Preparation method of ultrafine copper powder for conductive paste

A technology of ultra-fine copper powder and conductive paste, applied in the direction of coating, etc., can solve the problems of low tap density and crystallinity of copper powder, sintering and agglomeration of copper powder, and achieve good oxidation resistance, prevention of sintering and agglomeration, and good topographical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

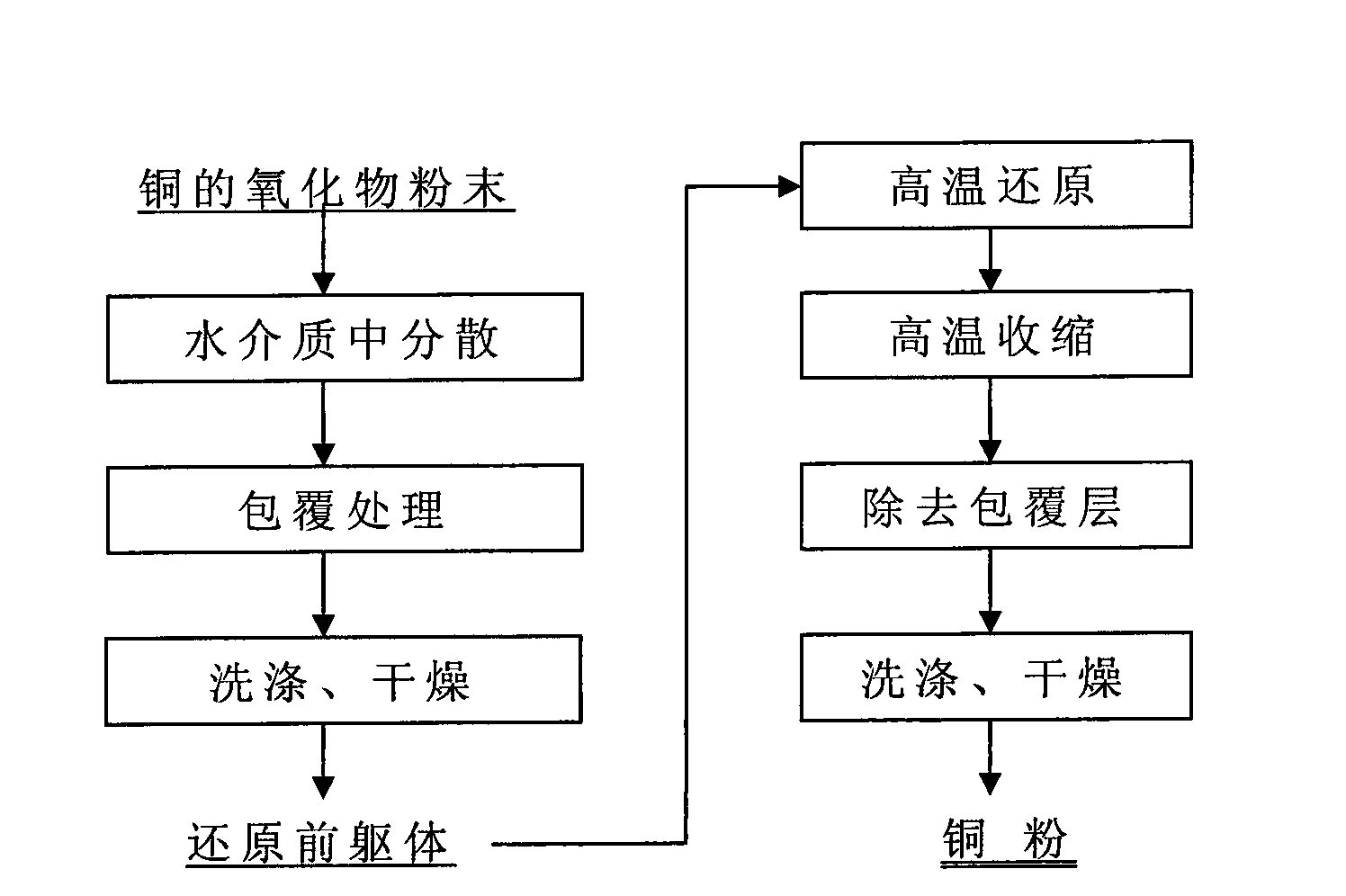

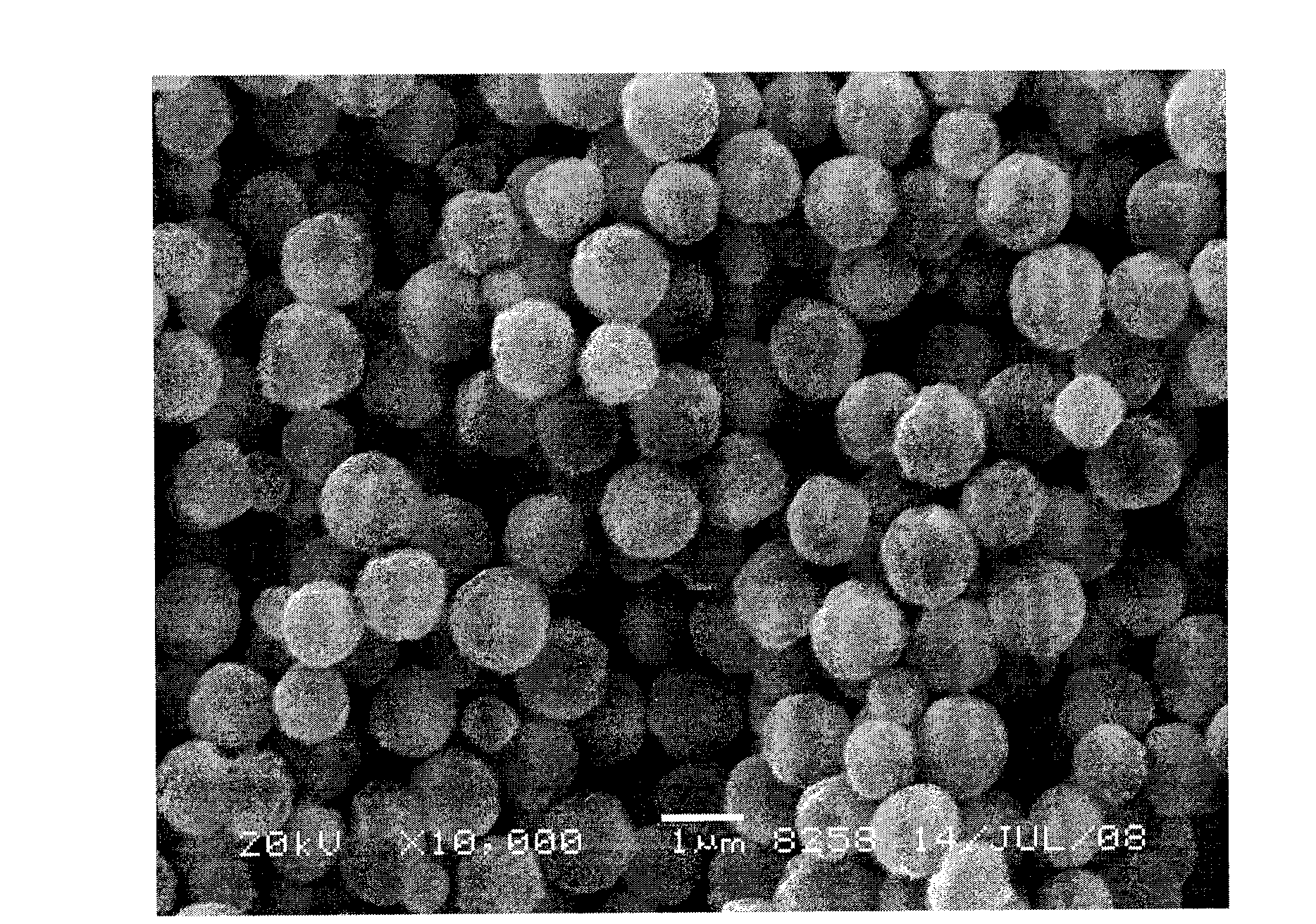

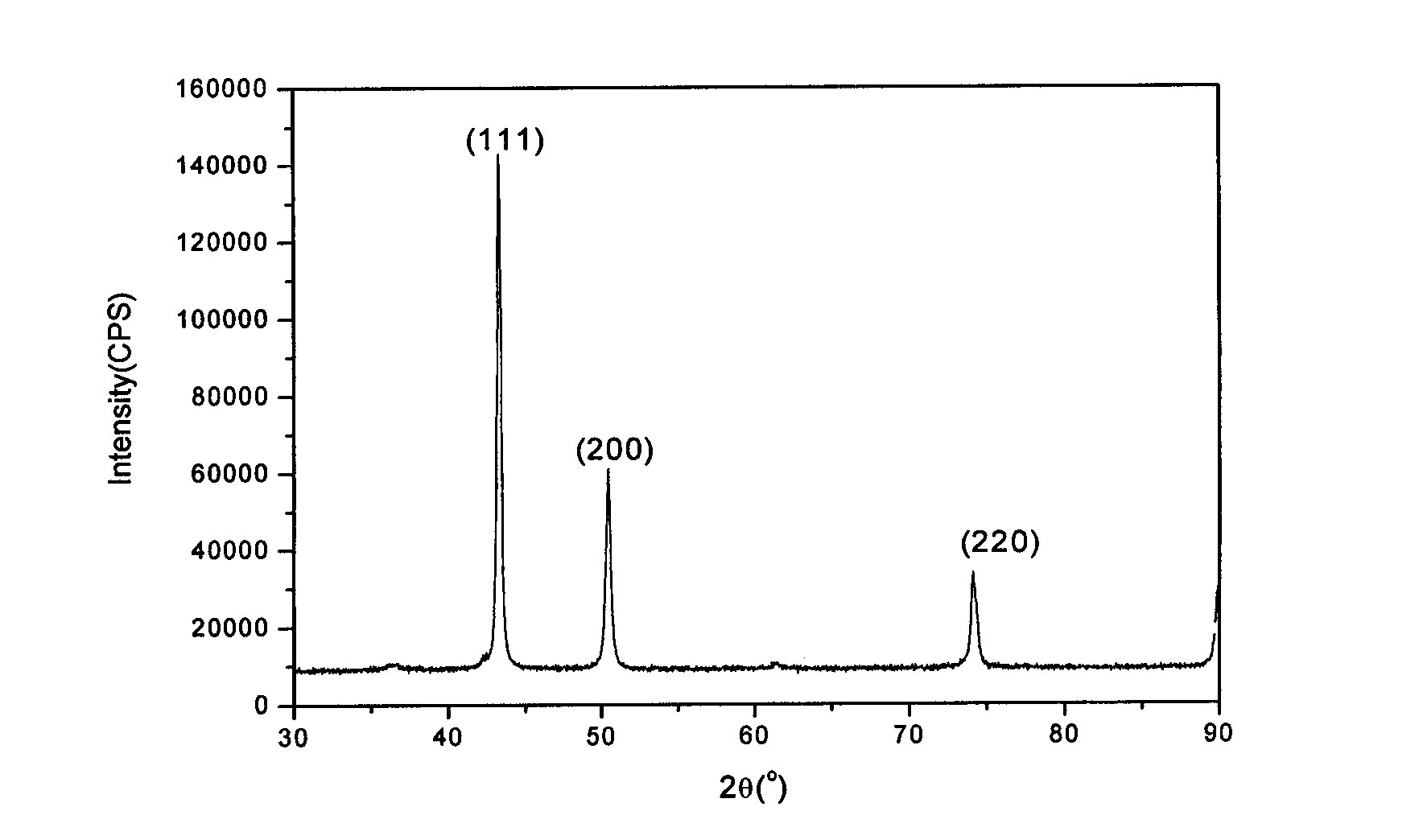

[0024] see figure 1 , uniformly disperse 15g of spherical cuprous oxide powder with an average particle size of 1.2μm and good dispersibility and 600mL of pure water in the reactor, and mix 6g / L MgCl 2 About 250mL of aqueous solution was slowly added to the reactor, and continued to stir, and then slowly added dropwise 2.5mol / L NaOH solution to adjust the pH value of the reaction system to above 10, and continued to stir for 30min. 2 During the generation process, it is precipitated and coated on the surface of cuprous