Patents

Literature

62results about How to "Guaranteed high temperature stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

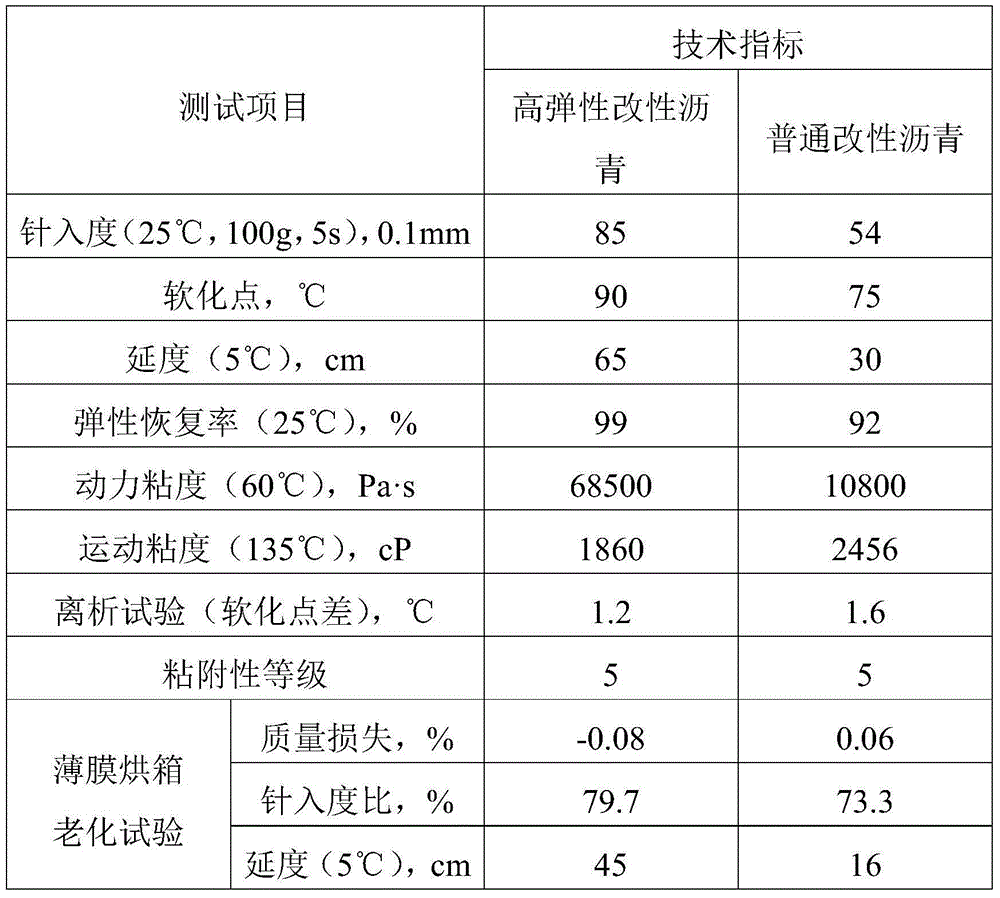

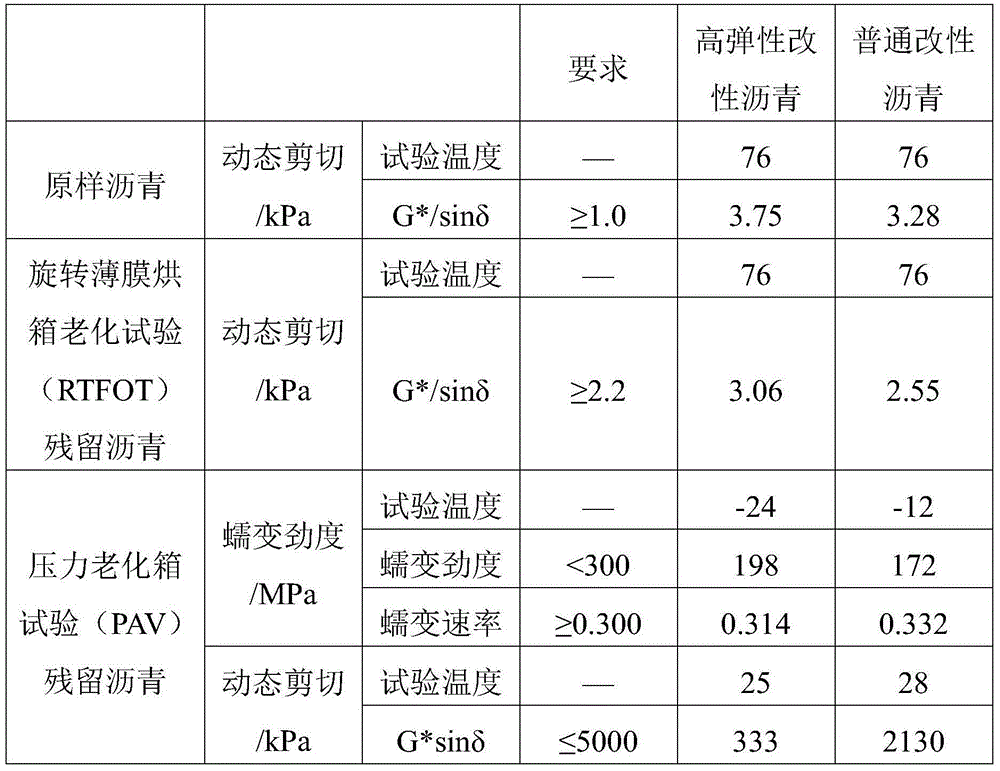

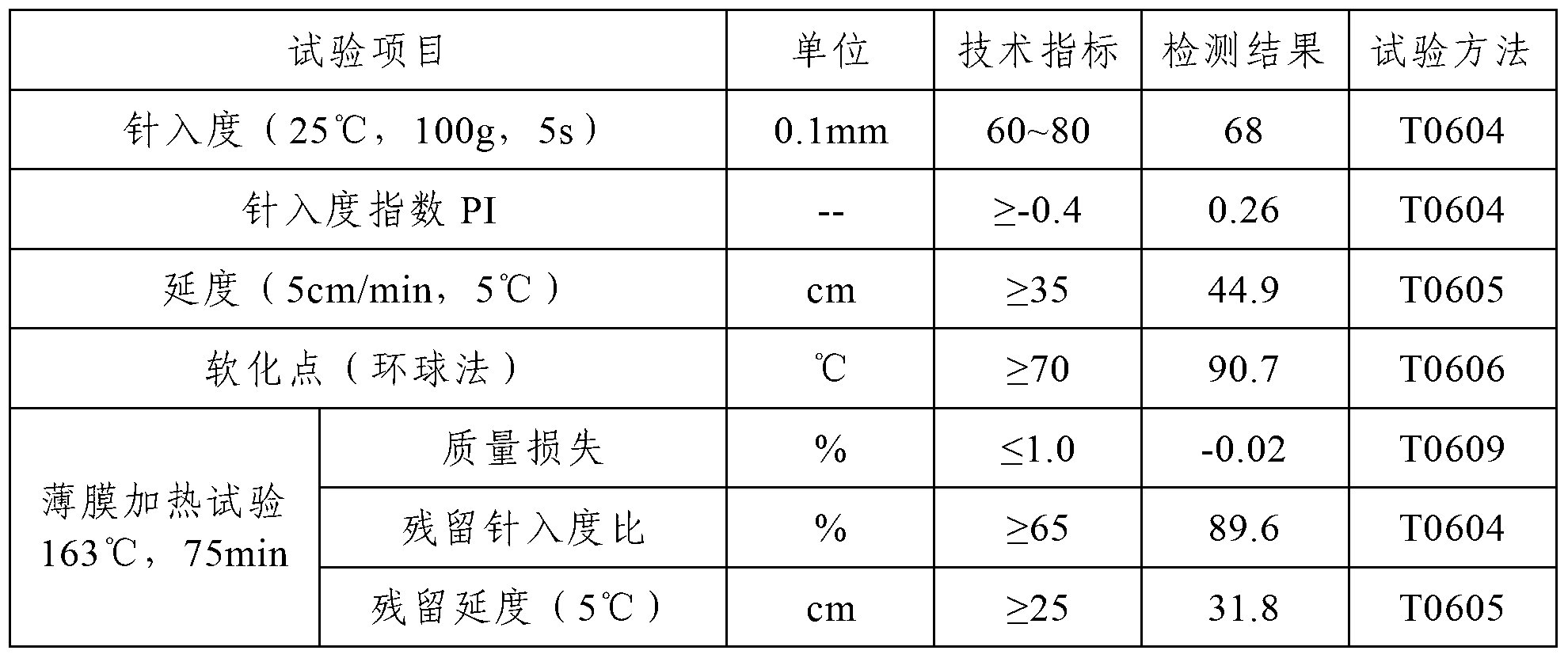

High-elasticity asphalt modified composition, modifier, modified asphalt, modified asphalt mixture and preparation method

ActiveCN104629391AImproved high temperature stability and elastic recoveryReduce melt viscosityBuilding insulationsButadiene-styrene rubberPlasticizer

The invention relates to a high-elasticity asphalt modified composition, a modifier, modified asphalt, a modified asphalt mixture and a preparation method. The modified composition comprises 100 parts of a styrene-butadiene-styrene segmented copolymer, 20-40 parts of a tackifier, 20-40 parts of a softener, 3-8 parts of a warm mixing agent, 15-40 parts of a plasticizer and 2-6 parts of a stabilizer. The preparation method of the modifier comprises the following steps: (1) mixing the styrene-butadiene-styrene segmented copolymer, the tackifier and the warm mixing agent according to a formula to obtain a melt; and (2) mixing the softener, the plasticizer and the stabilizer with the melt, and then extruding, cooling and dicing. The modified asphalt is prepared by doping the modifier into matrix asphalt and uniformly mixing. The modified asphalt mixture is prepared by mixing the modified asphalt and a raw material of a mineral mixture. The modified asphalt provided by the invention has good high-temperature and low-temperature stabilities and anti-fatigue capacity, and the modified asphalt mixture is strong in construction workability and good in pavement performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

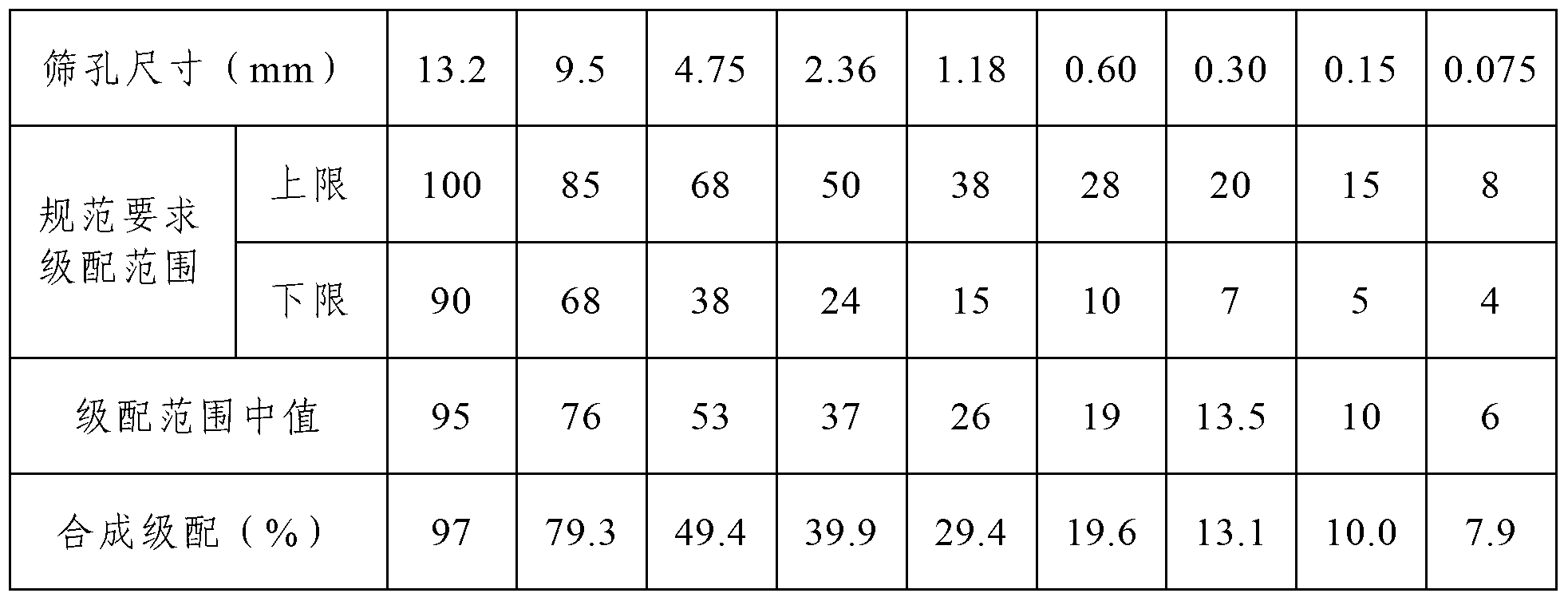

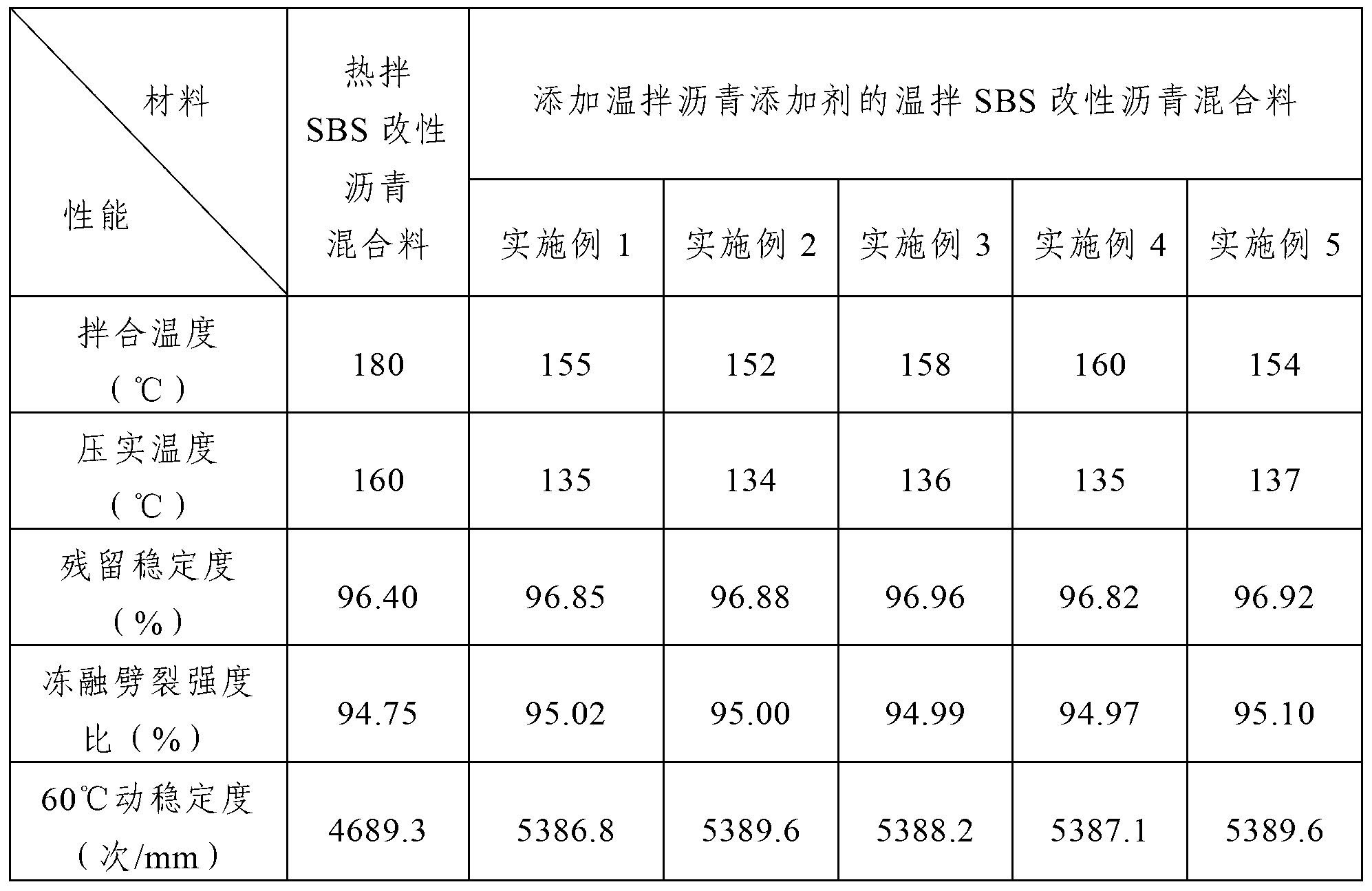

Warm mix asphalt additive and preparation method thereof

ActiveCN103242666AReduce high temperature viscosityReduce the temperatureClimate change adaptationBuilding insulationsChlorinated paraffinsBall mill

The invention provides a warm mix asphalt additive which is prepared from the following raw materials in parts by weight: 15-20 parts of polyethylene wax, 15-20 parts of chlorinated paraffin-70, 30-50 parts of kieselguhr, 1-3 parts of stearamide and 1-4 parts of solid anti-striping agent. The invention further provides a method for preparing the warm mix asphalt additive. The method comprises the following steps of: both grinding the polyethylene wax and stearamide into micro-powder, and subsequently putting the chlorinated paraffin-70, kieselguhr, the solid anti-striping agent and the grinded polyethylene wax and stearamide into a high-speed ball mill to be milled so as to obtain the warm mix asphalt additive. By utilizing the warm mix asphalt additive, the mixing and compressing temperature of an asphalt mixing material can be decreased by more than 20 DEG C on the premise that the property of the asphalt mixing material is not affected, so that the warm mix asphalt additive can be widely applied to asphalt mixing material construction in areas of different climates.

