Patents

Literature

194results about How to "Excellent corrosion protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin-oxidized graphene composite coating and application method thereof

InactiveCN104356860AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated surface

The invention provides an epoxy resin-oxidized graphene composite coating. The composite coating is prepared by using oxidized graphene as a packing and adding the packing to epoxy resin coating. A coating layer prepared on the surface of a matrix by utilizing the composite coating is excellent in binding force of the matrix, and further greatly improved in corrosion resistance, so as to effectively obstruct a corrosive medium from penetrating from the surface of the coating layer to the path of the matrix. Therefore, the epoxy resin-oxidized graphene composite coating is good in application prospect, and in particular suitable for the matrix in a highly-corrosive severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

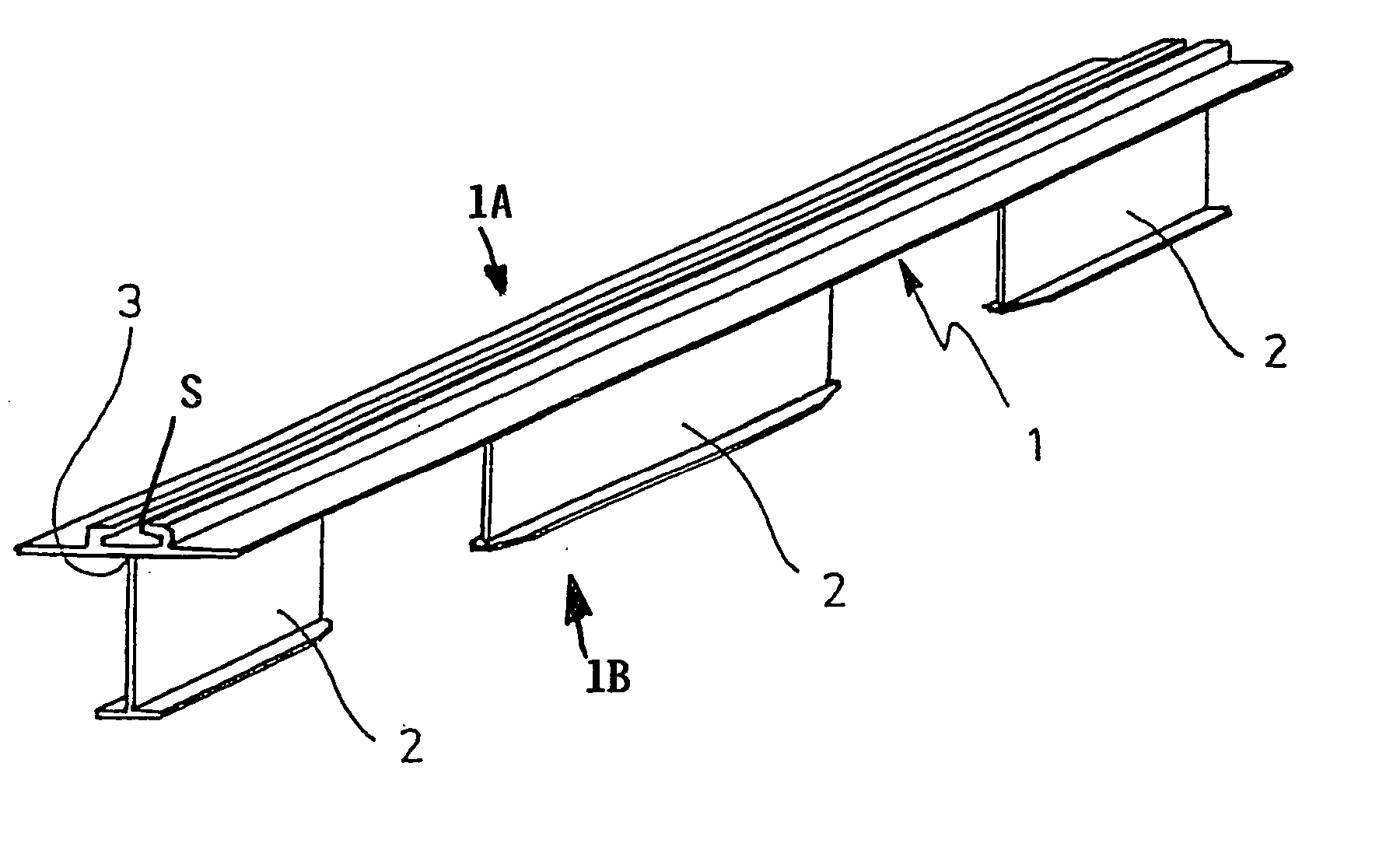

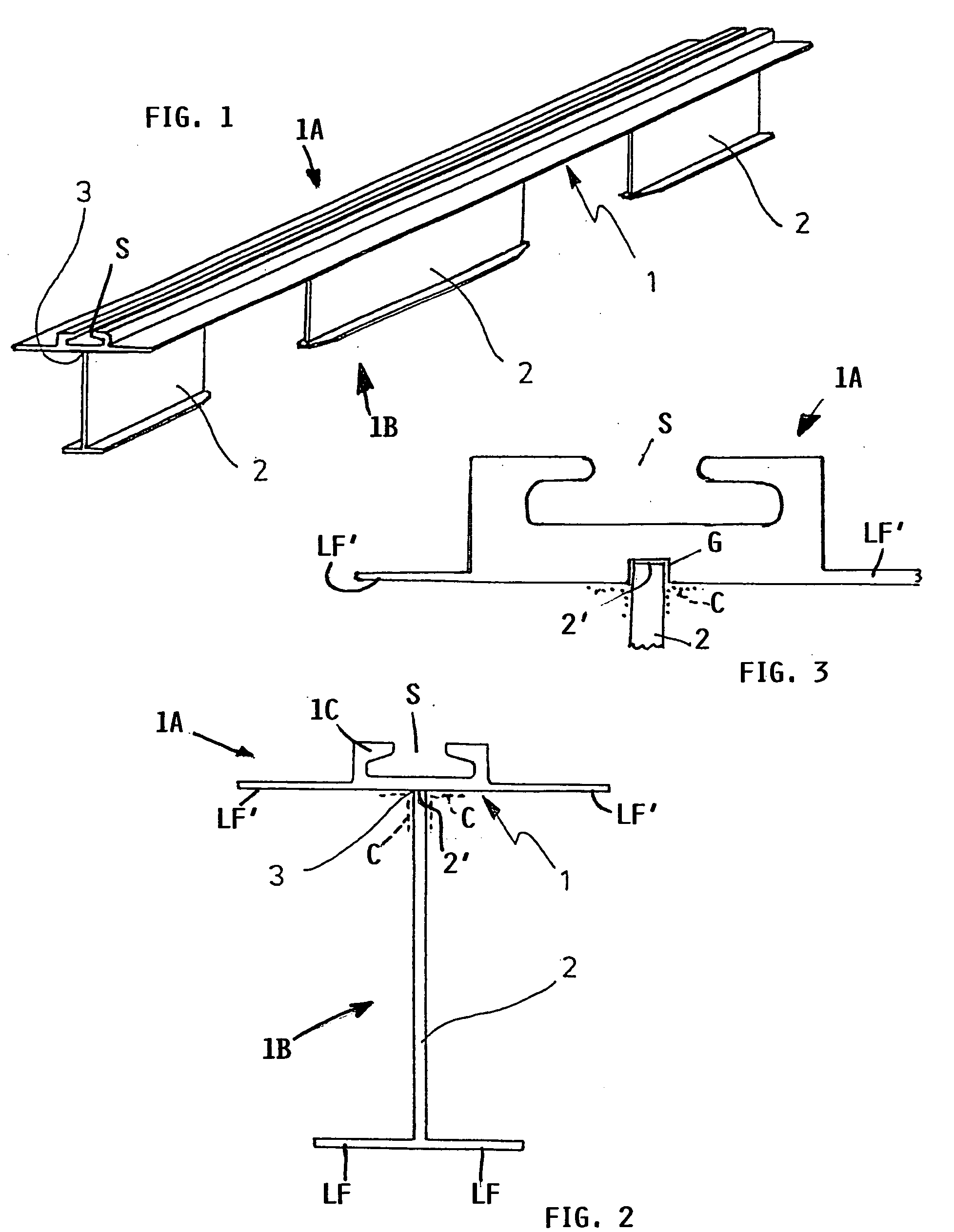

Seat mounting rail, particularly for a commercial aircraft

ActiveUS20050133666A1Improve corrosion resistanceAvoids significant weight increaseSeating arrangementsAir-treatment apparatus arrangementsEngineeringInterconnection

A seat mounting rail for securing seats to a floor of a passenger aircraft is made of a seat securing upper section and a rail mounting lower section. Both sections are made of different metals. The upper section is made of a titanium alloy for corrosion protection. The lower rail section is made of an aluminum alloy for weight reduction. The interconnection between the two sections is made as a thermal joint for example formed as a laser weld, which is preferably a butt weld to save welding material.

Owner:AIRBUS OPERATIONS GMBH

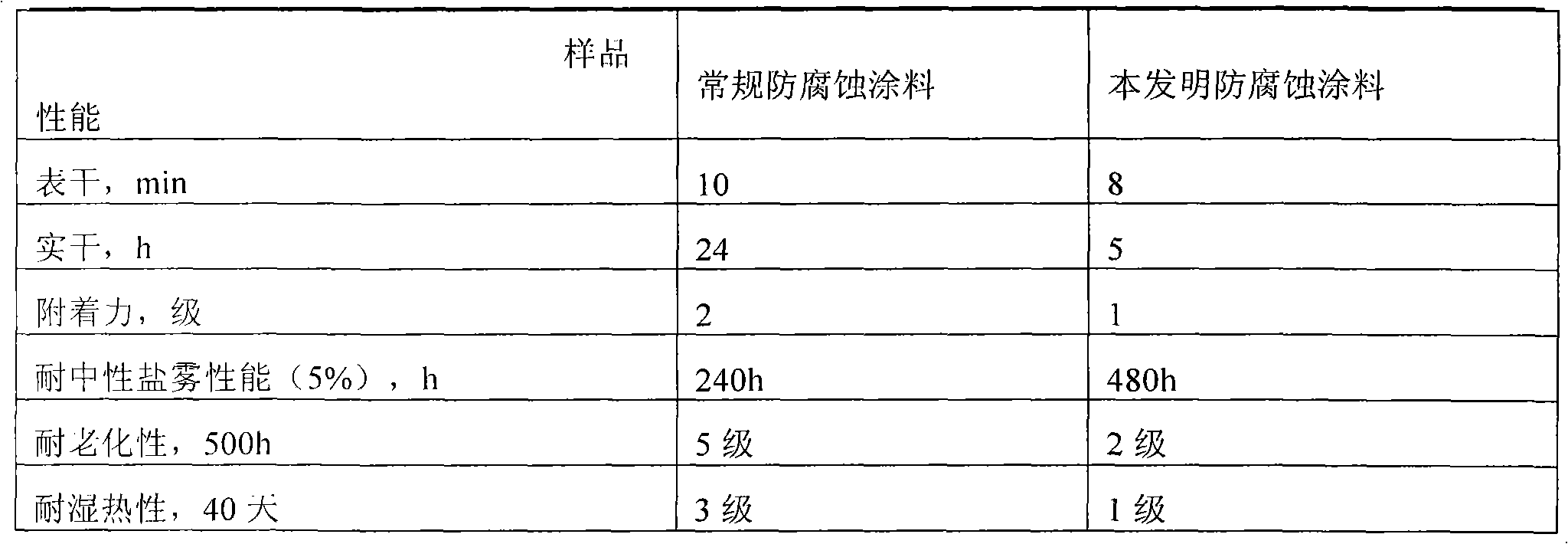

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

Preparation of metal working fluid special for aluminum alloy

InactiveCN101696367AExcellent lubricity and protection against aluminumExcellent corrosion protectionLubricant compositionCorrosionSemi synthetic

The invention relates to a semi-synthetic metal working fluid special for aluminum and aluminum alloys, which has an excellent lubricating property and protective properties for aluminum and various aluminum alloys. The excellent lubricating property of the metal working fluid is manifested by simultaneously satisfying various processing modes of the aluminum alloys, such as turning, milling, drilling, tapping and the like. The excellent protective properties for the aluminum and the aluminum alloys are manifested by processing various aluminum alloys, generating no corrosion to the aluminum alloys and ensuring the requirements on the luminance brightness of the aluminum alloys. Besides, the metal working fluid also has excellent anti-rust properties and anti-foaming properties, and is added with a biological inhibitor which can effectively inhibit the growth and the reproduction of bacteria, prolong the service life of the metal working fluid and reduce the cost.

Owner:益田润石(北京)化工有限公司

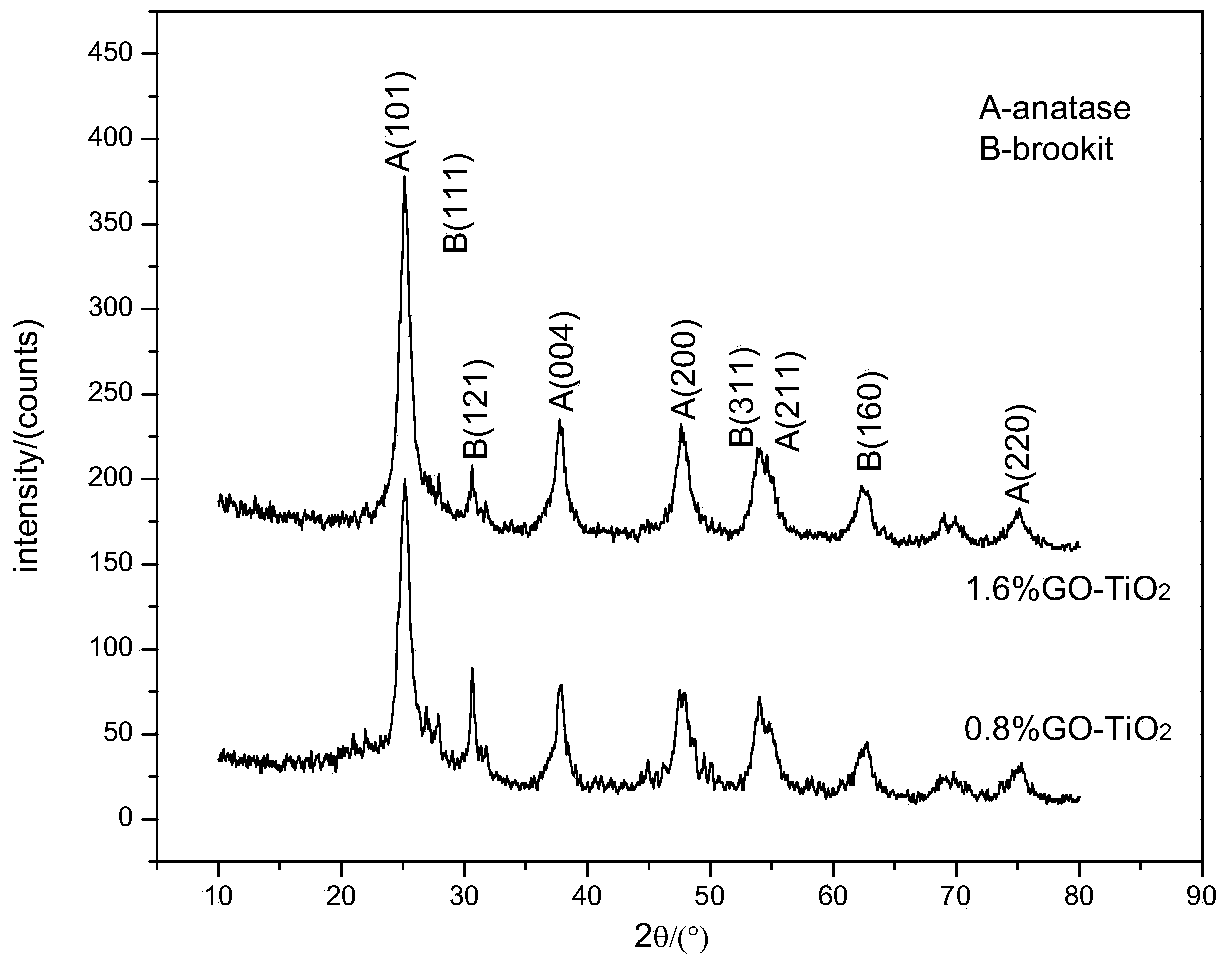

Making method of graphene modified titanium oxide metal anticorrosion coating

ActiveCN104388923AImprove electron transfer efficiencyNo reunionLiquid/solution decomposition chemical coatingSilanesPhotocathode

The invention discloses a making method of a graphene modified titanium oxide metal anticorrosion coating. The method comprises the following steps: preparing a graphene precursor solution, preparing a titanium oxide sol, preparing graphene modified titanium oxide powder, preparing a silane sol, making a composite coating, and making the metal anticorrosion coating. The thickness of the anticorrosion coating is 200-500nm. TiO2 particles in the graphene modified titanium oxide powder have uniform scales, and are uniformly distributed on a reduced graphene oxide layer, the crystal form structure of TiO2 is an anatase phase and brookite mixed crystal form, and the anatase phase and brookite mixed crystal form forms a compound energy zone structure, so the luminous energy utilization rate of titanium oxide is improved, the transfer path of electrons in the titanium oxide photocathode protection process is prolonged, the electron-hole recombination is reduced, and the photoinduced cathode protection effect of the coating is improved.

