Patents

Literature

40results about How to "Avoid sintering and agglomeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

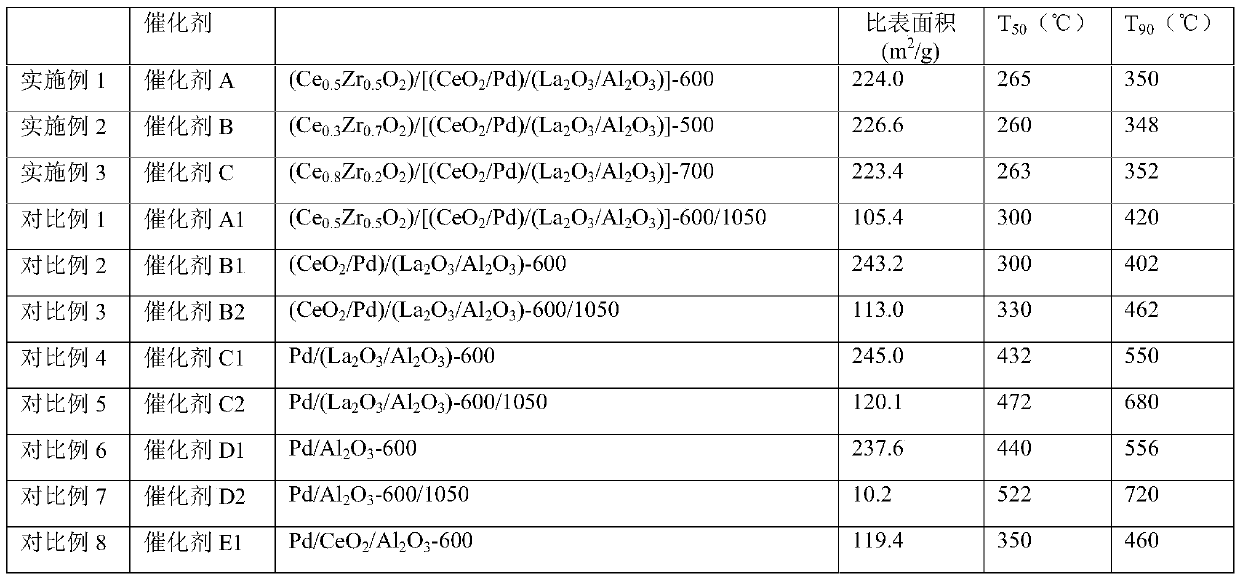

Catalyst for catalyzing methane combustion and preparation method thereof

ActiveCN107262093AGuaranteed high temperature stabilityImprove high temperature thermal stabilityHeterogenous catalyst chemical elementsDispersed particle separationActive componentOxygen vacancy

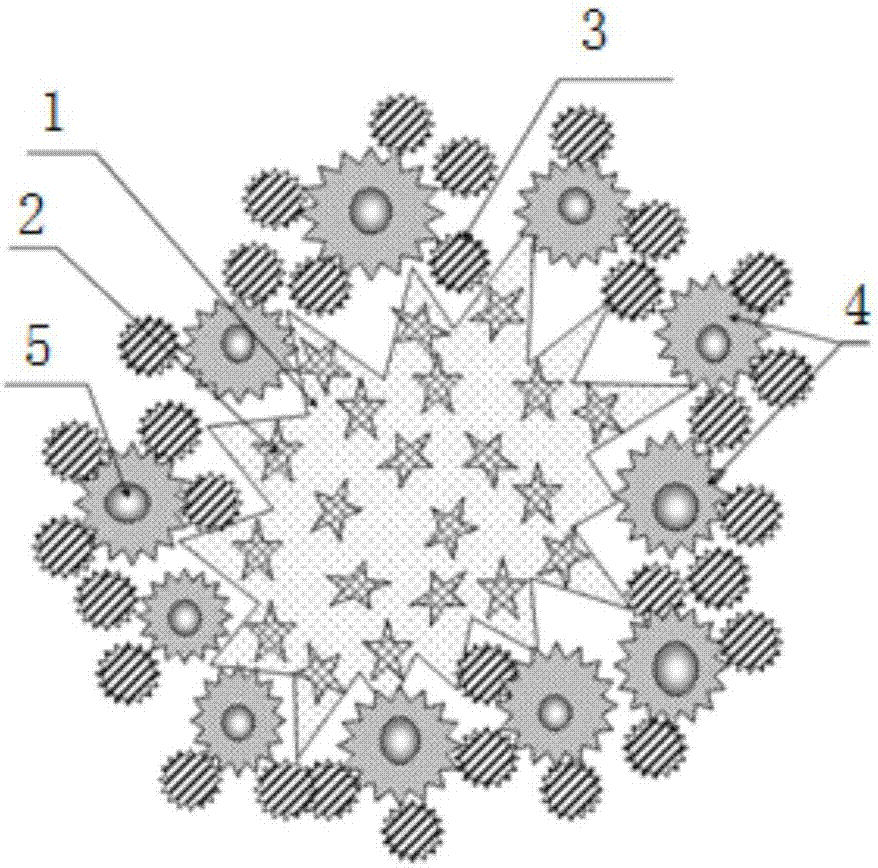

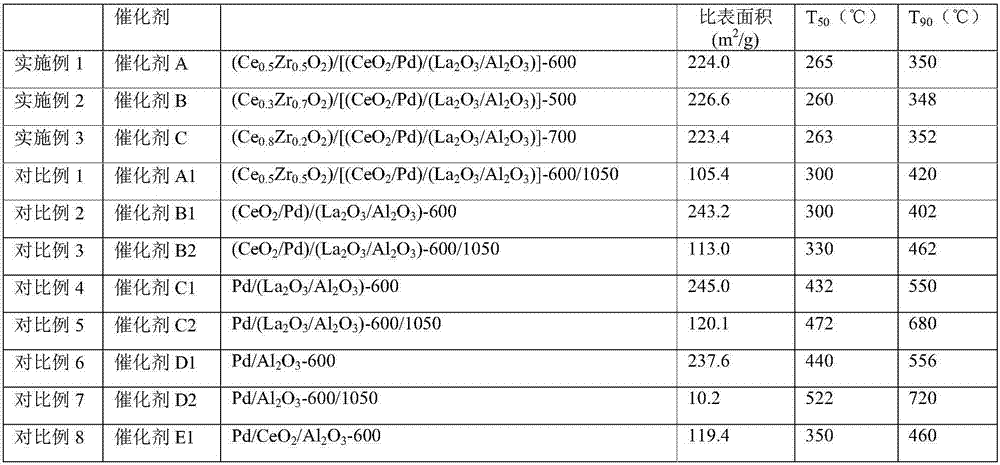

The invention provides a catalyst for catalyzing methane combustion and a preparation method thereof. The catalyst comprises a carrier, and an active component which is loaded on the carrier, wherein the active component is wrapped with a wrapping layer for providing oxygen vacancy. The catalyst further comprises a catalyst promotor which is a ceria-zirconia solid solution. According to the catalyst, the wrapping layer wraps the active component, so that oxygen molecule stored in the wrapping layer can be timely conveyed to the active component, so that the high-temperature stability of the active component of the catalyst is maintained; in addition, the catalyst further comprises the catalyst promotor which is the ceria-zirconia solid solution capable of generating more oxygen vacancies and timely effectively storing and discharging oxygen, so that the high-temperature stability of the active component of the catalyst is improved; in addition, the wrapping layer, the ceria-zirconia solid solution and the carrier are mutually dispersed and in contact, so that the mutual insulation effect is achieved, and the sintering of the carrier is inhibited, and as a result, the high-temperature thermal stability and the catalyzing activity of the catalyst can be improved.

Owner:FUZHOU UNIV +1

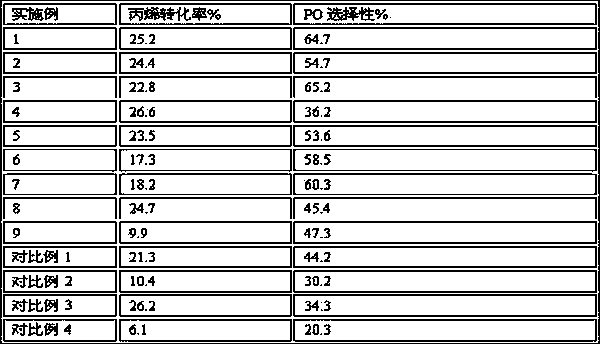

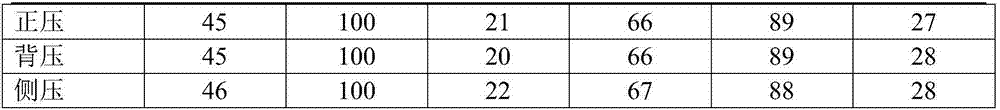

High-activity propylene gas-phase epoxidation catalyst and preparation method thereof

ActiveCN104128176AReduce pollutionLow costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsGas phaseMesoporous material

The invention discloses a high-activity propylene gas-phase epoxidation catalyst, TiO2-MoO3-Bi2SiO5 / SiO2, for preparing propylene oxide and a preparation method thereof. The catalyst is used for a propylene gas-phase epoxidation reaction for preparing the propylene oxide, which takes molecular oxygen (O2) or nitric oxide (NO) as an oxidant; reaction conditions are moderate and no inhibitor is needed; the catalyst has high catalytic activity. The catalyst takes a SiO2 mesoporous material Bi2SiO5 / SiO2 containing bismuth silicate (Bi2SiO5) as a carrier, MoO3 as an active component and TiO2 as an auxiliary agent. The catalyst comprises following components in percentage by mass: 64.6%-98.8% of the carrier Bi2SiO5 / SiO2, 1.1%-22.8% of the MoO3 and 0.1%-12.6% of the TiO2. The mol ratio of Si to Bi in the carrier Bi2SiO5 / SiO2 is 30-200. The catalyst is synthesized by using a hydrothermal method; molybdenum and titanium precursors in the active component MoO3 and the auxiliary agent titanic oxide are immersed into the carrier by an ultrasonic-assisted immersion method to prepare the catalyst.

Owner:FUZHOU UNIV

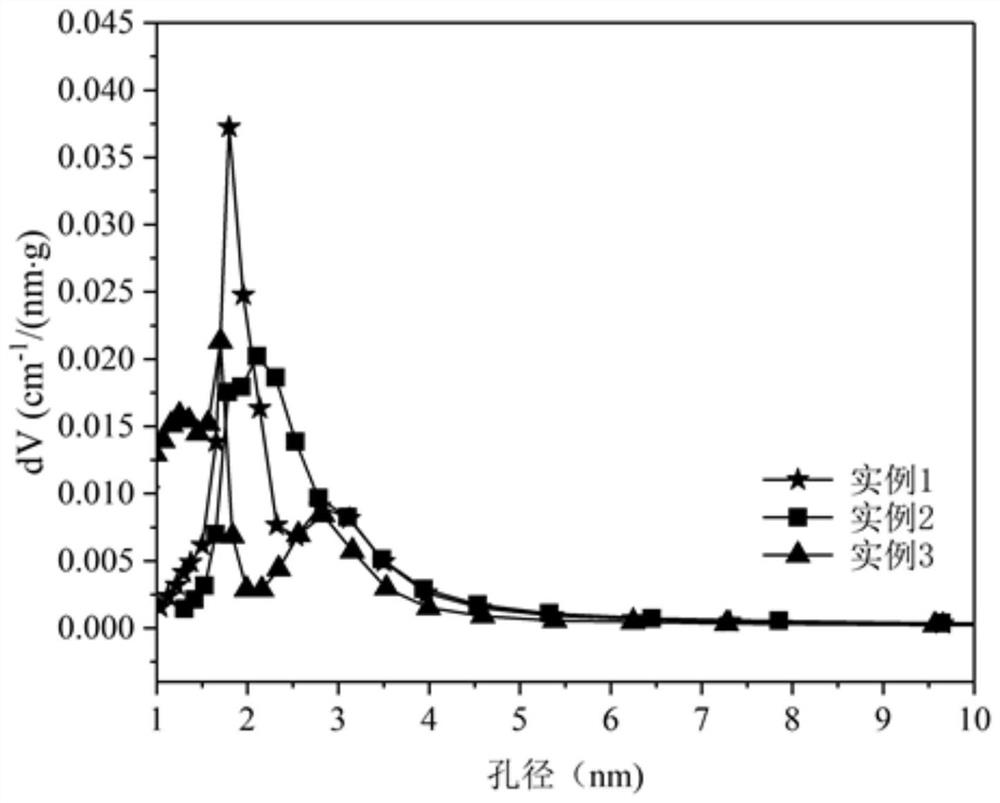

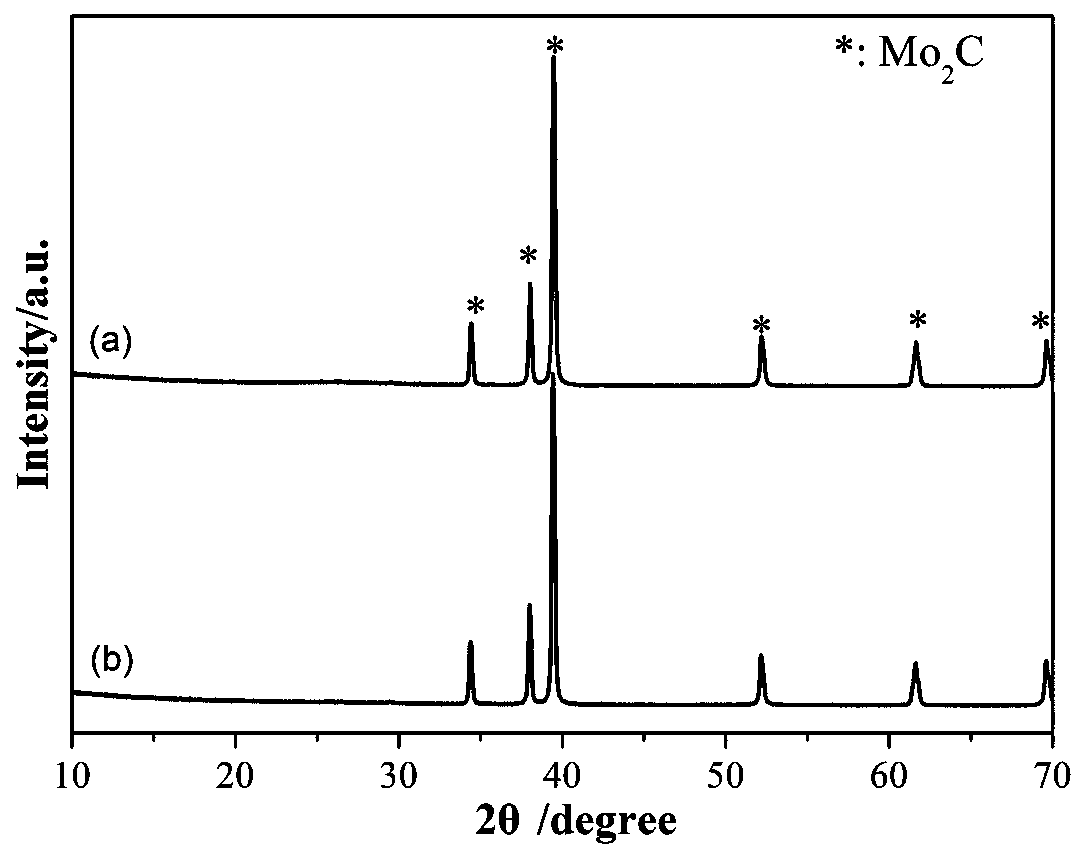

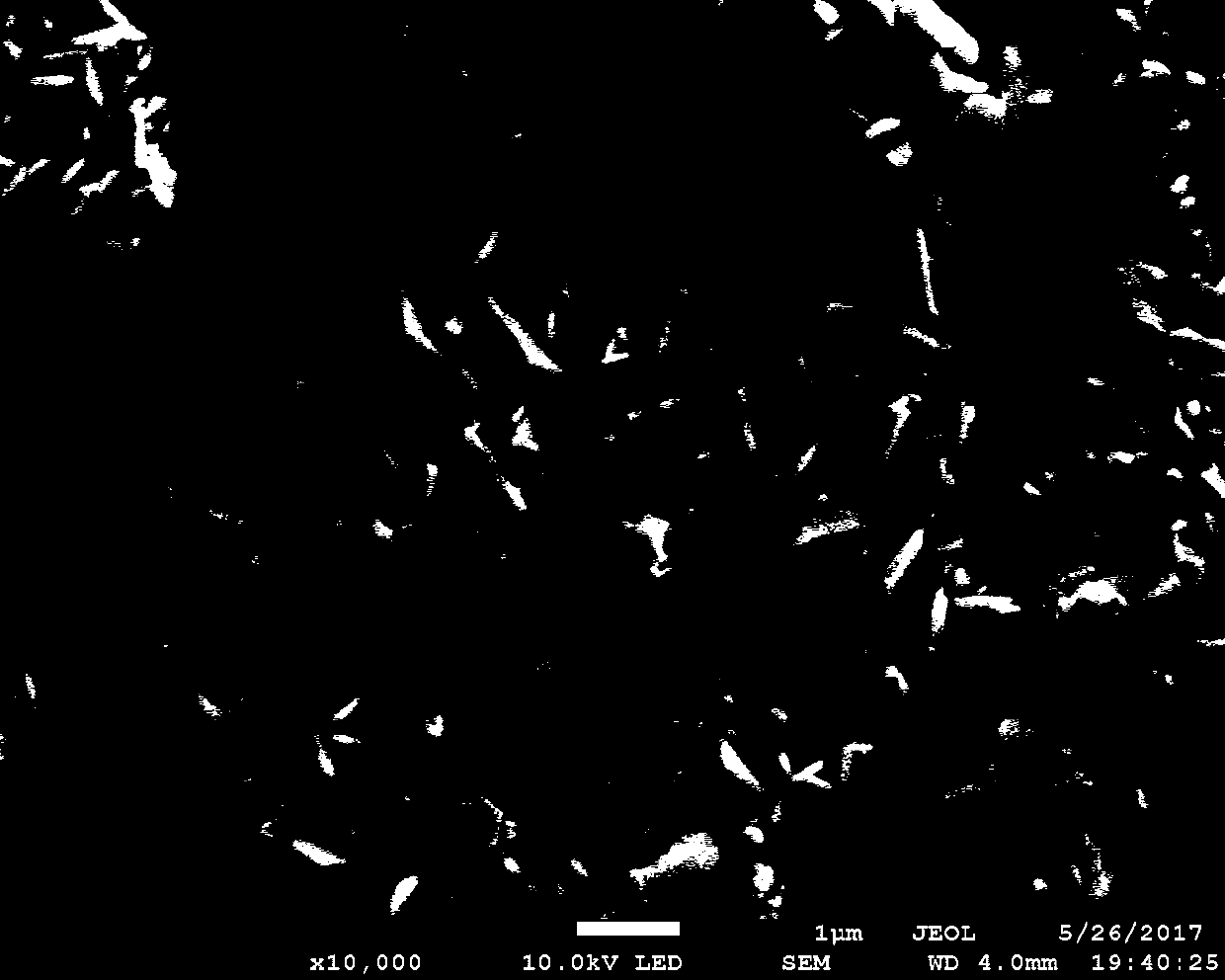

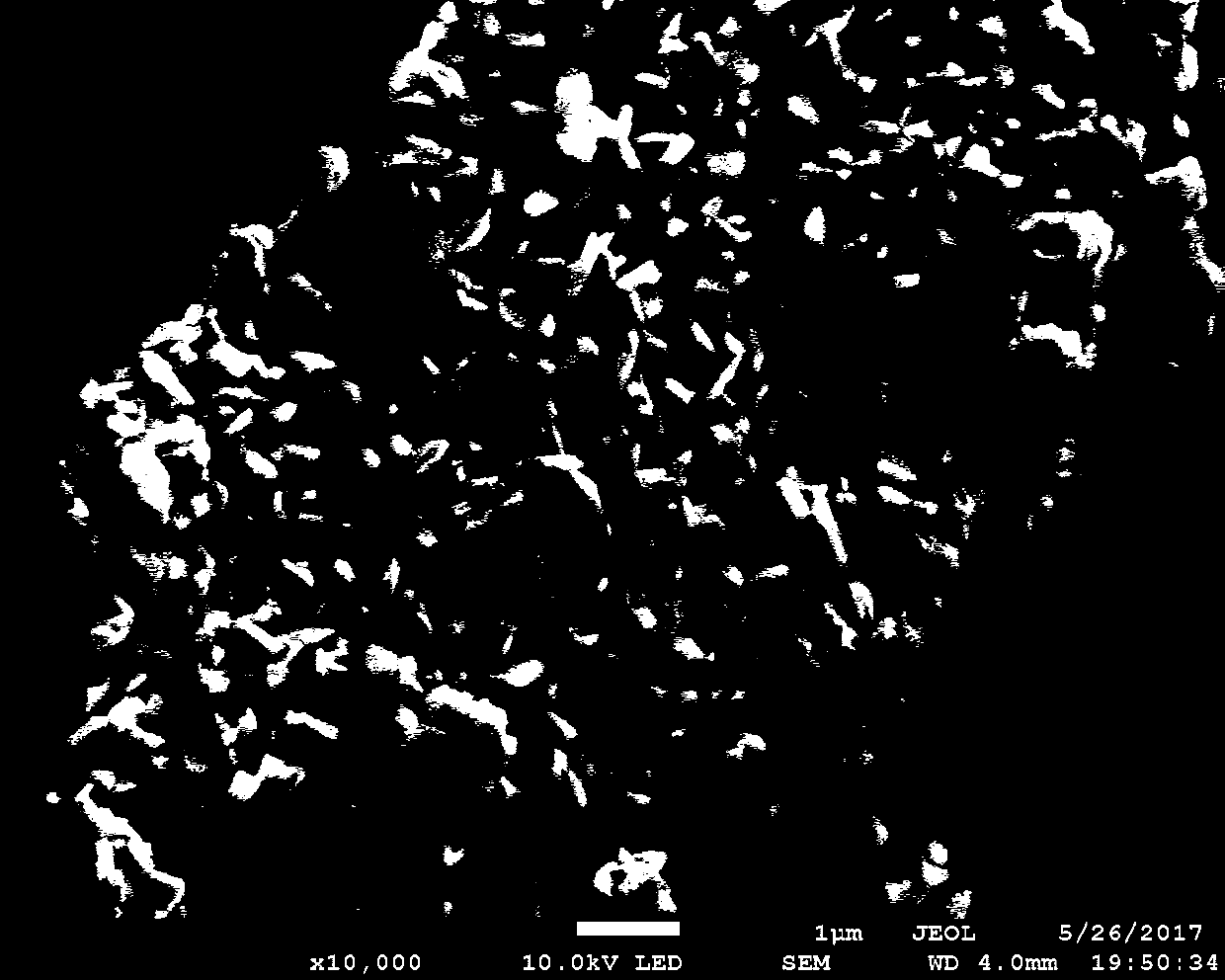

Preparation method of surface-functionalized molybdenum carbide-carbon catalyst for carbon dioxide hydrogenation reaction

