Patents

Literature

38 results about "Cupola" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In architecture, a cupola /ˈkjuːpələ/ is a relatively small, most often dome-like, tall structure on top of a building. Often used to provide a lookout or to admit light and air, it usually crowns a larger roof or dome.

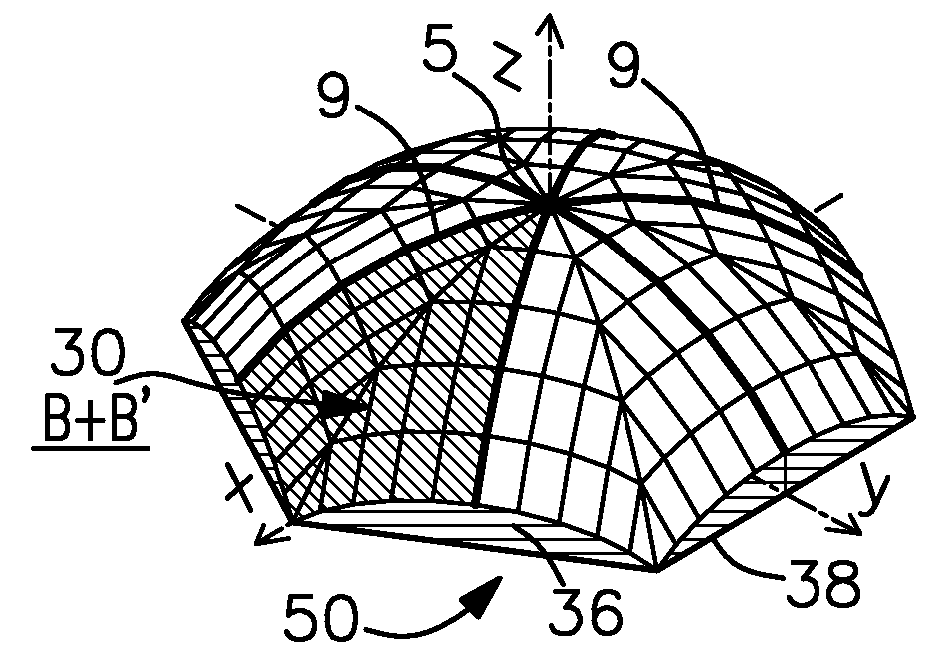

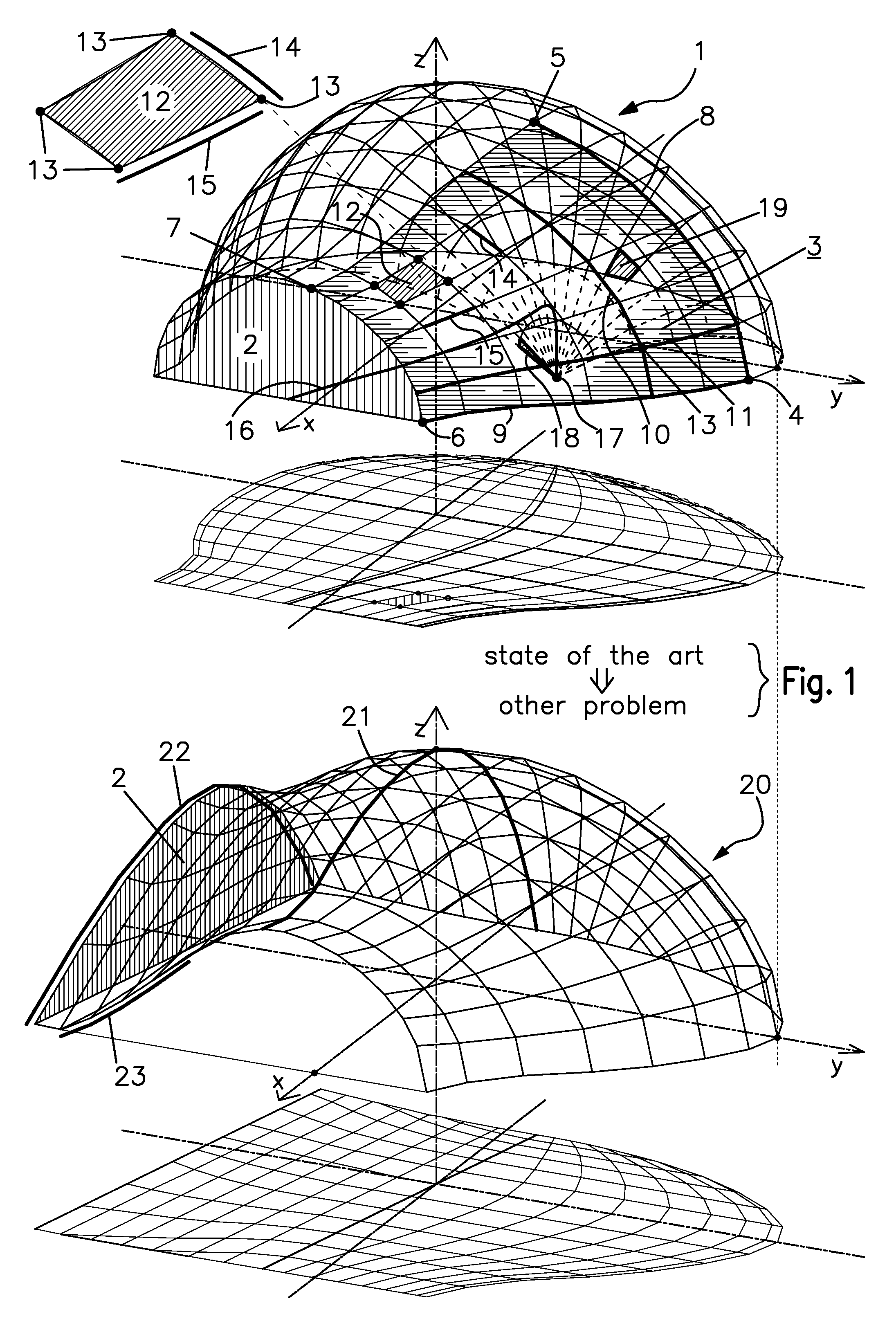

Double-curved shell

Owner:TUCZEK FLORIAN

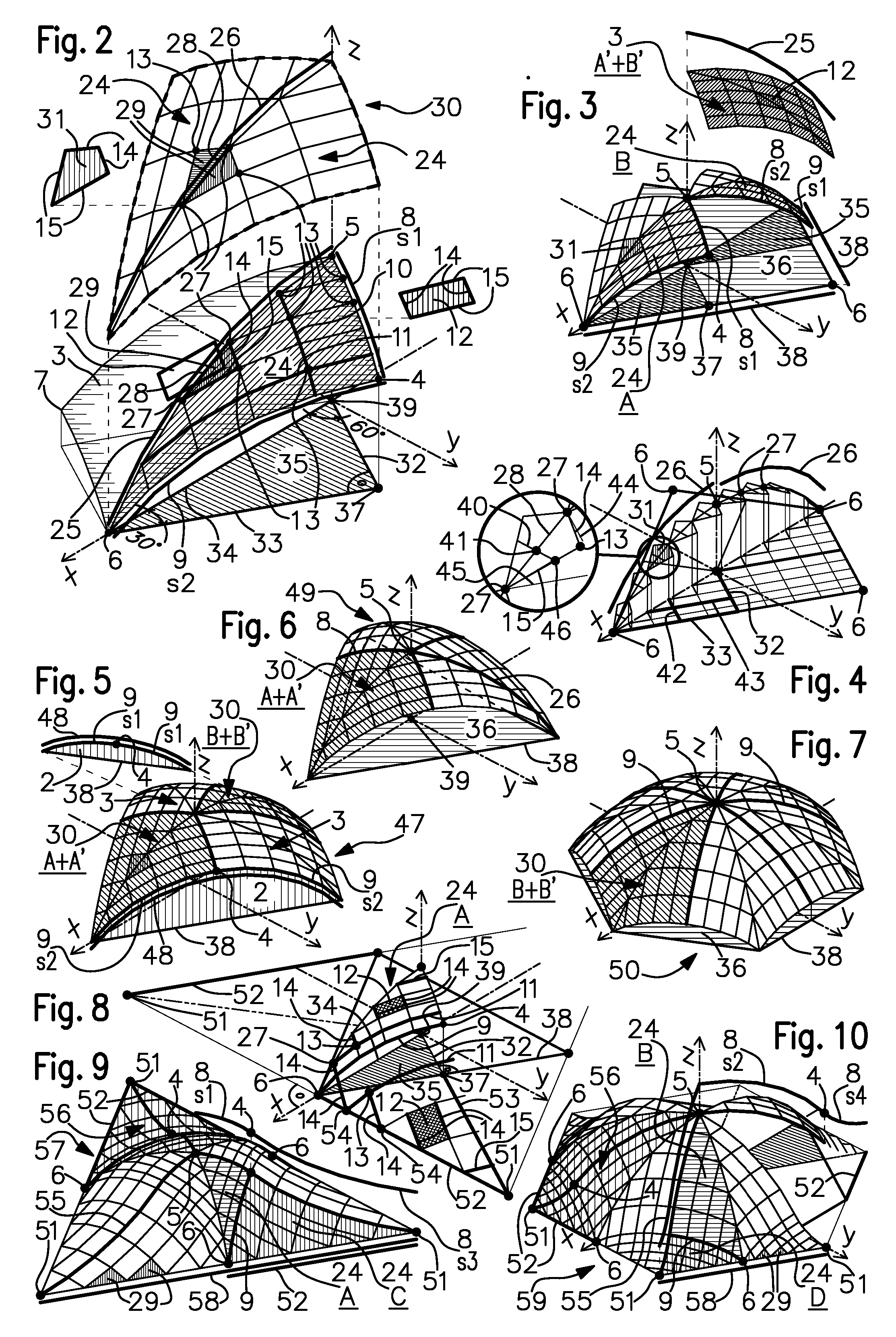

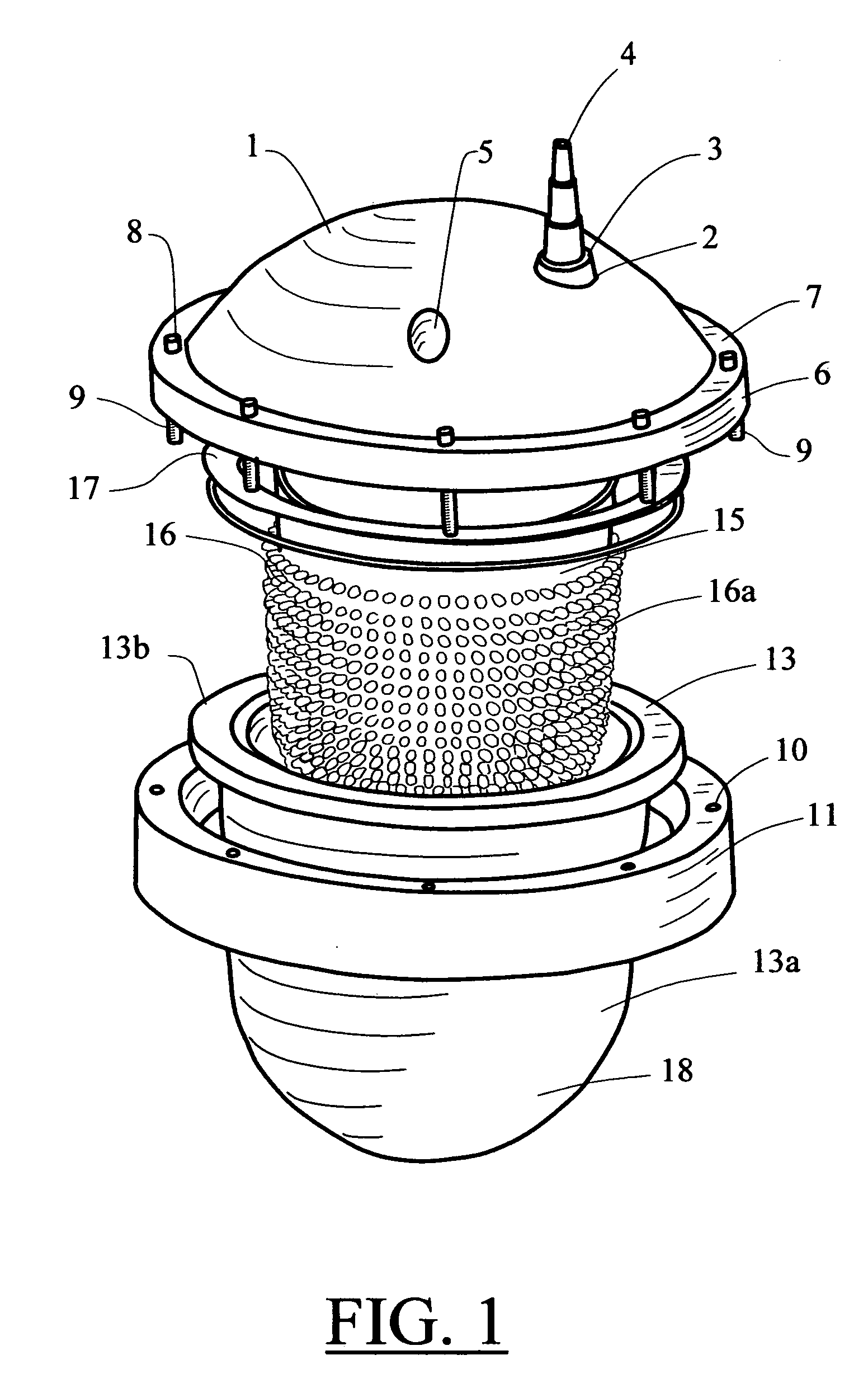

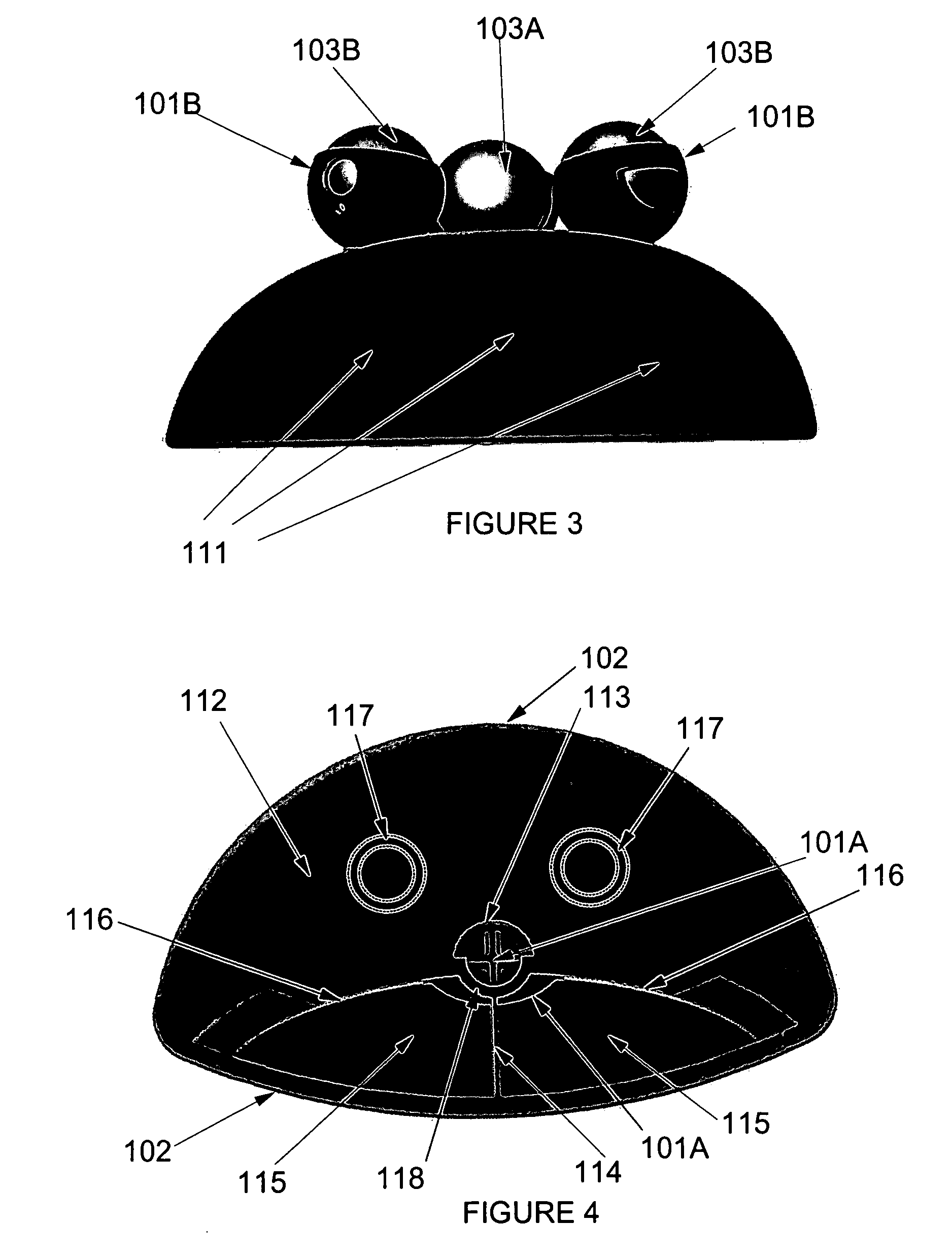

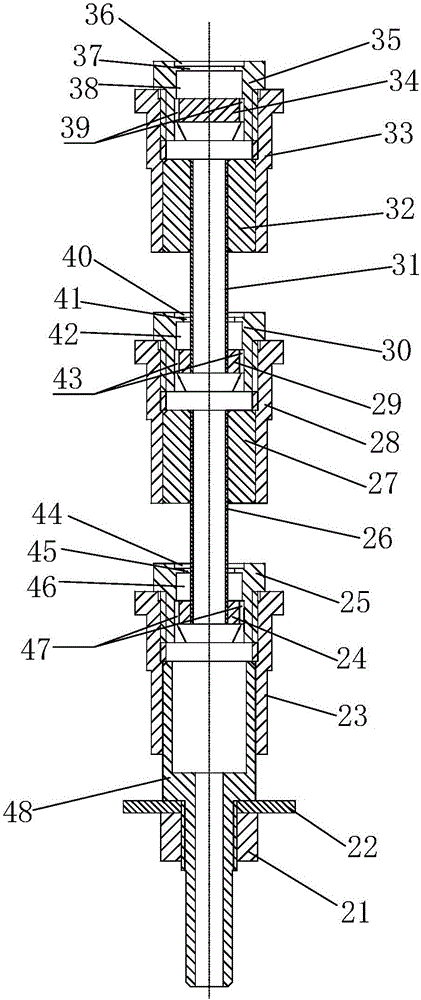

Submersible lamp for use in fotoperiod in processes of handling of salmon species

A submergible lamp for its use or application in photoperiod in processes of smolting, feeding and optimum handling of the reproductive process of salmon species, whose source of illumination are a group of green LED luminaries issuing light with an intensity of 500 to 550 nanometres, by means that allow for a lower consumption than the lamps currently in use and which not only represent economies in terms of costs, but also a favorable environmental impact in terms of a lower consumption of fuel or batteries, which might eventually represent a danger to the environment, becoming waste and by demanding a substantial infrastructure in their installation. The lamp consists of a semi-spherical casing with top side exit for the power cable covered by a threaded stuffing box through which the three-phase cable emerges, with an inner lining on the surface, transverse to said semi-spherical casing has a tunnel, which permits the affixing and installation of the lamp surrounded by a peripheral ring and base walls both of which have equidistant orifices which allow for joining and affixing by means of screw bolts, with the orifices of the central piece with a cylindrical cross section equipped on the inside with a peripheral body or projection that serves as support for the upper edge of the exterior body or glass cupola, with the upper zone of that peripheral body or projection. In turn, the peripheral projection has a central grooving where an “O” ring is placed that prevents water from entering the lamp; also, said lamp has another interior body or LED holder made of plastic, equipped with LEDs, said interior body is placed inside the exterior body of glass.