Owner:三防(山东)新材料科技有限公司

Multifunctional automobile protective wax and preparation method thereof

The invention discloses a multifunctional automobile protective wax, which comprises the following components: 19.6-30% of original wax formed by microcrystalline wax and paraffin, 10-13% of emulsifier formed by stearic acid and triethanolamine, 4.1-6.3% of assistant formed by diatomite, ethylene glycol monomethyl ether and methylsiliconeoil, and the balance water. In the invention, the multifunction automobile wax can be prepared by compounding the rigid microcrystalline wax and the soft paraffin and organically integrating the characteristics of high melting point, good radiance and strong adhesion of the rigid wax with the characteristics of low melting point, good toughness and favorable rust protection of the soft wax through adopting a dispersing emulsion method and controlling the fixed acid value in the emulsion process, and the multifunctional automobile protective wax has the functions of corrosion and rust resistance as well as polishing and beautifying.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Rinsable metal pretreatment methods and compositions

InactiveUS20060151070A1Improve corrosion protectionImprove adhesionSolid state diffusion coatingPretreatment methodPhosphate

Chromate-free and metal phosphate free treatments and compositions for applying a conversion or passivation coating for metals, more particularly, steel, zinc coated steel, and aluminum surfaces. The methods of the invention comprise contacting the requisite metal surface with a treatment composition comprising a member or members comprising one or more Group IV B elements, fluoride, and phosphonic acid or phosphonate. Optionally, a silane may be added as a treatment component.

Owner:CHEMETALL CORP

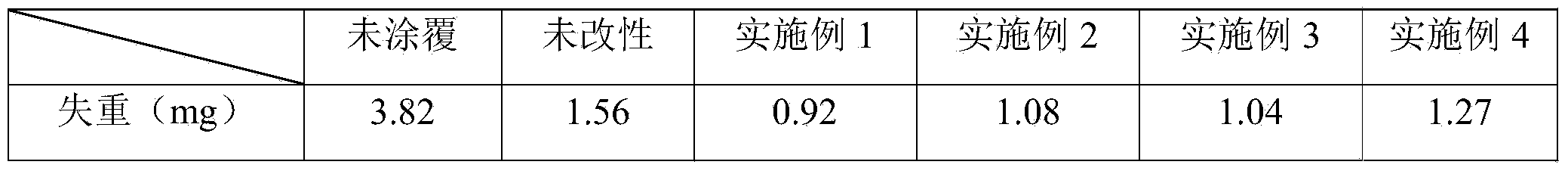

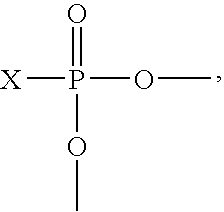

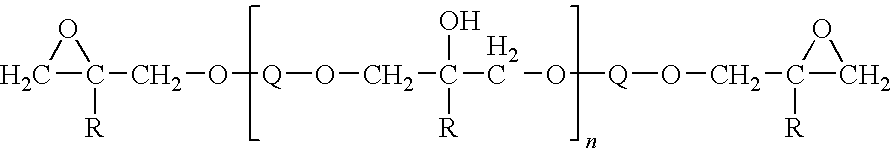

Electrocoat composition and process replacing phosphate pretreatment

ActiveUS20100167072A1Strong resistanceImprove anti-corrosion performanceElectrolysis componentsVolume/mass flow measurementPhosphateManganese oxide

An aqueous coating composition comprises a metal oxide selected from the group consisting of bismuth oxide, vanadium oxide, manganese oxide, cobalt oxide, zinc oxide, strontium oxide, yttrium oxide, molybdenum oxide, zirconium oxide, lanthanum oxide, oxides of the lanthanide series of elements and combinations thereof and an electrodepositable binder, the binder comprising (a) a phosphorous-containing groupin which X is a hydrogen, a monovalent hydrocarbon, an alkyl group such as an aminoalkyl group, or an oxygen atom having a single covalent bond to the phosphorous atom, and each oxygen atom has a covalent bond to a hydrogen atom, an alkyl group, an aryl group, an alkylaryl group, an arylalkyl group, or the resin, with the caveat that at least one oxygen atom has a covalent bond to resin; (b) a carboxylate group separated by from 2 to 4 carbons from an ester group; and (c) a tridentate amine ligand. The coating composition can be electrodeposited on a metal substrate to provide superior corrosion resistance.

Owner:BASF COATINGS GMBH

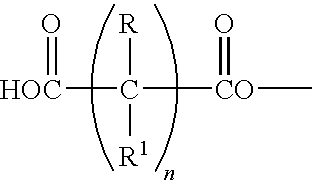

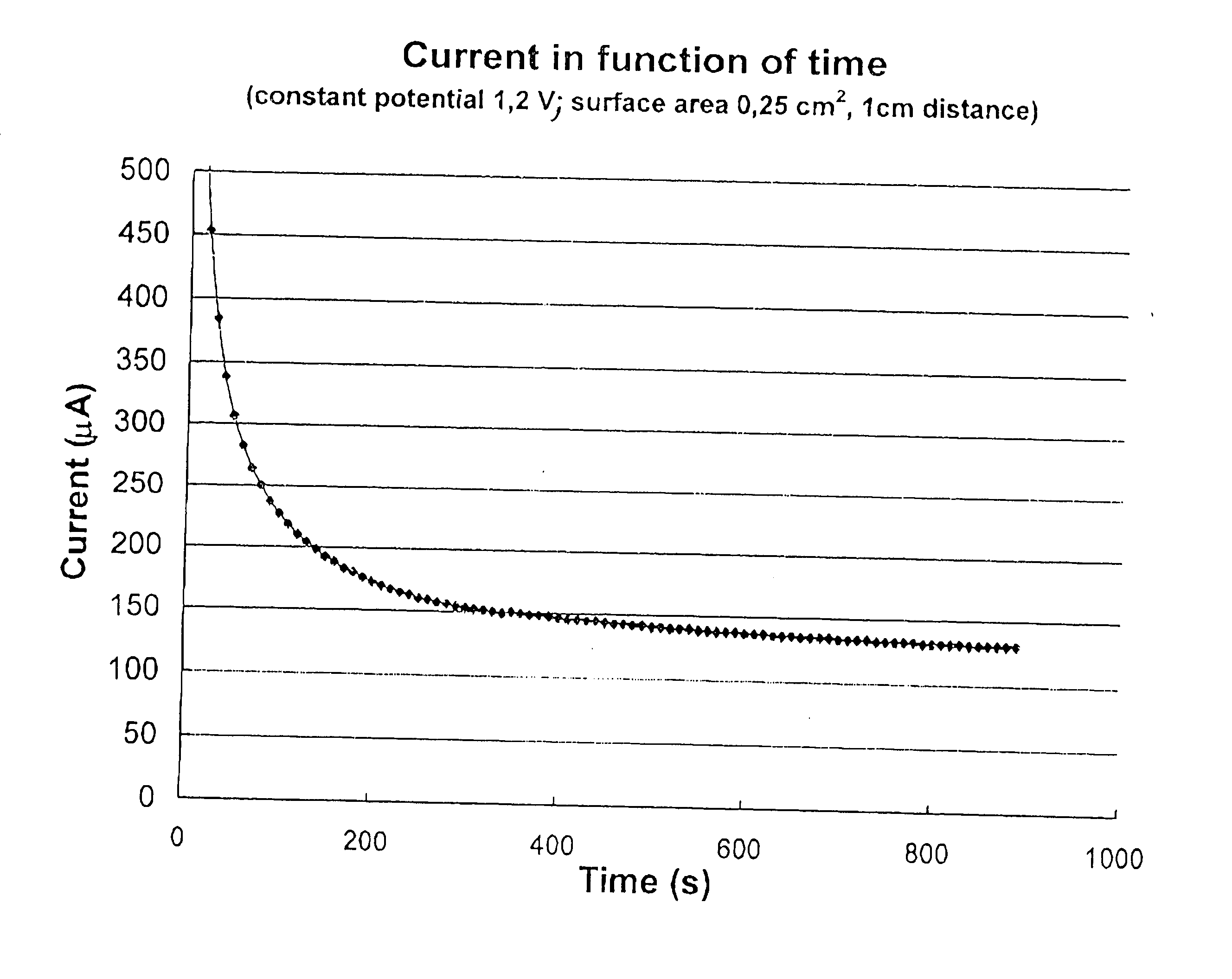

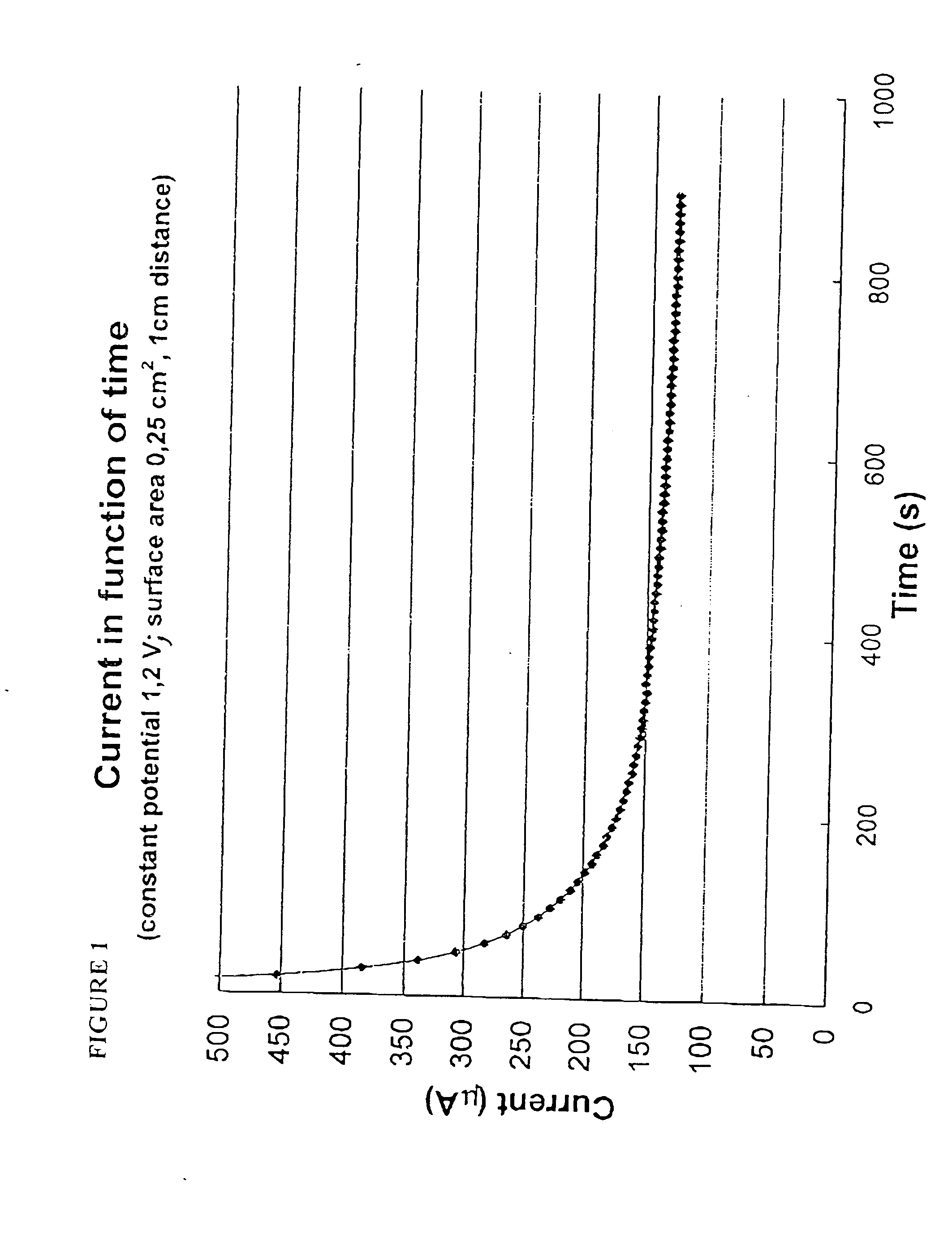

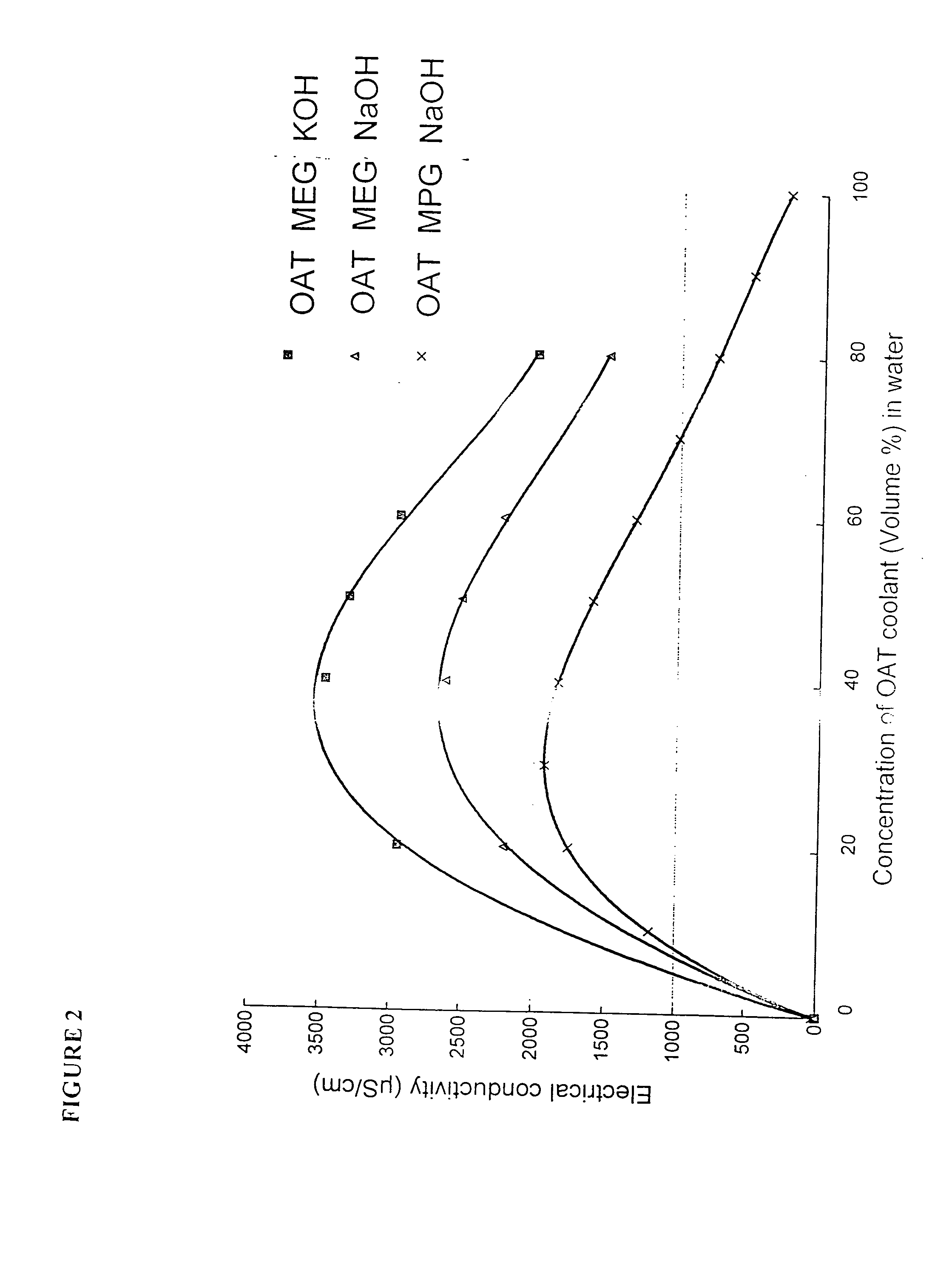

Corrosion inhibiting compositions and methods for fuel cell coolant systems

InactiveUS20050051754A1Low conductivityImprove conductivityOther chemical processesDomestic cooling apparatusTriazole antifungalsDepressant

Carboxylic acids or the salts thereof are suitable for use in cooling systems where low electrical conductivity is required. The compositions are of particular use in fuel cell stacks. The preferred salts are those of amines. The salts can be used with a liquid alcohol freezing point depressant such as monoethylene glycol. Thiazoles and / or triazoles may be included, as well as other corrosion inhibitors known in the art.

