Patents

Literature

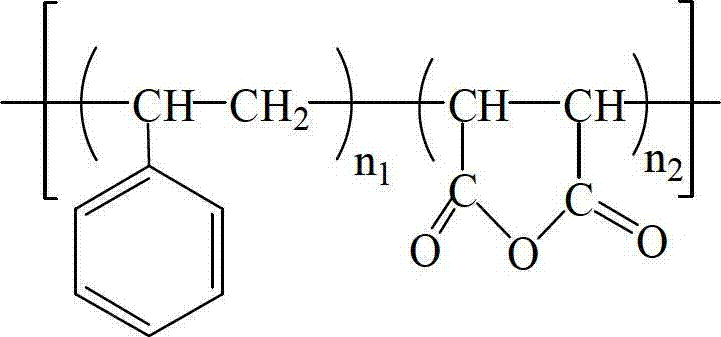

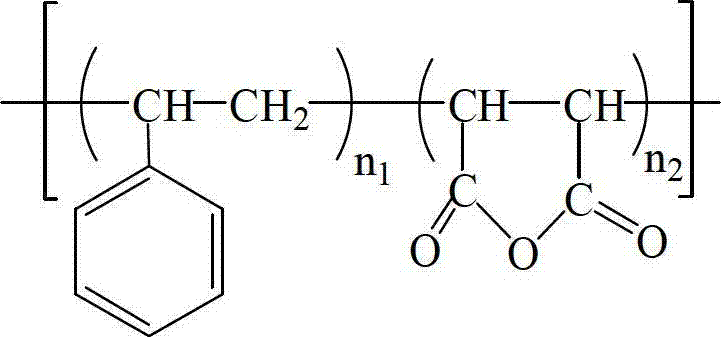

497 results about "Styrene-maleic anhydride copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

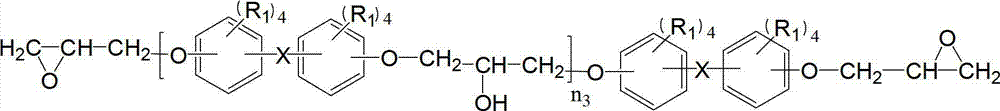

High-strength fiber glass reinforced ABS composite material and preparation method thereof

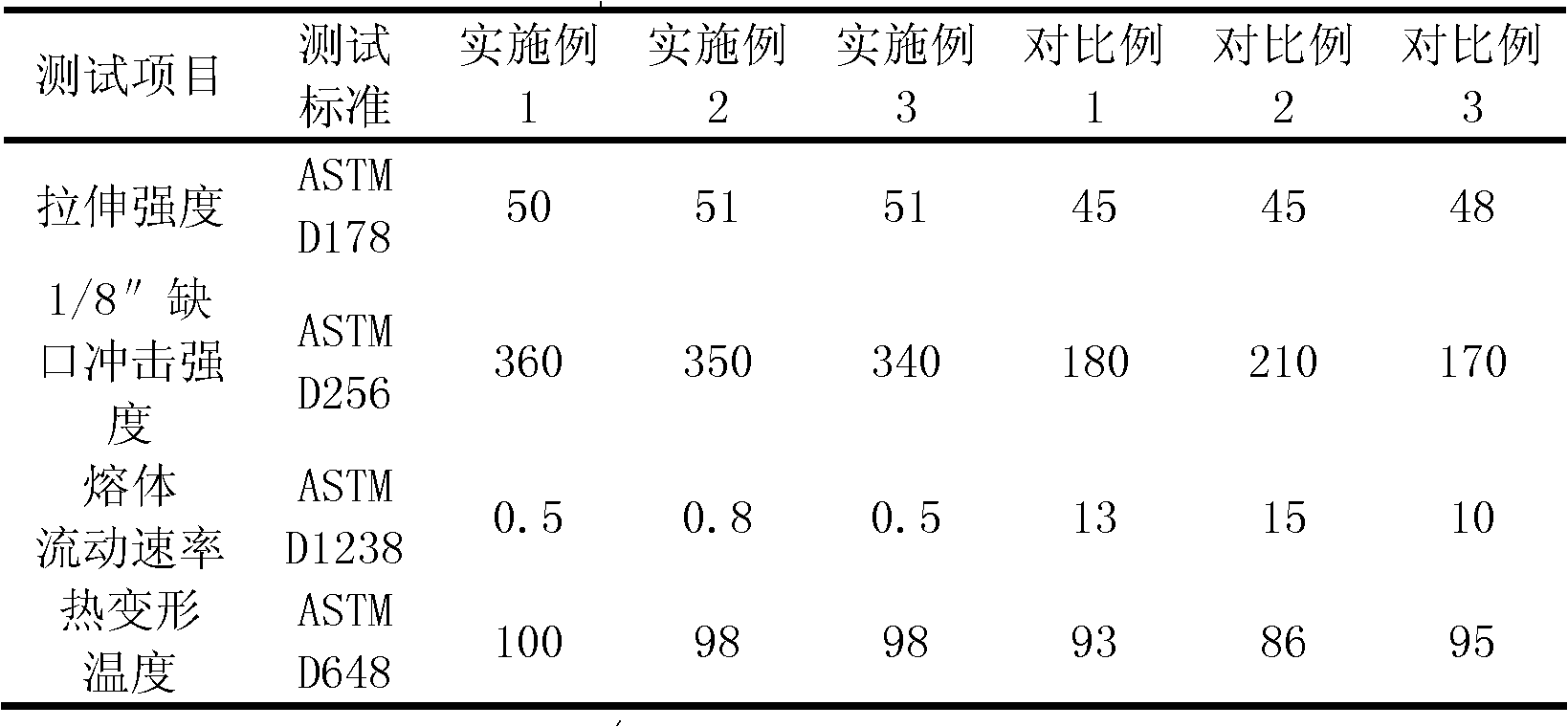

The invention discloses a high-strength fiber glass reinforced ABS composite material and a preparation method thereof. The composite material is prepared by ABS, glass fiber and a compatilizer, wherein the compatilizer is made by combining epoxide resin with styrene-maleic anhydride copolymer. Compared with the prior art, the invention has good compatibilization by using the epoxide resin and the styrene-maleic anhydride copolymer as a compatilizer; the glass fiber can be caked well with the ABS substrate; the prepared fiber glass reinforced ABS composite material is good in intensity, tenacity, heat-resistant property, flowing property, and the like; angularity is ideally solved; the composite material brings about no glass emergence on the surface in the process of injection molding, and has good surface quality and fabrication property. Besides, the invention has simple preparation process and is suitable for large-scale popularization and application.

Owner:贵州省复合改性聚合物材料工程技术研究中心

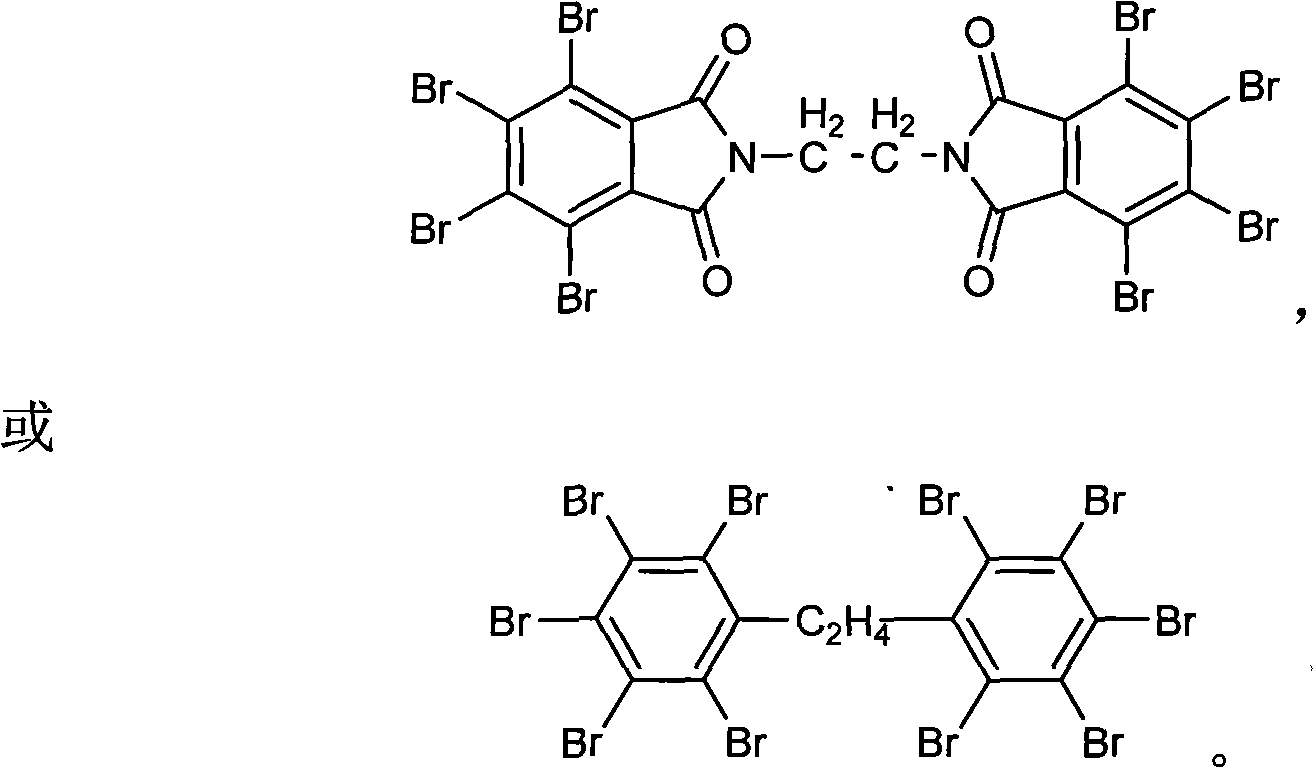

Thermosetting resin composition and use thereof

ActiveCN102964775AOvercoming the disadvantages of dielectric propertiesReduce the chance of delamination explosionSynthetic resin layered productsMetal layered productsEpoxyTetrabromobisphenol A

The invention discloses a thermosetting resin composition which comprises epoxy resins except brominated epoxy resin, an styrene maleic anhydride copolymer and an additive flame retardant, and further comprises an active ester. The thermosetting resin composition can be used for preparing resin sheet materials, resin compound metal copper foils, prepregs, laminates, copper clad laminates, printed circuit boards, etc. The thermosetting resin composition substantially reduces probability of delamination of PCB substrate, overcomes disadvantages of deterioration of system dielectric properties due to introduction of tetrabromobisphenol A, and has advantages of good heat stability and heat and humidity resistance, low dielectric constant and dielectric loss tangent, and good flame resistance.

Owner:GUANGDONG SHENGYI SCI TECH

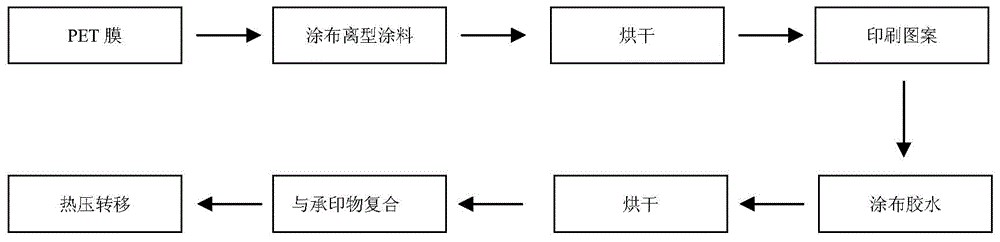

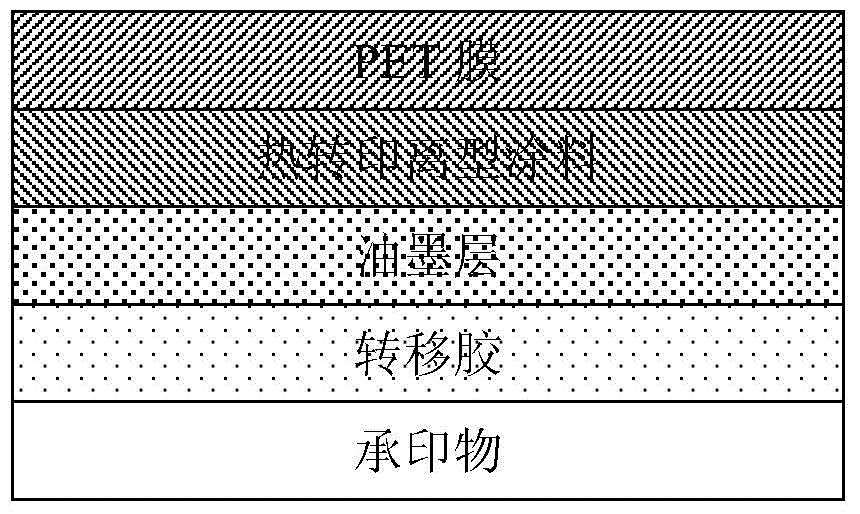

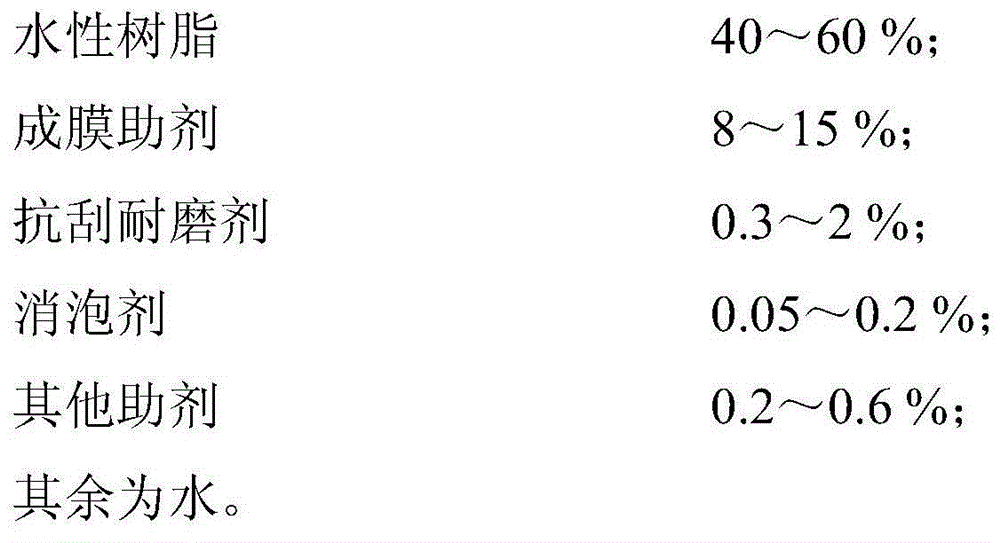

Water-based heat transfer printing release coating, and preparation method and application thereof

