A kind of preparation method of supported nickel-based catalyst

A nickel-based catalyst, supported technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of sintering of active components, larger particles of active components, and affecting the catalytic performance of catalysts. Achieve the effect of improving catalytic performance, reducing waste and avoiding sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

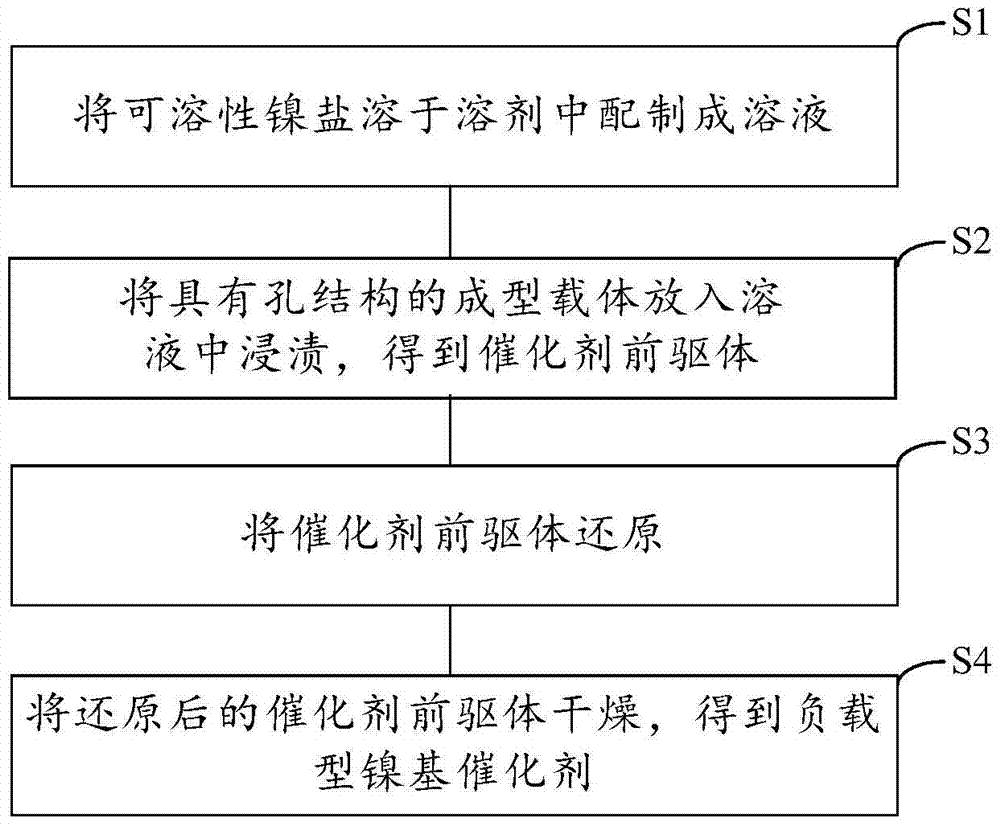

[0033] Such as figure 1 Shown, the embodiment of the present invention provides a kind of preparation method of supported nickel-based catalyst, comprises steps:

[0034] S1, dissolving the soluble nickel salt in a solvent to prepare a solution;

[0035] S2. Putting the shaped carrier with a pore structure into the solution and impregnating it to obtain a catalyst precursor;

[0036] S3, reducing the catalyst precursor;

[0037] S4, drying the reduced catalyst precursor to obtain a supported nickel-based catalyst.

[0038] The preparation method of the supported nickel-based catalyst provided by the embodiment of the present invention directly impregnates the shaped carrier in a solution containing a soluble nickel salt, and the active components in the catalyst can be highly dispersed in the pore structure of the shaped carrier, so after impregnation, no Heat treatment, in this way, can effectively avoid the sintering of the active components at a higher temperature, and p...

Embodiment 1

[0088] 1. Dissolve 4.24g of nickel acetate in 10ml of distilled water to make a solution;

[0089] 2. Knead 100g ZSM-5 molecular sieve carrier powder, 5g starch, 3g nitric acid and 60g water together to form, dry and roast;

[0090] 3. Put 10g of molded ZSM-5 carrier into the solution and soak for 4 hours, then dry it at 60°C for 4 hours to obtain the catalyst precursor;

[0091] 4. Place the catalyst precursor in an absolute ethanol solution of sodium borohydride with a concentration of 0.005 g / ml and a pH of 7 for overnight reduction;

[0092] 5. Dry the reduced catalyst precursor at 40° C. to obtain a shaped supported nickel-based catalyst.

[0093] Methane steam reforming performance test results:

[0094] Take 2 g of the molded supported nickel-based catalyst prepared in Example 1, put it into a reactor, raise the temperature to 500° C. of reaction temperature, and feed in methane gas with a flow rate of 76 ml / min, and simultaneously feed in a water flow rate of 0.15 ml...

Embodiment 2

[0097] 1. Dissolve 4.96g of nickel nitrate and 2g of PEG-1000 in 10ml of distilled water to make a solution;

[0098] 2. Mix 100g ZrO 2 Carrier powder, 5g ammonium carbonate, 2g acetic acid, 2g nitric acid and 60g water are kneaded, dried and roasted;

[0099] 3. Form 10g of ZrO 2 The carrier is subjected to water vapor treatment, the treatment time is 5 hours, and the treatment temperature is 500°C;

[0100] 4. Form ZrO 2 The carrier is immersed in the solution for 4 hours and then dried at 100°C for 4 hours to obtain a catalyst precursor;

[0101] 5. Place the dried catalyst precursor in a hydrazine hydrate solution with a concentration of 0.015 g / ml, a pH of 11, and a temperature of 80°C for 4 hours, wash, filter, and dry at 40°C to obtain a shaped supported nickel-based catalyst.

[0102] Methane steam reforming performance test results

[0103] Get the molded supported nickel-based catalyst 2g that embodiment 2 prepares, pack in the reactor, pass into the methane gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com