Owner:ARTECO NV

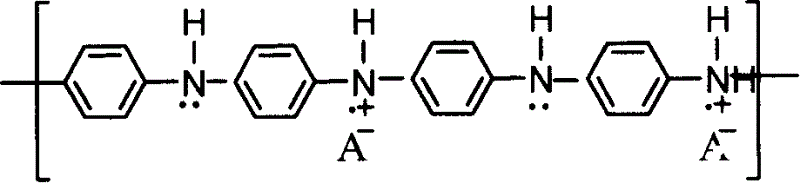

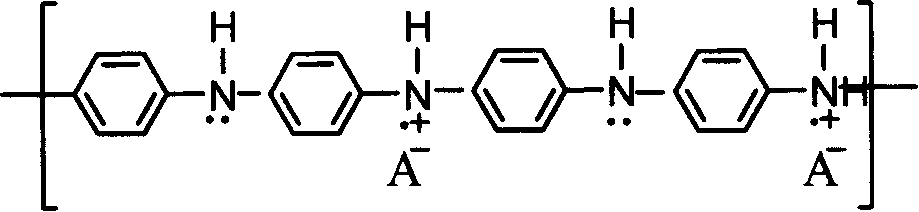

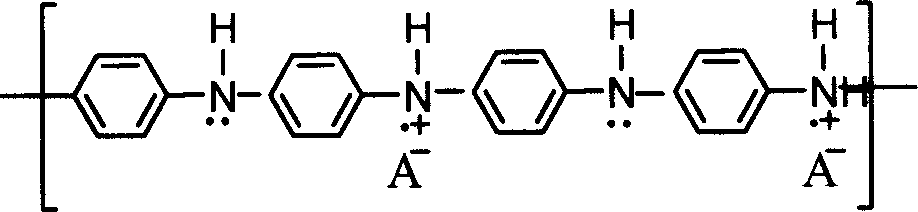

Phosphoric acid doped polyphenylamine phosphate priming paint and preparing process thereof

A phosphorizing priming paint of phosphoric acid doped polyphenylamine is composed of components A and B, and is prepared from the electrically conductive high-molecular material (phosphoric acid doped polyphenylamine), antirust phosphate pigments, and polyvinyl butyral resin. Its advantages are high adhesion and high antirust effect.

Owner:WUHAN UNIV OF TECH

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

Multifunctional efficent composite fuel additive for engine and preparing method thereof

This invention involves one maunfacturing method of multifunctional, highly active and complex dope of engine. Its main characteristic is that this dope consists of complex polar solvent, complex lustration dispersant, complex corrosion inhibitor, lubricant, demulsifier and lacquer solvent. This invention concerns the effects of different olefinic contents in crude oil, fuel oil has complete burning process and high fuel calorific efficiency in the engine, and simultaneously it concerns synergistic effects among the dope components, in order that little addition of dope (about 0.01%) greatly strengthen the power and reduce emission pollution.

Owner:天津开发区友仁科技发展有限公司

Treatment Solution for Coating Metal Surface

ActiveUS20110132497A1Small volumeReduce weightSolid state diffusion coatingChromium freeMOLYBDATE ION

A chromium-free aqueous treatment solution for coating metal surfaces is described. The treatment solution contains fluorocomplex ions of titanium and / or zirconium and molybdate ions, vanadium ions and one or more aromatic carboxylic acids with at least one carboxyl groups and at least two further functional groups, wherein the two further functional groups are selected from the group comprising carboxyl groups, hydroxyl groups, amino groups and nitro groups.

Owner:BULK CHEM

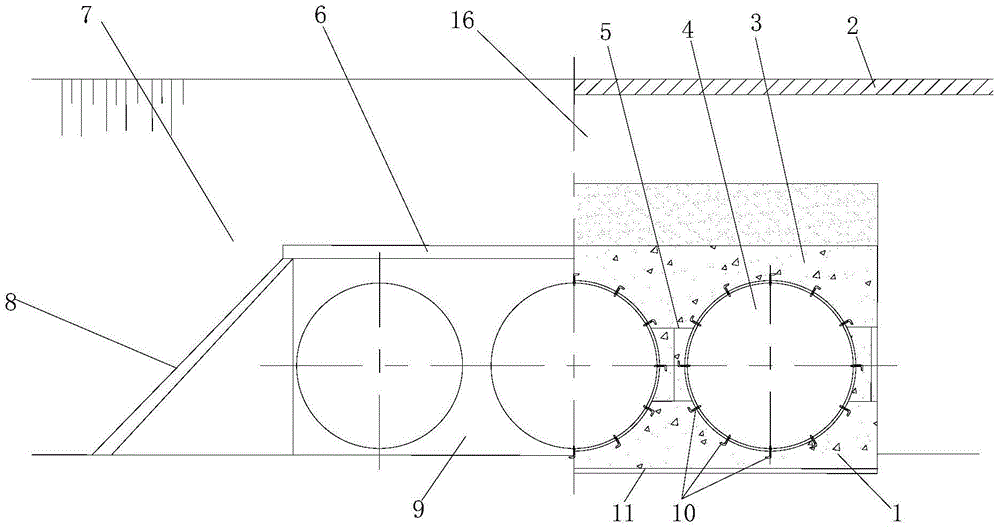

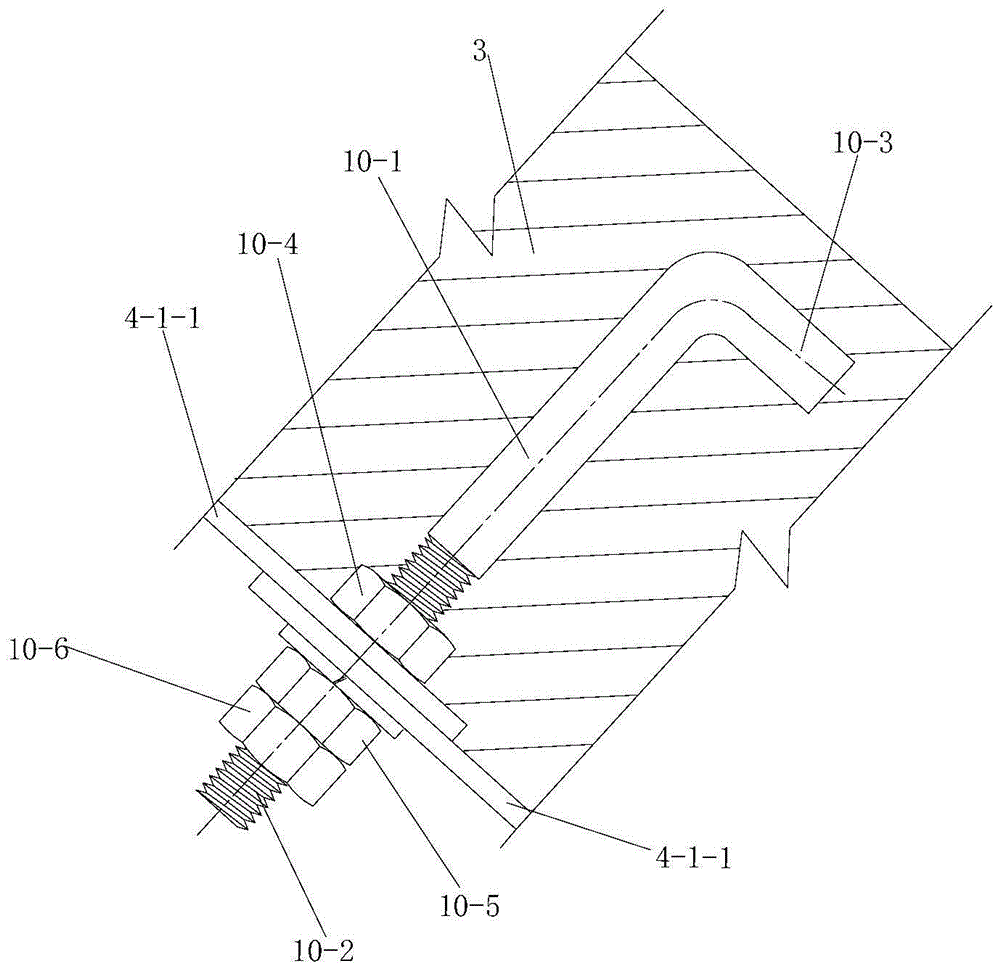

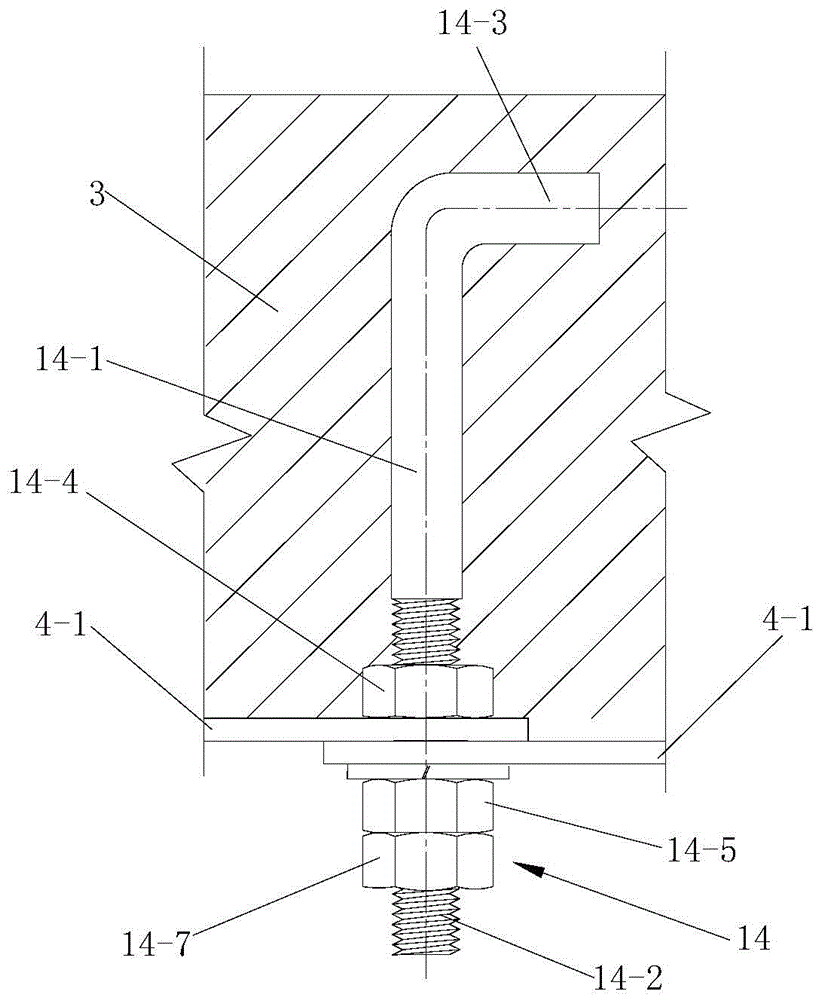

Multi-hole culvert structure adopting foam concrete and corrugated steel sheets and construction method of multi-hole culvert structure

ActiveCN105648933ASolve for uniformitySolve the problem of culvert collapseGround-workFoundation engineeringFoam concreteSheet steel

The invention discloses a multi-hole culvert structure adopting foam concrete and corrugated steel sheets. The multi-hole culvert structure comprises an arch shell formed by assembling corrugated steel materials and foam concrete arranged around the arch shell in a filling mode. Water passing structures comprise multiple steel sheet arch shell units. The steel sheet arch shell units are formed by assembling multiple single corrugated steel sheets. Every two adjacent single corrugated steel sheets are connected through a first connecting part which penetrates through a lap joint part between the every two adjacent single corrugated steel sheets. Every two adjacent steel sheet arch shell units are connected through a second connecting part which penetrates through a lap joint part between the every two adjacent steel sheet arch shell units. The multi-hole culvert structure has the advantages of being small in weight, low in requirement for foundation bearing capacity, high in adaptability to foundation deformation, good in mechanical stability and the like. The invention further discloses a culvert structure construction method. The culvert structure construction method includes the following steps of culvert foundation construction, water passing structure construction, filling body construction and road surface construction. By means of the method, the problem that traditional backfill materials such as gravels on top and the two sides of the water passing structures are difficult to tightly compact is effectively solved, and the unfavorable influence of the compaction process on the stability and the side walls of the water passing structures is eliminated.

Owner:CHANGAN UNIV +1

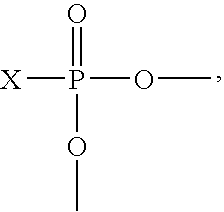

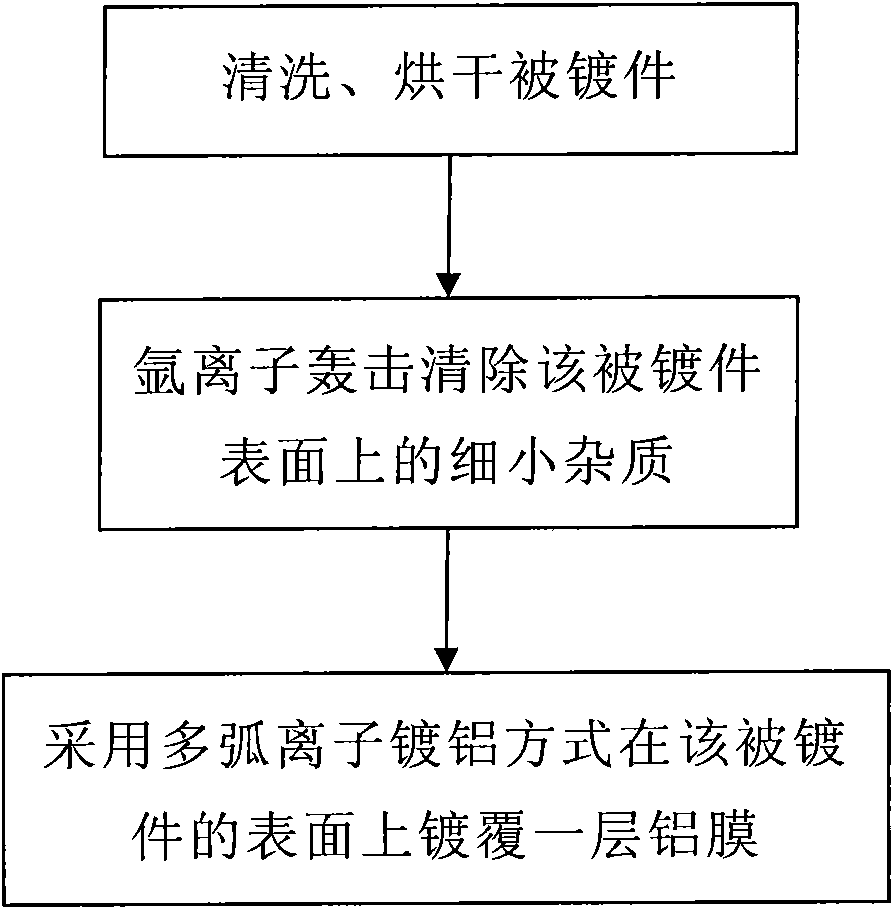

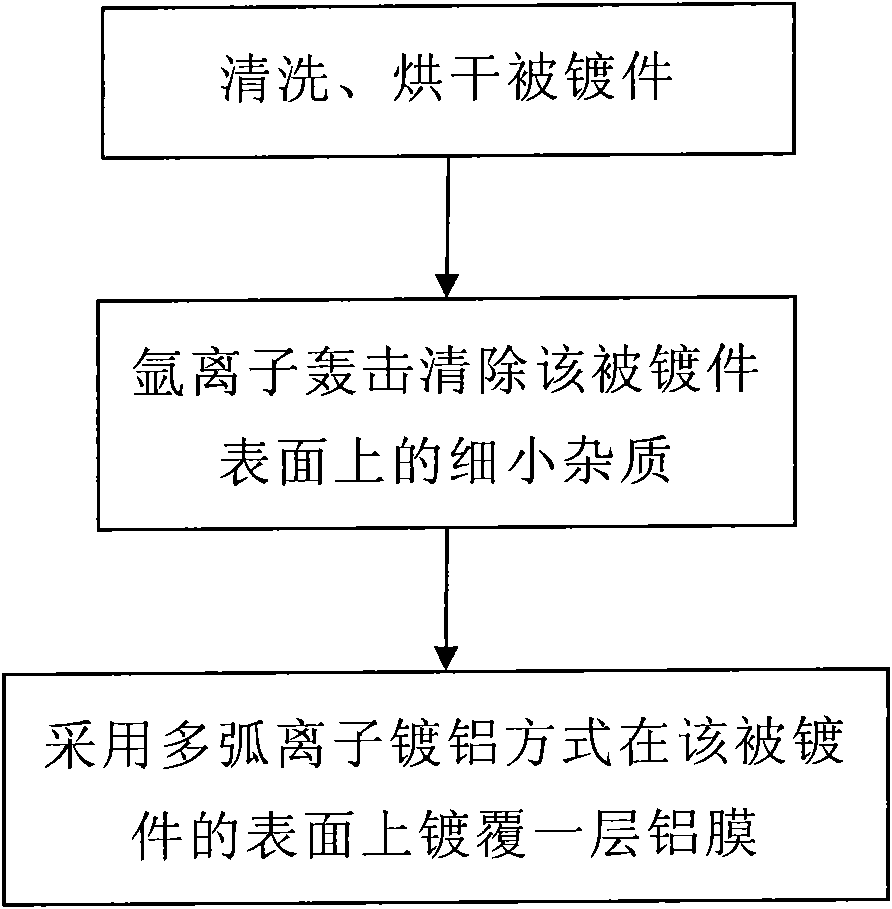

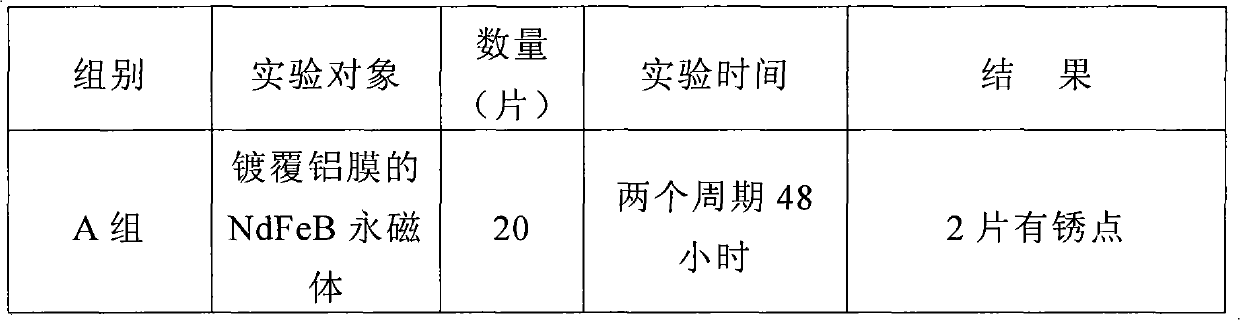

Method for preventing NdFeB permanent magnet from being corroded

InactiveCN102002671AExcellent corrosion protectionImprove corrosion resistanceVacuum evaporation coatingSputtering coatingIon bombardmentImpurity

