Warm mix asphalt additive and preparation method thereof

A technology of warm-mix asphalt and additives, which is applied in building insulation materials, building components, climate change adaptation, etc. It can solve the problems of negative impact on asphalt's low-temperature crack resistance, inability to widely apply to asphalt pavement, and reduce the performance of asphalt mixture. Low cost, improved performance, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

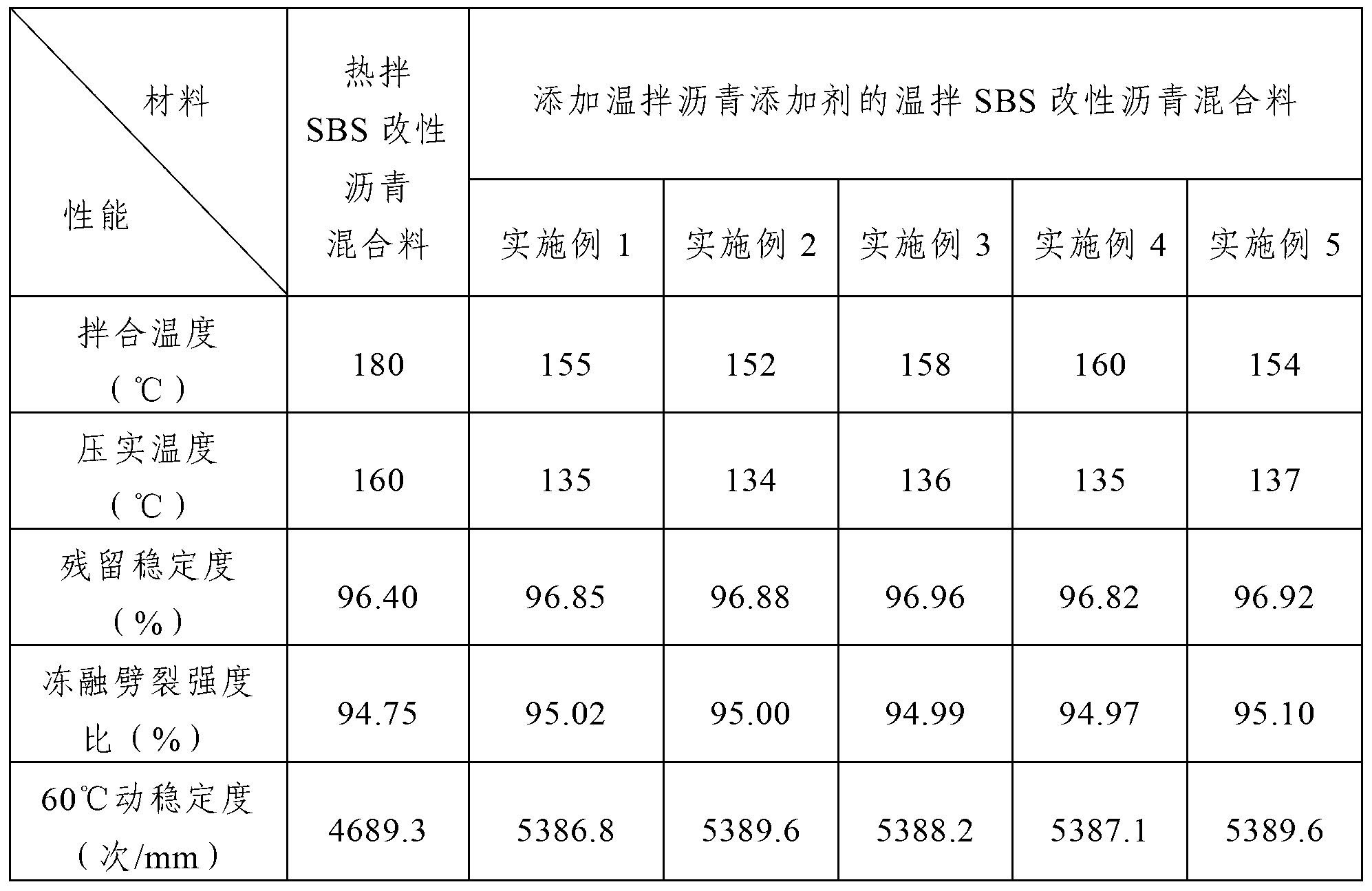

Embodiment 1

[0019] The warm-mix asphalt additive in this embodiment is made of the following raw materials in parts by weight: 16 parts of polyethylene wax, 18 parts of chlorinated paraffin-70, 40 parts of diatomaceous earth, 2 parts of stearamide, and 3 parts of solid anti-stripping agent; preferably Preferably, the polyethylene wax has a melting point of 100° C., and the solid anti-stripping agent is sodium lignosulfonate.

[0020] The preparation method of the warm mix asphalt additive in this example is as follows: respectively grind polyethylene wax and stearamide into micropowders with a particle size not greater than 0.075 mm, and then grind chlorinated paraffin-70, diatomaceous earth, solid anti-stripping agent and The final polyethylene wax and hard amide were placed together in a high-speed ball mill, and ball milled at a ball milling rate of 350r / min for 35min to obtain a warm mix asphalt additive.

Embodiment 2

[0022] The warm-mix asphalt additive in this embodiment is made of the following raw materials in parts by weight: 18 parts of polyethylene wax, 7016 parts of chlorinated paraffin, 42 parts of diatomaceous earth, 1.5 parts of stearamide, and 2 parts of solid anti-stripping agent; preferably , the melting point of the polyethylene wax is 105° C., and the solid anti-stripping agent is sodium dodecylbenzenesulfonate.

[0023] The preparation method of the warm mix asphalt additive in this example is as follows: respectively grind polyethylene wax and stearamide into micropowders with a particle size not greater than 0.075 mm, and then grind chlorinated paraffin-70, diatomaceous earth, solid anti-stripping agent and The final polyethylene wax and hard amide were placed together in a high-speed ball mill, and ball milled at a ball milling rate of 500r / min for 38min to obtain a warm mix asphalt additive.

Embodiment 3

[0025] The warm-mix asphalt additive in this embodiment is made of the following raw materials in parts by weight: 15 parts of polyethylene wax, 15 parts of chlorinated paraffin-70, 50 parts of diatomaceous earth, 2 parts of stearamide, and 4 parts of solid anti-stripping agent; preferably Specifically, the polyethylene wax has a melting point of 110° C., and the solid anti-stripping agent is sodium lignosulfonate.

[0026] The preparation method of the warm mix asphalt additive in this example is as follows: respectively grind polyethylene wax and stearamide into micropowders with a particle size not greater than 0.075 mm, and then grind chlorinated paraffin-70, diatomaceous earth, solid anti-stripping agent and The final polyethylene wax and hard amide were placed together in a high-speed ball mill, and ball milled at a ball milling rate of 500r / min for 30min to obtain a warm mix asphalt additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com