Patents

Literature

41 results about "Hydroxide magnesium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium-magnesium hydrogen producing agent

InactiveCN102783691AOut-of-the-boxStrong reducing agentCosmetic preparationsToilet preparationsWrinkle skinSkin elasticity

The invention discloses a calcium-magnesium hydrogen producing agent, of which the main component is a hydrogen producing agent. The hydrogen producing agent is selected from one or various combination of calcium hydride, magnesium hydride, calcium hydroxide magnesium, magnesium-magnesium hydride, calcium-calcium hydride, magnesium-calcium hydride, calcium-magnesium hydride, calcium-magnesium-magnesium hydride, calcium-magnesium-calcium hydride, calcium-magnesium-magnesium hydride-calcium hydride, coral calcium hydroxide magnesium, Na MgH3, and Mg2FeH6. the calcium-magnesium hydrogen producing agent can be added into water, beverage or wine as an additive, or can be coated on the surface of skin or taken as soaking liquid to remove internal or surface active oxygen. The calcium-magnesium hydrogen producing agent has a remarkable prompting effect for recovering various oxidized damages, relieving discomfort caused by drinking, diluting stain and wrinkle of the skin, recovering skin elasticity, and delaying senescence.

Owner:李志林

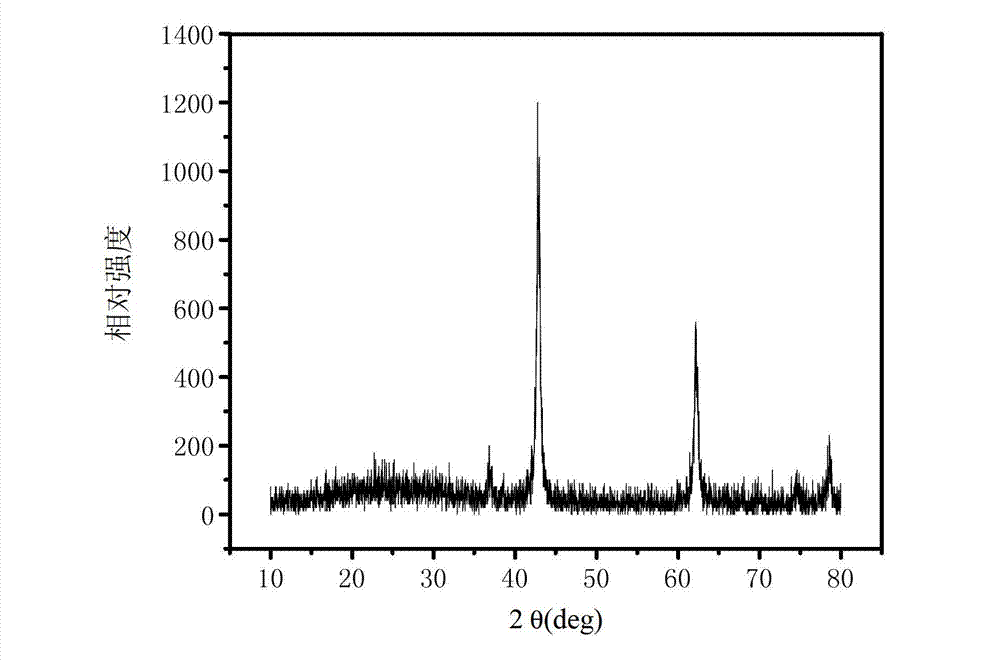

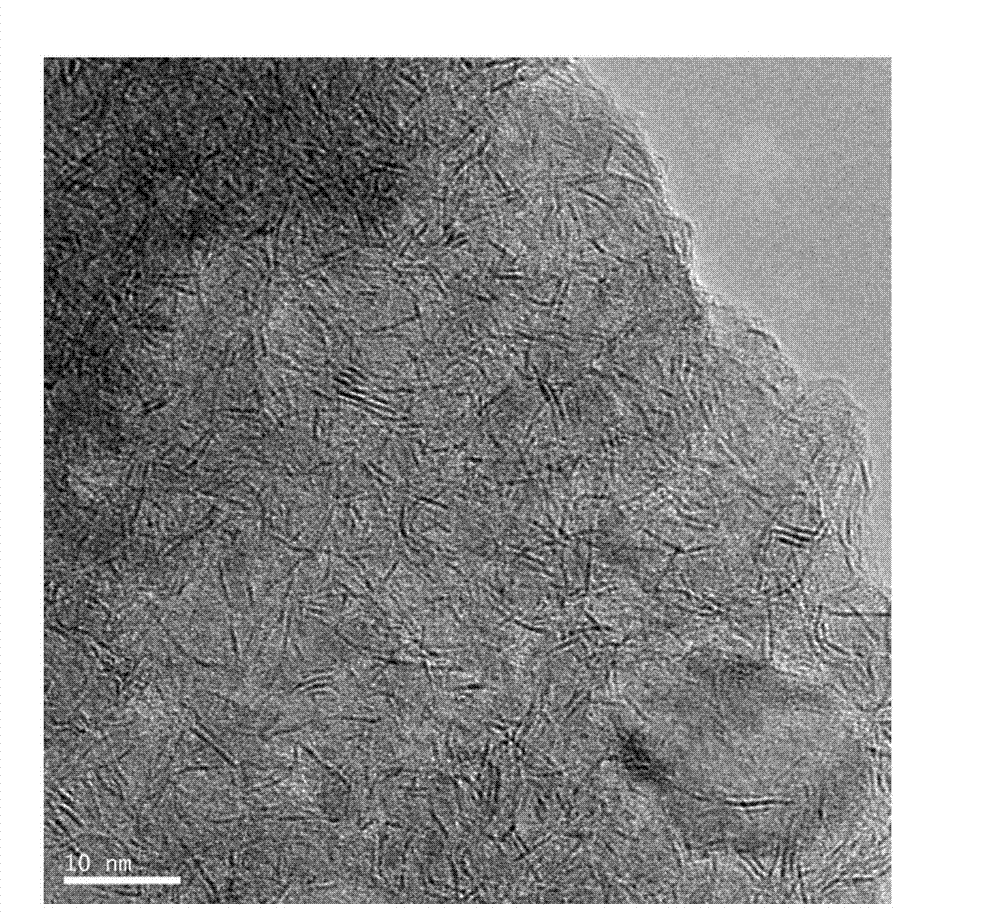

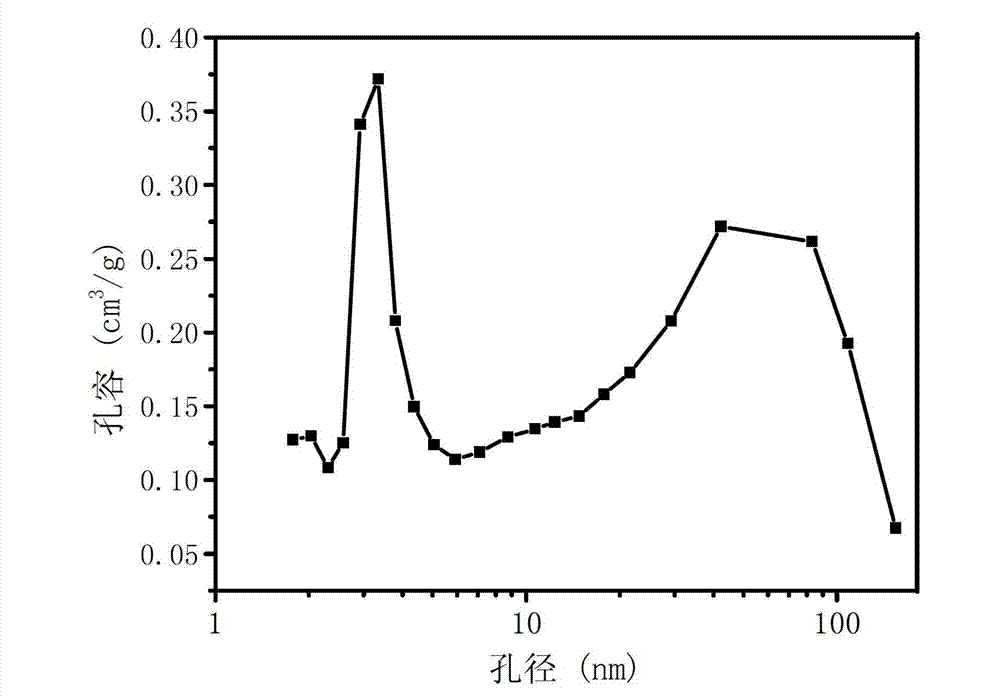

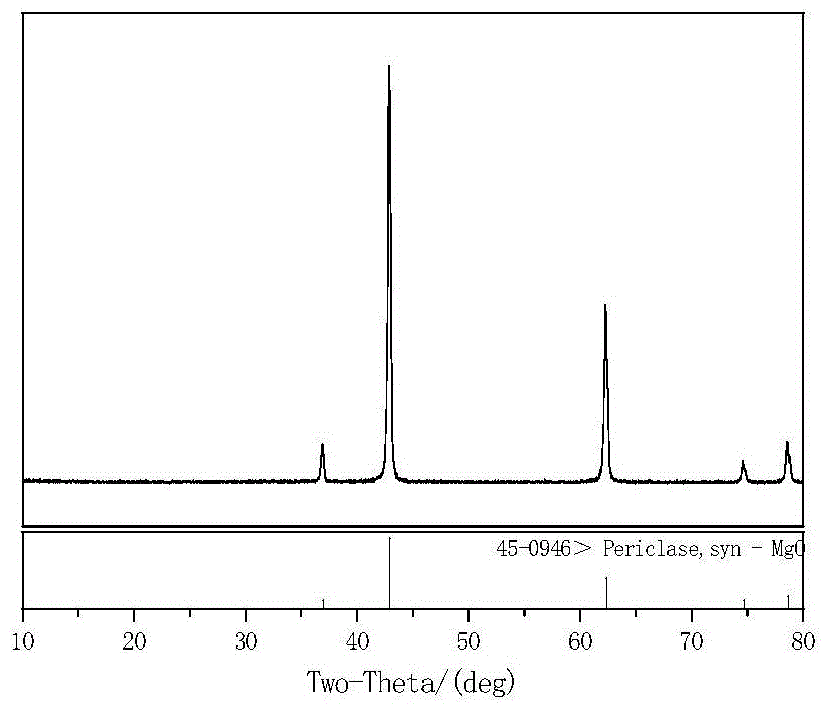

Mesoporous magnesium oxide, hydrodesulfurization catalyst loading CoMo metal sulfide and application thereof

ActiveCN103157518ALarge specific surface areaHigh activityCatalyst carriersMagnesiaSilanesHydrodesulfurization

The invention discloses a mesoporous magnesium oxide, a hydrodesulfurization catalyst loading CoMo metal sulfide and an application thereof. The mesoporous magnesium oxide is prepared through the following steps that (1) water is used as reaction medium, magnesium hydroxide fully reacts with carbon dioxide under room temperature in an airtight reaction still, then reaction liquid in the reaction still is filtered, and filtrate which contains Mg (HCO3)2 is obtained; (2) macromolecule surfactant N, N-Diethyl-N-Cetyl-N- (3-methoxy silane propane) ammonium iodide are added into the filtrate which contains the Mg (HCO3)2, mixture is heated to 80 DEG C-95 DEG C and maintained to 0.5h-2h under stirring, the mixture is calcinated for 3h-4h after the mixture is filtered and dried, and the mesoporous magnesium oxide is obtained. The hydrodesulfurization catalyst loading CoMo metal sulfide is prepared by that the mesoporous magnesium oxide is used as carriers, is suitable for hydrodesulfurization reactions of dibenzothiophene, and exerts high catalytic activity.