Owner:辽宁奥鹏交通科技集团股份有限公司

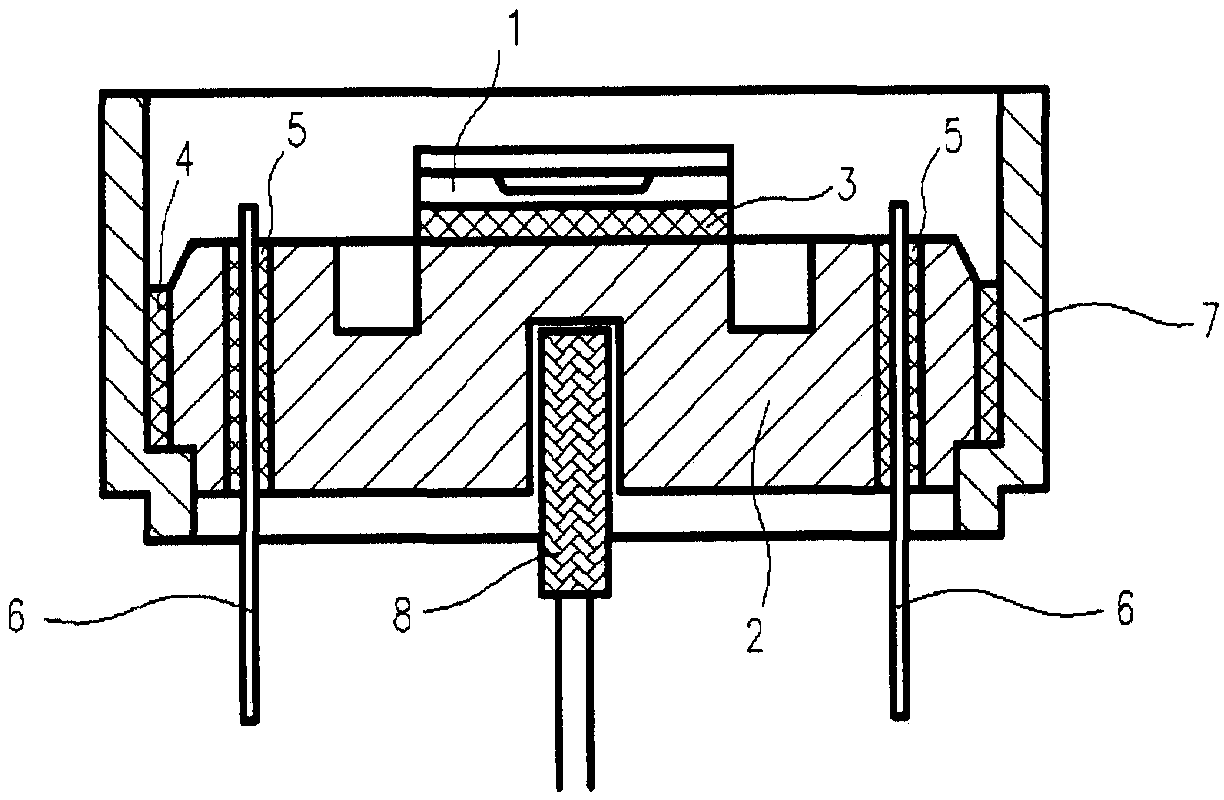

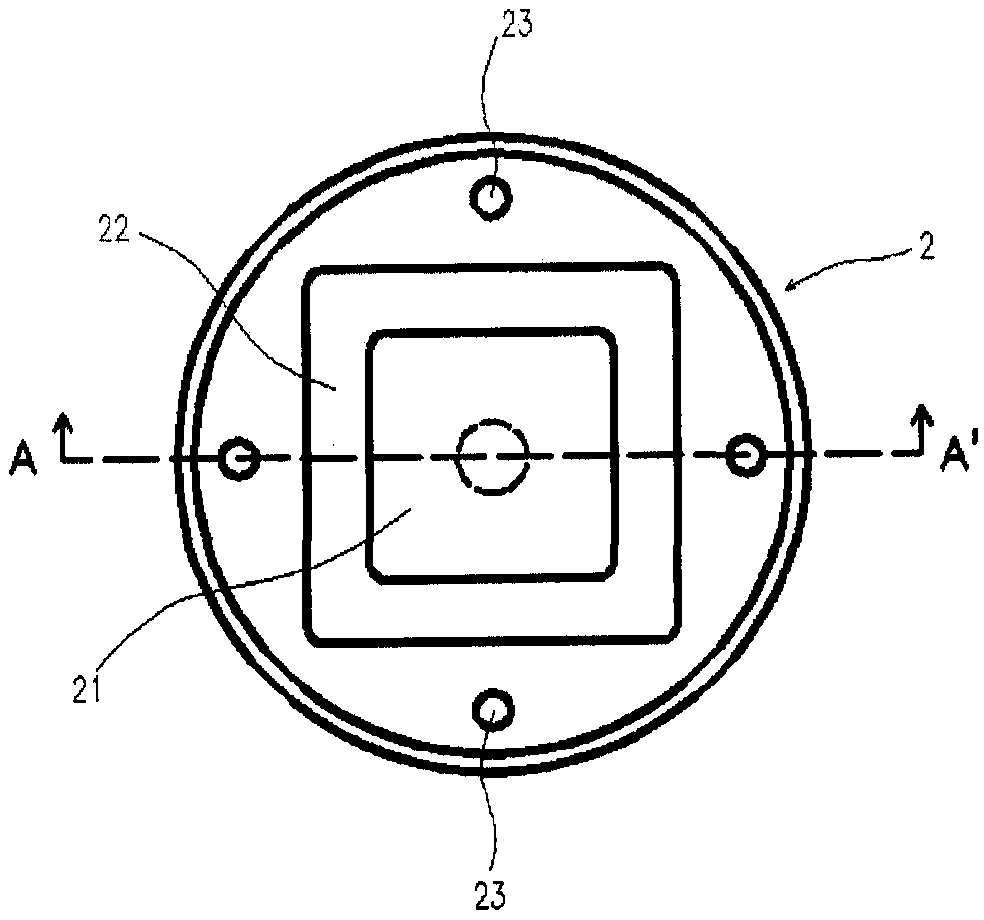

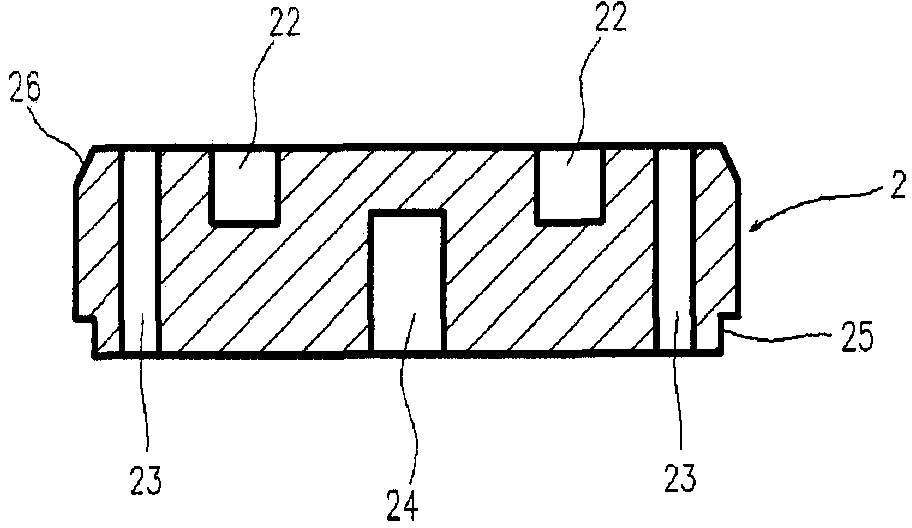

A high temperature pressure sensor packaging structure

ActiveCN106134489BReduce the impactMinimize adverse effects on high temperature performanceSemiconductor/solid-state device detailsSolid-state devicesMems pressure sensorNitrogen

The invention relates to a package structure of a high-temperature pressure sensor, comprising a silicon carbide sensitive chip, an aluminum nitride base, a stress buffer substrate, a high-temperature sealing glass, a lead post, a Kovar outer cover and a thermocouple, wherein the aluminum nitride base is There is a boss on the surface, a stress buffer substrate is placed on the boss, and a silicon carbide sensitive chip is placed on the stress buffer substrate; the periphery of the boss is a stress isolation groove, and there are two or more through holes on the periphery of the stress isolation groove. The column passes through the through hole and is sintered by high-temperature sealing glass to realize the fixed connection between the lead column and the aluminum nitride base. The thermocouple is installed on the lower surface of the aluminum nitride base, and the aluminum nitride base is placed on the Kovar housing through the positioning steps. In addition, the aluminum nitride base and the Kovar cover are sintered and connected through high-temperature sealing glass. The packaging structure is resistant to high temperature, effectively reduces the influence of process stress and high temperature thermal stress on the sensitive chip of the MEMS pressure sensor, and further improves the high temperature measurement accuracy of the sensor.

Owner:BEIJING RES INST OF TELEMETRY

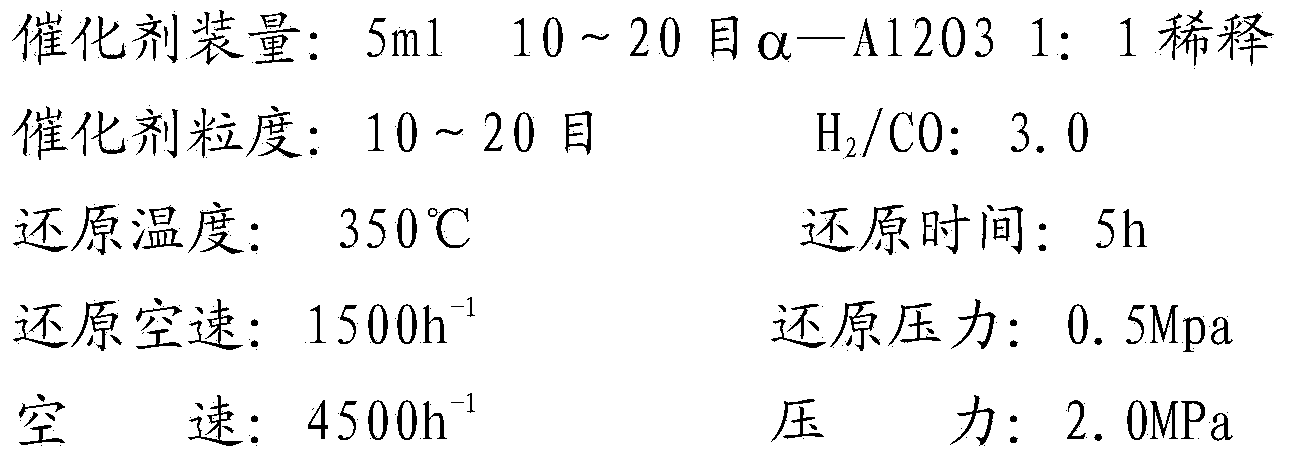

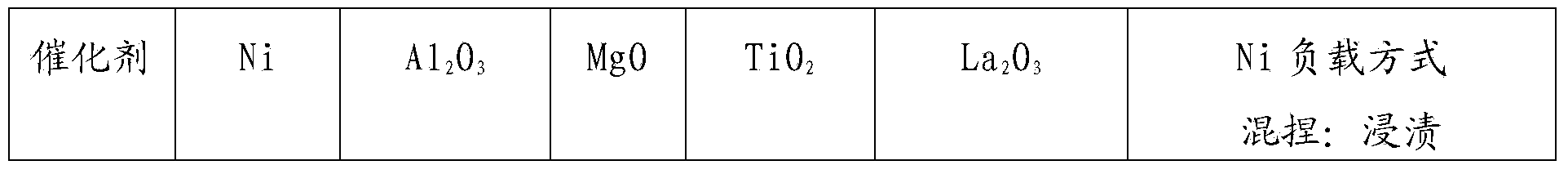

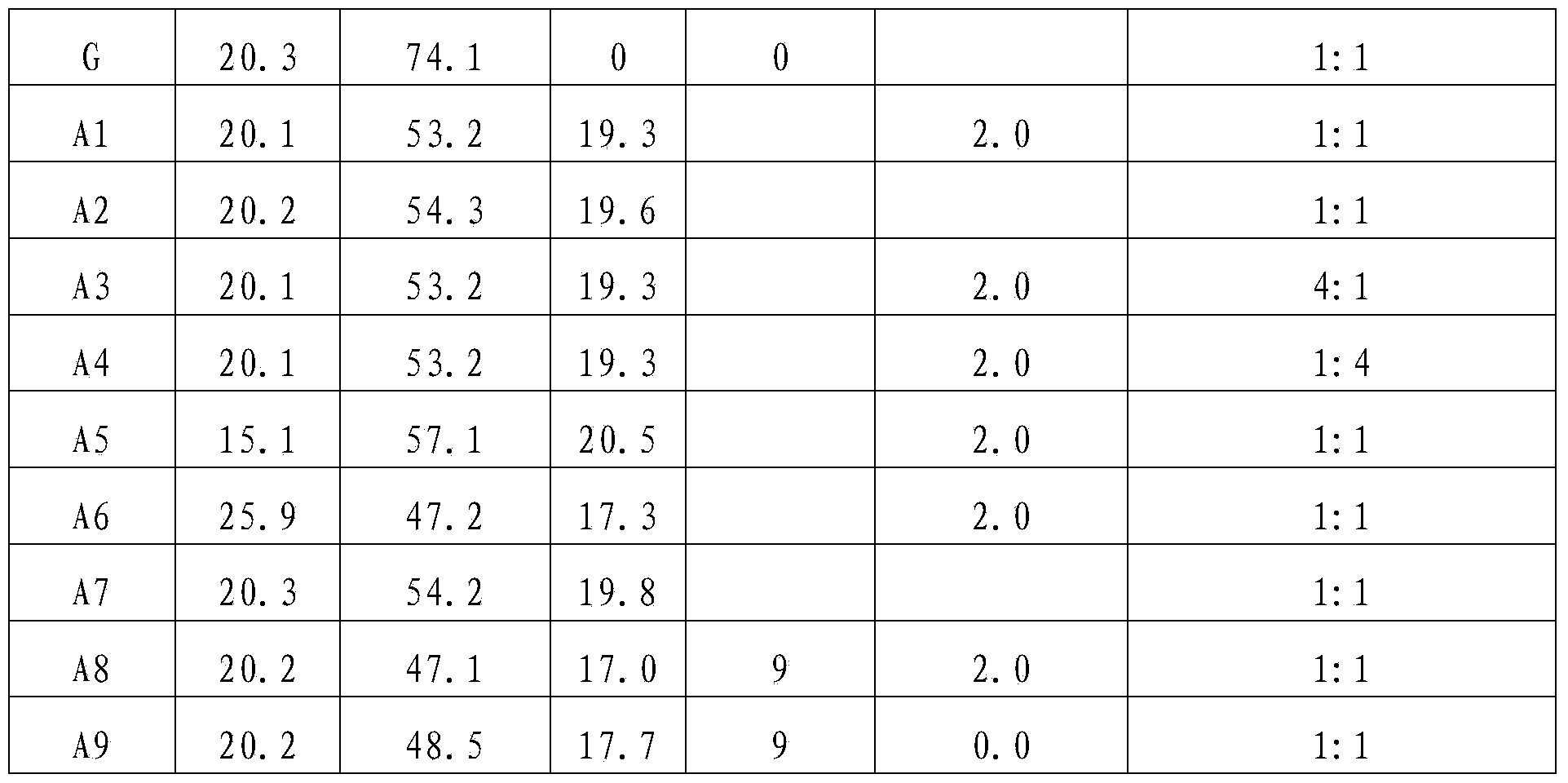

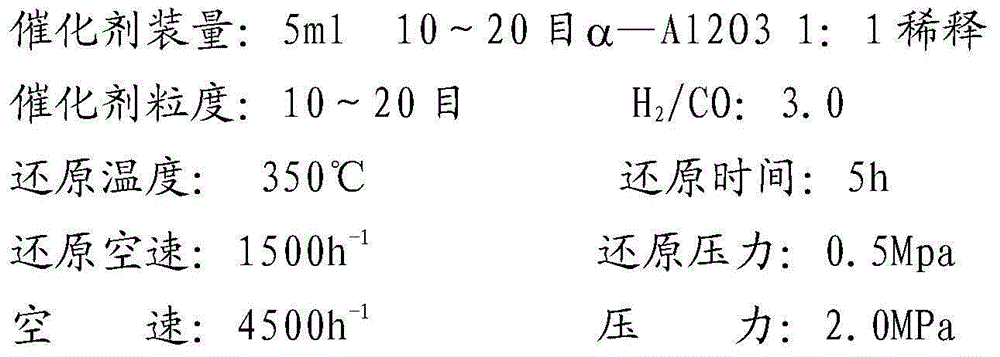

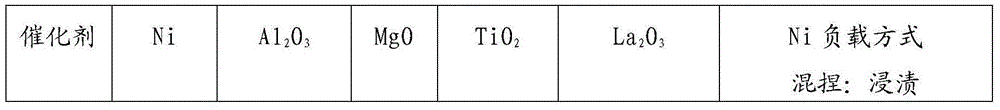

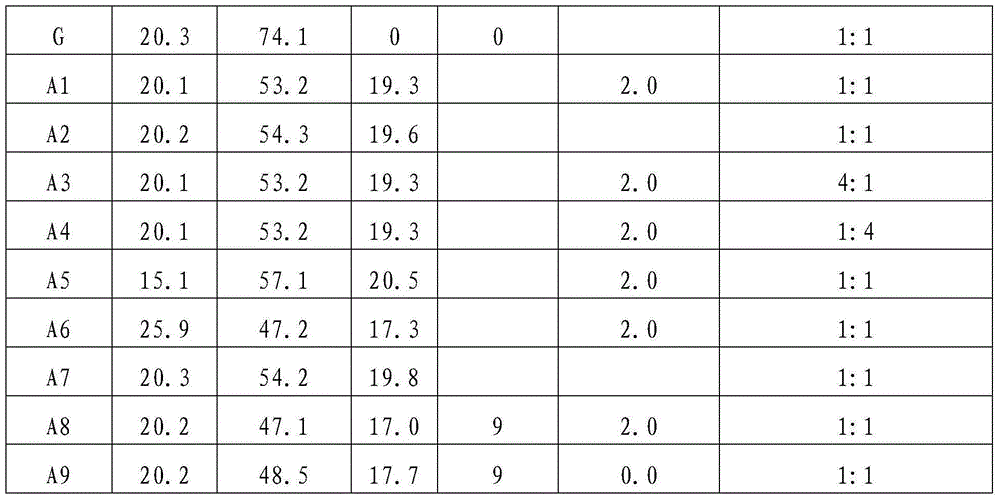

Preparation method of high-temperature methanation catalyst applicable to preparation of methane by reacting CO and CO2 with hydrogen

ActiveCN103933994AGuaranteed high temperature stabilityGuaranteed high activity at low temperatureMetal/metal-oxides/metal-hydroxide catalystsMethanationOxide composite

The invention discloses a preparation method of a high-temperature methanation catalyst applicable to preparation of methane by reacting CO and CO2 with hydrogen. A carrier of the catalyst is an MgO-Al2O3 spinel carrier or a multi-element inorganic oxide compound carrier which consists of MgO-Al2O3 spinel and TiO2; an active ingredient of the catalyst is Ni which exists in the catalyst in a form of nickel oxide; an auxiliary ingredient of the catalyst is La2O3 and / or CeO2; the active ingredient in the catalyst is added in two steps through a kneading method and a dipping method. The preparation method has the beneficial effects that one part of Ni is firstly added through the kneading method, so that the high-temperature stability of the catalyst can be guaranteed; the other part of Ni is loaded through the dipping method, so that the low-temperature high activity of the catalyst can be guaranteed; the catalyst is burned at the temperature of 480-600 DEG C to generate magnesia-alumina spinel, so that the energy consumption and the cost are reduced.

Owner:昌邑凯特新材料有限公司

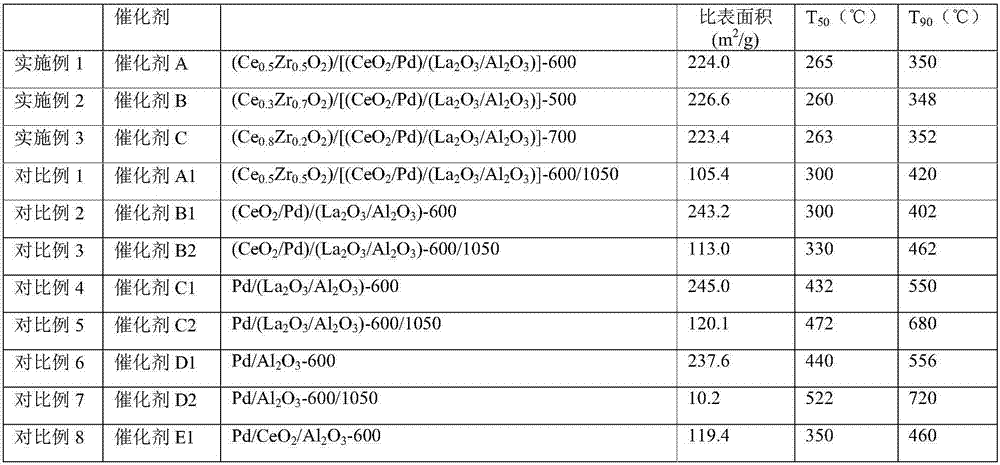

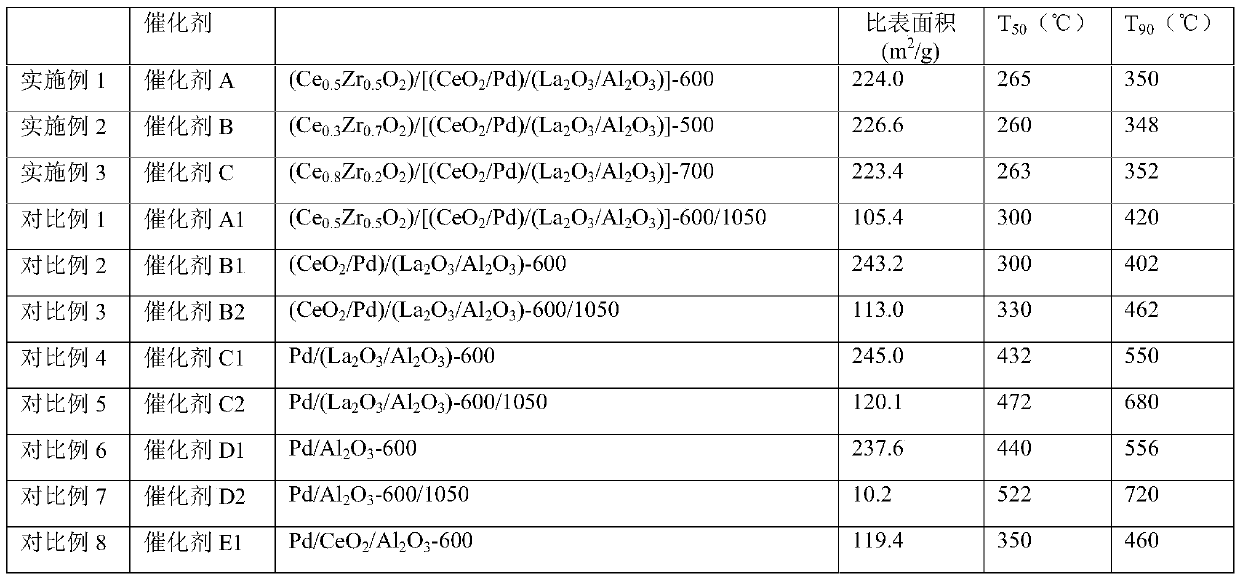

Catalyst for catalyzing methane combustion and preparation method thereof

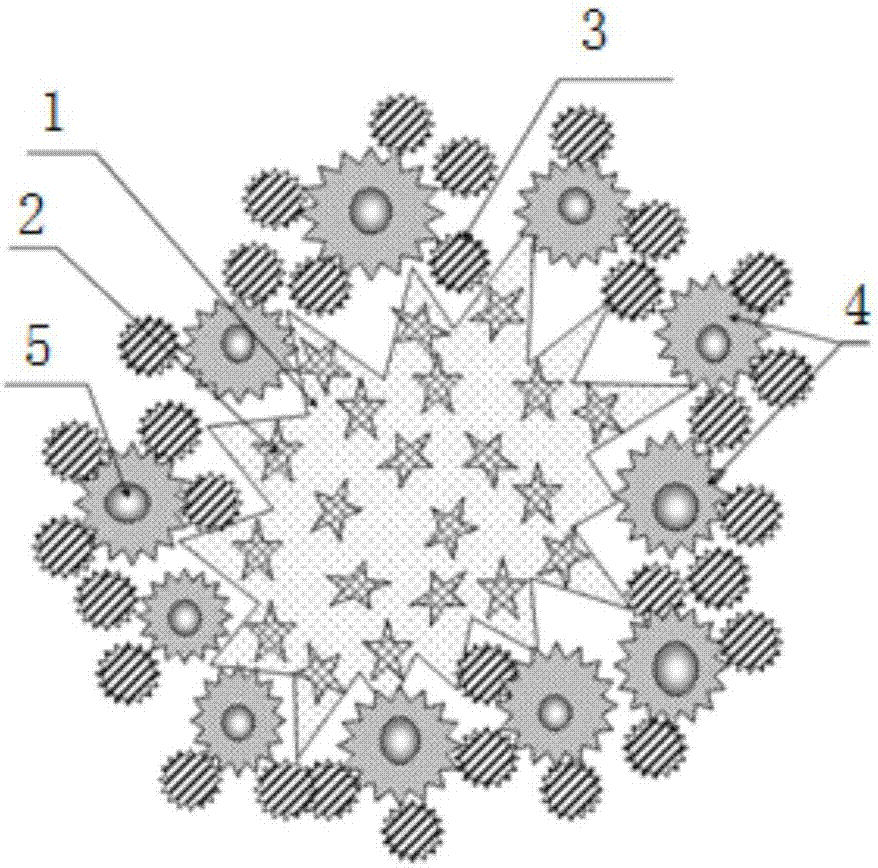

ActiveCN107262093AGuaranteed high temperature stabilityImprove high temperature thermal stabilityHeterogenous catalyst chemical elementsDispersed particle separationActive componentOxygen vacancy

