Preparation technology for bionic ceramic/metal laminating composite support coating

A metal lamination and composite stent technology, applied in the direction of metal material coating process, coating, stent, etc., can solve the problems of coating brittleness and insufficient binding force, and achieve the improvement of anticoagulation and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation process of biomimetic ceramic / metal laminated composite stent coating, the steps are:

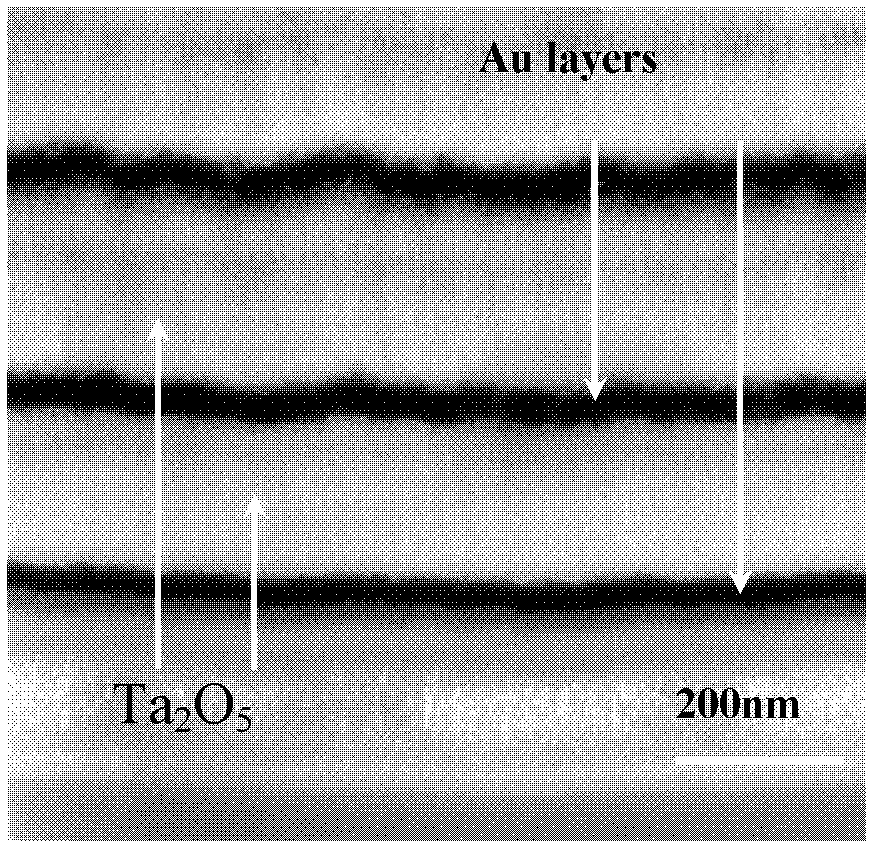

[0026] a. First, the Ta layer was deposited by double-cathode plasma sputtering. The process parameters were as follows: target voltage 600V, workpiece voltage 280V, distance between target and workpiece 15mm, working pressure 35Pa, deposition temperature 800℃; sputtering time 15min, obtained 200nm thick Ta layer.

[0027] b. Then perform ion oxidation, and the process parameters are as follows: workpiece voltage 600V, oxidation temperature 500°C, working pressure 35Pa, oxygen partial pressure 0.5Pa, ion oxidation for 8min;

