Method for preparing centrifugal nodular cast iron pipe

A technology of centrifugal nodular cast iron and cast iron pipes, which is applied to the device and coating of the surface coating liquid, which can solve the problems of desulfurization, improper spheroidizing process, shortened service life of iron cast pipes, and affecting the quality of iron cast pipes , to achieve the effect of high appearance quality, stable molten iron composition and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is suitable for preparing a centrifugal ductile iron pipe whose specification is DN500mm, and its preparation steps are as follows:

[0048] (A) Using a blast furnace or a cupola to smelt pig iron at high temperature to obtain molten iron with a sulfur content of 0.02% and a carbon equivalent fluctuation of 0.1%;

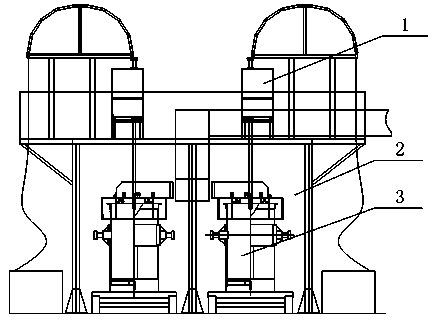

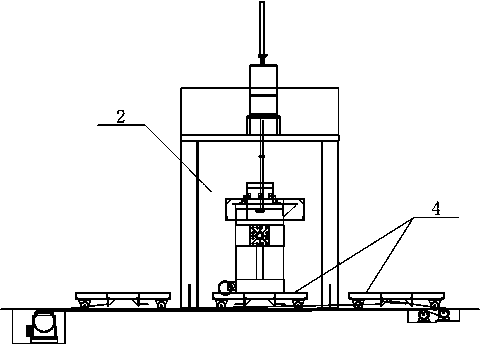

[0049] (B) sending the molten iron obtained in step (A) to the spheroidizing station, figure 1 , figure 2 is a schematic diagram of the structure of the spheroidization station, such as figure 1 , figure 2 As shown, the spheroidizing bag 3 is sent into the spheroidizing chamber 2 of the spheroidizing station by the electric flat car 4, and the molten iron is spheroidized by the spheroidizing wire feeding mechanism 1 of the spheroidizing station. The molten iron obtained after melting contains: 3.2% carbon, 0.008% sulfur, 2.3% silicon, 0.07% phosphorus, 0.04% magnesium, 0.32% manganese, and 0.025% rhenium. Nodulizing agent and inoculant, ...

Embodiment 2

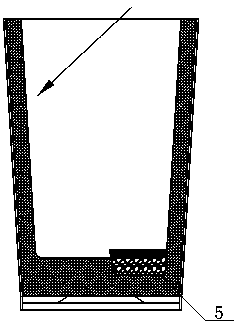

[0055] The difference between this embodiment and Embodiment 1 is that the spheroidization process involved in this embodiment is the flushing spheroidization method, and the structure of the spheroidization package 3 is as follows: image 3 As shown, the bottom of the spheroidizing bag 3 and one side of the dam of the spheroidizing bag form a groove 5 for accommodating the nodulizer and the inoculant. and inoculant, in actual operation, the molten iron is tapped by the spheroidizing wire feeding mechanism 1 along the spheroidizing ladle dam on the side where the groove 5 is not formed, namely image 3 indicated by the arrow symbol.

[0056] The spheroidizing agent used in this embodiment is a rare earth magnesium silicon spheroidizing agent, which contains 20% rare earth, 25% magnesium and 50% silicon by weight percentage.

[0057] The inoculant used in this embodiment is ferrosilicon or silicon-calcium alloy, and the inoculant contains 50% silicon and 1.5% calcium by weight...

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that the spheroidization process involved in this embodiment is the flushing spheroidization method, and the structure of the spheroidization package 3 is as follows: Figure 4 As shown, the bottom of the spheroidizing bag 3 and one side of the dam of the spheroidizing bag form a groove 5 for accommodating the nodulizer and the inoculant. and inoculant, in actual operation, the molten iron is tapped by the spheroidizing wire feeding mechanism 1 along the spheroidizing ladle dam on the side where the groove 5 is not formed, namely Figure 4 indicated by the arrow symbol.

[0060] The spheroidizing agent used in this embodiment is a rare earth magnesium silicon spheroidizing agent, which contains 19% rare earth, 22% magnesium and 48% silicon by weight percentage.

[0061] The inoculant used in this embodiment is ferrosilicon or silicon-calcium alloy, and the inoculant contains 47% silicon and 1.4% calcium by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com