The invention provides a catalyst for catalyzing methane combustion and a preparation method thereof. The catalyst comprises a carrier, and an active component which is loaded on the carrier, wherein the active component is wrapped with a wrapping layer for providing oxygen vacancy. The catalyst further comprises a catalyst promotor which is a ceria-zirconia solid solution. According to the catalyst, the wrapping layer wraps the active component, so that oxygen molecule stored in the wrapping layer can be timely conveyed to the active component, so that the high-temperature stability of the active component of the catalyst is maintained; in addition, the catalyst further comprises the catalyst promotor which is the ceria-zirconia solid solution capable of generating more oxygen vacancies and timely effectively storing and discharging oxygen, so that the high-temperature stability of the active component of the catalyst is improved; in addition, the wrapping layer, the ceria-zirconia solid solution and the carrier are mutually dispersed and in contact, so that the mutual insulation effect is achieved, and the sintering of the carrier is inhibited, and as a result, the high-temperature thermal stability and the catalyzing activity of the catalyst can be improved.

Owner:FUZHOU UNIV +1

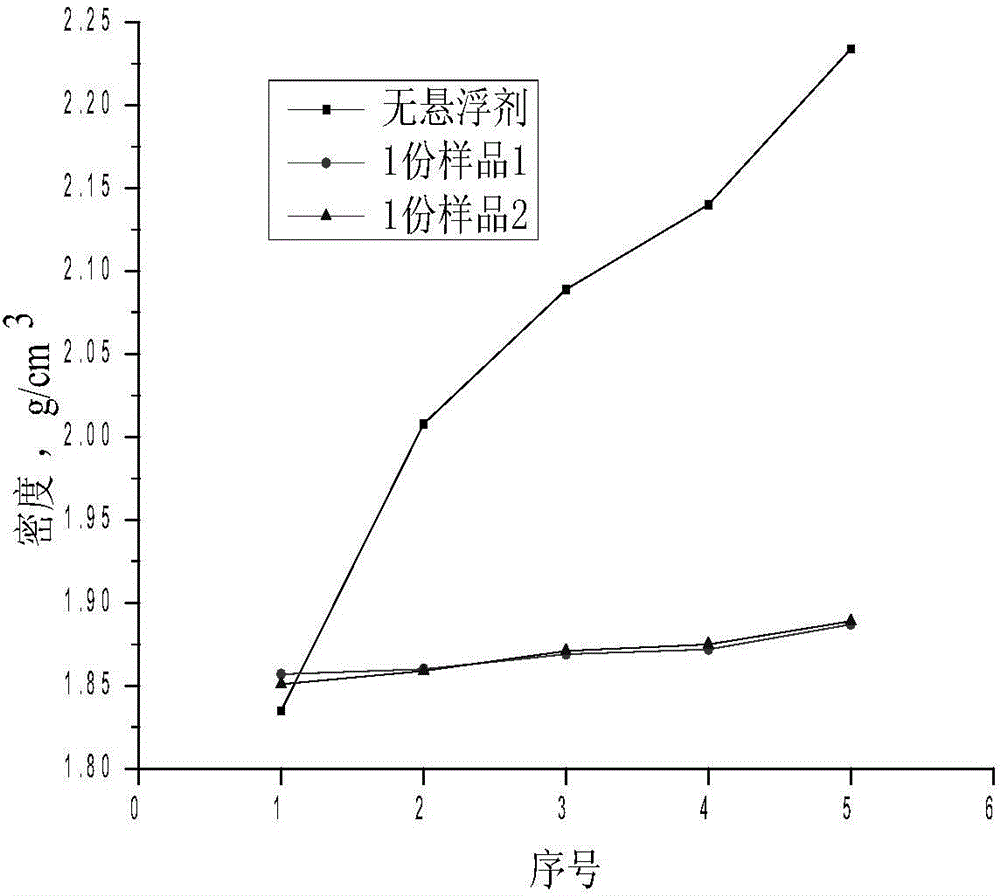

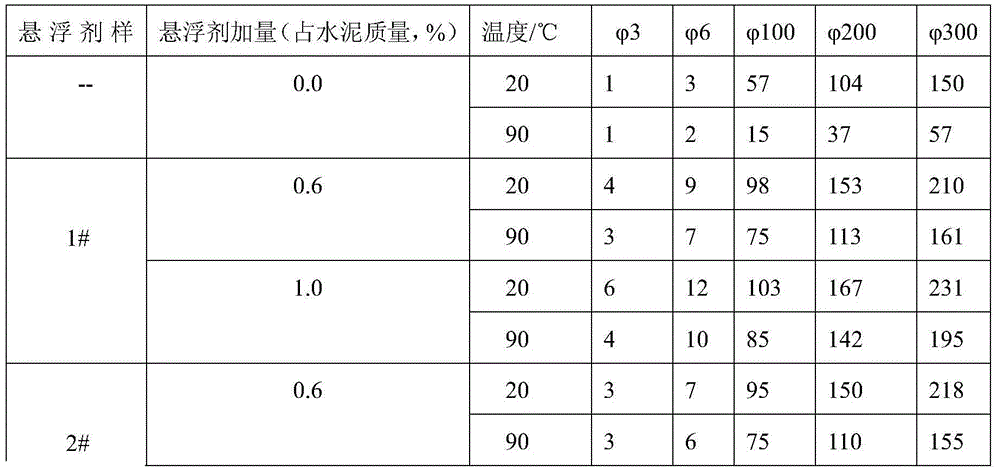

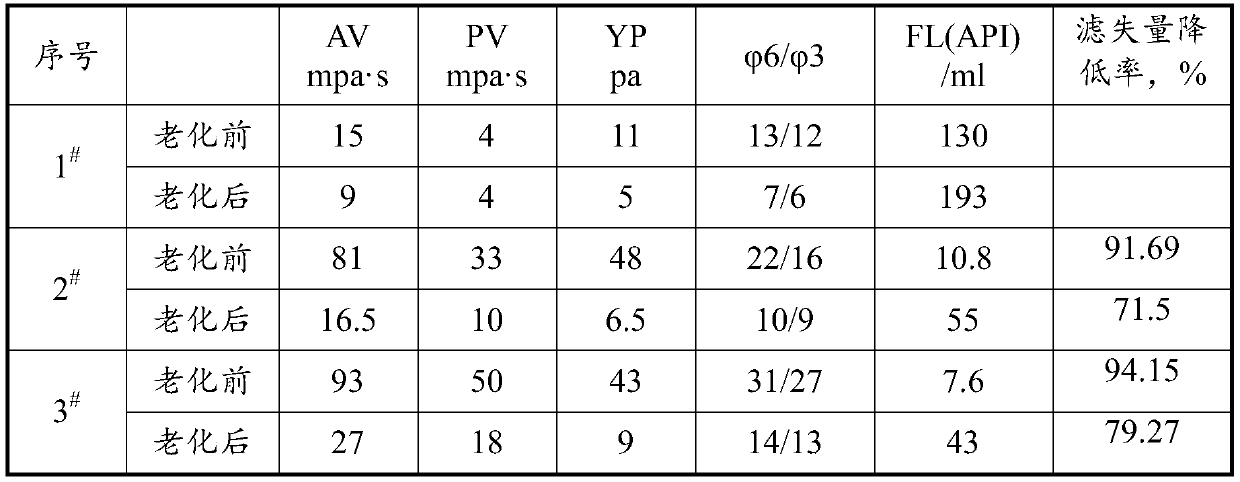

Oil well cement high temperature resistance suspending agent

ActiveCN105199690ASuspension stabilityImprove stabilityDrilling compositionSodium BentonitePolymer science

The invention relates to an oil well cement high temperature resistance suspending agent. The oil well cement high temperature resistance suspending agent is prepared from well drilling bentonite and a hydrophobic association water-soluble polymer on the basis that the mass ratio is 5:1. A hydrophobic associated compound is a quadripolymer synthetized by adopting the soap-free emulsion polymerization method. A polymerization monomer comprises, by mass, 35-80 parts of 2-acrylamide-2-methyl propyl sulfonic acid, 10-60 parts of acrylamide, 5-10 parts of N,N-dimethyl acrylamide and 5-20 parts of a monomer containing hydrophobic groups. The high temperature resistance suspending agent can resist the temperature of 170 DEG C, the stability of cement slurry can be effectively achieved, the oil well cement high temperature resistance suspending agent cannot be excessively thickened at low temperature and cannot be excessively diluted at high temperature, and the comprehensive performance is good.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

High-specific-surface-area vanadium-zinc-series modified denitration catalyst and preparation method

ActiveCN103894184ASmall and uniform particle sizeIncrease the areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCombined methodOxide composite

The invention discloses a high-specific-surface-area vanadium-zinc-series modified denitration catalyst. The catalyst is characterized in that a carrier is TiO2, TiO2-SiO2 or one of polynary inorganic oxide complex species containing TiO2, wherein TiO2 is prepared by heating and modifying metatitanic acid by virtue of H2O2; the carrier of the catalyst is in a honeycomb ceramic form; active components of the carrier include V2O5, ZnO and WO3. The catalyst has the beneficial effects that a kneading-dipping combined method is utilized in a preparation process, and Zn is added into the catalyst step-by-step, so that synergistic effects of V and Zn as well as W and Zn are exerted, and the low-temperature activity and high-temperature stability of the catalyst are guaranteed; by carrying out chemical processes of complexing and dispersing ions of the metatitanic acid and H2O2, the specific surface area and uniformity of the metatitanic acid are improved, and a next forming step is benefited; meanwhile, as the frequently-used industrial titanium dioxide is evaded, the cost is lowered.

