Manganese molybdate nanosheet material and preparation method and application thereof

A manganese molybdate nanometer and nanosheet technology is applied in the direction of metal material coating process, electrode, coating and the like, and achieves the effects of simple preparation process, good electrolytic water catalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

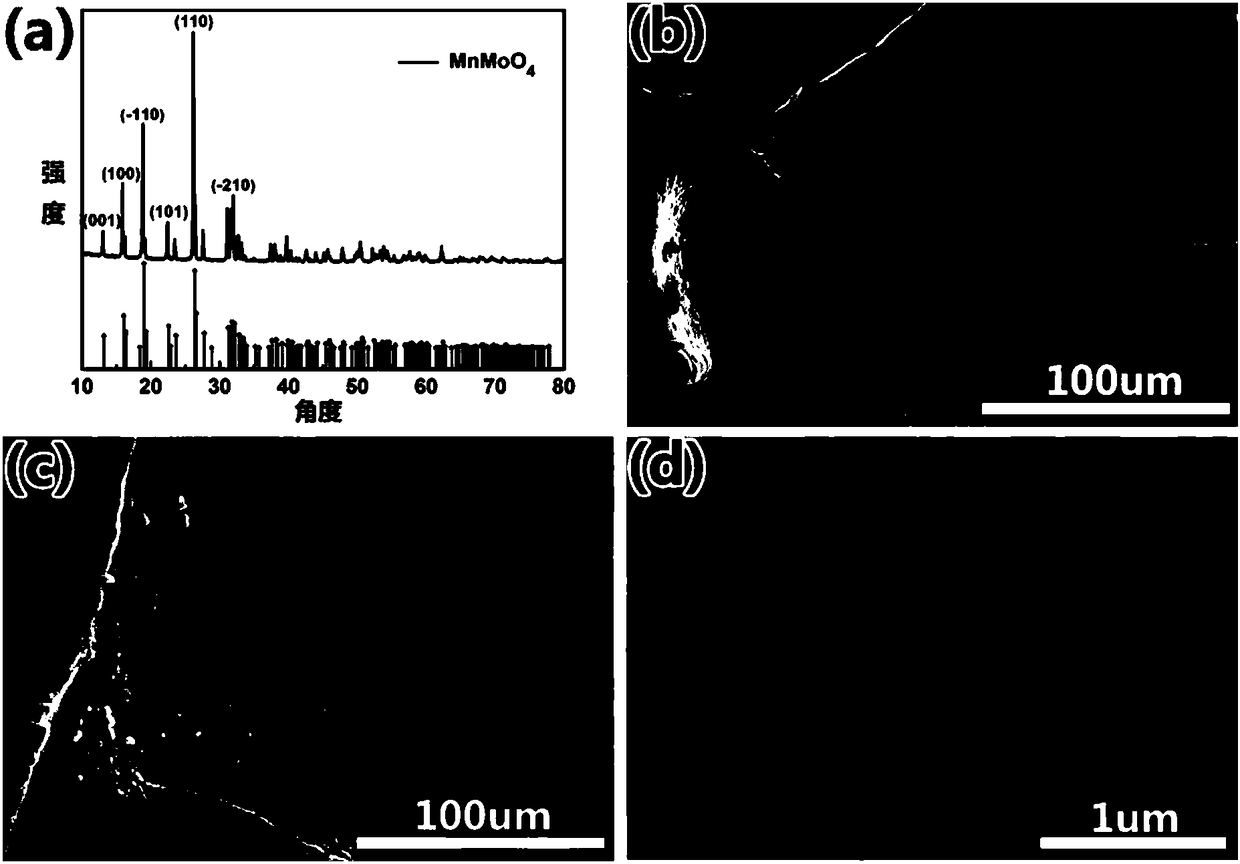

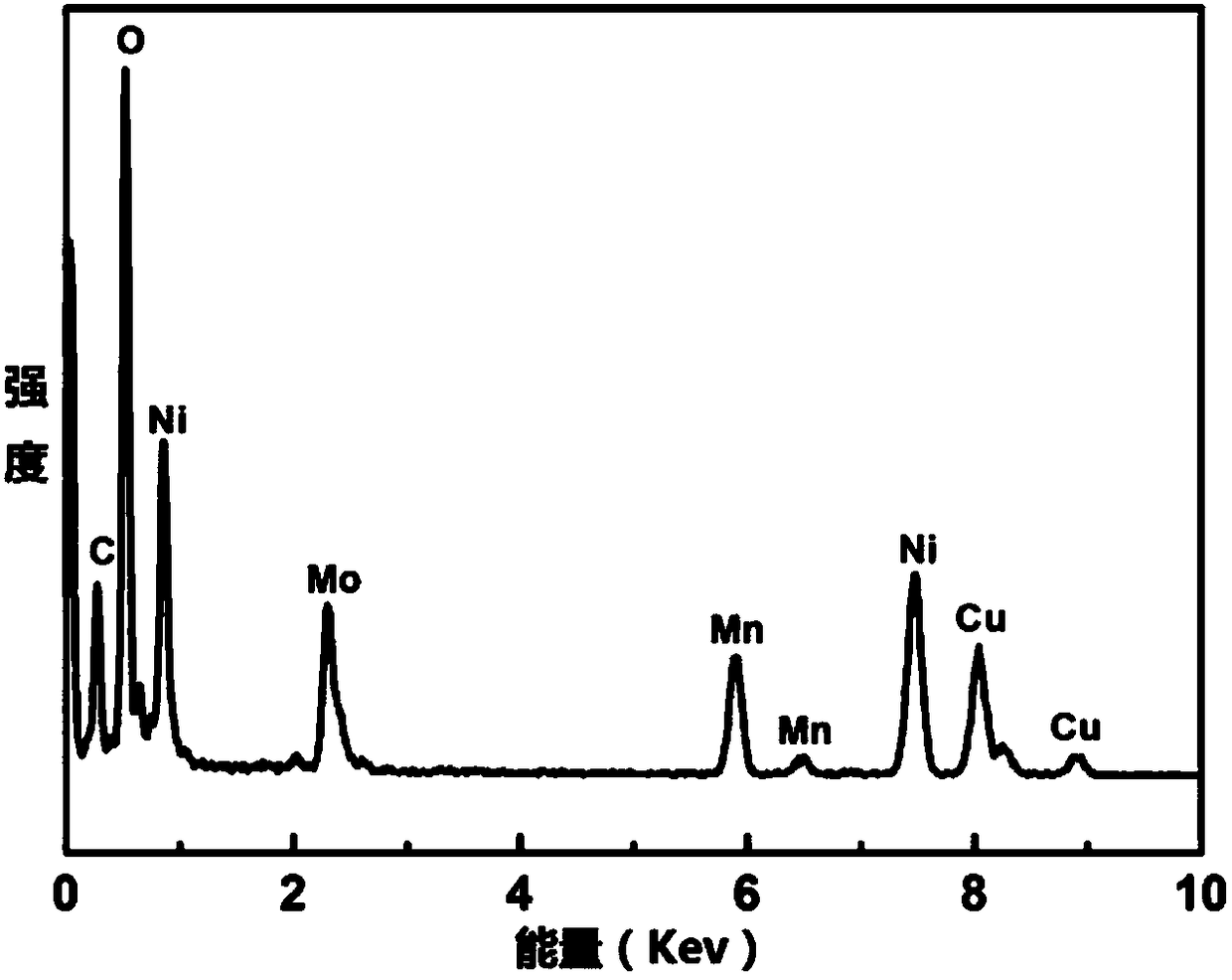

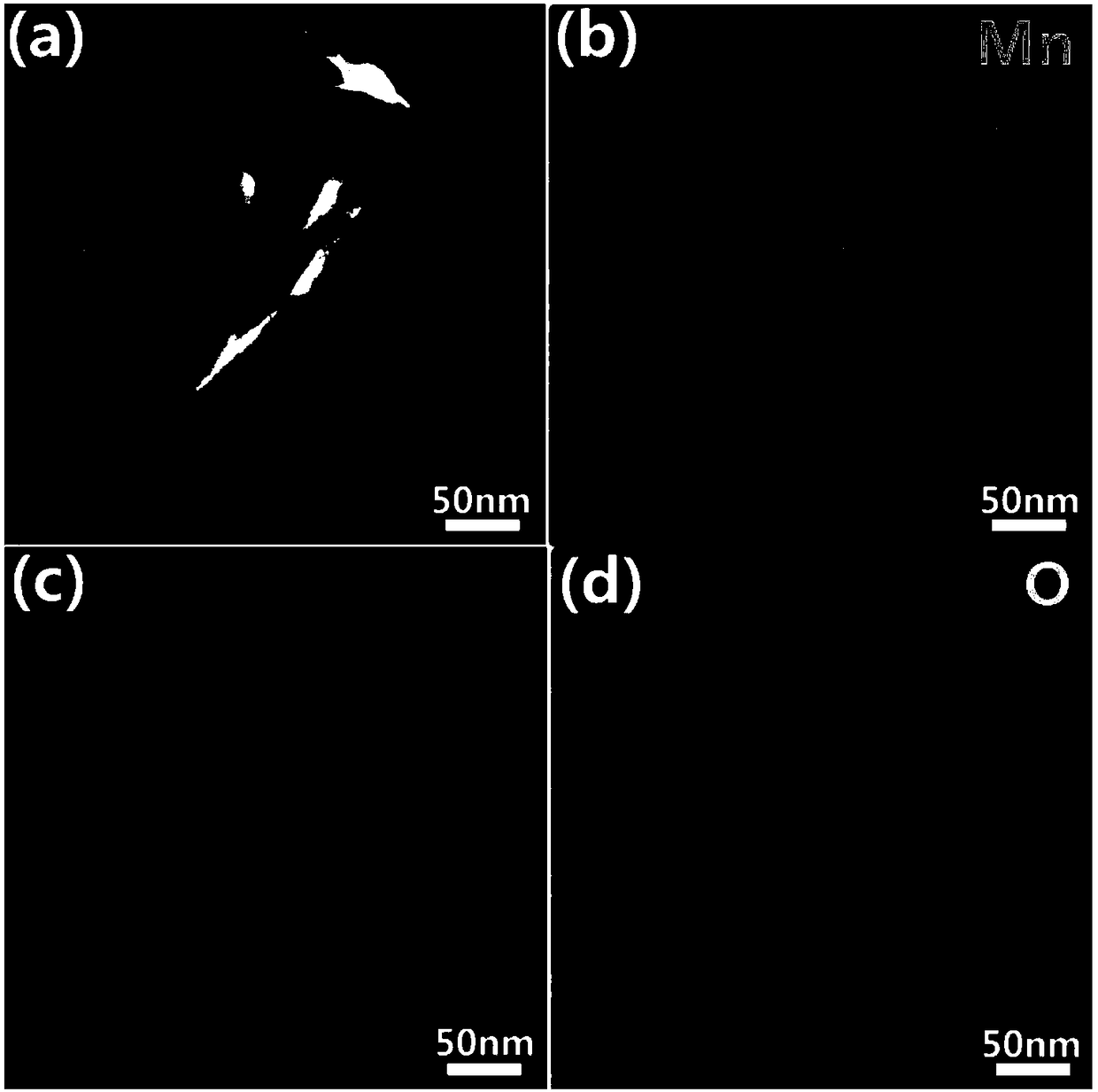

[0025] A preparation method of manganese molybdate nanosheet material, comprising the steps of:

[0026] Step A, sodium molybdate and manganese chloride are mixed together in water, so that the concentration of sodium molybdate in the solution after mixing is 0.5~1.5 mmol / liter, and the concentration of manganese chloride is 0.5~1.5 mmol / liter, thereby producing A precursor mixed solution was obtained.