Owner:NAVARRO ALVAREZ MARIA CRISTINA

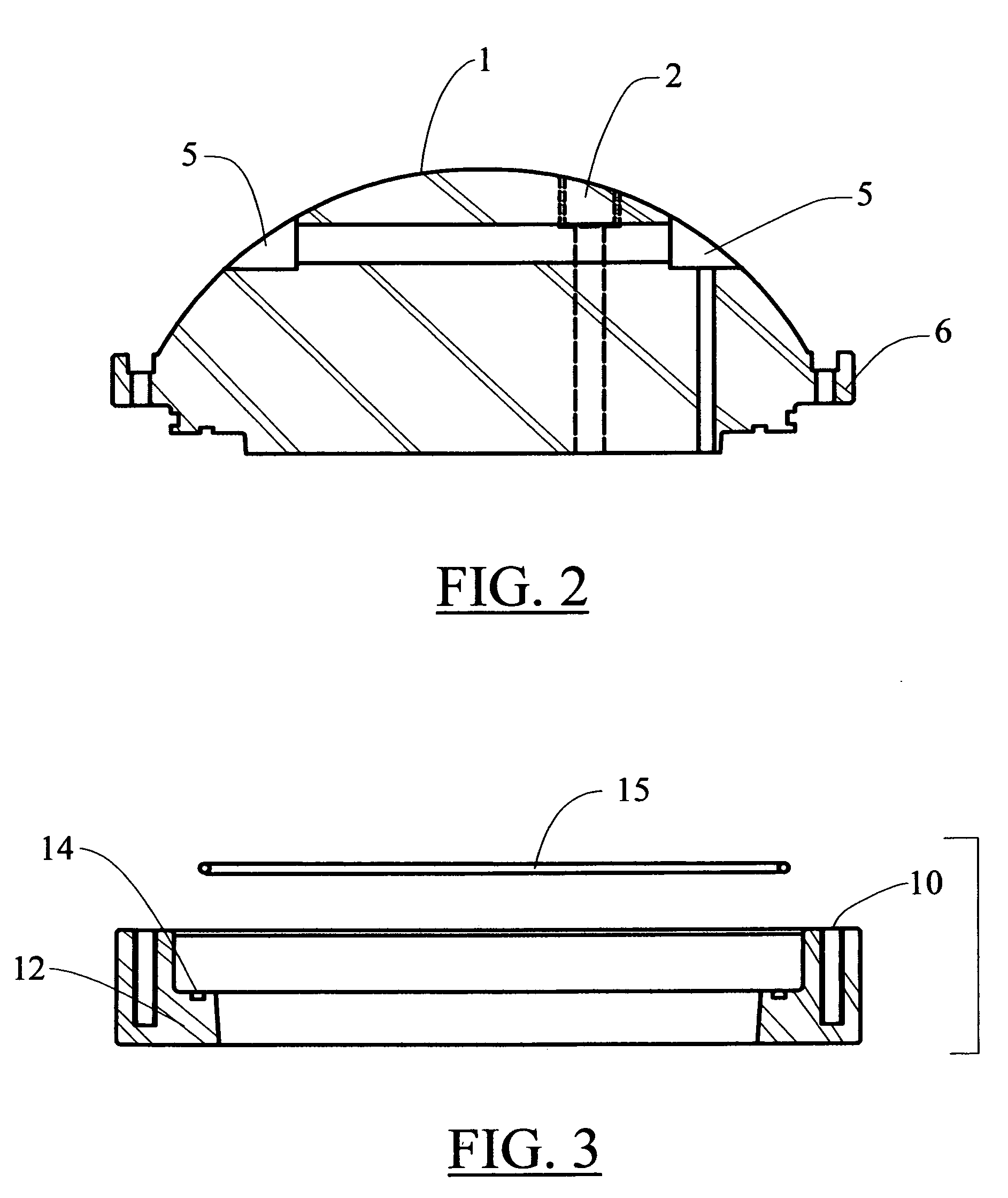

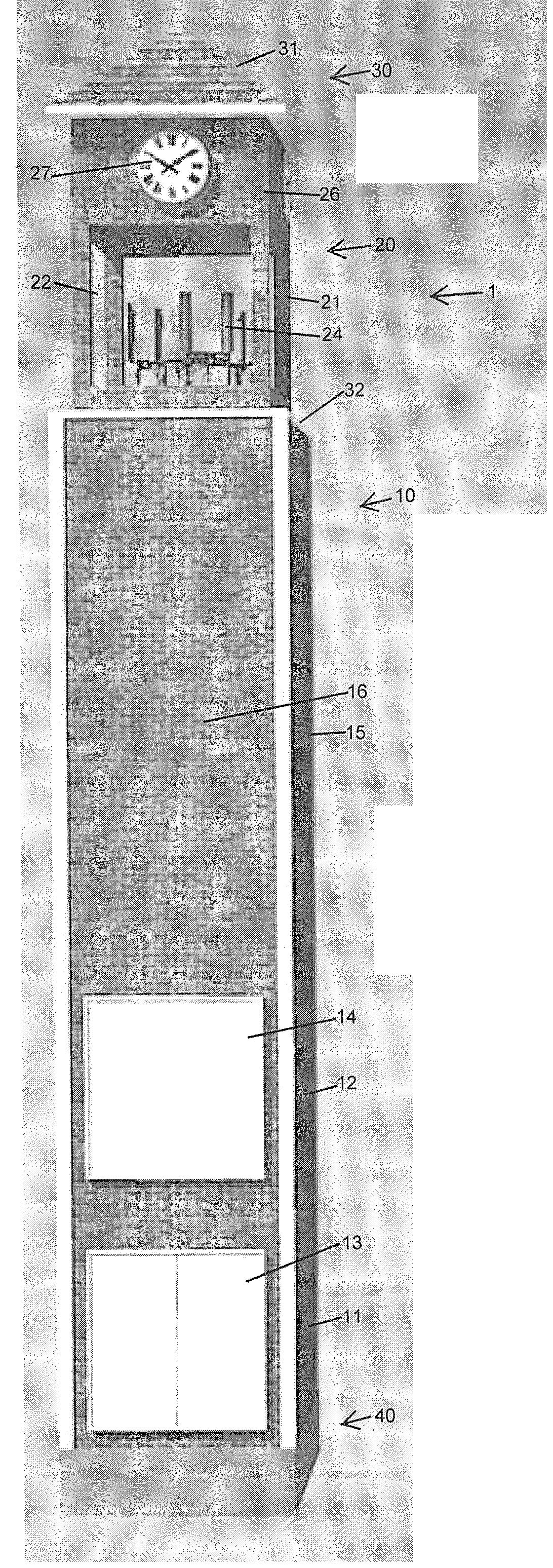

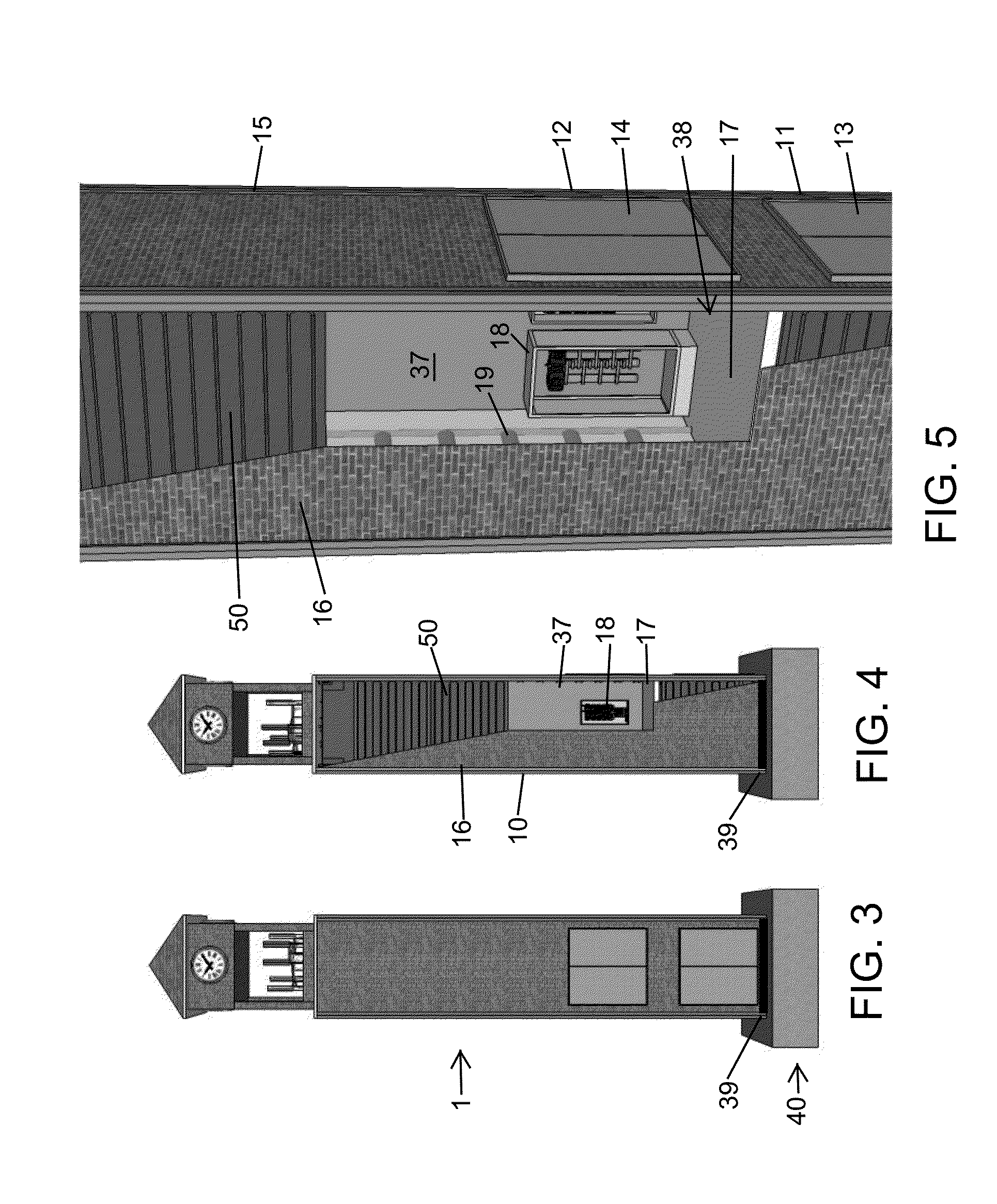

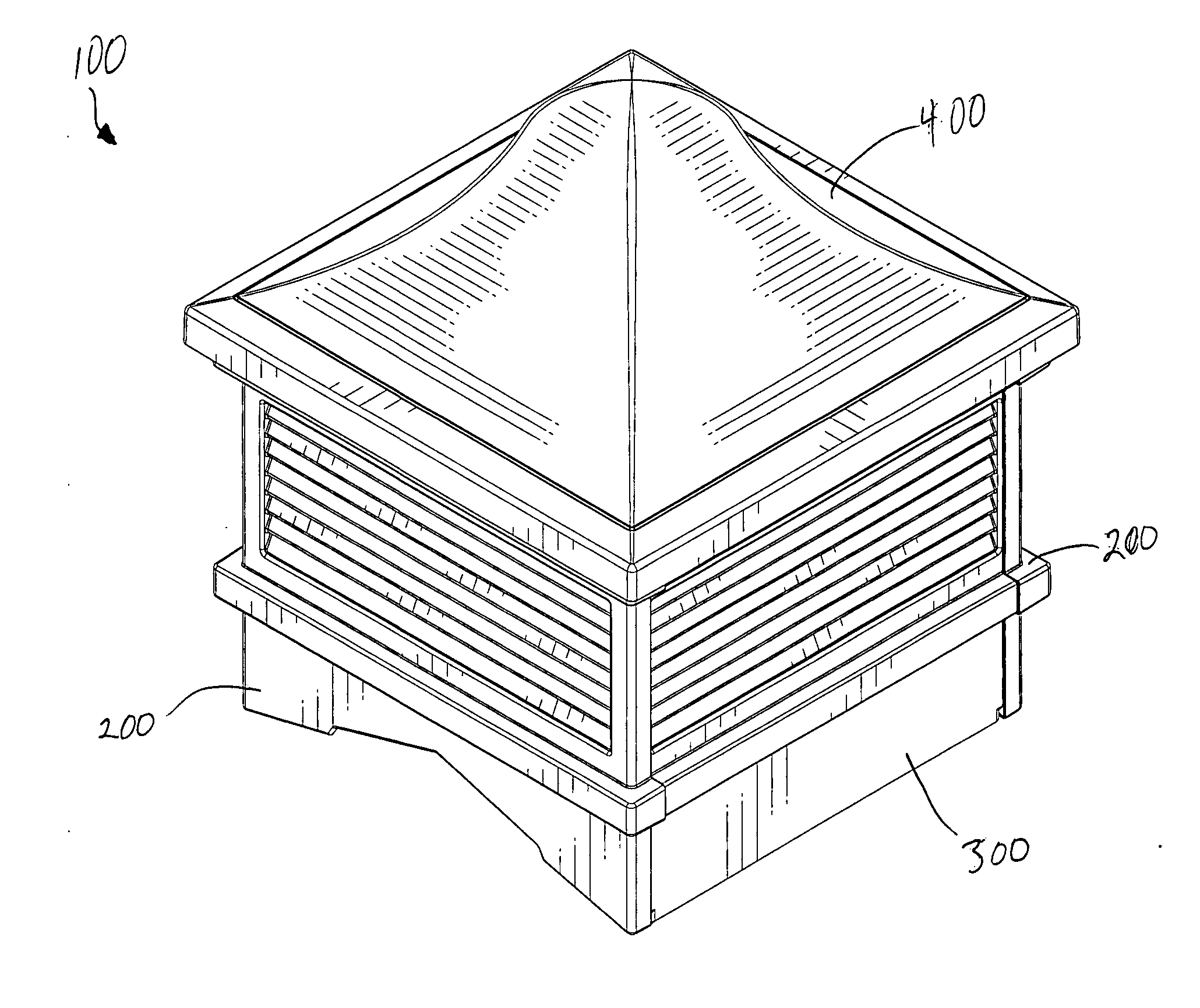

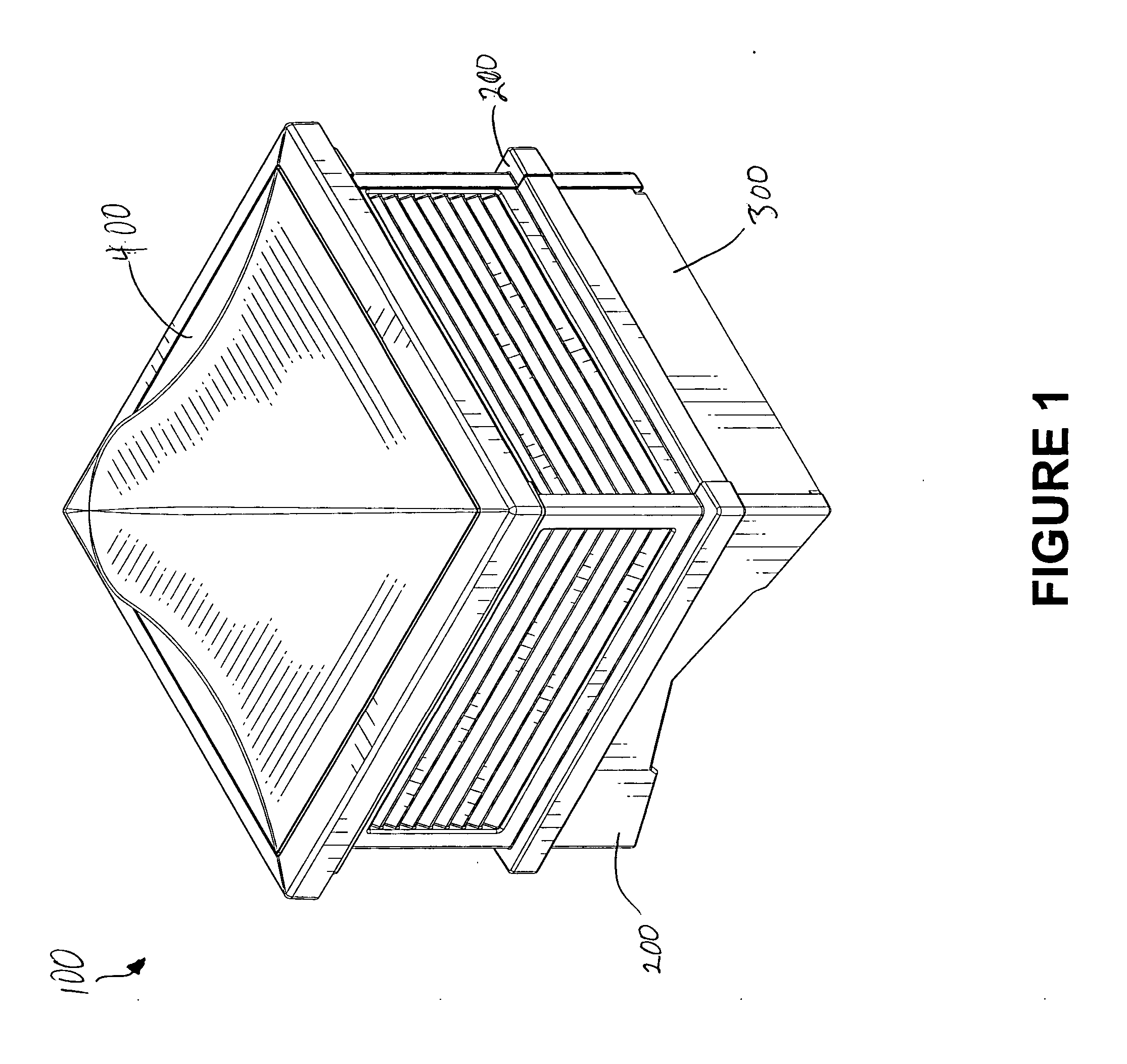

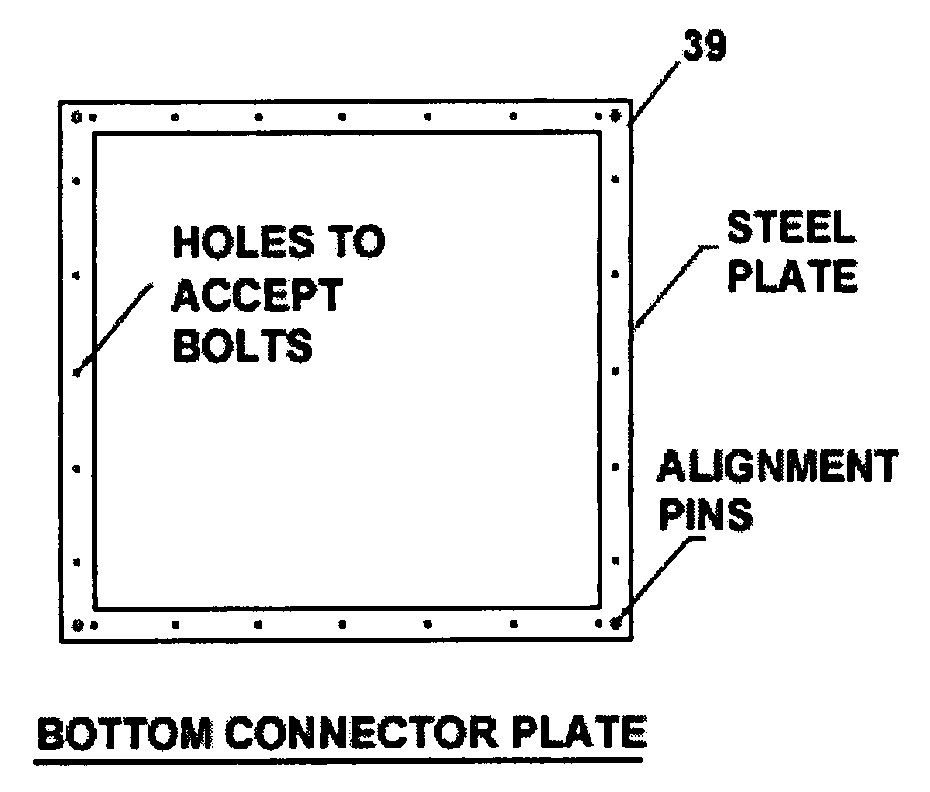

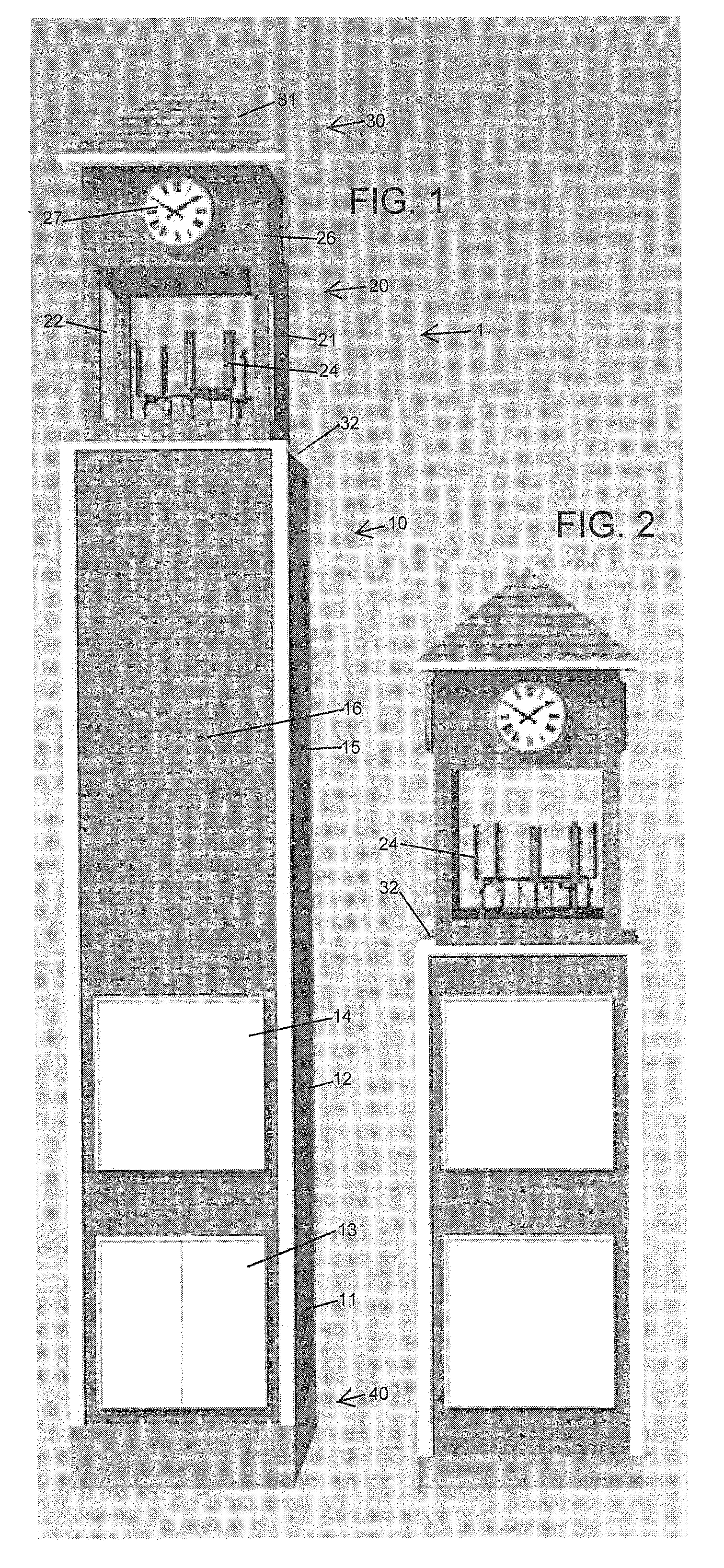

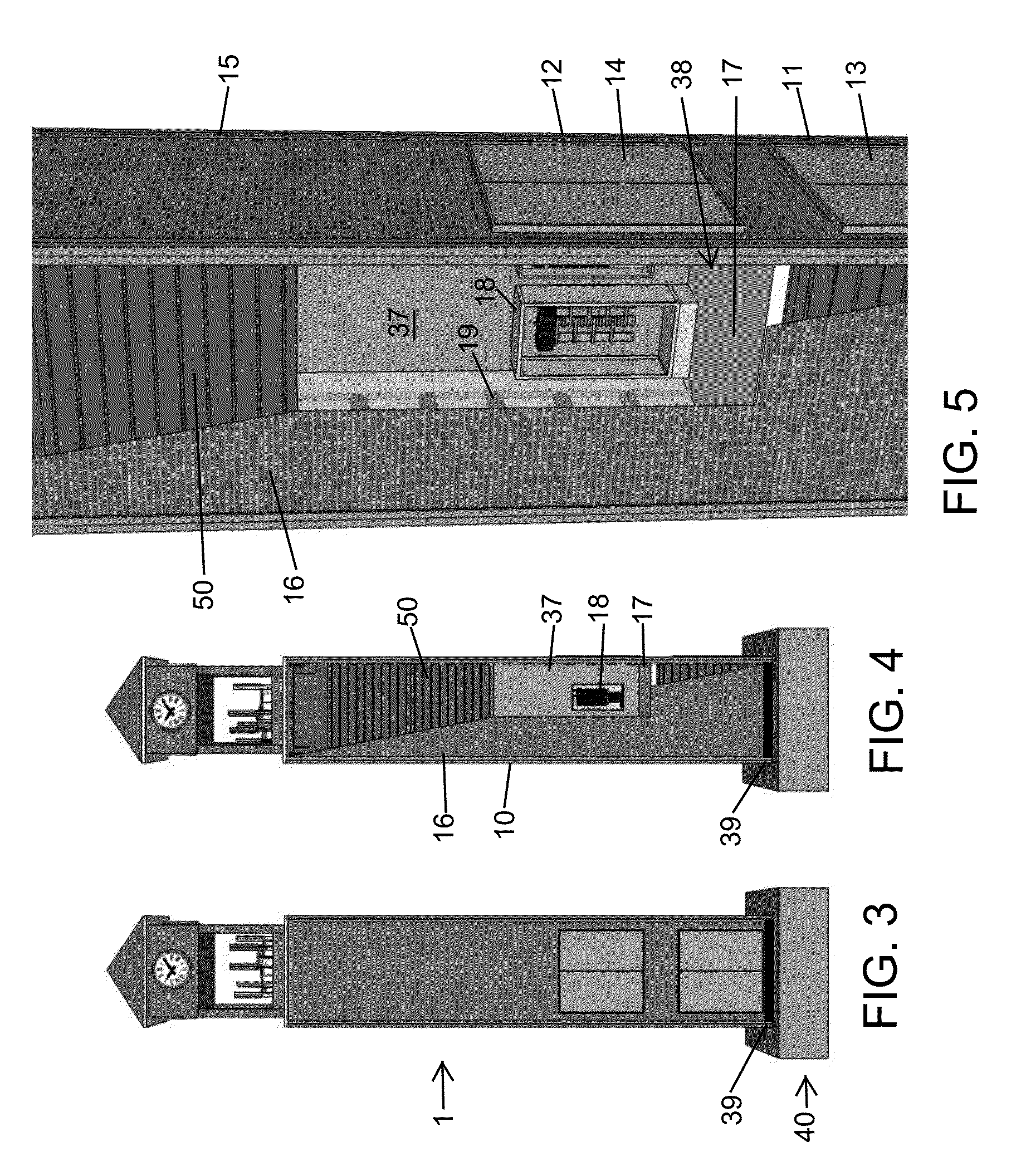

Cellular Antenna Tower and Equipment Enclosure Based on Shipping Container

ActiveUS20140259978A1Easily and quickly fabricatable and deployableLow costRoof covering using slabs/sheetsRoof covering using tiles/slatesInterior spaceCupola

An antenna tower structure for wireless communication antennas includes an antenna cupola mounted on a tower based on at least one standardized ISBU shipping container that has been modified and erected to stand upright on a foundation. The modifications may include longitudinal reinforcements along at least two longitudinal edges of the container, mounting hardware at the two ends of the container, an access door on a side of the container, an access hatch in the upper end of the container, a ladder extending longitudinally inside the container, and a floor extending perpendicular to the longitudinal axis of the container. The container provides a weather-protected climate-controlled interior space for sheltering electronics equipment. The cupola has antennas installed on at least one level, and may include shutters, a clock, a bell etc. to hide the antennas and disguise the tower. The exterior of the structure may be finished to match surrounding buildings.

Owner:WALTON CHADWICK J

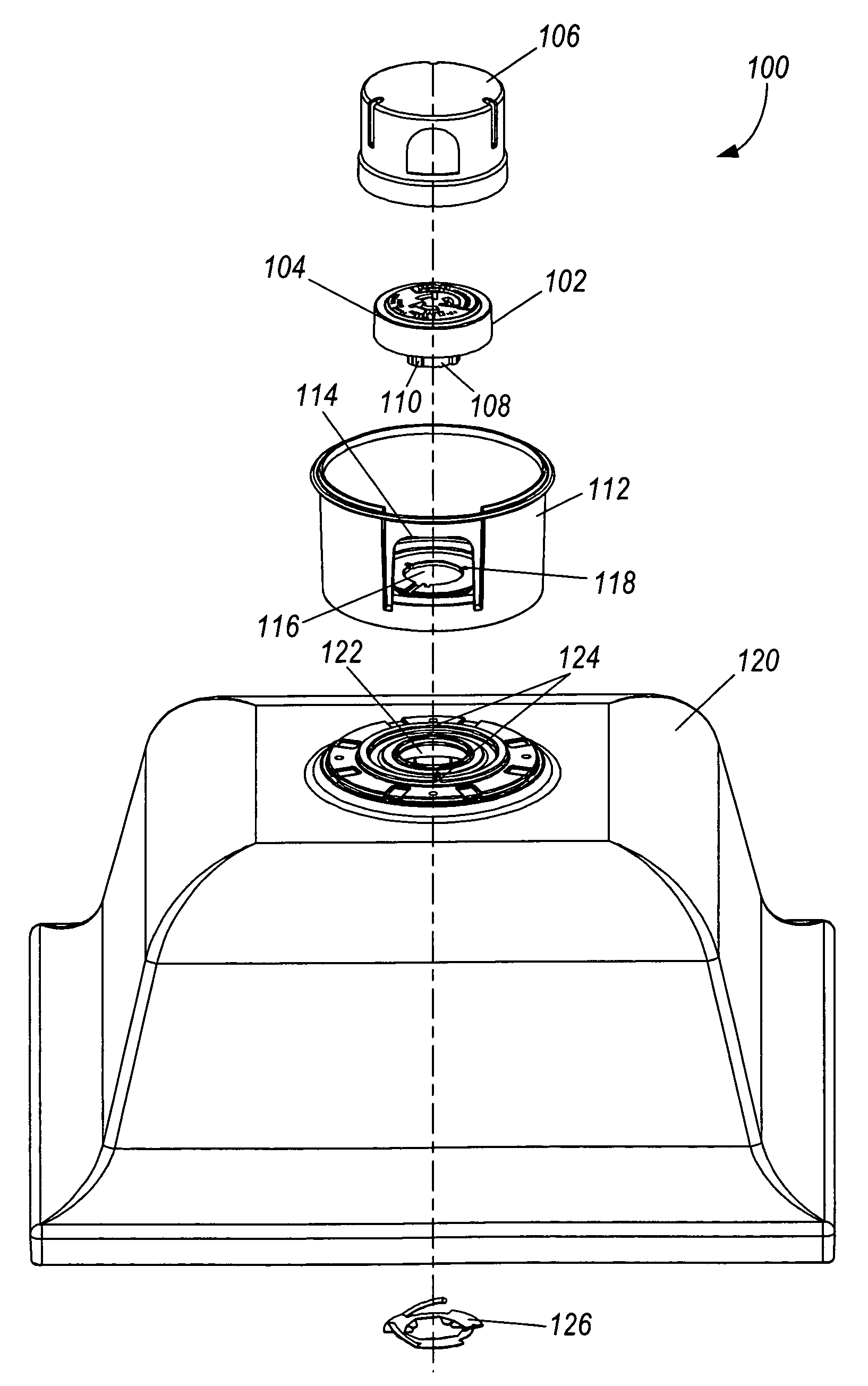

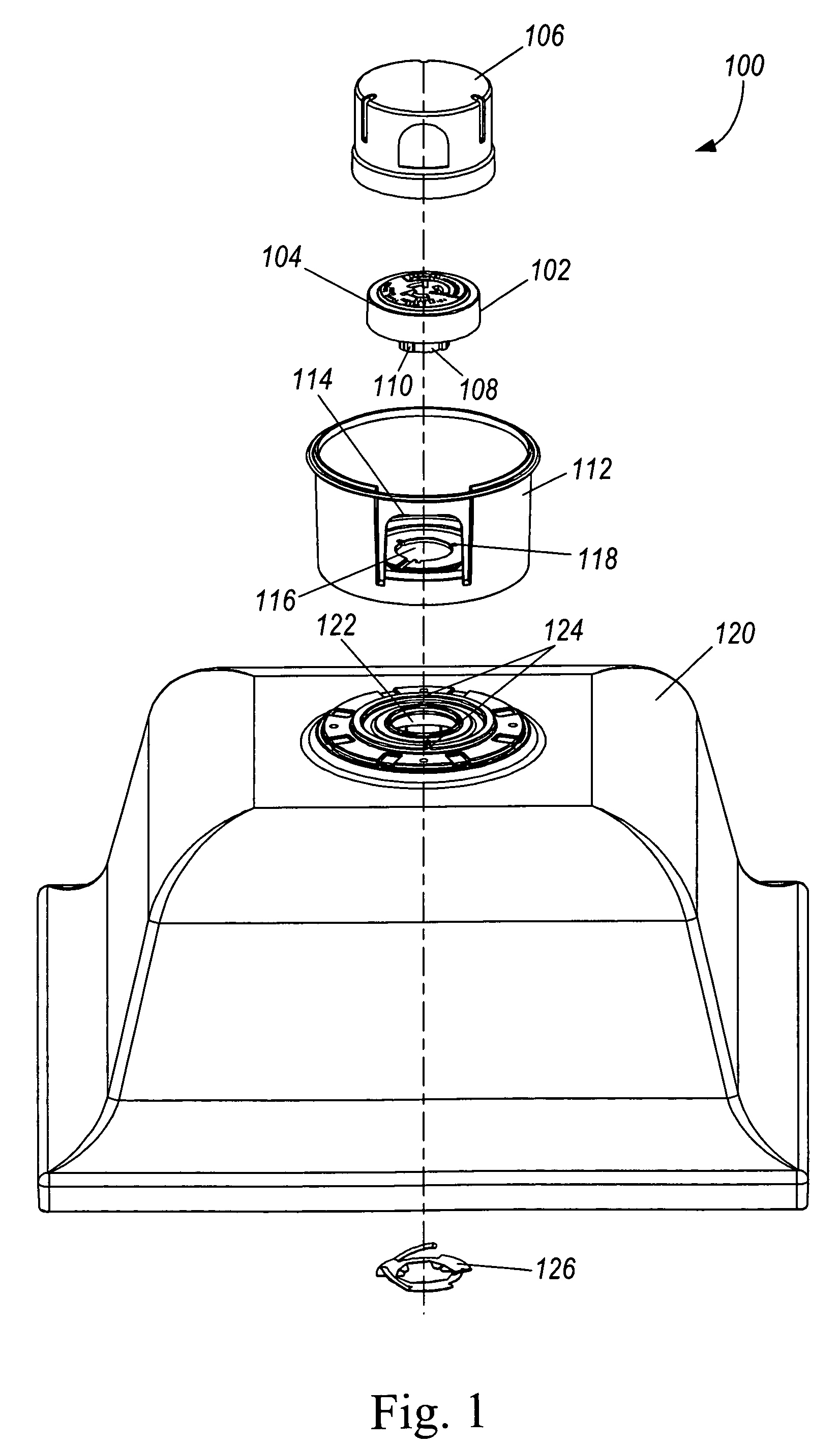

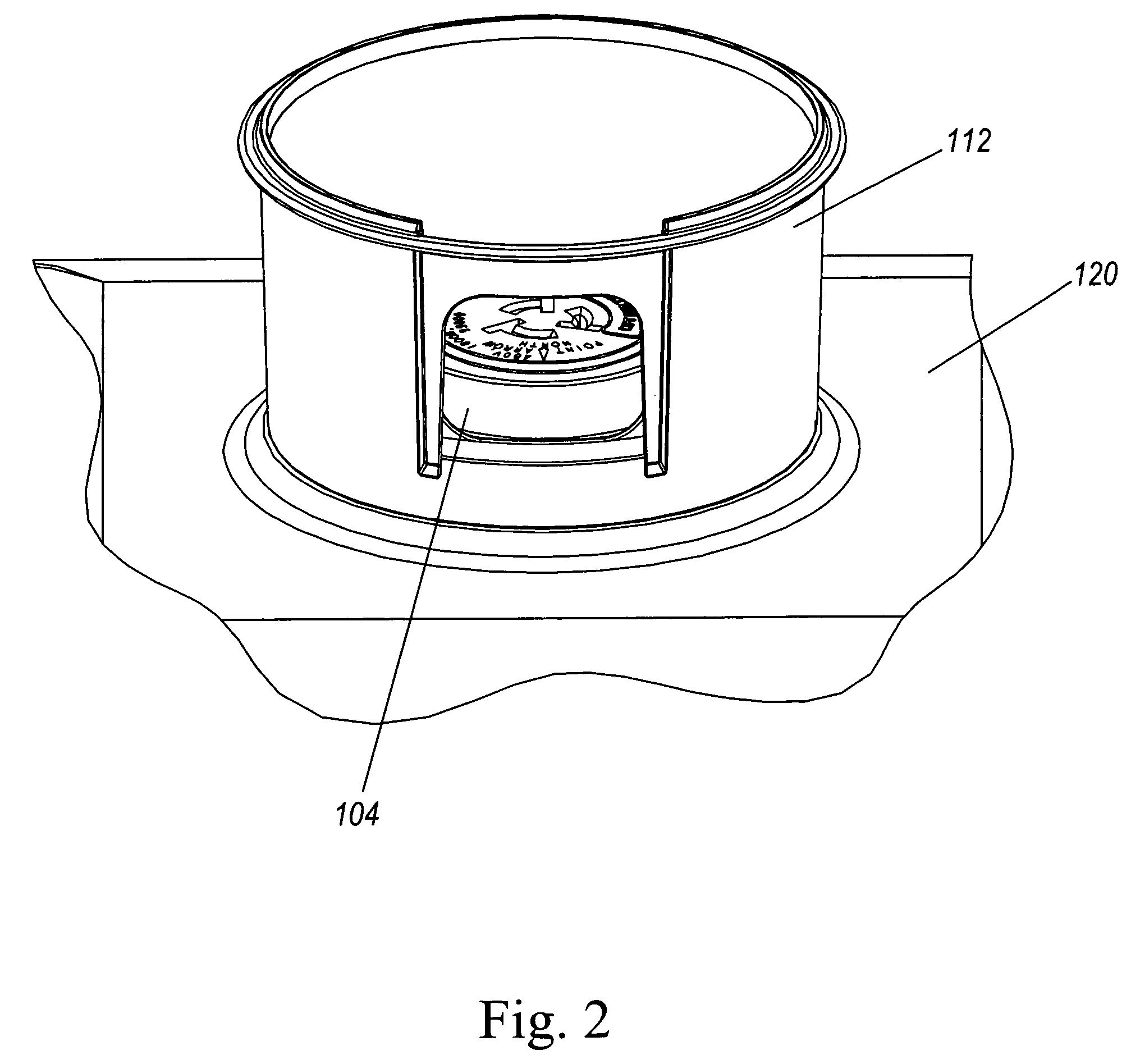

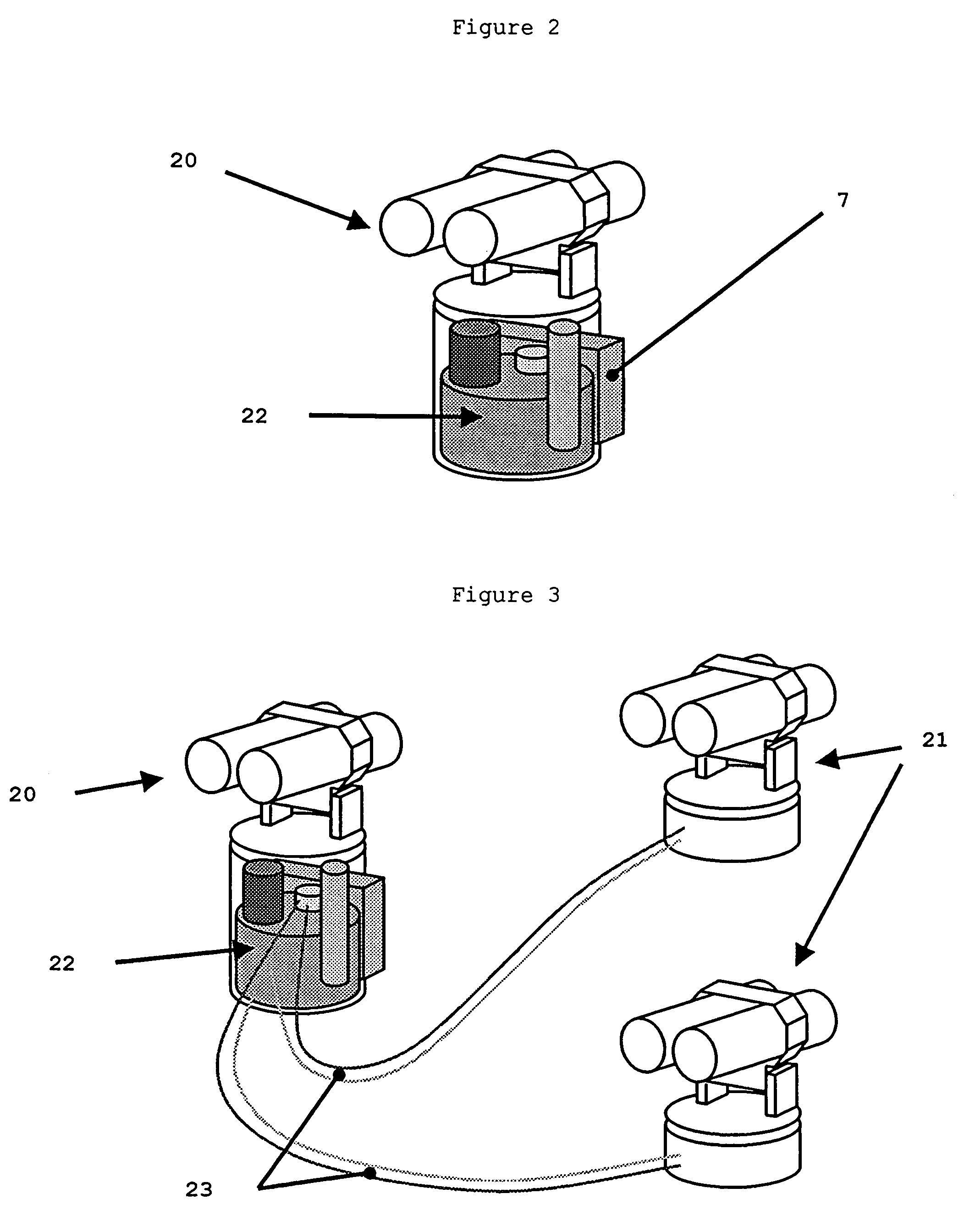

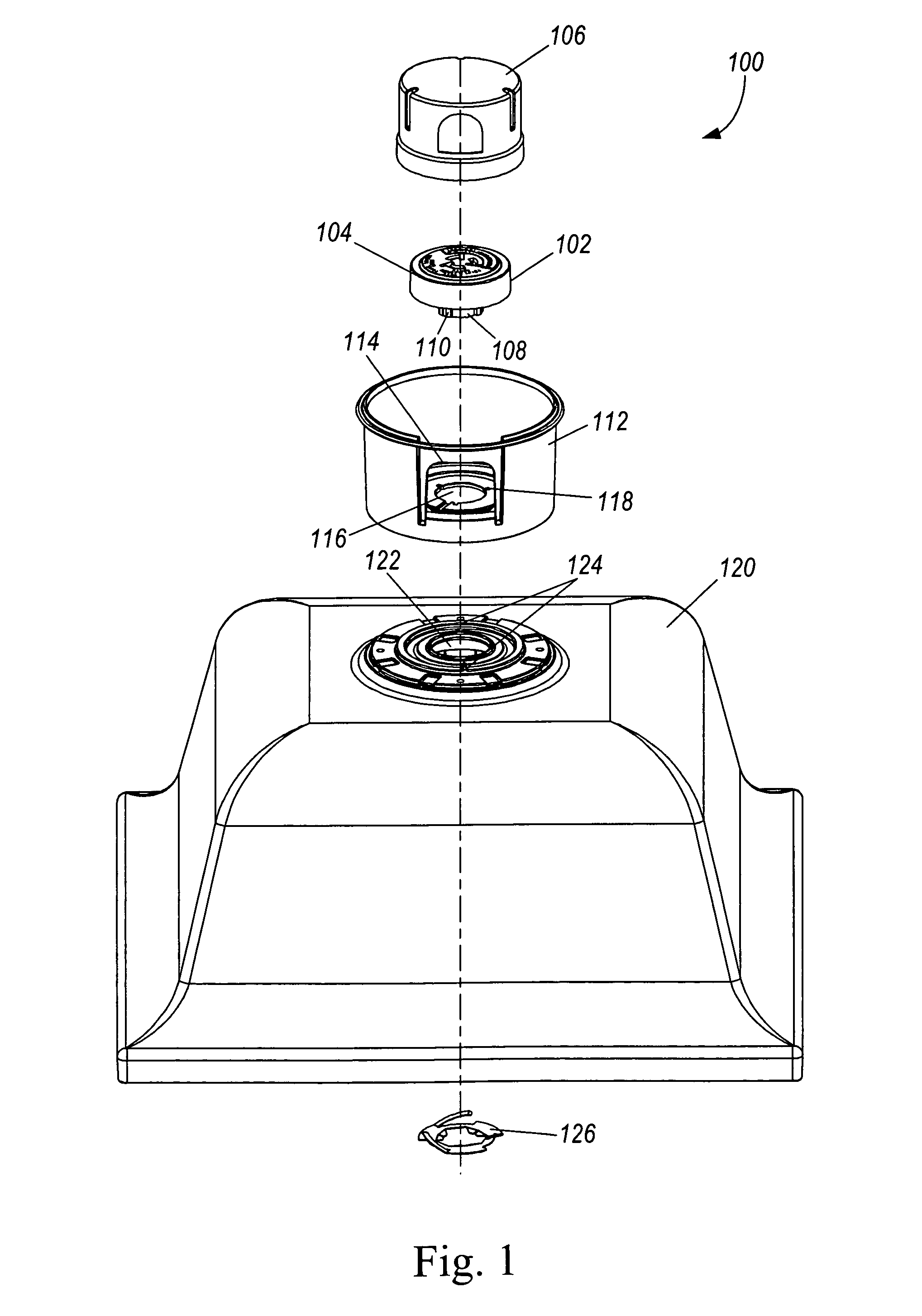

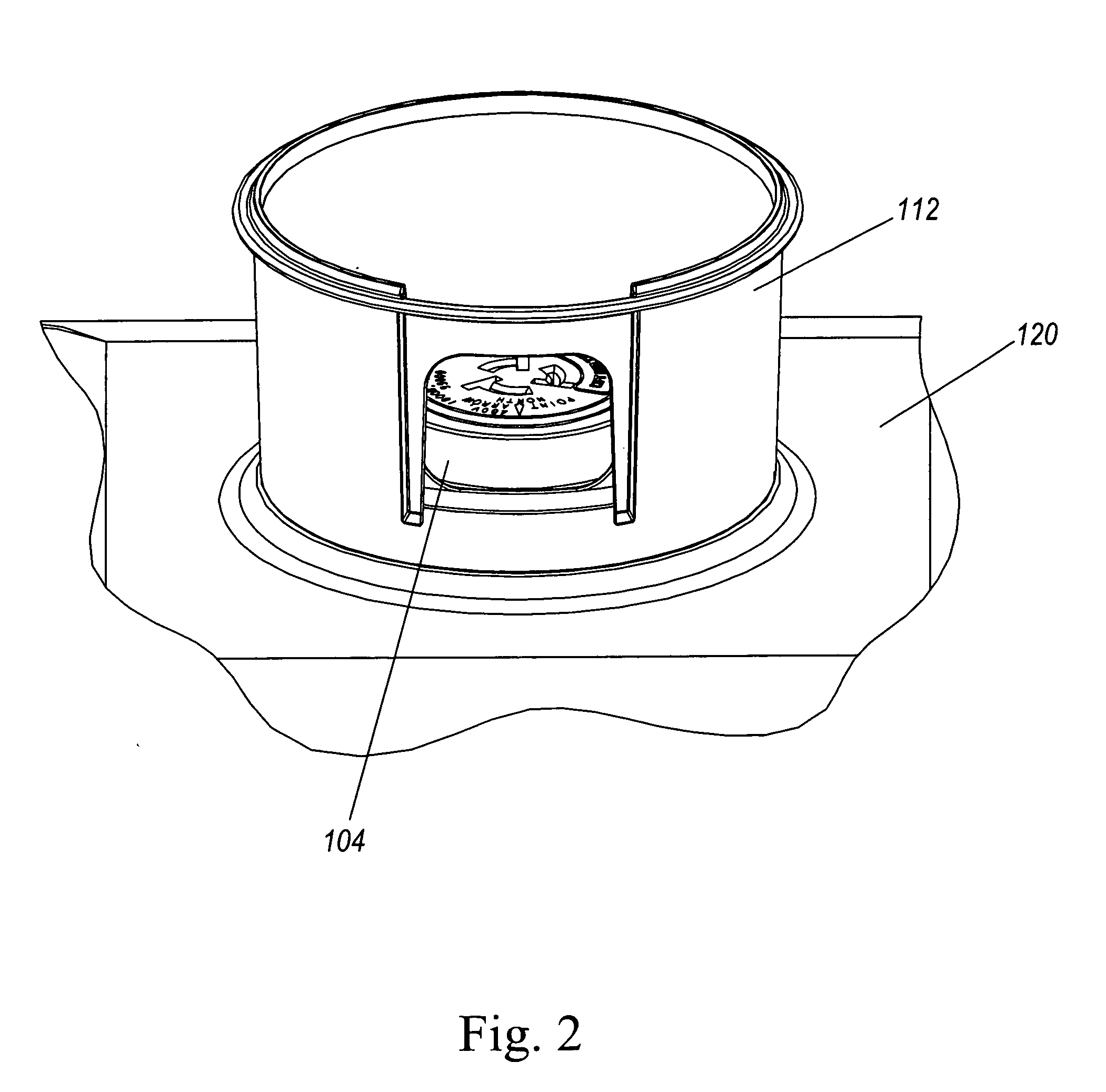

Toolessly adjustable cupola and photocontrol receptacle assembly

ActiveUS7622701B2Maintain alignmentPrevent rotationInstruments for comonautical navigationIncorrect coupling preventionCupolaEngineering

Certain embodiments of the present invention provide a cupola and photocontrol receptacle assembly that allows a user to adjust the direction of the cupola base and the photocontrol receptacle simultaneously without using tools. A fixture housing may have an opening for receiving a photocontrol receptacle connection member and one or more ribs located in proximity to the fixture housing opening. A cupola base may include an opening for receiving the connection member and features adapted to detachably engaged the fixture housing ribs. In addition, a spring may be coupled to the connection member and configured to allow the photocontrol receptacle to move in a first direction upon the application of a force in the first direction and recoil when the force is removed or decreased.

