High-melt-strength special compound for automobile tail fin and preparation method thereof

A technology of high melt strength and composition, which is applied in the field of high melt strength special composition for automobile tail fins and its preparation, can solve the problems of uneven product surface, insufficient melt strength, poor thermal stability, etc., and achieve improved melting Improve body strength, improve heat resistance, and improve the effect of heat resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 60Kg acrylonitrile-butadiene-styrene copolymer, 30Kg styrene-maleic anhydride copolymer (15% MAH), 3Kg acrylonitrile-styrene-glycidyl methacrylate copolymer (10% GMA) and 0.3Kg of antioxidant was added into a high-speed mixer and stirred for 20 minutes before discharging to obtain a mixture. The weight average molecular weight of the acrylonitrile-butadiene-styrene copolymer is 100,000-200,000, the relative density is 1.03-1.05, and the average diameter range is 200-1000nm; wherein, the weight percentage content of butadiene is 10-20% The weight average molecular weight of the styrene-maleic anhydride copolymer is 100,000 to 300,000, and the glass transition temperature is 130 to 170°C; the weight average molecular weight of the acrylonitrile-styrene-glycidyl methacrylate copolymer 40,000 to 100,000.

[0023] The above mixture is extruded and granulated through a twin-screw extruder, the barrel temperature of the extruder is 180-260° C., and the screw speed is 180-600 ...

Embodiment 2~3

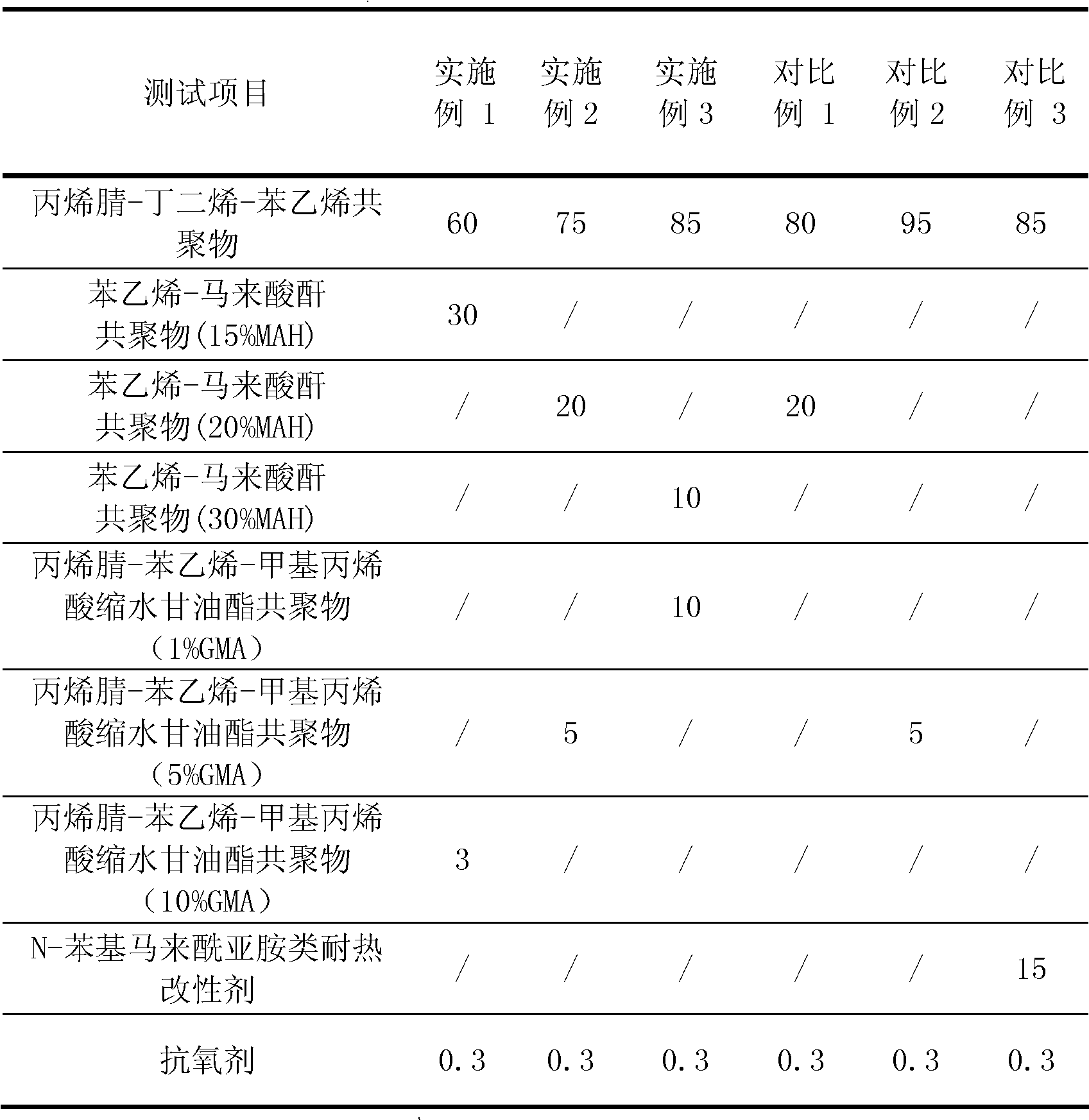

[0025] In order to better embody the characteristics of the above-mentioned high-melt strength special composition for automobile tail, the present invention uses the styrene-maleic anhydride copolymers of different maleic anhydride contents and the styrene-maleic anhydride copolymers of different dosages respectively using embodiments 2 to 3. Ethylene-maleic anhydride copolymers, acrylonitrile-styrene-glycidyl methacrylate copolymers with different glycidyl methacrylate contents, and different amounts of acrylonitrile-styrene-glycidyl methacrylate copolymers The impact of material properties, the specific preparation method is the same as in Example 1, and the specific material formulation is shown in Table 1. In addition, the parts by weight of the antioxidant in Examples 2 and 3 can be any value from 0.05 to 0.5. In order to enhance the comparability with Example 1, the part by weight selected here is 0.3.