The invention discloses a method for preventing an NdFeB permanent magnet from being corroded, which comprises: cleaning and drying a plated part; removing fine impurities from the surface of the plated part by argon ion bombardment; and plating a layer of aluminum film on the surface of the plated part by multi-arc ion aluminum plating. In the invention, a layer of uniform aluminum film is plated on the surface of the NdFeB permanent magnet by multi-arc ion aluminum plating, so the corrosion resistance of the NdFeB permanent magnet is improved and the service life of the NdFeB permanent magnet is prolonged.

Owner:耿学红

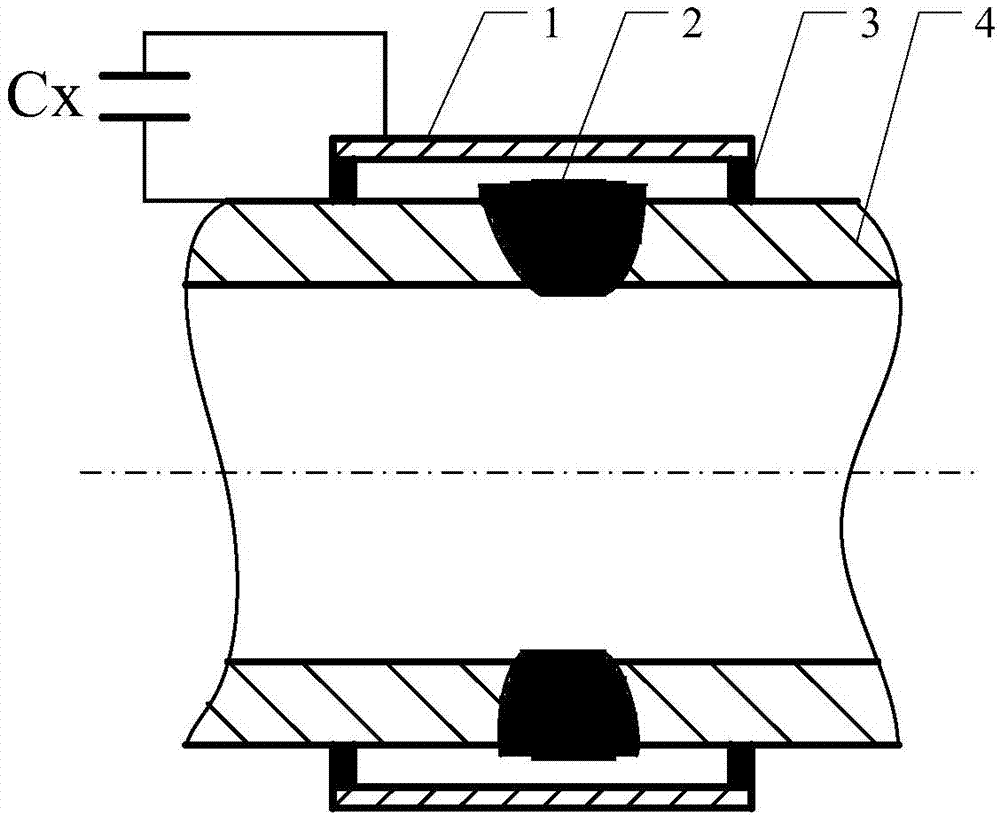

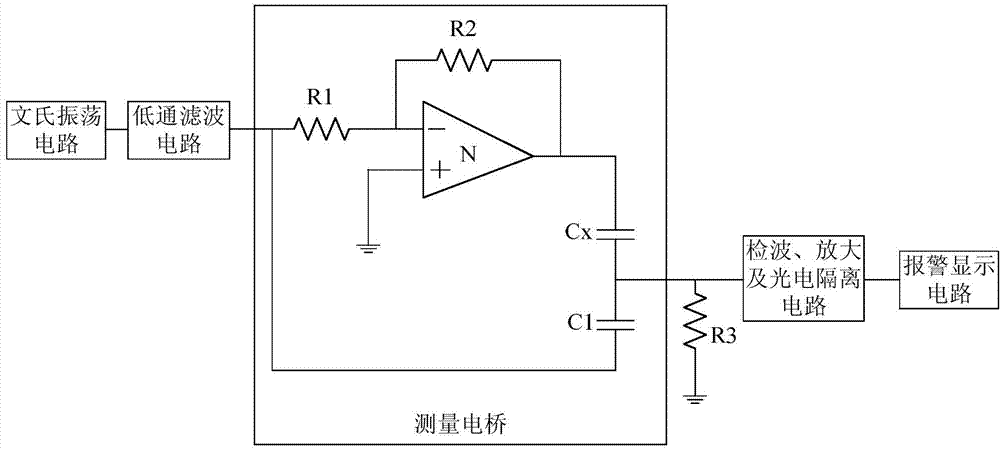

Leakage on-line detection method for weld joint of petroleum and natural gas pipeline

ActiveCN103925474ARealize real-time detectionEliminate and reduce impactPipeline systemsParasitic capacitanceCarrier signal

The invention discloses a leakage on-line detection method for a weld joint of a petroleum and natural gas pipeline, and the method is mainly used for solving the technical problem that an existing leakage detection method of the petroleum and natural gas pipeline is poor in real-time performance. According to the technical scheme, based on the capacitance-type sensor principle, a same core column capacitor is formed by surrounding the petroleum and natural gas pipeline with a stainless steel cladding layer, and by adopting an active bridge circuit suitable for precise capacitance measurement, real-time detection of tiny regional leakage of the weld joint is achieved; a Wien bridge oscillating circuit which is low in power consumption and cost is adopted for producing an excitation carrier signal of a measuring bridge, and low-cost real-time detection of the regional leakage of the weld joint is achieved; by adopting the nearby measuring and pre-warning indication method, influences of parasitic capacitance are effectively eliminated or reduced; by adopting ultrathin stainless steel as cladding layer materials, the anticorrosive and protective effects of the weld joint and nearby regions of connectors are further improved.

Owner:BEIJING CNTEN SMART TECH CO LTD

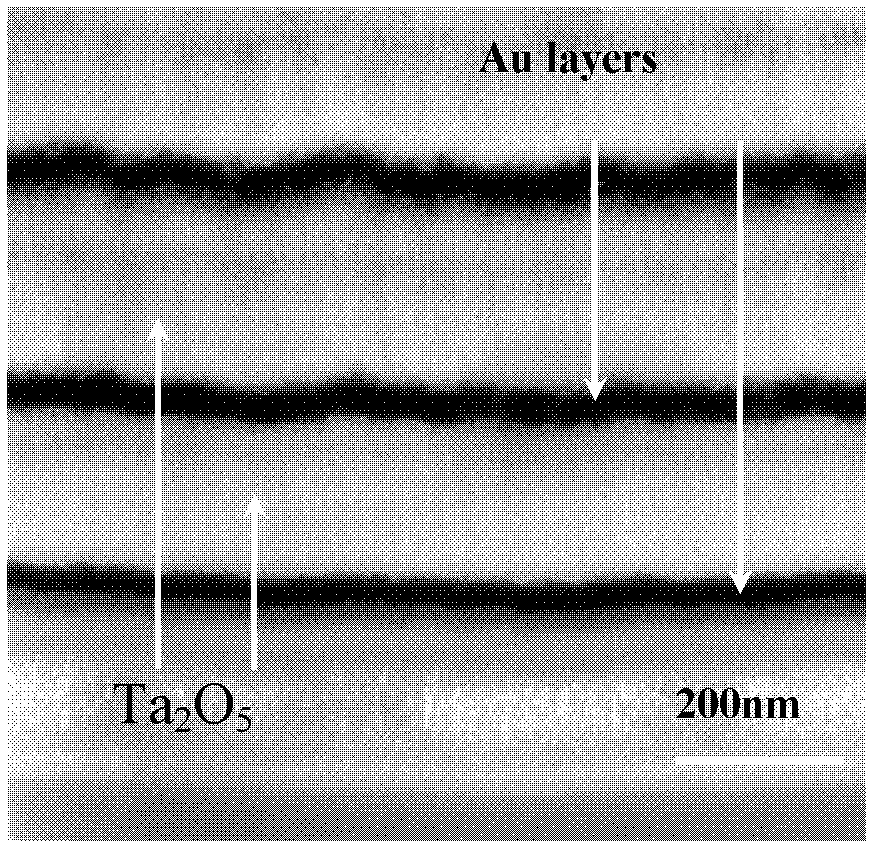

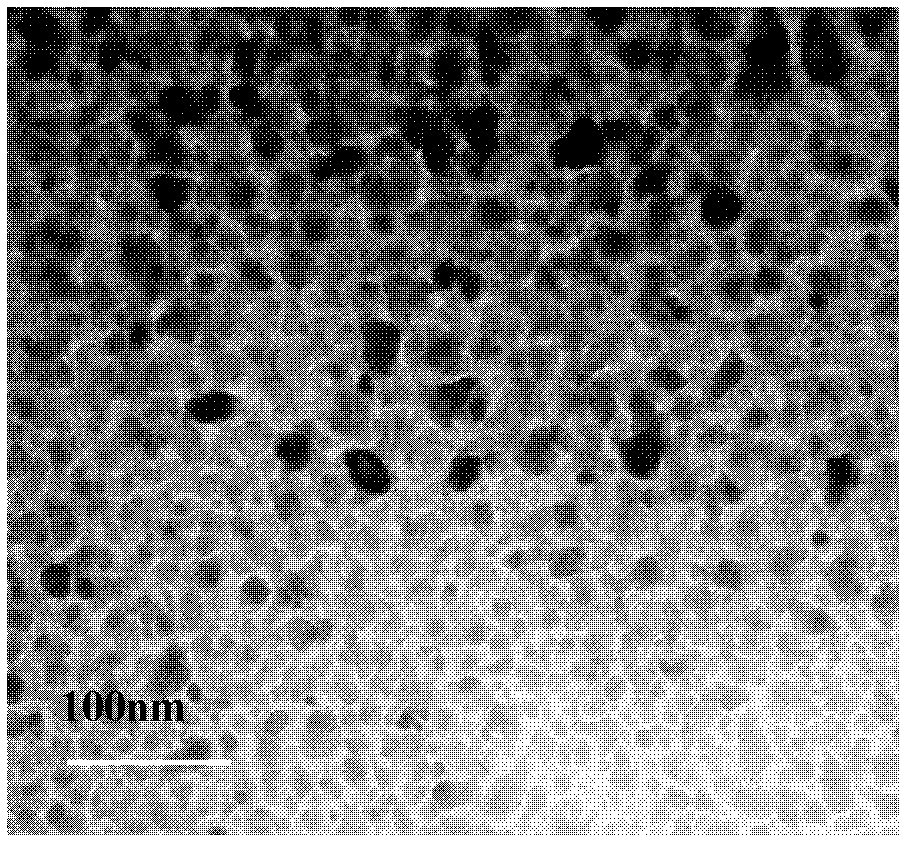

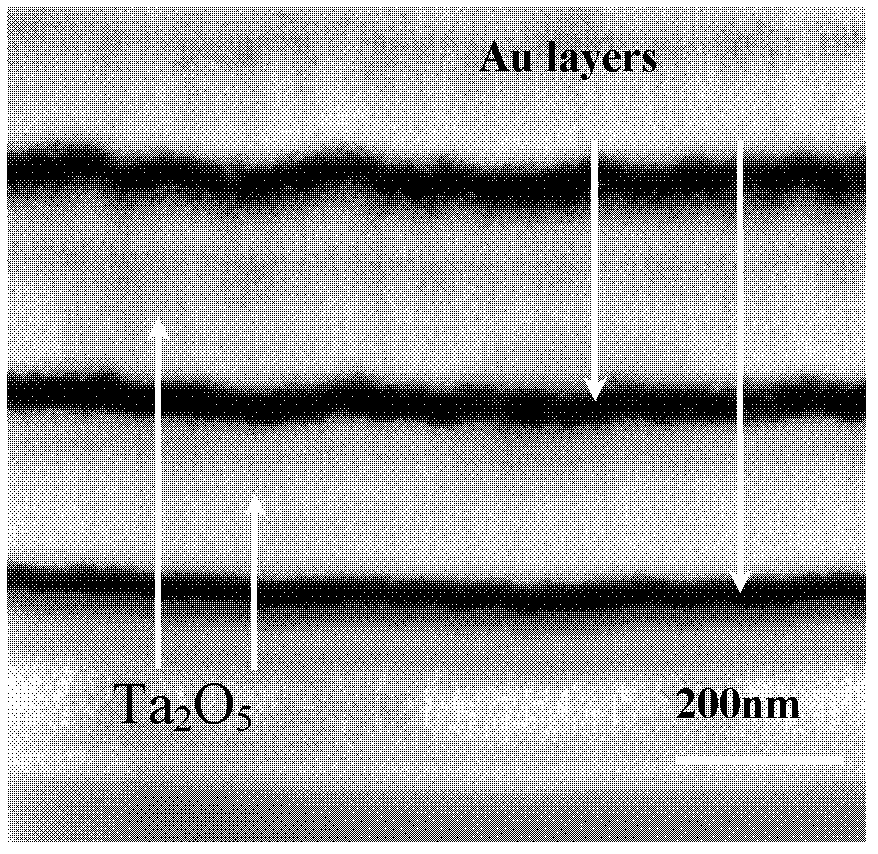

Preparation technology for bionic ceramic/metal laminating composite support coating

InactiveCN102644077AImprove mechanical propertiesIncreased mechanical toughnessStentsVacuum evaporation coatingBiocompatibilityCeramic metal

Preparation technology for a bionic ceramic / metal laminating composite support coating includes steps of a, performing double-cathode plasma sputtering deposition for a Ta layer to obtain a Ta layer with the thickness of 100-200nm at first; b, performing ion oxidation for 5-10min; and c, performing double-cathode plasma sputtering decomposition for an Au or Mg layer to obtain an Au or Mg layer with the thickness of 10-20nm, and repeating the steps a, b and c to obtain a laminating coating. Sputtered targets include targets made of one of Au and Mg and pure-Ta targets; and materials of workpieces include 316L stainless steel. The Ta2O5 layer in the coating has good corrosion resistance and blood compatibility, the metal Au or Mg layer has low elastic modulus and good biocompatibility, toughness of the coating can be increased, and furthermore, bonding strength of the coating and a base material can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

