Water film dust removing and desulferizing device for furnace cupola

A technology of water film dust removal and desulfurization device, which is applied to furnaces, vertical furnaces, furnace types, etc., can solve the problems of large investment cost of dust collectors, large power energy consumption, lower flue gas temperature, etc., and achieve maintenance costs and use costs. Low power consumption, low power consumption, energy saving and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

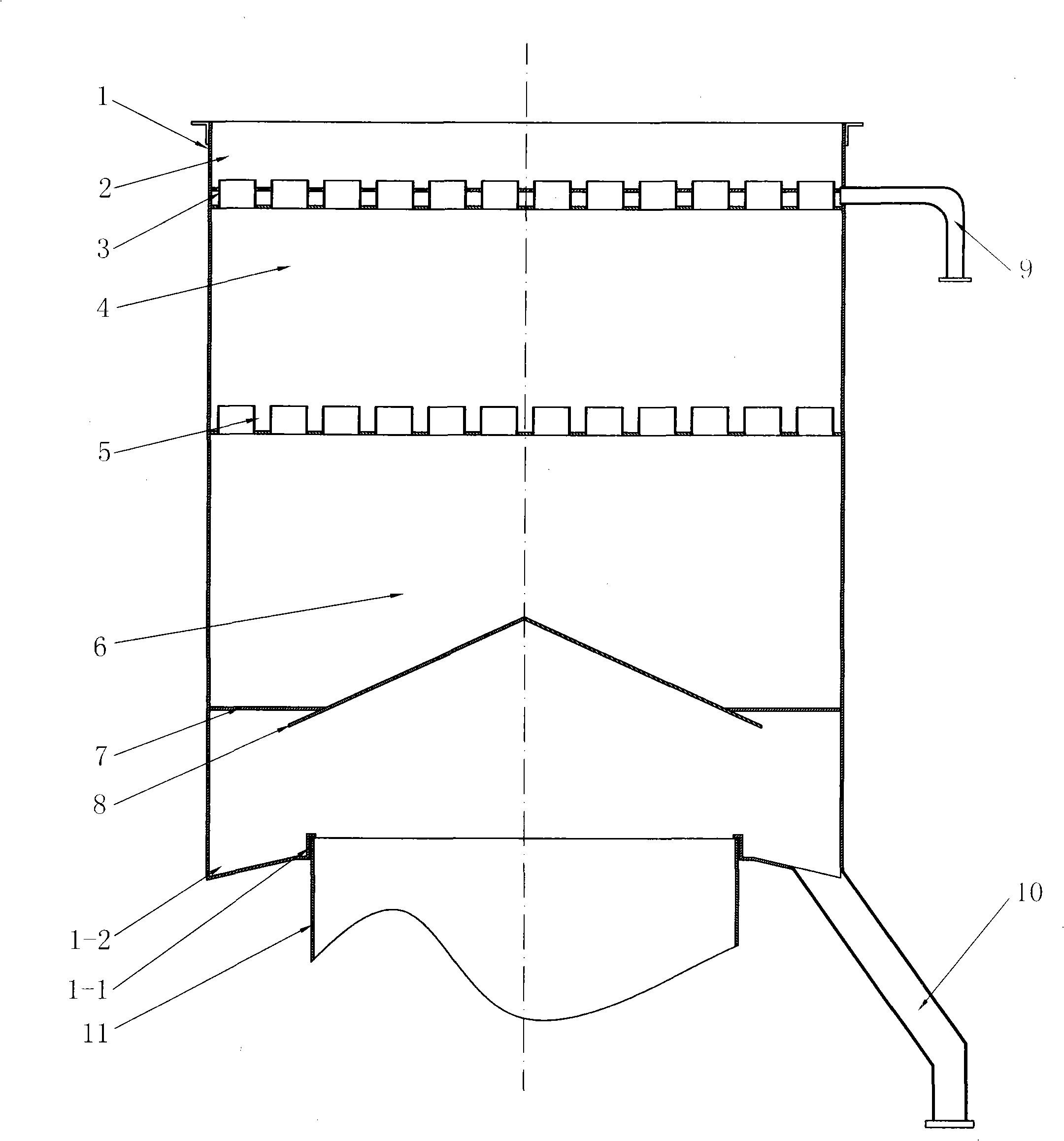

[0017] The embodiment shown in the figures comprises a casing 1 and a conical cupola cap 8, the diameter of the casing 1 being 1.5 times the diameter of the cupola. The above-mentioned conical cupola cap 8 is fixed on the inner wall of the housing 1 through the connecting strip 7, and the bottom surface of the housing 1 is provided with a bottom hole 1-1, so that the housing 1 forms an annular bottom surface, which is inclined downward from inside to outside. The shell 1 is connected to the top of the cupola furnace body 11 through the bottom hole 1-1, and the inclined annular bottom surface of the shell 1 forms a drainage groove 1-2.

