Method for preparing photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and composition thereof

A polyurethane acrylate and water-based oligomer technology, applied in the field of polymer chemical materials, can solve the problems of poor water resistance, encapsulation, and low hardness, and achieve the effects of improving hydrophobicity and enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Taking the synthesis of a photopolymerizable silicone urethane acrylate water-based oligomer as an example with the preferred raw materials, the synthesis principle is as follows:

[0052] The first step: react trimethylolpropane, 2,2-dimethoxypropane, p-toluenesulfonic acid and chloroform at 65°C for 16 hours, cool to room temperature, add anhydrous sodium carbonate and stir for 2 hours, Filtration, the filtrate was evaporated under reduced pressure to remove chloroform, and the product 1 was obtained; the molar ratio of trimethylolpropane to 2,2-dimethoxypropane was 1:1.1, and the amount of p-toluenesulfonic acid was trimethylolpropane 1% of the total mass of propane and 2,2-dimethoxypropane, and the molar ratio of anhydrous sodium carbonate to p-toluenesulfonic acid is 2:1. The reaction equation is as follows:

[0053]

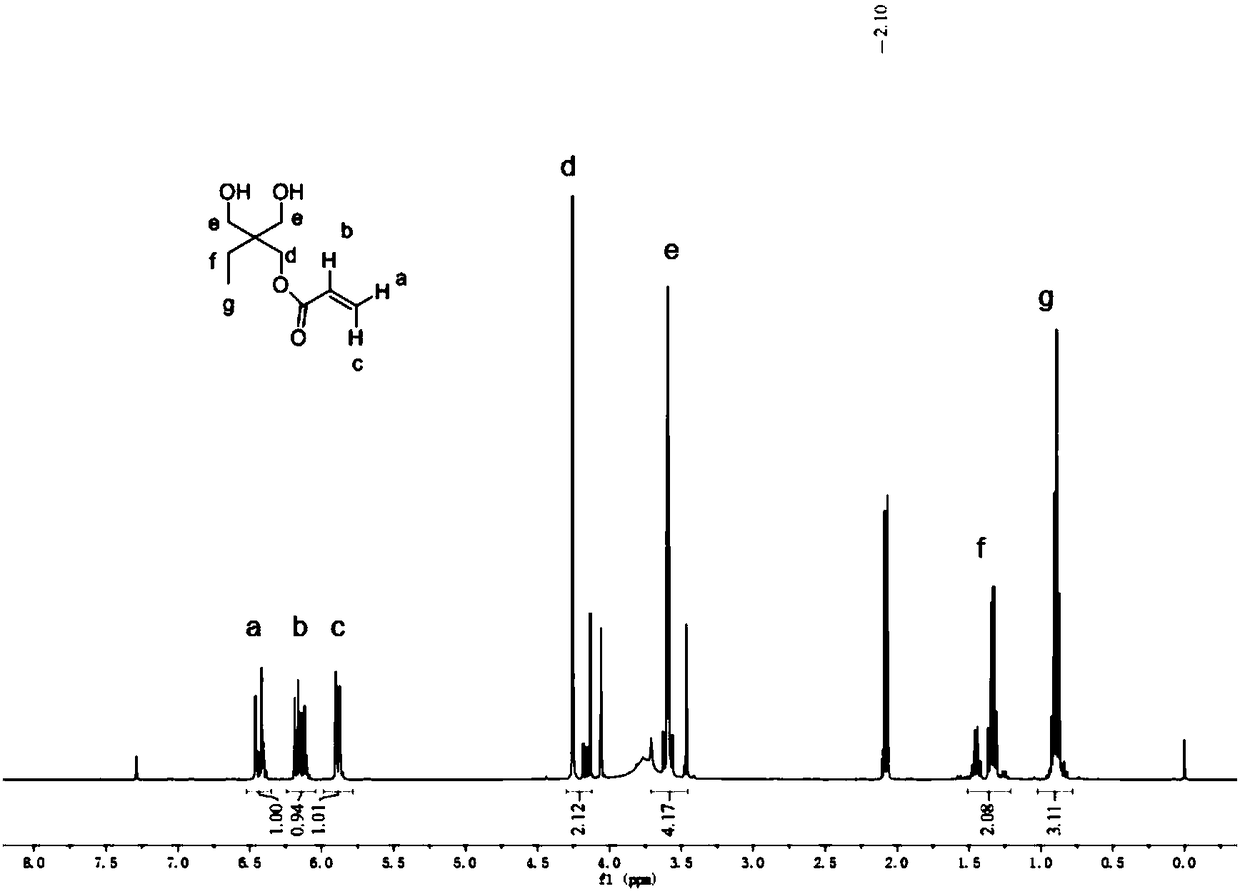

[0054] The second step: react (meth)acryloyl chloride, triethylamine, product 1 and dichloromethane at 0°C for 2 hours, raise the temperature to...