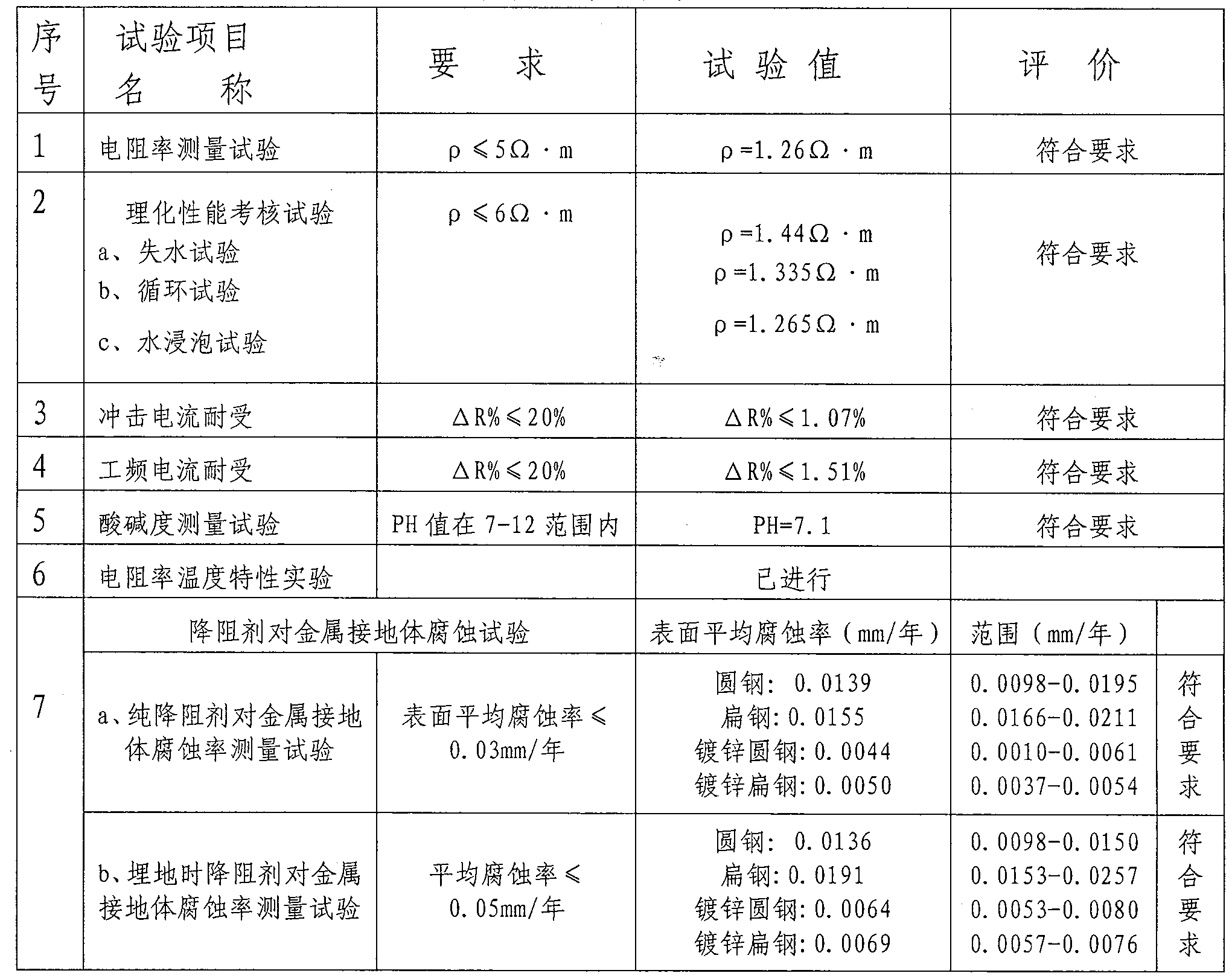

Long-lasting grounding anti-corrosion resistance reduction agent (modified type)

InactiveCN1866409AExcellent corrosion protectionStable chemical propertiesNon-metal conductorsChemical inhibitorsElectricityErosion rate

The invention discloses a long-acting ground antiseptic resistance-reducing agent (modified), which is characterized by the following: consisting of sodium base alta-mud and graphite; making each item of parameter satisfy all index; keeping resistance property stable under multitime industrial frequency and punching electricity action; protecting ground metal; reducing erosion rate from 0.0245 mm per year to 0.0064 mm per year.

Owner:肖竹升

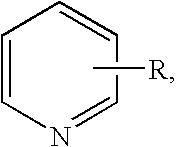

Pyridine group-containing electrocoat composition with metal oxide

InactiveUS20100167071A1Strong resistanceImprove anti-corrosion performancePretreated surfacesMixingLanthanideManganese oxide

A coating layer prepared from an aqueous electrodeposition coating composition comprising an electrodepositable binder, the binder comprising a aromatic amine group-containing resin, and a metal oxide selected from the group consisting of bismuth oxide, vanadium oxide, manganese oxide, cobalt oxide, zinc oxide, strontium oxide, yttrium oxide, molybdenum oxide, zirconium oxide, lanthanum oxide, oxides of the lanthanide series of elements and combinations of these provides corrosion protection to a metallic substrate.

Owner:BASF CORP

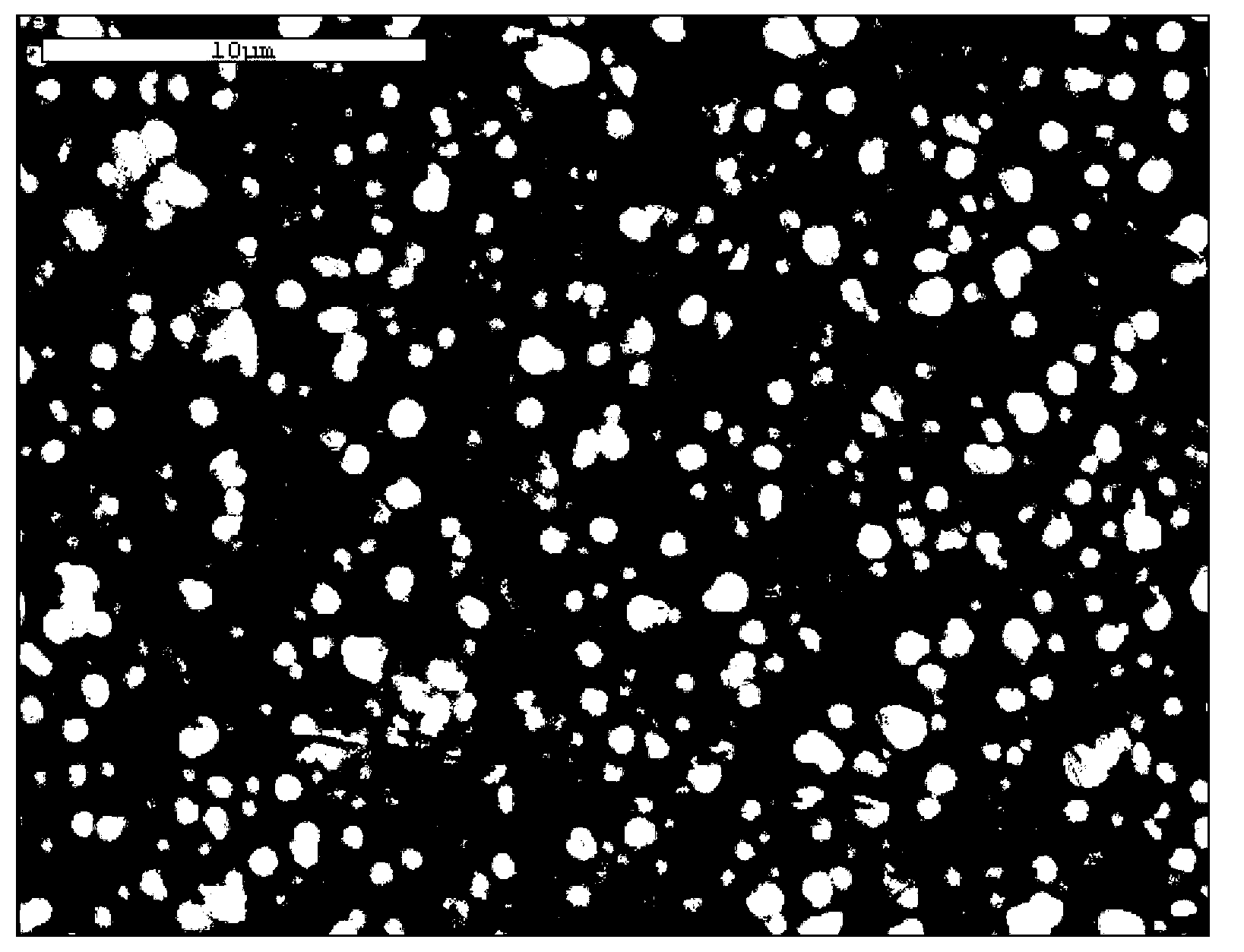

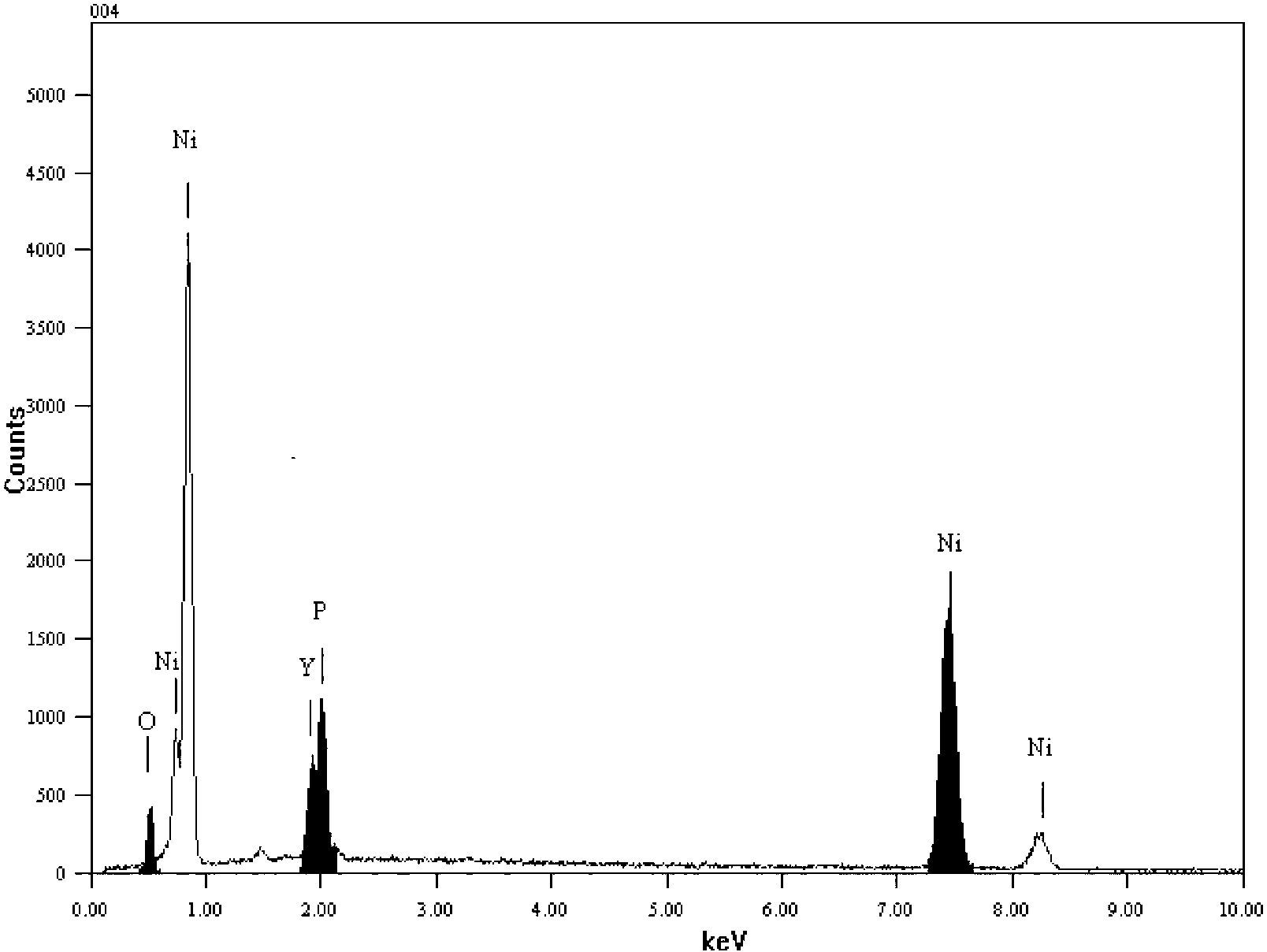

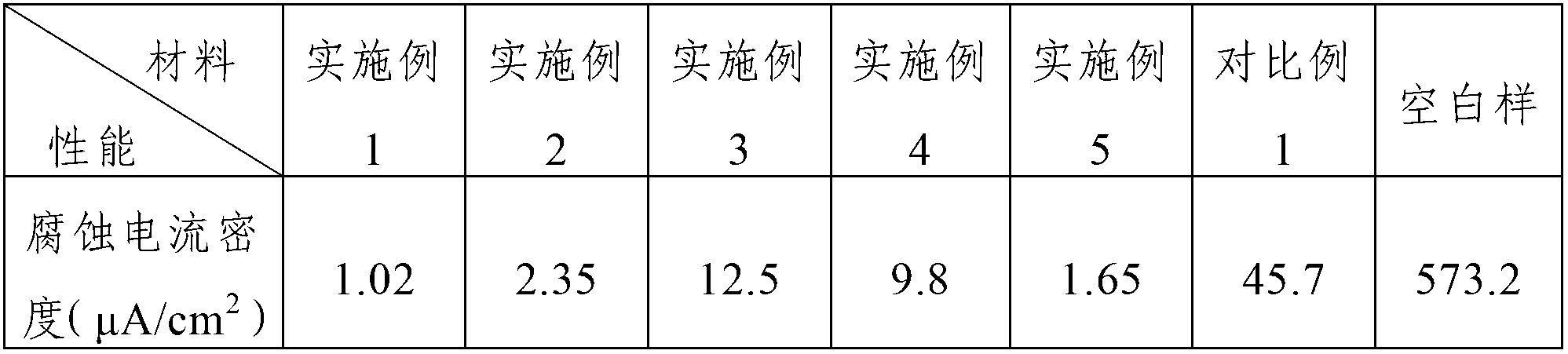

Method for preparing composite coating at surface of neodymium iron boron permanent magnet

InactiveCN103060803AExtended service lifeSimple preparation processLiquid/solution decomposition chemical coatingSuperimposed coating processBond propertiesYttrium

The invention provides a method for preparing a composite coating at surface of a neodymium iron boron permanent magnet. The method comprises the following steps of 1, carrying out surface pretreatment on the neodymium iron boron permanent magnet; 2, putting the neodymium iron boron permanent magnet into conversion processing liquid to convert, thereby obtaining a yttrium conversion coating at the surface of the neodymium iron boron permanent magnet; 3, carrying out sealing treatment in hole sealing solution; 4, activating in activate fluid; 5, putting into electroless plating solution to carry out electroless plating treatment, thereby finally obtaining a yttrium / nickel yttrium phosphorus composite coating at the surface of the neodymium iron boron permanent magnet. The method is simple in preparation process, long in service life of the conversion processing fluid and the electroless plating solution, low in treatment cost, simple and convenient to maintain, convenient to produce and wide in application prospect, and technological parameter is easy to control. The bonding property of the yttrium / nickel yttrium phosphorus composite coating prepared by the method disclosed by the invention and the neodymium iron boron permanent magnet is excellent, and the decay resistance of the neodymium iron boron permanent magnet can be obviously improved.