oxide. Solid-liquid separation was performed on the suspension after the coating was completed, the coating was washed several times with pure water, and then dried with absolute ethanol. The dried cladding was placed in a porcelain boat and placed in a tube furnace, and heated with H at a temperature of 150 °C. 2 Reduction for 3 hours, and then heat preservation at 600°C for 1 hour for shrinkage and densification treatment. After the furnace temperature drop...

Embodiment 2

[0026] see figure 1 , uniformly disperse 15g of spherical copper oxide powder with an average particle size of 1μm and good dispersibility and 600mL of pure water in the reactor, and 300mL of Mg(OH) prepared in advance 2 Colloidal solution composed of water (among them, Mg(OH) 2 The content of 5g / L) was slowly added into the reactor, and the coating was continued for 30 minutes with stirring. then use H 2 The reduction temperature is 200°C, the high-temperature shrinkage temperature is 700°C, and other steps are the same as in Example 1 to obtain copper powder. As a result, the copper powder kept the original shape of copper oxide, with an average particle size of 0.8 μm, and it was confirmed that at least 80% of the particles had a particle size between 0.7 and 0.9 μm, with good dispersion and no sintering and agglomeration.

Embodiment 3

[0028] see figure 1 15g of cuprous oxide powder with an average particle size of 1.2μm and good dispersibility and 600mL of pure water were uniformly dispersed in the reactor, and the pre-prepared volume of 300mL of Fe(OH) 3 Colloidal solution composed of water (wherein, Fe(OH) 3 content of 10g / L) was slowly added into the reactor, and the coating was continued for 30 minutes with stirring. then use H 2The reduction temperature is 150°C, the high-temperature shrinkage temperature is 600°C, and other steps are the same as in Example 1 to obtain copper powder. As a result, the copper powder kept the original shape of cuprous oxide, with an average particle size of 1 μm, and it was confirmed that at least 80% of the particles had a particle size between 0.9 and 1.1 μm, with good dispersion and no sintering and agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com