Patents

Literature

53results about How to "Reduce free water content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

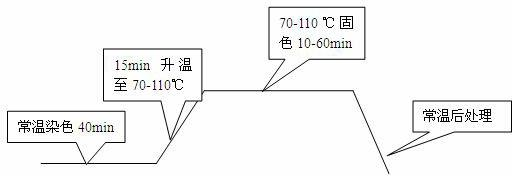

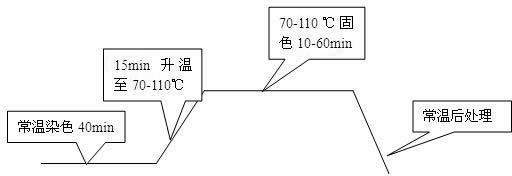

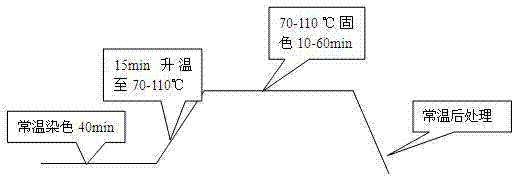

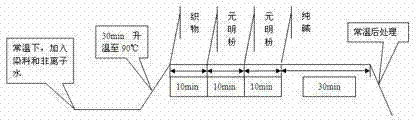

Dyeing process of pure cotton fabric

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

High-strength and low-density cement paste using fluid loss agent

The invention discloses a high-strength and low-density cement paste using a fluid loss agent, relating to the technical field of oil field well sealing cement paste. The high-strength and low-density cement paste using the fluid loss agent comprises the following components in part by weight: 100 parts of G-level oil well cement, 23-50 parts of lightening admixture 6.5-8 parts of microsilica, 2 parts of fluid loss agent and 0.05-0.15 parts of setting retarder, wherein the using amounts of the fluid loss agent and the setting retarder are the percentage of the total mass of the G-level oil well cement, the lightening admixture and the microsilica; the ratio of water to solid in the cement paste is 0.7-0.75 and is the ratio of water to the total mass of the G-level oil well cement, the lightening admixture and the microsilica. The cement paste has a density of 1.20-1.35g / cm<3>, has high strength, good fluidity, no free water and good systematic stability, and can meet well sealing requirements on long-term sealing or full sealing of a deep well in an easily-leaking stratum.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Modification method of phosphogypsum for PVC material production

InactiveCN105482503AImprove processing rheologyHigh strengthPigment treatment with non-polymer organic compoundsFilling materialsParaffin oils

The invention relates to the technical field of PVC production filling materials and especially relates to a modification method of phosphogypsum for PVC material production. The method comprises mixing fresh phosphogypsum and quicklime until pH is in a range of 6-8 so that phosphogypsum free water content is reduced, carrying out heating treatment through a stirring heater, controlling the temperature in a range of 150-180 DEG C so that the fresh phosphogypsum is transformed into semi-hydrated phosphogypsum, adding paraffin into the semi-hydrated phosphogypsum so that phosphogypsum plasticity and rheological properties are improved and the dry phosphogypsum adsorbs water to form crystal water with an unstable structure, carrying out dry grinding and screening so that crystal water in the phosphogypsum is exposed, related content of phosphogypsum impurities in unit volume is reduced and phosphogypsum whiteness is improved, and carrying out stir-frying at a temperature of 180-200 DEG C so that a part of crystal water in phosphogypsum is lost. The prepared phosphogypsum is a mixture of semi-hydrated gypsum, III-type anhydrite and II-type anhydrite, has high rheological properties and plasticity and improves PVC quality.

Owner:GUIZHOU KAILIN GRP CO LTD

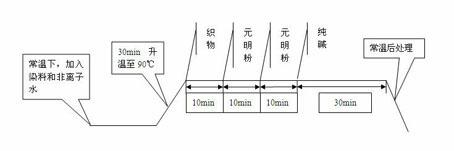

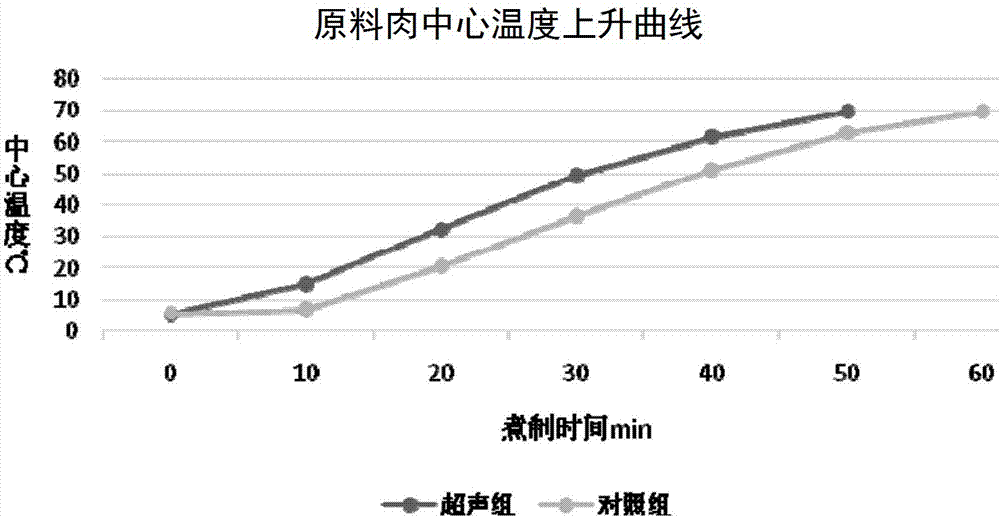

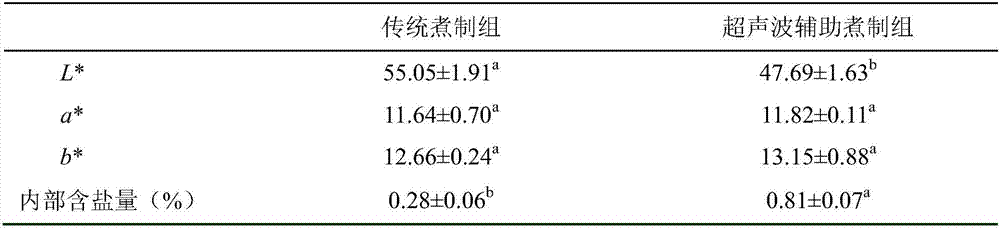

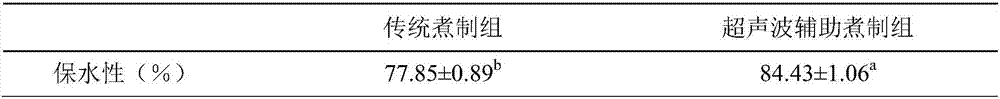

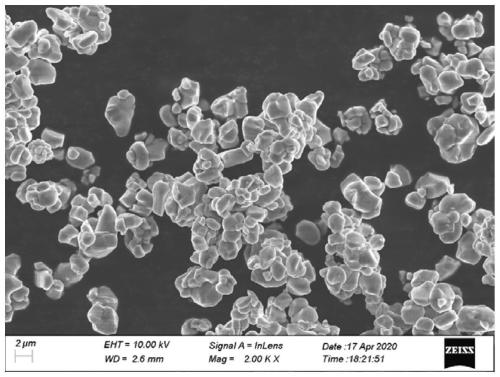

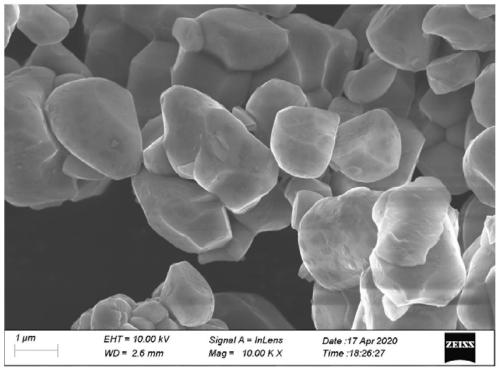

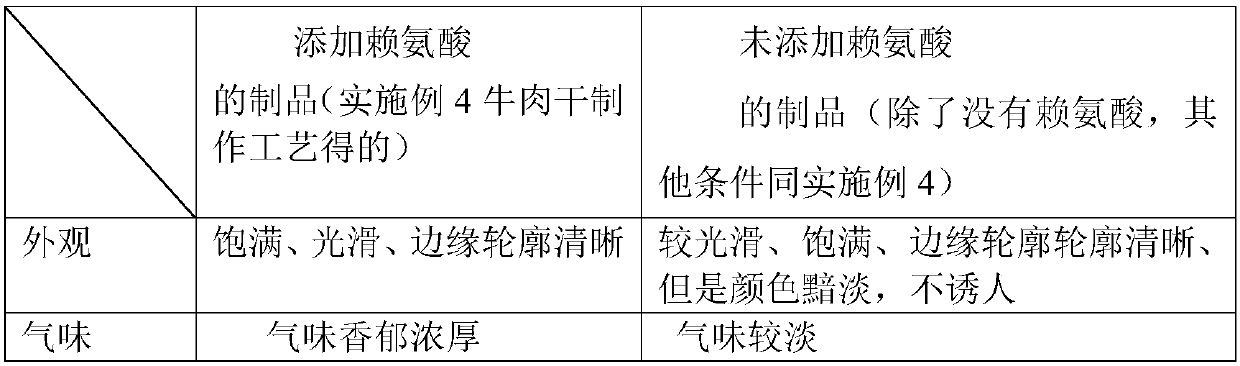

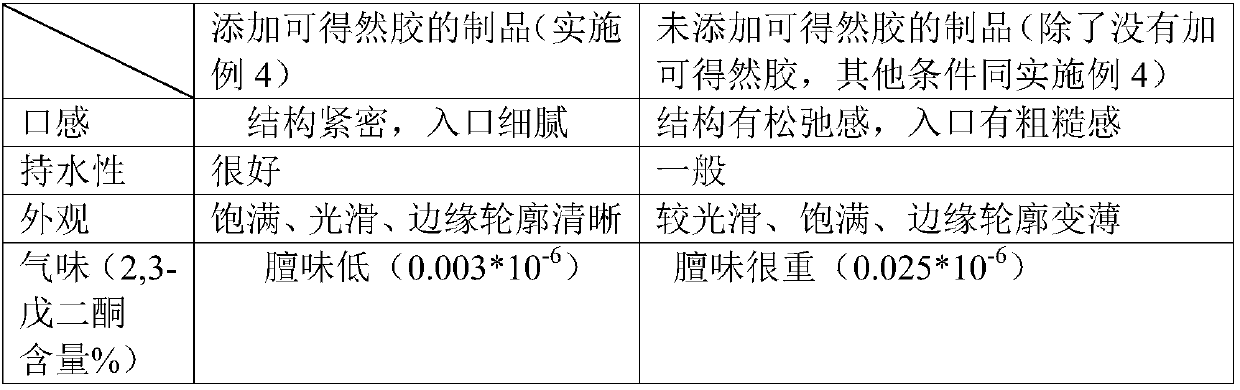

Method for processing soy sauce stewed beef by ultrasonic assisted boiling

InactiveCN106858365AImprove qualityColor deepeningFood ultrasonic treatmentUltrasonic assistedCavitation

The invention discloses a method for processing soy sauce stewed beef by ultrasonic assisted boiling. In a heating and boiling process, heating is assisted by ultrasonic waves and rapid boiling is carried out. According to the method disclosed by the invention, mechanical effect, cavitation effect and heat effect of the ultrasonic waves are applied, so that the boiling time of the soy sauce stewed beef is shortened, energy sources are saved and the production cost is reduced; the penetration efficiency of stewing soup is remarkably improved and the salt content at a central part of a large piece of the soy sauce stewed beef is increased; the water-retaining property of a meat product is improved, so that the production efficiency is improved; the rigidity of the product is reduced, the tenderizing effect is realized and the quality of the product is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

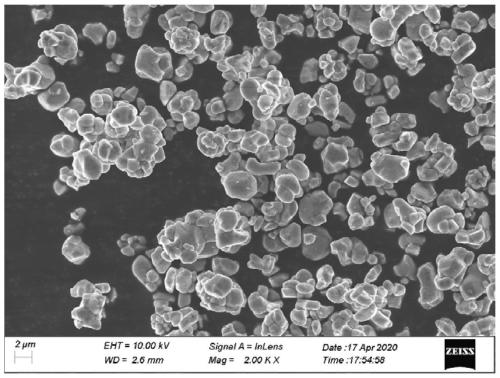

Composite positive electrode material for lithium ion battery and preparation method and application of composite positive electrode material

ActiveCN111490243AImprove ionic conductivityImprove structural stabilitySecondary cellsPositive electrodesLithium-ion batteryIonic conductivity

The invention discloses a composite positive electrode material for a lithium ion battery and a preparation method and application of the composite positive electrode material. The composite positiveelectrode material comprises a positive electrode material core and a halide coating layer coating the surface of the positive electrode material core. The halide comprises Li3YX6, and X is at least one of halogens. According to the halide-coated positive electrode material disclosed by the invention, through coating of the halide coating layer, the ionic conductivity and the structural stabilityof the positive electrode material are greatly improved, and the surface impedance of the material is reduced, so that the capacity, the first effect and the cycle performance of the material are improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