Owner:ABL IP HLDG

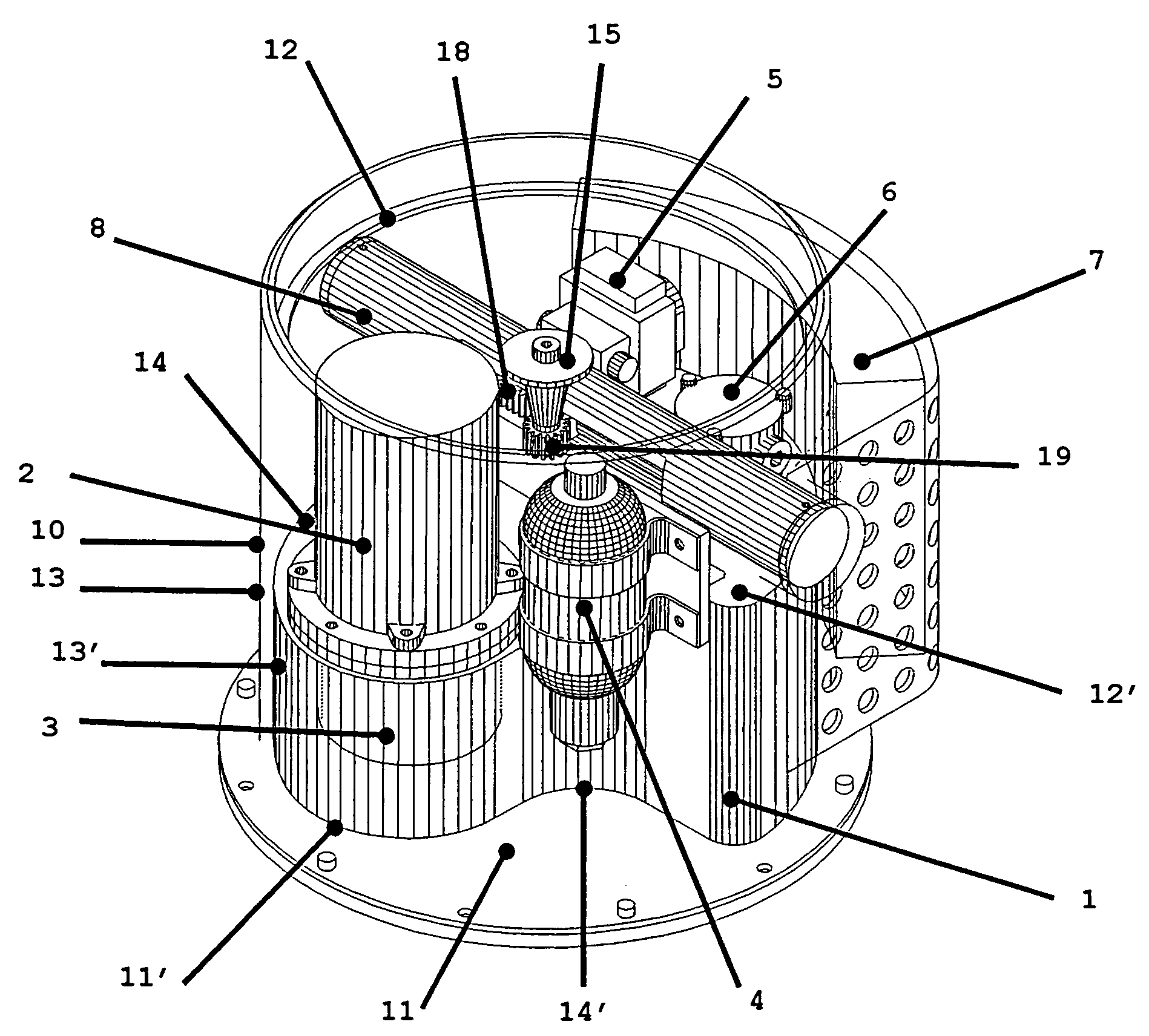

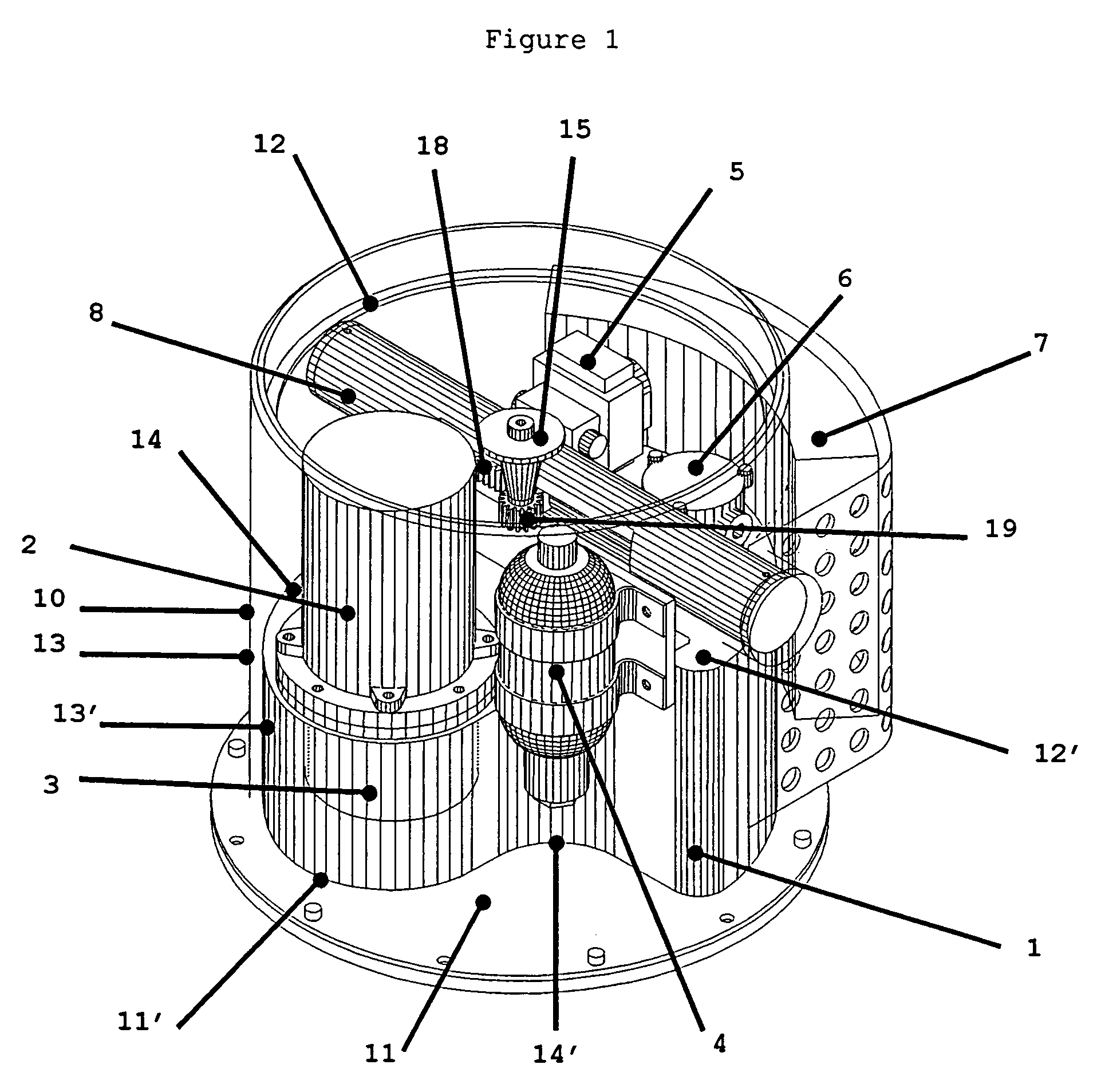

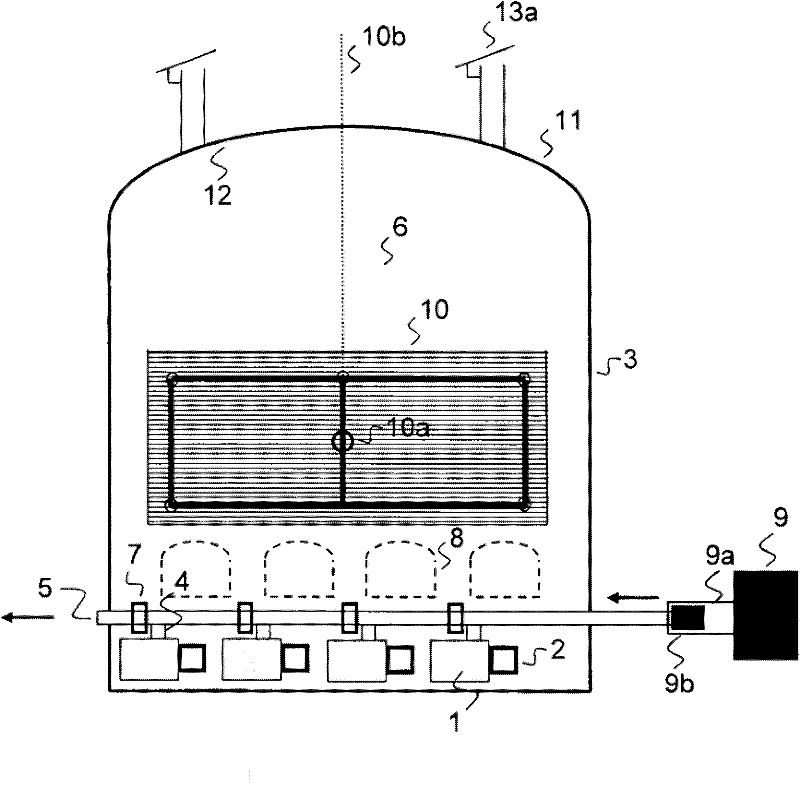

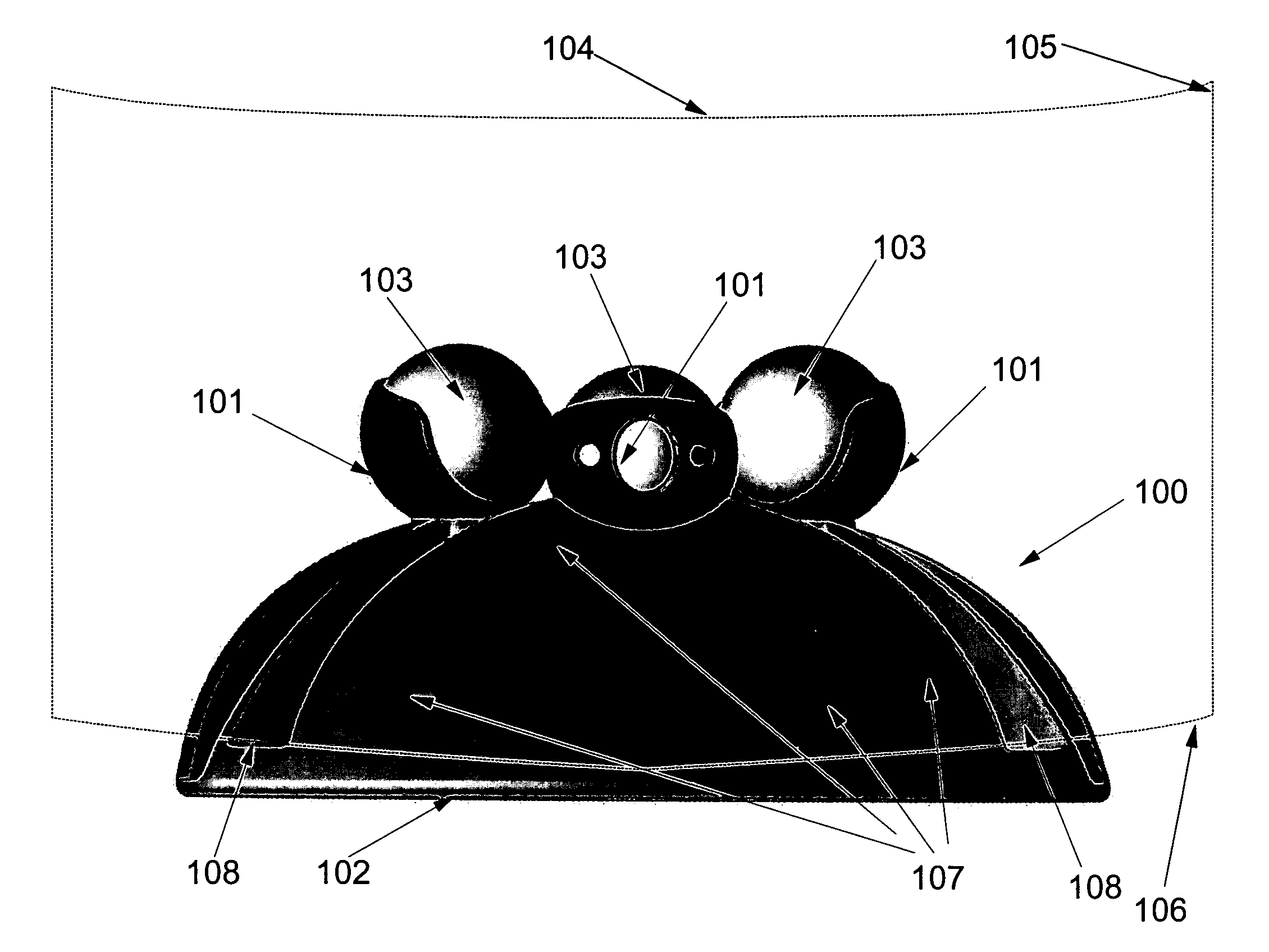

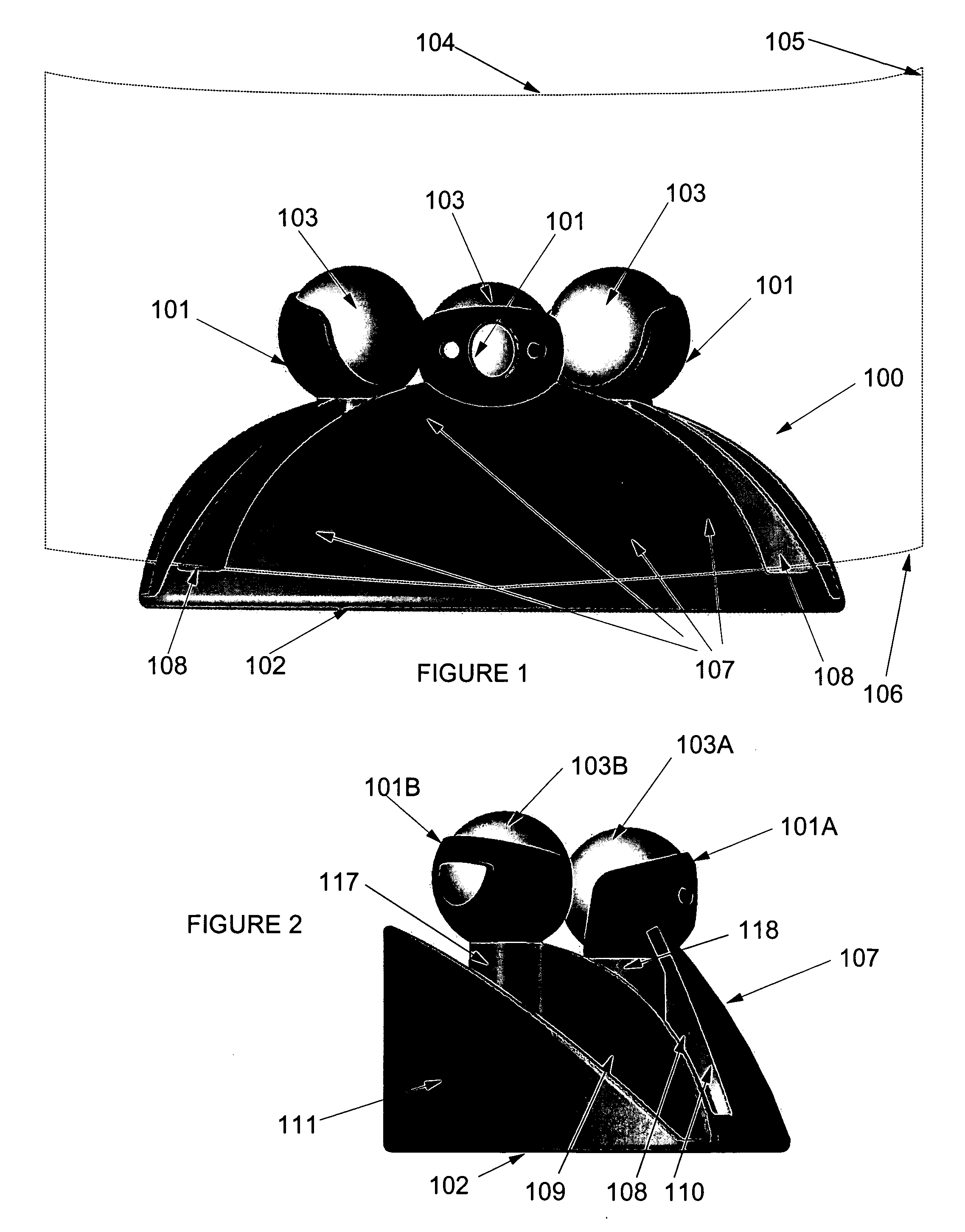

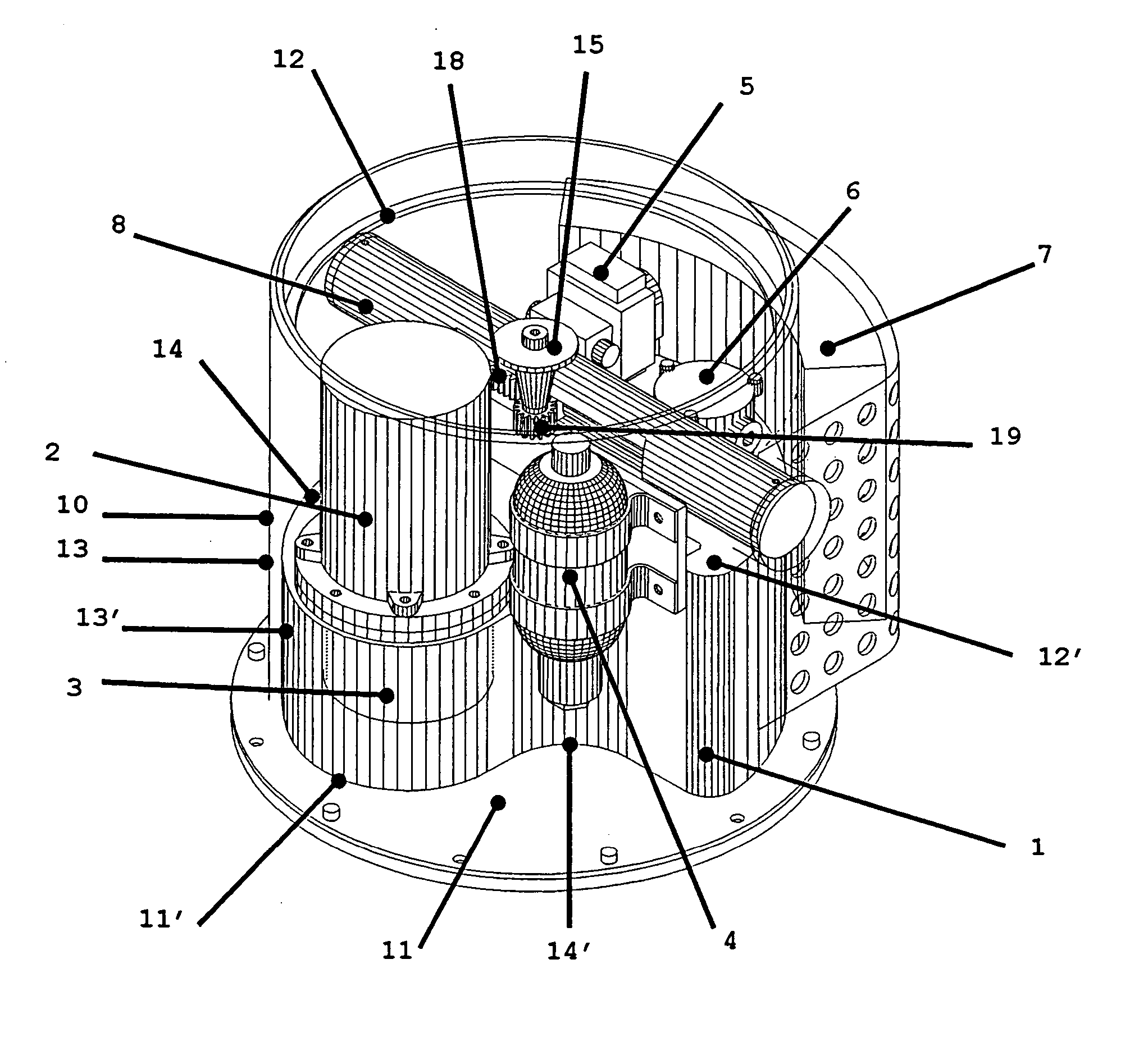

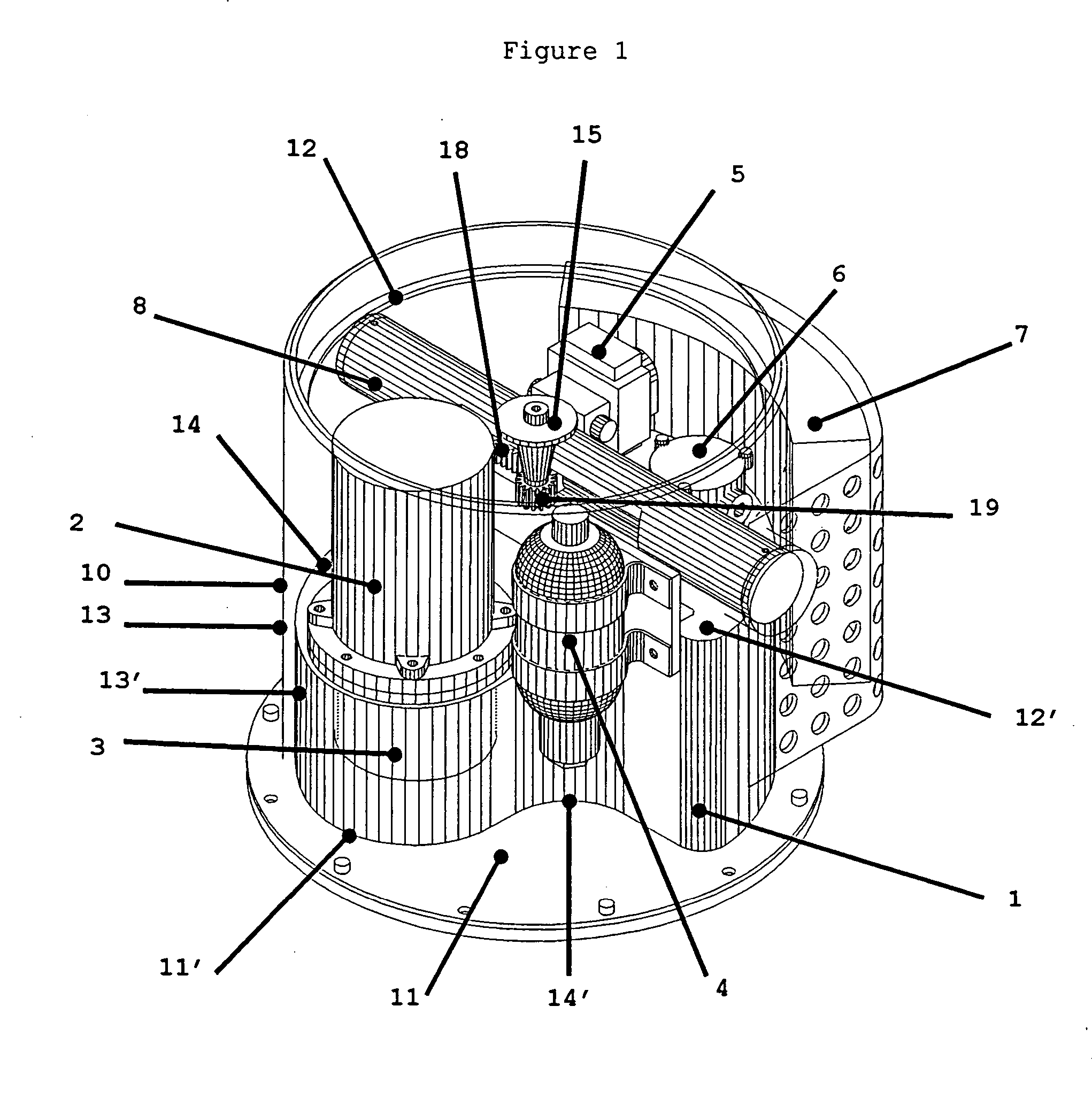

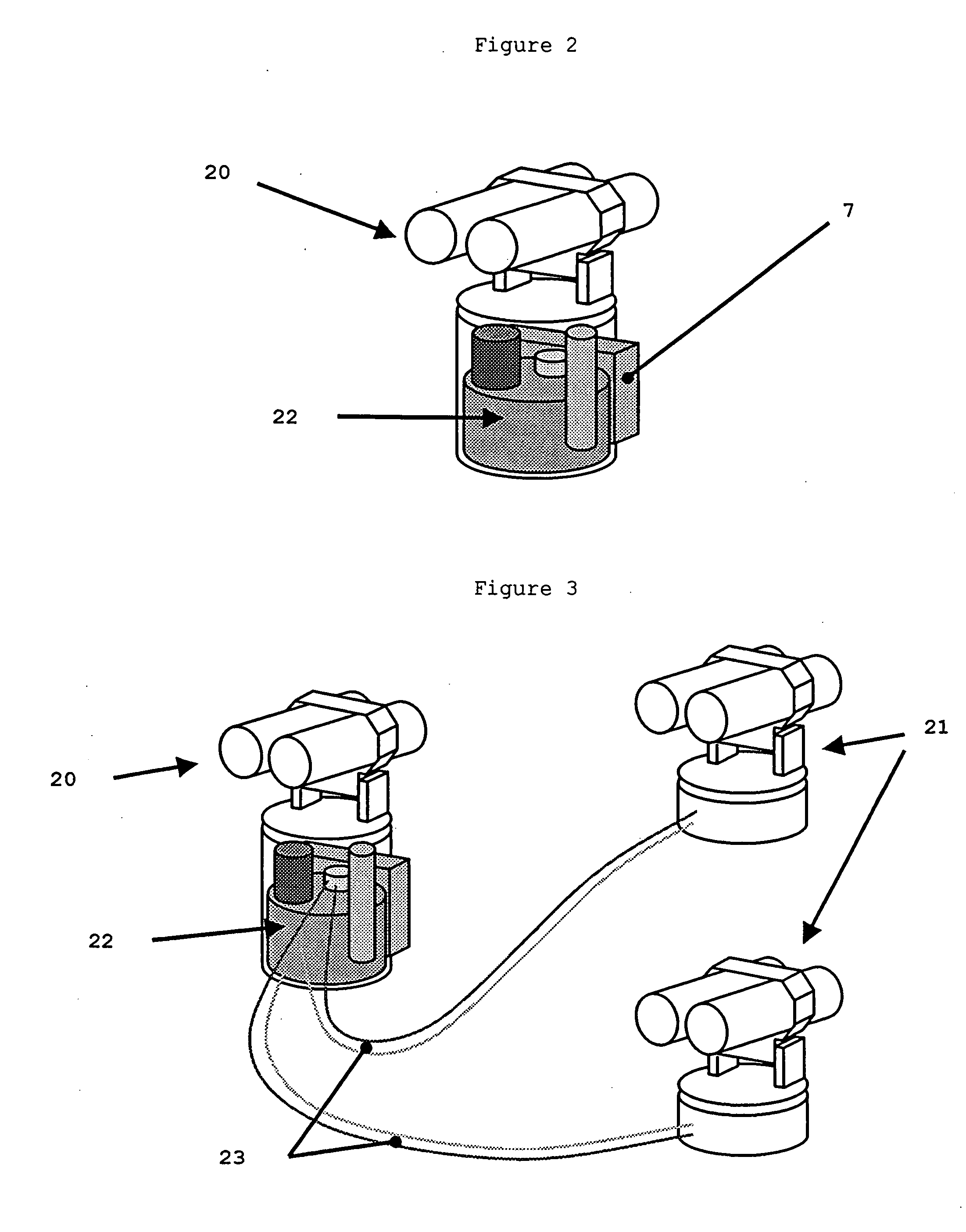

Compact electro-hydraulic generator to motorize cupola

InactiveUS7047733B1Simple designGood flexibilityRotary clutchesAccumulator installationsCupolaElectro hydraulic

The present invention divulges a particularly compact electro-hydraulic generating set and its application in combination with a compact actuator to pilot the traverse movement of a close cupola head assembly or of one or several offset cupola head assemblies.The compactness of the electro-hydraulic generating set and the possibility of the close or offset mounting of one or several cupola head assemblies make various architectures possible.

