Patents

Literature

59results about How to "Increase compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

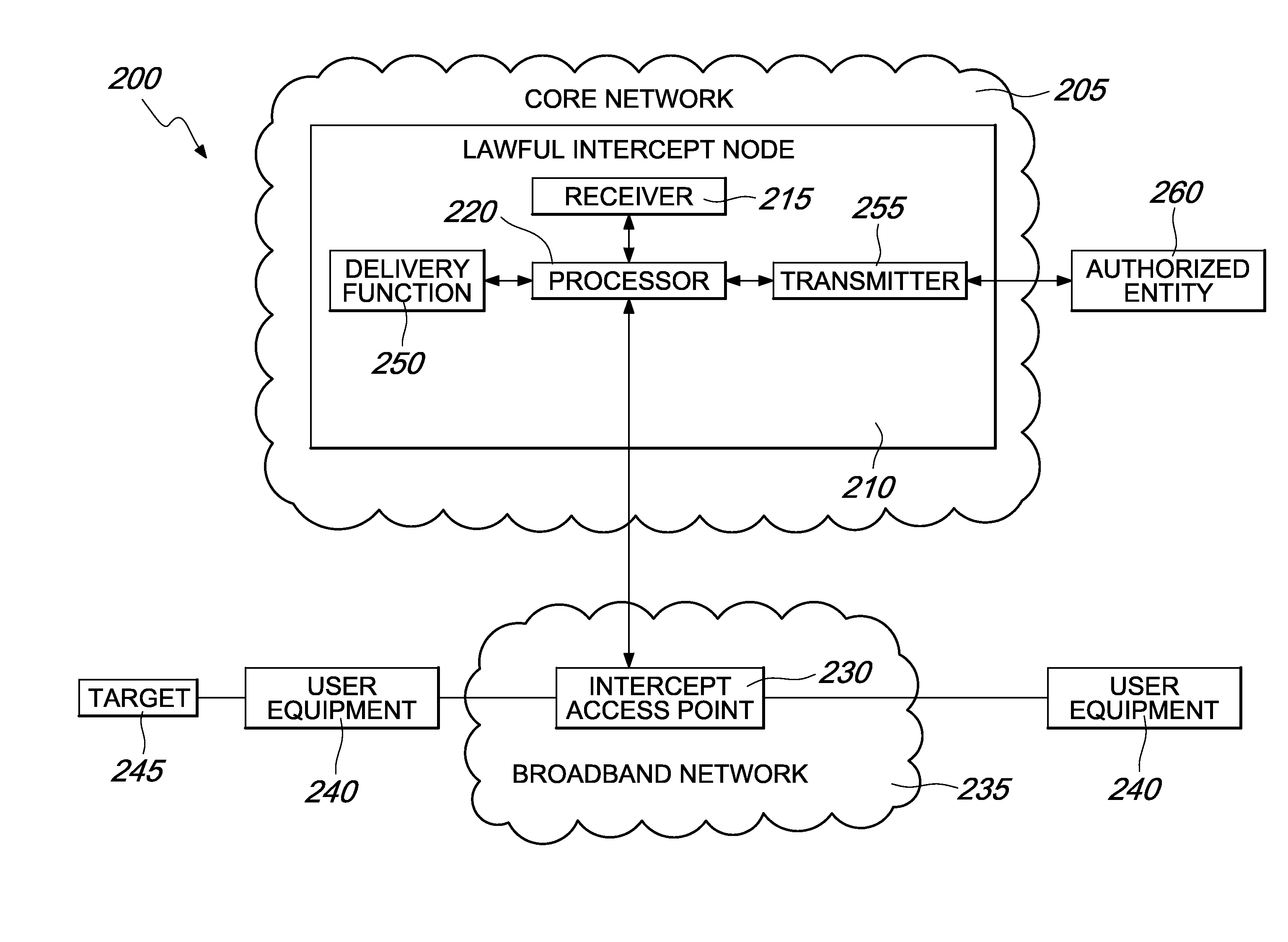

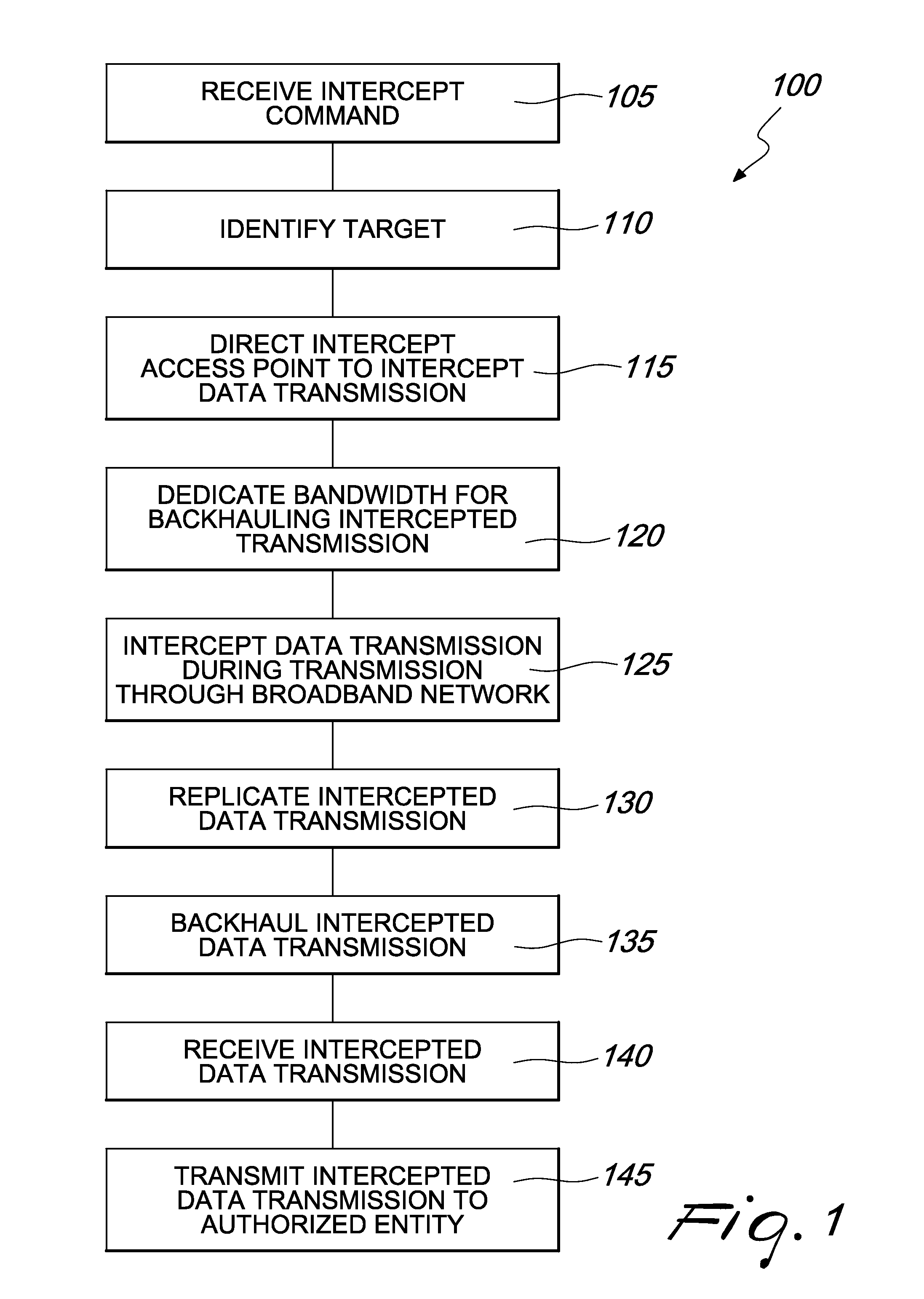

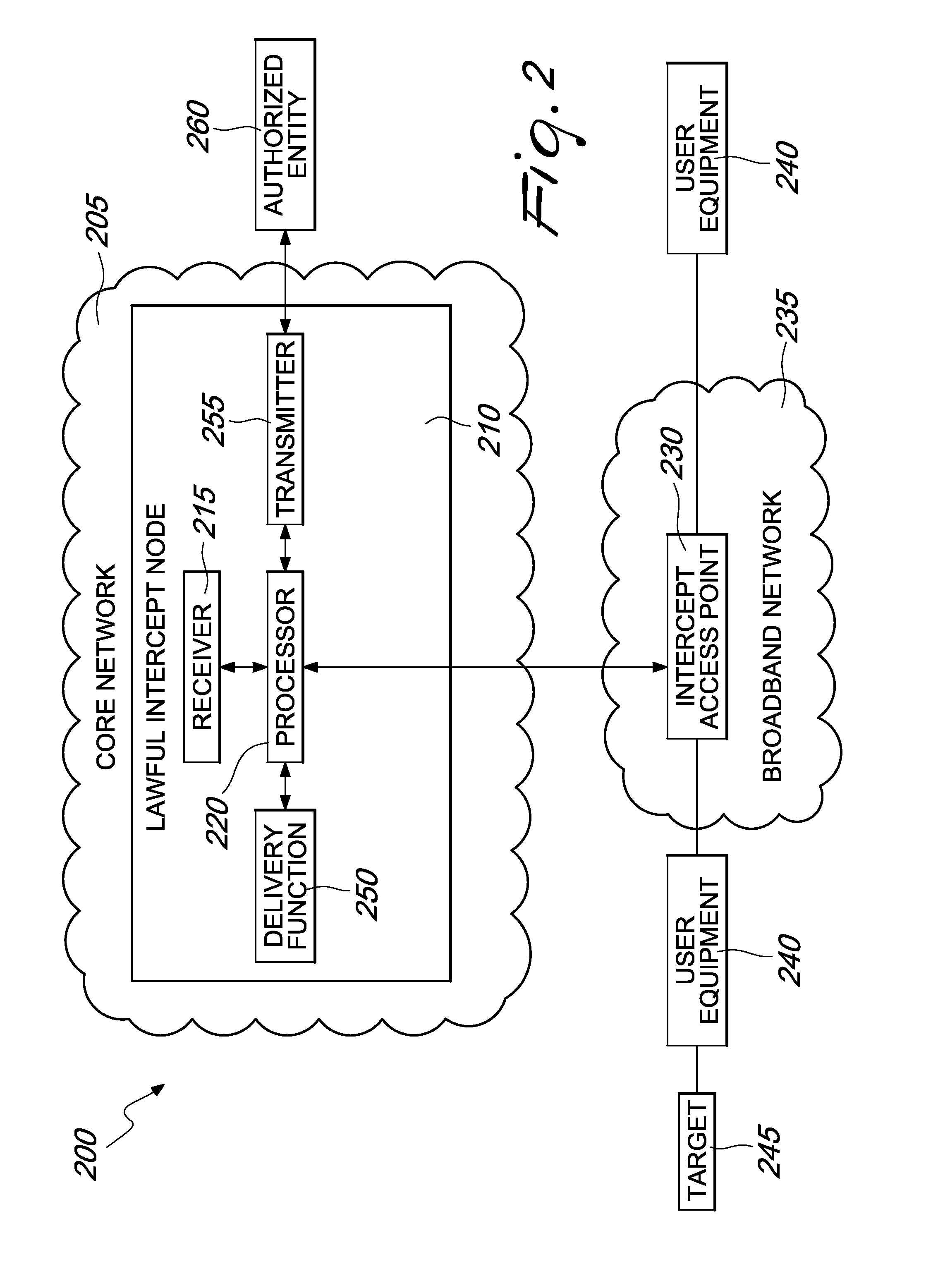

Lawful interception in wireline broadband networks

ActiveUS20100086119A1Improve efficiencyIncrease compatibilityInterconnection arrangementsSpecial service for subscribersData transmissionHigh bandwidth