Owner:WENZHOU UNIVERSITY

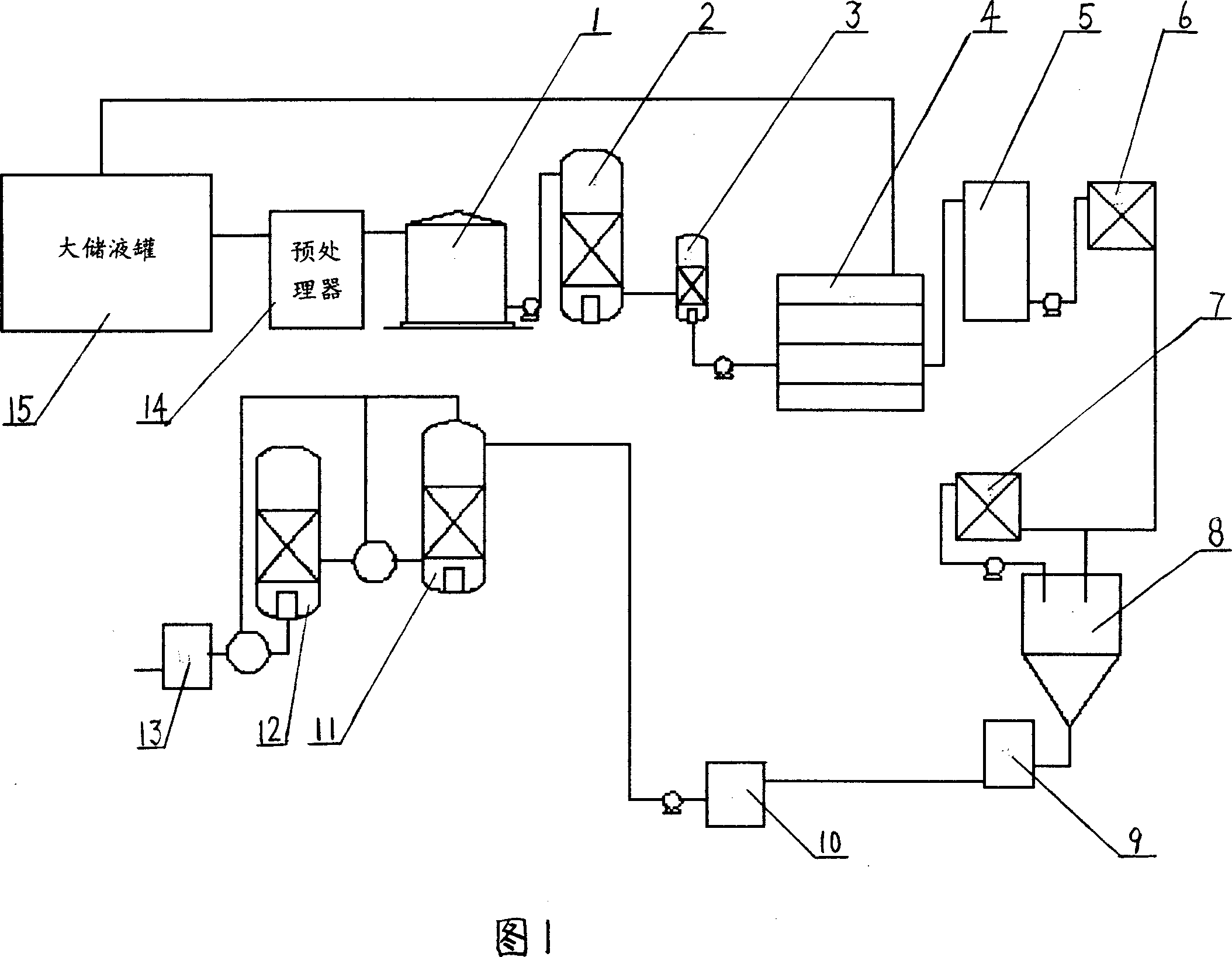

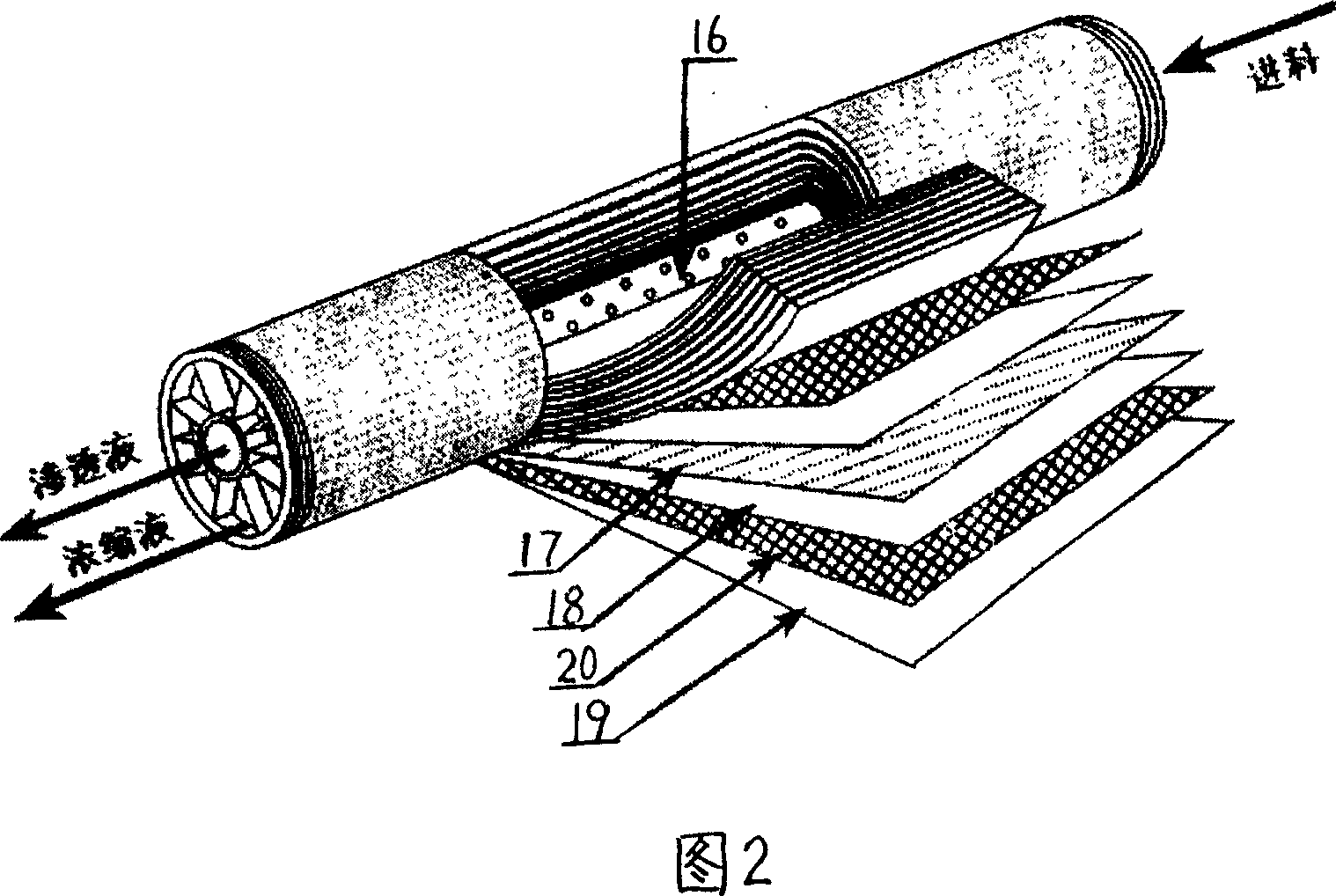

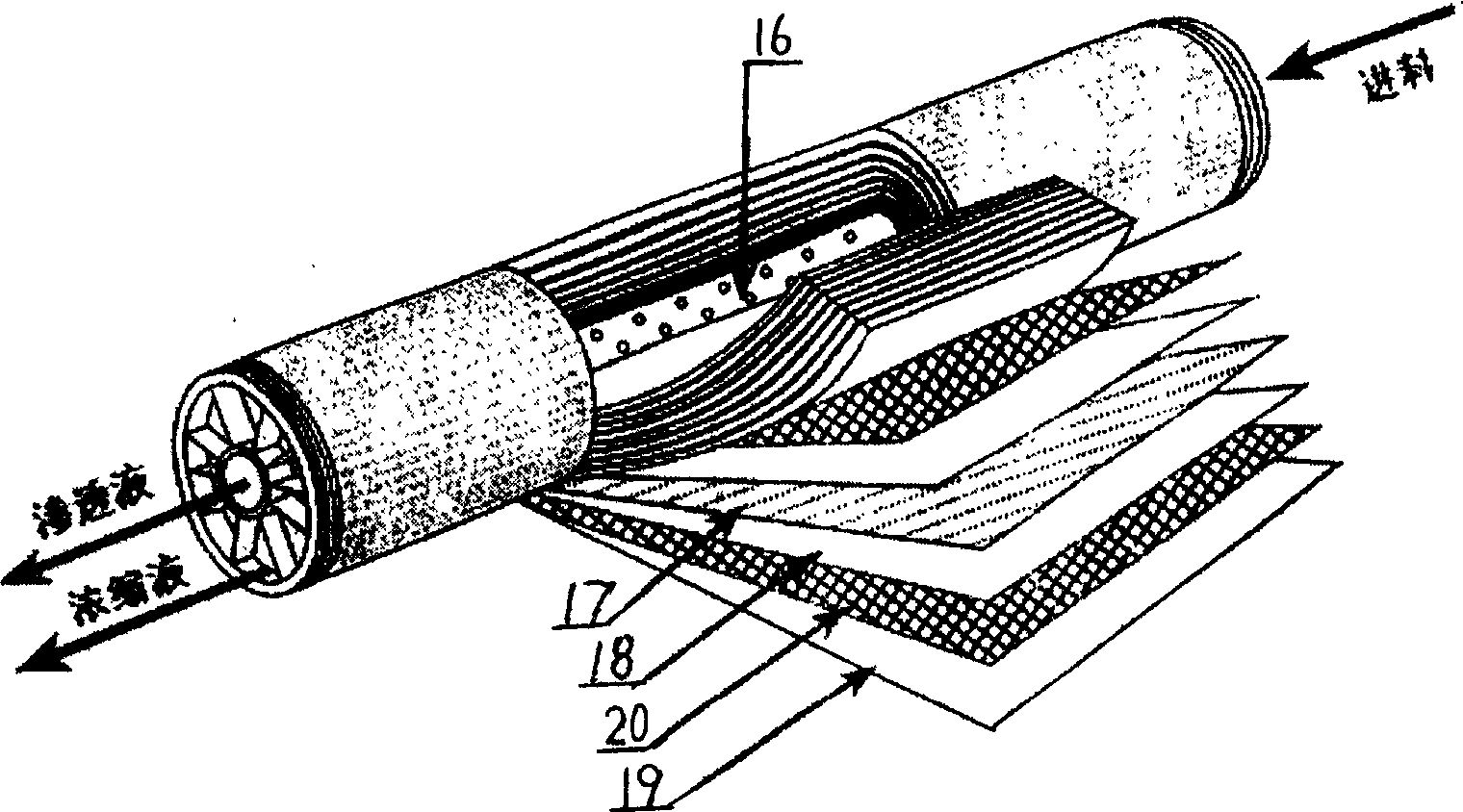

Method of eliminating magnesium sulfate from magnesium sulfate containing waste water solution

ActiveCN101016175ALow in magnesium sulfateIncrease concentrationWater contaminantsUltrafiltrationMagnesium saltBarium salt

The invention discloses a removing method of magnesium sulfate from waste water solution with magnesium sulfate, which comprises the following steps: predisposing waste water solution with magnesium sulfate; transmitting the solution into micro-filter film device to remove micro-particle impurity; transmitting the solution into nano-filter film; obtaining percolation liquid with low-content magnesium sulfate and condensate with high-content of magnesium sulfate; freezing the condensate; extracting the solid of magnesium sulphate heptahydrate or adding calcium salt or barium salt to obtain calcium sulfate or barium sulfate; reacting magnesium salt and calcium hydroxide to produce magnesium hydroxide and calcium salt; saving the disposing cost; protecting environment; recycling magnesium sulfate.

Owner:BEFAR GROUP CO LTD

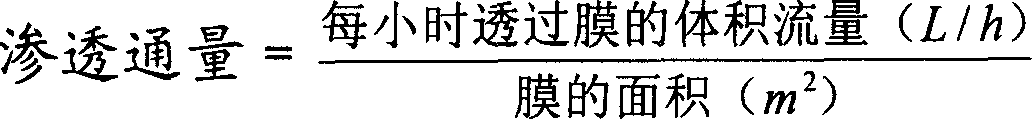

Process for producing in-situ modified nano-magnesium hydroxide by taking phosphate tailings as raw materials

InactiveCN104528778AHigh value-added utilizationKeep shapeMaterial nanotechnologySolid waste disposalFiltrationInterfacial adhesion

The invention discloses a process for producing in-situ modified nano-magnesium hydroxide by taking phosphate tailings as raw materials. The process comprises the following steps: putting the phosphate tailings obtained by flotation into an acidolysis reactor, reacting for a certain period of time, and then filtering; adding filtrate into an impurity removal reactor, firstly adding an oxidant for oxidation, further adding an alkaline compound, controlling the pH value, filtering a precipitate, then adding the filtrate, a silane coupling agent and a dispersant into an in-situ modification reactor, stirring for a period of time, then adding into a crystallization reactor, introducing ammonia gas, and performing crystallization and precipitation reaction to obtain surface-modified nano-magnesium hydroxide; and producing the filtrate which is rich in free ammonia after crystallization and filtration, obtaining the ammonia gas by air stripping, returning the ammonia gas into the crystallization working section, crystallizing a liquid phase to remove a large amount of ammonium sulfate, and then circulating to the acidolysis reaction process step, thereby realizing closed-loop circulation of wastewater of the process. Surface-modified nano-magnesium hydroxide produced by an in-situ modification method has good interfacial adhesion property and dispersivity in a polymer matrix and can be widely applied to the fields of plastics, coatings, environmental friendliness and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

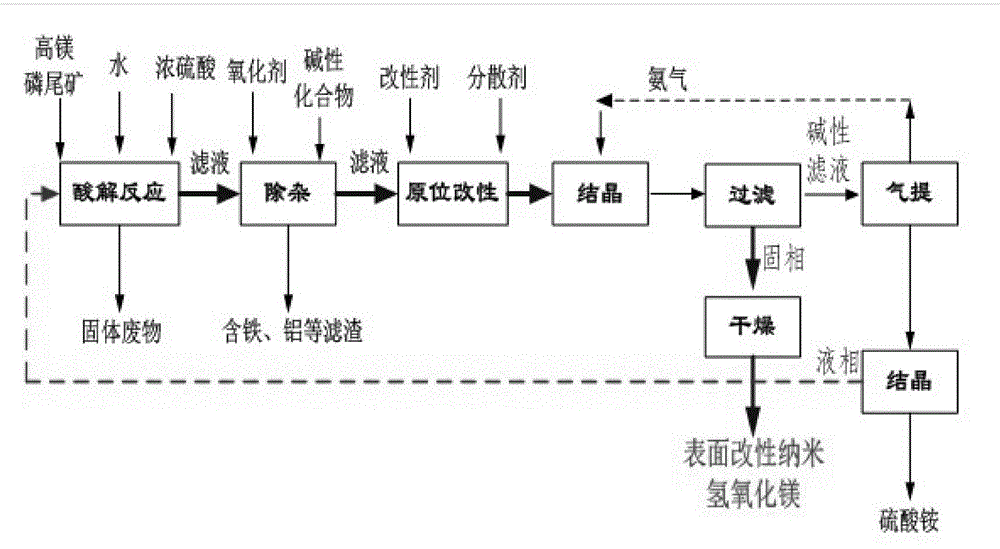

Method for preparing highly pure magnesium hydroxide and magnesium hexa-silicate by using olivine tailing mine

InactiveCN101607721AGuaranteed cycleReduce manufacturing costMagnesium silicatesSolid waste disposalSlurryOlivine

The invention discloses a method for preparing highly pure magnesium hydroxide and magnesium hexa-silicate by using olivine tailing mine, which comprises the following steps: step one. olivine tailing mine and muriatic acid are blended, leached and reacts; step two. pickle liquor leached by acid is added into an enamel reactor and oxidized by adding oxidant hydrogen peroxide; step three. the component of a solid product after reaction is a ferric oxide which is washed and dried after solid-liquid separation to be iron oxide red; step four. filtrate after solid-liquid separation is continously added with ammonia water; step five. sizing agent containing magnesium hydroxide stays in reactant, aged, washed, dried and ground to obtain highly pure magnesium hydroxide; step six. solid leached by muriatic acid reacts with caustic soda to produce serous fluid containing sodium silicate; and step seven. reaction product which reacts with caustic soda solution is filtered and washed to obtain magnesium hexa-silicate. The method causes magnesium oxide to be fully recycled. The method ensures complete circulation of ammonia, increases yield of magnesium oxide in mineral, reduces the cost of magnesium hydroxide, and simultaneously ensures the purity of the magnesium hydroxide which reaches more than 99%.

Owner:宜昌弘林华镁矿业投资有限公司

Long term-stabilized magnesium hydroxide suspension for covering iron mineral, a process for its production and application

InactiveUS20030141485A1Improve adhesionIncrease coverageOther chemical processesMixing methodsPolyelectrolyteSolid particle

A long term stabilized magnesium hydroxide suspension which can be used for covering pellets of several materials in order to avoid the agglomeration of a plurality of pellets when stored or subjected to a heat treatment and which can be stored for at least three months without substantial agitation and without experiencing substantial settlement and solid hard substrate formation, comprising a solid content of about 51% to 61%; a water content of about 39% to 49%; a viscosity of about 500 to 1,500 cp.; an average particle size of about 1 to 2.5 microns; a Mg(OH)2 content of about 50% to 60%; an equivalent magnesium oxide content of 34% to 42%; including an adherent compound at a concentration of at least 30% in an amount of 0.5 to 5%, by weight, on a dry basis and an anionic polyelectrolyte as a dispersant agent, and which is obtained by washing, filtering and repulping magnesium hydroxide solids to obtain agglomerated solid particles, dispersing the agglomerated solid particles by comminution in a dispersing equipment, to reduce the particle size providing a dispersed product, grinding the dispersed product, to additionally reduce the particle size to about 2 microns; and adding an adherent compound at a concentration of at least 30% in an amount of 0.5 to 5% on a dry basis and an anionic polyelectrolyte at a concentration of at least 25%, in an amount of about 0.5 to 2.5%, by weight, on a dry basis, as a dispersant agent.

