Magnesium hydroxide super-hydrophobic film and preparation method and application thereof

A magnesium hydroxide and superhydrophobic technology, applied in the field of materials, achieves the effect of low cost, low equipment requirements, and safe operating environment for personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

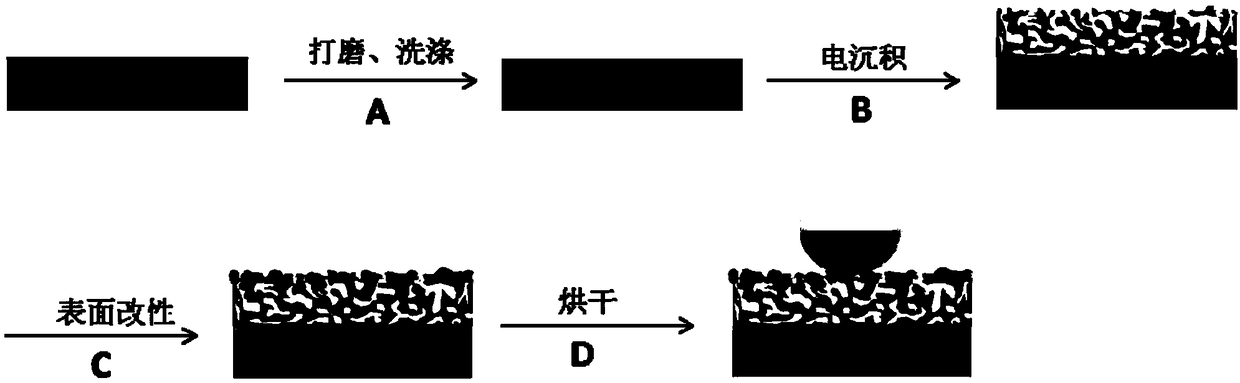

[0029] One aspect of the embodiments of the present invention provides a method for preparing a magnesium hydroxide superhydrophobic film layer, which includes:

[0030] providing a precursor solution comprising magnesium ions;

[0031] The metal substrate is used as the cathode, the cathode and the anode form an electrode system, and the metal substrate and the anode are immersed in the precursor solution, and the electrode system is used for electrochemical deposition, forming a microscopic electrode system on the surface of the cathode. Nanostructured magnesium hydroxide film layer;

[0032] And, the magnesium hydroxide film layer is subjected to surface modification treatment, and then dried to obtain a superhydrophobic film layer of magnesium hydroxide.

[0033] In some embodiments, the concentration of magnesium ions in the precursor solution is 0.01-0.5 mol L -1 .

[0034] Further, the precursor solution includes a magnesium salt solution such as an aqueous solution ...

Embodiment 1

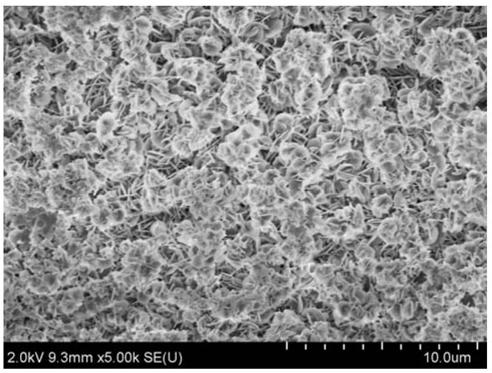

[0071] After the metal copper was polished with sandpaper, it was ultrasonically washed with ethanol, acetone, dilute hydrochloric acid and deionized water for 10 minutes in sequence, fixed with a conductive clip as the cathode, and a lead plate as the anode. At 0.01mol·L -1 electrolysis in aqueous magnesium chloride solution with a current density of 2A m -2 , the electrolysis time is 3 hours, and a magnesium hydroxide film layer with a micro-nano structure is formed on the surface of the metal copper cathode. The picture can be referred to Figure 1b , its SEM picture is as Figure 2a and Figure 2b As shown, it can be clearly seen that the micro-nano structure is formed by the aggregation of small plate-like structures, and its XRD pattern is as follows Figure 4 shown. Soak the metal copper cathode covered with magnesium hydroxide film layer to 0.01mol L -1 In the ethanol solution of stearic acid, the reaction conditions are normal temperature and pressure, and the so...

Embodiment 2

[0073] After the metal iron was polished with sandpaper, it was ultrasonically washed with ethanol, acetone, dilute hydrochloric acid and deionized water for 10 minutes in sequence, fixed with a conductive clip as the cathode, and a titanium alloy as the anode. at 0.5mol·L -1 electrolysis in aqueous magnesium nitrate solution with a current density of 100A m -2 , the electrolysis time is 2 minutes, and a magnesium hydroxide film layer with a micro-nano structure is formed on the surface of the metal iron cathode. Soak the metal iron cathode covered with a magnesium hydroxide film layer to 0.5mol L -1 In the acetone solution of stearic acid, the reaction conditions are normal temperature and pressure, and the soaking time is 30 minutes, so as to obtain the magnesium hydroxide film layer after the surface modification of stearic acid. The surface-modified magnesium hydroxide film layer was dried at 60°C for 10 minutes, and the contact angle between the obtained surface and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com