Owner:昌邑凯特新材料有限公司

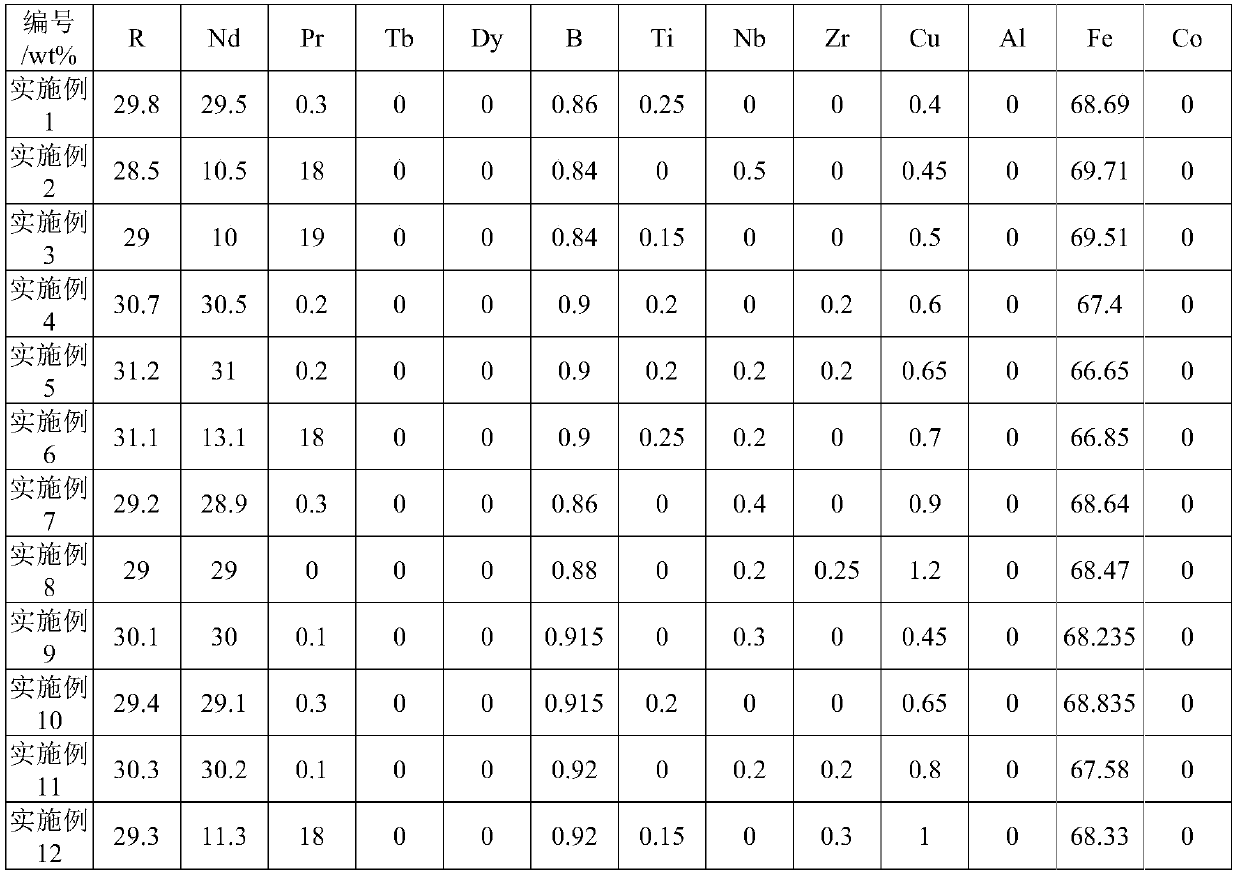

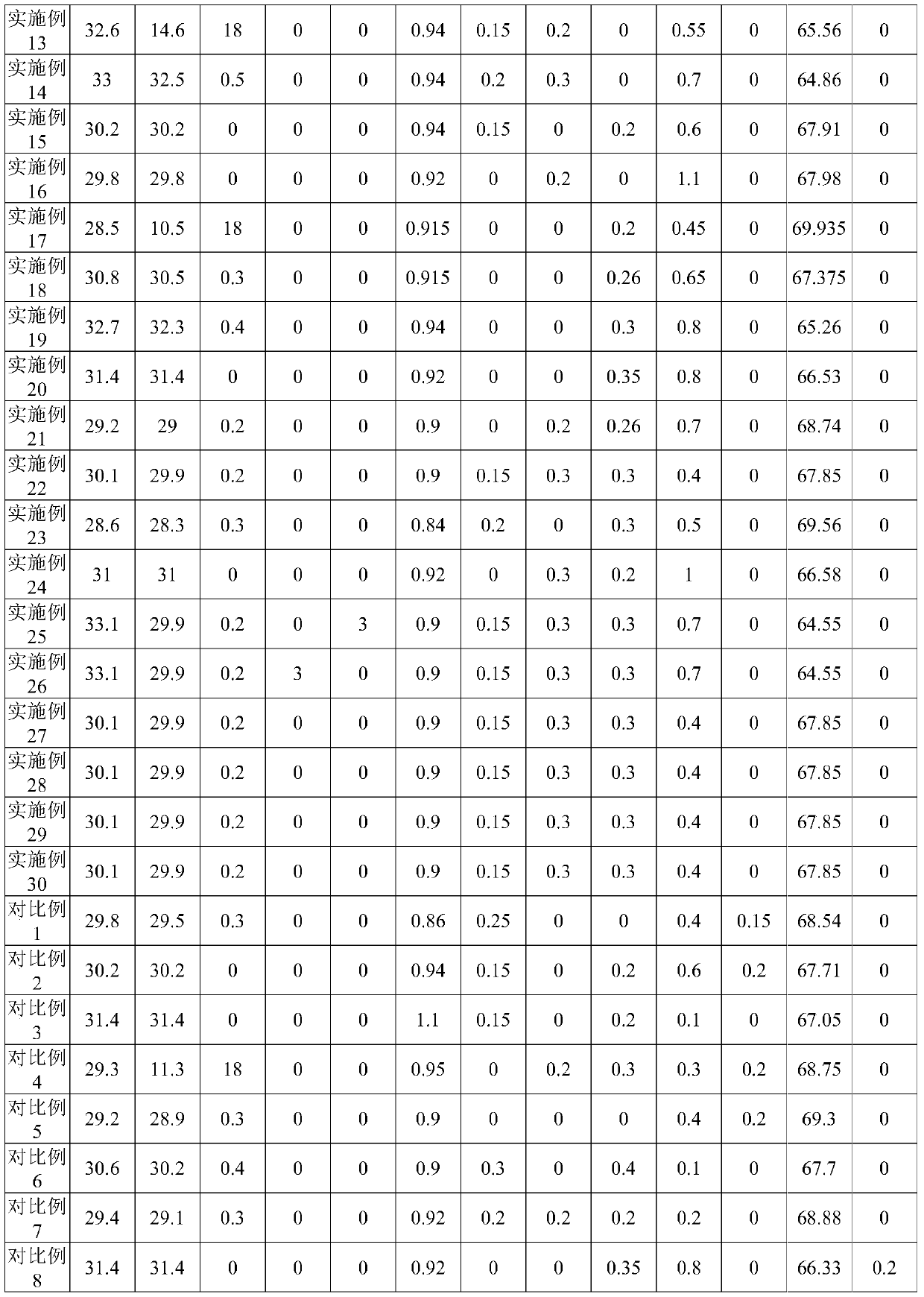

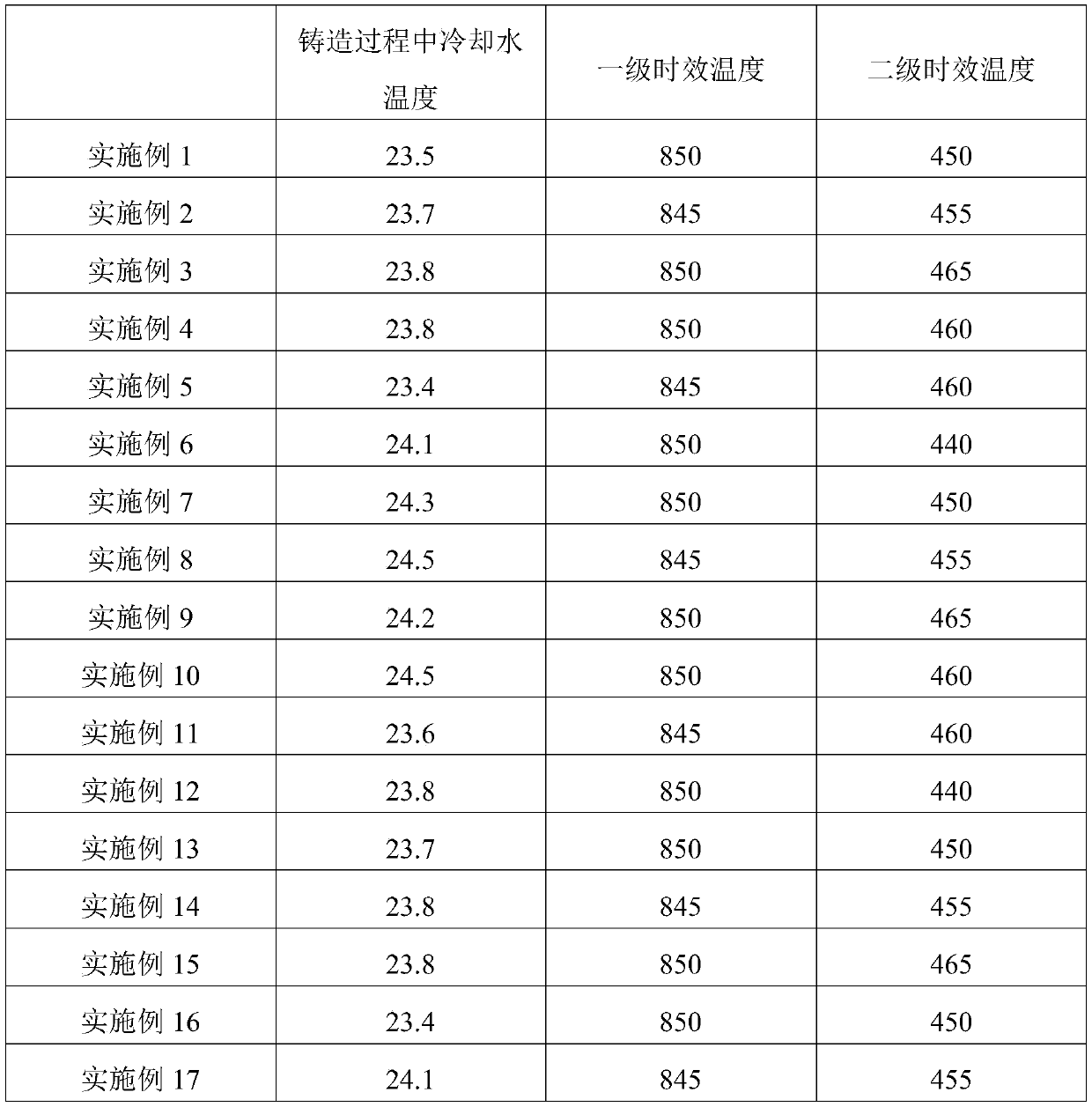

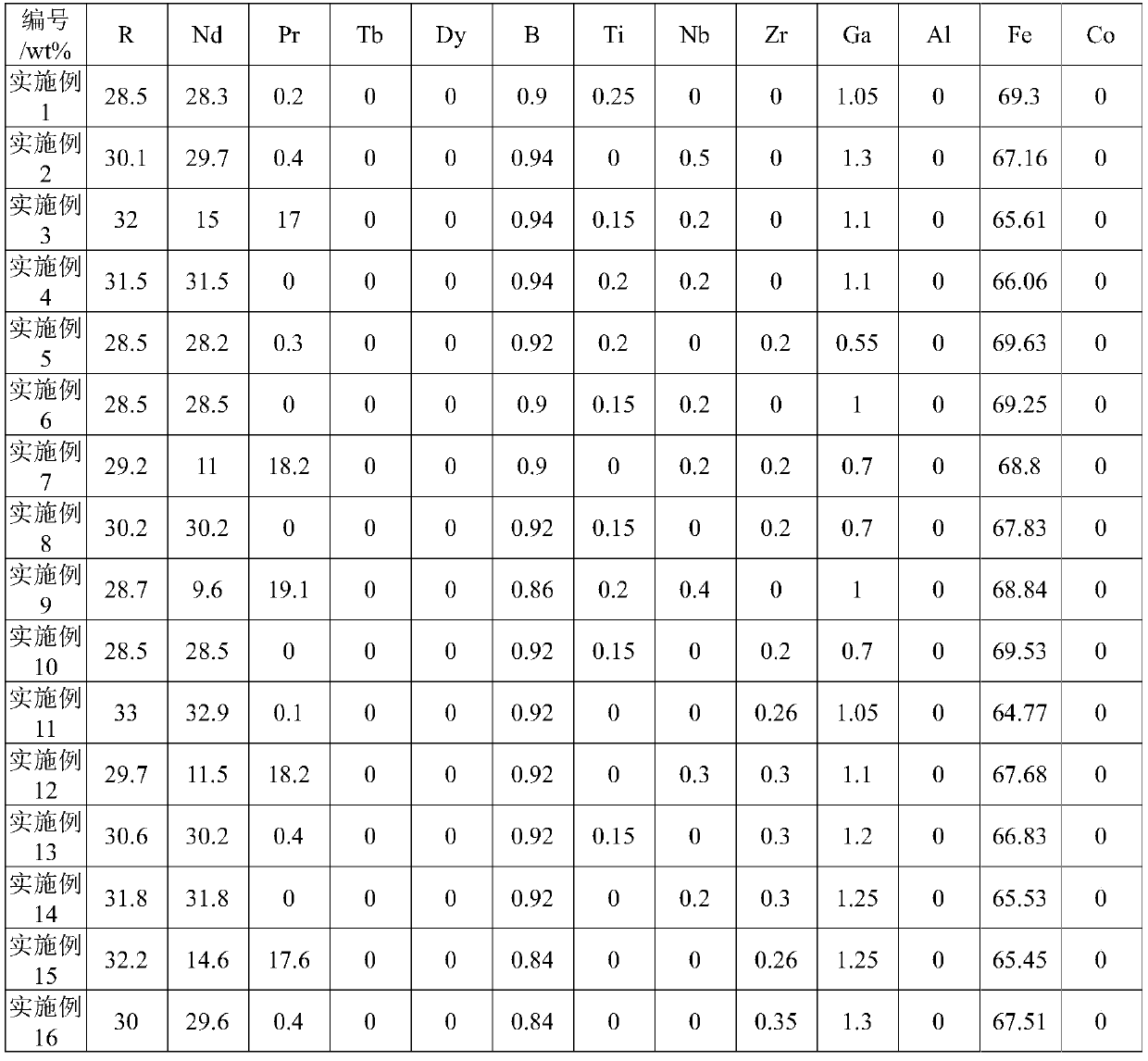

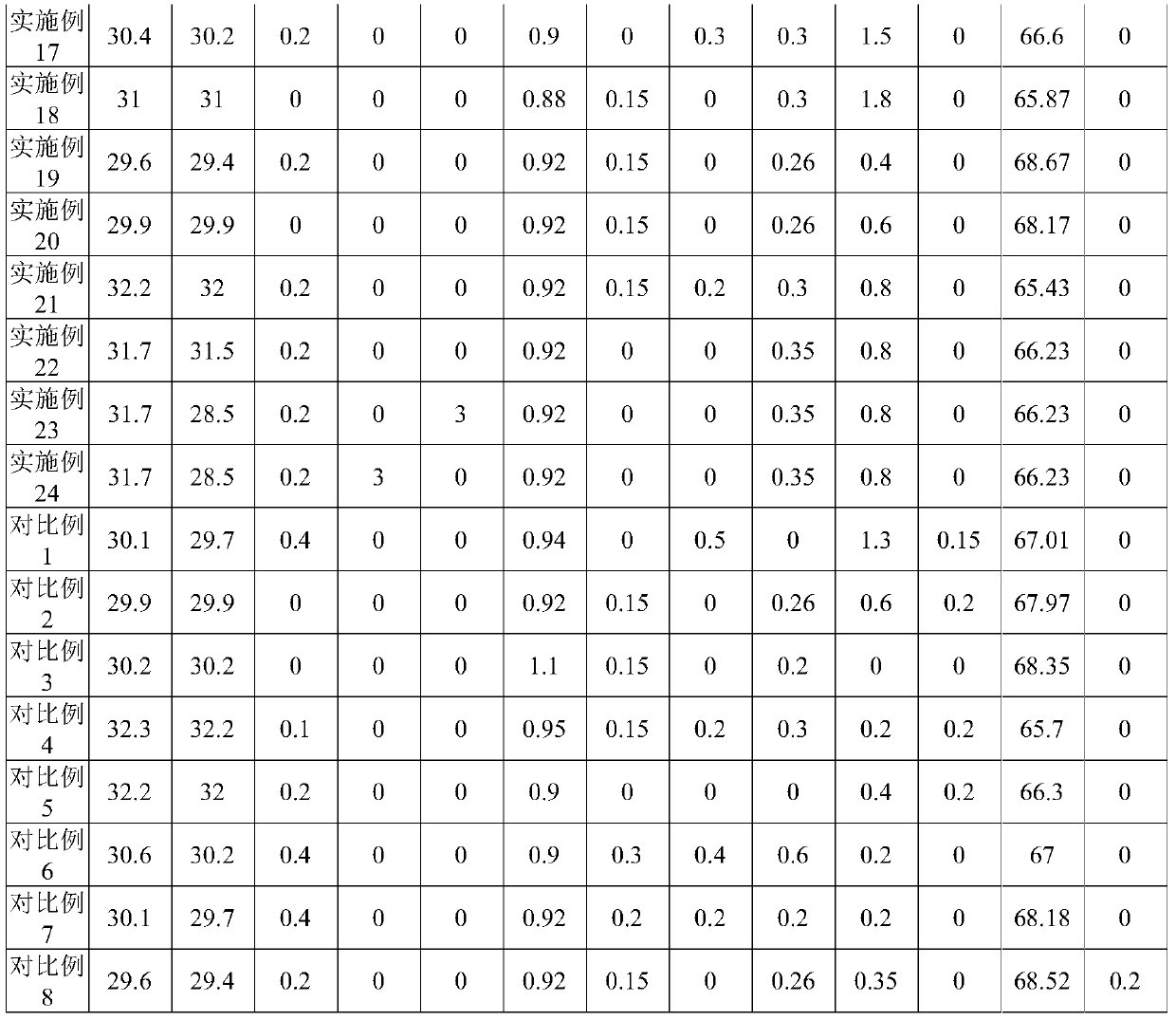

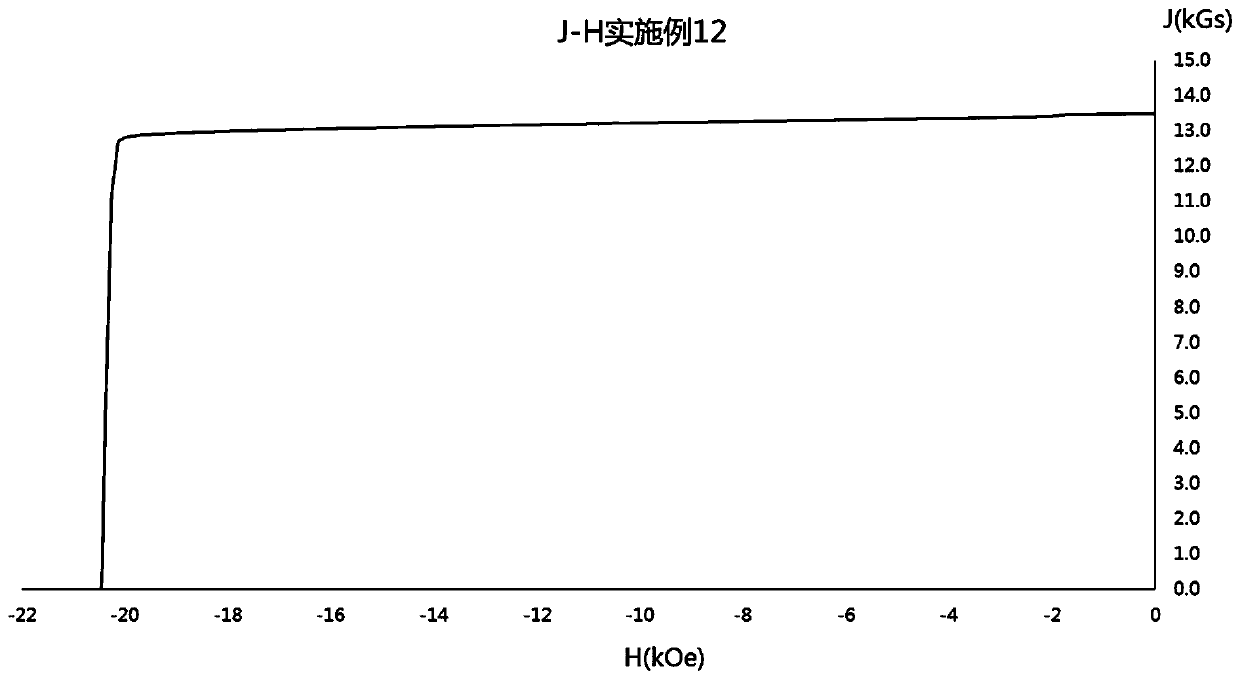

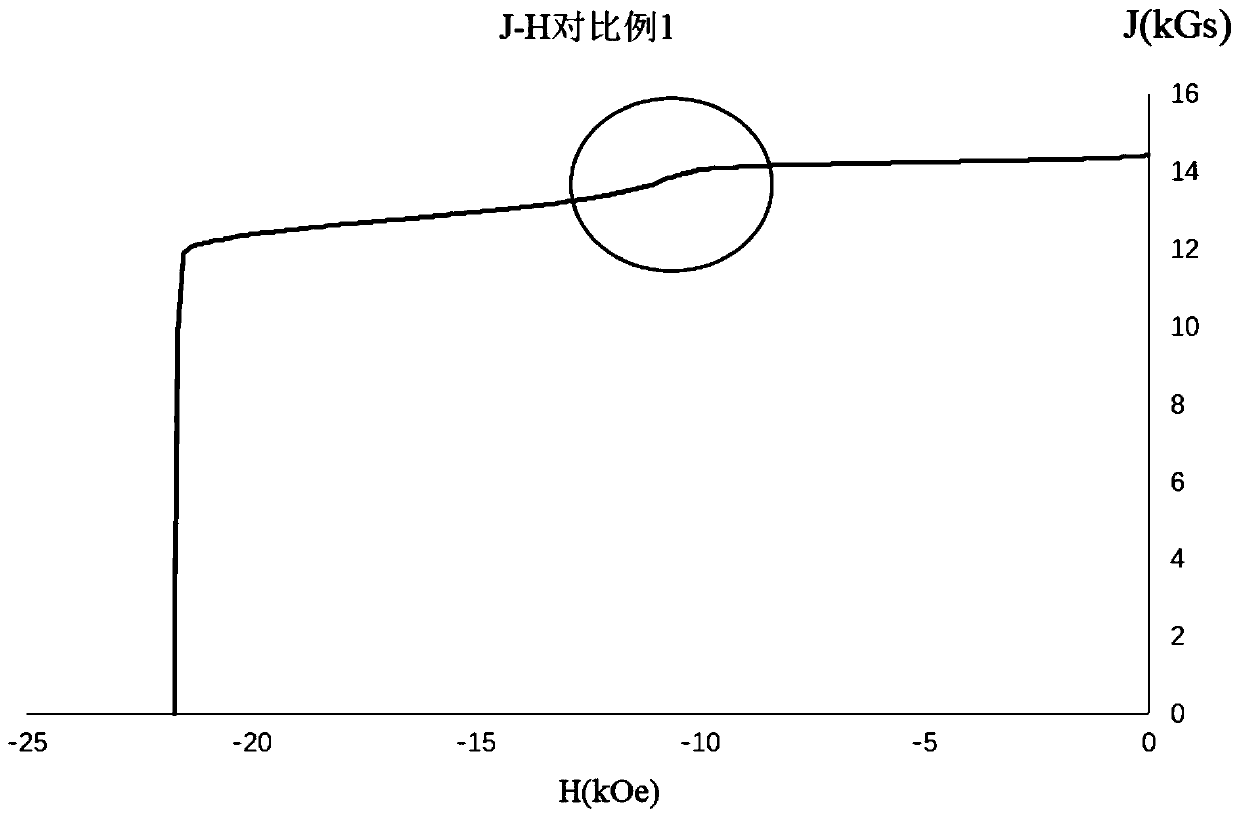

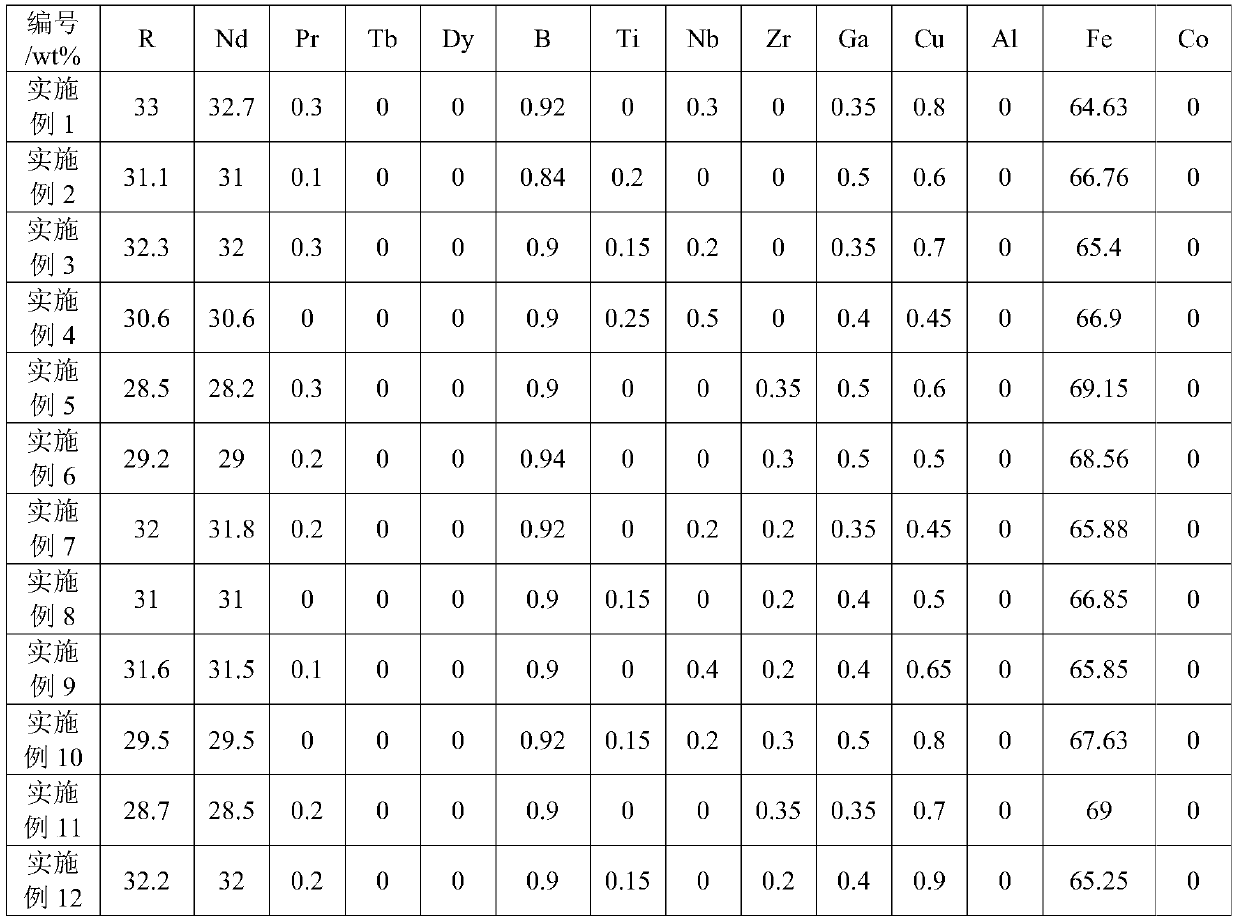

Neodymium iron boron material and preparation method and application thereof

ActiveCN111243809ALow in BHigh Cu contentInductances/transformers/magnets manufactureMagnetic materialsMetallurgyGrain boundary