Owner:SERVICIOS IND PENOLES S A DE

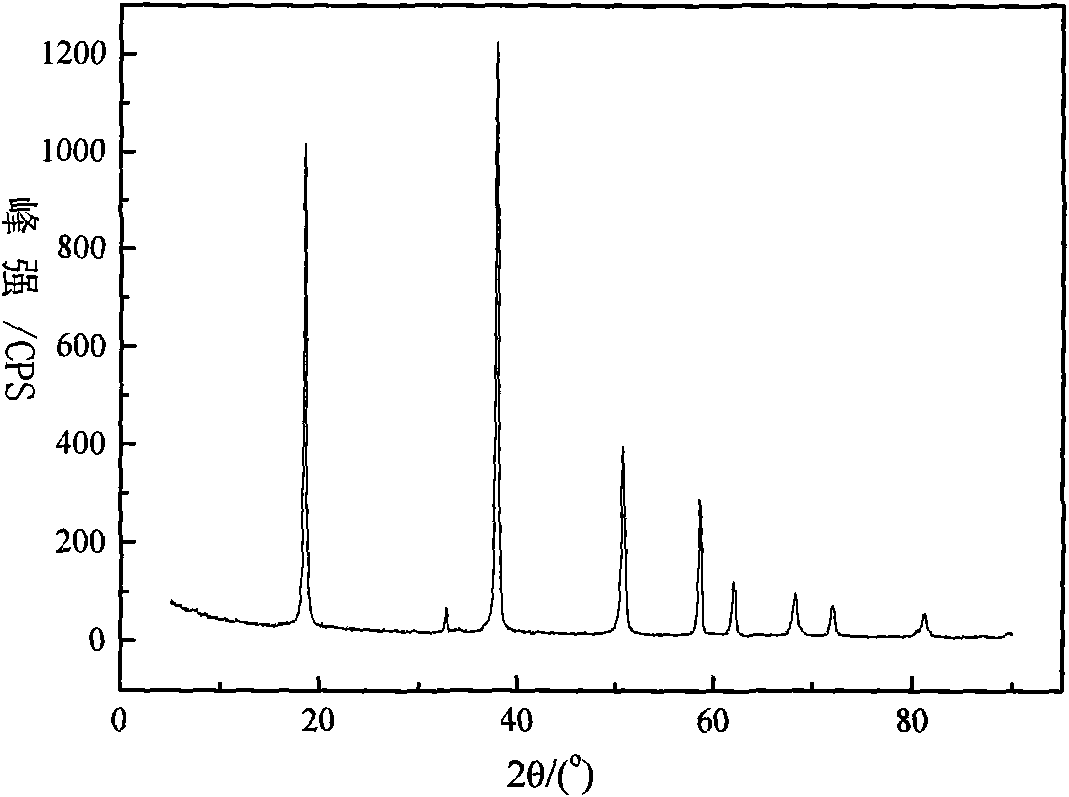

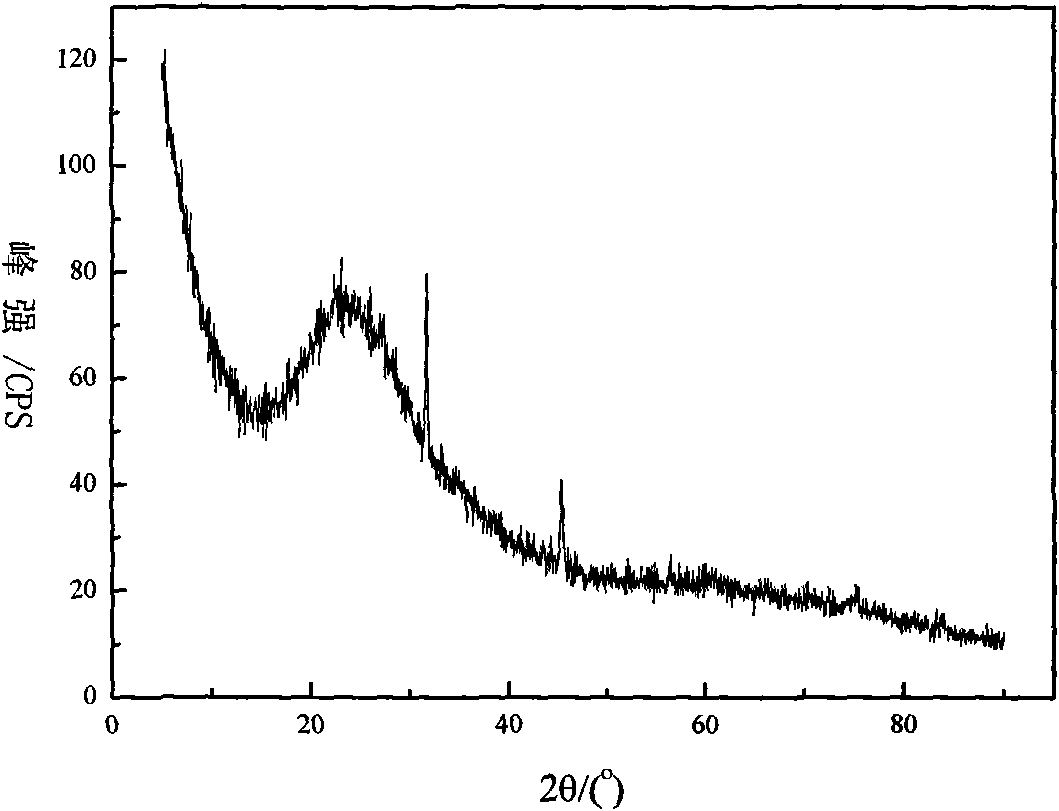

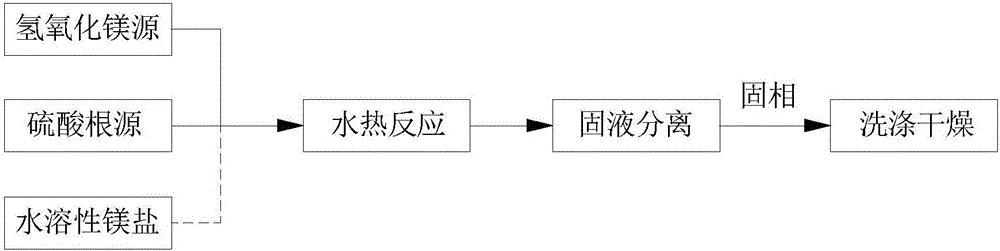

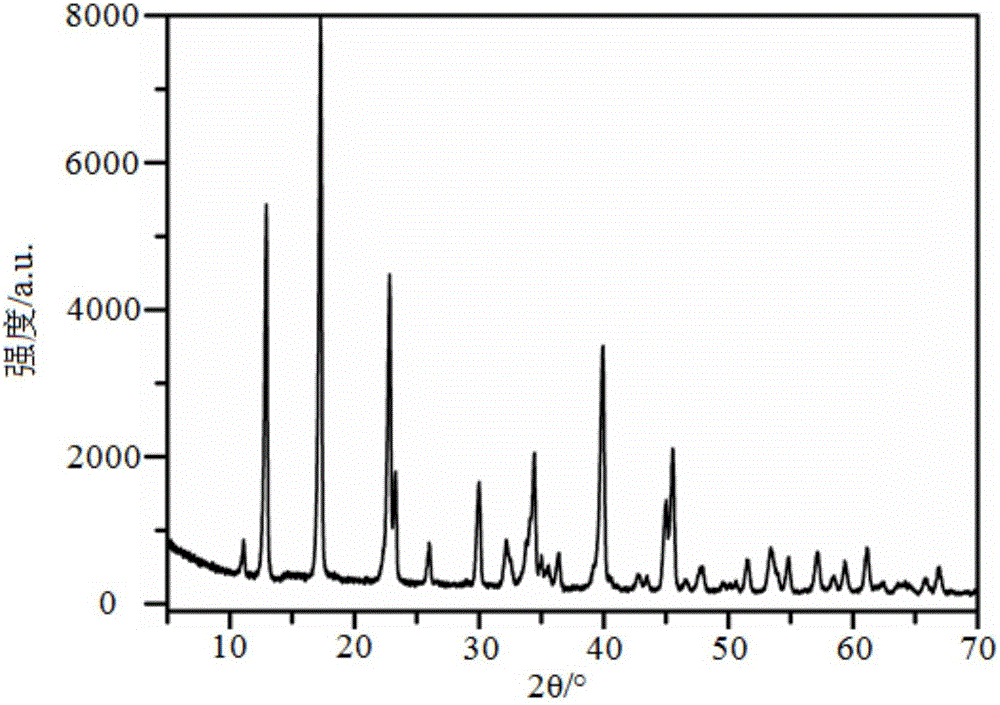

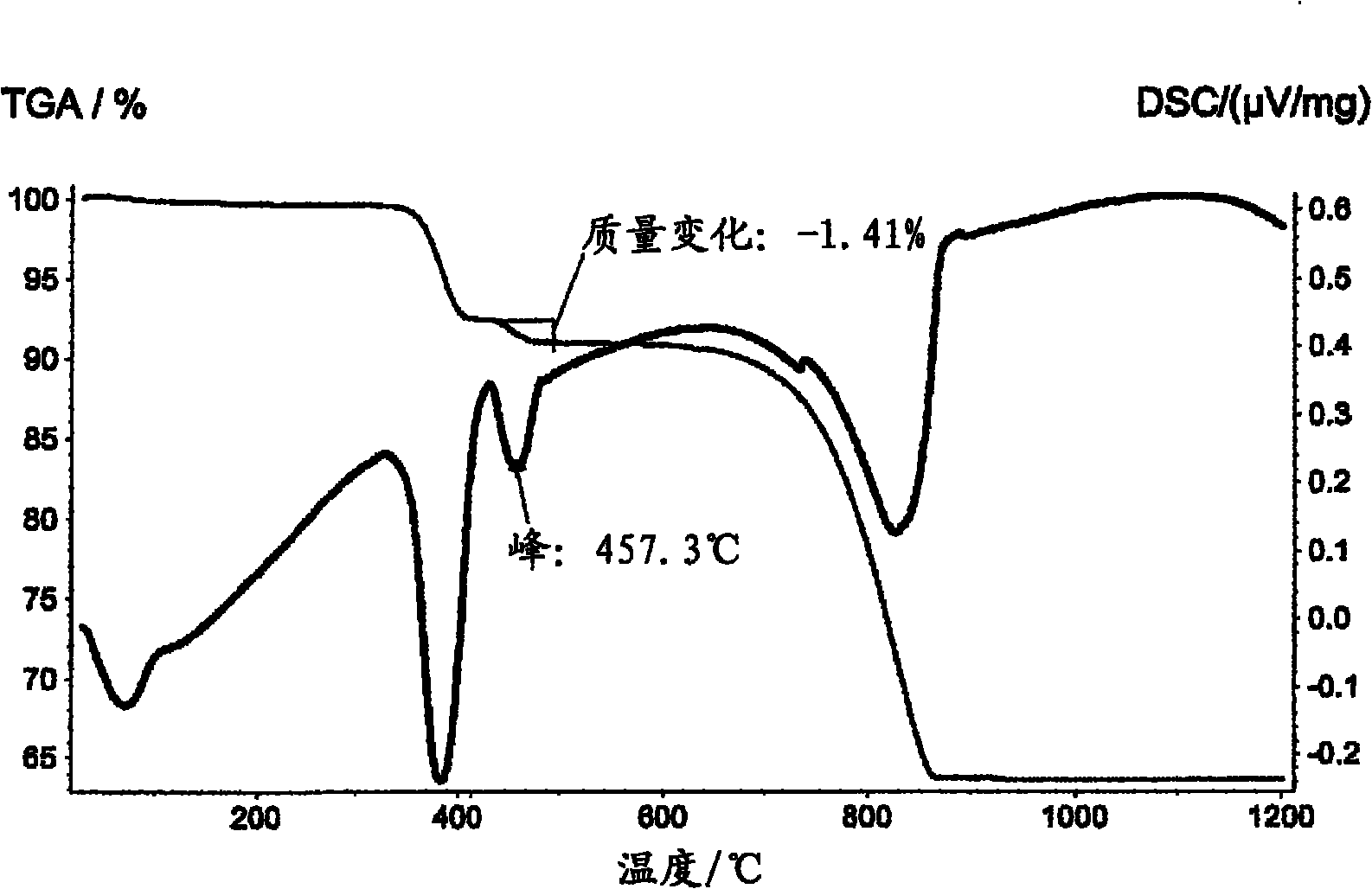

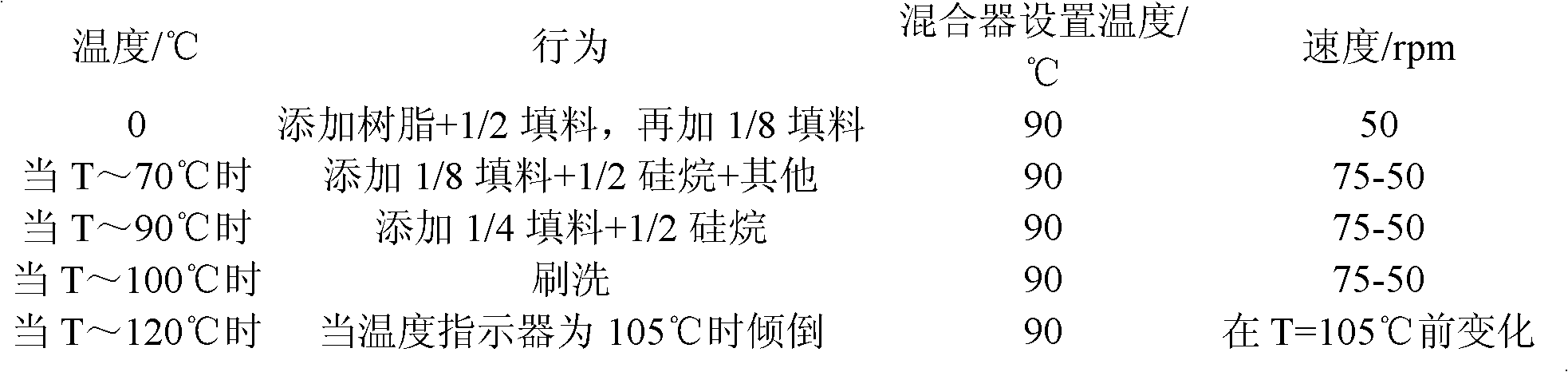

Preparation method of basic magnesium sulfate whiskers

The invention discloses a preparation method of basic magnesium sulfate whiskers. The preparation method comprises the following steps: S1, mixing a magnesium hydroxide source, a sulfate source and water to obtain a mixture, wherein the mass percent of magnesium hydroxide in the magnesium hydroxide source is not lower than 50%; S2, carrying out hydrothermal reaction on the mixture for 1-40 hours at the temperature of 100-300 DEG C, so as to obtain suspension; and S3, carrying out solid-liquid separation on the suspension, so as to obtain a solid phase and a liquid phase, washing, and drying the solid phase, so as to obtain the basic magnesium sulfate whiskers. According to the preparation method of the basic magnesium sulfate whiskers, the magnesium hydroxide source with relatively low magnesium hydroxide purity is taken as a preparation raw material; on one hand, the pollution and waste of byproduct magnesium hydroxide magnesium slag are reduced, and thus the magnesium harm problem is effectively controlled; and on the other hand, ammonia water, sodium hydroxide and the like are avoided from being used as a base source, and thus the preparation method is reduced. Meanwhile, the preparation method does not need other additives and is simple in technology; and the obtained basic magnesium sulfate product has high purity and good dispersibility.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