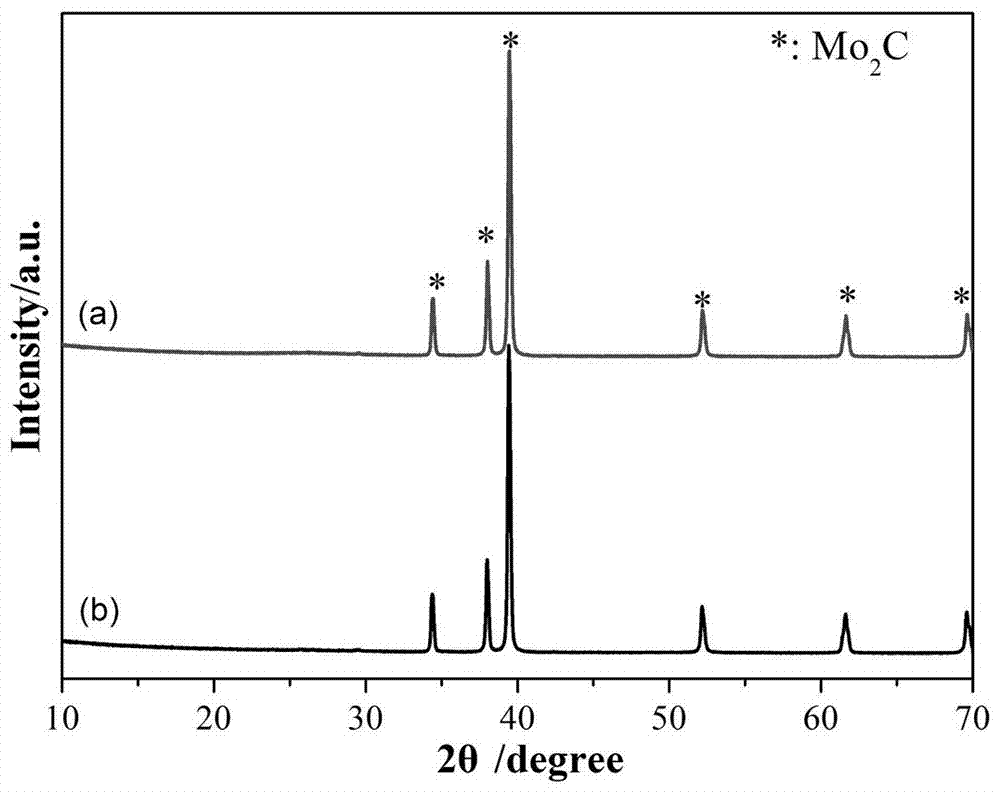

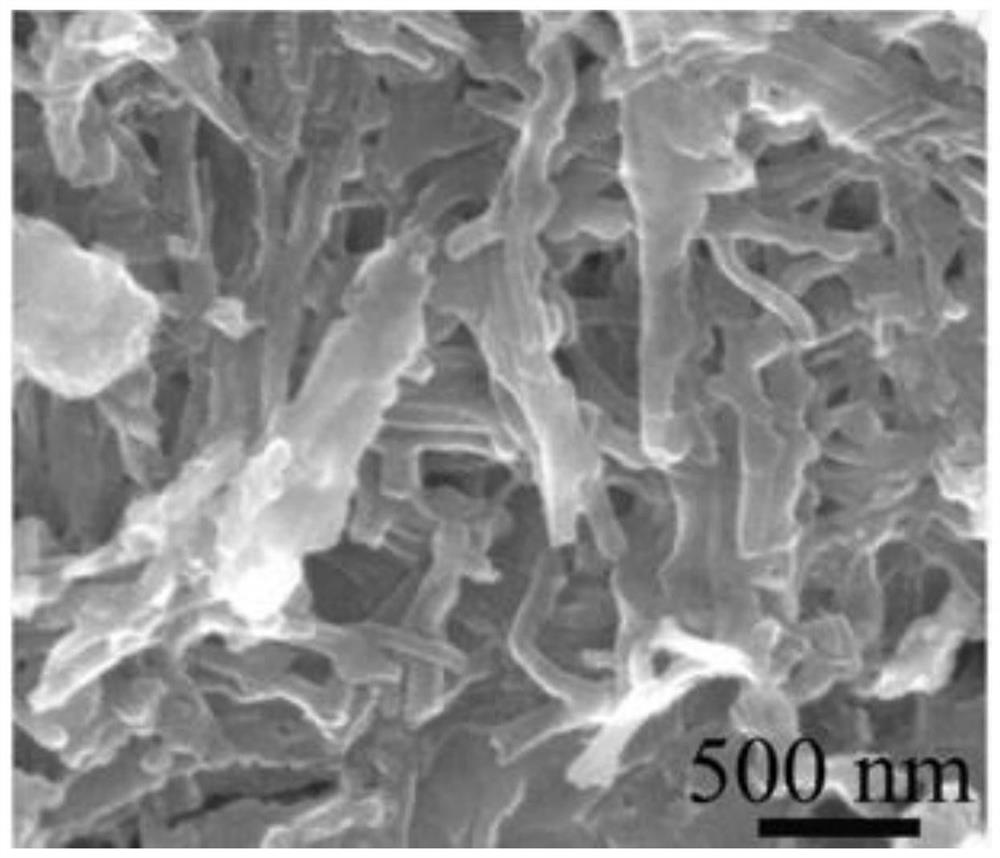

ActiveCN107138171AAvoid sintering and agglomerationLarge specific surface areaCatalyst activation/preparationFreeze-dryingMolybdenum carbide

The application discloses a preparation method of a surface-functionalized molybdenum carbide-carbon catalyst for a carbon dioxide hydrogenation reaction. The preparation method mainly comprises the following steps: firstly, using deionized water as a solvent, uniformly mixing sodium alginate with an ammonium molybdate solution, and then putting a mixed solution into a freeze drying oven for carrying out freeze drying; secondly, carrying out high-temperature roasting in an inert atmosphere to obtain porous graphite carbon-inlaid high-dispersibility molybdenum carbide; thirdly, mechanically lapping the prepared porous graphite carbon-inlaid high-dispersibility molybdenum carbide and urea, putting a lapped material into a muffle furnace, and carrying out annealing treatment to obtain the surface-functionalized molybdenum carbide-carbon catalyst. The catalyst prepared by the preparation method has the characteristics of large specific surface area, abundant pore structures and high dispersibility, and shows good catalytic activity and selectivity in the carbon dioxide hydrogenation reaction.

Owner:CHONGQING TECH & BUSINESS UNIV

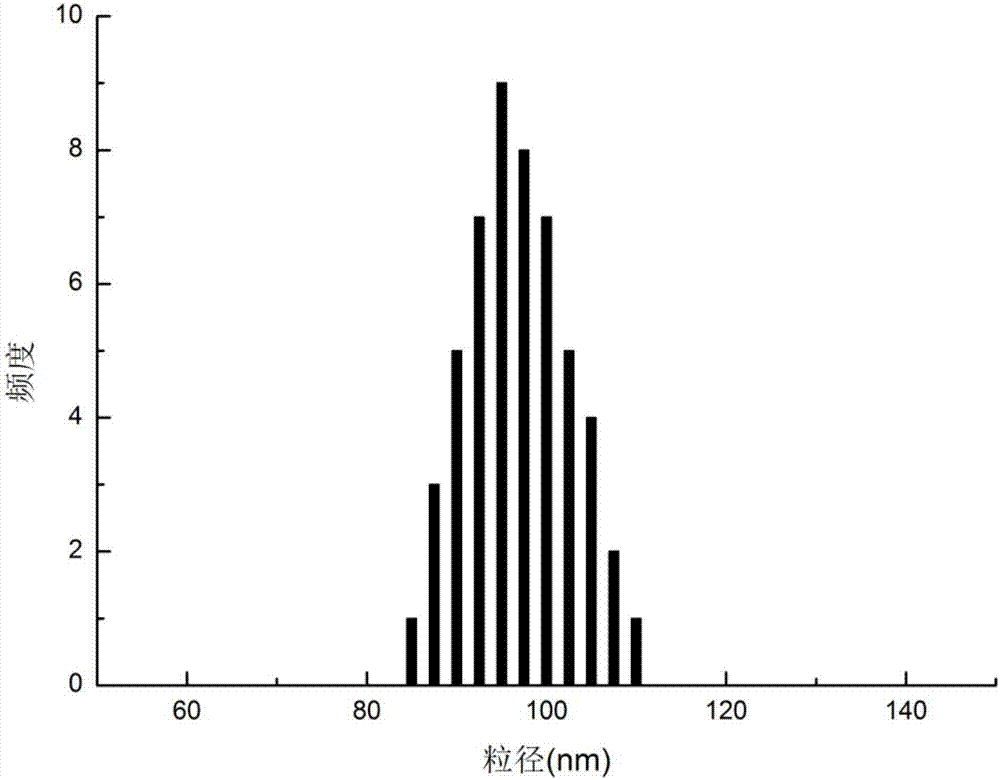

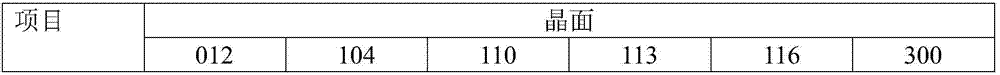

Propylene gas-phase epoxidation catalyst used at low temperature and preparation method of catalyst

InactiveCN108816242AReduce pollutionEasy to operateOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsUltrasonic assistedGas phase

The invention discloses a catalyst CuOX-MoO3-Bi2SiO5 / SiO2 for preparing propylene epoxide by propylene gas-phase epoxidation at the low temperature and a preparation method of the catalyst. The catalyst is applied to a reaction of preparing propylene epoxide from molecular oxygen (O2) or air as an oxidizing agent by the propylene gas-phase epoxidation, the reaction conditions are mild, inhibitorsare not required, and the catalyst keeps higher catalytic activity at the temperature of 300-380 DEG C. The catalyst adopts Bi2SiO5 / SiO2 as a supporter, MoO3 as an active component and Cu as a modification aid, and is prepared from the components in percentage by mass as follows: 75.0%-95.0% of the supporter Bi2SiO5 / SiO2, 4.2%-21.0% of MoO3 and 0.8%-4.0% of CuOX. A mole ratio of Si to Bi in the supporter Bi2SiO5 / SiO2 is 50, the supporter Bi2SiO5 / SiO2 is synthesized with a hydrothermal method, the active component MoO3 and the aid Cu impregnate Mo and Fe precursor to the supporter with an ultrasonic assisted co-impregnation method, and the catalyst is prepared accordingly.