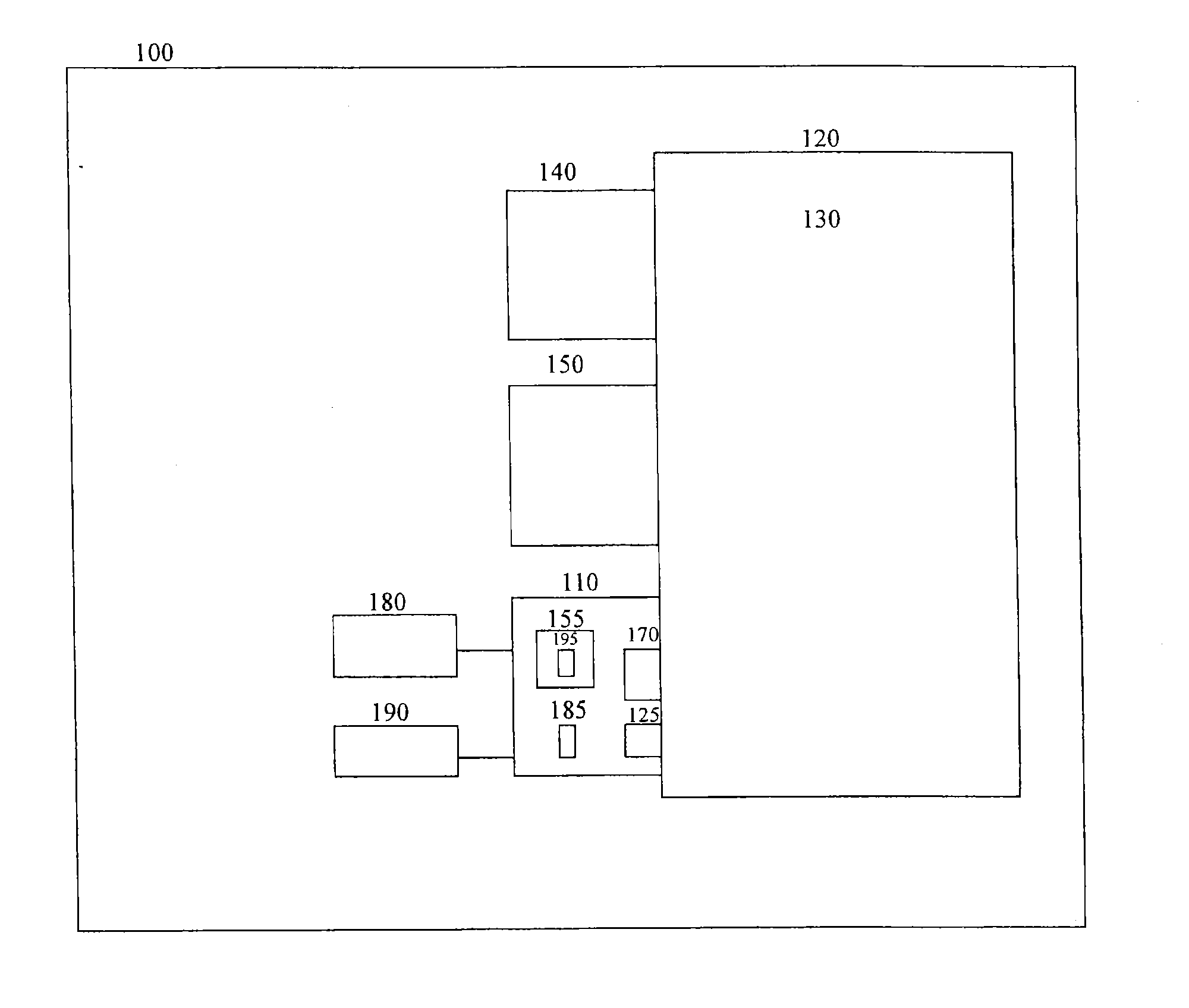

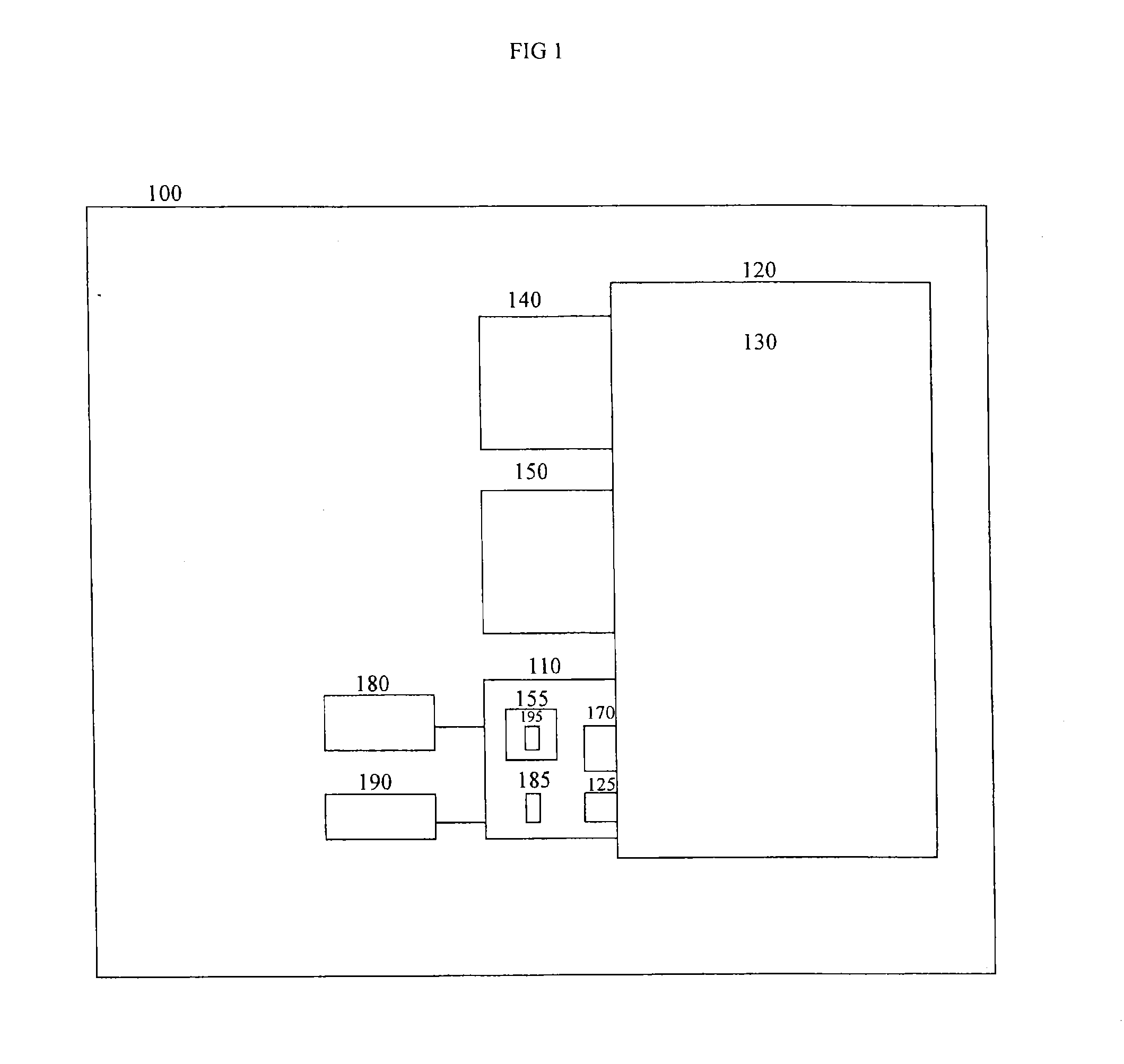

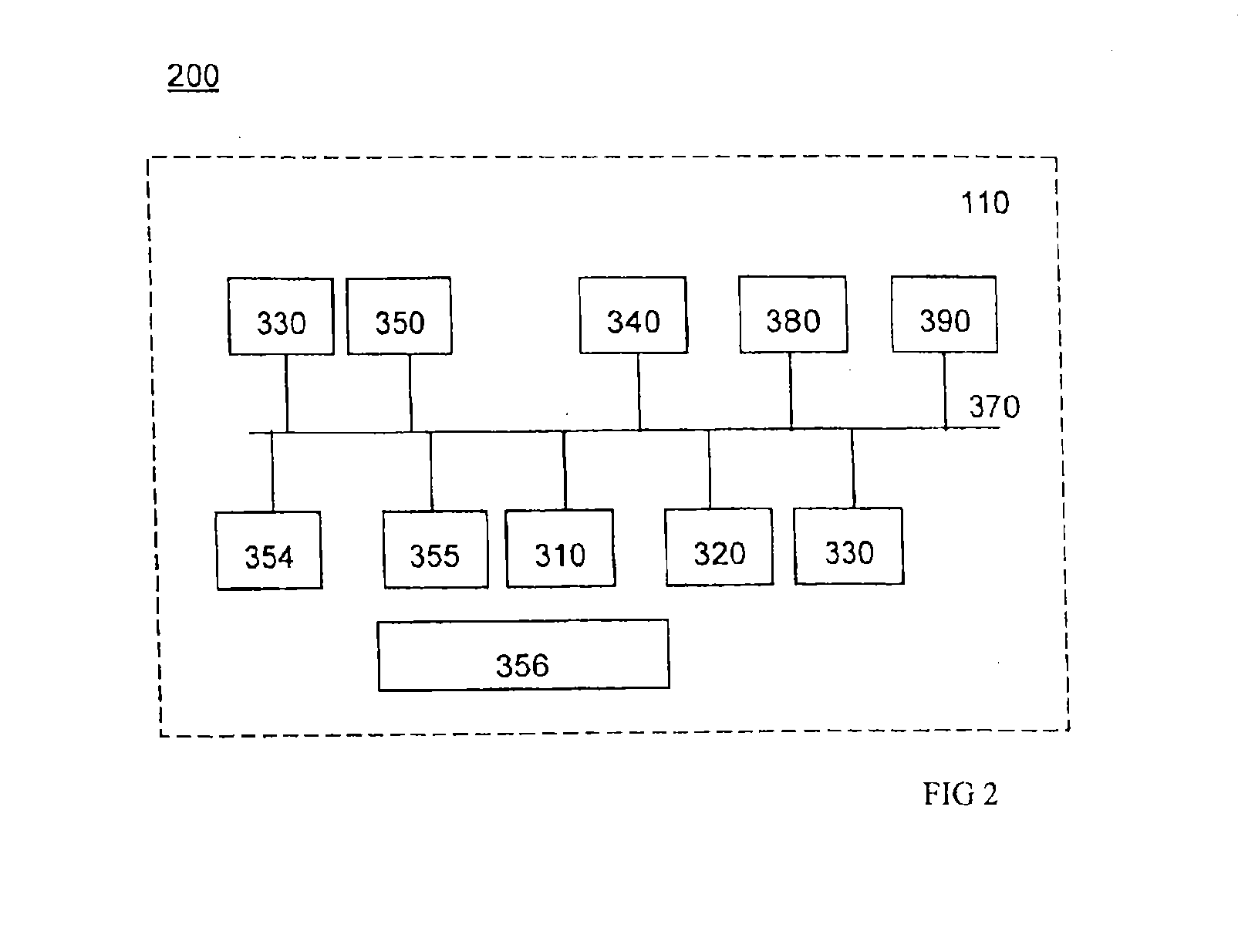

Systems and methods are provided for lawful interception of data transmissions through at least one broadband network. Data transmissions, including voice and data services as well as high bandwidth transmissions such as multimedia and video, are intercepted and routed to authorized agencies such as law enforcement monitoring facilities. The systems and methods also enable interception of data transmissions such as peer to peer type data transmissions that pass through broadband networks from source to recipient without passing through centralized core network elements. These transmissions are intercepted at access points distributed throughout the broadband networks and forwarded to lawful intercept node elements for transmission to authorized entities.

Owner:TELEFON AB LM ERICSSON (PUBL)

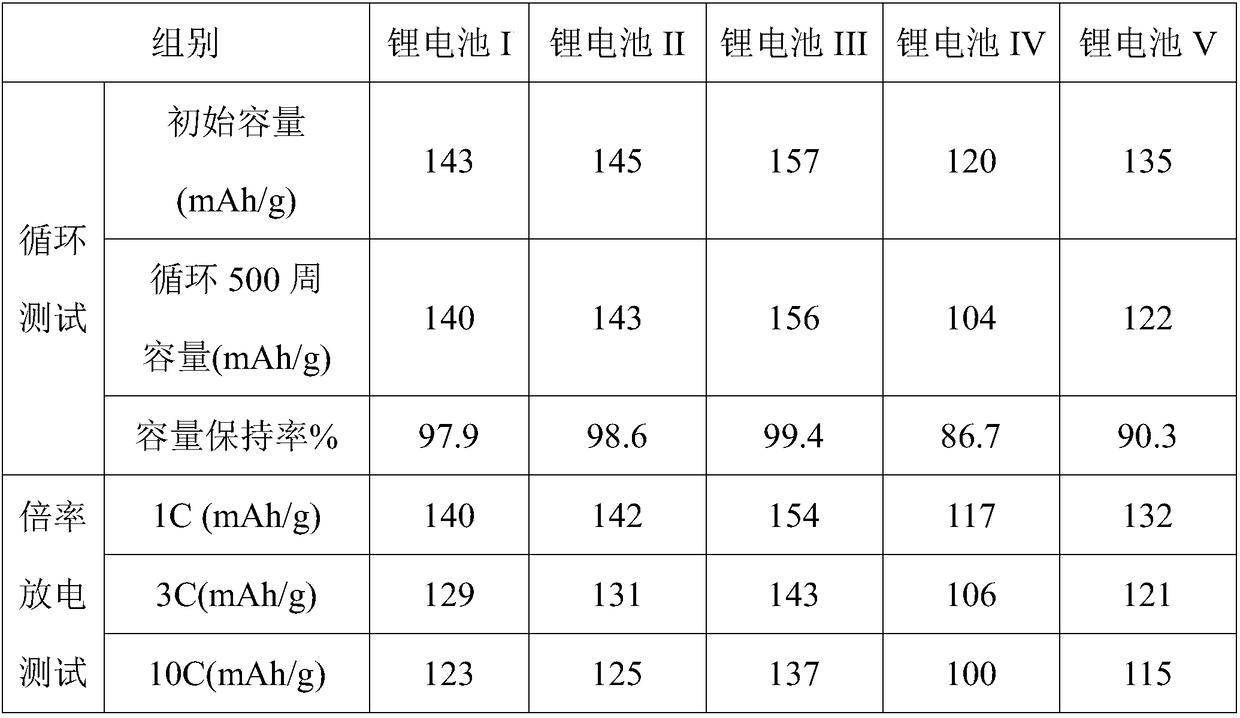

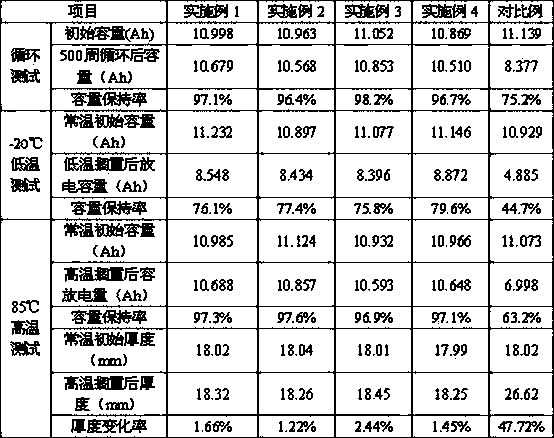

Non-aqueous electrolyte for lithium iron phosphate battery

The invention discloses a non-aqueous electrolyte for a lithium iron phosphate battery. The non-aqueous electrolyte comprises 70 to 85 weight percent of carbonic ester compound, 3 to 20 weight percent of various function additives and 11 to 17 weight percent of lithium hexafluorophosphate, wherein the carbonic ester compound is one of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate and diethyl carbonate or a mixture of more of the ethylene carbonate, the propylene carbonate, the butylene carbonate, the dimethyl carbonate and the diethyl carbonate; and the additives comprise one of 0.5 to 10 percent of film-forming additive, 0.5 to 10 percent of high-temperature additive, 0.5 to 10 percent of low-temperature additive, 0.5 to 10 percent of overcharge-preventing additive and 0.001 to 2 percent of stability additive, and a mixture of more of the additives. The non-aqueous electrolyte for the lithium iron phosphate battery has the advantages that the solubility and dissociation of the lithium hexafluorophosphate are improved, and electric conductivity is improved; the low temperature resistance of a solid electrolyte interphase (SEI) is reduced; the overall stability of the battery is improved, the overall service life of the battery is prolonged, the compatibility of an electrolyte and a cathode is improved, circulation of the battery is improved, and the service life is prolonged; and the non-aqueous electrolyte can have high performance at high temperature.

