Cupola

A cupola and furnace body technology, applied in furnaces, vertical furnaces, furnace components, etc., can solve the problems of reduced cotton yield, fluctuating melt flow rate, affecting furnace condition stability, etc., so as to improve cotton yield and improve The effect of stability and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

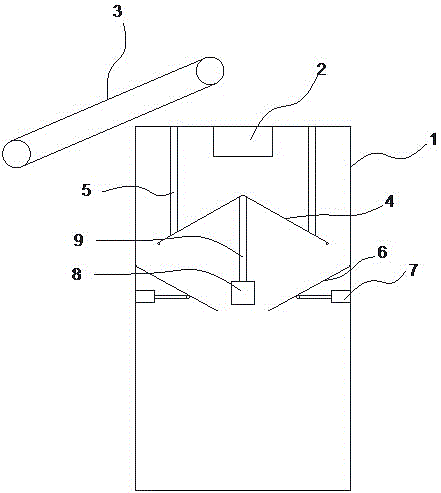

[0014] The invention as figure 1 As shown, the cupola includes a furnace body 1, a feed inlet 2 is provided in the middle of the top of the furnace body 1, and a conveyor belt 3 is provided above the feed inlet 2; Inside the body 1, the distributing mechanism includes a cone-shaped funnel 4, a weight 8 and a pair of symmetrical push plate mechanisms in turn. 5 is connected to the bottom surface of the top of the furnace body 1; during operation, the bottom surface of the funnel is provided with an interval from the inner wall of the furnace body, the funnel is convenient to pass through the small particle size material, and the large particle size material falls from the gap, and when it falls to the push plate , the push plate is driven by the hydraulic cylinder, collides the large particle size material with the heavy hammer, crushes it and falls down. The aperture of the leak hole of the funnel 4 gradually increases from the middle to the outside.

[0015] The weight 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com