Embodiment 6

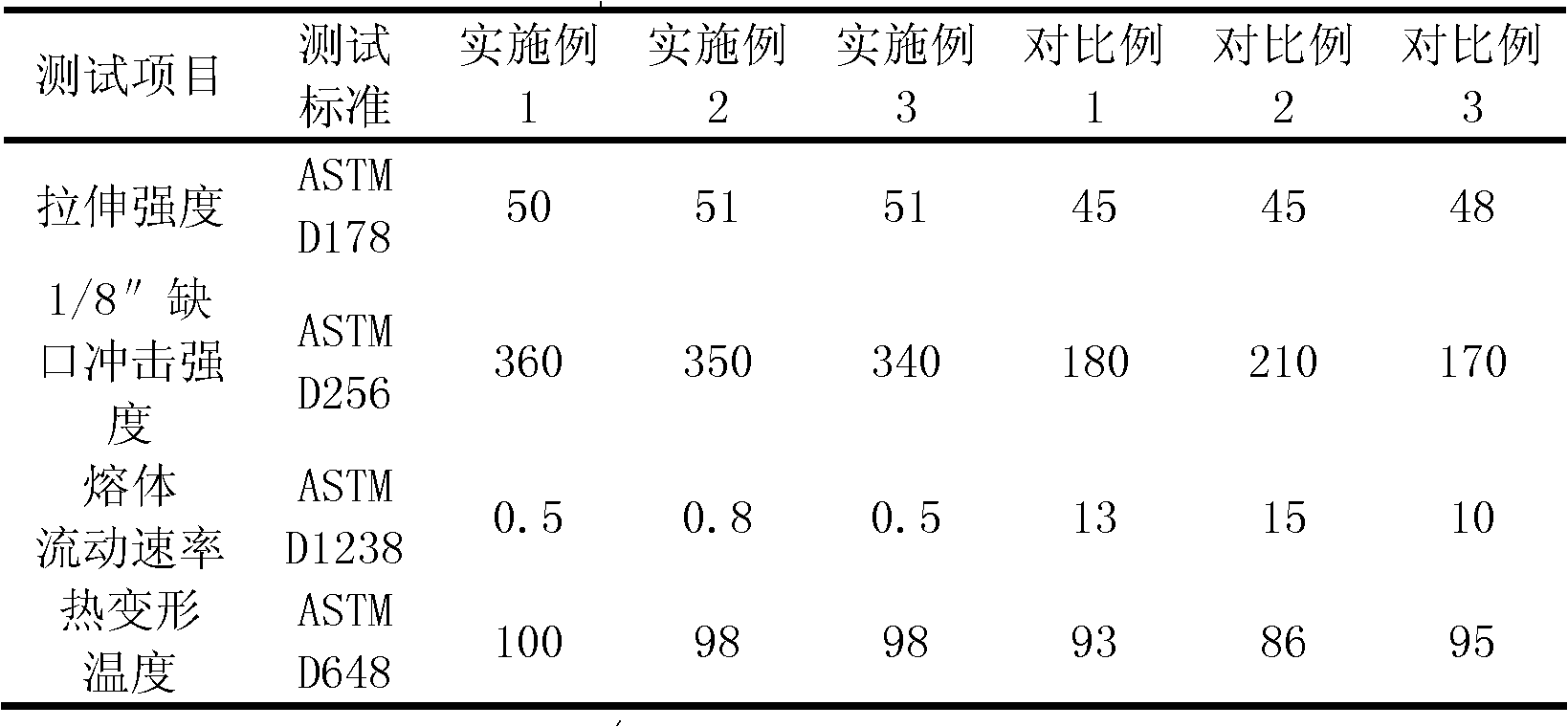

[0030] Embodiment 6, physical performance detection

[0031] For the high-melt-strength automobile rear fin special composition prepared according to Examples 1-3 and Comparative Examples 1-3 above, test specimens were prepared according to the same injection molding conditions, and the specific physical performance testing items were as follows:

[0032] Tensile Strength: Measure tensile strength according to ASTM D 178;

[0033] Flexural strength and flexural modulus: tested according to standard ASTM D790 (3mm / min);

[0034] Izod notched impact strength: measure the notched impact strength according to ASTM D256 (1 / 8″ notch, 23°C);

[0035] Melt flow rate: measure the melt flow rate according to ASTM D1238 (220°C, 10Kg);

[0036] Heat distortion temperature (HDT): Under the condition of 1.82MPa, the heat distortion temperature is measured according to ASTM D648 (1 / 4", 120°C / hr).

[0037] The test results are shown in Table 2:

[0038] Table 2 Performance comparison of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com