Owner:XIAN UNIV OF SCI & TECH

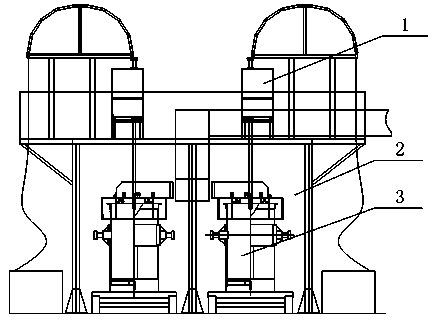

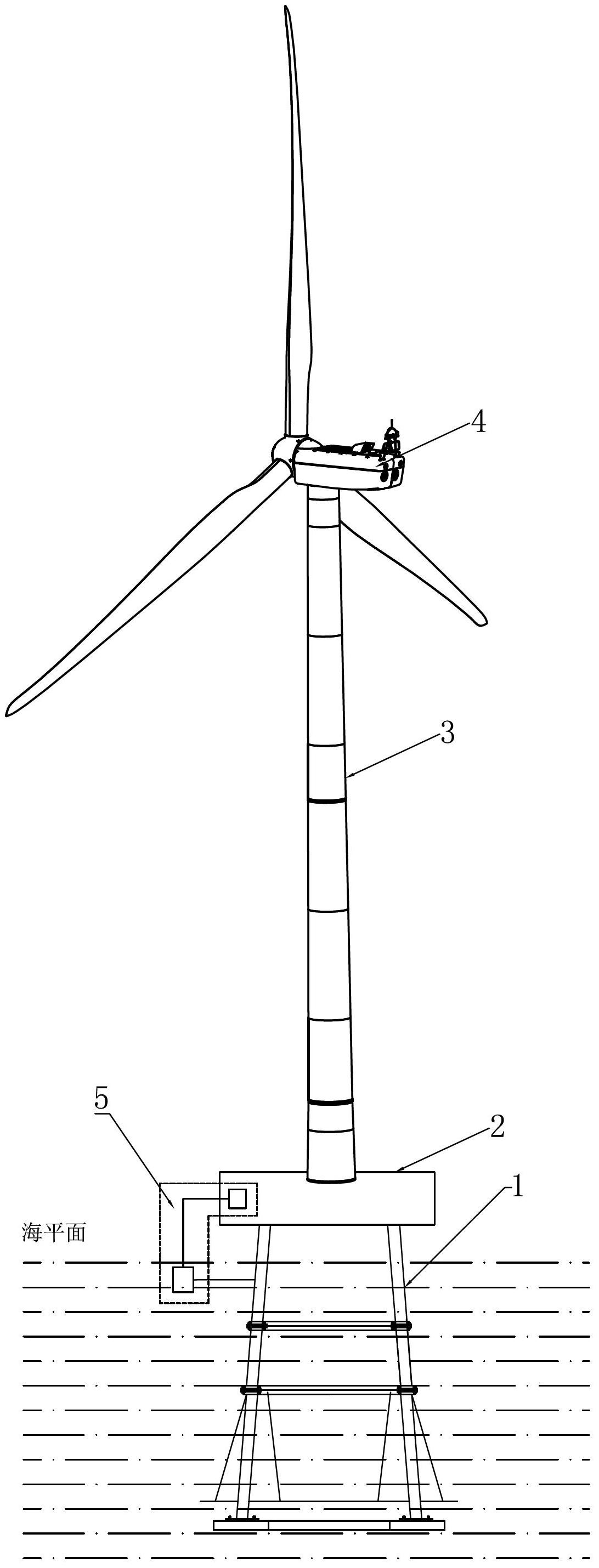

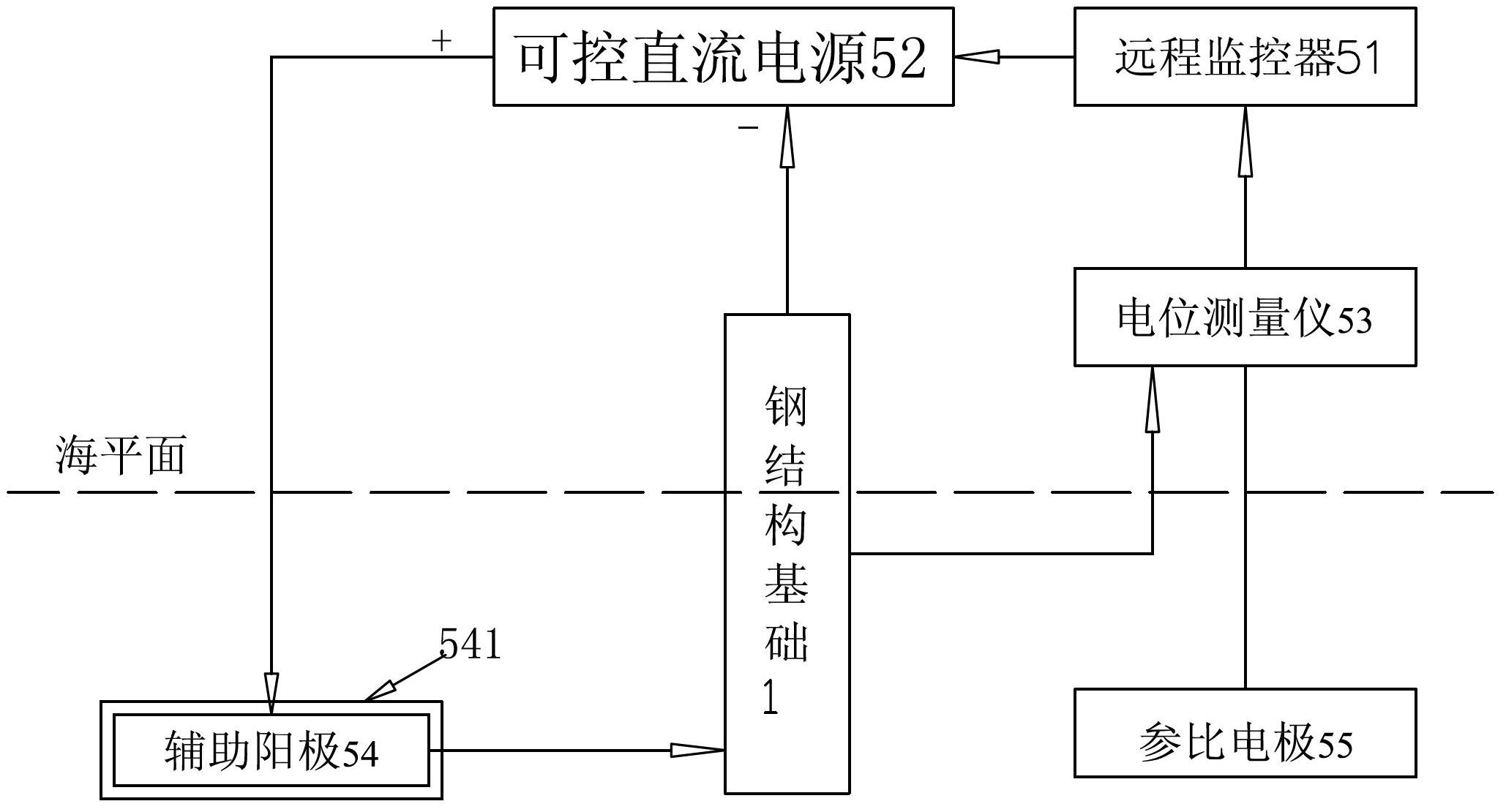

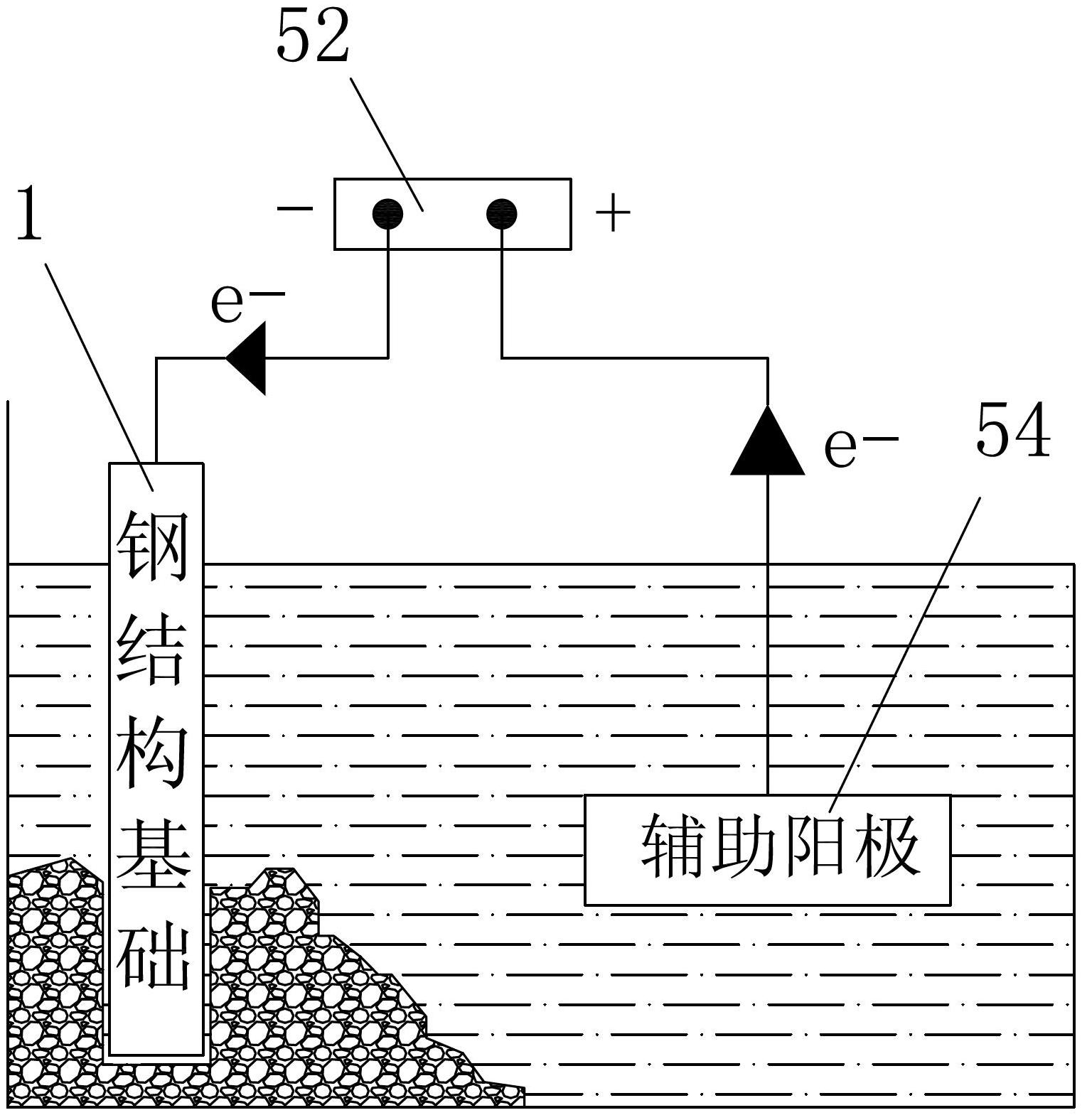

Offshore wind turbine comprising impressed current cathode anticorrosion protection and monitoring device

The invention discloses an offshore wind turbine comprising an impressed current cathode anticorrosion protection and monitoring device. The device comprises a steel structure foundation, wherein a column foot platform is arranged on the steel structure foundation; a tower is fixed on the column foot platform; a wind power main machine is arranged at the upper end of the tower; the steel structure foundation is connected with the impressed current anticorrosion protection and monitoring device; the impressed current anticorrosion protection and monitoring device comprises a monitor arranged on the column foot platform, a controllable direct current power supply, a potential measuring instrument, an auxiliary anode and a reference electrode, wherein the auxiliary anode and the reference electrode are fixed on the steel structure foundation; an anode shielding layer with a physical barrier function covers the surface of the auxiliary anode; the negative electrode of the controllable direct current power supply is connected with the steel structure foundation; the positive electrode is connected with the auxiliary anode; and the auxiliary anode is electrically connected with the steel structure foundation through a seawater medium after the circuit is communicated so as to form a closed loop. The invention aims to provide the offshore wind turbine which is provided with the impressed current cathode anticorrosion protection and monitoring device, has an electrochemical anticorrosion protection function and is convenient for implementation and maintenance.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Weather-resistant waterproof coating

InactiveCN103571316AStrong adhesionAvoid generatingAnti-corrosive paintsPolyurea/polyurethane coatingsIsolation effectOxygen

The invention discloses weather-resistant waterproof coating. The weather-resistant waterproof coating comprises the following components in parts by weight: 10-30 parts of alkyd resin, 5-12 parts of polyurethane, 10-15 parts of flame retardant, 10-20 parts of antirust agent, 6-10 parts of dimethyl silicon oil, 5-10 parts of urea, 6-8 parts of quartz powder, 7-9 parts of mica powder and 10-12 parts of deionized water. The antirust agent adopted by the weather-resistant waterproof coating can form a compact protective layer with strong adhesive force on the surface of a steel pipe and can be used for preventing or slowing down the permeation of oxygen and water in environments through the isolation effect, so that the generation of corrosive micro batteries is hindered, and a good anti-corrosion protective effect is achieved.

Owner:QINGDAO HUARUI RUBBER IND EQUIP

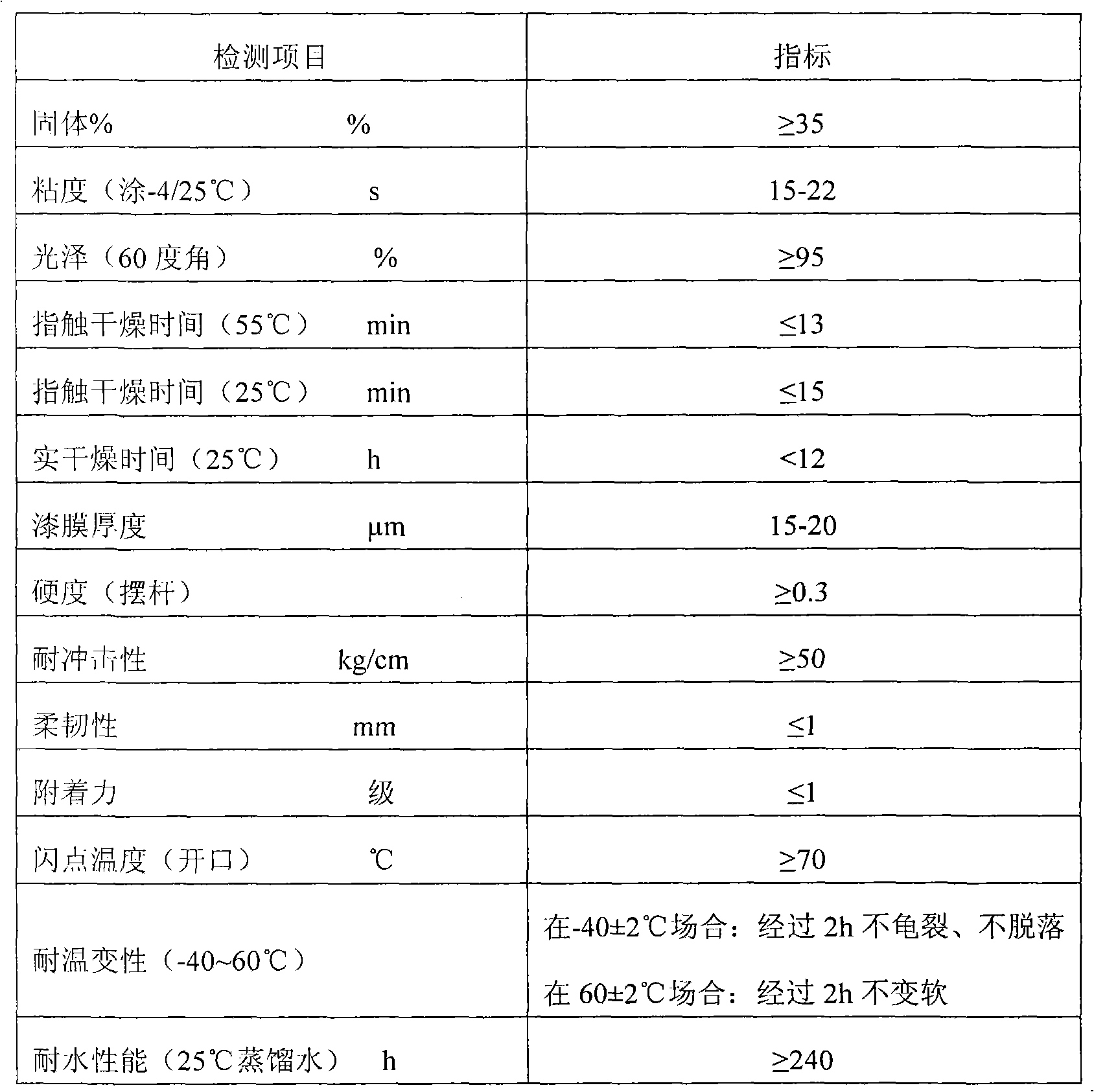

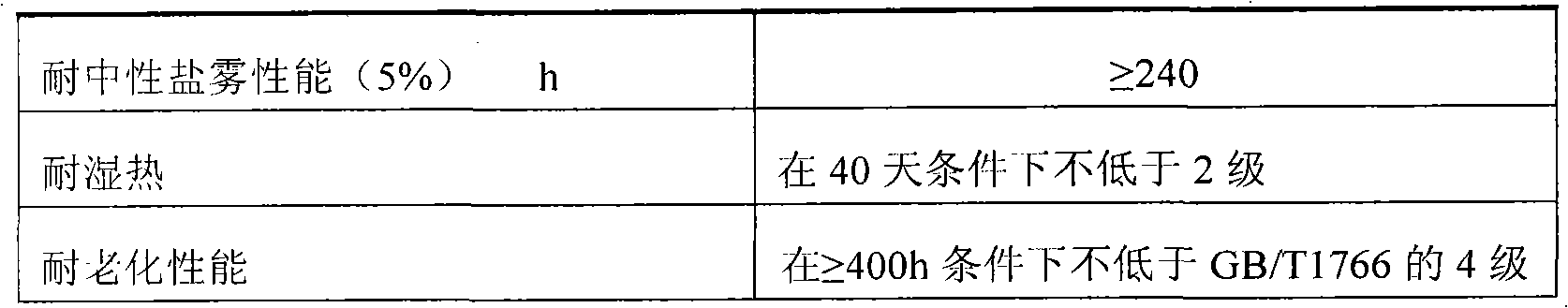

Water-based epoxy anti-corrosion primer

InactiveCN106634424AAchieve self-cleaning effectEasy to deployAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based epoxy anti-corrosion primer which consists of a component A and a component B, wherein the component A is prepared from the following raw materials in percentage by weight: 10 to 20 percent of a modified amine hardener, 25 to 40 percent of deionized water, 5 to 30 percent of pigment, 15 to 35 percent of a filler, 5 to 15 percent of an antirust pigment, 0.1 to 0.4 percent of a defoaming agent and 0.3 to 0.8 percent of a leveling agent; the component B is prepared from the following raw materials in percentage by weight: 10 percent of an emulsifier, 50 percent of liquid epoxy resin, 39.8 percent of deionized water and 0.2 percent of a defoaming agent; the quality indexes are as follows: the fineness is less than or equal to 15 [mu]m, the epoxy value is 0.28 to 0.30, and the solid content is 55 + / - 2 percent. The invention further discloses a processing method. The primer is solvent-free and can realize odorlessness and zero discharge; a paint film can be naturally dried, smooth, flat and compact; solvent discharge is eliminated in storage, transportation and use processes; the performance meets the requirements of the standard HG / T4759-2014.