Owner:FUZHOU UNIV

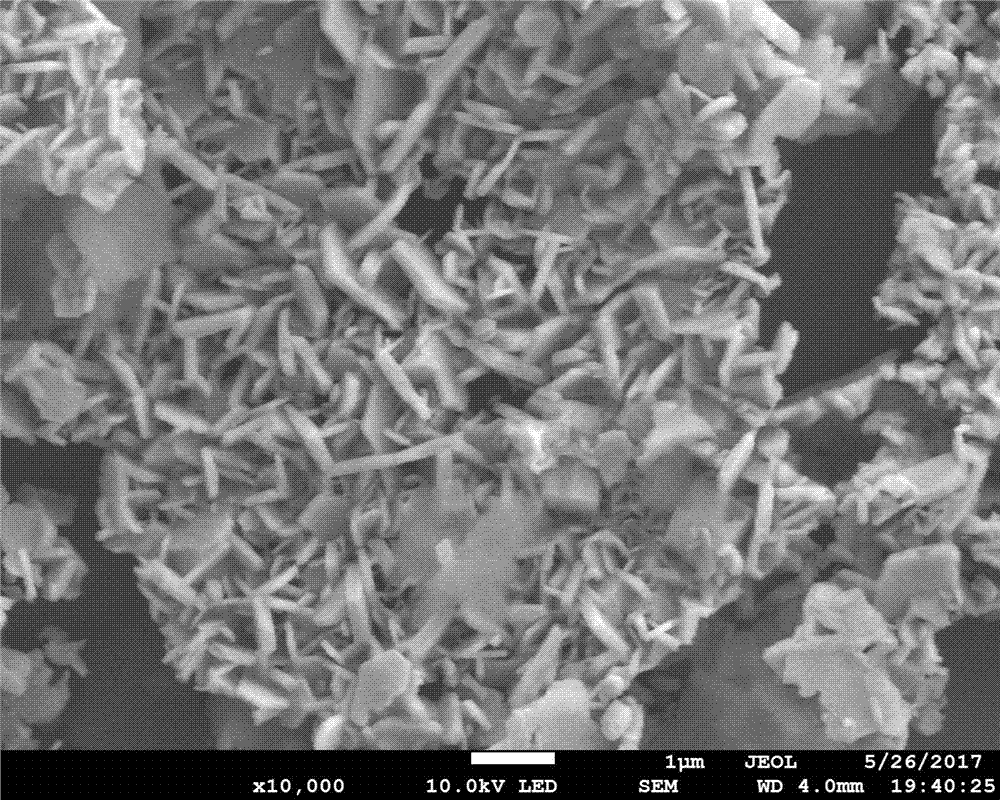

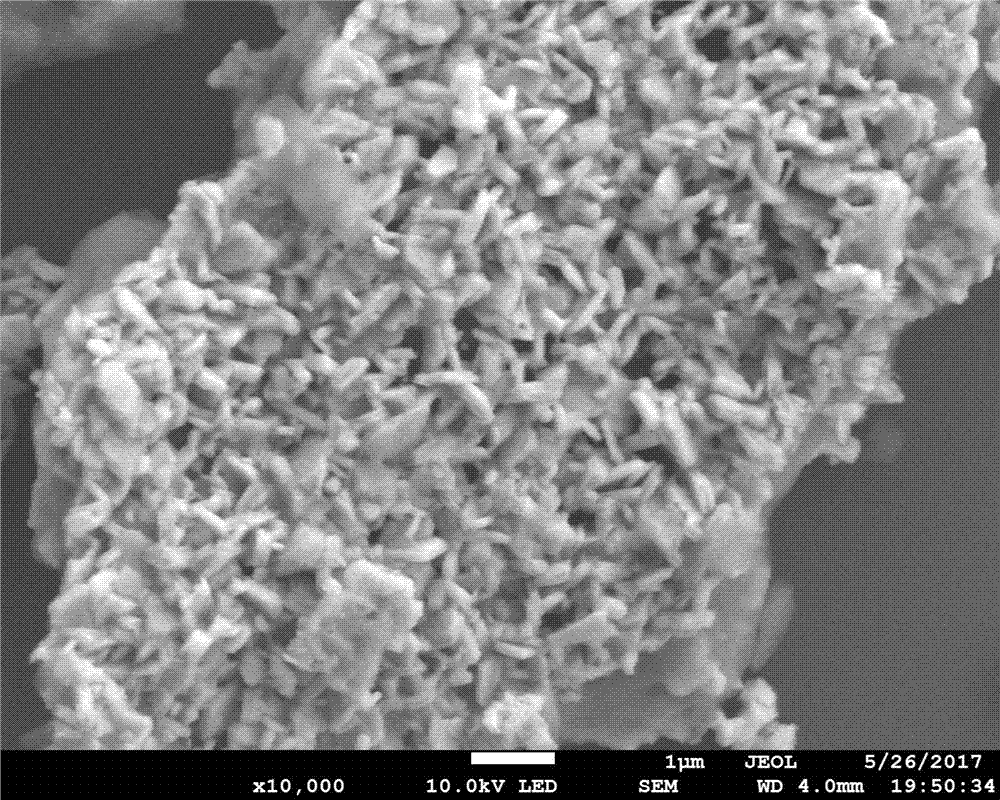

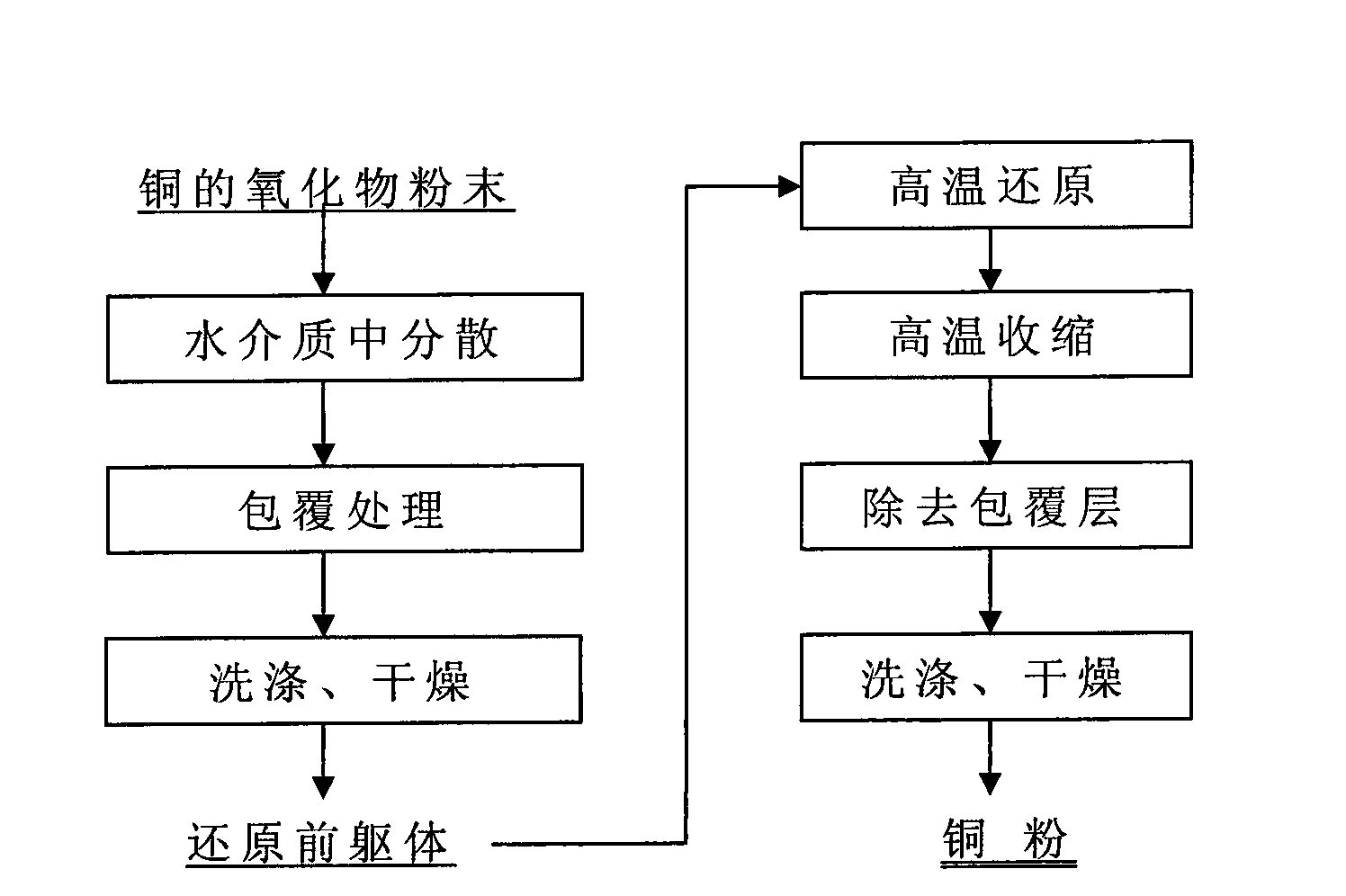

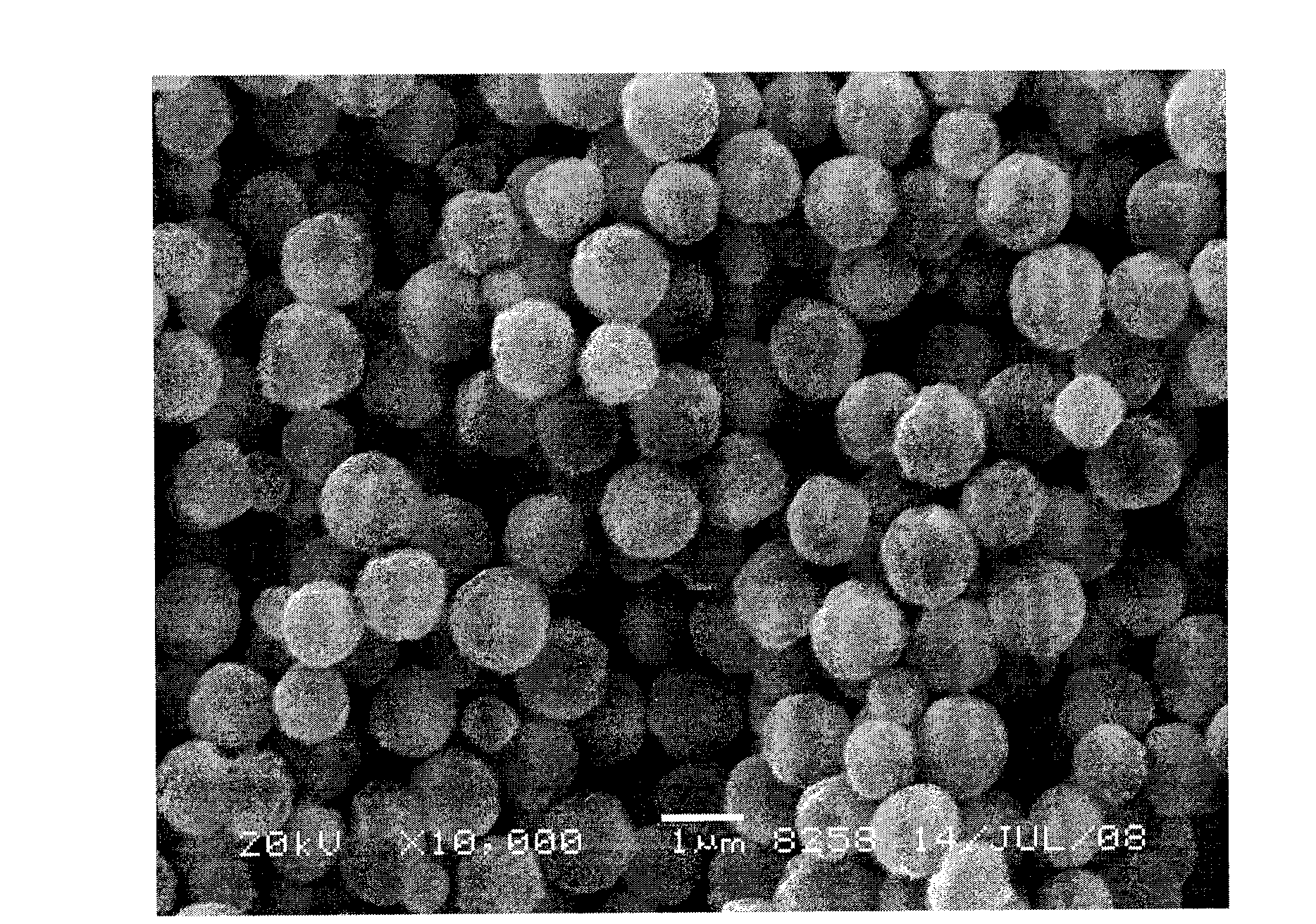

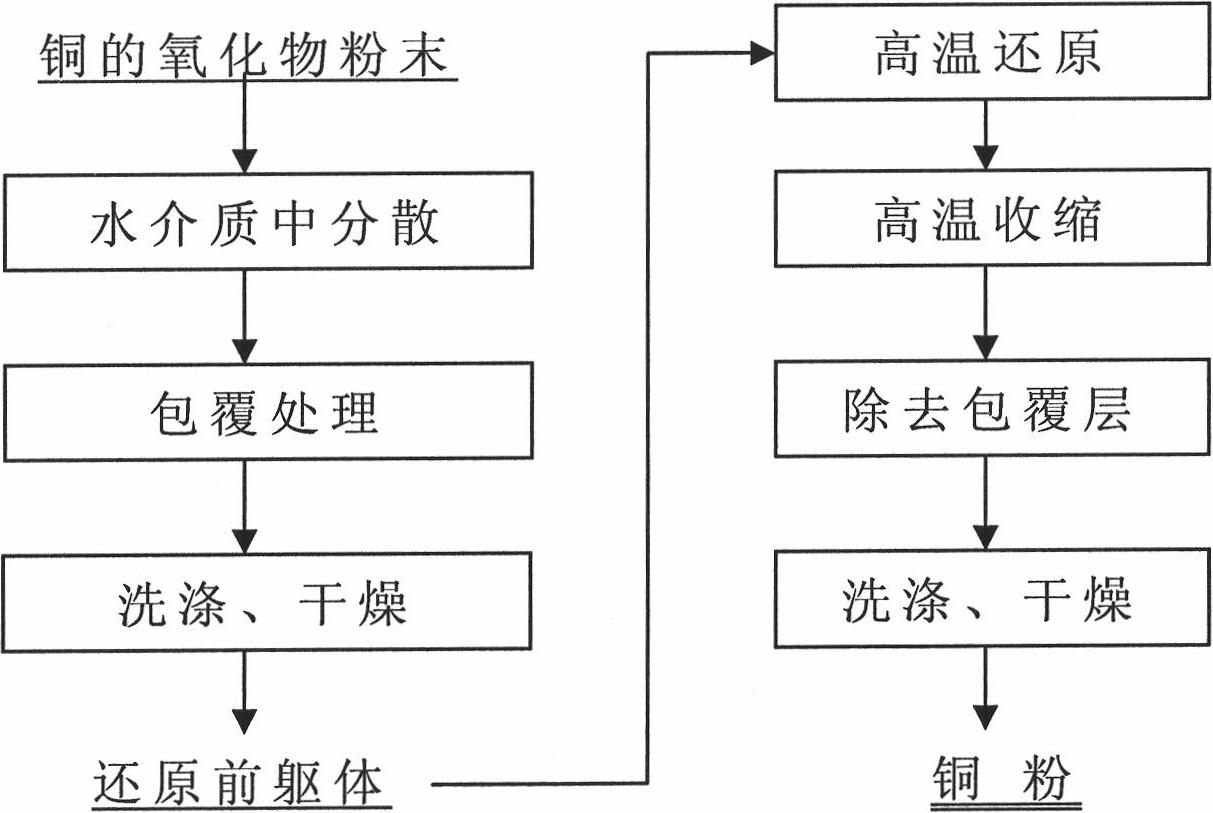

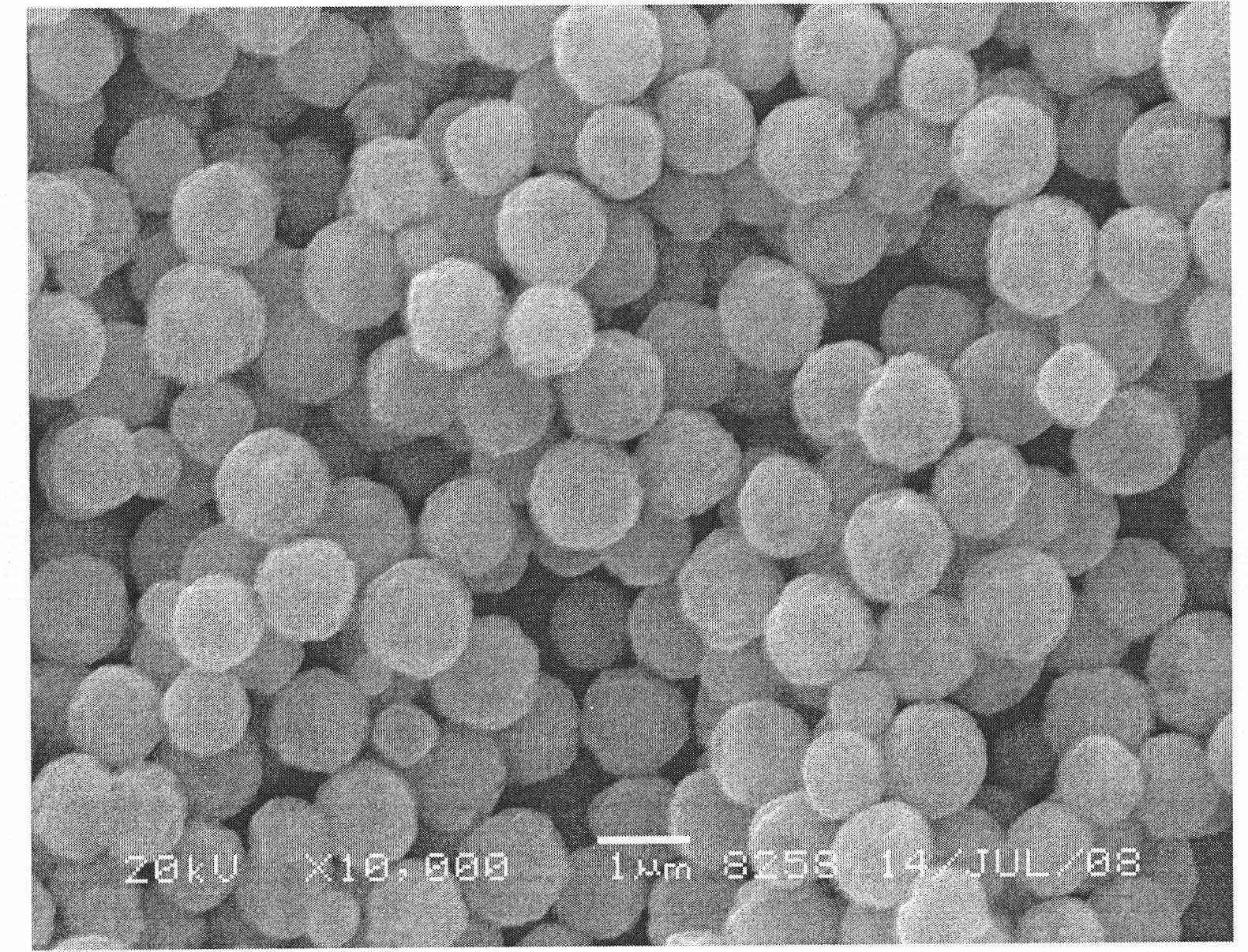

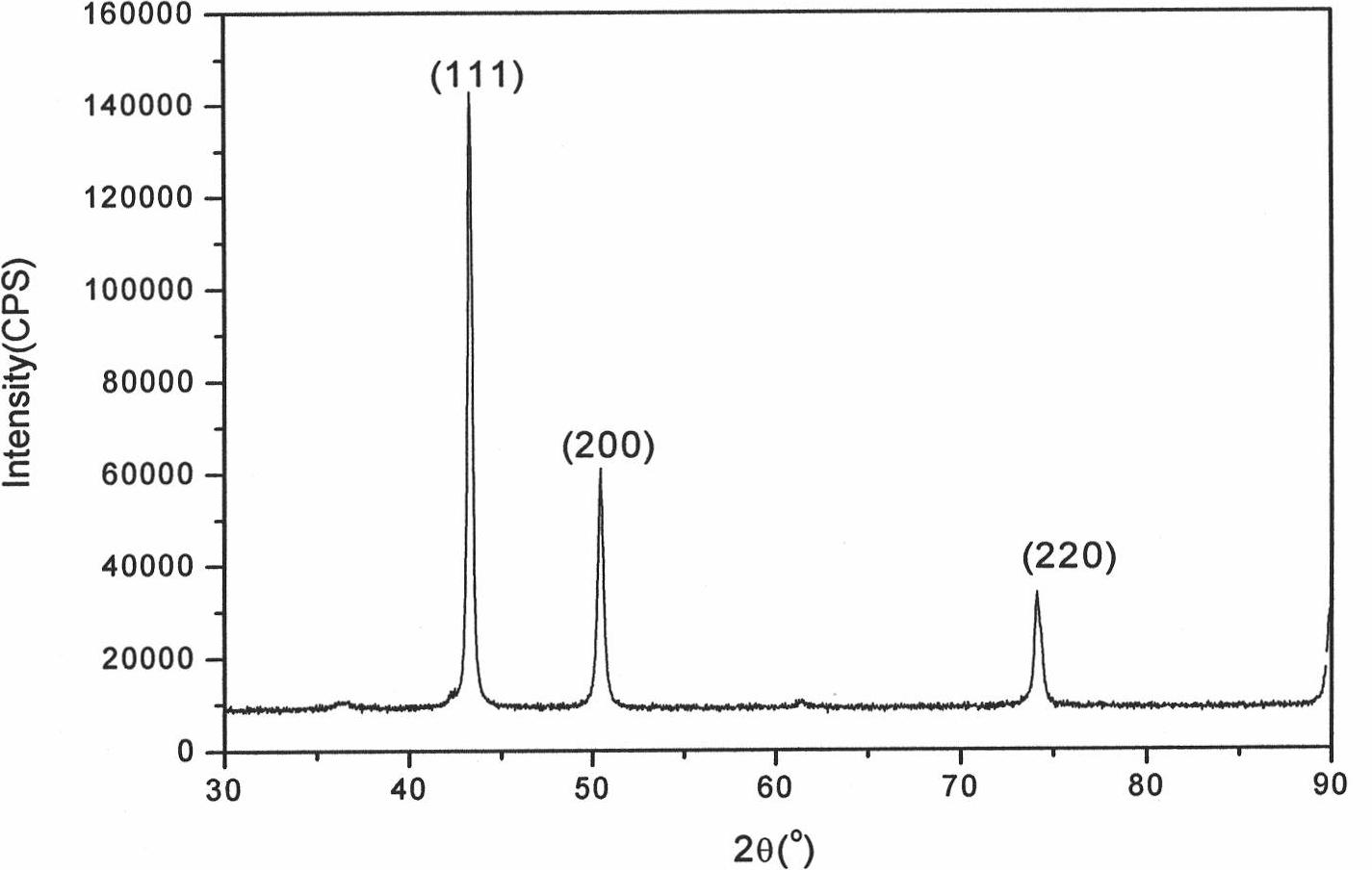

Preparation method of ultrafine copper powder for conductive paste

InactiveCN101513675AFine crystallinityAvoid sintering and agglomerationCoatingsConductive pasteHigh density

The invention discloses a preparation method of ultrafine copper powder for conductive paste. The preparation method comprises the following steps: firstly, coating copper oxide with a compound, reducing the coated copper oxide at high temperature to prepare copper powder, and finally densifying the obtained copper powder at high temperature. The preparation method overcomes preparation cost defect and product performance defect of preparing the copper powder by a gas-phase method and a liquid-phase reduction method, and help produce the ultrafine copper powder which has controllable grain size, good dispersibility, high density and mature crystal form, and meet production requirements for electrodes of multilayer ceramic capacitors. The preparation method has simple equipment and short process flow, and is applicable to industrialized production of the copper powder.

Owner:CENT SOUTH UNIV

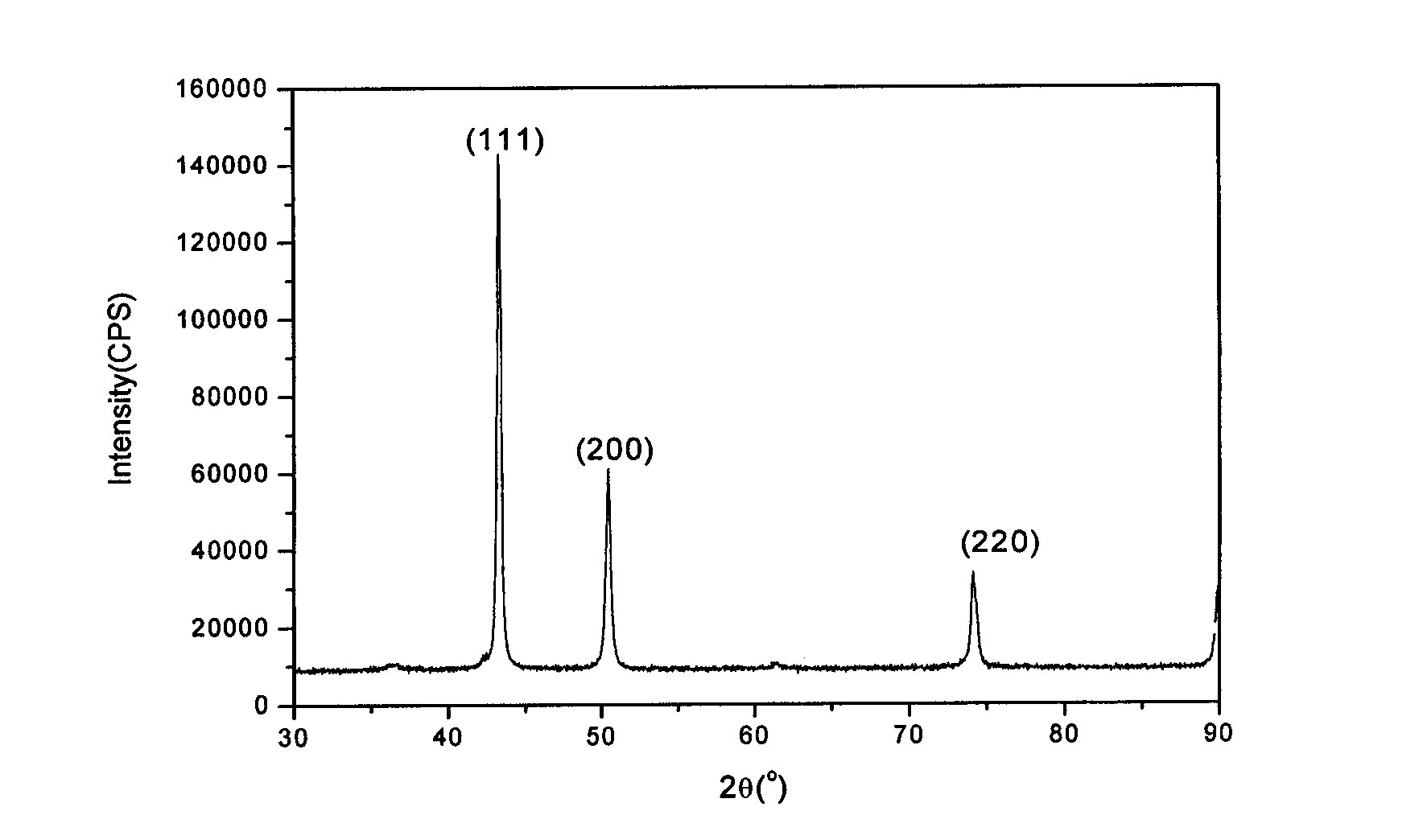

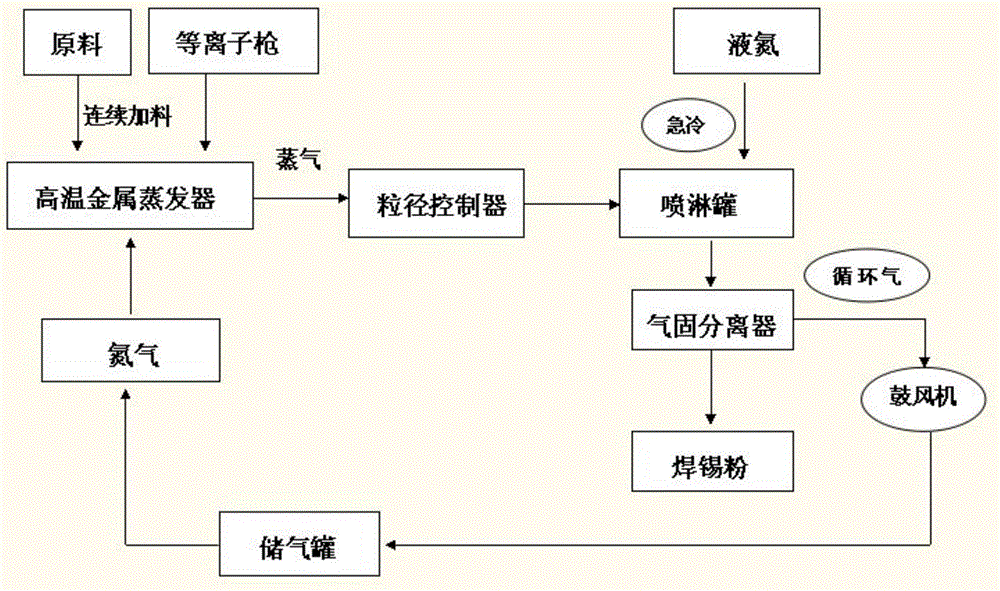

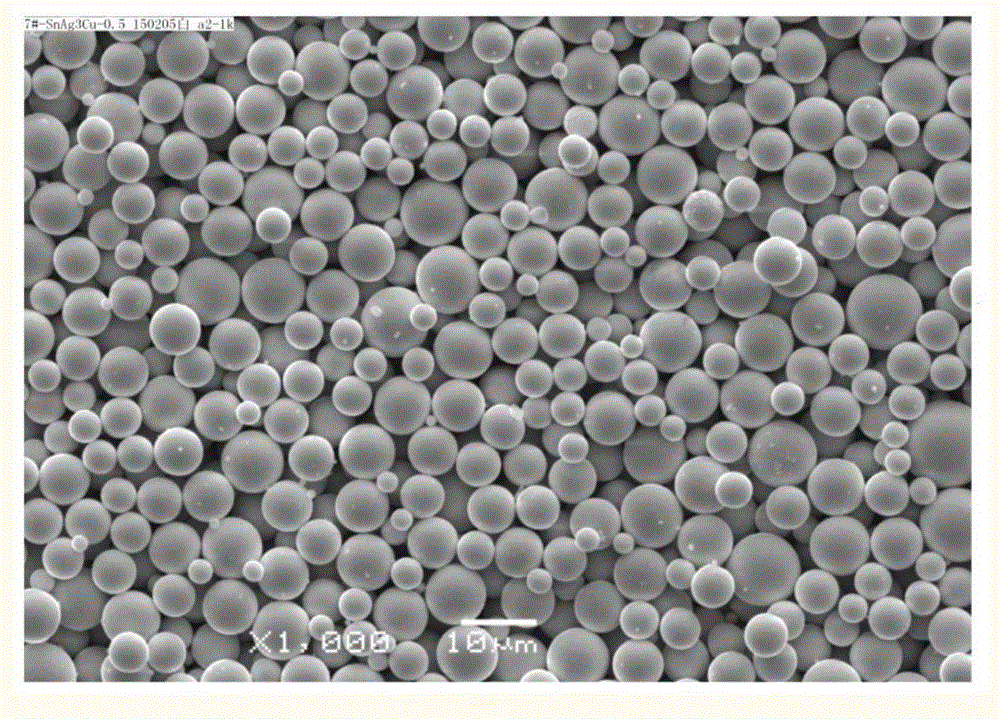

Method for producing superfine lead-free solder powder

The invention provides a method for producing superfine lead-free solder powder. The method is implemented in a reaction system composed of a high-temperature evaporator, a grain controller, a spraying tank, a collector and the like which are all communicated in sequence. Tin alloy is placed in the high-temperature evaporator to be heated and melted, the temperature is maintained for 1 to 3 hours to acquire even alloy liquid, the power of a plasma gun is then increased rapidly, the flow of nitrogen is adjusted, metal steam is conveyed to the grain controller so as to be gradually cooled, collide with one another and grow, and alloy drops are generated; the alloy drops enter the spraying tank through air flow and rapidly cooled through liquid nitrogen to form solder powder, the solder powder is conveyed to the collector along with the nitrogen, attached to the outer wall of a gas-solid separator in the collector and then collected to a collecting hopper at the bottom of the collector, and therefore the superfine solder powder is acquired, wherein the nitrogen is cyclically used. The superfine lead-free solder powder produced through the method is hemispherical, the average grain diameter ranges from 2 micrometers to 7 micrometers, the powder is distributed narrowly, the oxygen content is low, the purity is high, and alloy components are even.