InactiveCN104403544ASolve the hardnessSolve the shortcomings of poor scratch resistancePolyurea/polyurethane coatingsThermographyWater basedEpoxy

The invention belongs to the technical field of preparation of release coatings and discloses a water-based heat transfer printing release coating, and a preparation method and application thereof. The water-based heat transfer printing release coating comprises the following ingredients by mass percent: 40-60 percent of water-based resin, 8-15 percent of a coalescing agent, 0.3-2 percent of a scratch-resistant anti-wear agent, 0.05-0.2 percent of a foam killer, 0.2-0.6 percent of other additives and the balance of water, wherein the water-based resin is at least one of polyurethane resin, polyacrylic acid resin, polycarbonate, polymide resin, polyethersulfone resin, epoxy resin, thermoplastic polyester resin, a styrene-maleic anhydride copolymer and phenolic resin. According to the invention, application of the water-based formula to preparation of the water-based heat transfer printing release coating is realized, the material prescription is environment-friendly, and the preparation process is safe and environment-friendly. Compared with a conventional solvent product, the water-based heat transfer printing release coating is better in heat resistance, high in glossiness and better in printing ink adhesion, effectively enhances the printing ink protecting function and can be kept colorful in a long term.

Owner:GUANGZHOU HUMAN CHEM

Polyether graft poly-carboxylic acid concrete water reducer preparation

Production of polyether graft poly-carboxylic acid concrete water reducer is prepared by sulfonating styrene-anhydride multipolymer with anhydride content 10í½50 mol% and relative molecular mass 2000í½20000 from sulfonating agent of non-destructive acid anhydride group, esterifying grafting polyether side chain on acid anhydride key, and dissolving in water. Its advantages include simple process, no catalyst, higher fluidity of cement concrete and compression strength.

Owner:海南中科翔新材料科技有限公司

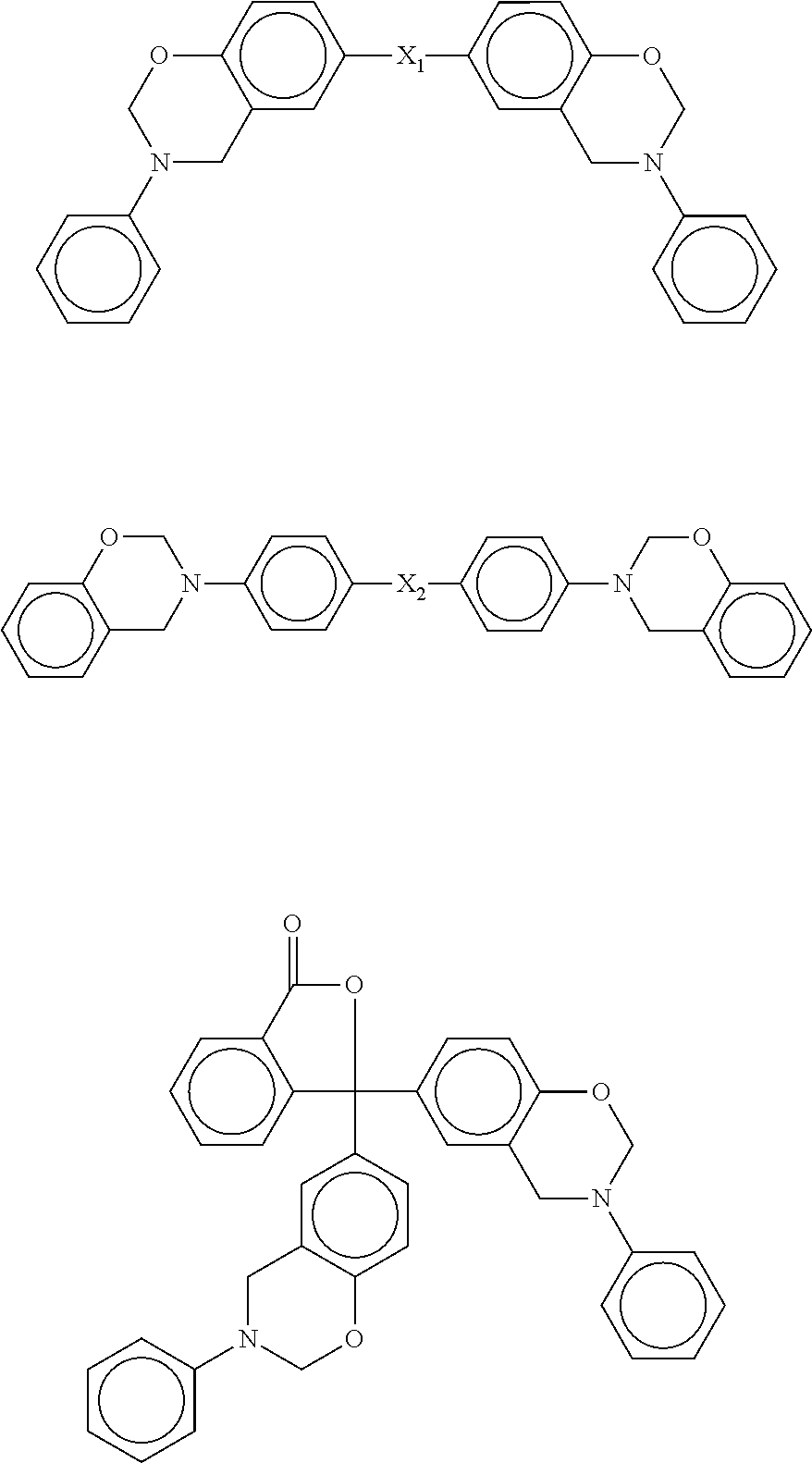

Modified ABS antistatic material and preparation method thereof

The invention discloses a modified ABS antistatic material and a preparation method thereof. The antistatic material is formed by melting the mixture in an injection machine after mixing PEEA, maleic anhydride grafted ABS resin (or styrene maleic anhydride copolymer SMA), ABS resin, zlnc oxide whisker, coupler and other additives according to a given proportion. The antistatic ABS material has the advantages of low surface resistance, permanent static resistance, light color and good mechanics performance; and moreover, the antistatic ABS material has appropriate cost, no toxicity and pollution, simple formation processing technology, easy realization and promising application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

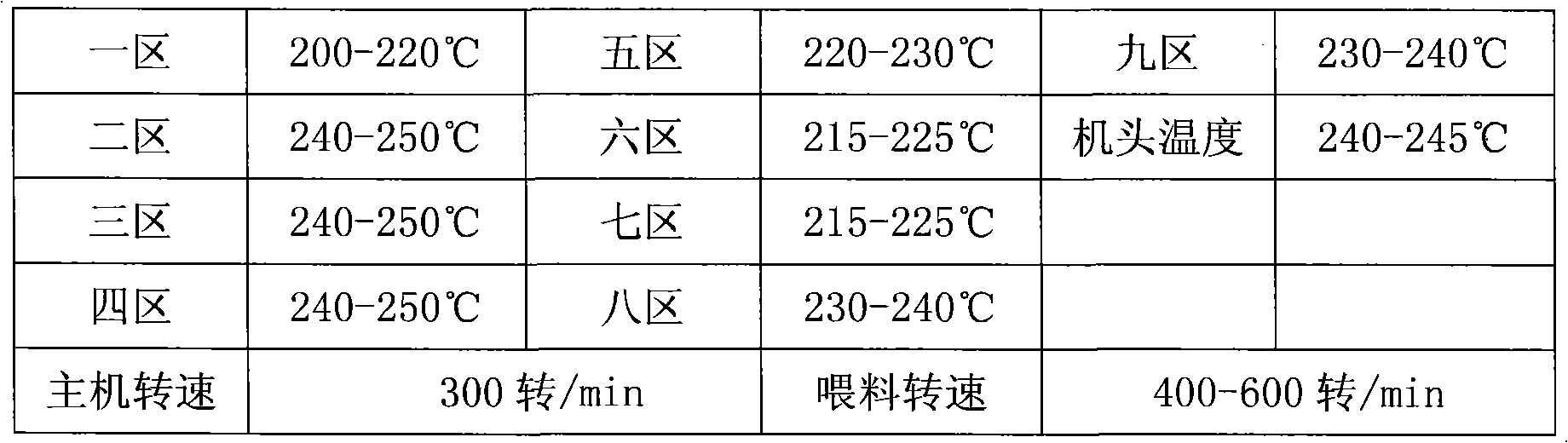

Preparation of weather resistant PC and ASA copolymer alloy

A method for preparing weather resistance polycarbonate / acrylonitrile-styrene-acrylic ester copolymer alloy (PC / ASA alloy) is to prepare the PC / ASA alloy by adopting PC resin, ASA resin, SMA resin, E-EA-MAH, antioxidizer, lubricant, antiultraviolet absorbent and the like which are treated with blending and extrusion in a double screw extruder. The manufactured PC / ASA alloy has greatly increased weather resistance, high impact strength, good fluidity, good heat resistance, excellent comprehensive performance, with the poor weather resistance of original PC / ABS being improved, and the PC / ABS alloy is applicable to the places with higher requirement on weather resistance.

Owner:深圳市比克新材科技有限公司

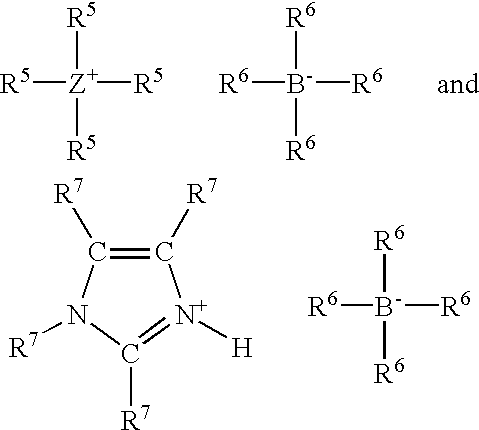

Thermosetting resin composition and application

The invention discloses a thermosetting resin composition, which comprises the following components: bifunctional or multifunctional epoxy resin, styrene-maleic anhydride copolymer SMA as a curing agent with styrene / maleic anhydride molar ratio of 5-12:1, low-bromine or high-bromine BPA type epoxy resin or tetrabromo bisphenol A as a fire retardant, an accelerator and a solvent. The resin composition after curing has quite low dielectric property, higher heat reliability and better toughness, has quite low dielectric constant and dielectric loss coefficient, high Td, better toughness and excellent PCB processability with a copper-clad plate made of glass fiber cloth and other reinforcing materials, is suitable for manufacturing a copper-clad plate and a semi-cured plate for PCB, and can also be used in common application of the epoxy resin, such as molding resin, composite materials for buildings, automobiles and aviation, and the like.

Owner:ITEQ DONGGUAN

Powder coating composition, method for the curing thereof, and articles derived therefrom

InactiveUS20030134978A1Avoid coatingSynthetic resin layered productsThin material handlingAcrylic resinPolymer SMA

A powder coating composition includes an acid-functional polyester resin and a matting agent selected from styrene-maleic anhydride copolymers and acid-functional acrylic resins. The compositions provide low gloss finishes at low curing temperatures, as well as consistent gloss over a wide range of curing temperatures.

