UV-cured heat-conducting silica gel composition

A heat-conducting silica gel and composition technology, applied in the direction of adhesives, heat exchange materials, adhesive additives, etc., can solve the problems of incomplete curing, etc., and achieve the effect of being conducive to construction, good adhesion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

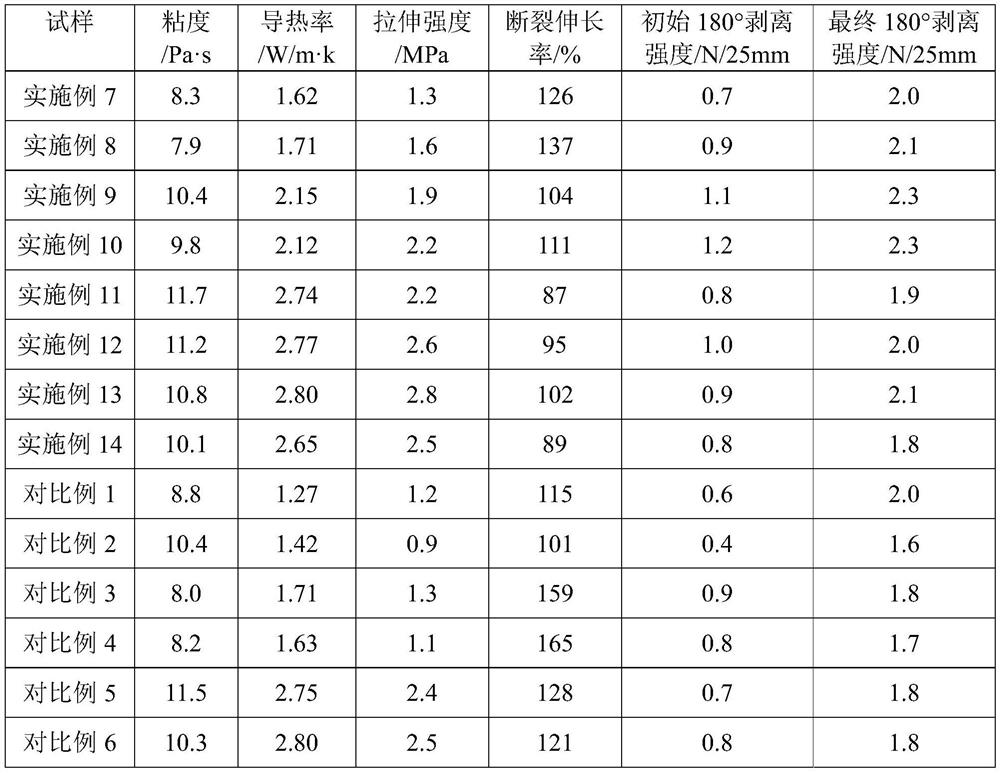

Examples

Embodiment 1~3

[0050] Examples 1-3 Preparation of Modified Polysiloxane

Embodiment 1

[0052] Polysiloxane ViSiMe 2 (OSiMe 2 )a (OSiMeR 2 ) b (OSiMeR 3 ) c OSiMe 2 Vi, Me, Vi as above, R 2 is 3-methacryloyloxypropyl, R 3 is phenyl, a:b:c=0.88:0.07:0.05, and the polysiloxane viscosity (25°C) is 2750 mPa.s. Polysiloxane can be composed of octamethylcyclotetrasiloxane, 3-methacryloyloxypropylmethyldimethoxysilane and tetramethyltetraphenyl, with tetramethylammonium hydroxide as a catalyst, Tetramethyldivinyldisiloxane is used as end-capping agent, and it is obtained by reaction at 110-120°C.

[0053] The above-mentioned polysiloxane and trimethoxyhydrosilane are put into the reaction vessel at a ratio of 1:2 of the molar number of vinyl in the polysiloxane and the mole number of silicon-hydrogen bonds in the trimethoxyhydrosilane, and the reaction system weight is 0.1wt. % hydroquinone, be warming up to 90 ℃ and add Karstedt catalyst (in terms of Pt, add-on is 20ppm of the weight of the reaction system), maintain the reaction temperature at 110-120 ℃ and r...

Embodiment 2

[0055] Polysiloxane ViSiMe 2 (OSiMe 2 ) a (OSiMeR 2 ) b OSiMe 2 Vi, Me, Vi as above, R 2 It is 3-methacryloyloxypropyl group, a:b=0.95:0.05, and the polysiloxane viscosity (25°C) is 3840 mPa.s.

[0056] The above-mentioned polysiloxane and trimethoxyhydrosilane are put into the reaction vessel at a ratio of 1:1.8 of the number of moles of vinyl in the polysiloxane and the number of moles of silicon-hydrogen bonds in the trimethoxyhydrosilane, and 0.1wt of the reaction system weight is added. % hydroquinone, be warming up to 90 ℃ and add Karstedt catalyst (by Pt, the addition is 20ppm of the weight of the reaction system), maintain the reaction temperature at 110-120 ℃ and react for 3.5 hours, remove the excess trimethoxyl group under reduced pressure Hydrosilane, to obtain a modified polysiloxane, the viscosity at 25°C is 4270 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com