Owner:JIANGSU BOQIAN NEW MATERIALS

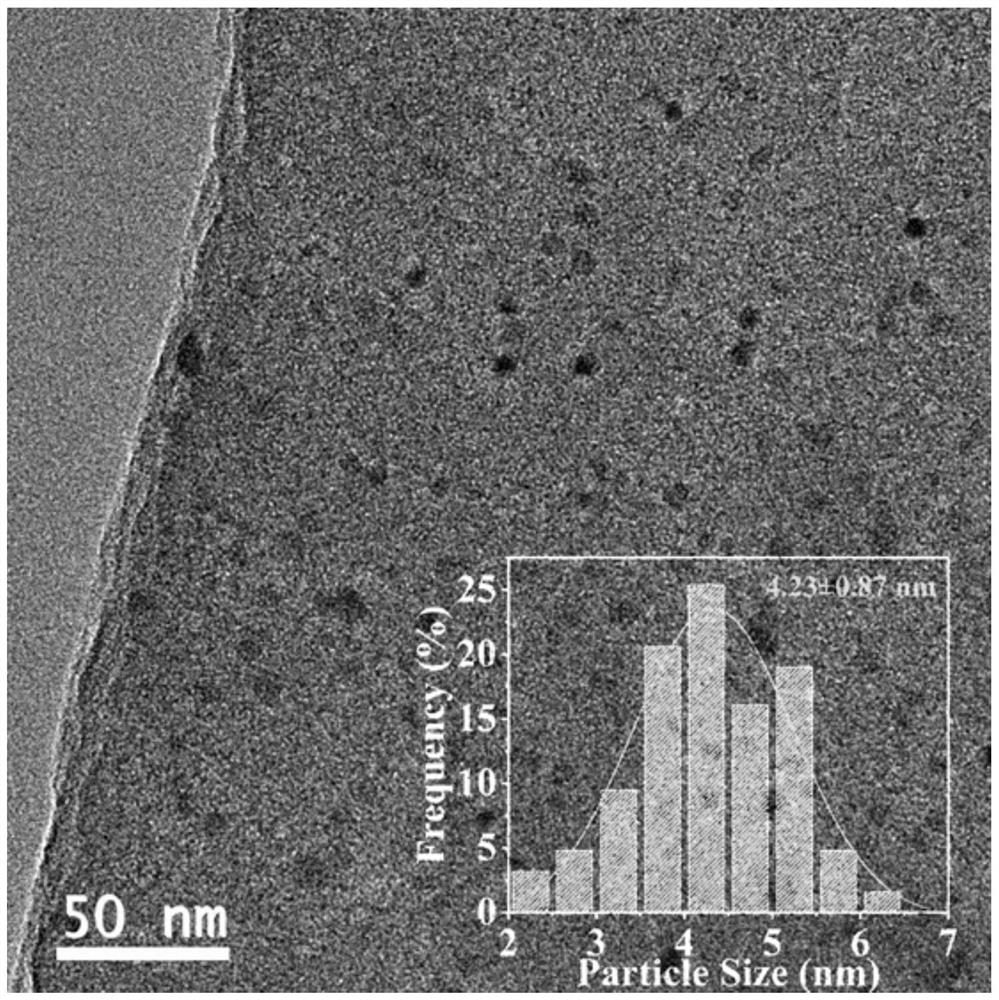

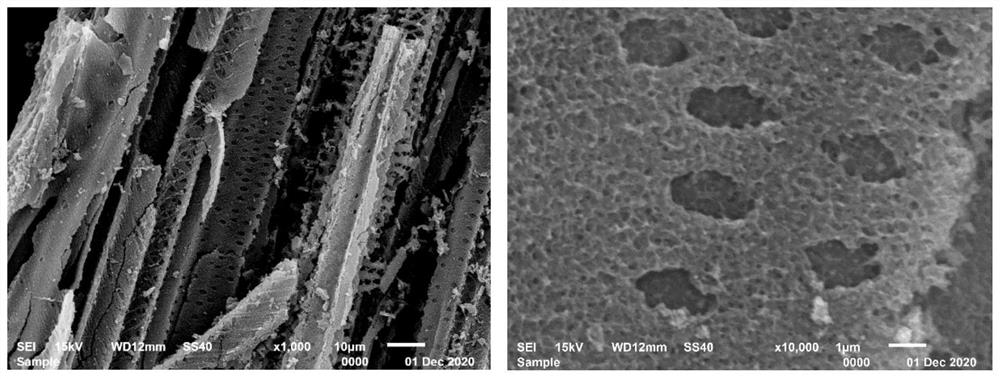

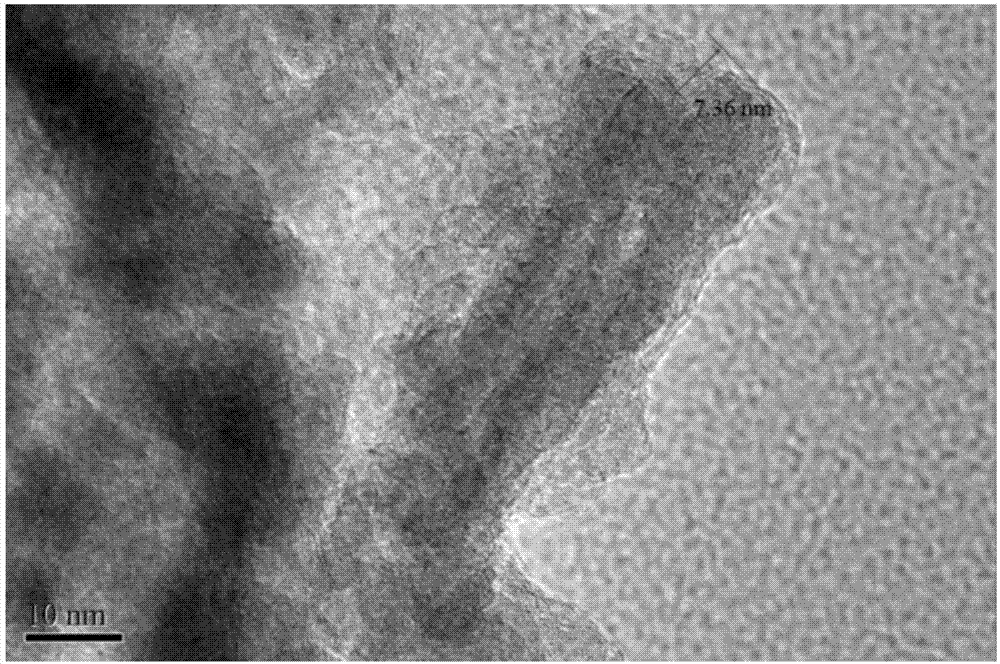

Biomass-based carbon material supported nano-nickel catalyst, preparation method and application thereof

ActiveCN112844476AEasy to prepareLow costHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsNickel catalystBiomass carbon

The invention discloses a biomass-based carbon material loaded nano nickel catalyst, a preparation method and application thereof. According to the invention, the catalyst is synthesized from biomass carbon and metallic nickel through a one-step hydrothermal method, wherein the metallic nickel is loaded into degraded gaps of the carbon material while the carbon material is generated, the content of the metallic nickel is 5-10 wt%, the content of a carbon-based carrier is 90-95 wt%, the particle size of metal nickel can reach 4.23 nm, and the dispersity of nickel reaches 23.64%; low-cost biomass carbon is used as a carrier, and nickel nanoparticles which are small in particle size and uniform in distribution are obtained; the used catalyst can be used for recovering nickel metal through simple calcination, so that cyclic utilization of the nickel metal is realized; the catalyst is applied to the technical field of synthesis gas preparation through carbon dioxide reforming; the catalyst prepared by the invention can be maintained for at least 500 hours and is not inactivated in a carbon dioxide reforming stability experiment, and the conversion rates of methane and carbon dioxide can be respectively stabilized at 80-92% and 90-98%; and the catalyst has high activity and stability, and carbon deposition is hardly generated in the reaction process.

Owner:WUHAN UNIV OF SCI & TECH

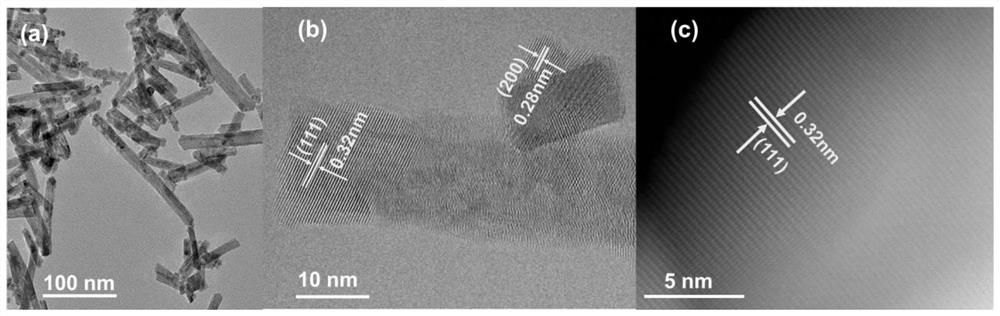

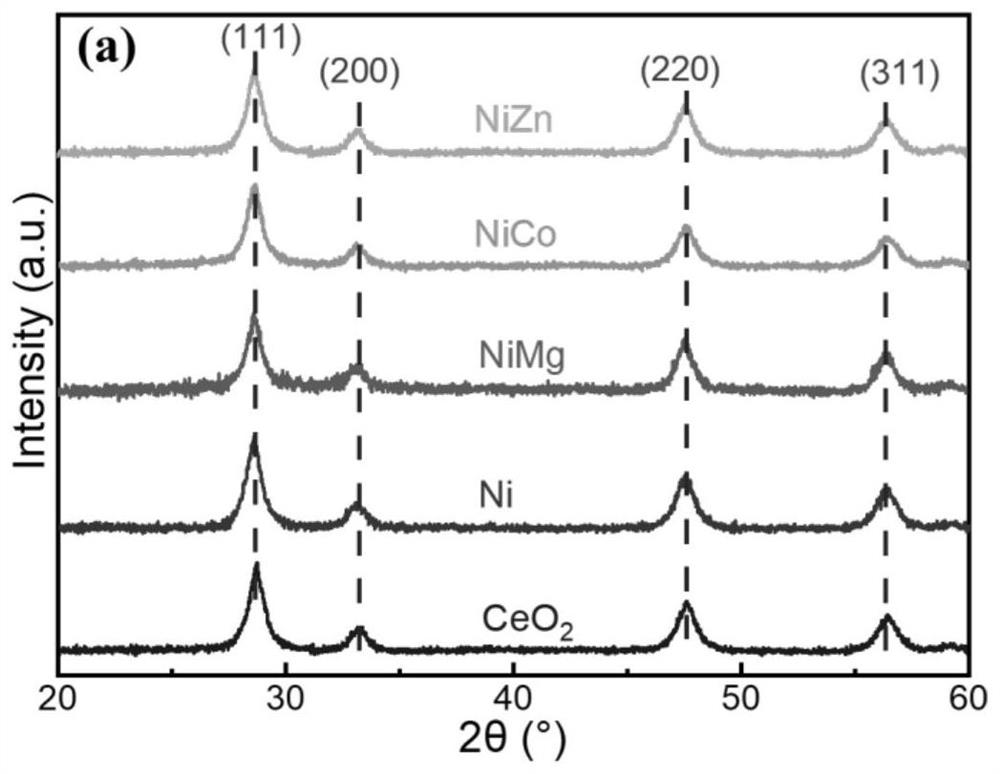

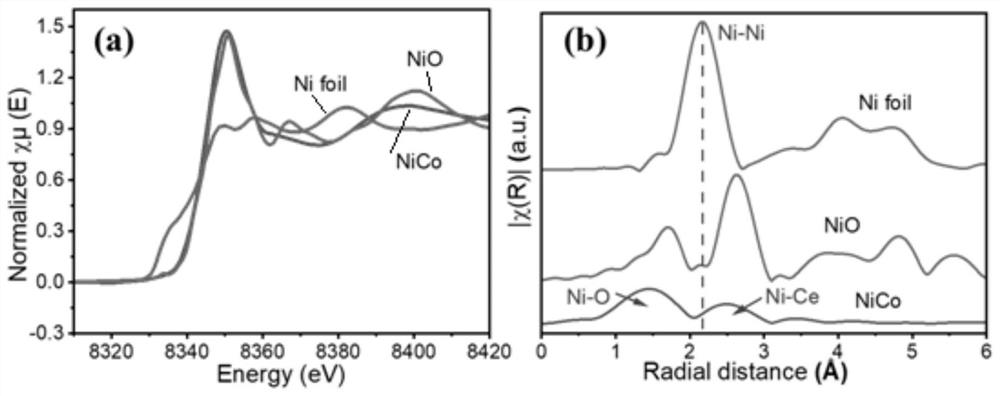

Monatomic catalyst for preparing synthesis gas by methane dry reforming as well as preparation method and application of monatomic catalyst

PendingCN113813964AHigh activityActive influenceHydrogenHeterogenous catalyst chemical elementsActivated carbonPtru catalyst

The invention discloses a preparation method of a monatomic catalyst for preparing synthesis gas by methane dry reforming , the preparation process adopts a one-step synthesis method, the active component metal Ni in the obtained catalyst is uniformly dispersed on a carrier CeO2 in an isolated atom form, the catalytic stability can be effectively improved, and the preparation method has the advantage of simple steps. The invention also discloses the monatomic catalyst prepared by the method, monatomic dispersed Ni has high catalytic activity, Ni is limited by oxygen vacancy of CeO2, and sintering agglomeration of Ni at high temperature can be effectively prevented; and the doped second metal regulates and controls the oxygen vacancy concentration on the surface of CeO2, a large number of oxygen vacancies can effectively activate carbon dioxide, surface active oxygen is generated, and the influence of carbon deposition on the activity of the catalyst is inhibited. The invention also discloses an application of the monatomic catalyst in preparation of synthesis gas by methane dry reforming, the catalyst can be continuously used for 150 hours without obvious deactivation, and a good technical effect is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

