Weather-resistant automotive interior leather

A technology for automotive interior and weather resistance, applied in the direction of layered products, fiber types, synthetic resin layered products, etc., can solve the problems affecting the service life of TPU interior leather, and achieve the effect of improving weather resistance and compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

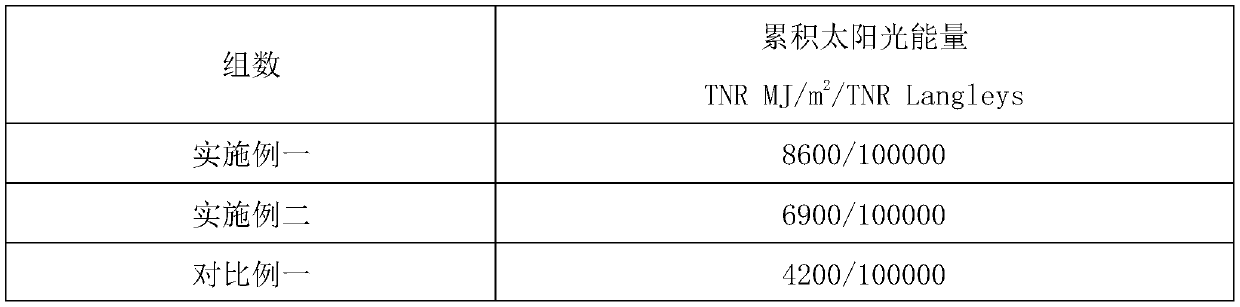

Embodiment 1

[0029] A weather-resistant automotive interior leather, comprising a bottom-up foaming base layer, a bonding layer, a thermoplastic polyurethane elastomer layer and a water-based polyurethane decorative layer, between the foaming base layer, the bonding layer, and a thermoplastic polyurethane elastomer layer Bonded by hot pressing, the water-based polyurethane layer is coated on the thermoplastic polyurethane elastomer layer, and the adhesive layer is a TPU hot-melt adhesive film, characterized in that: the thermoplastic polyurethane elastomer layer is made in the following manner : Mix the following raw materials according to the ratio of parts by weight, including 100 parts of TPU particles, 15 parts of cheap agent, 8 parts of aramid chopped fiber, 2 parts of thickener, 2 parts of polytetrahydrofuran glycol, 2 parts of carboxylate , put the mixture into the internal mixer and mix evenly, then further mix through the open mill and calender into a film through the pair of rolle...

Embodiment 2

[0043] A weather-resistant automotive interior leather, comprising a bottom-up foaming base layer, a bonding layer, a thermoplastic polyurethane elastomer layer and a water-based polyurethane decorative layer, between the foaming base layer, the bonding layer, and a thermoplastic polyurethane elastomer layer Bonded by hot pressing, the water-based polyurethane layer is coated on the thermoplastic polyurethane elastomer layer, and the adhesive layer is a TPU hot-melt adhesive film, characterized in that: the thermoplastic polyurethane elastomer layer is made in the following manner : Mix the following raw materials according to the ratio of parts by weight, including 100 parts of TPU particles, 15 parts of cheap agent, 8 parts of aramid chopped fiber, 2 parts of thickener, 2 parts of polytetrahydrofuran glycol, 2 parts of carboxylate , put the mixture into the internal mixer and mix evenly, then further mix through the open mill and calender into a film through the pair of rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com