Embodiment 2

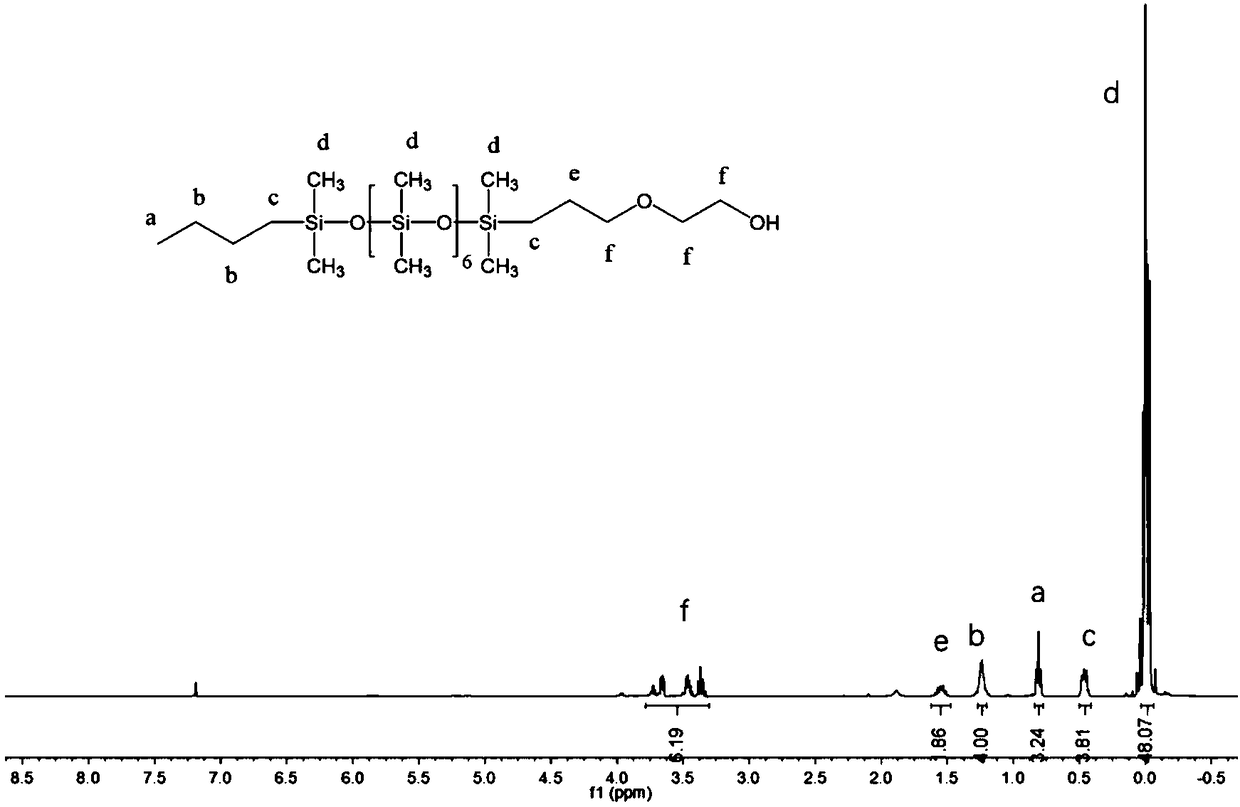

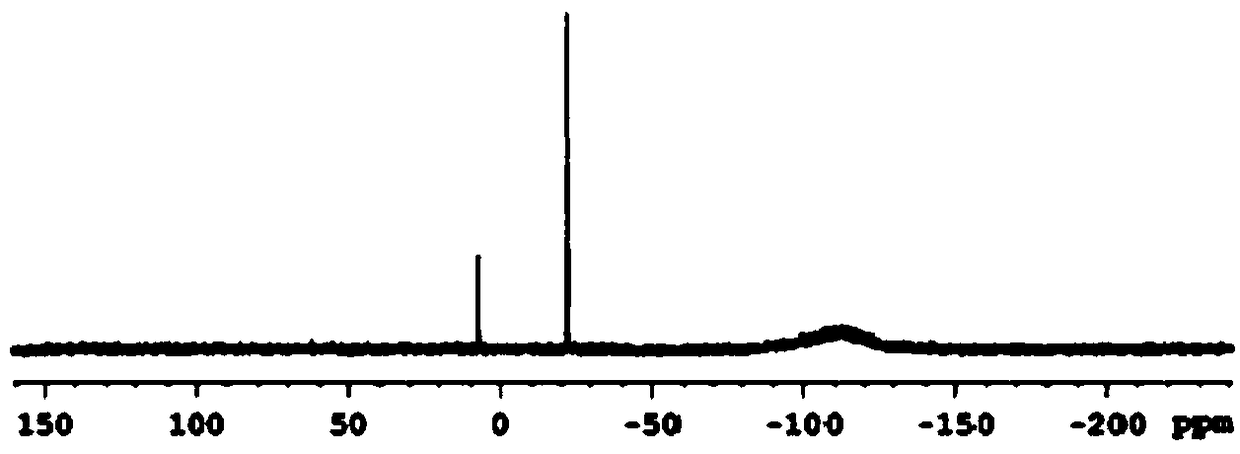

[0076] A kind of preparation method of photopolymerizable organosilicon urethane acrylate aqueous oligomer, comprises the following steps:

[0077](1) Add 20.10g of trimethylolpropane (TMP) and 17.16g of 2,2-dimethoxypropane into a single-necked flask, add 30mL of chloroform solvent and 0.37g of p-toluenesulfonic acid, and heat at 65°C Stir under reflux, cool to room temperature after 16 hours, add 0.46 g of anhydrous sodium carbonate, stir at room temperature for 2 hours to end the reaction, filter, and remove chloroform from the filtrate by rotary evaporation under reduced pressure to obtain product 1;

[0078] (2) In a 250mL three-neck flask equipped with a spherical condenser, magnetic stirring, thermometer and dropping funnel, add 17.40g (0.1mol) of product 1, 11.11g (0.11mol) of triethylamine and 50mL of anhydrous dichloromethane , cooled to 0°C in an ice-water bath, slowly added dropwise 9.96g (0.11mol) of acryloyl chloride, stirred in an ice-water bath for 2 hours, the...

Embodiment 3-4

[0084] The steps of Example 2 were repeated, except that the amounts of PCDL, HBA, and IPDI were different, as shown in Table 1.

[0085] The add-on of table 1. PCDL used in embodiment 3-4, HBA, IPDI raw material

[0086] raw material

[0087] The aqueous oligomer obtained in embodiment 3-4 is named as PCDL-PEG-HBA respectively 12 -WSi 8 PUA, PCDL-PEG-HBA 15 -WSi 8 PUAs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com