Owner:福建百花化学股份有限公司

Anticorrosive coating and preparation method thereof

InactiveCN103305092AImprove corrosion resistanceDry fastAnti-corrosive paintsEpoxy resin coatingsPolymer science(Hydroxyethyl)methacrylate

The invention provides an anticorrosive coating used for an external surface of a steel pipe. The anticorrosive coating is high in adhesive force and outstanding in resistance to weather and corrosion. The anticorrosive coating is prepared from the following components in parts by mass: 30 to 40 parts of epoxy acrylate, 5 to 10 parts of hydroxyethyl acrylate, 4 to 6 parts of hydroxyethyl methylacrylate, 5 to 8 parts of acrylic acid, 10 to 20 parts of terpene resin, and 2 to 3 parts of polymerization inhibitor. The anticorrosive coating is high in corrosion resistance, fast to dry and high in adhesive force and can provide excellent corrosion protection for the steel pipe under various severe various conditions.

Owner:无锡市华明化工有限公司

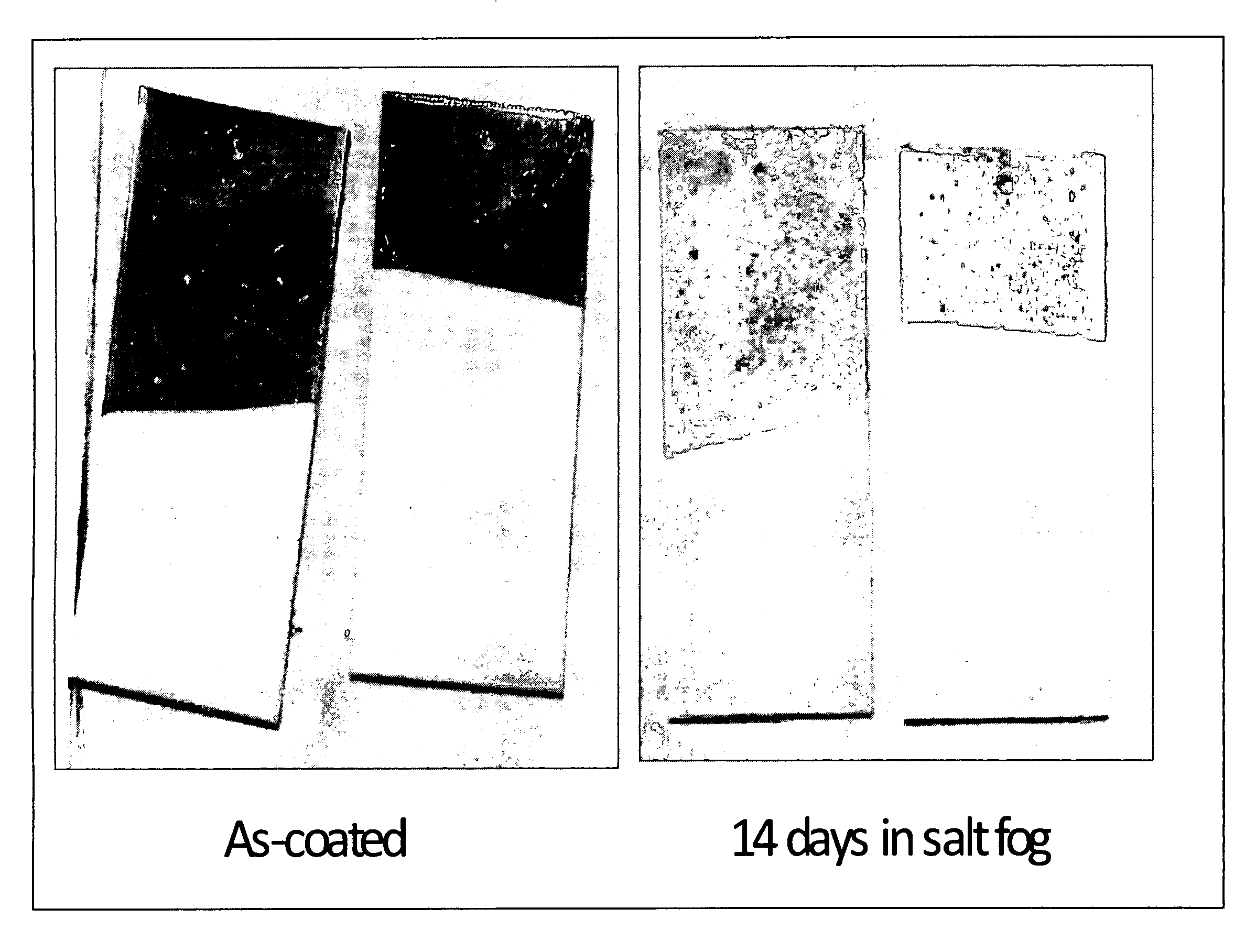

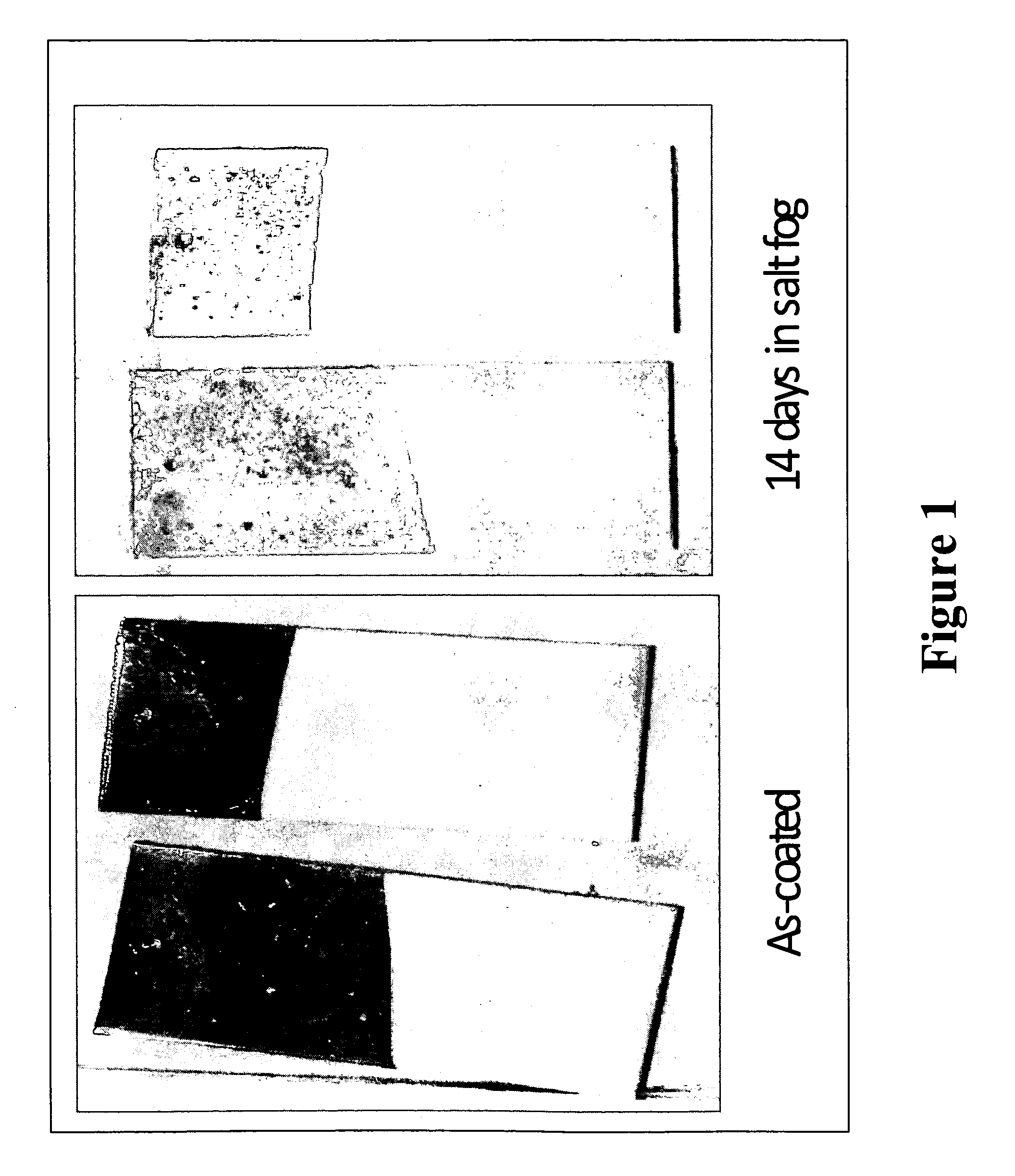

Coatings including tobacco products as corrosion inhibitors

InactiveUS20080295728A1Corrosion inhibition improveExcellent corrosion protectionOther chemical processesAnti-corrosive paintsSurface finishingTobacco product

The invention relates to coatings, such as paints, containing tobacco products and the use thereof as corrosion inhibitors. The tobacco products include various forms of tobacco such as dried tobacco leaves, stems, dust, liquid extracts, etc, that can be added to the coatings. The invention further relates to treatment methods and compositions for surface treatments such as descaling, pickling and removing surface deposits and corrosion products.

Owner:INHIBITROL

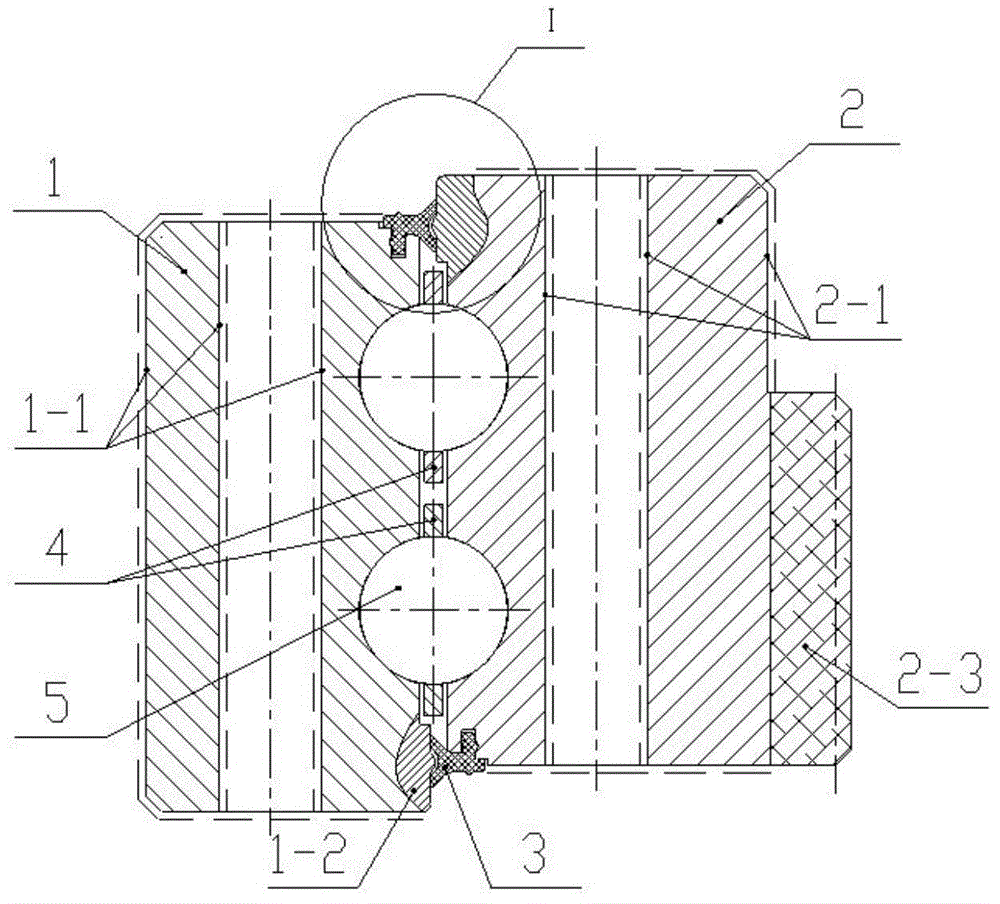

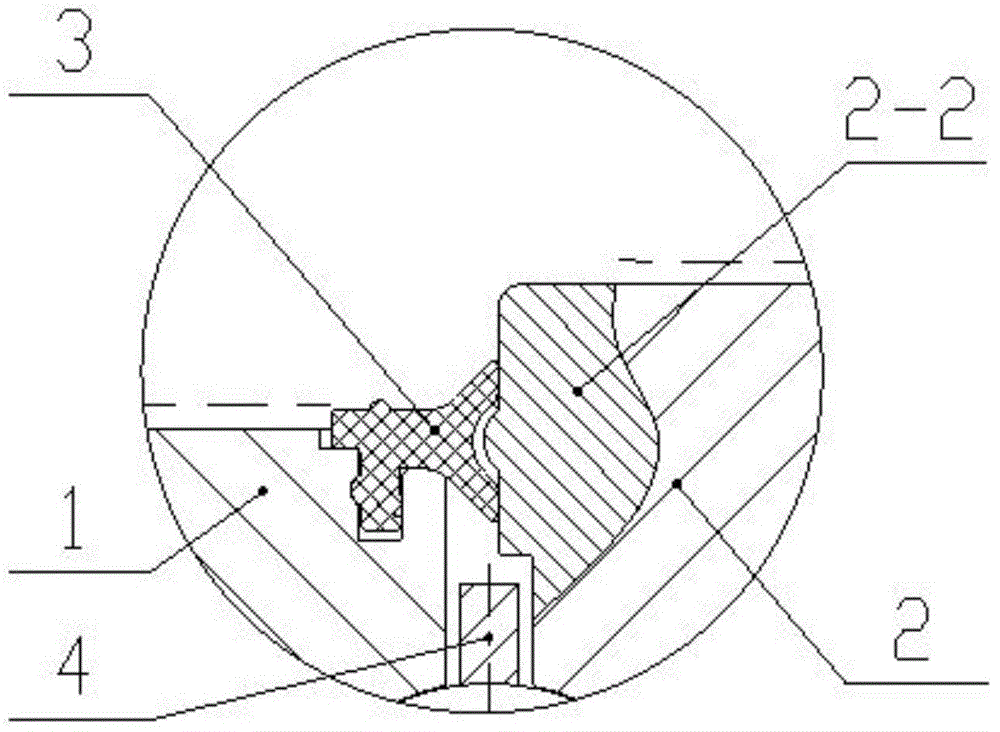

Pitch bearing of wind turbine generator and anti-corrosion processing method of pitch bearing

InactiveCN105020265AImprove anti-corrosion performanceAdapt to requirementsShaftsBall bearingsEpoxyElectricity

The invention discloses a pitch bearing of a wind turbine generator. The pitch bearing of the wind turbine generator comprises a bearing inner ring, a bearing outer ring and a rolling body located between the bearing inner ring and the bearing outer ring. The vertical connection lips of the bearing inner ring and the bearing outer ring are each provided with a sealing ring. Sealing faces corresponding to the sealing rings are sealing faces processed through the stainless steel surfacing welding technology. Epoxy zinc-rich primer, epoxy micaceous iron oxide intermediate and fluorocarbon finish are sequentially sprayed on the surface of the bearing inner ring and the surface of the bearing outer ring. Solid molybdenum disulfide coatings are sprayed on the surfaces of driving teeth on the inner wall of the bearing inner ring. The invention further discloses an anti-corrosion processing method of the pitch bearing of the wind turbine generator. Due to the fact that the sealing lips are processed through the stainless steel surfacing welding technology and anti-corrosion processing is performed on the surface of the pitch bearing through triple anti-corrosion protection and the solid molybdenum disulfide coatings, the anti-corrosion performance of the pitch bearing is greatly improved, and the pitch beating can well meet the requirement of the offshore wind turbine generator. The pitch bearing of the wind turbine generator is low in cost, high in machining efficiency and beneficial to application and popularization.

