Polyamide composition, and preparation method and application thereof

A polyamide composition and polyamide technology, applied in the field of compositions, can solve the problems of corrosion of extruders and other equipment, affecting the performance of polyamide compositions, easy precipitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

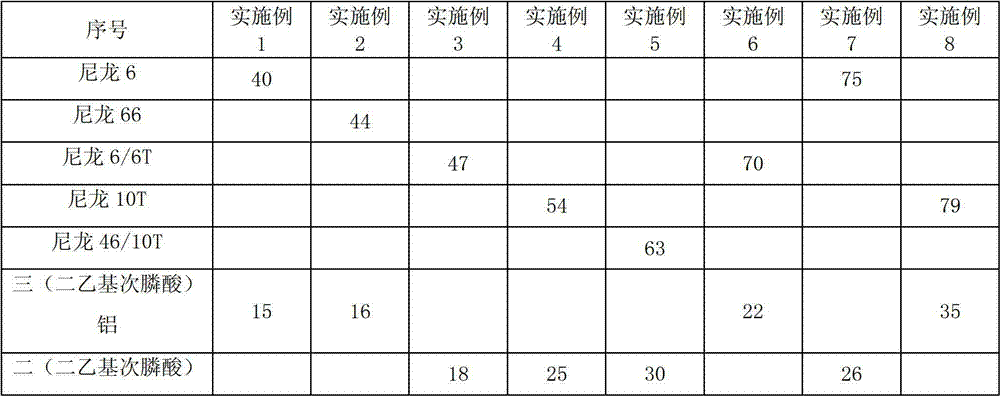

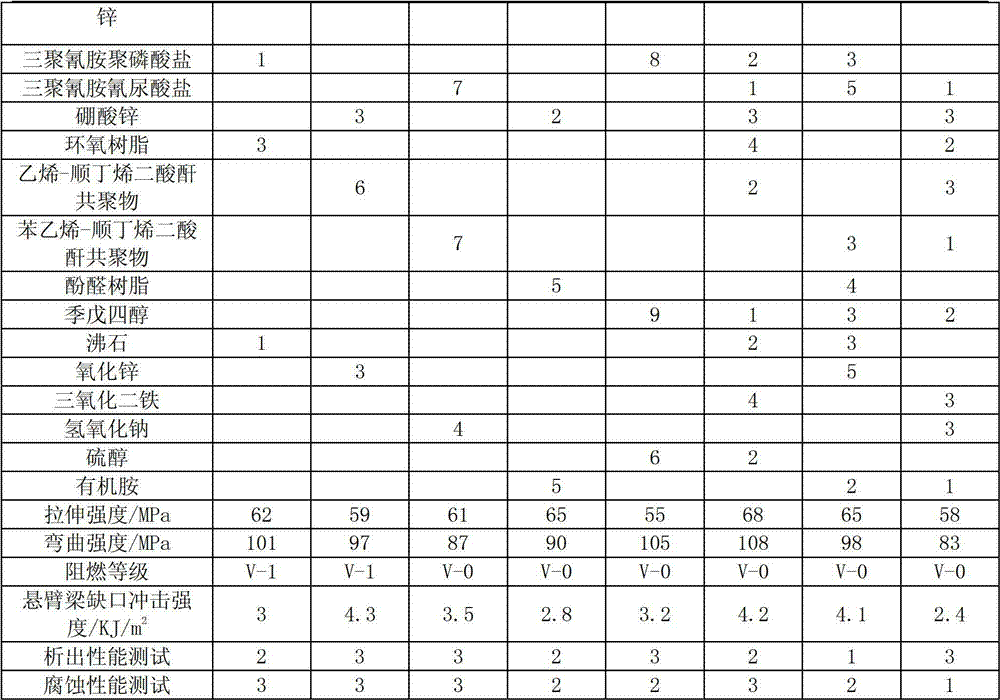

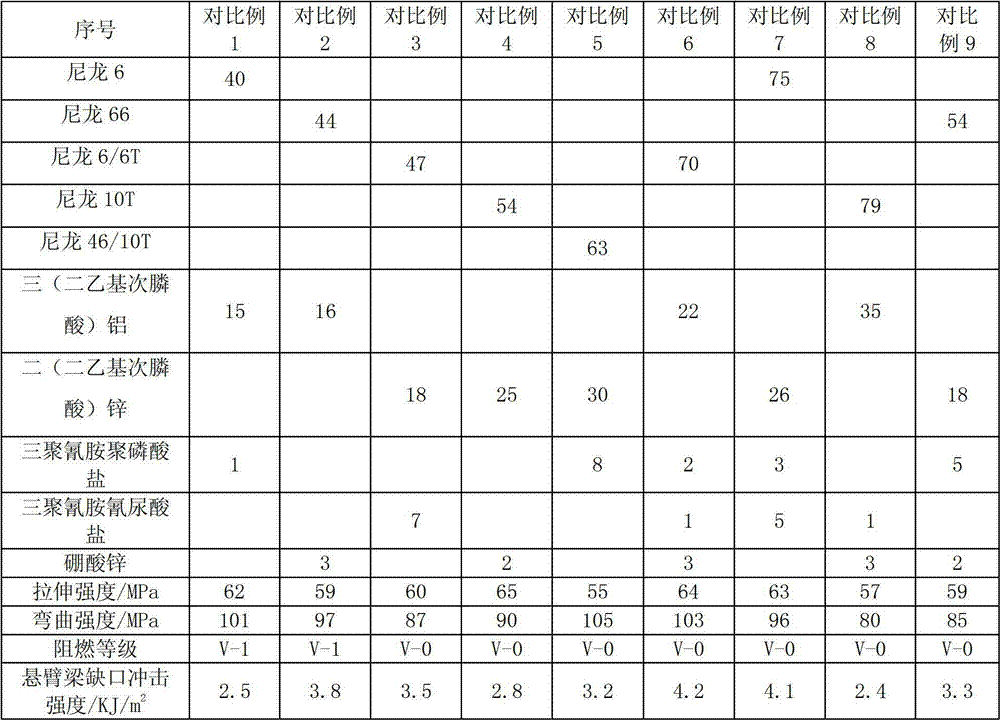

Embodiment 1

[0064] Add nylon 6, aluminum tris(diethylphosphinate), melamine polyphosphate, epoxy resin and zeolite into the twin-screw extruder through the main feed port of the twin-screw extruder according to the weight parts in Table 1 The polyamide composition is obtained after extrusion granulation, cooling, and drying; wherein, the process conditions of the extruder are: the temperature of the first and second stages of the twin-screw extruder is 230~250°C, and the temperature of the third and fourth stages is 250~270°C, the temperature of the fifth and sixth stages is 260~280°C, the temperature of the seventh and eighth stages is 240~270°C, the temperature of the head is 230~270°C, and the screw speed is 150~350 rpm.

[0065] The properties of the prepared polyamide composition were tested and listed in Table 1.

Embodiment 2

[0067] Nylon 66, tris(diethylphosphinate)aluminum, zinc borate, ethylene-maleic anhydride copolymer and zinc oxide were added to the double-screw extruder through the main feed port of the twin-screw extruder according to the weight parts