Offshore wind turbine comprising impressed current cathode anticorrosion protection and monitoring device

An anti-corrosion protection and monitoring device technology, applied in the field of offshore wind turbines, can solve the problems of heavy workload, performance degradation, and poor anti-corrosion protection performance, and achieve good anti-corrosion protection, constant protection potential, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a further detailed description in conjunction with the drawings and the embodiments of the present invention:

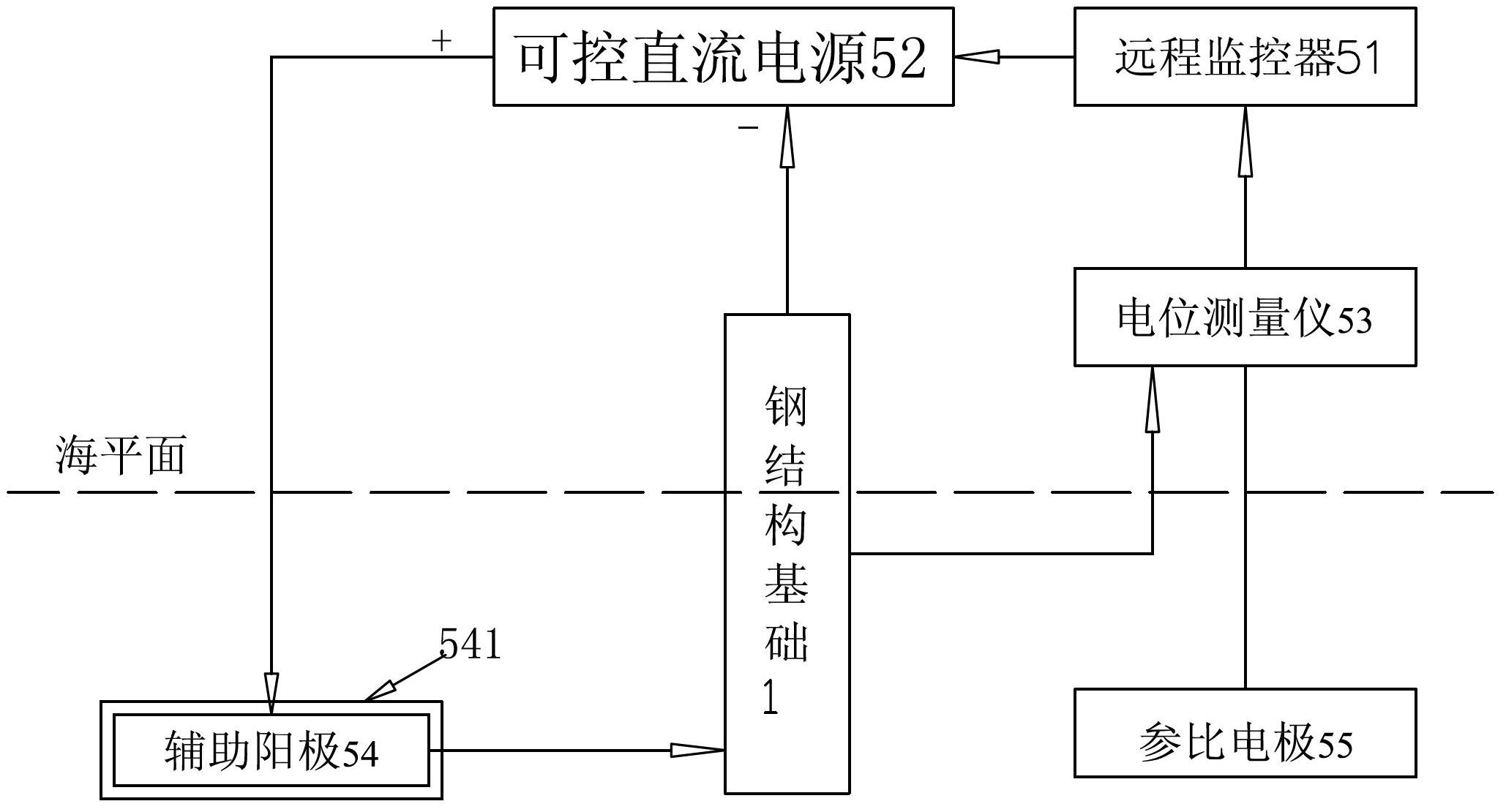

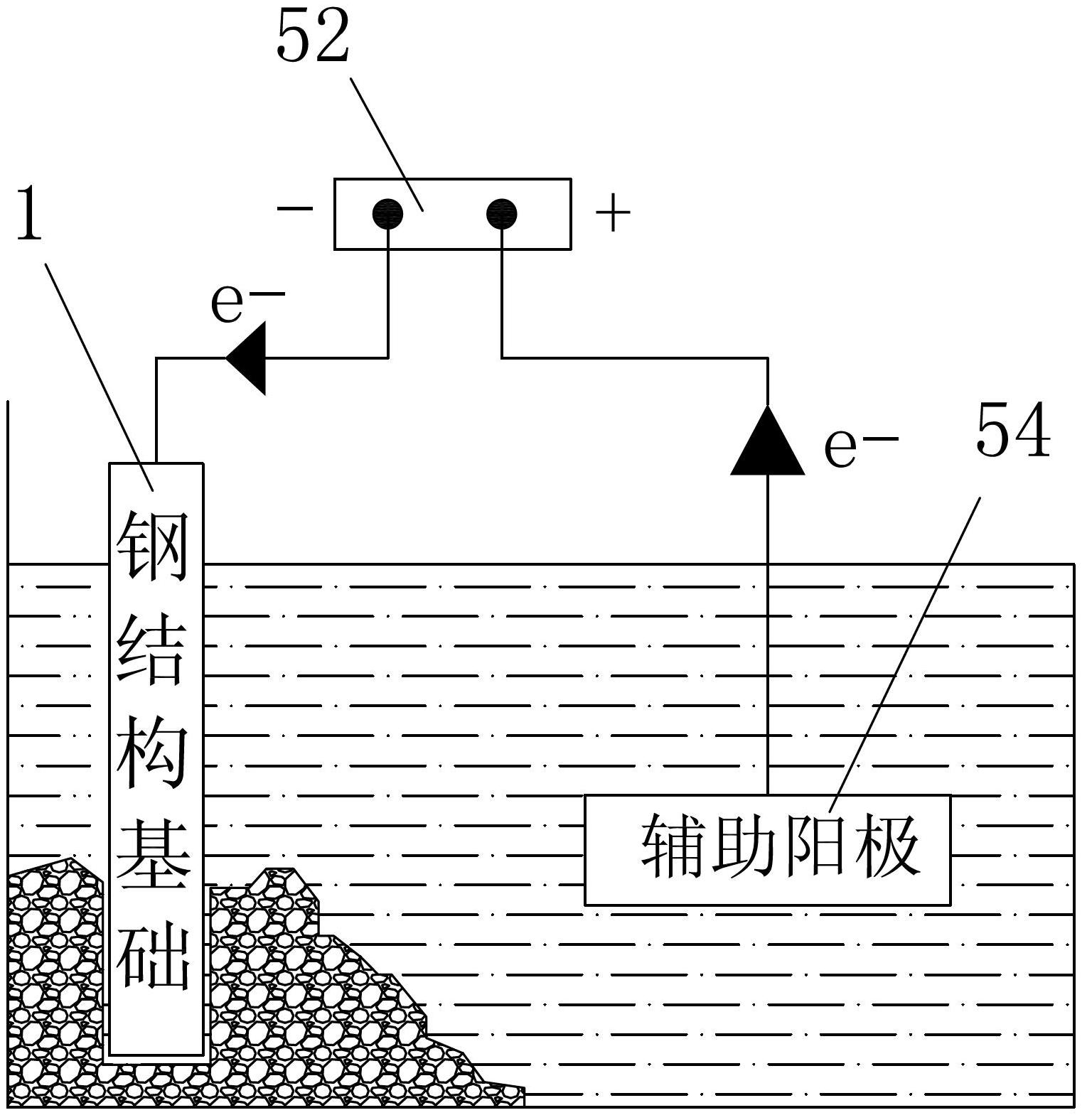

[0016] Each metal has a certain potential in a certain medium, which is called the corrosion potential of the metal. Generally speaking, the medium is soil or electrolyte solution. The corrosion potential indicates the relative difficulty for the metal to lose electrons. Negative is easier to lose electrons. We call the area where electrons are lost as the anode area and the area where electrons are obtained as