Preparation method of denitration demercuration integral filter material

An integral filter material technology, applied in the field of composite filter material, can solve the problems of hindering the exposure of catalyst active sites, affecting the effect of dust removal and denitrification, and low catalytic activity and efficiency, so as to achieve stable denitrification and mercury removal efficiency and avoid secondary Effects of pollution, simplification of production process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

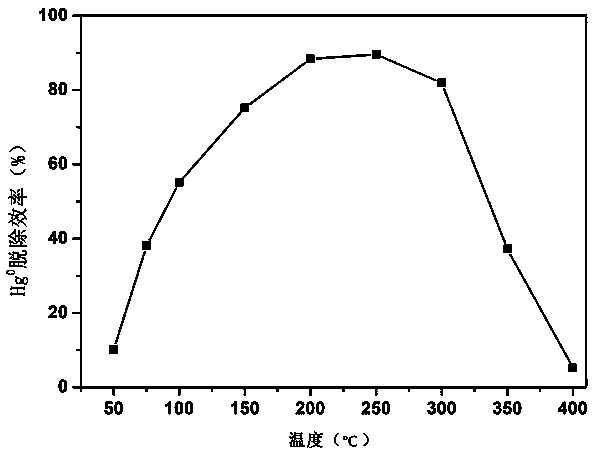

Examples

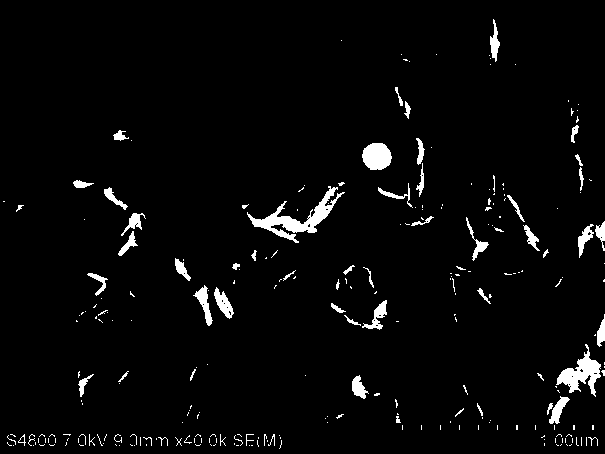

Embodiment 1

[0029] The stainless steel fiber felt was punched into discs with a diameter of 3 cm, and the three discs were ultrasonically washed with ethanol and 1 mmol / L hydrochloric acid for 1 h to remove surface oil and oxides, and then rinsed with deionized water at 60 °C. down dry;

[0030] First weigh the Mn(NO 3 ) 2 (5mmol) and Al(NO 3 ) 3 .9H 2 Dissolve O (2 mmol) in 80 ml of deionized water, stir vigorously until completely dissolved to form solution A, slowly add 25% ammonia water dropwise to solution A, adjust the pH value to 8.5±0.2, stir and dissolve to form a suspension, transfer Put it into a 100ml reaction kettle, put it into an oven, control the reaction temperature at 100°C, and the reaction time is 24h. After the reaction, take out the reaction kettle and cool it to room temperature, take out the precipitate, and wash it with deionized water and absolute ethanol for 3 times. Dry at 80°C for 12h. Get the precursor Co 3-x mn x Al-LDHs; the above product at 400 o ...

Embodiment 2

[0035] The nickel fiber mat was punched into discs with a diameter of 3 cm, and three discs were ultrasonically washed with ethanol and 1 mmol / L hydrochloric acid for 1 h to remove surface oil and oxides, and then rinsed with deionized water for 60 o Dry at C;

[0036] First weigh the Co(NO 3 ) 2 .6H 2 O (8 mmol), 50% Mn(NO 3 ) 2 (15mmol) and Al(NO 3 ) 3 .9H 2 Dissolve O (7 mmol) in 75ml of deionized water, stir vigorously until completely dissolved to form solution A, slowly add 2mol / L sodium hydroxide and sodium carbonate solution to solution A, adjust the pH value to 9.5±0.2 and stir Dissolve to form a suspension B, transfer the suspension B to a 100ml reaction kettle, put it into an oven, control the reaction temperature at 150°C, and the reaction time is 12 h. After the reaction, take out the reaction kettle and cool it to room temperature, take out the precipitate, and use The deionized water and absolute ethanol were washed by centrifugation three times, and dried...

Embodiment 3

[0040] The iron-chromium-aluminum fiber mat was punched into discs with a diameter of 3 cm, and three discs were ultrasonically washed with ethanol and 1 mmol / L hydrochloric acid for 1 h to remove surface oil and oxides, and then rinsed with deionized water. 60 o Dry at C;

[0041] First weigh the Co(NO 3 ) 2 .6H 2 O (10 mmol), 50% Mn(NO 3 ) 2 (20mmol) and Al(NO 3 ) 3 .9H 2 Dissolve O (10mmol) in 60 ml of deionized water, stir vigorously until completely dissolved to form solution A, slowly add 25% ammonia water dropwise to solution A, adjust the pH value to 10.5±0.2, stir and dissolve to form suspension B, Transfer the suspension B to a 100ml reactor and put it in an oven. The reaction temperature is controlled at 200°C and the reaction time is 8 h. After the reaction, take out the reactor and cool it to room temperature. Take out the precipitate and wash it with deionized water and absolute ethanol. Each was centrifuged and washed 3 times, and dried at 80°C for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com