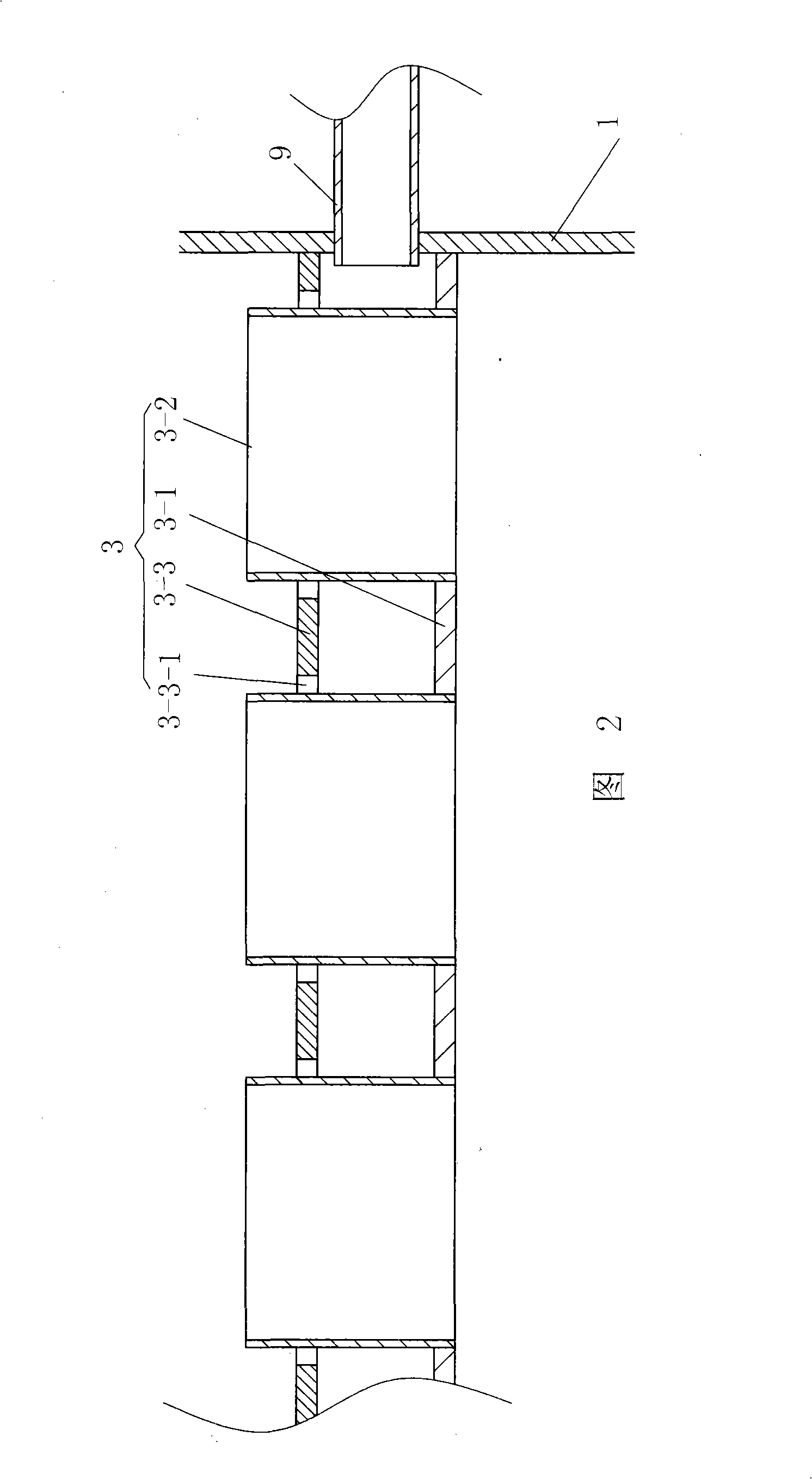

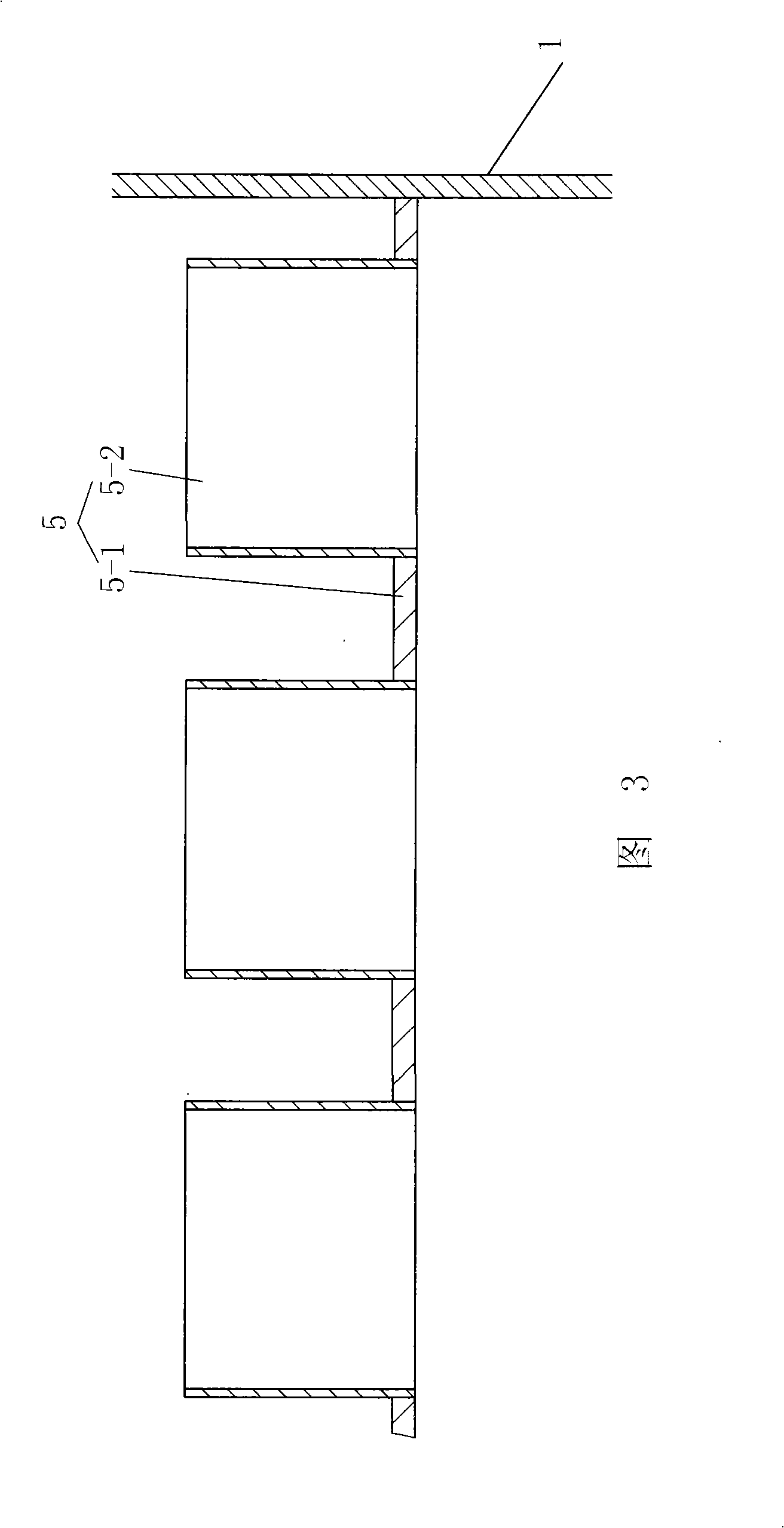

[0018] An upper spray group 3 and a lower spray group 5 are arranged above the cap 8 in the housing 1 . The distance between the upper and lower spray groups is 0.5 to 1 meter. The upper spray group 3 and the lower spray group 5 divide the inner cavity of the housing 1 into an upper smoke chamber 2 , a middle smoke chamber 4 and a lower smoke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com