Owner:NEXTER SYST SA

Toolessly adjustable cupola and photocontrol receptacle assembly

ActiveUS20080067322A1Maintain alignmentPrevent rotationInstruments for comonautical navigationIncorrect coupling preventionCupolaMechanical engineering

Certain embodiments of the present invention provide a cupola and photocontrol receptacle assembly that allows a user to adjust the direction of the cupola base and the photocontrol receptacle simultaneously without using tools. A fixture housing may have an opening for receiving a photocontrol receptacle connection member and one or more ribs located in proximity to the fixture housing opening. A cupola base may include an opening for receiving the connection member and features adapted to detachably engaged the fixture housing ribs. In addition, a spring may be coupled to the connection member and configured to allow the photocontrol receptacle to move in a first direction upon the application of a force in the first direction and recoil when the force is removed or decreased.

Owner:ABL IP HLDG

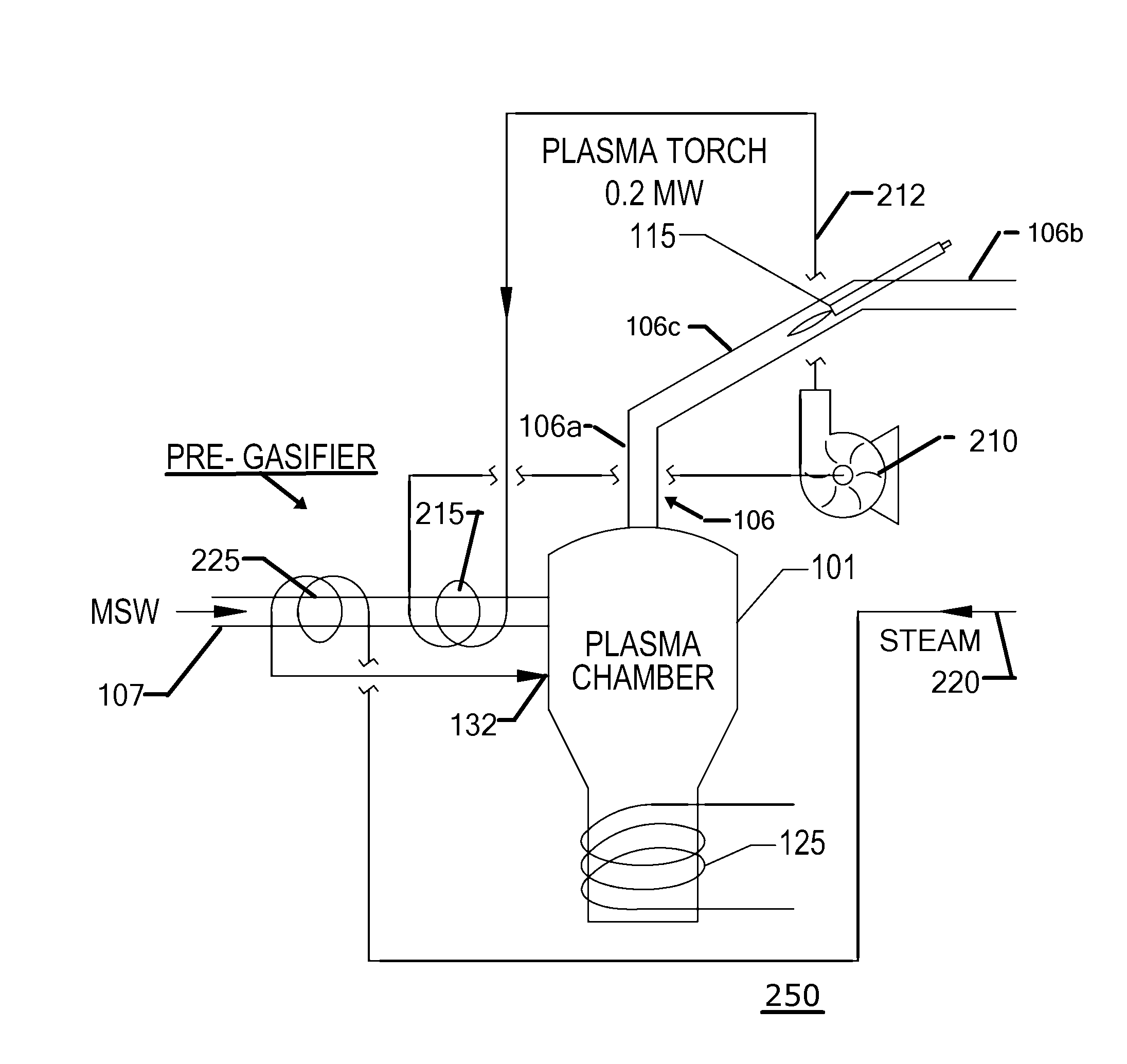

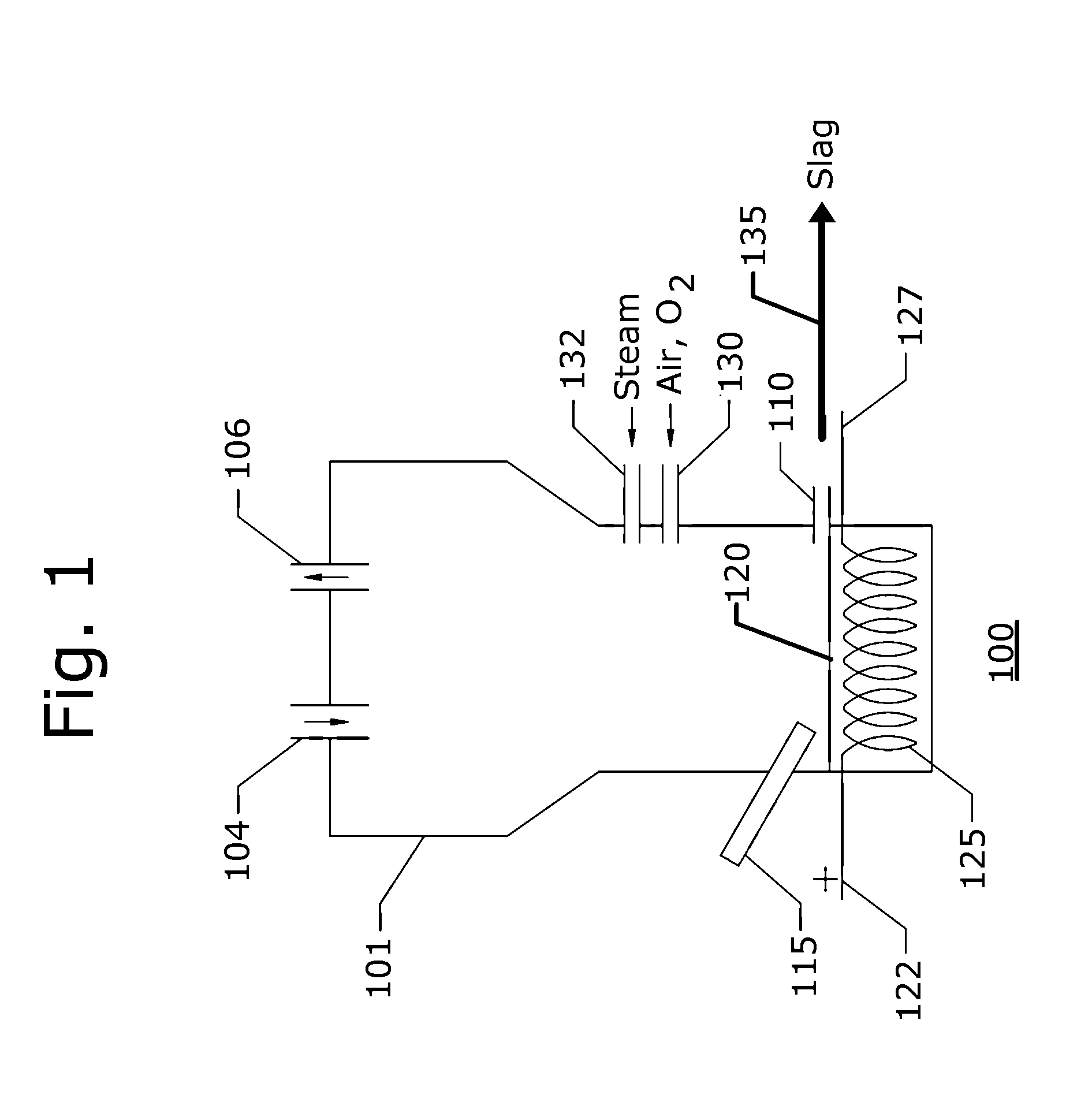

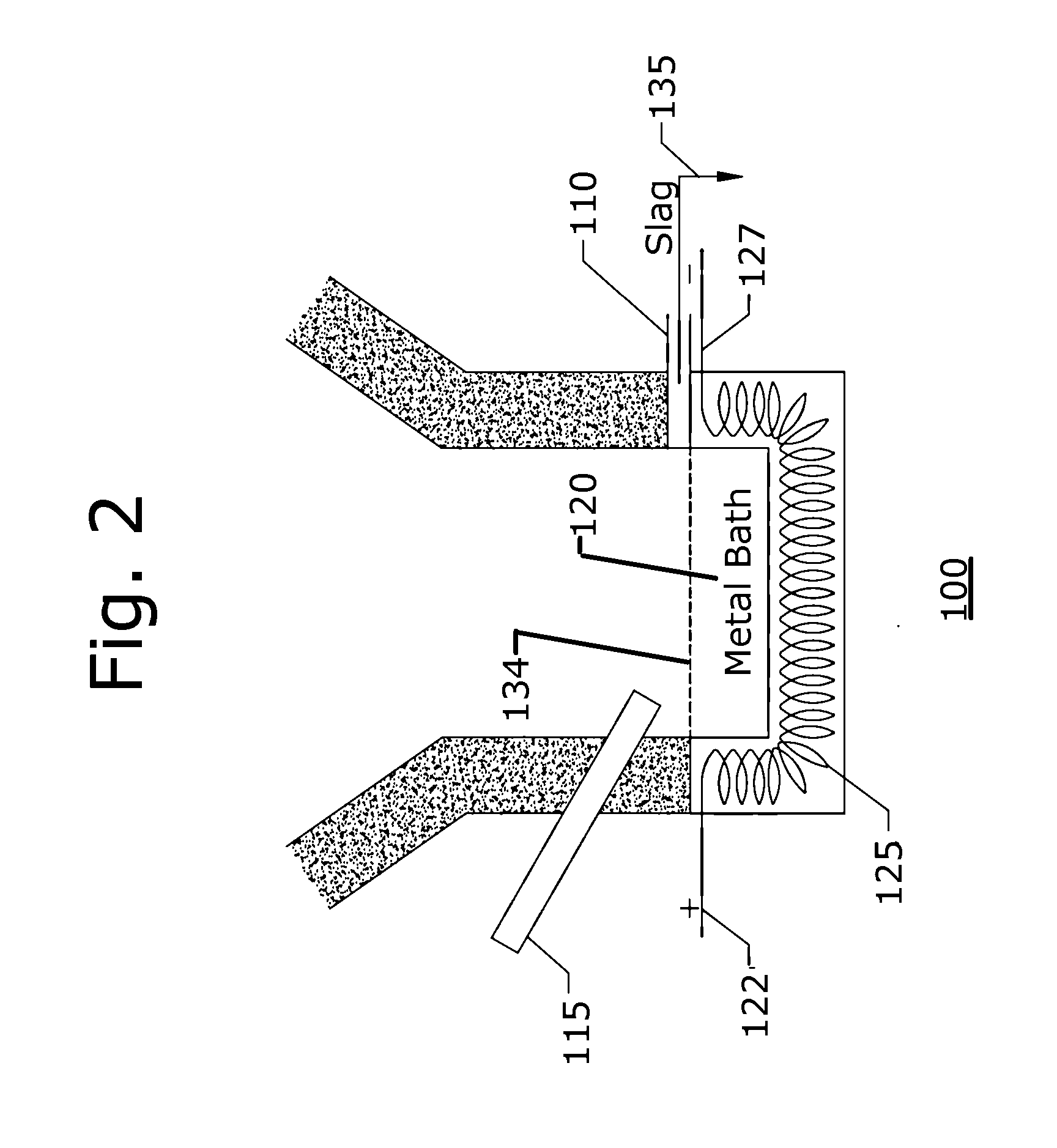

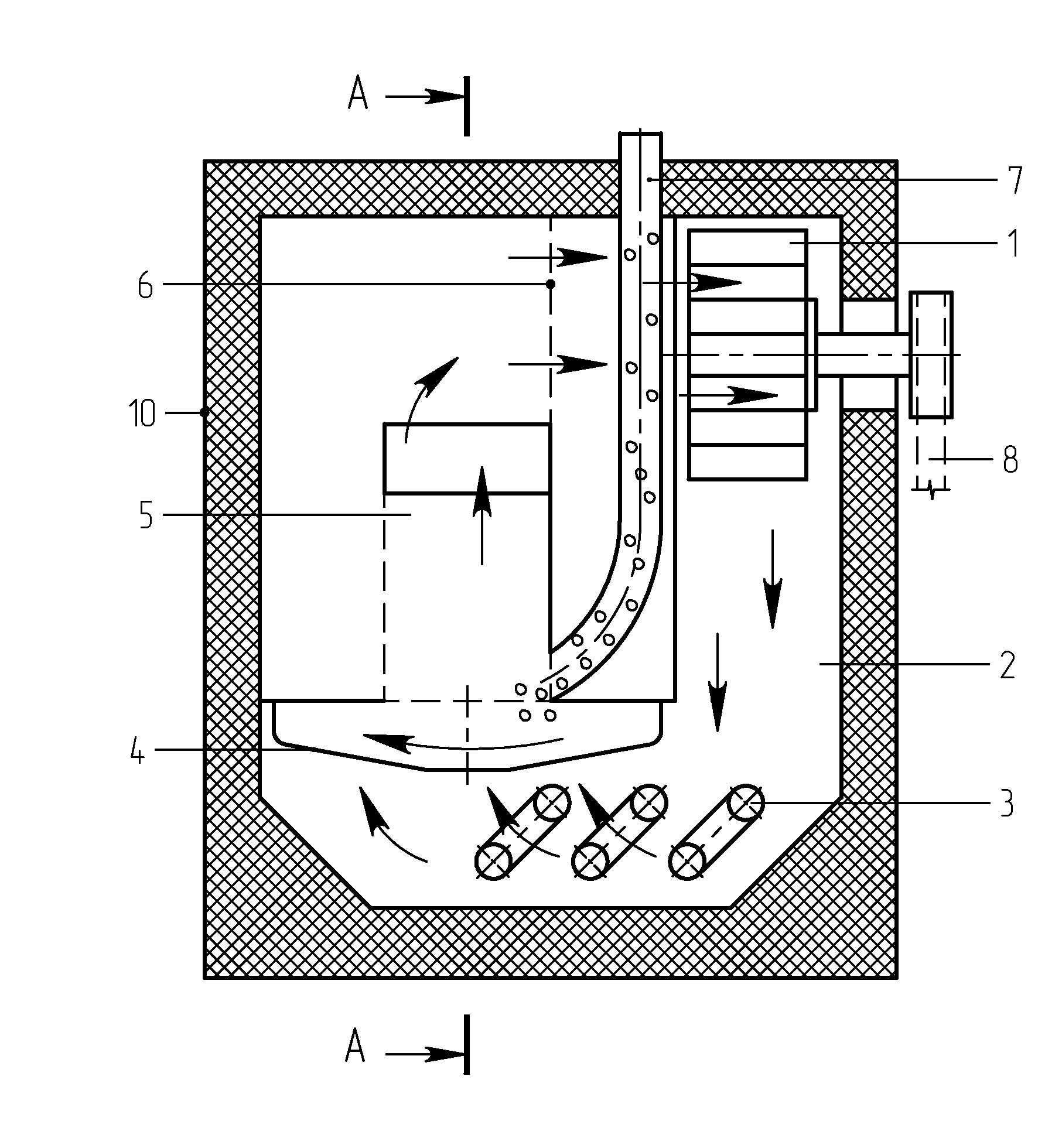

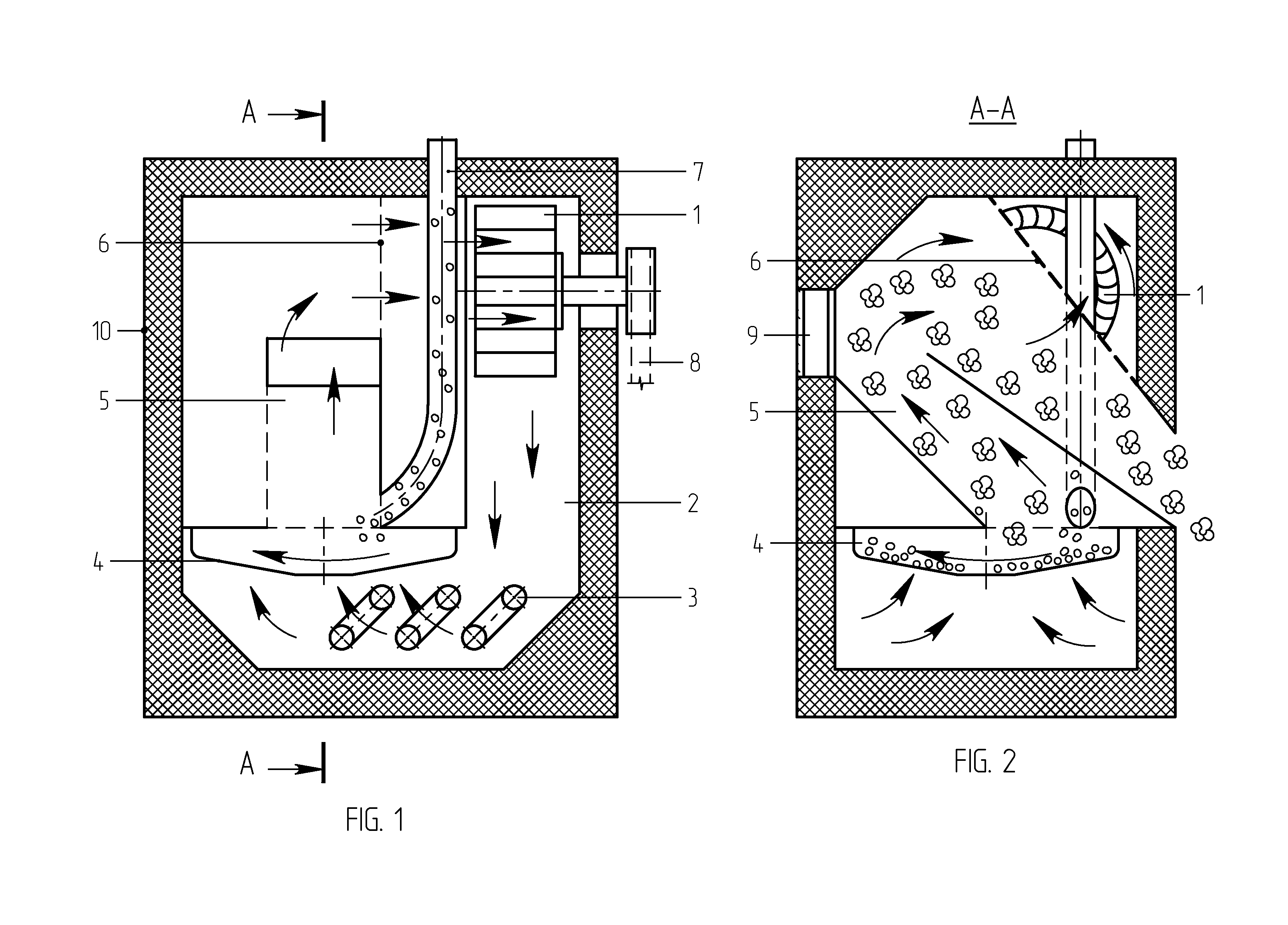

Inductive Bath Plasma Cupola

ActiveUS20140166934A1Reduce particulate and emissionWell mixedOther chemical processesEnergy inputSyngasCupola

A method of generating syngas as a primary product from renewable feedstock, fossil fuels, or hazardous waste with the use of a cupola. The cupola operates selectably on inductive heat alone, chemically assisted heat, or plasma assisted heat. Additionally, the operation of the cupola is augmented by the use of direct acting carbon or graphite rods that carry electrical current for additional heat generation into the metal bath that is influenced by the inductive element. The method includes the steps of providing a cupola for containing a metal bath; and operating an inductive element to react with the metal bath. Feedstock in the form of a combination of fossil fuel, a hazardous waste, and a hazardous material is supplied to the cupola. A plasma torch operates on the metal bath selectably directly and indirectly. Steam, air, oxygen enriched air, and oxygen are supplied in selectable combinations.

Owner:PLASMA TECH HLDG LLC

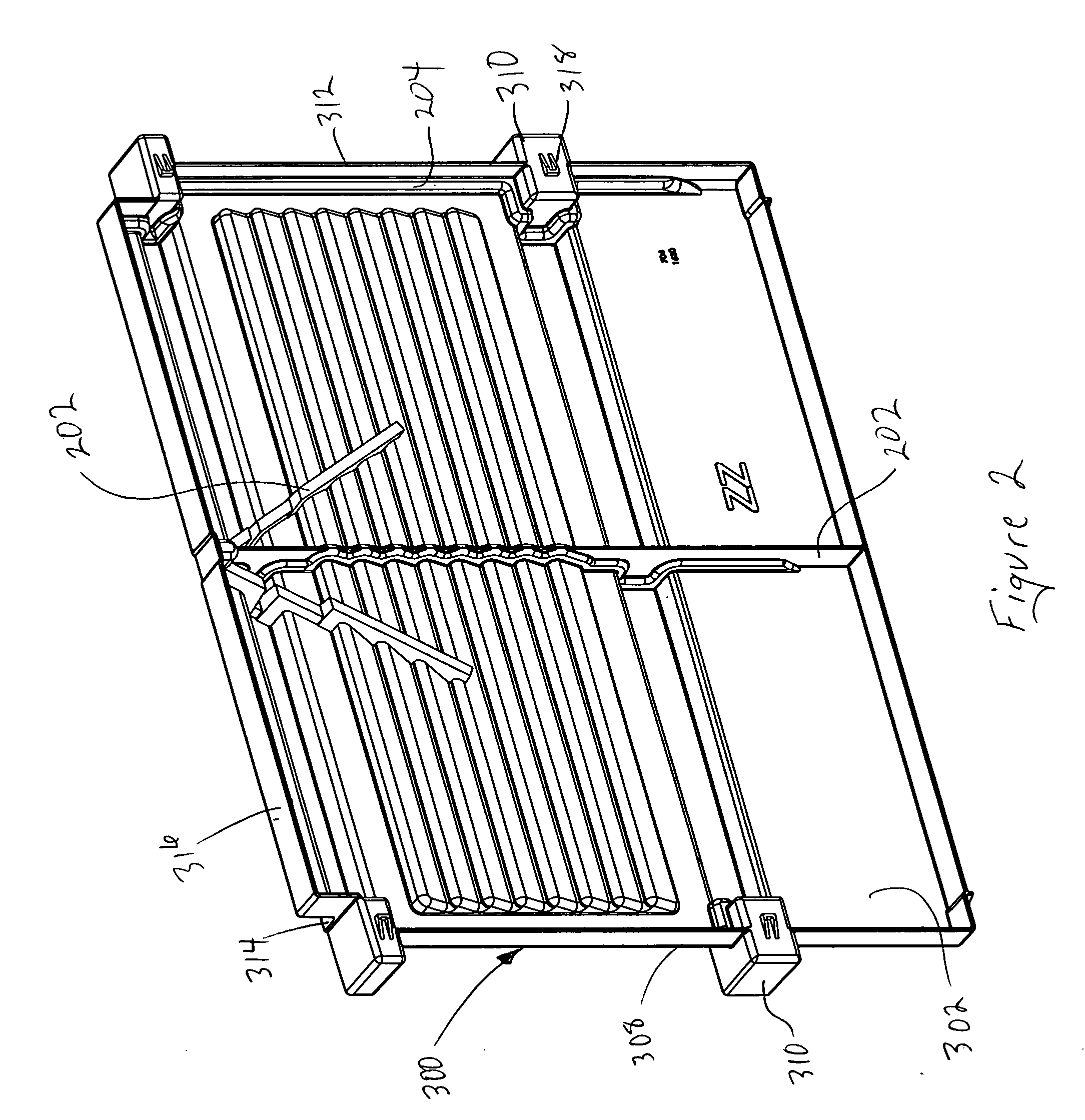

Stackable surface module for a wall surface

A stackable surface module is provided for a wall surface that can be both erected and dismantled. The stackable surface module is especially useful in certain applications, such as for earthquake-resistant walls, a cupola, a bridge, a site fence, a noise protection wall, an upwind power station, a heat exchanger or a coastal protection wall.

Owner:ZINSER KLAUS

Air metering system for secondary air in coking furnaces as a function of the ratio of cupola temperature to sole temperature

ActiveCN102165034ADoes not cause excessive coolingQuality improvementCombustible gas coke oven heatingCoke oven safety devicesCupolaCombustion

The invention relates to a device for metering secondary combustion air in the secondary air soles of coking chamber furnaces, wherein said device is formed by a pusher or a block-shaped device or plate displaced by means of a pushrod, wherein said pushrod is moved longitudinally parallel to the coking chamber furnace wall, so that the plates move away from the secondary air openings and open or close said openings. The pushrod is moved by means of a servomotor, wherein the force transmission is done hydraulically or pneumatically. Using suitable measurement parameters, the secondary heating can thus be optimized, so that the heating is even on all sides, thus achieving an improvement in coke quality.

Owner:ТІССЕНКРУПП УДЕ ҐМБГ

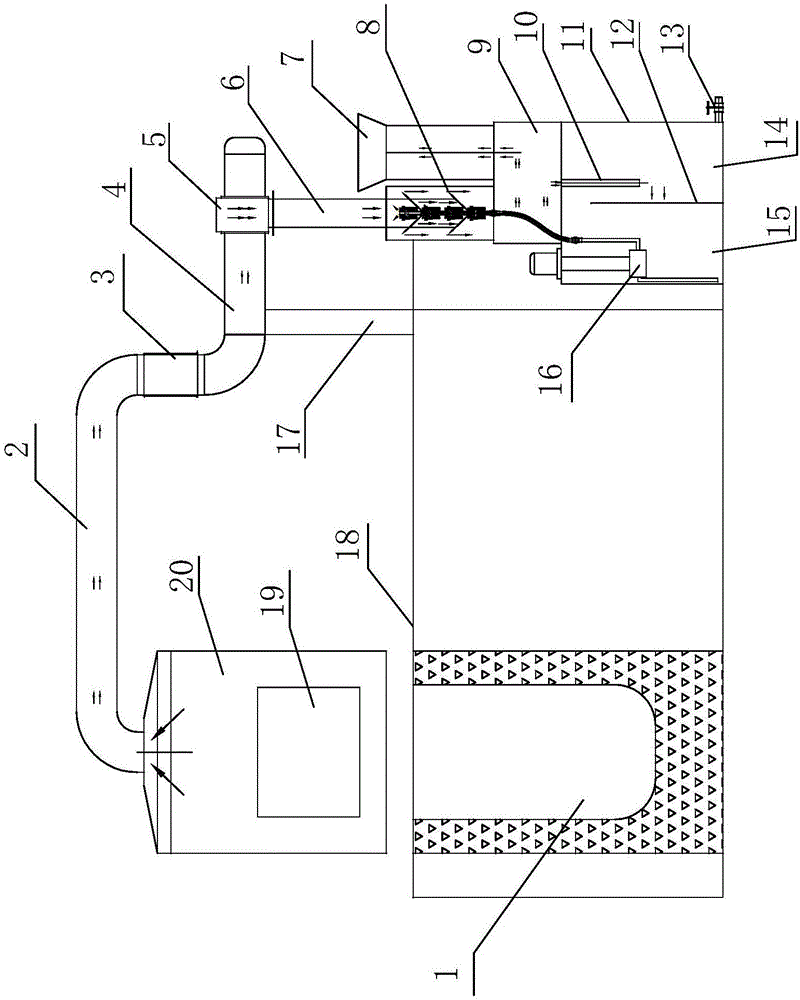

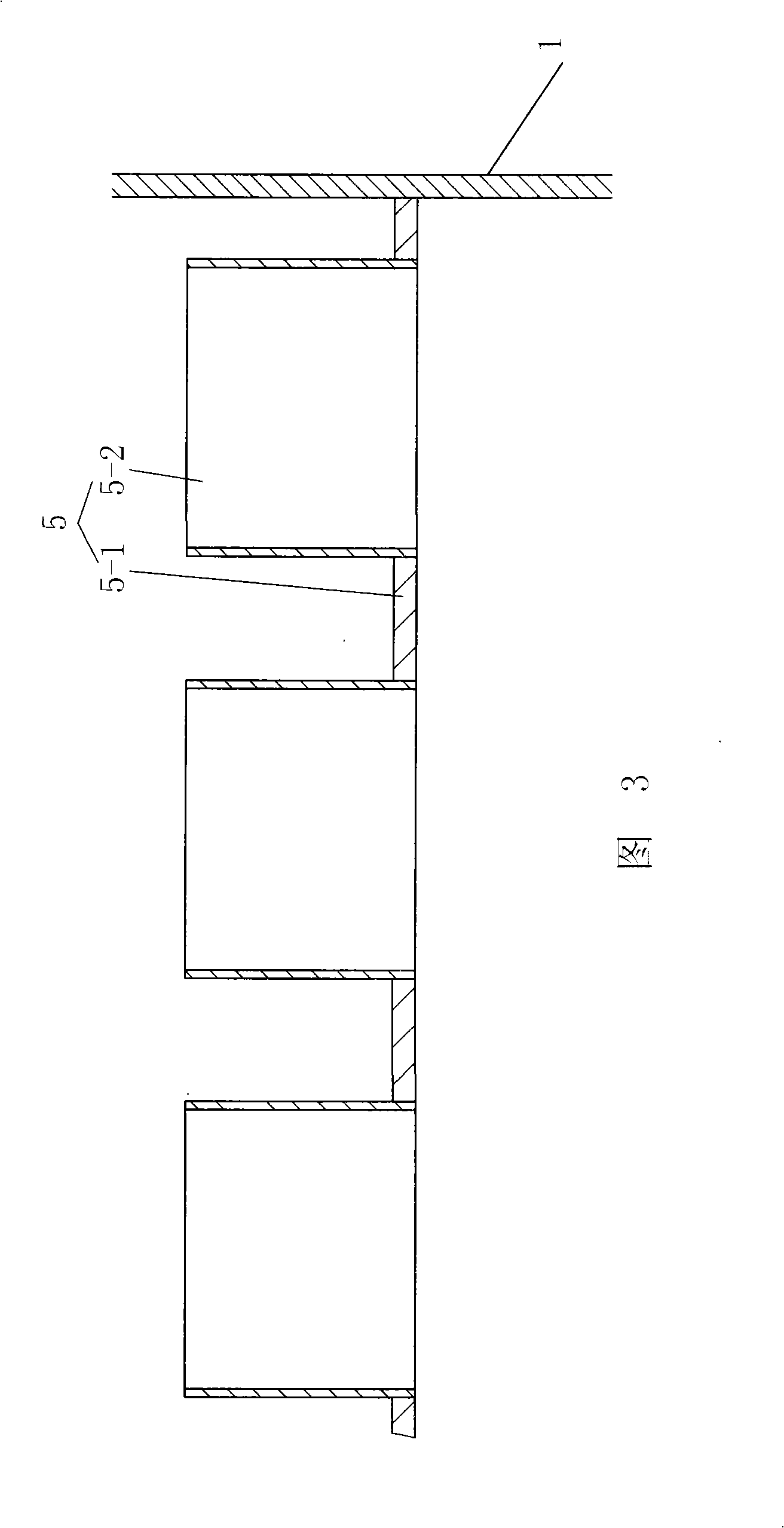

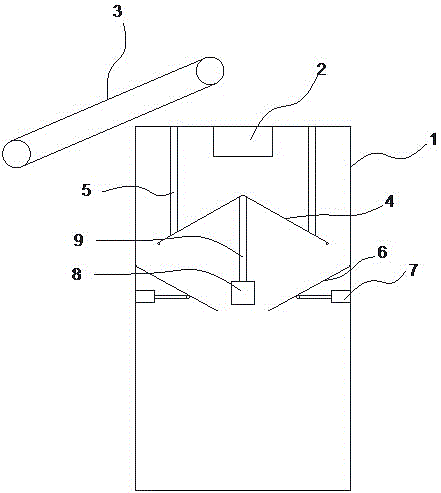

Cupola dust and waste gas treatment device

InactiveCN101537308AThorough treatmentReduce investmentUsing liquid separation agentVertical furnacesCupolaGas compressor

The invention relates to a soot treatment device of casting, metallurgy and other relevant industries. The device is a cupola dust and waste gas treatment device which needs two times of treatment, namely, firstly using atomized water and then using aqueous alkali for treatment, and can be suitable for small and medium-sized enterprises. The device mainly comprises a cupola, a chimney, a fan, a shower bath, an air compressor, a reaction tank, an air pipeline, etc. The air pipeline sequentially and circularly connects the cupola, the chimney, the fan, the shower bath, the air compressor, the reaction tank and the cupola. The shower bath is filled with water with certain depth, proper concentration of saponified oil is added, and the top part of the shower bath is provided with a device that atomizes water flow downward at high speed. The reaction tank is filled with aqueous alkali, after compressed by the air compressor, the waste gas with dust removed is sent to the bottom part of the reaction tank, and the air outlet end of the reaction tank is positioned at the upper part of the reaction tank. The dust and waste gas generated in the combustion of the cupola are sequentially treated by the shower bath and the reaction tank for two times, and the soot can be treated completely.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Cellular antenna tower and equipment enclosure based on shipping container

ActiveUS8950158B2Easily and quickly fabricatable and deployableLow costCollapsable antennas meansAntenna supports/mountingsInterior spaceCupola

An antenna tower structure for wireless communication antennas includes an antenna cupola mounted on a tower based on at least one standardized ISBU shipping container that has been modified and erected to stand upright on a foundation. The modifications may include longitudinal reinforcements along at least two longitudinal edges of the container, mounting hardware at the two ends of the container, an access door on a side of the container, an access hatch in the upper end of the container, a ladder extending longitudinally inside the container, and a floor extending perpendicular to the longitudinal axis of the container. The container provides a weather-protected climate-controlled interior space for sheltering electronics equipment. The cupola has antennas installed on at least one level, and may include shutters, a clock, a bell etc. to hide the antennas and disguise the tower. The exterior of the structure may be finished to match surrounding buildings.