Owner:ROHM & HAAS CO

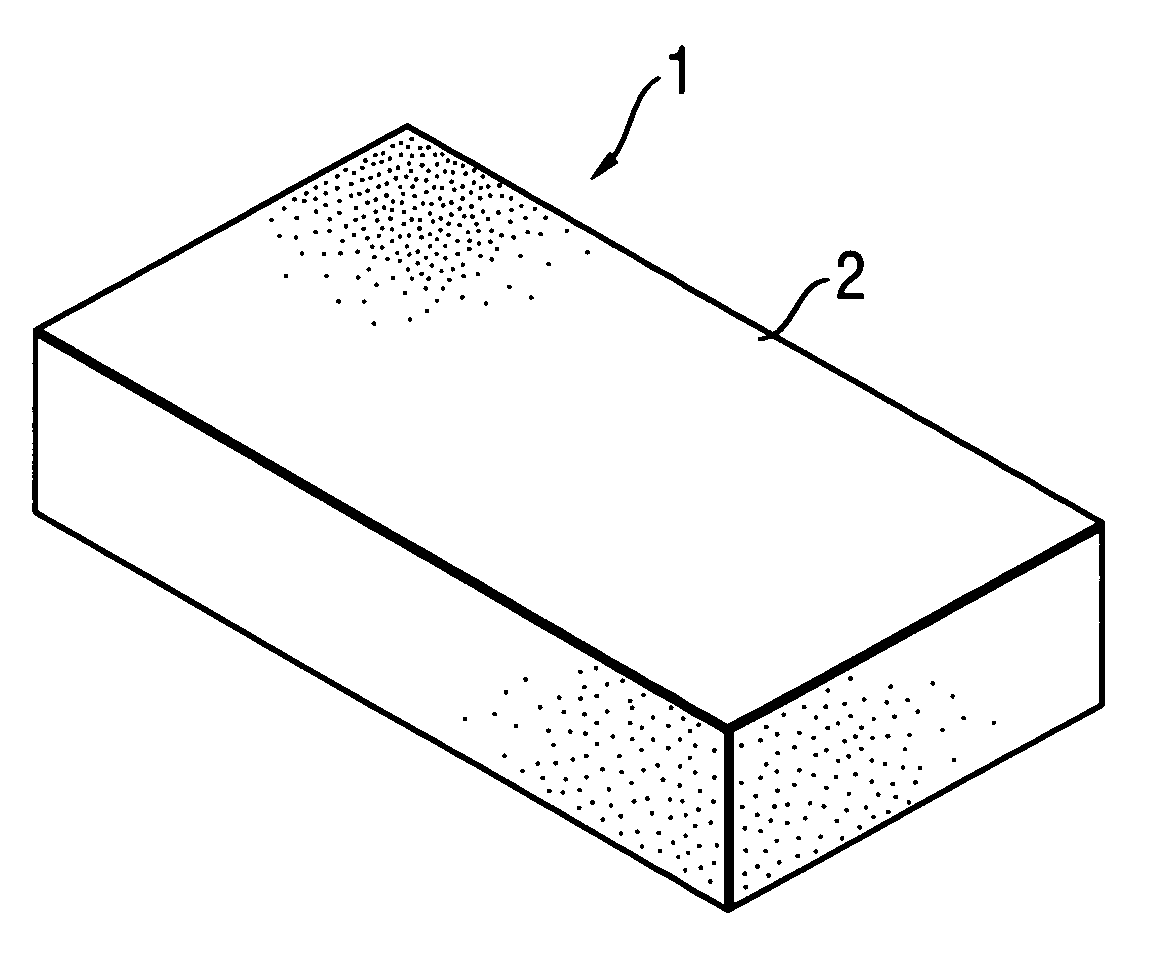

Cleaning implement comprising a modified open-cell foam

A cleaning implement comprises a modified open-cell foam with a density in the range from about 5 to about 1,000 kg / m3 and with an average pore diameter in the range from about 1 μm to about 1 mm, comprising an amount in the range from about 1 to about 2,500% by weight, based on the weight of the unmodified open-cell foam, of at least about one water-insoluble polymer (b), selected from polystyrene, styrene copolymers, polybutadiene, butadiene copolymers, polyvinylesters, polyvinylethers, copolymers from (meth)acrylic acid with at least one (meth)acrylate, and polyurethanes, with the proviso that styrene-acrylonitrile-C1-C10-alkyl (meth)acrylate terpolymers, styrene-butadiene-n-butyl acrylate terpolymers, and styrene-maleic anhydride copolymers are excluded.

Owner:THE PROCTER & GAMBLE COMPANY

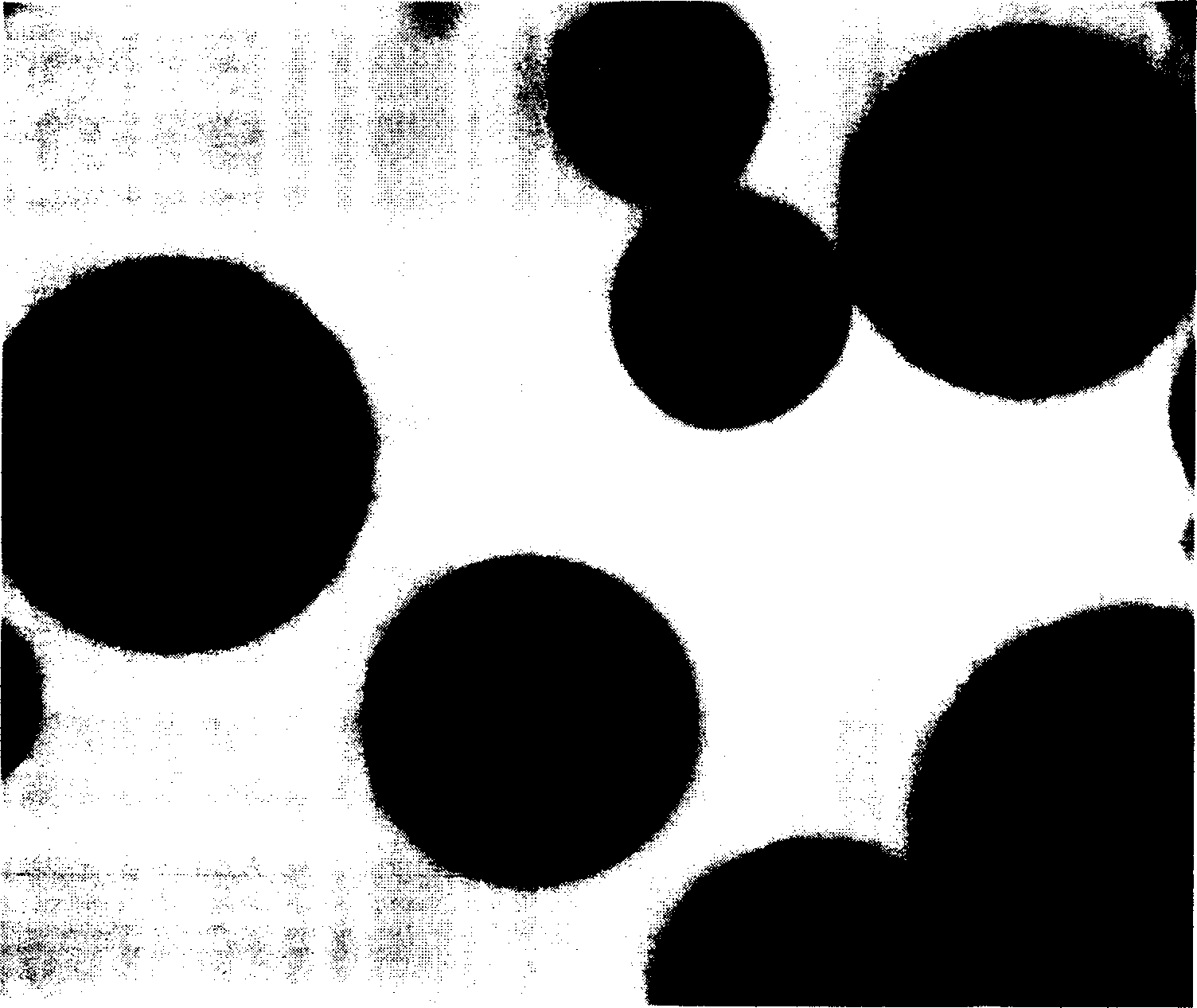

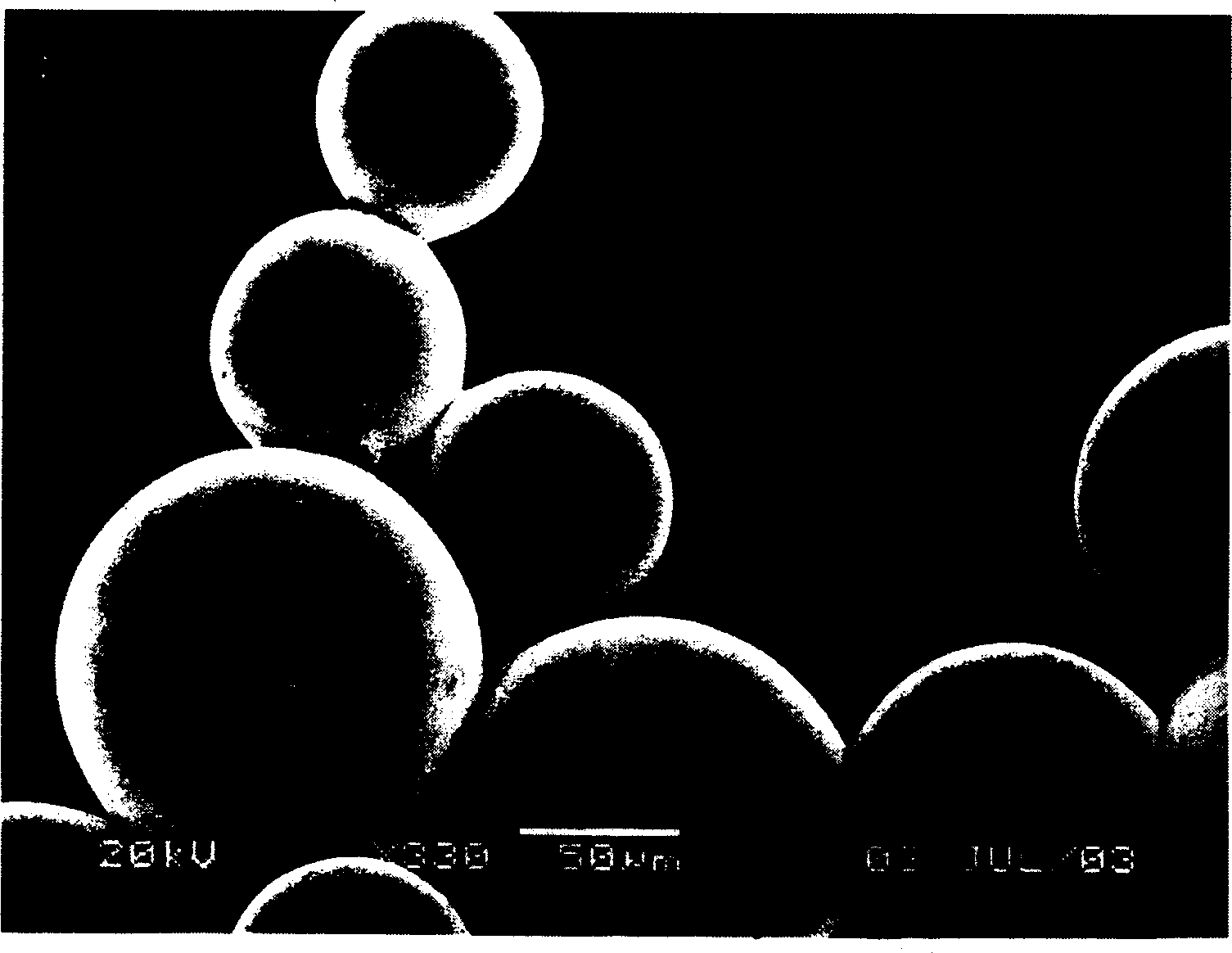

Preparation method of microcapsule for electrophoretic display

InactiveCN1544141AOvercoming performance shortcomingsUniform particle size distributionMicroballoon preparationNon-linear opticsHydrolysateElectrophoresis

The invention discloses an electrophoresis-displaying microcapsule and its preparing method, which recondenses hydrolysate of styrene-maleic anhydride copolymer and glutin to prepare the microcapsule. By the proper technique, it firstly emulsifies the encapsulated matter in the styrene-maleic anhydride copolymer solution, adds in the gultin, and then recondenses them by adding acid and / or water. Its advantages: provision of synthetic high-molecular styrene-maleic anhydride copolymer overcomes the disadvantage that the natural gum Arabic high molecule is easy to degrade so as to affect performance of the microcapsule, and reduces the cost. And by proper technique, it can prepare circular microcapsules which are stable, sealed and have more uniform particle size distribution.