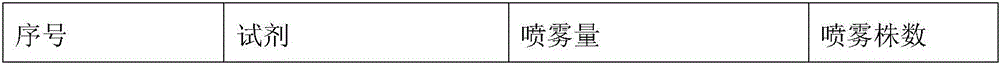

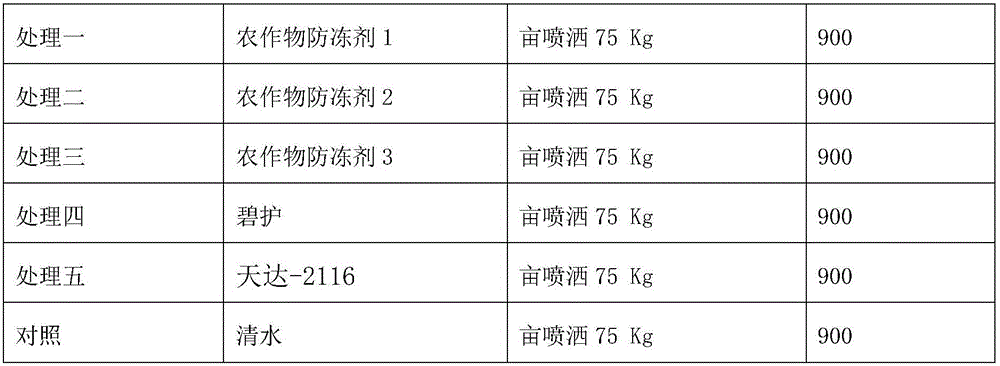

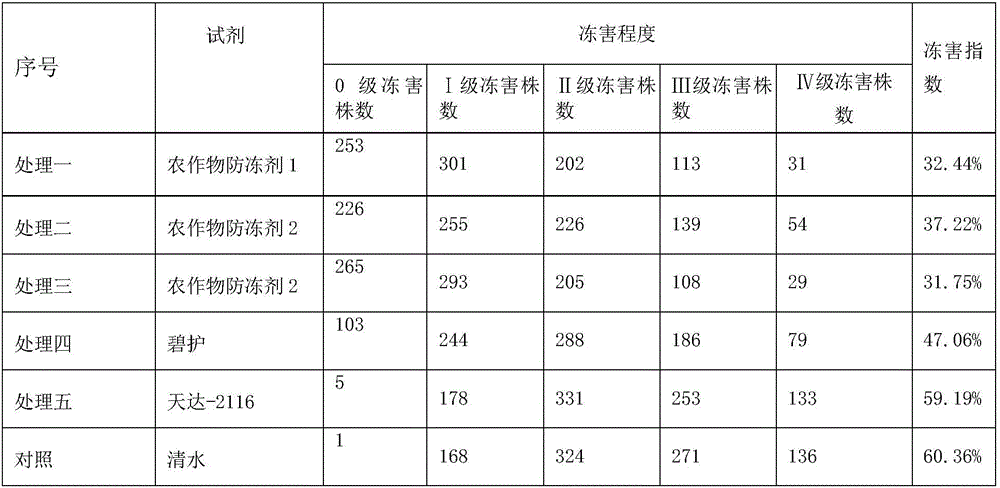

Anti-freezing agent for crops

InactiveCN105794842AImprove the lubrication effectGood moisturizing effectBiocidePlant growth regulatorsO carboxymethyl chitosanAbscisic acid

The invention belongs to the technical field of crop anti-freezing, and discloses an anti-freezing agent for crops.The anti-freezing agent is prepared from, by mass, 15-20 parts of polyethylene glycol, 10-15 parts of N,O-carboxymethyl chitosan, 1-2 parts of soybean hydrolyzed amino acid, 1-3 parts of calcium lactate, 1-3 parts of monopotassium phosphate, 0.01-0.03 part of 6-benzylamino adenine, 0.2-0.4 part of brassin, 0.02-0.04 part of diethyl aminoethyl hexanoate, 0.01-0.03 part of abscisic acid and 1000 parts of distilled water.The anti-freezing agent is good in anti-freezing effect and cannot cause excessive growth of plants.

Owner:郑龙

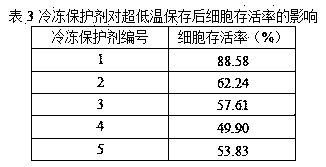

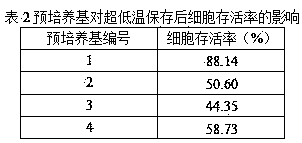

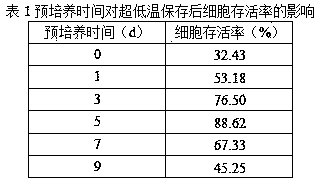

Ultralow-temperature preservation method for Eucommia ulmoides suspension cells

InactiveCN110476957ALow costStable storageDead plant preservationHorticulture methodsWater bathsPre cooling

The invention relates to an ultralow-temperature preservation method of Eucommia ulmoides suspension cells. The method comprises the following steps: (1) a step of establishing a cell suspension culture system; (2) a pre-culture step, namely a step of inoculating the suspension cells into a pre-culture medium, and culturing the cells at 4-6 DEG C for 5 days; (3) a pretreatment step, namely a stepof treating the suspension cells with a pre-cooled vitrification solution and a cryoprotectant in sequence; (4) a cryopreservation step, namely a step of adding a pre-cooled cryoprotectant into the suspension cells, and directly putting the suspension cells into liquid nitrogen for preservation; (5) a thawing and washing step, namely a step of thawing the cells in a water bath at 40 DEG C, and repeatedly washing the cells for 3-5 times; (6) a recovery culture step. Aiming at characteristics of the Eucommia ulmoides suspension cells, the proper pre-culture medium and the proper cryoprotectant are explored, the whole technical process is optimized, the survival rate of the Eucommia ulmoides suspension cells preserved through the method can reach 88% or above, needed equipment is simple, treatment steps are convenient, repeatability is good, cell preservation is safe and stable for a long time, and the cost is low.

Owner:徐宁

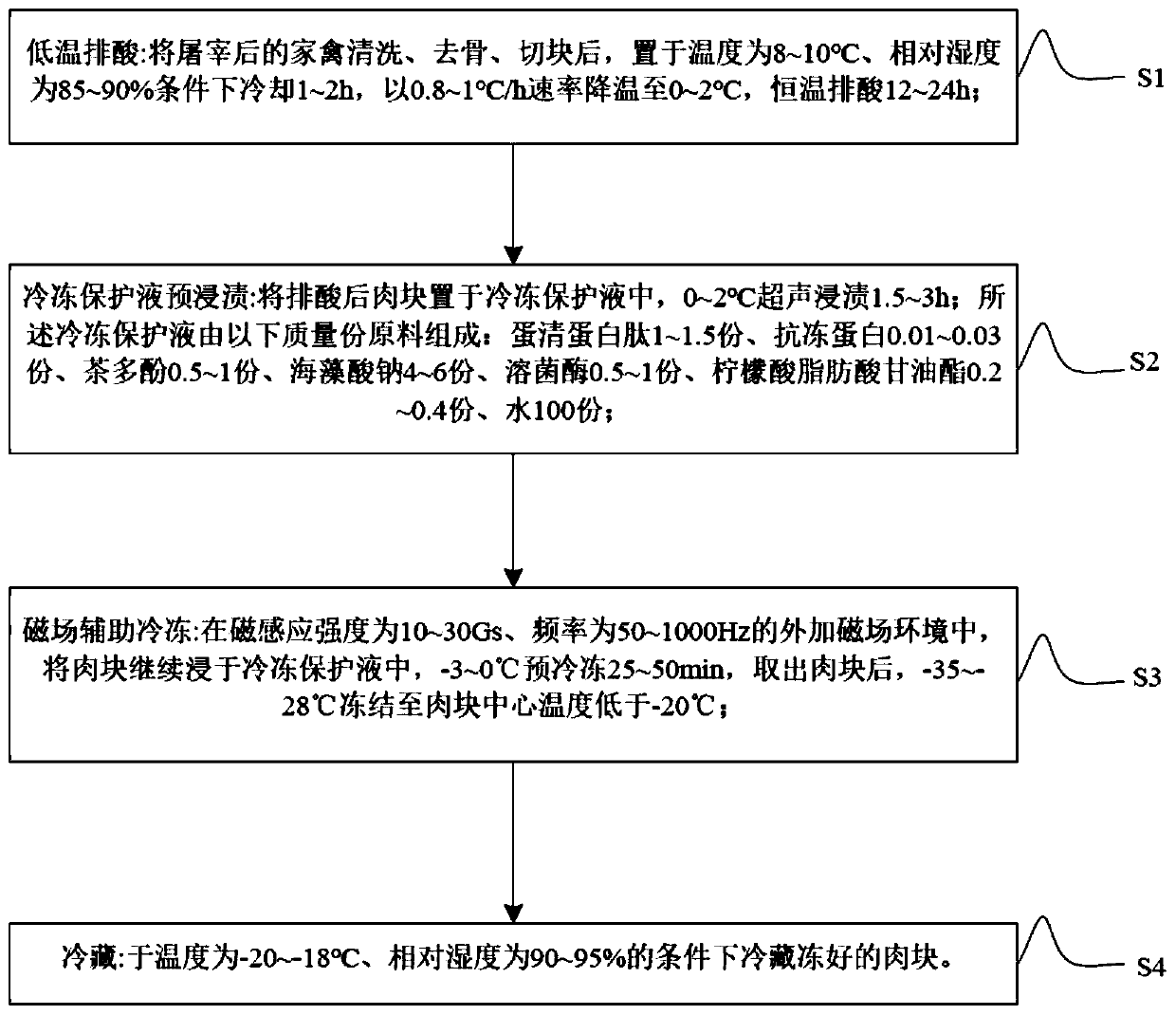

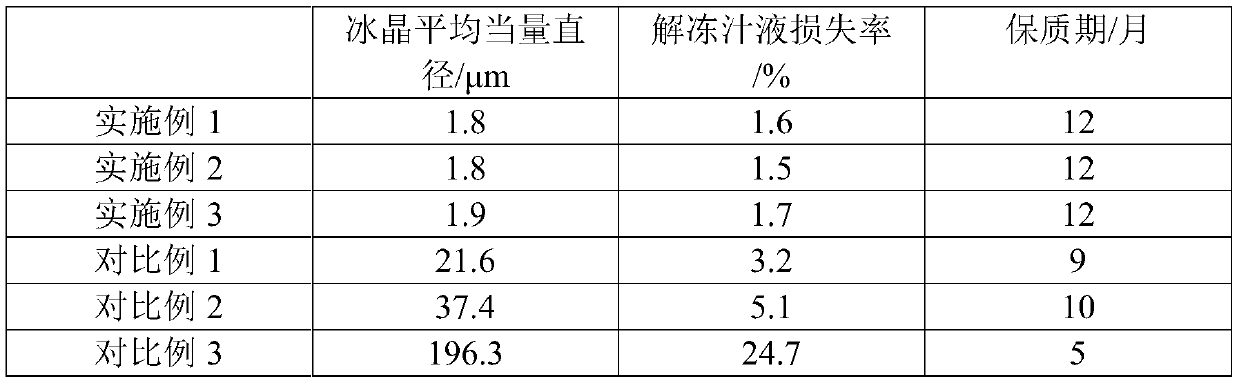

Poultry freezing and fresh-keeping method

ActiveCN111213707AImprove textureAdd flavorFood ingredient as antioxidantFood freezingBiotechnologyAnimal science

The invention discloses a poultry freezing and fresh-keeping method. The method comprises the following steps: S1, acid discharging at low temperature; S2, pre-impregnation: putting meat blocks into afreezing protection solution, and performing ultrasonic impregnation at 0-2 DEG C for 1.5-3h, wherein the freezing protection solution comprises the following raw materials in parts by mass: 1 to 1.5parts of egg white protein peptide, 0.01 to 0.03 part of antifreeze protein, 0.5 to 1 part of tea polyphenol, 4 to 6 parts of sodium alginate, 0.5 to 1 part of lysozyme, 0.2 to 0.4 part of CITREM and100 parts of water; S3, magnetic field-assisted freezing: in a magnetic field environment with the magnetic induction intensity of 10-30Gs and the frequency of 50-1000Hz, continuously soaking the meat blocks into the freezing protection solution for pre-freezing for 25-50min at -3 to 0 DEG C, taking out the meat blocks, and performing freezing at -35 to -28 DEG C until the central temperature ofthe meat blocks is lower than -20 DEG C; and S4, cold storage. According to the invention, a protection liquid impregnation way and a magnetic field-assisted technology are adopted to perform synergetic quick-freezing on poultry, so that the poultry is kept in a supercooled state, phase change is controlled, ice crystal growth and recrystallization are effectively inhibited, the integrity of cellsand tissues is kept, spoilage bacteria are killed or inhibited, and lipid oxidation is prevented.

Owner:安徽鲜森绿色食品有限公司

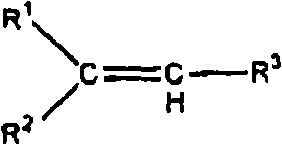

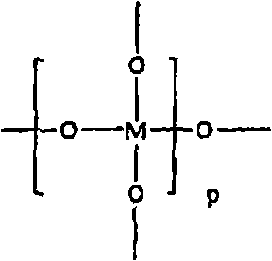

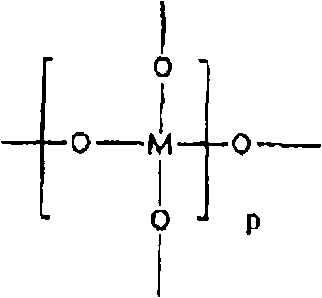

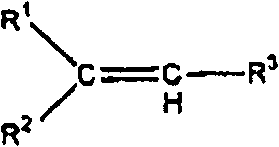

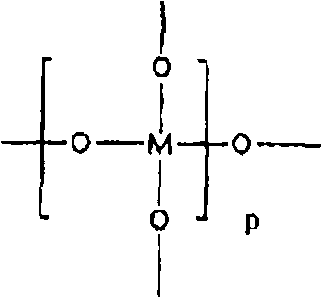

Organic-inorganic nanocomposite materials and methods of making and using the same

InactiveCN101563413AReduce free water contentReduce shrinkage effectsPorous dielectricsPrinted circuit manufactureOxide matrixInorganic polymer

The present invention relates to materials comprising organic-inorganic polymeric networks. In some embodiments, the present invention provides an organic-inorganic composite material comprising an inorganic metal oxide matrix interpenetrating with a polymeric phase. Additionally, the present invention provides methods of producing organic-inorganic composite materials.

