Dedusting system for LED light bar and machine provided with dedusting system

A technology for LED light strips and dust removal systems, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. Angle influence and other issues, to achieve the best dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

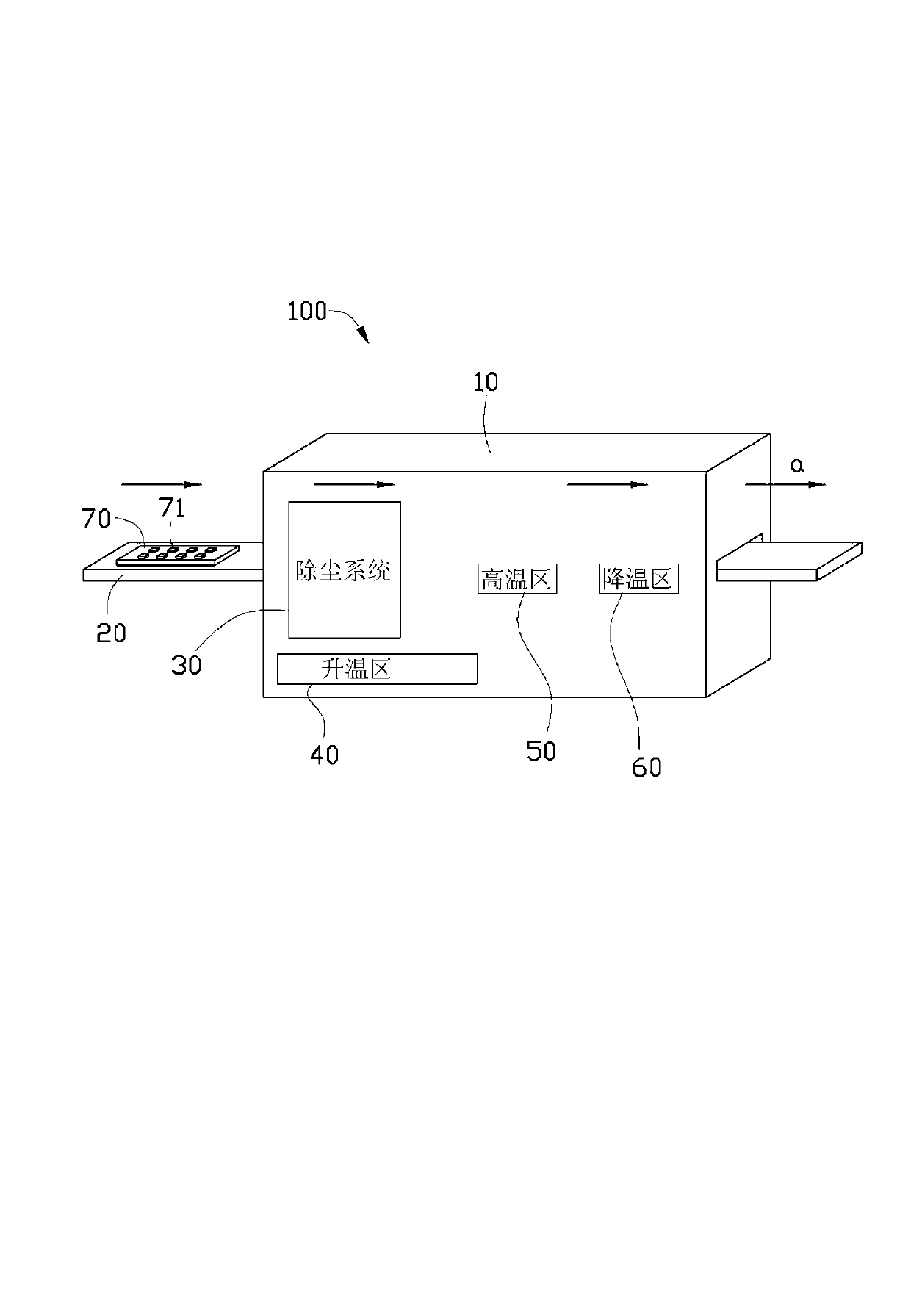

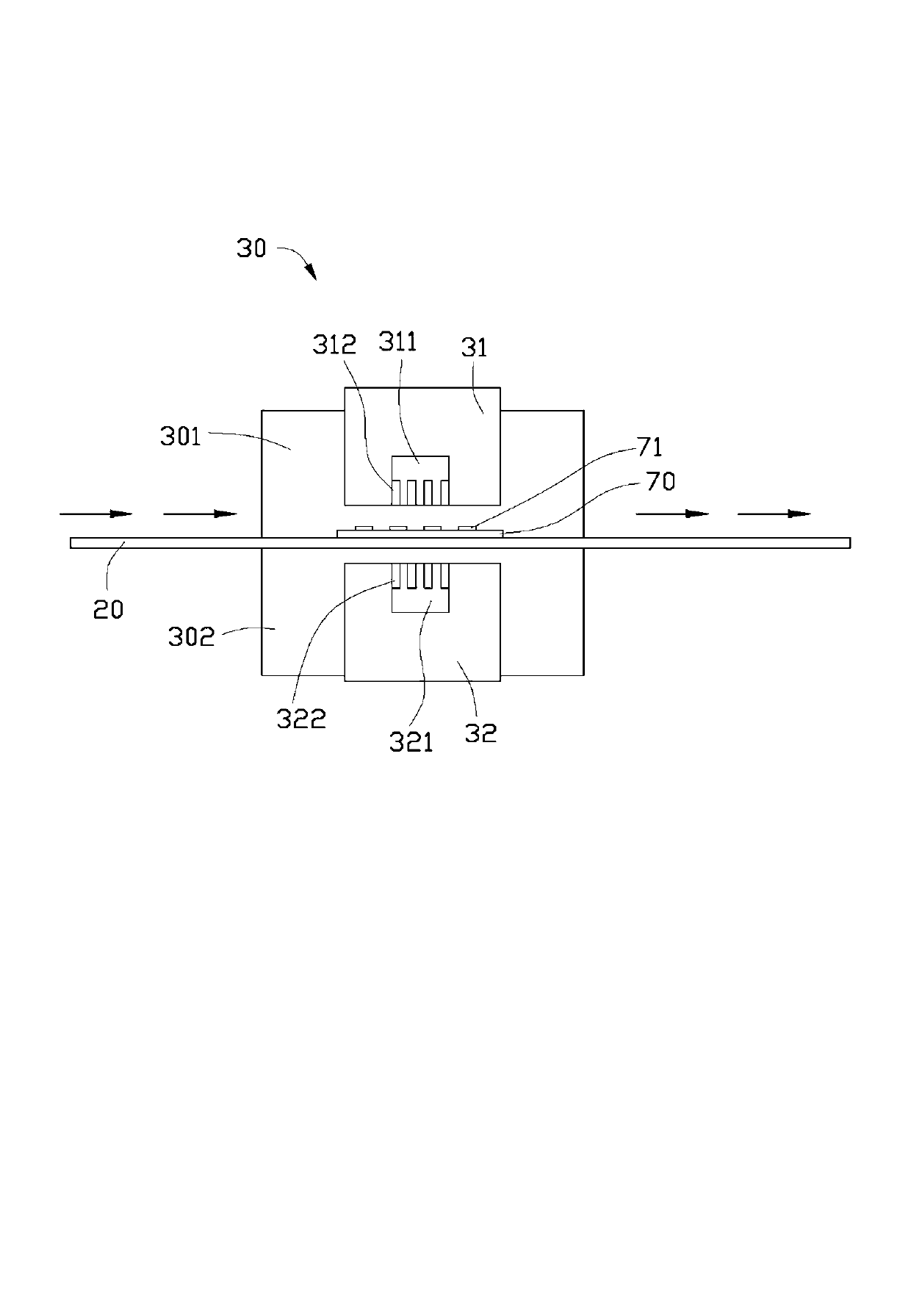

[0013] see figure 1 , shows a schematic diagram of a machine 100 with an LED light bar dust removal system according to the present invention. The machine 100 includes a working area 10 and a transport device. The transport device can pass through the working area 10 . In this embodiment, the transmission device is a transmission belt 20 . The working area 10 includes a dust removal system 30 , a heating zone 40 , a high temperature zone 50 and a cooling zone 60 . like figure 1 As shown, the conveyor belt 20 moves in the direction a. An LED light bar 70 with a plurality of LEDs 71 is mounted on the conveyor belt 20 and enters the working area 10 as the conveyor belt 20 moves. Entering the working area 10 from the conveyor belt 20 , passing through the heating zone 40 , the high temperature zone 50 and the cooling zone 60 successively, and then output fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com