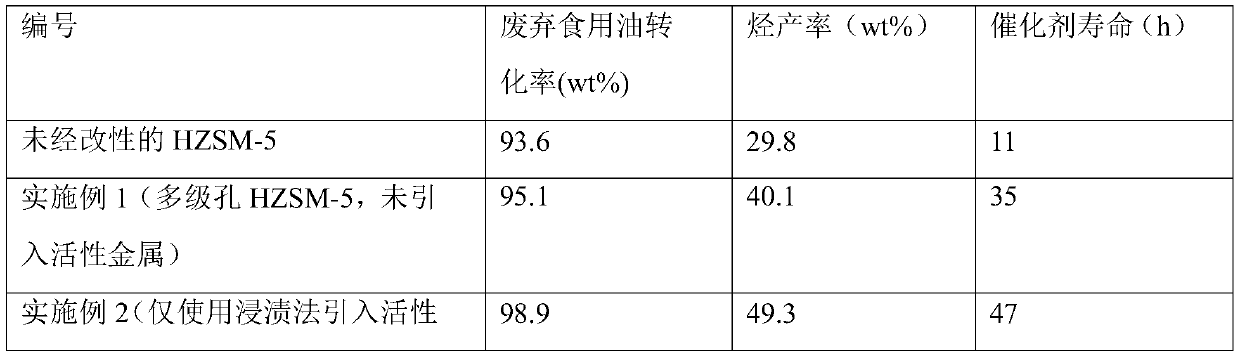

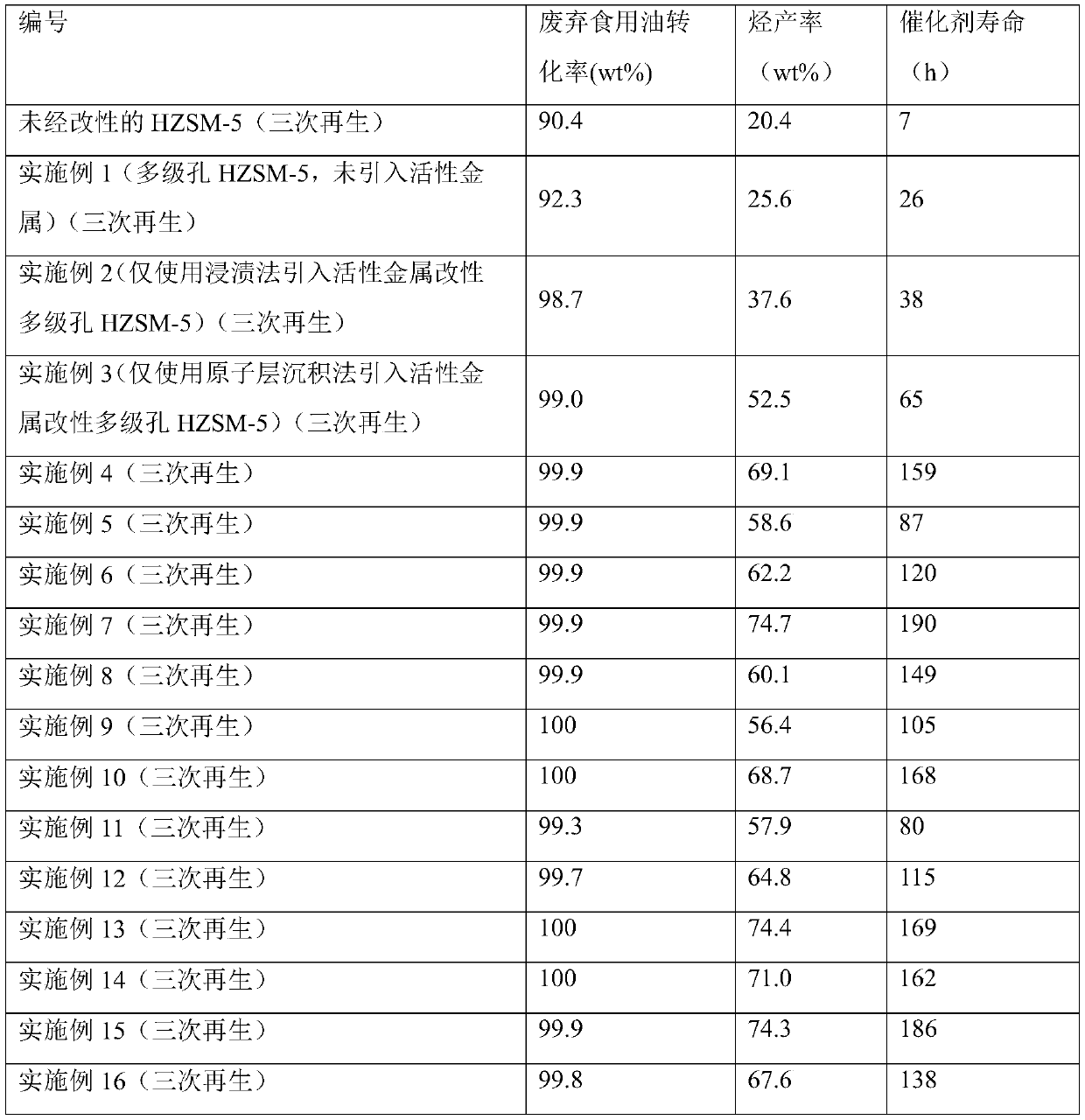

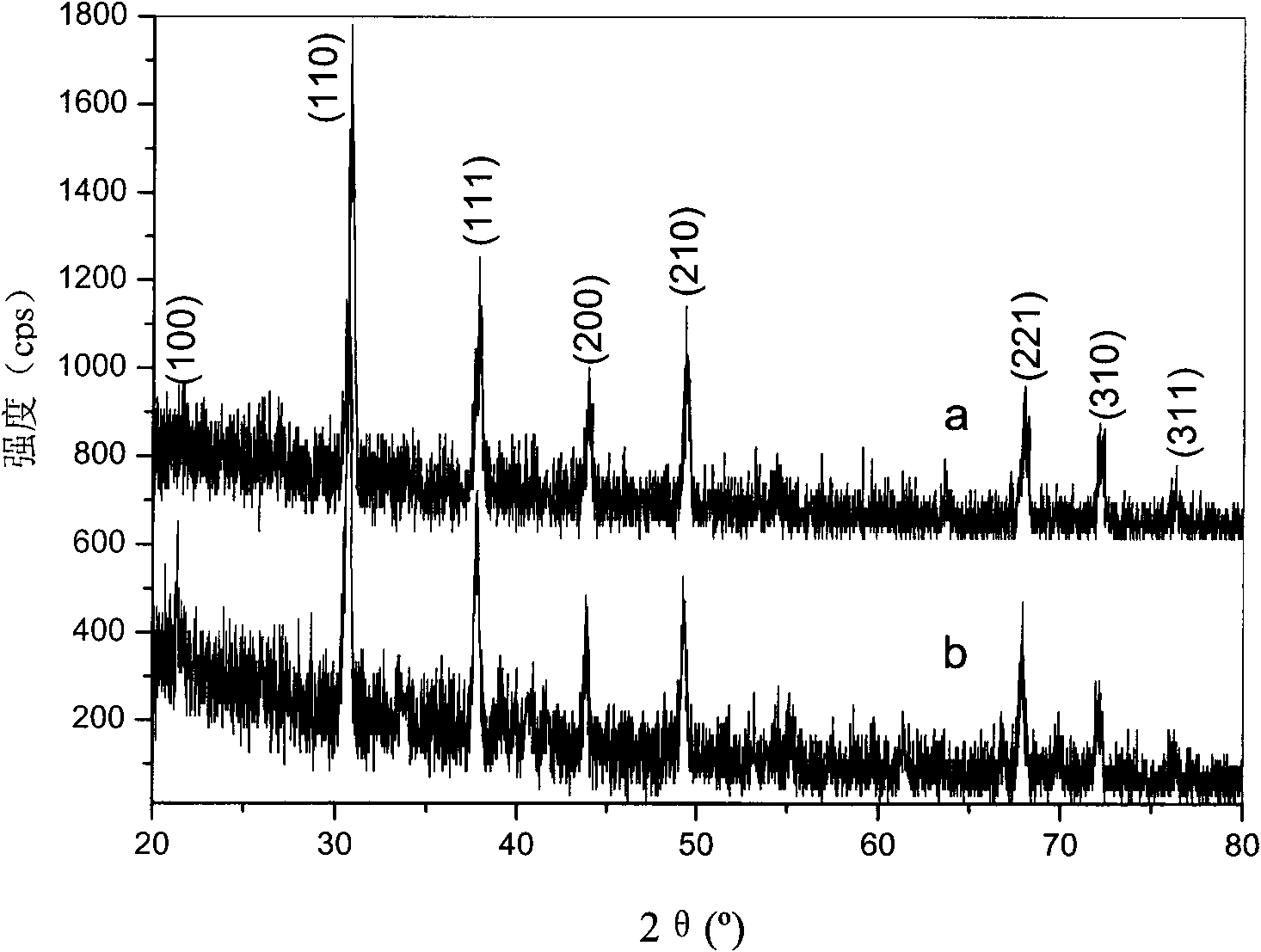

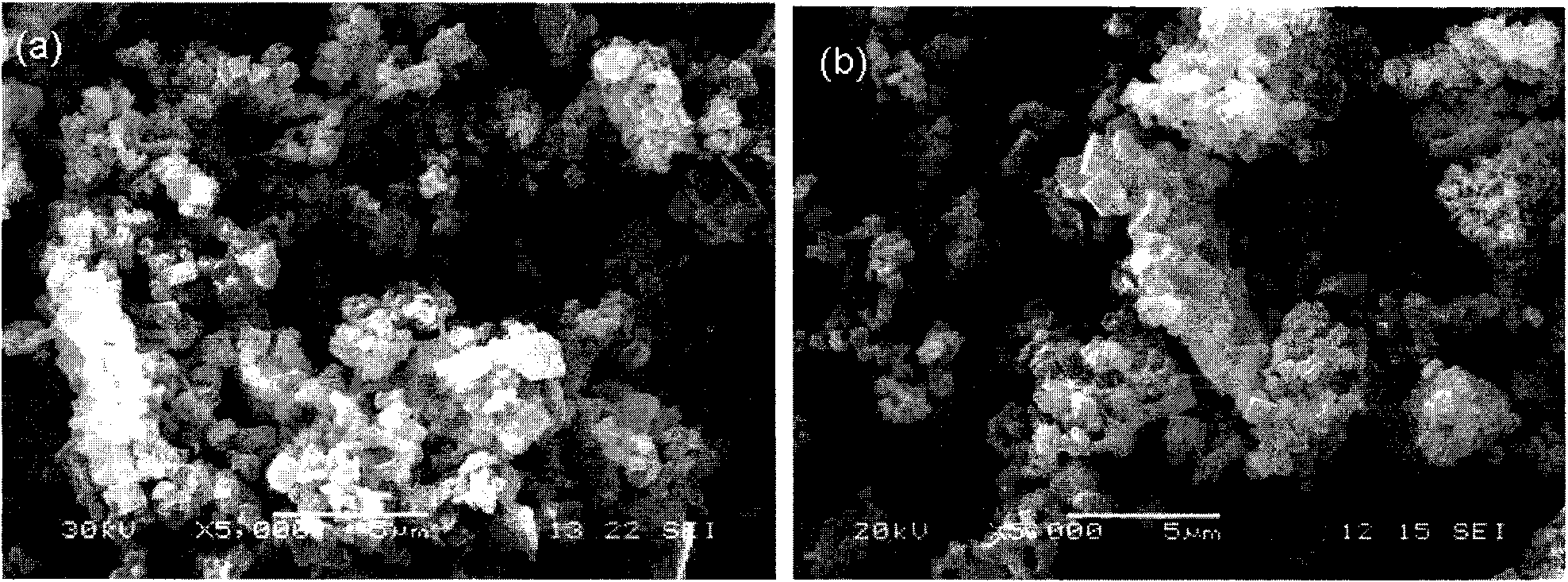

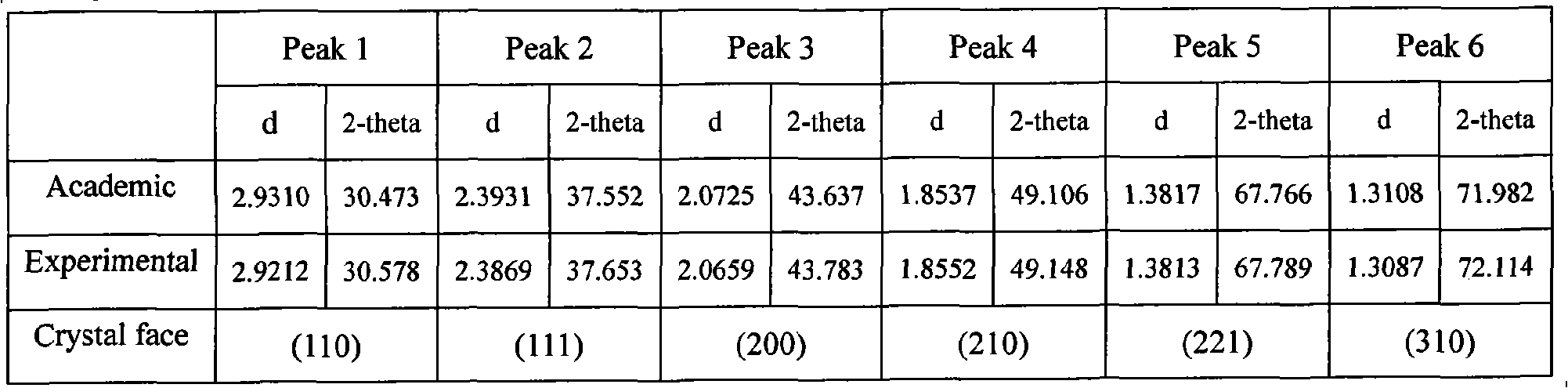

Catalyst for aromatization of waste edible oil and production method and application of catalyst for aromatization of waste edible oil

InactiveCN110694673AGuaranteed constitutive reactivitySolve the irreversible inactivation problemMolecular sieve catalystsHydrocarbonsPtru catalystAromatization

The invention discloses a production method of a catalyst used for producing light aromatic hydrocarbons through efficient aromatization of waste edible oil. The production method comprises firstly, conducting compound treatment on a carrier ZSM-5 by means of one or more of an acid, an alkali and water vapor to obtain hierarchical porous HZSM-5, then loading an aromatization active metal oxide onto the hierarchical porous HZSM-5 through a dipping method to obtain M / HZSM-5, then covering the interiors and the exteriors of pore channels of the HZSM-5 with metal oxide films, with aromatization catalysis activity, layer by layer by means of an atomic layer deposition method, and then introducing SiO2 films through the atomic layer deposition method to conduct selective passivating treatment onnon-shape-selective acidic sites on pore openings and the outer surface of M / HZSM-5@N. The catalyst produced through the production method of the catalyst used for producing the light aromatic hydrocarbons through efficient aromatization of the waste edible oil effectively improves the reaction activity, the selectivity and the stability of production of the light aromatic hydrocarbons through aromatization of the waste edible oil.

Owner:HUAIYIN TEACHERS COLLEGE

Method for inorganic synthesizing submicron CaB6 polycrytal powder

InactiveCN101549872AAvoid sintering and agglomerationPromote growthMetal boridesTime rangeGranularity

The invention relates to a method for inorganic synthesizing submicron CaB6 polycrytal powder. CaCI2 or Ca(OH)2 is reacted with B2O3 and magnesium powder at the temperature ranging from 700 to 850 DEG C, the mole ratio of the reaction is Ca2+:B2O3:Mg=0.5-1.5:2-4:8-14, and the reaction time range is 5-30 minutes. The product is isolated and purified to gain submicron CaB6 polycrytal powder. The submicron CaB6 polycrytal powder produced by the invention is regular in shape and uniform in distribution, and the granularity reaches the submicron. The invention has advantages of mild reaction condition, simple process, low energy consumption and being applicable to industrialization production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

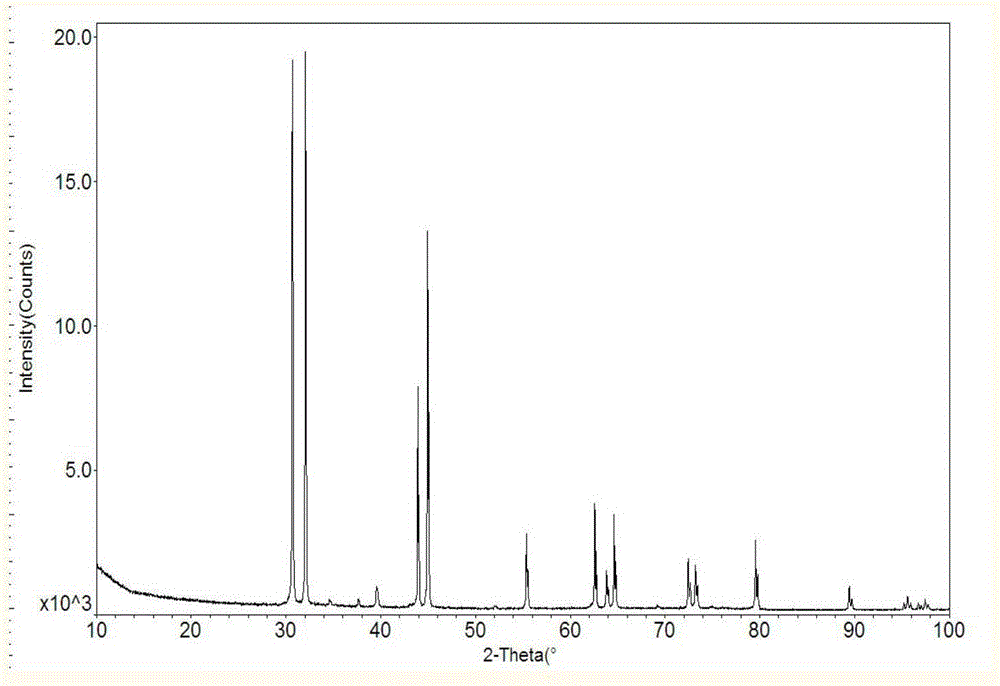

Preparation method of heavy metal adsorbent alpha-Al2O3 nanoparticles

The invention relates to a preparation method of heavy metal adsorbent alpha-Al2O3 nanoparticles and belongs to the technical field of preparation of a nanometer sewage treating agent. A glycol aluminum precursor is prepared by an alcohol aluminum hydrolysis method and high-temperature calcination is conducted to obtain the alpha-Al2O3 nanoparticles. The preparation method comprises the followingsteps: A, dissolving aluminum powder into anhydrous glycol, controlling the molar ratio of the aluminum powder to the anhydrous glycol to be 1:(25-30), stirring, adding PEG6000, adding AlCl3, performing catalytic reaction, and stirring for 5 to 8 hours by controlling the temperature to be 50 to 70 DEG C to obtain glycol aluminum white precipitate; B, adding deionized water into the glycol aluminumwhite precipitate obtained in the step A, stirring by controlling the temperature and performing hydrolysis at 60 to 70 DEG C for 2 to 5 hours to obtain hydrated alumina gel; C, drying the hydrated alumina gel at 60 to 80 DEG C for 24 to 48 hours to obtain dry gel; and D, heating to 1100 to 1200 DEG C at the heating speed of 5 to 10 DEG C / min and calcining the dry gel for 2 to 3 hours to preparethe alpha-Al2O3 nanoparticles. The method is mild and stable in preparation process; and the prepared nanometer aluminum oxide has high purity and has high adsorptive property on various heavy metal ions.

Owner:HEBEI MILSON TITANIUM DIOXIDE

A kind of highly active propylene gas phase epoxidation catalyst and preparation method thereof

ActiveCN104128176BReduce pollutionEasy to industrializeOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsGas phaseMesoporous material

Owner:FUZHOU UNIV

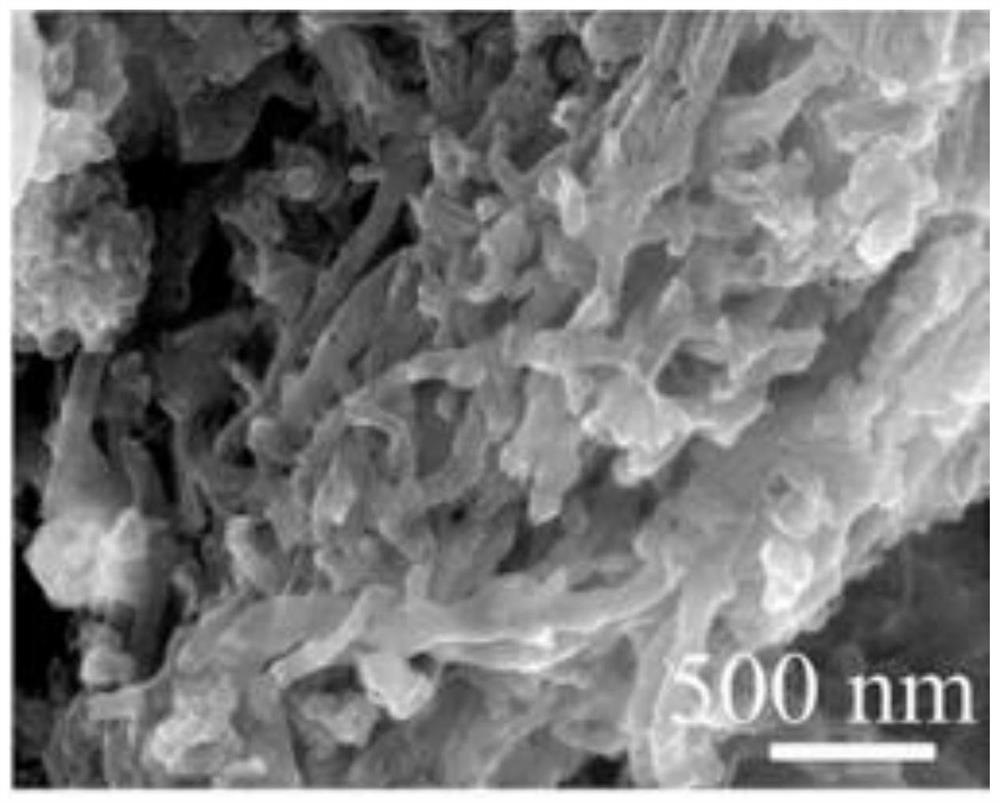

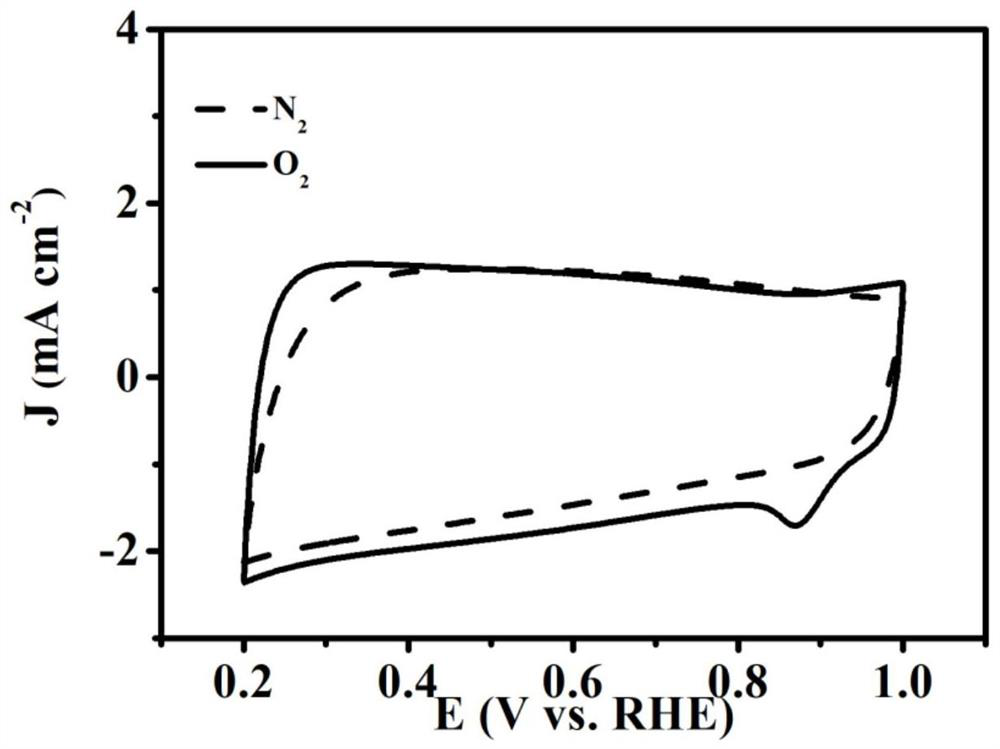

Carbon-based Fe/S/N co-doped oxygen reduction catalyst as well as preparation method and application thereof

ActiveCN113659158AEvenly dispersedAvoid sintering and agglomerationFuel and primary cellsCell electrodesPtru catalystChemical engineering

The invention provides a preparation method of a carbon-based Fe / S / N co-doped oxygen reduction catalyst, and the method comprises the following steps: S1) copolymerizing phenyl ferriporphyrin and a cross-linking agent under the action of a catalyst to obtain a ferriporphyrin-based cross-linked microporous polymer; S2) mixing the ferriporphyrin-based cross-linked microporous polymer with thiophene for adsorption, and then performing polymerization under the action of an initiator to obtain a polythiophene coated ferriporphyrin cross-linked microporous polymer composite structure; S3) carrying out carbonization treatment on the composite structure obtained in the step S2) to obtain the carbon-based Fe / S / N co-doped oxygen reduction catalyst. The oxygen reduction catalyst shows efficient oxygen reduction electrochemical performance and stability, the half-wave potential of the oxygen reduction electrochemical reaction is (0.89 Vvs.RHE), and the oxygen reduction catalyst is superior to commercial platinum carbon; the maximum output power of the zinc-air battery is 106mW / cm<2>, which is superior to that of 20wt% commercial platinum carbon.