Owner:ZHEJIANG UNIV

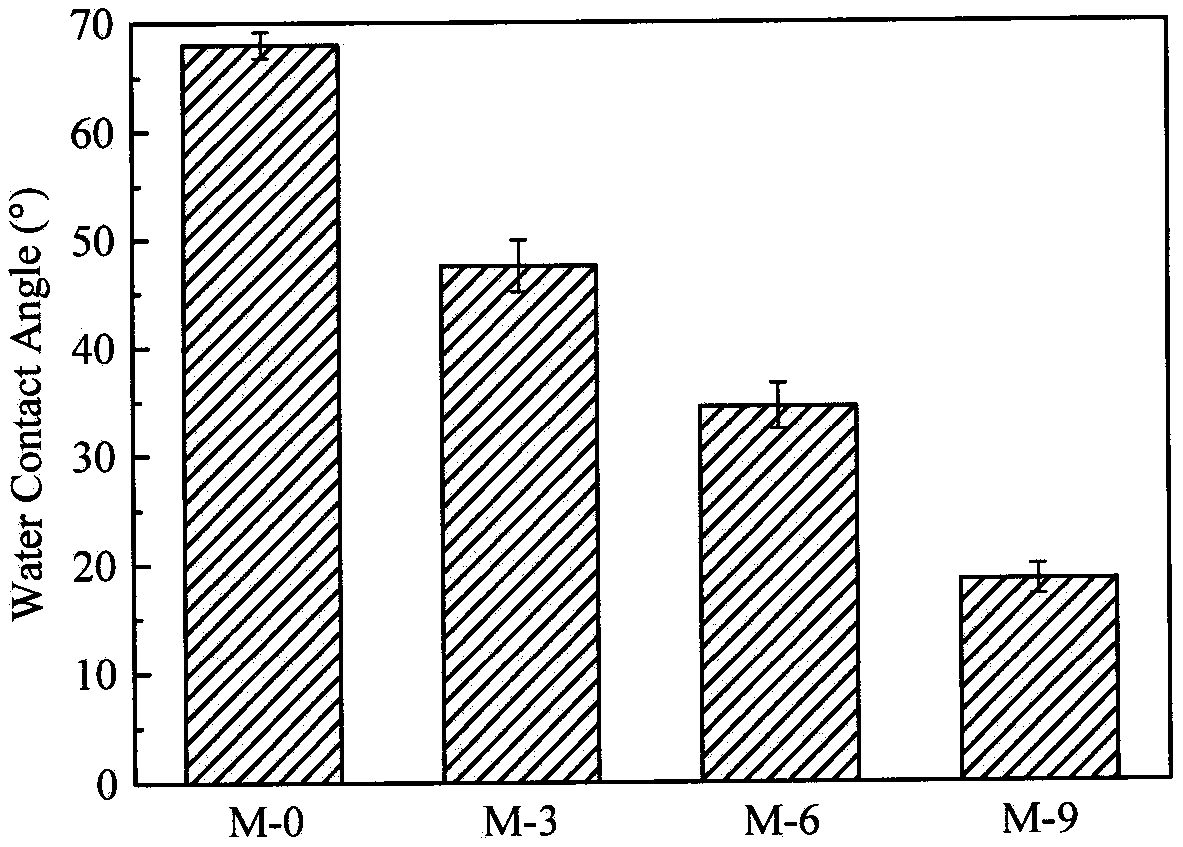

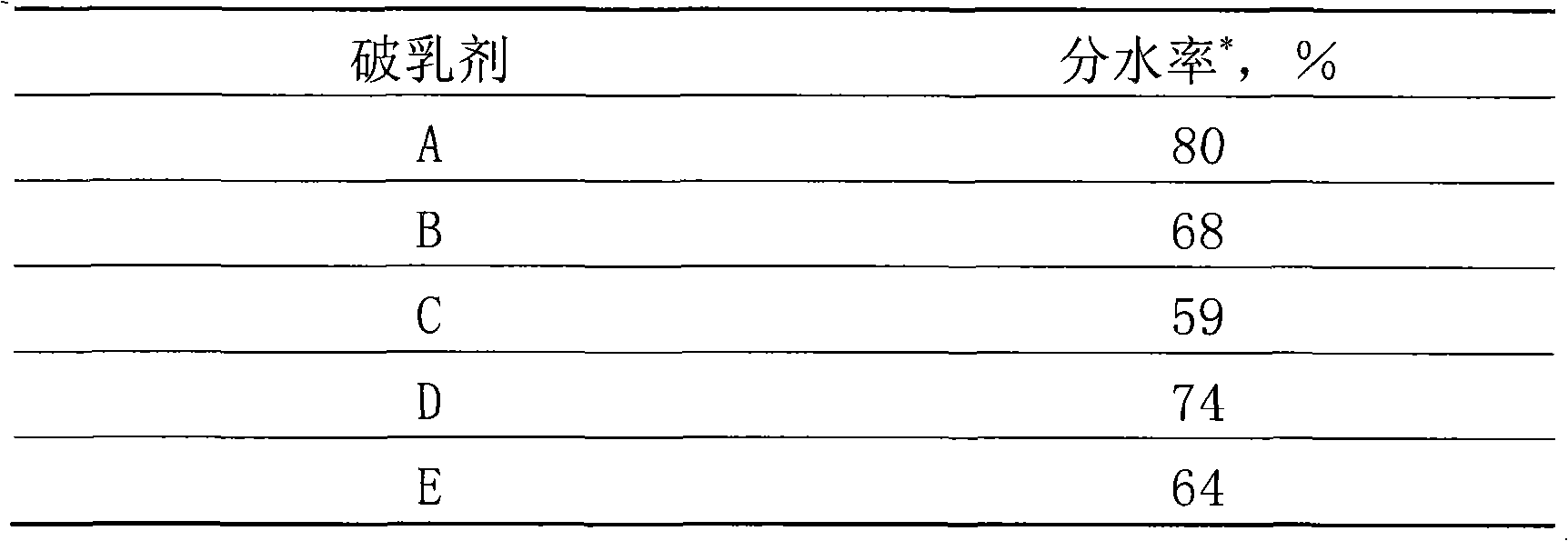

Preparation method of super-hydrophilic polymer membrane with demulsification function

ActiveCN109316981AWith demulsification functionMembranesSemi-permeable membranesTetrafluoroethyleneDemulsifier

The invention provides a preparation method of a super-hydrophilic polymer membrane with a demulsification function. Specifically, polyvinylidene fluoride (PVDF) or polypropylene (PP) or poly-tetrafluoroethylene (PTFE) is used as a base membrane material and blended with a styrene-maleic anhydride copolymer (SMA) to prepare a membrane casting solution, a PVDF / SMA hyperfiltration membrane is prepared by adopting an immersion precipitation phase inversion method, a hyperbranched polyether demulsifier is conjugated to the surface of the polymer membrane by utilizing a chemical reaction between anhydride on the surface of the membrane and a terminal hydroxyl group of the hyperbranched polyether demulsifier, and thus the demulsification effect, hydrophily, water flux and the retention rate of the modified membrane are all improved, efficient oil-water separation is achieved, membrane pollution is lowered, and the service life of the membrane is prolonged.

Owner:TIANJIN POLYTECHNIC UNIV

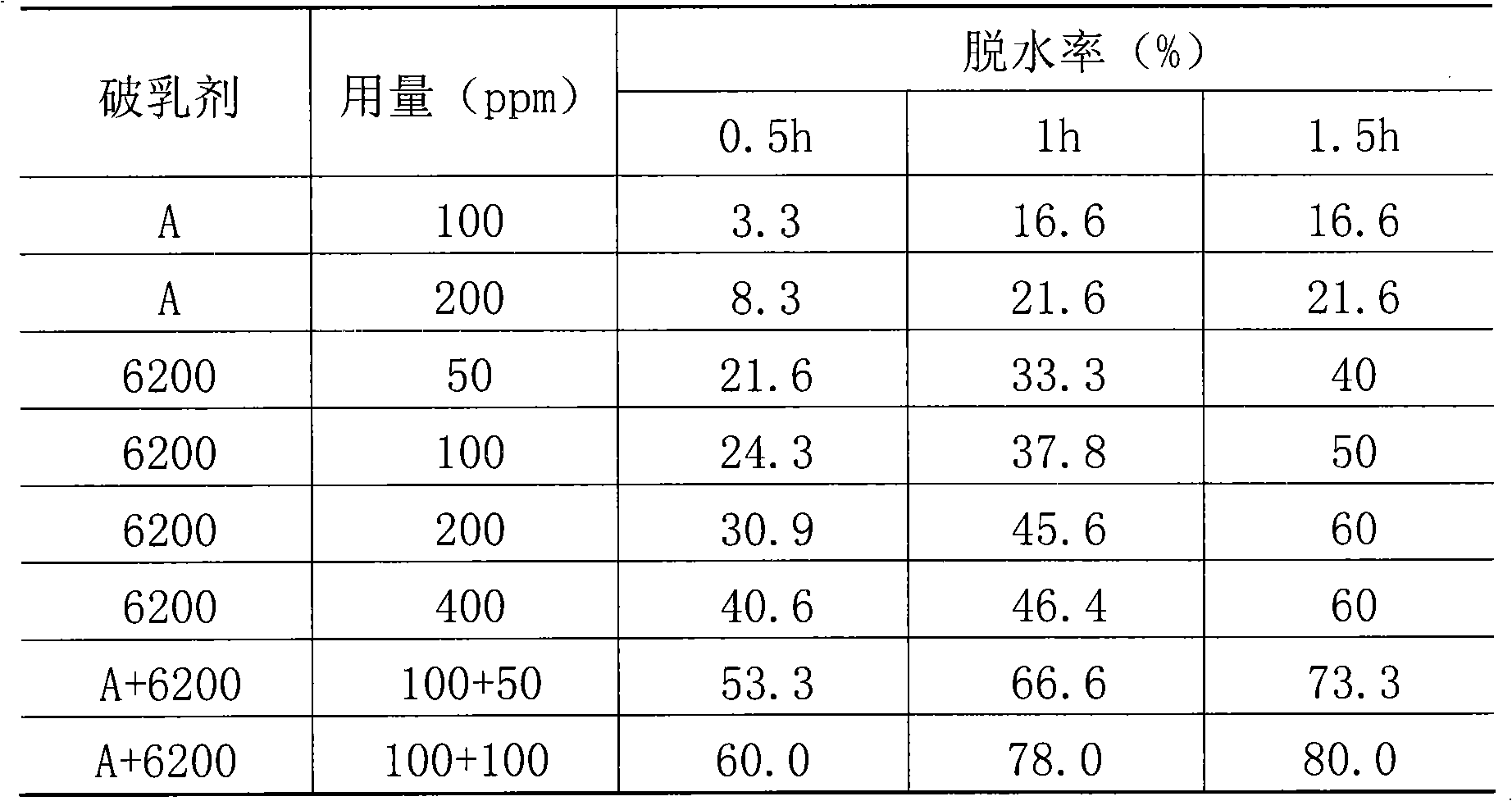

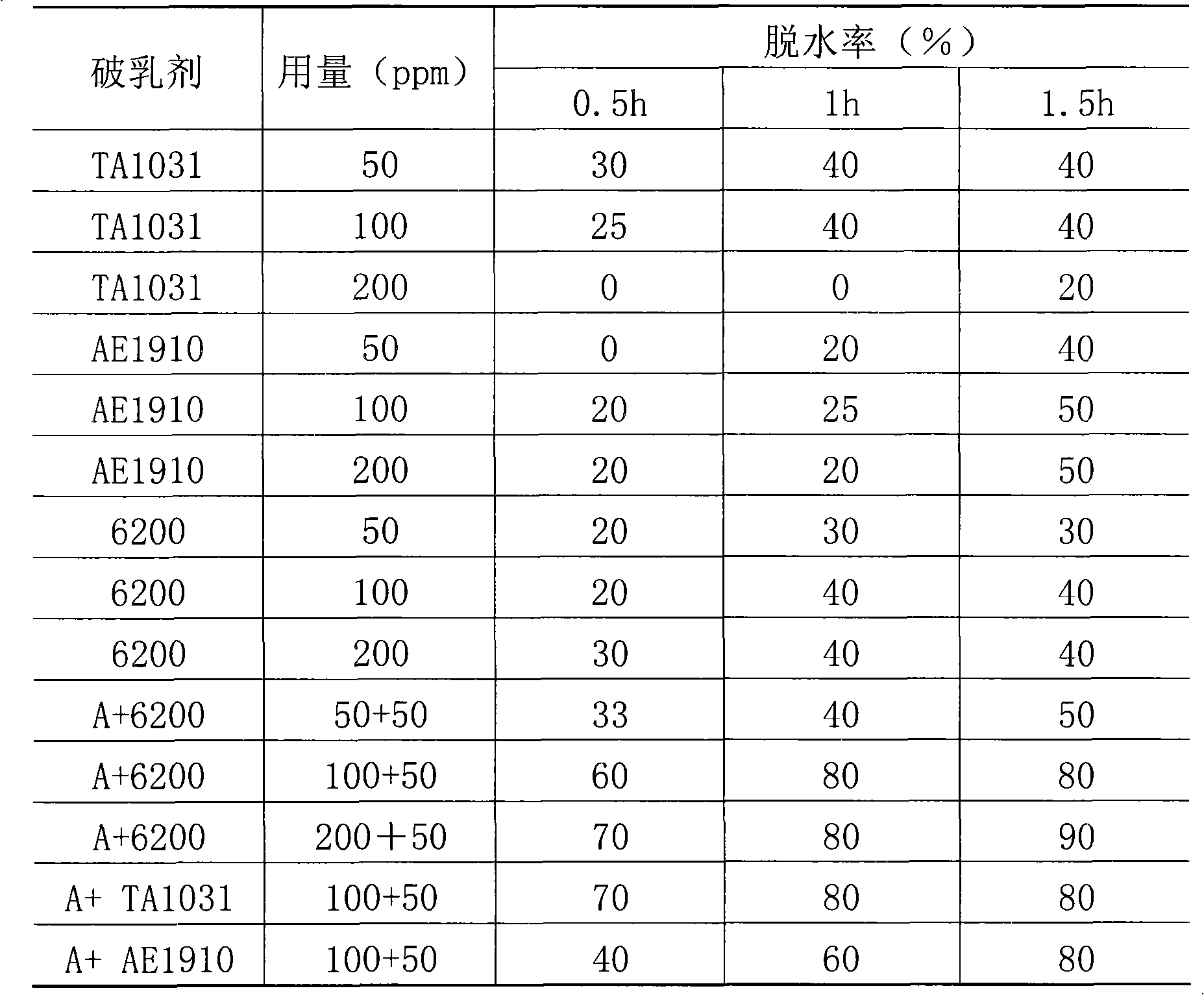

Compound demulsifying agent and method of use thereof

ActiveCN101352666AReduce dosageGood desalination effectTransportation and packagingMixingDemulsifierStyrene-maleic anhydride copolymer