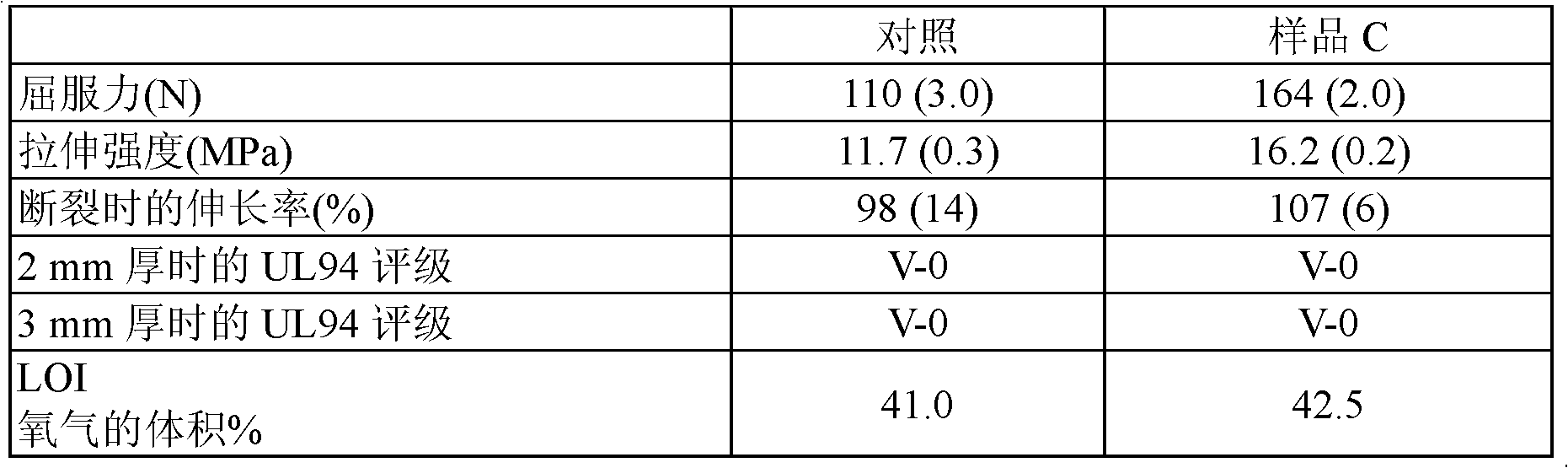

Magnesium hydroxide

Owner:IMERYS MINERALS

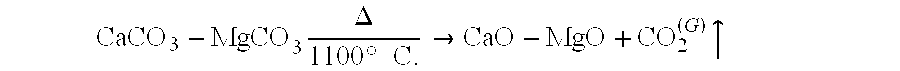

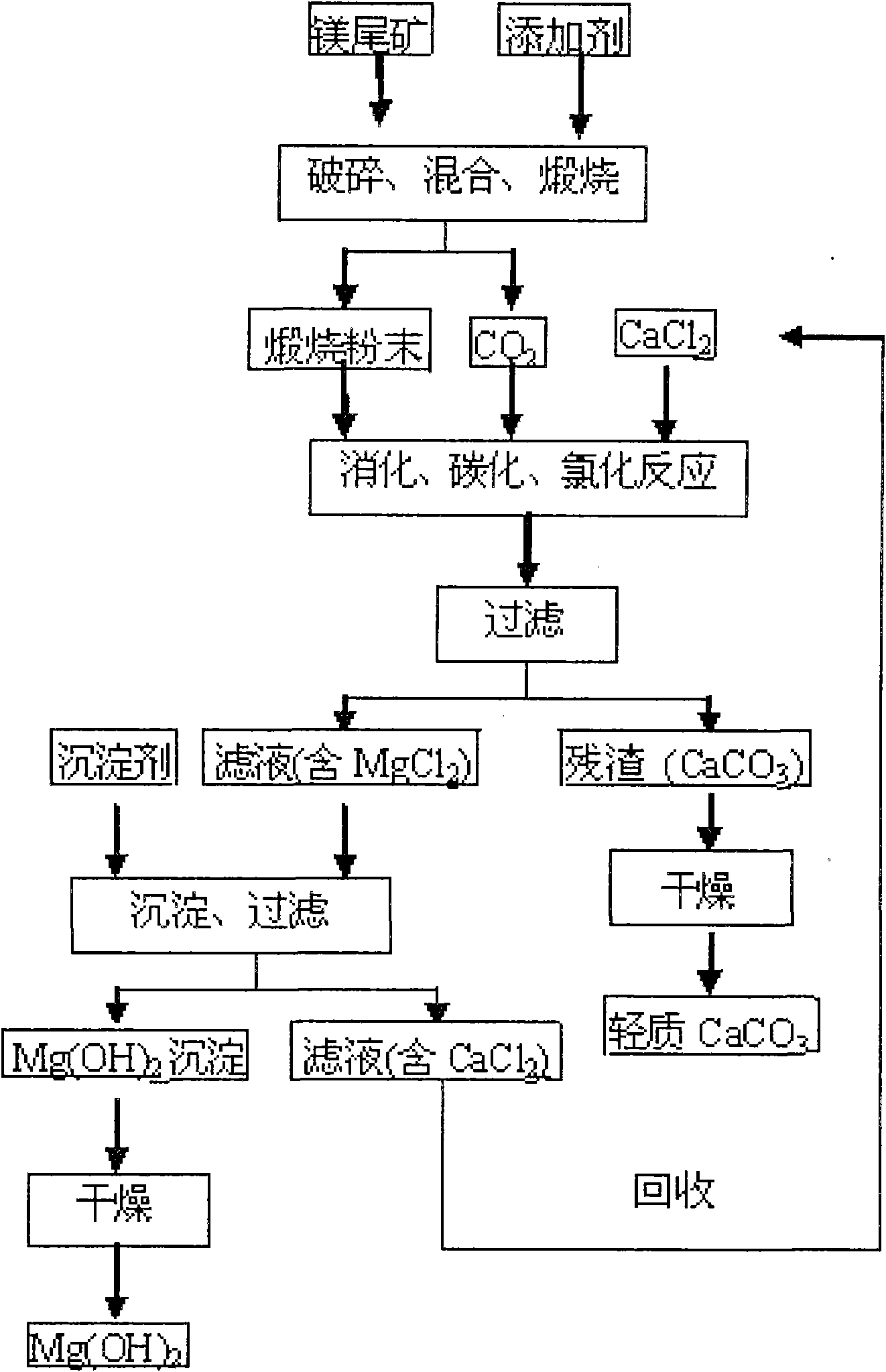

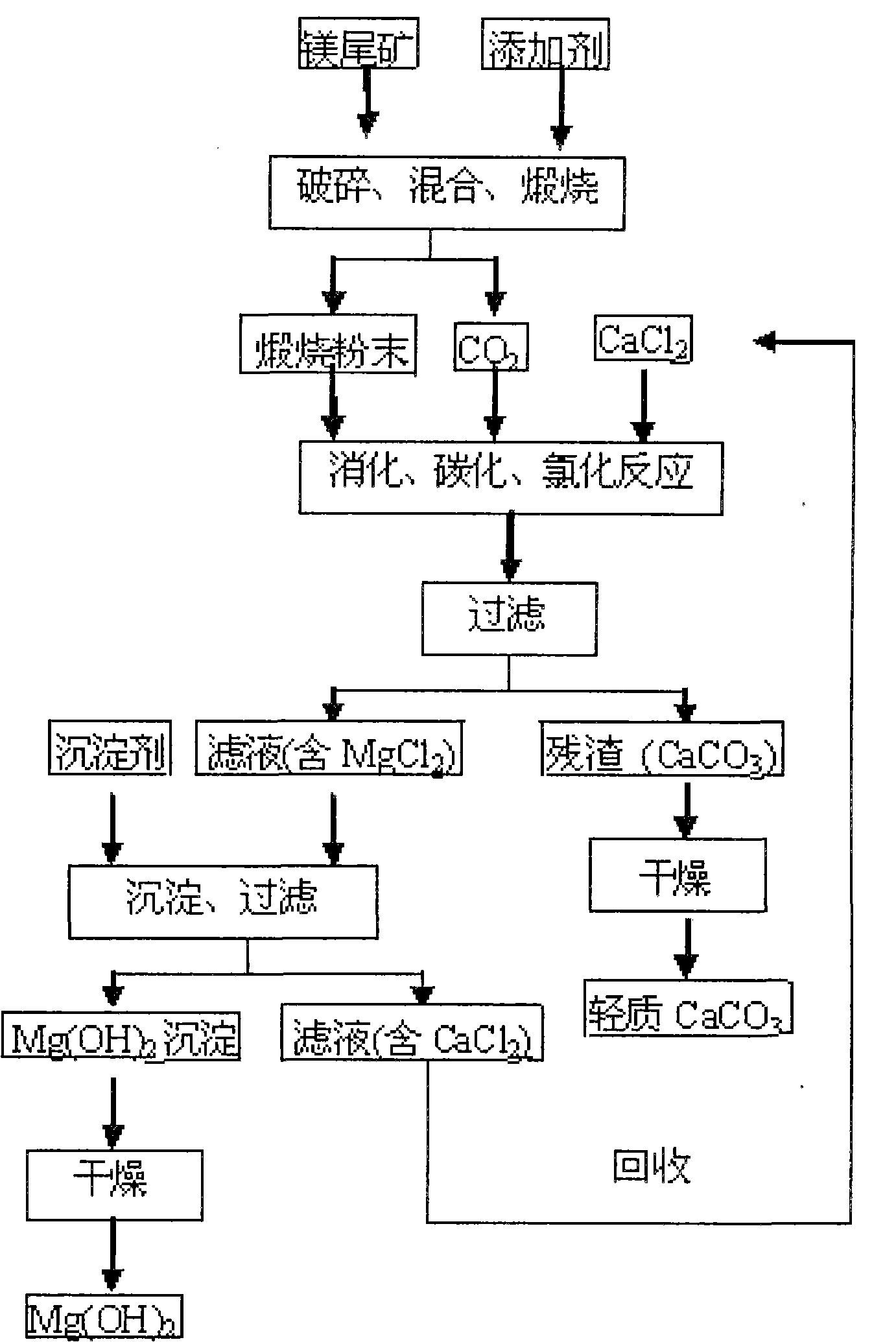

Method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings

InactiveCN101857258APromote decompositionSolve pollutionCalcium/strontium/barium carbonatesSolid waste disposalCarbonizationHydroxide magnesium

The invention discloses a method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings. A raw material is the magnesium tailings contain 18 to 36 weight percent of calcium oxide. The method comprises the following steps of: crushing and calcining the magnesium tailings to obtain calcined powder and CO2; performing digestion, carbonization and chlorination reaction on the calcined powder and the CO2 in the CO2 atmosphere under the condition of stirring so as to obtain MgCl2-containing solution and light CaCO3 precipitate; and reacting MgCl2 with a precipitator to generate Mg(OH)2 precipitate. In the method, the light calcium carbonate and magnesium hydroxide are prepared from the magnesium tailings discharged in a large quantity and other raw materials so as to solve the problem of environmental pollution and fulfill the aim of fully utilizing calcium and magnesium resources.

Owner:NORTHEASTERN UNIV

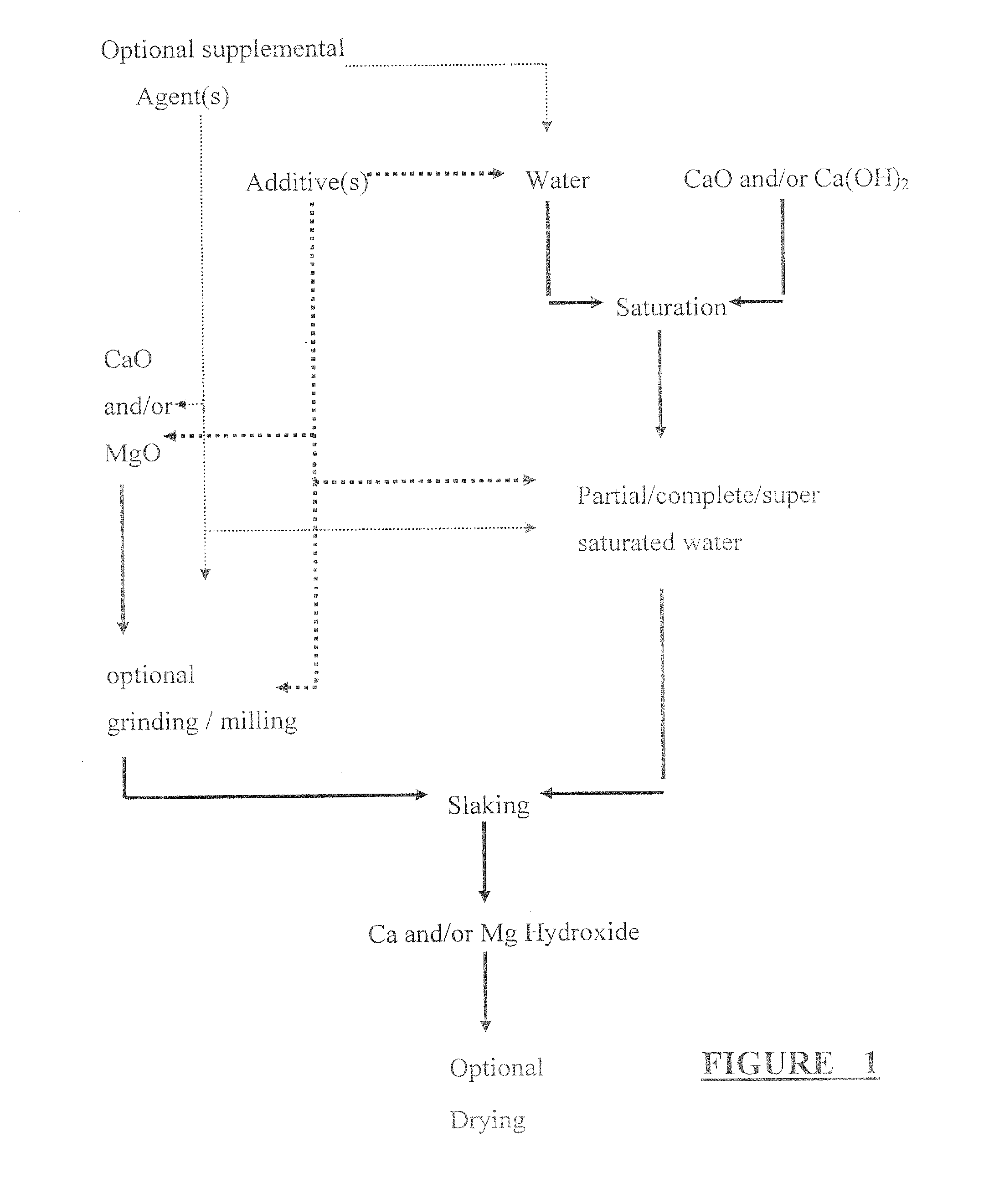

Calcium and/or magnesium hydroxide with very high reactivity, and preparation thereof

InactiveUS20100196239A1Reduce free water contentReduce and preventOther chemical processesUsing liquid separation agentDebyeCalcium hydroxide

Owner:LIME TECH CONSULTING

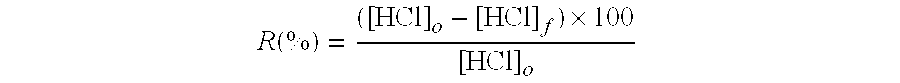

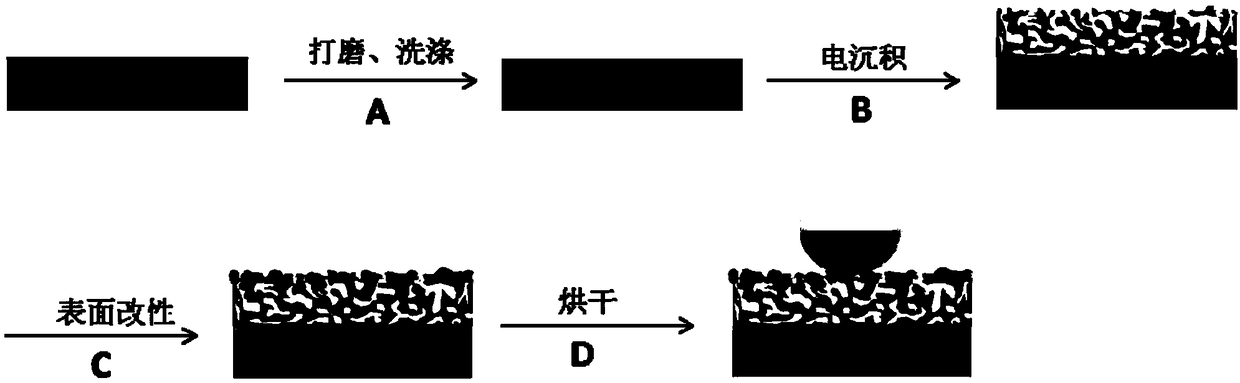

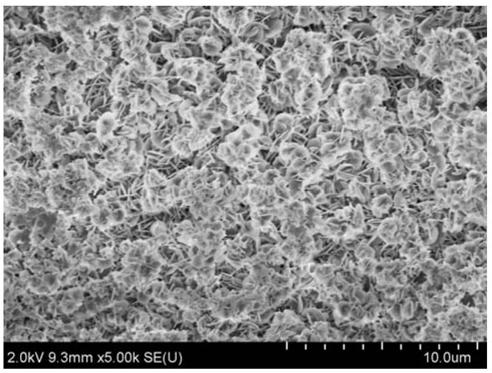

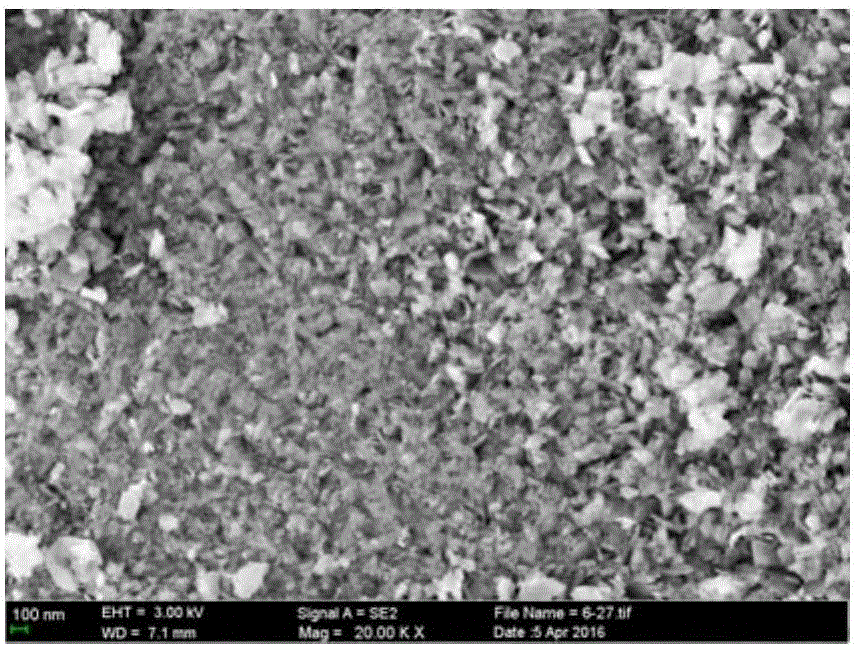

Magnesium hydroxide super-hydrophobic film and preparation method and application thereof

InactiveCN109137032AEasy to cleanThe preparation process steps are simpleElectrolytic inorganic material coatingMicro nanoHydroxide magnesium

The invention discloses magnesium hydroxide super-hydrophobic film and a preparation method and application thereof. The preparation method of the magnesium hydroxide super-hydrophobic film includes:providing a precursor solution containing magnesium ions; using a metal substrate as a cathode, enabling the cathode and an anode to form an electrode system, soaking the metal substrate and the anodein the precursor solution, and performing electrochemical deposition with the electrode system to form magnesium hydroxide film of micro-nano structure on the surface of the cathode; subjecting the magnesium hydroxide film to surface modification, and drying to obtain the magnesium hydroxide super-hydrophobic film. The electric deposition to prepare hydroxide magnesium layer of micro-nano structure is combined with a magnesium hydroxide surface modification technique herein; the preparation method has simple steps; the materials used are low in cost; the prepared novel magnesium hydroxide super-hydrophobic film has good water repelling performance and self-cleaning performance, and has a good application prospect in the fields, such as metal surface corrosion resistance and self-cleaning.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

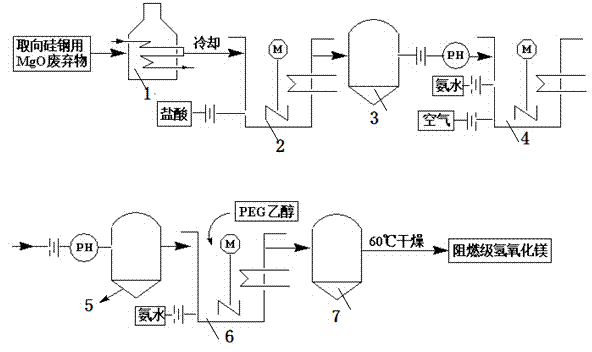

Method for preparing flame retardant grade magnesium hydroxide

ActiveCN104743585ASolve the technical problems of recyclingRealize resource utilizationSolid waste disposalMagnesium hydroxideAmmoniaMuffle furnace

The invention provides a method for preparing flame retardant grade magnesium hydroxide. The method comprises the following steps: calcining the oriented silicon steel in a muffle furnace by use of magnesium oxide wastes, next, cooling, adding the calcined silicon steel magnesium oxide to a dissolving tank by use of the magnesium oxide wastes, dissolving by use of an acid, adding the dissolved magnesium oxide wastes to a settling tank for settling, removing the undissolved substances, guiding the solution into a reaction tank, adding ammonia water, and continuously introducing compressed air so that Fe<2+> can be transformed into Fe<3+>, controlling the pH so that the Fe<3+> is completely settled and Mg<2+> is not settled, removing Fe(OH)3 precipitate, next, adding ammonia water, ethanol and a surfactant to the solution obtained after settlement in the reaction tank, controlling the pH so that the Mg<2+> can be completely settled, and drying Mg(OH)2 to obtain the retardant grade magnesium hydroxide. The method is used for solving the problems of the technical flow of recycling the magnesium oxide waste for the silicon steel; and the waste of resources is avoided.