Owner:PPG IND OHIO INC

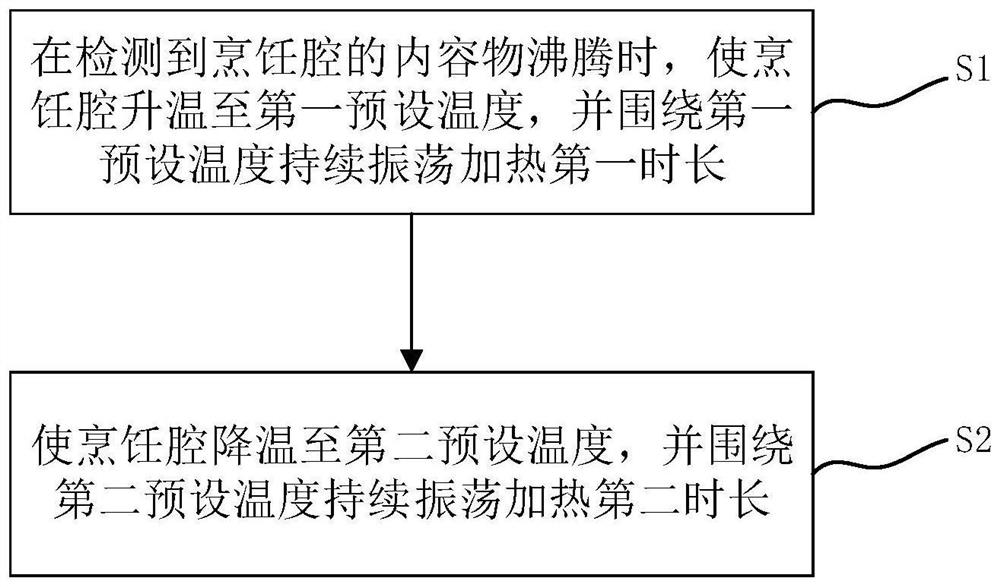

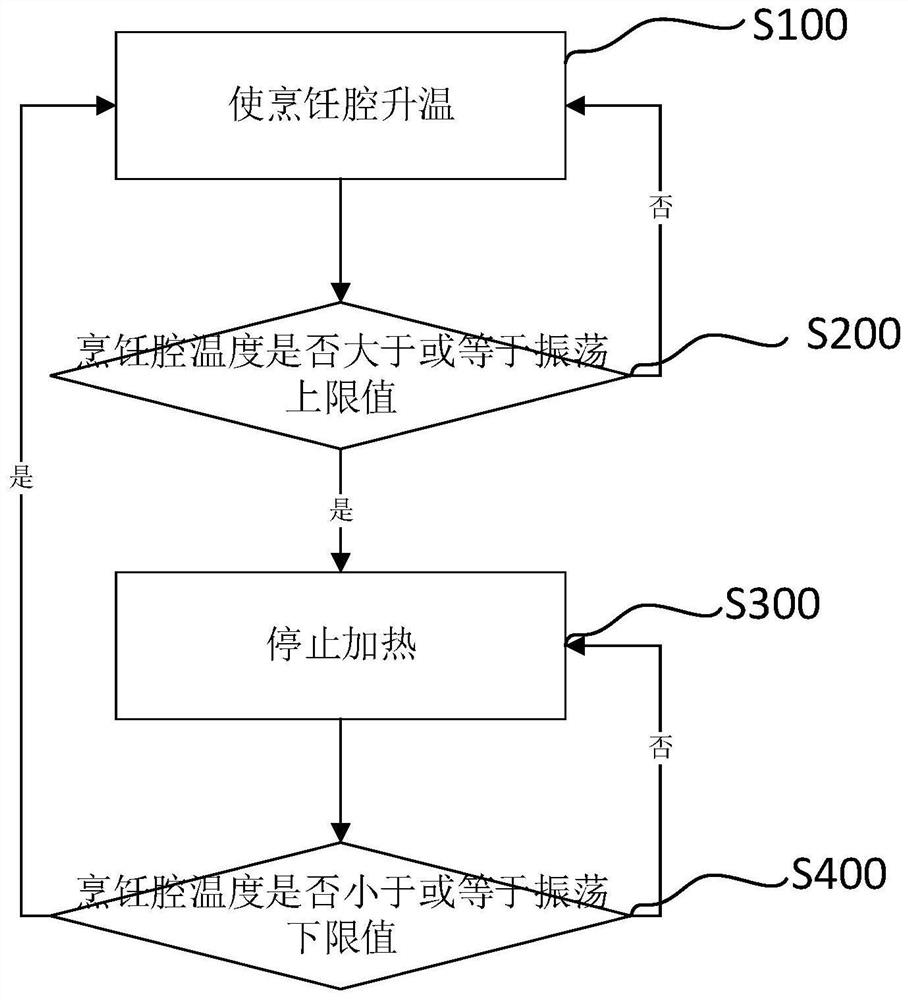

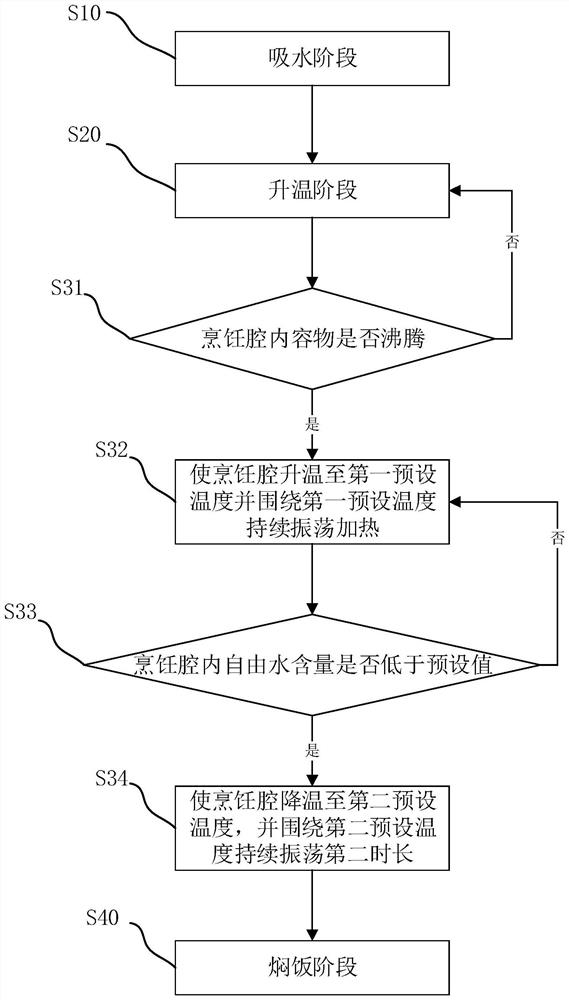

Cooking utensil, control method and device thereof, and storage medium

InactiveCN111938410AFully boiledPromote boilingTemperatue controlWarming devicesThermodynamicsProcess engineering

Owner:GREE ELECTRIC APPLIANCES INC

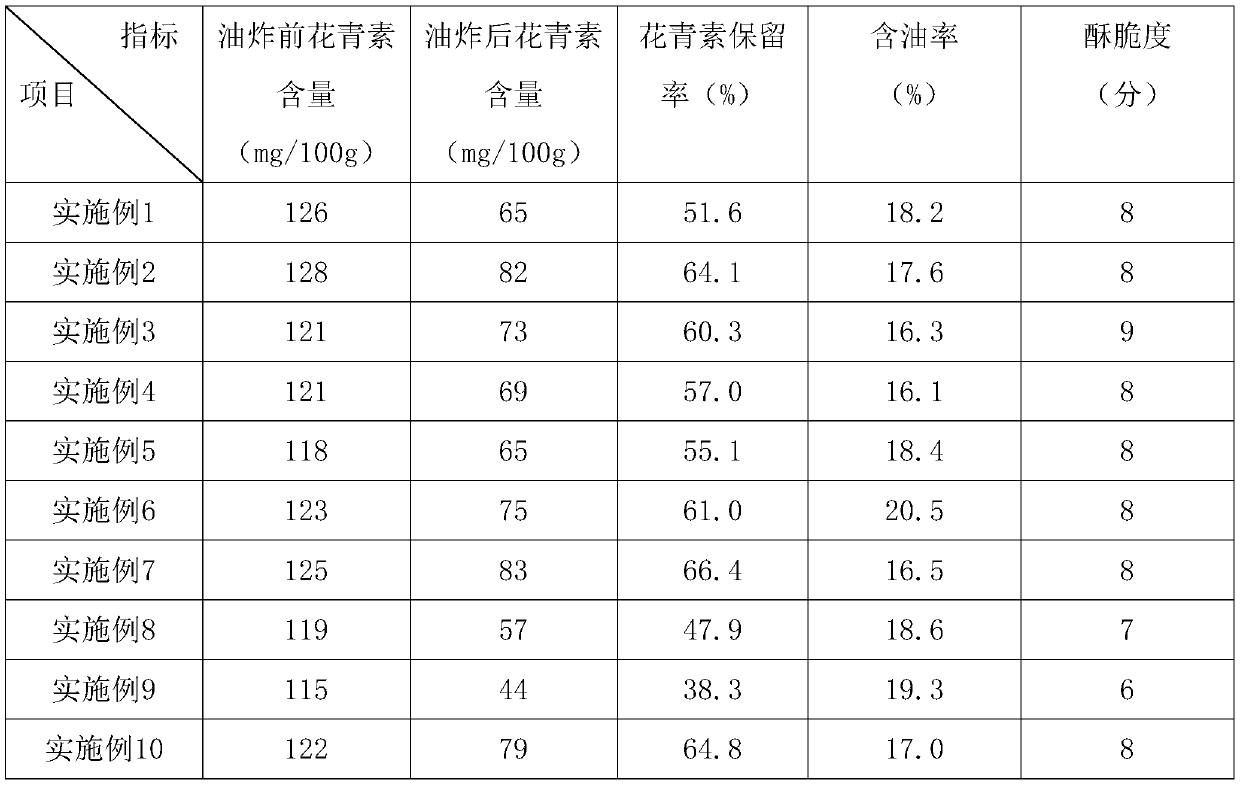

Rice crust frying and oil filtering process method

PendingCN111513256AReduce porosityCrispy tasteFood ingredient as antioxidantFood ingredient as thickening agentSodium CaseinatePhytic acid

The invention belongs to the technical field of food processing, and discloses a rice crust frying and oil filtering process method. The rice crust frying and oil filtering process method comprises the following steps of S1, washing glutinous rice, and cooking to obtain rice grains; S2, peeling purple sweet potatoes, cutting the peeled purple sweet potatoes into blocks, steaming the purple sweet potato blocks, and stirring the steamed purple sweet potatoes to obtain mashed purple sweet potatoes; S3, stirring the rice grains, the mashed purple sweet potatoes, table salt, white granulated sugar,nutritional seasonings, phytic acid and sodium caseinate, performing tabletting, and performing slicing so as to obtain glutinous rice and purple sweet potato slices; S4, spraying a film-forming agent to the surfaces of the glutinous rice and purple sweet potato slices, and then performing pre-drying; and S5, performing vacuum frying on the glutinous rice and purple sweet potato slices, and performing centrifugal deoiling to obtain the glutinous rice and purple sweet potato rice crust. The preparation method has the following advantages and effects that phytic acid can inhibit the expansion of starch in the glutinous rice and purple sweet potato paste, so that the porosity of the glutinous rice and purple sweet potato paste is reduced, and the oil absorption of the rice crust is reduced;and the film-forming agent can be combined with cross-linked modified starch to form a thin and uniform film on the surface of the glutinous rice purple sweet potato slice, so that the oil content ofthe rice crust is reduced.

Owner:湖北卧龙神厨食品股份有限公司

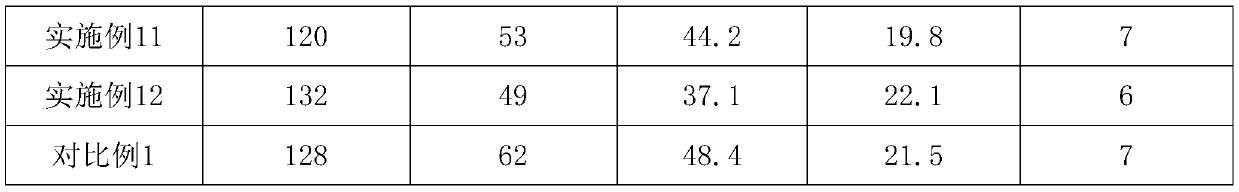

High-liquid limit soil reinforcement roadbed filling structure and method

PendingCN109629362AImprove permeabilityEnhance the skeletonRoadwaysSoil scienceStructural engineering

The invention relates to the field of road construction, in particular to a high-liquid limit soil reinforcement roadbed filling structure and method. The filling method comprises the steps that a construction road is divided according to a section layer structure, the roadbed filling structure is formed, each layer is filled with high-liquid limit soil or low-liquid limit soil of different components, and meanwhile each layer is doped with gravel or cement with different proportions; the filling structure comprises a 93 area, a 94 area and a 96 area which are arrayed from bottom to top in sequence, and each area is divided into a left piece and a right piece according to the center line of a cross section; the 94 area comprises a 94-1 layer, a 94-2 layer and a 94-3 layer which are arrayedfrom bottom to top in sequence, and the 96 area comprises a 96-1 layer, a 96-2 layer, a 96-3 layer and a 96-4 layer which are arrayed from bottom to top in sequence. The filling structure is suitablefor roadbed filling through a wet method, strength reinforcement of a road section is needed, the design and construction demand is met, so that the soil body forms the compact sandy soil body structure, the formwork function of coarse particles is obvious, and the CBR, compaction degree, resilience modulus and other indexes are obviously increased.