The invention relates to a compound demulsifier and a use method thereof. The compound demulsifier comprises alkyl ester of styrene-maleic anhydride copolymer and ethylene oxide-propylene oxide block polymer, the mass ratio of which is 0.1 to 10: 1. The compound demulsifier of the invention, through compound use of the alkyl ester of styrene-maleic anhydride copolymer and the ethylene oxide-propylene oxide block polymer, can achieve better demulsification effect and is particularly applicable to the demulsification and dehydration of high-asphaltene viscous oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

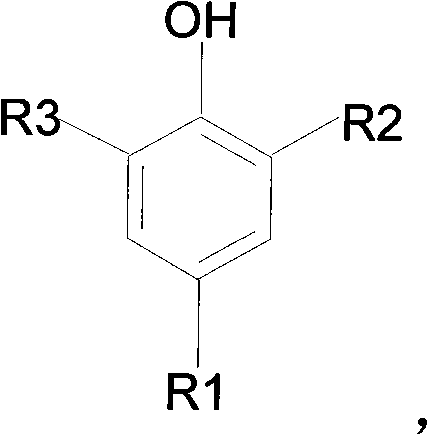

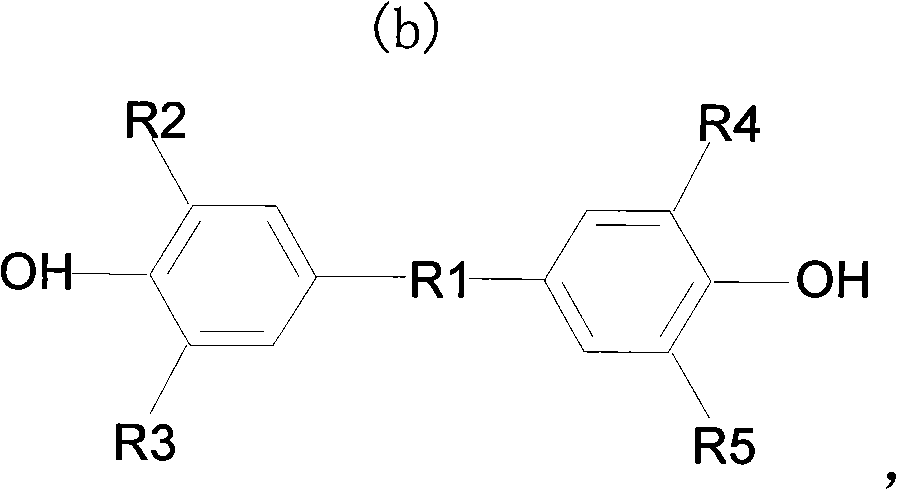

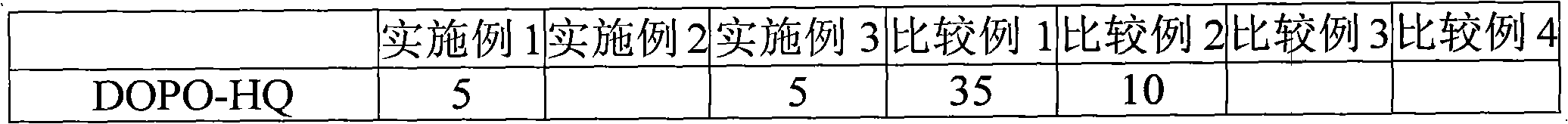

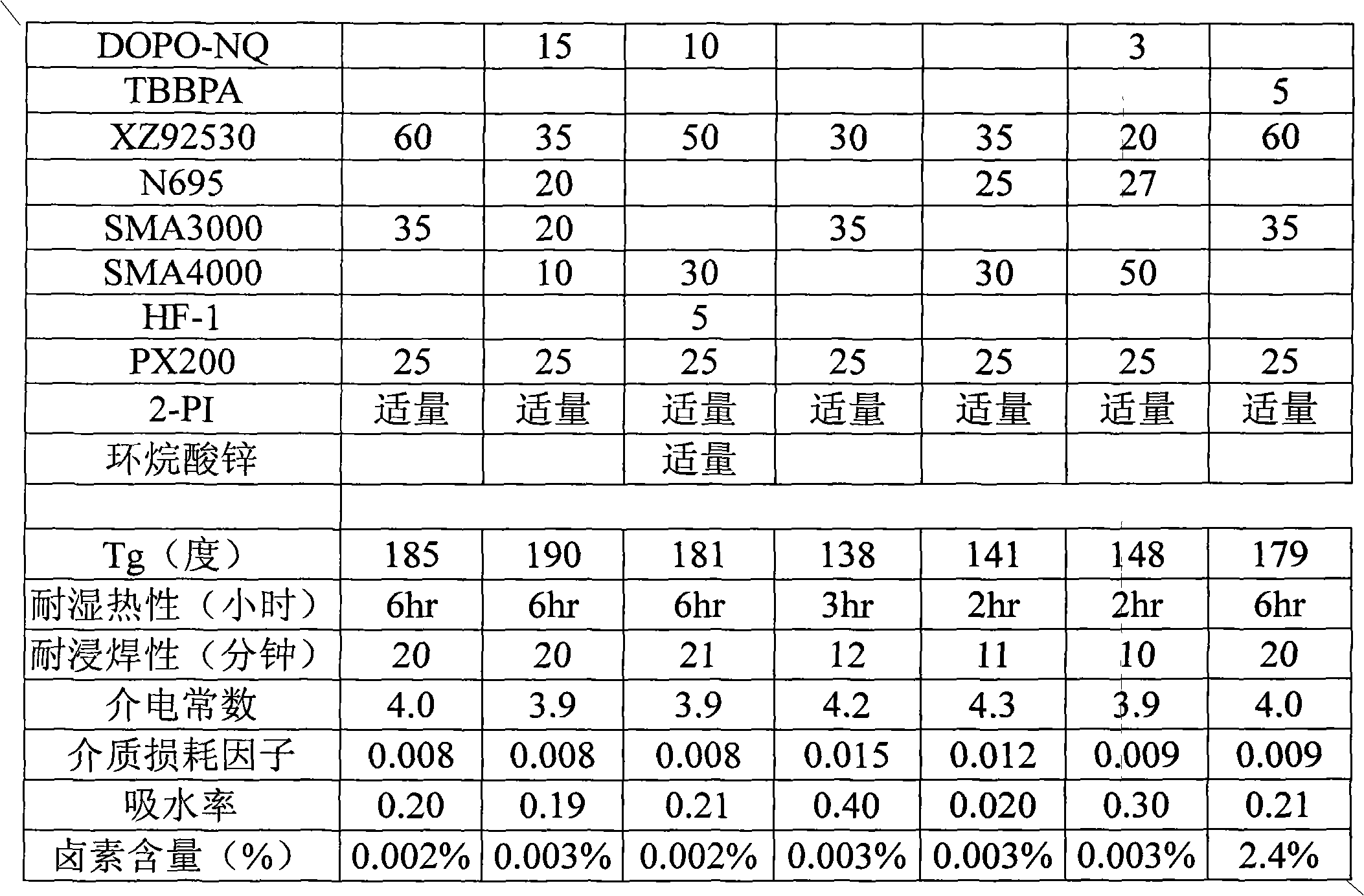

Halogen-free thermosetting resin composition, prepreg and metal clad foil laminated plate manufactured by using same

InactiveCN101928444AHeat resistantSolder dip resistantSynthetic resin layered productsMetal layered productsEpoxyHalogen

The invention relates to a halogen-free thermosetting resin composition, and a prepreg and a metal clad foil laminated plate manufactured by using the same. The halogen-free thermosetting resin composition comprises the following components in part by weight: 10 to 70 parts of bifunctional or multi-functional epoxy resin with a halogen-free molecular structure, 10 to 60 parts of styrene-maleic anhydride copolymer and 3 to 20 parts of co-curing agent, wherein the co-curing agent is halogen-free phenolic compound or phenolic resin. The prepreg manufactured by using the halogen-free thermosetting resin composition comprises a base material and the halogen-free thermosetting resin composition attached to the base material after impregnation drying. The metal clad foil laminated plate manufactured by using the halogen-free thermosetting resin composition comprises a plurality of layers of mutually overlapped prepregs and a metal foil pressed on one side or two sides of the overlapped prepregs, wherein each prepreg comprises the base material and the halogen-free thermosetting resin composition attached to the base material after impregnation drying.

Owner:GUANGDONG SHENGYI SCI TECH

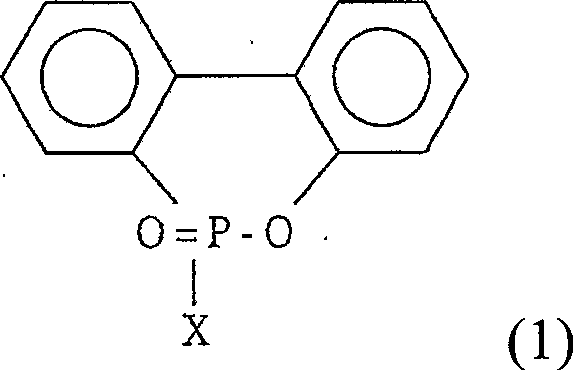

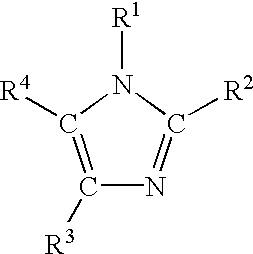

Phosphorous epoxy resin composition

ActiveCN100523081CIncrease flame retardancyImprove heat resistanceLiquid surface applicatorsOther chemical processesEpoxyHeat resistance

The phosphorus-containing epoxy resin composition of the present invention comprises: (A) phosphorus-containing epoxy resin, (B) curing agent, (C) one or more epoxy resins and (D) inorganic filler material; Wherein with component ( Based on the total weight of A), (B) and (C), the hardener of the component (B) includes 15 to 30% by weight of a benzoxazine compound, and 2.5 to 9% by weight of styrene-maleic di anhydride copolymer. The phosphorus-containing epoxy resin composition of the present invention uses a specific content of benzoxazine compound and styrene-maleic anhydride copolymer as a hardener, not only has good flame retardancy and heat resistance, but also has a high dimension Stability, low moisture absorption and excellent electrical properties are suitable for making prepregs, adhesive sheets, semiconductor packaging materials, copper foil laminates, printed circuit boards, and semiconductor packaging substrates.

Owner:ELITE MATERIAL

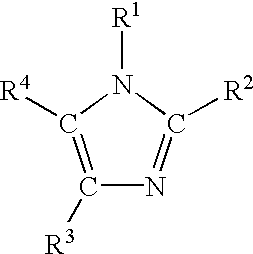

Controlled-Release Agricultural Chemical Formulation

InactiveUS20070224233A1Improve photostabilityControl dispersivityBiocideAnimal repellantsSalicylic acidStyrene maleic anhydride

An object of the present invention is to provide an agricultural chemical formulation which is able to control release of an agricultural chemical active ingredient. This agricultural chemical formulation includes a composition, containing an agricultural chemical active ingredient, styrene-maleic anhydride copolymer or mixture of styrene-maleic anhydride copolymer and polymer having repeating units derived from rosin or derivative thereof or salicylic acid or derivative thereof, and a release controller (a water-soluble polymer, a hydrophobically-treated silicon oxide, or a surfactant), forming a compatible state or matrix.