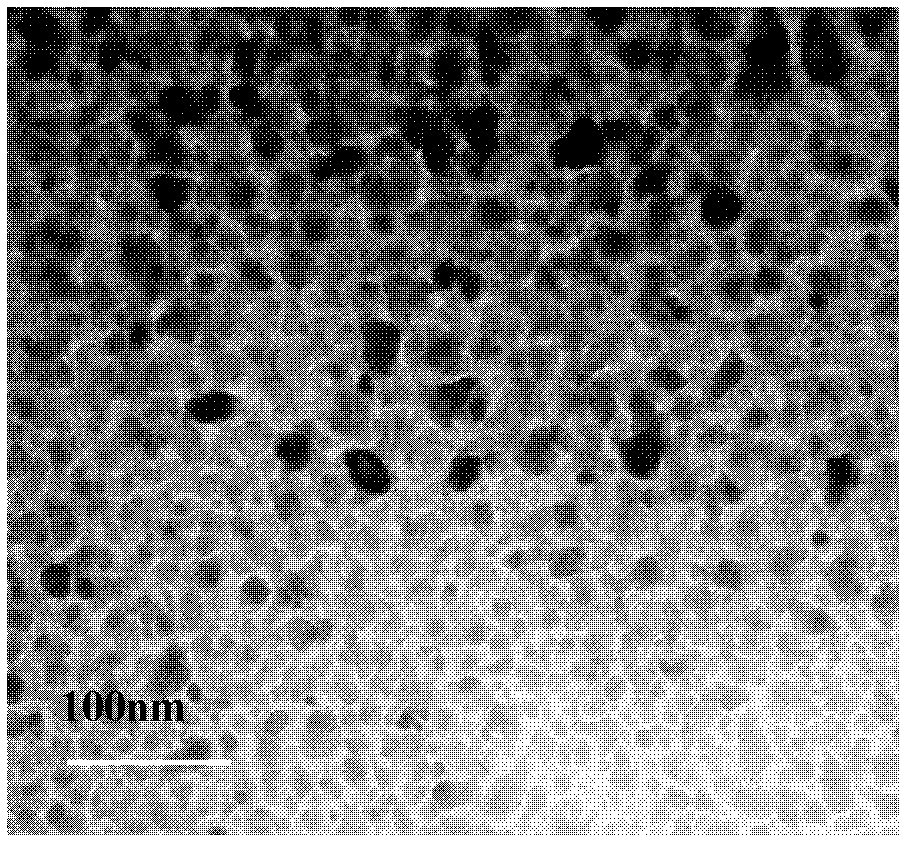

[0028] c. Deposit the Au layer by double-cathode plasma sputtering, the process parameters are as follows: target voltage 600V, workpiece voltage 220V, distance between target and workpiece 15mm, working pressure 35Pa, deposition temperature 400°C; sputtering time 8min, obtained 20nm thick Au layer. Repeat steps a-c at least 30 times to obtain ...

Embodiment 2

[0035] The preparation process of biomimetic ceramic / metal laminated composite stent coating, the steps are:

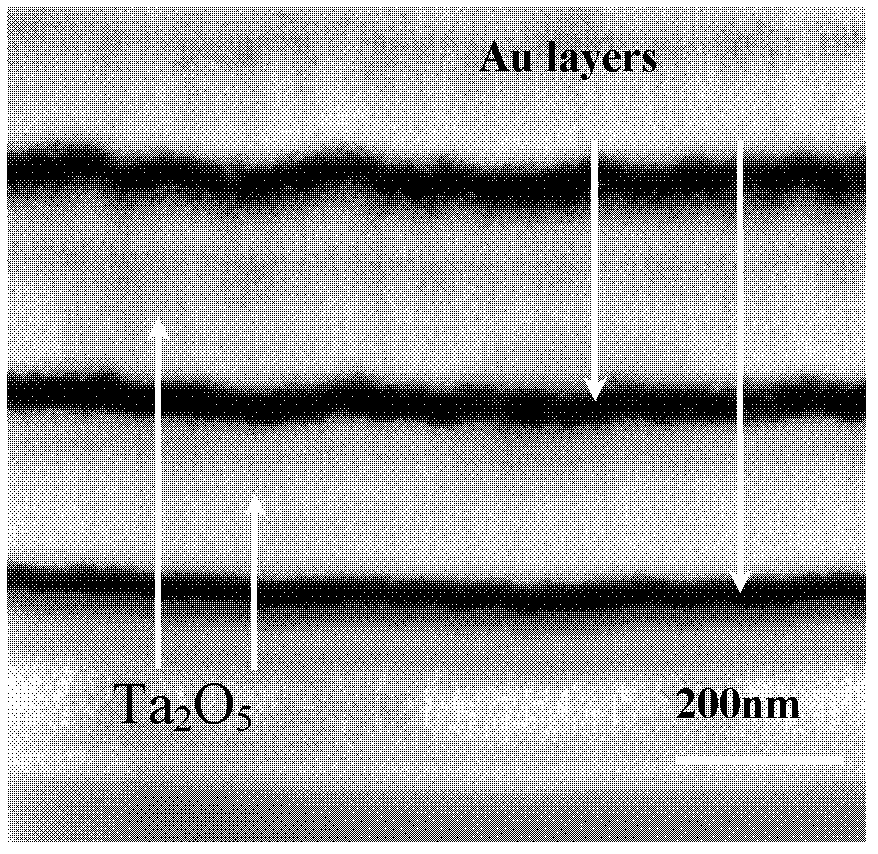

[0036] a. First, the Ta layer was deposited by double-cathode plasma sputtering. The process parameters were as follows: target voltage 650V, workpiece voltage 300V, distance between target and workpiece 20mm, working pressure 35Pa, deposition temperature 650℃; sputtering time 20min, obtained 200nm thick Ta layer;

[0037]b. Then perform ion oxidation, the process parameters are as follows: workpiece voltage 850V, oxidation temperature 600°C, working pressure 35Pa, oxygen partial pressure 1 Pa, ion oxidation 10min;

[0038] c. Deposit the Mg layer by double-cathode plasma sputtering. The process parameters are as follows: target voltage 650V, workpiece voltage 250V, distance between target and workpiece 20mm, working pressure 35Pa, deposition temperature 450°C; sputtering time 10min, obtain 20nm For a thick Mg layer, repeat steps a-c at least 30 times to obtain a lam...

Embodiment 3

[0044] The preparation process of the biomimetic ceramic / metal laminated composite stent coating is characterized in that the steps are:

[0045] a. First, the Ta layer is deposited by double-cathode plasma sputtering. The process parameters are as follows: target voltage 500V, workpiece voltage 250V, distance between target and workpiece 10mm, working pressure 35Pa, deposition temperature 450°C; sputtering time 10min, obtain 100nm Thick Ta layer;

[0046] b. Then perform ion oxidation, the process parameters are as follows: workpiece voltage 650V, oxidation temperature 450°C, working pressure 35Pa, oxygen partial pressure 0.1Pa, ion oxidation for 5min;

[0047] c. Deposit Au layer by double-cathode plasma sputtering, the process parameters are as follows: target voltage 400V, workpiece voltage 200V, distance between target and workpiece 10mm, working pressure 35Pa, deposition temperature 250°C; sputtering time 5min, obtain 10nm thickness Au layer, repeat steps a-c more than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com