Owner:NO 3 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY +1

Dyeing process of pure cotton fabric

ActiveCN102154849BIn line with the development directionSave waterDyeing processPre treatmentBall mill

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric to fully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

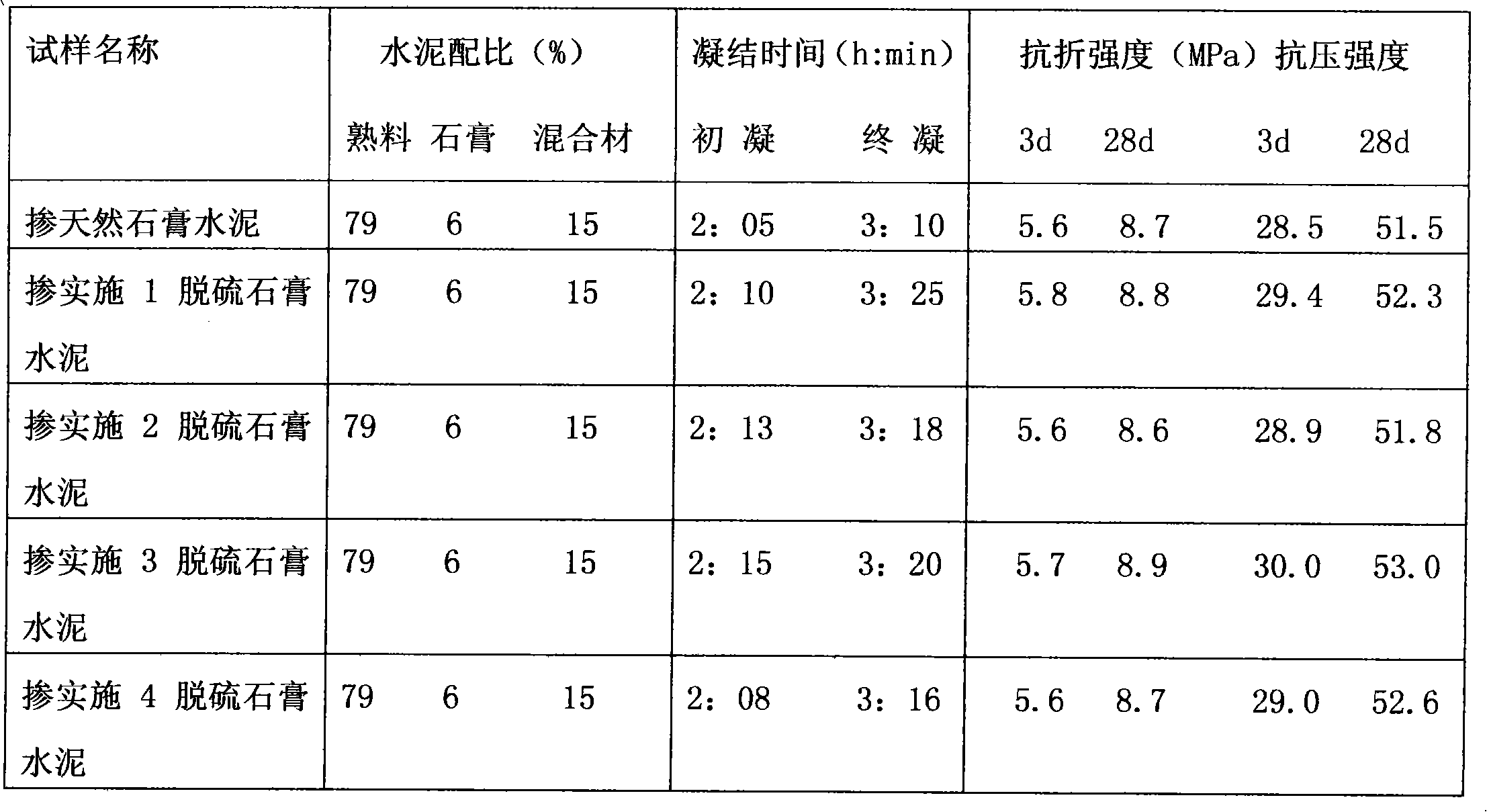

Method for drying and pelleting desulfurization gypsum for cement retarder

The invention discloses a method for drying and pelleting desulfurization gypsum for a cement retarder, which is used for flue gas desulfurization and building materials. The method comprises the following steps of: mixing 98 to 85 mass percent of raw desulfurization gypsum and 2 to 15 mass percent of calcium material and silicon-aluminum material and together stirring for 2 to 30 minutes in a mixer, wherein the stirring temperature is room temperature of 120 DEG C below zero; and storing the stirred mixed materials at room temperature of 100 DEG C below zero for more than 6 hours, wherein the calcium material is one or more of quick lime, slaked lime and carbide slag and accounts for 0.1 to 10 mass percent of the mixed materials; and the silicon-aluminum material is one or more of aluminate cement, sulfate aluminum cement, aluminoferic cement and portland cement and accounts for 0.1 to 10 mass percent of the mixed materials. The method for drying and pelleting the desulfurization gypsum does not need extruding and pelleting, and the desulfurization gypsum has low free water content and high liquidity, is stable to feed, is easy to control, and can be safely used for cement production.

Owner:襄阳安格尔建材科技有限公司

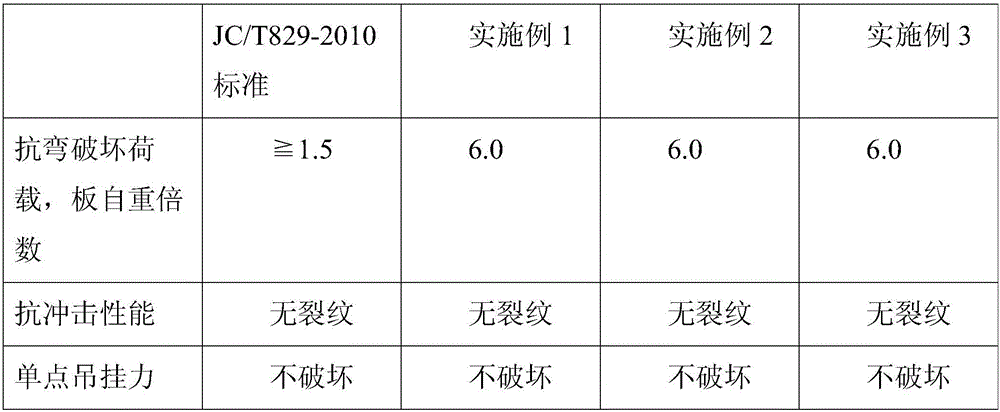

Gypsum panel with cavities and dry-method production method thereof

InactiveCN105731967AReduce water paste ratioReduce free water contentCeramic shaping apparatusGypsumMethods of production

The invention proposes a gypsum hollow slab and its dry production method, comprising 80-90 parts of gypsum powder, 1-2 parts of XK dry process additive, 15-20 parts of light materials and water, wherein water and gypsum powder The weight ratio of the body is 0.3‑0.33:1. The production method includes the following steps: 1) Weigh the gypsum powder, XK dry process additive and water, mix and stir, then add light materials, and mix and stir evenly by adjusting the force; 2) Inject the mixture obtained in step 1) into the intermittent hydraulic pressure Extrusion molding Gypsum hollow slab molding equipment, hydraulic extrusion molding, can be. The gypsum hollow slab produced by this method has a water-to-plast ratio as low as 0.3-0.33, and the product quality is far higher than the standard requirement of JC / T829-2010 "Gypsum Hollow Slab" for gypsum slabs.

Owner:ANHUI SENKE NEW MATERIAL

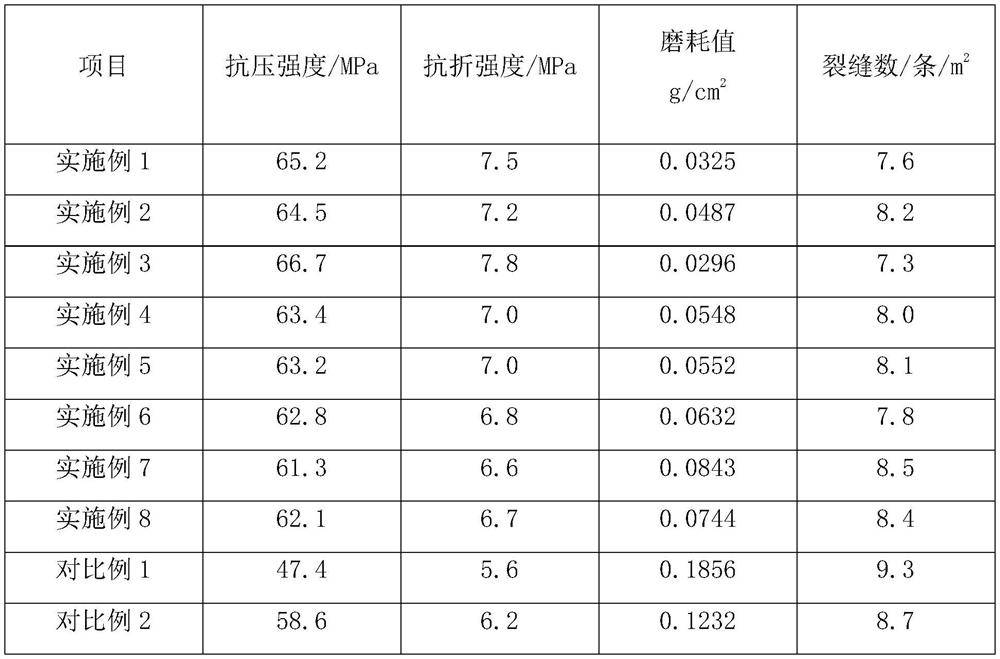

High-strength wear-resistant concrete and preparation method thereof

ActiveCN114276065AHigh mechanical strengthImprove wear resistanceSolid waste managementFiberWear resistance

The invention relates to the field of concrete, and particularly discloses high-strength wear-resistant concrete and a preparation method thereof. The high-strength wear-resistant concrete is prepared from the following raw materials in parts by weight: 28-42 parts of cement, 72-86 parts of river sand, 95-115 parts of gravel, 5-12 parts of fly ash, 10-20 parts of water, 4.2-6.8 parts of an additive, 2-8 parts of filling fibers and 5-15 parts of a wear-resistant filler, the wear-resistant filler is composed of rubber powder and coated aluminum nitride in a weight ratio of 1: (1-4); the preparation method comprises the following steps: weighing the cement, the river sand, the gravel and the fly ash, and uniformly mixing and stirring to prepare a primary mixture; weighing the filling fiber, the wear-resistant filler and the primary mixture, and uniformly mixing and stirring to obtain a mixture; weighing water, an additive and the mixture, mixing and stirring uniformly to obtain a mixture, and pouring and curing the mixture to obtain a finished product. The advantages of high strength and wear resistance are realized.

Owner:深圳市深建混凝土有限公司

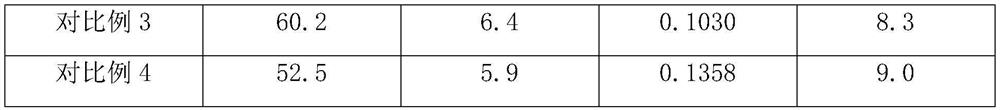

Processing method and device for rice bran preservation

PendingCN113475574AStop rancidity in timePrevent ranciditySievingFood thermal treatmentBiotechnologyEngineering

The invention relates to a processing method and device for rice bran preservation, and belongs to the technical field of food processing. The processing method comprises the steps that rice bran screening is conducted, rice bran suitable for eating is screened out, then steam enzyme deactivation is conducted on the rice bran, lipolytic enzyme released in the rice milling process and mixed with grease is inactivated, rancidity of the rice bran is prevented in time, then radio frequency enzyme deactivation is conducted on the rice bran, the interior of the rice bran is heated through high-frequency microwaves, the lipolytic enzyme in the core of the rice bran is inactivated, rancidity in the rice bran in the storage process is prevented, finally, the rice bran is dried, the content of free water in the rice bran is reduced, and decay of the rice bran in a water-rich state is relieved. According to the processing device, high-temperature steam is filled from the bottom of the rice bran and seeps out from gaps of the rice bran to fully heat the rice bran, waste heat of the steam is collected to be used as a heat source of the hot air drying mechanism, condensate water flows back to be supplied to a steam kettle, and the whole device generates little pollution and is environmentally friendly.