the cathode area. The anode area is corroded due to the loss of electrons, and the cathode area is protected by electrons.

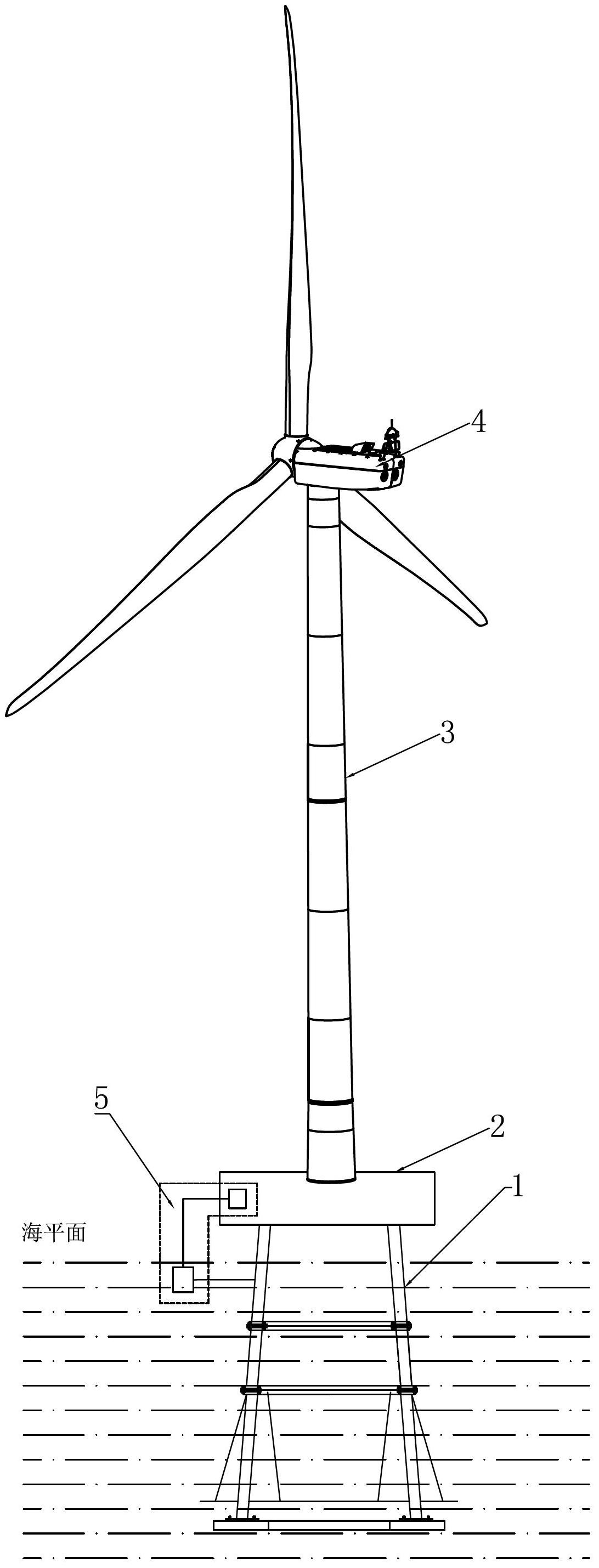

[0017] See Figure 1-2 As shown, an offshore wind turbine with an impressed current cathodic anti-corrosion protection and monitoring device includes a steel structure foundation 1 set on the sea, the steel structure foundation 1 is provided with a tower foundation platform 2, and the tower foundation platform 2 A tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com