Owner:广东金光高科股份有限公司

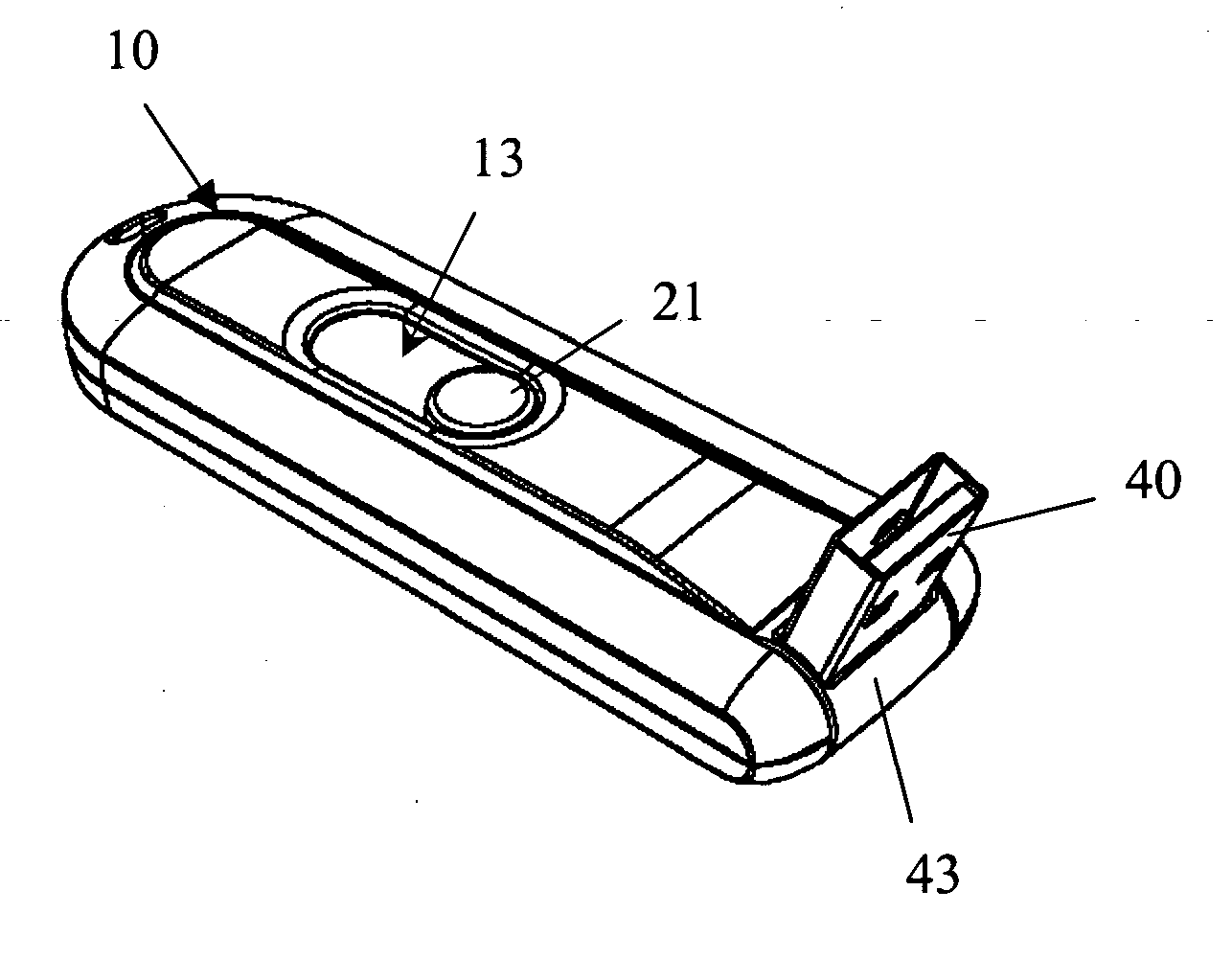

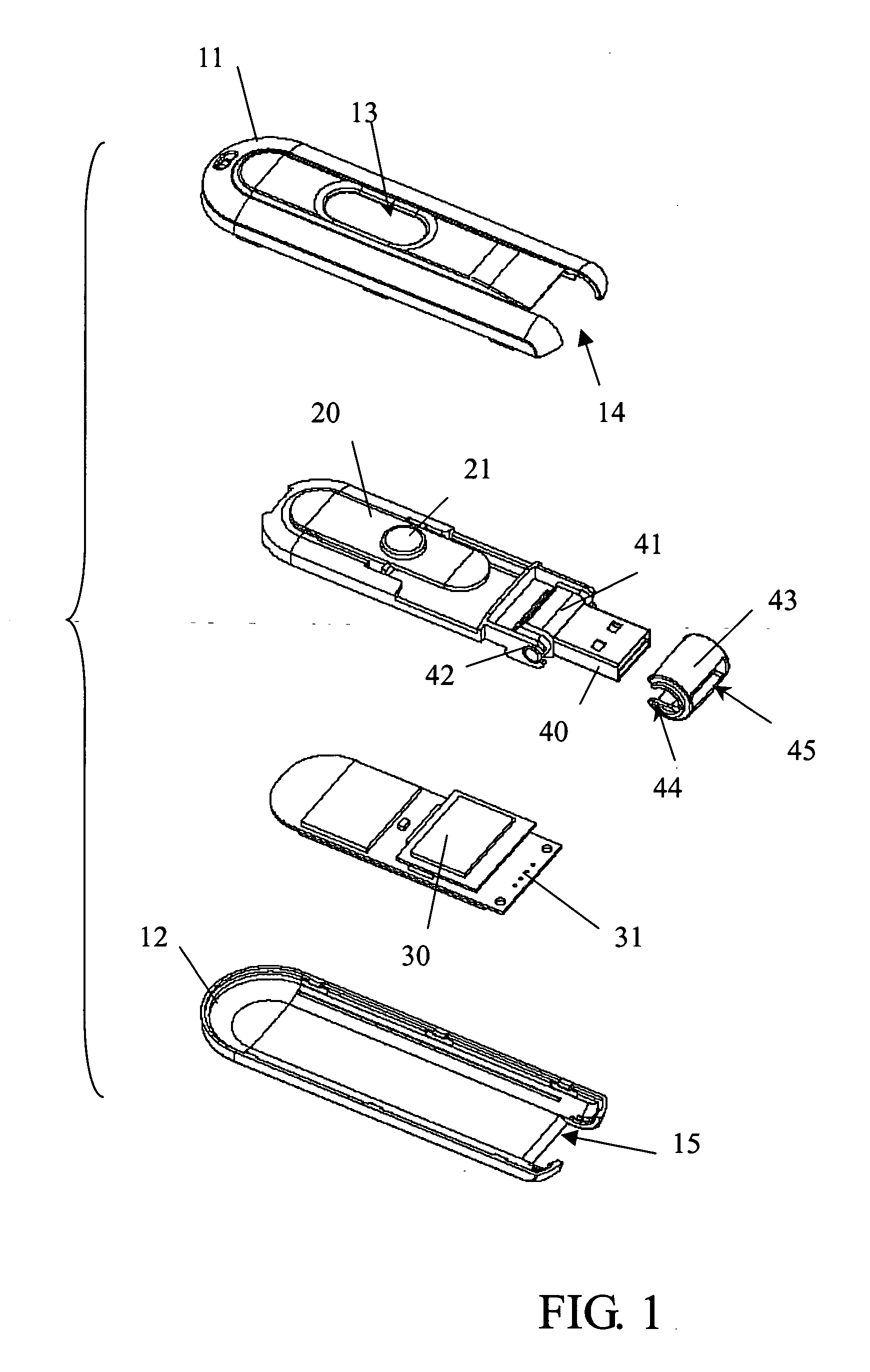

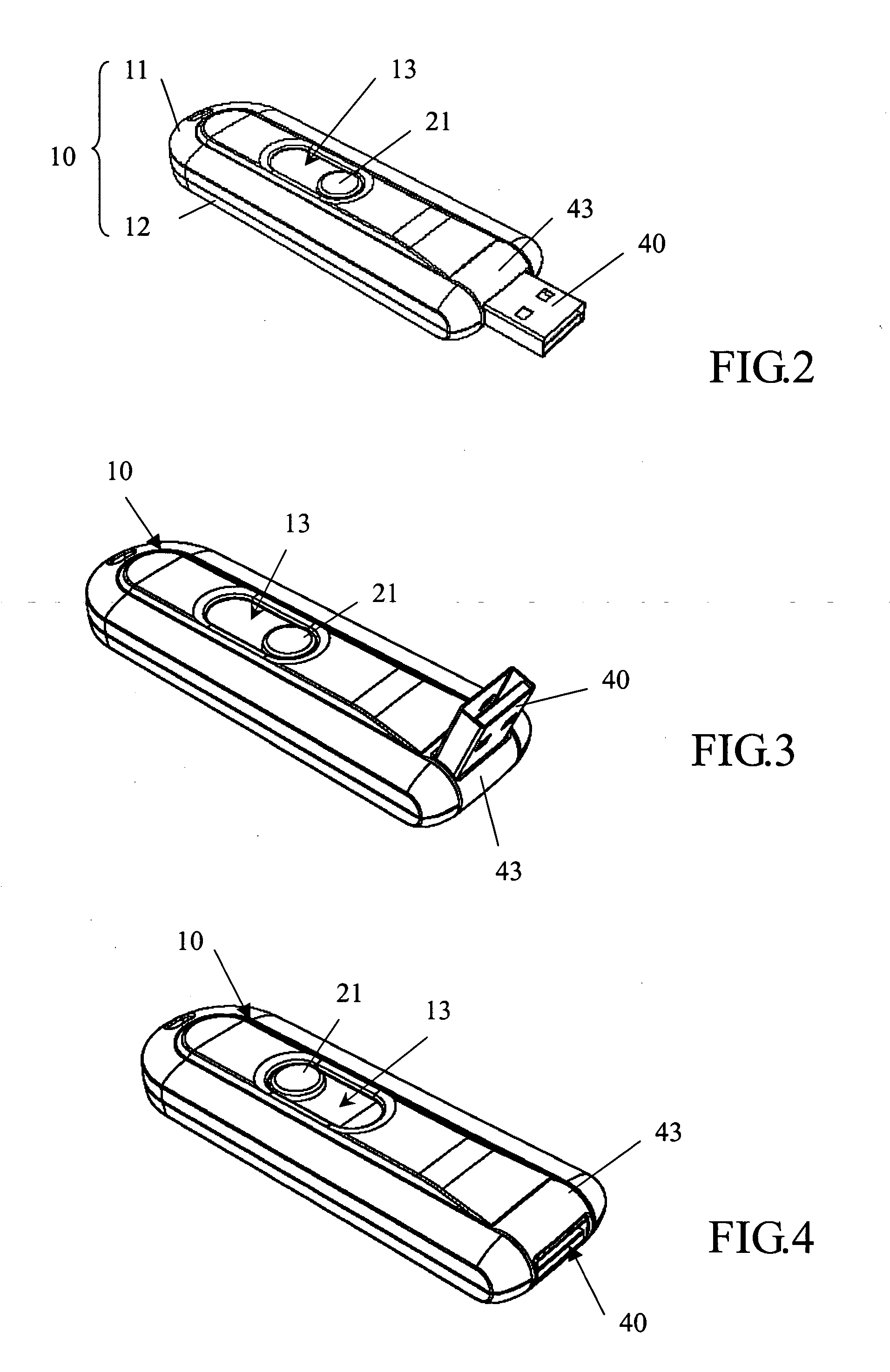

Memory device having a hiding and swing plug and method for hiding and swing a plug thereof

InactiveUS20060084284A1Increase compatibilityImprove compatibilityRotary current collectorTwo-part coupling devicesElectricityHead parts

The mean for the universal serial bus hide and swing, its body inside have a sliding unit its head pivot to establish on can swing from as of deal with USB, and a memory to equip the electricity conjunction in deal with USB. The USB can conceal in the body, or along with the sliding unit to swing after being moved the indentation of the body.

Owner:TUL CORP

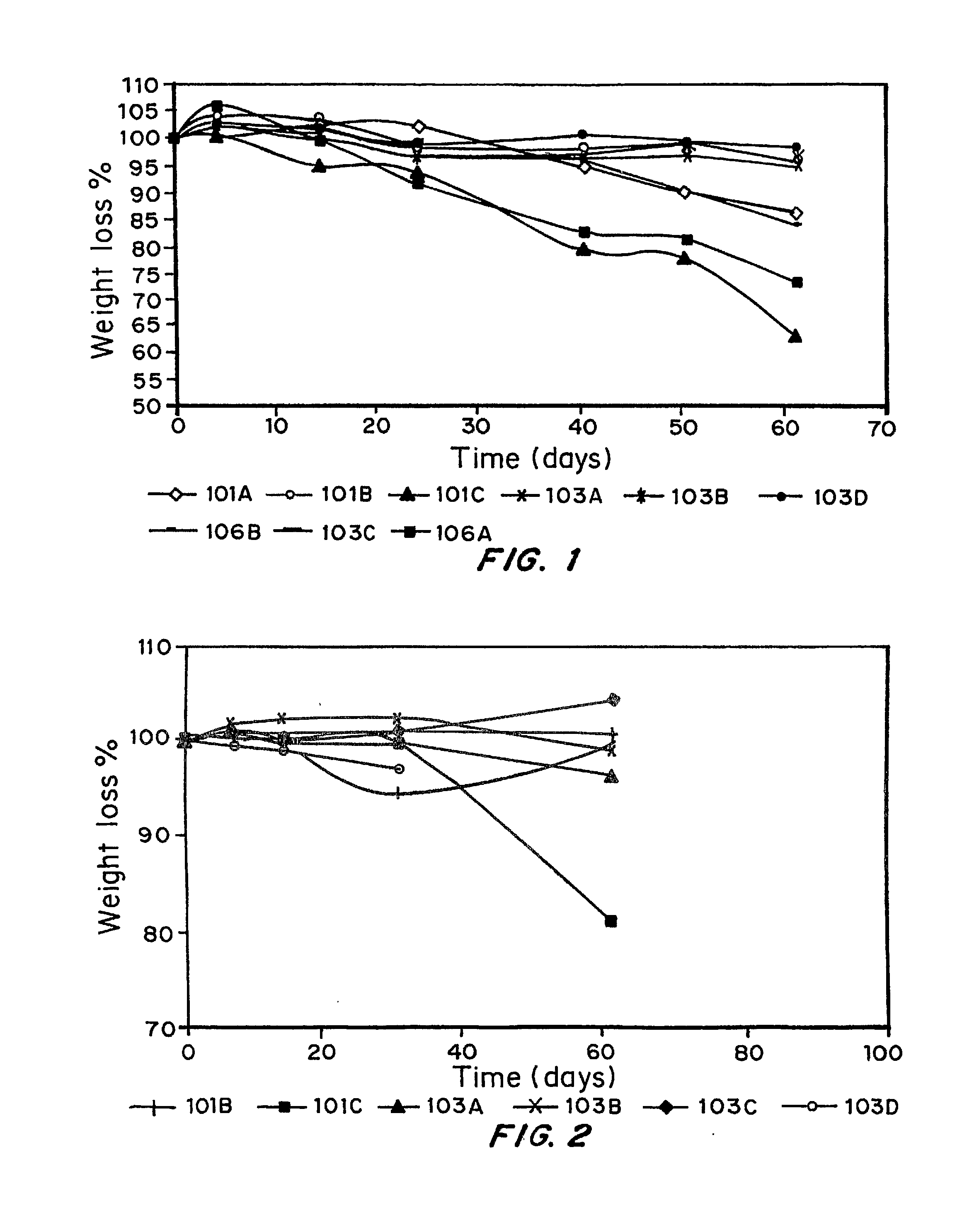

Disposable Medical Supplies From Hydrolytically Biodegradable Plastics

InactiveUS20080255267A1Increase compatibilityReduce interactionEngine sealsSynthetic resin layered productsBiodegradable plasticStandard technique

Hydrolytically degradable polymers in the form of biodegradable disposable medical devices for use in medicine and laboratories such as syringes, test tubes, catheters, tubing, trays, medical fabrics, and gloves are described. The devices are formed in whole or in part of a hydrolytically degradable polymer. In the preferred embodiment, the devices or structural components thereof degrade in a period of weeks to months, preferably within a year and more preferably within six months of exposure to aqueous solutions. Conventional hydrolytically degradable polymers may be utilized or these may be modified to increase mechanical or processing characteristics, for example, using a polyfunctional branching agent and / or a chain extending agent. In one embodiment, the hydrolytically degradable polymer is a member of a new class of polyesters comprising an aliphatic dicarboxylic acid, an aliphatic diol and optionally, one or more bifunctional fatty acids such as ricinoleic acid and / or castor oil. The devices are prepared using standard techniques, such as by injection molding, extrusion or melt spinning. The devices can be formed entirely of the degradable polymer, or they can be coated with a polymer coating in order to increase the compatibility of and reduce the possibility for interaction between the surface of the device and liquids that may come in contact with the device, or they may include core or other internal structural member formed of either the biodegradable or non-biodegradable material.