The invention discloses a neodymium iron boron material and a preparation method and application thereof, the neodymium iron boron material comprises R, Cu, Al, Fe and B, and also comprises one or more of Ti, Zr and Nb, the content of R is 28.5-33.2% by weight, the content of Zr is 23.5-33.2% by weight, and the content of Nb is 23.5-33.2% by weight. The content of Cu is more than 0.393%; the content of B is 0.84 to 0.945 percent; wherein the content of Al is less than 0.08%; the R-T-B series permanent magnet material does not contain Co; the R-T-B series permanent magnet material comprises anR2Fe14B main phase, a grain boundary phase and a rare earth-rich phase. The grain boundary phase comprises R < 6 > Fe < 13 > Cu; and the volume fraction of R6Fe13Cu is greater than or equal to 3.5%. The neodymium iron boron material is high in coercive force Hcj and Br, good in magnet temperature stability and excellent in performance; and the demagnetization curve has no step, the relative permeability is low, and the uniformity of the magnetic steel is good.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

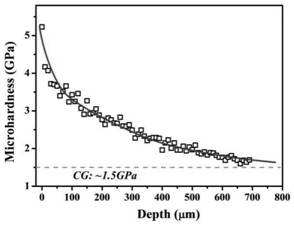

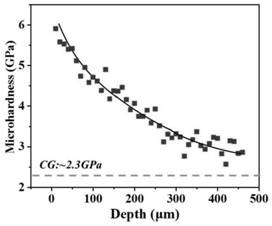

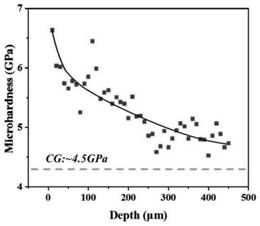

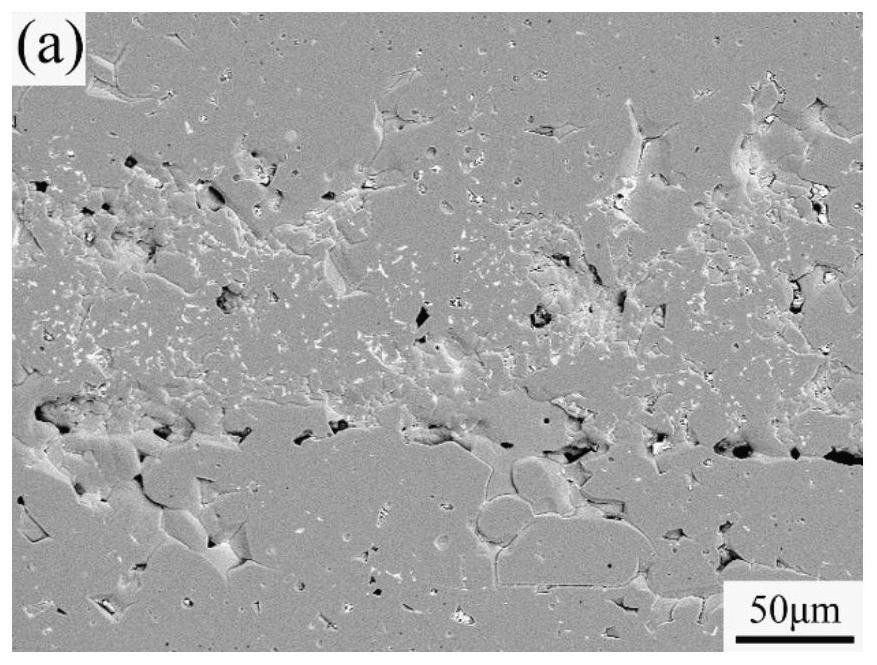

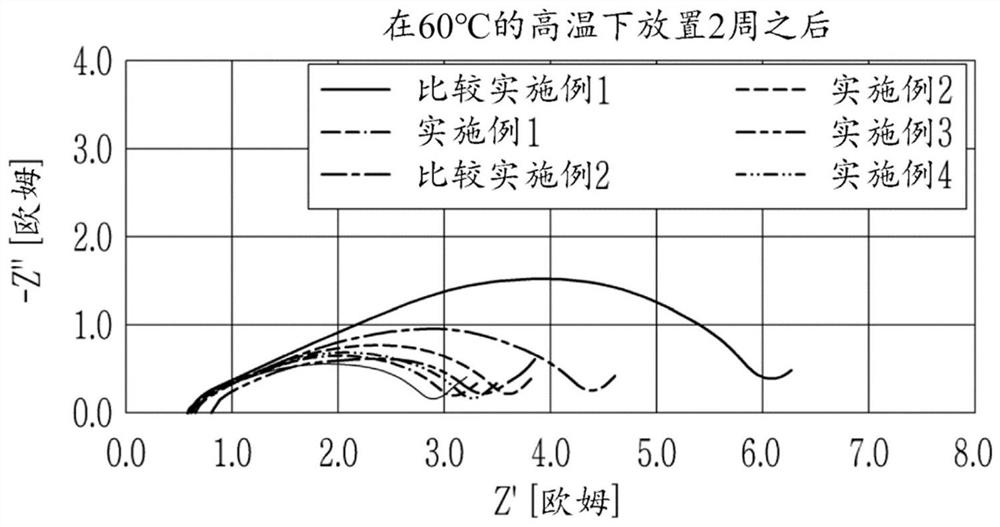

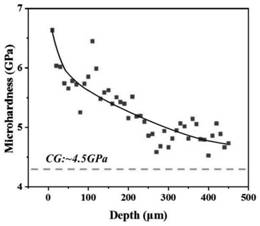

High-temperature alloy with gradient nanostructure surface layer and preparation method of high-temperature alloy

The invention discloses a high-temperature alloy with a gradient nanostructure surface layer and a preparation method of the high-temperature alloy, and belongs to the technical field of metal material surface nanocrystallization. The high-temperature alloy is treated through surface mechanical grinding technology, a spherical head is pressed into the surface of a material by a certain depth for grinding, gradient plastic deformation is generated on the surface layer of the material, a gradient organization structure for transition from nano-crystalline grains to micron-crystalline grains is formed on the surface of the high-temperature alloy, and a large hardness gradient is generated from outside to inside, so that the problems of coarse surface grains, uneven microstructure, insufficient mechanical properties and the like of the high-temperature alloy are solved. The high-temperature alloy with the gradient nanostructure surface layer and the preparation method of the high-temperature alloy have the characteristics of being simple in treatment, low in energy consumption, and suitable for industrial application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

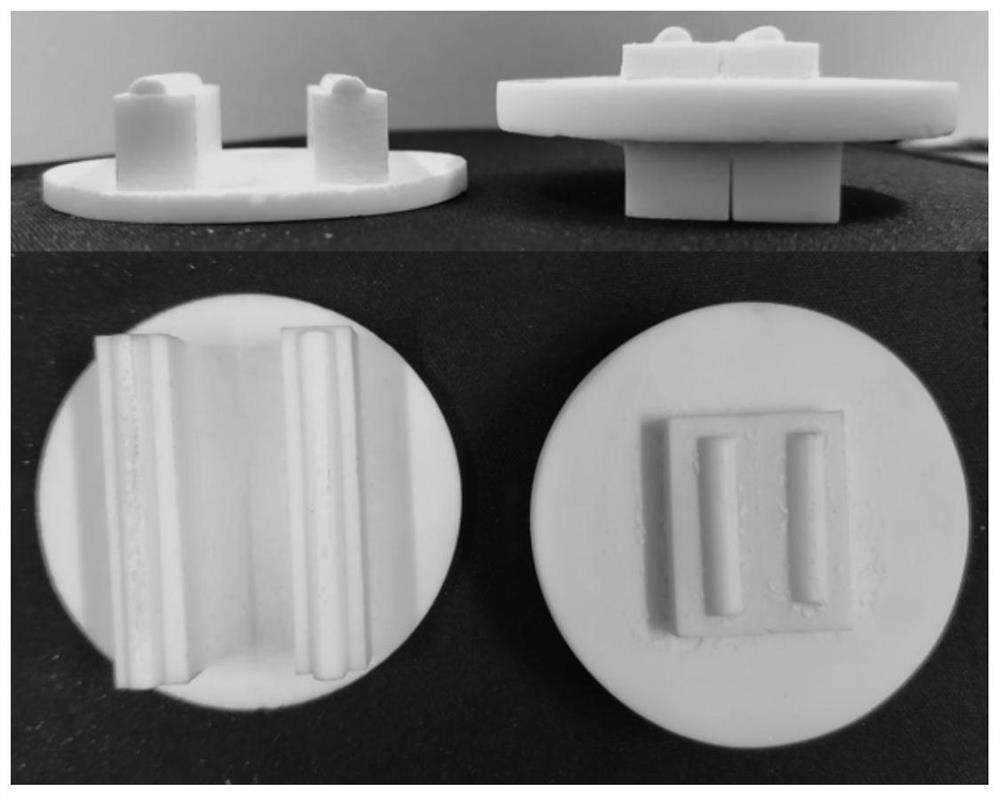

Preparation method of large-grained UO2 (uranium dioxide) fuel pellets with high heat conductivity

ActiveCN107871540AImprove high temperature stabilityImprove thermal conductivityNuclear energy generationReactor fuel susbtancesNetwork structureTemperature resistance

The invention discloses a preparation method of large-grained UO2 (uranium dioxide) fuel pellets with high heat conductivity. The surfaces of UO2-grain growth promoter compound spheres with good sphericity are uniformly coated with heat conductivity enhanced phase powder, coated particles are obtained and subjected to forming and sintering in a high-temperature atmosphere, so that UO2 grains growunder the action of the grain growth promoter, meanwhile, the heat conductivity enhanced phase coating the surfaces of the UO2 particles is intercommunicated after being liquefied at the high temperature, a three-dimensional network structure is formed, and the enhanced phase and a UO2 matrix form special UO2 fuel pellets with the three-dimensional network structure. The enhanced UO2 fuel palletsprepared with the method have the heat conductivity remarkably superior to that of pure UO2, besides, the size of UO2 grains is notably larger than that of conventional UO2 pellets, the high-temperature resistance and the irradiation stability are excellent, and the safety level of a reactor and a fuel system can be remarkably improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

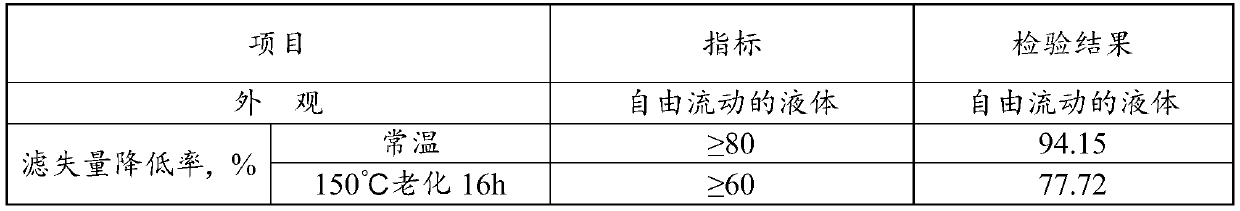

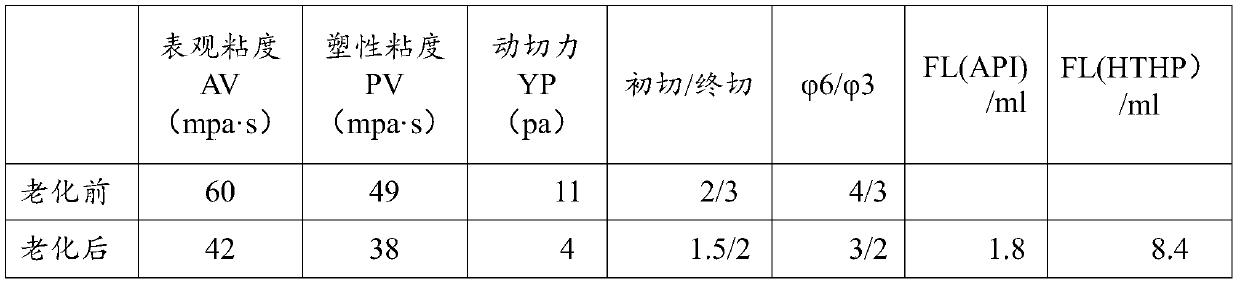

Filtrate loss reducer for water-based drilling fluid and preparation method of filtrate loss reducer

The invention provides a filtrate loss reducer for water-based drilling fluid and a preparation method of the filtrate loss reducer, and belongs to the technical field of drilling fluid. The filtrateloss reducer is in the form of water-in-oil emulsion, and is good in dispersity and convenient to use on site. The filtrate loss reducer can balance contradiction between the filtration loss reducingperformance and the rheological property, not only has good filtration loss reducing capability, but also can assist in adjusting the rheological property of the drilling fluid. The filtrate loss reducer comprises the following components: acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacryloyl propyl trimethyl ammonium chloride, sodium formate, sodium hydroxide, ammonium persulfate, span 80, span 20, water and white oil. The filtrate loss reducer is added into the water-based drilling fluid in a drilling process to control filtration loss.

Owner:BEIJING SHIDABOCHENG TECH +1

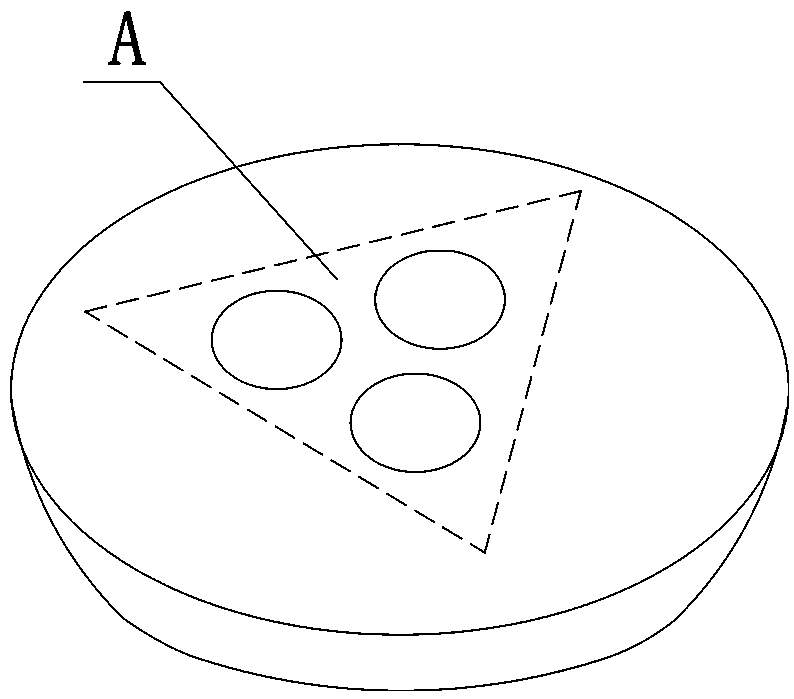

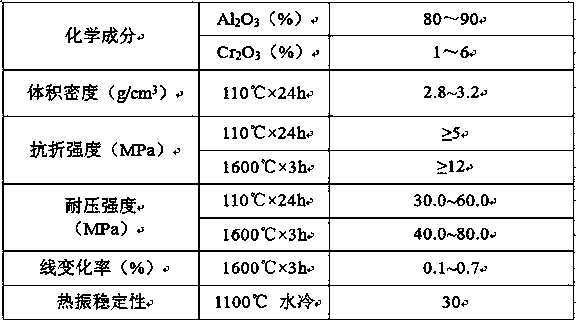

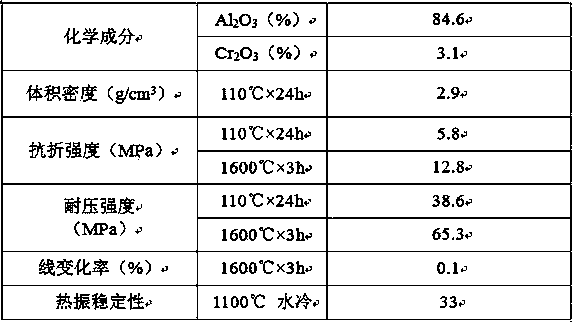

Special casting materials for triangular area prefabricated components of electric arc furnace roof

InactiveCN109160808AGood high temperature strength and thermal shock stabilityGuaranteed compactness and volume stabilityIndustrial wasteScrap

The invention discloses special casting materials for triangular area prefabricated components of an electric arc furnace roof. The special casting materials are prepared from the following raw materials: 20-35 parts of highly pure aluminum bauxite, 10-25 parts of tabular corundum, 15-32 parts of chromium corundum, 3-5 parts of spinel fine powder, 1.5-2.5 parts of kyanite, 5-9 parts of active aluminum oxide micro powder, 1-3 parts of chromium oxide green fine powder, 2-4 parts of silicon micro powder, 3.11-5.25 parts of a bonding agent, 0.03-0.06 part of organic fibers and 0.5-1 part of stainless steel fibers. According to the special casting materials disclosed by the invention, scientific grain size distribution is adopted for main body granules, so that the triangular area prefabricatedcomponents are guaranteed to have good high temperature strength and good hot vibration stability; materials of the spinel micro powder, pure calcium aluminate cement, active aluminum oxide and chromium oxide green and the like, which are added, are compounded, and after casting moulding and baking, a high-strength low-temperature solidified combination liner is formed, so that the compactabilityand the volume stability of the prefabricated components are guaranteed; the chromium corundum (Al2O3+Cr2O3 greater than or equal to 95%) in the raw materials is slag for smelting electrofusion chromium metal; through the use of the raw materials, the cost of products can be reduced, discharge of industrial waste can be reduced, and cyclic utilization of the industrial waste can be effectively realized.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Rapid preparation method and product of uranium dioxide/nano-diamond nuclear fuel pellet

ActiveCN108538409AEnhance macro thermal conductivityGuaranteed high temperature stability and radiation stabilityNuclear energy generationReactors manufacturePowder metallurgyThermal conductivity

The invention discloses a rapid preparation method and a product of a uranium dioxide / nano-diamond nuclear fuel pellet, and belongs to the field of energy and composite materials, particularly belongsto the field of powder metallurgy, and aims to solve the problems that safety requirements of a nuclear power station are difficultly met as heat conductivity of an existing ceramic uranium dioxide (UO2) pellet is poor. According to the method, the uranium dioxide / nano-diamond nuclear fuel pellet with a three-dimensional network structure is prepared by a powder metallurgy technique, the heat conductivity of uranium dioxide nuclear fuel is improved, high-temperature stability and radiation stability of the fuel pellet are improved, the method can effectively solves the problems, safety of theuranium dioxide nuclear fuel pellet is greatly improved, industrial large-scale production application requirements can be met, the method has high application value and good application prospect andis worthy of large-scale popularization and application.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Manufacturing method for Li-B base air suction material

InactiveCN103526094ASolve the problem of difficult processing and narrow applicationAchieve surface passivationOther chemical processesSpontaneous combustionSynthesis methods

The invention discloses a manufacturing method for a Li-B base air suction material. According to the manufacturing method, by mass, 30-70 % of Li, 20-50 % of B, 0.3-6 % of Mg and / or Al and 0.01-18% of C are heated to 350-370 DEG C, heat preservation is conducted, the components are stirred evenly and cooled along with a furnace, and Li-B base prealloy is obtained; the Li-B pre-alloy is processed into the shape needed by an air suction component at the room temperature in air with relative humidity lower than or equal to 2 %, the Li-B prealloy is heated to 600-700 DEG C in protective atmosphere, heat preservation is conducted on the Li-B alloy for 5-30 minutes and a finished product is obtained. The manufacturing method for the Li-B base air suction material not only solves the problem that Li-B alloy meeting the air suction material standard cannot be manufactured through a one-step synthesis method in the prior art and the problem that Li-B alloy air suction pieces cannot be manufactured through the powder process pressing method, but also reduces the difficulty of controlling the structure of the Li-B base air suction material, and improves the uniformity of the structure of the material; meanwhile, the spontaneous combustion phenomenon is successfully avoided, and the surface passivation of the Li-B base air suction material is achieved. The manufacturing method for the Li-B base air suction material is simple in preparation technology and can be produced in an industrialized mode conveniently.