Owner:WALTON CHADWICK J

Document holder

The present invention is a single or multiple sheet document holder with a base plate supporting three posts, each post having mounted at its top a cupola formed with an upwardly facing socket adapted to securely and easily rotatingly hold a metal ball. The document holder uses a support slot forming contact points for a paper sheet or sheets to be supported. The support slot receives one or more sheets for support via substantial lateral curvature up and down the page combined with substantial deviation from vertical support (the top of the sheets slant slightly back and away from the user).

Owner:SHIELDS MICHAEL PETER

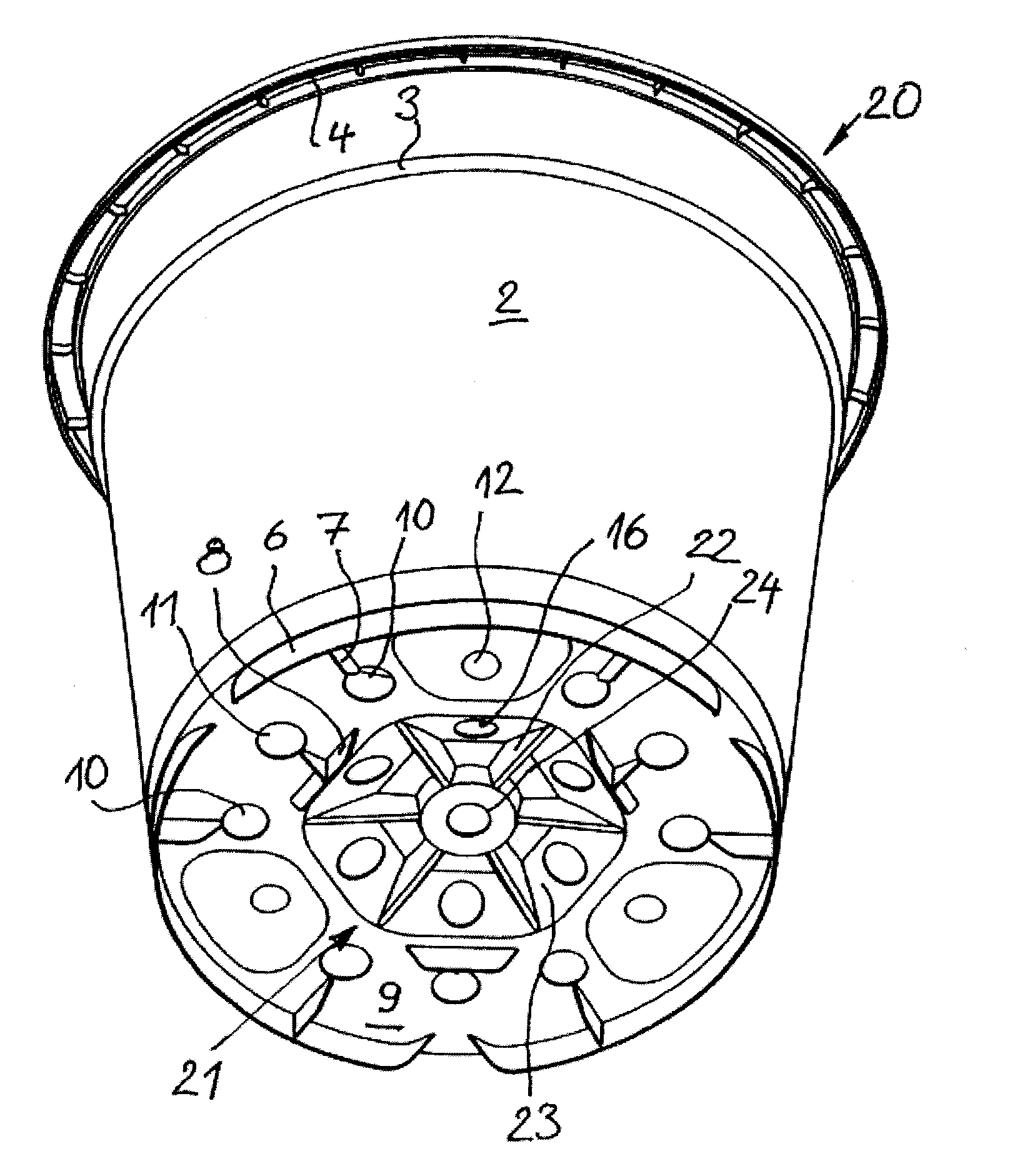

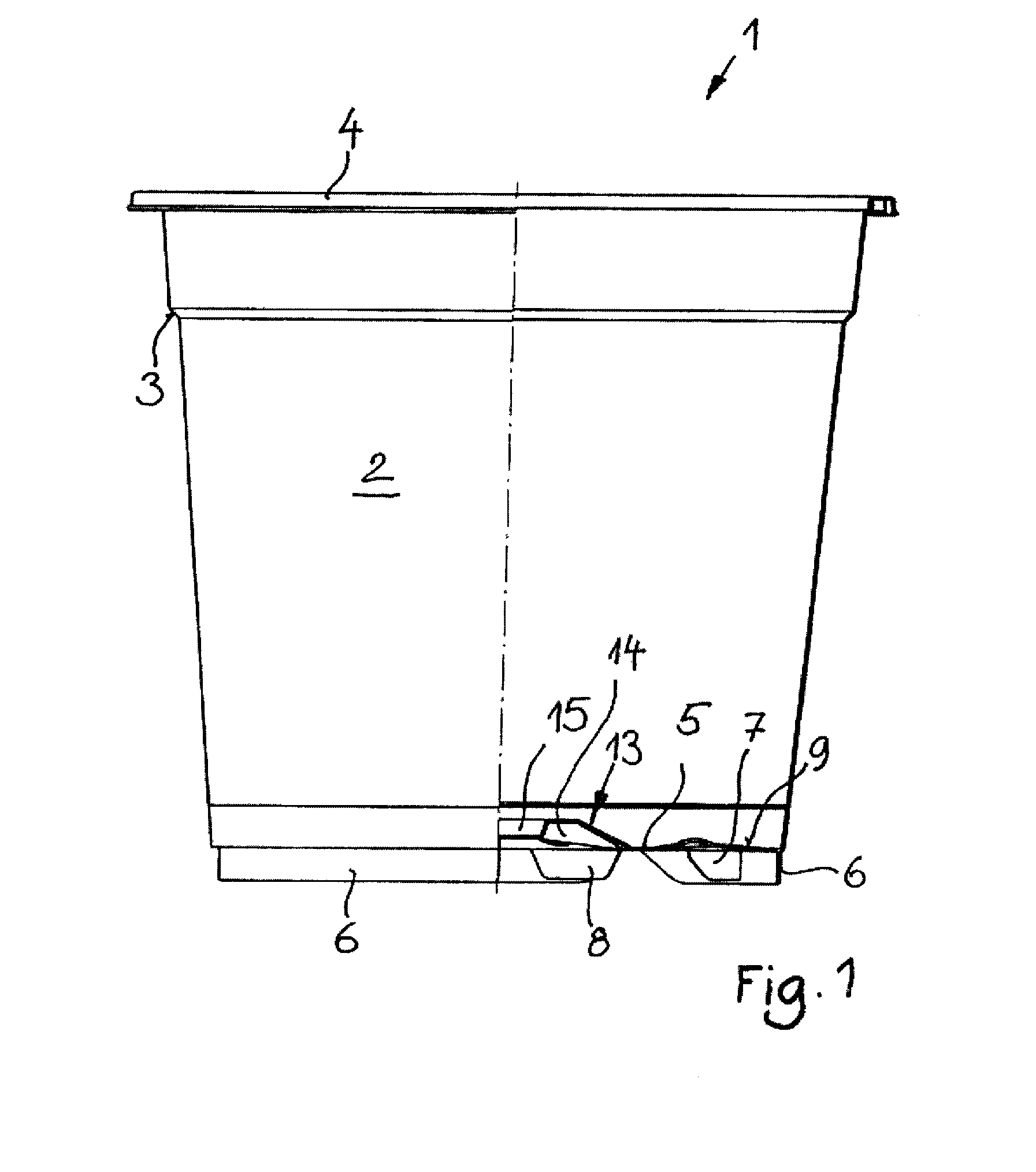

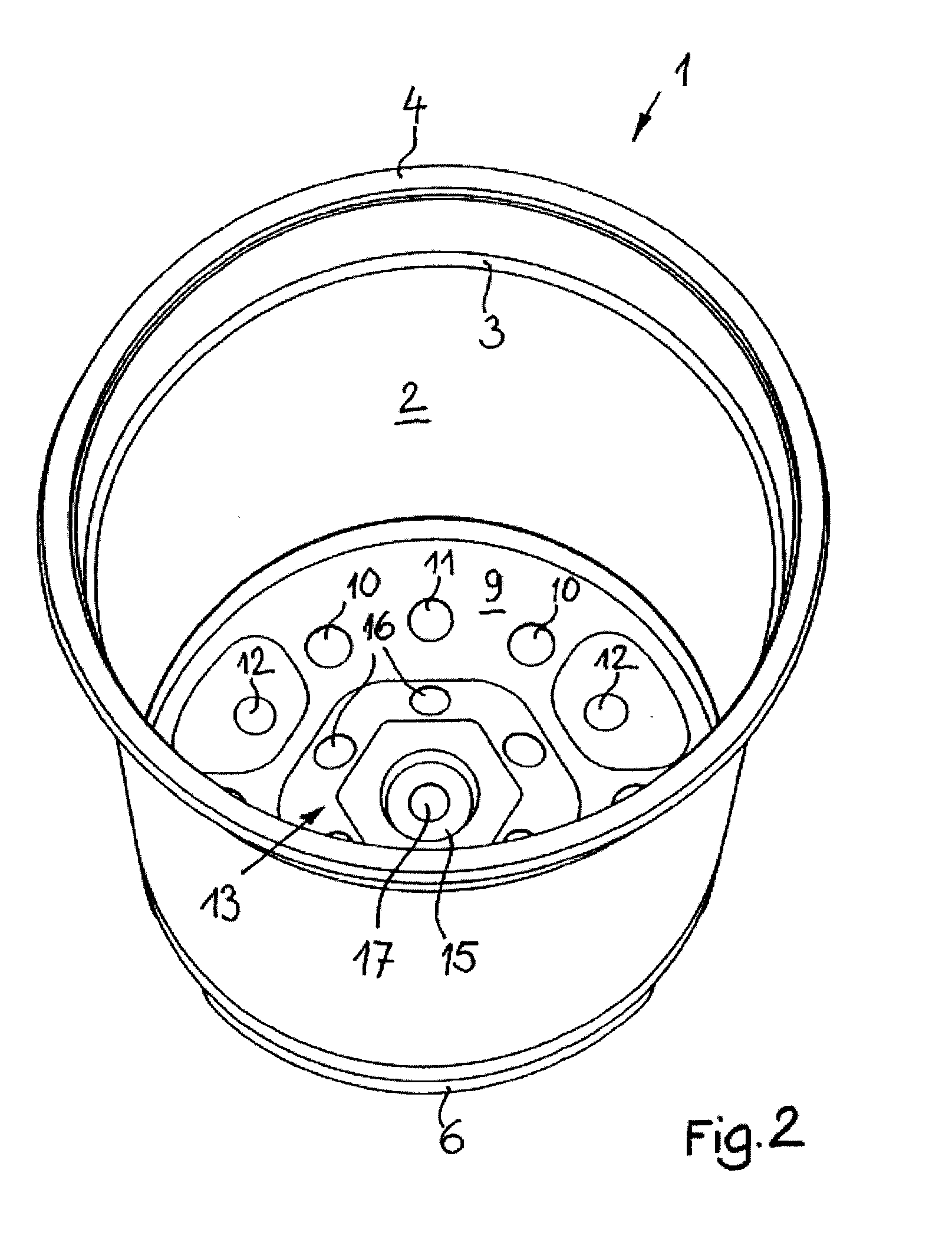

Plastic plant pot

A plant pot made of plastic with a predominantly vertically aligned wall and a predominantly horizontally aligned bottom connected on the edge with the wall, which is arched upwards at least in an inner part in the form of a cupola, is configured to secure the bottom area against being compressed through and dented through the material that is as thin-walled as possible, in such a way that the cupola is reinforced by profile braces that run as interties from a central area of the cupola to at least the peripheral areas of the cupola.

Owner:POEPPELMANN HLDG GMBH & CO KG

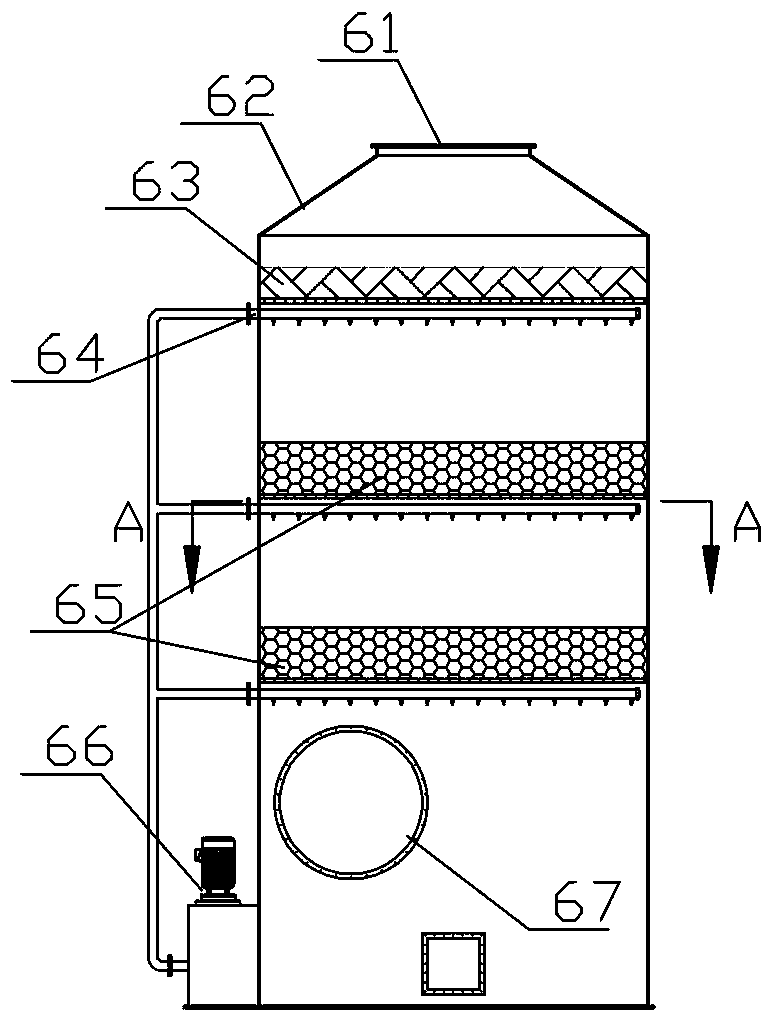

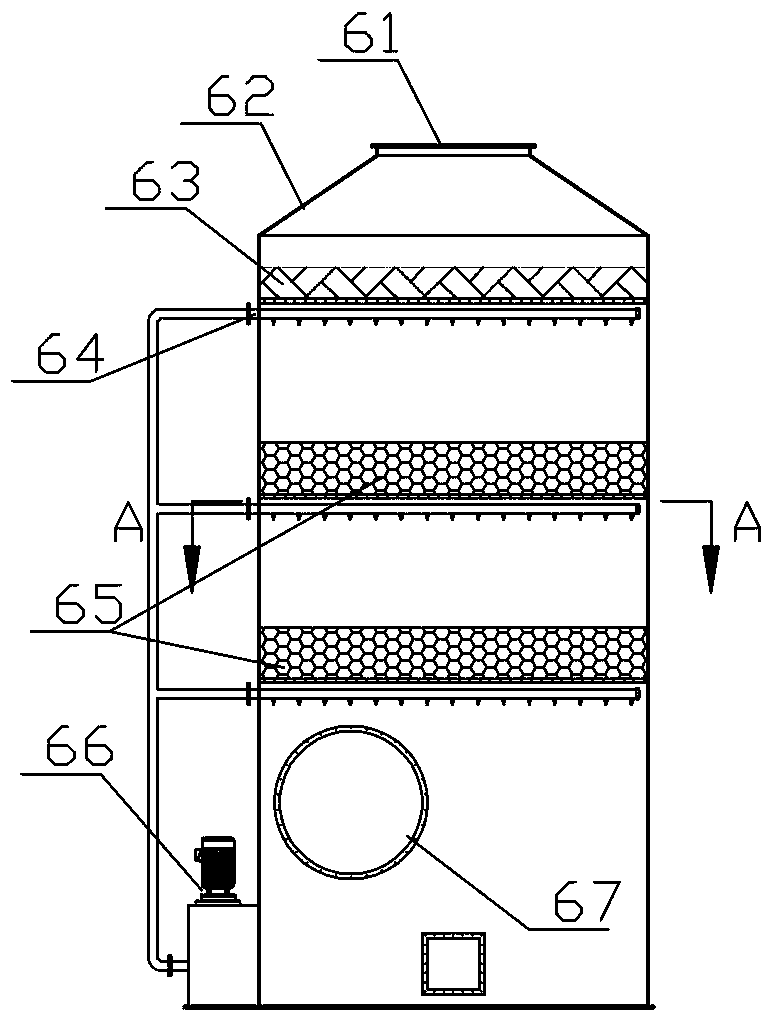

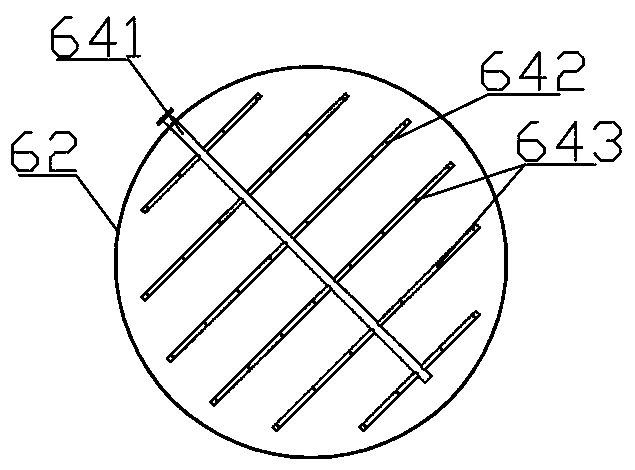

Smoke purifier

InactiveCN106178761AImprove purification effectAvoid pollutionGas treatmentUsing liquid separation agentPondingCupola

The invention provides a smoke purifier and relates to a purification device. The smoke purifier comprises a smoke cover covering a cupola, a smoke suction pipe connected with the smoke cover, an exhaust fan arranged in the smoke suction pipe and an exhaust pipe connected to the rear end of the exhaust fan and further comprises multiple layers of atomizers, a water pump and a ponding tank. The multiple layers of atomizers are connected to the end, away from the exhaust fan, of the exhaust pipe, the water pump is arranged on one side of the ponding tank, a filter net is arranged in the ponding tank and divides the ponding box into a pure water region and a sewage region, and a water drawing pipe of the water pump stretches into the pure water region of the ponding tank. A water outlet of the water pump is connected with water inflow pipe joints of the atomizers through a water inflow pipe, a water receiving tank is connected below the atomizers, the bottom end of the water receiving tank is connected with a water return pipe, and the bottom end of the water return pipe stretches into the sewage region of the ponding tank. The smoke purifier has the advantages of being simple in structure, low in cost, small in size, good in purification effect and the like.

Owner:LIUZHOU ZHIBAO MACHINERY +1

Efficient dust removal heat treatment device

InactiveCN107138012AImprove dust removal effectImprove practicalityHuman health protectionCombination devicesCupolaAtmospheric air

The invention discloses an efficient dust removal heat treatment device, which comprises a cupola body, wherein the top of the cupola body is communicated with a shell; a fan and a water pump are fixedly connected to the two sides of the bottom of an inner cavity of the shell respectively; the two sides of the fan are communicated with an air extraction pipe and an air outlet pipe respectively; the end, far away from the fan, of the air extraction pipe is communicated with an exhaust fume collecting hood; the bottom of the exhaust fume collecting hood is communicated with the top of the cupola body; the top and the right side of the water pump are communicated with a pumping pipe and a water filling pipe respectively. According to the device, the shell, the fan, the air extraction pipe, the exhaust fume collecting hood, a motor, the water pump, the pumping pipe, a support plate, a blowdown pipe, the water filling pipe, a filter plate, an exhaust pipe, a stirring rod, a dust removal box, the air outlet pipe and a rotating shaft are arranged, so that the problem of relatively poor dust removal effect in a running process of a conventional cupola is solved, the cupola with a good dust removal effect has the advantage of good dust removal effect, the atmospheric pollution is reduced, and the device has high popularization value.

Owner:长兴宏诚机械科技有限公司

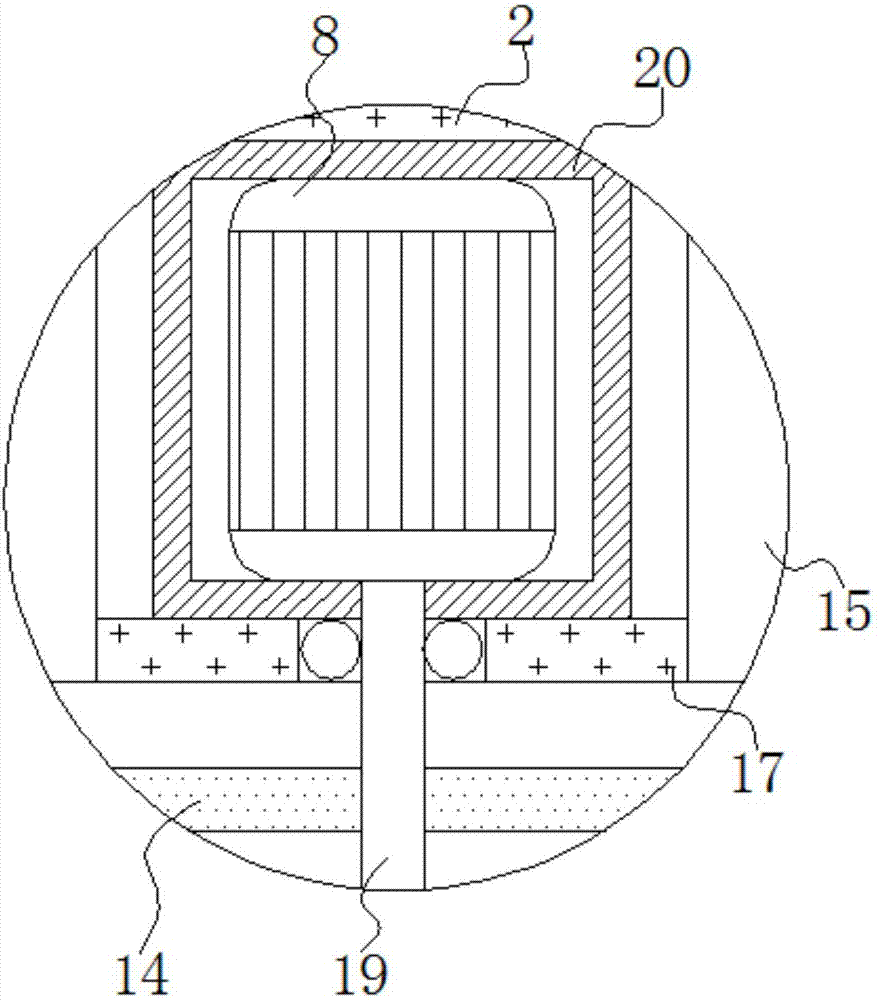

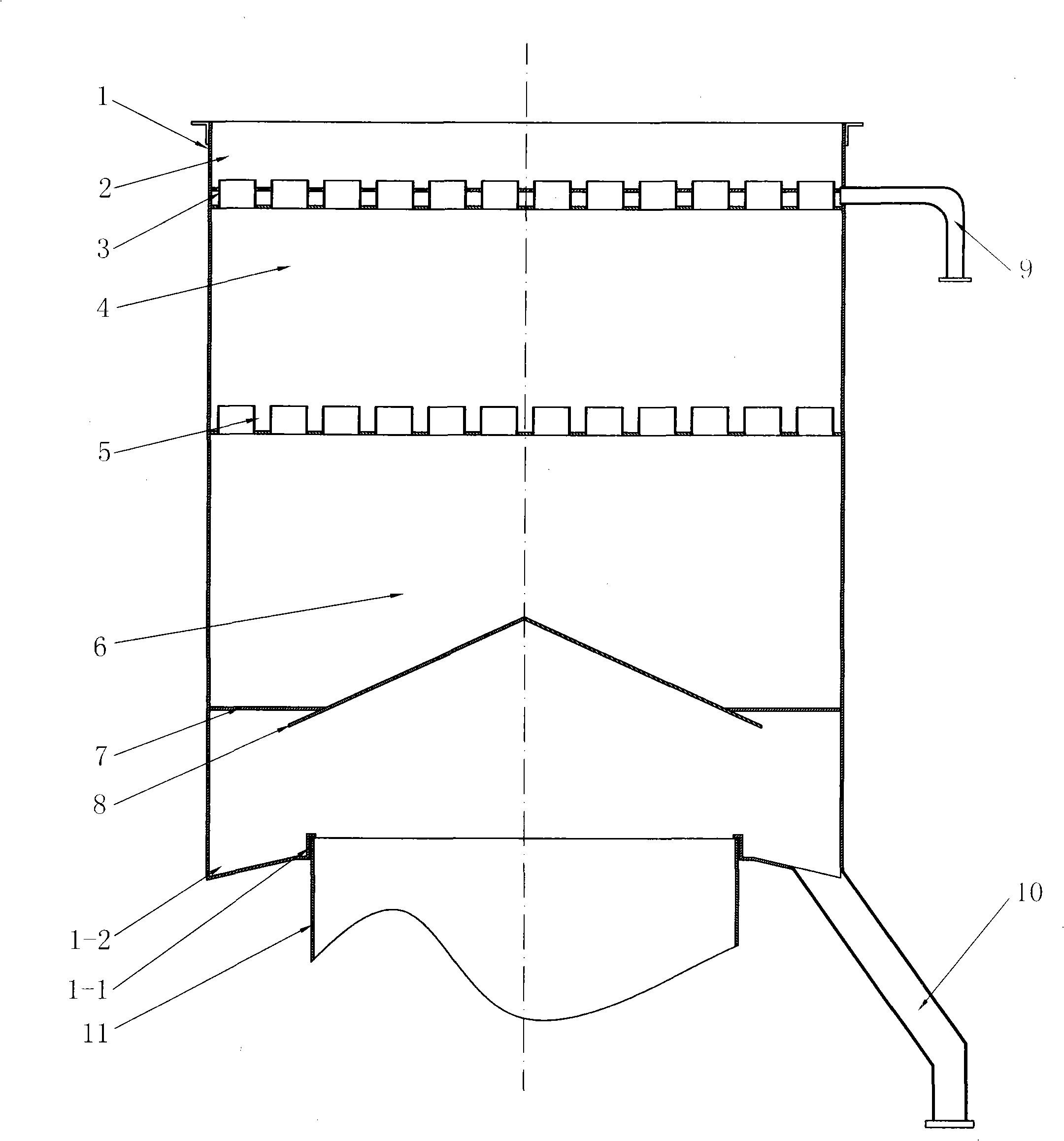

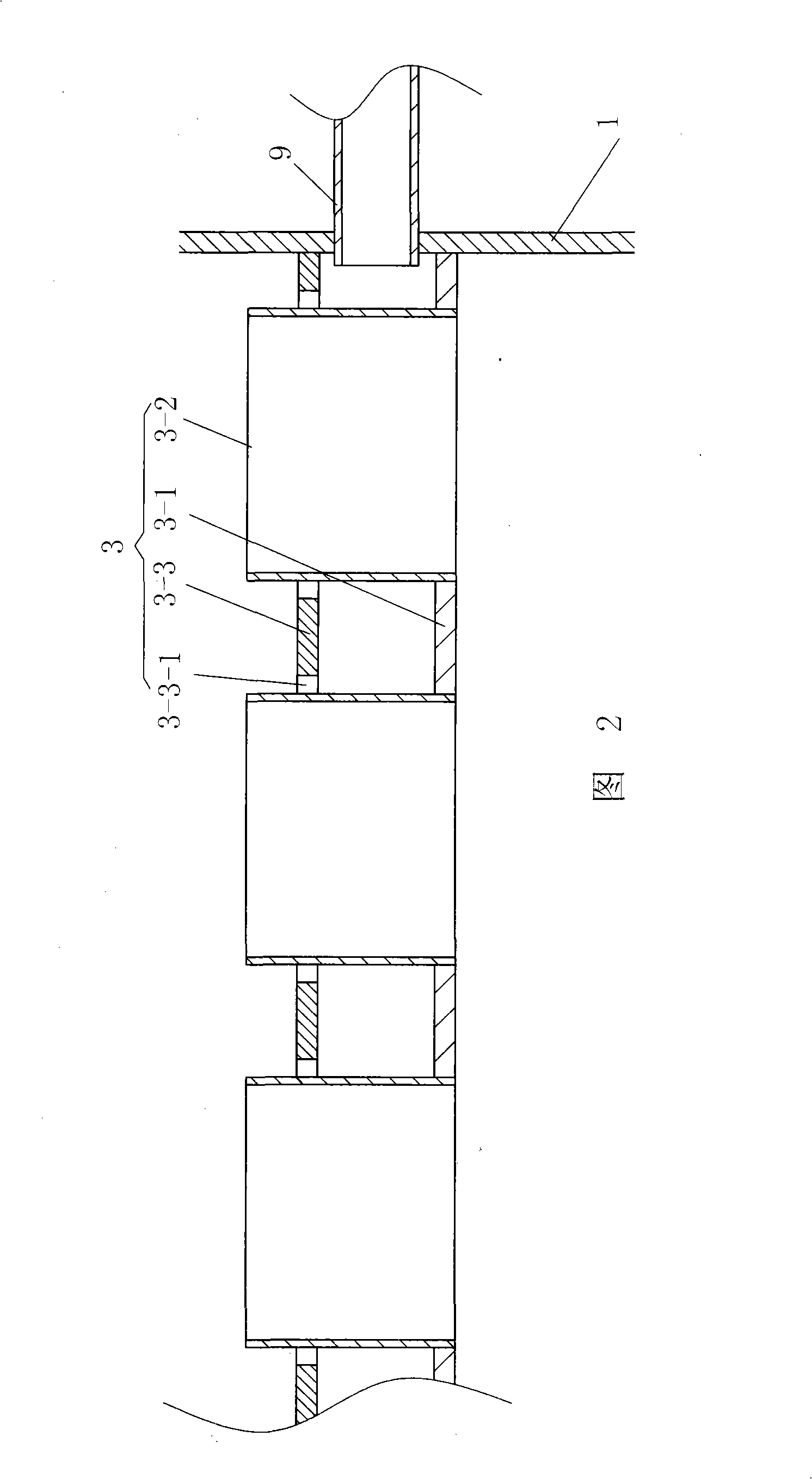

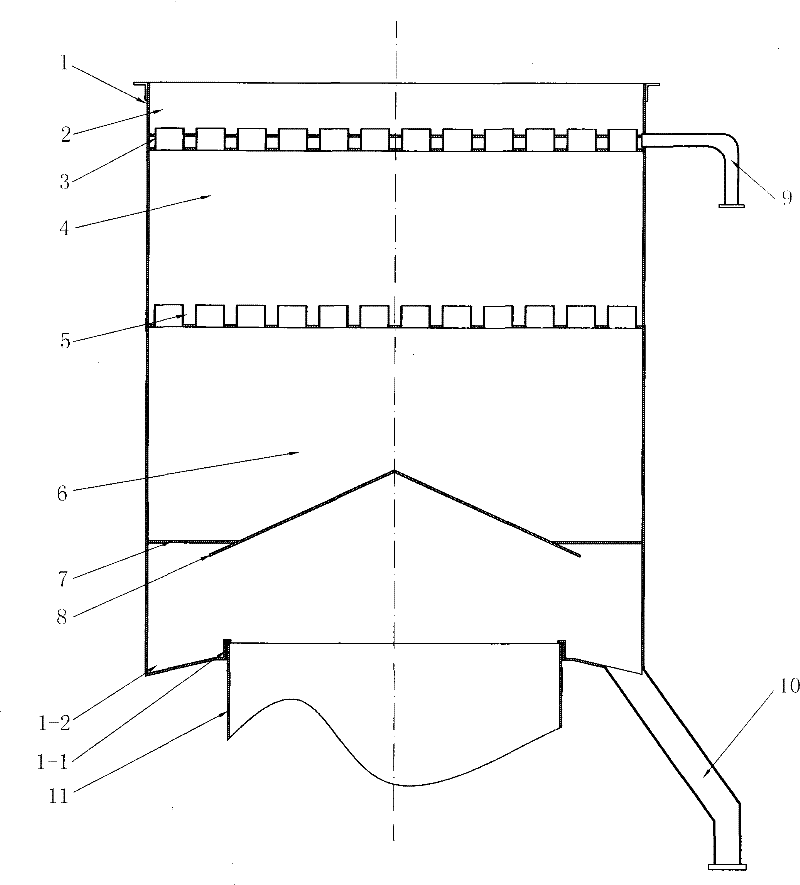

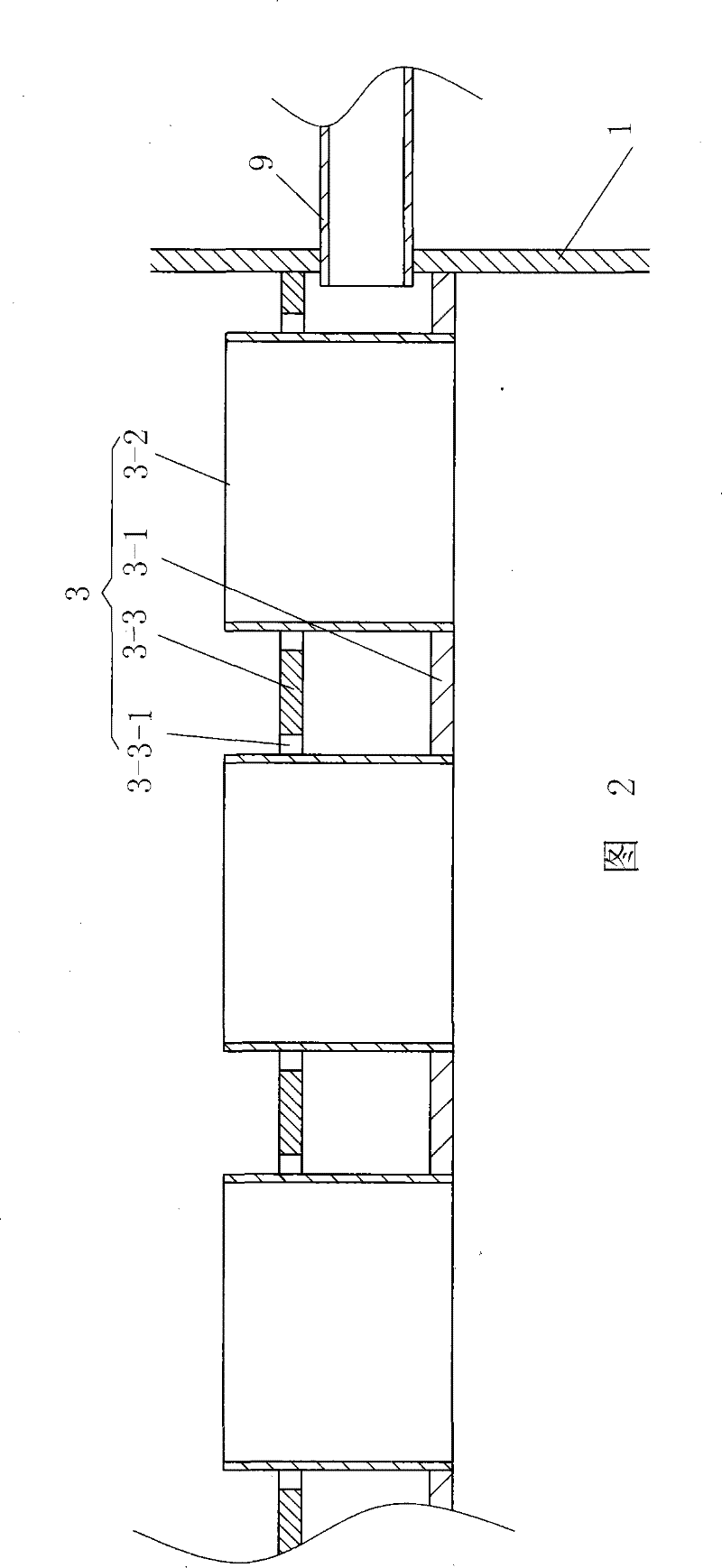

Water film dust removing and desulferizing device for furnace cupola

InactiveCN101327402AGood dust removalReduce power consumptionUsing liquid separation agentVertical furnacesCupolaEngineering

