Multi-hole culvert structure adopting foam concrete and corrugated steel sheets and construction method of multi-hole culvert structure

A technology of foam concrete and corrugated steel plate, which is applied in the field of culverts, can solve the problems of difficult compaction of fill, and achieve the effects of low foundation bearing capacity requirements, improved bearing capacity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

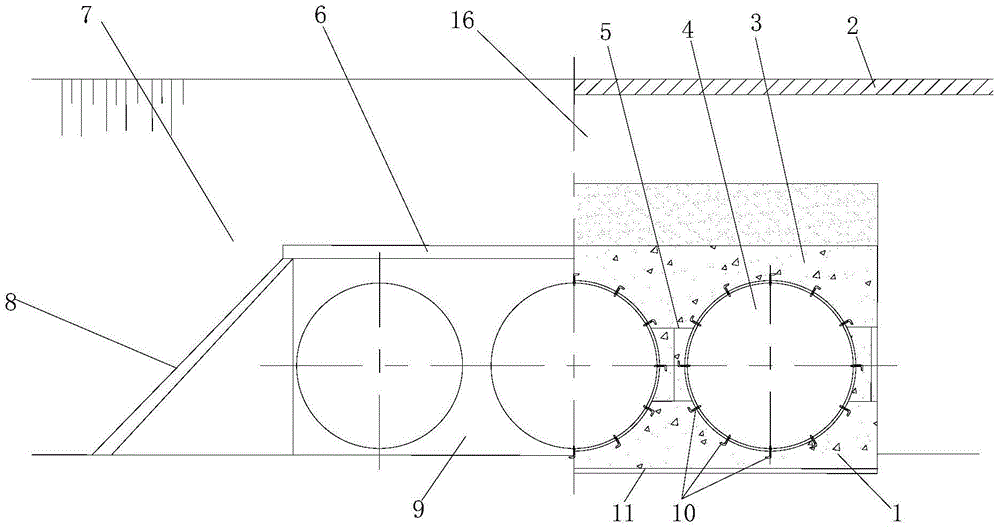

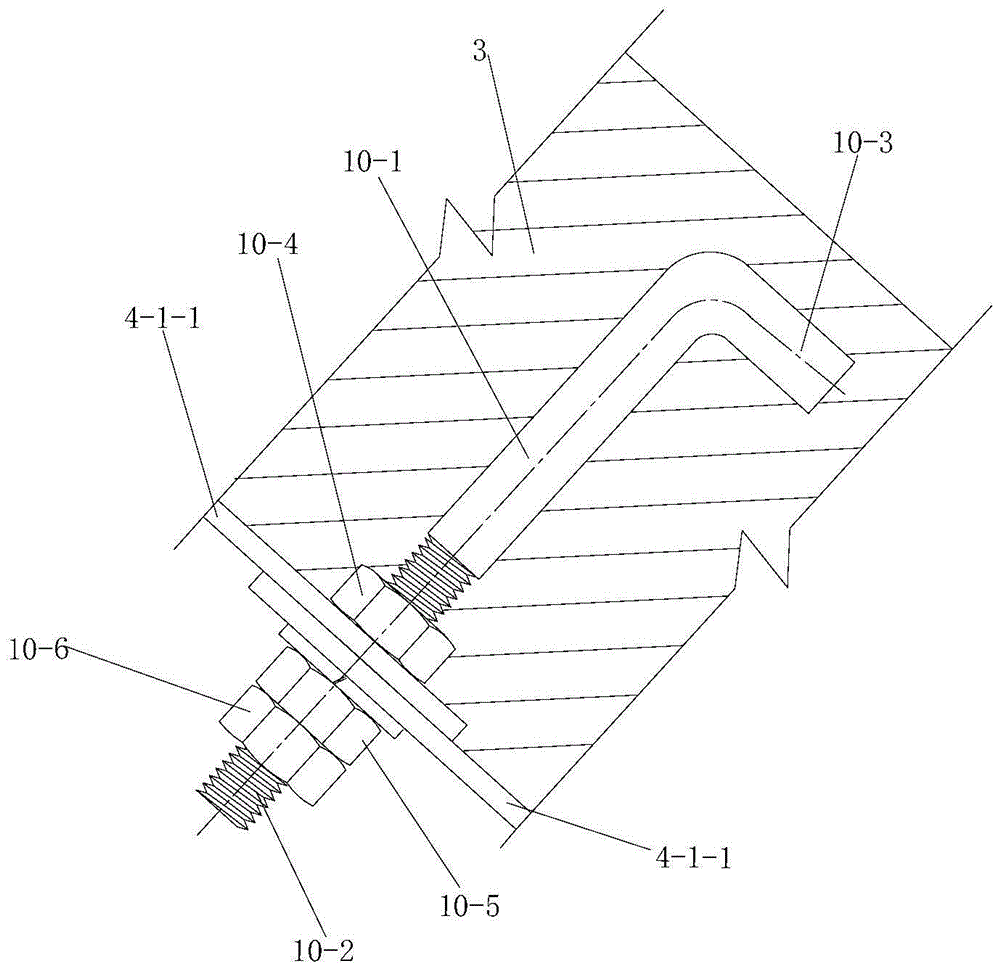

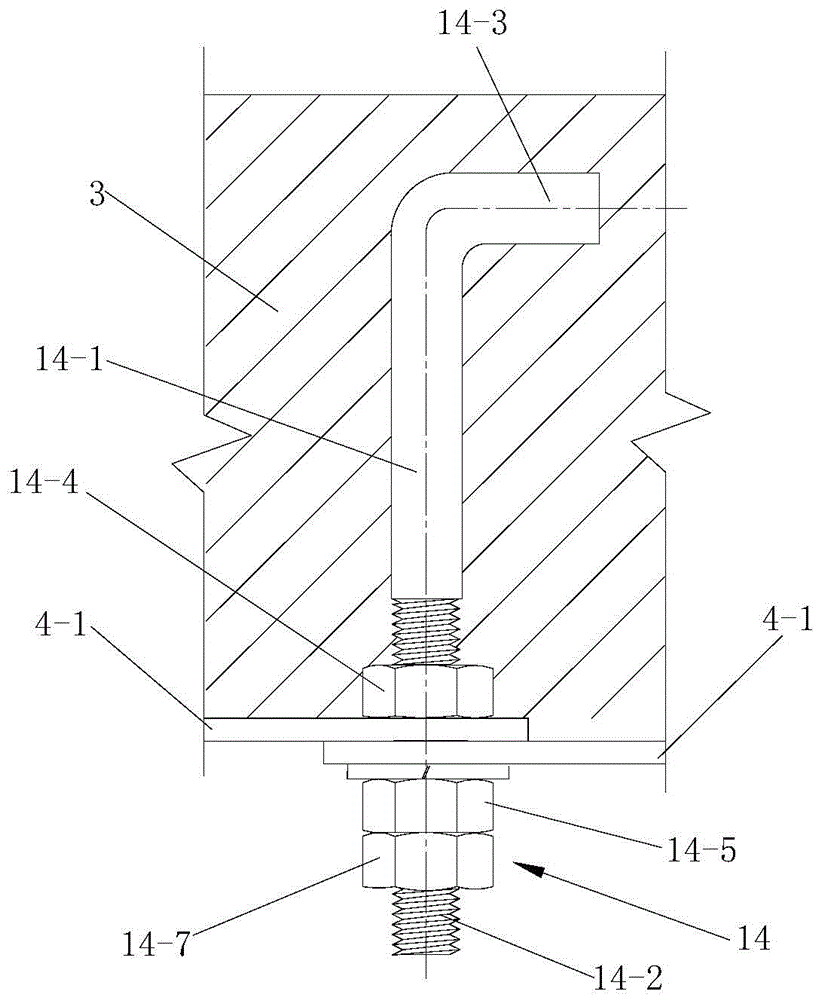

[0052] Such as figure 1 A porous culvert structure using foam concrete and corrugated steel plates is shown, including a culvert foundation 1, multiple water passing structures 4 assembled from corrugated steel plates, and filling bodies 3 located above and on both sides of the water passing structures 4 And the road surface 2 above the filling body 3; the water passing structure 4 includes a plurality of steel plate arch shell units 4-1 arranged along its water flow direction, and a plurality of steel plate arch shell units 4-1 are sequentially overlapped and connected, so The steel plate arch shell unit 4-1 is sequentially overlapped and connected by a plurality of single corrugated steel plates 4-1-1. The connecting pieces 10 are connected, and two adjacent steel plate arch shell units 4 - 1 are connected through the second connecting piece 14 passing through their overlapping parts.

[0053] In this embodiment, the foamed concrete and the corrugated steel plate are used i...

Embodiment 2

[0074] Such as Figure 5 As shown, the difference between the culvert structure of this embodiment and the culvert structure of Embodiment 1 is that: the culvert foundation 1 and the filling body 3 are all made of foam concrete layered pouring, and the culvert foundation 1 and the filling body 3 The second reinforcing steel mesh 12 is uniformly arranged between and between two adjacent layers of filling bodies 3 .