Owner:MASSACHUSETTS INST OF TECH

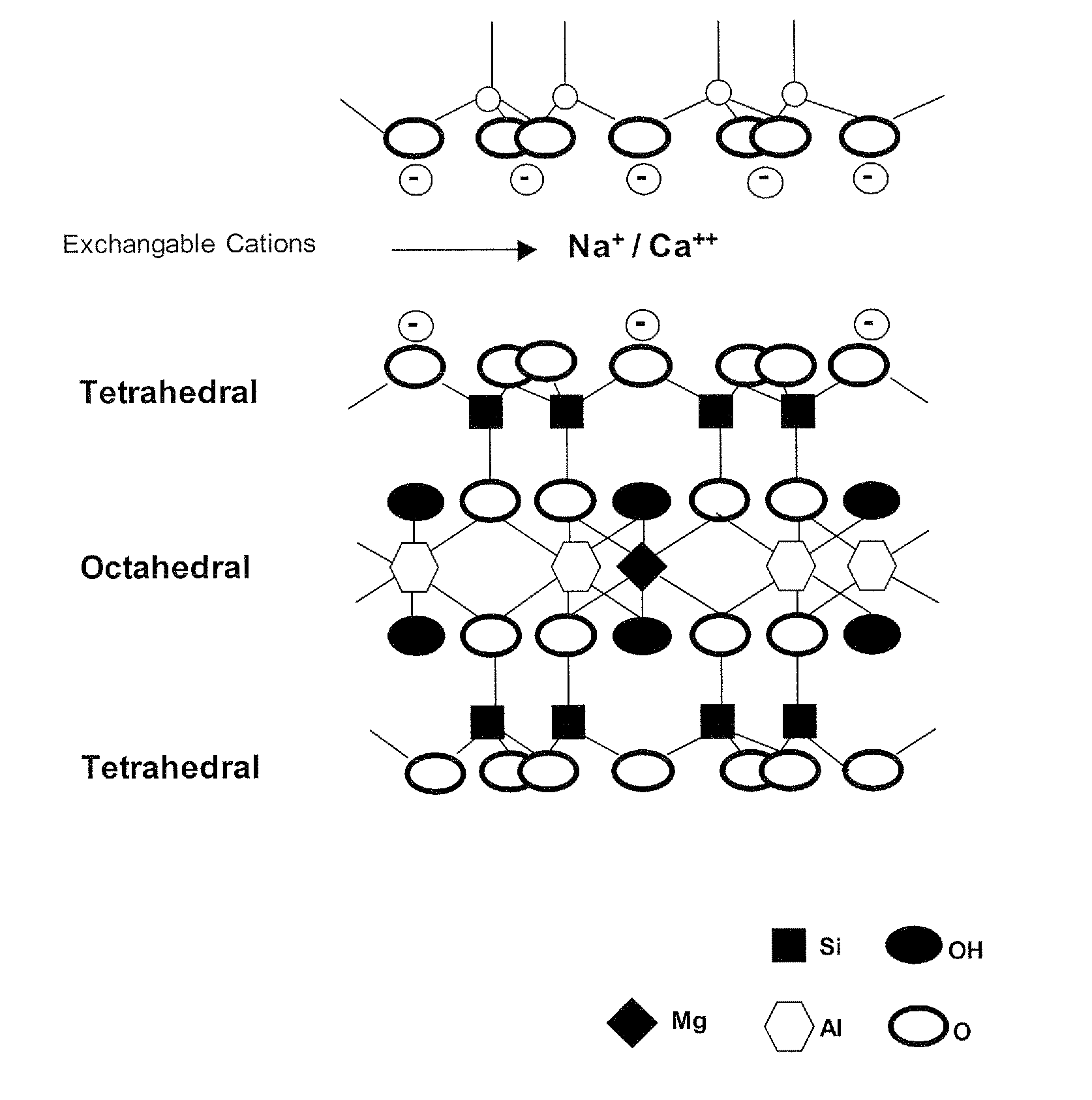

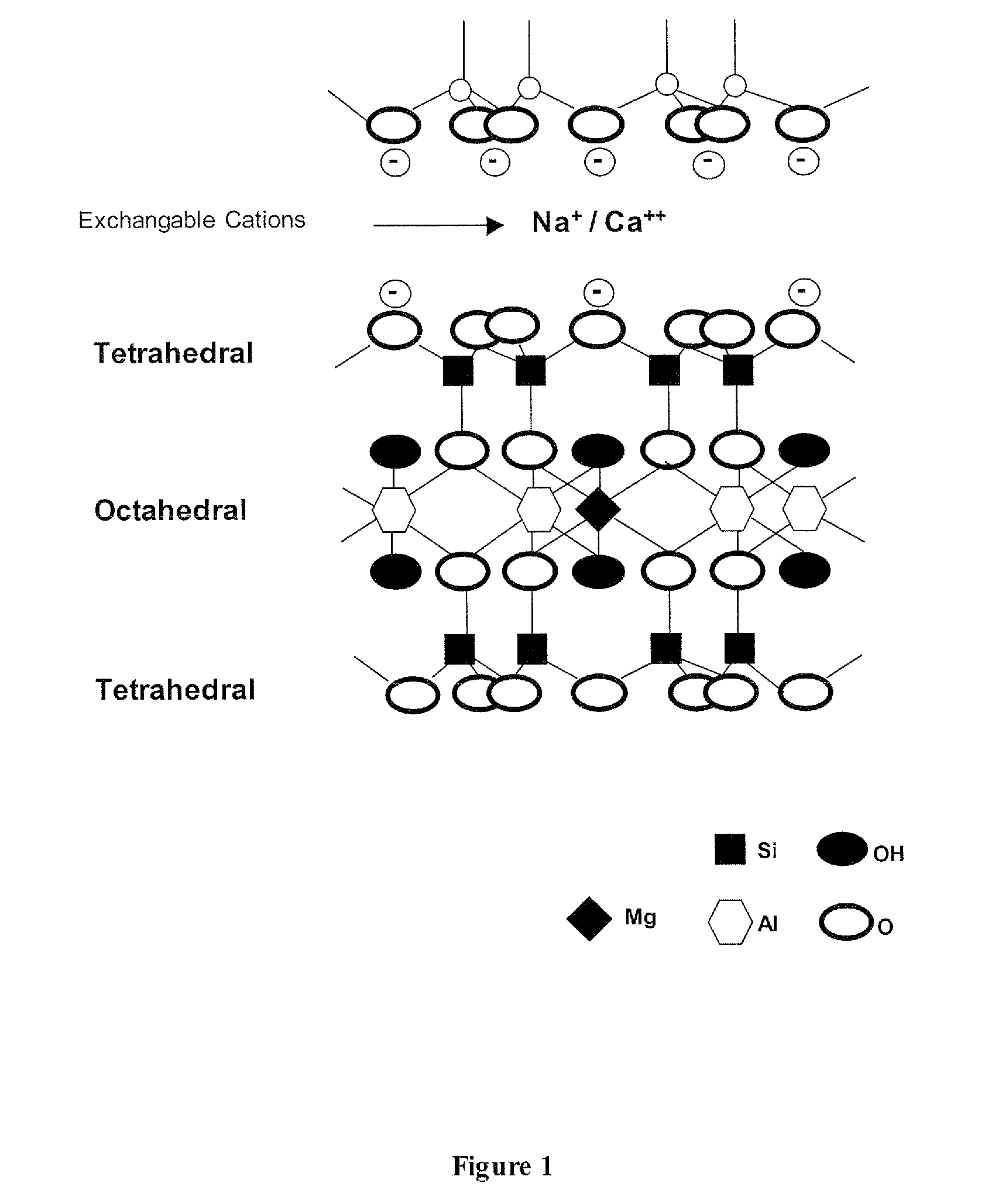

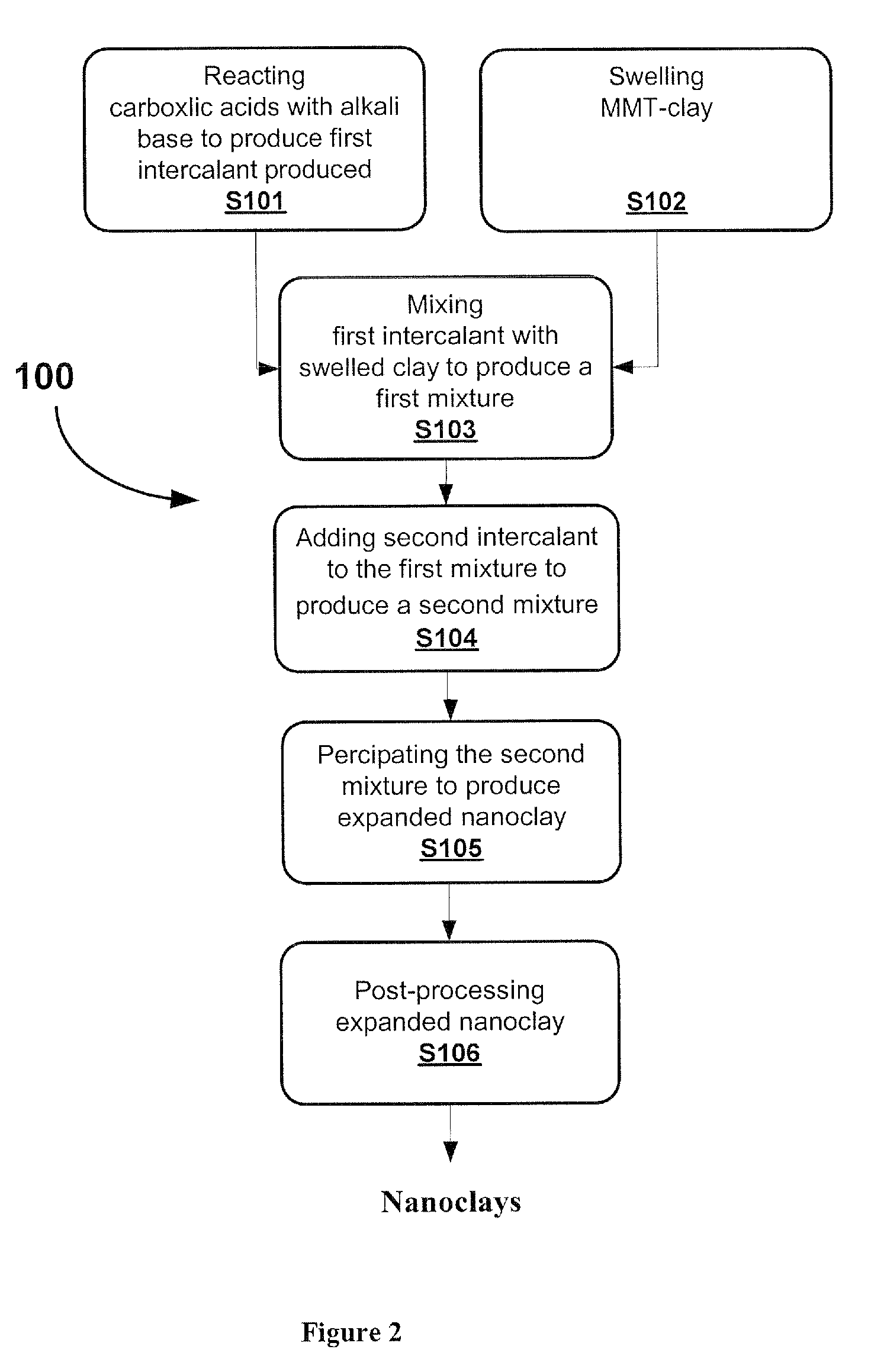

Expanded nanoclays and method of producing such expanded nanoclays

A method of producing nanoclays comprising the steps of preparing a first intercalant alkali salt of a carboxylic acid, adding the first intercalant to a swelled clay at a temperature of at least 50° C. so that the metal ions on the clay surface forms a complex with the carboxyl group that enlarges the space between the two galleries of clay. The method further comprises the step of adding an organic acid as a second intercalant to the clay modified by the first intercalant to form a clay / organic salt / organic acid complex. The clay / organic salt / organic acid complex may be post processed by precipitating, homogenizing with a solution comprising of water and alcohol, filtering, drying, milling, and sieving to produce the desired nanoclay.

