Dual-curing light guide glue for display screen backlight modules and preparation method of dual-curing light guide glue

A backlight module, dual-curing technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of high equipment requirements, high mold costs, large equipment investment, etc., to achieve high luminance and uniformity , The production process is short and the effect of reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

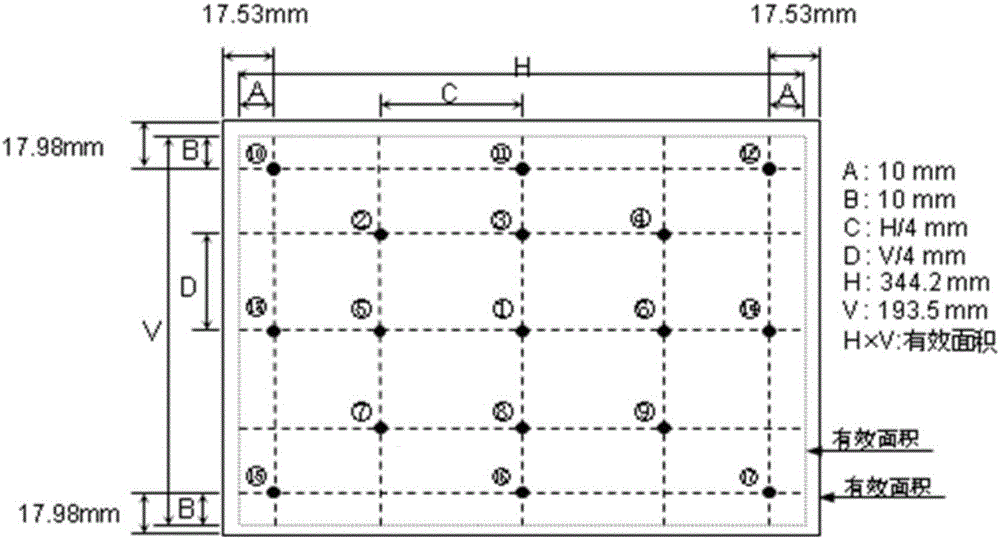

Image

Examples

Embodiment 1

[0047] This embodiment provides a dual-curing light-guiding adhesive for a display backlight module. The preparation method of the dual-curing light-guiding adhesive includes the following steps:

[0048] (1) Weigh 31 parts of bisphenol A diglycidyl ether and 100 parts of polyether diamine into the reaction kettle, stir at a speed of 195r / min, and keep the system temperature at 78°C for 0.8h to obtain epoxy resin modified sex fatty amine;

[0049] (2) Weigh 1 part of benzoin dimethyl ether, 67 parts of epoxy resin modified fatty amine, 5 parts of GPES type defoamer, 25 parts of nano-silica, 6 parts of fumed silica and join in the reaction kettle, stir The speed is 375r / min, and the system temperature is maintained at 32°C to react for 8 minutes, degas at -0.08MPa for 30 minutes, and filter through a 100-mesh filter to obtain component B;

[0050] (3) Take by weighing 100 parts of pentaerythritol triacrylate, 136 parts of polybutadiene dimethacrylate, 142 parts of aliphatic ur...

Embodiment 2

[0059] This embodiment provides a dual-curing light-guiding adhesive for a display backlight module. The preparation method of the dual-curing light-guiding adhesive includes the following steps:

[0060] (1) Weigh 28 parts of bisphenol F diglycidyl ether epoxy resin and 100 parts of 4,7,10-trioxy-1,13-tridecanediamine and add them to the reaction kettle at a stirring speed of 160r / min , keep the system temperature at 90°C and react for 0.5h to obtain epoxy resin-modified aliphatic amine;

[0061] (2) Weigh 1 part of 2-hydroxyl-2-methyl-1-phenylacetone, 46 parts of epoxy resin modified fatty amine, 2 parts of lauryl phenylacetate, 42 parts of polymethyl methacrylate micropowder, Add 3 parts of hydrogenated castor oil into the reaction kettle, stir at 350r / min, keep the system temperature at 25°C for 5 minutes, degas at -0.08MPa for 30 minutes, and filter through a 100-mesh filter to obtain component B;

[0062] (3) Take by weighing 100 parts of propoxylated glycerin triacryla...

Embodiment 3

[0071] This embodiment provides a dual-curing light-guiding adhesive for a display backlight module. The preparation method of the dual-curing light-guiding adhesive includes the following steps:

[0072] (1) Weigh 24 parts of polybutadiene epoxy resin and 100 parts of isophorone diamine into the reaction kettle, stir at 230r / min, keep the system temperature at 60°C for 2 hours to obtain epoxy resin Modified fatty amine;

[0073] (2) Weigh 1 part of 1-hydroxycyclohexyl phenyl ketone, 74 parts of epoxy resin modified fatty amine, 7 parts of GPES type defoamer, 21 parts of nano silicon dioxide, 8 parts of polyethylene wax and add to the reaction In the kettle, the stirring speed is 400r / min, and the reaction is maintained at a system temperature of 28°C for 12 minutes, degassing at -0.08MPa for 30 minutes, and filtered through a 100-mesh filter to obtain component B;

[0074] (3) Take by weighing 100 parts of pentaerythritol tetraacrylate, 154 parts of polybutadiene dimethacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com