[0075] In view of the insufficient bearing capacity of the foundation and the small filling height of the culvert subgrade, which may lead to uneven settlement in the culvert-subgrade transition section along the driving direction after construction, this embodiment adopts pouring foam concrete for the weak foundation and culvert. The side roadbed is filled with soil, and the steel plate arch shell is assembled on the poured foam concrete foundation, and the foam concrete is poured on both sides and the top of the steel plate arch shell.

[0076] In this embodimen...

Embodiment 3

[0080] Such as Figure 6 As shown, the difference between the culvert structure of this embodiment and the culvert structure of Embodiment 1 is that the water passing structure 4 is an arch culvert. The arch culvert is a double or porous corrugated steel arch culvert with large aperture.

[0081] In this embodiment, a plurality of arch ribs 13 are arranged on the side wall of the water passing structure 4 close to the filling body 3 , and the plurality of arch ribs 13 are arranged at intervals along the water flow direction of the water passing structure 4 . By setting the arch ribs 13, the rigidity of the side wall of the water passing structure 4 is effectively enhanced.

[0082] In addition, the difference between the construction method of the culvert structure of this embodiment and the construction method of the culvert structure of Embodiment 1 is that: the culvert foundation 1 includes the left foundation of the culvert and the right foundation of the culvert; a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com