Owner:ISIK KIVANC

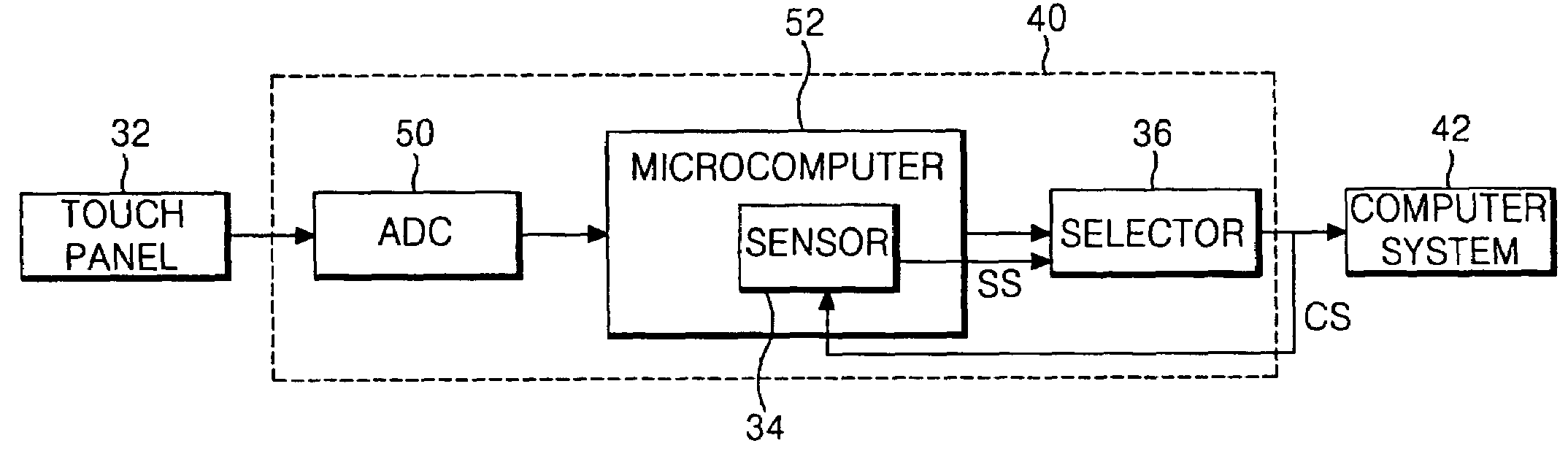

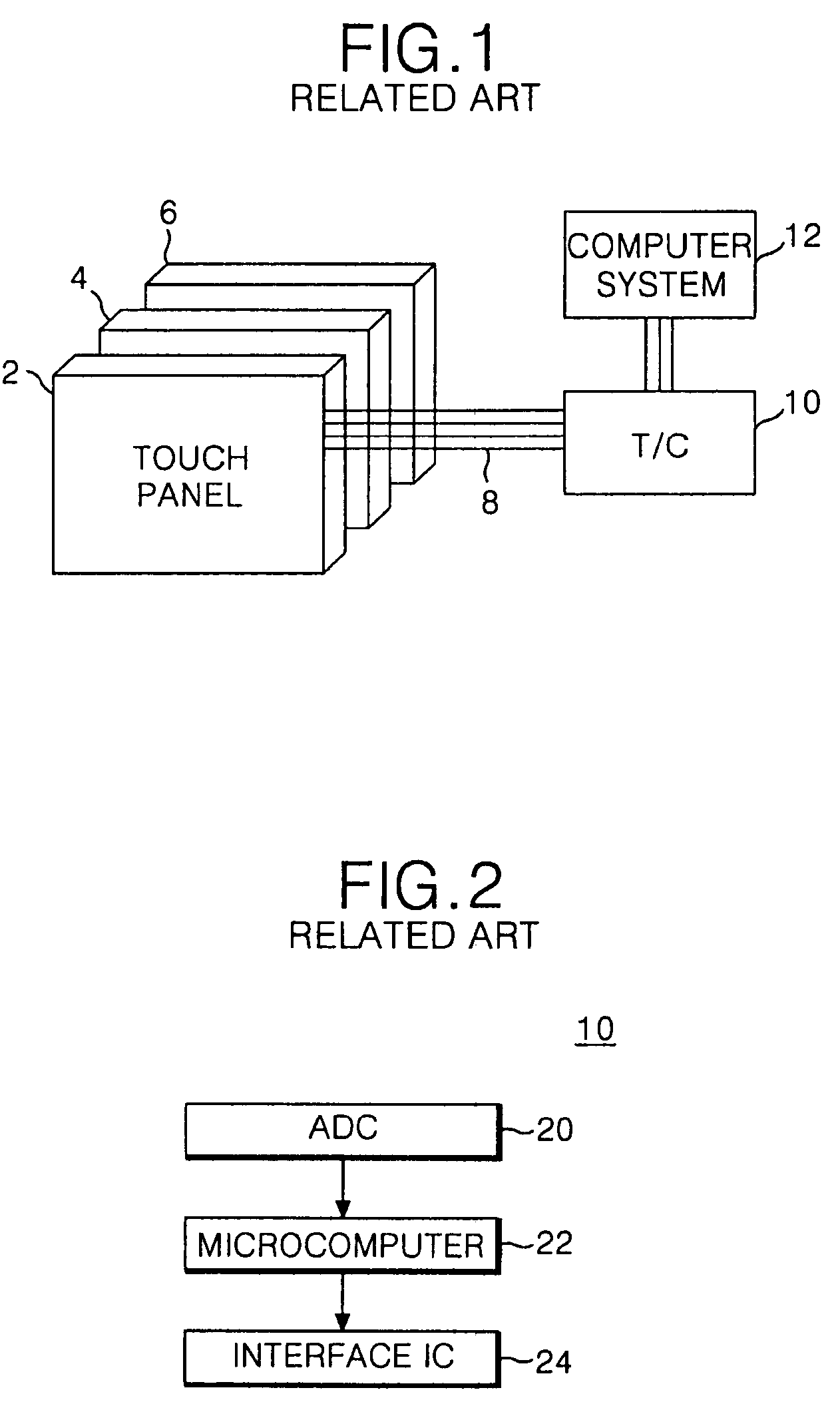

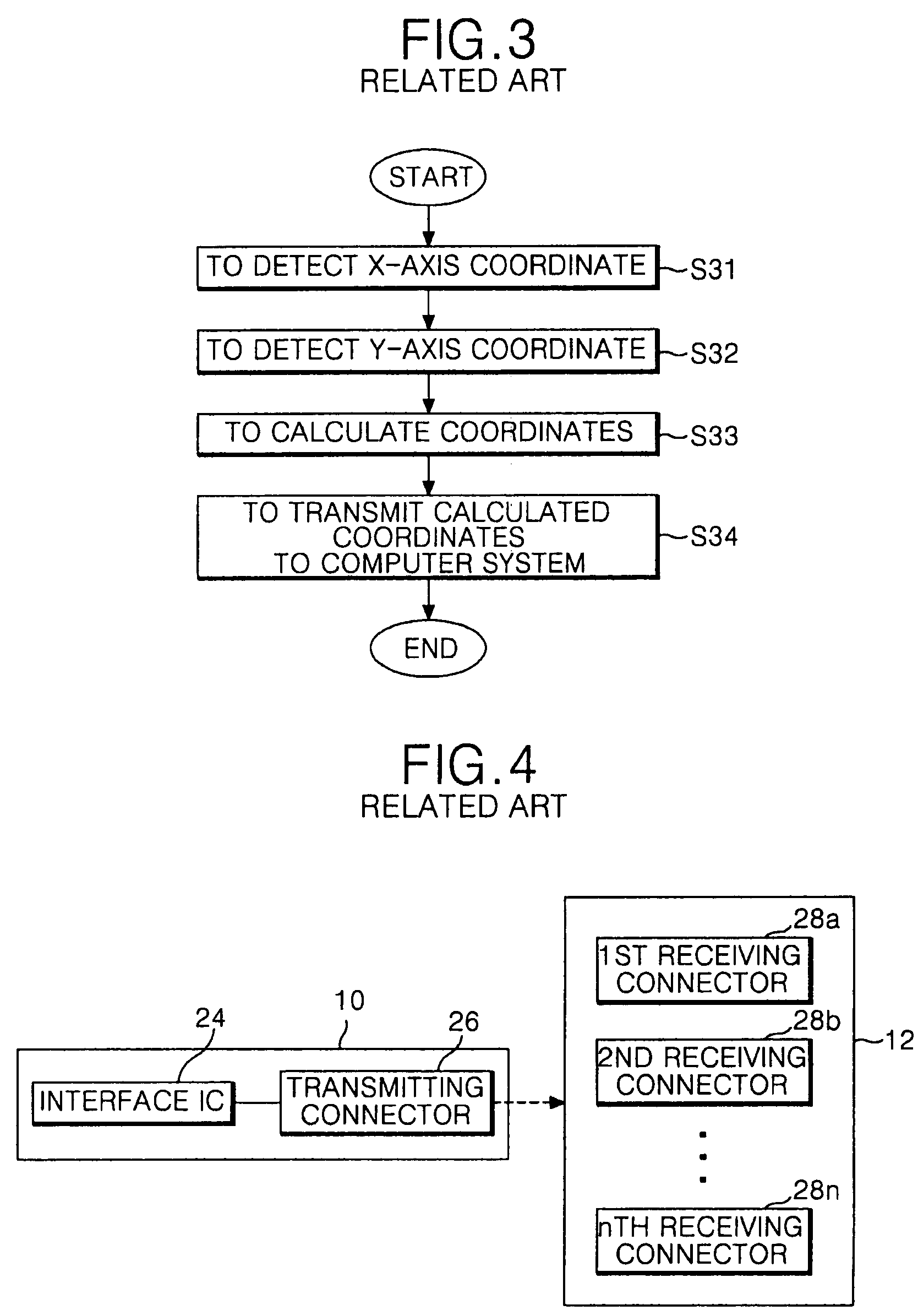

Apparatus and method for driving touch panel device

ActiveUS7439961B2Increase compatibilityImprove compatibilityInput/output for user-computer interactionTransmission systemsEmbedded systemTouch panel

A driving apparatus of a touch panel includes a touch panel for generating a coordinate signal according to a position of a contact point, at least two interface integrated circuits connected to the touch panel, a computer system driving the touch panel and connected to any one of the at least two interface integrated circuits, a sensor for automatically detecting the interface integrated circuit connected to the computer system, and a controller for converting the coordinate signal in accordance with the interface integrated circuit detected at the sensor and transmitting the converted coordinate signal to the computer system.

Owner:LG DISPLAY CO LTD

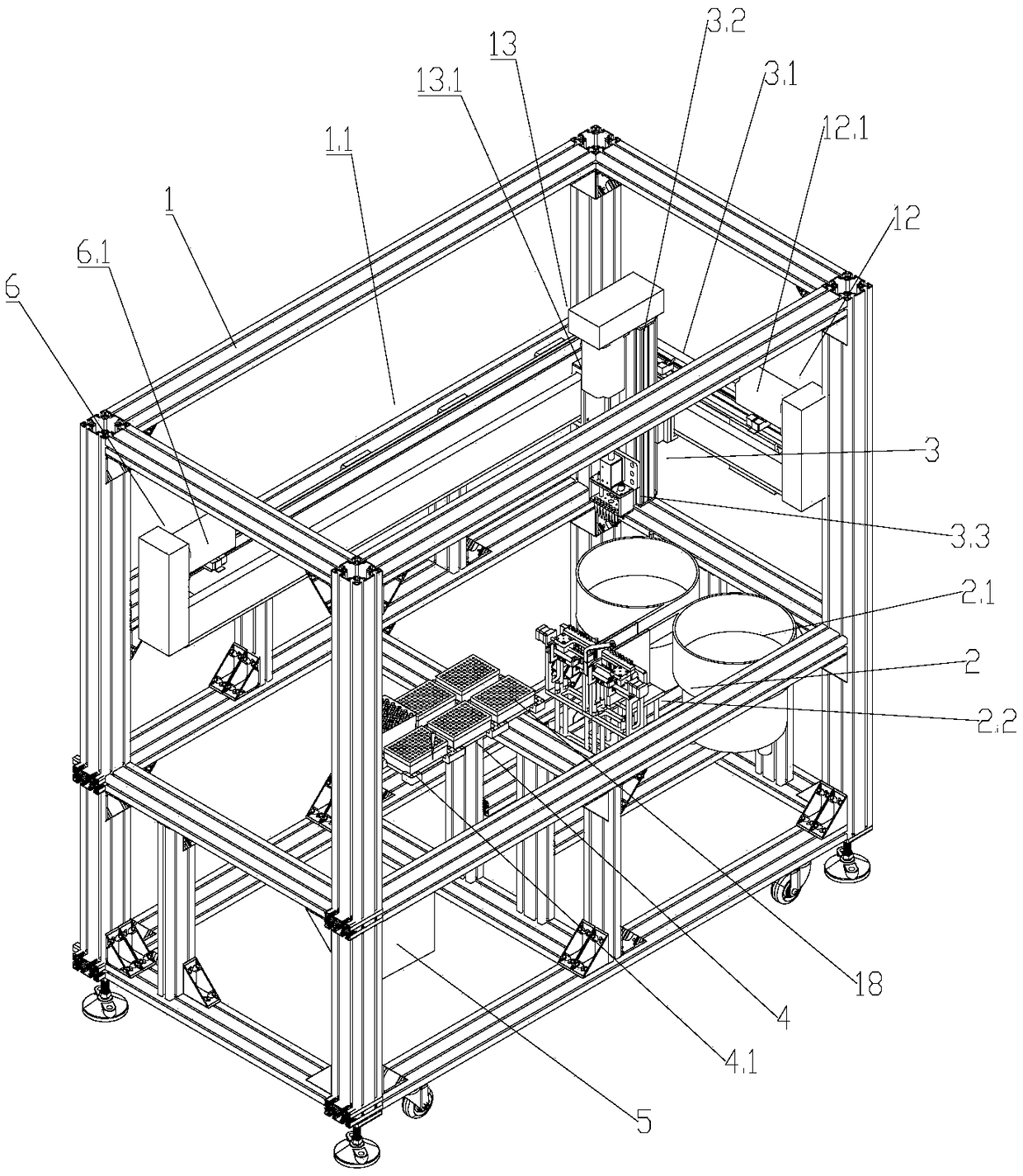

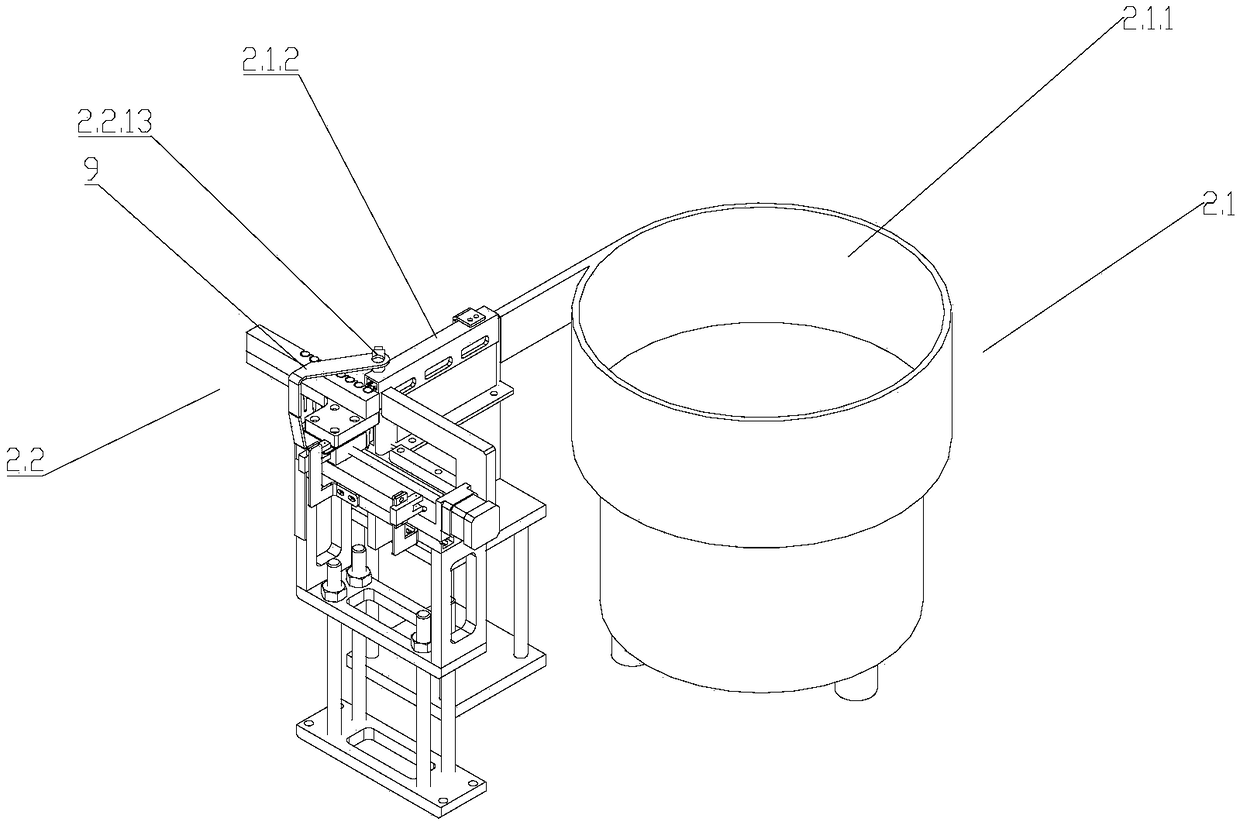

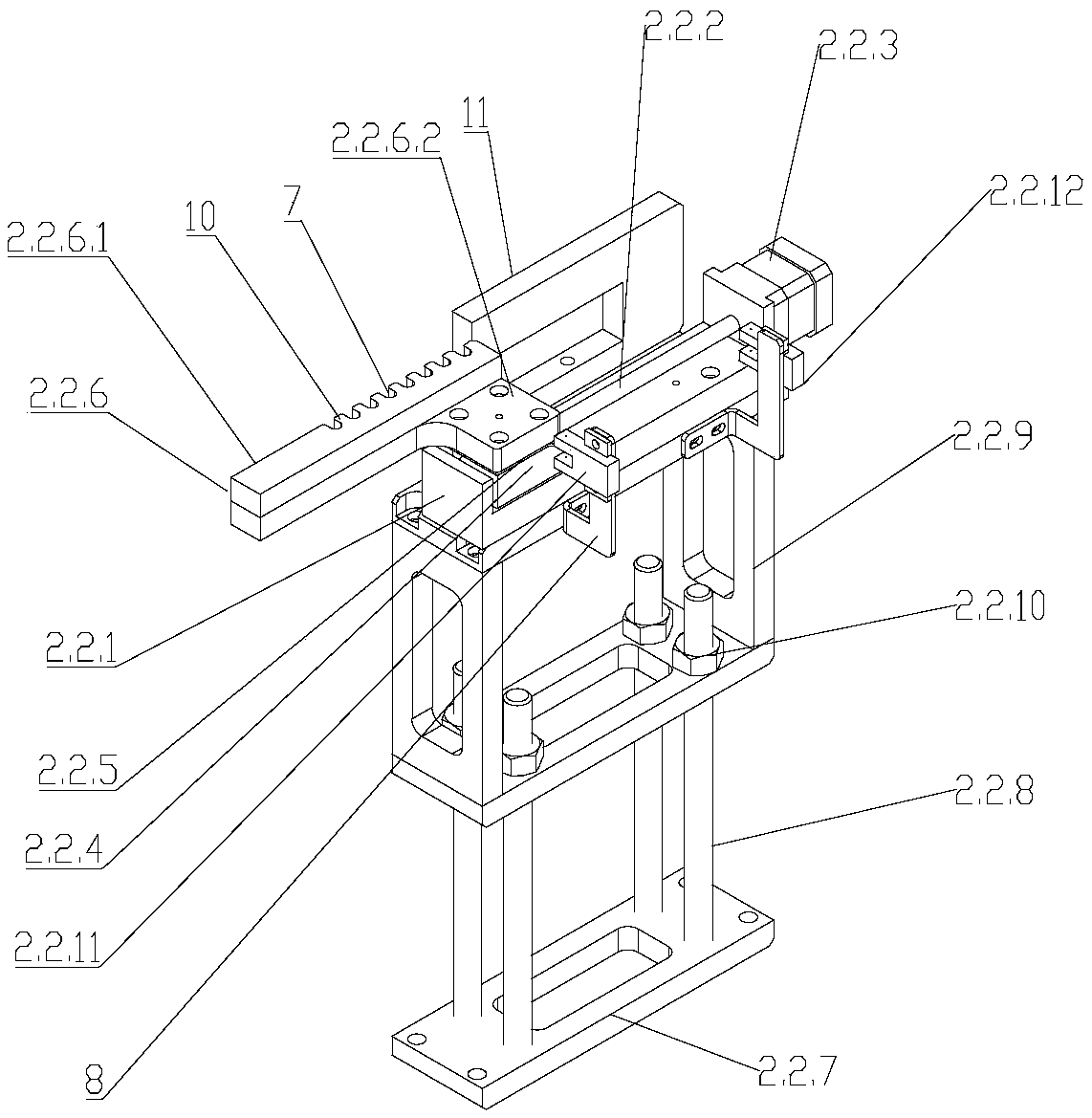

Fully-automatic pipette suction tip filling machine

PendingCN108792085AHigh degree of automationIncrease compatibilityPackaging automatic controlIndividual articlesSuction TipsEngineering

The invention discloses a fully-automatic pipette suction tip filling machine. The fully-automatic pipette suction tip filling machine comprises a rack, a plurality of sorting distributing units, a taking unit, a suction tip box storing plate for storing a suction tip box, and an electronic control box; an X-axial moving guide rail and a first driving device are fixed to the rack; the sorting distributing units comprise vibrating discs and distributing devices; the taking unit comprises a Y-axial moving guide rail, a second driving device, a Z-axial moving guide rail, a third driving device and a taking device; the first driving device, the second driving device and the third driving device control the taking device to move in the X-axis, Y-axis and Z-axis direction; and the electronic control box controls the first driving device, the sorting distributing units and the taking unit to automatically operate. According to the fully-automatic pipette suction tip filling machine, the wholeoperation process does not need human intervention, the automation degree is high, filling of suction tips of different specifications can further be automatically controlled, and the compatibility degree of the suction tips of different types is high.

Owner:上海括羽智能科技有限公司

High-temperature-resistant high-molecular conductive composite material

The invention belongs to the technical field of high molecular material, and especially relates to a high-temperature-resistant high-molecular conductive composite material. The high-temperature-resistant high-molecular conductive composite material is composed of, by weight, 40 to 55 parts of a high-molecular polymer base material, 15 to 20 parts of a conductive filler, 5 to 8 parts of an inorganic filler, 1 to 2 parts of a flame retardant, and 0.5 to 0.8 part of a dispersant. The method comprises the following steps: the high-molecular polymer base material, the conductive filler, the inorganic filler, the flame retardant and the dispersant are weighed at the formula ratio, and are mixed to be uniform so as to obtain a premixed raw material; melt blending and extruding are carried out soas to obtain the high-temperature-resistant high-molecular conductive composite material. According to a preparation method, the high-molecular polymer base material and the conductive filler are taken as main raw materials, and the flame retardant and the dispersant are added to provide the high-temperature-resistant high-molecular conductive composite material with high temperature resistance characteristic, and the compatibility degree of the various raw materials is increased; the adopted materials are nanometer grade particles, so that the conductivity is increased to a high degree, it is convenient for using, and the service life of the high-temperature-resistant high-molecular conductive composite material is prolonged.

