Method for inorganic synthesizing submicron CaB6 polycrytal powder

A submicron-scale, synthetic sub-technology, applied in the direction of boron/boride, metal boride, etc., can solve the problems of particle sintering, easy agglomeration, complex reaction route, unsuitable for industrial production, etc., achieve regular particle shape and simple preparation process , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

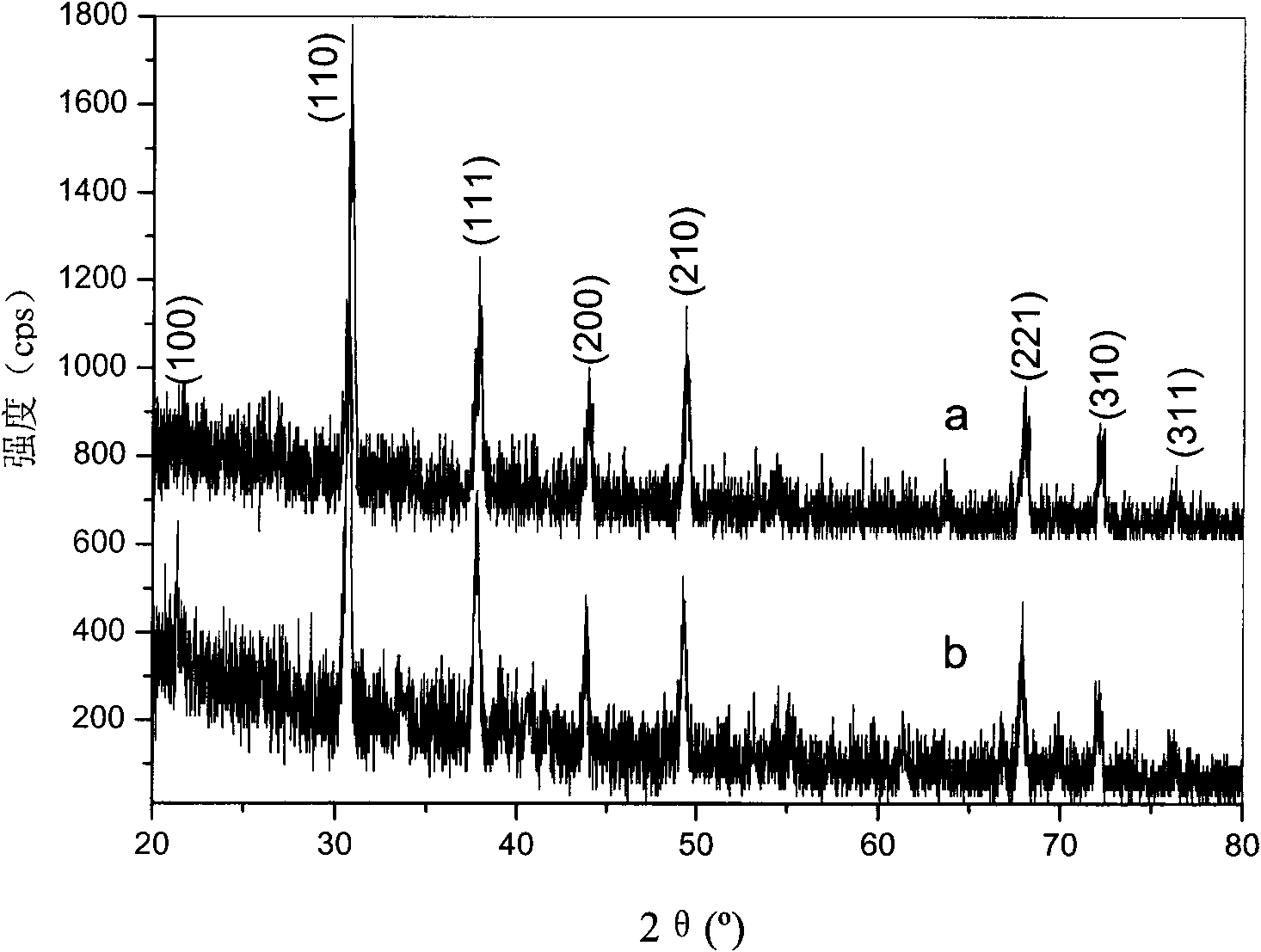

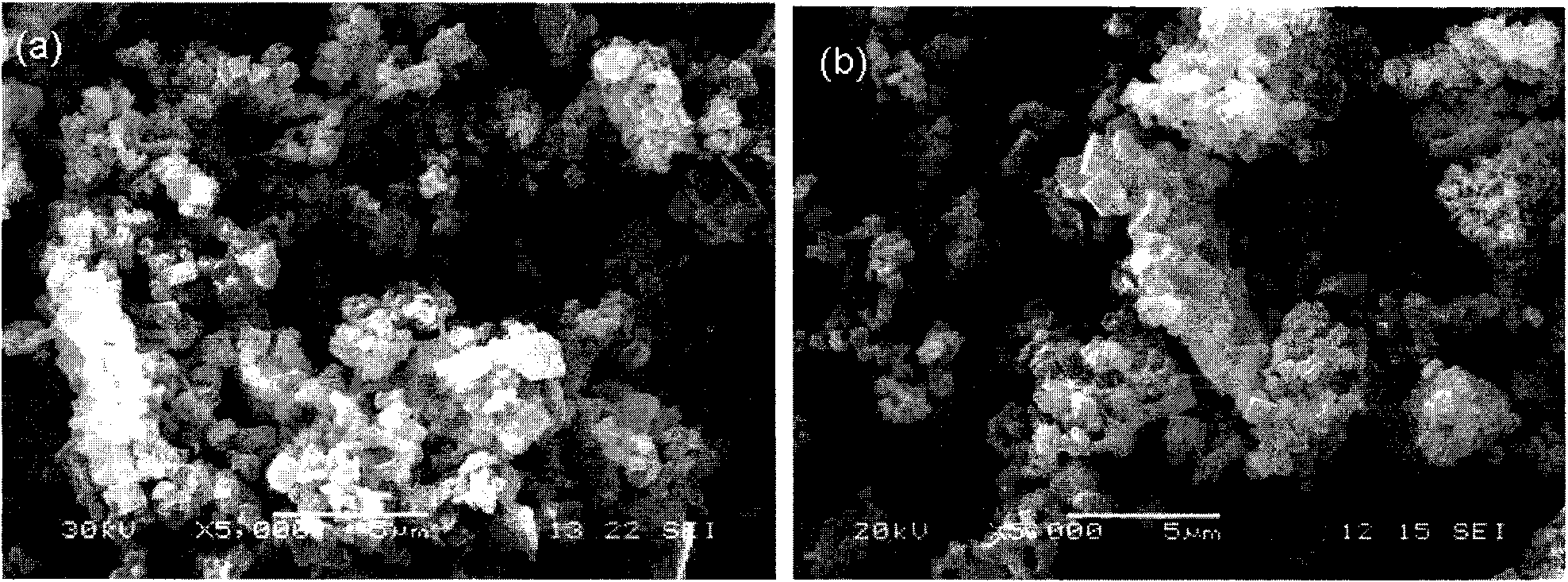

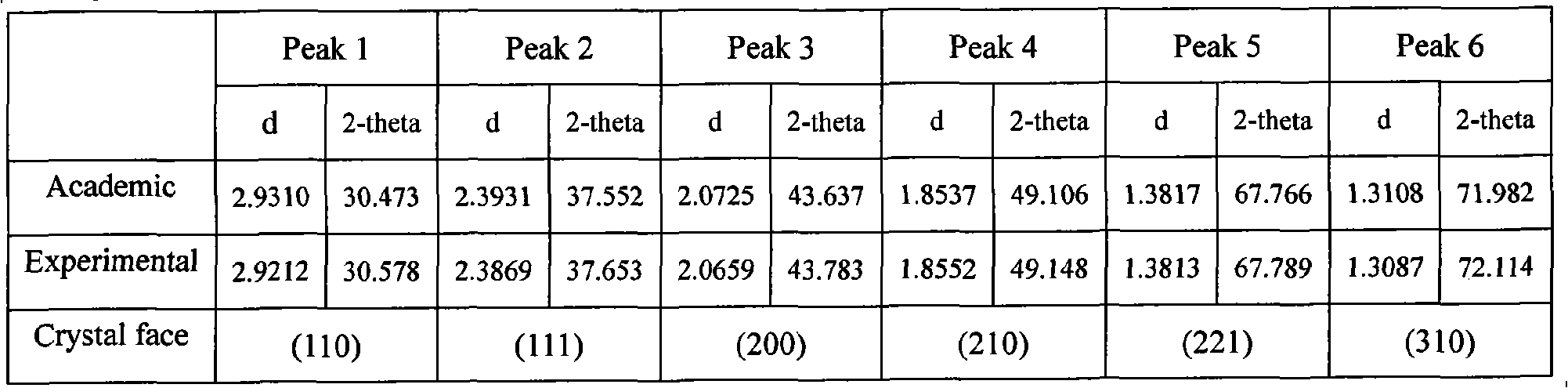

Embodiment 1

[0022] Take 5.29 g of anhydrous CaCl 2 , 11.02 g B 2 o 3 and 12.01 g of Mg powder with anhydrous CaCl 2 , B 2 o 3 And the raw material specification of Mg powder is: anhydrous CaCl 2 The particle size range is 380-400 mesh, B 2 o 3 The particle size range is 150-180 mesh, the Mg particle size range is 150-180 mesh, except B 2 o 3 is an industrial raw material, CaCl 2 , Mg powder and other reagents are all analytical reagents. After fully mixing, add the stainless steel reaction tank, put the reaction tank into an Ar atmosphere protection heating furnace, keep it at 750 ° C for 20 minutes, and then cool it naturally. Open the tank and process and collect the product. The product is first soaked in 2.5M dilute hydrochloric acid and stirred for 30 minutes to dissolve impurities such as magnesium oxide, then suction filtered and washed with water to remove water-soluble impurities such as magnesium chloride. The filter cake is dried at 80°C for 8 hours, and finally 4.87 ...

Embodiment 2

[0024] Take 3.52 grams of Ca(OH) 2 , 11.04 g B 2 o 3 and 15.02 grams of Mg powder, of which Ca(OH) 2 , B 2 o 3 And the raw material specification of Mg powder is: Ca(OH) 2 The particle size range is 200-250 mesh, B 2 o 3 The particle size range is 250-280 mesh, the Mg particle size range is 250-280 mesh, except B 2 o 3 In addition to industrial raw materials, Ca(OH) 2 , Mg powder and other reagents are analytical reagents, fully mixed and then added to the stainless steel reaction tank. The reaction tank was put into an Ar atmosphere protection heating furnace, kept at 800° C. for 10 minutes, and then cooled naturally. Open the tank and process and collect the product. The product is first soaked in 5M dilute hydrochloric acid and stirred for 30 minutes to dissolve impurities such as magnesium oxide, then suction filtered and washed with water to remove water-soluble impurities such as magnesium chloride. The filter cake is dried at 80°C for 20 hours to obtain 4.91 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com