Owner:CENT SOUTH UNIV

Rare earth permanent magnet material and preparation method and application thereof

ActiveCN111243810ALow in BHigh content of GaInductances/transformers/magnets manufactureMagnetic materialsMetallurgyMagnet

The invention discloses a rare earth permanent magnet material and a preparation method and application thereof. The rare earth permanent magnet material comprises R, Ga, Al, Fe and B, and further comprises one or more of Ti, Zr and Nb, and the rare earth permanent magnet material comprises the following components in percentage by weight: 28.5%-33.05% of R, 2.05%-3.05% of Ga, 2.05%-3.05% of Al, 2.05%-3.05% of Fe and 2.05%-3.05% of Nb. The content of Ga is greater than 0.35%; the content of B is 0.84 to 0.945 percent; wherein the content of Al is less than 0.08%; the R-T-B series permanent magnet material does not contain Co. The rare earth permanent magnet material is high in coercive force Hcj and Br, good in magnet temperature stability and excellent in performance; and the demagnetization curve has no step, the relative permeability is low, and the uniformity of the magnetic steel is good.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

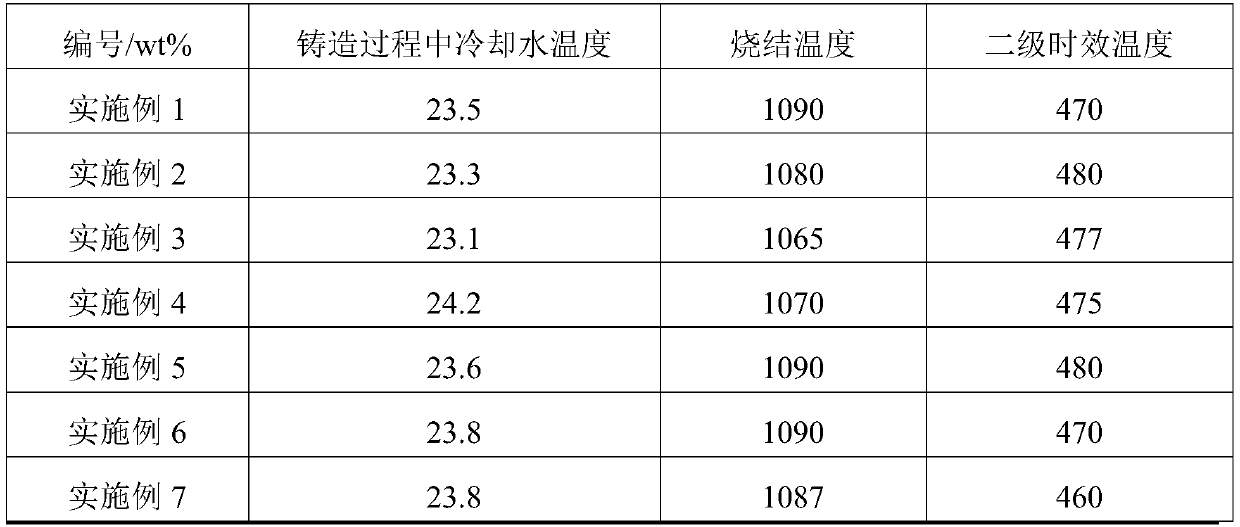

A kind of preparation method for the high-temperature methanation catalyst that is used for CO and CO2 and hydrogen reaction to produce methane

ActiveCN103933994BGuaranteed high temperature stabilityGuaranteed high activity at low temperatureMetal/metal-oxides/metal-hydroxide catalystsMethanationOxide composite

The invention discloses a preparation method of a high-temperature methanation catalyst applicable to preparation of methane by reacting CO and CO2 with hydrogen. A carrier of the catalyst is an MgO-Al2O3 spinel carrier or a multi-element inorganic oxide compound carrier which consists of MgO-Al2O3 spinel and TiO2; an active ingredient of the catalyst is Ni which exists in the catalyst in a form of nickel oxide; an auxiliary ingredient of the catalyst is La2O3 and / or CeO2; the active ingredient in the catalyst is added in two steps through a kneading method and a dipping method. The preparation method has the beneficial effects that one part of Ni is firstly added through the kneading method, so that the high-temperature stability of the catalyst can be guaranteed; the other part of Ni is loaded through the dipping method, so that the low-temperature high activity of the catalyst can be guaranteed; the catalyst is burned at the temperature of 480-600 DEG C to generate magnesia-alumina spinel, so that the energy consumption and the cost are reduced.

Owner:昌邑凯特新材料有限公司

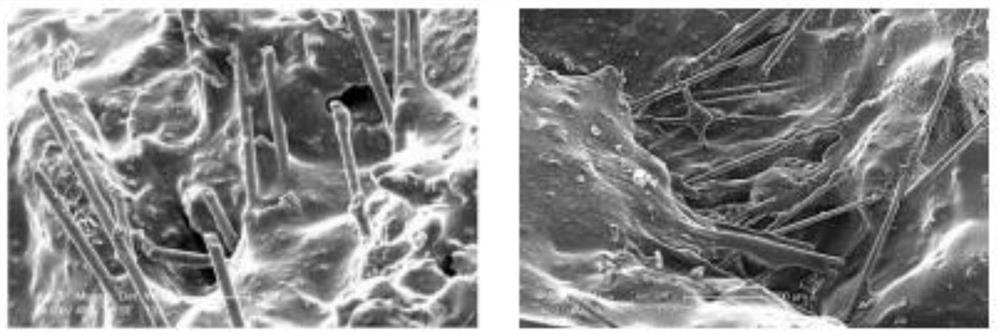

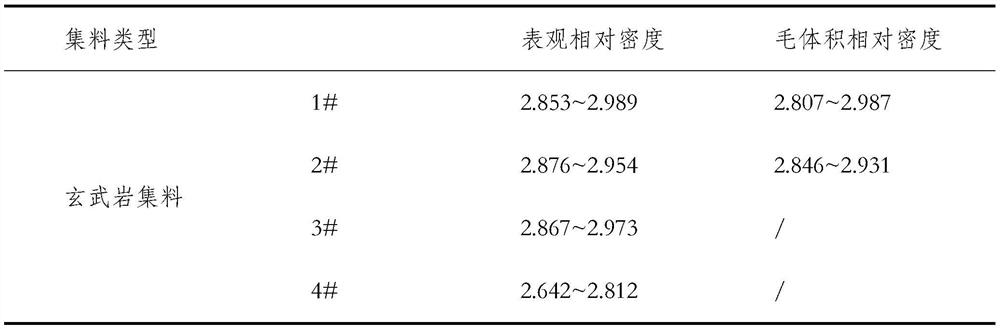

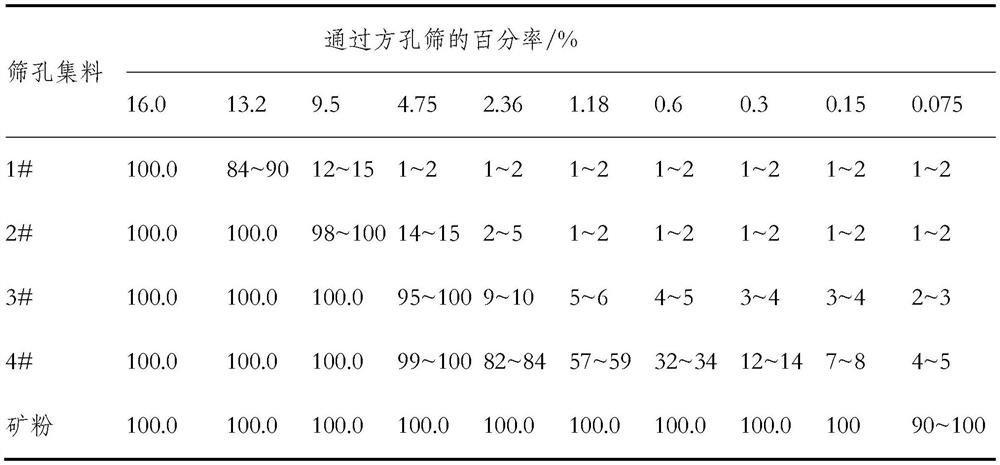

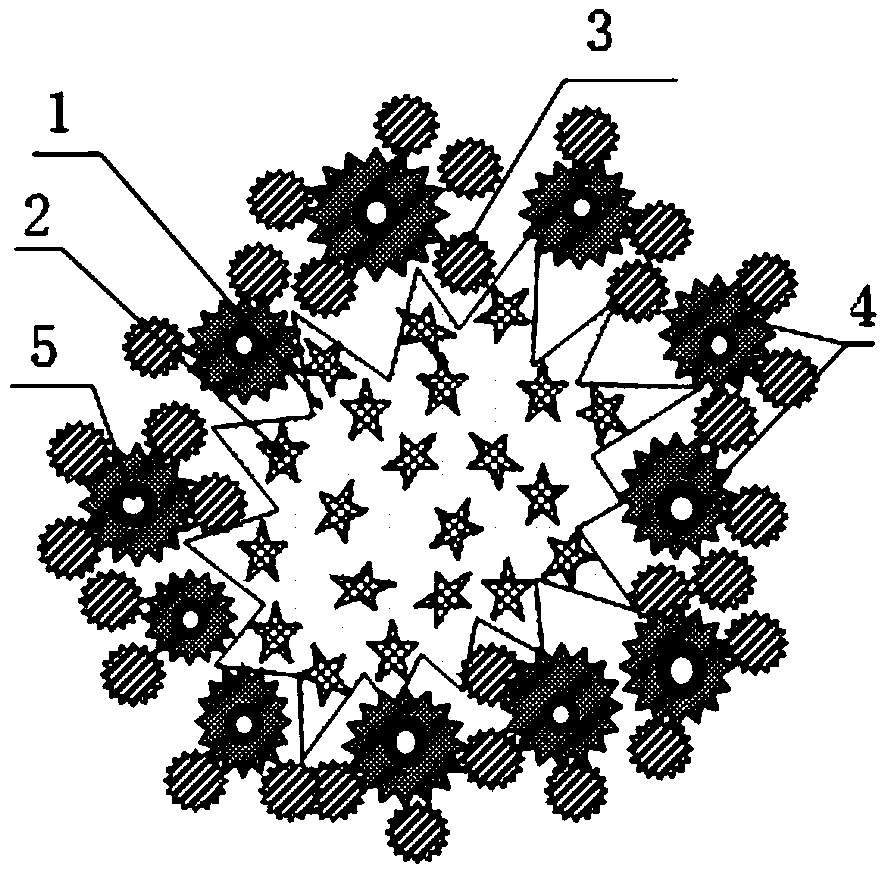

Method for interweaving basalt fibers in asphalt mixture

PendingCN113135693AImprove high temperature stabilityImprove water stabilityPolyesterPolymer science

The invention discloses a method for interweaving basalt fibers in an asphalt mixture, wherein the method comprises the steps: heating SBS modified asphalt to a molten state, and preserving heat for later use; preheating coarse and fine aggregates; heating an asphalt mixture mixing pot to 185+ / -5 DEG C, and mixing the preheated coarse and fine aggregates with chopped basalt fibers, lignin fibers and polyester fibers in the mixing pot; then adding the SBS modified asphalt for heat preservation for mixing; and finally doping mineral powder for mixing to prepare an asphalt mixture doped with the basalt fibers, the lignin fibers and the polyester fibers. On the basis of ensuring the improvement of the high-temperature stability and low-temperature crack resistance of the basalt fibers on the asphalt mixture, the defects of the basalt fibers on the improvement of the water stability are overcome, the improvement characteristics of different fibers on the pavement performance of the asphalt mixture are utilized, and strong points are learned to offset weakness, so that the effect of directionally improving the pavement performance is achieved, an interlacing scheme with optimal comprehensive benefits can be obtained, and thus the service life of a road is prolonged, and the manufacturing cost is reduced.

Owner:YANGZHOU UNIV

A kind of methane catalytic combustion catalyst and preparation method thereof

ActiveCN107262093BGuaranteed high temperature stabilityHigh catalytic activityHeterogenous catalyst chemical elementsDispersed particle separationOxygen vacancyActive component

The invention provides a methane catalytic combustion catalyst and a preparation method thereof. The catalyst includes a carrier and an active component loaded on the carrier. The outer part of the active component is coated with a coating layer that provides oxygen vacancies for it. The catalyst is also Including the catalytic promoter cerium-zirconium solid solution, on the one hand, by coating the coating layer on the outside of the active component, it is beneficial for the oxygen molecules stored in the coating layer to be transferred to the active component in time, thereby maintaining the active component of the catalyst. high temperature stability; on the other hand, the catalyst of the present invention also includes a catalytic promoter cerium-zirconium solid solution, which can generate more oxygen vacancies, and can store and release oxygen in time and effectively, thereby also improving the catalyst activity group. In addition, the cladding layer, the cerium-zirconium solid solution and the carrier are dispersed and contacted with each other, which plays a mutual barrier effect, inhibits the sintering of the carrier, and improves the high-temperature thermal stability and catalytic activity of the catalyst.

Owner:FUZHOU UNIV +1

R-T-B series permanent magnet material as well as preparation method and application thereof

ActiveCN111326305ALow in BHigh Cu contentInductances/transformers/magnets manufactureMagnetic materialsMagnetMetallurgy

The invention discloses an R-T-B series permanent magnet material and a preparation method and application thereof. The R-T-B series permanent magnet material comprises R, Ga, Cu, Al, Fe and B, and further comprises one or more of Ti, Zr and Nb, and the content of R is 28.5-33.03% in percentage by weight; contents of the R-T-B series permanent magnet material are as follows: the content of Ga is 0.35% or more, the content of Cu is 0.4% or above, the content of B is 0.84-0.945%,, the content of Al is less than 0.08%, and the R-T-B series permanent magnet material does not contain Co. The R-T-Bseries permanent magnet material is high in coercive force Hcj and Br, good in magnet temperature stability and excellent in performance; and the demagnetization curve of the R-T-B series permanent magnet material has no step, the relative permeability is low, and the uniformity of the magnetic steel is good.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

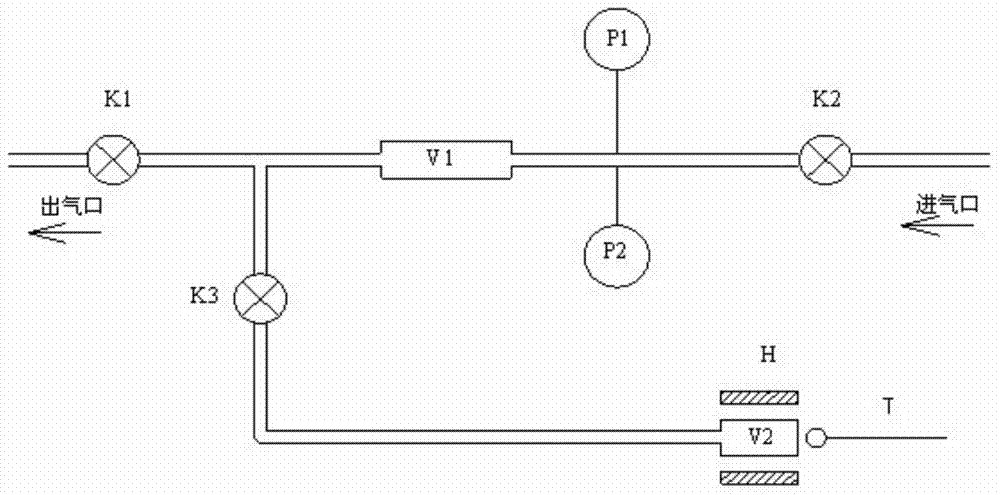

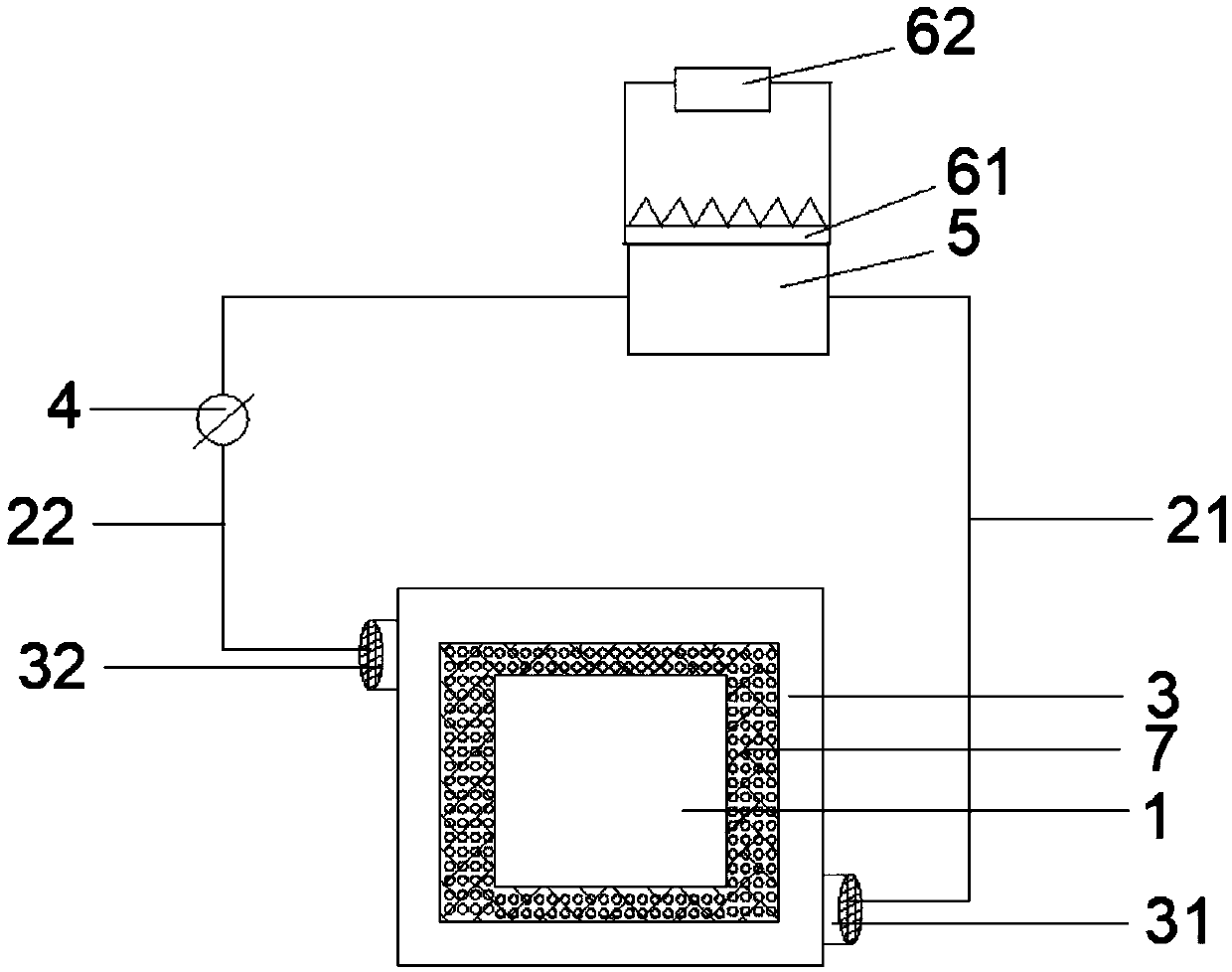

Electric automobile cooling and flame retardant mesh system

InactiveCN109546258AGuaranteed working temperatureImprove insulation effectBattery isolationSecondary cellsWorking temperatureFuel tank

The invention discloses an electric automobile cooling and flame retardant mesh system. The electric automobile includes a cell pack. The electric automobile cooling and flame retardant mesh system includes an insulation oil pipeline, a casing arranged outside the cell pack and an oil pump, wherein the insulation oil pipeline is provided with an insulation oil tank, the top of the insulation oil tank is provided with a cooling device, and the insulation oil direction of the insulation oil pipeline is provided with a circulating flowing through tank, an oil pump and the insulation oil tank. Thesystem is advantaged in that through setting the casing outside the cell pack, heat of the cell pack is taken away by the insulation oil through the casing, and the work temperature of the cell in operation is guaranteed; through setting the cooling device at the top of the insulation oil tank, heat exchange between the insulation oil tank and the cooling device is performed, temperature reduction of the oil in the insulation oil tank is continuously realized, and the heat of the insulation oil is radiated outside by the cooling device; a flame retardant mesh is arranged between the cell packand the casing, hollow glass micro balls are internally arranged, bump force can be buffered by the mesh, the vibration avoidance effect of the cell pack is improved, when the cell pack is combusted,flame retardant performance and safety performance of the cell pack are improved.