Owner:安徽律正科技信息服务有限公司

Cell phone reading mode using image timer

InactiveUS20130248604A1Increase speed and efficiencyIncrease compatibilityPayment architectureSpecial data processing applicationsImage captureVideo camera

An EIR terminal containing an image capture device configured to scan an image. The EIR terminal includes a lighting and exposure mechanism. The EIR terminal also includes a camera sensor interface with a stat FIFO. The stat FIFO is configured to receive data from the image capture device. When the stat FIFO, during image scanning, receives a pre-determined amount of image data, it fires an interrupt, which times the lighting and exposure mechanism in the EIR terminal.

Owner:HONEYWELL INT INC

High-adhesion wear-resistant antifouling paint

InactiveCN104559673AStrong coveringGood dispersionAntifouling/underwater paintsPaints with biocidesEpoxyWear resistant

The invention discloses a high-adhesion wear-resistant antifouling paint which is prepared from the following raw materials in parts by weight: 32-35 parts of dicyclopentadiene phenol epoxy resin, 25-28 parts of terpene resin, 10-13 parts of phenol formaldehyde resin, 17-20 parts of iron-titanium dioxide composite modified polystyrene microsphere, 10-13 parts of light calcium carbonate, 4-8 parts of nano attapulgite, 1-3 parts of mica powder, 0.8-1.2 parts of silane coupling agent KH-550, 1.2-1.5 parts of curing agent, 0.6-0.9 part of defoaming agent, 1.5-1.8 parts of leveling agent, 1.2-1.5 parts of pigment and 50-53 parts of solvent.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Hydrophobic full-degradable plastic film and making method of hydrophobic full-degradable plastic film

The invention discloses a hydrophobic full-degradable plastic film and a making method of the hydrophobic full-degradable plastic film. The making method of the hydrophobic full-degradable plastic film lies in that polyvinyl alcohol and potato starch are used as main film forming matters, and compared with the prior art, the making method is characterized in that with the adoption of a physical-chemical method, nanosilicon dioxide and potato starch are modified, and at the same time, through matching with other effective constituents, hydroxide radicals in potato starch and polyvinyl alcohol molecules are enabled to be preferably combined with an appropriate amount of nanosilicon dioxide surface hydroxyl groups to form hydrogen bonds, so that the compatibility degree of potato starch and polyvinyl alcohol is increased, part of hydroxide radicals in the potato starch and polyvinyl alcohol are blocked, the water resisting property of the plastic film is improved, and the prepared full-degradable plastic film has a good mechanical property and hydrophobic property, and further has no impacts on the biodegradation rate and can enable the biodegradable plastics to be extensively applied.

Owner:TONGLING FOUNDER PLASTICS TECH

Hypervolume stable lithium battery and preparation method thereof

PendingCN109346655AGood electrical conductivityWide chemical windowMaterial nanotechnologyCell seperators/membranes/diaphragms/spacersOperating temperature rangeOrganic solvent

The invention discloses a hypervolume stable lithium battery, the hypervolume stable lithium battery comprises a positive electrode, a negative electrode, a composite membrane and a nonaqueous electrolyte; the nonaqueous electrolyte comprises a lithium salt, a room temperature ionic liquid electrolyte and a composite additive, wherein the room temperature ionic liquid electrolyte comprises a quaternary ammonium salt cationic liquid and a cosolvent at the mass ratio of 1:(0.1-0.5); and the composite membrane comprises a multi-arc hole fiber based membrane and an inorganic nanometer coating on the surface of the multi-arc hole fiber based membrane. Compared with the prior art, in the provided hypervolume stable lithium battery and a preparation method of the hypervolume stable lithium battery, the nonaqueous electrolyte uses an ionic liquid to replace the traditional organic solvent, the range of the working temperature of the battery is expanded, the stability on the metal lithium is good, the safety of the battery at the high-power density is further improved, the potential safety hazard of the battery is eliminated; the composite membrane guarantees the better mechanical propertyand the electric conductivity of the composite membrane, and meanwhile, the thermal stability of the membrane is improved. Therefore, the hypervolume stable lithium battery is higher in ionic conductivity and excellent in thermal stability, chemical stability and electrochemical stability.

Owner:江苏微能电子科技有限公司

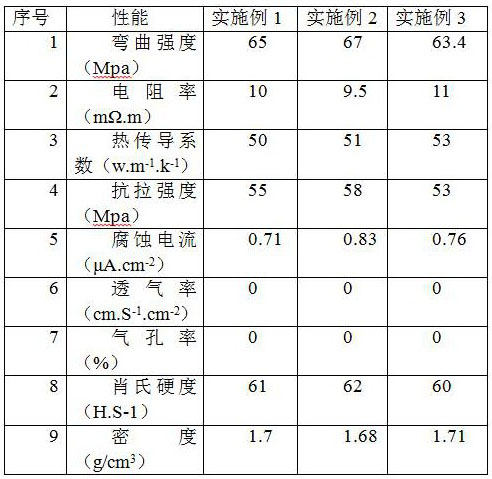

Composite graphite material for bipolar plate of fuel cell and preparation method of composite graphite material

The invention provides a composite graphite material for a fuel cell bipolar plate and a preparation method of the composite graphite material, and belongs to the field of novel composite graphite materials. The invention relates to a composite graphite material for a bipolar plate of a fuel cell, which comprises composite resin and a conductive filler. The invention also provides a preparation method of the composite graphite material for the bipolar plate of the fuel cell, which comprises the following steps: (1) mixing a phenolic resin solution, an acrylic acid solution and an epoxy resin solution to obtain a composite resin solution; (2) putting graphite powder, graphene, carbon microspheres and carbon black powder into a positive pressure stirrer to obtain a conductive filler; (3) grading and mixing the composite resin solution and conductive filler, and curing to obtain a composite graphite material; and according to the invention, the contact uniformity and the fitting degree are ensured. The prepared composite graphite material is high in corrosion resistance, high in toughness, good in compactness and high in conductivity.

Owner:ZHEJIANG HAROG TECH CO LTD

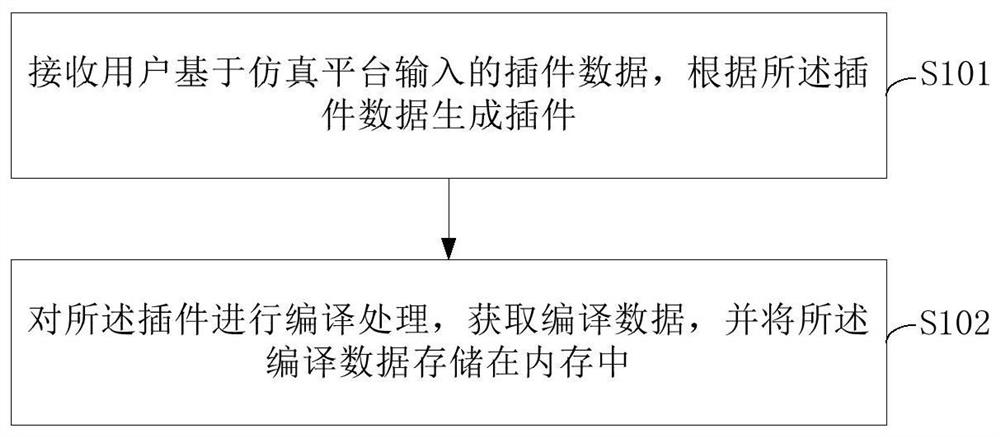

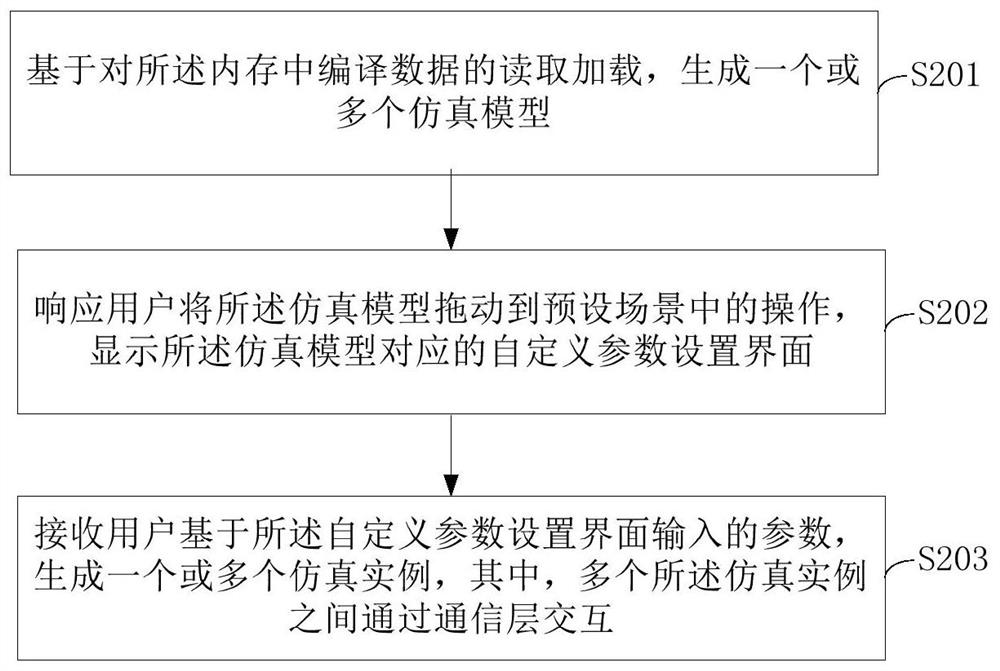

Simulation platform implementation method based on model driving

PendingCN113010227AIncreased speed of effectivenessHigh compatibilityDesign optimisation/simulationVisual/graphical programmingPlug-inData input

The invention provides a simulation platform implementation method based on model driving, and relates to a simulation technology. The method comprises the following steps: receiving plug-in data input by a user based on a simulation platform, and generating a plug-in according to the plug-in data; compiling the plug-in to obtain compiled data, and storing the compiled data in a memory; generating one or more simulation models on the basis of reading and loading the compiled data in the memory; responding to an operation of dragging the simulation model into a preset scene by a user, and displaying a user-defined parameter setting interface corresponding to the simulation model; receiving parameters input by a user based on the user-defined parameter setting interface to generate one or more simulation instances are generated, wherein the simulation instances interact with one another through a communication layer. According to the method, the speed of verifying the effectiveness of the simulation model by the platform is increased, and the compatibility degree of the platform to different simulation scenes is enhanced.

Owner:南京仁谷系统集成有限公司

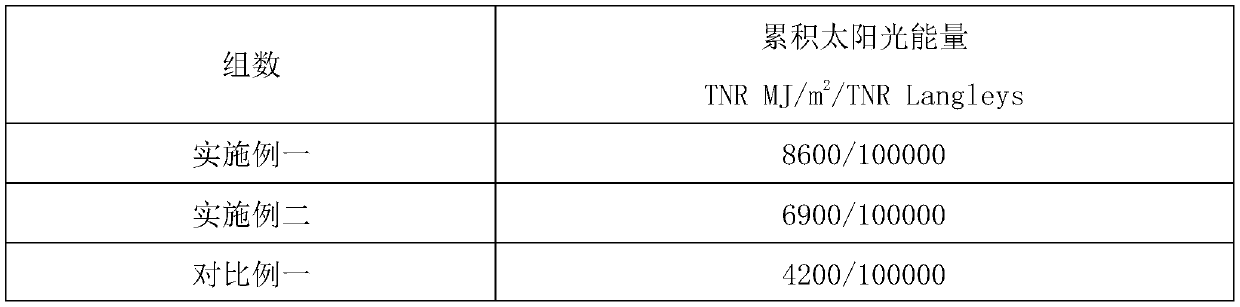

Weather-resistant automotive interior leather

PendingCN109849444AIncreased resistance to temperature changesGood weather resistanceFibre typesSynthetic resin layered productsWater basedWeather resistance

The invention discloses weather-resistant automotive interior leather. The automotive interior leather comprises a foaming base layer, a bonding layer, a thermoplastic polyurethane elastomer layer anda water-based polyurethane decorative layer from the bottom to the top; and the foaming base layer, the bonding layer and the thermoplastic polyurethane elastomer layer are bonded through hot pressing, the water-based polyurethane layer coats the thermoplastic polyurethane elastomer layer, the bonding layer is a TPU hot melt adhesive film, and especially a thermoplastic polyurethane elastomer isstructurally modified through aramid chopped fibers. According to the automotive interior leather provided by the invention, the purpose of performing modification through structural design and formulation to enhance the weather resistance of the automotive interior leather is realized.

Owner:烟台蓝海博隆超纤新材料有限公司

Light insect-proof fully-degradable plastic film and production method thereof

InactiveCN104893205AImprove water resistanceIncrease compatibilityBULK ACTIVE INGREDIENTPlastic film

The invention discloses a light insect-proof fully-degradable plastic film. Polyvinyl alcohol and brake root starch are adopted as main film-forming substances; compared with the traditional technology, nano silicon dioxide and brake root starch are modified in a physical-chemical method and matched with other active ingredients, so that hydroxyl in brake root starch and polyvinyl alcohol molecules can be combined with hydroxyl on the surface of an appropriate amount of nano silicon dioxide to form a hydrogen bond, the compatibility of the brake root starch and the polyvinyl alcohol can be improved, partial hydroxyl in the brake root starch and the polyvinyl alcohol is closed, the water resistance of the film can be improved, the prepared fully-degradable plastic film is light in weight and insect-proof and capable of being completely or partially degraded by microorganisms in the environment; moreover, the preparation method is simple in processing technology, capable of greatly reducing the production cost and easily realizing industrialized production and is good in industrial application prospect in the fields such as packaging, food transportation, agriculture and the like.

Owner:TONGLING FOUNDER PLASTICS TECH

Anticorrosive fresh-keeping fully-degradable plastic film for food packaging and preparation method thereof

InactiveCN104893202AIncrease compatibilityImprove water resistanceBULK ACTIVE INGREDIENTSilicon dioxide

The invention discloses an anticorrosive fresh-keeping fully-degradable plastic film for food packaging. Polyvinyl alcohol and cassava starch are adopted as film forming materials, and compared with the prior art, physical and chemical methods are adopted to perform modification on nano silicon dioxide and the cassava starch, and meanwhile other active ingredients are matched with the nano silicon dioxide and the cassava starch and cooperate with one another to ensure that hydroxyl radicals in the molecules of the cassava starch and polyvinyl alcohol can be bonded with an appropriate amount of hydroxyl radicals on the surface of the nano silicon dioxide in priority to form hydrogen bonds, so that the compatibility degree of the cassava starch and the polyvinyl alcohol is increased, the water resistance of the film is improved, and the prepared fully-degradable plastic film is high in strength and good in toughness, has good anticorrosive fresh-keeping performance and high temperature resistance, has a heat resistance temperature reaching 80-100 DEG C, can meet general use requirements, also can prevent static electricity, and is wide in application range and broad in prospect.

