Anti-sintering treatment method for heavy metal particles

A treatment method and heavy metal technology, which is applied in metal processing equipment, explosives, transportation and packaging, etc., can solve the problems of dispersant leakage, influence, and inability to ensure the uniform mixing of heavy metal particles and dispersant, so as to avoid sintering into agglomerates , the effect of controlling the damage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 90g of stearic acid, heat to 80°C and stir to melt, then add 10g of sodium nitrate and stir evenly.

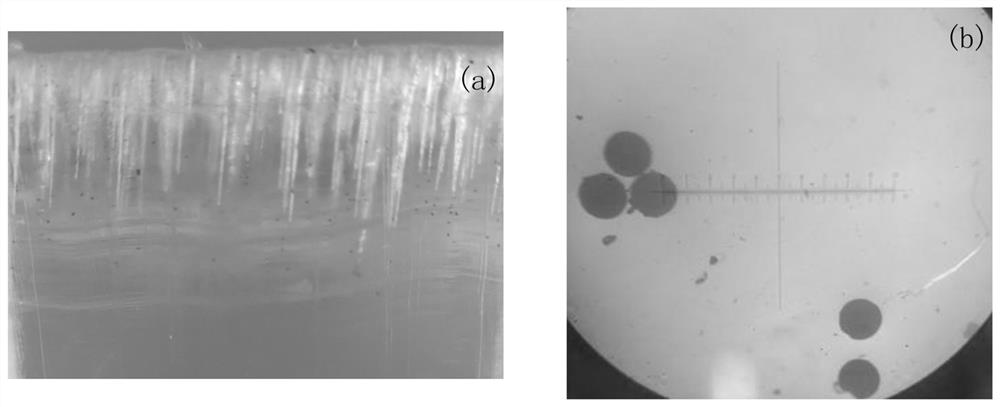

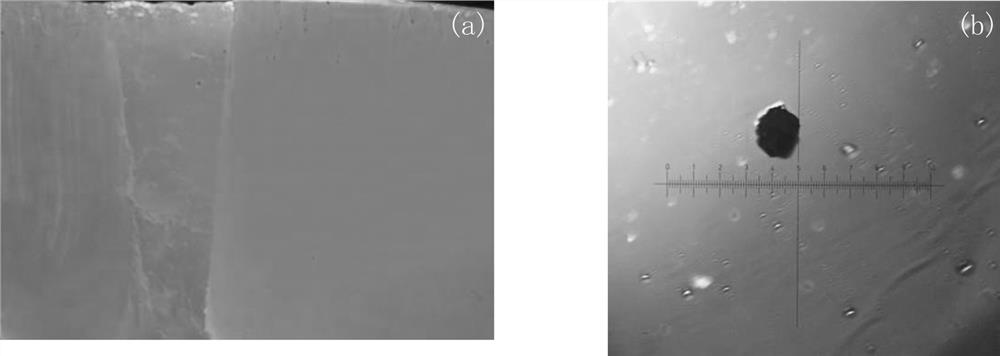

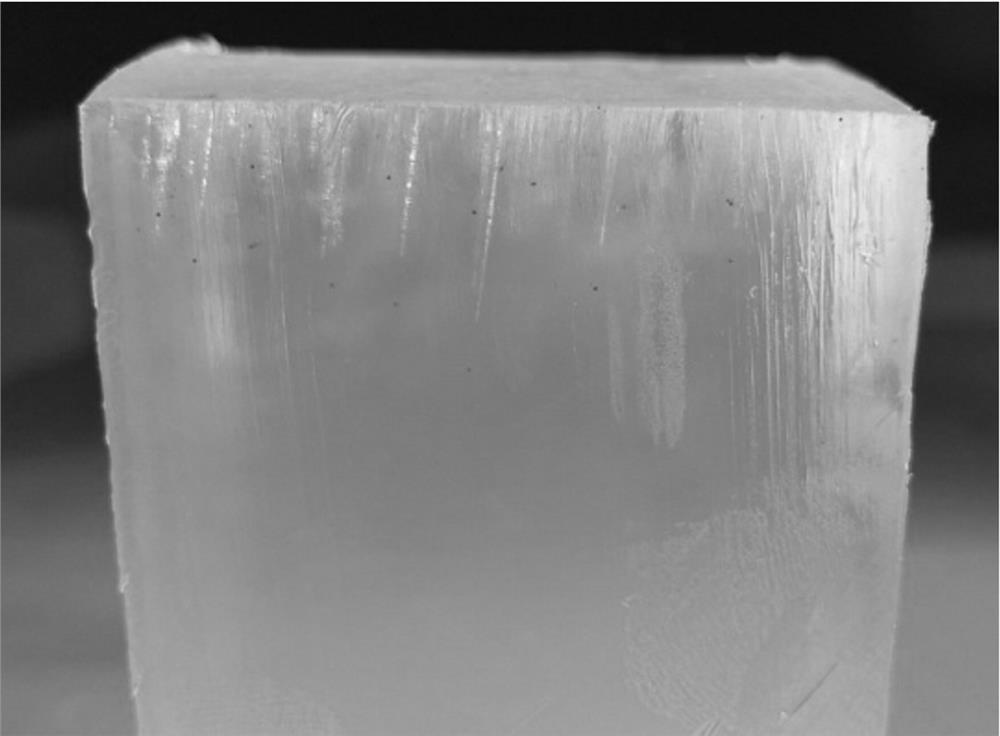

[0026] Weigh 350g of tungsten carbide particles with a particle size of 150-300μm, add them to the above molten mixture, keep the temperature above 70°C, stir and mix evenly, put them in a 20-mesh standard sieve, press with a rubber target, and make them pass through the sieve quickly , After cooling, anti-sintering tungsten carbide particles are obtained.

[0027] The above-mentioned anti-sintering tungsten carbide particles are placed in a forming mold, and pressurized and formed by a hydraulic press to obtain a thin-walled cylindrical ammunition insert containing tungsten carbide particles.

[0028] The above-mentioned ammunition embedded layer, high-energy explosive and carbon fiber shell are assembled into a low-collateral damage ammunition, detonated with a detonator and a booster charge, and soap with a Shore hardness of 30-40° is used as a damage element r...

Embodiment 2

[0032] Weigh 92.4g of stearic acid and 13.2g of calcium stearate, mix and stir evenly, heat to 80°C, add 4.4g of potassium nitrate and stir evenly.