Owner:BENGBU QIONGHUAI GRAIN & OIL

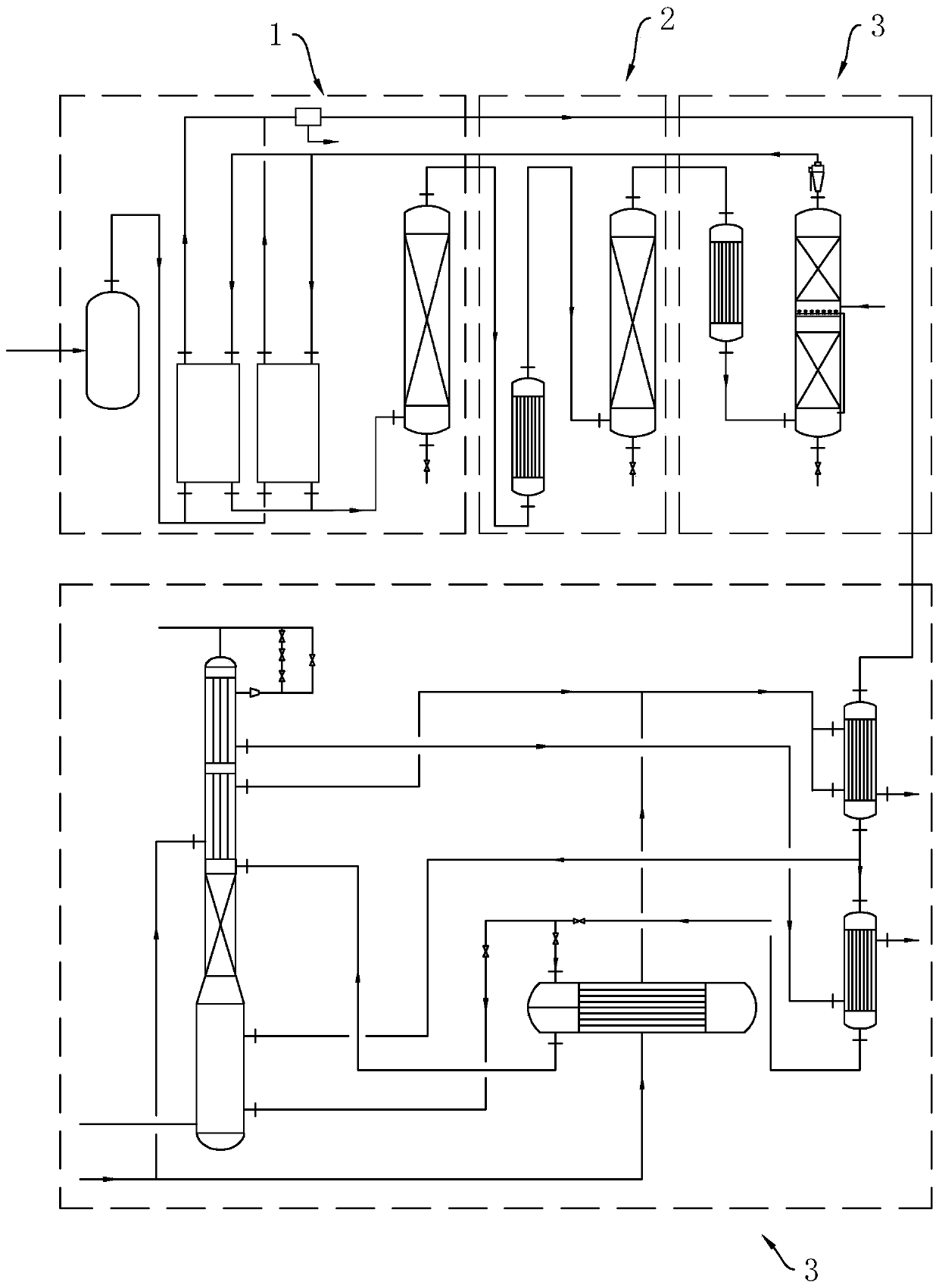

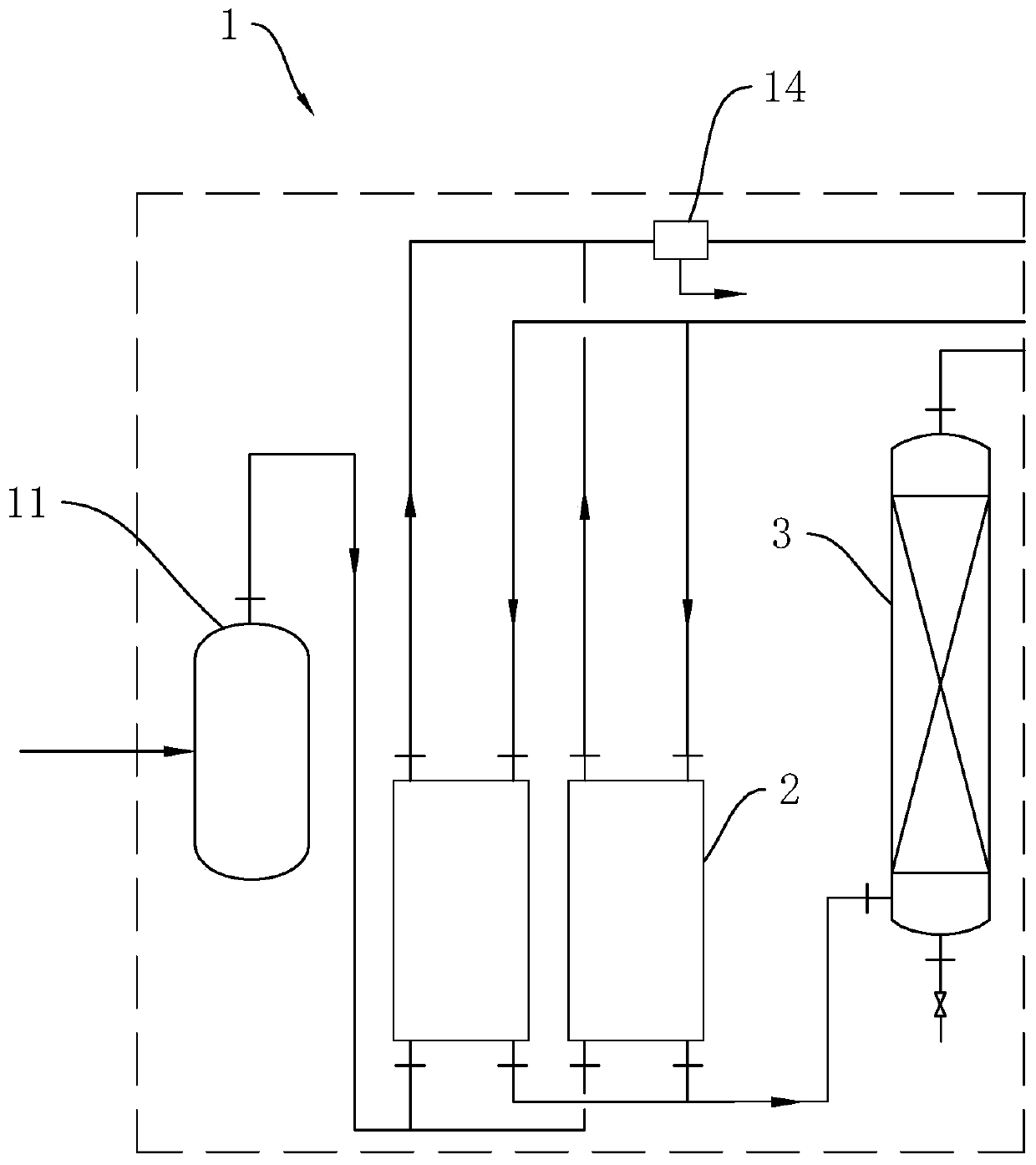

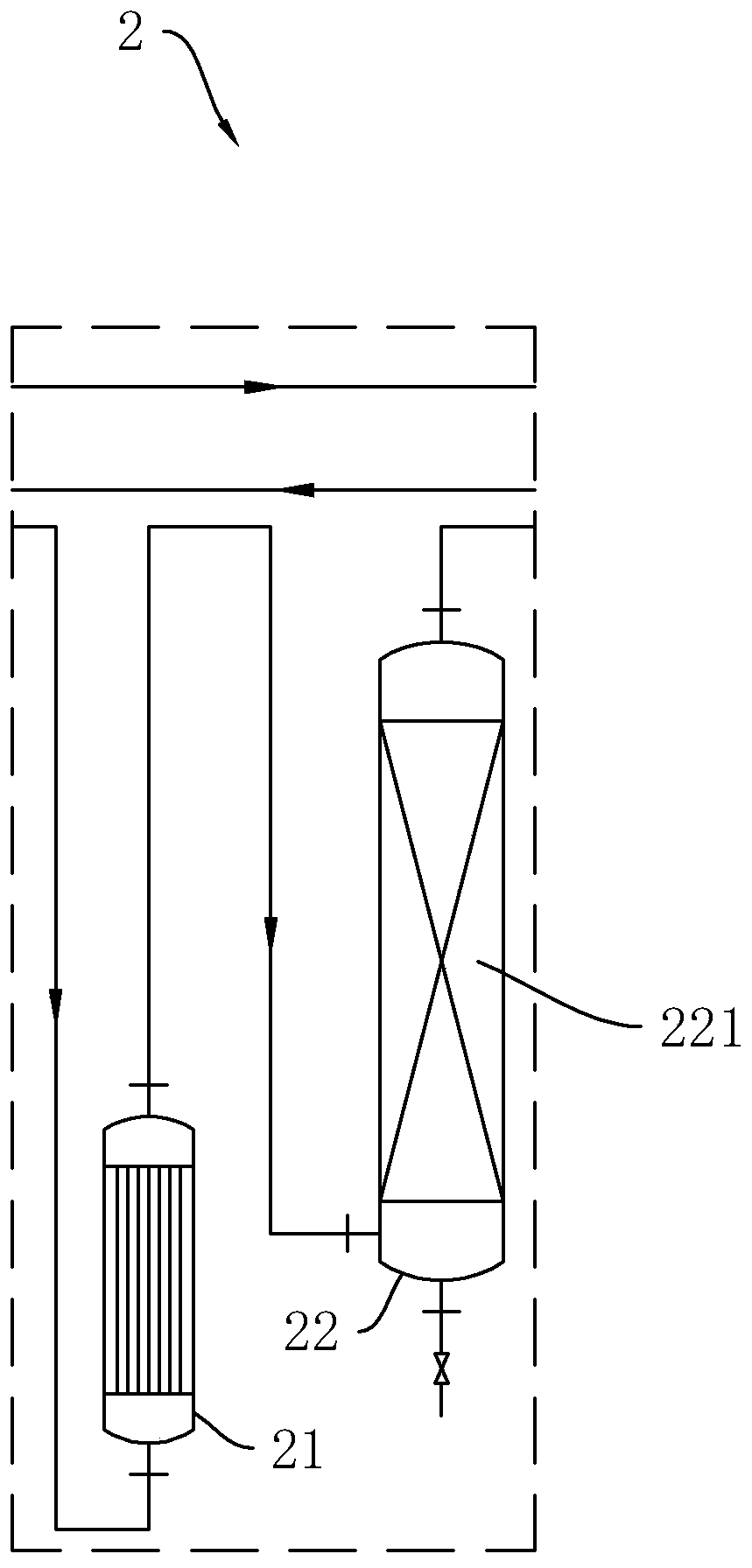

Food-grade carbon dioxide high-efficiency purifying system and process thereof

ActiveCN110015664ALess types of impuritiesAvoid poisoningCarbon compoundsSpecific gas purification/separationCatalytic oxidationWorking temperature

The invention relates to the field of food-grade carbon dioxide purification, and discloses a food-grade carbon dioxide high-efficiency purifying system and a process thereof. The system comprises inturn a compression power unit, a hydrolysis desulfurization unit, a fine desulfurization unit and a purification unit, and the compression power unit comprises a compressor for pressurization, the hydrolysis desulfurization unit comprises in turn a desulfurization heater and a hydrolysis desulfurization tower; the fine desulfurization unit comprises in turn a desulfurization water cooler and a fine desulfurization tower; the fine desulfurization tower is provided with, from bottom to top, a H2S desulfurization layer which is filled with a ZnO desulfurizer and a COS catalytic oxidation layer which is filled with iron filings, an ozone supply pipe is connected between the H2S desulfurization layer and the COS catalytic oxidation layer; and the purification unit includes in turn a dehumidifier, a precooler, a condenser and a purification tower. According to the system and the process, the working temperature of the hydrolysis desulfurization tower is regulated down, and the flow rate in the hydrolysis desulfurization tower is regulated up, and residual COS and H2S are oxidized for removal, therefore the quality of a finished product carbon dioxide is improved, the desulfurization efficiency is high, the cost is economical, and the effect is remarkable.

Owner:华东能源环保股份有限公司

Preparation technology of zinc sulfate heptahydrate by cold liquid hot flushing method

InactiveCN107098376ACoarse particlesEasy to dryZinc sulatesSolution crystallizationChemistryZINC SULFATE HEPTAHYDRATE

The invention discloses a preparation technology of zinc sulfate heptahydrate by a cold liquid hot flushing method. The preparation technology comprises the following steps of quickly cooling a saturated zinc sulfate solution for the first time, crystallizing, quickly cooling for the second time, adding a hot saturated solution, quickly cooling for the third time, cooling by cooling water, and crystallizing, so as to obtain a zinc sulfate heptahydrate product. The preparation technology has the advantages that when the zinc sulfate heptahydrate is applied to the industrial production, the large-particle zinc sulfate crystal can be obtained; the content of free water in the product is obviously reduced, the crystallizing time is shortened, and the production efficiency and the product quality are improved.