in Table 1. The polyamide composition is obtained after extruding, granulating, cooling, and drying in a screw extruder; wherein, the process conditions of the extruder are: the temperature of the first and second stages of the twin-screw extruder is 230~250°C, and the temperature of the third stage , The temperature of the fourth stage is 250~270°C, the temperature of the fifth and sixth stage is 260~280°C, the temperature of the seventh and eighth stage is 240~270°C, the temperature of the head is 230~270°C, and the screw speed is 150~350 rpm .

[0068] The properties of the prepared polyamide composition were tested and listed in Table 1.

Embodiment 3

[0070] Nylon 6 / 6T, bis(diethylphosphinate) zinc, melamine cyanurate, styrene-maleic anhydride copolymer and sodium hydroxide are passed through a twin-screw extruder according to the weight parts in Table 1 The main feed port of the twin-screw extruder is added into a twin-screw extruder to extrude, granulate, cool, and dry to obtain a polyamide composition; wherein, the process conditions of the extruder are: the temperature of the first and second sections of the twin-screw extruder is 230~250°C, the temperature of the third and fourth stages is 250~270°C, the temperature of the fifth and sixth stages is 260~280°C, the temperature of the seventh and eighth stages is 240~270°C, the temperature of the head is 230~270°C, the screw speed 150~350 rpm.

[0071] The properties of the prepared polyamide composition were tested and listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com