[0033] Weigh 330g of nearly spherical tungsten particles with a particle size of 150-200μm, add them to the above molten mixture, keep the temperature above 70°C, stir and mix evenly, place in a 20-mesh standard sieve, press with a rubber target, and make it pass through the sieve quickly After cooling, anti-sintering tungsten particles are obtained.

[0034] The anti-sintering tungsten granules are placed in a molding die, and pressurized by a hydraulic press to obtain a thin-walled cylindrical ammunition insert containing tungsten granules.

[0035] The above-mentioned ammunition embedded layer, high-energy explosive and carbon fiber casing are assembled into a low collateral damage ammunition, detonated with a detonator and a booster charge, and soap with a Shore hardness of 50° is used as a damage element receiving target, an...

Embodiment 3

[0039] Weigh 65.1g of paraffin and 9.3g of calcium stearate, mix and stir evenly, heat to 80°C, add 13.1g of sodium nitrate and stir evenly.

[0040] Weigh 350g of tungsten carbide particles with a particle size of 150-300μm, add them to the above molten mixture, keep the temperature above 70°C, stir and mix evenly, put them in a 20-mesh standard sieve, press with a rubber target, and make them pass through the sieve quickly , After cooling, anti-sintering tungsten carbide particles are obtained.

[0041] The above-mentioned anti-sintering tungsten carbide particles are placed in a forming mold, and pressurized and formed by a hydraulic press to obtain a thin-walled cylindrical ammunition insert containing tungsten carbide particles.

[0042] The above-mentioned ammunition embedded layer, high-energy explosive and carbon fiber shell are assembled into a low-collateral damage ammunition, detonated with a detonator and a booster charge, and soap with a Shore hardness of 30-40° i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com