Cupola dust and waste gas treatment device

A waste gas treatment device and cupola technology, applied in furnaces, vertical furnaces, furnace types, etc., can solve problems such as high cost, environmental pollution, and unsatisfactory effects, and achieve low cost of use, less investment, and good treatment effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

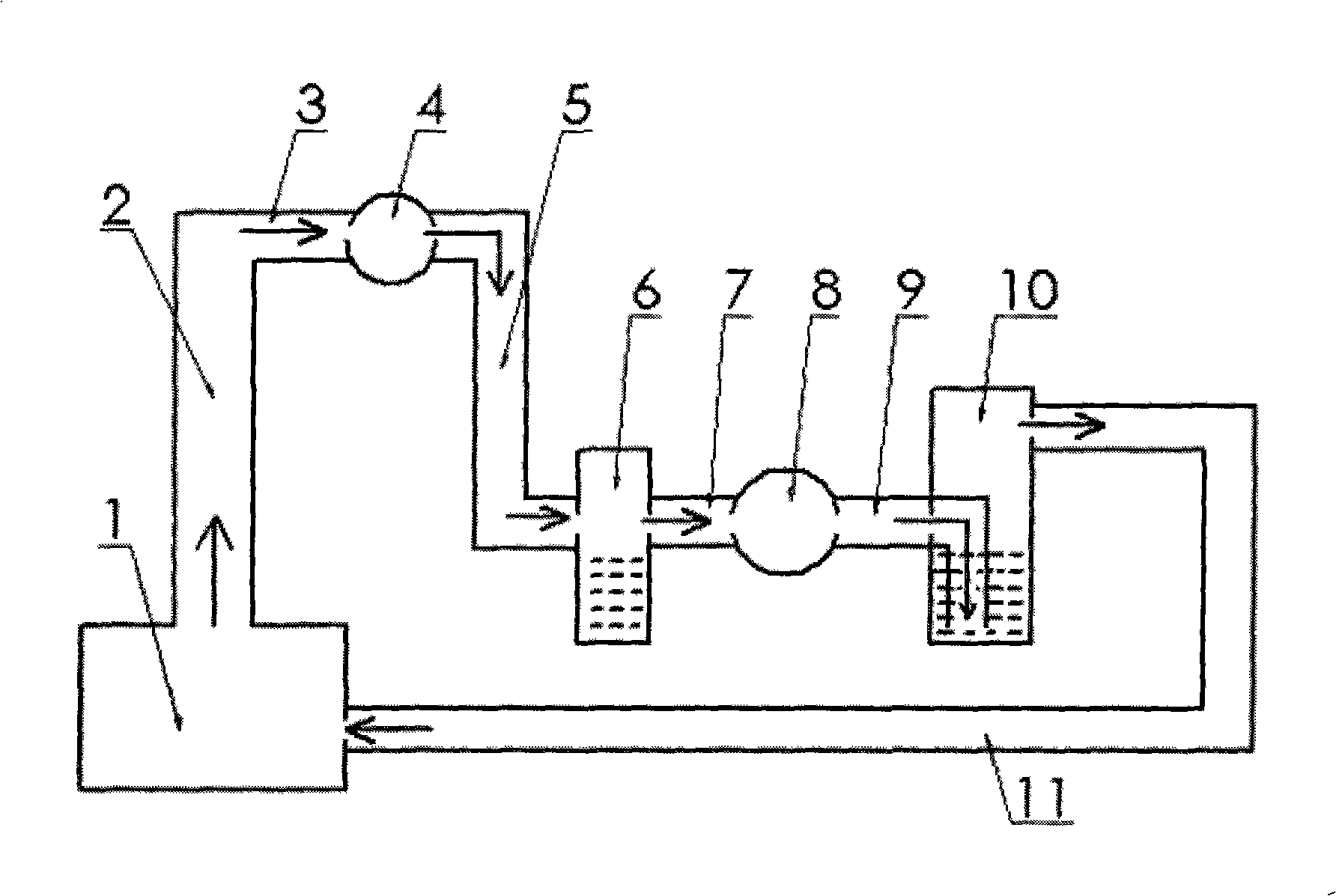

[0020] Such as figure 1 Among them, the gas pipeline I (3) connects the top of the chimney (2) with the fan (4), and the gas pipeline II (5) connects the air inlet of the fan (4) and the shower pool (6). The top of the shower pool (6) has a device that sprays the water flow at a high speed, and a water pump is installed at the bottom of the shower pool (6), and the water pump is connected to the top device; the shower pool (6) is equipped with a certain depth of water And add the saponification oil of suitable concentration; The shower tank (6) can be made of transparent material so as to observe; The bottom of the shower tank (6) has an outlet pipe. The air pipeline III (7) connects the air outlet of the shower pool (6) to the air inlet of the air compressor (8), one end of the air pipeline IV (9) is connected to the air outlet of the air compressor (8), and the other end Connect to the bottom of the reaction tank (10). The top of the reaction tank (10) has a feeding port t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com