Epoxy resin-oxidized graphene composite coating and application method thereof

A graphene composite and epoxy resin technology, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of weakened protective effect and reduced service life of the substrate, so as to improve corrosion resistance, excellent thermal performance, The effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

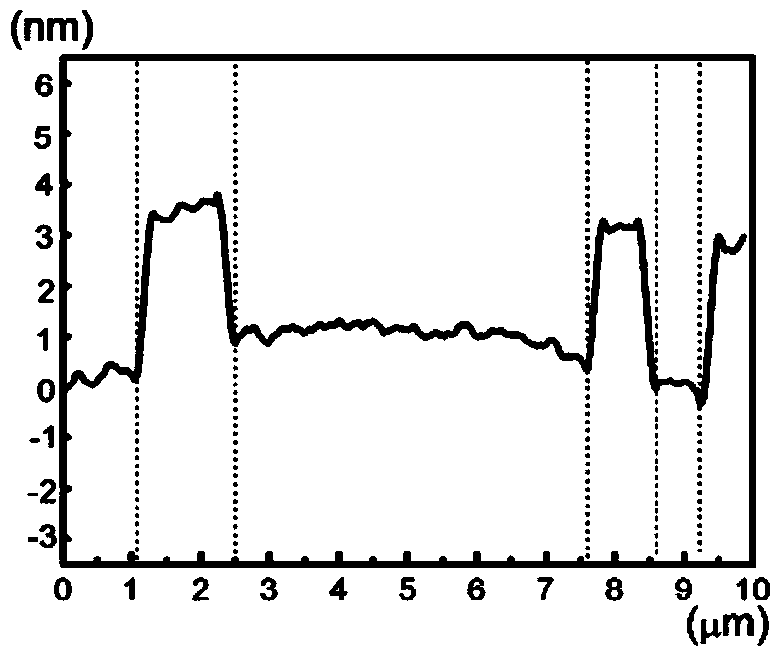

Image

Examples

Embodiment 1

[0043] In this example, the substrate is exactly the same as that in Comparative Example 1.

[0044] An epoxy resin coating is prepared by coating the surface of the substrate with an epoxy resin coating.

[0045] Epoxy coatings consist of A and B components.

[0046]Component A is composed of 1g mixed solvent, 10g epoxy resin and a certain amount of graphene oxide modified by silane coupling agent. Wherein, the solvent is a mixed solvent formed by mixing xylene and n-butanol at a mass ratio of 7:3, and the mass of graphene oxide accounts for 0.25% of the mass of the epoxy resin E51.

[0047] Component B is 5g of modified isophorone diamine curing agent and 0.03g of BYK-028 defoamer.

[0048] The preparation method of the silane coupling agent modified graphene oxide is: add 20g of silane coupling agent KH560 to 72g of ethanol and 8g of deionized water, after stirring evenly, add 1g of graphene oxide, ultrasonic dispersion for 1 hour, 60 ℃ water bath Stir mechanically in th...

Embodiment 2

[0053] In this example, the substrate is exactly the same as that in Comparative Example 1.

[0054] An epoxy resin coating is prepared by coating the surface of the substrate with an epoxy resin coating.

[0055] Epoxy coatings consist of A and B components.

[0056] Component A is composed of 1g mixed solvent, 10g epoxy resin and a certain amount of graphene oxide modified by silane coupling agent. Wherein, the solvent is a mixed solvent formed by mixing xylene and n-butanol at a mass ratio of 7:3, and the mass of graphene oxide accounts for 0.5% of the mass of the epoxy resin E51.

[0057] The B component is exactly the same as the B component in Example 1.

[0058] The preparation method of silane coupling agent modified graphene oxide is exactly the same as that of Example 1.

[0059] The preparation method of component A is basically the same as that of Example 1, except that the mass of modified graphene oxide added is 0.05 g.

[0060] The method for preparing an ep...

Embodiment 3

[0063] In this example, the substrate is exactly the same as that in Comparative Example 1.

[0064] An epoxy resin coating is prepared by coating the surface of the substrate with an epoxy resin coating.

[0065] Epoxy coatings consist of A and B components.

[0066] Component A is composed of 1g mixed solvent, 10g epoxy resin and a certain amount of graphene oxide modified by silane coupling agent. Wherein, the solvent is a mixed solvent formed by mixing xylene and n-butanol at a mass ratio of 7:3, and the mass of graphene oxide accounts for 0.75% of the mass of the epoxy resin E51.

[0067] The B component is exactly the same as the B component in Example 1.

[0068] The preparation method of silane coupling agent modified graphene oxide is exactly the same as that of Example 1.

[0069] The preparation method of component A is basically the same as that of Example 1, except that the mass of modified graphene oxide added is 0.075g.

[0070] The method for preparing an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com