Owner:NIPPON SODA CO LTD

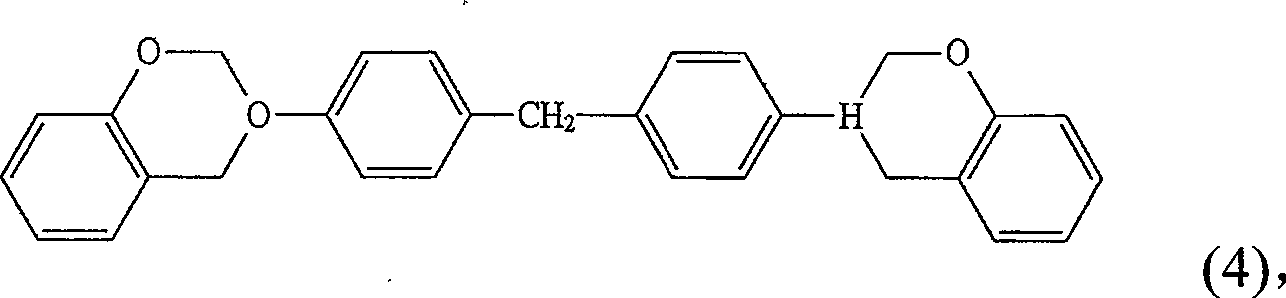

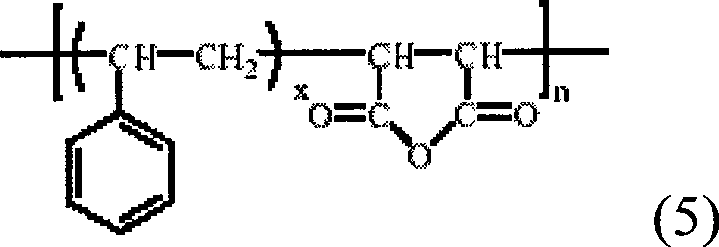

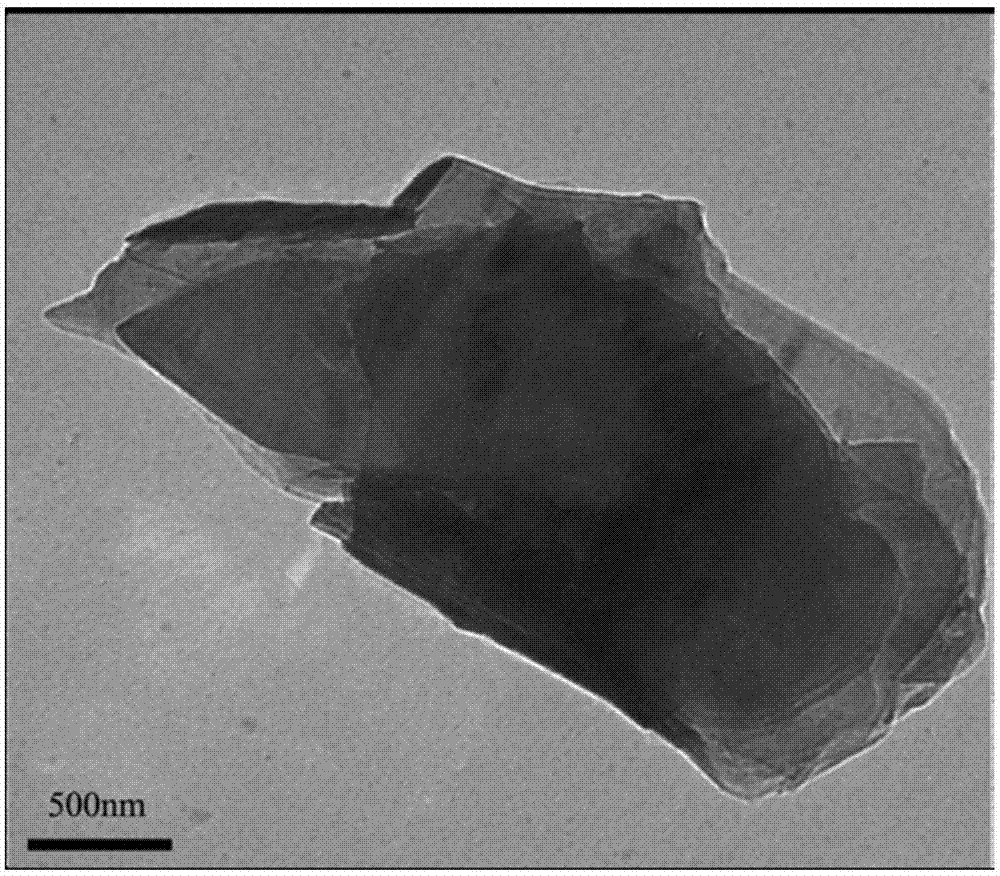

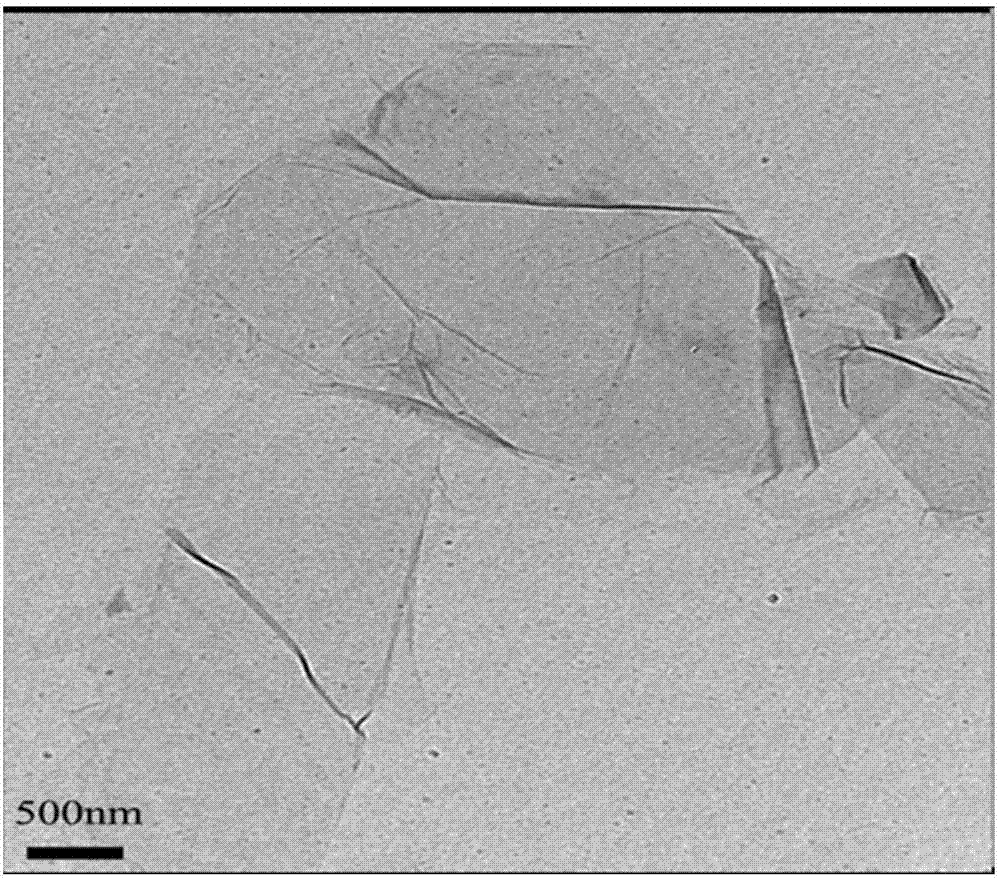

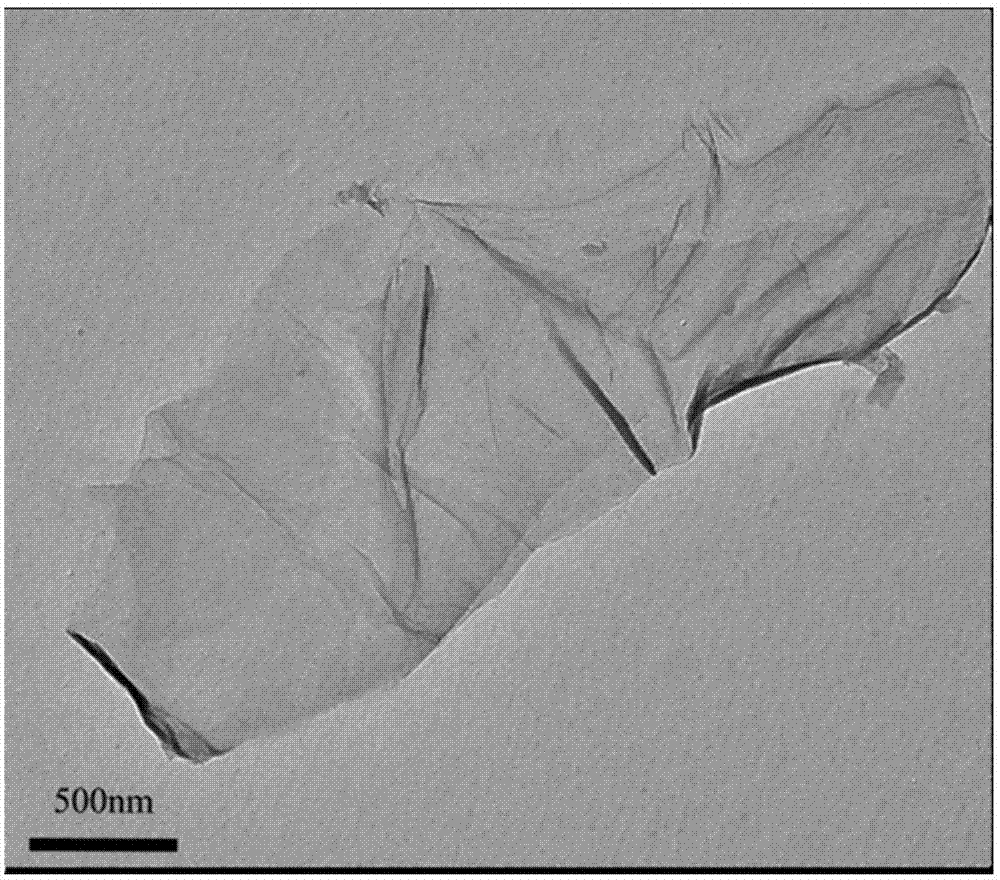

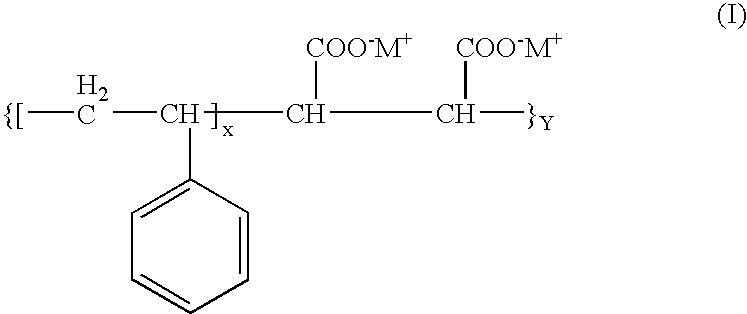

Method for carrying out graft modification on graphene by virtue of styrene-maleic anhydride copolymer

The invention discloses a method for carrying out graft modification on graphene by virtue of a styrene-maleic anhydride copolymer. The method comprises the following steps: taking graphite powder as a raw material, preparing graphene oxide (GO) by utilizing an improved Hummers' process, then grafting maleic anhydride to the GO by adopting a monomer grafting way, then taking a free radical initiator, styrene and maleic anhydride as functional modification reagents, carrying out in situ polymerization, solvent washing and centrifugal separation, and drying, so that styrene-maleic anhydride copolymer grafted graphene oxide is obtained. Grafting ratio of the obtained SMAFG is 20-50%. The styrene-maleic anhydride copolymer grafted graphene oxide can be well dispersed and form stable chemical bonding in a process of preparing a styrene-maleic anhydride copolymer grafted graphene oxide / polymer matrix composite material with the polymer matrix and has the effect of better improving mechanical and thermal properties of a polymer.

Owner:TIANJIN POLYTECHNIC UNIV

Use of styrene-maleic anhydride copolymer to control black-to-color bleed

ActiveUS20050027035A1Improved black-to-color bleedImprove propertiesDuplicating/marking methodsPattern printingStyrene maleic anhydrideStyrene-maleic anhydride copolymer

The use of a styrene-maleic anhydride copolymer in self-dispersed black pigment inks provides a means of achieving black-to-color bleed control against color.