Owner:SHANDONG ENERGY GRP +1

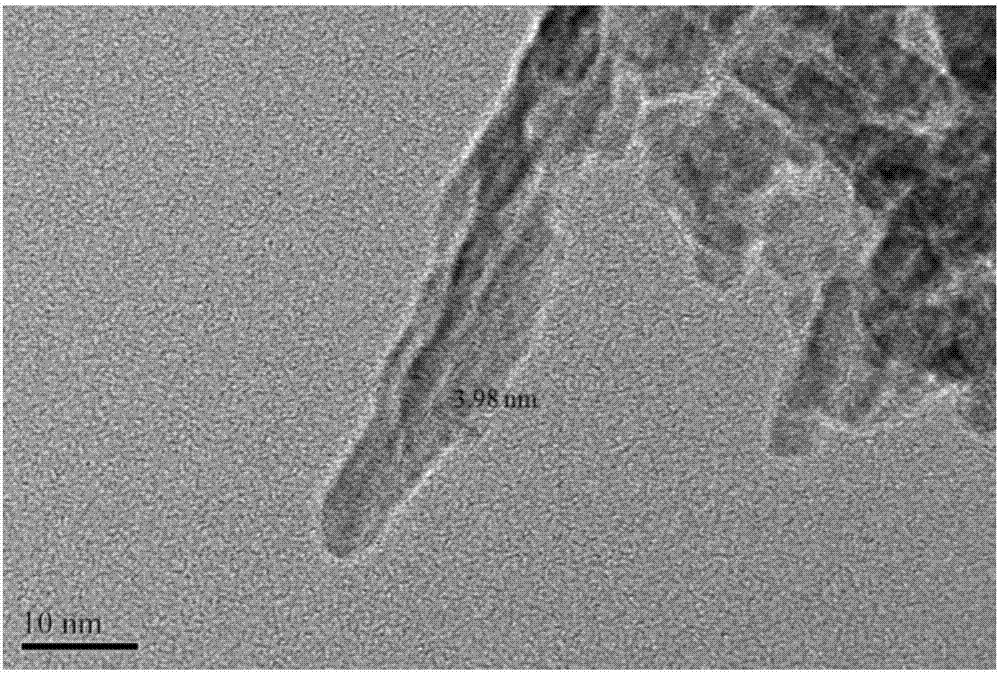

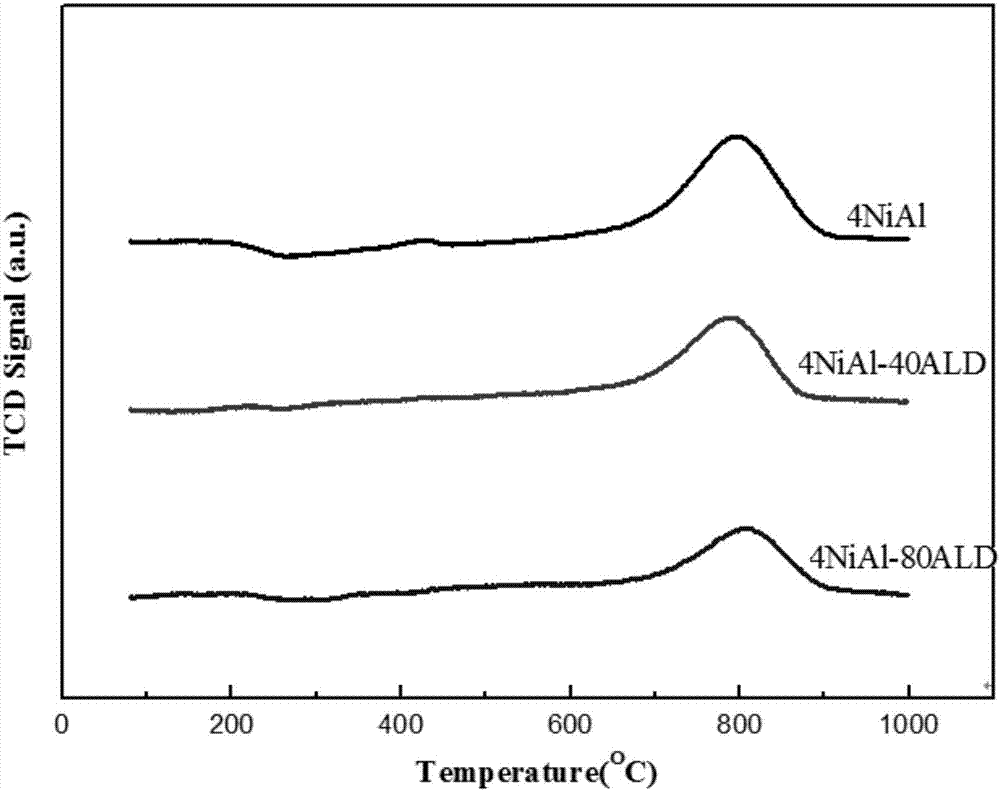

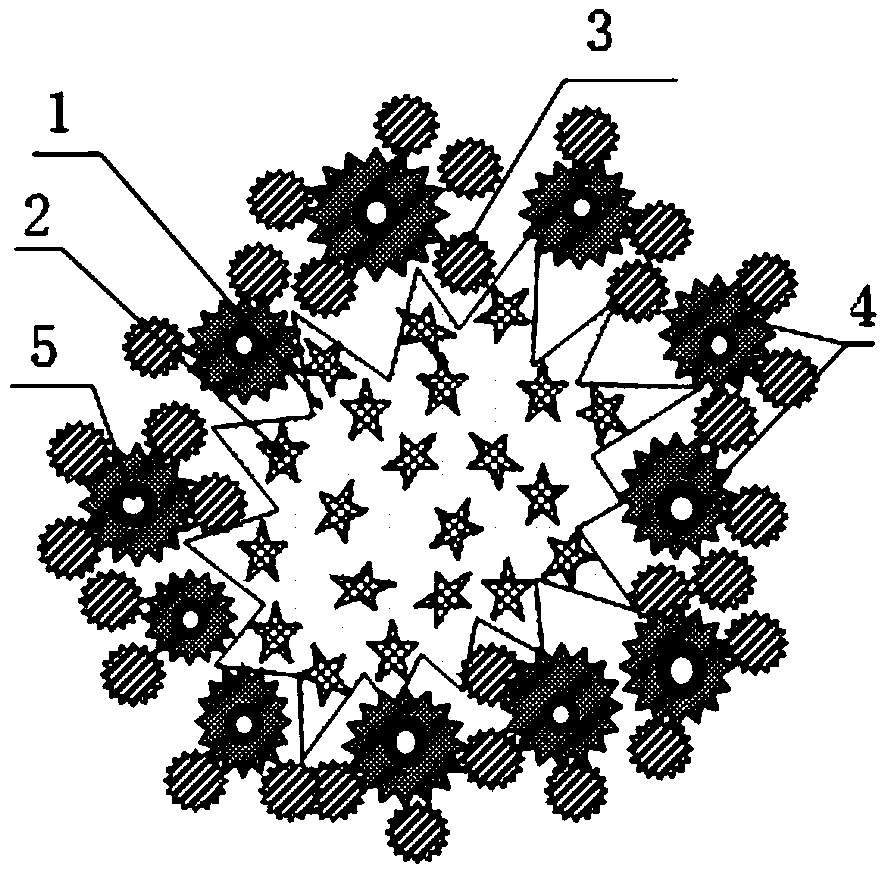

High-thermal-stability aluminum oxide/nickel/aluminum oxide sandwich structure catalyst as well as preparation method and application thereof

InactiveCN107376918AHigh activityImprove catalytic stabilityHydrogenHydrogen/synthetic gas productionThermal stabilityHigh activity

The invention relates to a high-thermal-stability aluminum oxide / nickel / aluminum oxide sandwich structure catalyst as well as a preparation method and application thereof. The high-thermal-stability Al2O3 / Ni / Al2O3 sandwich structure catalyst is of a sandwich structure and comprises a gamma-Al2O3 substrate layer, a Ni nano particle layer located on the gamma-Al2O3 substrate layer, and an inertia Al2O3 thin film located on the Ni nano particle layer. The high-thermal-stability Al2O3 / Ni / Al2O3 sandwich structure catalyst is used in CH4-CO2 reforming reaction. Compared with the prior art, the inner-layer Al2O3 carrier and the outer-layer Al2O3 thin film well protect and stabilize Ni nano particles to prevent the particles from being agglomerated and sintered, so that carbon deposition, poisoning and the like in a reaction process can be suppressed, and the catalyst is high in thermal stability; moreover, the catalyst has high activity and has a good application prospect in CH4-CO2 reforming reaction and other high-temperature thermo-catalysis reactions.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of ultrafine copper powder for conductive paste

InactiveCN101513675BAvoid sintering and agglomerationGood tap densityCoatingsConductive pasteHigh density

The invention discloses a preparation method of ultrafine copper powder for conductive paste. The preparation method comprises the following steps: firstly, coating copper oxide with a compound, reducing the coated copper oxide at high temperature to prepare copper powder, and finally densifying the obtained copper powder at high temperature. The preparation method overcomes preparation cost defect and product performance defect of preparing the copper powder by a gas-phase method and a liquid-phase reduction method, and help produce the ultrafine copper powder which has controllable grain size, good dispersibility, high density and mature crystal form, and meet production requirements for electrodes of multilayer ceramic capacitors. The preparation method has simple equipment and short process flow, and is applicable to industrialized production of the copper powder.

Owner:CENT SOUTH UNIV

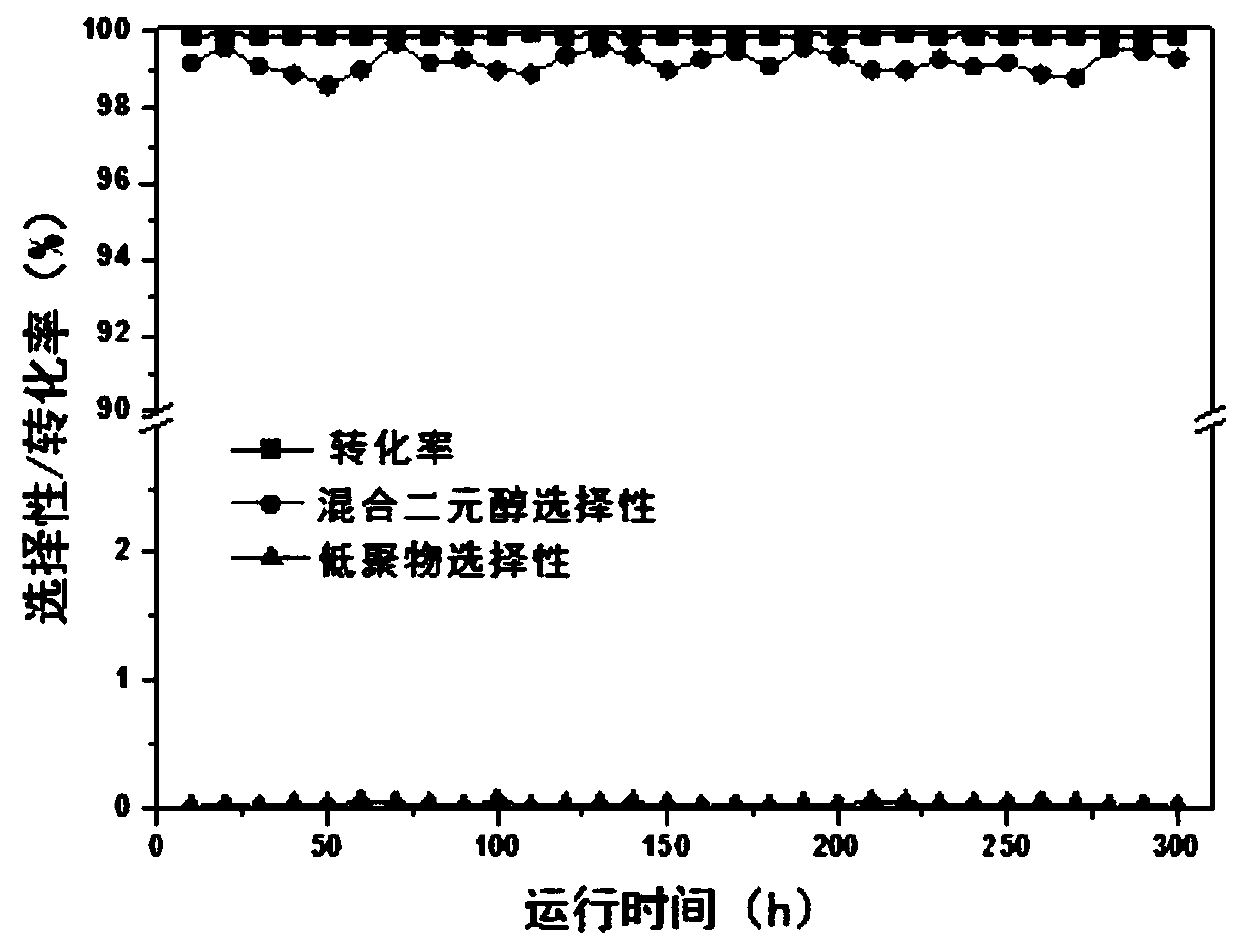

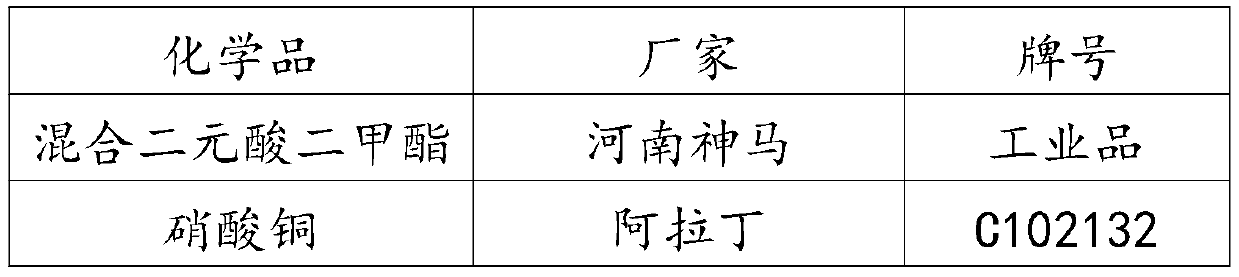

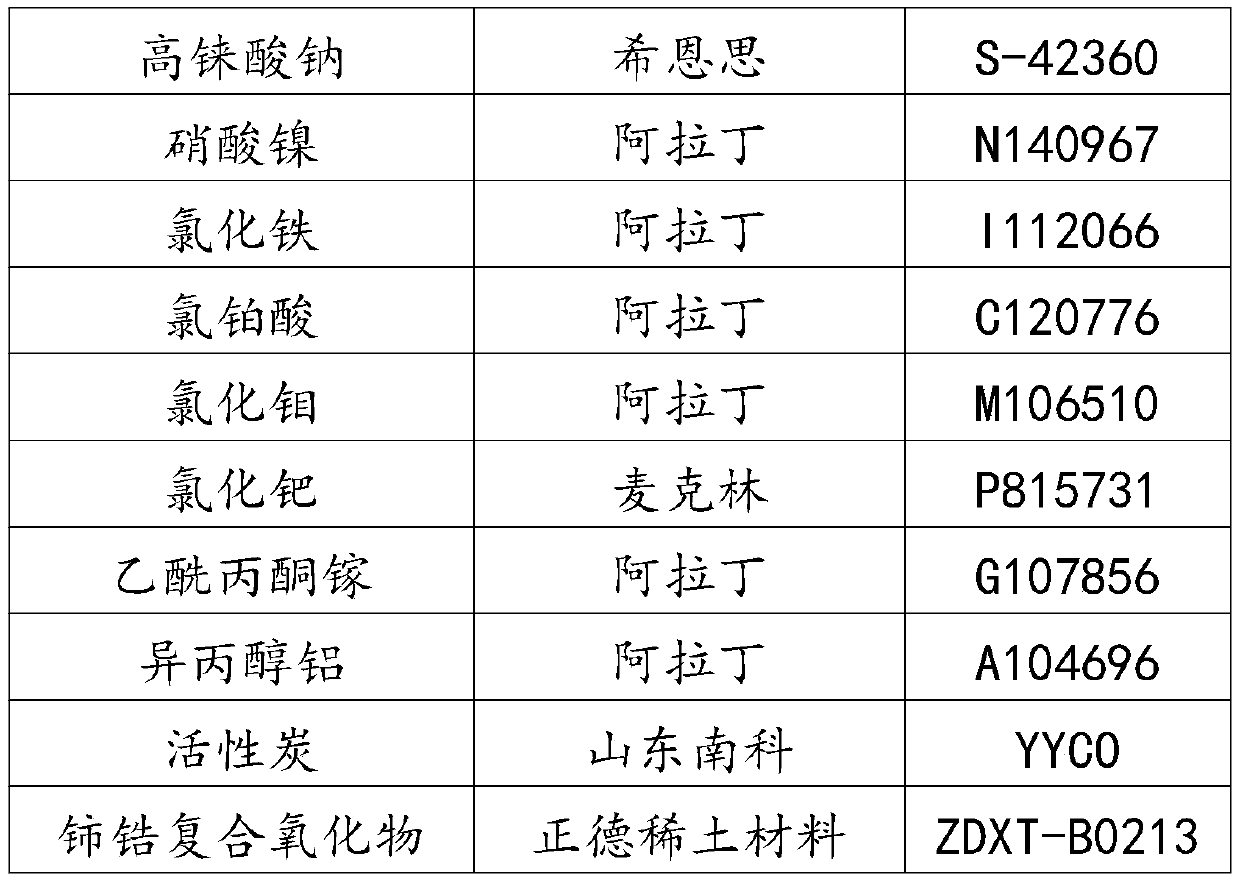

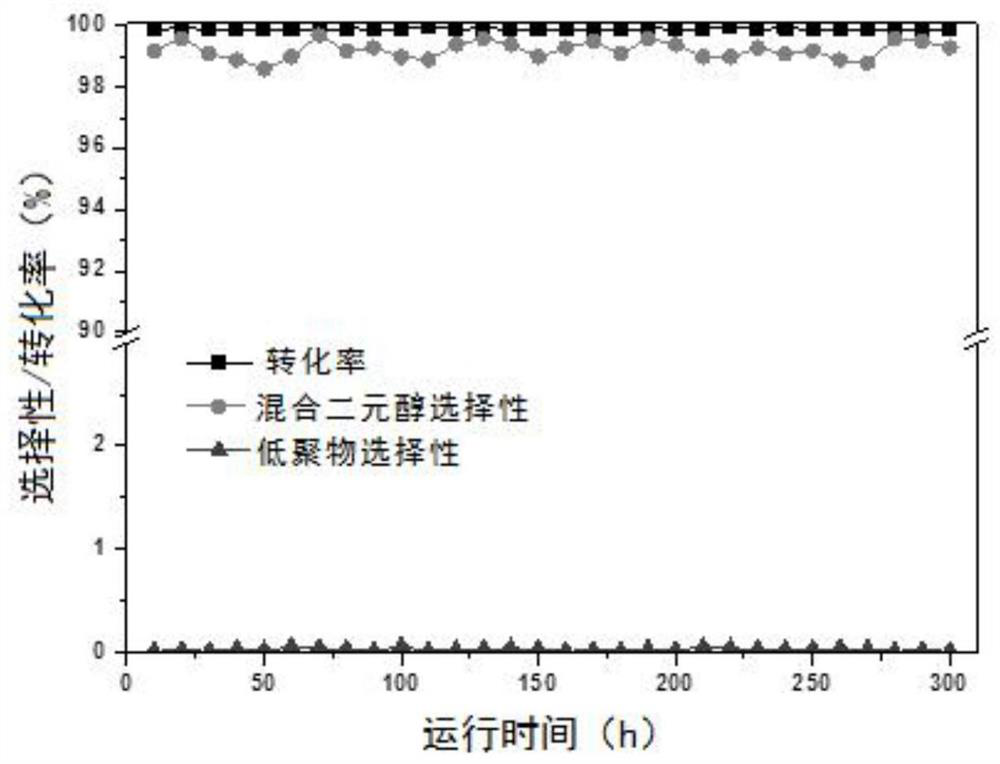

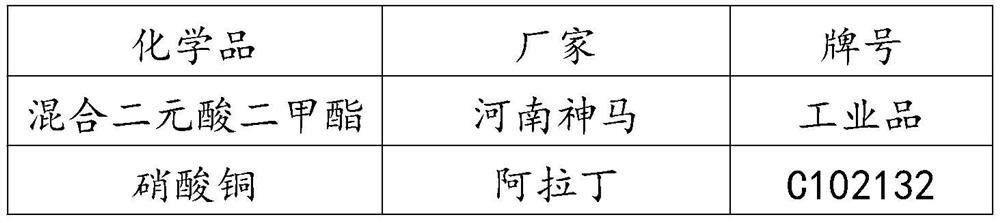

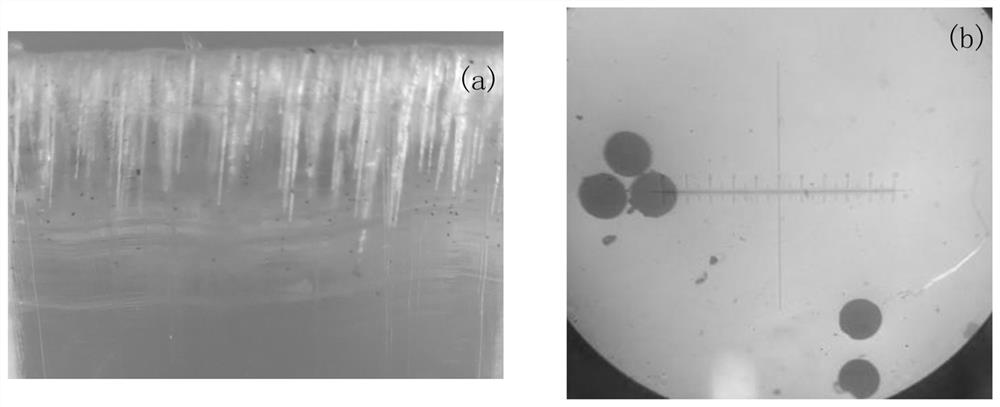

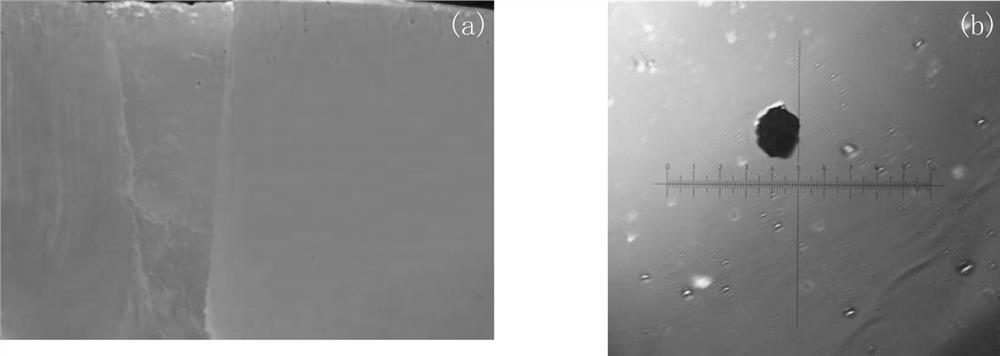

Modified supported copper-rhenium bimetal catalyst and preparation method and application thereof

ActiveCN109731581AGood dispersionImprove surface cleanlinessOrganic compound preparationHydroxy compound preparationRheniumChemical composition

The invention discloses a modified supported copper-rhenium bimetal catalyst, comprising an active body, an active aid, an alkaline aid and a supporter. The chemical composition of the active body isCuxRe(1-x)O, wherein x is 0.7-0.9. A preparation method of the catalyst herein is provided; the preparation method includes: (1) dissolving a copper-bearing compound, a rhenium-bearing compound, an active aid precursor and an alkaline aid precursor in water to obtain a mixed saline solution, dispersing the supporter in the mixed saline solution to obtain a slurry; (2) dropwise adding an alkaline precipitating agent into the slurry, adjusting pH of the slurry to 7-9, aging to obtain a slurry, wherein the temperature is controlled to 60-90 DEG C during dropwise adding; (3) post-treating the slurry to obtain the modified supported copper-rhenium bimetal catalyst. The preparation method and application of the modified supported copper-rhenium bimetal catalyst are provided herein; the modifiedsupported copper-rhenium bimetal catalyst provided herein has better reaction activity and diol selectivity.