Owner:苏州亿智英新能源科技有限公司

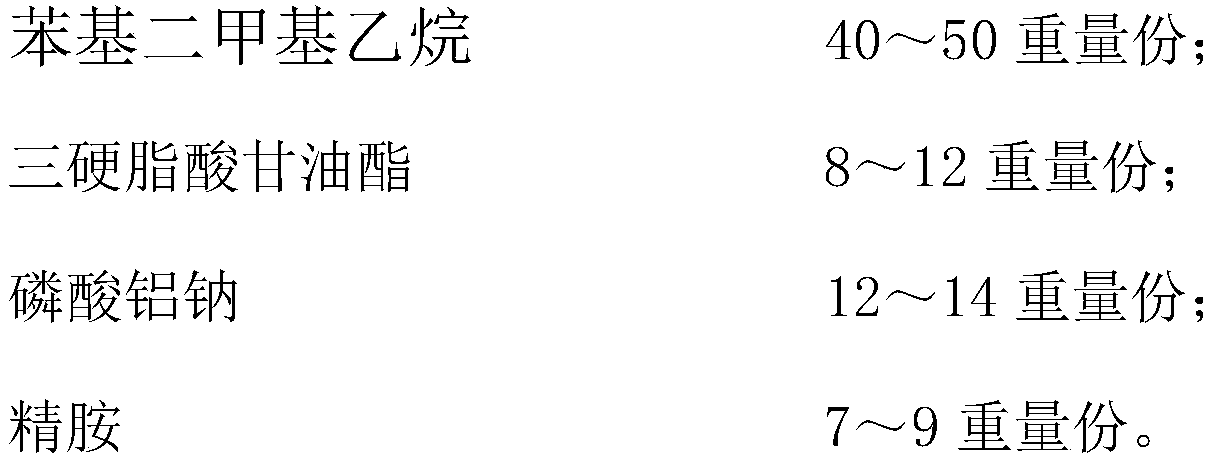

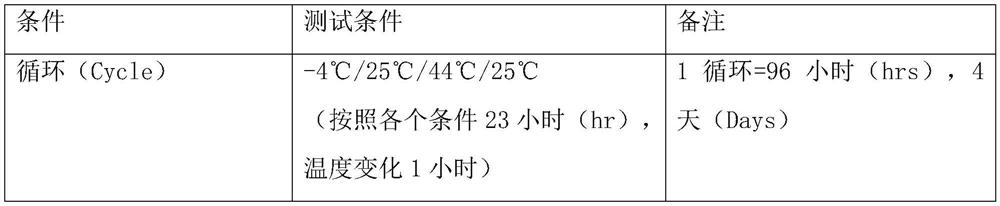

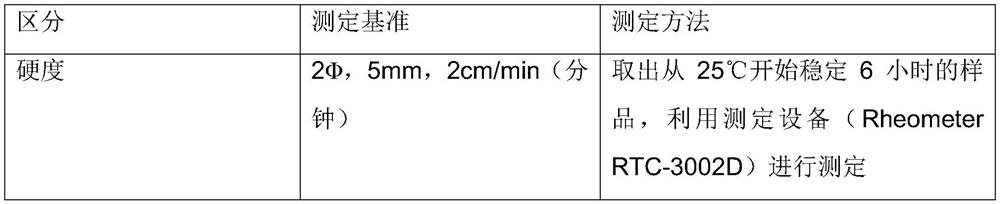

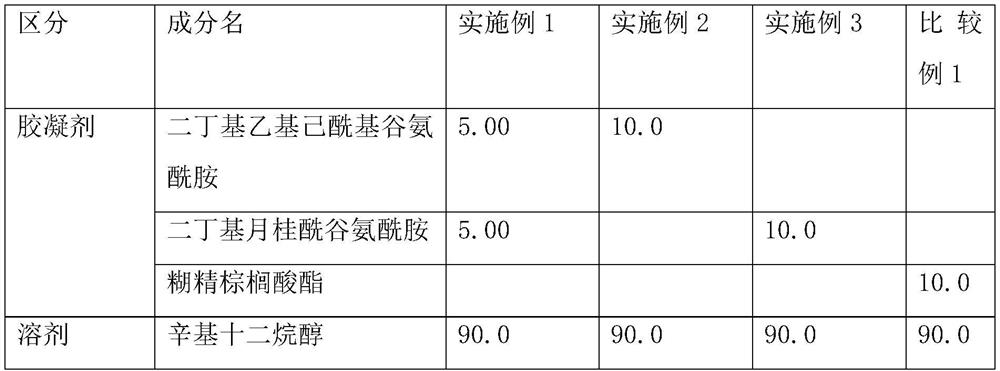

Solid cosmetic composition having improved high-temperature stability and feeling of use, and method for preparing same

PendingCN114831899AHigh melting pointGuarantee structureCosmetic preparationsMake-upPolymer scienceCosmetic component

Disclosed are a solid cosmetic composition having improved high-temperature stability and feeling of use, and a method for preparing the same. According to the solid cosmetic composition having improved high-temperature stability and feeling of use and the method for preparing the same of the present invention, it is possible to provide a solid cosmetic composition having improved high-temperature stability and feeling of use, which can maintain the structure of the contents and ensure high-temperature stability even at a high temperature of about 50 DEG C by increasing the melting point of the cosmetic, and which not only can withstand thermal stress at a high temperature, but also can provide a solid cosmetic composition having improved high-temperature stability and feeling of use. And the cosmetic can bear physical stress caused by external force. Moreover, even when applied to a grinding container, the cosmetic can be normally cut and discharged by a rotary cutting blade at a high temperature, has improved hardness, and can be lightly applied without feeling heavy when used. In addition, a thin and soft feeling of use is provided, so that a natural skin expression, which is a recent makeup trend, can be achieved, and this makes it possible to form hardness in a small amount instead of a conventional structuring agent comprising only waxes, thereby improving the degree of freedom in the design of cosmetic components.

Owner:COSMECCA KOREA CO LTD

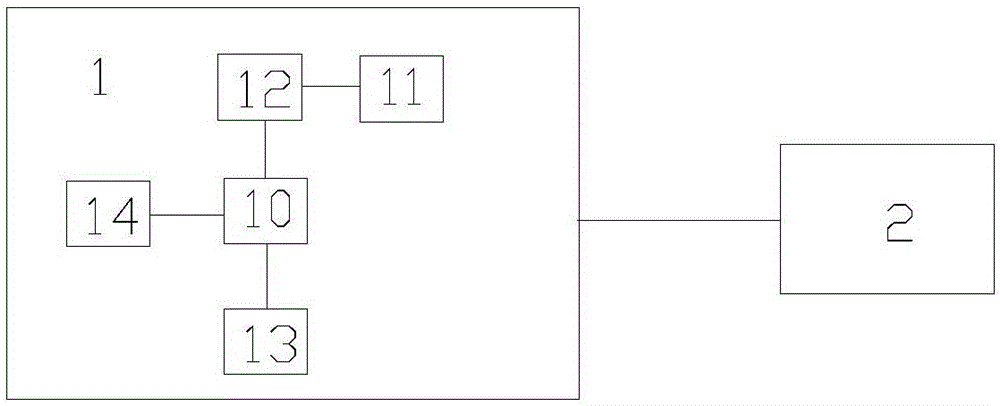

Intelligent surgery laser knife

ActiveCN106539621AGuaranteed high temperature stabilityImprove reliabilitySurgical instrument detailsLaser transmitterLaser Knives

The invention relates to an intelligent surgery laser knife comprising a laser emitter, a laser controller, a self-focusing lens, an optical fiber connector, an optical fiber, a coupler and a scalpel body. Laser beams output by the laser emitter are converged at a point via the self-focusing lens, and then enter the optical fiber via the optical fiber connector, then are coupled by the coupler via the optical fiber; then laser energy is transmitted to a laser knife pen; the laser controller comprises a microprocessing chip, a high-temperature temperature sensor, an analog-digital conversion circuit, a laser pulse width modulation circuit and a laser pulse peak value modulation circuit; the microprocessing chip comprises a temperature determining unit, a pulse width calculation unit, a pulse peak calculation unit, a pulse width control unit and a pulse peak control unit. The intelligent surgery laser knife has great reliability; and laser can be automatically adjusted via the laser knife, so high temperature stability produced by the laser knife can be effectively maintained.

Owner:上海和极实业发展有限公司

A kind of high-temperature connecting agent and its connecting method for alumina ceramic connection

ActiveCN113185316BGuaranteed stabilityAchieving densification by solid-state sinteringCruciblePhysical chemistry

The invention discloses a high-temperature connecting agent for connecting alumina ceramics. The raw material includes 1-10% Ta in terms of mass fraction 2 o 5 , 1~10% TiO 2 , 90%~98% Al 2 o 3 Powder, the sum of the mass fractions of each component is 100%. The invention also discloses a method for connecting alumina ceramics with the high-temperature bonding agent, including step 1: weighing Ta 2 o 5 、TiO 2 and Al 2 o 3 The powder is mixed by ball milling, dried, mixed with PVA, and added with alcohol for ultrasonic dispersion to obtain a suspension; Step 2: Apply the suspension evenly on the surface of the alumina ceramic block to be connected, and pressurize the surface to make good contact with the connecting agent; Step 3: Put the sample into an alumina crucible and place it in a muffle furnace, raise the temperature from room temperature to 1400°C~1650°C at 3°C / min~10°C / min, keep it warm for 0.5h~3h, and then heat it at 5°C / min The cooling rate of min~10°C / min is lowered to 1000°C, and well-connected alumina ceramics can be obtained after cooling. The connecting agent and connecting method of the present invention have high connection layer density, good connection matrix, high temperature resistance, corrosion resistance, The interface bonding strength is high.

Owner:SHAANXI UNIV OF SCI & TECH

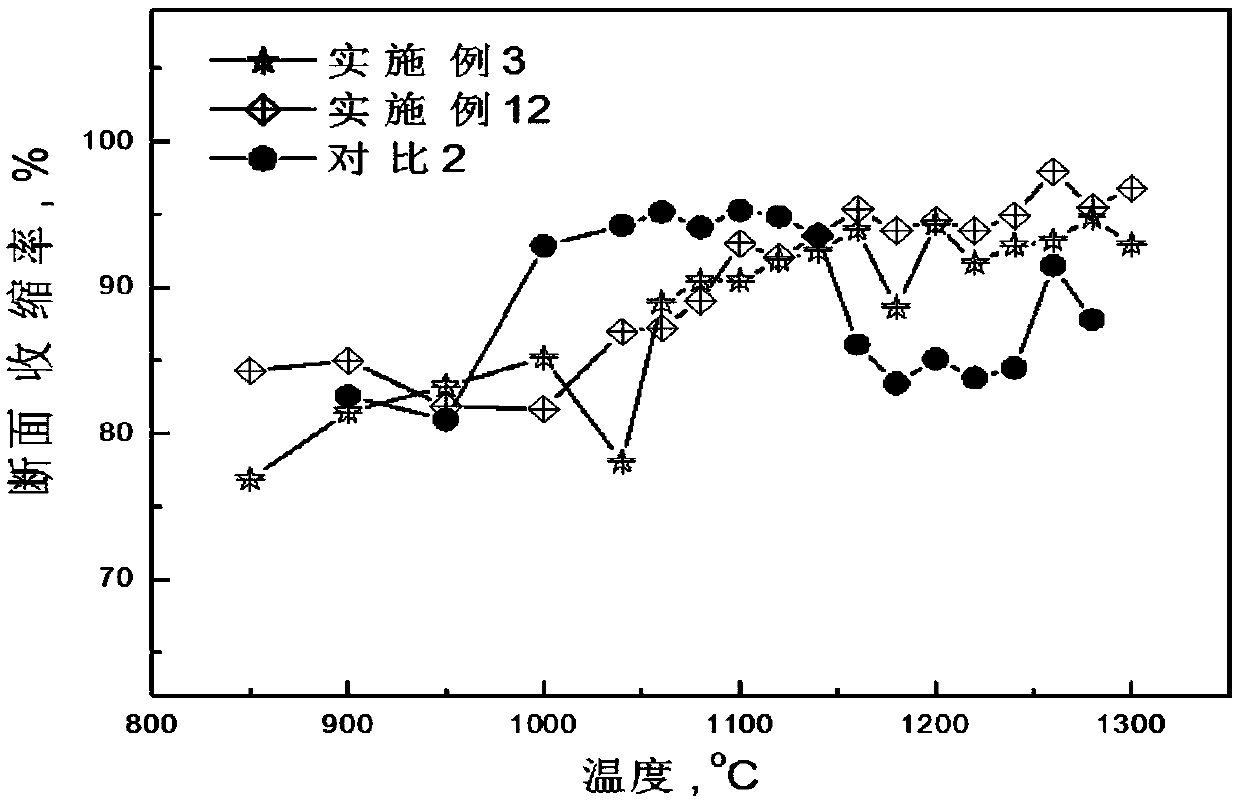

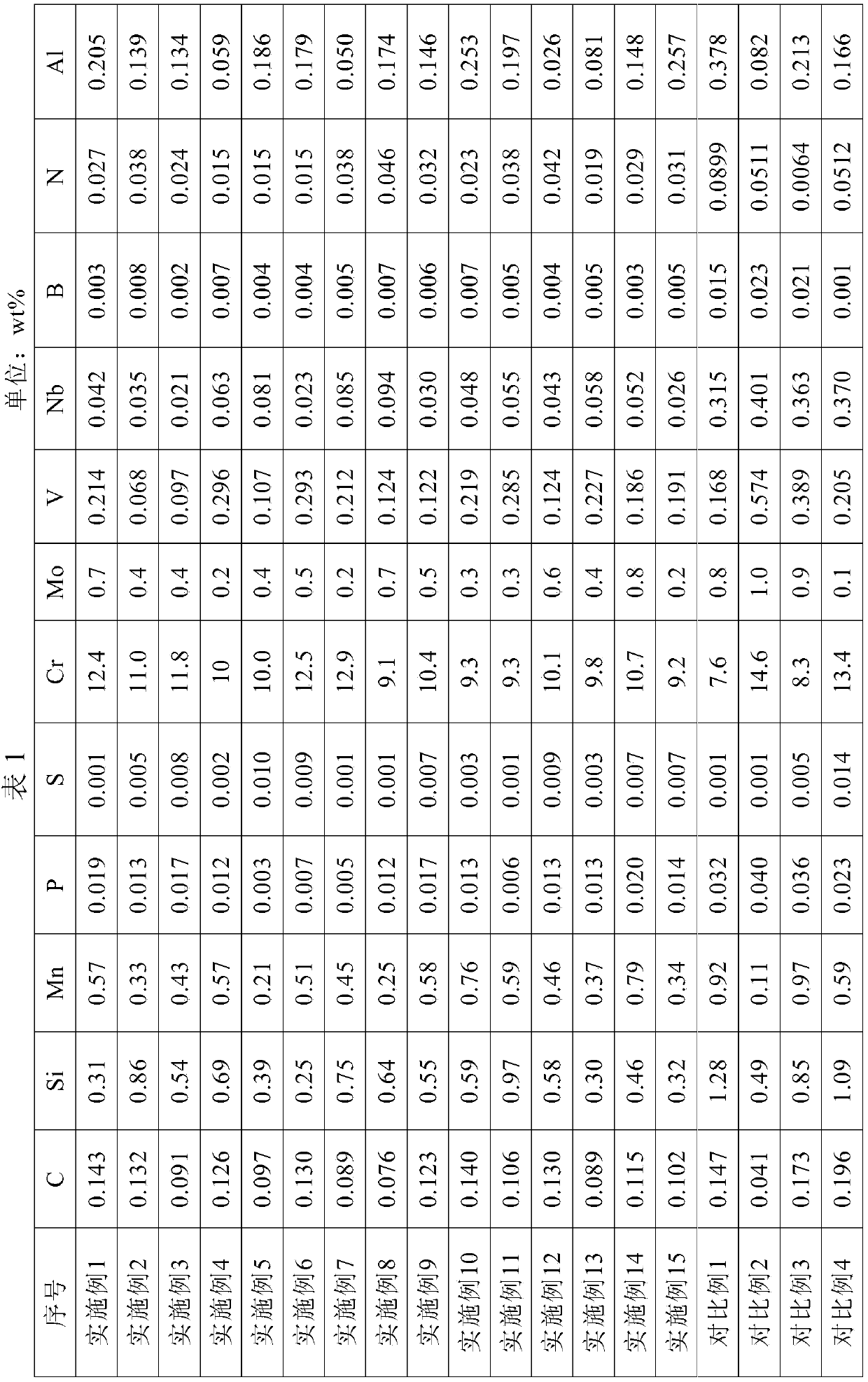

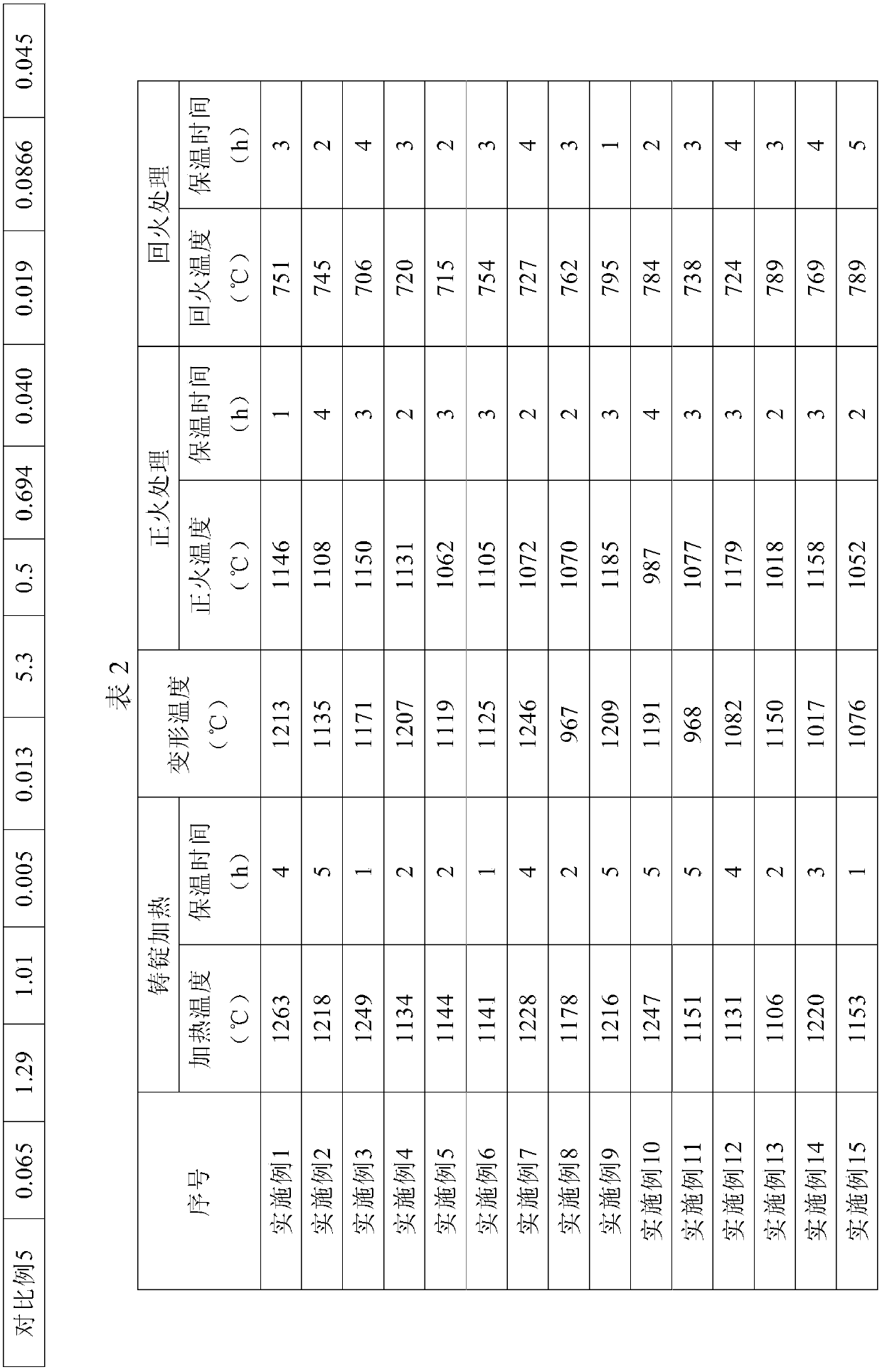

Ultra-supercritical thermal power generating unit steel excellent in steam corrosion oxidization resistance and high-temperature endurance property and preparing method thereof

InactiveCN110629110AImprove thermoplasticityGood industrial manufacturabilityChemical compositionUltimate tensile strength

The invention discloses ultra-supercritical thermal power generating unit steel excellent in steam corrosion oxidization resistance and high-temperature endurance property and a preparing method thereof. The steel comprises, by mass percent, 0.08 to 0.15% of C, 0.2 to 1.0% of Si, 0.2 to 0.8% of Mn, not larger than 0.02% of P, not larger than 0.01% of S, 9.0 to 13% of Cr, 0.2 to 0.8% of Mo, 0.05 to0.32% of V, 0.02 to 0.1% of Nb, 0.002 to 0.008% of B, 0.005 to 0.3% of Al, 0.01 to 0.05% of N, not larger than 0.05% of residual elements of Ni+Zr+Pb+Sn+As, and the balance Fe and inevitable impurities. (Cr+1.5Mo+1.5Si+2Nb+2V) / (0.3Mn+30C+20N) is larger than or equal to 2.3 and smaller than or equal to 4.5, the extrapolated 100-thousand-hour endurance strength of the steel at the temperature of 620 to 650 DEG C is larger than or equal to 60 MPa, weight increment of 2000-hour oxidation corrosion at the temperature of 625 DEG C is smaller than or equal to 20 mg / cm<2>, the coefficient of thermalexpansion is 9 to 15*10<-6>K, and the steel is particularly suitable for large-scale producing of boiler tubes of an ultra-supercritical thermal power generating unit of 620 to 650 DEG C or other heat-resisting devices.

