rechargeable alkali metal battery, comprising an amorphous carbon or polymeric carbon matrix, an optional carbon or graphite reinforcement phase dispersed in this matrix, and a lithium- or sodium-containing species that are chemically bonded to the matrix and / or the optional carbon or graphite reinforcement phase to form an integral layer that prevents dendrite penetration through this integral layer in the alkali metal battery, wherein the lithium- or sodium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R= a hydrocarbon group, x=0-1, y=1-4; and wherein the lithium- or sodium-containing species is derived from an electrochemical decomposition reaction.

Owner:GLOBAL GRAPHENE GRP INC

Method and apparatus for preparing a dialkyl carbonate, and its use in the preparation of diaryl carbonates and polycarbonates

InactiveUS20030153782A1Efficient use ofProcess control/regulationOrganic compound preparationManufactured apparatusChloroformate

Unexpected corrosion of downstream sections of a dialkyl carbonate manufacturing apparatus has been traced to alkyl chloroformate impurities, which slowly decompose to yield hydrochloric acid. An improved process and apparatus for dialkyl carbonate synthesis reduce corrosion by physically removing or chemically decomposing the alkyl chloroformate impurities within the corrosion-resistant upstream sections of the apparatus. The alkyl chloroformate may be decomposed by passing it through a passageway at a temperature of about 30° C. to about 130° C. for a time of about 0.5 hour to about 10 hours. The passageway may include one or more holding vessels or a tubular section that promotes plug flow.