Owner:上海永青环保新材料有限公司

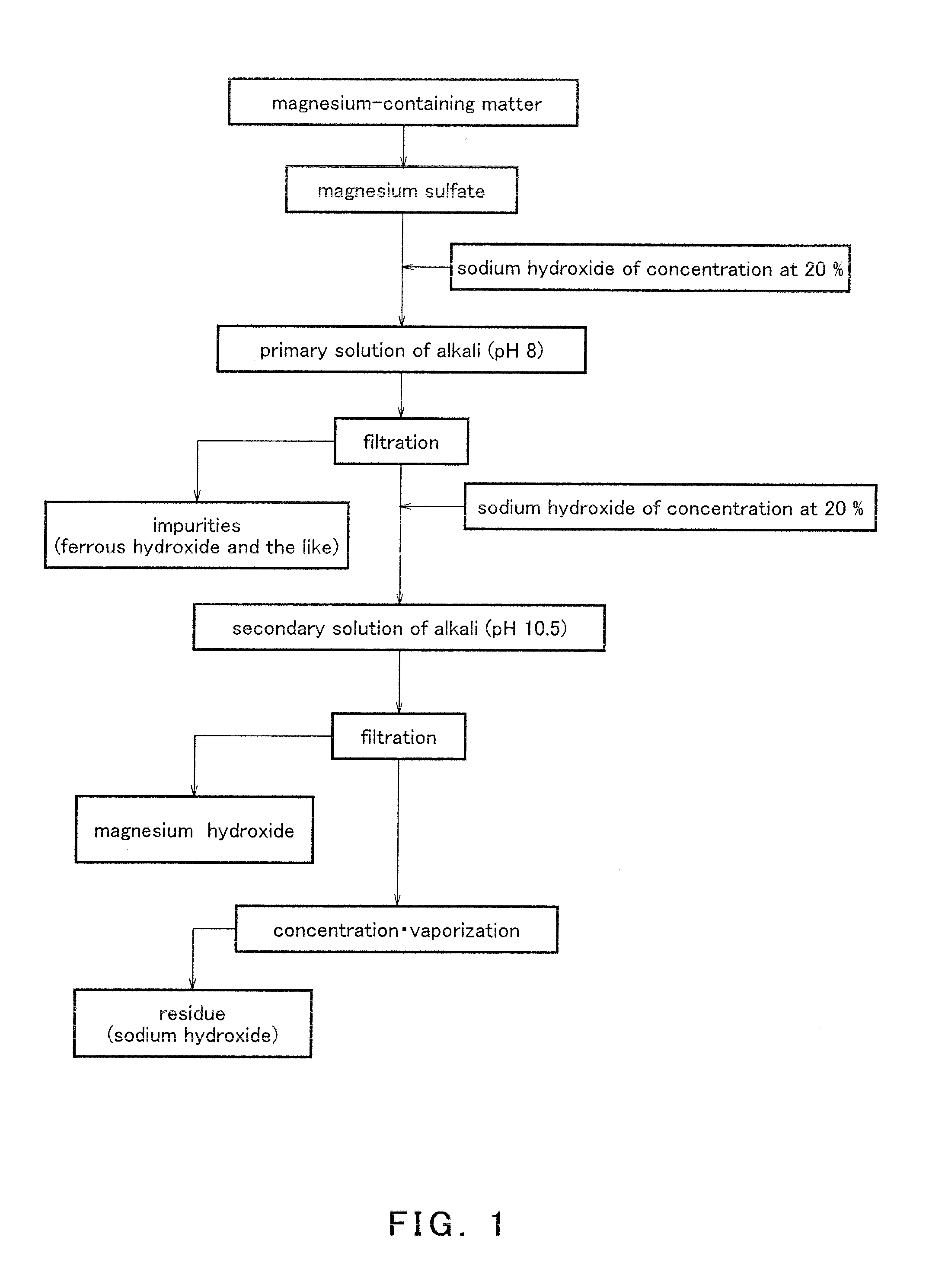

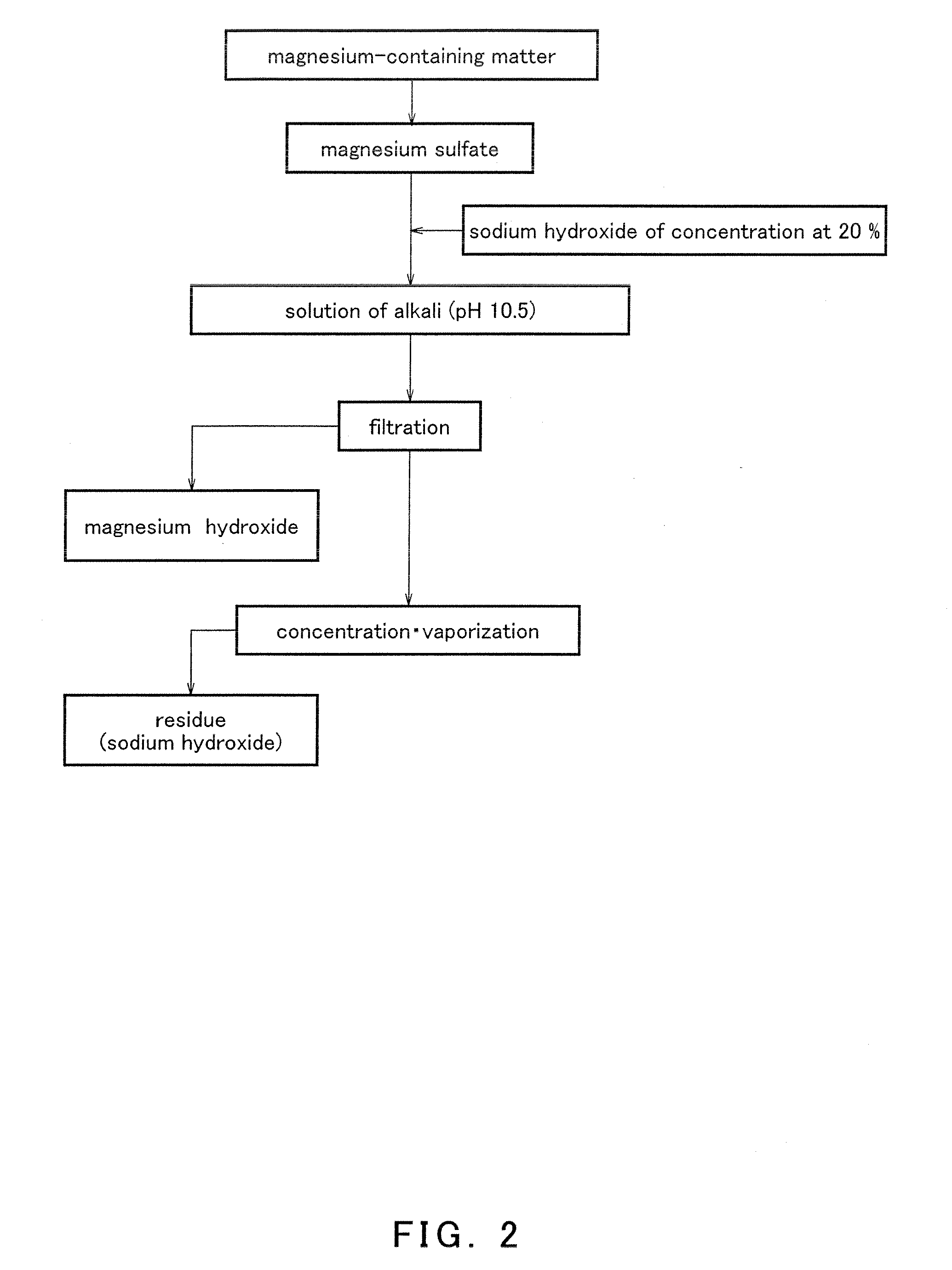

Magnesium hydroxide, method for producing magnesium hydroxide and a fire retardant comprising the magnesium hydroxide, and a fire-retarded resin composition containing the magnesium hydroxide

InactiveUS20100069555A1Large specific surface areaImprove dispersion qualityOxide/hydroxide preparationSynthetic resin layered productsAlkalinityHydroxide magnesium

Magnesium hydroxide having a large specific surface area is provided. A magnesium-containing matter is chemically decomposed by a solution of acid, and a primary solution of alkali with weak alkalinity is obtained by adding a solution of alkali to the solution of acid, and impurities contained in the primary solution of alkali are eliminated, and a secondary solution of alkali with strong alkalinity is obtained by adding a solution of alkali to the primary solution of alkali, and successively a magnesium hydroxide is deposited in secondary solution of alkali.

Owner:NOZAWA CORP

Method for preparing surface-modification ultrafine magnesium hydroxide

InactiveCN106280564AImprove mechanical propertiesImprove processing fluidityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsHeat stabilitySolvent

The invention discloses a method for preparing surface-modification ultrafine magnesium hydroxide. The method includes the following steps that (1) ultrafine magnesium hydroxide with the particle size of 4,000 meshes to 6,000 meshes is selected, stirred and preheated for 20 min to 40 min in the stirring speed of 3,000 r / min to 6,000 r / min in a high-speed stirrer at the temperature of 50 DEG C to 100 DEG C; (2) then surface modifier and solvent are slowly and evenly added, the mixture continues to be stirred, the surface-modification time is 50 minutes to 90 minutes, and the modified ultrafine magnesium hydroxide is obtained. According to the modified ultrafine magnesium hydroxide prepared with the method, the good compatibility and the heat stability of the modified ultrafine magnesium hydroxide and a high polymer material are improved, and the mechanical performance, the processing fluidity and the like of the high polymer composite material can be remarkably improved.

Owner:黄惠娟

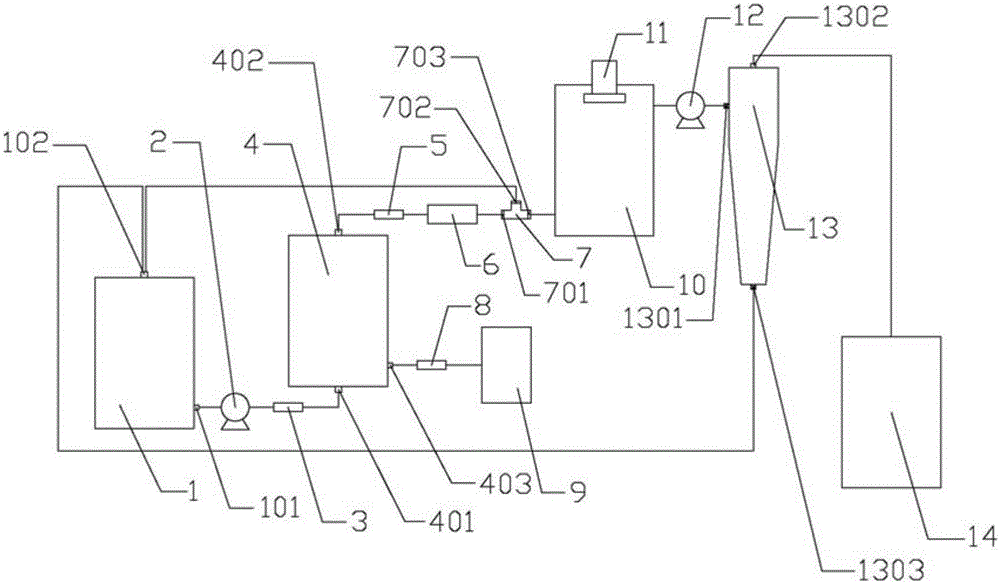

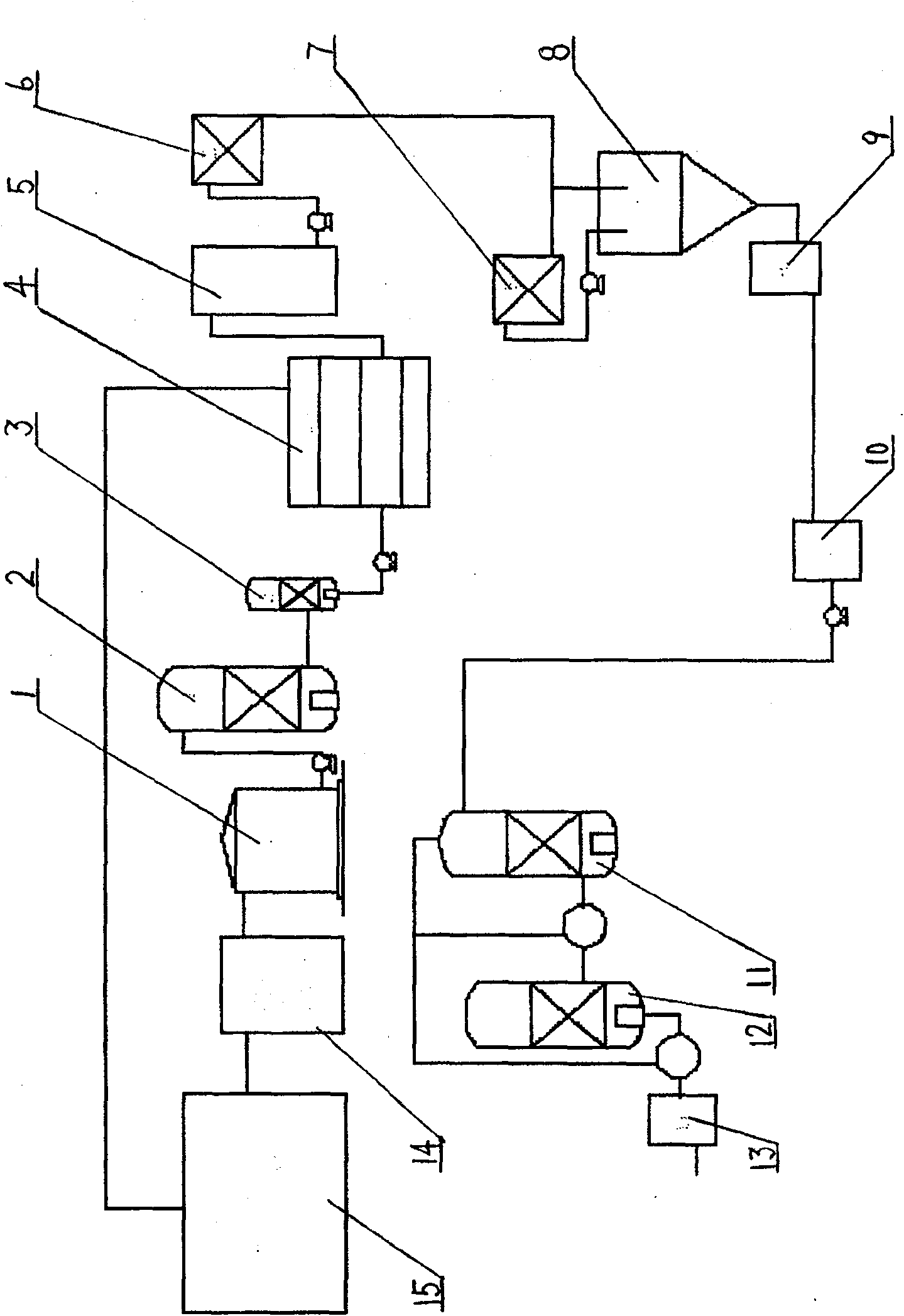

Device and method for preparing magnesium hydroxide through ultrasonic-assisted magnesium oxide efficient hydration

ActiveCN106365185AContinuous and efficient productionIncreased hydration rateEnergy based chemical/physical/physico-chemical processesMagnesium hydroxideUltrasonic assistedThree-phase

The invention relates to a device and method for preparing magnesium hydroxide through ultrasonic-assisted magnesium oxide efficient hydration. The device comprises a three-phase hydration system, a circulation cup, an ultrasonic generator, a booster pump II and a hydrocyclone. A discharge port of the three-phase hydration system is connected with an inlet of the hydrocyclone through the circulation cup and the booster pump, the ultrasonic generator is arranged in the circulation cup, and a bottom flow opening of the hydrocyclone is connected with a mixing tank in the three-phase hydration system. Online efficient preparation of magnesium oxide and purification of magnesium hydroxide are achieved.