The present invention relates to a water-film dust-removing desulphurization device that is used for a furnace cupola, which comprises a shell and a conical furnace cupola cover cap, wherein, the cover cap is fixed on the inner wall of the shell through a connection bar; the shell is connected to the top part of the furnace cupola body through a bottom hole; a water discharging groove is arranged on an annular bottom of the shell; an upper spraying unit and a lower spraying unit are arranged above the inner cover cap of the shell; the upper spraying unit comprises an upper bottom separation plate that is fixed on the inner wall of the shell; the upper bottom separation plate is provided with a plurality of uniformly-distributed smoke-pipe holes; each smoke-pipe hole is provided with an upper smoke-exhausting pipe; the upper ends of all upper smoke-exhausting pipes stay at the same plane; the lower spraying unit comprises a lower bottom separation plate that is fixed on the inner wall of the shell; the lower bottom separation plate is provided with uniformly-distributed smoke-pipe holes, and each smoke-pipe hole is provided with a lower smoke-exhausting pipe; the upper end surface of all lower smoke-exhausting pipe stay at the same plane; an inlet is arranged on the shell corresponding to the spraying units; a discharging port is arranged on the shell corresponding to the discharging groove; the water-film dust-removing desulphurization device has obvious energy conservation and drainage reduction effect, and has simple structure and low utilization cost, and is particularly suitable for the modification of the prior furnace cupola.

Owner:JIANGSU T Y ENVIRONMENTAL ENERGY +1

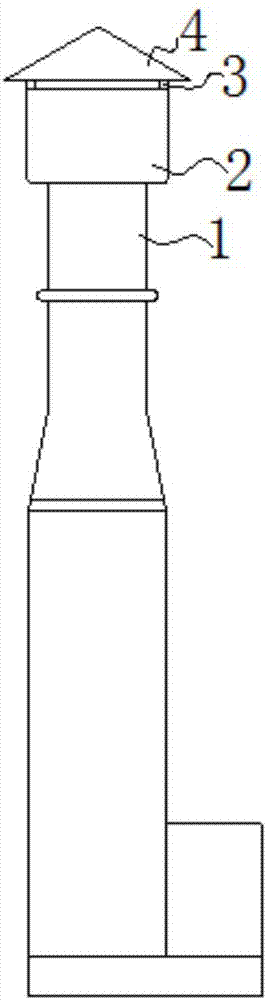

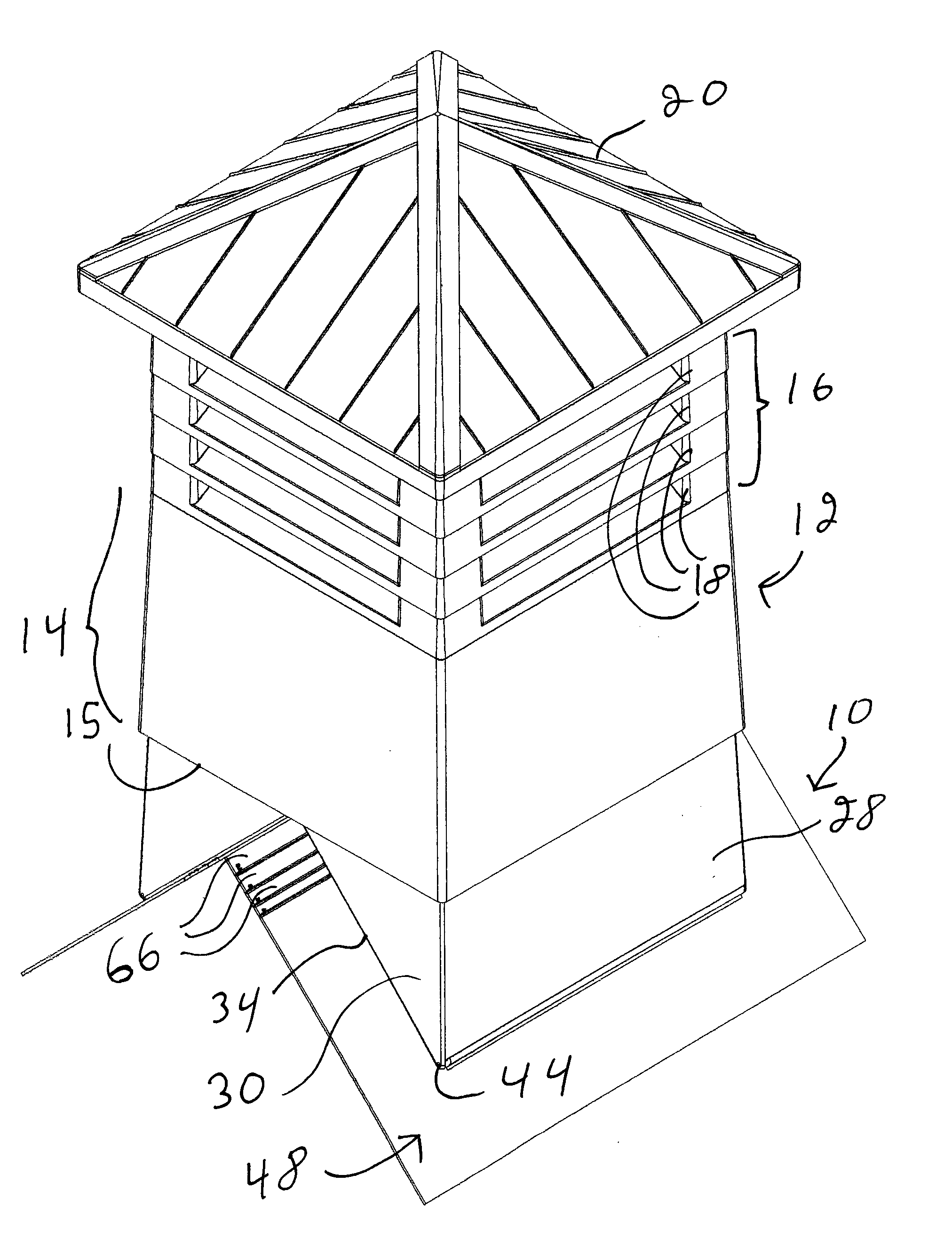

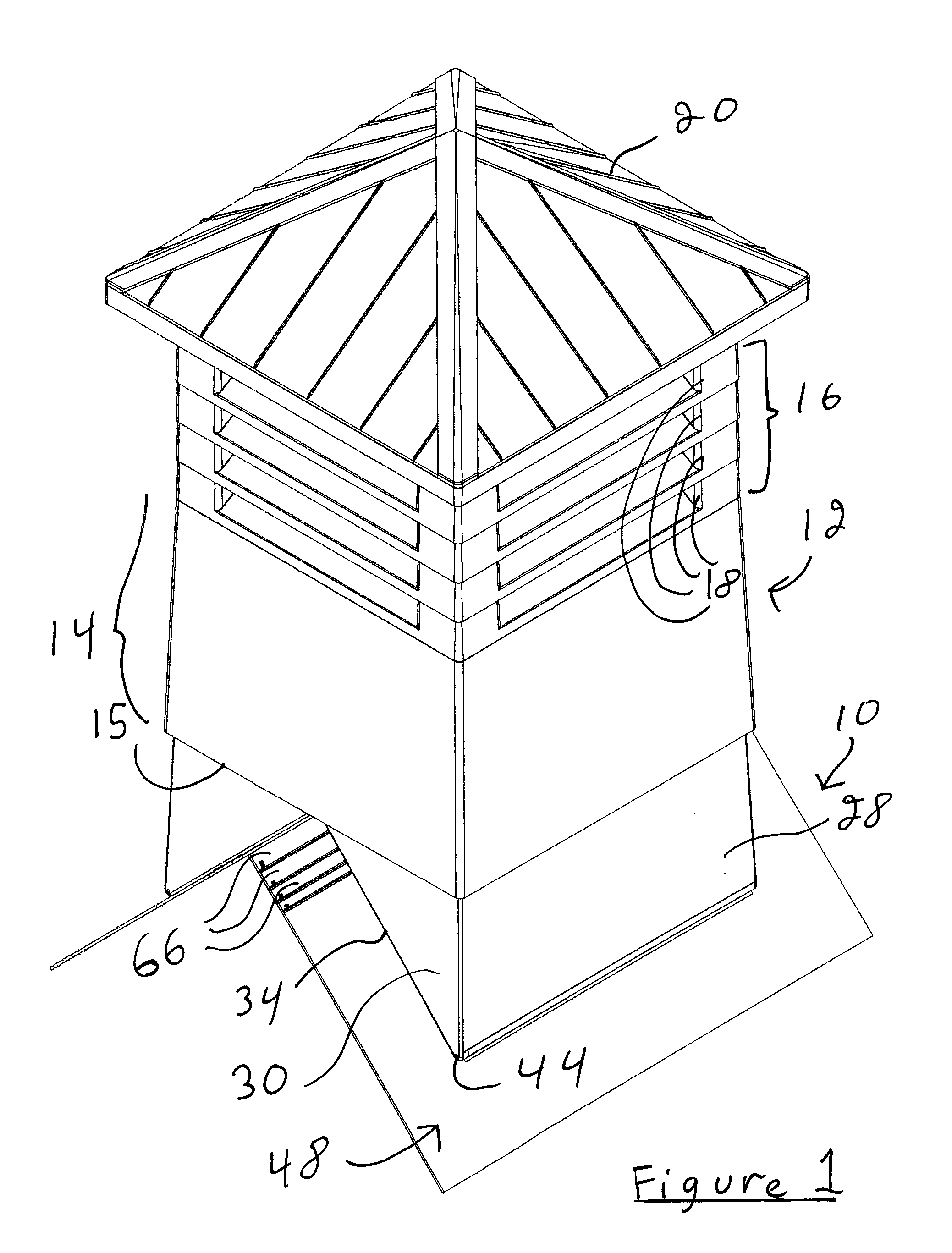

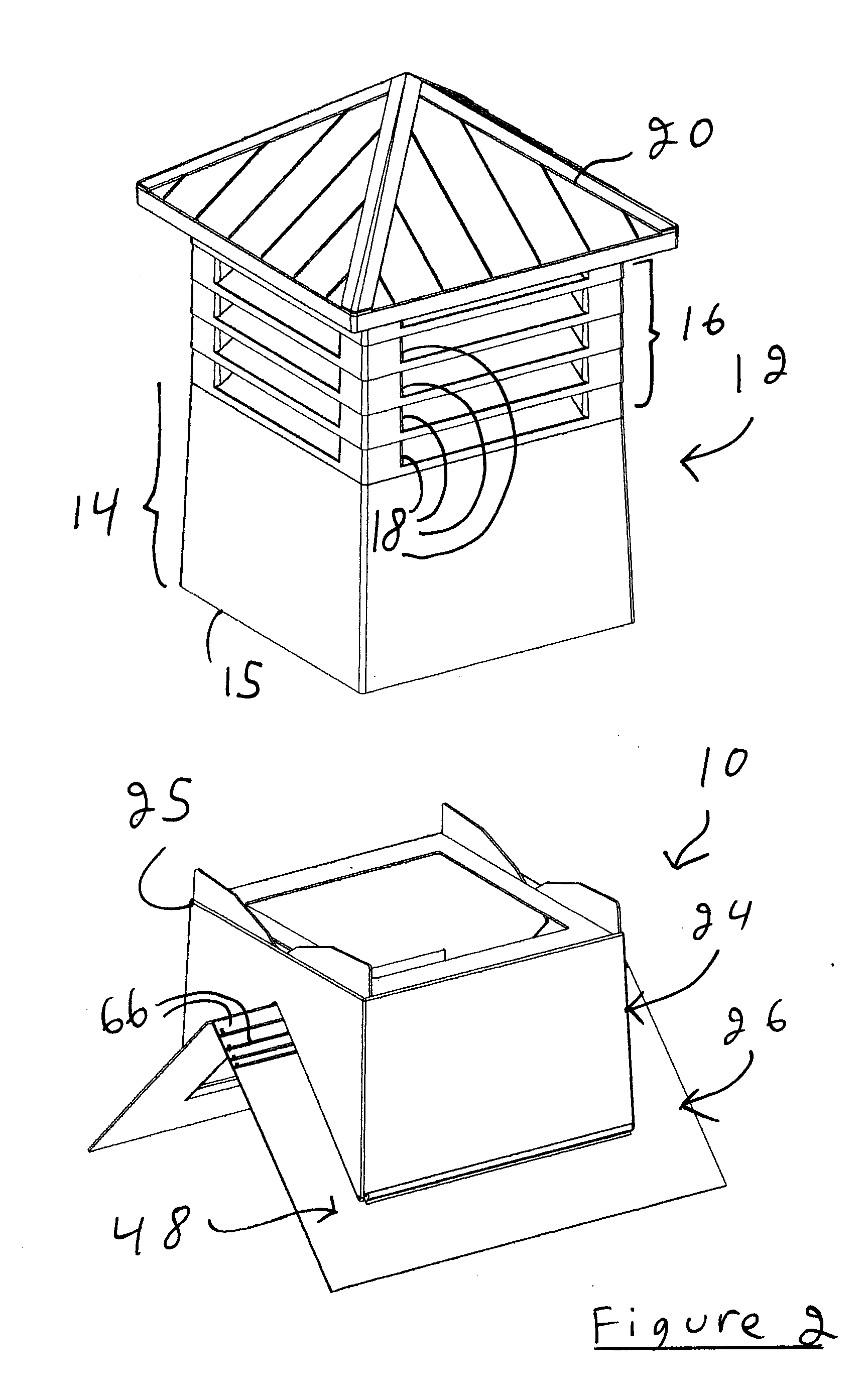

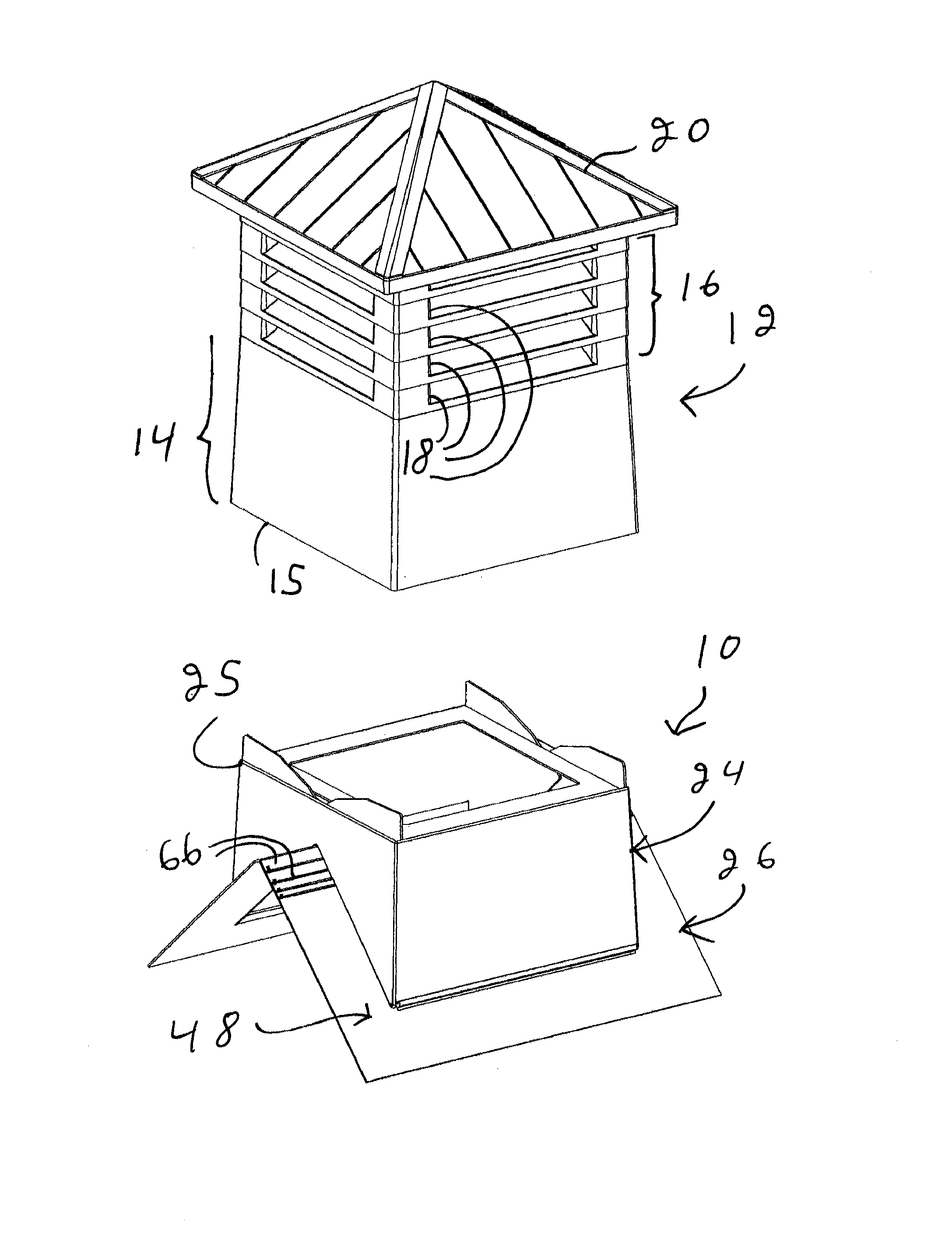

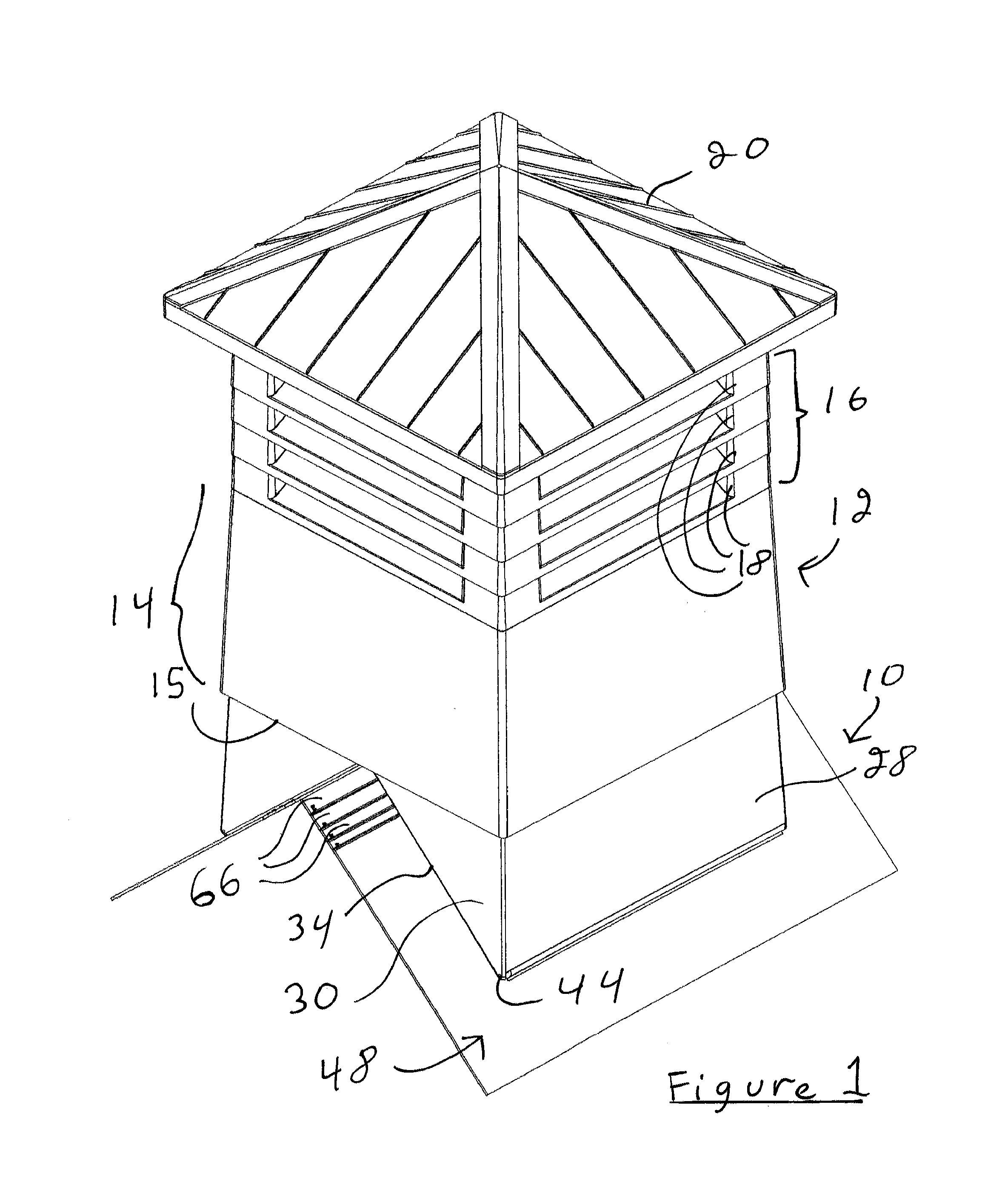

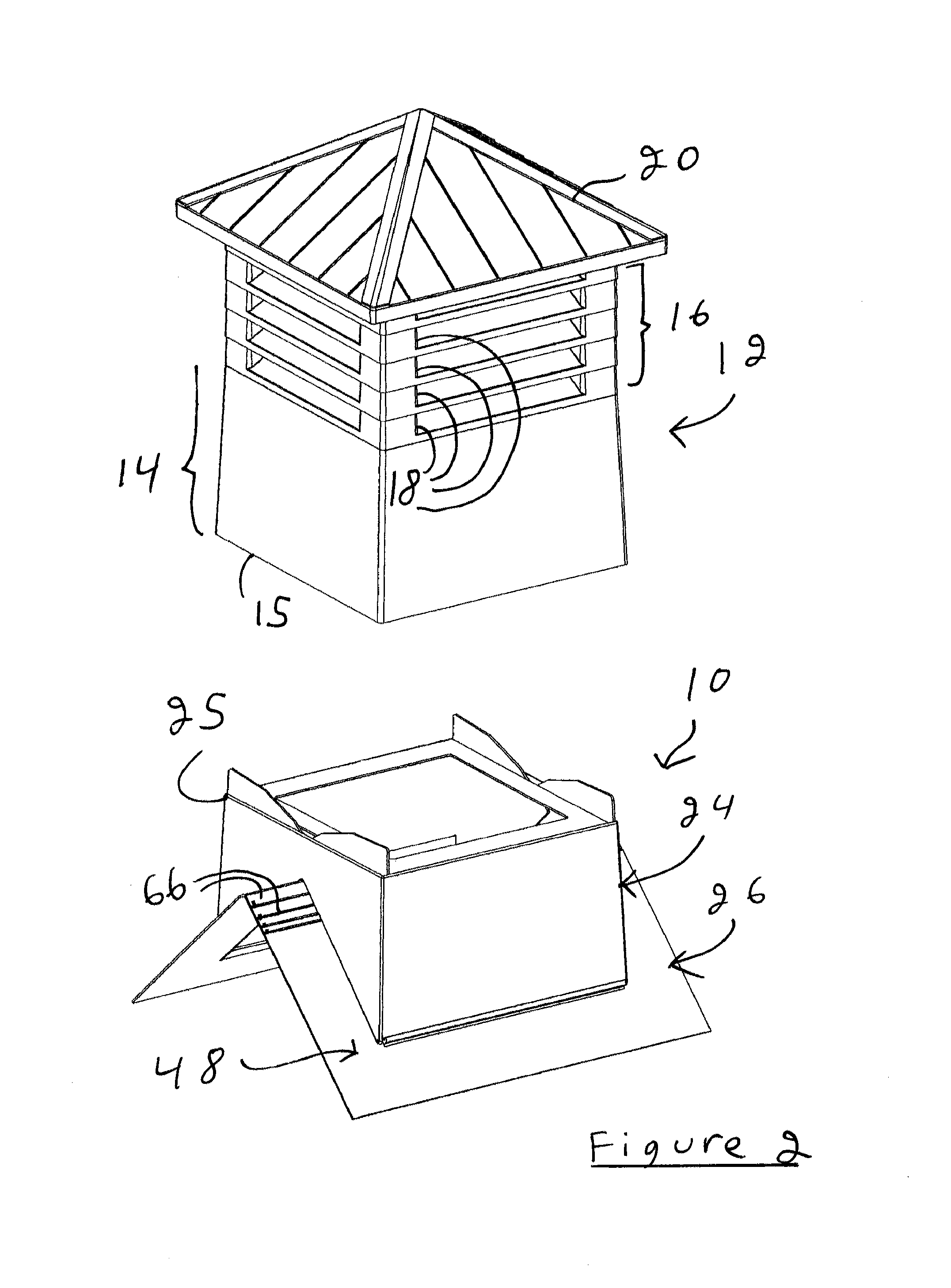

Adjustable roof ventilator base

ActiveUS20110302864A1Convenient shipmentBuilding roofsLighting and heating apparatusCupolaMechanical engineering

A roof ventilator mount for mounting a roof ventilator onto a gable-type roof (21), the roof ventilator including a roof ventilator base (10) defining a cupola mounting portion (25) for mounting a cupola (12) thereto, the roof ventilator mount comprising: a first mounting component (26), the first mounting component (26) including a first mounting plate (48) mountable to the roof (21); a second mounting component (26), the second mounting component (26) including a second mounting plate (48) mountable to the roof (21); the first and second mounting components (26) being mountable to the roof ventilator base (10) with proximal edges (47) thereof located substantially adjacent to each other and distal edges (49) thereof located spaced apart from each other; the first and second mounting plates (48) being each provided with a breakable segment (66) extending from the proximal edge (47), the breakable segment (66) being breakable from the remainder of the mounting plate (48) along a predetermined break line located at a predetermined distance from the distal edge (49).

Owner:RAMSAY SERGE +1

Compact electro-hydraulic generator to motorise cupola

InactiveUS20060096284A1Increase the occupied volumeEasy to handleRotary clutchesPump assembliesCupolaElectro hydraulic

The present invention divulges a particularly compact electro-hydraulic generating set and its application in combination with a compact actuator to pilot the traverse movement of a close cupola head assembly or of one or several offset cupola head assemblies. The compactness of the electro-hydraulic generating set and the possibility of the close or offset mounting of one or several cupola head assemblies make various architectures possible.

Owner:NEXTER SYST SA

Adjustable roof ventilator base

A roof ventilator mount for mounting a roof ventilator onto a gable-type roof (21), the roof ventilator including a roof ventilator base (10) defining a cupola mounting portion (25) for mounting a cupola (12) thereto, the roof ventilator mount comprising: a first mounting component (26), the first mounting component (26) including a first mounting plate (48) mountable to the roof (21); a second mounting component (26), the second mounting component (26) including a second mounting plate (48) mountable to the roof (21); the first and second mounting components (26) being mountable to the roof ventilator base (10) with proximal edges (47) thereof located substantially adjacent to each other and distal edges (49) thereof located spaced apart from each other; the first and second mounting plates (48) being each provided with a breakable segment (66) extending from the proximal edge (47), the breakable segment (66) being breakable from the remainder of the mounting plate (48) along a predetermined break line located at a predetermined distance from the distal edge (49).