Owner:SABIC GLOBAL TECH BV

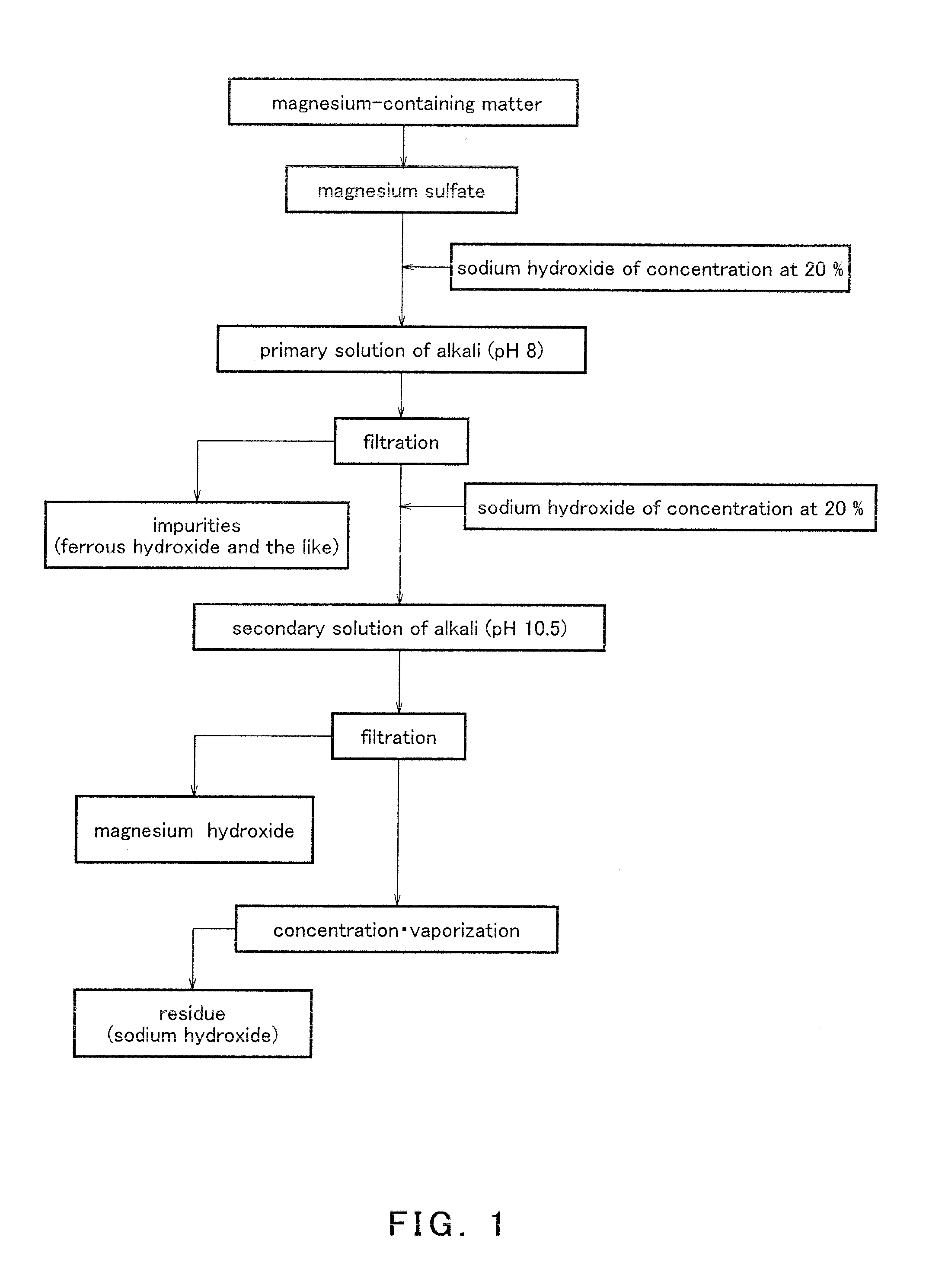

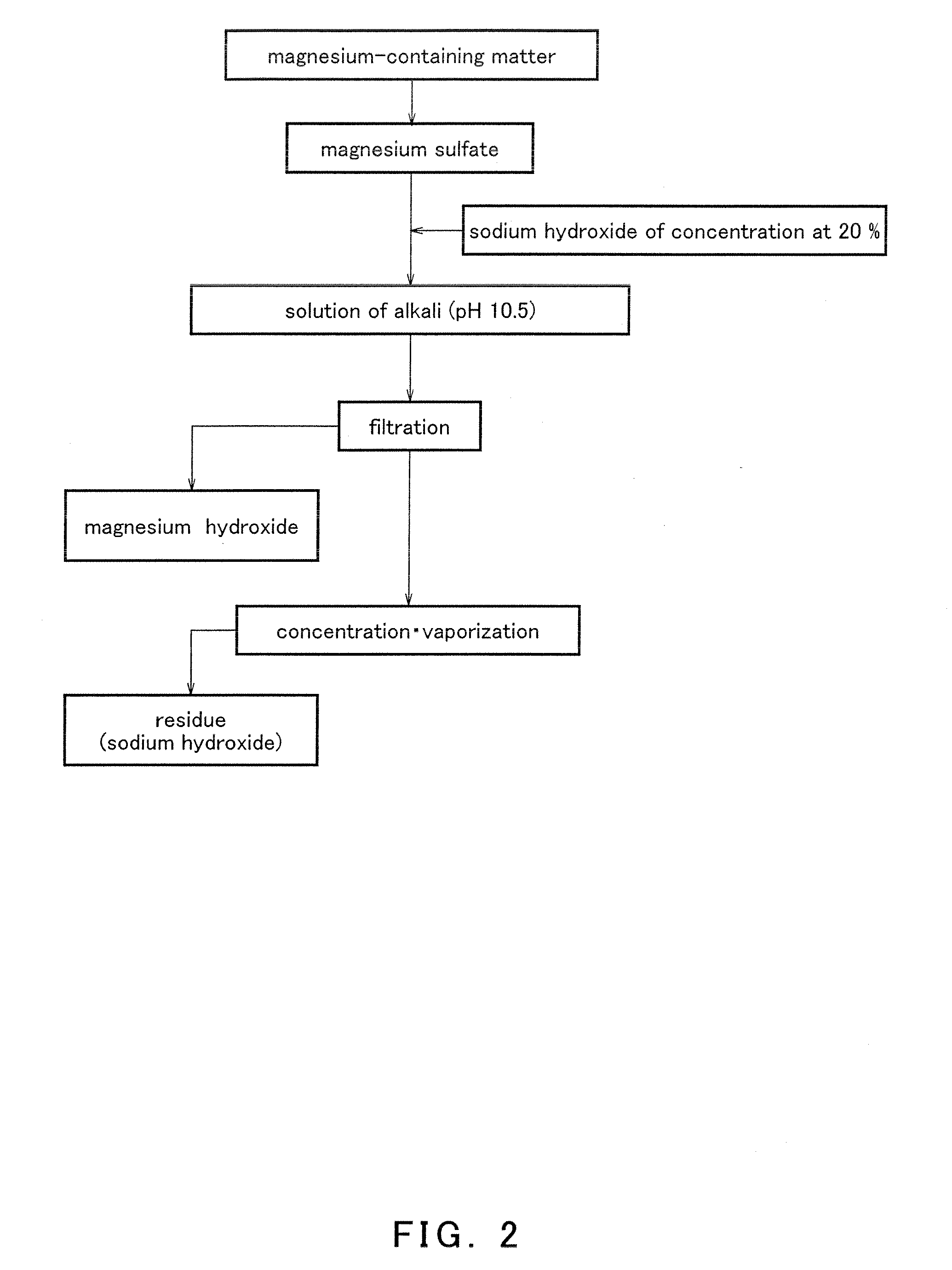

Magnesium hydroxide, method for producing magnesium hydroxide and a fire retardant comprising the magnesium hydroxide, and a fire-retarded resin composition containing the magnesium hydroxide

InactiveUS20100069555A1Large specific surface areaImprove dispersion qualityOxide/hydroxide preparationSynthetic resin layered productsAlkalinityHydroxide magnesium

Magnesium hydroxide having a large specific surface area is provided. A magnesium-containing matter is chemically decomposed by a solution of acid, and a primary solution of alkali with weak alkalinity is obtained by adding a solution of alkali to the solution of acid, and impurities contained in the primary solution of alkali are eliminated, and a secondary solution of alkali with strong alkalinity is obtained by adding a solution of alkali to the primary solution of alkali, and successively a magnesium hydroxide is deposited in secondary solution of alkali.

Owner:NOZAWA CORP

Method for preparing a dialkyl carbonate, and its use in the preparation of diaryl carbonates and polycarbonates

InactiveUS7514521B2Process control/regulationOrganic compound preparationManufactured apparatusPolycarbonate

Unexpected corrosion of downstream sections of a dialkyl carbonate manufacturing apparatus has been traced to alkyl chloroformate impurities, which slowly decompose to yield hydrochloric acid. An improved process and apparatus for dialkyl carbonate synthesis reduce corrosion by physically removing or chemically decomposing the alkyl chloroformate impurities within the corrosion-resistant upstream sections of the apparatus.