Owner:DALIAN MARITIME UNIVERSITY

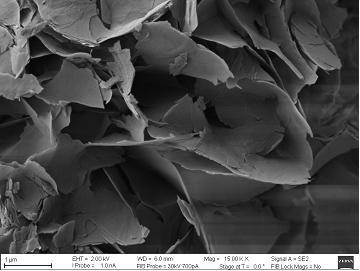

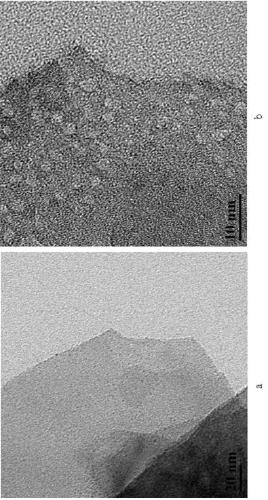

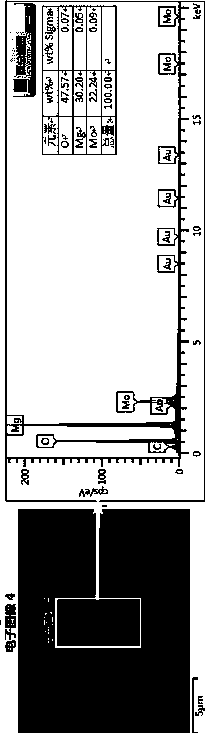

Preparation method of nano molybdenum oxide hybrid magnesium hydroxide flame retardant

The invention relates to a preparation method of a nano molybdenum oxide hybrid magnesium hydroxide flame retardant. The method includes the following steps that 1, MgCl2 6H2O is used for preparing amagnesium chloride solution with the concentration of 0.1-1.0 mol / L; 2, solid NaOH is added into the magnesium chloride solution and dissolved through stirring, and magnesium hydroxide slurry is obtained; 3, (NH4)6Mo7O24 4H2O is used for preparing an ammonium molybdate solution with the concentration of 0.014-0.14 mol / L; 4, under stirring, the ammonium molybdate solution is added into the magnesium hydroxide slurry to obtain mixed slurry; 5, the mixed slurry is transferred to a hydrothermal reaction kettle, placed in a homogeneous phase reactor for reaction, and naturally cooled to room temperature after reaction is over, and white suspension liquid is obtained; 6, the white suspension liquid is filtered, washed and dried, and a nano molybdenum oxide hybrid magnesium hydroxide flame-retardant sample is obtained. The process is simple, and the obtained product has special morphology and better flame retardancy and smoke suppression performance.

Owner:QINGHAI UNIVERSITY

Fe-based powder metallurgy material for valve element of check valve

The invention discloses an iron-based powder metallurgy material for a check valve core, which comprises the following components in terms of mass parts: 20-25 parts of silicon dioxide, 22-25 parts of titanium dioxide, 12-15 parts of iron oxide, 10 ‑12 parts of magnesium oxide, 12‑15 parts of aluminum oxide, 3‑5 parts of acrylamide, 8‑10 parts of nano tungsten carbide powder, 5‑6 parts of silver powder, 6‑7 parts of silicon carbide whiskers, 5‑6 parts of nano oxide Zinc, 10-15 parts of nano glass fiber, 10-15 parts of polytetrafluoroethylene, 12-15 parts of cobalt powder, 10-12 parts of ammonium phosphate, 7-10 parts of magnesium hydroxide, 200-250 parts of iron powder. The iron-based powder metallurgy material of the check valve spool interpenetrates the metal phase and the non-metal phase, and is tightly combined, which increases the wettability and adhesion of the non-metal phase and the metal phase, and can prevent component segregation, making the material structure Uniform, increased strength and toughness, and good heat resistance and corrosion resistance.

Owner:KAIPING GELAIMEI BATHROOM ACCESSORY

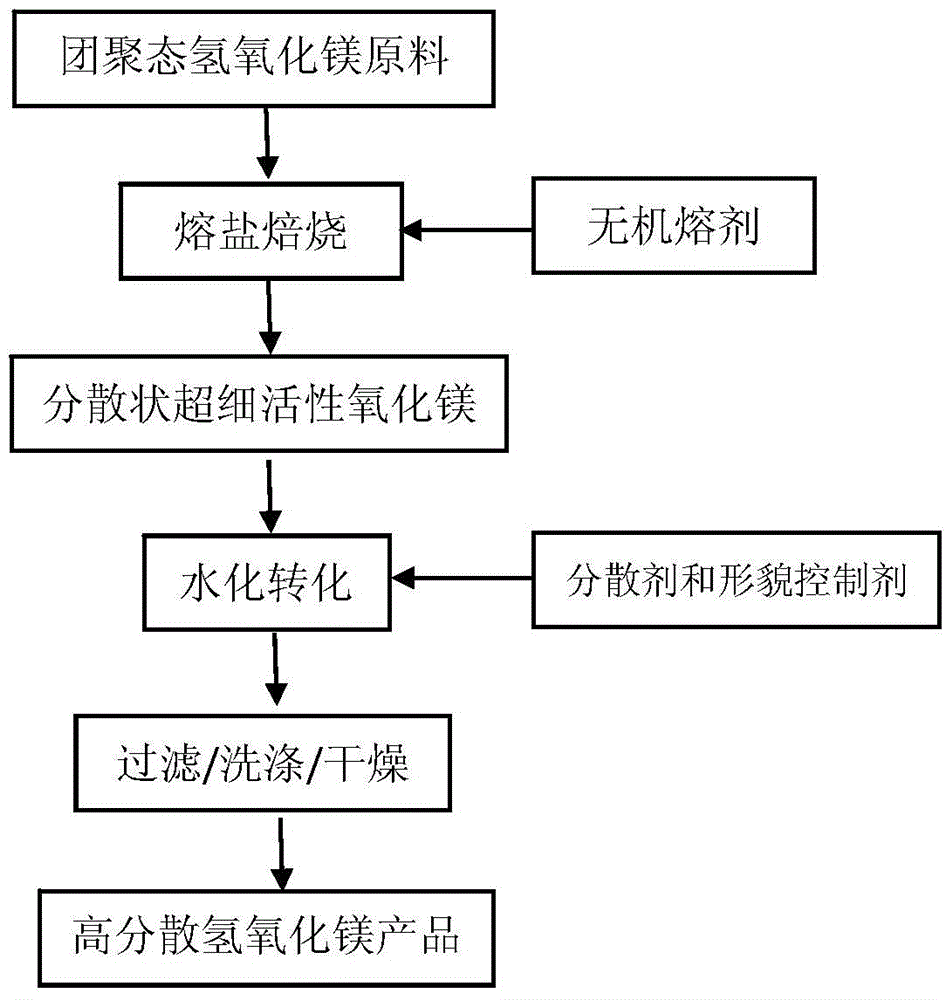

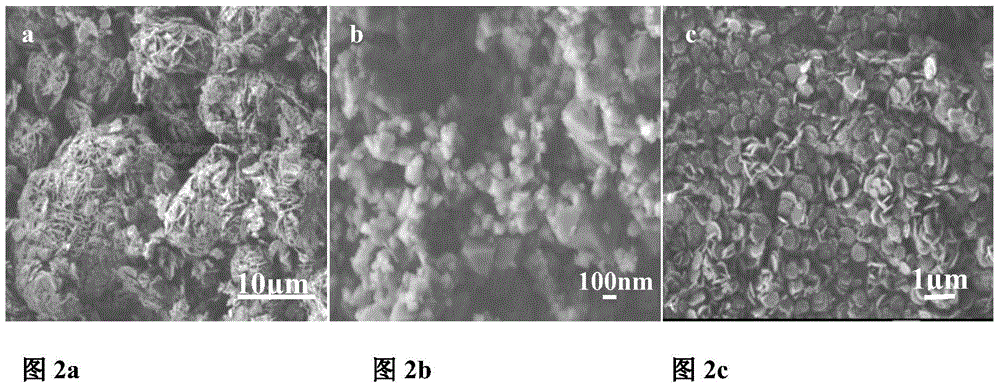

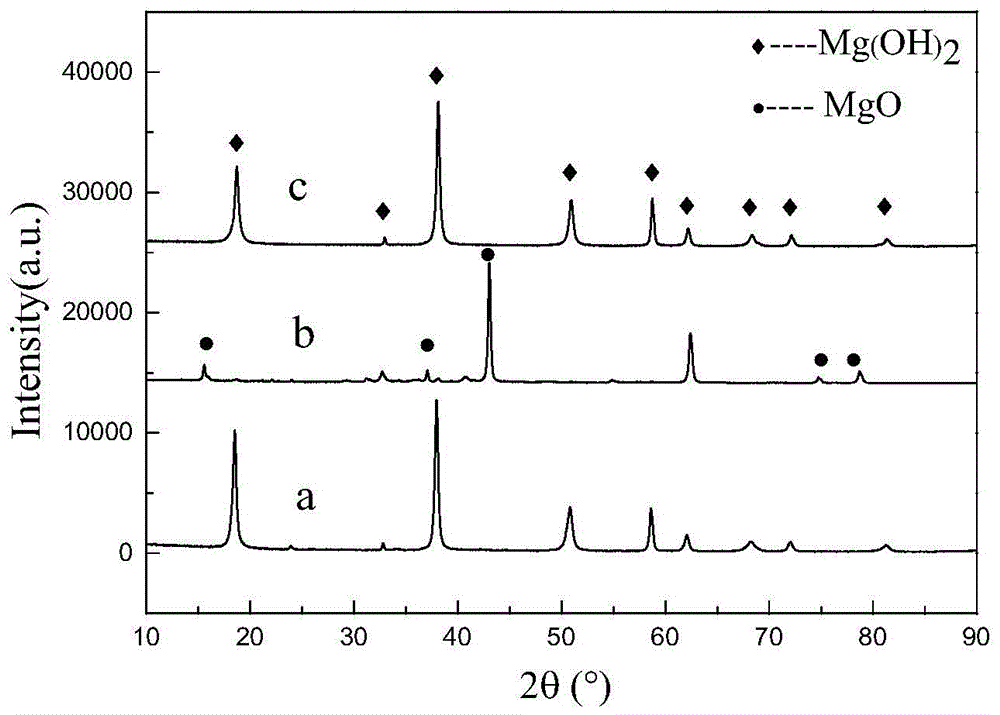

A method for preparing highly dispersed magnesium hydroxide using agglomerated magnesium hydroxide as raw material

ActiveCN104609449BGood dispersionIncrease added valueMagnesium hydroxideInorganic ChemicalWastewater

The invention relates to a method for preparing high dispersed magnesium hydroxide from agglomerated state magnesium hydroxide, and belongs to the technical field of the preparation of inorganic chemical industry materials. According to the method disclosed by the invention, the high dispersed magnesium hydroxide is prepared through the following steps: using agglomerated state magnesium hydroxide as a raw material, wherein the original average particle diameter is 0.1-3 microns, and the average agglomerated particle diameter is 5-50 microns, firstly, mixing the raw material with proper amount of inorganic solvent, and roasting the mixture for 0.5-6 hours at the temperature of 300-700 DEG C, so as to form dispersed superfine active magnesium oxide; then, adding the magnesia to an aqueous solution containing a dispersing agent and a morphological control agent, and performing hydration conversion for 0.5-6 hours at the temperature of 10-100 DEG C so as to obtain the high dispersed magnesium hydroxide of which the original average particle diameter is 0.1-3 microns, the average agglomerated particle diameter is 0.5-4.0 microns, the morphology is regular, and the particle diameters are homogeneous. The method disclosed by the invention is simple in technology, is mild in process, and is high in added value of a product. The magnesium hydroxide prepared by the method disclosed by the invention is regular in morphology and is good in dispersion, can be used as a basic inorganic chemical industry product to be used in the fields of flame resistance, foods, desulphurization, wastewater treatment and the like.

Owner:TSINGHUA UNIV

High-aspect-ratio magnesium hydroxide

ActiveUS9321895B2High aspect ratioHigh impact strengthOxide/hydroxide preparationSynthetic resin layered productsOrganic acidLongest Diameter

Magnesium hydroxide having a high aspect ratio, a production method thereof and a resin composition comprising the same.The method of producing the magnesium hydroxide having a long diameter (width) of not less than 0.5 μm and aspect ratio of not less than 10,comprising the steps of:(A) adding an alkali to and coprecipitating it with a mixed aqueous solution of a water-soluble magnesium salt and a monovalent organic acid or a salt thereof, or(B) adding an alkali aqueous solution to and coprecipitating it with an aqueous solution of a water-soluble magnesium salt and adding a monovalent organic acid or a salt thereof to the resulting product; and(C) hydrothermally treating the obtained slurry at 100° C. or higher.

Owner:SEA WATER CHEM INST INC +1

Method of eliminating magnesium sulfate from magnesium sulfate containing waste water solution

ActiveCN101016175BLow in magnesium sulfateIncrease concentrationWater contaminantsUltrafiltrationMagnesium saltBarium salt

The invention discloses a removing method of magnesium sulfate from waste water solution with magnesium sulfate, which comprises the following steps: predisposing waste water solution with magnesium sulfate; transmitting the solution into micro-filter film device to remove micro-particle impurity; transmitting the solution into nano-filter film; obtaining percolation liquid with low-content magnesium sulfate and condensate with high-content of magnesium sulfate; freezing the condensate; extracting the solid of magnesium sulphate heptahydrate or adding calcium salt or barium salt to obtain calcium sulfate or barium sulfate; reacting magnesium salt and calcium hydroxide to produce magnesium hydroxide and calcium salt; saving the disposing cost; protecting environment; recycling magnesium sulfate.

Owner:BEFAR GROUP CO LTD

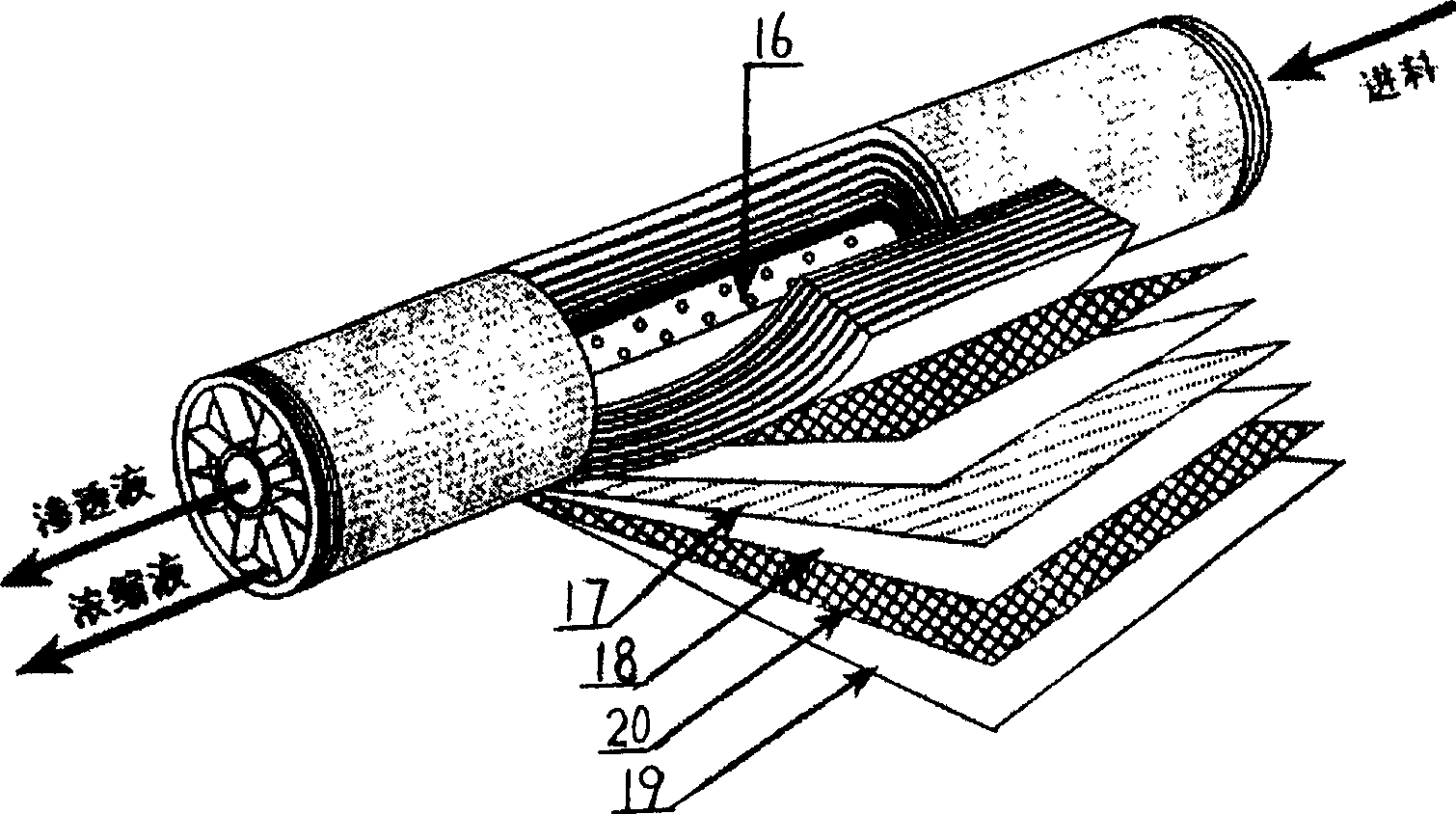

Method for recycling magnesium from heavy metal sludge to prepare magnesium hydroxide fire retardant