Owner:RAMSAY SERGE +1

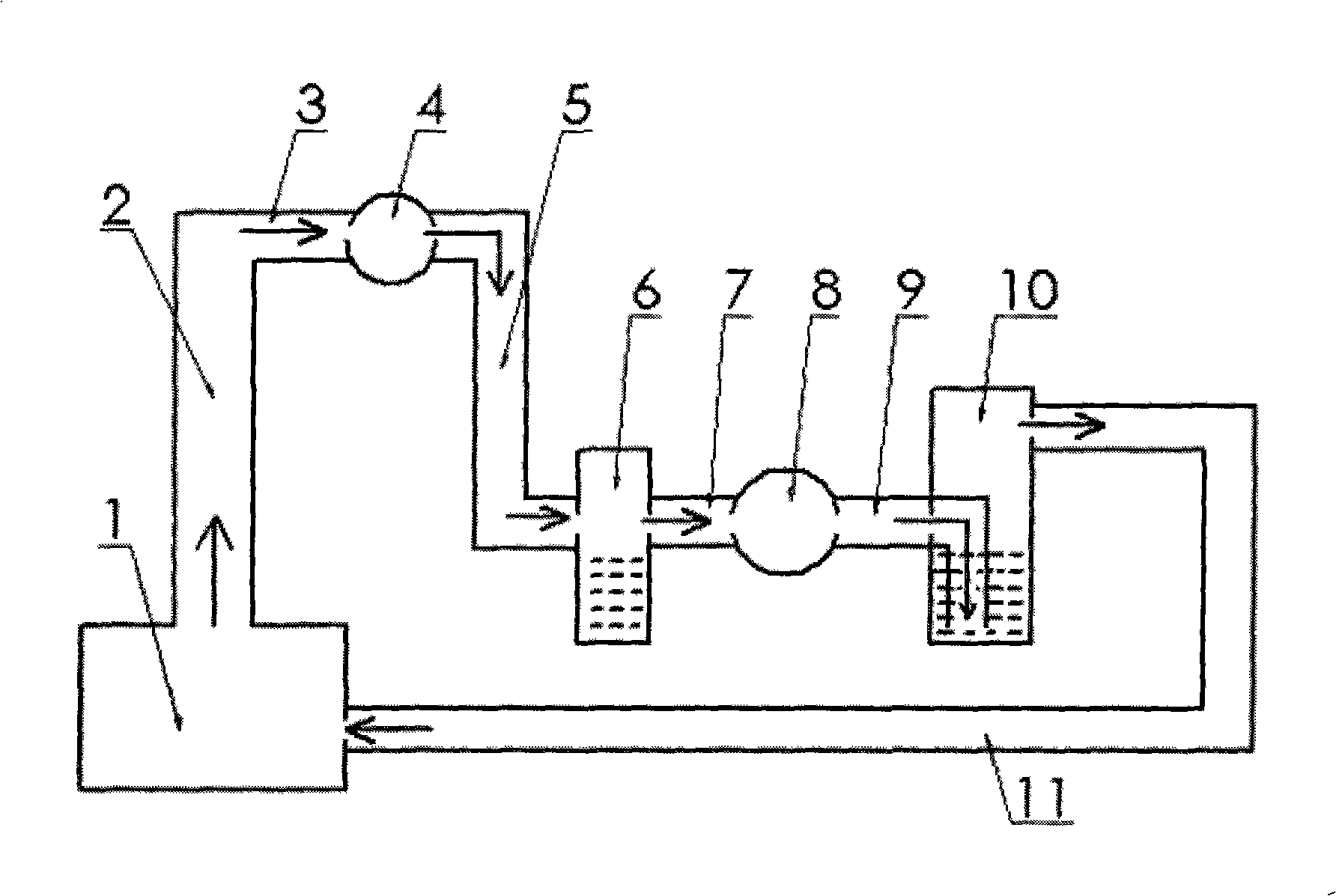

Cupola

InactiveCN105571309AImprove stabilityQuality improvementCharge manipulationVertical furnacesHydraulic cylinderCupola

The invention provides a cupola. The cupola is simple in structure and convenient to machine and operate, and distribution evenness is improved. The cupola comprises a cupola body, a feeding opening is formed in the middle of the top of the cupola body, and a conveying belt is arranged above the feeding opening. A distributing mechanism is arranged in the cupola body and sequentially comprises a conical funnel, a counter weight and a pair of symmetric push plate mechanisms. The conical tip of the funnel is arranged upwards, and the funnel is connected to the bottom face of the top of the cupola body through a pair of first connecting rods. The counter weight is connected to the center of the bottom face of the funnel through a second connecting rod. The push plate mechanisms comprise hydraulic cylinders and push plates, the hydraulic cylinders are fixedly arranged on the inner wall of the cupola body, the push plates are movably arranged on the inner wall of the cupola body, and the hydraulic cylinders horizontal move to push the push plates. The push plates in the push plate mechanisms are symmetrically located on the two sides of the counter weight. According to the cupola, the wool output rate is increased, and the quality of finished rock wool is improved.

Owner:ZHEJIANG YANWEI NEW MATERIAL SCI & TECHCO LTD

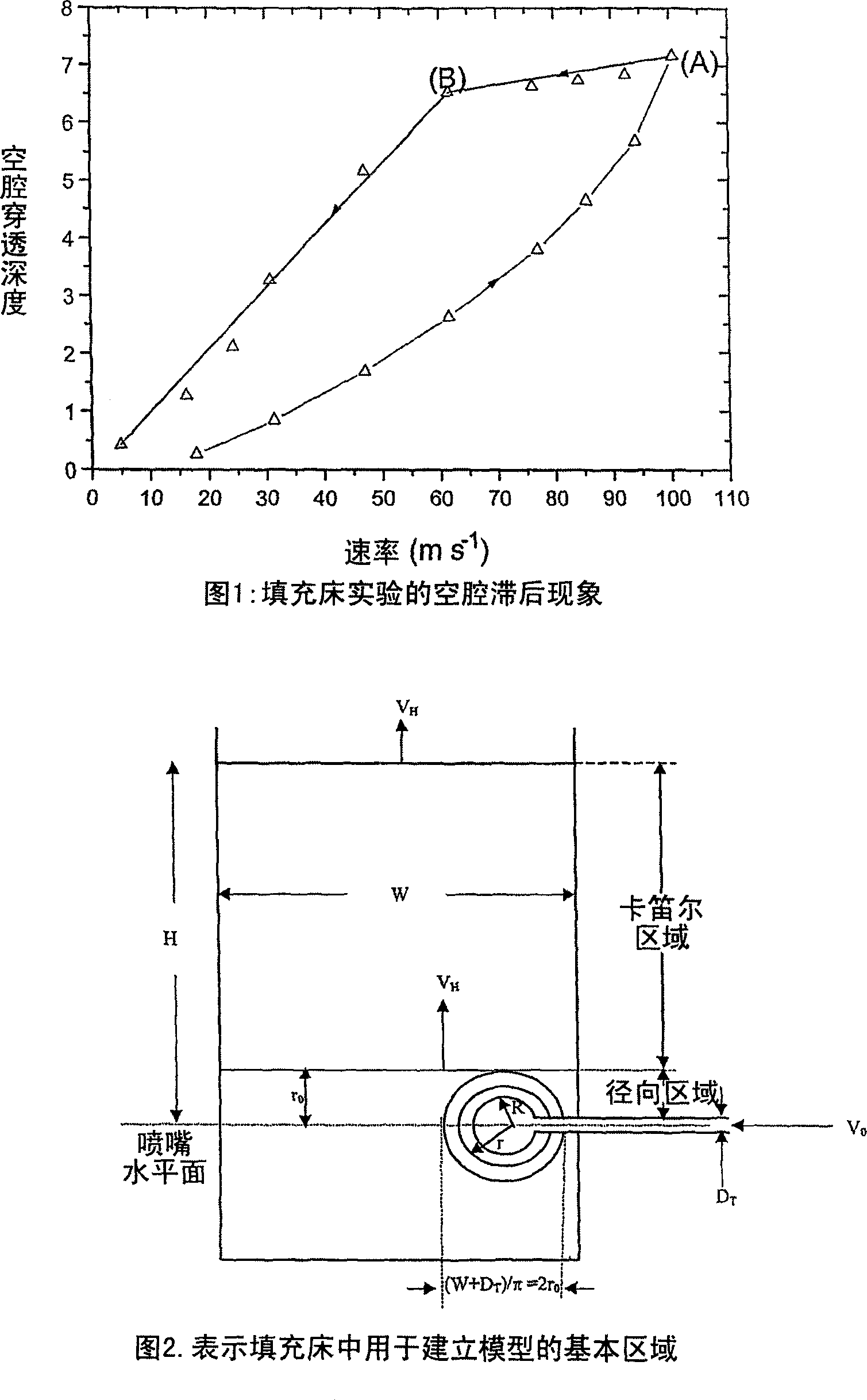

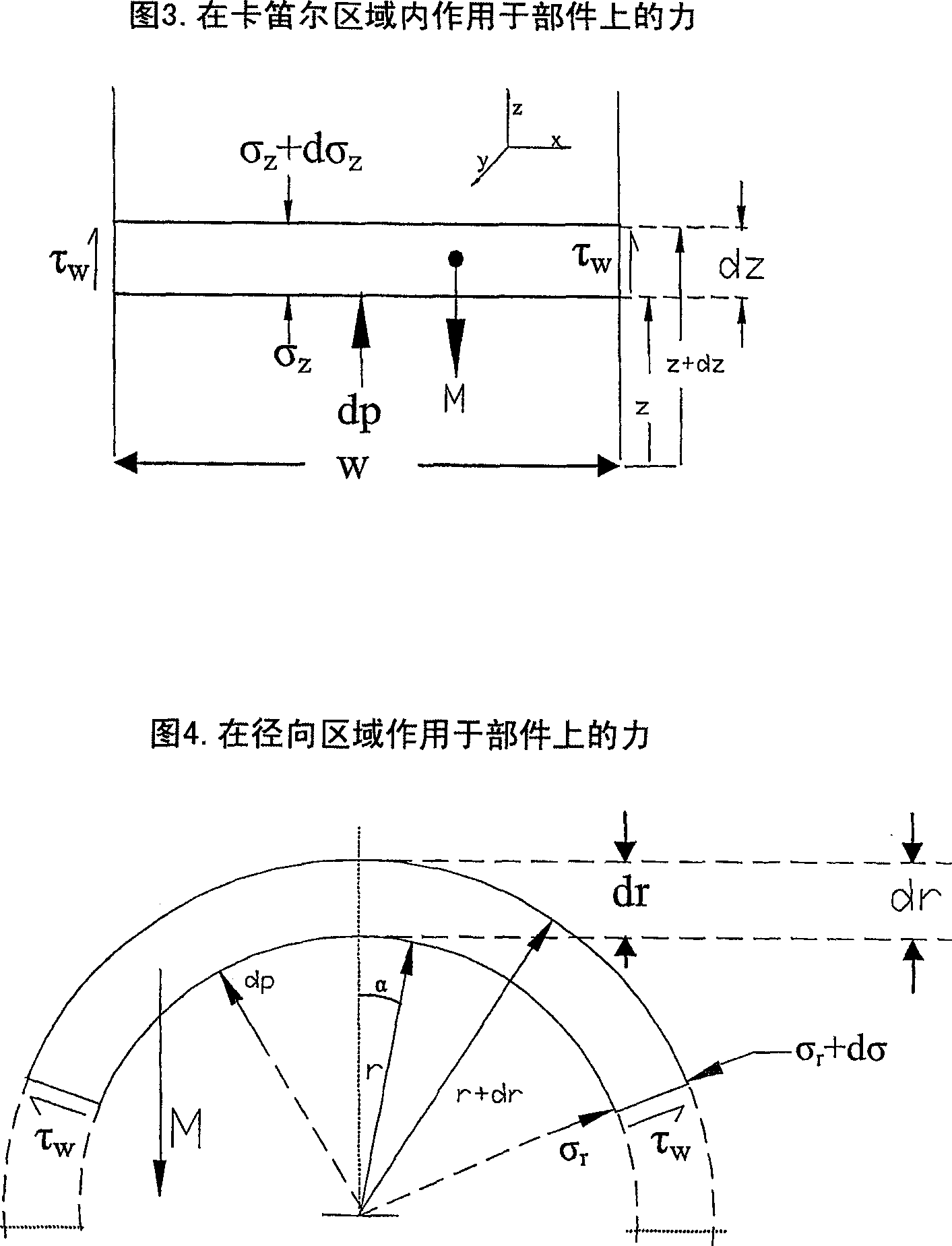

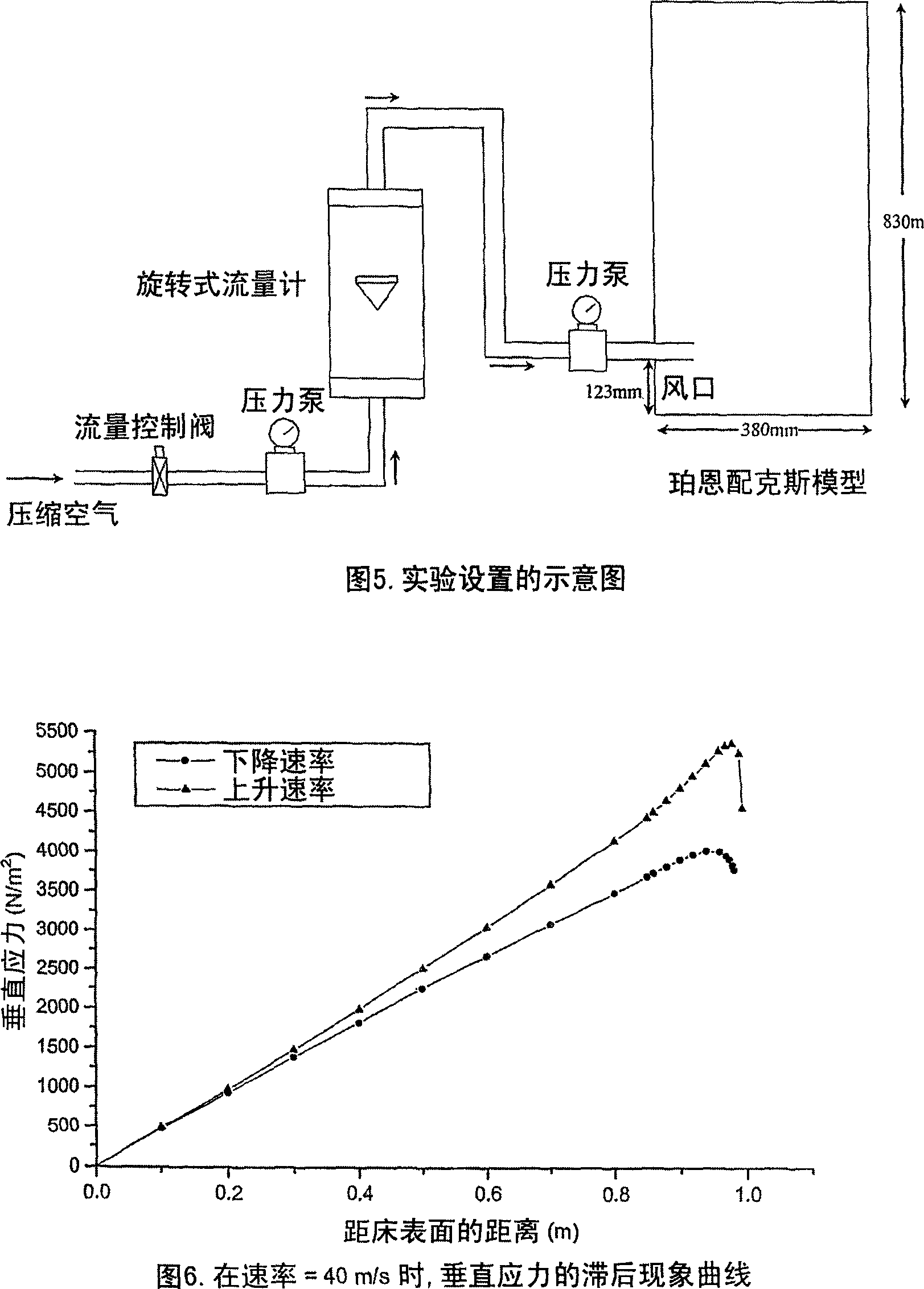

Prediction of cavity size in the packed bed systems using new correlations and mathematical model

The present invention relates to prediction of cavity size in the packed bed systems using new correlations and mathematical model and more particularly, using simplified equations, based on analytical solution of one-dimensional mathematical model, that have been developed along with the cavity correlations to describe the cavity size and hysteresis that give a universal approach to predict the cavity size which is applicable to any packed bed systems like blast furnaces, cupola, Corex, catalytic regenerator, etc. and is able to represent, in a good way, the data of other researchers provided the frictional properties of the particulate are known.

Owner:INDIAN INST OF SCI & IND

Popcorn Making Machine with Various Configurations of Roaster

A popcorn making machine is proposed in three embodiments including a roaster, provided with a circulated hot airflow, and a pipebranch coupled thereto, receiving popcorn from the roaster and discharging thereof. In the first embodiment, the roaster has truncated conical sidewalls, the pipebranch has a rectangular cross-section. In the second embodiment the roaster is configured as at least a portion of a deformed sphere having a lesser pole radius and a greater equator radius, the pipebranch is conjugated with the roaster without any acute angle, and continuously tapers transforming into a cylindrical shape. In the third preferred embodiment, the roaster and pipebranch are similar to the ones of the second embodiment, but the roaster additionally contains a central cavity configured in a cone-like shape, having a base, a cupola-like top, and a curved conjugation angle at the base. The aforementioned shapes reduce manufacturing costs and improve the popcorn machine's productivity.

Owner:KORIN MIKHAIL

Stackable surface module for a wall surface

A stackable surface module is provided for a wall surface that can be both erected and dismantled. The stackable surface module is especially useful in certain applications, such as for earthquake-resistant walls, a cupola, a bridge, a site fence, a noise protection wall, an upwind power station, a heat exchanger or a coastal protection wall.

Owner:ZINSER KLAUS

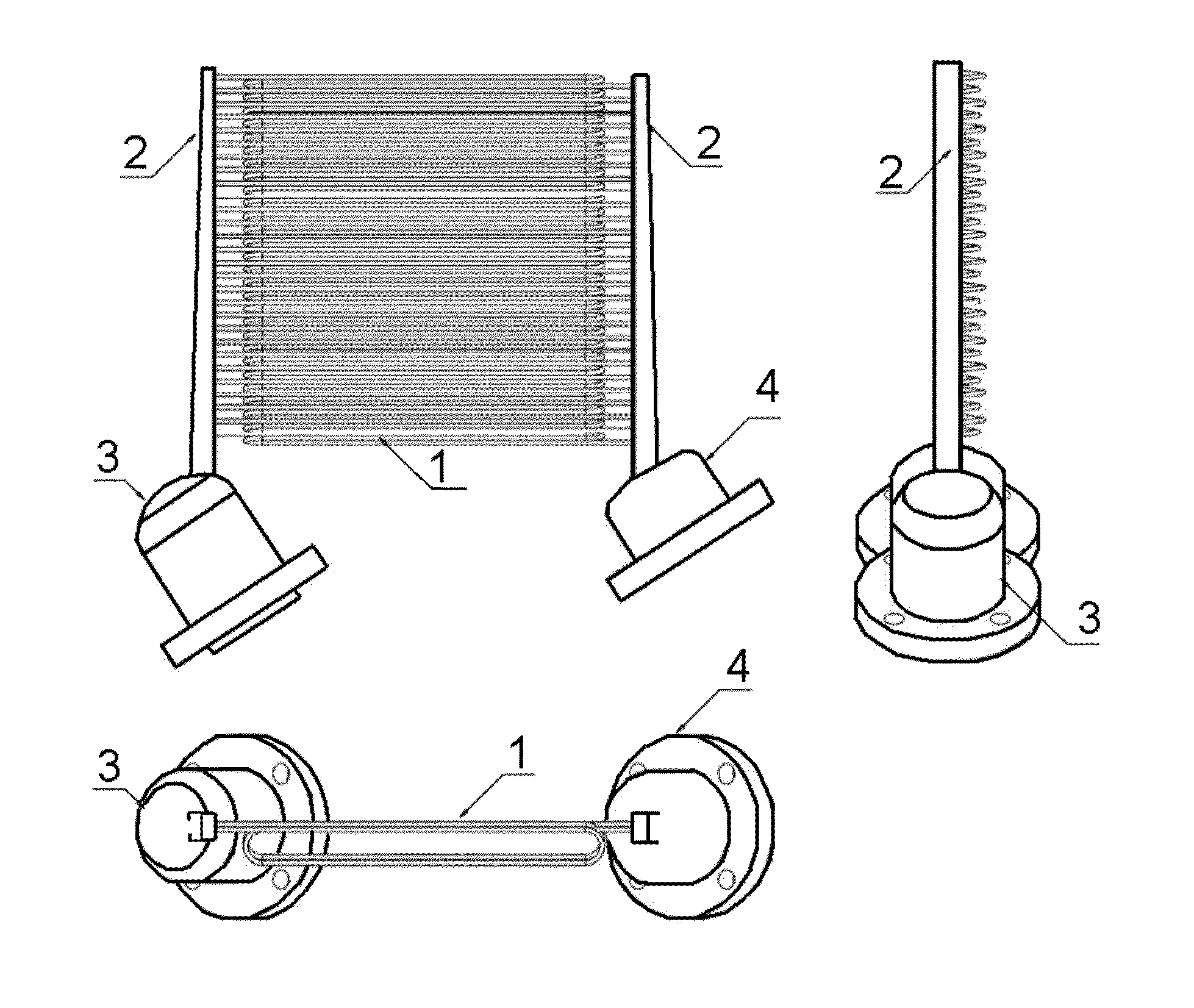

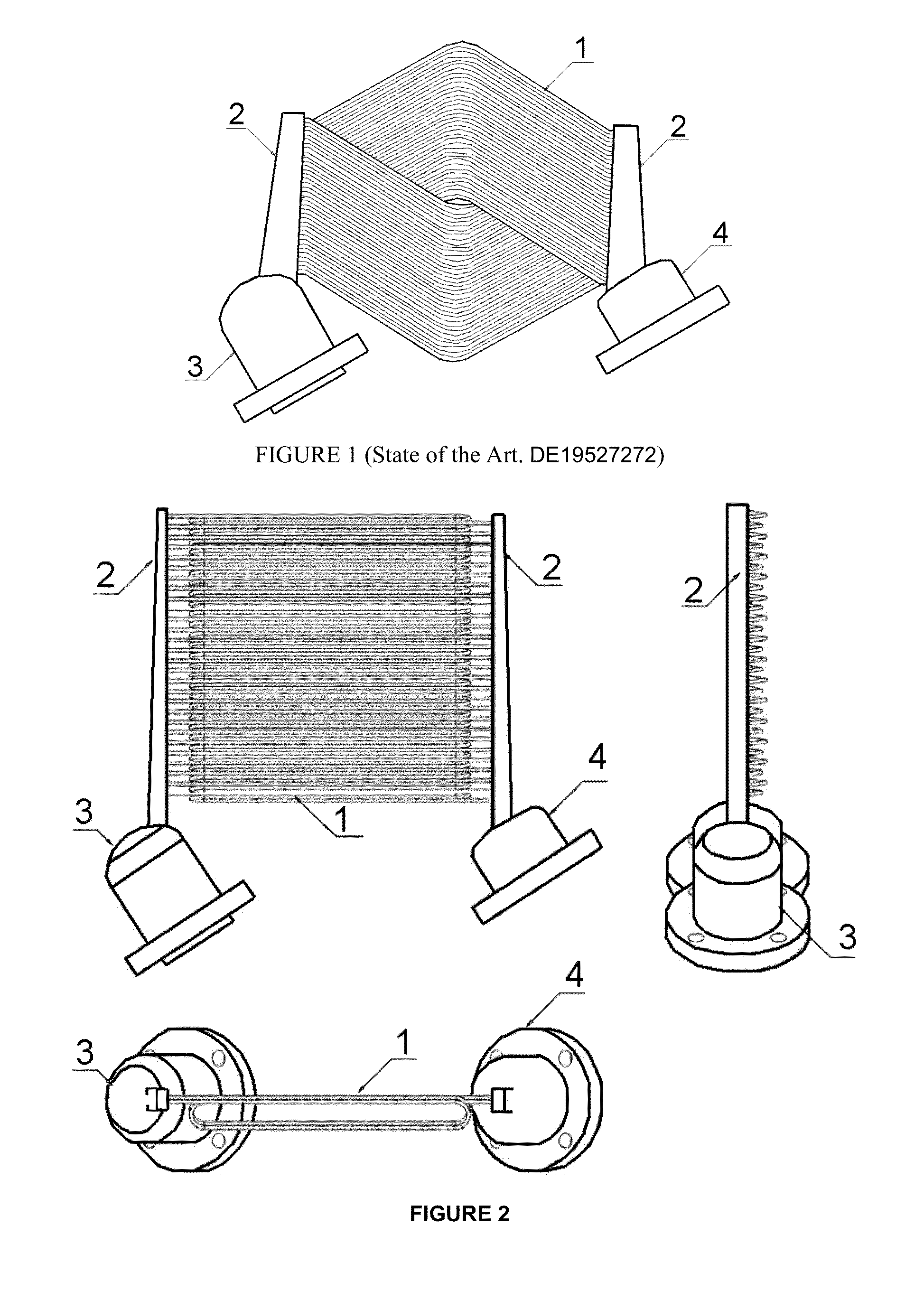

Coil solar receiver for a stirling disk and method for manufacturing same

InactiveUS20130213388A1Maximize radiationImprove overall thermo-mechanical behaviourSolar heating energySolar heat devicesStraight tubeEngineering

Coil solar receiver for a Stirling disk, the main components of which are pipes (where the sun hits), collectors, tanks and cupolas (of which there are two types, one that houses the regenerator, and the expansion cupola that is the area where the working gas is at a higher temperature) that includes a series of pipes (1) that perpendicularly exit from one collector (2) and perpendicularly enter another (2) and where each pipe consists of two semicircumferential curved parts (10) and three straight parts (11) parallel to one another: a center straight part (between curve and curve) and two straight parts on the ends (between the curve and the exit of one collector (2)), the two straight end parts being located on the same plane, while the center straight part is located in a separate plane.

Owner:ABENGOA SOLAR NEW TECH SA

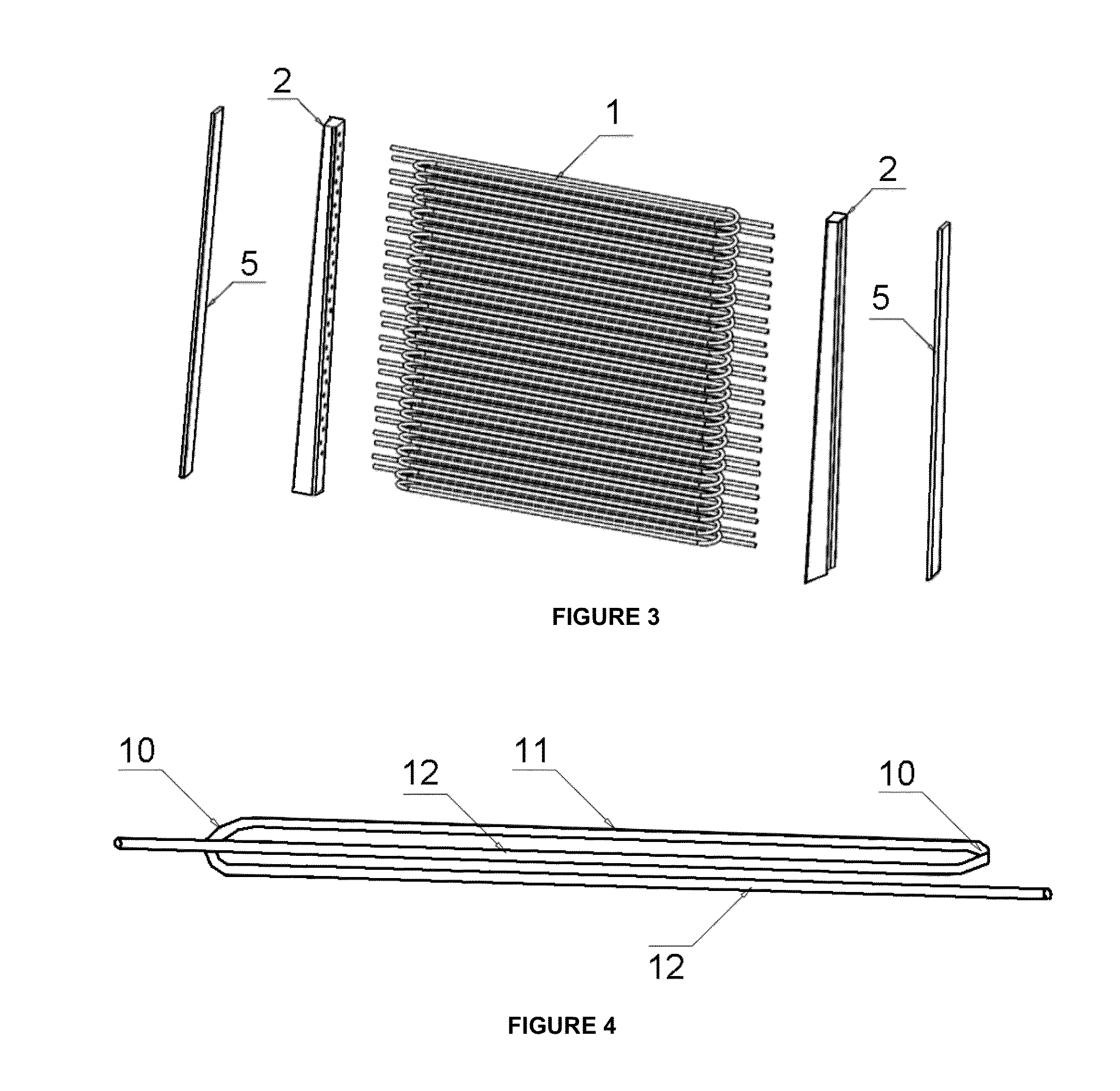

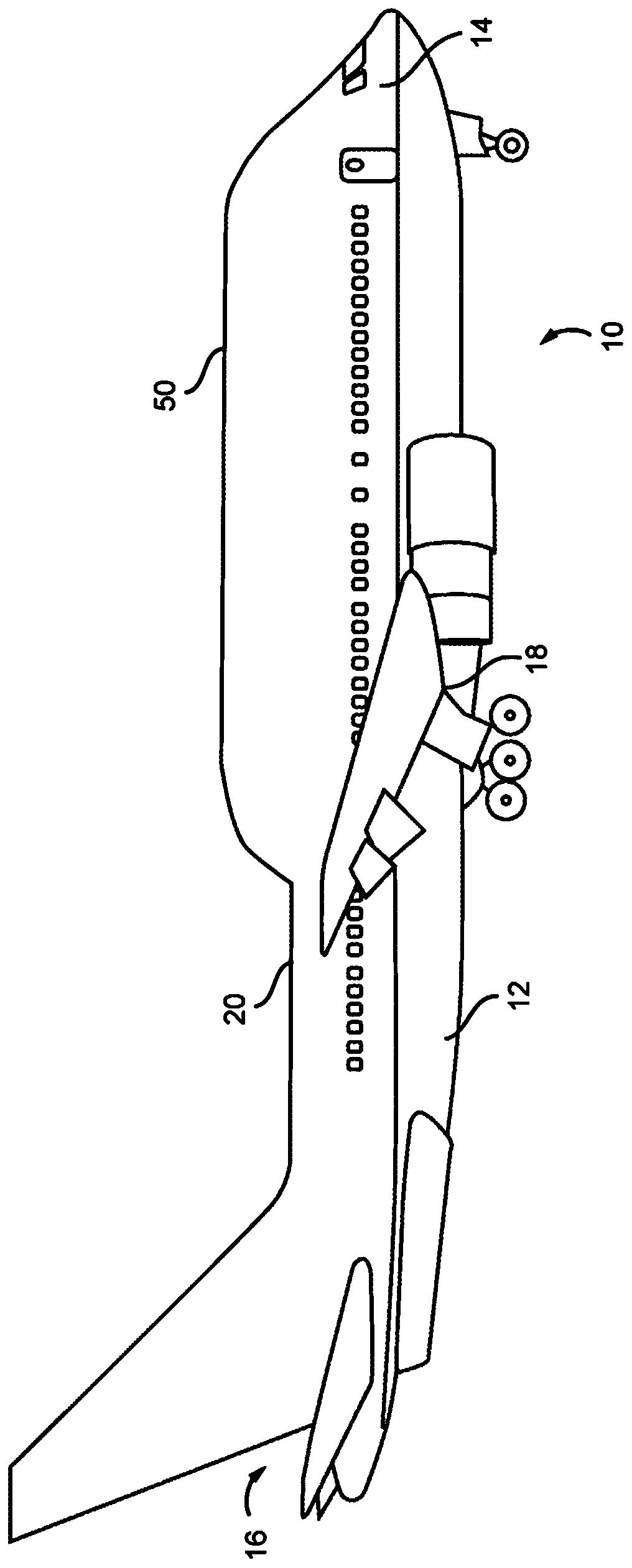

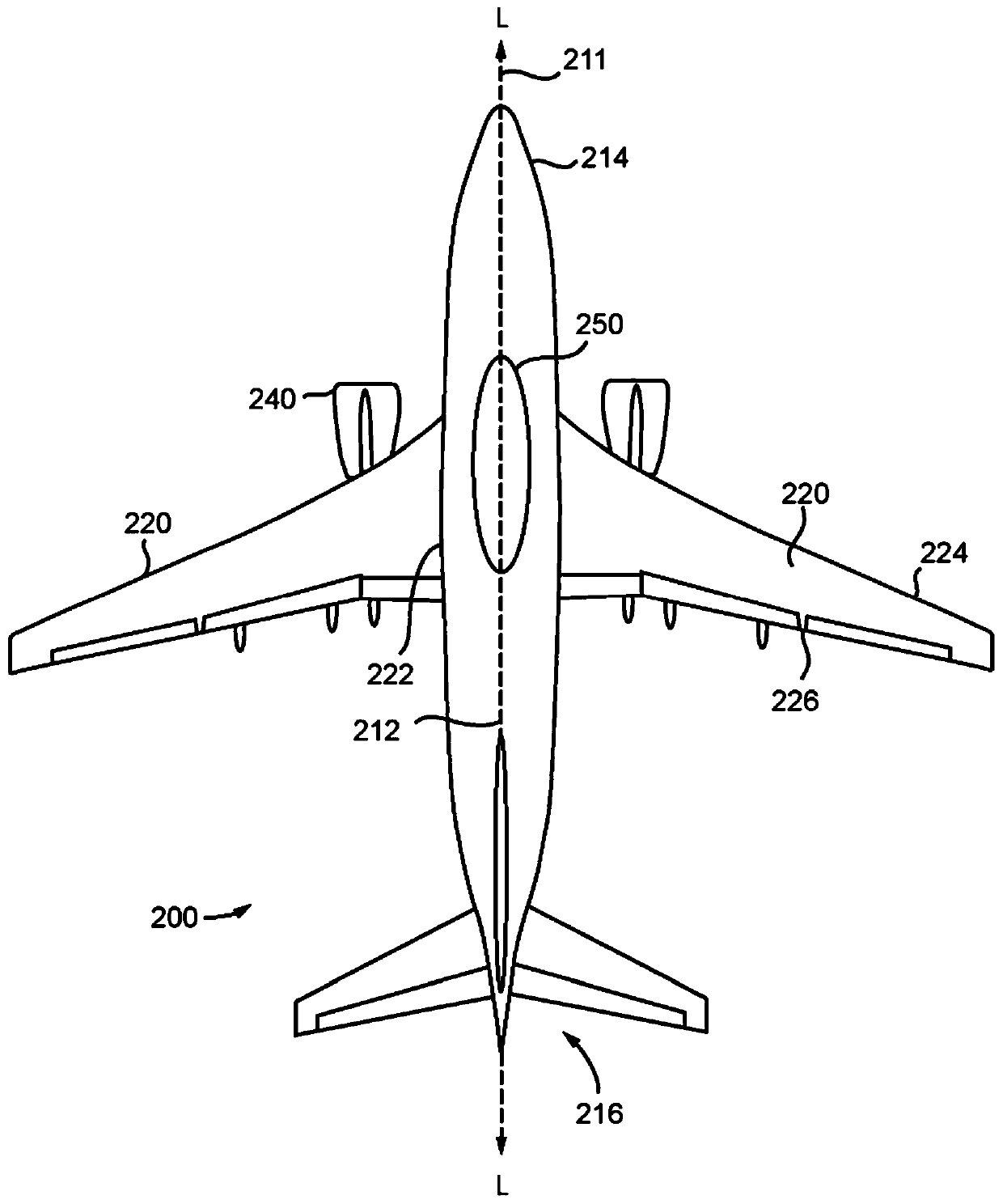

Cupola fairing for an aircraft and method for fabricating the same

A cupola fairing (250) for reducing drag and increasing lift on an aircraft fuselage (210) and wings (220). The fairing includes a housing length extending along a longitudinal axis, and a variable width extending normal to the longitudinal axis. The housing width is variable and defined by a plurality of cross-sectional areas of the cupola fairing. The fairing has a substantially smooth exteriorsurface that is curved along the length and the variable width of the housing. The housing surface has its longitudinal and transverse curvatures being defined by metrics corresponding to a referencewing root chord of the aircraft (200), a cross-sectional area of the fuselage, a percentage of the cross-sectional area to be covered by the fairing, and positioning of the cupola fairing on the crownportion of the fuselage (210). The housing has a lower surface configured to conform to a shape of the crown at which the cupola fairing (250) is positioned.

