Composite graphite material for bipolar plate of fuel cell and preparation method of composite graphite material

A composite graphite and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of material toughness and airtightness not meeting the requirements, poor toughness, low conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

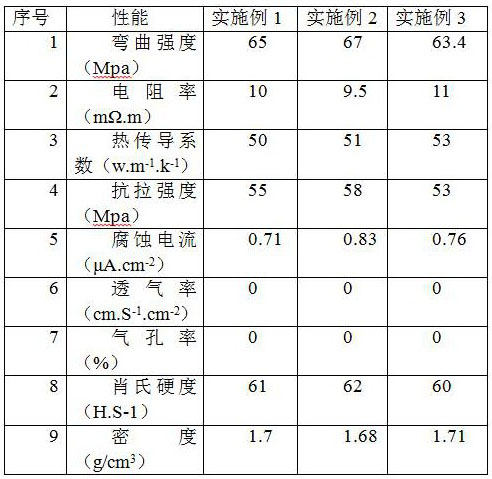

Embodiment 1

[0023] A composite graphite material for a fuel cell bipolar plate, comprising composite resin and conductive filler, the mass ratio of the composite resin to conductive filler is 25:65, and the composite resin amount includes 2 parts by weight of phenolic resin , 0.3 parts of acrylic acid, 6.0 parts of epoxy resin, the conductive filler includes 7.5 parts of expanded graphite powder, 0.2 part of graphene, 0.4 part of carbon microspheres, and 0.6 part of carbon black powder by weight.

[0024] A method for preparing a composite graphite material based on the aforesaid fuel cell bipolar plate, comprising the following steps:

[0025] (1) The phenolic resin solution, acrylic acid solution, epoxy resin solution, solubilizer, toughener, and antioxidant are sprayed into the negative pressure resin mixer according to a certain mass fraction ratio through a controllable multi-channel injector to obtain a composite resin solution , the pressure of the negative pressure resin stirrer i...

Embodiment 2

[0031] A composite graphite material for a fuel cell bipolar plate, comprising composite resin and conductive filler, the mass ratio of the composite resin to conductive filler is 27:73, and the composite resin amount includes 2.5 parts by weight of phenolic resin , 0.5 parts of acrylic acid, 7.0 parts of epoxy resin, the conductive filler includes 8.5 parts of expanded graphite powder, 0.1 part of graphene, 0.5 part of carbon microspheres, and 0.9 part of carbon black powder by weight.

[0032] A method for preparing a composite graphite material based on the aforesaid fuel cell bipolar plate, comprising the following steps:

[0033] (1) The phenolic resin solution, acrylic acid solution, epoxy resin solution, solubilizer, toughener, and antioxidant are sprayed into the negative pressure resin mixer according to a certain mass fraction ratio through a controllable multi-channel injector to obtain a composite resin solution , the pressure of the negative pressure resin agitato...

Embodiment 3

[0039] A composite graphite material for a fuel cell bipolar plate, comprising composite resin and conductive filler, the mass ratio of the composite resin and conductive filler is 25:60, and the composite resin amount includes 2.3 parts by weight of phenolic resin , 0.4 part of acrylic acid, 6.5 parts of epoxy resin, described conductive filler comprises 8 parts of expanded graphite powder, 0.15 part of graphene, 0.45 part of carbon microsphere, 0.7 part of carbon black powder by weight.

[0040] The mass ratio of the composite resin to the conductive filler is 27:73, the composite resin amount includes 2.5 parts by weight of phenolic resin, 0.5 part of acrylic acid, and 7.0 parts of epoxy resin, and the conductive filler includes expansion by weight. 8.5 parts of graphite powder, 0.1 part of graphene, 0.5 parts of carbon microspheres, and 0.9 parts of carbon black powder.

[0041] A method for preparing a composite graphite material based on the aforesaid fuel cell bipolar p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com