Owner:TONGLING FOUNDER PLASTICS TECH

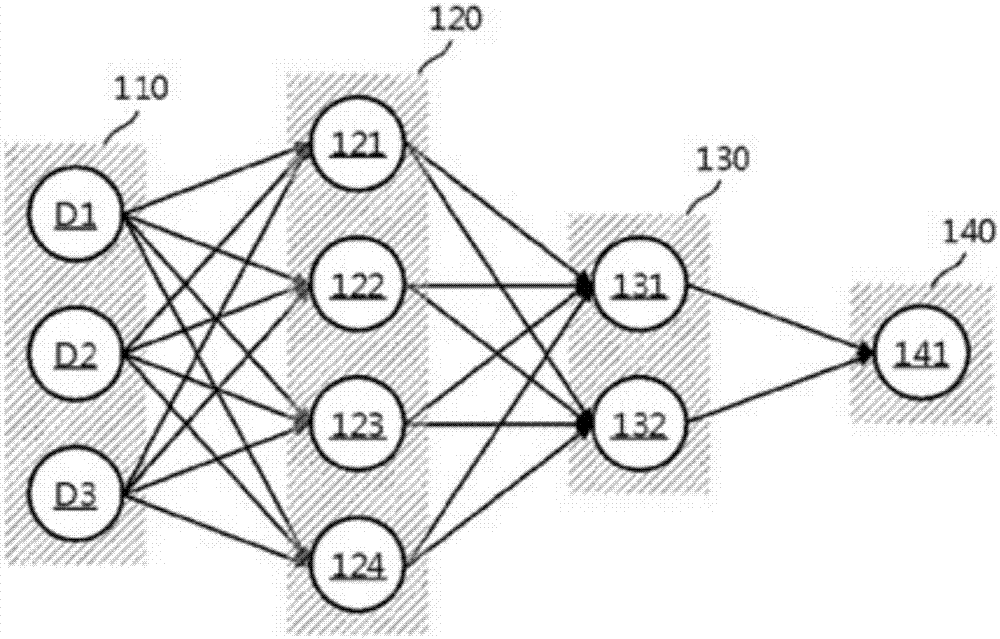

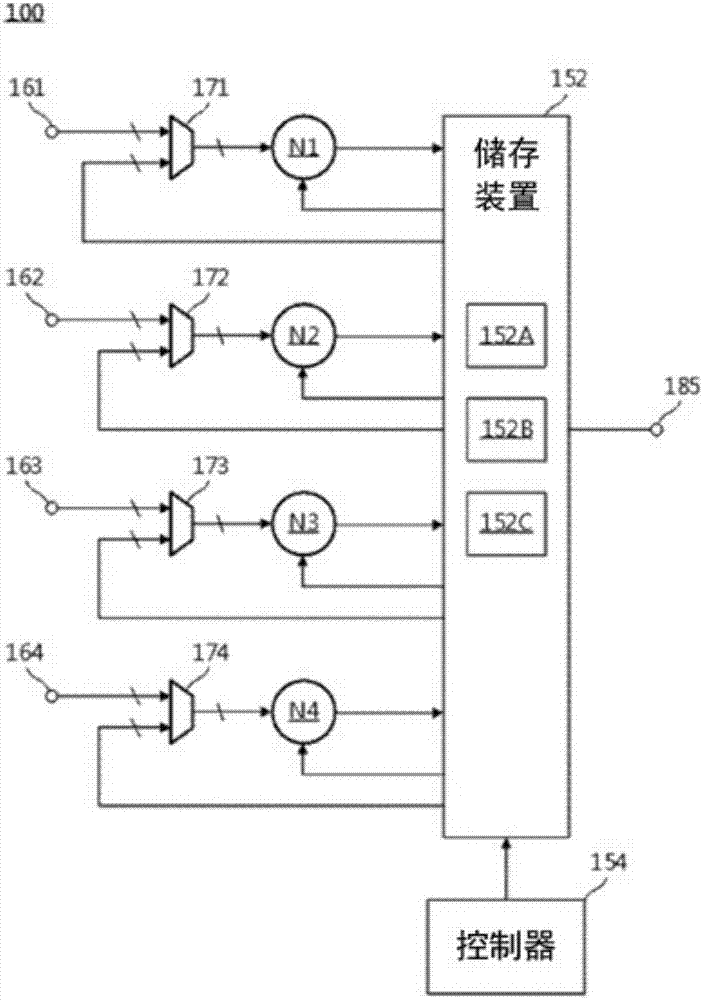

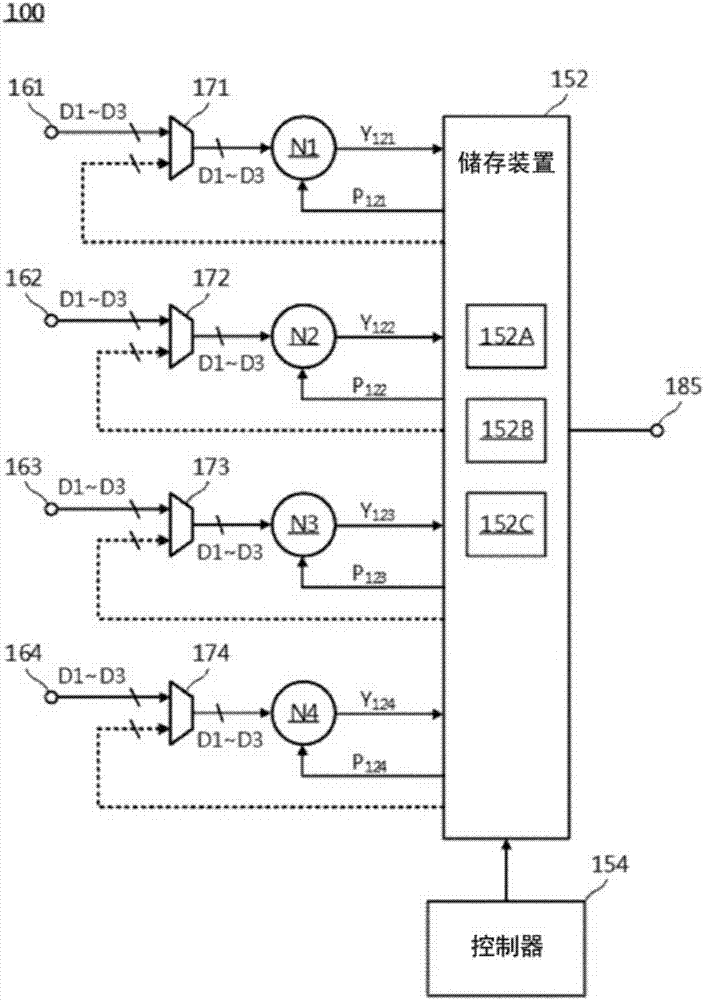

Multi-layer artificial neural network and controlling method thereof

ActiveCN107369108ALow costIncrease compatibilityData processing applicationsNeural architecturesNerve networkSimulation

A multi-layer artificial neural network including a plurality of artificial neurons, a storage device, and a controller is provided. The plurality of artificial neurons are used for performing computation based on plural parameters. The storage device is used for storing plural sets of parameters, each set of parameters being corresponding to a respective layer. At a first time instant, the controller controls the storage device to provide a set of parameters corresponding to a first layer to the plurality of artificial neurons so that the plurality of artificial neurons form at least part of the first layer. At a second time instant, the controller controls the storage device to provide a set of parameters corresponding to a second layer to the plurality of artificial neurons so that the plurality of artificial neurons format least part of the second layer.

Owner:KNERON INC

Full-degradable plastic film with good freezing resistance and toughness and production method thereof

InactiveCN104893208AImprove water resistanceExtensive sources of raw materialsPolyvinyl alcoholBULK ACTIVE INGREDIENT

The invention discloses a full-degradable plastic film with good freezing resistance and toughness. Polyvinyl alcohol and canna edulis ker starch are adopted as main film forming matters, and compared with the traditional technology, a physical-chemical method is adopted for modifying nano silica and canna edulis ker starch and other active ingredients are combined, so that hydroxyls in the canna edulis ker starch and polyvinyl alcohol can be preferentially bonded with right amount of hydroxyls on the surface of nano silica to form hydrogen bonds, compatibility of the canna edulis ker starch and polyvinyl alcohol can be enhanced, part of hydroxyls in the canna edulis ker starch and polyvinyl alcohol are blocked, and the water resistance of the film is improved. The obtained full-degradable plastic film has the advantages of wide raw material source, simple technology, full biodegradability and good freezing resistance and toughness.

Owner:TONGLING FOUNDER PLASTICS TECH

Non-aqueous electrolyte for lithium iron phosphate battery

The invention discloses a non-aqueous electrolyte for a lithium iron phosphate battery. The non-aqueous electrolyte comprises 70 to 85 weight percent of carbonic ester compound, 3 to 20 weight percent of various function additives and 11 to 17 weight percent of lithium hexafluorophosphate, wherein the carbonic ester compound is one of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate and diethyl carbonate or a mixture of more of the ethylene carbonate, the propylene carbonate, the butylene carbonate, the dimethyl carbonate and the diethyl carbonate; and the additives comprise one of 0.5 to 10 percent of film-forming additive, 0.5 to 10 percent of high-temperature additive, 0.5 to 10 percent of low-temperature additive, 0.5 to 10 percent of overcharge-preventing additive and 0.001 to 2 percent of stability additive, and a mixture of more of the additives. The non-aqueous electrolyte for the lithium iron phosphate battery has the advantages that the solubility and dissociation of the lithium hexafluorophosphate are improved, and electric conductivity is improved; the low temperature resistance of a solid electrolyte interphase (SEI) is reduced; the overall stability of the battery is improved, the overall service life of the battery is prolonged, the compatibility of an electrolyte and a cathode is improved, circulation of the battery is improved, and the service life is prolonged; and the non-aqueous electrolyte can have high performance at high temperature.

Owner:广东金光高科股份有限公司

Oil-proof pea protein powder-based full-degradable plastic film and preparation method thereof

InactiveCN104927265AIncrease compatibilityImprove water resistanceStress concentrationPolyvinyl alcohol

The invention discloses an oil-proof pea protein powder-based full-degradable plastic film. Polyvinyl alcohol and pea protein powder are used as main film forming matters, and compared with a traditional technology, the preparation method has the advantages that nano silica and pea protein powder are modified through physical and chemical methods and cooperate with other effective ingredients mutually, so that on one hand, hydroxyl groups in pea protein powder and polyvinyl alcohol molecules are preferentially combined with a proper amount of nano silica surface hydroxyl groups to form hydrogen bonds, therefore, the degree of compatibility of pea protein powder and polyvinyl alcohol is improved and the water resistance of the film is improved; on the other hand, uniformly-dispersed single nanoparticles and nano-clusters can generate stress concentration points, therefore, the strength of the film is improved, and the prepared full-degradable plastic film is transparent in appearance and smooth in surface and has the characteristics of heat resistance, excellent water resistance and oil resistance, high biodegradable speed and simple preparation method.

