High-activity propylene gas-phase epoxidation catalyst and preparation method thereof

A technology for epoxidation and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of propylene conversion rate less than 2.5%, storage and transportation problems Potential safety hazards, high molybdenum content in catalysts, etc., to improve catalytic activity and stability, reduce cost and environmental pollution, and reduce molybdenum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

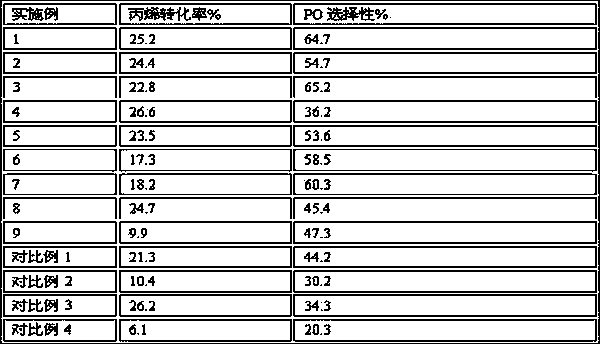

[0023] Embodiment 1: Catalyst TiO 2 -MoO 3 -Bi 2 SiO 5 / SiO 2 (Si / Bi=50, Mo / Bi=3, Ti / Mo=0.3) preparation. Weigh 25g template agent hexadecyltrimethylammonium bromide and dissolve in 3000mL deionized water, stir in an ice-water bath for 1h, then add 520g tetraethyl orthosilicate to the above template agent solution, stir to form solution A, And continue to stir in the ice-water bath for 1h; Weigh 24g of bismuth nitrate and dissolve it in 100mL of 50% by volume glycerin aqueous solution to form solution B; Add solution B dropwise to solution A to form a mixed solution, continue to mix in the ice-water bath Stir for 1 hour, transfer the obtained white emulsion into a 5000mL autoclave with a PTFE substrate, and conduct a hydrothermal reaction at 80°C for 20 hours; wash the obtained white gel with deionized water, and dry at 110°C After 12 hours, the obtained sample was ground and calcined at 550°C for 8 hours to obtain bismuth silicate (Bi 2 SiO 5 ) SiO 2 Mesoporous materi...

Embodiment 2

[0027] Embodiment 2: As in the catalyst system of embodiment 1, the molybdenum precursor used is ammonium dimolybdate, and the titanium precursor is tetraisopropyl titanate, and the amount of the precursor used is the same as that of embodiment 1, and the carrier is synthesized During the process, after adding solution B to solution A, continue to stir at 0°C for 9 hours, the hydrothermal condition for preparing the carrier is hydrothermal reaction at 50°C autogenous pressure for 48 hours, and the ultrasonic vibration impregnation condition for loading active components is at 4°C After 4 hours, the sample loaded with active metals was dried and ground and then calcined at 450° C. for 8 hours. The other reaction conditions were the same as in Example 1. The results of the epoxidation reaction are shown in Table 1.

Embodiment 3

[0028] Embodiment 3: as the catalyst system of embodiment 1, but be Si / Bi=50 by element molar ratio, Mo / Bi=5, the proportioning ratio preparation catalyst TiO of Ti / Mo=0.3 2 -MoO 3 -Bi 2 SiO 5 / SiO 2 , the titanium precursor is tetraisopropyl titanate, which has the same molar weight as that of butyl titanate in Example 1. When preparing the carrier, it was hydrothermally reacted at 100°C for 48 hours under autogenous pressure, and the ultrasonic vibration impregnation conditions when loading active components 0.2h at 30°C, and the other reaction conditions are the same as in Example 1. The content of each component in the catalyst is by mass percentage, and the carrier Bi 2 SiO 5 / SiO 2 79.5%, MoO 3 17.6%, TiO 2 was 2.9%. The results of the epoxidation reaction are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com