Owner:BAOSHAN IRON & STEEL CO LTD

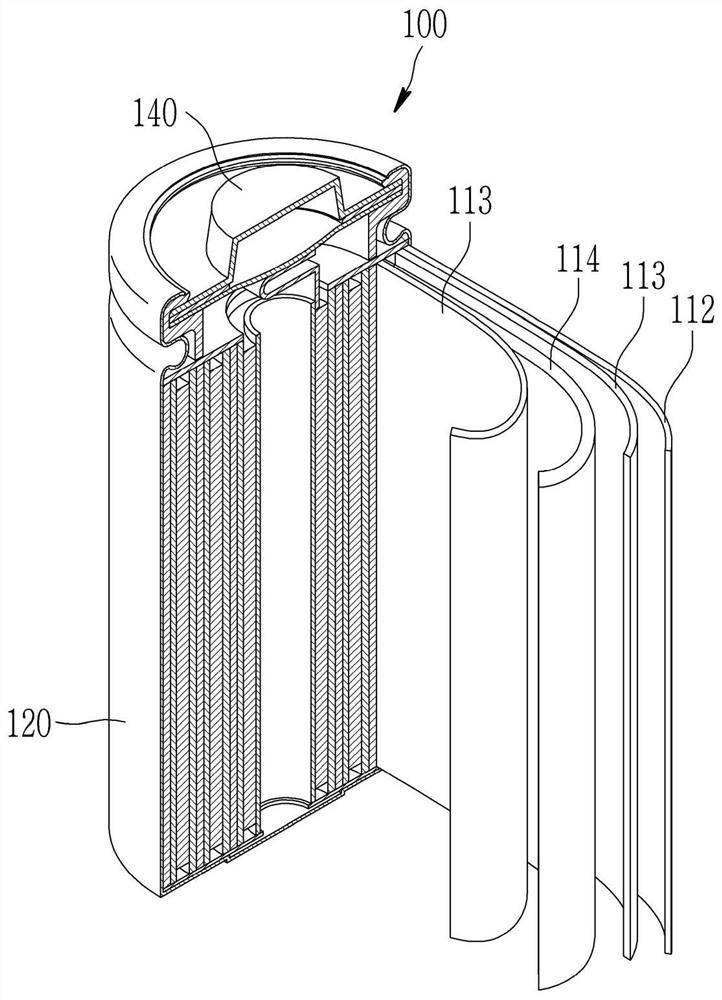

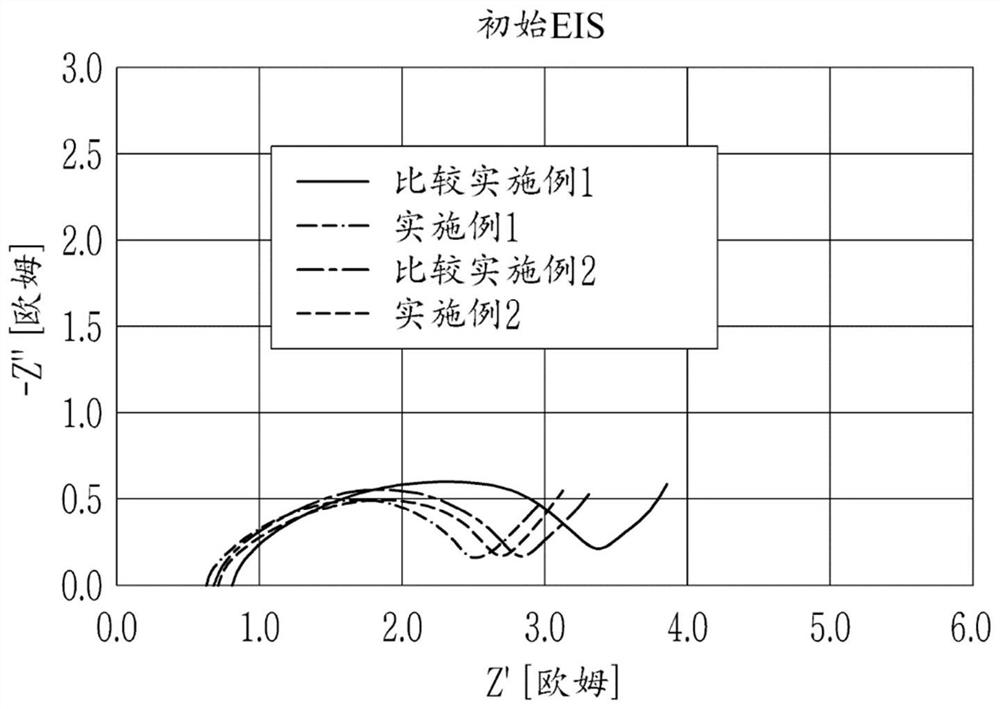

Electrolyte for lithium secondary battery and lithium secondary battery comprising same

PendingCN112567558AImproved cycle life characteristicsGuaranteed high temperature stabilityGroup 4/14 element organic compoundsSmall-sized cells cases/jacketsOrganic solventPhysical chemistry

The present disclosure relates to an electrolyte for a lithium secondary battery and a lithium secondary battery comprising same, the electrolyte comprising: a non-aqueous organic solvent; a lithium salt; and an additive, wherein the additive includes a compound represented by formula 1 and a cathodic film former. Formula 1 is as described in the specification.

Owner:SAMSUNG SDI CO LTD

A Construction Technology of Hot-mix Asphalt Mixture Equal-thick Gravel Pavement

ActiveCN105803883BStrong anti-rutting performanceRuts do not appearIn situ pavingsCrushed stoneRoad surface

The invention provides a construction technology of a pavement made from a hot-mix asphalt mixture and large-grain-size crushed stone.Crushed stone playing a supporting role is sprayed to a lower bearing layer in a bonding mode through a layer spreading method, then the hot-mix asphalt mixture is spread on the sprayed crushed stone, rolling and curing molding are performed, and the bituminous pavement is obtained.The technology comprises the following steps that firstly, a first layer of asphalt and crushed stone are sprayed, wherein the grain size D of the crushed stone is larger than Dmax-5 mm and smaller than or equal to Dmax; secondly, the crushed stone is trimmed and stably pressed; thirdly, a second layer of asphalt is sprayed after the crushed stone is stably pressed; fourthly, the hot-mix asphalt mixture is mixed; fifthly, the hot-mix asphalt mixture is conveyed; sixthly, the hot-mix asphalt mixture is sprayed; seventhly, the hot-mix asphalt mixture is rolled; eighthly, curing and traffic opening are performed.According to the construction technology, the problem that ruts are likely to be produced on a bituminous pavement is solved, the adopted technology is low in difficulty, the manufacturing cost is low, and the application range is wide.

Owner:王壹帆

A superalloy with gradient nanostructure surface layer and its preparation method

ActiveCN112646964BImprove mechanical propertiesGuaranteed high temperature stabilitySurface layerMetallic materials

The invention discloses a high-temperature alloy with a gradient nanostructure surface layer and a preparation method thereof, belonging to the technical field of nanometerization of the surface of metal materials. The surface mechanical grinding technology is used to process the superalloy, and the spherical head is pressed into the surface of the material to a certain depth for grinding, so that the surface layer of the material produces gradient plastic deformation, and the surface of the superalloy forms a gradient structure from nano-grains to micro-grains. The structure produces a large hardness gradient from the surface to the inside, which solves the problems of superalloys such as coarse grains on the surface, uneven microstructure, and insufficient mechanical properties. The invention has the characteristics of simple processing, low energy consumption, suitable for industrial application and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

An intelligent surgical laser knife

ActiveCN106539621BGuaranteed high temperature stabilityImprove reliabilitySurgical instrument detailsLaser transmitterLaser Knives

Owner:上海和极实业发展有限公司

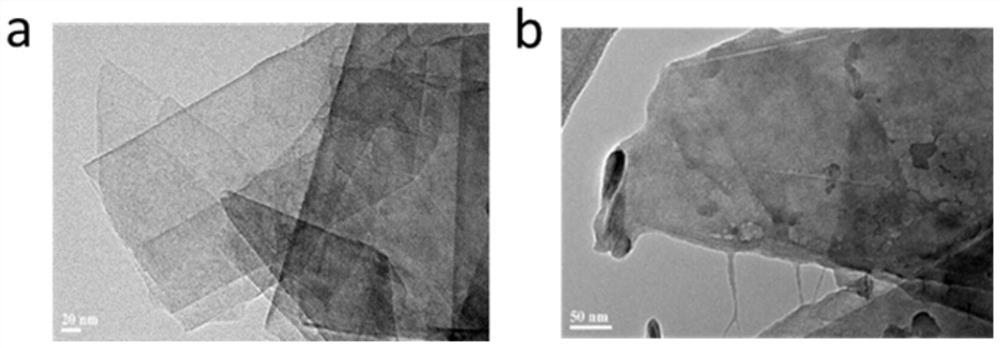

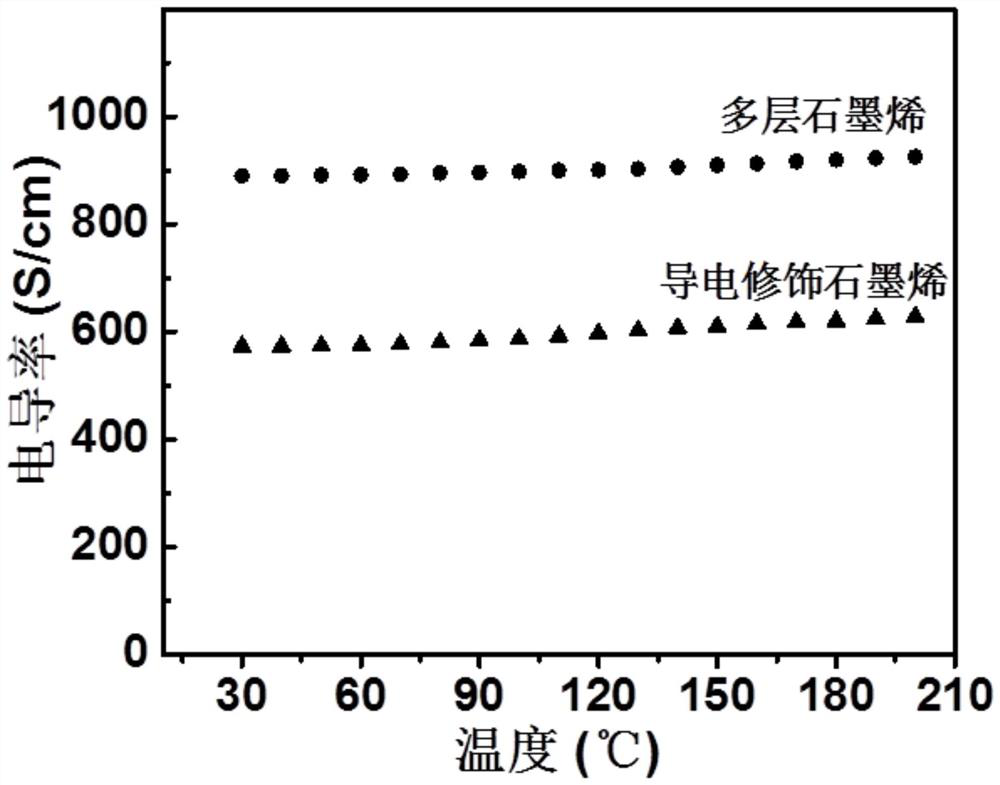

PTC composite material containing polyethylene, carbon black and conductive modified graphene and preparation method

The invention discloses a PTC composite material containing polyethylene, carbon black and conductive modified graphene, which is prepared from the following components in parts by weight: 50-75 parts of polyethylene, 1-8 parts of conductive modified graphene, 2-15 parts of compatibilizer and 20-40 parts of carbon black. The PTC composite material of the invention has the characteristics of low room temperature resistivity, high PTC strength, low NTC strength after peak temperature, good resistance reproducibility, low cost and the like, and can be used for preparing low room temperature resistivity and safe and reliable self-controlling temperature electricity Heat tracing devices and overcurrent and overheat protection devices have broad application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH +1

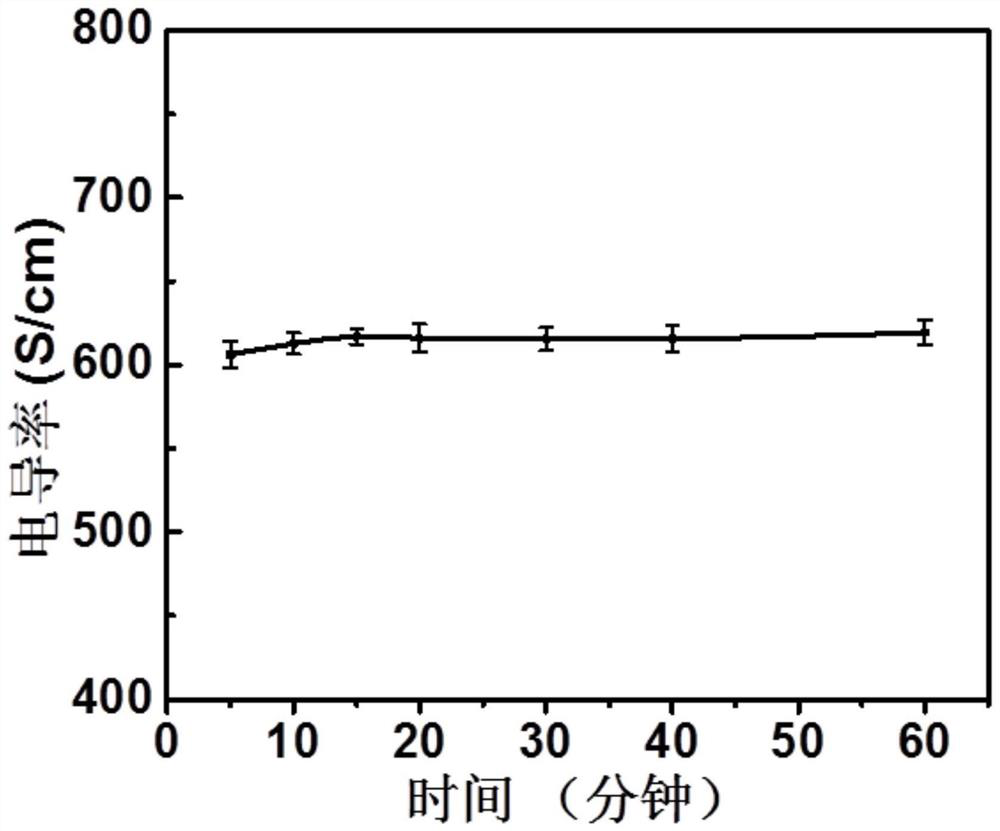

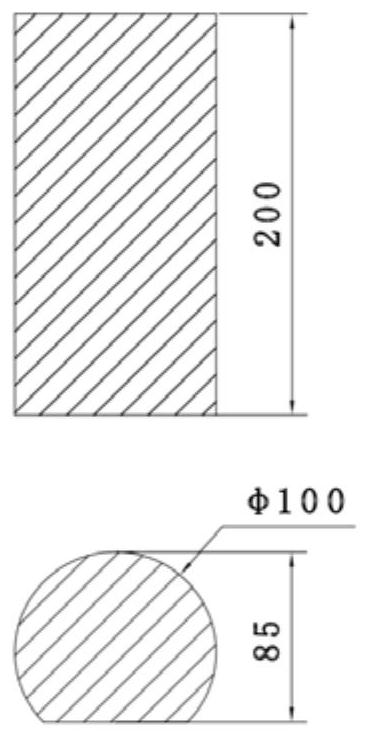

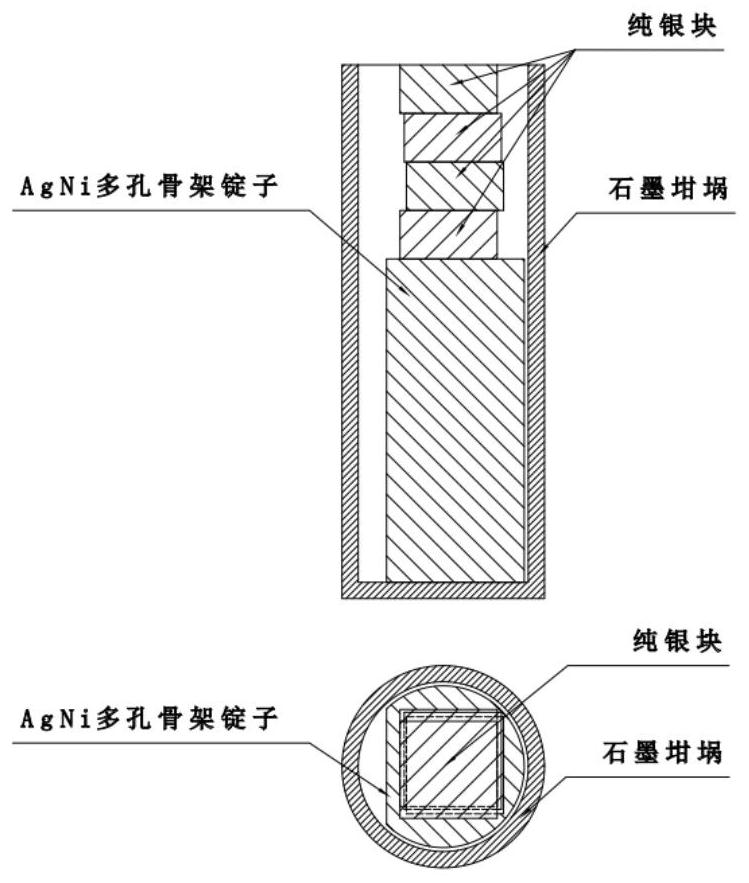

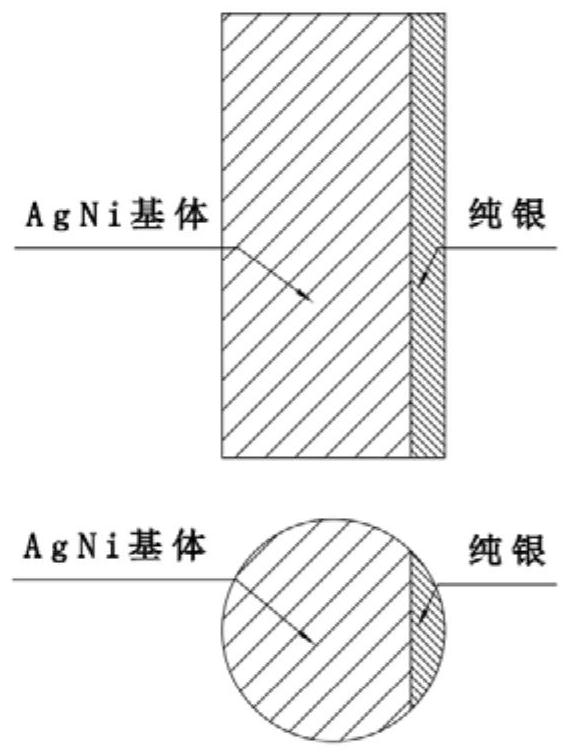

Method for preparing agni electrical contact material based on foaming infiltration process and product thereof

ActiveCN114086014BLow and stable temperature riseGuaranteed mechanical propertiesTransportation and packagingMetal-working apparatusFoaming agentIngot

The invention discloses a method and a product for preparing AgNi electrical contact materials based on a foaming infiltration process. The technical scheme is that a foaming agent is added to AgNi mixed powder for sintering strengthening, and the sintering-strengthened AgNi powder is wrapped with a separator and sintered Above the liquid phase, it is crushed and sieved to obtain high-strength porous AgNi powder. The porous AgNi powder is isostatically pressed into a special columnar porous skeleton ingot, and then the pure silver sheet is placed above the skeleton and placed in a graphite crucible. The skeleton ingot is infiltrated at high temperature to obtain AgNi / Ag composite ingot with high silver content and low resistivity, and the ingot is extruded into a thin strip and finally punched into AgNi electrical contact material. The invention simultaneously solves the problem of composite extrusion of thin strips and the problem that low-nickel and high-silver AgNi electrical contacts can only be made by solid-phase sintering process. The service life and other performance have been greatly improved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com