Owner:GUODIAN UNITED POWER TECH

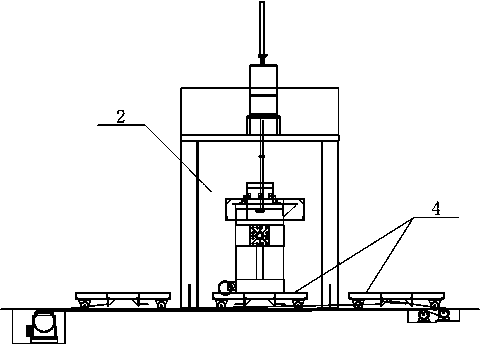

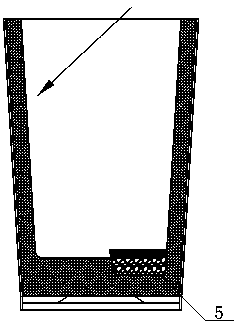

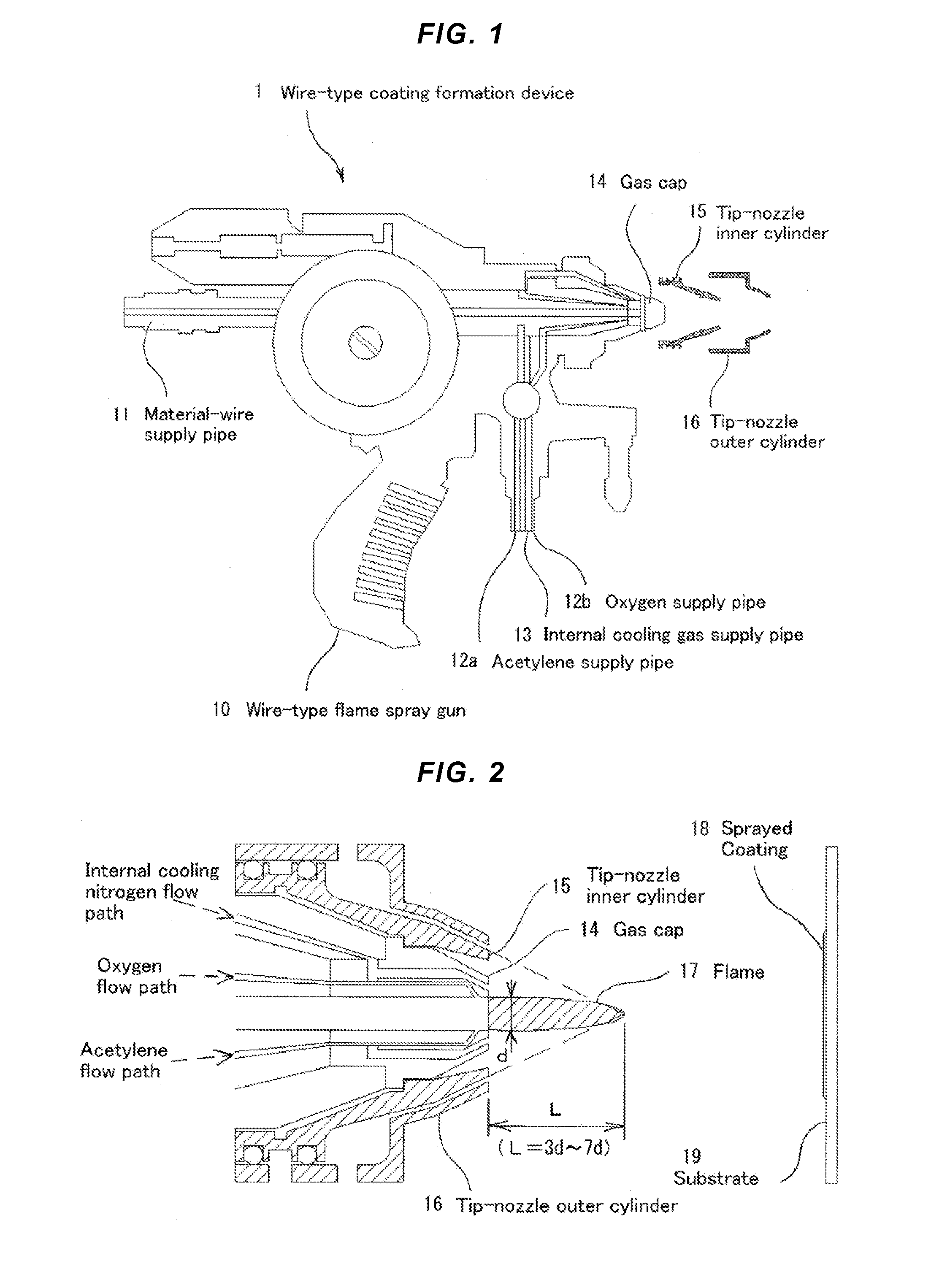

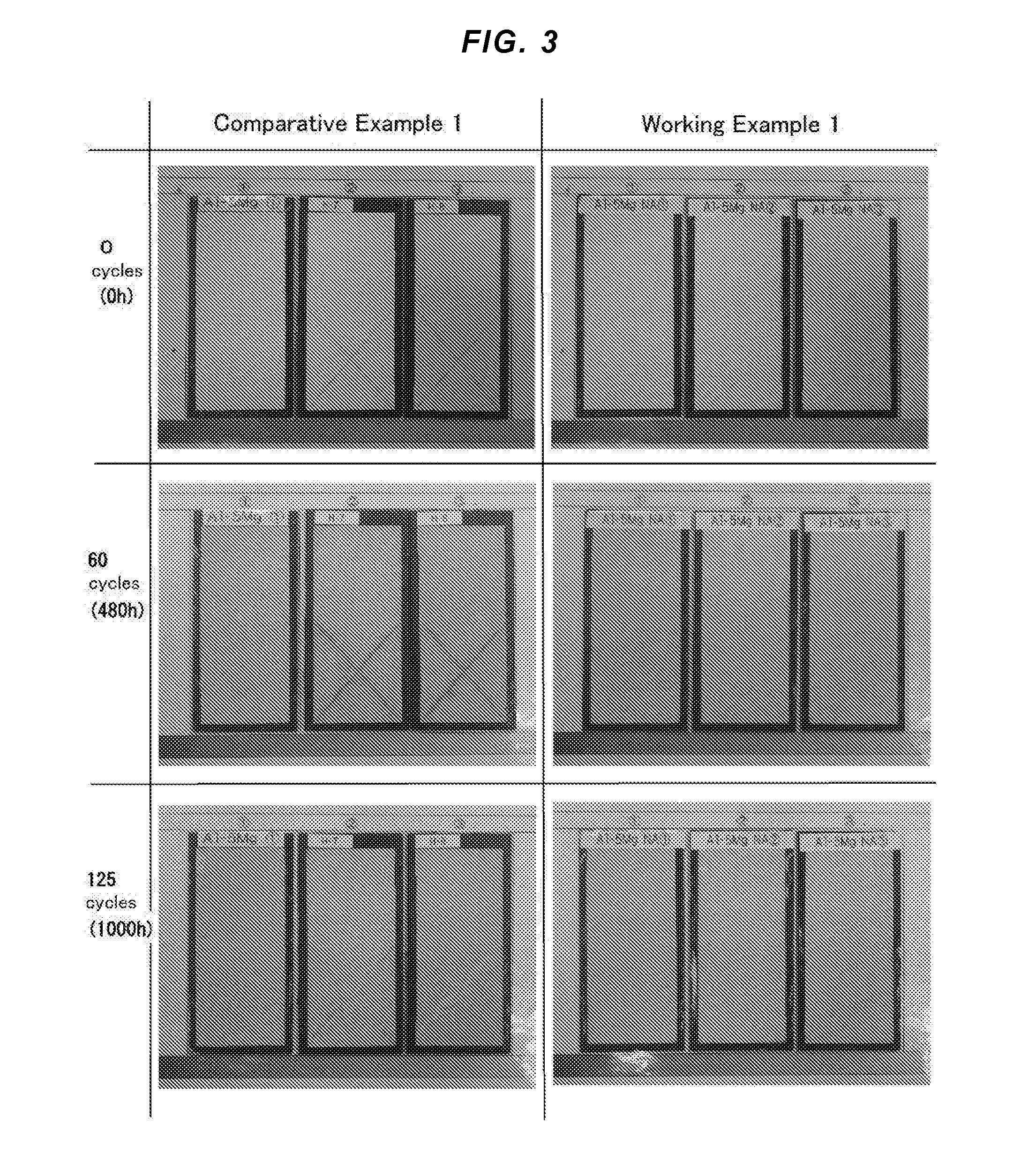

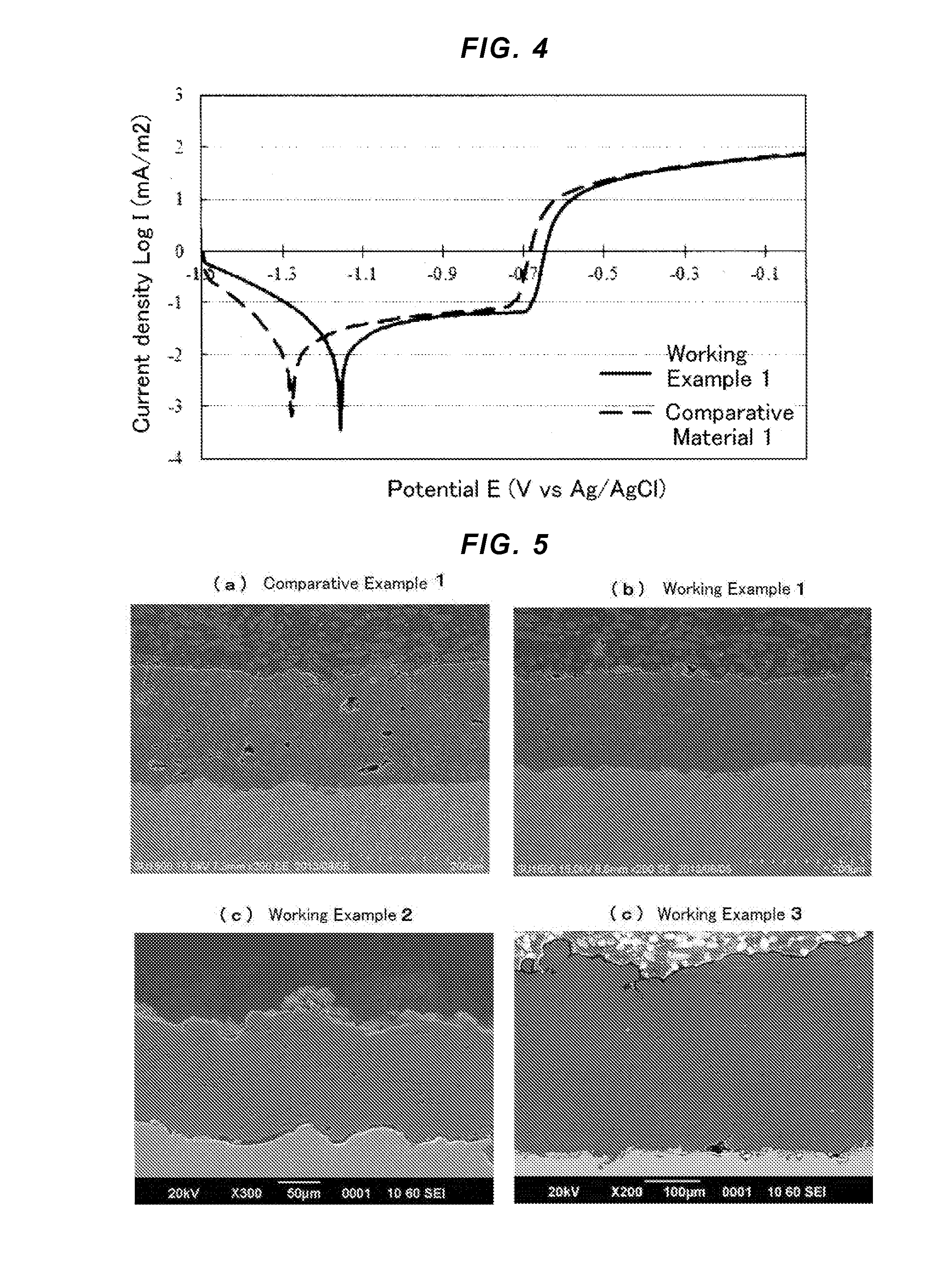

Corrosion-resistant sprayed coating, method for forming same and spraying device for forming same

ActiveUS20170015838A1Excellent corrosion protectionMolten spray coatingAnti-corrosive paintsCorrosion resistant alloySpray coating

[Problem] To provide a corrosion-resistant coating that exhibits greater corrosion protection in saltwater environments and the like than was conventional, a method for forming the same, and a device for forming the same.[Solution] A corrosion-resistant alloy coating is formed on a substrate surface by: a) using a thermal spray gun, having a function wherein a flame including melted material particles is jetted toward a substrate, and the flame is partitioned from the open air in an upstream region on said jet path (which is to say the region in which the material particles are melted), and a function wherein, in a downstream region (the area continuing from the upstream region), the material particles and the flame are forcibly cooled by a jet-gas or jet-mist before reaching the substrate; and b) using a corrosion-resistant alloy material comprising aluminum, for the material particles.

Owner:YOSHIKAWAIND CO LTD

Conductive grease and preparation method thereof

InactiveCN102768873AImprove conductivityAccelerated corrosionNon-conductive material with dispersed conductive materialCable/conductor manufactureLithium soapHeat resistance

The invention relates to the technical field of conductive materials and preparation methods thereof, in particular to conductive grease and a preparation method thereof. The conductive grease comprises the following components in part by weight: 5 to 15 percent of lithium soap, 60 to 70 percent of synthetic basic oil, 23 to 33 percent of pure copper powder, 1 to 2 percent of tin powder and 1 to 2 percent of silver powder. The preparation method comprises the following steps of: weighing the synthetic basic oil, the pure copper powder, the tin powder and the silver powder, adding the synthetic basic oil, the pure copper powder, the tin powder and the silver powder into a reactor, and uniformly mixing to obtain a pasty mixture for backup use; weighing the lithium soap, and smashing the lithium soap into powder; adding the lithium soap powder into the pasty mixture, uniformly mixing, and stirring and grinding to obtain the conductive grease; and putting the conductive grease into a package bottle to obtain a finished product. The conductive grease is relatively high in electrical conductivity, high in electrochemical corrosion resistance and heat resistance and high in conductive connection reliability; the preparation method for the conductive grease is scientific and rational; and the process is simple and convenient.

Owner:上海库革电气设备制造有限公司

Modified grounding anti-corrosion resistance reduction agent

InactiveCN100498978CExcellent corrosion protectionStable chemical propertiesNon-metal conductorsChemical inhibitorsElectricityErosion rate

The invention discloses a long-acting ground antiseptic resistance-reducing agent (modified), which is characterized by the following: consisting of sodium base alta-mud and graphite; making each item of parameter satisfy all index; keeping resistance property stable under multitime industrial frequency and punching electricity action; protecting ground metal; reducing erosion rate from 0.0245 mm per year to 0.0064 mm per year.

Owner:肖竹升

Preparation method of modified titanium oxide coating applied to metal matrix corrosive protection

ActiveCN102952419AExcellent corrosion protectionReduce surface defectsPretreated surfacesAnti-corrosive paintsSilanesSlurry

The invention relates to a preparation method of a modified titanium oxide coating applied to metal matrix corrosive protection. A titanium oxide semiconductor structure is regulated by using stannic oxide, wherein the molar ratio of the stannic oxide to the titanium oxide is 1:50-1:20, and the surface property of the coating is optimized by using gamma-methacryloxy propyl trimethoxyl silane. The preparation method specifically comprises the steps of: preparing modified titanium oxide sol, preparing modified titanium oxide powder, preparing silane sol, preparing coating slurry, pretreating the metal surface, and coating the modified titanium oxide coating. When coated on the surface of a metal matrix, the modified titanium oxide coating prepared by adopting the preparation method has the advantages of controllable thickness, flat surface, firmness in combination with the metal matrix and capability of effectively reducing intrusion of a corrosive medium and also shows a certain dewatering effect; and the modified titanium oxide coating has a cathode protection effect under a light condition, also can well protect the metal matrix under the condition of no light, and shows excellent corrosion protection property.

Owner:滕州市产品质量监督检验所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com