ActiveCN106367597AHigh recovery rateAchieve recyclingProcess efficiency improvementMagnesium hydroxideSlagSludge

The invention provides a method for recycling magnesium from heavy metal sludge. The method includes the following steps that the heavy metal sludge is added into pure water according to the mass ratio of the pure water to sludge dry matter being 8:1-15:1, and stirring is performed while heating is conducted; the mixture is heated to 80-85 DEG C and heat preservation is carried out; dilute sulphuric acid of 0.4g / L-0.6g / L is added in the heating and stirring processes until the pH is measured to be 7.0-8.0 at the temperature of 80-85 DEG C; stirring is continuously performed for 10-15min, so that a water-slag mixture is obtained, and filter liquor 1 is obtained through plate-frame pressure filtration dehydration; filter residues are washed with hot water, filtered and dehydrated for 1-3 times, and accordingly filter liquor 2 is obtained; and the filter liquor 1 and the filter liquor 2 are combined, and the obtained filter liquor is magnesium liquor. Based on the method, the invention further provides a method for recycling magnesium from heavy metal sludge to prepare magnesium hydroxide fire retardant. The method includes the following steps of pretreatment washing, alkaline liquor adding for magnesium settlement, surface modification, ageing, hydro-thermal treatment, dehydration, washing and drying. In the process of the invention, the one-time recovery rate of magnesium is increased while the precious metal cobalt-nickel recovery rate and purity of flame-retardant magnesium hydroxide coarse products are guaranteed.

Owner:JINGMEN GEM NEW MATERIAL

High-strength glass reinforced plastic

The invention relates to a high-strength FRP, which belongs to the technical field of FRP, and is characterized in that it consists of the following components in weight percent: 30-40 parts of unsaturated polyester resin, 10-30 parts of hydrogen peroxide, and 1-3 parts of potassium oxide 1-3 parts of phenol-modified tungsten hexachloride, 1-5 parts of flame retardant, 2-4 parts of nano filler, 10-20 parts of glass fiber, 1-3 parts of metal filler, 8-10 parts of magnesium hydroxide share. The beneficial effect of the present invention is: use unsaturated polyester resin and other auxiliary materials as curing system, use glass fiber yarn as reinforcing material, produce high-performance composite linear material, improve the strength of product through reasonable formula system; Magnesium is non-toxic and suppresses smoke production.

Owner:成都双瑞暖通设备有限公司

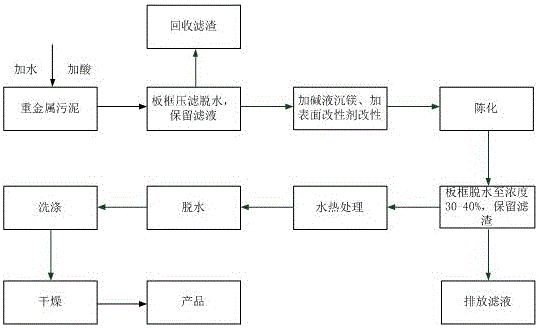

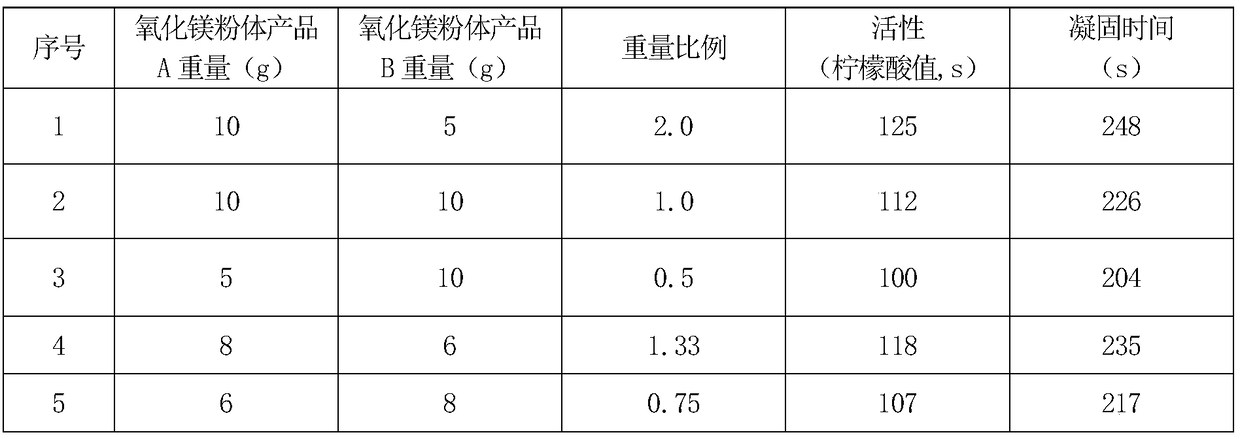

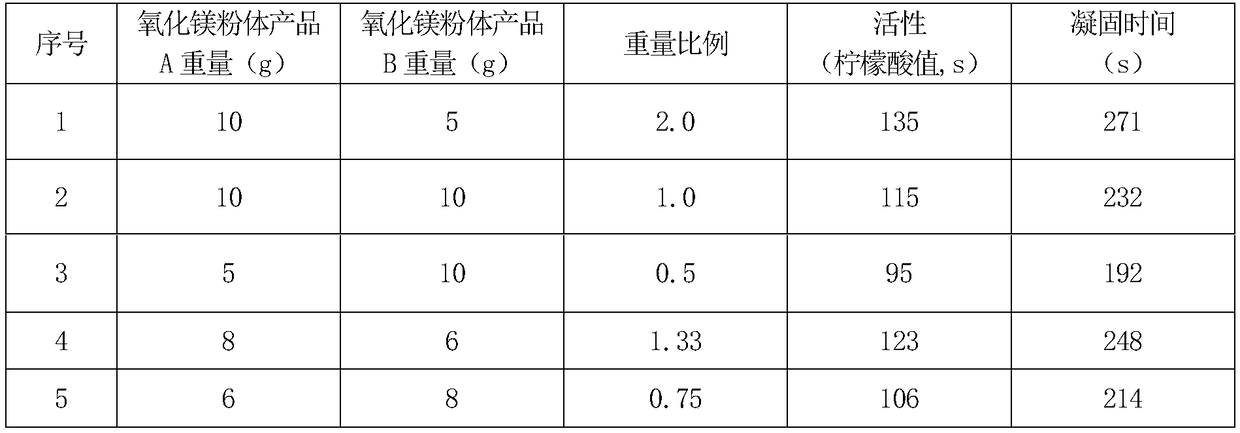

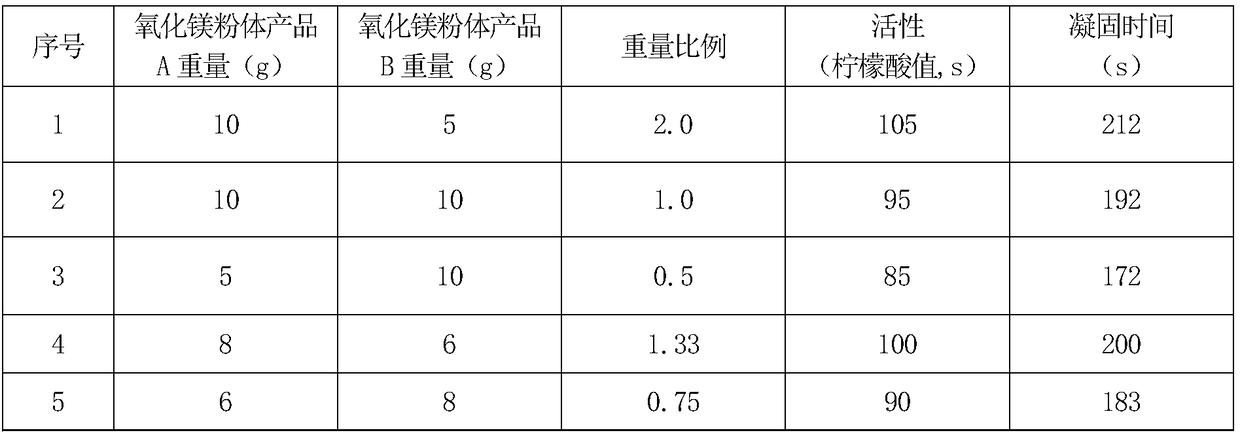

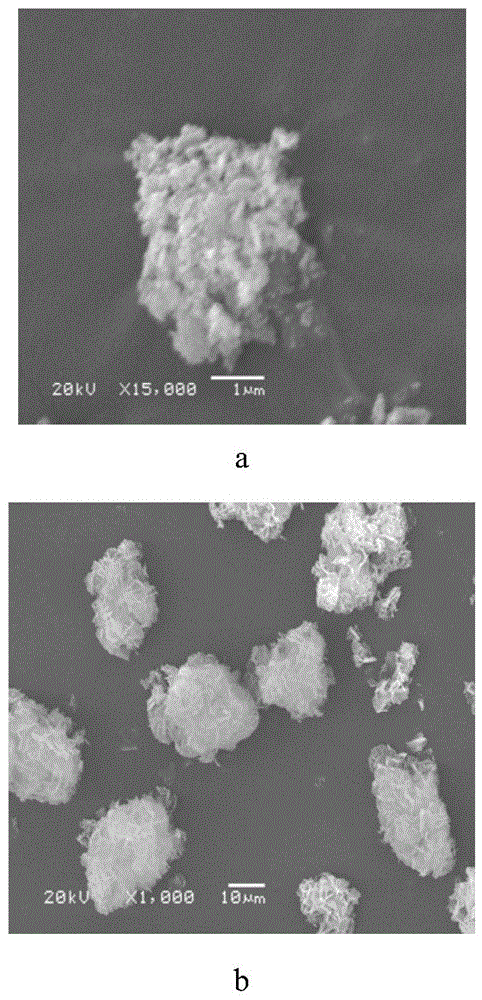

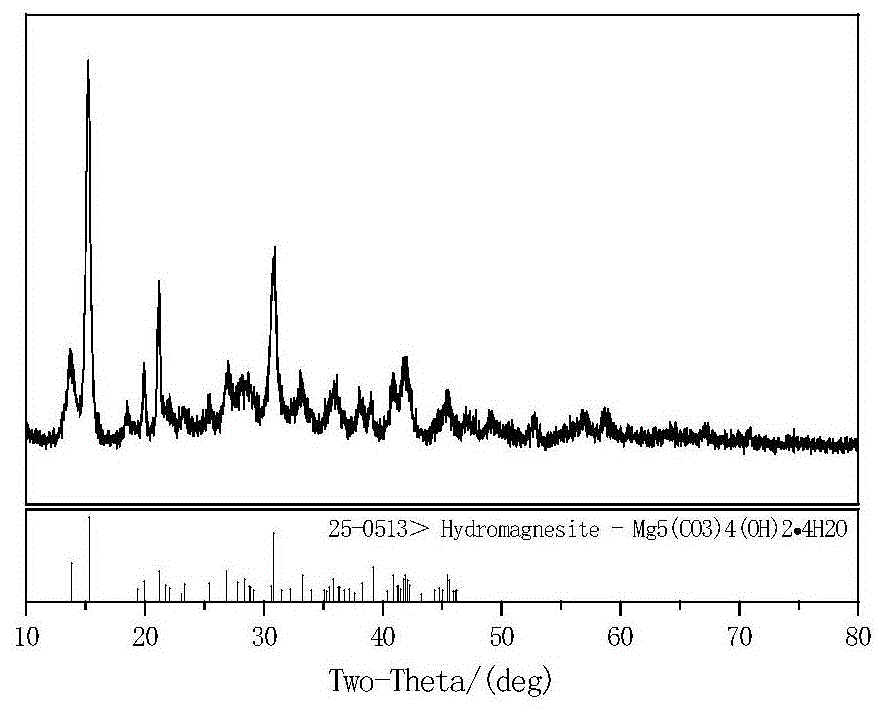

A kind of preparation method of composite magnesium oxide powder for dental alginate impression material

ActiveCN107032373BAccurate target solidification timeIncrease success rateImpression capsDental impression compositionsDispersityDecomposition

The invention belongs to the field of medical biological materials and relates to composite magnesium oxide powder for dental alginate impression material used in oral orthopaedics. High-quality magnesium hydroxide and light magnesium carbonate are used as raw materials, magnesium oxide different in activity and quality is obtained in a rotary kiln or a rotational flow dynamic-state furnace through high-temperature calcination and decomposition, and the composite magnesium oxide powder is obtained through ultrafine grinding and full mixing according to a certain proportion. The prepared composite magnesium oxide powder is small in fineness, white in color, large in size, good in dispersity and adjustable in activity, is used for adjusting and controlling the setting time of the dental alginate impression material and can increase impression hardness and smoothness and decrease impression deformation.

Owner:河北镁神科技股份有限公司 +1

A kind of high-efficiency magnesium hydroxide flame retardant wet preparation method

ActiveCN106348320BImprove resource utilizationSmooth processFlotationGrain treatmentsResource utilizationCrushed stone

The invention discloses an efficient magnesium hydroxide flame retardant wet-process preparation method, and relates to the technical field of wet-process mineral separation. According to the preparation method, wet purification is performed on low-grade brucite to prepare a magnesium hydroxide flame retardant, and particularly comprises the following steps: crushing brucite raw ore into gravels; putting the gravels into an overflow type ball grinder for wet ore grinding to prepare brucite slurry; performing sand removal and purification on the brucite slurry through a spiral sand remover and a hydrocyclone; removing ferric micro powder impurities, mixed during ball grinding, through a high-gradient magnetic separator, then adding a medicine for flotation classification for further purification; performing natural settling, water filtering, pressure filtering, drying and ultrafine smashing on the purified brucite slurry to prepare the magnesium hydroxide flame retardant with different particle sizes. By the adoption of a wet-process mineral separation process, the low-grade brucite can be purified, and the resource utilization rate of the brucite ore is greatly increased; meanwhile, the whole mineral separation process is completed by reasonably adopting large-sized treatment machinery, so that the mineral separation efficiency is greatly improved.