Owner:SABIC GLOBAL TECH BV

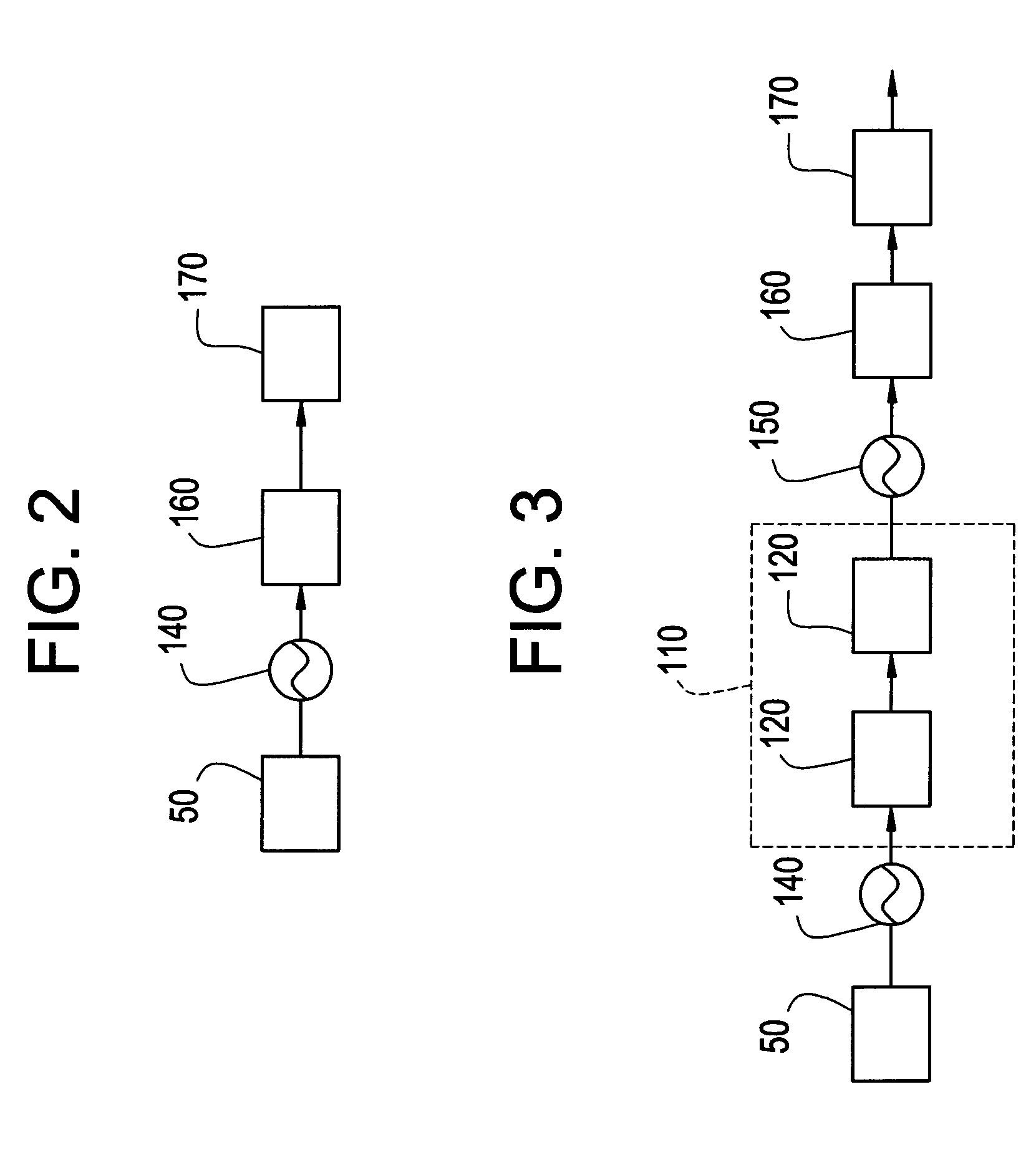

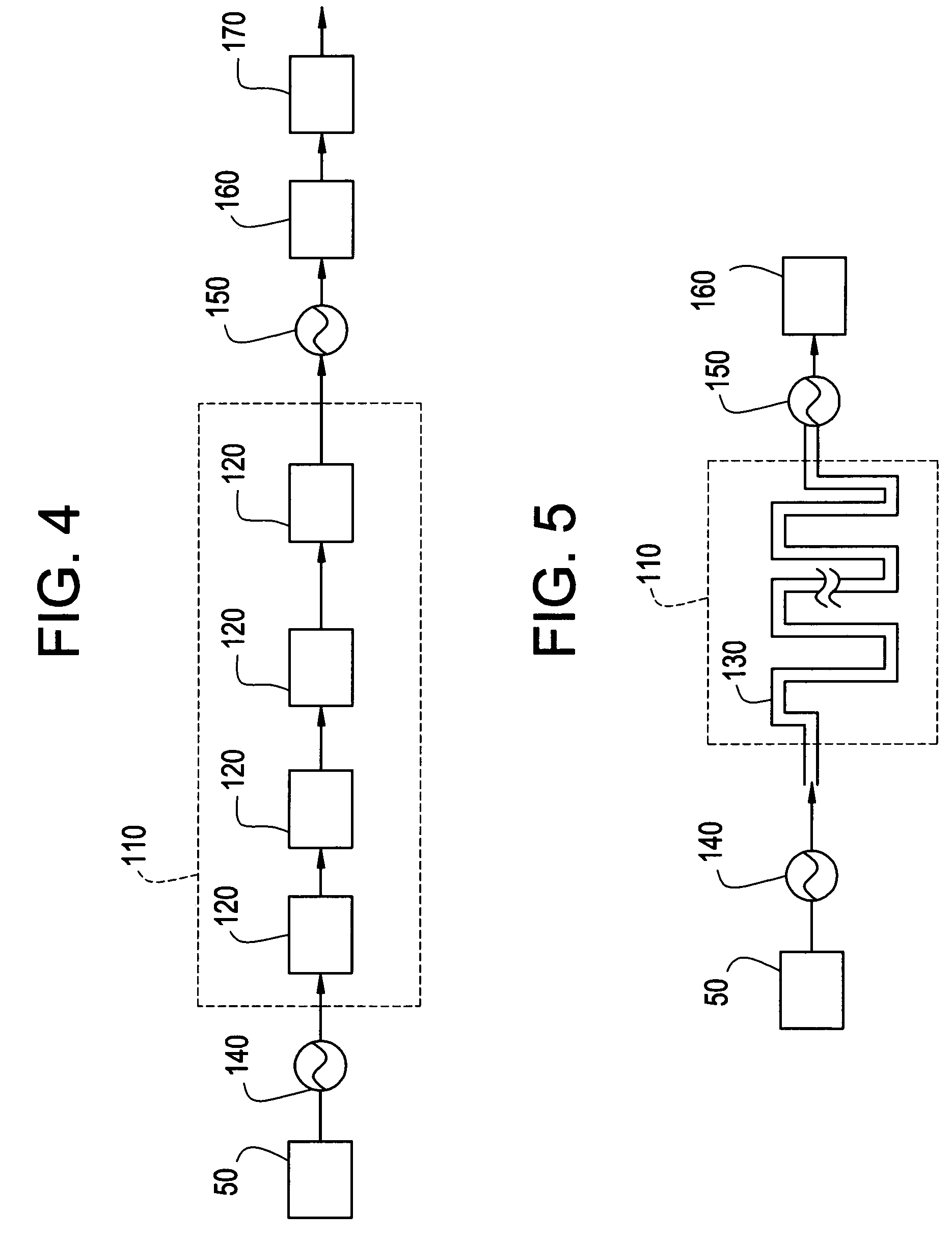

Process to Improve the Yield of Chemical Polyurethane Foam Recycling

InactiveUS20160347927A1Improve efficiencyGeneration of dust can be suppressedPlastic recyclingChemical/physical/physico-chemical stationary reactorsMaterials scienceWetting

A process to enhance the chemical recycling of polyurethane foam comprises improving the process of grinding (which is a necessary precursor to chemolysis reactions), by employing a wetting process, concurrent with grinding, which reduces the loss of foam during grinding process.

Owner:POLYMER RES TECH

Bioresin composition for use in forming a rigid polyurethane foam article

A bioresin composition is used to form a rigid polyurethane article that includes a first and a second biopolyol and is substantially free of aprotic solvents that chemically decompose in the presence of water. The first biopolyol includes a natural oil component. The second biopolyol includes the reaction product of a natural carbohydrate and an alkylene oxide. The rigid polyurethane foam article includes the reaction product of the bioresin composition and an isocyanate which are reacted in the presence of a chemical blowing agent.

Owner:BASF SE

Rapid gel electrophoresis system

InactiveUS20080164149A1Easy to separateComponents is relatively effectiveCellsFatty/oily/floating substances removal devicesPower controllerElectrophoresis