Owner:HEWLETT PACKARD DEV CO LP

Halogen-free resin composition

ActiveUS20130316155A1Low dielectric constantImprove heat resistanceSynthetic resin layered productsPrinted circuit aspectsEpoxyDielectric loss factor

A halogen-free resin composition includes 100 parts by weight of epoxy resin; 10 to 100 parts by weight of benzoxazine resin; 10 to 100 parts by weight of styrene-maleic anhydride copolymer; and 10 to 90 parts by weight of dicyclopentadiene phenol novolac resin. The halogen-free resin composition features specific ingredients and proportions thereof to attain low dielectric constant (Dk), low dielectric dissipation factor, high heat resistance and high non-flammability and produce prepregs or resin film, and is thus applicable to copper clad laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Powder coating composition, method for the curing thereof, and articles derived therefrom

InactiveUS6905778B2Synthetic resin layered productsThin material handlingAcrylic resinStyrene maleic anhydride

A powder coating composition includes an acid-functional polyester resin and a matting agent selected from styrene-maleic anhydride copolymers and acid-functional acrylic resins. The compositions provide low gloss finishes at low curing temperatures, as well as consistent gloss over a wide range of curing temperatures.

Owner:ROHM & HAAS CO

High temperature resistant material for cross flow fan of air-conditioning internal machine

The invention provides a high temperature resistant material for a cross flow fan of an air-conditioning internal machine, which is characterized by consisting of the following components in part by weight: 30 to 55 parts of universal acrylonitrile styrene copolymer, 10 to 30 parts of heat resistant acrylonitrile styrene copolymer, 3 to 5 parts of compatilizer, namely styrene-maleic anhydride copolymer, 4 to 8 parts of heat resistant agent, namely sodium carboxymethyl starch, 29 to 31 parts of glass fiber, 0.5 to 1 part of lubricant TAF, 0.1 to 0.3 part of antioxidant 1076, 0.2 to 0.4 part of antioxidant 168 and 0.2 to 0.4 part of silane coupling agent KH550. Compared with the prior art, the material has the advantage of guaranteeing that at a high temperature, the fan alleviates the deformation phenomenon by rotating at a high speed.

Owner:SHANGHAI CHENLI IND

Reverse osmosis compound scale inhibitor

InactiveCN101973644AExcellent chelating solubilizationExtended shelf lifeScale removal and water softeningReverse osmosisCarboxylic acid

The invention provides a reverse osmosis compound scale inhibitor and belongs to the field of reverse osmosis water treatment. The scale inhibitor comprises the following components in percentage by weight: 10 to 20 percent of 1-hydroxyethylidene-1,1-diphosphonic acid, 30 to 40 percent of hydrolytic polymaleic anhydride, 30 to 40 percent of polyacrylic acid and 10 to 20 percent of sulfonated styrene-maleic anhydride copolymer, and the scale inhibitor comprises also comprises a bactericide. The reverse osmosis compound scale inhibitor fully utilizes the synergistic effect among organic phosphorous scale inhibitors, polycarboxylic acid scale inhibitors and sulfonic acid scale inhibitors, has good scale inhibition and dispersion performance; and when used in a reverse osmosis water inflow system, the scale inhibitor can effectively lighten pollution of calcium carbonate, calcium sulfate and silicate to reverse osmosis membranes and prolongs the cleaning period and service life of the reverse osmosis system.

Owner:NANJING UNIV

Environment-friendly skip hot-stamping alumite hot-stamping foil and preparation method thereof

ActiveCN105818560AIncrease usageIncrease profitPolyurea/polyurethane coatingsThermographyHot stampingEnvironmental resistance

The invention discloses environment-friendly skip hot-stamping alumite hot-stamping foil and a preparation method thereof. The adhesive force of an existing alumite hot-stamping foil coating to a base film layer and the adhesive force between coatings are low. A coloring layer of the hot-stamping foil is prepared from, by weight percent, 20%-40% of thermosetting acrylic resin, 2%-10% of blocked isocyanate, 3%-8% of a styrene-maleic anhydride copolymer, 1%-8% of cellulose acetate butyrate, 2%-10% of adhesive force promotion resin, 2%-7% of dye, 30%-60% of butanone and 1%-10% of cosolvent. The special adhesive force promotion resin is added in the formula, so that the adhesive force of the coloring layer and a base film layer and the adhesive force of the coloring layer and a vacuum aluminum coating layer are effectively improved. A water-soluble paint formula is adopted in a water-based back glue layer, an adhesion promoter is added, and therefore the usage amount of a low-softening-point low-molecular-weight auxiliary is reduced, meanwhile, the adhesive force of the water-based back glue layer to the vacuum aluminum coating layer and the temperature resistance of the water-based back glue layer are improved, and the utilization rate can be increased to 90% or above from original 40%-50%.

Owner:云南玉溪东魅包装材料有限公司

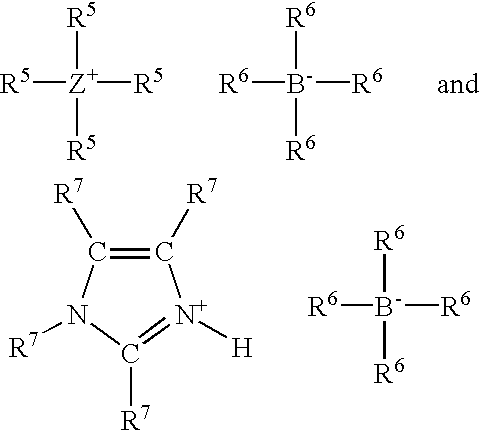

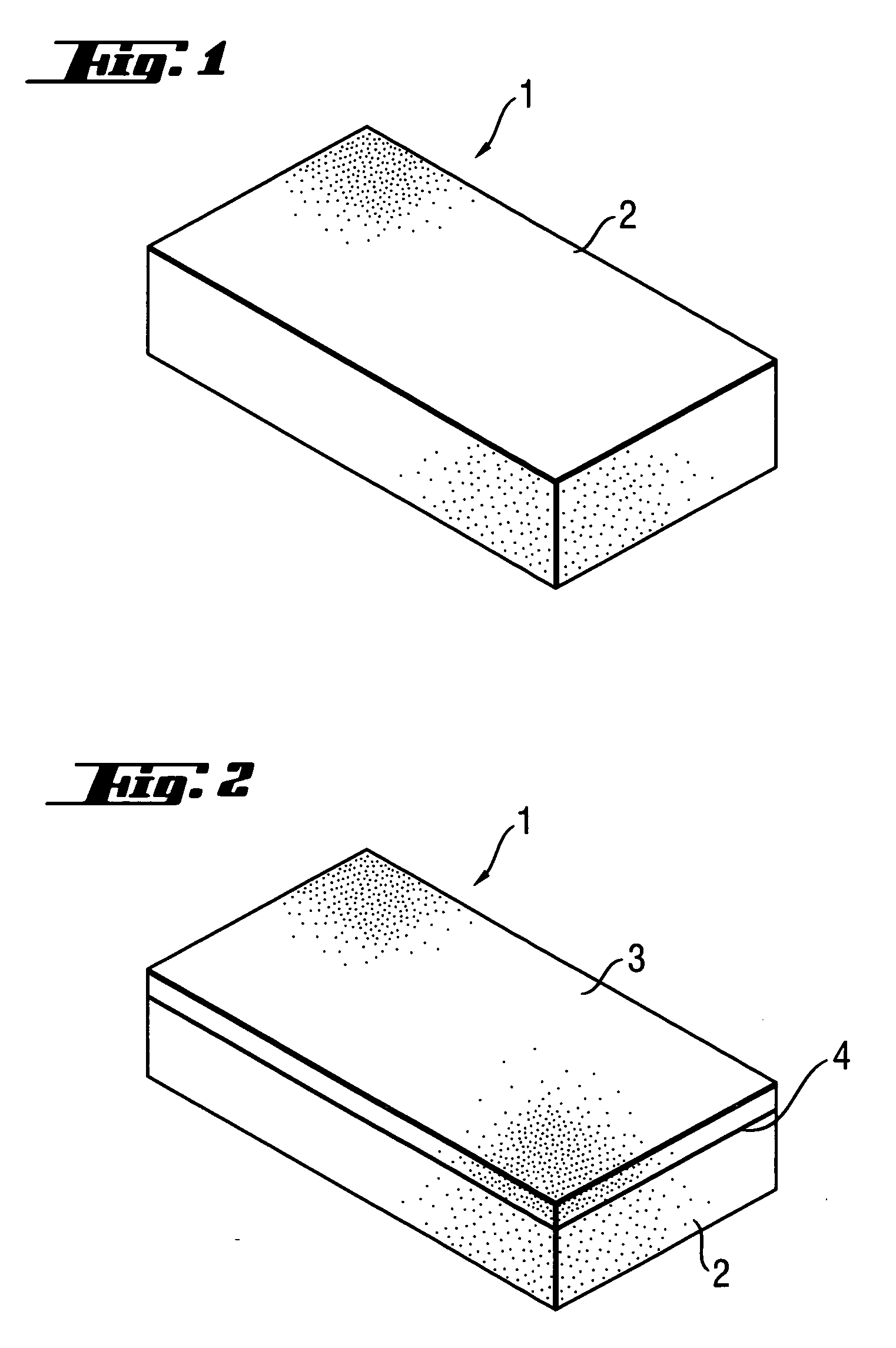

Maleic anhydride copolymers as soluble support material for fused deposition modelling (FDM) printer

ActiveUS20130317164A1Avoid accumulationImprove adhesionOrganic dyes3D object support structuresState of artStyrene maleic anhydride

The invention relates to a novel support material for the fused deposition modelling process for producing three-dimensional objects. The invention relates more particularly to a 3D printing process involving support materials which are easier to remove than in the prior art. The support materials according to the invention are styrene-maleic anhydride copolymers for example.

Owner:EVONIK OPERATIONS GMBH

Maleic anhydride copolymers as soluble support material for fused deposition modelling (FDM) printer

ActiveUS8822590B2Avoid accumulationImprove adhesionOrganic dyes3D object support structuresState of artStyrene maleic anhydride

The invention relates to a novel support material for the fused deposition modelling process for producing three-dimensional objects. The invention relates more particularly to a 3D printing process involving support materials which are easier to remove than in the prior art. The support materials according to the invention are styrene-maleic anhydride copolymers for example.

Owner:EVONIK OPERATIONS GMBH

Halogen-free high frequency resin composition

ActiveCN103554834AImprove heat resistanceEasy to processSynthetic resin layered productsEpoxyDielectric loss

The invention discloses a halogen-free high frequency resin composition. The halogen-free high frequency resin composition comprises, by weight, 20-50 parts of a dicyclopentadiene type epoxy resin, 10-40 parts of a styrene-maleic anhydride copolymer, 10-30 parts of a benzooxazine resin, 5-20 parts of a multifunctional epoxy resin and 20-40 parts of at least one phosphorus-containing fire retardant. A copper-clad plate made by using the halogen-free high frequency resin composition has the characteristics of low dielectric constant, low dielectric loss, high heat resistance, low hygroscopic coefficient, low expansion coefficient, good PCB processability and the like.

Owner:ITEQ DONGGUAN

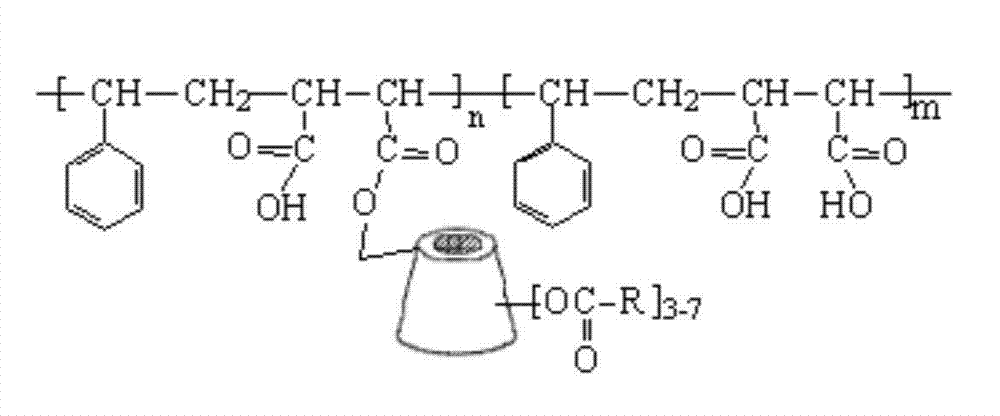

Cyclodextrin immobilized macromolecular polymer and preparation method and application thereof

ActiveCN102872836AImprove adsorption capacityEasy to prepareOther chemical processesWater/sewage treatment by sorptionWater insolubleCyclodextrin

The invention discloses immobilized macromolecular polymer and a preparation method and application thereof. The polymer is prepared from styrene-maleic anhydride copolymer and cyclodextrin by immobilization and acylation. The method comprises the following steps of: reacting the cyclodextrin with the styrene-maleic anhydride copolymer at the temperature of 40 to 75 DEG C to obtain cyclodextrin immobilized macromolecules, and partially esterifying at the temperature of 60 to 90 DEG C by using acyl chloride to obtain water-insoluble cyclodextrin immobilized macromolecular polymer. The synthesis reaction is simple, conditions are mild, and the method is easy to industrialize; and the polymer prepared by the method can be used as an adsorption material and can effectively adsorb organic basic dyes (basic fuchsin and methylene blue) and part of toxic heavy metal ions (Pb<2+>, Hg<2+> and Cd<2+>) in water.