Owner:HEFEI ZHONGKE FLAME RETARDANT NEW MATERIAL

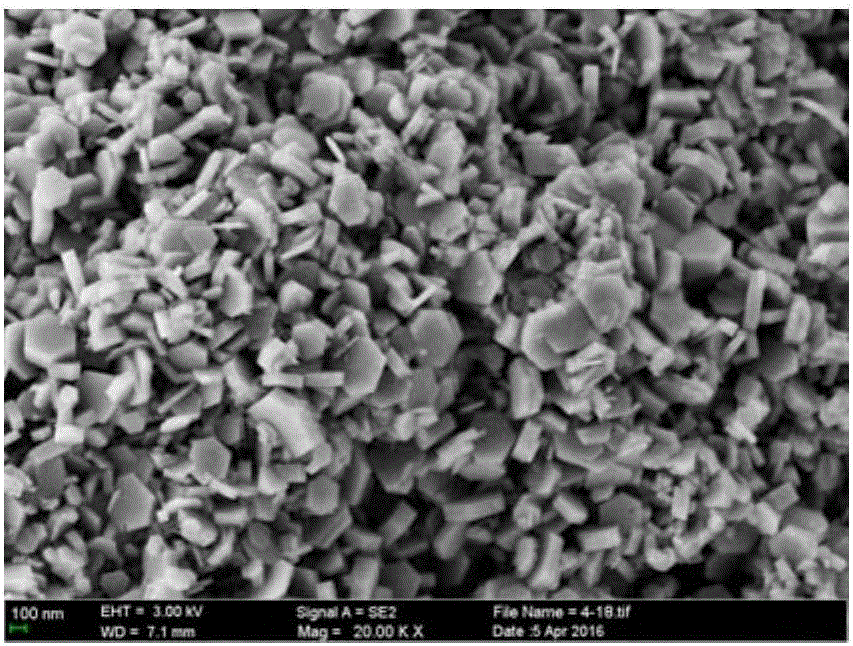

A method for preparing nano-scale magnesium hydroxide by phosphate rock demagnesization waste liquid

InactiveCN106745106BPrevent leakageConsistent concentrationNanotechnologyMagnesium hydroxideFlue gasPhosphorite

The invention discloses a method for preparing nanometer magnesium hydroxide from phosphorus ore magnesium removal waste liquor. The method specifically includes subjecting ammonia gas and the phosphorus ore magnesium removal waste liquor to further neutralizing and edulcorating reaction in a submerged circulating impinging stream reactor, and performing solid-liquid separation after the reaction so as to obtain mother liquor; adding a dispersant into the mother liquor, and continuing to feed the ammonia gas for magnesium precipitation reaction so as to reach a pH value of 10-11; performing solid-liquid separation, washing and drying after the reaction so as to obtain nanometer magnesium hydroxide powder. The nanometer magnesium hydroxide prepared by the method has the purity up to 98%, is small in particle size and regular in shape and can be widely applied to the fields of fire retardants and flue gas desulfurizing agents, and secondary utilization of resources is achieved effectively.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

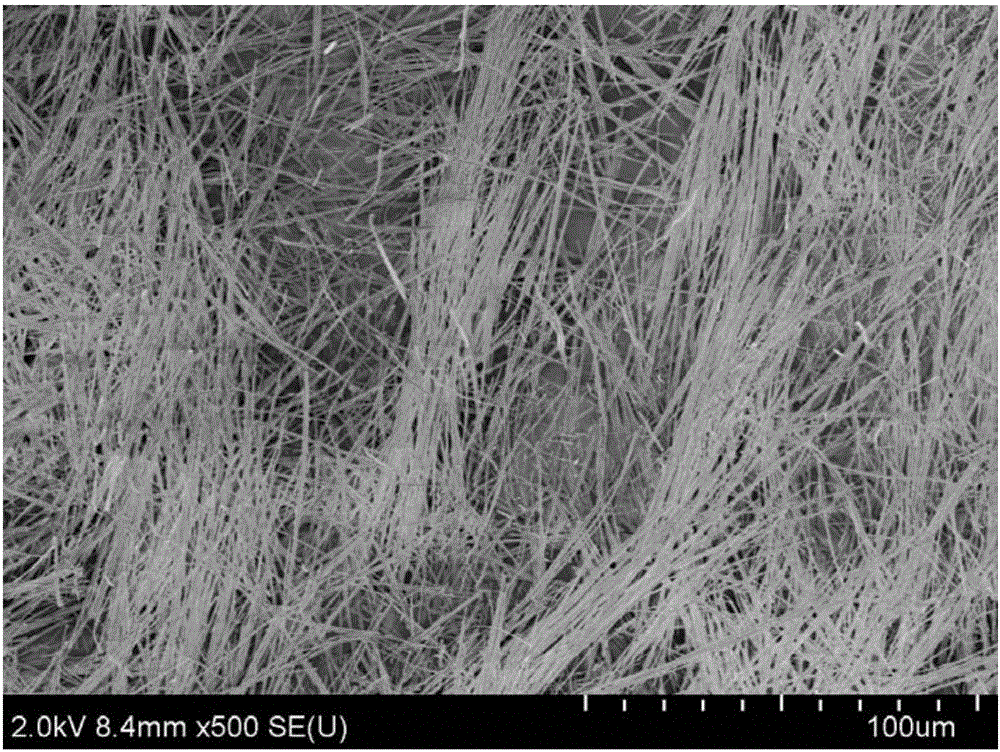

Process for preparing magnesium hydroxide whiskers and calcium sulfate from phosphorus tailings

InactiveCN105442048BRealize high-value utilizationImprove qualityPolycrystalline material growthFrom normal temperature solutionsPhosphateFiltration

The invention discloses a process for preparing a magnesium hydroxide whisker and calcium sulfate by using phosphate tailings as raw materials. The process comprises the following steps: mixing phosphate tailings obtained through flotation with hydrochloric acid to react and obtaining a mixed solution containing magnesium chloride and calcium chloride after impurity removal and filtration; mixing the phosphate tailings with sulfuric acid to react and obtaining a magnesium sulfate solution after impurity removal and filtration; mixing the two solutions and obtaining a calcium sulfate precipitate and magnesium chloride filtrate after reaction and filtration; adding alkali liquor to the magnesium chloride filtrate and obtaining a liquid-solid mixture containing a basic magnesium chloride whisker after reaction and aging; adding an alkaline solution later and obtaining the magnesium hydroxide whisker after reaction and aging; returning ammonia gas recovered through gas stripping of the filtrate to the section for producing the magnesium hydroxide whisker and returning the liquid phase after gas stripping to the acidolysis section after the liquid phase is crystallized to remove ammonium chloride. The process has the beneficial effects that the phosphate tailings are used as the raw materials to produce the magnesium hydroxide whisker and the byproduct calcium sulfate, and meanwhile, higher value application of the phosphate chemical solid wastes and cleaner production are achieved by recycling surplus ammonia gas.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of highly-dispersed nano-magnesium hydroxide

ActiveCN104495882AGood dispersionSmall particle sizeMaterial nanotechnologyMagnesium hydroxideTetramethylammonium hydroxideMagnesium salt

The invention relates to a preparation method of highly-dispersed nano-magnesium hydroxide. The preparation method comprises the following steps: dissolving tetramethylammonium hydroxide in anhydrous ethanol to prepare a 2.0-8.0mol / L solution A; preparing a soluble magnesium salt aqueous solution B; slowly adding the solution B into the solution A; and after the solution B is added and sunk under a room temperature condition, filtering, washing the filter cakes, and washing by anhydrous ethanol and drying to obtain a target product. The preparation method provided by the invention has the advantages of simple process and mild reaction condition, and can be used for synthesizing highly-dispersed nano-magnesium hydroxide which is uniform in size distribution.

Owner:CHINA RES INST OF DAILY CHEM IND

A kind of preparation method of highly dispersed nano magnesium hydroxide

ActiveCN104495882BGood dispersionSmall particle sizeMaterial nanotechnologyMagnesium hydroxideTetramethylammonium hydroxideAlcohol

The invention relates to a preparation method of highly-dispersed nano-magnesium hydroxide. The preparation method comprises the following steps: dissolving tetramethylammonium hydroxide in anhydrous ethanol to prepare a 2.0-8.0mol / L solution A; preparing a soluble magnesium salt aqueous solution B; slowly adding the solution B into the solution A; and after the solution B is added and sunk under a room temperature condition, filtering, washing the filter cakes, and washing by anhydrous ethanol and drying to obtain a target product. The preparation method provided by the invention has the advantages of simple process and mild reaction condition, and can be used for synthesizing highly-dispersed nano-magnesium hydroxide which is uniform in size distribution.

Owner:CHINA RES INST OF DAILY CHEM IND

A process for preparing high-purity silicon steel grade magnesium oxide from magnesium hydroxide

The invention discloses a process for preparing high-purity silicon steel magnesium oxide from magnesium hydroxide. The process comprises the following steps: performing light roasting on magnesium hydroxide, adding magnesium hydroxide into water, heating to hydrate, further cooling, and slowly adding an ammonium bicarbonate solution into water to carbonize, thereby obtaining a suspension;filtering the suspension, washing and drying the residues obtained after filtration, and further roasting at high temperature, thereby obtaining the high-purity silicon steel magnesium oxide. According to the process, magnesium hydroxide is adopted as a raw material to prepare silicon steel magnesium oxide which is regular in morphology and high in purity, the process procedure is short, and the prepared magnesium oxide is stable in quality and high in production efficiency, and the industrial production requirements are met.

Owner:CENT SOUTH UNIV

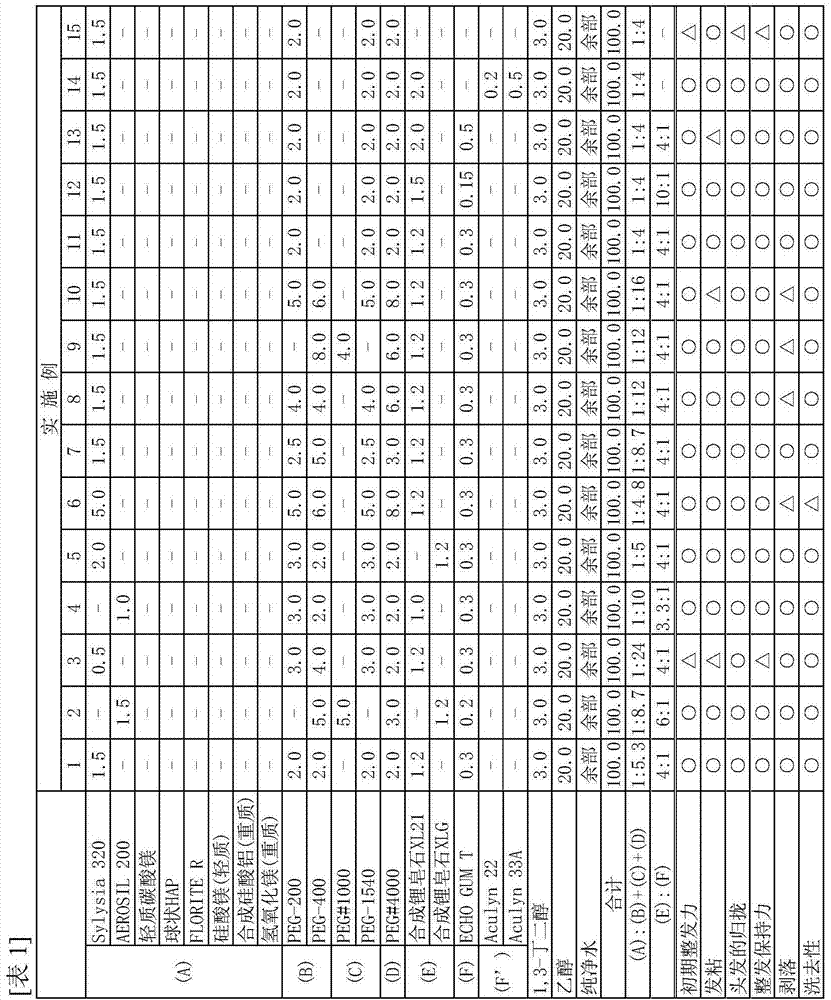

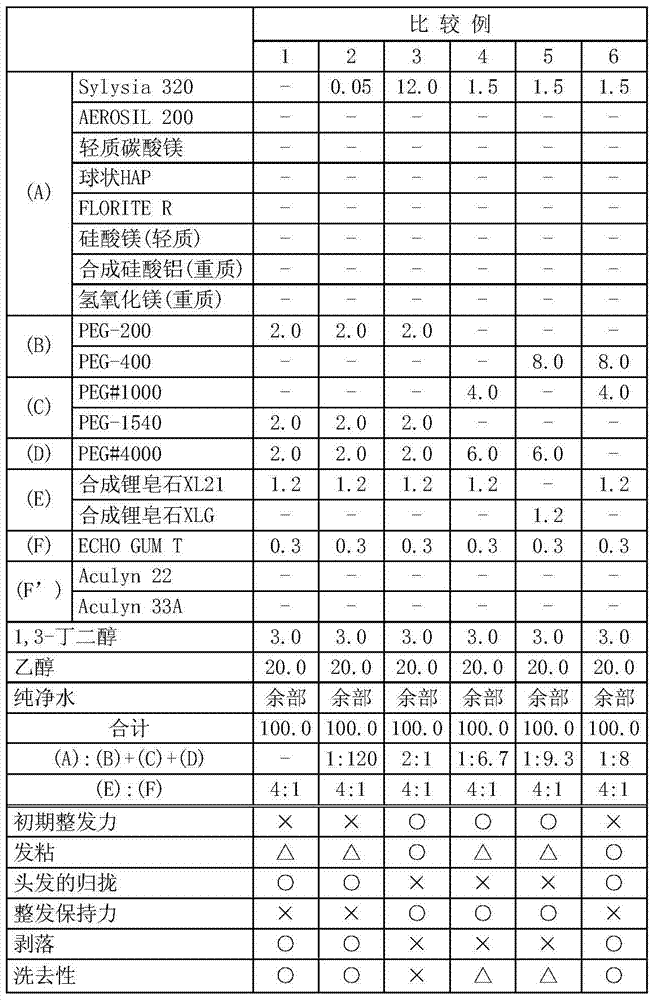

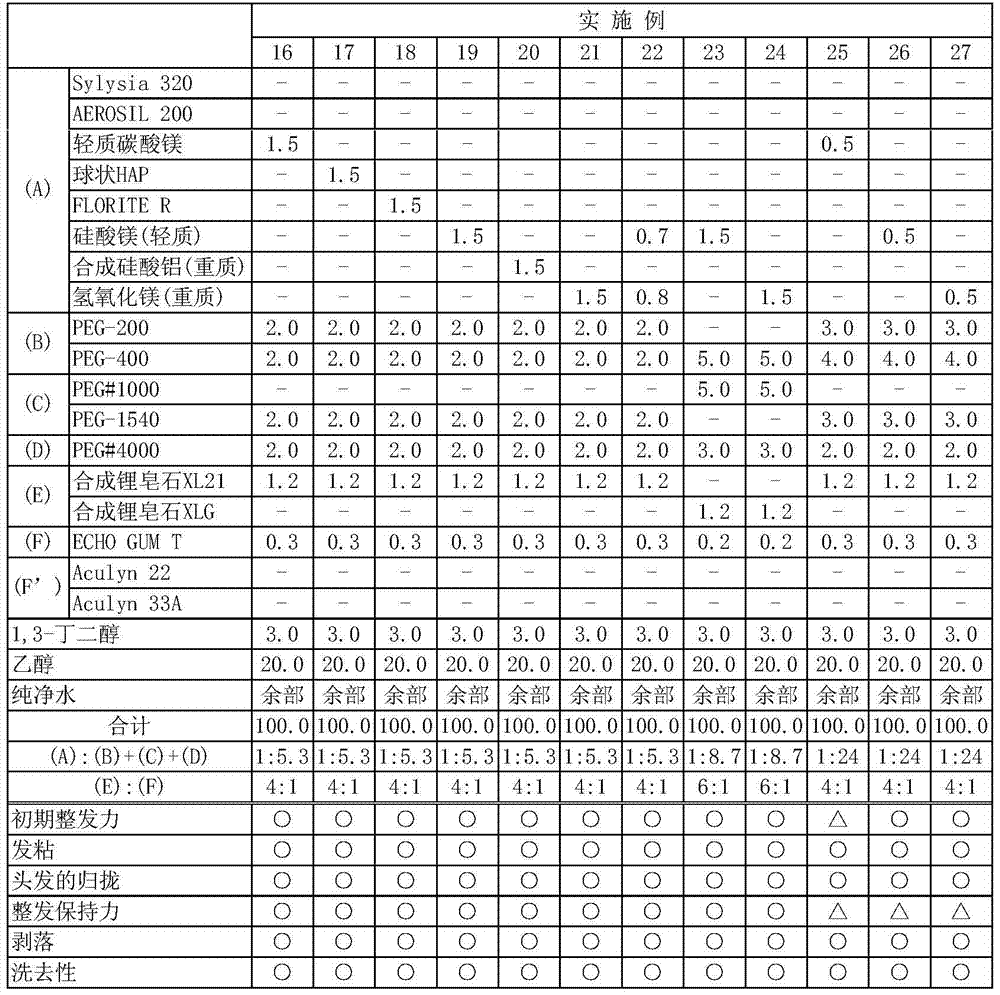

Hairdressing composition and method for producing hairdressing composition

InactiveCN105025868BExcellent initial hair stylingSoft finishCosmetic preparationsHair cosmeticsCalcium silicateClay minerals

Provided is a hairstyling composition that has increased storage stability by suppressing syneresis or separation of the composition or precipitation of powder during long-term storage, and can, by suppressing an increase in viscosity, have increased affinity and spreadability when applied. The hairstyling composition contains: particles (component A) selected from the group consisting of silica, calcium carbonate, magnesium carbonate, hydroxyapatite, titanium oxide, zinc oxide, calcium silicate, magnesium silicate, aluminum silicate, and magnesium hydroxide; a clay mineral (component B); and a polysaccharide compound (component C). The hairstyling composition has 0.1-10 mass% inclusive of component A content, and has a mass ratio of component B content and component C content of 2:1 to 10:1.

Owner:MANDOM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com