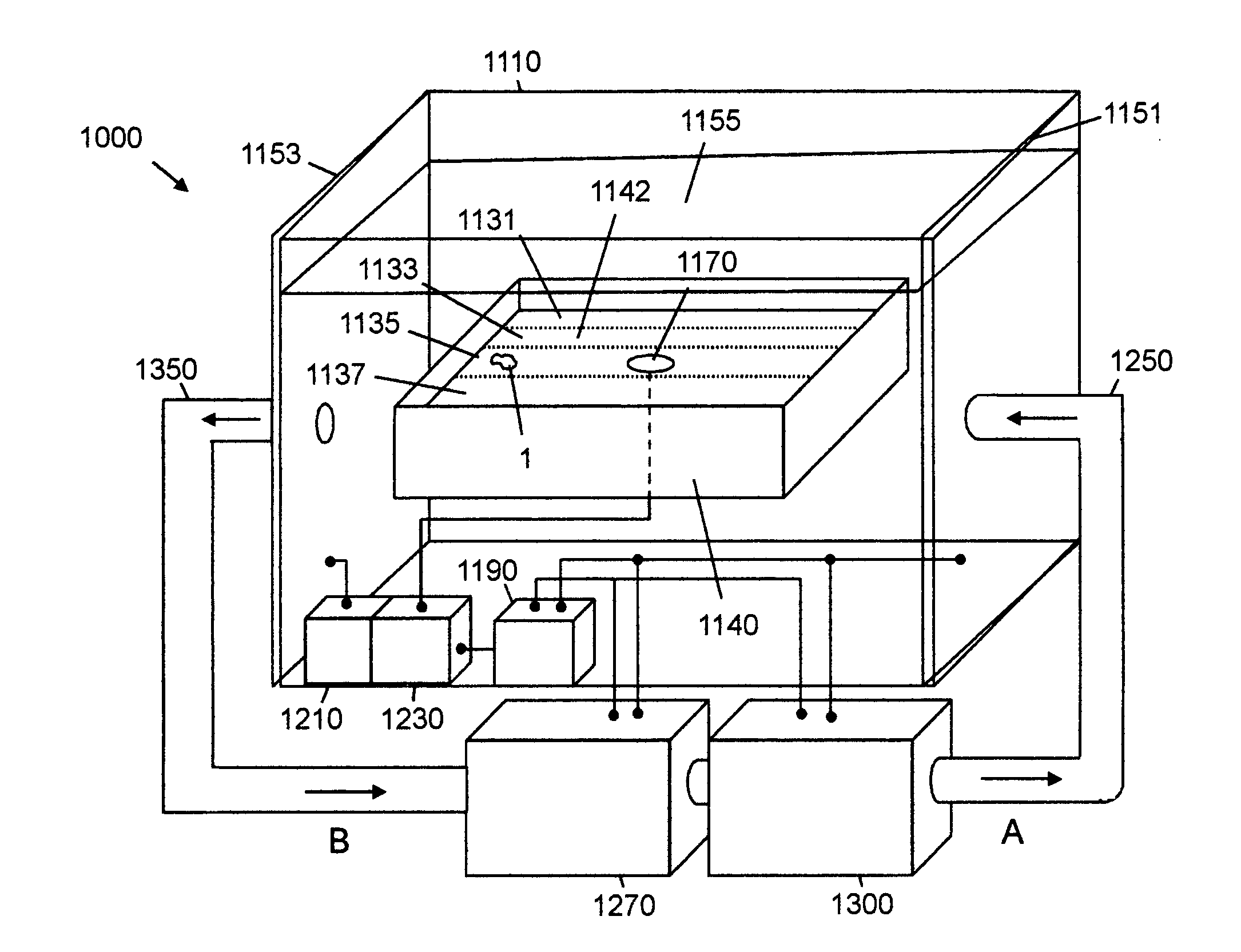

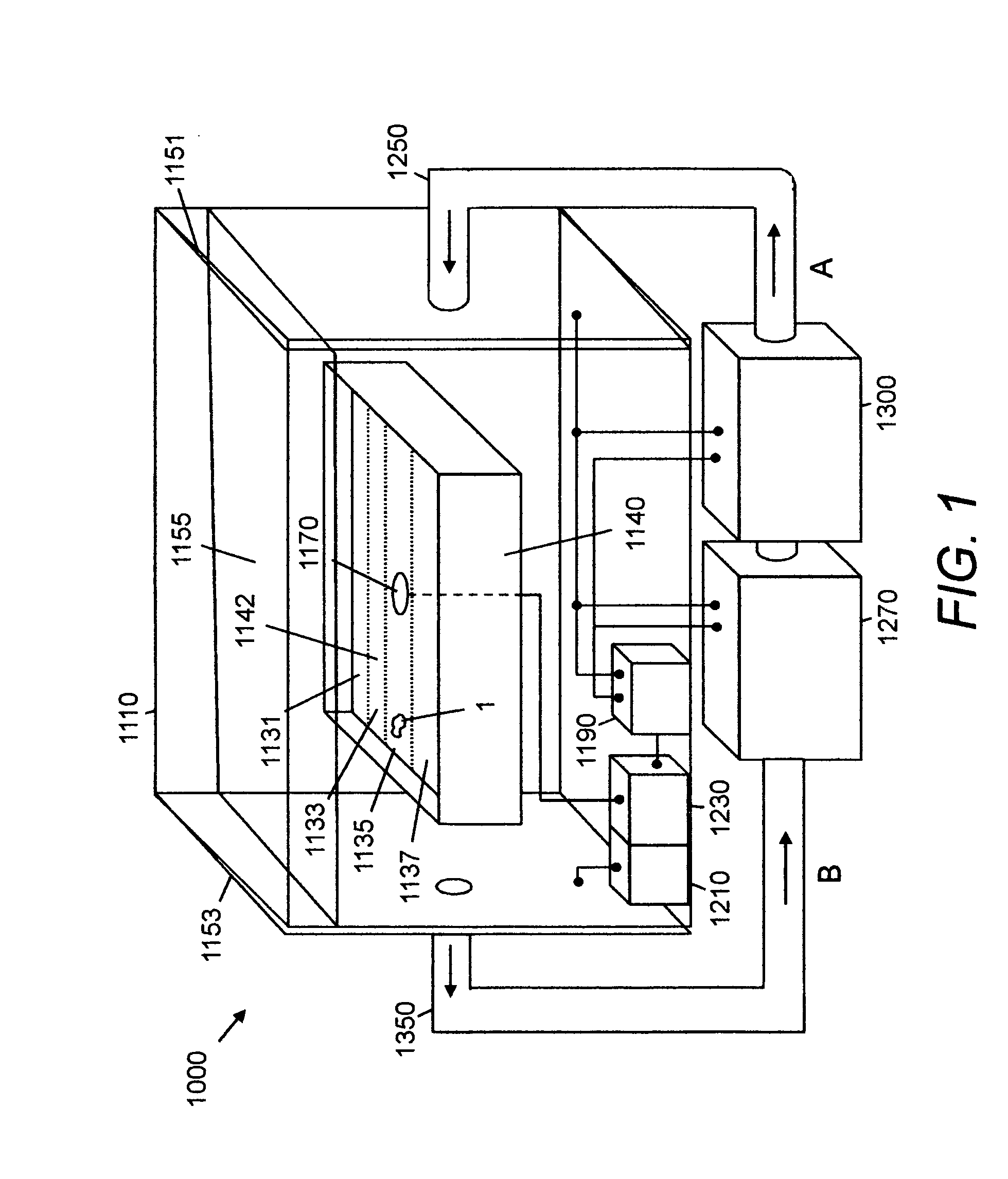

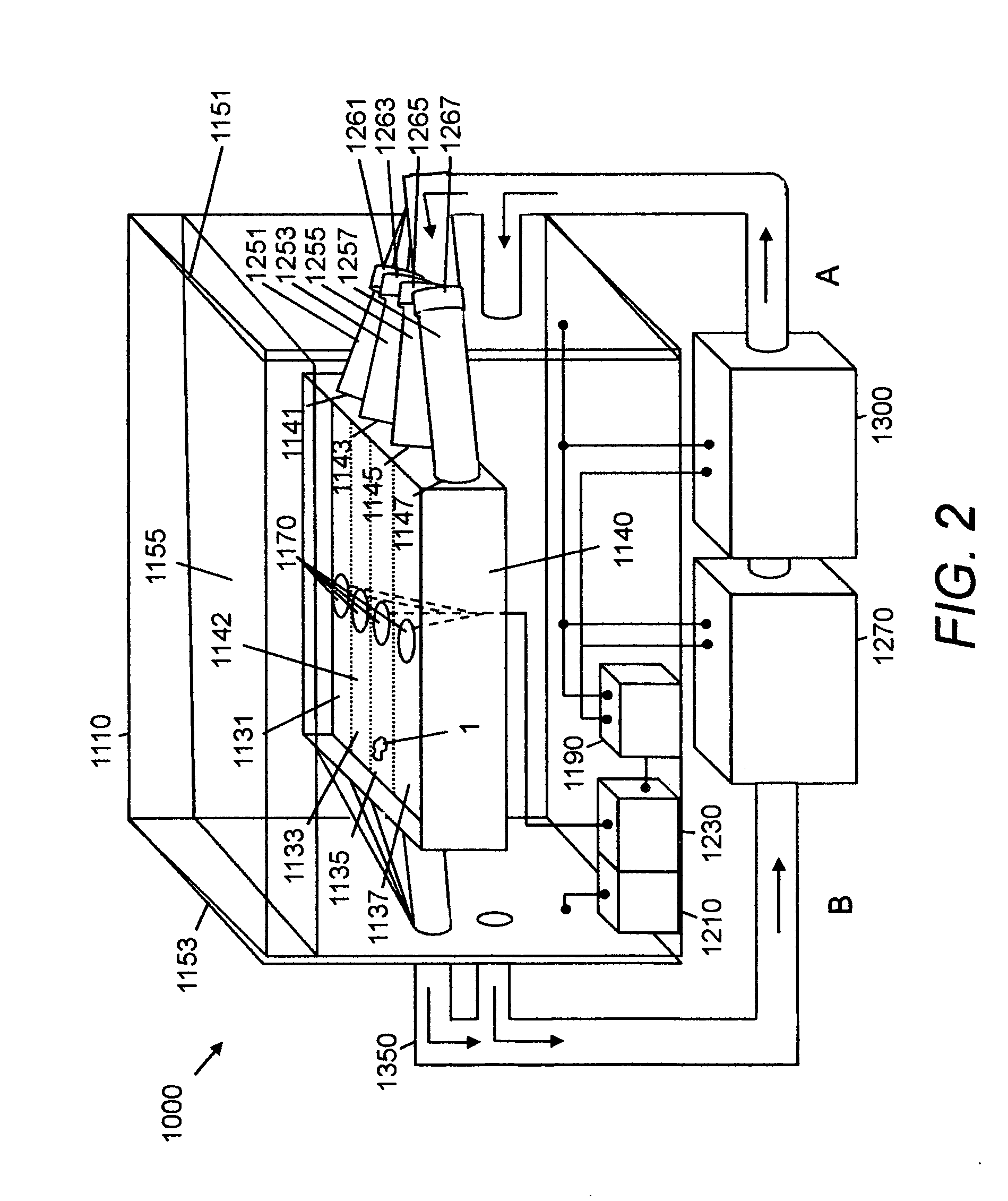

A rapid electrophoresis system [1000] provides rapid separation of an unknown sample [1] into its component compounds. An unknown sample [1] which is to be identified is placed in an inert electrophoresis gel [1142] in a gel container [1140] in housing [1110]. The housing [1110] has electric plates [1151, 1153] straddling housing [1110]. A plurality of temperature sensors measure the temperature or chemical breakdown of gel [1142] in each track [1131, 1133, 1135, 1137] running the length of the gel container [1140]. The tracks [1131, 1133, 1135, 1137] are monitored, selectively cooled or heated by a thermal controller [1210] to bring them all to a pre-defined optimum temperature. The power across the plates is also adjusted by power controller [1210] to prevent heating and the gel [1142] from being chemically altered so that it maintains its functionality, while providing optimum performance. The temperature at each location and time, and the progression of the components could be standardized to compare current results to stored results of other components.

Owner:ARTZ MATTHEW R

Decomposition agent for extracting fuel oil from dirty oil mud

InactiveCN1907890ASimple ingredientsIngredients ScienceWaste water treatment from quariesSludge treatmentDecompositionAdditive ingredient

This invention involves a chemical agent, particularly a decomposition agent extracting fuel oil from sewage oil sludge. The decomposition agent includes (weight percentage): silica 65-75, alum 14-20, sodium hydroxide 4-8, potassium permanganate 0.05-0.1, water 3.9-5, and sodium carbonate 3-4. The decomposition has simple components, and is scientific, rational and effective. Against most sewage oil sludge having acidic characteristics, the basic ingredients such as sodium hydroxide are added to sewage oil sludge for demulsification so as to be close to a neutral pH value, and different components respectively with effects like water absorption, impurities removal, adsorption and coagulation aid are added, which make oil, soil and water degrade effectively, therefore the sewage sludge decomposition and purification effect is effectively improved and sewage sludge degrades more thoroughly.

