Water-based heat transfer printing release coating, and preparation method and application thereof

A heat-transfer, water-based technology, applied in polyester coatings, polyamide coatings, epoxy resin coatings, etc., can solve the problems of easy whitening of coatings, construction adaptability, performance, and environmental protection. Solve the problems of molded coatings and poor appearance of finished products, achieve good heat resistance and high gloss, safe and environmentally friendly preparation process, and better surface decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

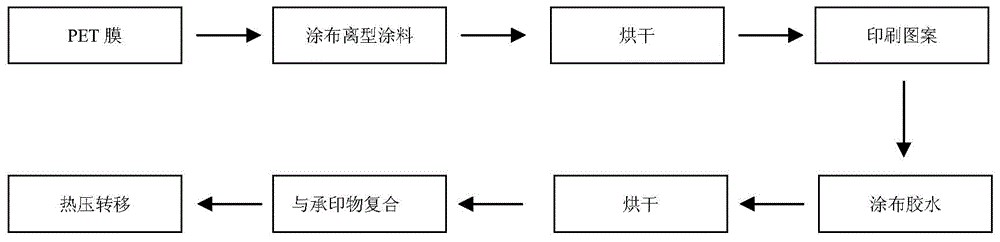

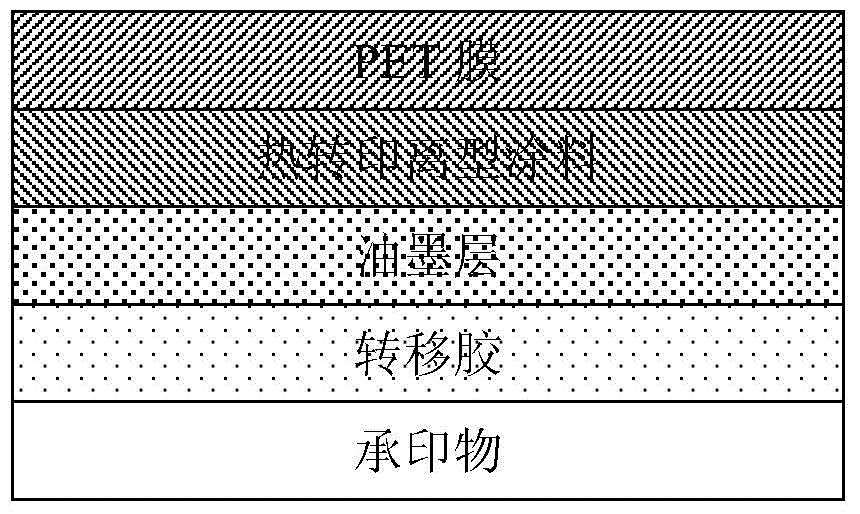

Method used

Image

Examples

Embodiment 1

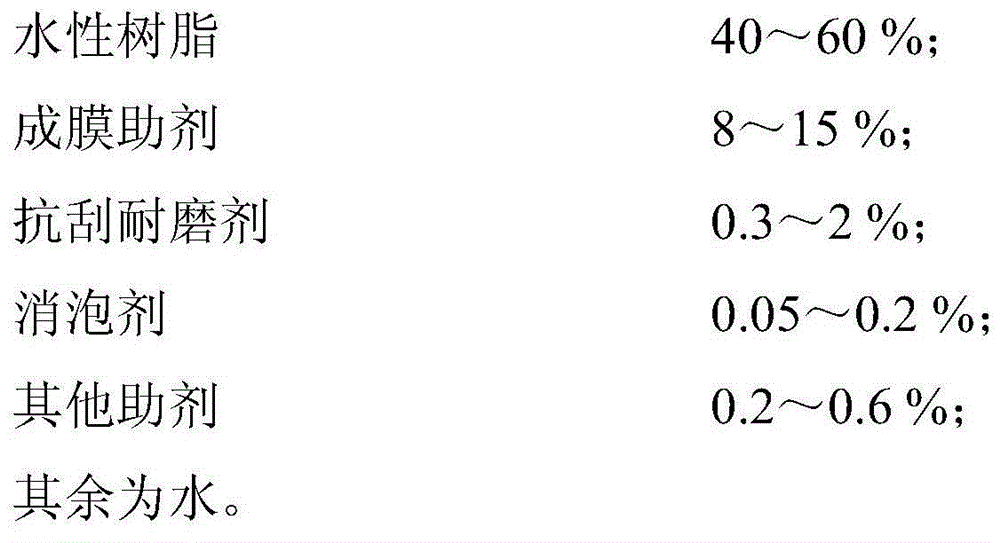

[0062] A water-based thermal transfer release coating, comprising the following components by mass percentage:

[0063]

[0064] The total amount of the above components is 100%.

[0065] The preparation process of the coating is as follows:

[0066] (1) In the reaction kettle, mix the film-forming aid (5.5kg ethanol, 3kg isopropanol, 4kg butanol, 2.5kg propylene glycol methyl ether) evenly, stir at 400r / min for 15min, add 0.1kg leveling agent BYK333 (German BYK chemical, silicone modified polyether leveling agent), 0.2kg wetting agent Tego-245 (Germany Tego, polyether siloxane copolymer), 0.6kg 9184 (Slok Chemical, high molecular weight polysiloxane emulsion), stirred at 600r / min for 10min to dissolve, then added deionized water and dispersed into a uniform liquid phase to obtain dispersion system 1.

[0067] (2) Select solid styrene-maleic anhydride resin SMA 1000 (Sartomer, styrene-maleic anhydride copolymer) and water-based acrylic emulsion Craymul 8405 (Crayville, F...

Embodiment 2

[0073] A water-based thermal transfer release coating, comprising the following components by mass percentage:

[0074]

[0075] The total amount of the above components is 100%.

[0076] Polyurethane resin is composed of the following components by mass percentage

[0077]

[0078]

[0079] The preparation process of the polyurethane resin is as follows: In the reaction kettle, the polybutylene adipate and toluene diisocyanate after vacuum dehydration are mixed evenly, and the temperature is raised to 80 ° C for 1 hour, and then dihydroxymethyl propionic acid is added, and 85 ℃ for 2 hours, add a few drops of aliphatic amine catalyst, acetone appropriate amount of 60 ℃ for 4 hours, cool down to 25 ℃ and discharge, neutralize the prepolymer with triethylamine, add deionized water for high-speed emulsification, reduce The water-based polyurethane resin is obtained after pressure distillation to remove the solvent, and the solid content of the resin is about 35%.

[0...

Embodiment 3

[0087] A water-based thermal transfer release coating, comprising the following components by mass percentage:

[0088]

[0089] The total amount of the above components is 100%.

[0090] Polyurethane resin is composed of the following components by mass percentage

[0091]

[0092] The preparation process of polyurethane resin is as follows: In the reaction kettle, put dehydrated polybutylene adipate and sodium ethylenediaminoethanesulfonate, slowly raise the temperature to 100°C, keep the temperature for 1 hour to completely dissolve, and then slowly cool down When the temperature is about 60°C, add isophorone diisocyanate and organotin catalysts, an appropriate amount of methyl ethyl ketone, and slowly raise the temperature to 80-90°C for 3-4 hours at a constant temperature. Add an appropriate amount of methyl ethyl ketone according to the system year, neutralize with triethanolamine and then add deionized water for high-speed dispersion and emulsification. After vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com