Owner:SHANDONG DAZHENG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Gypsum calcining method

The invention discloses a gypsum calcining method. A gypsum calcining system is used in the method. The gypsum calcining system comprises a feeding device, a gypsum calcining device, a fluidized-bed furnace cooler and a grinding device which are connected in sequence, wherein the gypsum calcining device comprises a rotary kiln and a double-screw feeder arranged at the front end of the rotary kiln, the front end of the double-screw feeder is connected with a feeding device for conveying gypsum raw materials, and a material returning opening is formed in the rotary kiln and connected with the front end of the double-screw feeder through a circulating conveying device. The gypsum calcining method comprises the following steps: the feeding device feeds the gypsum raw materials into the rotary kiln through the double-screw feeder for drying and calcining; middle returned materials in the rotary kiln enter the front end of the double-screw feeder through the material returning opening and the circulating conveying device; gypsum powder calcined in the rotary kiln is fed into a fluidized-bed furnace cooler for cooling; and the cooled gypsum powder is fed into the grinding device for grinding.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

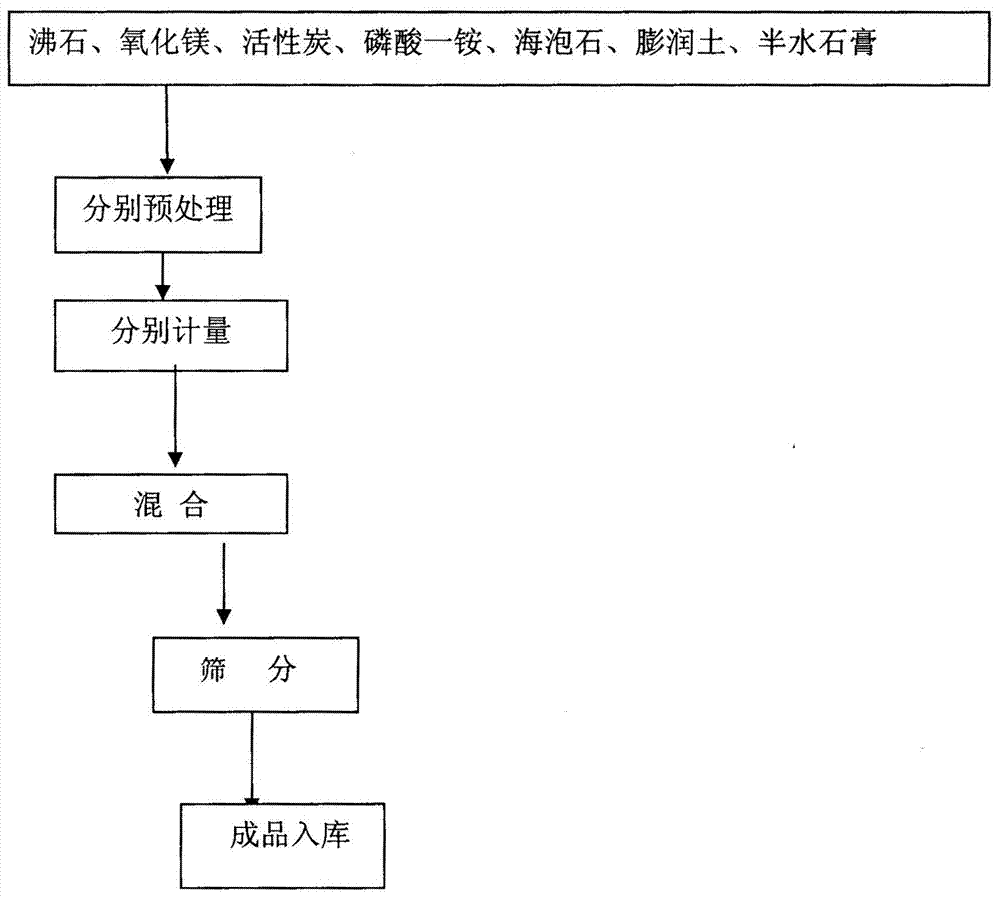

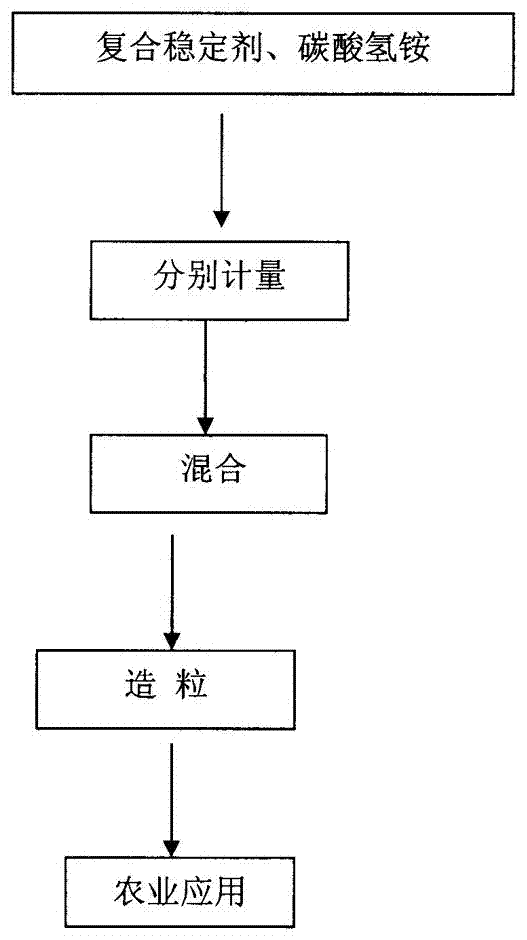

Ammonium bicarbonate compound stabilizer and preparation method thereof

PendingCN106946612AReduce free water contentImprove physical and chemical propertiesCalcareous fertilisersMagnesium fertilisersFertilizerActivated carbon

The invention discloses an ammonium bicarbonate compound stabilizer and a preparation method thereof. Zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite and semi-hydrated gypsum are subjected to smashing pretreatment and mixed according to weight ratio to obtain mixture; and then the mixture is mixed with ammonium bicarbonate in a ratio of (4-25):(75-96), so that stability of ammonium bicarbonate can be effectively improved. According to the invention, the zeolite, magnesium oxide, activated carbon, monoammonium phosphate, sepiolite, bentonite and semi-hydrated gypsum which contain a lot of essential nutrient elements for plant growth are taken as the raw materials for preparing the ammonium bicarbonate compound stabilizer, technology is simple, complex equipment is not required, and stability of ammonium bicarbonate can be improved after the compound stabilizer is mixed with ammonium bicarbonate in proportion; and when the compound stabilizer is applied to agricultural production as fertilizer, effect period of fertilizer can be greatly prolonged, production cost can be reduced, soil conditions and quality of agricultural products can be improved, and crop yield can be increased.

Owner:HENAN CHEM IND RES INST

Semi-dry production method for mechanically and continuously preparing ardealite building block, and ardealite building block

ActiveCN113461397AReduce water consumptionReduce manufacturing costShaping press ramCompression moldingHydration reaction

Owner:遵义汉丰装饰材料有限责任公司

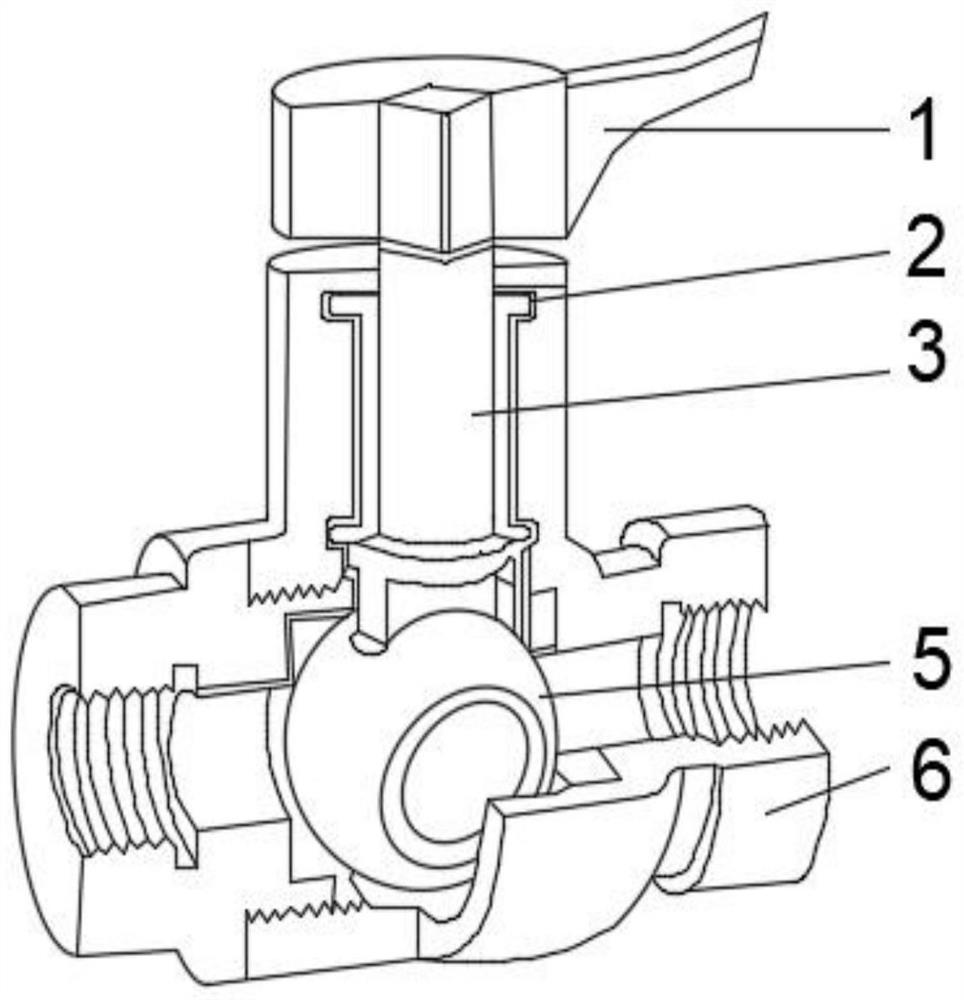

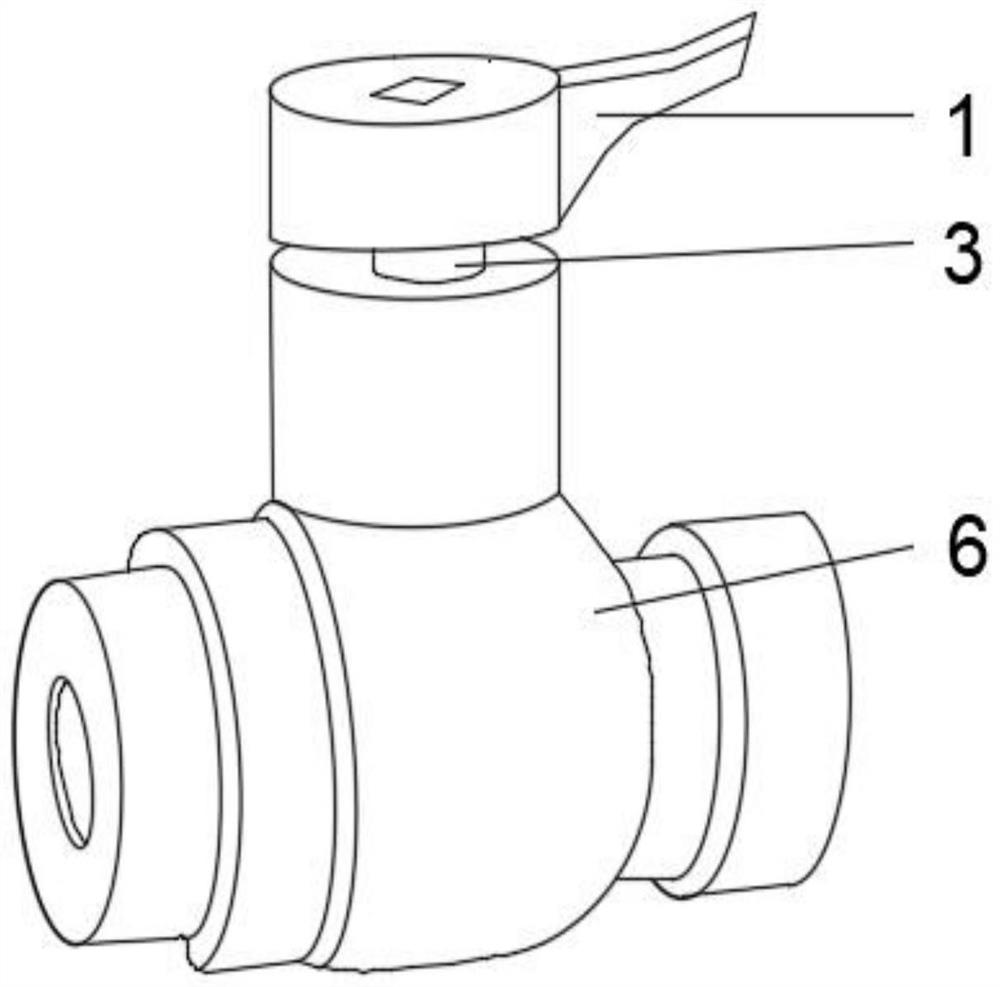

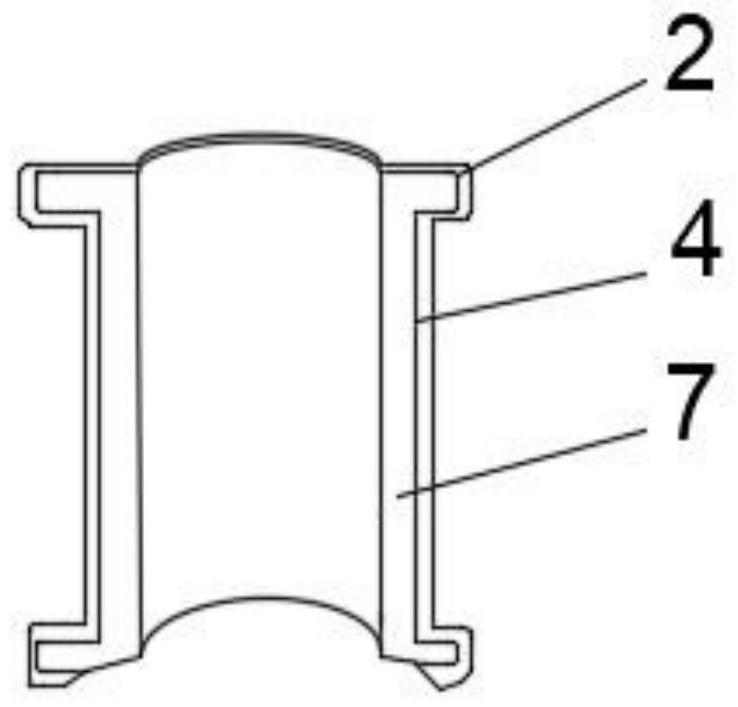

Rust-proof gate valve with high sealing performance

PendingCN113606357ANot easy to slideIncrease compatibilitySpindle sealingsPlug valvesEngineeringGate valve

The invention discloses a rust-proof gate valve with high sealing performance, and relates to the field of gate valves. The rust-proof gate valve comprises a handle, a valve rod and a valve body, the valve rod is mounted in the valve body, the top of the valve rod penetrates through the valve body, the handle is mounted at the top of the valve rod, a ball is mounted at the bottom of the valve rod, and a protective layer is arranged between the valve rod and the valve body. The problems that an existing gate valve is poor in sealing performance and prone to rusting are solved, a rust-proof layer has the lower water absorption capacity compared with traditional resin, a polybenzoxazine and Si-O-Si double-crosslinking network exists in the rust-proof layer, the structure of the rust-proof layer can be more compact, the Si-O-Si network is also a polymer network good in hydrophobicity, the compact double-crosslinking network can inevitably and effectively inhibit water permeation, and the rust-proof layer can effectively prevent water permeation on the surface and in a main network, so that the permeation rate of water in a coating is obviously reduced, and the coating can have good corrosion resistance in a humid environment.