Owner:韩东

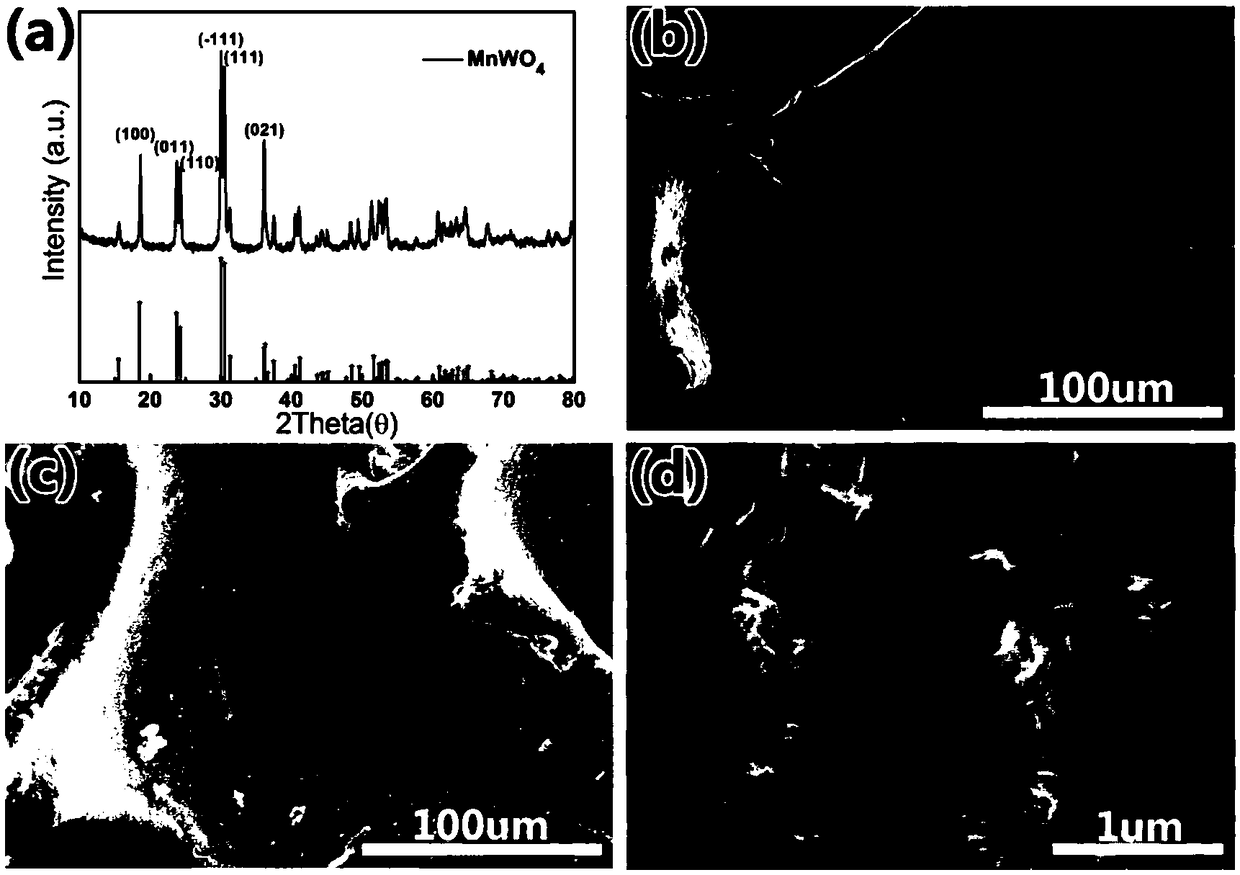

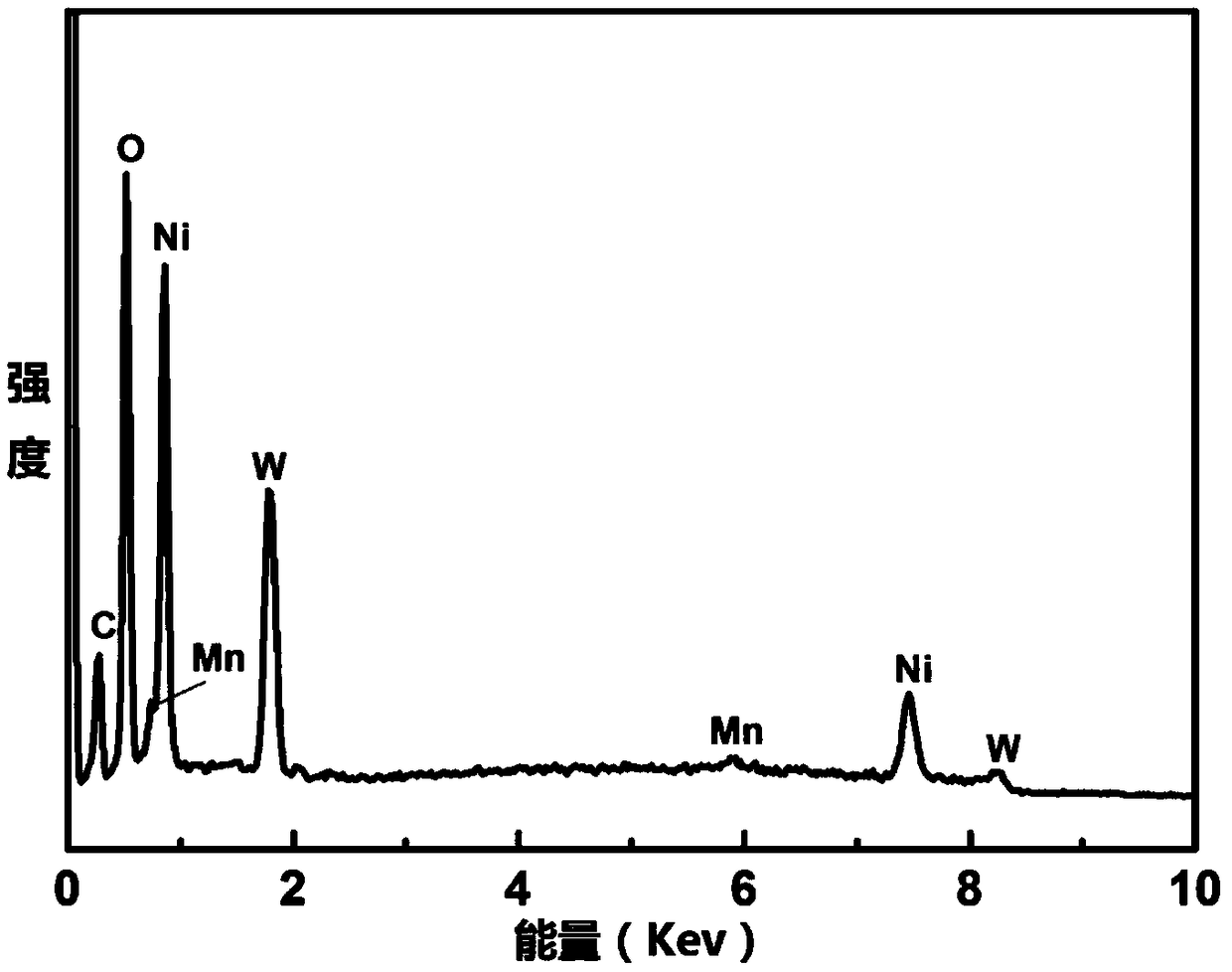

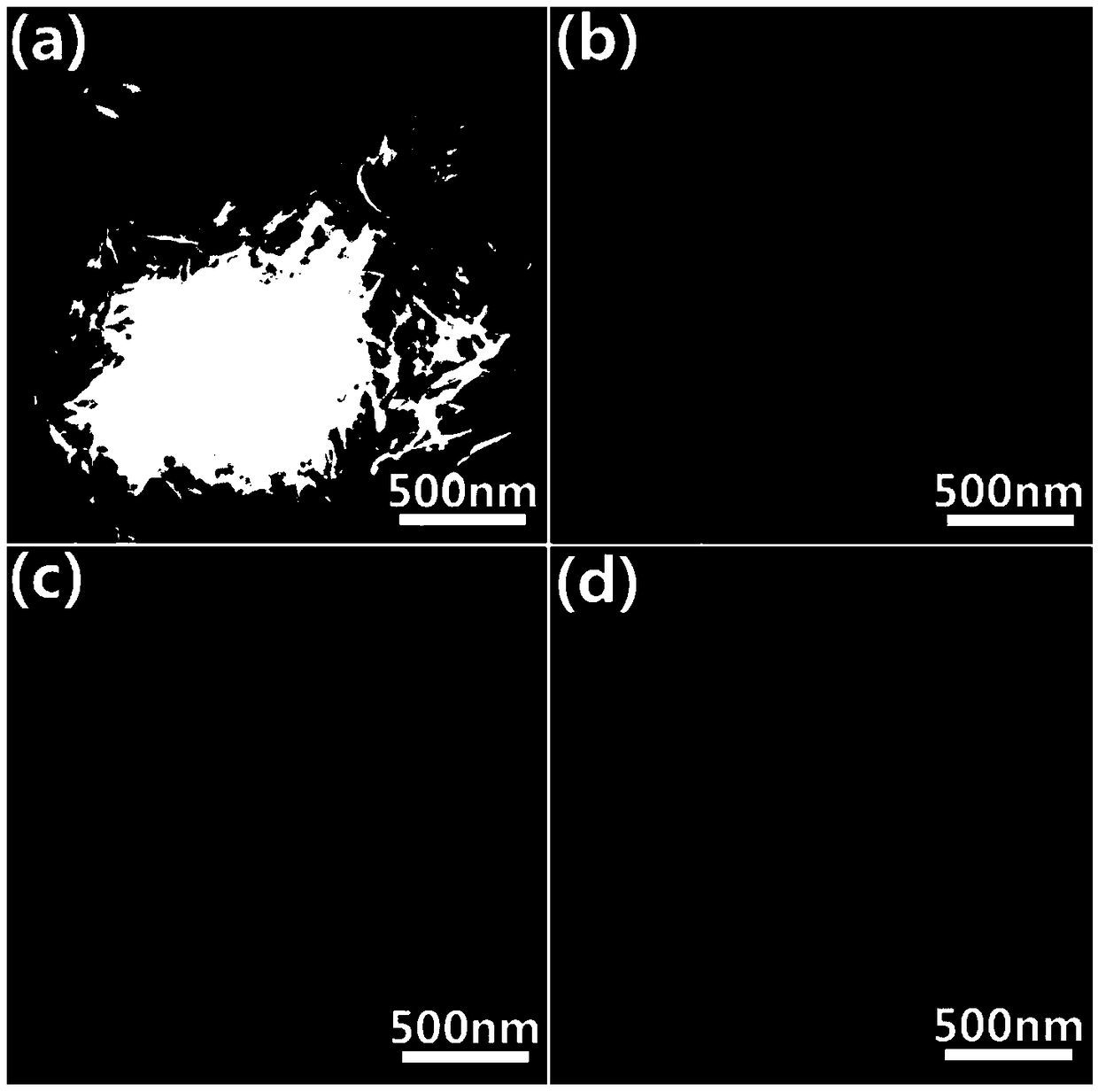

Manganese tungstate nanosheet material and preparation method and application thereof