Owner:AERO DESIGN LABS INC

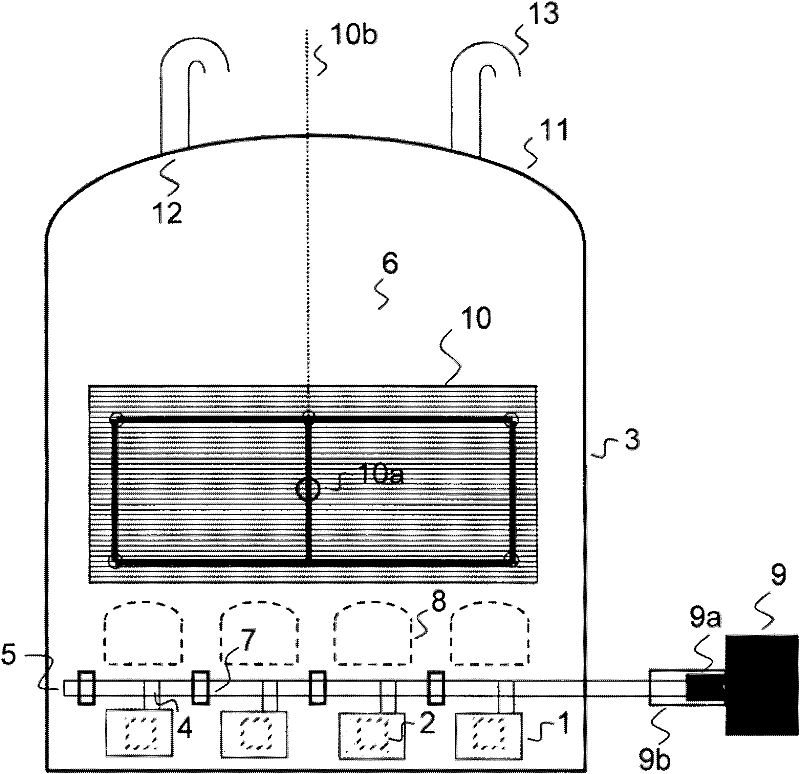

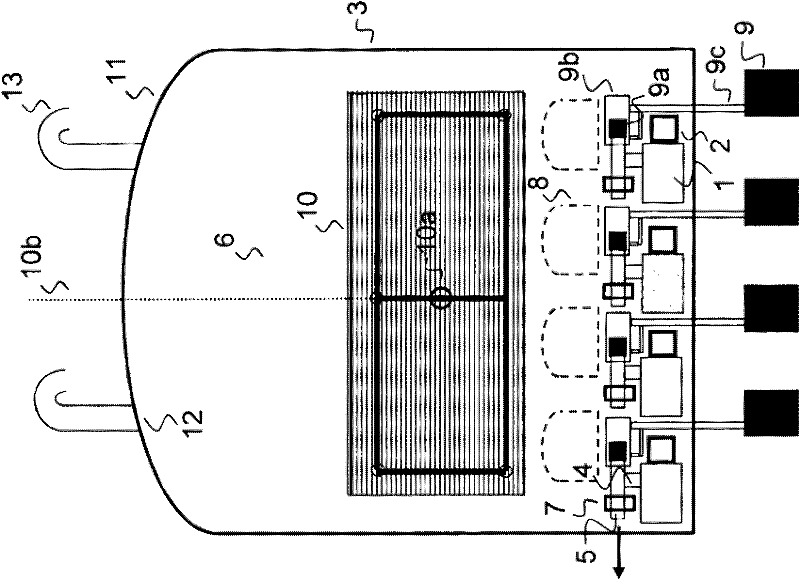

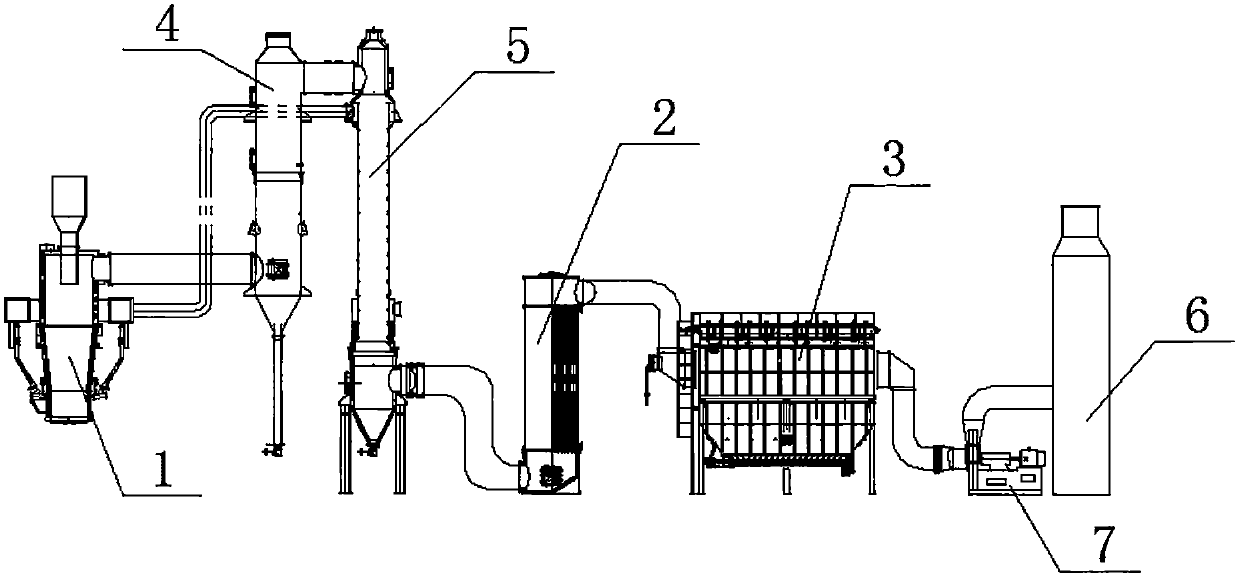

Cupola tail gas treatment system

InactiveCN105536374AAvoid enteringBurn out preventionGas treatmentAuxillary pretreatmentCupolaCombustion chamber

The invention relates to the field of environmental protection and particularly relates to a cupola tail gas treatment system. The cupola tail gas treatment system comprises a multi-pipe water cooler, a bag-type dust collector, a first combustion chamber and a heat exchanger which are sequentially connected in series, wherein the multi-pipe water cooler is used for reducing the temperature of cupola tail gas; the bag-type dust collector is used for filtering small dust in tail gas; the heat exchanger is used for heating the air entering the cupola by using the tail gas led out of the first combustion chamber; and the tail gas led out of the cupola sequentially goes through the multi-pipe water cooler, the bag-type dust collector, the first combustion chamber and the heat exchanger and is finally discharged out of a tail gas outlet of the heat exchanger. The transformation cost is low; the problems of reduction of heat exchange efficiency, increase of clearing cost and increase of shutdown maintenance time caused by a large quantity of dust in the tail gas entering the heat exchanger and adhered to the tube wall of the heat exchanger can be avoided, the production efficiency is improved, and the production cost is reduced; the sparks in the tail gas are effectively extinguished to prevent the sparks from entering the bag-type dust collector and burning out the bag; and moreover, natural gas consumption of the second combustion chamber of a curing furnace can be effectively reduced.

Owner:青岛青力环保设备有限公司

Water film dust removing and desulferizing device for furnace cupola

InactiveCN101327402BGood dust removalReduce power consumptionUsing liquid separation agentVertical furnacesCupolaEngineering

The present invention relates to a water-film dust-removing desulphurization device that is used for a furnace cupola, which comprises a shell and a conical furnace cupola cover cap, wherein, the cover cap is fixed on the inner wall of the shell through a connection bar; the shell is connected to the top part of the furnace cupola body through a bottom hole; a water discharging groove is arrangedon an annular bottom of the shell; an upper spraying unit and a lower spraying unit are arranged above the inner cover cap of the shell; the upper spraying unit comprises an upper bottom separation plate that is fixed on the inner wall of the shell; the upper bottom separation plate is provided with a plurality of uniformly-distributed smoke-pipe holes; each smoke-pipe hole is provided with an upper smoke-exhausting pipe; the upper ends of all upper smoke-exhausting pipes stay at the same plane; the lower spraying unit comprises a lower bottom separation plate that is fixed on the inner wall of the shell; the lower bottom separation plate is provided with uniformly-distributed smoke-pipe holes, and each smoke-pipe hole is provided with a lower smoke-exhausting pipe; the upper end surface of all lower smoke-exhausting pipe stay at the same plane; an inlet is arranged on the shell corresponding to the spraying units; a discharging port is arranged on the shell corresponding to the discharging groove; the water-film dust-removing desulphurization device has obvious energy conservation and drainage reduction effect, and has simple structure and low utilization cost, and is particularly suitable for the modification of the prior furnace cupola.

Owner:JIANGSU T Y ENVIRONMENTAL ENERGY +1

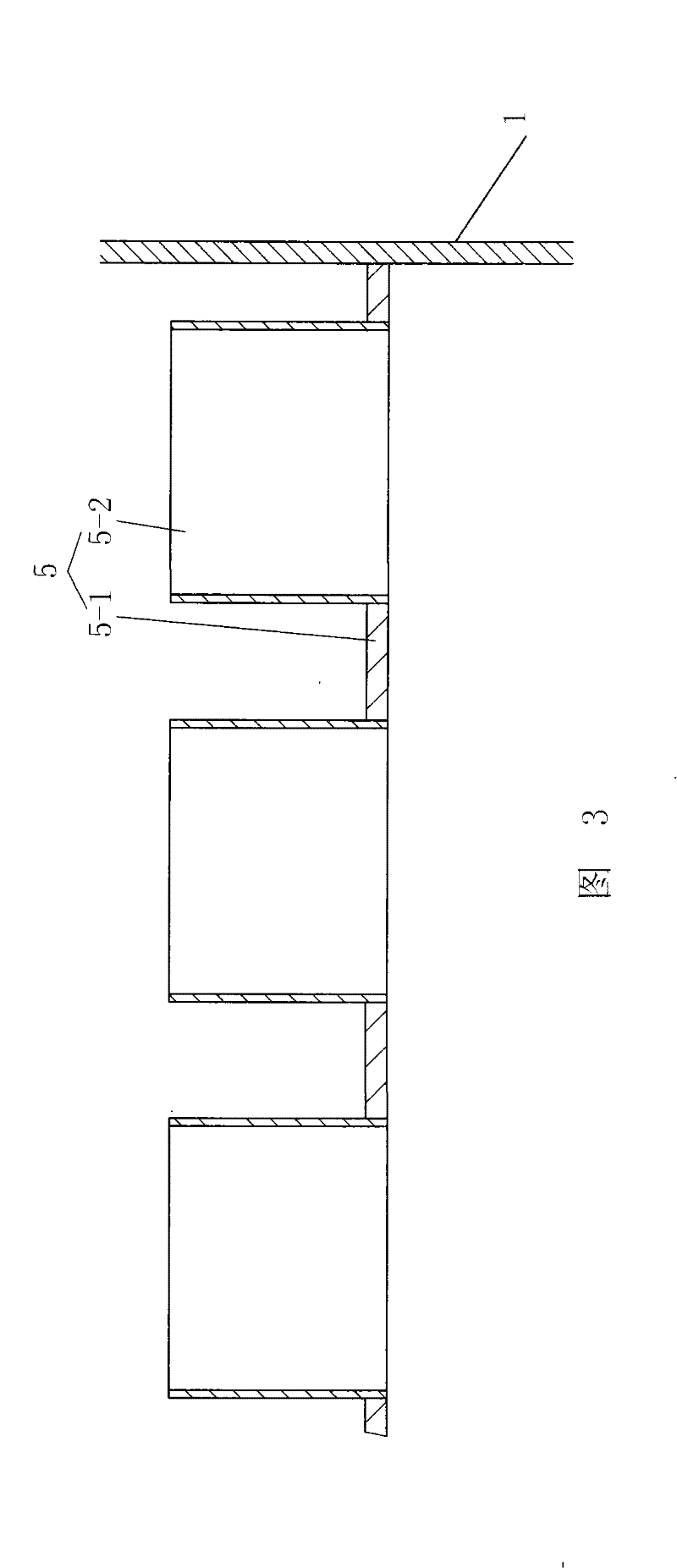

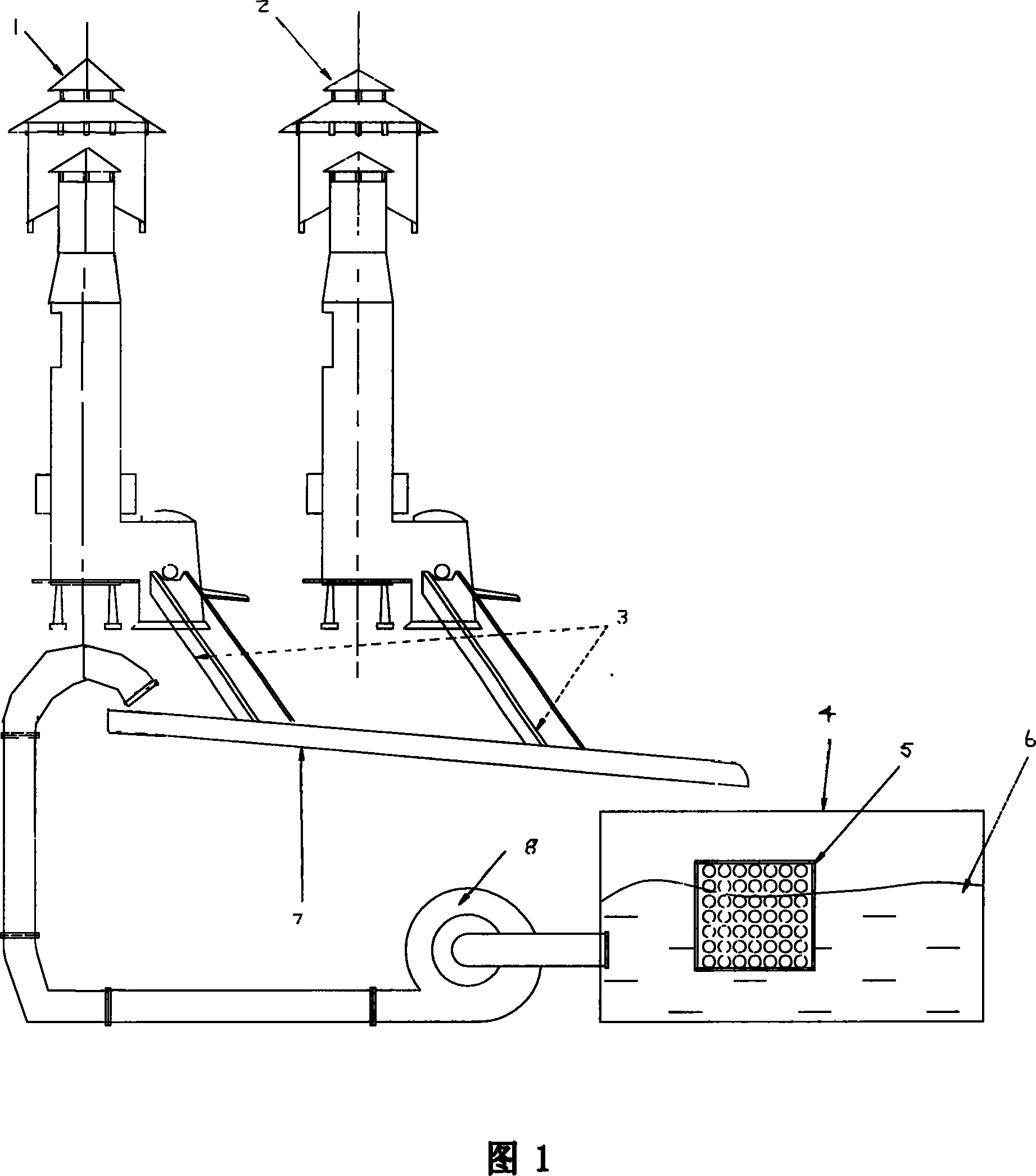

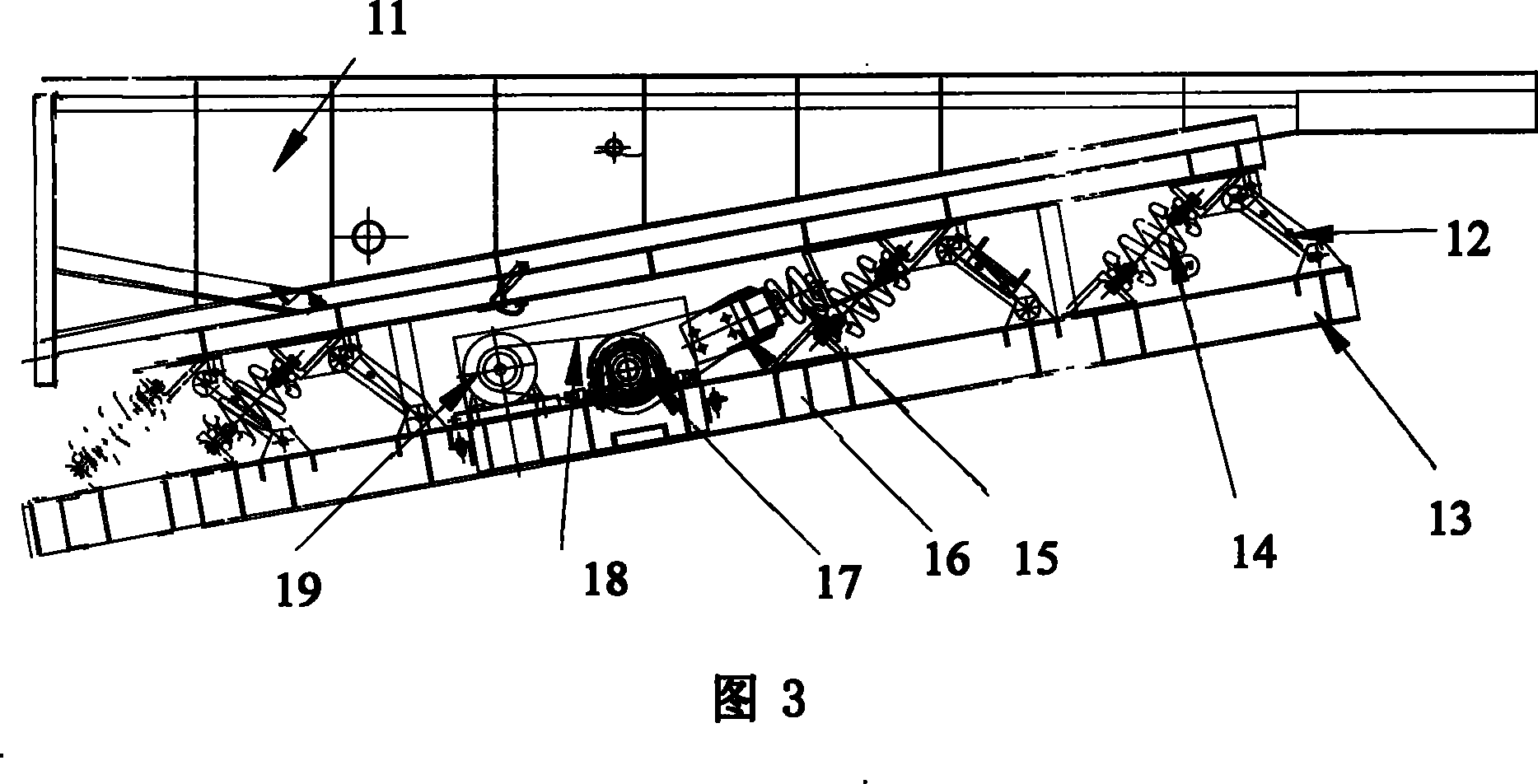

Oscillating conveyer for cupola deslagging and deslagging method thereof

InactiveCN101096712AGuaranteed continuous operationAvoid wastingRecycling and recovery technologiesJigging conveyorsCupolaSlag

The invention discloses an oscillating conveyer for removing the slag of the cupola, which comprises the following parts: a slag basin, a seat, a connecting device which can move and a power device, wherein the cupola discharges the furnace slag to the slag basin from the dirt-excluding groove, the bottom of the slag basin is oblique plane, the interior of the slag basin fills the water, the furnace slag can drop in the water depth, the bottom and the seat of the slag basin is parallel, the motion connecting device is connected with the slag basin and the seat separately and can produce the displacement between the slag basin and the seat, two ends of the power device are connected with the slag basin and the seat separately in order to provide the displacement power between the slag basin and the seat. The invention also discloses a method of the oscillating conveyer for removing the slag, which comprises the following steps: deepening the basin of the oscillating conveyer; forming the slag basin; putting the water for cooling the furnace slag in the slag basin. The invention changes the traditional cooling and collecting method.

Owner:天津勤美达工业有限公司

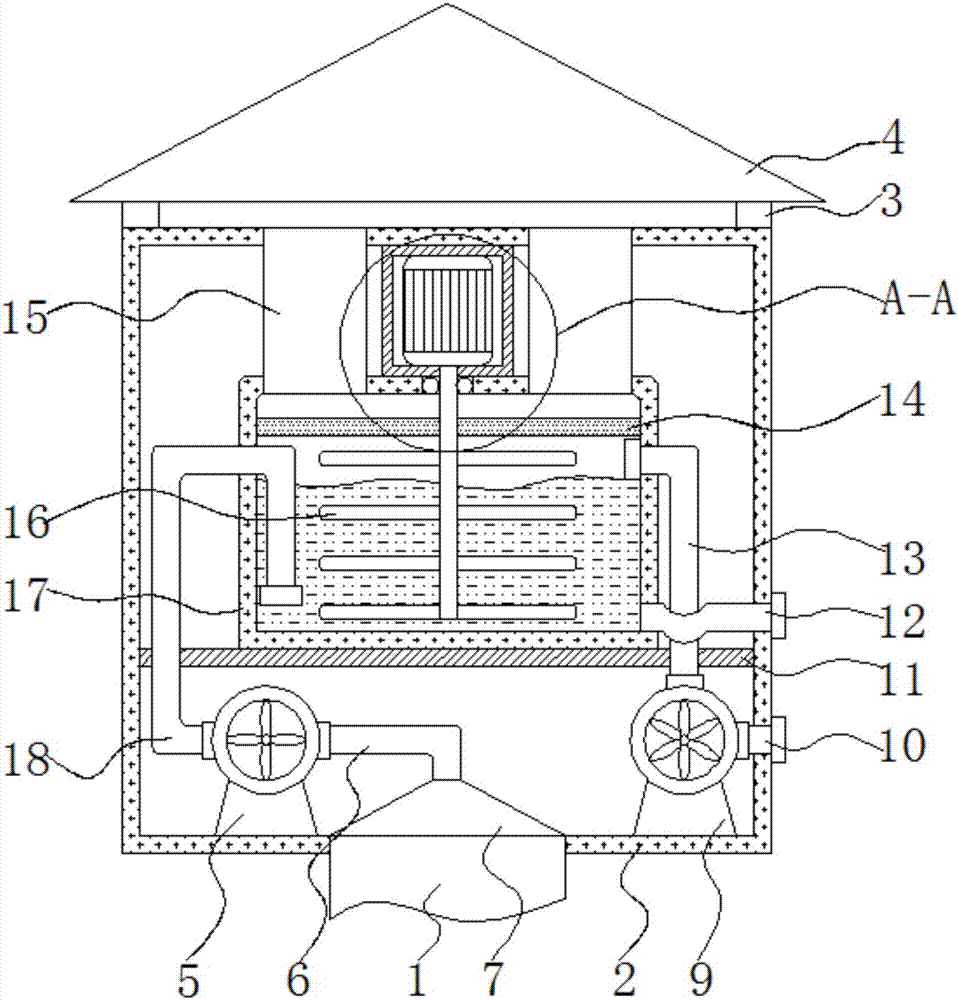

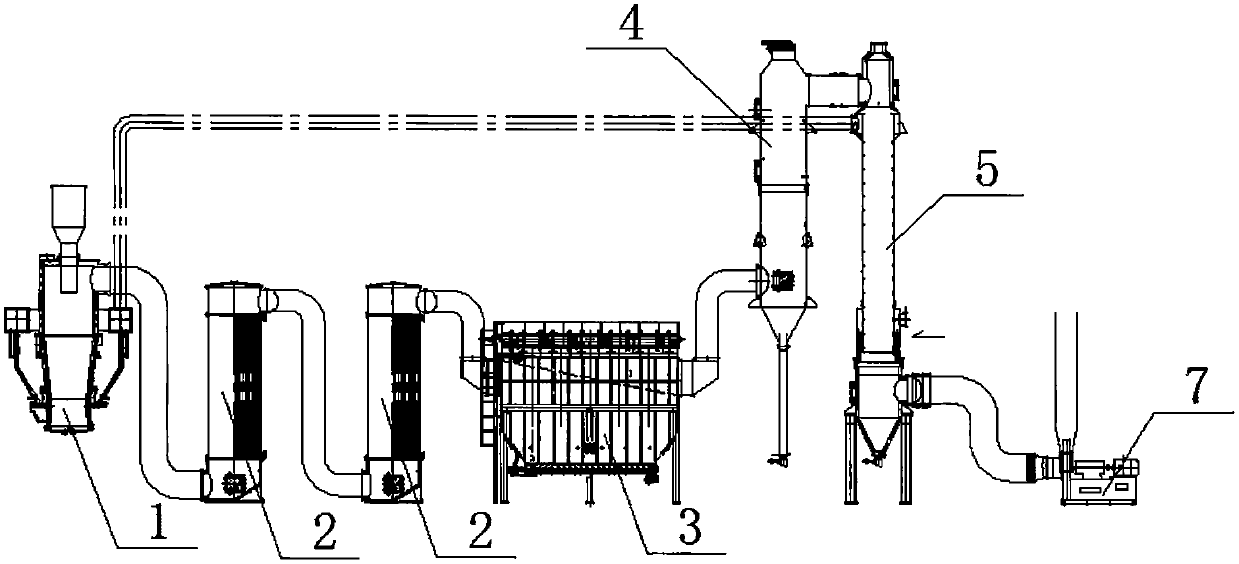

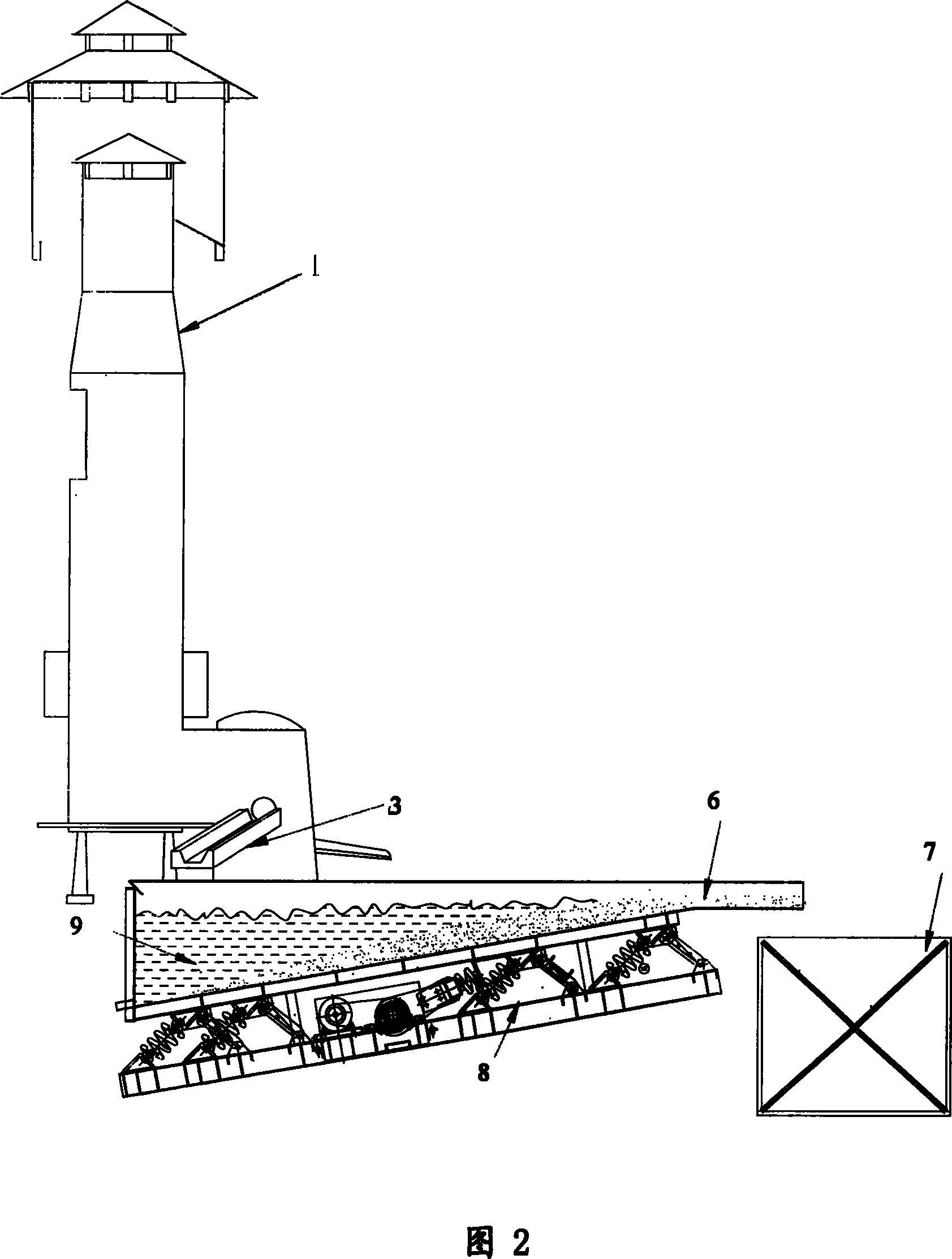

Dedusting system used for cupola

InactiveCN110585834AIncrease throughputImprove processing efficiencyCombination devicesGas treatmentCupolaSpray tower

The invention relates to the technical field of dedusting, in particular to a dedusting system used for a cupola. The dusting system used for the cupola comprises a dust cage installed on a smoke venton the top of the cupola, and is characterized in that an induced draft fan A is connected with the dust cage through a pipeline, the induced draft fan A and an air inlet of a cyclone dust collectorare connected, an air outlet of the cyclone dust collector is connected with an air inlet of a spray tower through a pipeline provided with an induced draft fan B, an air outlet of the spray tower isconnected with an air inlet of a dehydrater through a pipeline, and an air outlet of the dehydrater is connected with an inlet of a chimney through a pipeline provided with an induced draft fan C. Bymeans of the dusting system used for the cupola, dust and sulfurous gas which are exhausted by the cupola are greatly reduced, an environmental protection effect is obvious, and the dusting system used for the cupola is suitable for modification on an existing cupola dedusting device.

Owner:湖北八环机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com