Owner:WANHUA CHEM GRP CO LTD

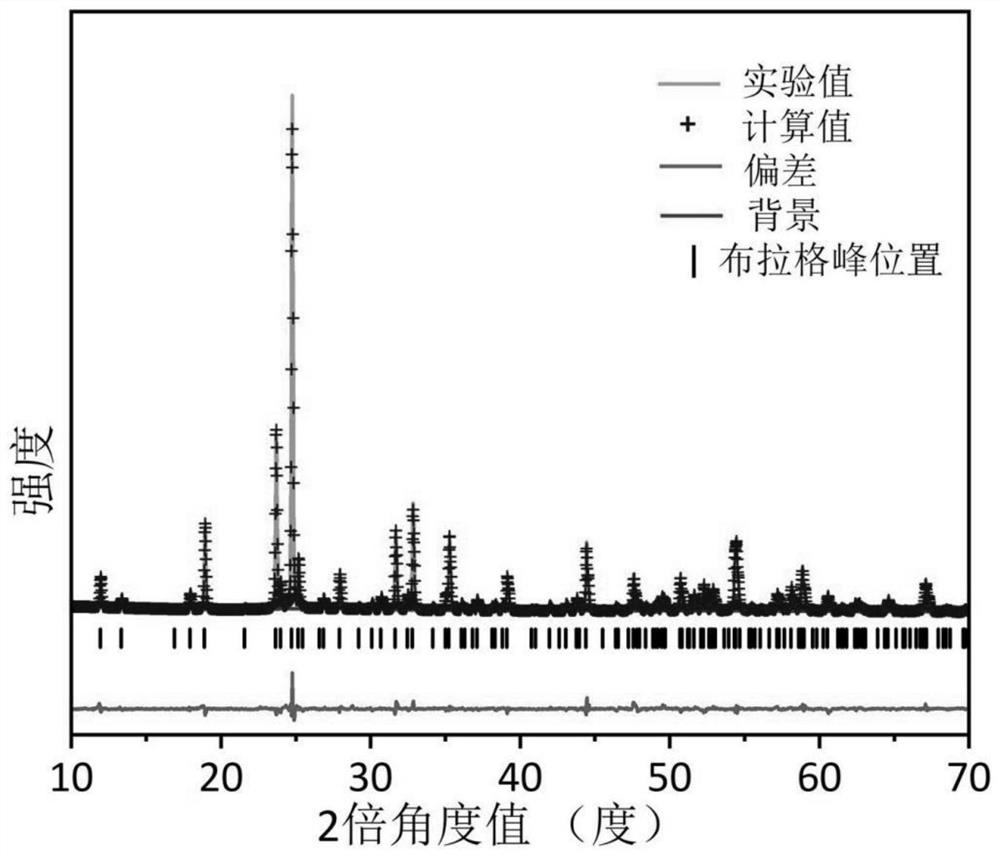

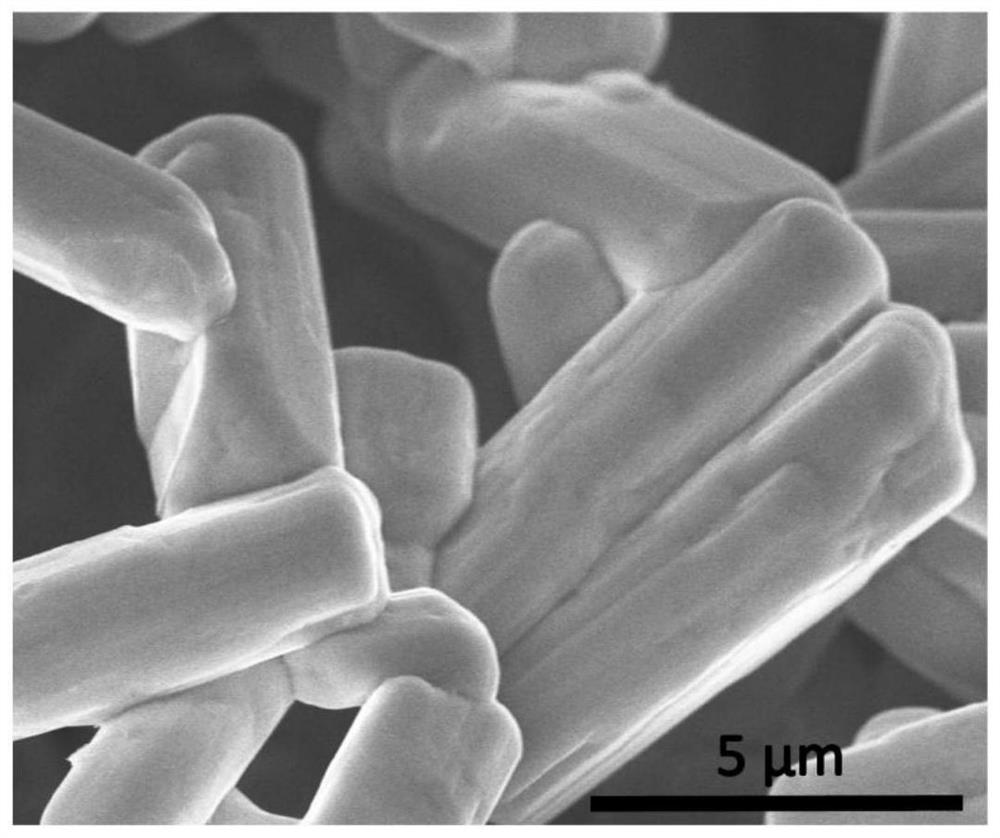

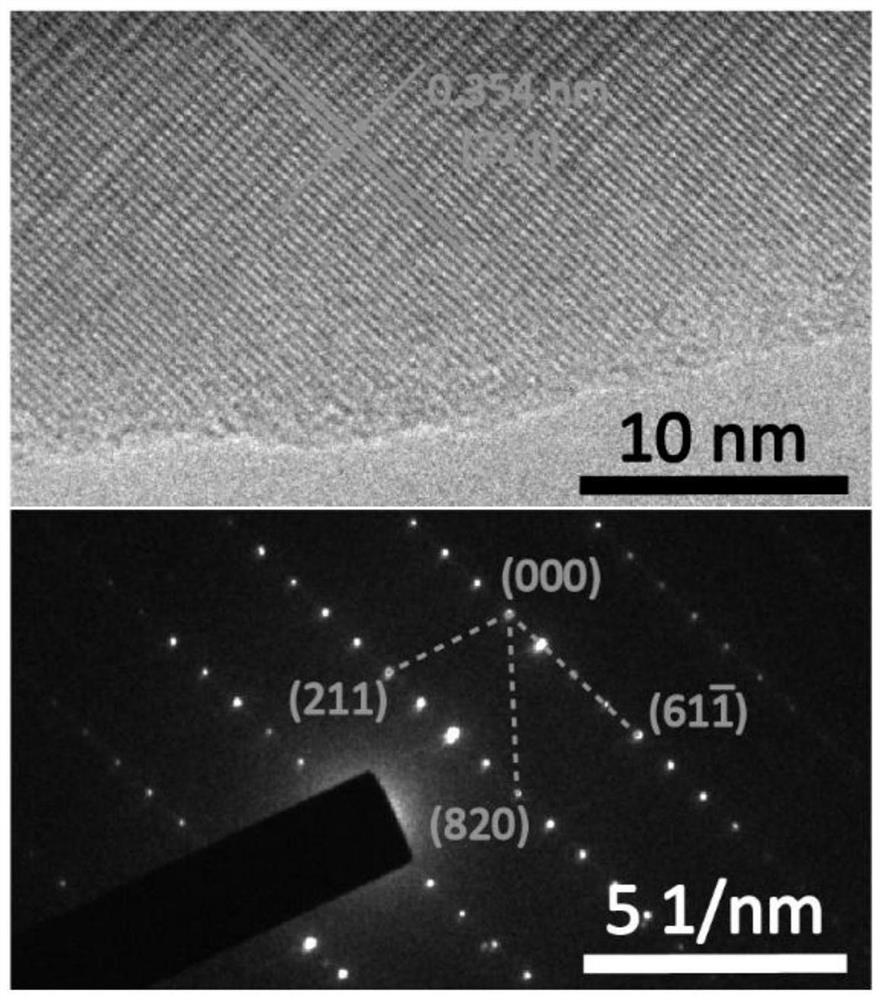

Niobium tungstate material for high-safety lithium ion battery as well as preparation method and application of niobium tungstate material

InactiveCN112397709APromote circulationHigh capacity retentionCell electrodesSecondary cellsTungstic acidTungstate

The invention belongs to the technical field of material synthesis and energy, and discloses a niobium tungstate material for a high-safety lithium ion battery as well as a preparation method and application of the niobium tungstate material. The molecular formula of the niobium tungstate material is Nb14W3O44, and the niobium tungstate material is prepared by uniformly mixing hydrated niobium oxalate, ammonium metatungstate and fuel in inorganic acid, carrying out self-propagating combustion reaction at the temperature of 1050-1250 DEG C in an air atmosphere and then carrying out calcinationreaction at the temperature, wherein the fuel is more than one of glycine, urea or glucose. The Nb14W3O44 material prepared by the method has excellent cycle performance, the capacity can be kept at 215.9 mAh g<-1> after 200 cycles at 0.5 C, and the capacity retention rate is as high as 98.1%. The electrochemical stability of the electrode material is obviously superior to that of a conventional Nb14W3O44 material synthesized by a solid-phase method and that of a commercial Li4Ti5O12 material.

Owner:GUANGDONG UNIV OF TECH

A kind of methane catalytic combustion catalyst and preparation method thereof

ActiveCN107262093BGuaranteed high temperature stabilityHigh catalytic activityHeterogenous catalyst chemical elementsDispersed particle separationOxygen vacancyActive component

The invention provides a methane catalytic combustion catalyst and a preparation method thereof. The catalyst includes a carrier and an active component loaded on the carrier. The outer part of the active component is coated with a coating layer that provides oxygen vacancies for it. The catalyst is also Including the catalytic promoter cerium-zirconium solid solution, on the one hand, by coating the coating layer on the outside of the active component, it is beneficial for the oxygen molecules stored in the coating layer to be transferred to the active component in time, thereby maintaining the active component of the catalyst. high temperature stability; on the other hand, the catalyst of the present invention also includes a catalytic promoter cerium-zirconium solid solution, which can generate more oxygen vacancies, and can store and release oxygen in time and effectively, thereby also improving the catalyst activity group. In addition, the cladding layer, the cerium-zirconium solid solution and the carrier are dispersed and contacted with each other, which plays a mutual barrier effect, inhibits the sintering of the carrier, and improves the high-temperature thermal stability and catalytic activity of the catalyst.

Owner:FUZHOU UNIV +1

Rare earth toughened solid silica aerogel

Owner:TIANJIN LANGHUA TECH DEV CO LTD

A preparation method of surface functionalized molybdenum carbide-carbon catalyst for carbon dioxide hydrogenation reaction

ActiveCN107138171BAvoid sintering and agglomerationLarge specific surface areaCatalyst activation/preparationGraphite carbonFreeze-drying

The application discloses a preparation method of a surface-functionalized molybdenum carbide-carbon catalyst for a carbon dioxide hydrogenation reaction. The preparation method mainly comprises the following steps: firstly, using deionized water as a solvent, uniformly mixing sodium alginate with an ammonium molybdate solution, and then putting a mixed solution into a freeze drying oven for carrying out freeze drying; secondly, carrying out high-temperature roasting in an inert atmosphere to obtain porous graphite carbon-inlaid high-dispersibility molybdenum carbide; thirdly, mechanically lapping the prepared porous graphite carbon-inlaid high-dispersibility molybdenum carbide and urea, putting a lapped material into a muffle furnace, and carrying out annealing treatment to obtain the surface-functionalized molybdenum carbide-carbon catalyst. The catalyst prepared by the preparation method has the characteristics of large specific surface area, abundant pore structures and high dispersibility, and shows good catalytic activity and selectivity in the carbon dioxide hydrogenation reaction.

Owner:CHONGQING TECH & BUSINESS UNIV

Titanium silicalite molecular sieve and modification method and application thereof

ActiveCN113457734AAchieve activationEasy to follow upOrganic chemistryMolecular sieve catalystsMolecular sievePetrochemical

The invention discloses a titanium silicalite molecular sieve and a modification method and application thereof, and belongs to the technical field of petrochemical engineering, and the modification method comprises the following steps: 1, pretreating the titanium silicalite molecular sieve, then mixing the pretreated titanium silicalite molecular sieve with silane and alkali metal hydroxide, and then carrying out ball milling treatment to obtain the titanium silicalite molecular sieve subjected to ball milling treatment; 2, uniformly dispersing the ball-milled titanium silicalite molecular sieve in an alkali solution, and then performing reacting at the temperature of 80-160 DEG C for 3-18 hours to obtain a primarily modified titanium silicalite molecular sieve; 3, in an inert gas atmosphere, carrying out heat preservation on the primarily modified titanium silicalite molecular sieve at the temperature of 500-800 DEG C for 4-36 hours to complete modification of the titanium silicalite molecular sieve. The modification method provided by the invention is simple to operate, and the prepared titanium silicalite molecular sieve has strong hydrophobicity, titanium species are not easy to lose, the stability is good, and the catalytic performance in propylene and hydrogen peroxide gas phase epoxidation reaction is good.

Owner:XIAN AERONAUTICAL UNIV

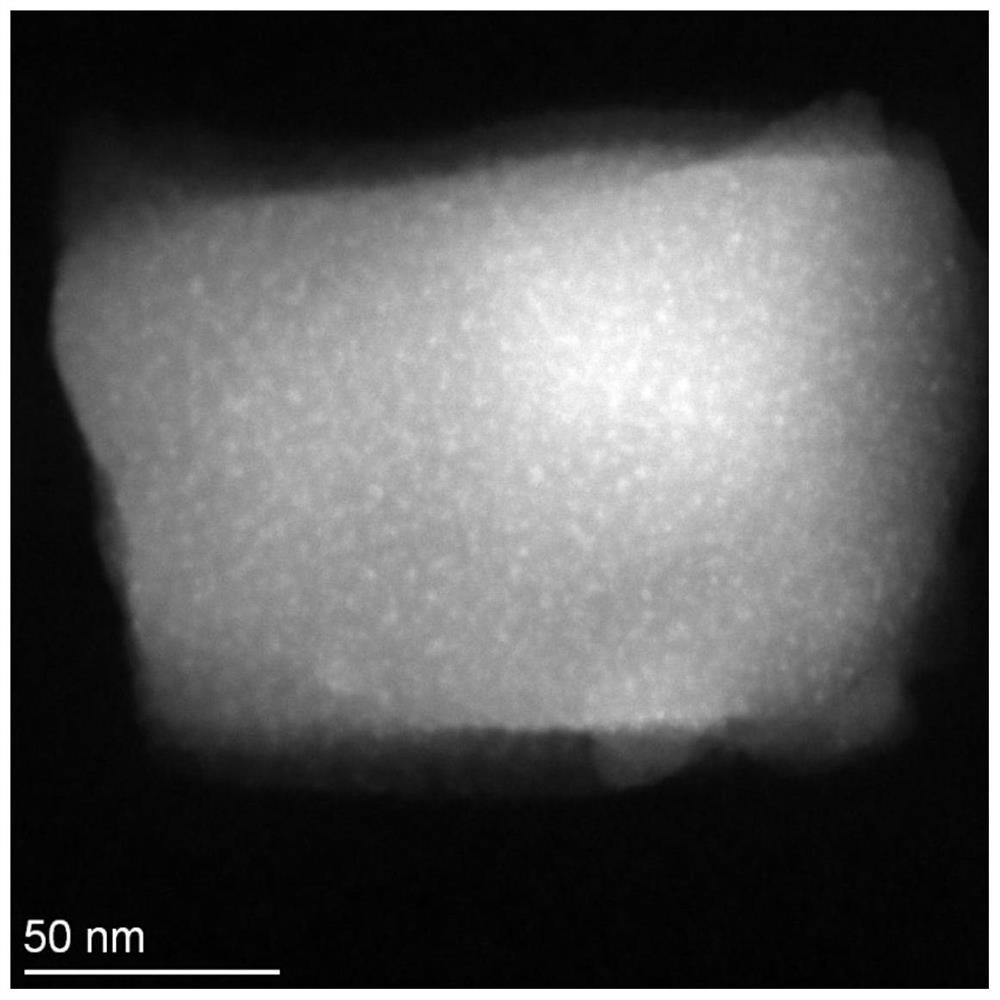

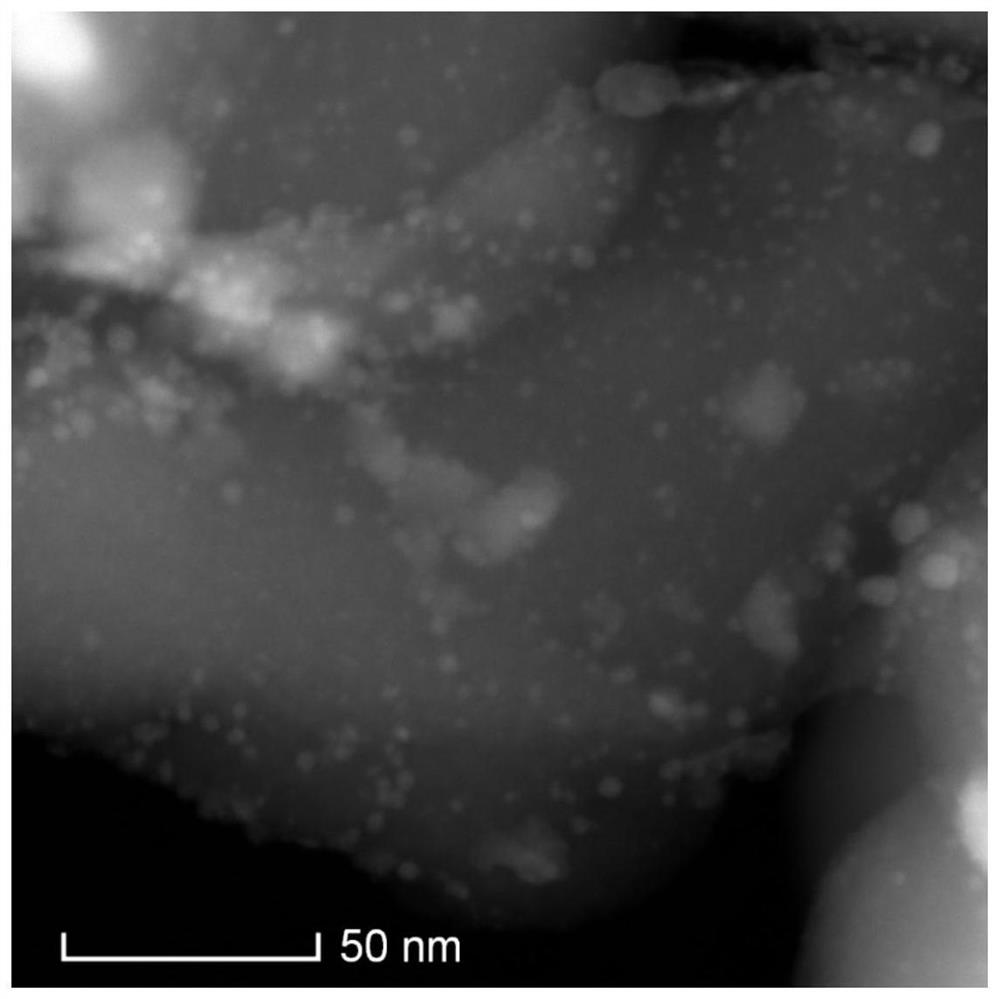

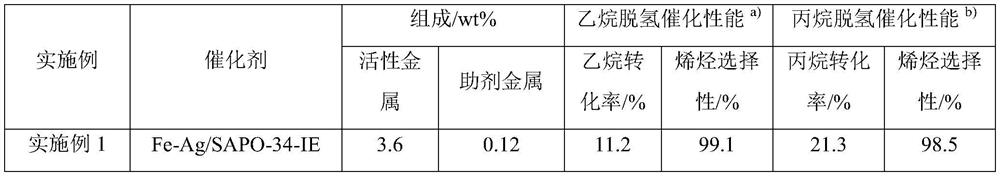

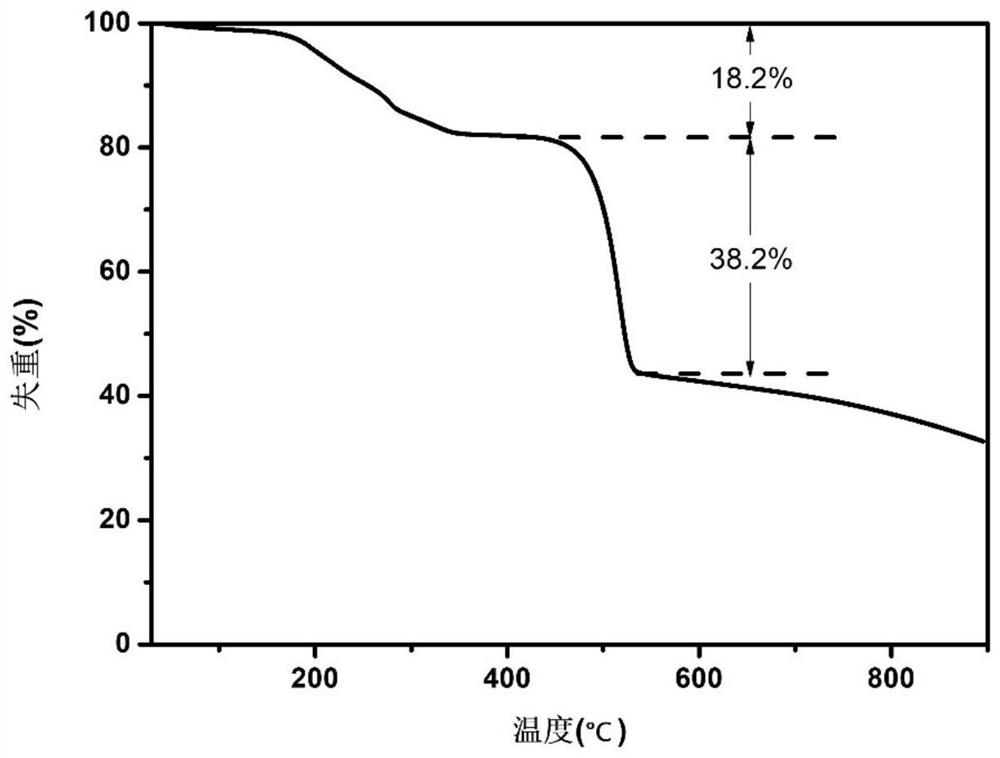

A kind of low-carbon alkane dehydrogenation catalyst and its preparation method and application

ActiveCN111569937BImprove stabilityStable structureMolecular sieve catalystsCatalyst activation/preparationAlkaneMolecular sieve

The invention discloses a low-carbon alkane dehydrogenation catalyst, a preparation method and application thereof, and belongs to the field of low-carbon alkane chemical utilization. The catalyst prepared by the present invention is one or more than two kinds of active metals in Fe, Co, Ni, Ru, Rh and Pd, one or more than two kinds of auxiliary agents and SAPO‑34, 3A, 5A and 4A molecular sieves The carrier is composed of, wherein the active metal component accounts for 0.5-10% of the mass of the catalyst, the auxiliary metal component accounts for 0.01-2% of the mass of the catalyst, and the balance is the carrier. The catalyst prepared by the preparation method of the invention can effectively catalyze low-carbon alkanes (C2-C6) to generate olefin products, has high conversion rate of alkanes per pass, selectivity of olefins in the range of 97-99.5%, and has very good stability. The catalyst preparation method of the invention is relatively simple and has industrial application prospects.