ActiveCN108754526AEfficient preparationGood catalytic activity for electrolysis of waterMaterial nanotechnologyLiquid/solution decomposition chemical coatingElectrolysisTungstate

The invention discloses a manganese tungstate nanosheet material and a preparation method and application thereof. The preparation method comprises: mixing sodium tungstate and manganese chloride in water to allow the sodium tungstate concentration of the obtained solution to be 0.5-1.5 mmol / L and the manganese chloride concentration of the solution to be 0.5-1.5 mmol / L so as to prepare a precursor mixture solution; putting a substrate into the precursor mixture solution; transferring the substrate and the precursor mixture solution together into an autoclave; reacting at 160-180 DEG C for 360-480 min; and cleaning and drying to prepare a MnWO4 nanosheet on the substrate. The manganese tungstate nanosheet material is adopted directly as a working electrode for electrochemical decompositionof water. The material has good water electrolysis catalytic activity in electrolyte environments having various pH values, and is rapid, efficient, cheap, simple to prepare, free of pollution to theenvironment and suitable for large-scale industrial production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

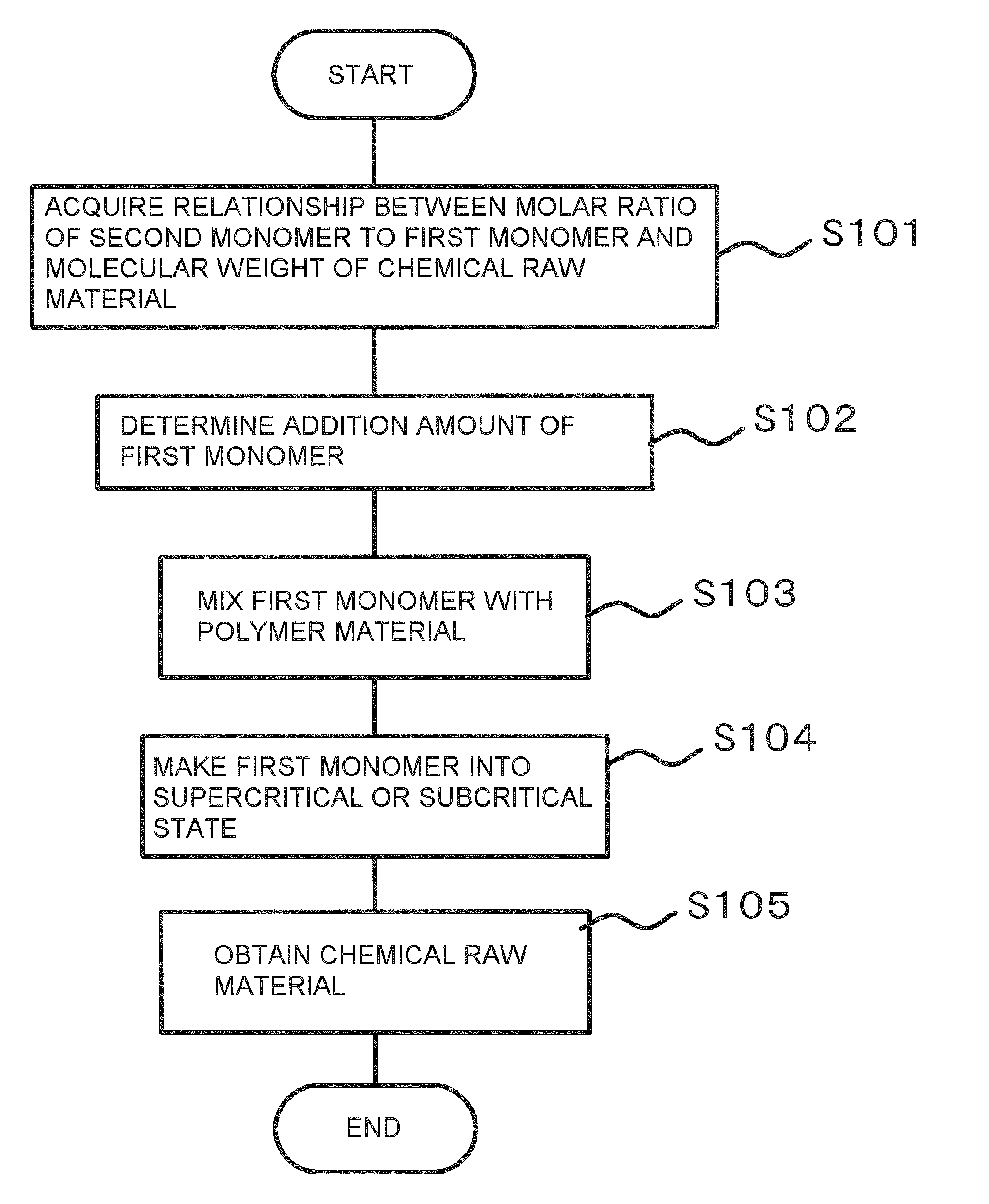

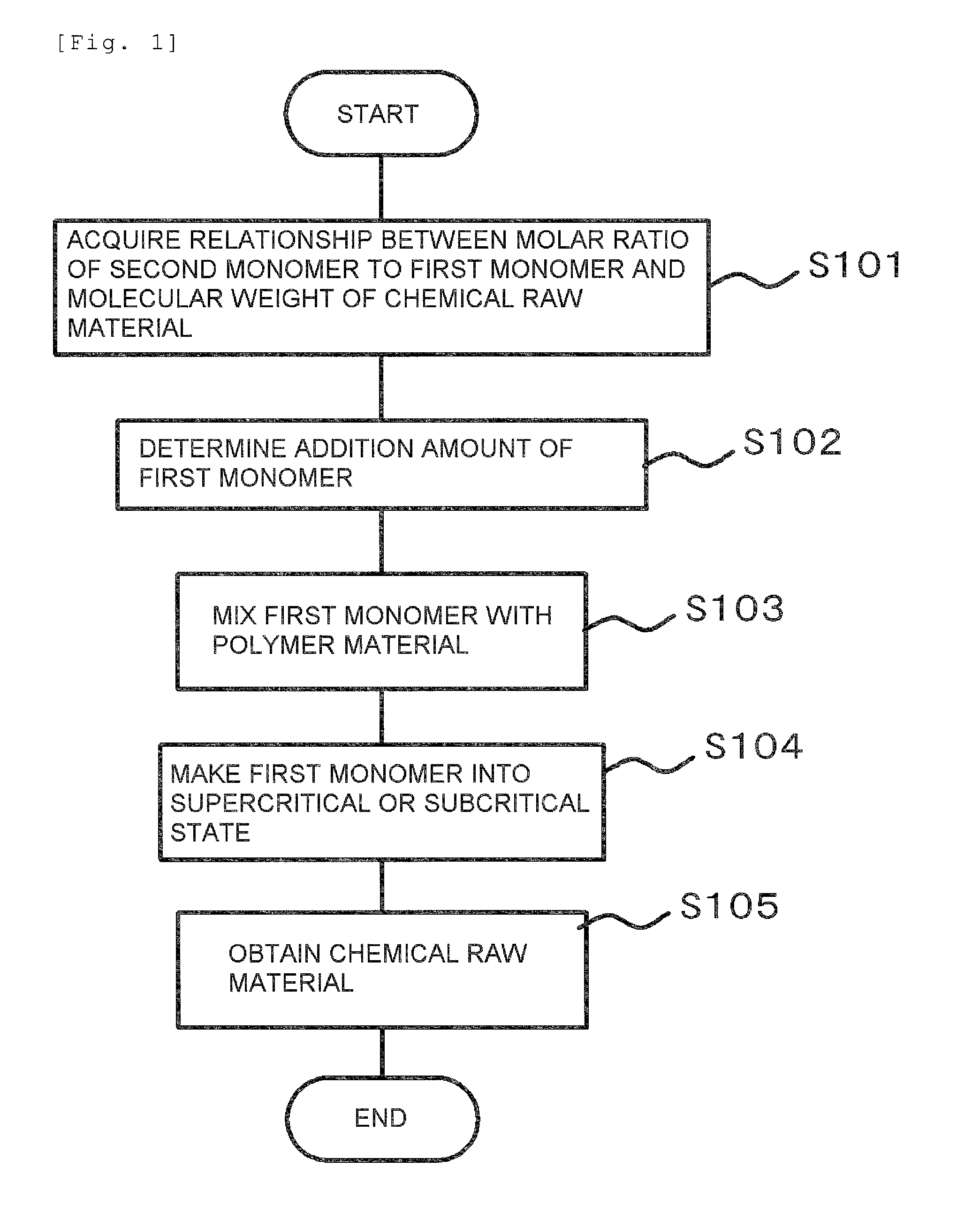

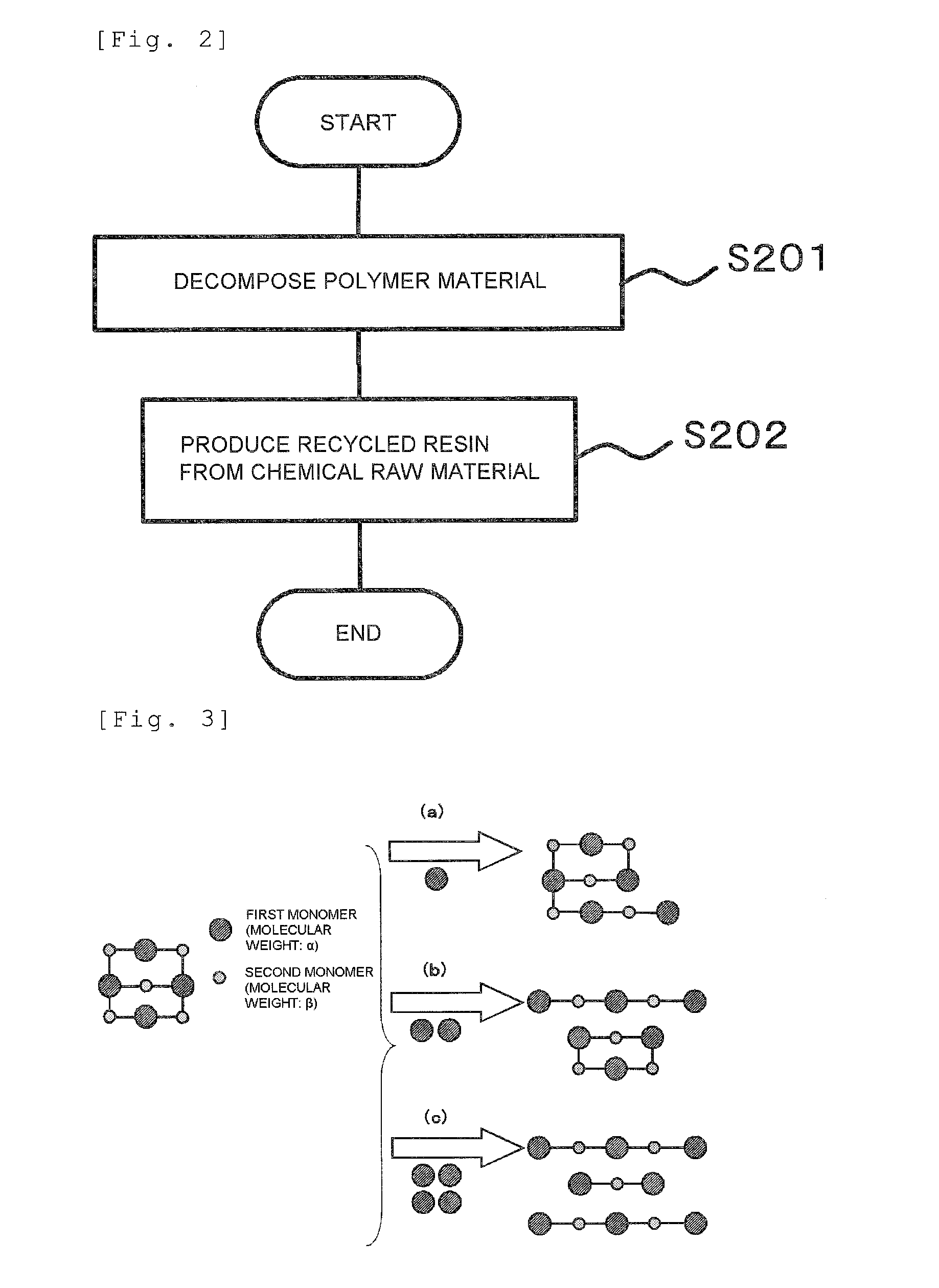

Method for decomposing polymer material, method for producing recycled resin, and method for recovering inorganic filler

InactiveUS20110184077A1High purityImprove decomposition rateSilicaUltra-high pressure processesReaction systemPolymer chemistry

The present invention is a method for decomposing a polymer material by chemically decomposing a polymer material containing a first monomer and a second monomer in a mixture of the polymer material with the first monomer or a derivative of the first monomer to produce a chemical raw material. A relationship between a proportion of number of molecules of the second monomer to number of molecules of the first monomer in a reaction system for decomposing the polymer material and the molecular weight of the chemical raw material produced in the reaction system is acquired in advance (S101). Subsequently, an addition mount of the derivative of the first monomer to be added to the polymer material is determined based on the above relationship (S102). The first monomer in the addition amount determined is then mixed with the polymer material (S103).

Owner:SUMITOMO BAKELITE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com