Owner:TONGLING FOUNDER PLASTICS TECH

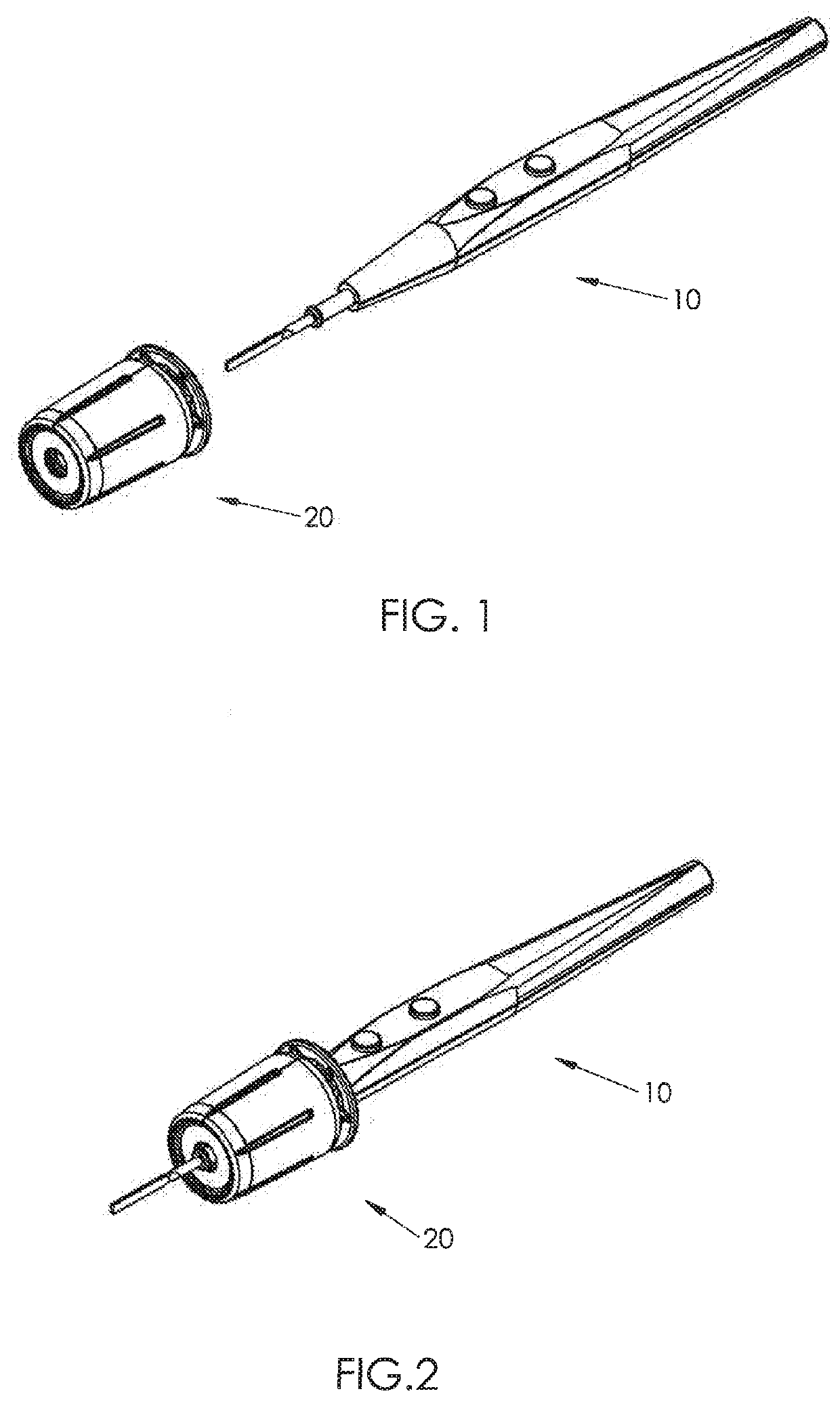

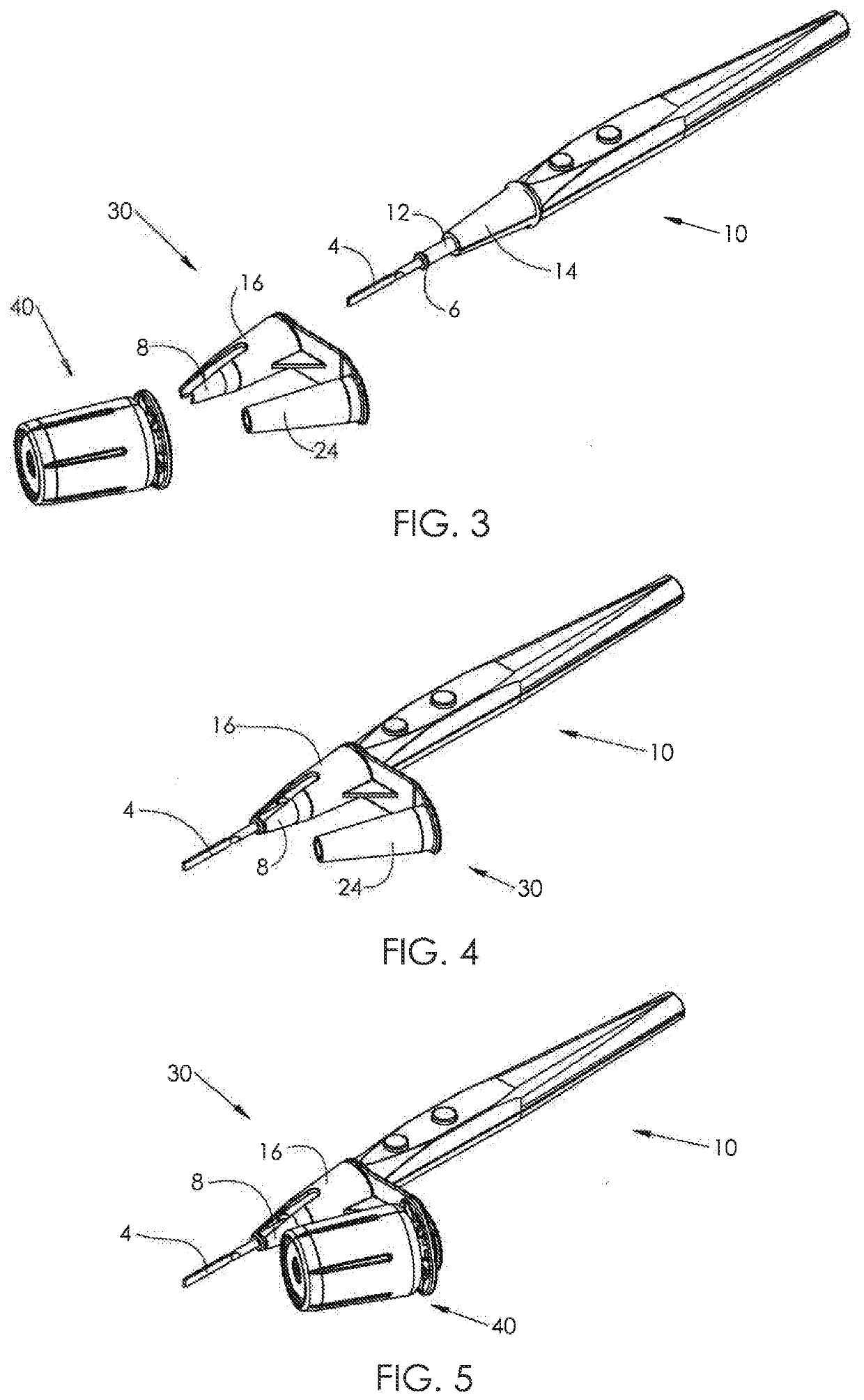

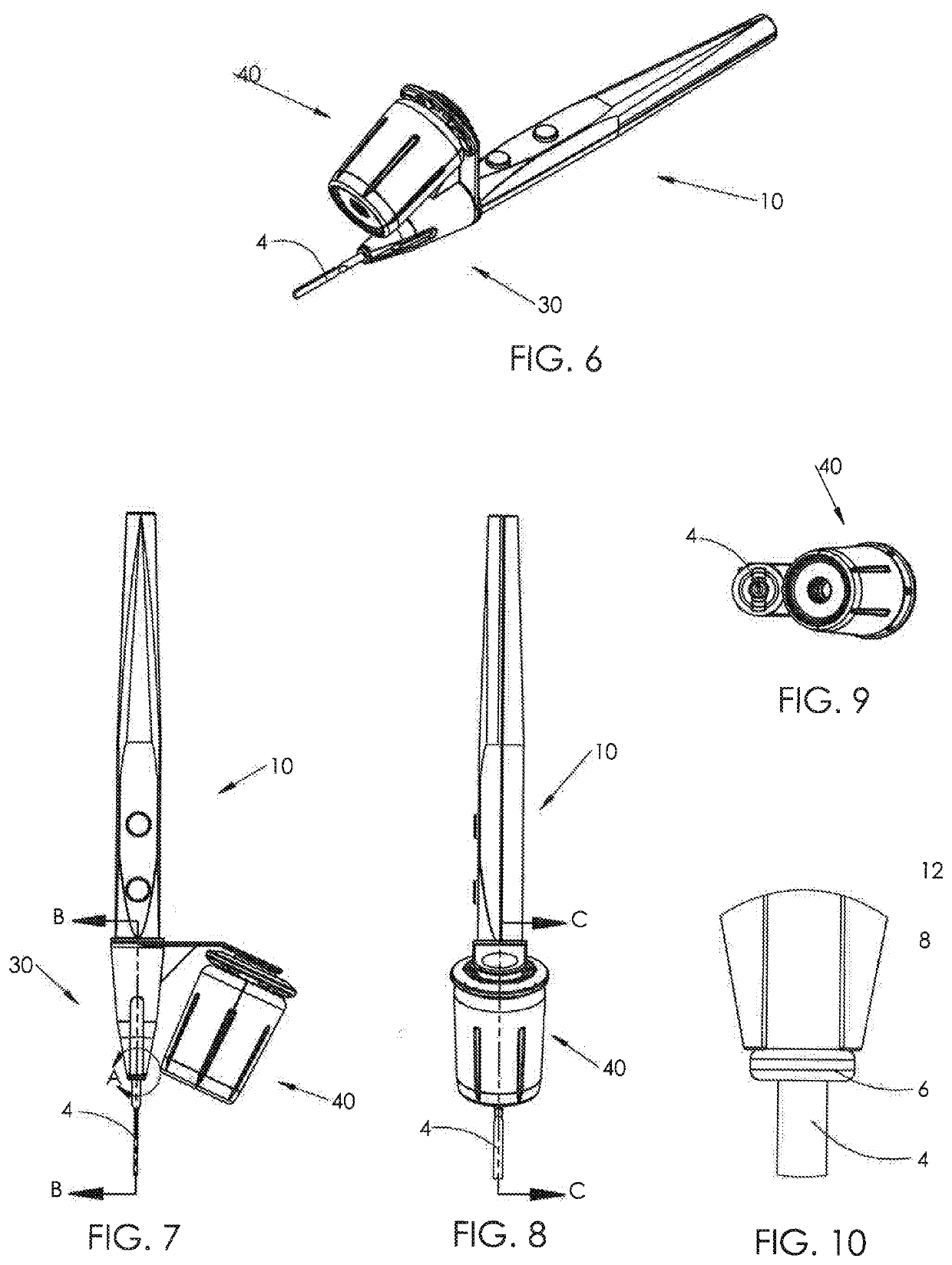

Adapter assembly for attaching a lighting device to a handheld electrosurgical instrument

ActiveUS20200121305A1Increase compatibilityImprove compatibilitySurgical furnitureDiagnosticsSurgical instrumentMedical physics

An adapter assembly is disclosed for attaching a lighting device to a handheld surgical instrument, which includes a first body portion configured to engage a distal end portion of the surgical instrument at a position along a central axis thereof, and a second body portion configured to support a lighting device adjacent the distal end portion of the surgical instrument, such that an illumination axis of the lighting device angularly intersects the central axis of the surgical instrument.

Owner:PATHY MEDICAL LLC

Method for manufacturing modified polyropylene fiber

ActiveCN102618963BWith chemical adsorption functionImprove gripOther chemical processesArtificial filament heat treatmentMethacrylatePolymer science

The invention discloses a method for manufacturing modified polyropylene fiber. The method is based on synthesizing a methacrylate ester polymer, realizes synchronous in-situ reaction compatibilization as well as spinning and forming synchronously in a double-screw extruder, integrates grafting and forming processes, ensures that prospective grafting reaction is conducted on materials during melting extrusion, and adopts the technological processes as follows: (1), a process for manufacturing the methacrylate ester polymer; (2), a process for in-situ reaction compatibilization and melt spinning; and (3) post-processing process for modified fiber: stretching the modified polyropylene fiber to be a fiber of which the length is 2 to 8 times that of the modified polyropylene fiber in a 70 to 130 DEG C hot box, and carrying out relaxation heat setting for 0.5 to 20 min in the 70 to 130 DEG C hot box, so as to obtain the modified polyropylene fiber.

Owner:TIANJIN POLYTECHNIC UNIV

Full-degradable plastic film with wide using temperature range and strong toughness and manufacturing method thereof

InactiveCN104893199AIncrease compatibilityImprove water resistancePlastic shopping bagPolyvinyl alcohol

The invention discloses a full-degradable plastic film with wide using temperature range and strong toughness. Polyving akohol and acorn starch are used as main film-forming materials for manufacturing the full-degradable plastic film. Compared with a traditional technology, a manufacturing method of the full-degradable plastic film has the advantages that nanosilicon dioxide and the acorn starch are modified by a physical chemistry method and mutually matched with other effective constituents at the same time so that the acorn starch and hydroxide radicals in polyving akohol molecules are preferentially combined with surface hydroxyl groups of a defined amount of nanosilicon dioxide to form hydrogen bonds, thus increasing the compatibility of the acorn starch and the polyving akohol and improving the water tolerance of the film. The manufactured full-degradable plastic film has excellent biodegradability, good toughness, relatively high tear resistance and wide using temperature range, can meet the performance requirements of plastic products producing relatively serious white pollution such as disposable packages, tableware and plastic shopping bags on the market and is wide in application prospect.

Owner:TONGLING FOUNDER PLASTICS TECH

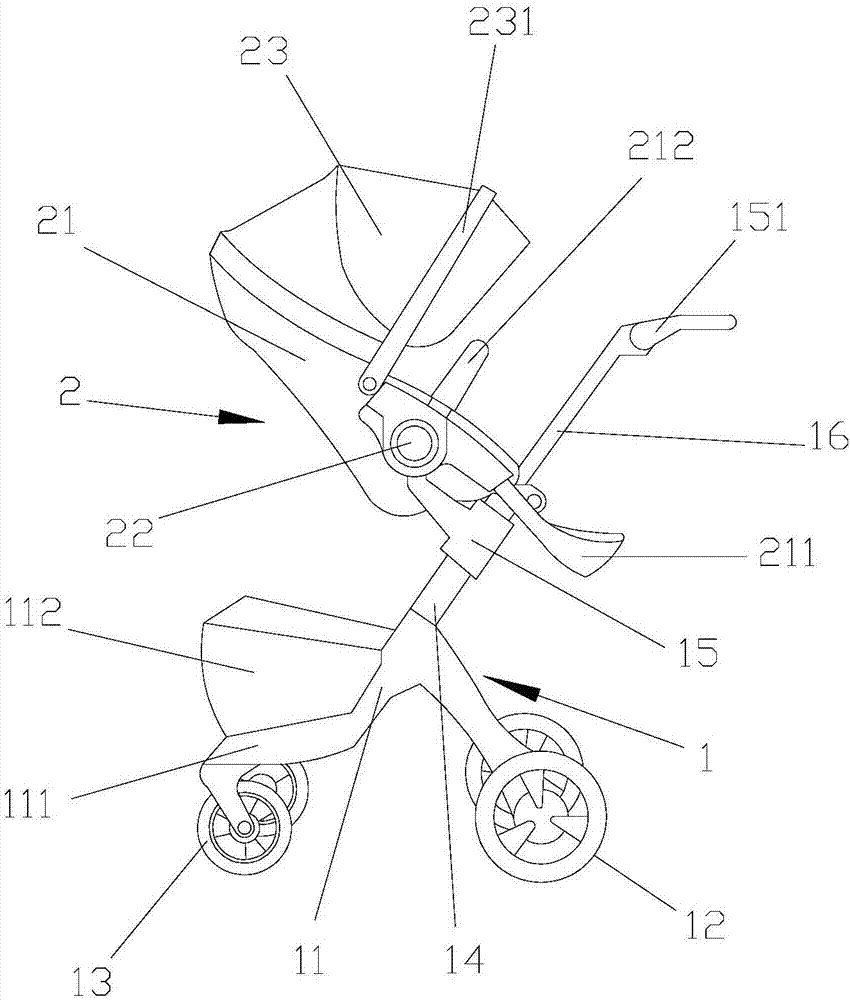

Baby stroller adopting electric automatic folding

ActiveCN107972720AHigh hardnessHigh densityCarriage/perambulator with multiple axesVehicle frameEngineering

The invention discloses a baby stroller adopting electric automatic folding. The baby stroller comprises an electric stroller frame and a baby seat arranged above the electric stroller frame, and thebaby seat and the electric stroller frame are fixed; the electric stroller frame comprises a stroller frame main body, rear wheels arranged on one side of the lower portion of the stroller frame mainbody, front wheels arranged on the other side of the lower portion of the stroller frame main body, an electric pushing rod arranged above the stroller frame main body, a fixing seat arranged at the upper end of the electric pushing rod and a main rod arranged above the electric pushing rod and connected with the electric pushing rod, wherein the fixing seat and the electric pushing rod are fixed;and the baby seat comprises a seat body, screws arranged on both sides of the seat body and used for being connected with the fixing seat and a canopy arranged at the upper end of the seat body and used for sunshading. By combining the electric stroller frame and the baby seat to form the baby stroller capable of being folded electrically and automatically, using through folding can be convenientfor a user, and the baby stroller adopting electric automatic folding has the advantages of being safe, reliable, convenient to use and quick in automatic folding.

Owner:浙江多宝贝科技有限公司

Transparent anti-impact hard PVC particle composition and preparation method thereof

The invention discloses a transparent anti-impact hard PVC particle composition and a preparation method thereof. The transparent impact-resistant hard PVC particle composition is characterized in that vinyl chloride-vinyl acetate-butyl acrylate ternary copolymerized resin is used as a bridging agent and cooperates with other modifiers, then mixed granulation is performed to obtain the transparent anti-impact hard PVC particle composition; the composition comprises the following components in parts by weight with each 100 parts by weight of PVC as the benchmark: 100 parts of polyvinyl chloride, 8-15 parts of an anti-impact modifier, 0-4 parts of a bridging agent, 1-3 parts of a heat stabilizer, 2-3 parts of a plasticizer, 0.3-0.8 part of a lubricant, and 0.1-0.3 part of a color toner. By selection of the particle size of anti-impact modifier colloidal particles and introduction of the vinyl chloride-vinyl acetate-butyl acrylate ternary copolymerized resin as the bridging agent, the transparent anti-impact rigid PVC particle formula is improved, the purpose of improving the impact resistance and transparency of the material is finally reached, and the requirements of high-quality transparent anti-impact hard PVC products on high transparency and high impact resistance are met.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD

Compound branched chain amino acid injection

ActiveCN101332195AAdjustability hasIncrease contentOrganic active ingredientsMetabolism disorderBlood plasmaNitrogen balance

The present invention provides a compound branched chain amino acid injection. The injection provided by the present invention increases the weight parts of the branched chain amino acid to lead the weight parts within 35 to 50 percent of the total amount of amino acid and effectively keeps a nitrogen balance of the organism; the prescription ratio of necessary amino acid and unnecessary amino acid is increased to about 1.7, thus better recovering the inordinate plasma amino acid spectrum of the organism in trauma to the normal range and achieving the ideal nutritious effect on the patient under the stress state.

Owner:MITSUBISHI PHARMA GUANGZHOU

UV-cured heat-conducting silica gel composition

ActiveCN114774074AGood compatibilityGood dispersionNon-macromolecular adhesive additivesHeat-exchange elementsPolymer scienceSilica gel

The invention relates to the technical field of heat-conducting electronic adhesives, and provides a UV-cured heat-conducting silica gel composition which comprises the following raw material components in parts by weight: 100 parts of modified polysiloxane, 1-1000 parts of a modified heat-conducting filler, 1-5 parts of a photoinitiator and 5-20 parts of a curing aid, the structural general formula of the modified polysiloxane is (R1O) 3-nSiMenCH2CH2SiMe2 (OSiMe2) a (OSiMeR2) b (OSiMeR3) cOSiMe2CH2CH2MenSi (R1O) 3-n, and the structural general formula of the curing aid is ViSiMe2 (OSiMe2) x (OSiMeR6) yOSiMe2Vi. The UV-cured heat-conducting silica gel composition disclosed by the invention is good in mechanical property, good in heat conductivity and high in adhesion strength after being cured.

Owner:XIAMEN WELDTONE TECH CO LTD

High-strength high-elasticity fully degradable plastic film and preparation method thereof

InactiveCN104893204AIncrease compatibilityImprove water resistanceStress concentrationPolyvinyl alcohol

The invention discloses high-strength high-elasticity fully degradable plastic film taking polyvinyl alcohol and sweet potato starch as main film forming substances. Compared with a traditional technique, a preparation method provided by the invention has the characteristics that a physical-chemical method is adopted to modify nano silica and potato starch in cooperation with other active ingredients, so that hydroxyls in sweet potato starch and polyvinyl alcohol molecules preferably bond with a proper amount of hydroxyls on the surface of nano silica to form hydrogen bonds so as to increase the compatibility degree of sweet potato starch and polyvinyl alcohol and further improve the waterproofness of the film; and moreover uniformly dispersed single nano particles and nanoclusters can form a stress hard spot to improve the strength of the film. The prepared fully degradable plastic film is transparent, soft, non-poisonous, harmless and fully degradable and has high elasticity.

Owner:TONGLING FOUNDER PLASTICS TECH

Non-toxic polyvinyl alcohol environment-friendly full-degradable plastic film and manufacture method thereof

The invention discloses a non-toxic polyvinyl alcohol environment-friendly full-degradable plastic film. Polyvinyl alcohol and wheat starch are used as main film forming matters, and compared with a traditional technology, the invention has the advantages that nano silica and wheat starch are modified through physical and chemical methods and cooperate with other effective ingredients mutually, so that hydroxyl groups in wheat starch and polyvinyl alcohol molecules are preferentially combined with a proper amount of nano silica surface hydroxyl groups to form hydrogen bonds, therefore, the degree of compatibility of wheat starch and polyvinyl alcohol is improved, partial hydroxyl groups in the wheat starch and polyvinyl alcohol are sealed, water resistance of the film is improved and the prepared full-degradable plastic film has the advantages of non-toxicity, hydrophobicity, fertilizer conservation and the like and can be used as an agricultural film.

Owner:TONGLING FOUNDER PLASTICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com