Owner:铜陵荣景科技有限公司

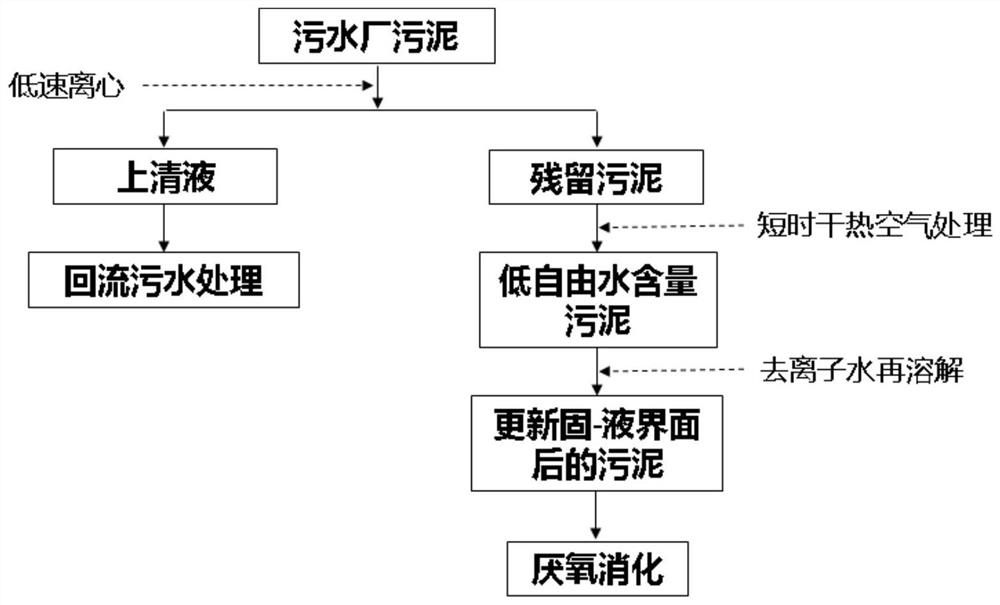

Method for strengthening anaerobic digestion based on sludge solid-liquid interface updating

ActiveCN112047592ALower energy barrierImprove the efficiency of enzymatic reactionsSludge treatment by de-watering/drying/thickeningWater treatment parameter controlSoftened waterMethane yield

The invention relates to a method for strengthening anaerobic digestion based on sludge solid-liquid interface updating. The method comprises the following steps: sequentially carrying out centrifugaltreatment, heat drying treatment and softened water redissolution treatment on sludge to update a solid-liquid interface in the sludge, and then carrying out anaerobic digestion to increase the anaerobic biotransformation methane production amount of sludge organic matters. Compared with the prior art, the anaerobic digestion unit organic matter methane yield of the sludge treated through the method is increased by 50%-200%, and the anaerobic digestion efficiency of the sludge is greatly improved; the method is remarkable in effect; and the method for strengthening anaerobic digestion based on sludge solid-liquid interface updating has important significance for improving the application of a sludge anaerobic digestion technology.

Owner:TONGJI UNIV

Method for preparing meal replacement stick by adopting tea

PendingCN109567187AStable flowAbundant resourcesFood ingredient as antioxidantFood freezingCooking & bakingBanana powder

The invention discloses a method for preparing a meal replacement stick by adopting tea. The method for preparing the meal replacement stick by adopting the tea comprises the following steps that fresh green tea is laid in a layered mode, water is sprayed layer by layer, stacking is carried out, and fermentation is carried out; the fermented tea is stacked into a large pile, the large pile is subjected to natural sedimentation, compression and stabilization, and then holes are dug for ventilation and aging; steaming, stage drying and crushing are carried out so as to obtain tea powder; and banana powder, corn flour, whey protein powder, the tea powder, beef powder, longan kernel powder and semen phaseoli powder are uniformly stirred so as to obtain powder, edible oil is added, uniform mixing is carried out, compression moulding is carried out, and baking and maturing are carried out. The method has the advantage that the basic nutrition needed by patients with obesity is provided.

Owner:宜昌清溪沟贡茶有限公司

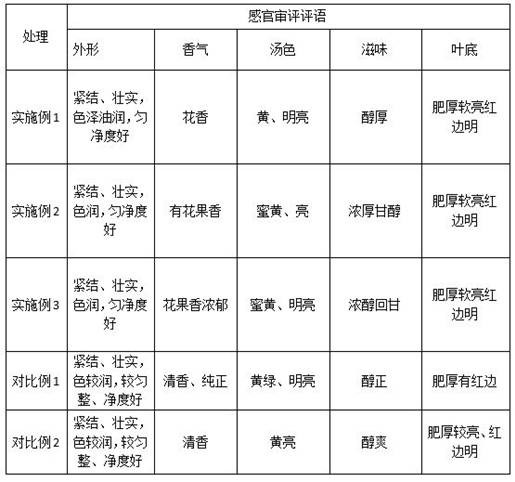

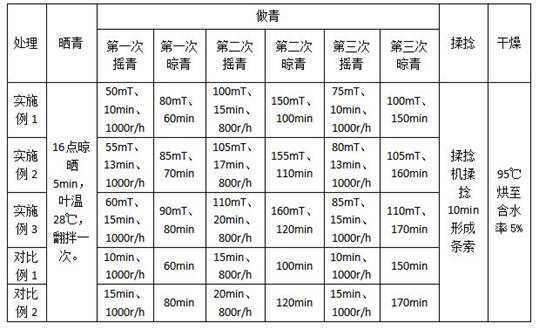

Method for processing oolong tea with assistance of static magnetic field

PendingCN114376017AReduce bitternessPromote oxidationPre-extraction tea treatmentClimate change adaptationTea catechinWater soluble

The invention discloses a method for assisted processing of oolong tea by using a static magnetic field, which comprises the following six steps: picking, sunning, rocking, airing, fixation, shaping and drying, and rocking and airing are respectively carried out for three times under the static magnetic field; the key conception of the method is that leaves in the stage of fine manipulation (rocking and airing) of oolong tea are exposed in magnetic field environments with different intensities, magnetic field potential energy is cut through different motion states such as rotating, throwing and standing of the leaves in the rocking and airing processes, water potential energy in the leaves is changed, and the water potential energy in the leaves is changed. Through redistribution of polar free water and polar compounds (amino acid, catechin and the like) in the leaves, the oxidation efficiency of substances contained in the fresh leaves is improved, the quality of the oolong tea is improved, and the processing time is shortened. The oolong tea prepared by the process has rich flower and fruit fragrance after being brewed, polyphenol compounds are fully oxidized, and the content of water-soluble amino acid is remarkably increased.

Owner:FUJIAN AGRI & FORESTRY UNIV

Organic-inorganic nanocomposite materials and methods of making the same and uses thereof

InactiveCN101563413BReduce free water contentReduce shrinkage effectsPorous dielectricsPrinted circuit manufactureOxide matrixInorganic polymer

The present invention relates to materials comprising organic-inorganic polymeric networks. In some embodiments, the present invention provides an organic-inorganic composite material comprising an inorganic metal oxide matrix interpenetrating with a polymeric phase. Additionally, the present invention provides methods of producing organic-inorganic composite materials.