[0027] Step B, placing the substrate in the precursor mixed solution, and transferring the substrate and the precursor mixed solution into an autoclave, then reacting at 160-180°C for 360-480 minutes, and then cleaning and drying , so that MnMoO was prepared on the substrate 4 Nano sheet, that is to obtain manganese molybdate nano sheet material. The manganese molybdate nanosheet material can be directly used as a working electrode for electrochemical water splitting.

[0028] Wherein, the substrate can be nickel foam (Nickel Foam, NF), carbon fiber cloth or titanium foil, ...

Embodiment 1

[0038] A kind of manganese molybdate nano sheet material, its preparation method comprises the steps:

[0039] Step a, mixing sodium molybdate and manganese chloride in water, so that the concentration of sodium molybdate in the solution after mixing is 1.0 mmol / L, and the concentration of manganese chloride is 1.0 mmol / L, so as to obtain a mixed precursor solution.

[0040] Step b, using nickel foam (NF) with a size of 1×4cm as the substrate, placing the substrate in the precursor mixed solution, and transferring the substrate and the precursor mixed solution to a 50mL autoclave, and then React at 160°C for 360 minutes, then use deionized water and ethanol in sequence to treat the substrate and the MnMoO grown on the substrate 4 The nanosheets are ultrasonically cleaned to remove residual substances attached to the surface, and the cleaned substrate and the MnMoO grown on the substrate 4 Nanosheets were dried to produce MnMoO on nickel foam substrates 4 Nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com