Cupola fairing for an aircraft and method for fabricating the same

A technology for fairings and aircraft, which is applied in aircraft assembly, aircraft parts, fuselage, etc., and can solve problems such as increasing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

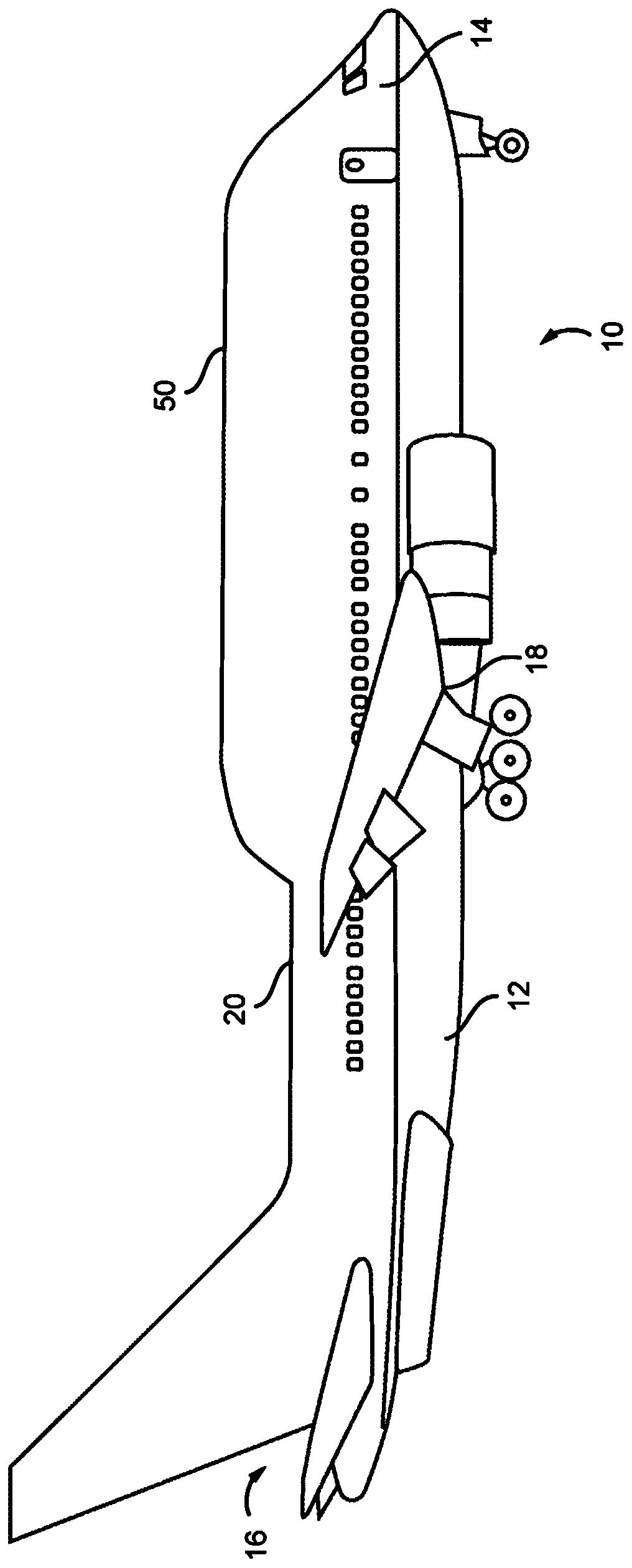

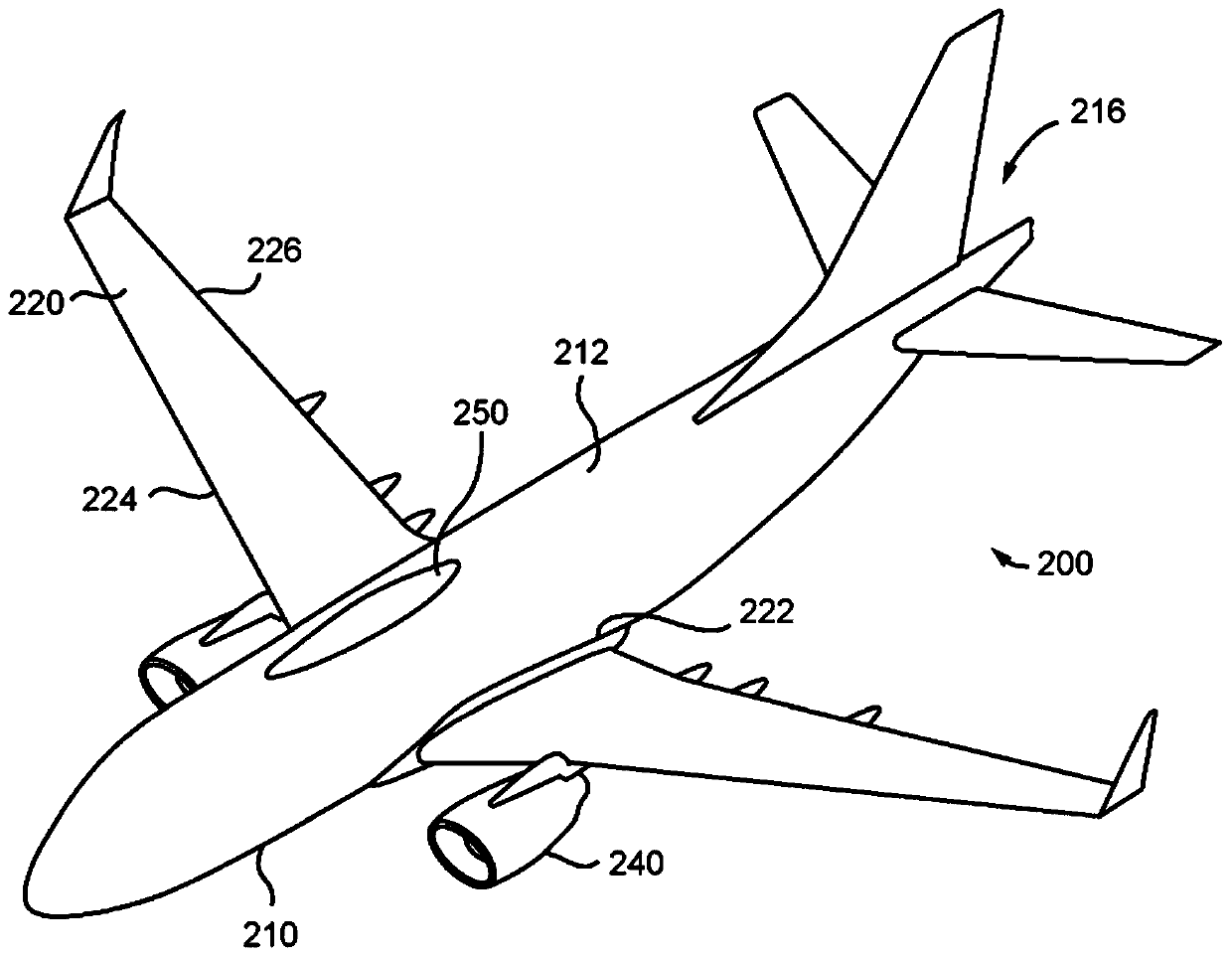

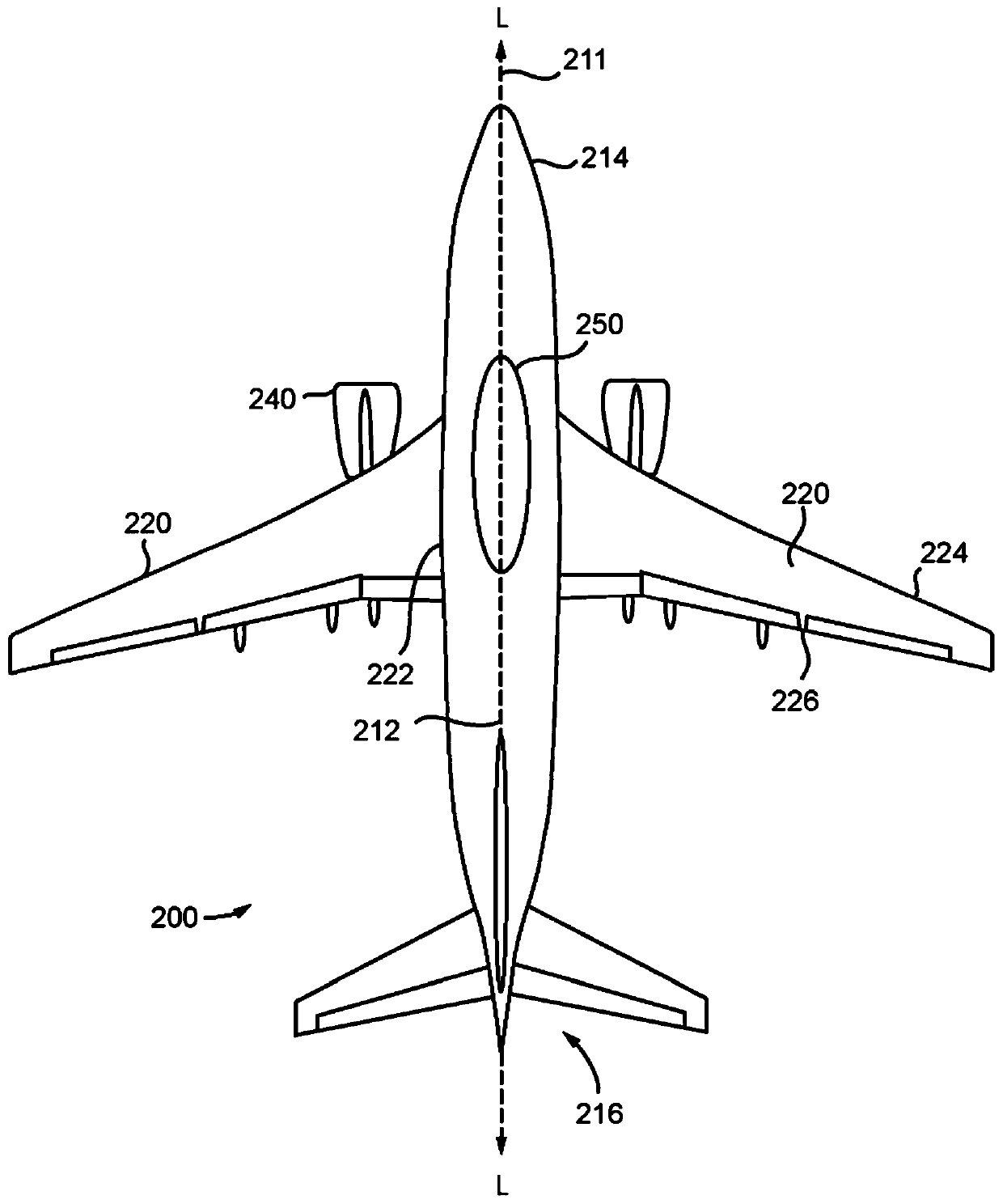

[0049] The invention relates to a dome fairing positioned on the top portion of an aircraft fuselage. the dome fairing is sized and dimensioned to fit over the top portion of the fuselage and to extend longitudinally along the fuselage at a spanwise location near between the wings of the aircraft to optimize airflow around the fuselage, This makes the airflow straighter along the wing at the root of the wing. In particular, domed fairings help reduce drag on parts of the aircraft, thereby increasing fuselage lift and spanwise (wingtip to wingtip) lift, making it more nearly elliptical. Other advantages include reduced leading edge stagnation drag and trailing edge separation drag, as well as reduced wing-to-fuselage and fuselage-to-wing swirl and associated drag.

[0050] Furthermore, a reduction in drag in other regions of the fuselage can be achieved. These modifications may be specific to the aircraft configuration, for example, tail effects are different on conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com