Owner:ANHUI UNIV OF SCI & TECH

Styrenic resin composition and articles produced therefrom

Styrenic resin composition comprising a rubber modified styrene maleic anhydride copolymer and polybutene. The resin is prepared by several methods including adding polybutene into the reactor, or adding polybutene to the syrup exiting the reactor and prior to entering the devolatilizer, or compounding polybutene into the polymer in an extruder after the polymer exits the devolatilizer. The polybutene ranges from 0.1 to 8% by weight and has a number average molecular weight from 900 to 2500. The rubber ranges from 4% to 20% by weight and has a particle size from 0.1 micron to 11 microns. The resin can be extruded into sheet and thermoformed into an article or can be coextruded to produce a laminated article, which may be a container for packaged foods that can be heated in microwave ovens and which container has improved toughness, elongation, and heat distortion resistance properties.

Owner:NOVA CHEM INC

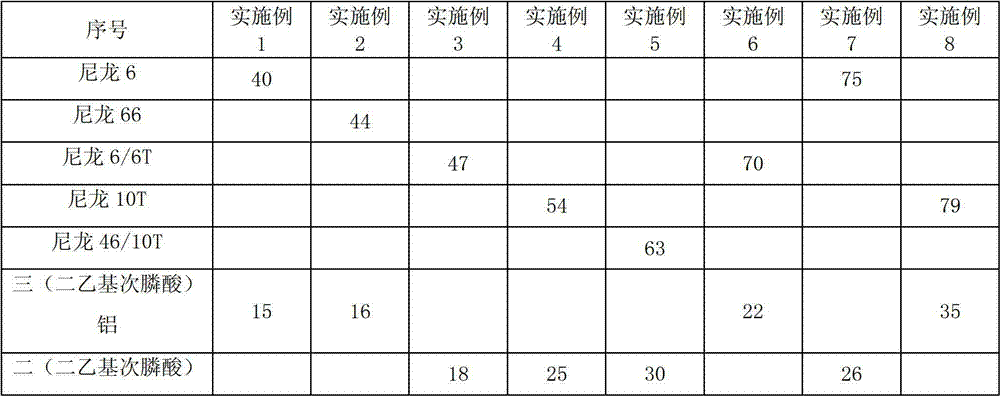

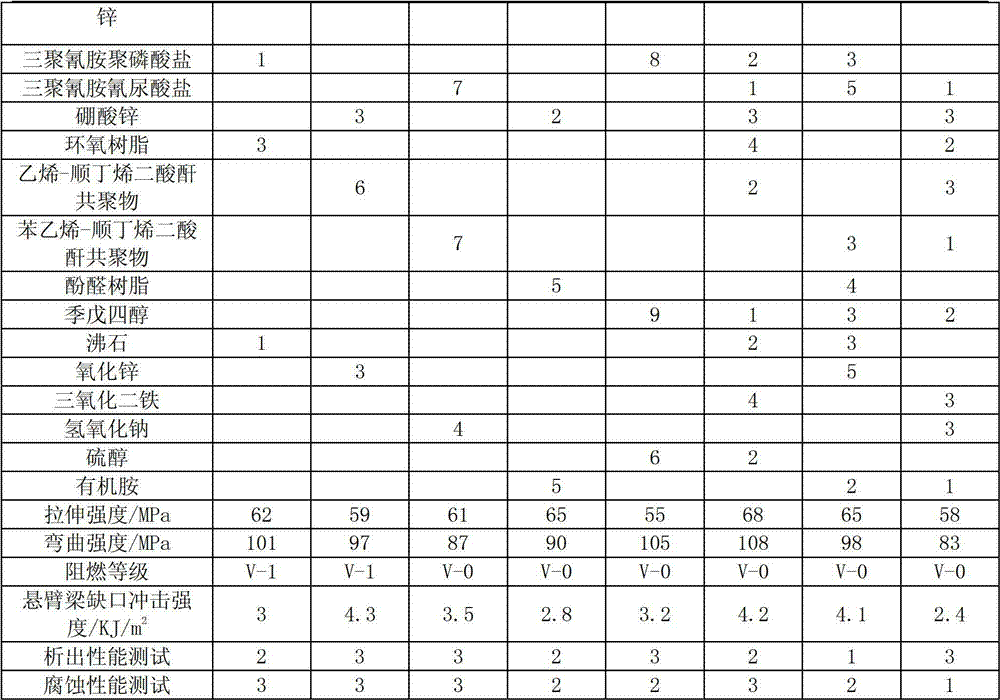

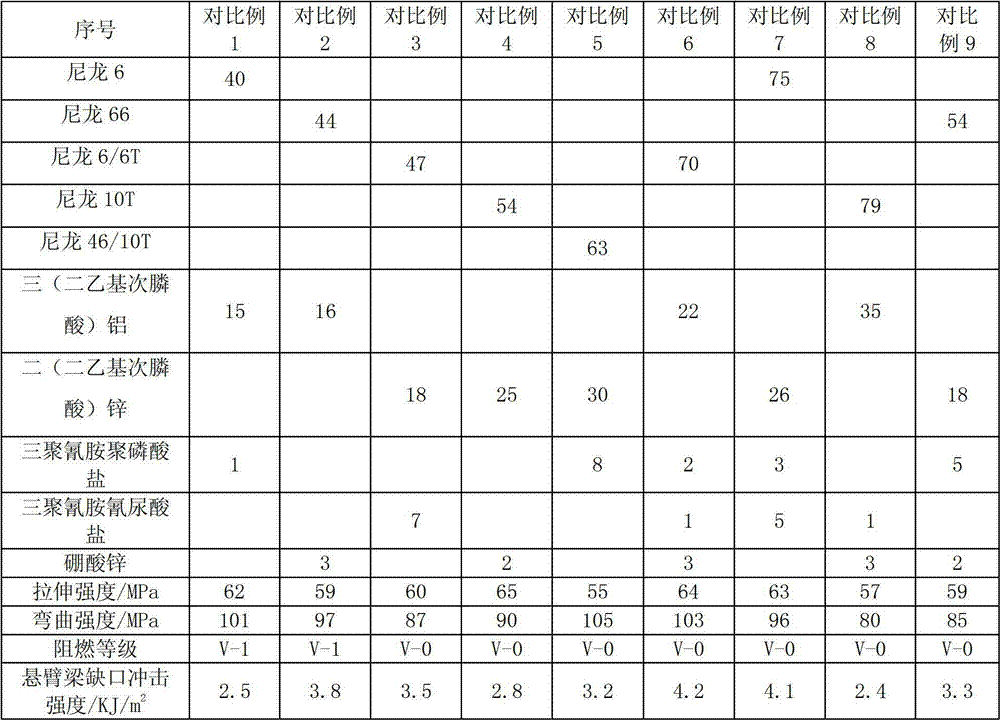

Polyamide composition, and preparation method and application thereof

The invention discloses a polyamide composition, a preparation method and application thereof. The polyamide composition comprises polyamide, a flame retardant, a flame retardant synergistic agent, a cross-linking agent and an acid absorption agent; and the cross-linking agent is epoxy resin, a vinyl-maleic anhydride copolymer, a styrene-maleic anhydride copolymer, a phenolic resin and / or pentaerythritol. The invention also discloses the preparation method and application of the composition. The preparation method comprises the following steps: adding the components of the composition into a double screw extruder for extrusion and granulation; and cooling and drying to obtain the polyamide composition. The polyamide compositions provided by the invention has characteristics of good flame retardation, little flame retardant precipitation, and little corrosion on processing equipment, etc.

Owner:TIANJIN KINGFA NEW MATERIAL +1

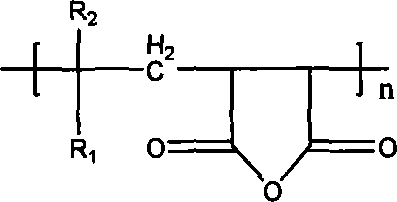

Esterified object of maleic anhydride of styrene, preparation method, and application

This invention relates to a method for preparing styrene-maleic anhydride esterification product. The method comprises: dissolving styrene-maleic anhydride copolymer in solvent, adding alcohol, adding basic catalyst, reacting, purifying the product, and refining. The product can be used as controlled release agent aid for pH-sensitive drugs, paint dispersant, high-efficiency water-reducing agent, polyelectrolyte and phase-separating material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

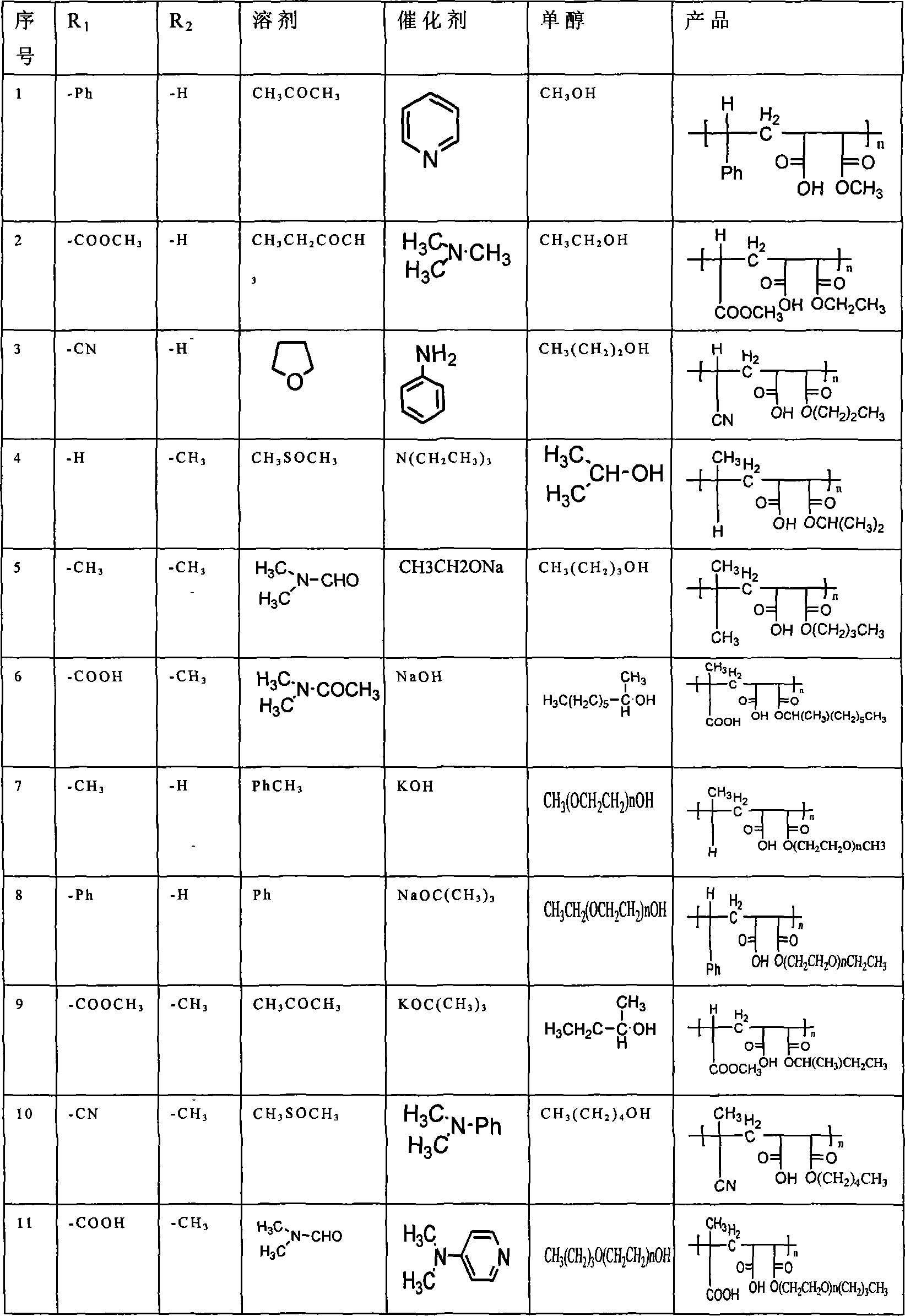

High-melt-strength special compound for automobile tail fin and preparation method thereof

The invention relates to a high-melt-strength special compound for an automobile tail fin and a preparation method thereof. The high-melt-strength special compound for the automobile tail fin is prepared by melting, blending and extruding raw materials in a dual-screw extruder, wherein the raw materials comprise the following ingredients in parts by weight: 60-85 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of styrene-maleic anhydride copolymer, 3-10 parts of acrylonitrile-styrene-glycidyl methacrylate copolymer and 0.05-0.5 parts of antioxidant. The high-melt-strength special compound for the automobile tail fin has the characteristics of high melt strength, good vertical and transverse extension balance, good size stability, high heat distortion temperature, easiness of manufacturing and the like. The problems in heat-resistant ABS (Acrylonitrile Butadiene Styrene) blow molding automobile tail fin at home and abroad of poor melt strength, bad wall built-up, poor thermal stability, distortion in high-temperature and low-temperature cycling tests, unfairness on product surface and the like can be solved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com