Owner:PPG IND OHIO INC

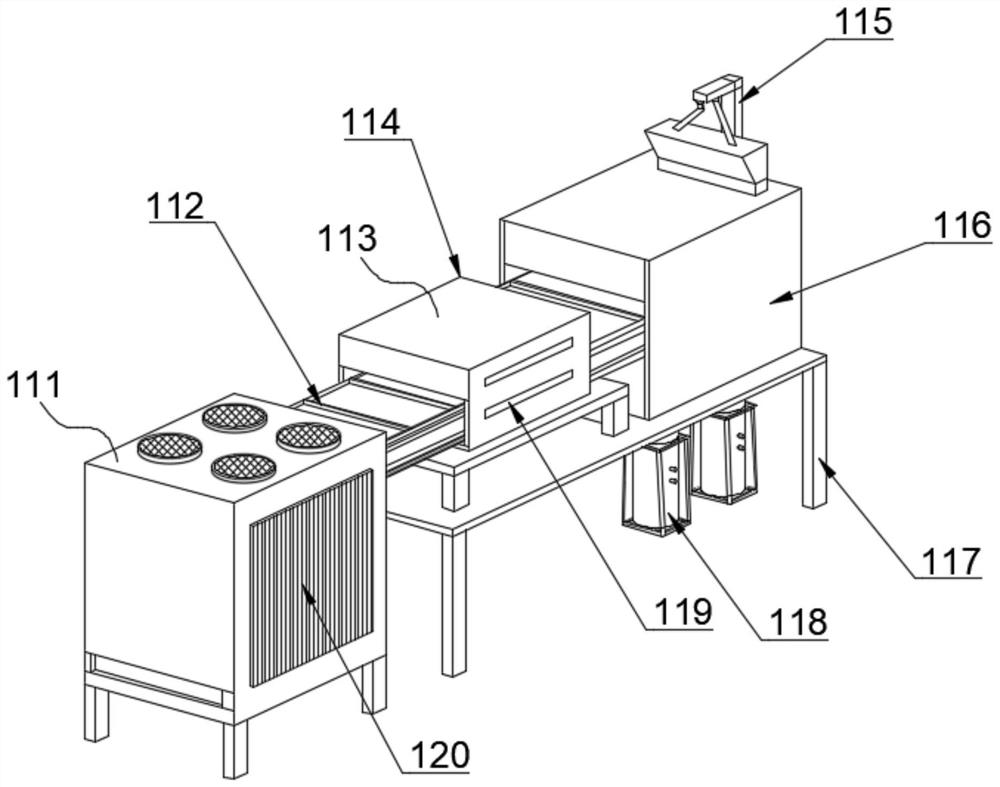

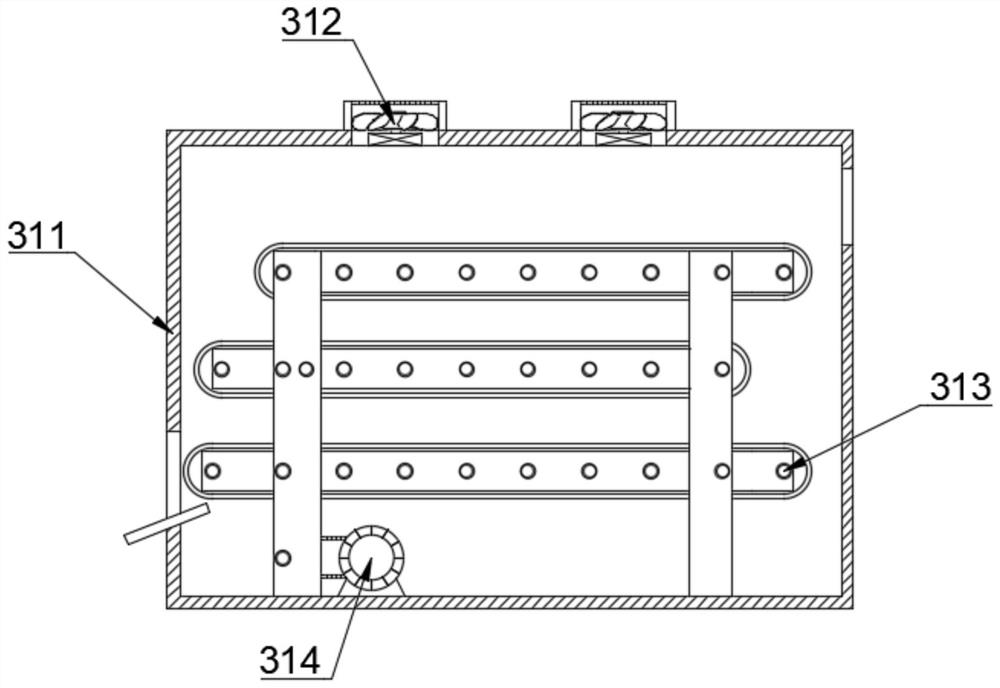

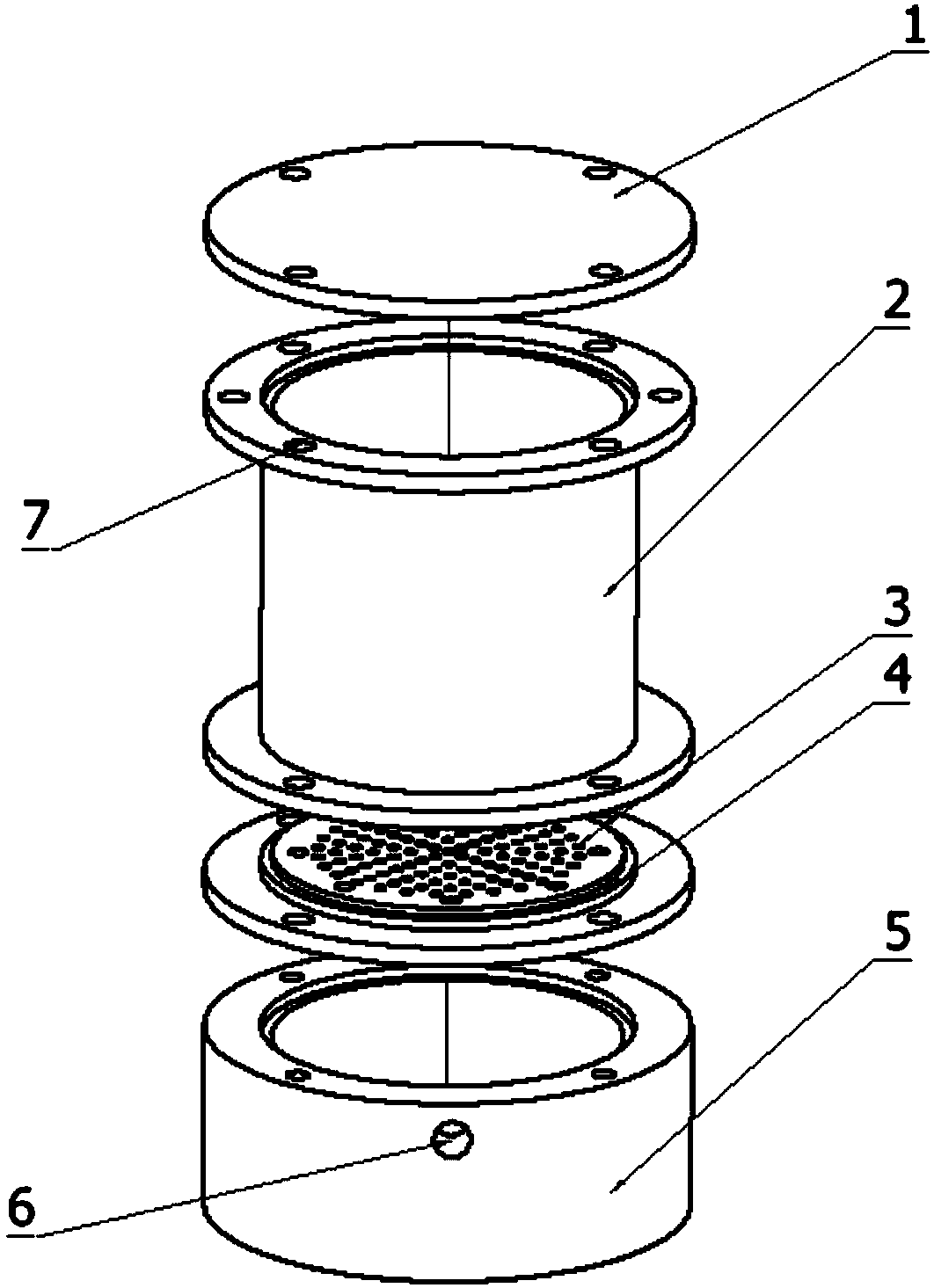

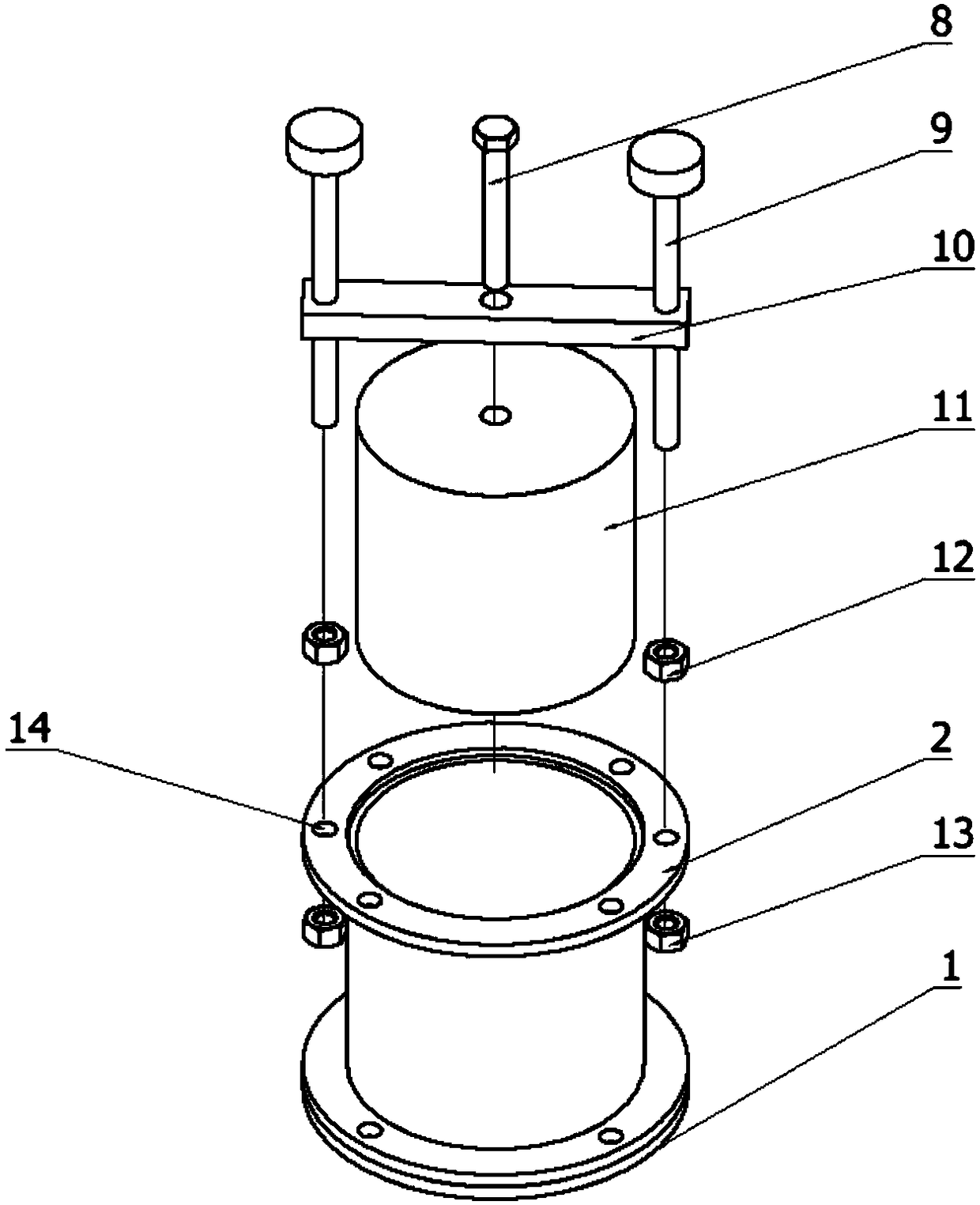

Environment-friendly plant fiber foaming and sound absorption material and preparation method thereof as well as water filtering mold and molding device

PendingCN109111754AGood sound absorptionReduce free water contentStationary filtering element filtersPre treatmentMicrowave oven

The invention relates to an environment-friendly plant fiber foaming and sound absorption material and a preparation method thereof as well as a water filtering mold and a molding device. According tothe environment-friendly plant fiber foaming and sound absorption material, waste paper and bagasse are used as raw materials and are subjected to fiber separation, fibrillation and alkali pre-treatment, the raw materials are mechanically stirred and put into the water filtering and molding device; a foaming material subjected to water filtering and molding is put into a microwave oven and is subjected to microwave foaming; after drying and finishing modification are carried out, the foaming material with a certain pore structure can be obtained. The environment-friendly plant fiber foaming and sound absorption material has the advantages that the material is cheap in price and easy to obtain; a specific formula is selected and an inner pore structure is enhanced; the material has a soundabsorption function and also has good properties of impact resistance, heat preservation and heat insulation, flame-retarding and anticorrosion performance, green and degradable performance and the like. Furthermore, a specially-designed mold is adopted and the problem of existing free foaming is solved, so that an obtained foaming body has a uniform surface, no concave part at the center, and aregular shape.

Owner:SOUTH CHINA UNIV OF TECH

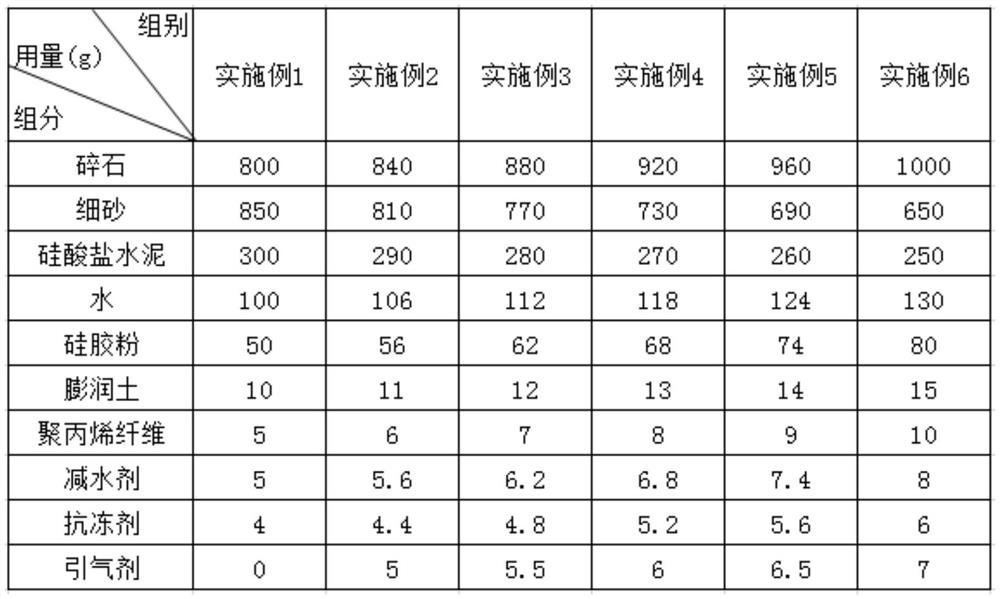

High-frost-resistance concrete and preparation method thereof

ActiveCN112537931AReduce free water contentReduce water-cement ratioBuilding materialSilicate Cement

The invention relates to the field of concrete building materials, and particularly discloses high-frost-resistance concrete and a preparation method thereof. The high-frost-resistance concrete comprise the following raw materials in parts by weight: 800-1000 parts of gravels, 650-850 parts of fine sand, 250-300 parts of Portland cement, 100-130 parts of water, 50-80 parts of silica gel powder, 10-15 parts of bentonite, 5-10 parts of polypropylene fibers, 5-8 parts of a water reducing agent and 4-6 parts of an anti-freezing agent. The preparation method comprises the following steps: S1, mixing of main materials; S2, mixing of auxiliary materials; and S3, mixing of additives. The high-frost-resistance concrete disclosed by the invention has the advantages of excellent frost resistance andgood construction performance.

Owner:中意世兴实业(武汉)有限公司

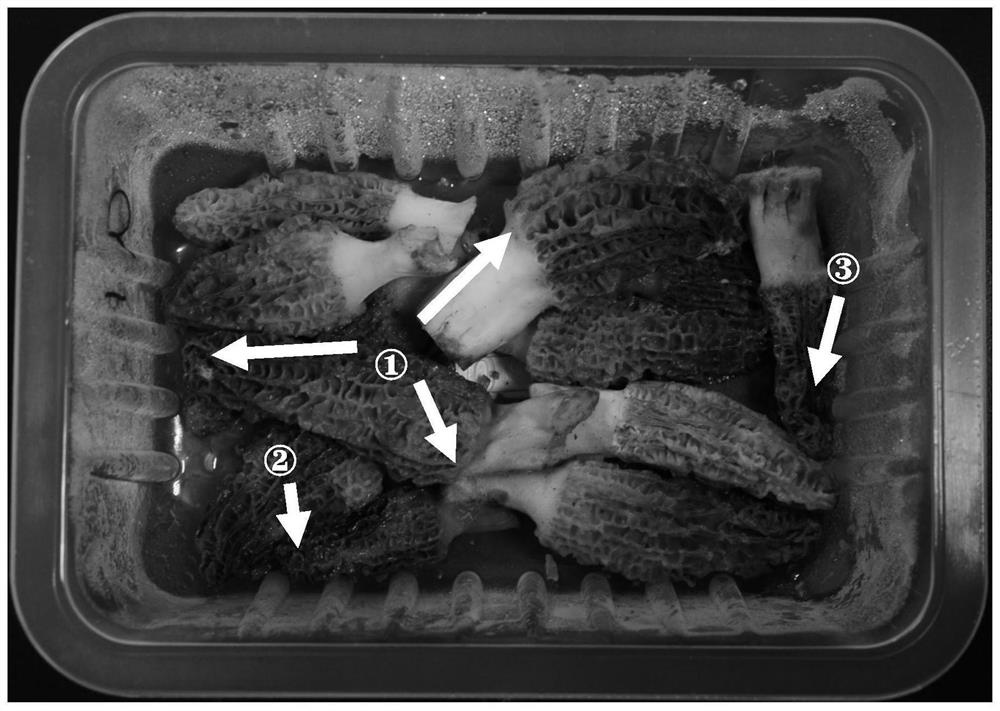

Composite preservation method for morchella esculenta by adopting low-temperature ozone drying agent

InactiveCN113100287AKeep the flavorAvoid damageFruit and vegetables preservationFood ingredientsDesiccantEnvironmental engineering

The invention relates to a composite preservation method for morchella esculenta by adopting a low-temperature ozone drying agent, which belongs to the field of preservation of morchella esculenta. The method comprises steps of carrying out pre-cooling treatment on the harvested morchella esculenta for 4-5 hours at the temperature of 3-5 DEG C, fumigating the precooled morchella esculenta in an ozone closed space with the concentration of 16 mg / m<3> to 19 mg / m<3> for 10 to 30 minutes, boxing the fumigated morchella esculenta and allochroic silicagel desiccant according to the weight ratio of (12-20): 1, and sealing a film and storing in an environment of 4 DEG C. The method has the advantages that under the condition that the appearance, smell and taste of the morchella esculenta are not affected, completeness and cleanness of morchella esculenta bodies are kept, cleaning, spraying and soaking of liquid are avoided, exogenous pollution is reduced, self enzyme activity is inhibited, and therefore the freshness degree of the morchella esculenta is kept, the preservation period is prolonged, and the method is a morchella esculenta fresh-keeping composite technology which is simple and convenient to operate and suitable for popularization.

Owner:GUIZHOU CROP VARIETIES RESOURCE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com