Owner:JIANGNAN UNIV

Preparation method of denitrification catalyst carrier titanium dioxide

ActiveCN106268730BLow impurity contentLarge specific surface areaCatalyst activation/preparationTitanium dioxideAcetic acidFiltration

The invention discloses a preparation method of a denitration catalyst carrier TiO2. The preparation method comprises the following steps: firstly, preparing TiO2 used as a raw material into metatitanic acid by adopting a sulfuric acid method, and preparing the metatitanic acid into a suspension, and adjusting the pH of the suspension to be not more than 1; then, drop by drop adding a titanous sulfate solution, and performing filtration and washing; then anew preparing obtained filter residues into a suspension, and adjusting the pH value of the suspension to be 7.5+ / -0.5 by ammonia water, and performing filtration and washing; then anew preparing obtained filer residues into a suspension again, and adjusting the pH value of the suspension to be 6.5 to 7.0 by acetic acid, and then performing filtration and washing; and carrying out low-temperature vacuum drying on the suspensions processed through the above-mentioned steps; finally, cooling and grinding to form powder. According to the invention, the existing preparation method of the denitration catalyst carrier TiO2 is improved, and the TiO2 preparation method which has simple process and does not require high-temperature heating is put forward, furthermore, the obtained product is high in quality and the high catalytic efficiency of a denitration catalyst is ensured.

Owner:ADANA FOOD TECH LIUZHOU

Solid acid-bimetallic nanoparticle composite material as well as preparation method and application thereof

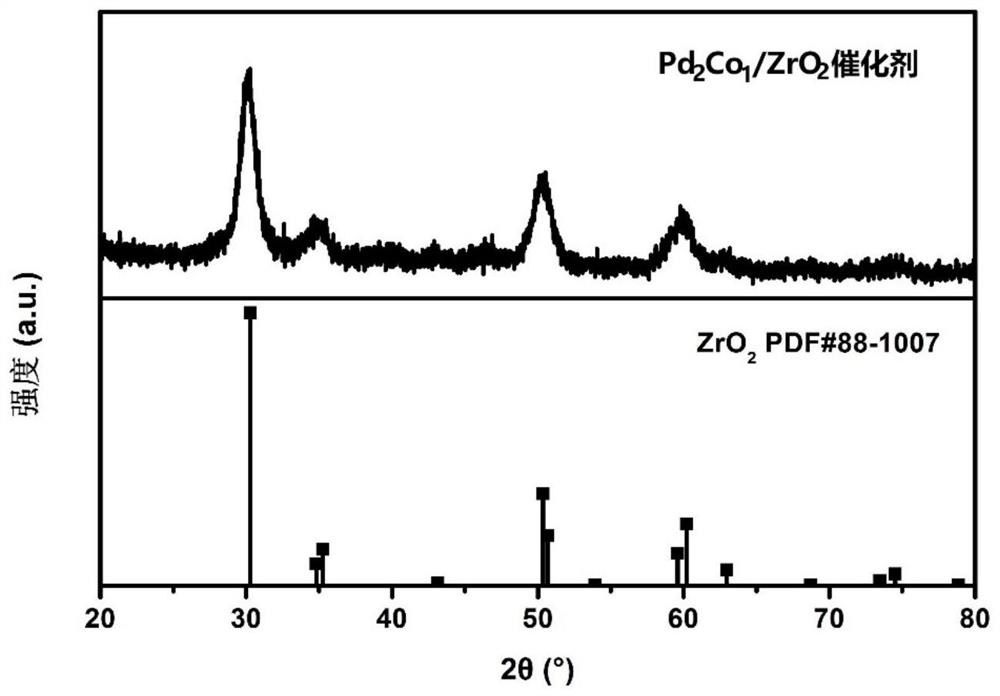

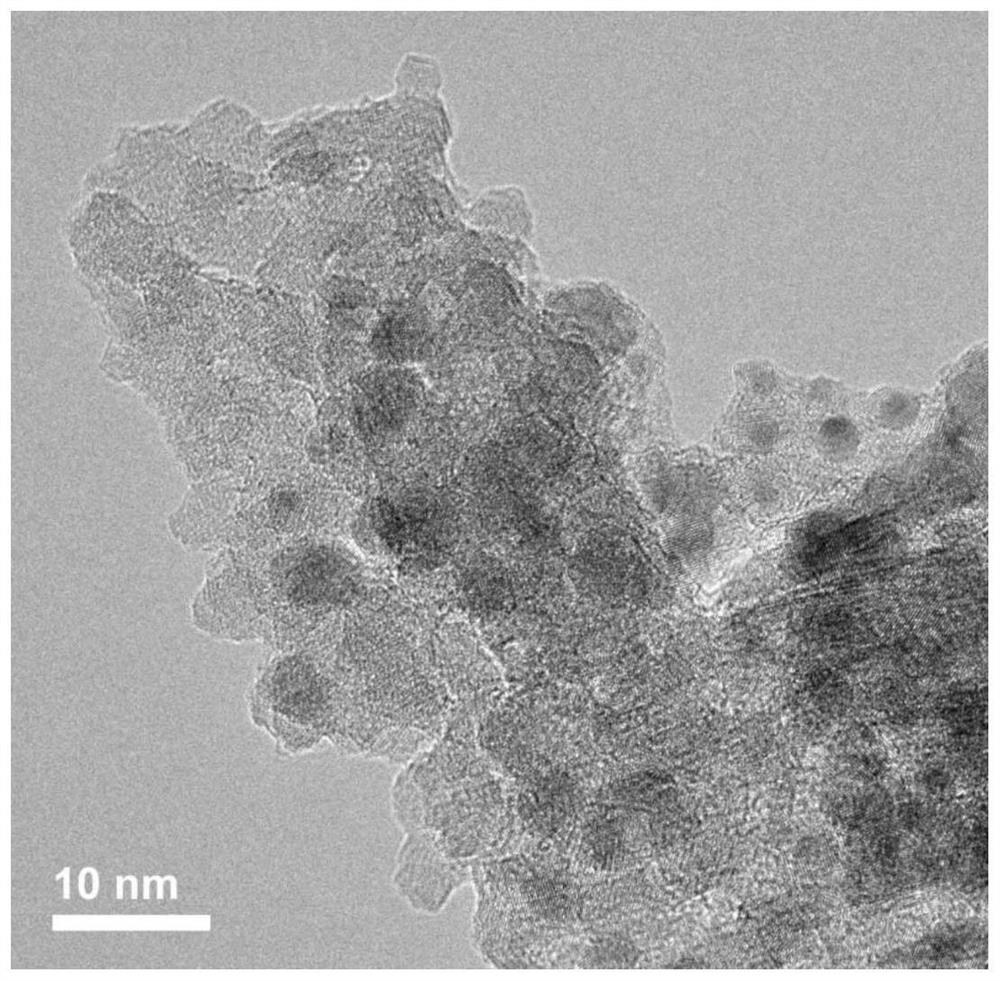

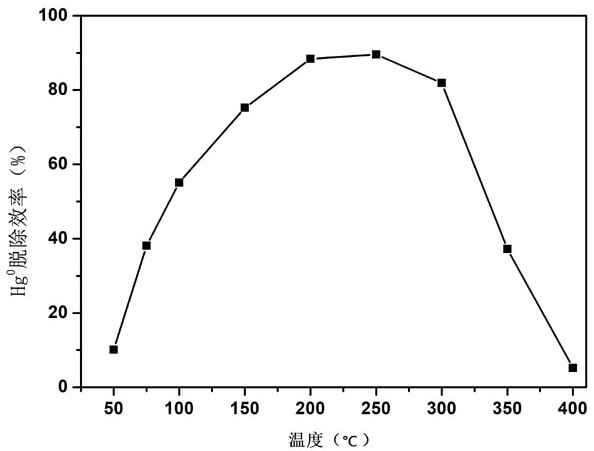

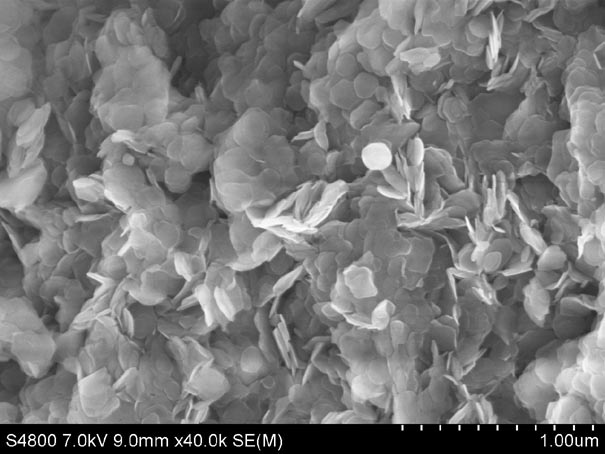

PendingCN114405518AHigh catalytic activityGood stabilityGas treatmentDispersed particle separationAlloy nanoparticlePyrolysis

The invention discloses a solid acid-bimetallic nanoparticle composite material as well as a preparation method and application thereof. The composite material disclosed by the invention is prepared from Pd-Co bimetallic alloy nanoparticles and a solid acid carrier ZrO2. The preparation method comprises the following steps: 1) dispersing zirconium salt, a polydentate carboxylic acid ligand and acid in an organic solvent, and carrying out solvothermal reaction to obtain a UiO-67-H material; 2) dissolving a palladium salt and a cobalt salt in a solvent, adding the UiO-67-H material, and carrying out a coupling coordination reaction to obtain a UiO-67-H immobilized PdCo salt material; and (3) the UiO-67-H immobilized PdCo salt material is subjected to a temperature programmed reduction pyrolysis reaction in a reducing atmosphere, and the solid acid-bimetallic nanoparticle composite material is obtained. The composite material can resist chlorine poisoning, has high catalytic activity and good stability, and is suitable for catalytic oxidation of chlorine-containing volatile organic pollutants.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

A kind of preparation method of denitrification and mercury removal integral filter material

ActiveCN108926911BUniform Load CouplingAvoid sintering and agglomerationDispersed particle filtrationFiltration separationPtru catalystDust control

Owner:YANCHENG ENVIRONMENTAL ENG TECH RES & DEV CENT TSINGHUA UNIV

Anti-sintering treatment method for heavy metal particles

ActiveCN112047794BAvoid sintering and agglomerationWell mixedTransportation and packagingMetal-working apparatusExplosive AgentsMetallurgy

Owner:ZHONGBEI UNIV +1

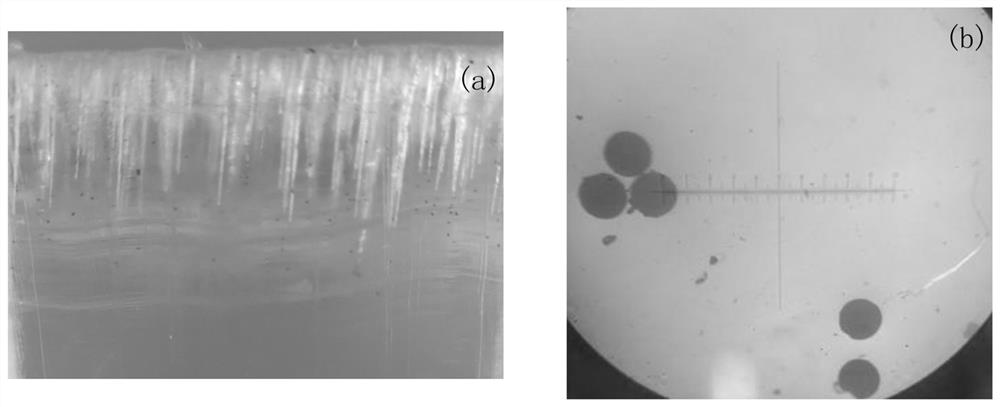

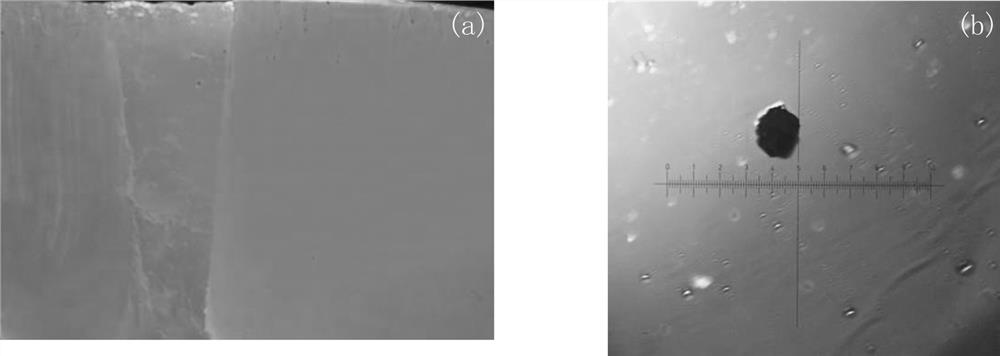

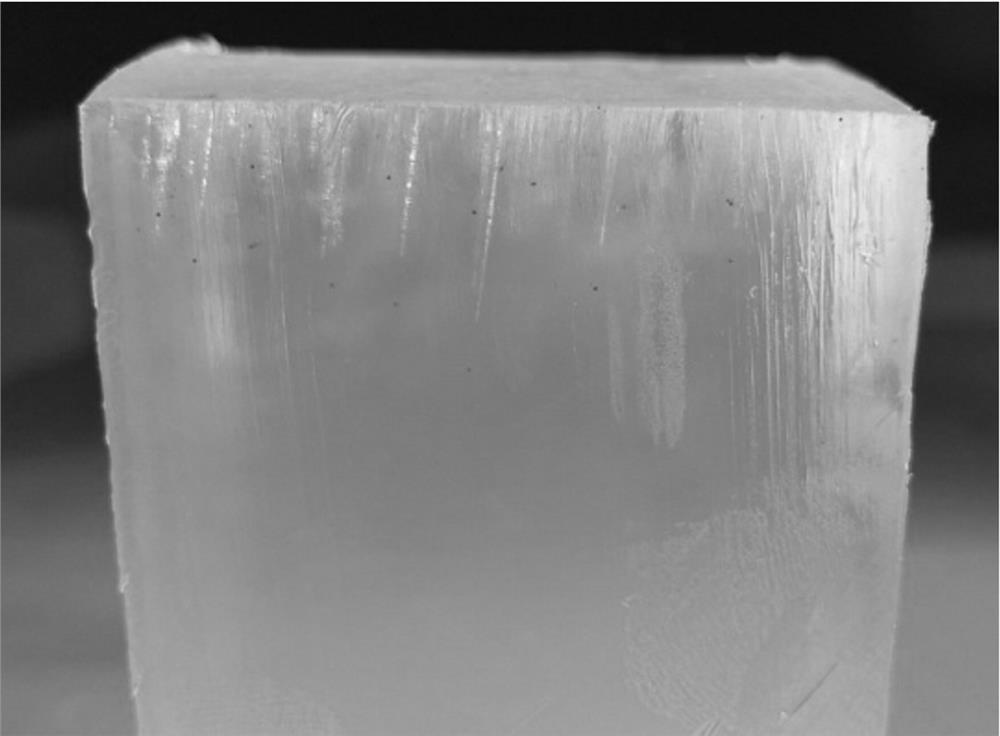

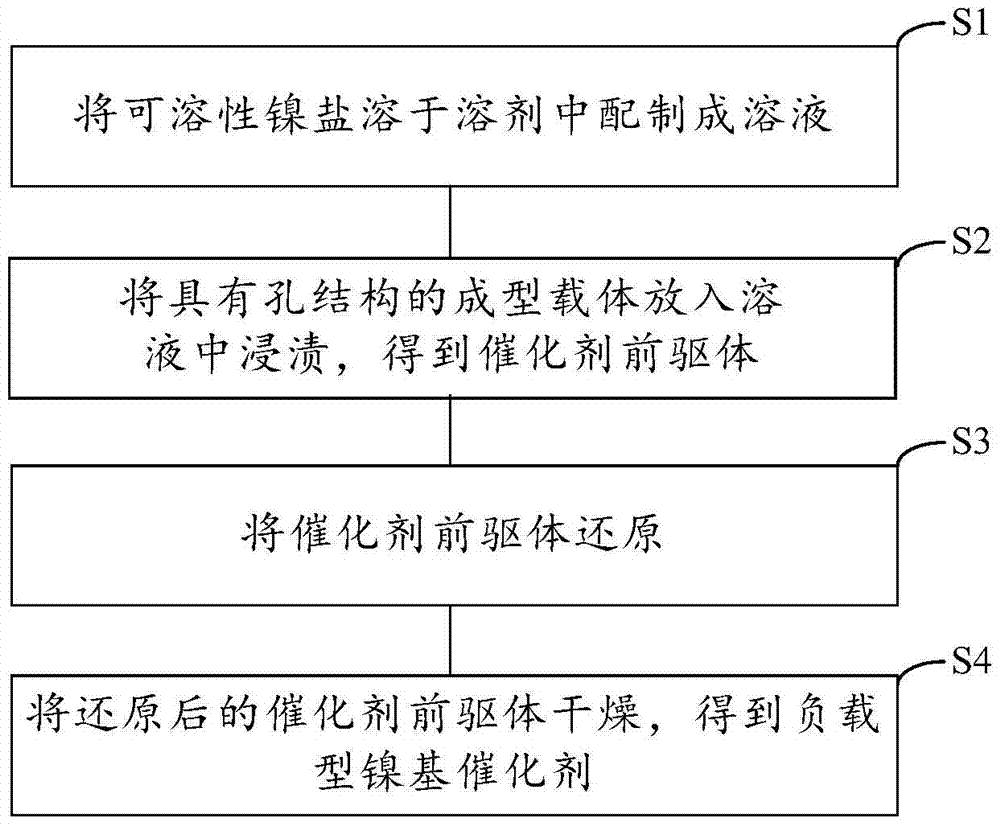

A kind of preparation method of supported nickel-based catalyst

ActiveCN104801333BAffects catalytic performanceImprove catalytic performanceHydrogenMolecular sieve catalystsNickel saltBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a supported nickel-based catalyst, relates to the technical field of catalysts, and can improve the dispersion degree of active components and avoid sintering of the active components, thereby improving the catalytic performance of the catalyst. The preparation method of the supported nickel-based catalyst disclosed by the present invention comprises the following steps: 1) dissolving soluble nickel salt in a solvent to prepare a solution; 2) impregnating a shaped carrier with a pore structure in the solution to obtain a catalyst precursor ; 3) reducing the catalyst precursor; 4) drying the reduced catalyst precursor to obtain a supported nickel-based catalyst. The preparation method of the supported nickel-based catalyst disclosed by the invention is suitable for the preparation of the catalyst in methane reforming to produce synthesis gas.

Owner:ENN SCI & TECH DEV

Modified supported copper-rhenium bimetallic catalyst and its preparation method and application

ActiveCN109731581BGood dispersionImprove surface cleanlinessOrganic compound preparationHydroxy compound preparationPtru catalystChemical composition

Owner:WANHUA CHEM GRP CO LTD

A method for preparing waterborne epoxy coating used for an inner compartment of a ship

InactiveCN109535925AAvoid sintering and agglomerationRegular shapeEpoxy resin coatingsPolyester coatingsEmulsionOxide

A method for preparing waterborne epoxy coating used for an inner compartment of a ship is disclosed. The method includes fully mixing aluminum nitrate, zinc borate, polyvinyl alcohol 6000 and water;adding ammonia water dropwise under stirring until the pH value of the system is 8-8.4; stirring the mixture to obtain a white emulsion suspension; performing a hydrothermal reaction, centrifugation,washing, drying, calcination and cooling to obtain a material a; stirring bisphenol A type epoxy resin, bisphenol F type epoxy resin, epoxy alkyd resin, and trimethylhexamethylenediamine to obtain a material b; and stirring the material b, the material a, nanometer talc powder, vermiculite powder, diatomite, fly ash, zinc oxide, zinc phosphate, polyethylene glycol, a film forming auxiliary agent,an antibacterial agent, a dispersing agent, an anti-mold agent, a defoamer, a wetting agent and water to obtain the coating.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Anti-sintering treatment method of heavy metal particles

ActiveCN112047794AAvoid sintering and agglomerationWell mixedTransportation and packagingMetal-working apparatusExplosive AgentsMetallurgy

The invention discloses an anti-sintering treatment method of heavy metal particles, which comprises the following steps: by using heavy metal particles as damage elements, uniformly mixing with a molten anti-sintering agent, carrying out hot sieving granulation, and cooling to obtain the anti-sintering heavy metal particles. Tthe anti-sintering agent is any one or a mixture of more of stearic acid, calcium stearate and paraffin in any proportion. The anti-sintering heavy metal particles obtained through the anti-sintering treatment method have good formability and can be conveniently pressedinto a low-attached damage ammunition embedded layer, the heavy metal particles serving as damage elements are scattered in a single particle mode within a certain distance away from an explosion center under explosive loading of explosives. A damage range of the damage element is effectively controlled.

Owner:ZHONGBEI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com